Page 1

C45 / M50 / MT50 / A50

Level 2.5e

Repair Documentation

V 1.1

V1.1 Page 1 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 2

Table of Contents:

1 LIST OF AVAILABLE LEVEL 2,5E PARTS C45, M50, MT50 AND A50 ............ 4

2 REQUIRED EQUIPMENT FOR LEVEL 2,5E......................................................5

3 REQUIRED SOFTWARE FOR LEVEL 2,5E C45, M50, MT50 AND A50...........5

4 RADIO PART.................................................................................................... 6

4.1 Power Supply RF-Part.................................................................................... 7

4.2 Frequency generation .................................................................................... 9

4.2.1 Synthesizer: The discrete VCXO (26MHz) ...........................................................................9

4.2.2 Synthesizer: LO1 ................................................................................................................11

4.2.3 Synthesizer: LO2 ................................................................................................................13

4.2.4 Synthesizer: PLL.................................................................................................................14

4.3 Antenna switch (electrical/mechanical)...................................................... 15

4.4 Receivers....................................................................................................... 17

4.4.1 Receiver: GSM900/1800 –Filter to Demodulator................................................................17

4.4.2 IC Overview ........................................................................................................................19

4.5 Transmitter....................................................................................................20

4.5.1 Transmitter: Modulator and Up-conversion Loop ...............................................................20

4.5.2 Transmitter: Power Amplifier ..............................................................................................21

5 POWER SUPPLY.............................................................................................. 22

5.1 Overview and Voltages ................................................................................ 22

5.2 Power Supply ASIC ...................................................................................... 23

5.3 Battery and Charging ................................................................................... 26

5.3.1 Battery ................................................................................................................................26

5.3.2 Charging Concept...............................................................................................................26

6 LOGIC PART.....................................................................................................28

6.1 Overview Logic/control............................................................................... 28

6.2 EGOLD (PMB6850) V1.3/V2.x....................................................................... 30

6.3 EGAIM inside the EGOLD+ ..........................................................................31

6.3.1 Tasks of the EGAIM inside the EGOLD+ ...........................................................................32

6.4 Real Time Clock (integrated in the EGOLD+)............................................. 35

6.5 SRAM ............................................................................................................. 36

V1.1 Page 2 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 3

6.6 FLASH............................................................................................................ 37

7 ACOUSTICS......................................................................................................38

7.1 General .......................................................................................................... 38

7.2 Vibra............................................................................................................... 39

7.3 Microphone and Loudspeaker (Ringer)..................................................... 40

7.3.1 Loudspeaker.......................................................................................................................40

7.3.2 Microphone .........................................................................................................................40

7.3.3 Loudspeaker/Ringer ...........................................................................................................41

8 ILLUMINATION:................................................................................................ 42

8.1 Illumination ...................................................................................................42

9 SIM-CARD AND CONNECTORS...................................................................... 43

9.1 SIM-Card........................................................................................................ 43

9.2 Display connector.........................................................................................44

9.3 I/O-Connector................................................................................................ 45

9.4 Battery Connector ........................................................................................ 46

10 IMPORT INFORMATION................................................................................ 47

11 HANDLING OF BGA COMPONENTS ........................................................... 49

12 ADDITIONAL L2.5E DOCUMENTS ............................................................... 49

V1.1 Page 3 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 4

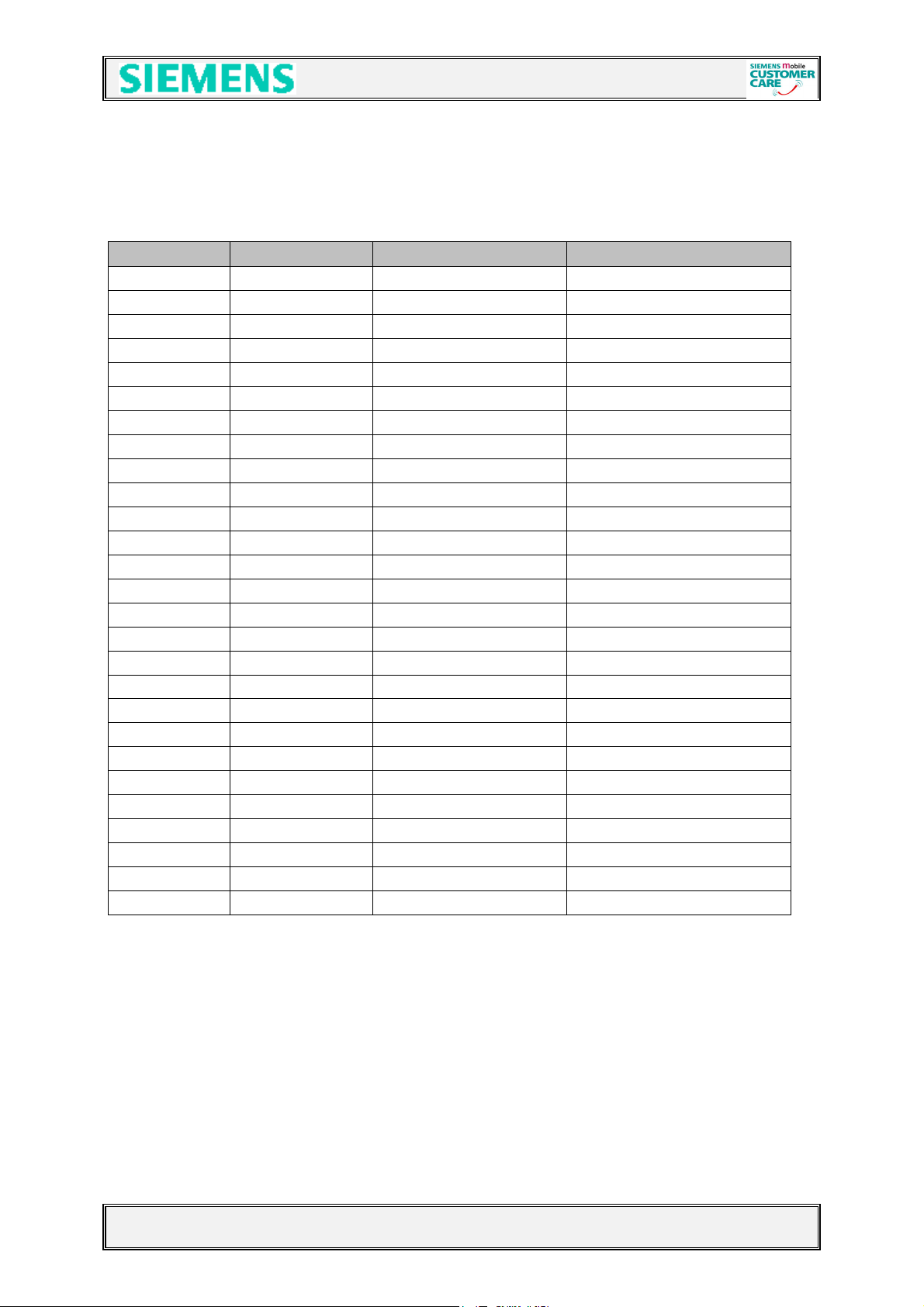

1 List of available level 2,5e parts C45, M50,

MT50 and A50

ID-No Type Name, Location Part-No.

D100 IC Egold+ (V1.3) L36810-G6132-D670

D100 IC Egold+ (V2.10) L36810-G6107-D670

D361 IC ASIC L36145-J4682-Y29

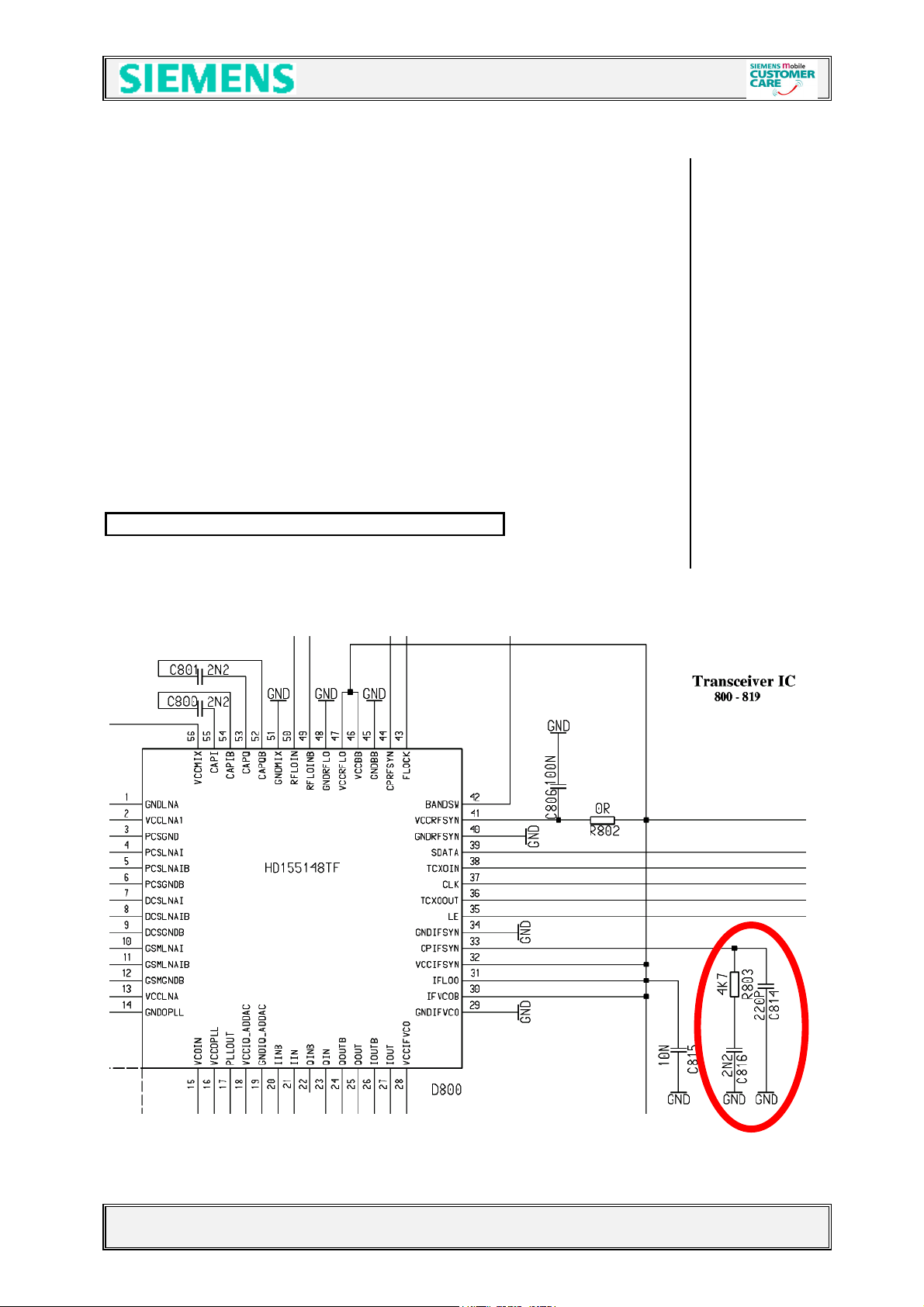

D800 IC Transceiver IC L36820-L6081-D670

D920 IC PA_Comperator L36820-L6084-D670

N386 IC Volt.Regulator_ZUB L36820-C6161-D670

N840 IC Volt.Regulator_RF L36810-C6065-D670

R959 Resistor Temp_Resistor L36120-F4223-H

L366 Diode Diode_AF L36840-D3084-D670

V342 Transistor Tran._Charge L36830-C1104-D670

V344 Diode Diode_Charge L36840-D5061-D670

V442 Transistor Tran._SW_Vibra L36830-C1097-D670

V850 Transistor Tran._VCO_Switch L36820-C6047-D670

V880 Transistor Tran._Sw_Diplexer L36820-C6047-D670

V881 Transistor Tran._Sw_Diplexer L36820-C6047-D670

V920 Diode Feedback_Diode L36840-D5049-D670

V922 Transistor Tran._PA_Control L36840-C4009-D670

V950 Transistor Tran._26MHz_Ampl. L36840-C4049-D670

V951 Diode Capa_Diode L36840-D61-D670

Z100 Quartz Quarz/Egold L36145-F102-Y8

Z850 VCO 1LO_VCO L36145-G100-Y93

Z851 Filter Filter_BALUN L36145-K260-Y31

Z880 IC Ant_Switch_Diplexer L36145-K280-Y181

Z890 VCO Transmitter_VCO L36145-G100-Y92

Z900 IC Power_Amplifier (PA107) L36851-Z2002-A45

Z900 IC Power_Amplifier (PA122) L36851-Z2002-A58

Z950 Quartz Oszillator_26MHz L36145-F260-Y16

V1.1 Page 4 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 5

2 Required Equipment for Level 2,5e

- GSM-Tester (CMU200 or 4400S incl. Options)

- PC-incl. Monitor, Keyboard and Mouse

- Bootadapter 2000/2002 (L36880-N9241-A200)

- Troubleshooting Frame C45 (F30032-P135-A1)

- Power Supply

- Spectrum Analyser

- Active RF-Probe incl. Power Supply

- Oscilloscope incl. Probe

- RF-Connector (N<>SMA(f))

- Power Supply Cables

- Dongle (F30032-P28-A1)

- BGA Soldering equipment

Reference: Equipment recommendation V1.0 (downloadable from the technical support page)

3 Required Software for Level 2,5e C45, M50,

MT50 AND A50

- Windows NT Version4

- Winsui version1.38 or higher

- Windows software for GSM-Tester ( Cats(Willtekaaaaa) or CMU-GO(Rohde&Schwarz) )

- Software for reference oscillator adjustment

- Internet unblocking solution

V1.1 Page 5 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 6

4 Radio Part

The radio part of the C45, M50, MT50 AND A50 consists of a Hitachi RF chip-set.

The radio part is designed for Dual Band operation, covering EGSM900 as well

as GSM 1800 frequencies, and can be divided into 4 Blocks.

- Power supply for RF-Part

- Transmitter

- Receiver

- Synthesizer,

The RF-Part has it´s own power supply realised by a voltage regulator

which is directly connected to the battery. The voltages for the logic part are

generated by the Power-Supply ASIC

The transmitter part converts the I/Q base band signals supplied by the

logic (EGOLD+) into RF-signals with characteristics as defined in the

GSM recommendation (www.etsi.org

Amplifier the signal is radiated via the internal or external antenna.

The receiver part converts the received GMSK signal supplied by the

antenna into IQ base band signals which can then be further processed by

the logic (EGOLD+).

The synthesizer generates the required frequencies for the transmitter and

Receiver. A 26MHz oscillator is acting as a reference frequency.

Restrictions:

- The mobile phone can never transmit and receive in both bands simultaneously.

- Only the monitor time slot can be selected independently of the frequency band.

- Transmitter and receiver can of course never operated simultaneously.

) After amplification by a power

V1.1 Page 6 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 7

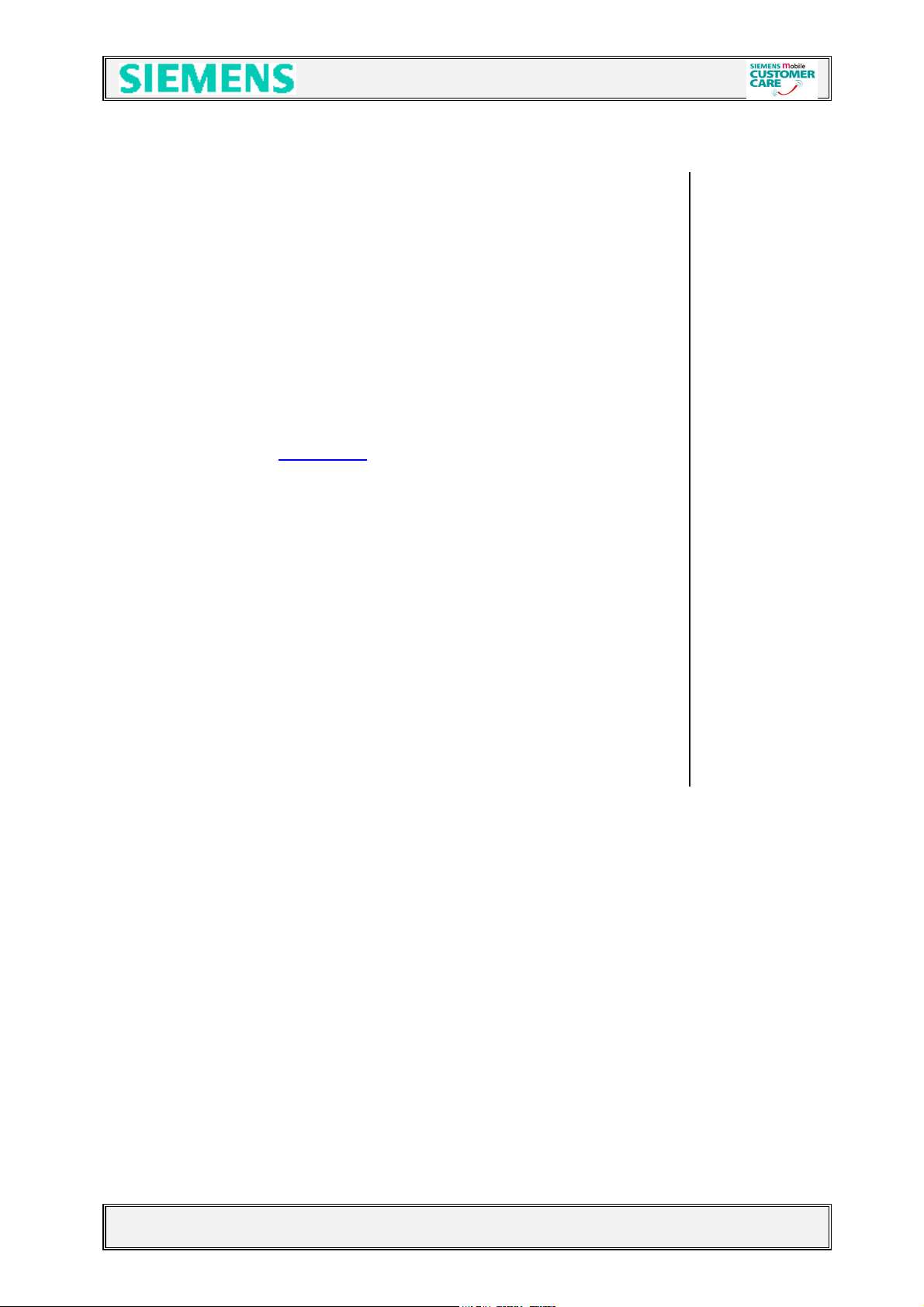

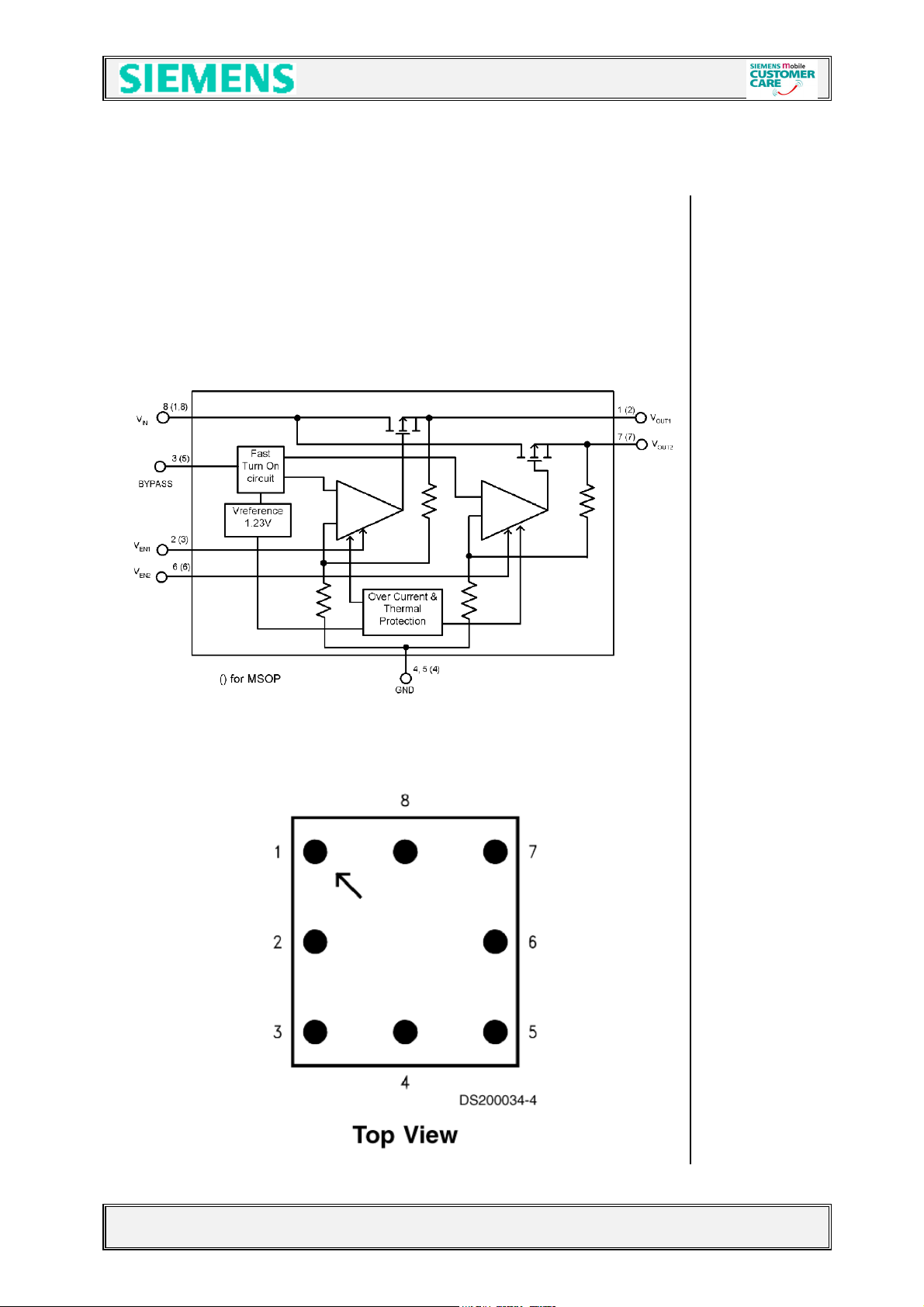

4.1 Power Supply RF-Part

A directly to Batt+ connected voltage regulator, with a nominal output voltage

of 2.8V is used, to perform the required “RF-Voltages” named VCC2_8 and

VCC_SYN.

The voltage regulator is activated as well as deactivated via SLEEPQ and

VCXOEN provided by the EGOLD+

The temporary deactivation is used to extend the stand by time.

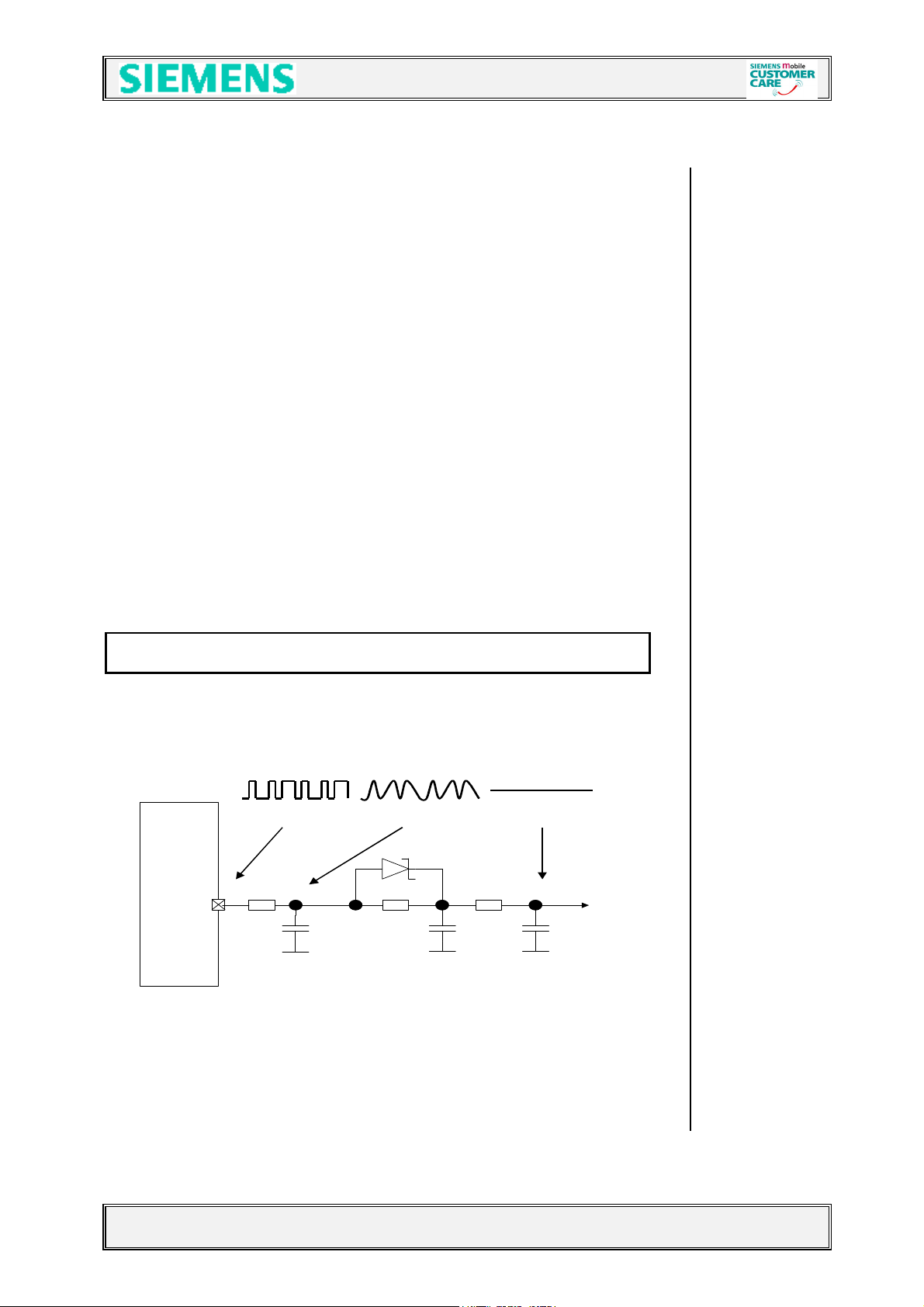

Blockdiagram

PIN-OUT

V1.1 Page 7 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 8

Circuit diagram

Type Part No. Signal Source Output

Hitachi N840 Pin 6 SleepQ EGOLD+ L11 Pin 7 VCC2_8

Pin 2 VCXOEN EGOLD+ P7 Pin 1 VCC_SYN

V1.1 Page 8 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 9

4.2 Frequency generation

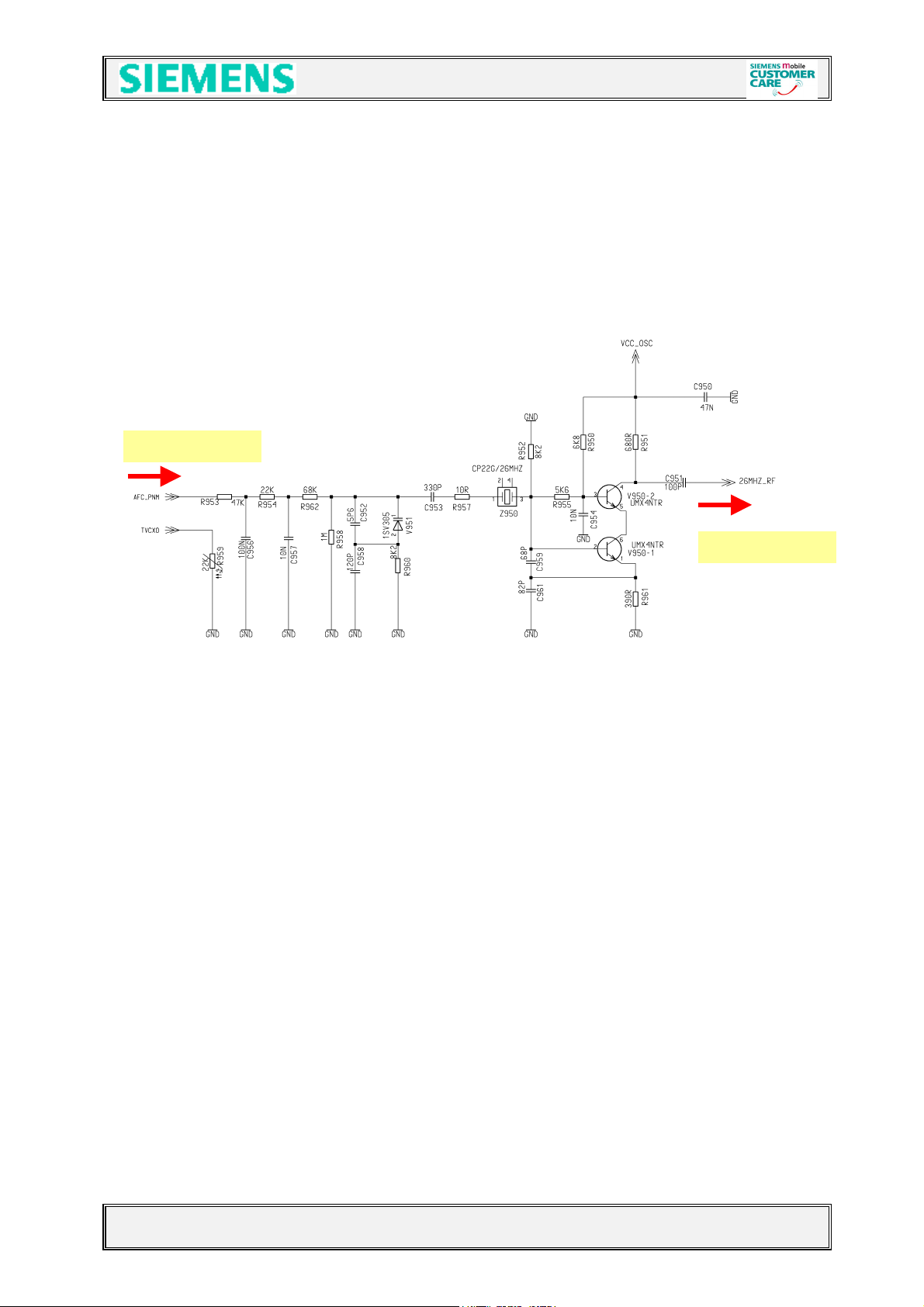

4.2.1 Synthesizer: The discrete VCXO (26MHz)

M46 mobile is using a reference frequency of 26MHz for the Hitachi chip set.

The generation of the 26MHz signal is done via a discrete “Colpitts” VCXO .

This oscillator consists mainly of:

A 26MHz crystal Z950

An oscillator switch V950

A capacity diode V951

TP 951 after dividing by two

The oscillator output signal is directly connected to the BRIGHT IC (pin 38) to be

used as reference frequency inside the Bright and to be divided by 2.

This so gained signal SIN13MHZ_BB is used from the EGOLD+

To compensate frequency drifts (e.g. caused by temperature) the oscillator

frequency is controlled by the (AFC_PNM) signal, generated through the internal

EGOLD+ (D100

(functional R3)) PLL via the capacity diode V951.

Reference is the base station frequency.

To compensate a temperature caused frequency drift, the temperature-depending

resistor R959 is placed near the VCXO to measure the temperature. The

measurement result TVCXO is reported to the EGOLD+

(baseband L4) via R136 as

the signal TENV.

The required voltage VCC_OSC is provided by the N840 (VCC_SYN) through

R863 and R861

Waveform of the AFC_PNM signal from EGOLD+ to Oscillator

(functional M14).

Signalfo rm

EGOLD+

V1.3

AFC

123

V602

12 3

R106

30K 22K

C110

AFC_PNM

100N

GND

BAS170W

R615

47K

R600

C616

100N

GND

C600

10N

GND

V1.1 Page 9 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 10

Circuit diagram

from EGOLD

to Bright IC

V1.1 Page 10 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 11

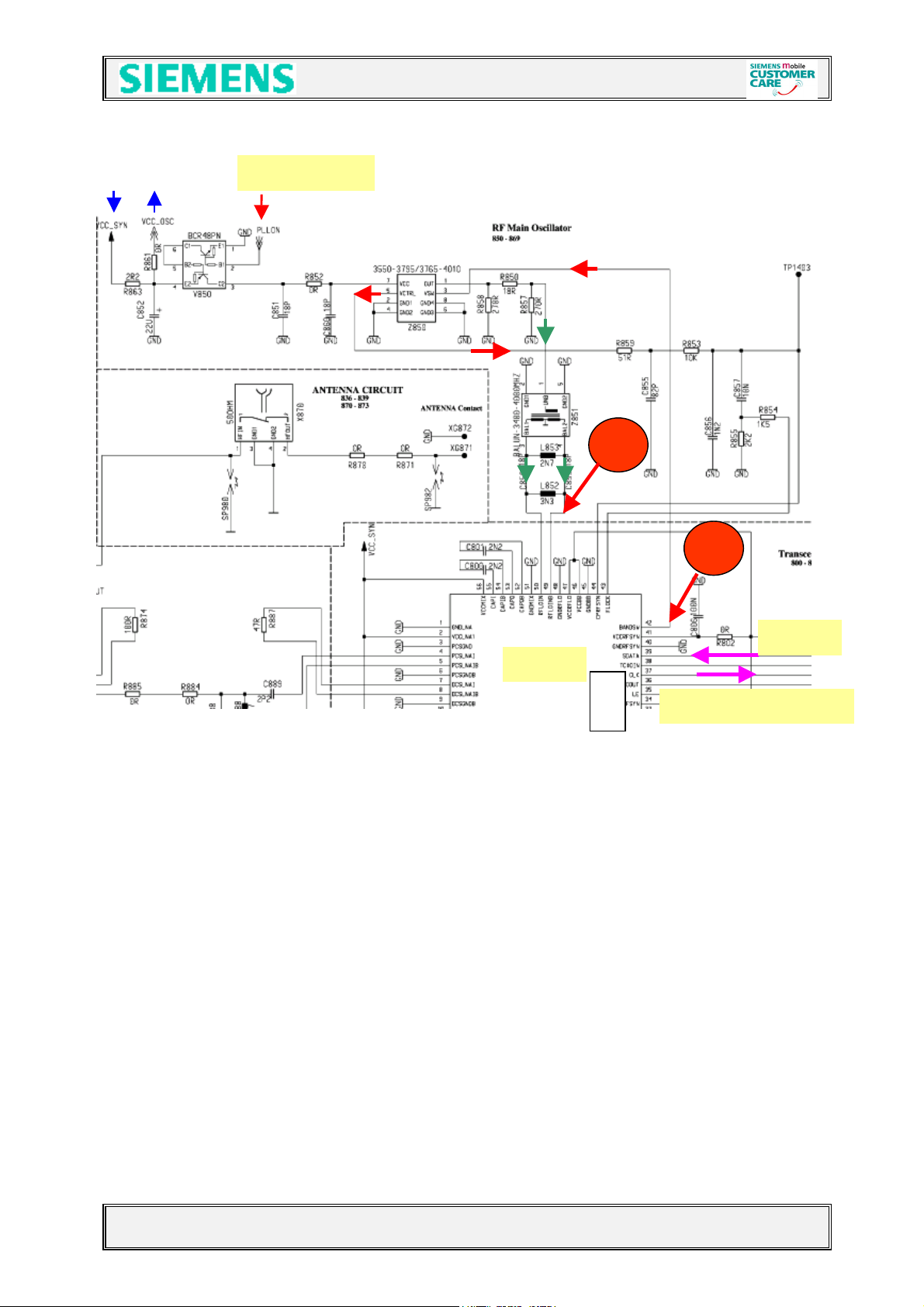

4.2.2 Synthesizer: LO1

The first local oscillator is needed to generate frequencies which enable the

transceiver IC to mix an “IF” and to perform the channel selection in the TX part.

To do so, a control voltage for the LO1 is used. Gained by a comparator

(located inside the Transceiver -IC).

This control voltage is a result of the comparison of the divided LO1 and a reference

Signal. The division ratio of the dividers is programmed by the EGOLD+, according

to the network channel requirements.

The first local oscillator (LO1) is part of the PLL which consists of the comparator

inside the Bright (D800), a loop filter and the VCO (Z850) module.

This LO1 circuit generates frequencies from:

3700-3840 MHz for GSM900

3610-3760 MHz for GSM1800

(The VCO can be switched via the signal VSW (Pin 3) to generate frequencies for

GSM900 and GSM1800)

RX IF = no IF required TX IF-GSM900 = 45…46MHz

TX IF-GSM1800 = 90…92MHz

Formula to calculate the frequencies:

st

LO freq. RX EGSM = Ch. * 4

1

PCN = Ch. * 2

The VCO (Z850) is switched on by the EGOLD+ signal PLLON

via V850 and therefore supplied with VCC_SYN. The VCO guarantees by using the

control voltage at pin5 a coverage of the GSM900 and GSM1800 band.

The channel programming of the PLL happens via the EGOLD+ signals SYGCCL,

SYGCDT, SYNSTR

(RF Control K14, K15, M15).

The required voltage VCC_SYN is provided by the N840

(TDMA-Timer J12)

V1.1 Page 11 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 12

Circuit diagram

from EGOLD+

4221

Bright

4222

26MHz

1

:

2

13MHz to EGOLD

V1.1 Page 12 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 13

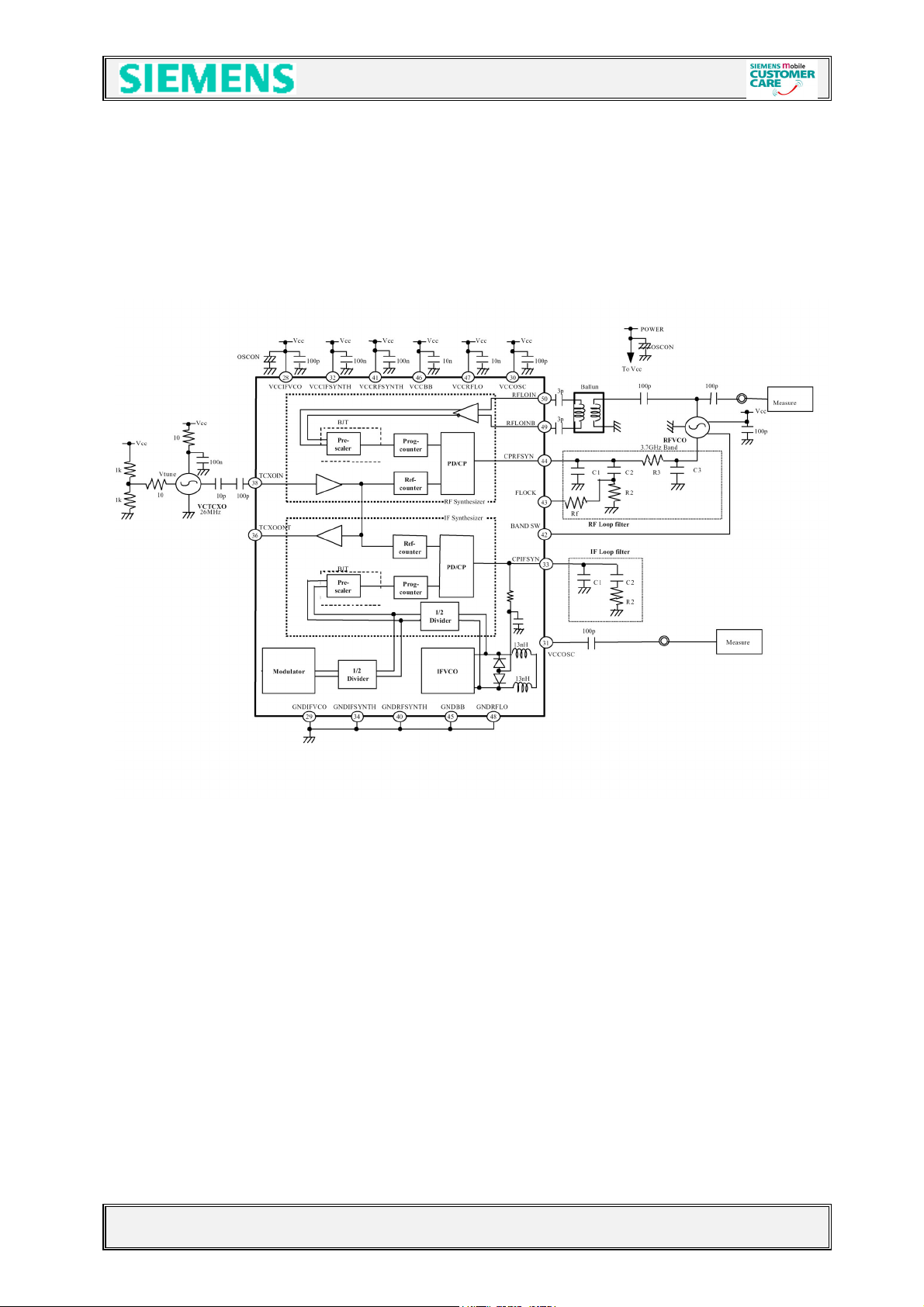

4.2.3 Synthesizer: LO2

The second local oscillator (LO2) consists of a PLL and a VCO which are

integrated in Bright IV and a second order loopfilter which is realized external.

Due to the direct conversion receiver architecture, the LO2 is only used for

transmit-operation. To avoid inband-spurious in the transmit-signal, the

LO2-frequency assignment is not fixed for the whole band.

Before the LO2-signal gets to the modulator it is divided by 8 for GSM900 and by 4

for GSM1800. So the resulting

TX-IF frequencies are 45…46 MHz. GSM900

TX-IF frequencies are 90…92 MHz. GSM1800

nd

LO freq. = 360…368 MHz divided by 8 = 45…46 MHz,

2

divided by 4 = 90…92 MHz

The LO2 PLL and power-up of the VCO is controlled via the tree-wire-bus of

Bright IV+.(EGOLD+ signals SYGCCL, SYGCDT, SYNSTR

The required voltage VCC_SYN is provided by the N840

Circuit diagram

(RF Control K14, K15, M15))

Loop-filter LO2

V1.1 Page 13 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 14

4.2.4 Synthesizer: PLL

PLL as a part of the BRIGHT IC

Blockdiagram

V1.1 Page 14 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 15

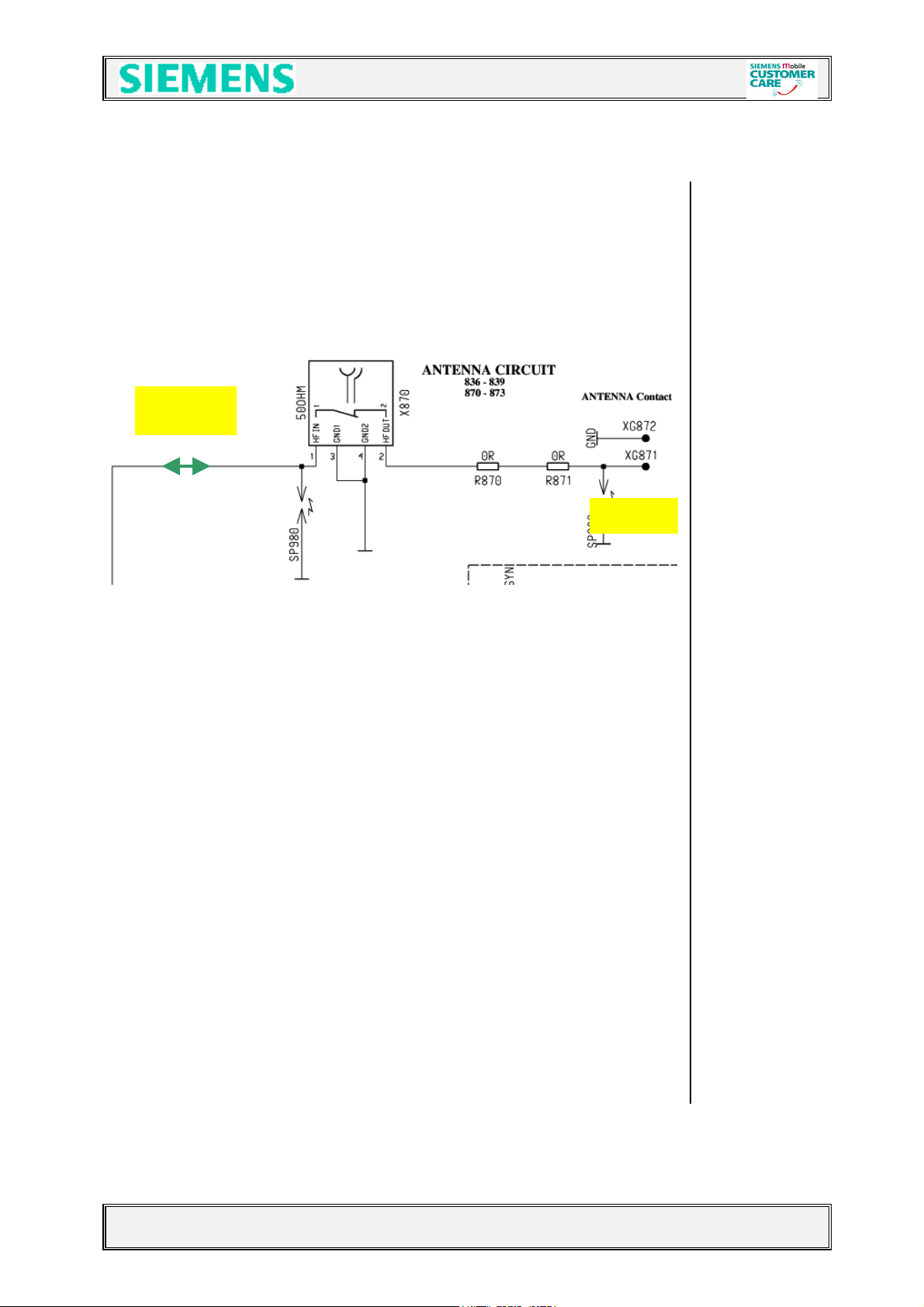

4.3 Antenna switch (electrical/mechanical)

Internal/External <> GSM1900/PCS <> Receiver/Transmitter

The M46 mobile has two antenna switches.

a) The mechanical antenna switch for the differentiation

between the internal and external antenna

to / from

diplexer

Internal

V1.1 Page 15 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 16

b) The electrical antenna switch, for the differentiation between the receiving

and transmitting signals.

To activate the correct settings of this diplexer, some logical switches and

switching signals are required. (V880, V881)

Bright

V1.1 Page 16 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 17

4.4 Receivers

4.4.1 Receiver: GSM900/1800 –Filter to Demodulator

From the antenna switch, up to the demodulator the received signal passes the

following blocks to get the demodulated baseband signals for the EGOLD+:

Filter >>>>>>>> LNA >>>>>>>> Demodulator>>>>>>>> PGC

Z880 Bright Bright Bright

The GSM900 and GSM 1800 filters are located inside the frontend module.

Filter:

The Filter are centered to a frequency of 942,5MHz for GSM900 and 1847,5MHz

for GSM1800. The symmetrical filter output is matched via LC-Combinations to

the LNA input of the BRIGHT (D800)

The LNA´s are located inside the BRIGHT and is able to perform an

LNA:

amplification/attenuation from ~ 20dB. The LNA is can be switched in HIGH and

LOW mode and is controlled by the Bright.

Demodulator:

GSM Signals. To do so the LO1 is required.

The channel depending frequencies for 1900MHz band are divided by´2 for

internally.

After demodulation the “I” and “Q” signals are amplified by the internal

PGC:

PGC-Amplifier whereby the “I” and the “Q” path are amplified independently

From each other. The performance of this PGC is 80dB (-22 up to 58dB),

switchable in steps of 2dB. The control is realised through the EGOLD+

signals (SYGCCL, SYGCDT, SYNSTR).

After passing an internal switch, the signals are ready for further processing

through EGOLD+

The required voltage VCC_SYN is provided by the N840

The Bright IC performs a direct demodulation of the received

V1.1 Page 17 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 18

from LO1

progr. signals

to EGOLD+

V1.1 Page 18 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 19

4.4.2 IC Overview

IC Overview

BRIGHT IV

V1.1 Page 19 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 20

A

4.5 Transmitter

4.5.1 Transmitter: Modulator and Up-conversion Loop

The modulation is also based on the principle of the

“up-conversion modulation phase locked loop” and is accomplished via the

BRIGHT IC(D800). The internal TX IF-LO provides the quadratic modulator with the

TX IF frequencies (79…81 MHz) by generating 632…648 MHz frequencies,

which are divided by 8.

This so generated IF GMSK RF signal is compared in a phase detector with the

down mixed GMSK RF output from the TX-VCO (Z890).

To get the comparison signal PCN_PA_IN signal appearing at Pin 10 of the (Z890)

is mixed with the LO1 signal (divided by 2).

The output (PLLOUT) signal of the phase detector passes a discrete loop filter

realised by capacitors and resistors to set the TXVCO to required frequency.

The large loop band width (~1,5MHz) guarantees that the regulating process is

considerably quicker than the changes in the modulation signal.

The required voltage VCC_SYN and VCC2_8 is provided by the N840

LO1

from EGOLD+

to P

V1.1 Page 20 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 21

4.5.2 Transmitter: Power Amplifier

The output signal (PCN_PA_IN) from the TX-VCO are led to the power amplifier

(Z900) passing a matching circuit. The PA is a “two in one” PA (GSM part not used)

and, is connected directly to Batt+.

After amplification, a part of the output signal (TX_PCN_OUT) is decoupled via a

directional coupler. The other part runs through the antenna switch (Z880) and the

antenna connector (X870) to the Antenna. The decoupled part is equalised by the

detector diode (V920) and used from the (N920) to get a PA control voltage by

comparing this voltage with the PA_RAMP signal provided from the

EGOLD+ (

The (N920) is activated through the signal TXONPA and TXON1.

The required voltage BATT+ is provided by the battery.

The required voltage VCC2_8 is provided by N840.

Blockdiagram of LML361 (PA control IC9

Vhome

Ramp

TC

Gnd

GAIM/BASEBAND H2).

Vdd

Vf

Vr

Comp1

Comp 2

Vdd

Vdd

Vss

Vdd

Vss

Vdd

Vss

Vss VddBS PA_ON

Out A

Out B

V1.1 Page 21 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 22

5 Power Supply

5.1 Overview and Voltages

Leerlaufspannung:

3,2V..4,2V

2,0 A

peak

Ri

current

PA

+Treiber

+Regelung

150 µF

NiMH

Audio-

Amplifier

[ASIC]

Linear-

Regler

[ASIC]

Linear-

Regler

[ASIC]

Linear-

Regler

[ASIC]

Linear-

Regler

[ASIC]

35 mA(pk), 7 mA(avg)

75 mA max.

80 mA

2,0V +-5%

2,07V (1,92V) +- 3%

140mA max.

2,65V +-3%

100mA max.

2,9V +-3%

140mA max.

Linearregler

2,8V +- 3,5%

Magnetischer Ringer

VDDRTC

EGOLD Core

EGAIM,

EGOLD Portpins,

LCD controller

Flash, SRAM, SIM,

Light, Soundchip,

Vibra-motor, Altimeter

IrDA

LED

Powercontrol-ASIC,

TXVCO

Linearregler

2,8V +- 3,5%

145 mA max.

Transceiver IC,

VCXO

V1.1 Page 22 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 23

Overview of HW Structure

All power supply functions of the mobile phone, except the RF-Part, are carried out

by the power supply ASIC (D361)

General:

The pin POWER of the I/O-Connector is used for charging the battery.

For accessories, which provide a variable charging current, the current will

be set via a pin SB (current byte) (e.g. S25 chargers corresponding to

Car Kits etc.).

- The S45/ME45 power supply is unregulated and cannot be controlled by

the SB signal.

- The SB signal is used to distinguish between various chargers.

The following restrictions must be considered:

- The phone cannot be operated without battery.

- The phone will be damaged if the battery is inserted the wrong way

- In the charging branch a fuse element is inserted against over current.

5.2 Power Supply ASIC

The power supply ASIC (D361) contains the following functions:

- Control of “Switch On” of the mobile phone via the ON/OFF switch.

- Recognition of external chargers connected on POWER.

- Control of “Switch On” of the mobile phone via the ON/OFF1 (RTC)

- Watchdog monitoring

- Control of mobile phone “SWITCH OFF” via WATCHDOG_mP connection.

- “Switch off “of mobile phone in the case of overvoltage at battery connection.

- Generation of RESET signal for EGOLD+ and Flash

- Voltage generation via “Linear regulator 2.90 V “

- Voltage generation via “Linear regulator 2.65 V “

- Voltage generation via “Linear regulator 2.07 V “

- Battery charge support: interrupted if there is an over-temperature

- Software-controlled switching of voltage supply for the accessories

- Light switching

- Voltage generation for “SIM-CARD”

- VIBRA switching

- Ringer tone switching

- Audio switching

Switch “ON” sequence

- Falling edge recognition KB7, or RTC_INT

- Generation of the “2,07; 2,65; 2,9” voltages

- Generation of the “RESET_2,0V and RESET_2,65V”

- 32,768 KHz oscillator

- Generation of the “Watch Dog” signal through the EGOLD+

after “POWER_ON”

- 26MHz oscillator

V1.1 Page 23 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 24

“Switch-On” timing

V1.1 Page 24 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 25

“Switch-Off” timing

“PIN-OUT” ASIC D361

V1.1 Page 25 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 26

5.3 Battery and Charging

5.3.1 Battery

A Li-Ion battery with a nominal capacity of 840mAh is used for the S/ME45 series

and a NiMH battery with a nominal capacity of 550mAh for the C45. M50 and MT50

are delivered out with a Li-Ion battery of 650 mAh. A temperature sensor

(22kW at 25°C) is integrated to monitor the battery temperature.

Battery connector:

5.3.2 Charging Concept

The battery is charged in the unit itself. The hardware and software is designed for

Li-Ion or NiMH with 4.2V technology.

The battery will be charged as long as the GAIM part of the EGOLD+ measures

changes in the values of the battery voltages during the charging process.

There are two ways to charge the battery:

Normal charging also called “fast charging”

Trickle charging

Normal Charging

As soon as the phone is connected to an external charger, charging starts. The

customer can see this via the “Charge” symbol in the display

Charging is enabled via a FET-Switch (V342) in the phone. This FET-Switch activates

the circuit form the external charger to the battery. The EGOLD+ takes over the

steering of this switch depending on the charge level of the battery, whereby a

disable function in the ASIC (D361) hardware can override/interrupt the charging in

the case of overvoltage of the battery (only in case of NEC batteries).

The charging software is able to charge the battery with an input current within the

range of 350-600mA. If the FET-Switch is switched off, no charging current will flow

into the battery (exception is trickle charging, see below).

For controlling the charging process it is necessary to measure the ambient (phone)

temperature and the battery voltage.

V1.1 Page 26 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 27

For temperature detection, a NTC resistor (22kW at 25°) is assembled in the

battery pack. Via the pin 2 of the battery connector connected to the

EGOLD+

The voltage is measured from the GAIM-part of the EGOLD+ (see description

In chapter 7)

(GAIM L3) is carrying out the measurement.

Trickle charge

If the phone has not been used for a longish time (longer than approx. 1 month), the

battery could be totally self-discharged. (battery voltage less then 3,2V), so that

it is not possible to charge the battery via the normal charging circuit. In this case

only trickle charge is possible.

The STV-ASIC (D361) controls the charging circuit himself.

- Battery voltage below 2,8 Volt charging current 20mA.

- Battery voltage below 3,2 Volt charging current 50mA.

- Battery voltage over 3,2 Volt “Normal charging”.

Power supply for the ASIC (D361) in this mode is the external charger.

(VDD_CHARGE)

The switch into normal charging mode, is done automatically if the required voltage

is reached.

Trickle Charging Power Supply

“Normal/Trickle” charging activation

!! Attention!!

- a charger voltage >15V can destroy resistors or capacitors in the charging path

- a charger voltage >20V can destroy the MOS-FET switch transistor in the

charging path.

V1.1 Page 27 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 28

6 Logic Part

6.1 Overview Logic/control

Overview to the HW structure

The hardware in the M50 / MT50 can be split up into two function groups:

At first there is the baseband chipset with its periphery comprising the EGOLD+,

Flash and power supply ASIC. This function group is basis for all equipment variants.

V1.1 Page 28 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 29

The logic part of the M50 consists of:

The EGOLD+

Hardware µC-part

Software µC-part

Software SP (Signal Processor) part Equaliser

EGAIM inside the EGOLD+

RTC (Real Time Clock)

V1.1 Page 29 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 30

6.2 EGOLD (PMB6850) V1.3/V2.x

VBIN

VBOUT

BPDM1

VCLK

DACI

BPDM2

TMS

TCK

TDO

DACQ

TDI

TRST

2 MHz (to GAIM)

PE.1

RXD1 / EX1IN & T5EUD /

TXD1 / CC04IO / PE.0

DSPOUT0 / A22 / PF.3

Interface

DSP Serial

Communication

Enhanced Handsfree / DAI

5

Unit

Cipher

A51/52

Audio & Speech

HW

Viterbi

Accelerator

H. Meschede, HL AS CR CE,

16 bit I/O Ports

E-GOLD Architecture

Enable Signals to

X- and PD-Bus

VCXO_EN / - / PE.8

VSSa

VDDa

PDOUT / A23 / PF.4

CLKSXM / A21 / PF.5

CLKANA

F13M

RXDD / RXD1 / PF.7

RFSD / - / PF.9

523

SCLK / T6EUD / PF.8

TFSD / T2IN / PF.10

TXDD / TXD1 / PF.6

RXD0 / - / PE.3

TXD0 / - / PE.4

SSCCLK / - / PE.5

MTSR / - / PE.6

MRST / - / PE.7

RTCOUT

VDDRTC

F32K

requires ext. crystal

and special bondout

Peripherals

Power

Generator

Peripheral Enable

Clock Generation

2

ASC1

GPT1/GPT2

Detect

ASC0

Autobaud

SPI

SSC

compatible

32 kHz

RTC

2 x 8 bit

CAPCOM

Osc.

32.768 kHz

16

RESET_IN

CC00IO / T3OUT / PC.2

READY / WAKEUP / PC.1

DSP Timer2

DSP Timer1DSP Timer1

Management

Watchdog

8

CC01IO / NMI & DSPOUT2 / PE.2

CC02IO / - / HOLD & DSPOUT1 / PF.0

HLDA / CC03IO & DSPIN0 & T2IN / PC.3

P RAM

P ROM

48k x 16

OAK+ DSP

52 MHz

MCU

13 MHz / 32 kHz

READY#

NMI#

PD-Bus

ID Register

DSPOUT1 / A22 / PF.1

CLKOUT / CC05IO / PC.0

T5IN / T2EUD & T3IN / PC.4

CC06IO / A21 & EX7IN / PF.11

RX and TX

Voiceband Filters

Y RAM

5k x 16

2k x 16

X ROM

18k x 16

Interleaving / De-Interleaving Speech Decoding (FR, HR, EFR) Speech Coding (FR, HR, EFR) Level Measurement Channel Decoding (FR, HR, EFR) Channel Coding (FR, HR, EFR) Equalization Encryption / Decryption Voice Memo / Voice Dia ling

X-Bus

C166CBC

Interrupt Controller

OCDS DPEC

HOLD#

HLDA#

CLKOUT

RSTOUT#

60

Interrupt

Extension

6

Multicore

Debug Support

MON1

MON2

TRIGIN

TRIGOUT

D8 / CC20IO / PA.8

Baseband Filter

X RAM

6k x 16

De-Interleaving 12k x 4

16 bit write access

4/16 bit read access

1k x 16

Dual Port RAM

8

D10 / - / PA.10

D11 / - / PA.11

D13 / T7IN / PA.13

D9 / CC16IO / PA.9

D12 / EX5IN / PA.12

D14 / CC22IO / PA.14

D15 / CC18IO / PA.15

GMSK Modulator

Interleaving

2 x 28 x 116 x 1

Dual Port 512 x 16

Shared Memory

Bus

Unit

Interface

Interrupt Controller

SEIB

OCEM

Block

Boot

1k x 16

PRAM

1k x 16

PROM

External

Bus & Port

8 16

21 24

D(7:0)

A(20:0)

AFC Unit

Controller

CS(4:0)2

5

3

RD

WR

CS0

CS1

CS2 / CC02IO / PF.12

BHE / CC00IO / PF.15

CS4 / DSPOUT2 / PF.14

RSTOUT / EX6IN & T3EUD / PF.2

CS3 / EX4IN & DSPIN0 & T4EUD / PF.13

JTAG

TAP Controller

Boundary Scan

Company confidential

RF Control

GSM

TDMA Timer

SRAM

xk x 16 (x = 0...64)

to MCU &

High Speed

Interface

SIM card

(F=512, D=8/16)

Keypad

Pulse-Carry Mod.

AFC

Interface

4

33

5

9

Clock Generation Unit

CCIN

CCIO

CCLK

64

VSS2.0x, x=a,b,c

VSS2.(4:1)

I/O Driver

VDD2.0x, x=a,b,c

VDD2.(4:1)

VSS1.(2:0)

Core

VDD1.(2:0)

RFCLK

RFDATA

RFSTR0

RFSTR1

RFSTR2 / CC07IO / PD.0

RFSTR3 / CC18IO / PD.1

RFSTR4 / EX2IN / PD.2

GAIMCLK

GAIMSTR

GAIMDATA

GAIMRXON

T_OUT0

T_OUT1

T_OUT2

T_OUT3

T_OUT4 / DSPIN0 / PD.3

T_OUT5 / CC17IO / PD.4

T_OUT6 / T4IN / PD.5

T_OUT7/ CAPIN / PD.6

T_OUT8 / CC23IO / PD.7

T_OUT9 / T7IN & EX3IN / PD.8

T_OUT10 / EX1IN & DSPIN1 / PD.9

T_OUT11 / CC19IO / PD.10

T_OUT12 / A23 / PD.11

CCVZ / - / PB.10

CCRST

& T6IN / PB.11

CCIOSW / T6OUT & T0IN

KP0 / T2EUD & EX0IN / PB.0

KP1 / CC06IO / PB.1

KP2 / CC20IO / PB.2

KP3 / CC16IO / PB.3

KP4 / - / PB.4

KP5 / - / PB.5

KP6 / EX5IN / PB.6

KP7 / T7IN / PB.7

KP8 / CC22IO / PB.8

KP9 / CC18IO / PB.9

V1.1 Page 30 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 31

6.3 EGAIM inside the EGOLD+

V1.1 Page 31 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 32

EGAIM inside the EGOLD+

6.3.1 Tasks of the EGAIM inside the EGOLD+

- Measurement of Battery and Ambient temperature

- Measurement of Battery Voltage

- A/D conversion of MIC-Path signals incl. coding

- D/A conversion of EP-Path signals incl. decoding

- Generating of the PA-Control Signal “PA_Ramp”

V1.1 Page 32 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 33

Measurement of Battery and Ambient Temperature

The temperature is measured as a voltage equivalent of the temperature on the

voltage dividers R131,R136,R135 for the ambient temperature by the EGAIM.

The battery temperature is measured directly at (l3) of the EGOLD+. For this,

the integrated SD converter of the EGAIM of the RX-I base band branch is used.

This SD converter compares the voltage of TBAT and TENV internally with a

reference voltage BREF.

Via an analog multiplexer, either the RX-I base band signal, or the TBAT signal

and the TENV signal can be switched to the input of the converter.

The signal MEAS_ON from the EGOLD+

(GSM TDMA-TIMER G11) activates the

measurement and is used to generate to BREF by the help of R137,R132

Measurement of the Battery Voltage

The measurement of the battery voltage is done in the Q-branch of the EGAIM.

for this BATT+ is connected via a voltage divider R118, R120 to the EGOLD+

(GAIM N2) (Input limitation 1.33V to 5.91V) .An analog multiplexer does the

switching between the baseband signal processing and the voltage

measurement.

V1.1 Page 33 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 34

A/D conversion of MIC-Path signals incl. coding

The Microphone signals (MICN2, MIpN2, MICP1, MICN1) arrive at

the voiceband part of the EGAIM. For further operations the signals will

be converted into digital information, filtered, coded and finally formed

into the GMSK-Signal by the internal GMSK-Modulator.

This so generated signals

given to the SMARI IC / Bright IC in the transmitter path.

D/A conversion of EP-Path signals incl. decoding

Arriving at the Baseband-Part the demodulated signals (MOD_A, MOD_AX,

MOD_B, MOD_BX ) will be filtered and A/D converted. In the voiceband part

after decoding (with help of the uC part) and filtering the signals will be D/A

converted amplified and given as (EPP1, EPN1, EPP2, EPN2) to the internal

earpiece or the external loudspeaker.

(MOD_A, MOD_AX, MOD_B, MOD_BX) are

Generation of the PA Control Signal (PA_RAMP)

The RF output power amplifier needs an analog ramp up/down control voltage.

For this the system interface on EGOLD+ generates 10 bit digital values which

have to be transferred serially to the power ramping path. After loading into an

10 bit latch the control value will be converted into the corresponding analog

voltage with a maximum of ~2V

-

V1.1 Page 34 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 35

6.4 Real Time Clock (integrated in the EGOLD+)

The real time clock is powered via its own voltage regulator inside the ASIC (D361)

directly from the battery. The so gained voltage VDD_RTC is buffered by a capacitor

(C369) to keep the data (e.g. clock) in the internal RAM during a battery change for

at least 30 seconds.

An alarm function is also integrated which allows to switch the phone on and off.

via RTC_INT

The reference oscillator for the RTC is (Z100)

V1.1 Page 35 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 36

6.5 SRAM

Memory for volatile data.

Memory Size: 4Mbit

Data Bus: 16Bit

Access Time: 70ns

The SRAM (D250) is provided with 2.07V from the ASIC (D361) . It is used

from the EGOLD+ to store temporally data.

The communication is controlled and activated from the EGOLD+.

V1.1 Page 36 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 37

6.6 FLASH

Non-volatile but erasable and re-programmable (software update) program

memory (Flash) for the EGOLD and for saving user data (menu settings),

linguistic data (voice memo) and mobile phone matching data.

There is a serial number on the flash which cannot be forged.

Memory Size: 48 Mbit (32 Mbit + 16 Mbit)

Data Bus: 16 Bit

Access Time: 70ns (32 Mbit)

90ns (16Mbit)

Boot Block: Top

V1.1 Page 37 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 38

l

7 Acoustics

7.1 General

The Electro-Acoustic components are: a) The Vibra

b) The Microphone

c) The Loudspeaker/Ringer

Internal

microphone

M46: Audio-concept

MICP2

MICN2

MICP1 MICN1

PMB6850

EGold+

PWM (50% duty cycle)

EPN2

EPP2

EPN1

EPP1

I/O-connector

AUDO N

AUDO P

Schalk e Asic

MUX

A1

A2

B1

B2

C1

C2

RINGIN

Headset

32W

Interna

speaker

16W

V1.1 Page 38 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 39

7.2 Vibra

The vibrator is assembled in the lower case shell. The electrical connection is

carried out via spring contacts The Vibra is driven and controlled from the

power supply ASIC (

The vibrator is directly connected to the ASIC´s 2,9V. The diode V440 is used to

protect the circuit against over voltage and switching spikes.

D361

pin B3)via the signal VIBRA

15,5..20,3µs

3,6V..4,2V

50µs

0,5s 0,5s

Vibra-Timing

V1.1 Page 39 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 40

Microphone and Loudspeaker (Ringer)

7.3

7.3.1 Loudspeaker

Loudspeaker (EPP1_FIL, EPN1_FIL, EPP2, EPN2) and Microphone (MIC2, MICN2-

MICP1, MICN1) are connected directly to the Voiceband-Part of EGOLD+

7.3.2 Microphone

Both Microphones are directly connected to the EGOLD+.(Voiceband F1-F4) via the

signals MICN1, MICP1 (Internal Microphone )and MICN2, MICP2

(External Microphone/Headset). Power supply for the Microphone is

VMIC (

Voiceband E1)

V1.1 Page 40 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 41

7.3.3 Loudspeaker/Ringer

The internal Loudspeaker (Earpiece) is connected to the voiceband part of the

EGOLD+ (

VOICEBAND D1,E2) via the mono audio amplifier inside the ASIC (D361).

Input EPN1_FIL - EPP1_FIL Output to earpiece EPN1 - EPP1

The ringing tones are generated with the loudspeaker too. To activate the ringer, the

signal RINGIN from the EGOLD+ (

Miscellaneous,E9) is used

V1.1 Page 41 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 42

8 Illumination:

8.1 Illumination

The Light is switched via an analogue switch inside the ASIC (D361). It is controlled

from the EGOLD+ (

signal LIGHT, which is connected via the MMI connector X550 to the keypad LED´s.

and directly to display backlight section

TDMA-TIMER,L15) with the signal LIGHT_OFF. Output is the

D361

V1.1 Page 42 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 43

9 SIM-CARD and Connectors

9.1 SIM-Card

The SIM-CARD is supplied via X520 at pin3 with CCVCC (2,9V) The CCVCC is a

ASIC (D361) switched 2,9V voltage, activated by CCVZQ from the

EGOLD+

If no SIM-CARD is connected, or if there is no response (CCIO) from the SIM-CARD,

the EGOLD+ tries 3 times to connect the SIM-CARD. After this time the EGOLD+

stops trying. That means, if the EGOLD+ is losing the connection while normal

operation of the mobile phone, the mobile must be switched off and on again.

The communication between the EGOLD+ and the SIM-CARD is done via the CCIO

X520 pin6 by using CCCLK as a clock signal.

The diodes V520/521 are used to protect signal lines versus switching peaks.

(Address-Data G13)

V1.1 Page 43 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 44

9.2 Display connector

The display is provided with 2,65V from the ASIC (D361). The communication with

the EGOLD+ by the LCD-Signals, directly connected to the EGOLD+

LCD_CS SIM L9

LCD_RESET Miscellaneous N7

LCD_RS Serial-Interface R14

LCD_CLK Serial-Interface P11

LCD_DAT Serial-Interface N11

V1.1 Page 44 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 45

9.3 I/O-Connector

Name IN/OUT Notes

Pin

1 GND

2 SB O Control line for external power supply

3 POWER I Power input from external power supply

4 FBatt+ O Voltage for external accessories.

5 TX O Serial interface

6 RX I Serial interface

7 ZUB_CLK I/O Clock line for accessory bus

Use as DTC In data operation

8 ZUB_DATA I/O Data line for accessory bus.

Use as CTS in data operation

9 GND_MIC For external microphone

10 MICP2 I External microphone

11 EPP2 O

12 EPN2 O For external loudspeaker

For external loudspeaker

V1.1 Page 45 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 46

9.4 Battery Connector

The battery is connected via the battery connector (X386) to the battery contacts

on the RF-Board.

Directly connected to battery, there is a voltage regulator (N386). This regulator

Is used to provide the external accessories with the required voltage.

To extend STAND-BY time, the regulator is switched on with the signal ZUB_On

only if accessories are recognised.

Responsible for the ZUB_ON signal is the ASIC (D361).

Pin

1 Batt+ I/O Battery voltage

2 Akku_Temp O Temperature control of the battery pack.

3 GND

V1.1 Page 46 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Name IN/OUT Notes

Page 47

10 Import Information

Exchange of Level 2,5e Components

Due to the increased number of “wrong” repairs we want to highlight again, that a

defective Level 2,5e component has to be replaced exactly versus the original

spare part from the e-commerce. This includes especially the function state of the

component.

Below the different function states are described by the 2 mostly affected

components

The C45 mobile phone has depending on the production date 2 different

power amplifiers which are not directly compatible

One PA has the part number L36851-Z2002-A45 (PA107)

The other one is the L36851-Z2002-A58 (PA122)

How to identify:

To identify the different function state of the components always have a look onto

the top side of the component.

.

L36851-Z2002-A58 (PA122)

L36851-Z2002-A45 (PA107)

V1.1 Page 47 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 48

b) The EGOLD depending on the production date the internal mask of the EGOLD

has changed. They are also not directly compatible

One EGOLD has the part number L36810-G6132-D670 (V1.3)

The other one is the L36810-G6107-D670 (V2.10)

The version of the EGOLD and the Mask have to be checked.

!

L36810-G6107-D670 (V2.10)

L36810-G6132-D670 (V1.3)

V1.1 Page 48 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Page 49

l

"

11 Handling of BGA Components

The level 2,5e requires a special kind of handling and storage of BGA-Components.

The following instruction describes the procedure.

BGA spare parts must be stored in a metallized vacuum bag and handled as

electrostatic sensitive components.

If the vacuum bag is opened and a BGA-component is removed, the component

must be soldered immediately. The vacuum package must be vacuum sealed again.

If more than one component is removed, the BGA-Components must be stored in

a 60° Celsius environment (e.g. oven )

If components are outside the vacuum package for more then 7 days, they must be

baked at 125° Celsius for 24 hours before soldering.

If the baking operation is not performed, soldering may not be successful.

BGA storage conditions

- Temp. 5 – 30°C (before opening of vacuum package)

- Humid. 40 – 60% RH (after opening of vacuum package)

- Duration 1 Year (before opening of vacuum package)

after 7 Days 125° C / 24hrs. baking is required

12 Additional L2.5e Documents

On our Internet page www.communication-martket.siemens.de

documents as download for Level 2.5e repair.

Dokumentation_13M

Hz-Tool_V1.0.doc

"GSM Test_Technica

instruction_V1.1.doc

are additional

V1.1 Page 49 of 49 ICM MP CCQ ST

C45, M50, MT50 AND A50 Company Confidential © Copyright Siemens AG 10/02

Loading...

Loading...