Page 1

SERVICE MANUAL

This document has been published to be used for

CODE: 00ZXEA147/S1E

ELECTRONIC

CASH REGISTER

XE-A107/A137/A147(V)

MODEL XE-A1BT

CHAPTER 1. SPECIFICATION ············································································ 1-1

CHAPTER 2. OPTIONS ······················································································· 2-1

CONTENT

CHAPTER 3. MATSER RESET············································································ 2-1

CHAPTER 4. HARDWARE DISCRIPTIONS & OPERATION PRINCIPLE ········ 4-1

CHAPTER 5. DIAGNOSTIC ················································································· 5-1

CHAPTER 6. OTHERS ························································································· 6-1

CHAPTER 7. ERROR CODE ··············································································· 7-1

CHAPTER 8. PARTS LIST ··················································································· 8-1

Parts marked with “!” are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for mainta ining the safety and performance of the set.

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

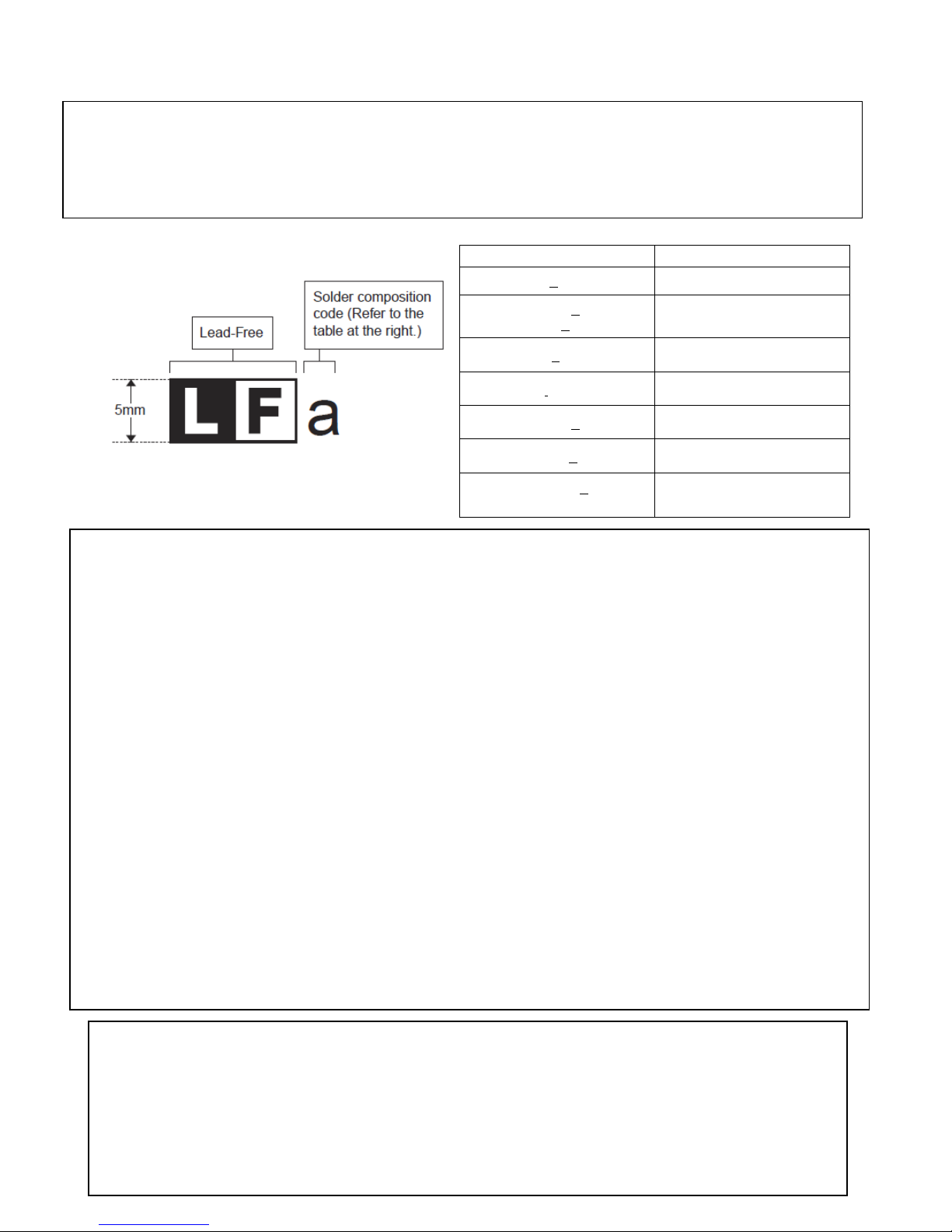

Solder composition

Solder composition code

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

<Solder composition code of lead-free solder>

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi z

Sn-In-Ag-Bi i

a

b

Sn-Cu-Ni n

Sn-Ag-Sb s

Bi-Sn-Ag-P

Bi-Sn-Ag

p

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread. Never use conventional lead solder thread, which may cause a

breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, t he use of the exclusive-use soldering iron is recommendable.

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C hi gher than that of conventional l ead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the sol dering iron tip

after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

THERE IS A RISK OF EXPLOSION IF THE BATTERY

IS REPLACED BY AN INCORRECT TYPE.

PROPERLY DISPOSE OF USED BATTERIES ACCORDING

CAUTIONS

TO THE INSTRUCTIONS.

Page 3

CHAPTER 1. SPECIFICATIONS

(Including the drawer)

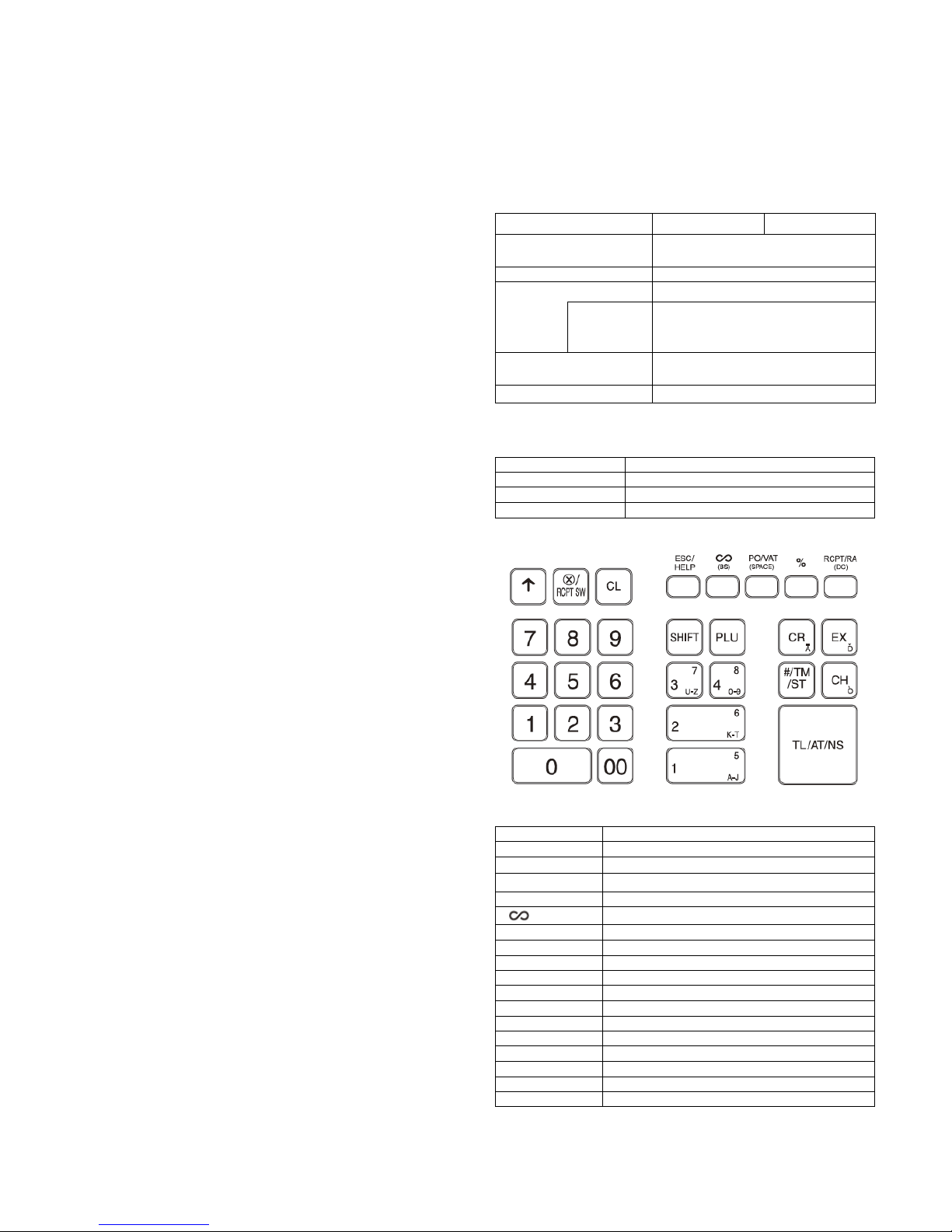

Power

AC adapter

Operating: 8.1W

Type

Normal keyboard

Key position

STD / MAX 30

Key Pit ch

19 (W) x 19 (H) mm

Key layout

Fixed type

0-9, 00

Numeric keys

Paper feed key

Multiplication / Receipt switch key

CL

Clear key

(BS)

ESC/ HELP

Escape / help key

%

Percent key

PO/VAT (Space)

Paid out / VAT key

PCPT / RA (DC)

Receipt / Received on account key

SHIFT

Department shift key

PLU

PLU (Price Look Up) key

CR

Credit key

EX

Exchange Key

CH

Check key

#/TM/ST

Non add / Time / Subtotal

TL/AT/NS

Total / Amount tendered / No sale key

1. PRODUCTS OUTLINE

The XE-A107, A137 and A147 are developed in accordance with

following basic concepts.

1) The XE-A137 and XE-A147 are a mass-route popular class

ECR and low-class European Fiscal model.

2) Main features of XE-A137 and XE-A147 are 1-sheet drop-in

thermal printer, and SD card slot.

3) XE-A147 also has features of RS-232 port and battery option.

2. MAIN FEATURE & FUNTTION

1) New design

2) Color variation (Black and white)

3) 1-Sheet drop-in thermal printer (XE-A137/XE-A147)

- Print speed: Approx. 7 lines/Sec.

- Paper width: 58mm

4) SD-card slot standard: for Programming and data export

(XE-A137/XE-A147)

5) PC link (Programming tool) (XE-A137/XE-A147)

6) Local language support (XE-A137/XE-A147)

7) RS232C port(D-sub) standard: for FISCAL control box

connection (XE-A147 only)

8) Battery option is available (XE-A147 only)

[1] XE-A137 / XE-A147

1. BASIC SPECIFICATIONS

XE-A137-BK/WH XE-A147-BK/WH

External dimension

Weight

source

Power consumption

Working temperature

Europe/

Asia/ME/

Oceania etc

335(W) x 360 (D) x 190 (H) mm

Approx 5kg

AC220-230V (50/60Hz)

AC230- 240V (50Hz)

Stand-by: 1.9W

0~40°C (32 to 104°F)

2. KEYBOARD

1) KEYBOARD OUTLINE

2) KEYBOARD LAYOUT

3) KEY LIST

Key top Description

↑

X

○

/RCT SW

DEPT 1-4 (5-8) Department 1-4 (5 -8) key

Void key

1-1

Page 4

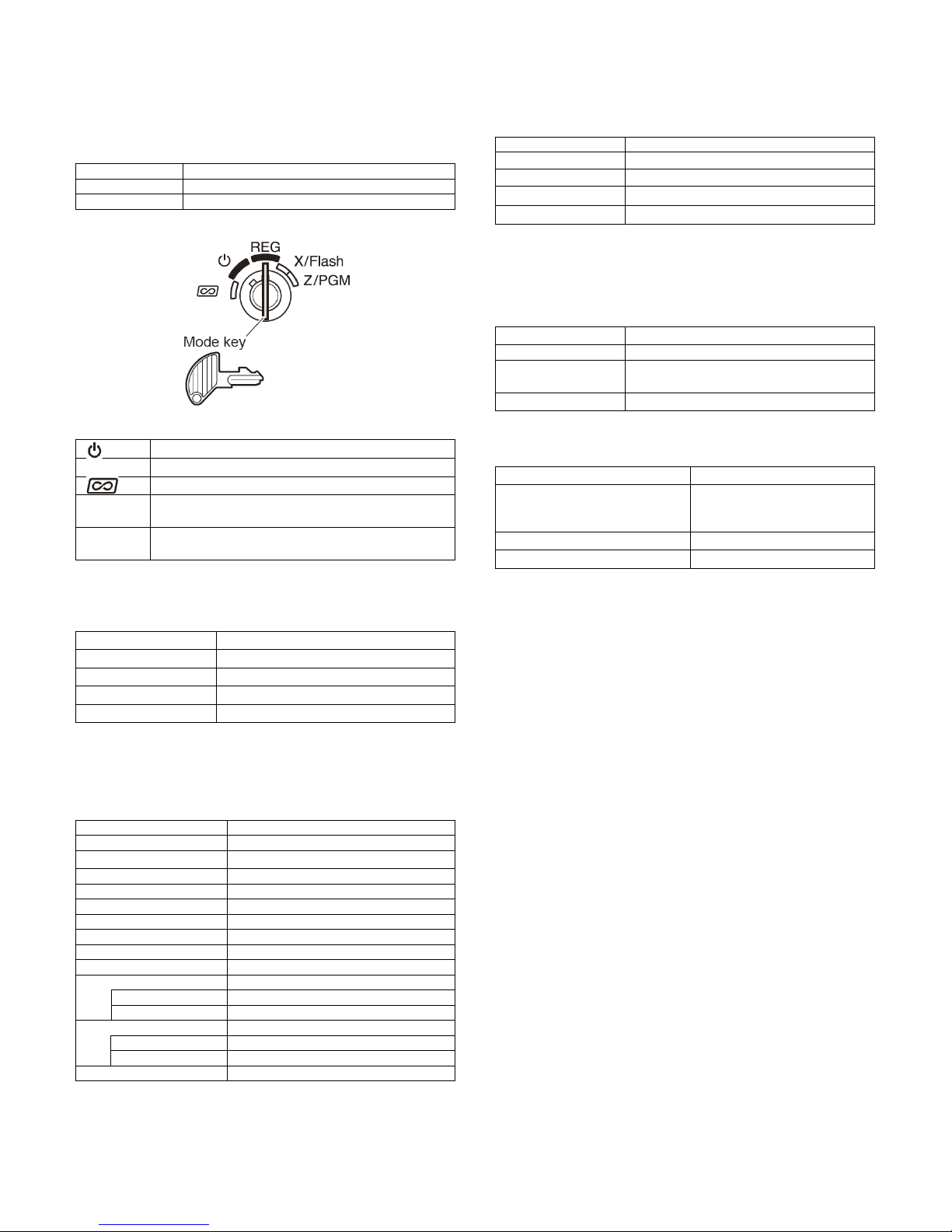

3. MODE SWITCH

Type

Rotary switch type with Mode key

STEP

5

Turns the display off. No operations are possible

REG

Permit transaction entry

flash reports

programming

Display device

LED numeric display

Number of line

1 line

Color of display

Yellow Green

Character size

Numeric: 14.2 (H) x 8.0 (W) mm

Printing digits

30 digits

Character size

1.25 mm(W) x 3.0 mm (H)

Printing speed

Approx. 7lines / Sec.

Validation printing

None

Logo stamp

None

Ink roller

None

Graphic Logo Print

Yes (Size: 360 mm(W) x 180 mm(H))

Paper end sensor

Receipt side

Yes

Paper near end sensor

Receipt side

None

Journal side

None

Paper type

Thermal paper

Paper roll diameter

66 to 72g/m2

Plastic

Bell

--

bottom

Separation from the drawer

Disallowed

compartments

Bill separator

-

Number of compartments

3B/6C (V model)

1) MODE SWITCH OUTLINE

2) LAYOUT

2) PAPER

Paper roll width 57.5 ±0.5mm

φ80mm

Paper Thickness

Paper weight

72 to 78μm

6. DRAWER

1) DRAWER BOX AND DRAWER

Material

3) FUNCTION

X/Flash

Z/PGM

Permit correction after final a transaction

Permits printing of sales reports and display the

Permits printing and resetting of sales reports and

4. DISPLAY

1) OPERATOR DISPLAY

Number of positions 9 digits numeric display (V model)

5. PRINTER

1) PRINTER

Printing system Thermal printer

Release lever

Drawer open sensor

Standard equipment: situated at the

--

2) MONEY CASE

Separation of the bill

compartments from the coin

Allowed

Cutter type Manual

Ink Ribbon None

Journal side None

Printer cover key None

1-2

Page 5

[2] XE-A107

(Including the drawer)

Weight

Approx 4.0kg

etc

AC220 - 230V (±10%)

Power consumption

Operating: 2.3W

Type

Normal keyboard

Key position

STD / MAX 30

Key Pit ch

19 (W) x 19 (H) mm

Key top

Description

0-9, 00

Numeric keys

Paper feed key

Multiplication / Time key

CL

Clear key

ESC

Escape / help key

%

Percent key

PO

Paid out key

SHIFT

Department shift key

PLU

PLU (Price Look Up) key

DEPT 1-4 (5-8)

Department 1-4 (5 -8) key

EX

Exchange key

CH

Check key

#/ST

Non add / Subtotal

Type

Rotary switch type with Mode key

STEP

5

Turns the display off. No operations are possible

REG

Permit transaction entry

Permit correction after final a transaction

flash reports

programming

Display device

LED numeric display

Number of line

1 line

Color of display

Yellow Green

Character size

Numeric: 14.2 (H) x 8.0 (W) mm

Printing capacity

Max. 13 characters

Character size

1.6 mm(W) x 2.1 mm (H)

Printing speed

Approx. 1.4lines / Sec.

Validation printing

None

Logo stamp

None

Ink roller

None

Graphic Logo Print

None

Paper end sensor

Receipt side

None

Paper near end

Receipt side

None

Journal side

None

Printer cover key

None

1. BASIC SPECIFICATIONS

XE-A107-BK/WH

External dimension

Power

source

Europe/

Asia/ME/

Oceania

335(W) x 360 (D) x 190 (H) mm

AC adapter

Stand-by: 1.5W

3. MODE SWITCH

1) MODE SWUTCH OUTLINE

2) LAYOUT

Working temperature

0~40°C (32 to 104°F)

2. KEYBOARD

1) KEYBOARD OUTLINE

Key layout Fixed type

2) KEYBOARD LAYOUT

3) KEY LIST

3) FUNCTION

X/Flash

Z/PGM

Permits printing of sales reports and display the

Permits printing and resetting of sales reports and

4. DISPLAY

1) OPERATOR DISPLAY

Number of positions 9 digits numeric display (V model)

5. PRINTER

1) PRINTER

Printing system P rint wheel selective type

↑

X

○

/TM

Void key

RA/VAT Received on account / VAT key

CR Credit key

TL/AT/NS Total / Amount tendered / No sale key

Cutter type Manual

Ink Ribbon None

Journal side None

sensor

1-3

Page 6

2) PAPER

Paper type

Bond paper

Paper roll diameter

Paper weight

47 to 64g/m2

Plastic

Bell

--

bottom

Separation from the drawer

Disallowed

compartments

Bill separator

-

Power consumption

7.2V / 1265mh

Type

Nickel Metal Hydride (Ni-MH) battery

Re-chargeable

Paper roll width 57.5 ±0.5mm

φ80mm

Paper Thickness

0.06 to 0.085mm

6. DRAWER

1) DRAWER BOX AND DRAWER

Material

Release lever

Drawer open sensor

2) MONEY CASE

Separation of the bill

compartments from the coin

Number of compartments 3B/6C (Vmodel)

Standard equipment: situated at the

--

Allowed

[3] XE-A1BT

Installable model XE-A147 only

1-4

Page 7

CHAPTER 2. OPTIONS

Optional battery

Price

Fix angle A

(for tumble prevision)

Fix angle B

(for tumble prevision)

Price

5 Rolls / Pack

Ink roller

(For XE-A107)

5 Rolls / Pack

XE-A147)

Price

rank

RS232C loop back test tool

(For XE-A147)

1. OPTIONS

Product name Model Description

Optional battery XE-A1BT

(for XE-A147)

2. SERVICE OPTIONS

Parts code

LANGK7612BHZZ AF

LANGK7613BHZZ AN

XHBS730P06000 AC Screw (for set the fix angle)

rank

Description

3. SUPPLIES

Item Parts code

Roll paper DPAPR1025CSZZ AV

INK Roller NROLR1022RCZB AZ

Thermal

paper

*Handled as service par ts

TPAPR6656RC05 BA

rank

Description

(For XE-A107)

(For XE-A137 /

4. SPECIAL SERVICE TOOLS

Parts code

UKOG-2374RCZZ AV

Description

CHAPTER 3. MASTER RESET

Master reset:

Clears all the memory and initializes each preset parameter.

The master reset should be performed by using the following

procedure.

1. Turn off the power (Power OFF). (See Note 1))

2. Let the ECR be without the memory back up battery.

3. Turn the mode switch to the others of Power-off position.

4. Turn on the power (Power ON). (See Note 2))

When the master rest is completed, the buzzer sounds

intermittently three times.

5. Attach the memory back up battery to the ECR.

The master reset can also be accomplished in the foll owing

case. (See Note 3))

Note 1) Power OFF:

Means disconnecting the AC power supply to the

machine. (Specifically, unplugging the machine)

Note 2) Power ON:

Means connecting the AC power to the ma-chine.

(Specifically, plugging in the machine)

Note 3) In case a power failure occurs when the machine

has no battery installed, the master reset operation is

automatically performed after the power has been

restored.

2-1

Page 8

CHAPTER 4. HARDWARE DESCRIPTI O N & OPE RATIO N P RICIPLE

ME/Africa

1. OUTLINE

XE-A107 XE-A137,XE-A147

CPU

PRINTER 58mm Print wheel type 58mm Thermal Printer

Rolling up

SRAM None 1Mbit(128kByte x8)

ROM For Program MASK ROM in CPU FLASH ROM in CPU

DISPLAY 7segments LED

Display

digits

KEY Normal KEY: 30key

Mode S/W 5 steps rotary type

I/F

POWER SUPPLY AC adapter for XE-A107 AC adapter for XE-A137or XE-A147

BATTERY

DRAWER Standard: 1 unit

EU/Oceania/Asia/

EU/Oceania/Asia/

ME/Africa

USB None

SD None 1slot

DRAWER 1port (For Standard drawer only. There is no optional drawer port)

RS232 None 1port ( for XE-A147)

EFT None

MEMORY BACK UP LR6 (AA size)

OPTIONAL

OPERATION BATTERY

8bit MASK CPU

uPD780023AGC *4.19MHz

MASK ROM Built in (For Program)

Yes None

9 digits

None Option: XE-A1BT (XE-A147only)

32bit CPU

MB9AF116N *16MHz

FLASH ROM Built in (For Program)

4-1

Page 9

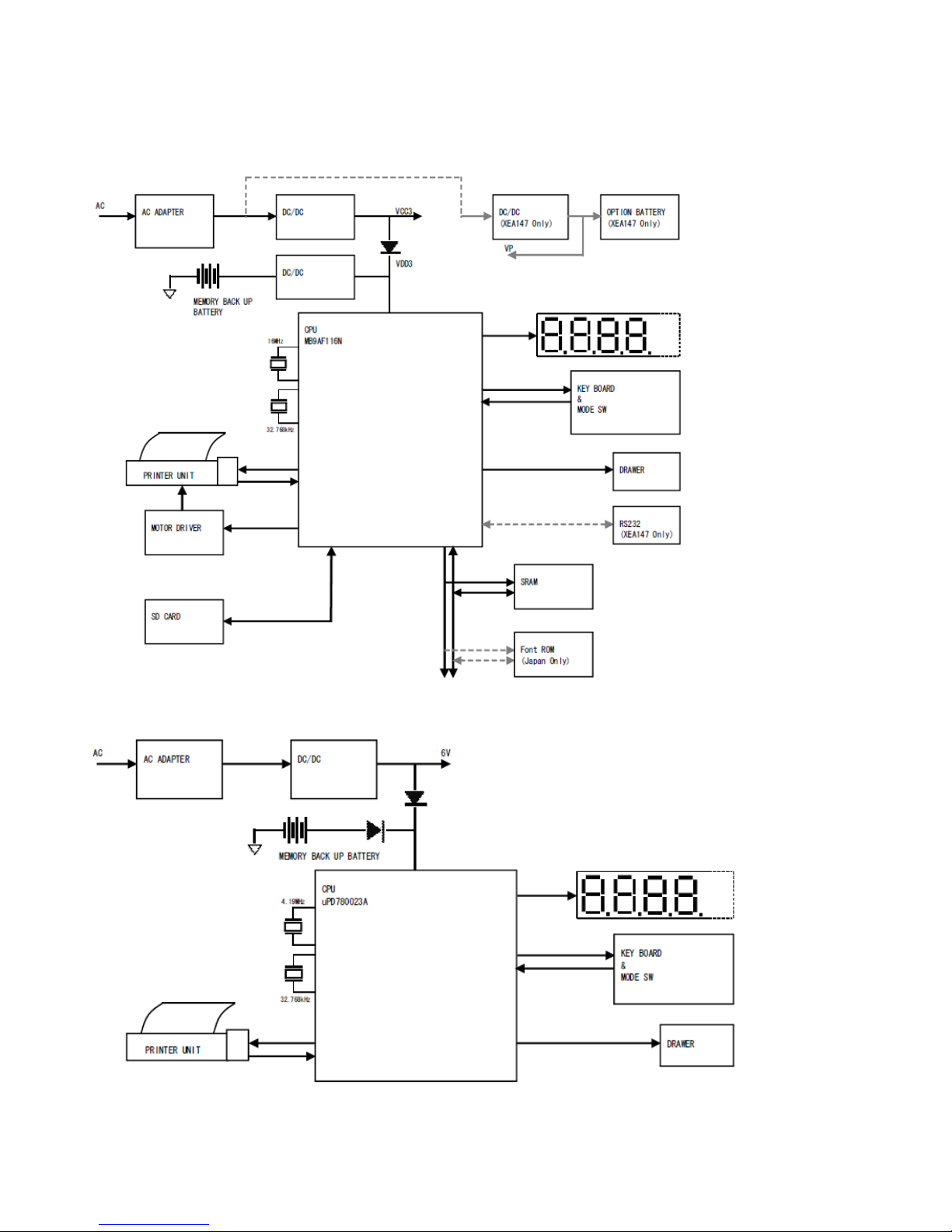

2. Block diagram

1) XE-A147 / XE-A137

2) XE-A107

4-2

Page 10

3. Description

Key top

Description

CL

Clear key

Void key

ESC

Escape / help key

%

Percent key

PO

Paid out key

PLU

PLU (Price Look Up) key

DEPT 1-4 (5-8)

Department 1-4 (5 -8) key

CR

Credit key

EX

Exchange key

TL/AT/NS

Total / Amount tendered / No sale key

1) DISPLAY

The display of these models is LED type. And there are 2 types

such as 8 digits and 9 digits. It is depend on the destination of

models.

a. Display content

Display

Departments/PLU Code:

The department code or PLU code entered appears on the left.

For example, if the key for department 1 is pressed, "1" would

appear in the extreme left position.

Repeat:

Indicates the number of times the same department key is

pressed. If an entry is repeated more than ten times, only the

first digit is displayed (12 displays as "2").

( ) Low battery:

This symbol appears when the power of the installed batteries is

below a certain level or you need to replace the batteries with

new ones. (see the "Maintenance" section for explanation.)

) No battery:

(

This symbol appears when no batteries are installed,

installed batteries are empty.

In addition, the following appear when appropriate:

The minus sign (-) can appear in positions 2 to 8.

The decimal point appears in positions 1 to 3.

When entry of the secret code is necessary, "---" appears in

positions 1 to 4.

or the

2) KEYBOARD AND MODE SW

a. Keyboard layout (ex XE-A107)

( ) Error:

This symbol appears, accompanied by a warning beep, when an

error is made. If this occurs during a transaction because of an

excessive digit entry, simply press [CL] and re-enter correctly.

( ) Program:

This symbol Appears on the display when the cash register is

being programmed in the Z/PGM mode.

( ) Finalization:

This symbol appears when a transaction is finalized by pressing

[CA/ AT/NS], [CH] or [CHK].

( ) Subtotal:

This symbol appears when [#/SBTL] is pressed and the cash

register computes the subtotal, and also when the amount

tendered is less than the total sale amount.

( ) Change:

This symbol appears whenever the change due amount is

displayed.

( ) Exchange:

This symbol appears

in foreign currency

when [EX] i s pressed to c alculate a s ubtotal

b. Key list

0-9, 00 Numeric keys

↑

X

○

/TM

RA/VAT Received on account / VAT key

SHIFT Department shift key

CH Check key

#/ST Non add / Subtotal

Paper feed key

Multiplication / Time key

4-3

Page 11

Mode switch layout

Permit correction after final a transaction

X/Flash

flash reports

Z/PGM

programming

c. Function

REG

Turns the display off. No operations are possible

Permit transaction entry

Permits printing of sales reports and display the

Permits printing and resetting of sales reports and

3) BATTERY

a. MEMORY BACK UP BATTERY

For memory back up, the dry battery ULM-3 (3 pieces) are

needed.

1. Memory holding time:

Approx. 1 year after New dry batteries are installed.

(It is depend on the battery capacity)

2. Battery exchange method:

When the low battery symbol "L" lights up, replace the

batteries (3 AA) replaced by the following method;

1) Power on t he ECR.

2) Mode switch turn to "REG" mode.

3) Remov e the OLD dry batteries (3 pieces).

4) The no-battery symbol "

5) Insert the NEW dry batteries (3 pieces).

6) Confirm the low battery symbol "L" and no-battery

symbol "

L" is off .

L" light up.

b. LOW BATTERY

c. NO BATTERY

If the user forgets to replace the battery and the battery voltage

falls below a certain level, or if a power failure occurs with no

batteries installed, the memory contents cannot be retained. The

CPU judges it as no battery and performs the master reset. In this

case, all the settings and registrations are cleared. If, however, the

power is continuously supplied to the AC cord, the memory

contents are retained.

Low battery: Batteries are installed, but the voltage is

No battery: Batteries are not installed or the voltage is extremely

Low battery & No battery indication will appear at the most left

position of display when the battery voltage is low.

CASE 1: When any numeric entry & item entry is not done or

CASE 2: When numeri c ent ry or item entry is done.

low. Memory back up can be done.

low. The master reset is executed when a power

failure occurs, when the batteries are not properly

changed.

just after

finalization.

The machine can indicate the battery condition. (Always)

Battery condition is not appeared.

Exceptionally, at the power is restored after power failure,

the low battery & No battery indication will appear on the

display only when the battery voltage is low.

And the indication will disappear after any key entry.

[Display sample]

" 0.00" : Battery is OK.

"L 0.00" : Low battery

L 0.00" : No battery

"

After finalization

"F 12.34": Battery is OK.

"L 12.34": Low battery ("L" indicate instead of "F".)

L 12.34": No battery ("L" indicate instead of "F"

"

Low battery indication will appear on the left side of display when

the battery voltage is low.

CASE 1: When sitting idle or after completion of transaction. The

CASE 2: Low battery indication will not appear during key

machine can indicate the low battery condition (Always)

operations, but will appear after power up of the cash

register.

[Display sample]

“0.00”: Battery is OK.

"L 0.00": Low battery (The batteries have to be replaced.)

After finalization

"F 12.34": Battery is OK.

"L 12.34": Low battery ("L" indicate instead of "F".)

4-4

Page 12

CHAPTER 5. DIAGNOSTICS

4

Drawer test

8

CLOCK test

characters

position

version

[Z/PGM]

1. XE-A137/XE-A147

1) Diagnostic menu

DIAG menu DESCRIPTION

1 Mode switch test

2 Key test

3 Display test

5 Printer test

6 Printer paper sensor test

7 AD conversion level test

Destination display /

9

ROM version

10 SD card test

11 RS232C (XE-A147 only)

12 ROM (Japan only)

13 RAM

To check the mode key function

Keyboard check

To check a display

To check a drawer opening

Printer test

To check a printer paper sensor

AD conversion check

To check the clock on CPU

To check the Destination setting and

ROM version

To check the SD-card write protection

To execute the loopback test

To check the ROM for Japanese

To execute the RAM read write test

2) Entering procedure

It is possible to enter the DIAG mode with following procedure;

1. To set the mode switch to Z/PGM position

2. To input the job code in accordance with below list

3. To push the PO key

4. Start the Diagnostic mode

DIAG menu

Mode switch test

Key test

Display test

Drawer test

Printer test

Printer Paper sensor test

AD conversion level test

CLOCK test

Destination display / ROM

SD card test

RS232C (XE-A147 only)

ROM check (Japan only)

RAM check

Mode key

Z/PGM ‘1’ + PO key

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Key code

‘2’ + PO ke y

‘3’ + PO ke y

‘4’ + PO ke y

‘5’ + PO ke y

‘6’ + PO ke y

‘7’ + PO ke y

‘8’ + PO ke y

‘9’ + PO ke y

‘10’ + PO key

‘11’ + PO key

‘12’ + PO key

‘13’ + PO key

3) Description

3-1) MODE KEY SWITCH

a. Test Procedure

Change over the mode switch as follows. If the mode switch data

in the proper sequence is not read with the above operat ion, an

error is printed.

To cancel this test mode, set the mode switch to any a position

other than [Z/PGM] to [Z/PGM]. In this case, the completion print is

performed.

During the test, the display indicates hard codes which correspond

to the switch position.

The mode switch is set to the “OFF position”, it will no-display.

<Note>

In the test, the mode key should be fixed over 1second in each

position.

b. Mode switch operation

MODE: [Z/PGM] → [X/FLASH] → [REG] → [OFF] → [VOID]

c. Display

5-1

Page 13

d. Test result print

[TL] key pushed

When a test results is OK, following result is printed out

M ODE KEY SWITCH OK

When a test result is NG, following result is oriented out.

MODE KEY SWITCH NG

3-2) KEY TEST

a. Test Procedure

Perform the keyboard check with the sum check data of the key

code.

Enter the any key other than [TL] key, and then enter the [TL] key,

finally. In the process above, machine records the sum, and after

[TL] key entered, compare with check sum proper check sum.

It is possible to re-operate from the beginning, enter the [CL] key 3

times, when operation is wrong.

b. Display

Entered key code:

(According to entering)

Original check sum:

1761(4 digits)

c. Test result print

When a test results is OK, following result is printed out

KEY XXXX-YYYY - OK

When a test result is NG, following result is printed out.

KEY XXXX-YYYY - NG

3-3) DISPLAY TEST

a. Test Procedure

Check the continuous buzzer sound and the display state.

<Check points>

1. The all segments are lighted up correctly.

2. The brightness of all segments is same level.

1. Segments display test

The following pattern is displayed. When [TL ] key pushed,

the display pattern is changed to next.

< Display >

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

5-2

Page 14

2. Shift display test

The following pattern is displayed. When [TL] key pushed,

the display pattern is changed to next.

Finally, all segments are lighted on.

< Display >

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

[TL] key pushed

3. Completion of test

When [TL] key pushed after above test, the test is finished

as OK status.

When other than [TL] key pushed after above test , the test

is finished as NG status.

b. Test result print

When a test results is OK, following result is printed out

DISPLAY&BUZZER OK

When a test result is NG, following result is printed out.

DISPLAY&BUZZER NG

3-4) DRAWER TEST

a. Test Procedure

The drawer opens with the above key operation. Check that the

drawer is open.

After drawer open, check the drawer opening,

When drawer open correctly, push the [TL] key, test will finish with

OK status.

If not, push other than [TL] key, test will finish with NG status.

b. Test result print

When a test results is OK, following result is printed out

DRAWER OK

When a test result is NG, following result is printed out.

DRAWER NG

3-5) PRINTER TEST

a. Test Procedure

With the above key operation, the print test pattern is printed as

below.

Check the print result s.

When print result is OK, push the [TL] key, test will finish with OK

status.

If not, push other than [TL] key, test will finish with NG status.

/////////// ------- ///////////

/////////// ------- ///////////

/////////// ------- ///////////

//////////////////////////////////////////////

//////////////////////////////////////////////

All “/” 6 lines

5-3

Page 15

b. Test result print

1

BBA TTERY V OLT AGE

Back up battery voltage

2

HEAD TEMP

Head temperature

(XE-A147 only)

(XE-A147 only)

< BBA TTERY V OLT AGE >

< HEAD VO LT A GE >

< BA TTERY VOLTAGE > (for XE-A147 only)

< BATTERY TEMP > (for XE-A147 only)

When a test results is OK, following result is printed out

PRINT ER OK

When a test result is NG, following result is printed out.

PRINT ER NG

3-6) PRINTER PAPER SENSOR TEST

a. Test Procedure

With the above key operation, the sensor test is started.

The status of printer paper sensor is displayed by real time.

When [TL] key pushed, the status of printer paper sensor is

printed out then the test is finished.

b. Display

<Printer Paper is detected>

<Printer Paper is not detected>

c. Test result print

When print printer paper is being detected.

SENSO R PAPER YES

When print printer paper is being detected.

SENSO R PAPER NO

3-7) AD CONVERSION TEST

a. Test Procedure

With the above key operation, the AD conversion level is started.

The AD conversion reading data is displayed by real time.

The displaying is done by following sequence:

3 HEAD V OLTAGE Head voltage

4 BATTERY V OLTAG E Option Battery voltage

5 BA T TERY TEMP Option Battery temperature

When [TL] key pushed, the status of following data is printed out

then the test is finished.

b. Display

< HEAD TEMP >

5-4

Page 16

c. Test result print

Display

Hour

Minute

Second

Blink each 500msec

ROM ver

Destination

code

When the test completion, following result is printed out

< XE-A147 >

A/D

1 HEAD VOLTAGE X.XXV

2 HEAD TEMP X.XXV

3 BBATTERY VOLTAGE X.XXV

4 BATTERY VOLTAGE X.XXV

5 BATTERY TEMP X.XXV

<XE-A137>

A/D

1 HEAD VOLTAGE X.XXV

2 HEAD TEMP X.XXV

3 BBATTERY VOLTAGE X.XXV

3-8) CLOCK TEST

a. Test Procedure

With the above key operation, the clock test is starte d.

The clock data is read from CPU and displayed by real time.

If count up is done c orrectly, the result is OK, push the [ TL] key,

test will finish with OK status.

If not, push other than [TL] key, test will finish with NG status.

b. Display

c. Test result print

When a test result is OK, following result is printed out

CLO CK OK

When a test result is NG, following result is printed out

CLO CK NG

3-9) Destination display / ROM version check

a. Test Procedure

With the above key operation, the Destination display / ROM

version check is started.

The CPU version and destination setting are read from CPU then

displayed. The destination code is as follows;

North America EU Japan

0 1 2

Print

U V J

If the displayed destination is correct, the result is OK, push the

[TL] key, test will finish with OK status.

If not, push other than [TL] key, test will finish with NG status.

* In case of check sum is not correct, even if [TL] key is pushed,

but, it may judged “NG”. Because of OK/NG is automatically

judged by the program.

b. Display

<North America>

<EU>

<Japan>

c. Test result print

When a test result is OK, following result is printed out

DESTINATION U OK

ROM ver. 1.00

When a test result is NG, following result is printed out

DESTINATION U OK

ROM ver. 1.00

5-5

Page 17

3-10) SD card TEST

Output

Input

DTRn

RTSn

DSRn

DCDn

CTSn

NO.

CONTENTS

3-11) RS232C LOOP BACK TEST (XEA147 only)

a. Test Procedure

With the above key operation, the SD-card test is started.

The status of SD card is displayed by real time.

When [TL] key is pushed, the test is completion.

CD: Card detected.

WP: Write protection

b. Display

<CD: No / WP: No >

<CD: No / WP: Yes >

<CD: Y es / WP: No>

<CD: Y es / WP: Yes>

c. Test result print

<CD: No / WP: No >

SD CARD

CD: NO , WP: NO

<CD: No / WP: Yes >

SD CARD

CD : NO , WP: YES

<CD: Y es / WP : No>

SD CARD

CD: Y ES , WP: NO

<CD: Yes / WP: Yes>

SD CARD

CD : YES , WP: YES

a. Test Procedure

Before turn the power on, connect the loopback test jig:

UKOG-6646RCZZ to RS232C port. And turn the power on then

set to [Z/PGM] mode then push [1] [1] and [PO] key, the RS232C

loop back test is started.

When stat the test mode, the machine checks the reading of input

control signal, at first.

< The control signal check >

The read check is that DTR and RTS changed in accordance with

following pattern then check the logic of DSR, DCD and CTS. In

this time, if the checked logic is same as following list, the test

result is OK. If not, it is displayed ‘ERROR’.

<Control signal check>

OFF OFF OFF OFF OFF

OFF ON OFF ON ON

ON OFF ON OFF OFF

ON ON ON ON ON

< Data transfer check >

As a check data, the 256 bytes (from 00H to 0FFH) loop back

transfer is done. In this time the BAUDRATE setting is 38.4kbps.

< Completion of test mode >

Push the [TL] key, the test is finished then test result is printed out.

b. Test result print

When a test result is OK, following result is printed out

RS232C OK

When a test result is NG, following result is printed out

RS232C NG---ERROR NO.XXX

1 DTR-DSR

2 RTS-DCD

3 RTS-CTS

4 SD-RD(DATA)

3-12) ROM check (Japan only)

This test mode is not available without Japan model.

5-6

Page 18

3-13) RAM Check

a. Test Procedure

With the above key operation, the RAM check is st a r t e d.

At first, the address touch on address lines in all RAM area is

checked.

<For example the address touch test in all RAM area>

To check the following address

0x61000000、0x61000001、0x61000002、0x61000004

0x61000008、0x61000010、0x61000020、0x61000040

0x61000080、0x61000100、0x61000200、0x61000400

0x61000800、0x61001000、0x61002000、0x61004000

0x61008000、0x61010000、0x61020000

To write ‘55h’ to 0x61000000

To write ‘AAh’ to other than 0x61000000

To check the data in 0x61000000, if 55h is written, the result is

OK. If not, result is NG.

To c heck the data in the other than 0x61000000, if ‘AAh’ is

written, the results is OK, if not, result is NG

To write ‘55h’ to 0x61000001

To write ‘AAh’ to other than 0x61000001

To check the data in 0x61000001, if 55h is written, the result is

OK. If not, result is NG.

To c heck the data in the other than 0x61000001, if ‘AAh’ is

written, the results is OK, if not, result is NG

To write ‘55h’ to 0x61020000

To write ‘AAh’ to other than 0x61020000

To check the data in 0x61020000, if 55h is written, the result is

OK. If not, result is NG.

To c heck the data in the other than 0x61020000, if ‘AAh’ is

written, the results is OK, if not, result is NG

Secondly, the write & verify test is executed.

The different writing data are written in to each address.

<For example>

Address Written data

0x6100_0000~0x6101_FFFF 00h write & verify

0x6100_0000~0x6101_FFFF FFh write & verify

0x6100_0000~0x6101_FFFF 55h write & verify

0x6100_0000~0x6101_FFFF AAh write & verify

The test result is displayed and printed out then test is finished

when the [TL] key pushed.

b. Test result print

When a test result is OK, following result is printed out

RAM CHECK OK

When a test result is NG, following result is printed out

RAM CHECK NG

5-7

Page 19

2. XE-A107

8

CLOCK test

Mode key

[Z/PGM]

[X/FLASH]

[REG]

[OFF]

[VOID]

1) Diagnostic menu

DIAG MENU DESCRIPTION

1 Mode switch test

2 Key test

3 Display test

4 Drawer test

5 Printer test

6 CPU ver. display

7 Battery level test

9 Destination display

To check the mode key function

Keyboard check

To check a display and buzzer

To check a drawer opening

Printer test

CPU version check

Battery condition check

To check the clock on CPU

To check the Destination setting

2) Entering procedure

It is possible to enter the DIAG mode with following procedure;

1. To set the mode switch to Z/PGM position

2. To input the job code in accordance with below list

3. To push the PO key

4. Start the Diagnostic mode

DIAG menu

Mode switch test

Key test

Display test

Drawer test

Printer test

CPU ver. display

Battery level test

CLOCK test

Destination display

position

Z/PGM ‘1’ + PO ke y

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Z/PGM

Key code

‘xxxx2’ + PO key

‘3’ + PO ke y

‘4’ + PO ke y

‘5’ + PO ke y

‘6’ + PO ke y

‘7’ + PO ke y

‘8’ + PO key

‘9’ + PO ke y

3) Description

3-1) MODE KEY SWITCH

a. Test Procedure

Change over the mode switch as follows. If the mode switch data

in the proper sequence is not read with the above operat ion, an

error is printed.

To cancel this test mode, set the mode switch to any a position

other than Z/PGM to Z/P GM. In this case, the completion print is

performed.

During the test, the display indicates hard codes which correspond

to the switch position.

The mode switch is set to the “OFF position”, it will no-display.

<Note>

In the test, the mode key should be fixed over 1second in each

position.

b. Mode switch operation

MODE: [Z/PGM] → [X/FLASH] → [REG] → [OFF] → [VOID]

c. Display

d. Test result print

When a test results is OK, following result is printed out

When a test result is NG, following result is printed out.

01

----01

5-8

Page 20

3-2) KEY TEST

CHECK SUM

a. Test Procedure

Perform the keyboard check with the sum check data of the key

code.

Enter the sum check data of each model in the four digits

preceding the DIAG number 02, and compare the data with the

key position code which is added until the [TL] key is pushed.

If the data coincides with the code, the completion print is

performed.

If not, the error print is performed

<Note>

The check sum above should be higher 0100.

0001 to 0099 check sum does not reflect.

b. Display

4 digits

c. Test result print

When a test results is OK, following result is printed out

02

When a test result is NG, following result is oriented out.

----02

3-3) DISPLAY TEST

a. Test Procedure

Check the display state.

1. The decimal point will shi ft from the lower digit to the upper,

step by step (500msec).

2. The all segments light up

In this time, the buzzer sound will stop. But the segments

are all lights up until any key pushed.

3. To cancel the test mode, press any k ey, after that the test

result is printed.

<Check points>

1. The all segments are lighted up correctly.

2. The brightness of all segments is same level.

b. Display

c. Test result print

When pushed any key, the test mode is cancelled, and the

completion print is performed.

03

3-4) DRAWER TEST

a. Test Procedure

The drawer opens with the above key operation. Check that the

drawer is open. After drawer open, the test will finish automatically

and print the following report.

b. Test result print

04

3-5) PRINTER TEST

a. Test Procedure

With the above key operation, the print test pattern is repeatedly

printed as below.

Pushing any key will terminate the test after the completion of one

cycle print. (The receipt is issued until any key pushed.)

<Check points>

1. There is no lack character.

2. There is no unclear character.

b. TEST Pattern

<U model> <V model>

€・- 98765432X

0123456789 -CG

000X

111Z

222RA

333PO

444VD

555%

666@

777ST

888TX

999CA

---CH

・・・CK

€ € € CG

000X

111Z

222RA

333PO

444VD

555%

666@

777ST

888TX

999CA

---CH

・・・CK

###CG

#・- 98765432X

0123456789 -CG

5-9

Page 21

3-6) CPU version PRINT

0155 or greater

Normal

0138 or smaller

No battery display

North Americ a

EU

Japan

Display 0 1

2

Hour

Minute

Second

Blinking per 0.5sec

3-9) DESTINATION DISPLAY

a. Test Procedure

The CPU version is pri nted wit h above key operation.

This mode is finished automatically when print completed.

b. Test result print

(When Version 1.00)

← CPU Version No.

← 06

3-7) MEMORY BATTERY VOL T AGE SENSOR TEST

a. Test Procedure

Displays A/D conversion port read value of memory battery.

To terminate the test, press any key.

<The displayed value and status>

0154 or smaller Low battery display

b. Test result print

3-8) TIME DISPLAY T EST

a. Test Procedure

Displays time of CPU with above key operation.

<Check point>

1. To blink the “-“ (hyphen)

2. To count up the clock

To terminate the test, press any key.

b. Display

c. Test result print

yymmdd-hhmmss

0100

06

(MRS is done when power on)

07

08

a. Test Procedure

The following destination code in the firmware is dis played with

above key operation.

To terminate the test, press any key.

b. Display

c. Test result print

09

5-10

Page 22

CHAPTER 6. OTHERS

[1] Installing the Fixing Angle Bracket

To prevent the register from moving when the drawer opens, the

fixing angle bracket is provided with option. By attaching the

bracket to the table where the register is installed, it is possible to

hook the register on this bracket and secure the register to its

position.

a. How to install the fixing angle bracket

1) To fix the fix angle-A (LANGK7612BHZZ) by the Screw

(XHBS730P06000) to the bottom of the resister.

2) Thoroughly clean the location where the fixing angle-B

(LANGK7613BHZZ) is to be placed.

3) Peel off the adhesive tape on the fixing angle bracket.

4) Hook the angle bracket onto the fix angle-A which is located

at the bottom rear of the register.

5) Firmly stick the fixing angle B to the table surface that

cleaned above.

b. How to remove the register from the fixing angle bracket

1) Lift up the front of the register and pull the register towards

you.

[2] Printer for XE-A137/A147 series

Since there are no service parts for this model printer, only the

printer unit is supplied. Therefore, the printer component parts are

not supplied and no service document is issued.

For troubleshooting of the printer, refer to the below:

a. Thermal Printer Troub leshooting

a. Loading and removing the journal paper

Procedure for loading and removing the journal paper

1) Journal paper loading procedure:

Please release the platen unit before loading the journal

paper.

When loading the journal paper, please set the paper

straight with the leading edge of the paper 5cm or longer

sticking out from the top face of the printer mechanism.

2) Journal paper removal procedure:

Please release the platen unit before removing the journal

paper.

3) Paper removal procedure at the time of the paper jam

Please take off the jammed paper in accordance with the

Journal paper removal procedure.

Notes for loading and removing journal paper

Please release the platen unit before loading the journal

paper. The jour nal paper cannot be loaded by the auto

loading function on this product.

When loading the journal paper, please set the paper

straight with the leading edge of the paper 5cm or longer

sticking out from the top face of the printer mechanism.

When installing the platen unit, the platen unit drive gear

contacts with the deceleration gear, and in some cases,

the platen unit cannot be installed. In this case, please

release the platen unit, and then try to install it again.

When the journal paper is skewed, please keep feeding

the paper until the paper is straightened or reload the

journal paper.

When taking off the journal paper due the paper jam,

please release the platen unit first. Please do not forcibly

pull out the jammed paper otherwise it may cause the

damage.

b. Cleaning of the thermal head

If the surface of the thermal head gets dirty for some reasons,

please clean the thermal head, otherwis e it may lead to the print

error etc.

Cleaning procedure of the thermal head

Please be sure to shut OFF the power before cleaning the

thermal head.

Please release the platen unit.

When cleaning the thermal head, please wipe out the

contamination on the heating element section using the

cotton swab moistened with the ethyl alcohol or the isopropyl alcohol.

After the alcohol is completely volatilize, please install the

platen unit.

Notes for the thermal head cleaning

Right after the printout, the thermal head and its sur-

roundings reach the high temperature so please be sure

not to clean the thermal head right after the printout.

When cleaning the thermal head, please release the pla-

ten unit.

Please be sure not to clean the thermal head with the tool

which may damage the heating element such as the sand

paper and the cutter etc.

6-1

Page 23

[2] Printer for XE-A107 series

nected

mode switch to "REG" and press "CL" key)

down

Paper thickness: 0.06~0.085mm

Since there are no service parts for this model printer, only the

printer unit is supplied. Therefore, the printer component parts are

not supplied and no service document is issued.

For troubleshooting of the printer, refer to the table below:

b. Trouble shooting

Phenomena Check point/possible cause Repair

The printer motor is locked and the buzzer

sounds intermittently

The printer does not work properly

Defective print (Lack on the upper/ lower or

left/right side)

Thin print Check if the ink roll life is reached Replace the ink roll.

Uneven pitch of print paper feed Check if the roll paper size is proper Use roll paper as specified below;

Check if the printer cable is discon-

Check if the printer life is reached Replac e the printer

Check if any foreign material is attached

to the printing type wheel or the gear

section

Check if the printing type is worn down Replace the printer.

Check if any foreign material is attached

to the printing type wheel

Check if the printing type wheel is worn

down

Check if the ink roll is properly installed Install the ink roll properly

Check if the printing type wheel is worn

Check and repair the printer cable

Remove the foreign material.

(After removing the foreign material, set the

Install the ink roll properly

Replace the printer

Replace the printer

Paper width: 57.5 0.5mm

Outside diameter: ϕ80mm or less

Inside diameter of paper tube: ϕ12mm or less

Check if a load is applied to the roll paper during paper feeding. This may result from a foreign materials attached to

the roll paper.

Remove any foreign material.

6-2

Page 24

CHAPTER 7. ERROR CODE

Error

E01

Registration error

Make a correct key entry.

E02

Miss operation error

Make a correct key entry.

E11

Compulsory depression of the [#/TM/ST] key

Press the [#/TM/ST] key and continue the operation

E12

Compulsory tendering

Make a tendering operation.

E34

Overflow limitation error

Make a registration within a limit of entry

E35

The open price entry is inhibited

Make a preset price entry.

E37

The direct finalization is inhibited

Make a tendering operation.

E67

Subtotal void is not allowed.

E80

The battery trouble is occurred

Change the battery

When the following error codes are displayed, press the [CL] key and take a proper action according to the table below.

code

Error status Action

E33

E36 The preset price entry is inhibited Make an open price entry

Compulsory SCM (starting cash memory) entry

Make the SCM (starting cash memory) entry.

Finalize the transaction, and correct the wrong entries in the mode.

7-1

Page 25

8-1

CHPTER 8. PARTS LIST

NO. PARTS CO DE

PRICE

RANK

NEW

MARK

DESCRIPTION

1 0RDS1PSA19502 AR

N MODE SWITCH ASSY 107

0RDS1PSA19512 AR N MODE SWITCH ASSY 137/147

2 0RDS1PSA19501 BB N KEY UNIT ASSY 107

0RDS1PSA19529 BB N KEY UNIT ASSY 137/147

3 0RDS1PSA19532 BM N MONEY CASE UNIT (EA-BK)

0RDS1PSA19533 BM N MONEY CASE UNIT (EA-WH)

4 0RDS1PSA19462 AN N PRINTER COVER ASSY 107B

0RDS1PSA19541 BC N PRINTER COVER ASSY 107W

0RDS1PSA19544 BC N PRINTER COVER ASSY 147B

0RDS1PSA19545 BC N PRINTER COVER ASSY 137B

0RDS1PSA19546 BC N PRINTER COVER ASSY 147W

0RDS1PSA19547 BC N PRINTER COVER ASSY 137W

5 0RDS1PSA19549 BF N TOP CAB UNIT (A107 E-B)

0RDS1PSA19550 BF N TOP CAB UNIT (A107 E-W)

0RDS1PSA19551 BG N TOP CAB UNIT (A137 E-B)

0RDS1PSA19552 BG N TOP CAB UNIT (A137 E-W)

0RDS1PSA19553 BG N TOP CAB UNIT (A147 E-B)

0RDS1PSA19554 BG N TOP CAB UNIT (A147 E-W)

6 0RDS1PSA19563 BP N ASSY DRAWER SERVICE (A107B)

0RDS1PSA19566 BP N ASSY DRAWER SERVICE (A107W)

0RDS1PSA19568 BP N ASSY DRAWER SERVICE (A137B / A147B)

0RDS1PSA19570 BP N ASSY DRAWER SERVICE (A137W / A147W)

7

0RDDDCASST003

BC N

AC ADAPTOR 107B4

0RDDDCASST004 BC N

AC ADAPTOR 1

07B6

0RDDDCASST005 BC N

AC ADAPTOR 1

07B7

0RDDDCASST006 BC N

AC ADAPTOR 1

07B8

0RDDDCASST009 BC N

AC ADAPTOR 1

37B4

0RDDDCASST010 BC N

AC ADAPTOR 1

37B6

0RDDDCASST011 BC N

AC ADAPTOR 1

47B7

8 0RDS1PSA19467 BG N MAIN PCB ASSY 107

0RDS1PSA19485 BS N MAIN PCB ASSY 147

0RDS1PSA19513 BR N MAIN PCB ASSY 137

9 0RDS1PSA19475 AF N PRINTER PCB ASSY 107

NOTE

0RDS1PSA19491 AP N

PRINTER PCB ASSY 1

37/147

10 0RDS1PSA19477 AR N DC JACK PCB ASSY 107

0RDS1PSA19495 AV N

DC JACK PCB ASSY 1

37/147

11 0RDS1PSA19473 AW N 7SEG PCB ASSY 107

0RDS1PSA19497 AX N

7SEG PCB ASSY 1

37/147

12 0RDS1PSA19499 AL N Battery PCB ASSY (147)

13

0RDS00EEF0020

AB N E RING (PHAI2)

14

0RDS0GCJB9050

AC N SCREW B-TIGHT

15

0RDS1PM336259

AE N LOCK LEVER

16

0RDS1PM336264

AC N MONEY CASE ROLLER

17

0RDS1PM424072

AC N SCREW M3X8 P-TIG HT F

18

0RDS1PM429041

AC N 2.6X4 B-TIG HT FL A T H

19

0RD1QB200AJ0B

AL N WIRE ASSY (PRINTER-MAIN)

20

DUNT-1475BHPZ

BG

PRINTER UNIT (LPT01-245-01) 137/147

KI-OB2015BHPB

BA

PRINTER UNIT 107

NOTE

21

0RDS1PM225998

AF N

SPOOL (A107)

22

0RDS1PM336274

AD N

SPOOL DISK (A107)

23

0RDS1PM440848

AZ N

MOTOR GUM (A107)

NOTE

* When replace the PRINTER UNIT 107 (KI-OB2015BHPB), the soldering is needed with the PRINTER PCB ASSY 107

(0RDS1PSA19475).

Page 26

8-2

B4 B5 B6 B7 B8 B9 B4 B5 B6 B9 B4 B5 B6 B7 B9

W4 W5 W6 W7 W8 W9 W4 W5 W6 W9 W4 W5 W6 W7 W9

0RDDDCASST003 AC ADAPTOR 107B4

○ ○ ○

0RDDDCASST004 AC ADAPTOR 107B6 ○

0RDDDCASST005 AC ADAPTOR 107B7 ○

0RDDDCASST006 AC ADAPTOR 107B8 ○

0RDDDCASST009 AC ADAPTOR 137B4 ○ ○ ○ ○ ○ ○

0RDDDCASST010 AC ADAPTOR 137B6 ○ ○

0RDDDCASST011 AC ADAPTOR 147B7 ○

EUROPE (w/o Germany, UK)

Southeast

Asia & Middle East

Germany

UK, Malaysia

Australia, New Zealand

South Africa

Indonesia

EUROPE (w/o Germany, UK)

Southeast

Asia & Middle East

Germany

UK, Malaysia

Indonesia

EUROPE (w/o Germany, UK)

Southeast

Asia & Middle East

Germany

UK, Malaysia

Australia, New Zealand

Indonesia

Parts namePart Number

AC-adaptor destination table

XE-A107 XE-A137 XE-A147

Page 27

8-3

PARTS OUTLOOK

1. Mode SW ASSY 2. KEY UNIT ASSY 3. MONEY CASE UNIT 4. PRINTER CO VER ASSY

5. TOP CAB UNIT 6. ASSY DRAWER SERVICE 7. AC ADAPTER 8. MAIN PCB ASSY (137/147)

8. MAIN PCB ASSY (107) 9. PRINTER PCB ASSY (137/147) 9. PRINTER PCB ASSY (107) 10. DC JACK PCB ASSY

11. 7SEG PCB ASSY 12. BATTERY PCB ASSY 15. LOCK LEVER 16. MONEY CASE ROLLER

19 WIRE ASSY (PRINTER-MAIN) 20. PRINTER UNIT (A137/147) 20. PRINTER UNIT (A107) 21. SPOOL (A107)

22. SPOOL DISK (A107) 23. PRINTER GUM (A107)

Page 28

SHARP CORPORATION

Business Solution CS Promotion Center II

Yamatokoriyama, Nara 639-1186, Japan

COPYRIGHT○C 2012 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

2012 August Printed in Japan

Loading...

Loading...