Page 1

Accelerating the progress of

renewable fuels with Siemens

automation and instrumentation

National Corn-to-Ethanol Research Center

Pioneering partnership

Biofuels – renewable energy sources

derived from organic material such

as corn – are increasingly viewed

as a cleaner, cheaper, more efficient

alternative to traditional fossil fuels.

For nearly two decades, the National

Corn-to-Ethanol Research Center

(NCERC) at Southern Illinois University

Edwardsville has accelerated the growth

of the biorenewables industry through

the commercialization of advanced

biofuel products and technologies.

Featuring analytical and fermentation

laboratories, an intermediate-level

fermentation suite and a demonstrationscale pilot plant, the center is uniquely

positioned to provide clients with a full

range of commercialization services –

from project design and proof of

concept to validation and scale-up.

Biofuel and bio-based material

producers across the globe make use of

NCERC’s vast resources to evaluate new

ingredients, processes and equipment,

with the ultimate goals of improving

yields and reducing costs.

instrumentation solutions from

Siemens. For well over a decade,

Siemens has partnered with NCERC to

elevate renewable fuel production with

state-of-the-art technology for process

control, simulation and monitoring.

A flexible DCS to meet diverse needs

Originally designed as a small cornto-ethanol production facility, NCERC’s

24,000-square-foot pilot plant has

been modified and upgraded to handle

a much wider variety of biofuels,

biopolymers and specialty chemicals.

At the heart of its operations is the

SIMATIC PCS 7 distributed control

system, which automates, visualizes and

optimizes the core process equipment

for every client. With PCS 7, NCERC has

the flexibility to offer continuous or

batch runs for multiple feedstocks.

PCS 7 has been operating at NCERC

since 2007, when Siemens made a

formal donation of the DCS. The center

has since modernized to PCS 7 Version 9

to take advantage of intuitive operator

tools such as alarm management and

interlock visualization. Their installation

includes SIMATIC PLCs (S7-1200

To ensure the success of every project,

NCERC provides clients with access to a

world-renowned staff of experienced

engineers, operators and scientists –

and to facilities equipped with leadingedge process automation and

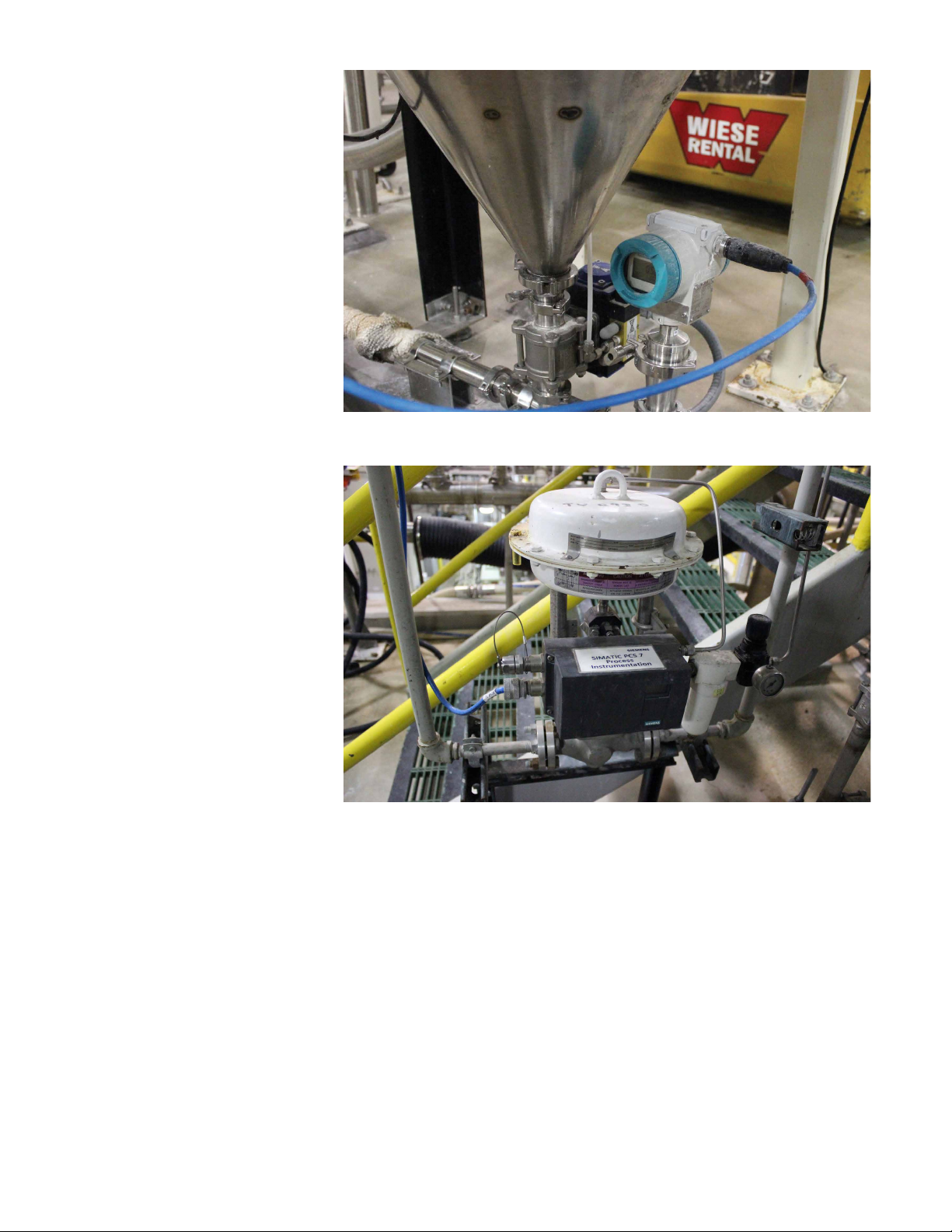

The SIMATIC PCS distributed control system automates, visualizes and optimizes the core

process equipment for every NCERC client.

usa.siemens.com/process

Page 2

controllers and S7-1500 controllers with

PROFINET) as well as SIMATIC AS 410

controllers connected to SIMATIC ET200

distributed IO.

NCERC also utilizes SIMATIC BATCH addon software for batch automation, which

allows them to configure, plan, control

and log batch processes directly in PCS 7,

as well as the PCS 7 Process Historian

server solution for centralized archiving

and reporting of all batch data, process

values, tags and alarms in real time.

With their modular approach to PCS 7

configuration, NCERC is able to change

campaigns quickly and with minimal

effort – making it possible to support

a large number of clients with diverse

needs. “We depend on PCS 7 with BATCH

and Process Historian to gather all

process data and export it directly to our

clients,” says John Caupert, Executive

Director of NCERC. “PCS 7 enables us to

provide every client with the information

they need to make important decisions

about how to move forward with their

project – whether the campaign lasts

three days or nine months.”

Real-world experience with

simulation

As the only organization in the world

to offer both classroom training and

hands-on instruction specific to the

biorenewables industry, NCERC plays a

key role in filling the growing need

for qualified personnel to operate and

manage biofuel refineries. Each year

the center hosts dozens of motivated

college students, interns and

apprentices interested in learning

how to operate a process plant. The

centerpiece of this dynamic workforce

education program is the SIMIT

Simulation Platform for PCS 7.

SIMIT creates a virtual model of a plant’s

original PCS 7 control screens, making it

possible to train operators on a variety

of procedures and critical scenarios –

without disrupting production or

endangering worker safety. NCERC

uses SIMIT to develop fully functional

replicas of the DCS operating in their

pilot plant. The software is downloaded

to a SIMIT Virtual Controller, which

emulates a physical controller and

eliminates the need for additional

hardware. NCERC leverages two unique

features of the Virtual Controller to

enhance the effectiveness of training:

Virtual Time Management, which

allows users to speed up or slow down

simulations, and Snapshots, which

save current controller and simulation

states to be re-loaded for future

training sessions.

“SIMIT has proven very cost-effective in

training students and interns as well as

new part-time and full-time employees,”

says Caupert. “When we hire someone

with little to no experience, we use the

software as part of their onboarding

process to familiarize them with PCS 7 –

how to turn on a pump, how to trend,

how to detect whether something

is going wrong. SIMIT really helps

to optimize the NCERC workforce

by familiarizing them with the

important control system terminology

and technology.”

Additionally, as NCERC uses the

Advanced Process Library (APL) feature

of PCS 7, they benefit from tight

integration between PCS 7 and SIMIT.

APL includes pre-configured function

NCERC trains students and new hires using the SIMIT Simulation Platform, which creates a virtual model of a plant’s original PCS control screens.

Page 3

blocks, faceplates and block icons with

corresponding templates in SIMIT that

accept the outputs from the control

system with no manual adaptions

necessary. The APL upgrade is paying

dividends for NCERC since they can

easily test potential changes to the

physical plant with SIMIT before putting

anything into production – resulting in

“right the first time” campaigns that

save time and money.

Intelligent, integrated

instrumentation

NCERC relies on Siemens as a trusted

technology supplier for more than just

process control and simulation. Today,

there are more than 3,300 data points

throughout NCERC’s pilot plant –

including a variety of intelligent

Siemens field instruments. Designed for

full integration into PCS 7, these devices

oversee the health of each product

stream and transmit all process data

seamlessly back to the control system.

As fermentation is the most common

method for producing biofuels, the

plant operates four 6,000-gallon,

jacketed fermenters with eductor

pumps for solids sweeping. The tanks,

eductors and other key points in the

fermentation process are monitored by

SITRANS FC Coriolis mass flow meters,

SITRANS P pressure transmitters and

SITRANS LR radar level indicators, with

SIPART valve positioners controlling

pneumatic valves.

SITRANS P pressure transmitter monitoring the pressure in an eductor.

Many of the Siemens instruments in use

have built-in PROFIBUS PA capabilities

across a digital network, allowing for

high-speed, two-wire communication

of not only measured process values,

but also cost-saving diagnostic and

preventative maintenance information.

The SIMATIC PDM (Process Device

Manager) application integrated into

PCS 7 collects this valuable data from

all PA- and HART-enabled field devices

in the plant to support NCERC operators

in minimizing plant downtime –

while additionally simplifying device

configuration, parameter assignment,

commissioning and calibration. This

centralized asset management tool

allows NCERC to continually interrogate

their instrumentation via the PCS 7 HMI

screen, ensuring consistently accurate

and high-quality production runs. PDM

also works with NCERC’s smart electrical

devices from Siemens, including the

SIPART valve positioner on a carbon dioxide scrubber.

SIMOCODE Pro motor management

system and SINAMICS variable

frequency drives.

To further drive innovation, the

center has incorporated Siemens gas

analytics products into the facility.

The NCERC team is not afraid to take

on a challenge – so when a client

asked about evaluating a biochemical

application, NCERC added a bank of

OXYMAT and ULTRAMAT gas analyzers

for measuring oxygen and CO2 levels

in the fermentation process. The client

production runs led to the results they

had hoped for as they moved to fullscale production.

NCERC appreciates the versatility and

sophistication of Siemens process

automation and instrumentation,

motors and drives, and analytics – but

also the technical expertise that comes

with it. According to Caupert, “The level

of support we receive both directly from

Siemens and from our local Siemens

distributor is consistently high. They are

very responsive to our needs and their

deep knowledge means that everything

will be up and running quickly, which

is particularly reassuring when an

installation is complicated or our staff

is too busy. We like to think of Siemens

support as the ‘ace in our pocket.’”

Page 4

Fueling the future of an industry

To date, NCERC has assisted in the

commercialization of more than 70

biofuel products and technologies

generating nearly $6 billion in revenue,

and is responsible for the direct

creation of 5,000 jobs. The continued

technology partnership between NCERC

and Siemens ensures an ever-brighter

future for the biorenewables industry.

SITRANS FC Coriolis flow meter installed on a

fermenter tank.

NCERC added a bank of OXYMAT and ULTRAMAT gas analyzers for measuring oxygen levels in the

fermentation process.

Siemens Industry, Inc.

Triangle Parkway

Norcross, GA

---

info.us@siemens.com

Subject to change without prior notice

All rights reserved

Printed in USA

© 2020 Siemens Industry, Inc.

All photos courtesy of the National

Corn-to-Ethanol Research Center.

NCERC’s installation includes SIMATIC PLCs.

Level monitoring on the fermenters is carried

out by SITRANS LR radar level indicators.

The technical data presented in this document is based on an actual case or

on as-designed parameters, and therefore should not be relied upon for any

specific application and does not constitute a performance guarantee for any

projects. Actual results are dependent on variable conditions. Accordingly,

Siemens does not make representations, warranties, or assurances as to the

accuracy, currency or completeness of the content contained herein. If

requested, we will provide specific technical data or specifications with

respect to any customer’s particular applications. Our company is constantly

involved in engineering and development. For that reason, we reserve the

right to modify, at any time, the technology and product specifications

contained herein.

Loading...

Loading...