Page 1

CD-CH1000

SERVICE MANUAL

No. S8070CDCH1000

AUDIO TOWER SYSTEM

MODEL

CD-CH1000 Audio Tower System consisting of CD-CH1000 (main

unit) and CP-RW5000 (speaker system).

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

CD-CH1000

CONTENTS

Page

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)...................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................ 2

NAMES OF PARTS .......................................................................................................................................................... 3

OPERATION MANUAL..................................................................................................................................................... 5

DISASSEMBLY................................................................................................................................................................. 8

REMOVING AND REINSTALLING THE MAIN PARTS.................................................................................................. 11

CD CHANGER MECHANISM MAIN BASE PARTS ASSEMBLING/ADJUSTING PROCEDURE ................................. 13

ADJUSTMENT................................................................................................................................................................ 20

TEST MODE ................................................................................................................................................................... 21

ERROR MESSAGE LIST................................................................................................................................................ 24

NOTES ON SCHEMATIC DIAGRAM ............................................................................................................................. 25

TYPES OF TRANSISTOR AND LED.............................................................................................................................. 25

BLOCK DIAGRAM .......................................................................................................................................................... 26

SCHEMATIC DIAGRAM ................................................................................................................................................. 32

WIRING SIDE OF P.W.BOARD...................................................................................................................................... 43

WAVEFORMS OF CD CIRCUIT..................................................................................................................................... 52

TROUBLESHOOTING .................................................................................................................................................... 53

FUNCTION TABLE OF IC .............................................................................................................................................. 55

LCD DISPLAY................................................................................................................................................................. 62

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR U.S.A. ONLY)

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CD-CH1000

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

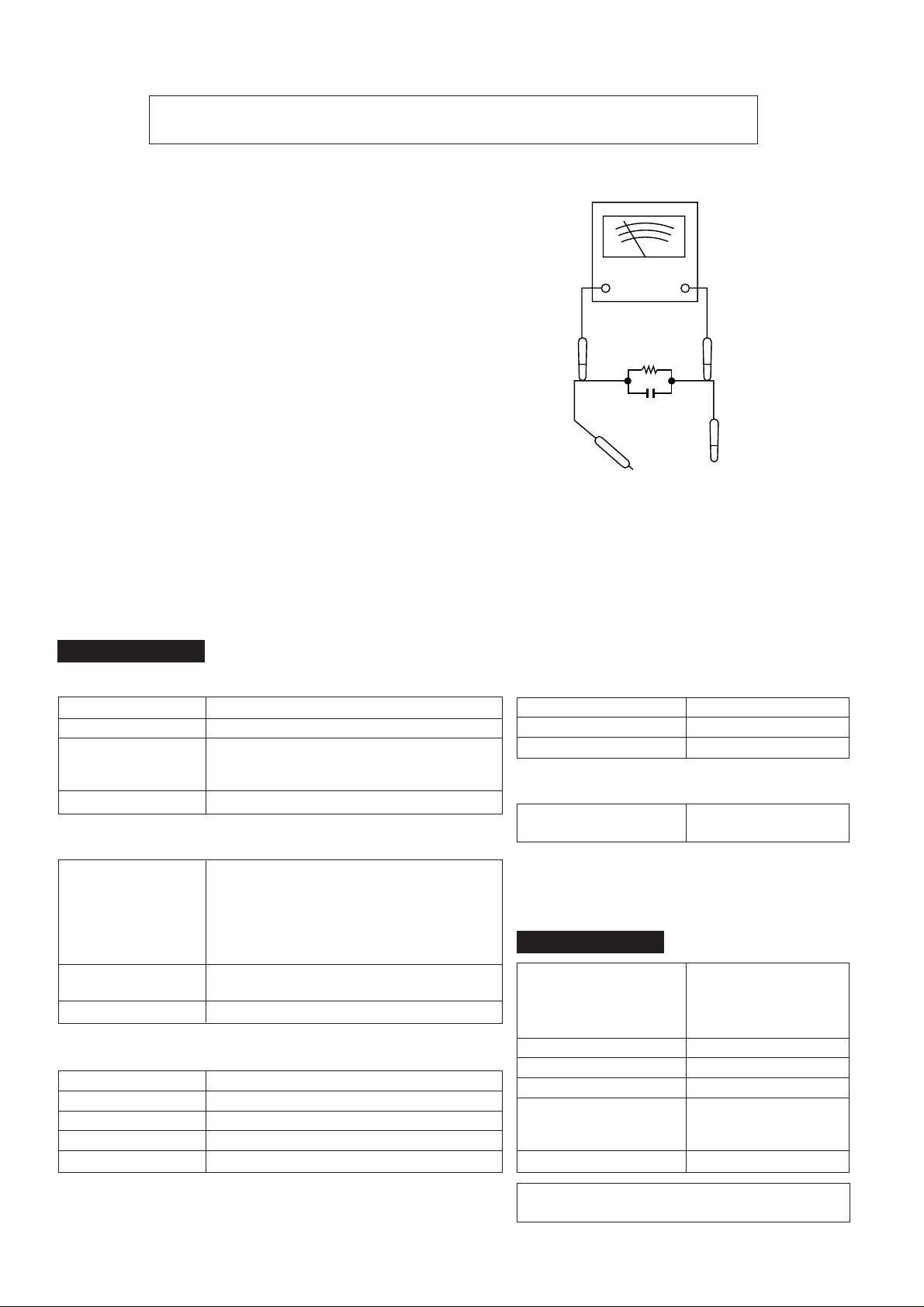

IMPORT ANT SER VICE NOTES (FOR U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment covers

or shields, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

All tests must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

SPECIFICATIONS

CD-CH1000

■ General

Power source AC 120 V, 60 Hz

Power consumption 175 W

Dimensions Width: 7-7/8" (200 mm)

Height: 13-7/8" (352 mm)

Depth: 14-7/8" (377 mm)

Weight 21.4 lbs. (9.7 kg)

■ Amplifier

Output power 100 watts minimum RMS per channel into 6 ohms from

Output terminals Speakers: 6 ohms

Input terminals Auxiliary: 500 mV/47 kohms

60 Hz to 20 kHz, 10 % total harmonic distortion

Subwoofer: 60 W/ch

(60 Hz - 200 Hz, 6 ohms, 10 % T.H.D.)

Main: 40 W/ch

(200 Hz - 20 kHz, 6 ohms, 10 % T.H.D.)

Headphones: 16-50 ohms (recommended; 32 ohms)

■ CD player

Type 6-disc multi-play compact disc changer player

Signal readout Non-contact, 3-beam semiconductor laser pickup

D/A converter

Frequency response 20 - 20,000 Hz

Dynamic range 90 dB (1 kHz)

1-bit D/A converter

■ Cassette deck

Frequency response 50-14,000 Hz (Normal tape)

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.3 % (WRMS)

■ Tuner

Frequency range FM: 87.5-108.0 MHz

AM: 530-1,720 kHz

CP-RW5000

Type 3-way type speaker system

2" (5 cm) Tweeter

5-1/4" (13 cm) Woofer

5-1/4" (13 cm) Subwoofer

Maximum input power (Total)

Rated input power (Total) 100 W

Impedance 6 ohms

Dimensions Width: 8-1/4" (210 mm)

Weight 11.2 lbs. (5.1 kg)/each

200 W

Height: 15-7/16" (392 mm)

Depth: 13-9/16" (345 mm)

– 2 –

Specifications for this model are subject to change

without prior notice.

Page 3

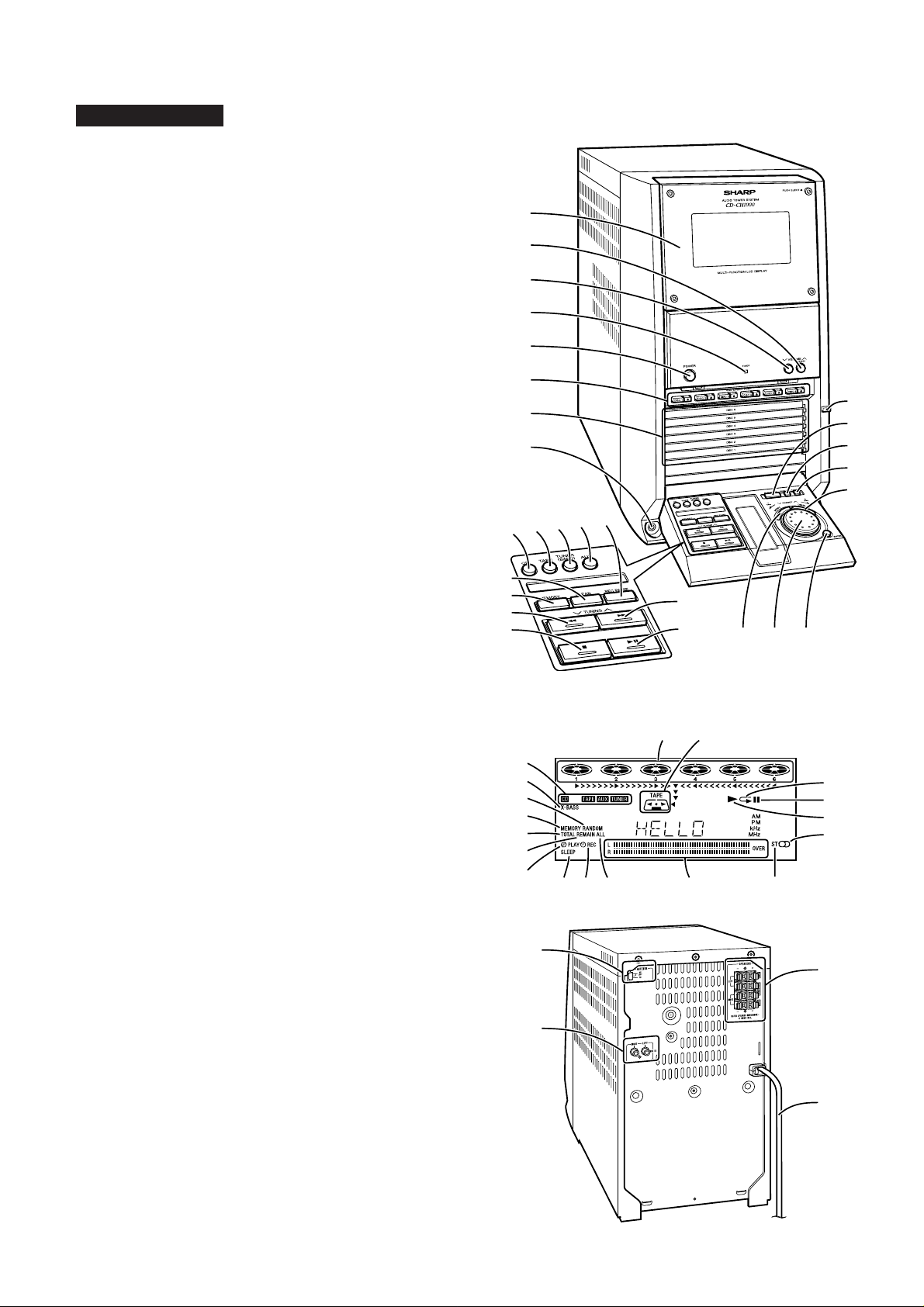

CD-CH1000

1

2

3

4

5

6

7

8

22

23

24

25

26

27

14 15 16

17

19

21

18

20

9

10

11

12

13

3

4

1

2

1

2

3

4

5

6

7

8 9

10 11 12 13 14

15

16

17

18

CD-CH1000

■ Front panel

01.

Cassette Compartment

02.

Volume Up/Demo Button

03.

Volume Down Button

04.

Timer Set Indicator

05.

Power Button

06.

CD Direct Play Buttons (with Indicator)/

CD Eject Buttons

07.

Disc Trays

08.

Headphone Jack

09.

Control Panel Open/Close Button

10.

CD Play Mode Select Button

11.

Equalizer Mode Select Button

12.

Extra Bass Button

13.

Display Button

14.

Menu Button

15.

Jog Dial

16.

Enter Button

17.

CD Button

18.

Tape Button

19.

Tuner (Band) Button

20.

Auxiliary Button

21.

Tape Record Pause Button

22.

Clear Button

23.

Memory Button

24.

Tuning Down/

Fast Reverse Button (with Indicator)

25.

Stop Button (with Indicator)

26.

Tuning Up/

Fast Forward Button (with Indicator)

27.

CD Play or Pause/

Tape Play Button (with Indicator)

NAMES OF PARTS

■ Multi-function LCD display

01.

Function Indicator

02.

Extra Bass Indicator

03.

04.

05.

06.

07.

08.

09.

10.

11.

12.

13.

14.

15.

16.

17.

18.

■ Rear panel

01.

02.

03.

04.

Random Play Indicator

Memory Indicator

Total Indicator

Remain Indicator

Timer Play Indicator

CD Indicators

Cassette Indicator

Sleep Indicator

Timer Recording Indicator

All Disc Play Indicator

Level Meter

FM Stereo Mode Indicator

CD Repeat Indicator

CD Pause Indicator

CD Play Indicator

FM Stereo Indicator

FM/AM Antenna Jack

Auxiliary Input Jacks

Speaker Terminals

AC Power Cord

– 3 –

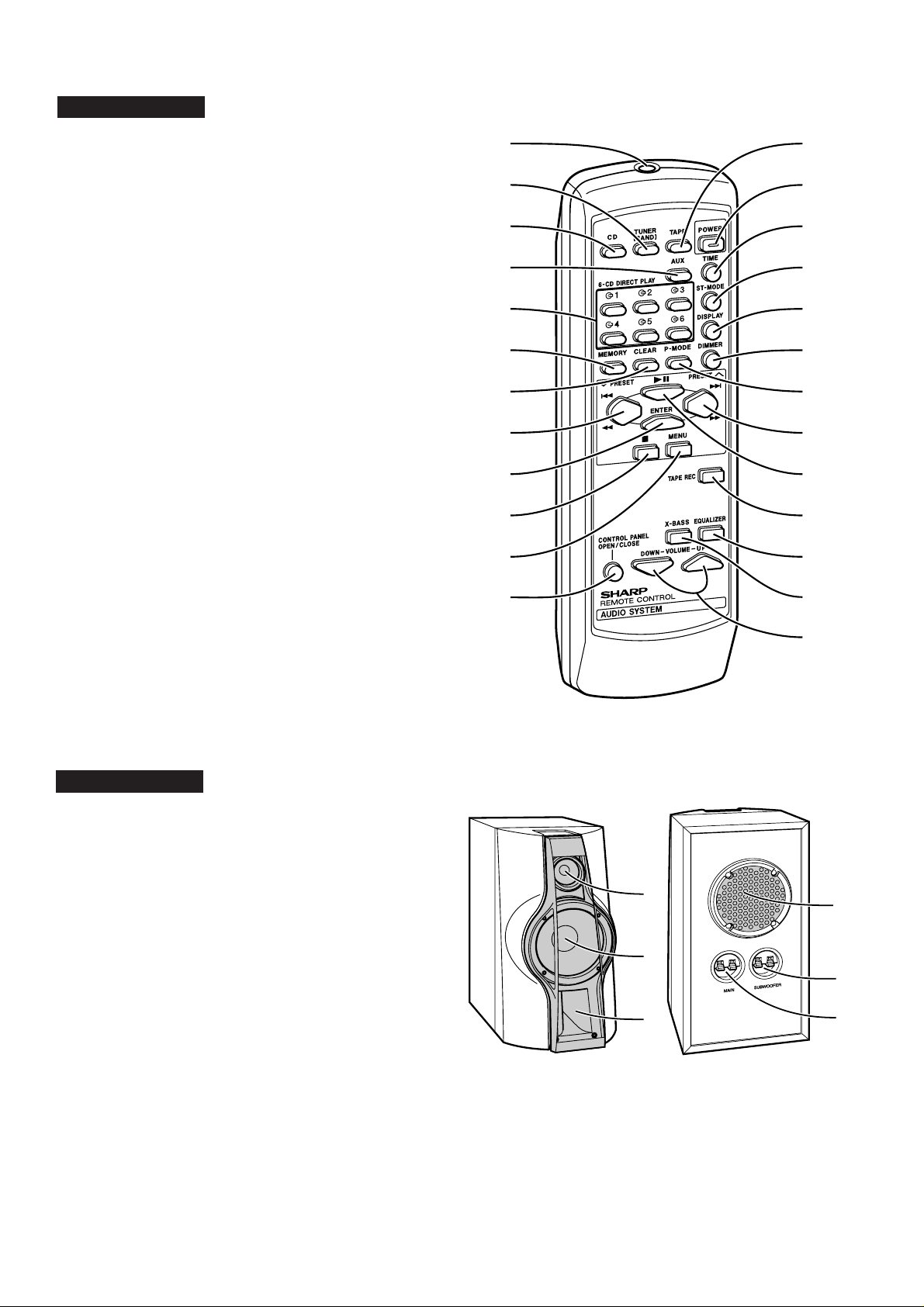

Page 4

CD-CH1000

CD-CH1000

■ Remote control

01.

Remote Control Transmitter

02.

Tuner (Band) Button

03.

CD Button

04.

Auxiliary Button

05.

CD Direct Play Buttons

06.

Memory Button

07.

Clear Button

08.

Fast Reverse/Preset Down Button

09.

Enter Button

10.

Stop Button

11.

Menu Button

12.

Control Panel Open/Close Button

13.

Tape Button

14.

Power Button

15.

Time Button

16.

FM Stereo Mode Button

17.

Display Button

18.

Dimmer Button

19.

CD Play Mode Select Button

20.

Fast Forward/Preset Up Button

21.

CD Play or Pause/Tape Play Button

22.

Tape Record Pause Button

23.

Equalizer Mode Select Button

24.

Extra Bass Button

25.

Volume Up or Down Buttons

10

11

12

1

2

3

4

5

6

7

8

9

13

14

15

16

17

18

19

20

21

22

23

24

25

CP-RW5000

01.

Tweeter

02.

Woofer

03.

Bass Reflex Duct

4.

Subwoofer

5.

Subwoofer Terminals

6.

Main Speaker Terminals

1

2

3

4

5

6

– 4 –

Page 5

OPERATION MANUAL

To confirm the time display:

Press the DISPLAY button. The time display will appear for about 3 seconds.

Note:

The “CLOCK” will appear or time will flash at the push of the DISPLAY button when the

AC power supply is restored after a power failure or after unplugging the unit.

Reset the clock as follows.

To reset the clock:

Perform “Setting the Clock” from the beginning.

At this time, step 4 (for selecting the 12-hour or 24-hour display) will be skipped.

To change the 12-hour or 24-hour display:

Clear all the programmed contents.

[Refer to “If trouble occurs (reset)” on page 30 for details.]

Perform “Setting the Clock” from the beginning.

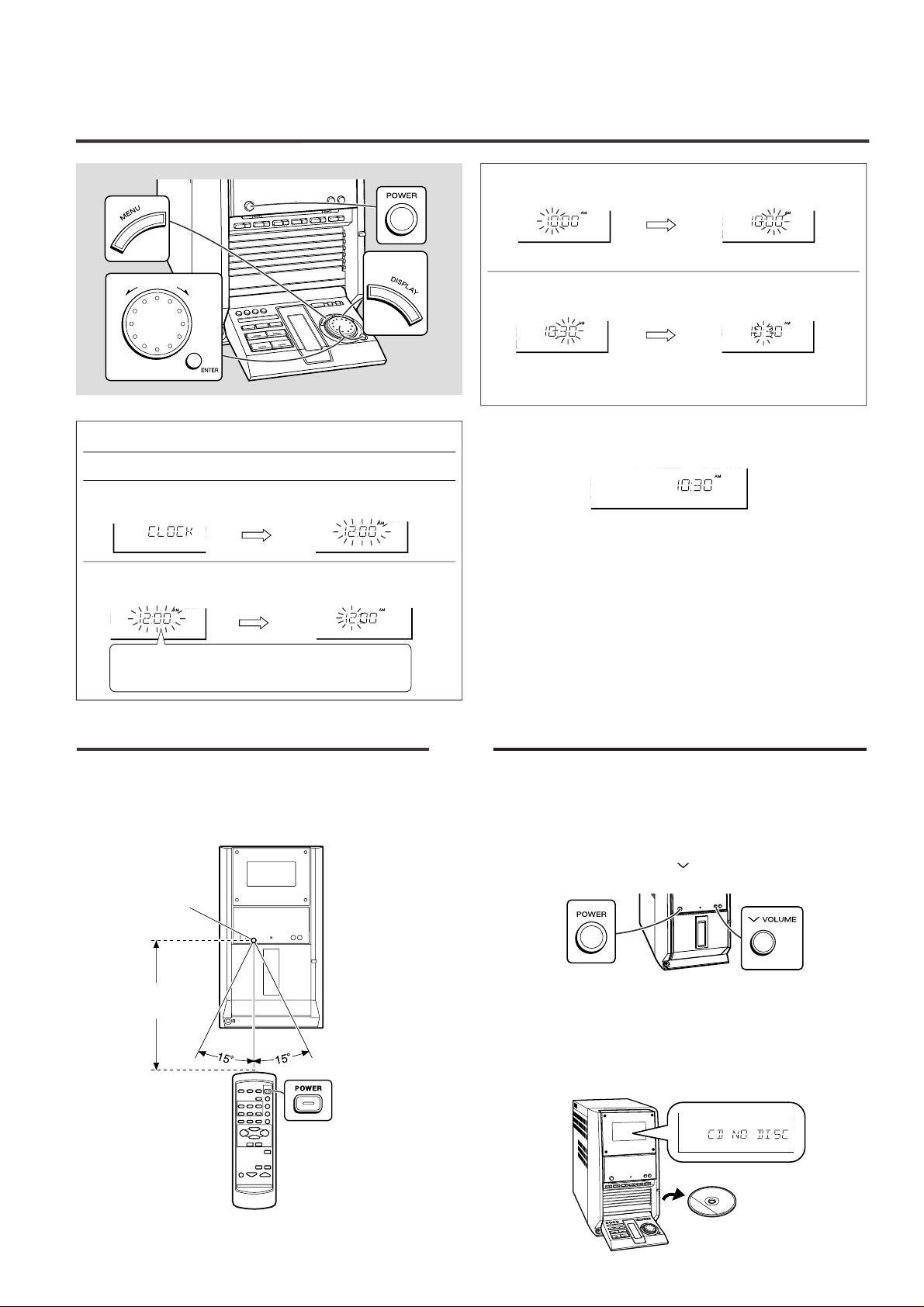

Setting the Clock

In this example, the clock is set for the 12-hour (AM12:00) display.

1

Press the POWER button to turn the power on.

2

Press the MENU button.

3

Turn the jog dial to select “CLOCK” and within 10 seconds, press

the ENTER button.

4

Turn the jog dial to select the 12-hour or 24-hour display and

within 2 minutes, press the ENTER button.

5

Turn the jog dial to adjust the hour and within 2 minutes, press

the ENTER button.

●

When the 12-hour display is selected, “AM” will change automatically to “PM”.

6

Turn the jog dial to adjust the minutes and within 2 minutes, press

the ENTER button.

●

The hour will not advance even if minutes advance from “59” to “00”.

● The clock starts from “0” second. (Seconds are not displayed.)

The time display will disappear after a few seconds.

“AM 12:00”→

The 12-hour display will appear. (AM 12:00 - PM 1 1:59)

“AM 0:00” →

The 12-hour display will appear. (AM 0:00 - PM 1 1:59)

“0:00” → The 24-hour display will appear. (0:00 - 23:59)

CD-CH1000

Remote Control

■

Test of the remote control

Face the remote control directly to the remote sensor on the unit.

The remote control can be used within the range shown below:

Press the POWER button. Does the power turn on? Now, you can enjoy the music.

Remote sensor

8" - 20'

(0.2 m - 6 m)

Troubleshooting Chart (continued)

■

If trouble occurs (reset)

When this product is subjected to strong external interference (mechanical shock, excessive static electricity, abnormal supply voltage due to lightning, etc.) or if it is operated incorrectly, it may malfunction.

If such a problem occurs, do the following:

1. Press the POWER button to enter the power stand-by mode.

2. While pressing down the VOLUME button, press the POWER button until “ALL CLEAR” appears.

Caution:

This operation will erase all data stored in memory including clock and timer settings,

and tuner and CD presets.

■

Before transporting the unit

Remove all CDs from the unit. Y our unit checks whether there are any discs inside the

unit when the tray is closed. “CD NO DISC” appears if no disc is left. Then, set the unit

to the power stand-by mode. Carrying the unit with discs left inside can damage it.

– 5 –

Page 6

CD-CH1000

4

Setting the clock

Ajuste del reloj

In this example, the clock is set for the 12-hour (AM12:00) display.

En este ejemplo, el reloj está ajustado para la visualización de 12 horas (AM12:00).

1

2

3

4

5

Turn the jog dial to select “CLOCK” and

within 10 seconds, press the ENTER button.

Gire el mando de lanzadera para seleccionar

"CLOCK", y antes de transcurrir 10 segundos,

pulse el botón ENTER.

Turn the jog dial to select the 12-hour or

24-hour display and within 2 minutes, press

the ENTER button.

Gire el mando de lanzadera para seleccionar la

visualización de 12 horas o de 24 horas, y antes

de transcurrir 2 minutos, pulse el botón ENTER.

Turn the jog dial to adjust the minutes and

within 2 minutes, press the ENTER button.

Gire el mando de lanzadera para ajustar los

minutos, y antes de transcurrir 2 minutos, pulse

el botón ENTER.

Press the POWER button to turn the power

on.

Pulse el botón POWER para conectar la

alimentación.

Press the MENU button.

Pulse el botón MENU.

“AM 12:00” “AM 0:00” “0:00”

6

The control panel automatically opens when the

power is turned on.

El panel de control se

abrirá automáticamente

cuando se conecte la

alimentación.

Turn the jog dial to adjust the hour and

within 2 minutes, press the ENTER button.

Cuando se seleccione la visualización de 12 horas,

"AM" cambiará automáticamente a "PM".

When the 12-hour display is selected, “AM” will

change automatically to “PM”.

Gire el mando de lanzadera para ajustar la hora,

y antes de transcurrir 2 minutos, pulse el botón

ENTER.

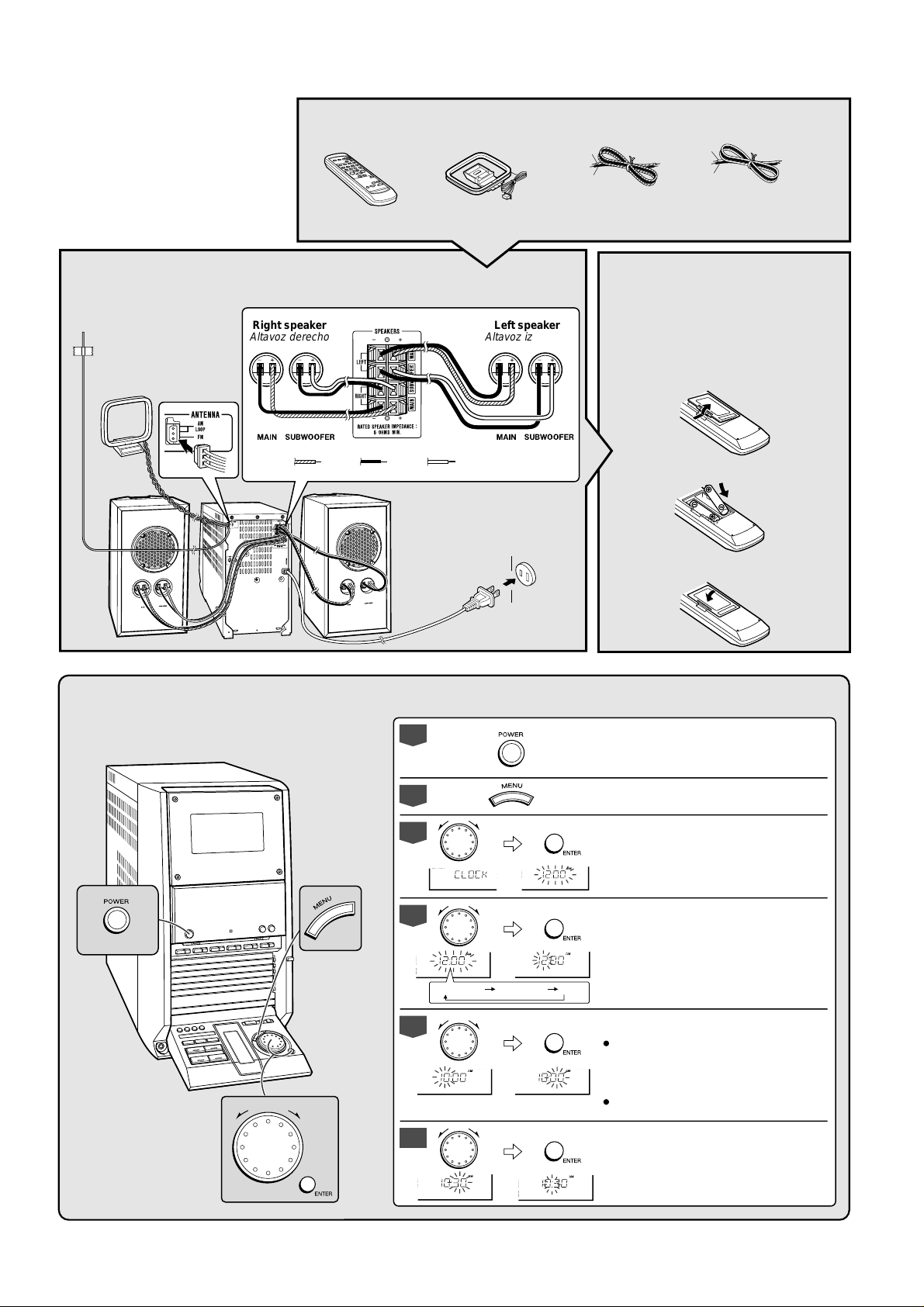

1

Accesorios

Remote control × 1

Controlador remoto × 1

2

System Connections

Conexiones del sistema

FM antenna

Antena de FM

AM loop antenna

Antena de cuadro de AM

Right

speaker

Altavoz

derecho

Right speaker

Altavoz derecho

Blue

Azul

Accessories

FM/AM loop antenna × 1

Antena de FM/cuadro de AM × 1

Black

Negro

Left

speaker

Altavoz

izquierdo

Left speaker

Altavoz izquierdo

Red

Rojo

AC outlet

(AC 120 V, 60 Hz)

A un tomacorriente de CA

(120 V de CA, 60 Hz)

Blue

Azul

Black

Negro

Speaker wire for

MAIN terminals × 2

Cable del altavoz para

los terminales MAIN

3

Battery installation

Use 2 “AA” size batteries (UM/SUM-3, R6, HP-7 or similar).

Batteries are not included.

Use dos pilas del tamaño“AA” (UM/SUM-3, R6, HP-7 o

equivalentes).

Las pilas no están incluidas.

1

Remove the battery cover.

Extraiga la cubierta

2

Insert the batteries.

Inserte las pilas.

3

Replace the cover.

Vuelva a colocar la cubierta de las pilas.

Red

Rojo

Black

Negro

Speaker wire for

SUBWOOFER terminals × 2

Cable del altavoz para

×

2

los terminales SUBWOOFER

de las pilas.

×

2

– 6 –

Page 7

CD-CH1000

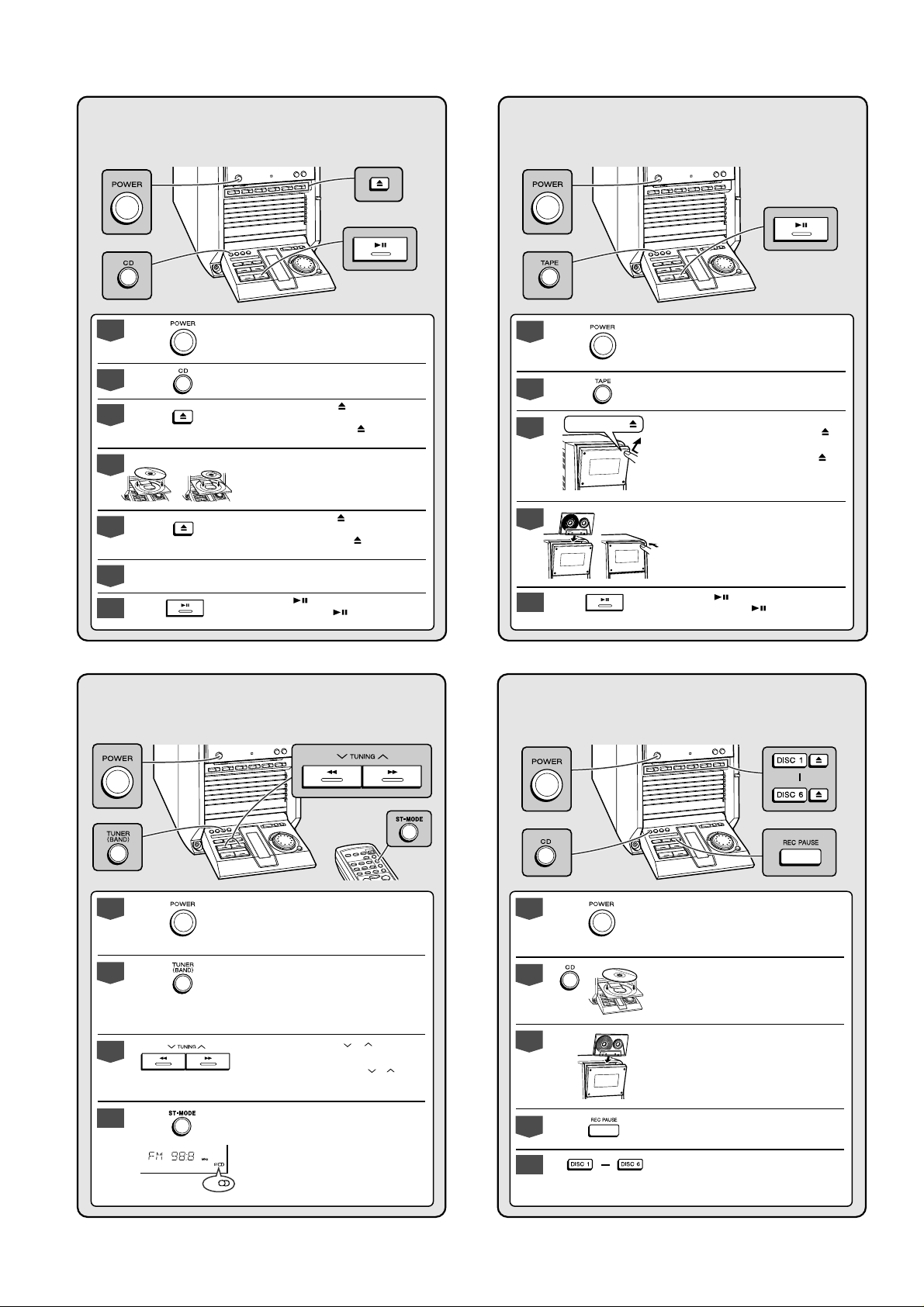

Listening to a CD (CDs)

Audición de un disco CD (CDs)

1

2

3

4

5” (12 cm)

3” (8 cm)

5

Y

ou can place discs on the trays 2 - 6 by following the steps 3 - 5.

6

Podrá colocar discos en las bandejas 2 - 6 según los pasos 3 - 5.

7

Press the POWER button to turn the

power on.

Pulse el botón POWER para conectar

la alimentación.

Press the CD button.

Pulse el botón CD.

Press the DISC 1 button to open

the disc tray 1.

Pulse el botón DISC 1 para abrir la

bandeja del disco 1.

Place the CD on the disc tray 1,

label side up.

Coloque el disco compacto en la

bandeja del disco 1, con el lado de la

etiqueta hacia arriba.

Press the DISC 1 button to close

the disc tray 1.

Pulse el botón DISC 1 para cerrar la

bandeja del disco 1.

Press the button to start playback.

Pulse el botón para iniciar la

reproducción.

Listening to a Cassette Tape

Audición de un cassette

1

2

3

4

5

PUSH EJECT

Press the POWER button to turn the

power on.

Pulse el botón POWER para conectar

la alimentación.

Press the TAPE button.

Pulse el botón TAPE.

Open the cassette door by pushing

the area marked “PUSH EJECT ”.

Abra la puerta del cassette pulsando

la parte marcada "PUSH EJECT ".

Load the cassette into the cassette

compartment.

Inserte el cassette en el compartimiento del cassette.

Press the button to start playback.

Pulse el botón para iniciar la

reproducción.

Listening to the Radio

Audición de la radio

1

2

3

4

Press the POWER button to turn the

power on.

Pulse el botón POWER para conectar

la alimentación.

Press the TUNER (BAND) button to

select the desired frequency band

(FM or AM).

Pulse el botón TUNER (BAND) para

seleccionar la banda de frecuencia

deseada (FM o AM).

Press the TUNING ( or ) button to

tune into the desired station.

Pulse el botón TUNING ( o ) para

sintonizar la emisora deseada.

To receive an FM stereo transmission,

press the ST-MODE button on the

remote control. The “ST” indicator

lights up.

Para recibir la transmisión de FM en

estéreo, pulse el botón ST-MODE del

ST

controlador remoto .Se enciende el

indicador “ST”.

Recording from the CD

Grabación de un disco CD

1

2

3

4

5

Press the POWER button to turn the

power on.

Pulse el botón POWER para conectar

la alimentación.

Press the CD button and load the

desired disc.

Pulse el botón CD y ponga el disco

deseado.

Load a cassette into the cassette

compartment.

Inserte un cassette en el compartimiento del cassette.

Press the REC PAUSE button.

Pulse el botón REC PAUSE.

Press the

start recording.

Pulse el botón DISC 1 - DISC 6 para

iniciar la grabación.

DISC 1 - DISC 6

button to

– 7 –

Page 8

CD-CH1000

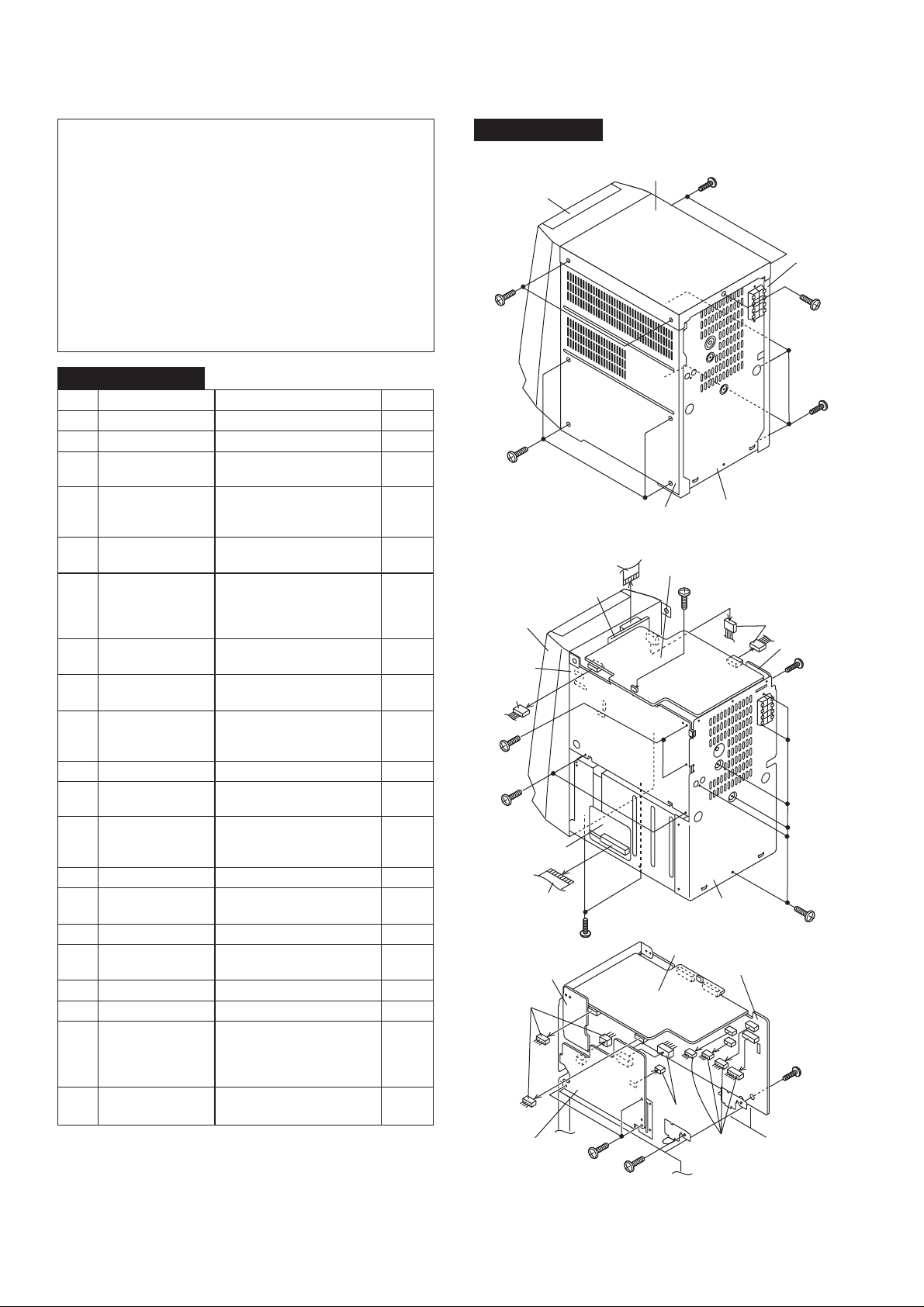

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

CD-CH1000

(A1)x2

ø3x16mm

Front Panel

Top Cabinet

(A1)x2

ø3x16mm

Side Panel

(Left)

(A1)x1

ø3x10mm

CD-CH1000

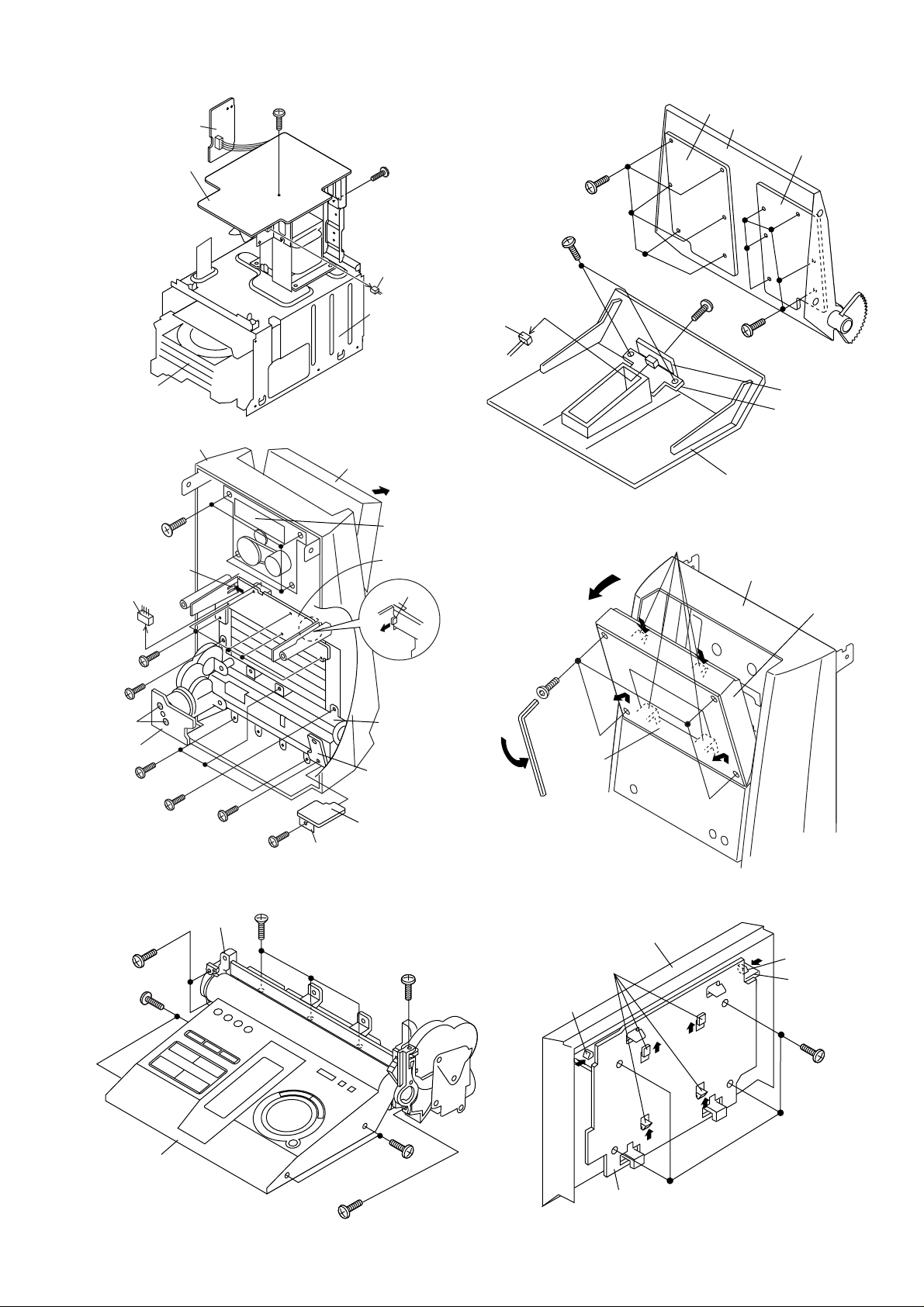

STEP REMOVAL

1 Top Cabinet 1. Screw ................ (A1) x5 8-1

2 Side Panel

3 Rear Panel 1. Screw ................ (C1) x3 8-2

4 Front Panel 1. Flat Cable.......... (D1) x1 8-2

5 Sub Trans PWB 1. Screw ................ (E1) x3 8-2

6 Main PWB 1. Flat Cable.......... (F1) x1 8-2

7 Power PWB/ 1. Socket ............... (G1) x1 9-1

Speaker PWB 2. Screw ................ (G2) x2

8 Tape Mechanism 1. Open the cassette holder 9-2

9 CD Switch PWB 1. Socket ............... (J1) x1 9-2

10 Switch PWB 1. Screw ................ (K1) x1 9-2

11 Headphones PWB 1. Screw ................ (L1) x1 9-2

12 CD Changer door 1. Screw ................ (M1) x3 9-2

panel/ 2. Screw ................ (M2) x2

Control Panel

13 Motor PWB 1. Solder ................(P1) x2 9-2

14 CD Changer door 1. Screw ................ (Q1) x4 9-3

panel

15 Control Panel 1. Screw ................ (R1) x7 9-3

16 Control PWB 1. Screw ................ (S1) x6 9-4

17 Jog PWB 1. Screw ................ (T1) x6 9-4

18 LED B PWB 1. Screw ................ (U1) x3 9-4

19 Cassette holder 1.

Cover 2. Screw ................ (V1) x4

20 Display PWB/ 1. Screw ................ (W1) x4 9-6

LED A PWB 2. Hook .................. (W2) x6

(Left/Right)

PROCEDURE

1. Screw ................ (B1) x8 8-1

2. Screw ................ (C2) x6

2. Screw ................ (D2) x4

3. Socket ............... (D3) x6

2. Socket ............... (E2) x5

2. Screw ................ (F2) x2

3. Screw ................ (F3) x1

4. Socket ............... (F4) x1

2. Screw ................ (H1) x4

2. Screw ................ (J2) x6

3. Hook ..................(J3) x2

2. Bracket .............. (L2) x1

2. Socket ............... (S2) x1

Open the cassette holder Cover

3. Display Panel .... (V2) x1

4. Hook ..................(V3) x4

FIGURE

9-5

(B1)x4

ø3x10mm

Tape Mechanism PWB

Front Panel

Main PWB

(F4)x1

(C1)x2

ø3x10mm

(F2)x2

ø3x10mm

CD PWB

(F1)x1

(D2)x2

ø3x8mm

Speaker

PWB

(E2)x3

Side Panel(Right)

Figure 8-1

(D1)x1

Rear Panel

Power PWB

(F3)x1

ø3x8mm

Panel

Power PWB

(E2)x2

Rear

ø3x10mm

Main PWB

(D3)x2

Speaker

(C2)x6

(D2)x1

ø3x8mm

(B1)x4

ø3x10mm

PWB

(C1)x1

ø3x10mm

– 8 –

Sub Trans

PWB

(E1)x3

ø3x8mm

(D3)x4

(D2)x1

ø3x8mm

Figure 8-2

Page 9

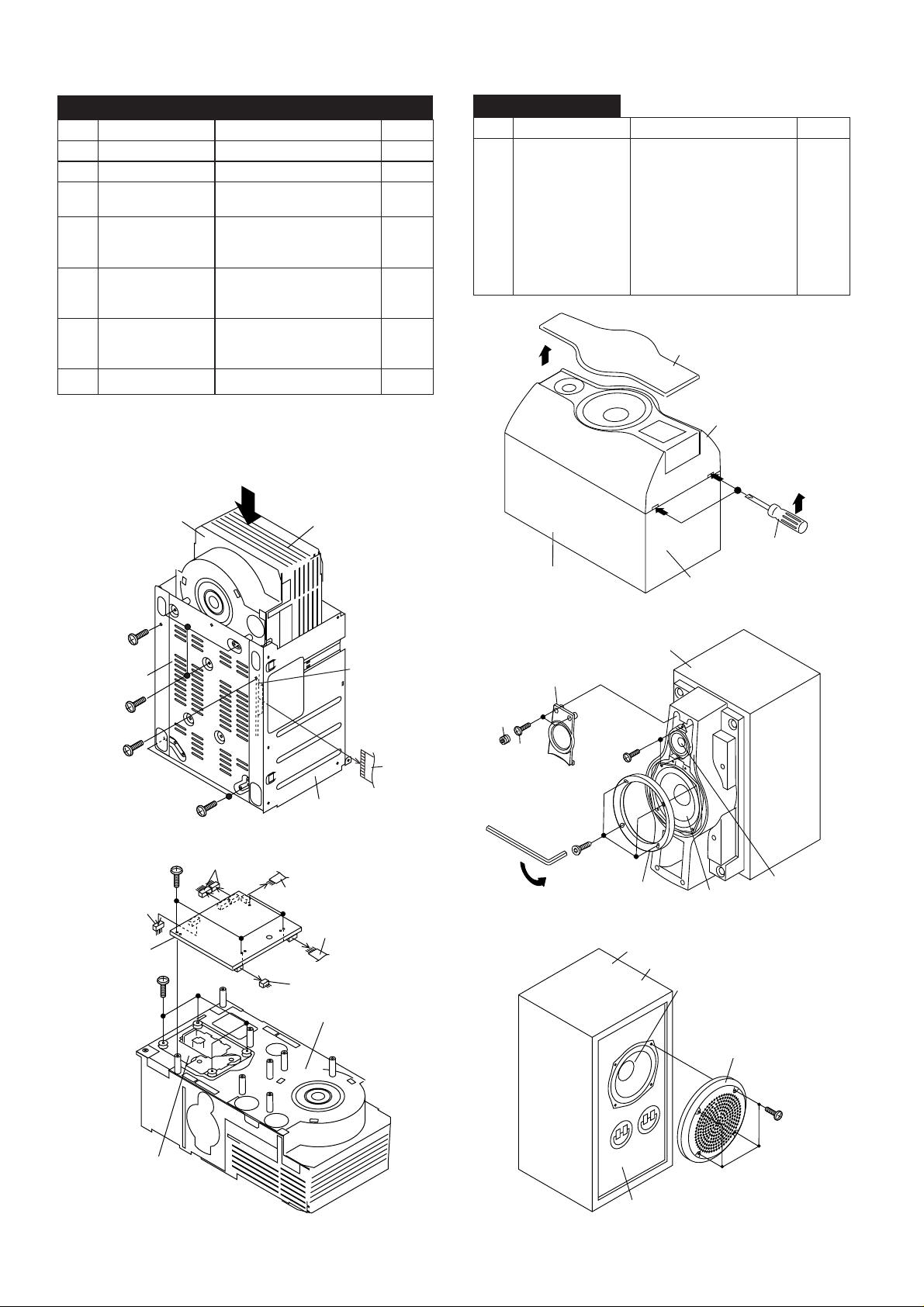

CD-CH1000

(V1)x4

ø2.6x12mm

Front Panel

(V2)x1

(V3)x4

Open

Cassette

Holder Cover

(W1)x4

ø3x14mm

(W2)x4

(W2)x1

LED A

PWB

Cassette

Holder Cover

Display PWB

(W2)x1

Power PWB

CD Changer

Block

Front Panel

(H1)x4

ø3x10mm

(J1)x1

Speaker

PWB

(J3)x1

Figure 9-1

(G2)x1

ø3x10mm

(G2)x1

ø3x10mm

Main

Chassis

Cassette

Holder

(G1)x1

Open

Tape

Mechanism

CD Switch

PWB

(J3)x1

(S2)x1

(S1)x6

ø2.6x10mm

(U1)x2

ø2.6x10mm

Control PWB

(U1)x1

ø2.6x10mm

Figure 9-4

Control Panel B

(T1)x6

ø2.6x10mm

Control Panel A

Jog PWB

LED B PWB

LED Holder

(J2)x6

ø3x10mm

(M2)x1

ø3x20mm

(P1)x2

Motor

PWB

(M1)x3

ø3x10mm

ø3x20mm

(Q1)x2

ø2.6x10mm

(R1)x2

ø2.6x12mm

(M2)x1

(K1)x1

ø2.6x10mm

CD Changer

Door Panel

(L1)x1

ø3x10mm

Figure 9-2

(R1)x3

ø2.6x12mm

(L2)x1

CD Changer

Door Panel

Switch PWB

Headphones

PWB

(Q1)x1

ø2.6x10mm

Figure 9-5

Control Panel

Figure 9-3

(R1)x2

ø2.6x12mm

(Q1)x1

ø2.6x10mm

Figure 9-6

– 9 –

Page 10

CD-CH1000

CD-CH1000 (CD CHANGER MECHANISM UNIT)

STEP

1 Top Cabinet 1. Screw ................ (A1) x5 8-1

2 Side Panel

3 Rear Panel 1. Screw ................ (C1) x3 8-2

4 Front Panel 1. Flat Cable.......... (D1) x1 8-2

5 CD Changer 1. Flat Cable.......... (X1) x1 10-1

6 CD PWB 1. Screw ................ (Y1) x4 10-2

7 CD Mechanism 1. Screw ................ (Z1) x4 10-2

REMOVAL PROCEDURE

(Left/Right)

Mechanism 2. Screw ................ (X2) x2

(Note) 2. Socket ............... (Y2) x4

1. Screw ................ (B1) x8 8-1

2. Screw ................ (C2) x6

2. Screw ................ (D2) x4

3. Socket ............... (D3) x6

3. Screw ................ (X3) x5

3. Flat Wire............ (Y3) x2

FIGURE

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

CD Changer

Mechanism

Front Side

CP-RW5000

STEP REMOVAL

1 Woofer/Tweeter/ 1. Net................... (A1) x1 10-3

Sub Woofer 2. Front Panel ..... (A2) x1

PROCEDURE

3. Screw .............. (A3) x4 10-4

4. Ring ................. (A4) x1

5. Catching holder(A5) x2

6. Screw .............. (A6) x2

7. Cover............... (A7) x1

8. Screw .............. (A8) x2

9. Screw .............. (A9) x4 10-5

10. Cover............. (A10) x10

(A1)x1

(A2)x1

Driver should

be pried away

from Speaker Box.

Screw Driver

FIGURE

(X2)x1

ø3x10mm

Bottom Side

(X3)x3

ø3x10mm

(X2)x1

ø3x10mm

(Y1)x4

ø3x10mm

(Y2)x1

CD PWB

(Z1)x4

ø2.6x10mm

(X3)x2

ø3x10mm

Figure 10-1

(Y2)x2

Main Chassis

(Y3)x1

(Y3)x1

(Y2)x1

CD Changer

Mechanism

CD PWB

(X1)x1

(A5)x2

(A6)x2

ø3x10mm

Speaker Box

(A7)x1

(A3)x4

ø4x16mm

Figure 10-3

Speaker Box

(A8)x2

ø3x10mm

(A4)x1

Figure 10-4

Speaker Box

Bottom Side

Tweeter

Woofer

Top Side

Sub Woofer

(A10)x1

CD Mechanism

Figure 10-2

(A9)x4

ø4x20mm

Rear Side

Figure 10-5

– 10 –

Page 11

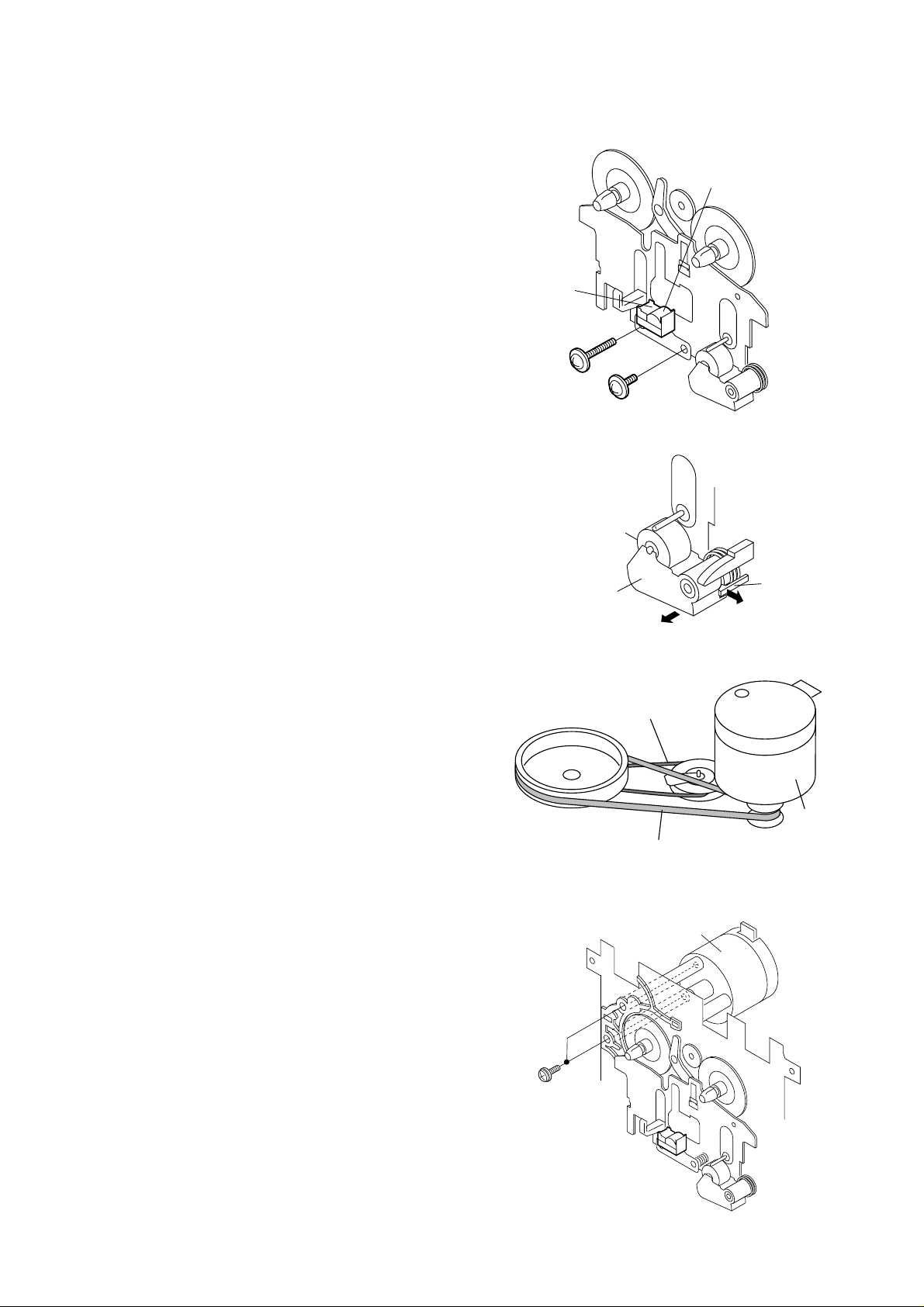

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 4 and 8 of the disassembly method to

remove the tape mechanism.

How to remove the record/playback and erase

heads (See Fig. 11-1)

1. Carefully remove the record/playback head and erase head

screws (A1) x 2 pcs.

How to remove the pinch roller (See Fig. 11-2)

1. Carefully bend the pinch roller pawl in the direction of the

arrow <A>, and remove the pinch roller (B1) x1 pc., in the

direction of the arrow <B>.

Note:

When installing the pinch roller, pay attention to the spring

mounting position.

Erase

Head

(A1)x1

Ø2 x 9mm

Pinch Roller

(B1)x1

(A1)x1

Ø2 x 5mm

Figure 11-1

Pull

<B>

Figure 11-2

CD-CH1000

Record/Playback

Head

Pinch

Roller

Pawl

Pull

<A>

How to remove the belt (See Fig. 11-3)

1. Remove the motor.

2. Remove the main belt (C1) x 1 pc., from the motor side.

3. Remove the FF/REW belt (C2) x 1 pc.

How to remove the motor (See Fig. 11-4)

1. Remove the belt.

2. Remove the screws (D1) x 2 pcs., to remove the motor.

(D1)x2

Ø 2.6 x 5mm

FF/REW Belt

(C2)x1

Motor

Main Belt

(C1)x1

Figure 11-3

Motor

– 11 –

Figure 11-4

Page 12

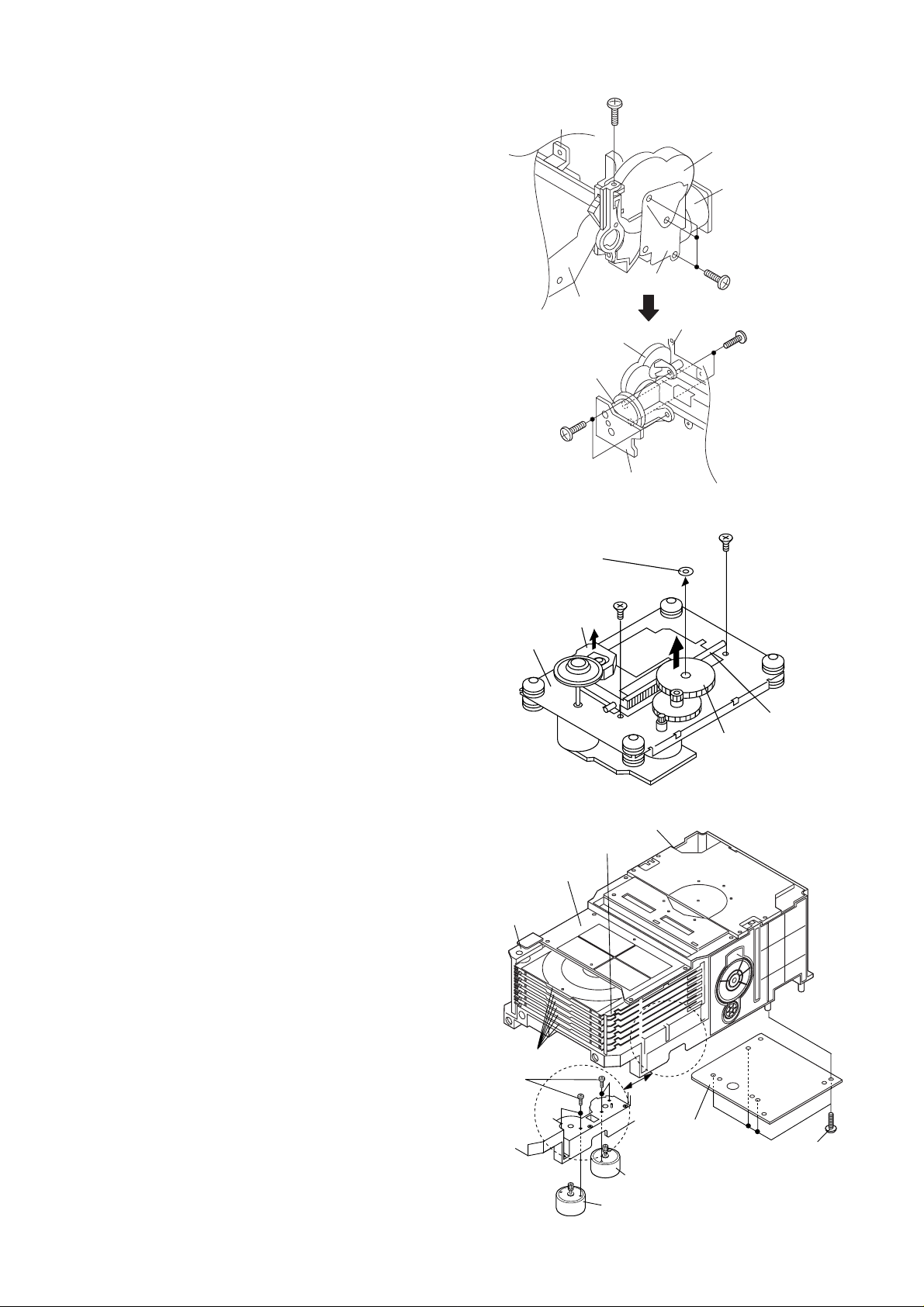

CD-CH1000

Main Cam Motor

Tray Motor

CD PWB

(1)Front Top Plate

(2)Changer Box,

Left

(2)Changer Box,

Right

(3)Disc Tray,1~6

CD Changer Mechanism

(B1)x4

ø3x10mm

(B2)x4

ø2.6x4mm

FRONT PANEL SECTION

Perform steps 1 to 4 of the disassembly method to remove the

front panel.

How to remove the control panel motor

(See Fig. 12-1)

1. Remove the control panel.

2. Remove the screws (E1) x 6 pcs., to remove the CD changer

door panel.

3. Remove the screws (F1) x 2 pcs., to remove the control

panel motor.

CD MECHANISM SECTION

Perform steps 1 to 7 of the disassembly method to remove the

CD mechanism. (See page 10.)

How to Remove the pickup (See Fig. 12-2.)

1. Remove the screws (A1)x 2 pcs., to remove shaft (A2)x 1

pc.

2. Remove stop washer (A3)x 1 pc., to remove gear (A4)x 1 pc.

3. Remove the pickup.

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

CD Changer

Door Panel

Control Panel

Control

Panel Motor

(E1)x2

ø2.6x10mm

Stop Washer

(A3) x1

Pickup

CD

Mechanism

Gear Box A

Figure 12-1

(A1) x1

ø2.6 x6mm

(E1)x1

ø2.6x10mm

Gear Box B

CD Changer

Door Panel

Motor PWB

(A1) x1

ø2.6 x6mm

Gear Box A

Control

Panel Motor

(E1)x3

ø2.6x10mm

(F1)x2

ø2x5mm

Gear

(A4) x1

Shaft

(A2) x1

CD CHANGER MECHANISM SECTION

Perform steps 1 to 5 of the disassembly method to remove the

CD changer mechanism. (See page 10.)

How to Remove the tray motor/main cam motor

(See Fig. 12-3.)

1. Remove the screws (B1)x 4 pcs., to remove the CD PWB.

2. Remove the (1)front top plate, (2)changer box, left/right and

(3)disc trays 1~6. After that, disassemble as shown in the

figure.

3. Remove the screws (B2)x 4 pcs.

4. Remove the tray motor and main cam motor.

Note:

The parts of (1), (2) and (3) correspond to the drawing Nos.

117, 102, 103 and 108 to 113 of the CD change mechanism

disassembly drawing.

Remove the screws of 117, 102 and 103, and the parts of (1),

(2) and (3) will be ready for removal and the screws of the tray

motor and main cam motor will be visible.

Figure 12-2

Figure 12-3

– 12 –

Page 13

CD-CH1000

CD CHANGER MECHANISM MAIN BASE PARTS ASSEMBLING/ADJUSTING

PROCEDURE

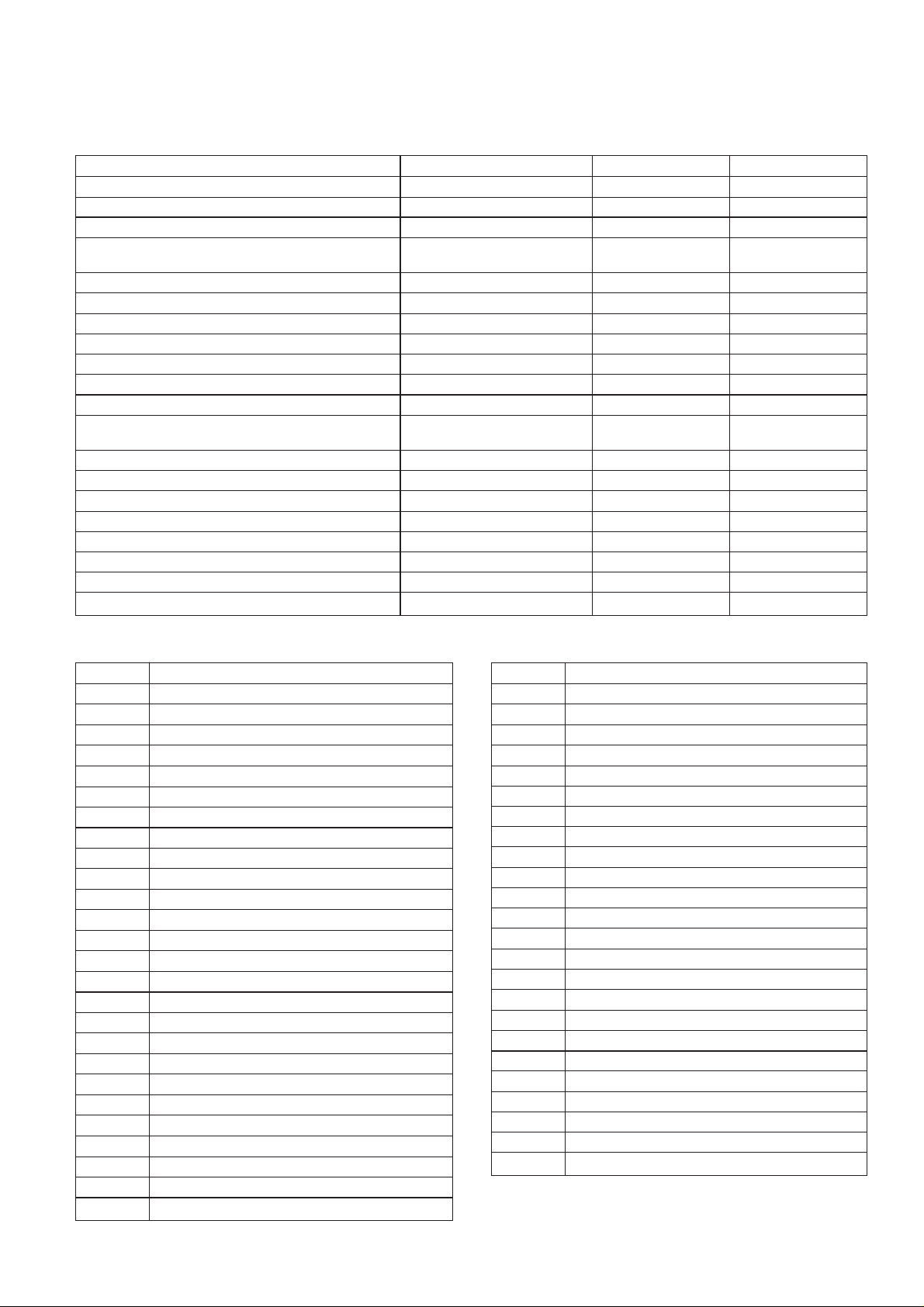

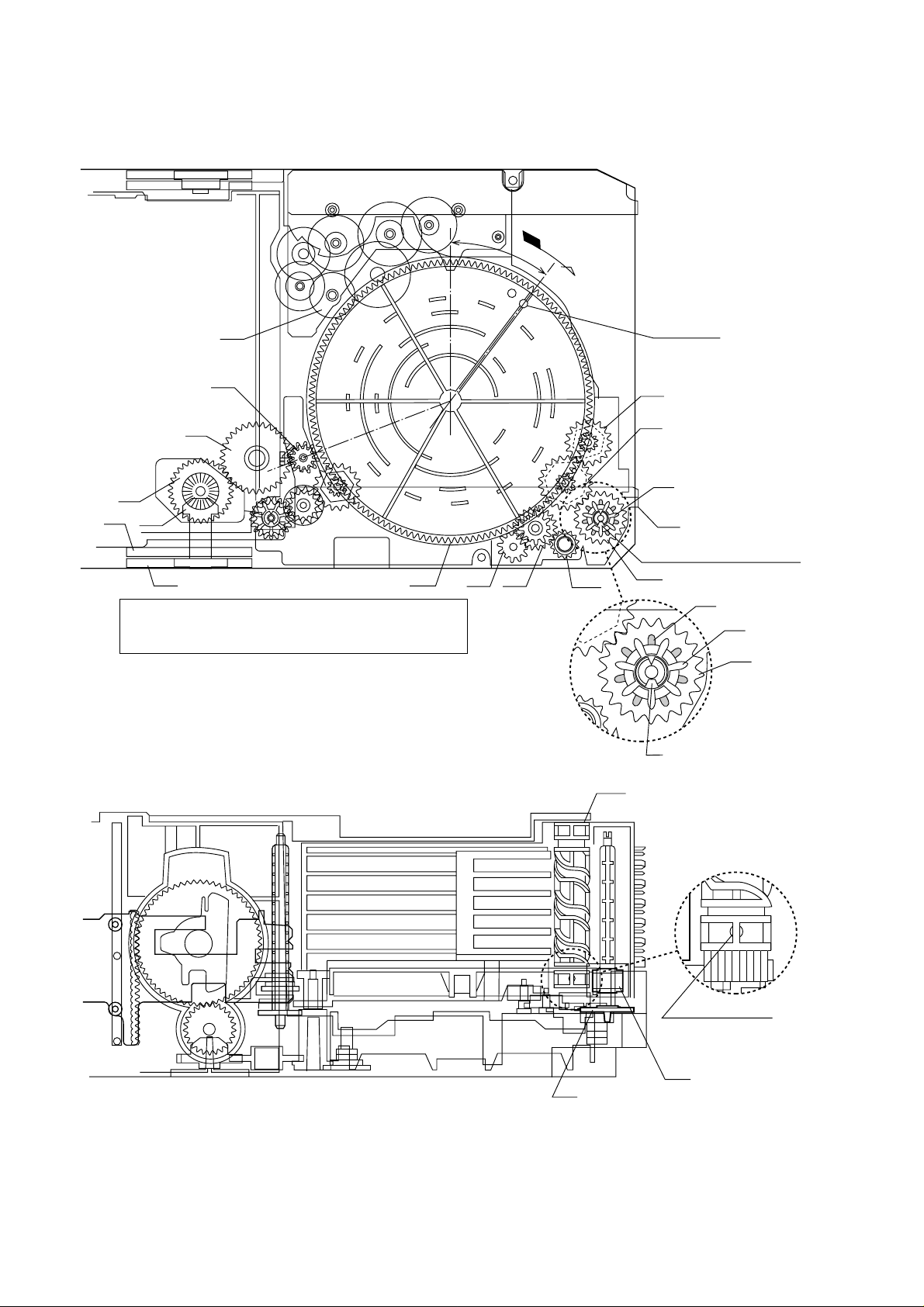

Work content

1. Motor assembly (X 2) mounting (screw x 4) 101/129 Fig.14

2. MT idle gear mounting (screw x 1) 125 Fig.14

3. MT system gear assembly 123/124/126/127 Fig.14

4. STB/tray drive system gear and others assembling/ 137/138/145/146 (153)/147/148 Fig.14

mounting (screw X 3)

5. Tray big gear assembly 131 Fig.14 Gear positioning

6. T.M SW PWB mounting (screw x 3) Fig.15

7. STB holder assembling 103 Fig.14

8. STB drive gear L/R assembly mounting (screw x 2) 111 (110)/112 (110) Fig.14

9. Tray joint gear R/tray drive gear R assembling 134/136 Fig.15 Gear positioning

10. Tray gear A/B assembling 132/133 Fig.15 Gear positioning

11. Lift gear B/C assembling 143/144 Fig.16 Gear positioning

12. MT idler gear F assembling, mode big gear 128/142 Fig.16

mounting (screw x 1)

13. Change box R mounting (screw x 4) 104 Fig.16

14. Lift gear A assembling 142 Fig.16 Gear positioning

15. Change box L assembly mounting (screw x 4) 102/130/135 Fig.17

16. Lift cam assembling (shaft inserting) 144 Fig.17 Gear positioning

17. STB holder height adjusting Fig.18 Check/adjustment

18. Top plate F/disc OB LEV. mounting (screw x 6) 180 Fig.18

19. Trays 1 - 6 assembling 191/192/193/194/195/196 Fig.19

20. Top plate R mounting (screw x 6) -

Applied part No.

Assembly fig. No.

Remarks

No.

101 MAIN BASE

102 CHANCE BOX L

103 STB HOLDER

104 CHANGE BOX R

110 STB DRIVE GEAR A

111 STB DRIVE GEAR L

112 STB DRIVE GEAR R

120 STABILIZER FH

123 MT IDLER GEAR A

124 MT IDLER GEAR B

125 MT IDLER GEAR C

126 MT IDLER GEAR D

127 MT IDLER GEAR E

128 MT IDLER GEAR F

129 MOTOR GEAR

130 TRAY DRIVE GEAR F

131 TRAY BIG GEAR

132 TRAY GEAR A

133 TRAY GEAR B

134 TRAY DRIVE GEAR R

135 TRAY JOINT GEAR F

136 TRAY JOINT GEAR R

137 TRAY GEAR C

138 TRAY IDLER GEAR

Part name

CD CHANGER MECHANISM PARTS LIST

Part nameNo.

140 LIFT CAM

141 MODE BIG GEAR

142 LIFT GEAR A

143 LIFT GEAR B

144 LIFT GEAR C

145 STB GEAR A

146 STB GEAR B

147 STB GEAR C

148 STB GEAR D

150 LIFT LEVER

151 TRAY LOCK LEVER

152 DISC OB LEVER

153 STB GEAR ANG.

180 TOP PLATE F

181 TOP PLATE R

191 TRAY T1

192 TRAY T2

193 TRAY T3

194 TRAY T4

195 TRAY T5

196 TRAY T6

– 13 –

Page 14

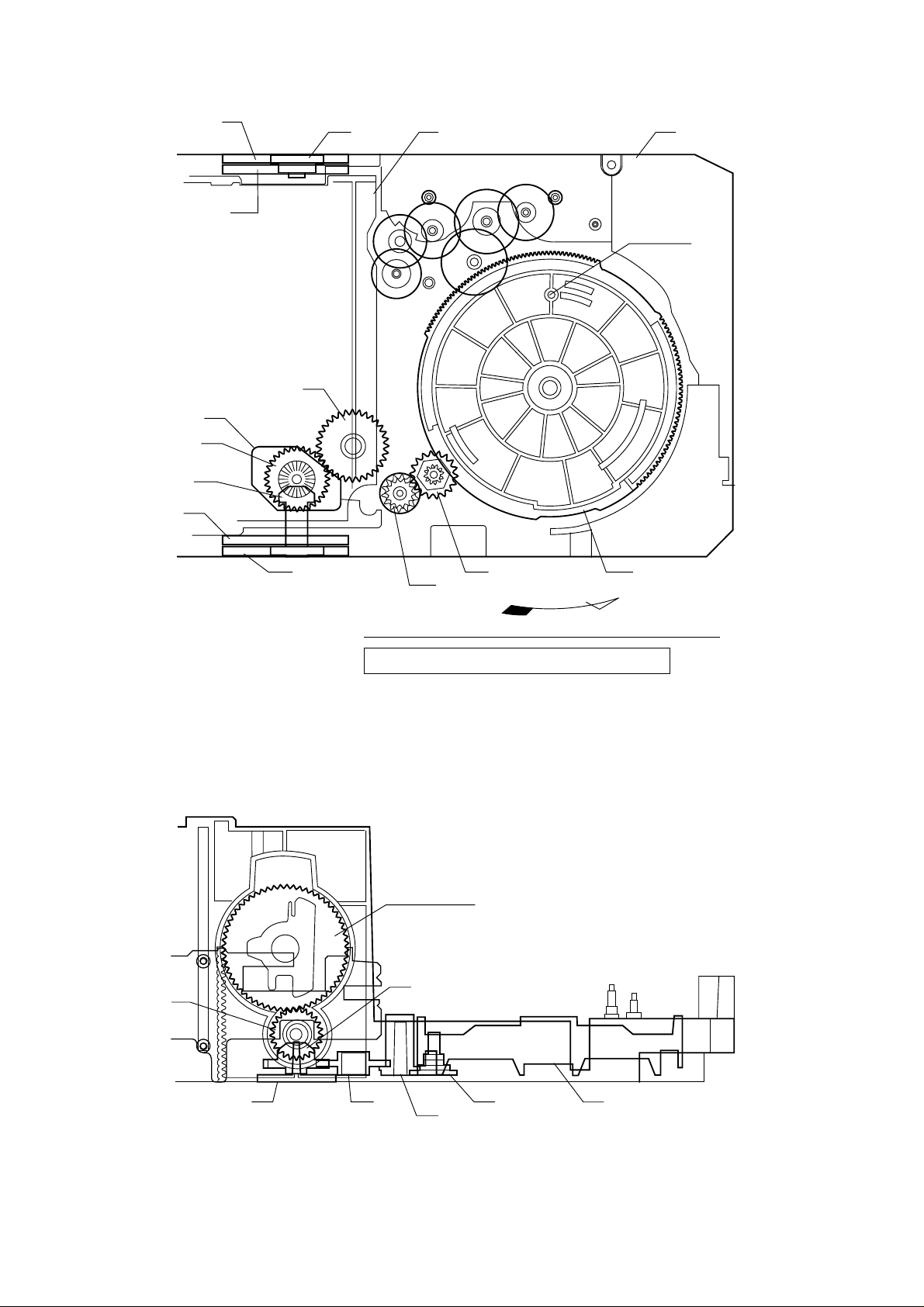

CD-CH1000

STB DRIVE GEAR R

STB DRIVE GEAR A

STB GEAR ANG.

STB GEAR B

STB GEAR C

110

STB DRIVE GEAR A

(ASSY)

153

146

147

112

110

STB GEAR A

145

148

STB GEAR D

126

103

STB HOLDER

129

127

123

125

124

123

101

MAIN BASE

129

Mark position

STB GEAR C

147

STB DRIVE GEAR L

111

(ASSY)

138

TRAY IDLER GEAR

137

TRAY GEAR C

131

TRAY BIG GEAR

After assembly TRAY BIG GEAR, turn it in the arrow direction.

TRAY BIG GEAR ASSEMBLING POSITION

111(/112) (110)

STB DRIVE GEAR L(/R)

(ASSY)

146

STB GEAR B

STB GEAR ANG.

153

STB GEAR A

145

138

TRAY IDLER GEAR

137

TRAY GEAR C

Figure 14

– 14 –

131

TRAY BIG GEAR

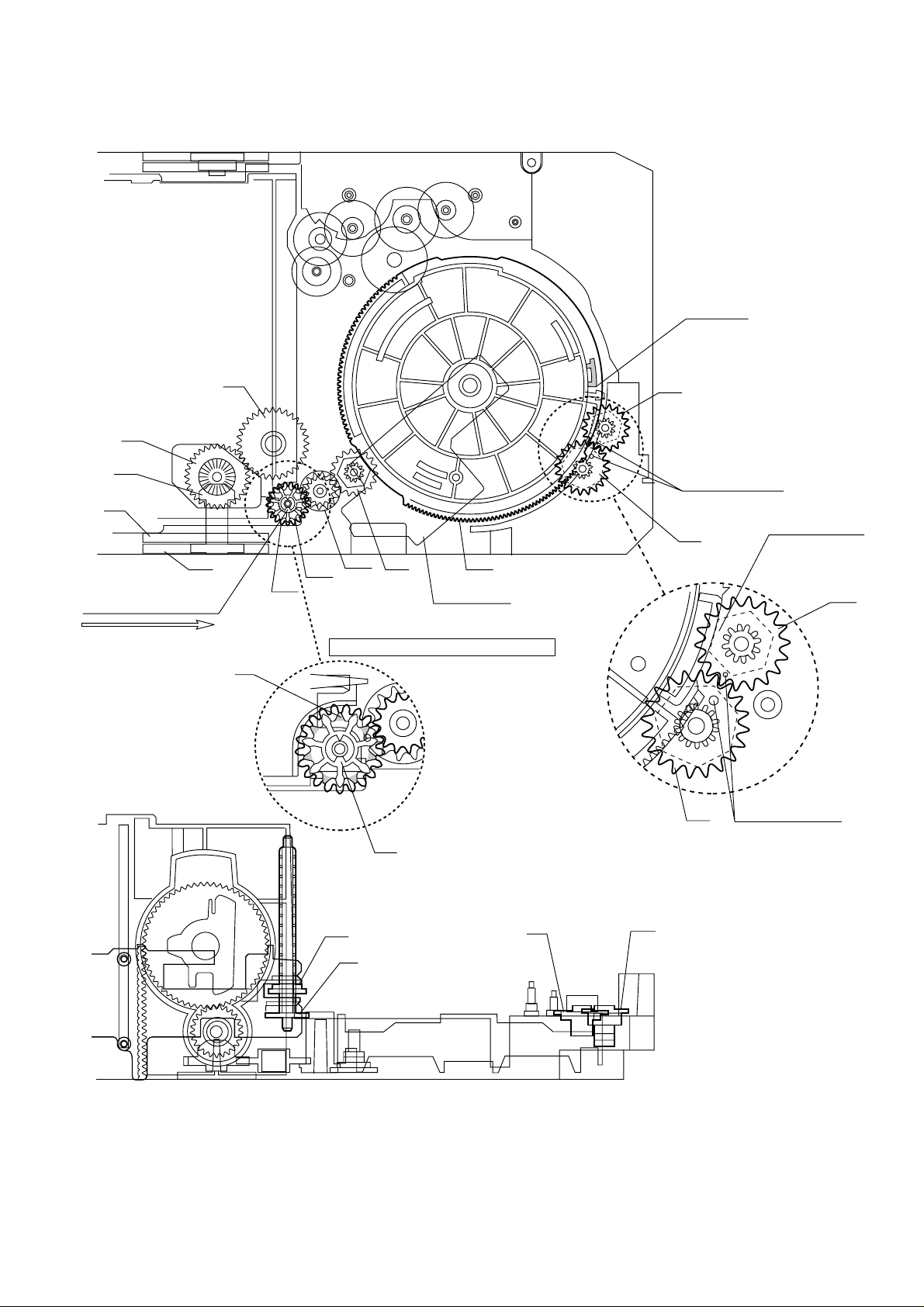

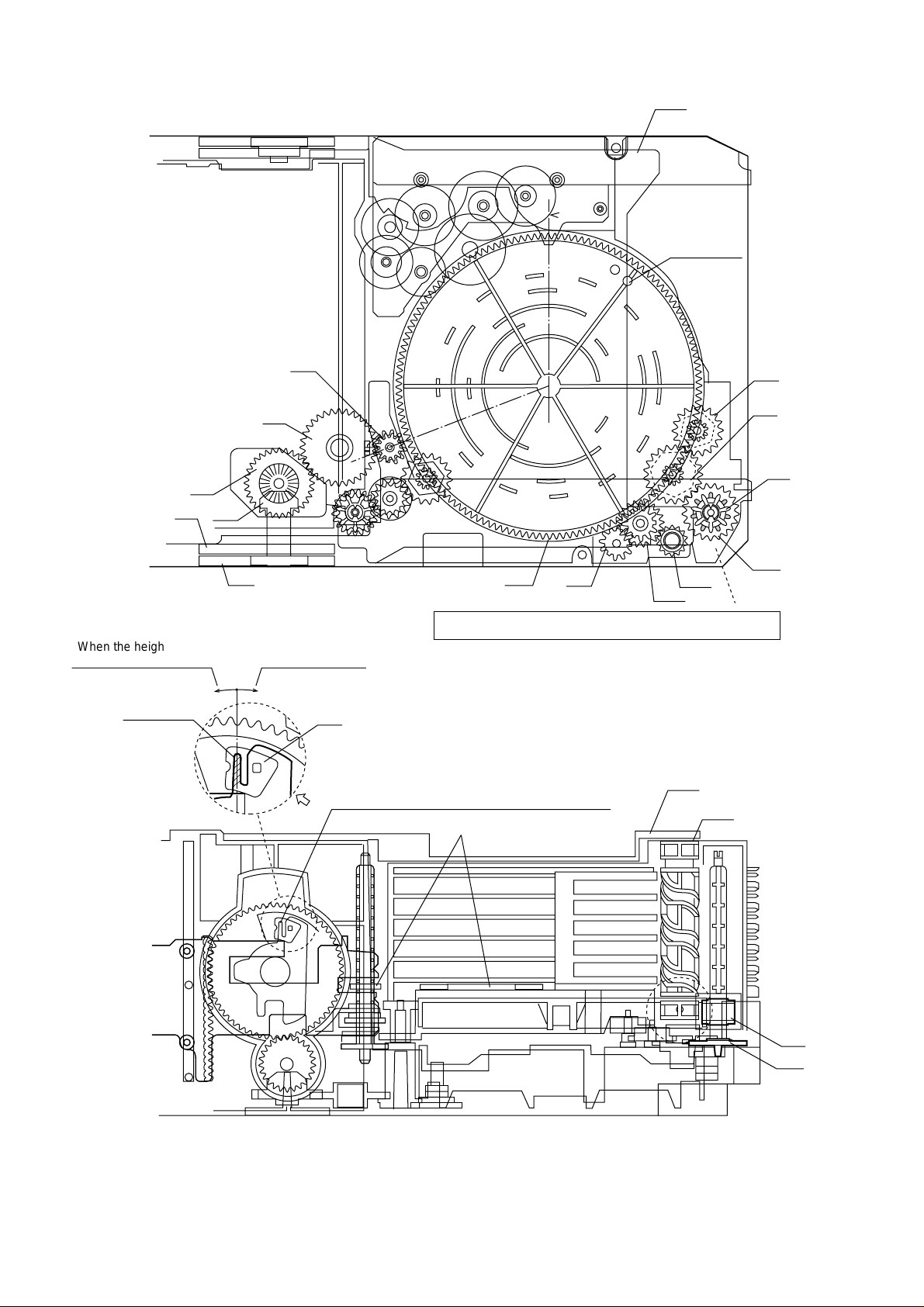

Page 15

CD-CH1000

146

147

110

111

Direct the recess part

(trapezoidal side) of the axis

135 in this direction.

145

129

126

123

125

127

138

134

TRAY DRIVE GEAR R

136

TRAY JOINT GEAR R

124

137

129

123

131

M T SW PWB

Scale: 2 magnifications

Mark position

* This position becomes the

reference (stock) position

of the tray.

132

TRAY GEAR A

The hole must align.

It must not rotate in contact

with the peripheral (hatched)

part of 131.

133

TRAY GEAR B

132

Scale: 2 magnifications

*2

TRAY BIG GEAR SET POSITION

*1: To position the axis part of 136, engage it with 138.

*2: When it is aligned as described in *1, the hatched part

*1

(low gear-height part of gear) will be positioned in this position.

Note: After positioning the tray big gear in the set position, engage these gears.

134

TRAY DRIVE GEAR R

136

TRAY JOINT GEAR R

TRAY GEAR B

133

133

132

TRAY GEAR A

The hole must align.

After assembling 132,

assemble 133.

Figure 15

– 15 –

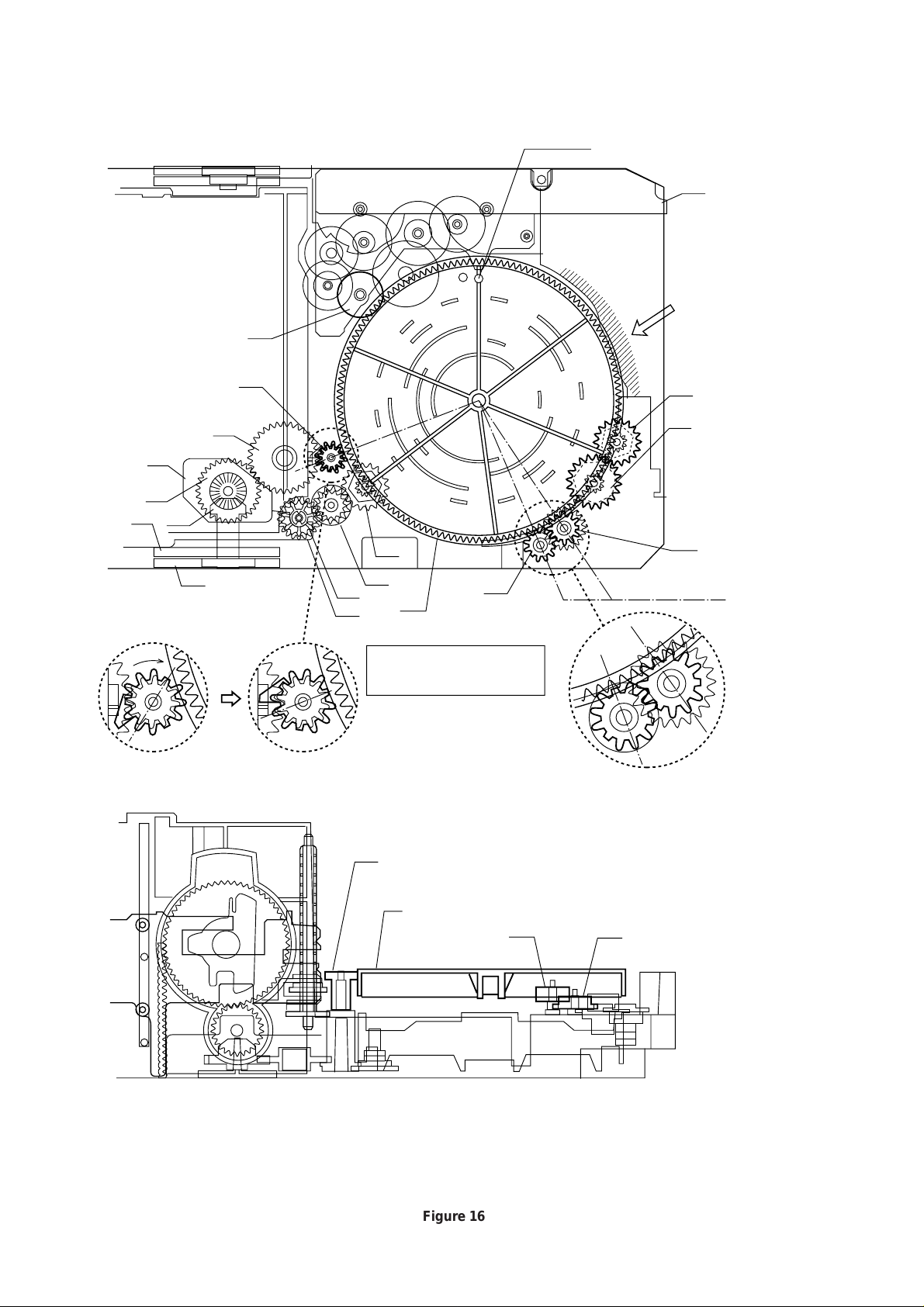

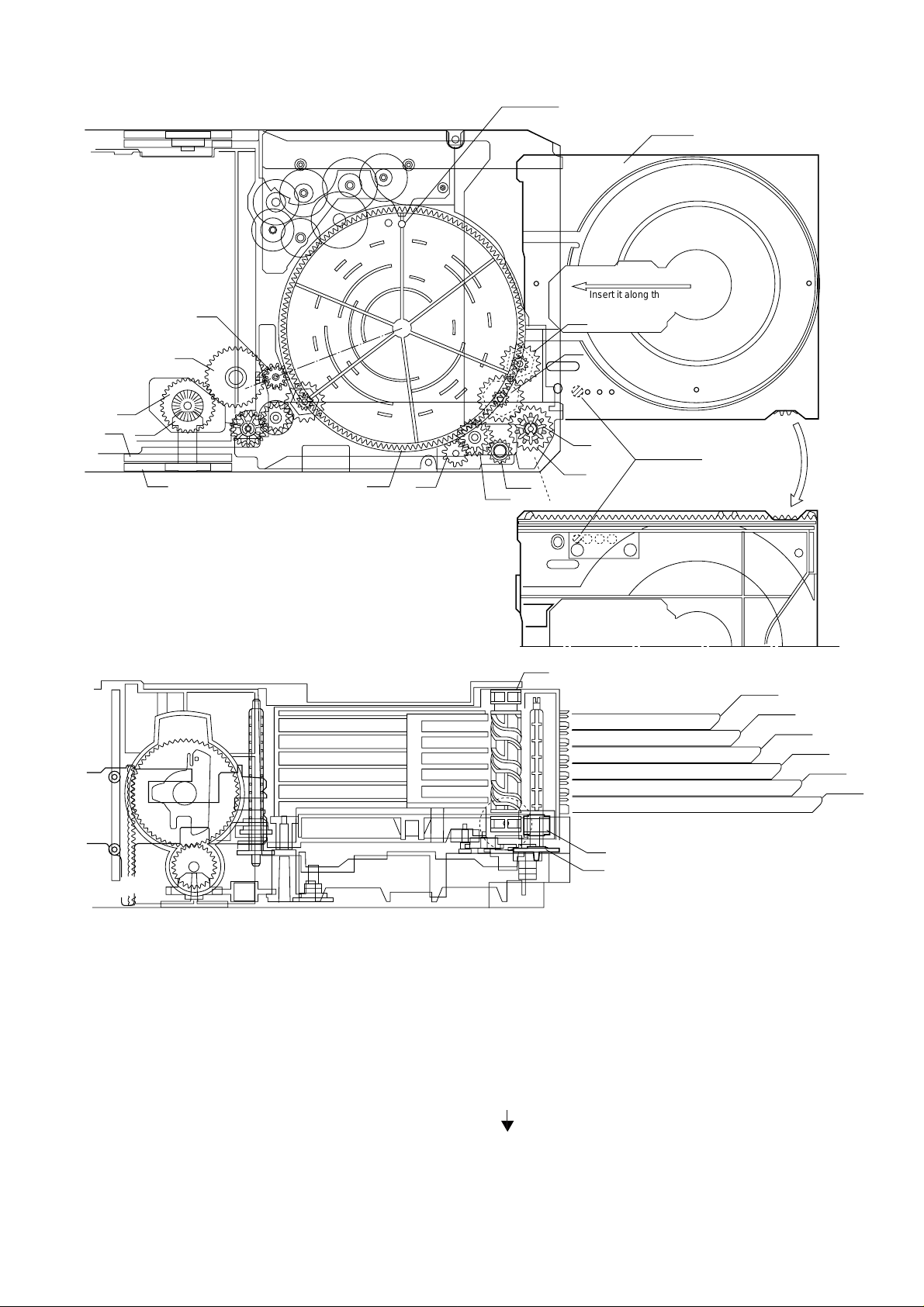

Page 16

CD-CH1000

MT IDLER GEAR F

128

142

LIFT GEAR A

Mark position

(Assemble the mode big gear in this position.)

104

CHANGE BOX R

Note

To assemble the mode

big gear, incline it,

bring it into contact with

the circumference and

put the center hole into

position since the

hatched part of the main

base is overlapped with

the circumference.

132

110

153

146

147

111

Scale: 2 magnifications

(A)

145

(B)

137

134

136

138

141

MODE BIG GEAR

143

LIFT GEAR B

MODE BIG GEAR

LIFT GEAR A/B/C

ASSEMBLING POSITION

<Assembling method of lift gear>

After setting up the mode big gear in the

shown position, engage it with the STB gear A

(gear on the lower side) at the position (A),

and assemble them, turning it in the arrow direction

into the position (B). (The short tooth directs toward the

center of the mode big gear.)

142

LIFT GEAR A

133

144

LIFT GEAR C

Direct the short tooth

toward the center.

Scale: 2 magnifications

141

MODE BIG GEAR

LIFT GEAR B

Figure 16

– 16 –

143

144

LIFT GEAR C

Page 17

37°

CD-CH1000

128

145

142

141

143 144

Scale: 2 magnifications

LIFT GEAR A

146

110

147

111

TRAY JOINT GEAR F

(CHANGE BOX L ASS'Y) ASSEMBLING POSITION

LIFT CAM

Assembling procedure

1. Turn the mode big gear approx. 37 degrees in the arrow direction.

2. Assemble the change box L ass'y.

Note: At this time, the tray joint gear F must be located in the position shown in figure.

Moreover, the gear must be engaged securely.

3. After assembly, return the mode big gear to the initial position.

4. Assemble the lift cam.

Note: At this time, the lift cam must be located in the position shown in figure.

140

LIFT CAM

Mark position

132

133

130

TRAY DRIVE GEAR F

102

CHANGE BOX L

Direct the recess part (trapezoidal side)

of the axis 135 in this direction.

135

TRAY JOINT GEAR F

*1

140

LIFT CAM

*2

130

TRAY DRIVE GEAR F

135

TRAY JOINT GEAR F

*1: To position the axis part

of 135, engage it with 133.

*2: When it is aligned as

described in *1, the hatched part

(low gear-height part of gear)

will be positioned in this position.

Since this gear engagement is not

visually checked, verify that it does

not float when the gear box L is installed.

Scale: 2 magnifications

Figure 17

– 17 –

135

TRAY JOINT GEAR F

During assembly, make the

O part visible in this direction.

Note: Among 4 ribs on the

circumference, one rib alone

is provided with O.

130

TRAY DRIVE GEAR F

Page 18

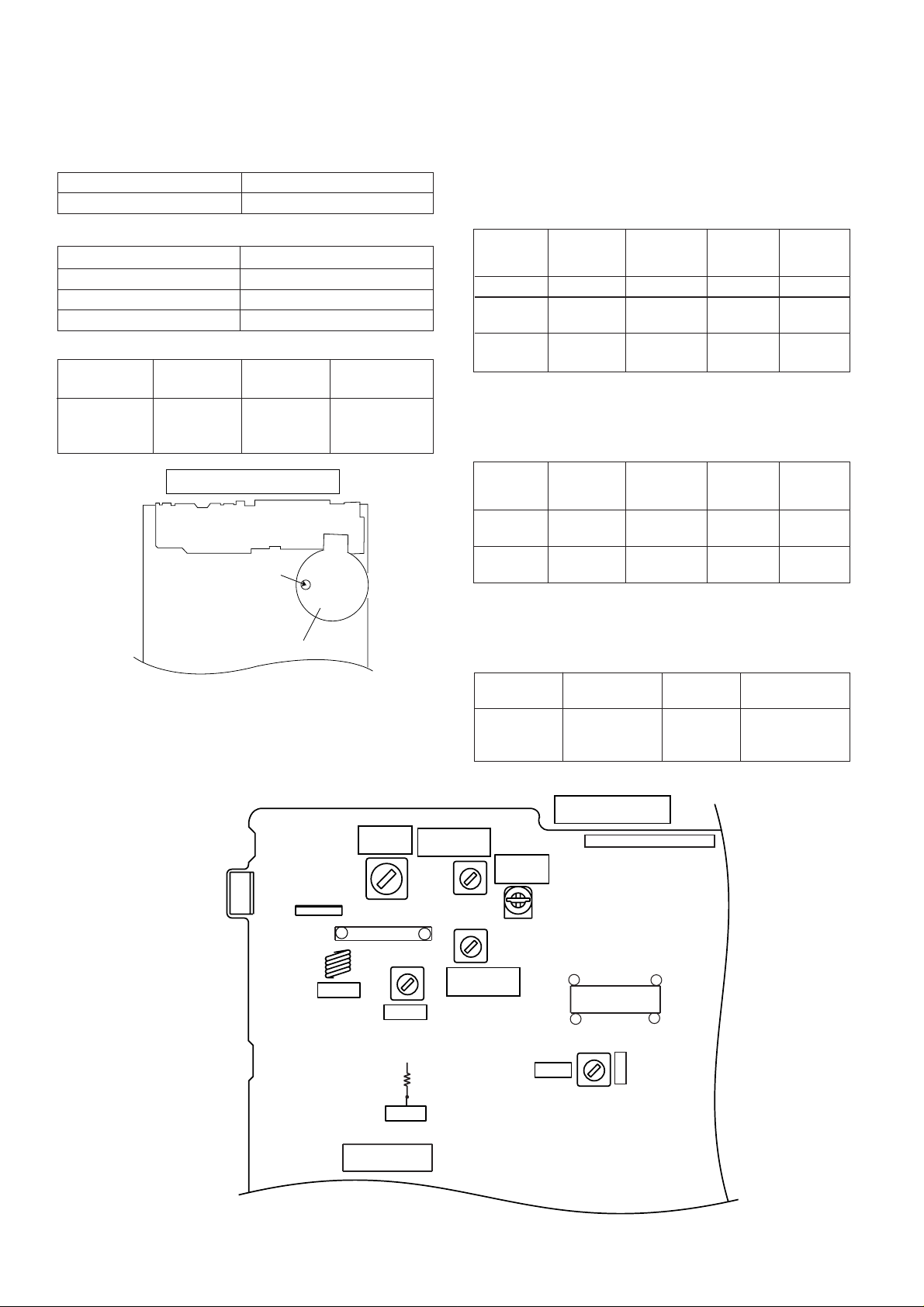

CD-CH1000

180

TOP PLATE F

Mark position

146

110

When the height of

STB holder is low,

(Increase the clearance.)

Bend this part.

Scale: 2 magnifications

LIFT GEAR A

145

147

111

When the height of

STB holder is high,

(Decrease the clearance.)

142

141

STB HOLDER HEIGHT ADJUSTING METHOD

Adjusting procedure

1. Turn the mode big gear approx. 37 degrees in the arrow direction.

2. Viewing from the front side of the mechanism, verify that the guide ribs

(CHANGE BOX L/R and STB HOLDER)of tray are as tall as each other.

3. If they are not, bend the lever for adjustment. (Refer to the details.)

240

OS LEVER

Bend this part to adjust the height of the STB holder.

Details

Note: Also apply the same adjustment on the R side.

Height of the rib

143

132

133

130

135

140

144

180

TOP PLATE F

140

Figure 18

– 18 –

130

135

Page 19

142

LIFT GEAR A

Mark position

Be sure to assemble the tray into this position.

191~196

TRAY1~TRAY6

Insert it along the guide of

the change box.

132

CD-CH1000

145

146

110

147

111

Tray installing method: (After adjusting the height of the STB holder)

1. Turn the mode big gear to the mark position to lower the STB holder to the bottom area.

2. From the front side, install the tray. (Securely insert it to the lock position.)

141

143

144

140

140

133

135

130

TRAY No.1~6

Rear surface: Stamped.

Note: During insertion, don't mistake No.

TRAY 6

TRAY 5

TRAY 4

Rear side

TRAY 3

TRAY 2

TRAY 1

130

135

Figure 19

Measure to be taken when a disc cannot be removed due to a mechanism trouble

First, remove the mechanism unit section from the set, and check for the state of the disc.

(Remove the top plate R if necessary.)

<State of the disc>

(1) When the disc is in the normal PLAY (chucking) position -> Try to eject the disc by turning the mode big gear/tray big gear

manually.

* At this time, be sure to adjust the tray's position (height).

(2) When the disc is in the normal STOCK position -> Try to eject the disc by turning the tray big gear manually.

* At this time, be sure to adjust the tray's position (height).

(3) When the disc is not in the normal position -> The tray or disc is not in the normal position. (The tray or disc may catch

somewhere.)

Remove the TOP PLATE F/DISC OB lever.

Unlock the tray lock lever and pull out the tray which is not caught.

Move the caught tray or disc and remove the disc.

In case of (1) and (2), the mechanism is normal (defective circuit parts, etc.). However, it may stop somewhere.

This is the reason why you should try to turn the tray big gear first.

In case of (3), either of the big gears does not turn.

– 19 –

Page 20

CD-CH1000

ADJUSTMENT

MECHANISM SECTION

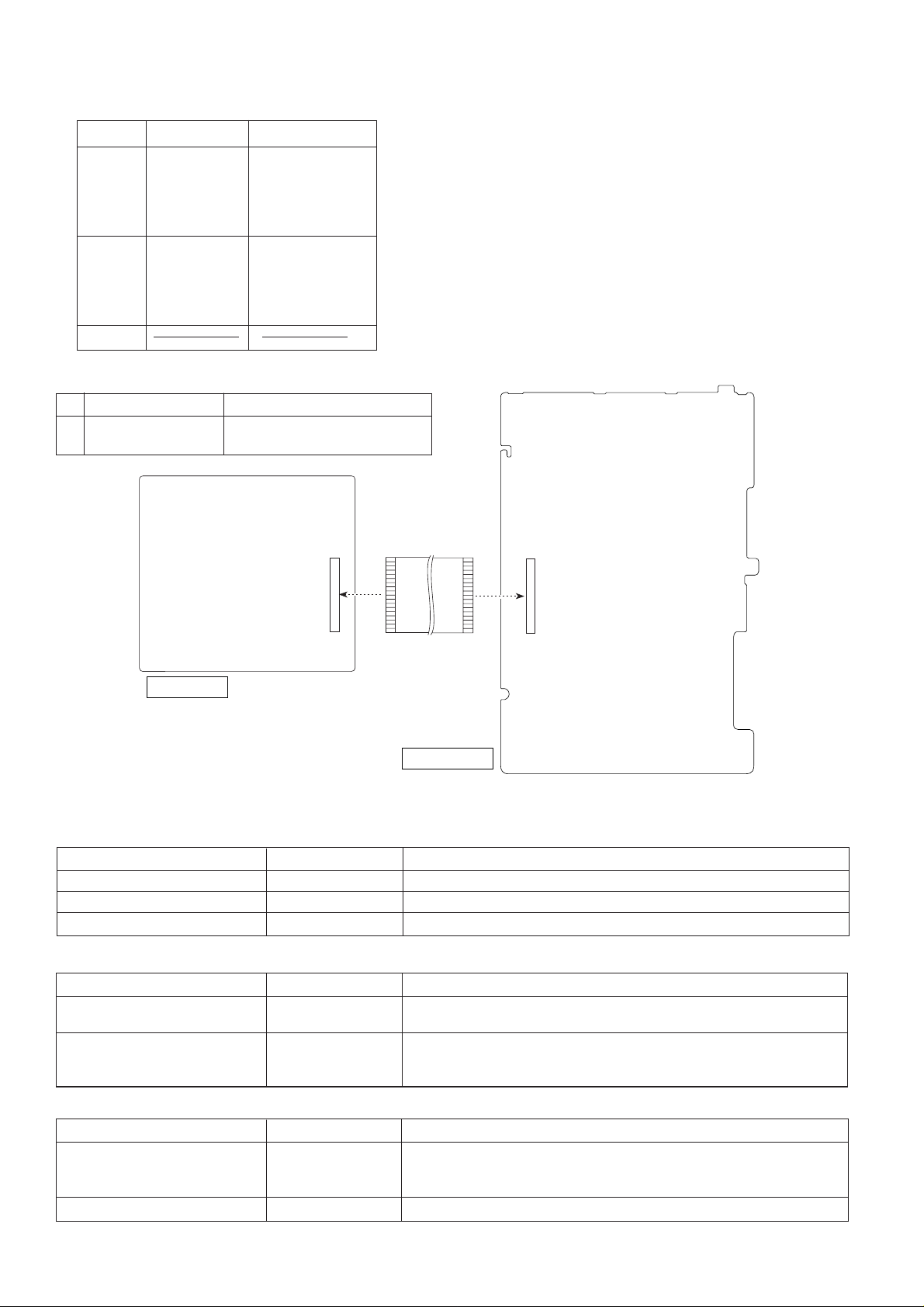

• Driving Force Check

Torque Meter

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 60 g. cm

Fast forward: TW-2231 60 to 120 g.cm

Rewind: TW-2231 60 to 120 g.cm

• Tape Speed

Test Tape

MTT-111 Variable 3,000 ±90 Hz Speaker

Adjusting

Point

resistor in terminal

motor.

TAPE MECHANISM

Variable

Resistor

in motor

Specified Value

Specified Value

Specified

Value

Instrument

Connection

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Frequency

AM IF 450 kHz 1,720 kHz T351 *1

AM Band — 530 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM 990 kHz 990 kHz T302 *1

Tracking

*1. Input: Antenna Output: Speaker Terminal

*2. Input: Antenna Output: TP301

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage

FM Band — 87.50 MHz (fL): T311 *1

Coverage 1.3 ± 50mV

FM RF 98.00 MHz 98.0 MHz L312 *2

*1. Input: Antenna Output: TP301

*2. Input: Antenna Output: Speaker Terminal

Frequency Display

Frequency Frequency

Display

(10~30 dB)

Setting/

Adjusting

Parts

Setting/

Adjusting

Parts

Instrument

Connection

Instrument

Connection

Tape motor

Figure 20-1 ADJUSTMENT POINT

CNP303

FM/AM

ANTENNA

SOCKET

3

2

1

CNP303

AM

GND

FM

T302

BF301

1

L312

FM RF

AM

Tracking

IC301

T312

FM IF

AM Band

Coverage fL

T306

9

FM Band

Coverage fL

R345

• FM Mute Level (FM ST MODE)

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

98.00 MHz 98.00 MHz VR351*1 Input:CNP303

(26 dBµV) Output: Speaker

Display

Adjusting

Parts

Instrument

Connection

Terminal

*1. Adjust so that an output signal appears.

MAIN PWB

15

13

T311

FM Mute

Level

VR351

AM IF

24

1

1

BI960

IC303

12

T351

CF352

TP301

IC302

Figure 20-2 ADJUSTMENT POINTS

– 20 –

Page 21

CD-CH1000

TEST MODE

Outline

While the unit is turned off, press the POWER key while holding down the VOLUME-DOWN and PANEL OP/CL keys to enter

the test mode selection mode. Then, the unit is started, the panel is opened, and the microcomputer's version/destination/span

is displayed. If the following data is entered from the keyboard while in the test mode selection mode, the unit directly enters

the specified test mode. This operation is applied to the main unit's keys only.

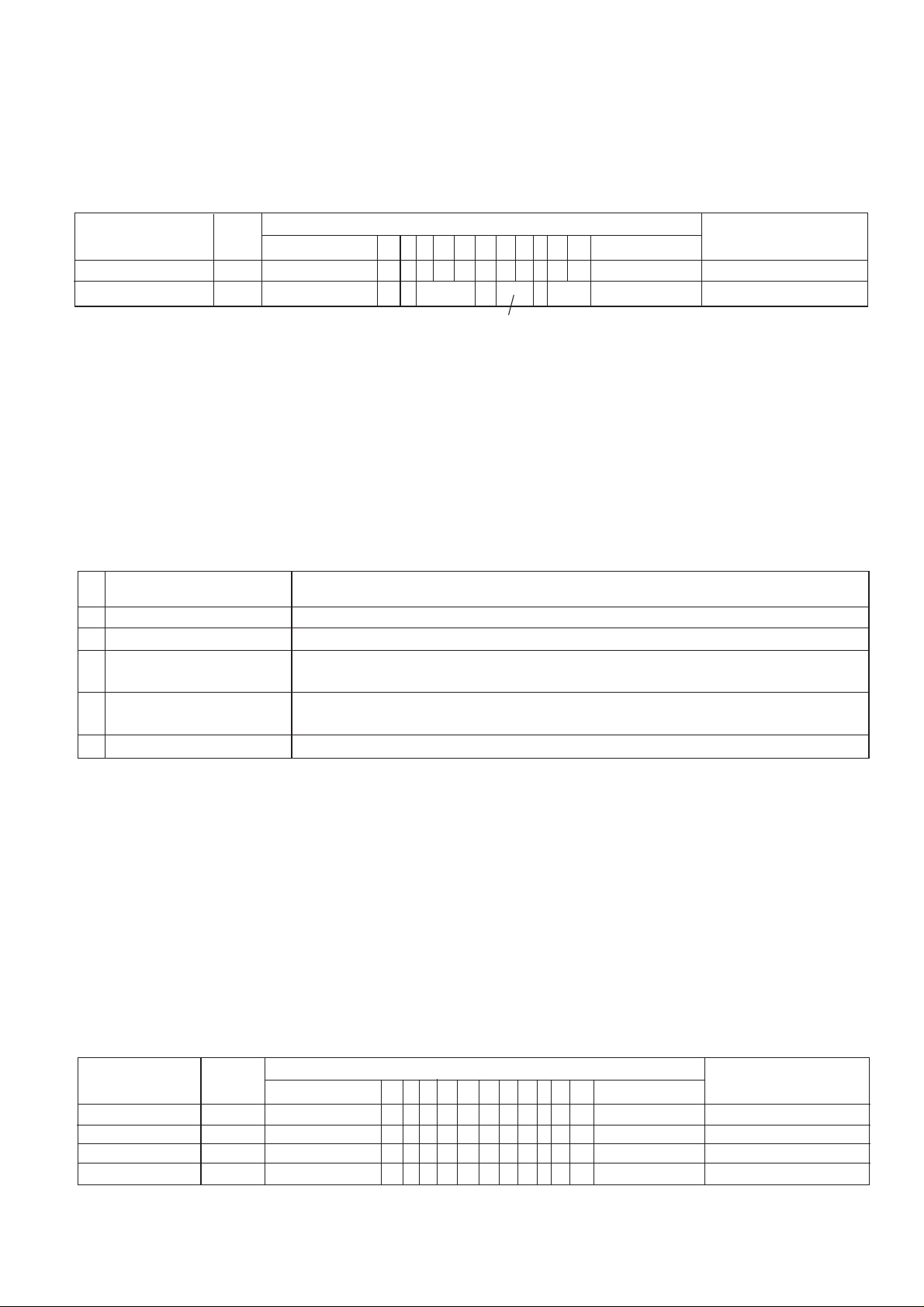

Character display

Item Type Auxiliary display 1 2 3 4 5 6 7 8 : 9 10 Auxiliary display Note

Version•Destination V * • * Left adjust in the first line

Number

:

Span

Example: V1. 1_W:_9

In the destination display, a destination code (H/W/U/J) is displayed. For the span display, "9" means 9 kHz/50 kHz, and "10"

means 10/100 kHz. All pictures will disappear except the characters.

By pressing the specific key, you can enter the test mode whose functions are as follows:

Menu display Shortcut Key Model

System INITIAL CD1 PLAY ALL Shipping status setting

SOFT_RESET CD2 PLAY ALL Soft rest

CD CD_TEST CD1 EJECT ALL CD test

Tuner TUN_PRESET CD4 EJECT ALL Tuner test frequency preset

TUNER_TEST CD5 EJECT ALL Tuner test

Outline of Test Mode

Name Description

1 Shipping status setting Sets up the unit for shipping.

2 Soft set setting Initializes the unit.

3 CD test Performs tests such as the CD mechanism test, hardware test,

and constant setting test.

4 Tuner test Presets the test frequency.

frequency preset

5 Tuner preset clear setting Clears all presets.

Destination

Shipping status setting test mode

Purpose: To Set up the unit for shipping.

Function: To check the unit for a CD disc, and initialize all functions.

Operation: While checking for a CD disc, the test name (INITIAL) is displayed.

The initial operation for a CD disc is performed. In this operation, the unit is checked for a CD disc.

If a CD disc is found in the unit during the initial operation, "CD* OPEN" is displayed, the tray is opened (only for the

disc found first), and the unit is turned on via the CD function normally.

If no CD disc is found, the CD mechanism is placed in the chucking status.

After the unit is checked for discs, all settings are initialized, "FINISH" is displayed as in the sample display, and data entry is

prohibited including data to turn on or off the unit.

To exit the test mode

The unit returns to the normal operation through reset entry (hard).

Table Character display for test mode 1

Character display

Item Type Auxiliary display 1 2 3 4 5 6 7 8 : 9 10 Auxiliary display Note

Test mode name I N I T I A L

CD disc inserted

Set-Up Complete Function F I N I S H

In the destination display, a destination code is displayed. For the span display, "9" means 9 kHz/50 kHz, and "10" means 10/

100 kHz.

Operation

CD* OP E N

– 21 –

Page 22

CD-CH1000

2. Soft reset

Purpose: To initialize the unit.

Function: To initialize all functions.

Operation: "ALL CLEAR" is displayed, all functions are initialized, and the unit is turned on.

To exit the test mode

When the initialization through soft reset is complete, the unit is turned on.

Table Character display for test mode 2

Character display

Item Type Auxiliary display 1 2 3 4 5 6 7 8 : 9 10 Auxiliary display Note

Reset operation

display

3. CD test mode (If this test mode is not activated, refer to CD troubleshooting on page 54.)

In the CD test mode, each step can be performed even if the LID-SW is off. However, if you cannot obtain a focus in step

3 or if other kind of error handling starts, you cannot proceed to the following steps. In error handling, press the POWER key

to exit the test mode, or press the STOP key to prohibit operations other than returning to step 1.

(1) Step 1 mode

In the CD test mode, the following display appears, CD initialization is performed, and you are prompted for data.

Reset operation display / Operation

Operation

ALL CL E A R

"CD_TEST"

After lighting up for one second

"T1___________0:00"

The keys you can press here and the resulting operations are as follows:

"POWER"........... The test mode is turned off, the power is turned off, and the unit is placed in the normal standby mode.

"FWD" ................ While holding down this key, the pickup moves outward after returning to the innermost track.

"REV" ................. While holding down this key, the pickup moves inward after returning to the innermost track.

"PLAY" ............... Jumps to step 2.

"STOP"............... Cancelled.

"TAPE REC" ...... Jumps to step 5.

* While the pickup is moving to the innermost track in the initialization, none of the keys except POWER is accepted. When PU-

IN SW ON cannot be detected in ten seconds, the unit stops the slide motor and shows the following error code. Then, you

can press the POWER key to exit the test mode, or the STOP key to return to step 1. You cannot perform other operations.

"E--CD01"

(2) Step 2 mode

When the "PLAY" key is pressed in the above mode, the laser is turned on. At this time, another operation must not be

performed.

Display "T2___________0:00"

The keys you can press here and the resulting operations are as follows:

"POWER" ........... The test mode is turned off, the power is turned off, and the unit is placed in the normal standby mode.

"FWD"................. While holding down this key, the pickup is moved outward.

"REV".................. While holding down this key, the pickup is moved inward.

"PLAY"................ Jumps to step 2.

"STOP" ............... Returns to step 1.

"TAPE REC"....... Jumps to step 5.

– 22 –

Page 23

CD-CH1000

(3) Step 3 mode

Performs focus search and turns on the focus servo.

Focus search is repeated until it is brought into focus.

Display "T3___________0:00"

The keys you can press here and the resulting operations are as follows:

"POWER" ........... The test mode is turned off, the power is turned off, and the unit is placed in the normal standby mode.

"FF/FWD" ........... While holding down this key, the pickup is moved outward.

"REW/REV" ........ While holding down this key, the pickup is moved inward.

"PLAY"................ Jumping to step 4 when a focus is obtained. Otherwise, data entry is prohibited.

"STOP" ............... Returns to step 1.

"TAPE REC"....... Jumps to step 5.

* You should return to step 1 if it is out of focus after bringing it into focus.

(4) Step 4 mode

Rotate a disc.

Displayed string: "T4___________0:00"

The clock display should always be "0:00".

The keys you can press here and the resulting operations are as follows:

"POWER" ........... The test mode is turned off, the power is turned off, and the unit is placed in the normal standby mode.

"FF/FWD" ........... While holding down this key, the pickup is moved outward.

"REW/REV" ........ While holding down this key, the pickup is moved inward.

"PLAY"................ Jumps to step 5.

"STOP" ............... Returns to step 1.

"TAPE REC"....... Jumps to step 5.

* You should return to step 1 if it is out of focus.

(5) Step 5 mode

Start playback. When the pickup reaches the outermost track, it does not stop. The LCD screen shows the replay time elapsed

as in the normal CD playback.

Display "T5___________0:00"

The keys you can press here and the resulting operations are as follows:

"POWER" ........... The test mode is turned off, the power is turned off, and the unit is placed in the normal standby mode.

"FWD"................. While holding down this key, the pickup is moved outward.

"REV".................. While holding down this key, the pickup is moved inward.

"PLAY"................ Canceled.

"STOP" ............... Returns to step 1.

* You should return to step 1 if it is out of focus.

Notes:

• In the test mode, TOC IL is not performed.

• Only the keys for adjusting the volume are accepted except the keys described

4. Tuner test frequency preset

Purpose: To preset a test frequency for an in-factory test.

Function: To preset each preset number to the band and frequency shown in Table 24 based on the initial setting for the

destination.

Operation: To preset the band and frequency shown in the table below and turn the unit on with the following setting.

Function Tuner

Band FM monaural

Tuning mode Preset call selection

Call preset number Preset number 1 frequency

Band's last preset channel See Table 24

X-BASS Off

Preset equalizer FLAT

For other functions, the value which was set when the unit was turned off last time is valid (last state).

To exit the test mode

After the frequency is preset and the set-up is done, the unit is turned on and normal operations start.

– 23 –

Page 24

CD-CH1000

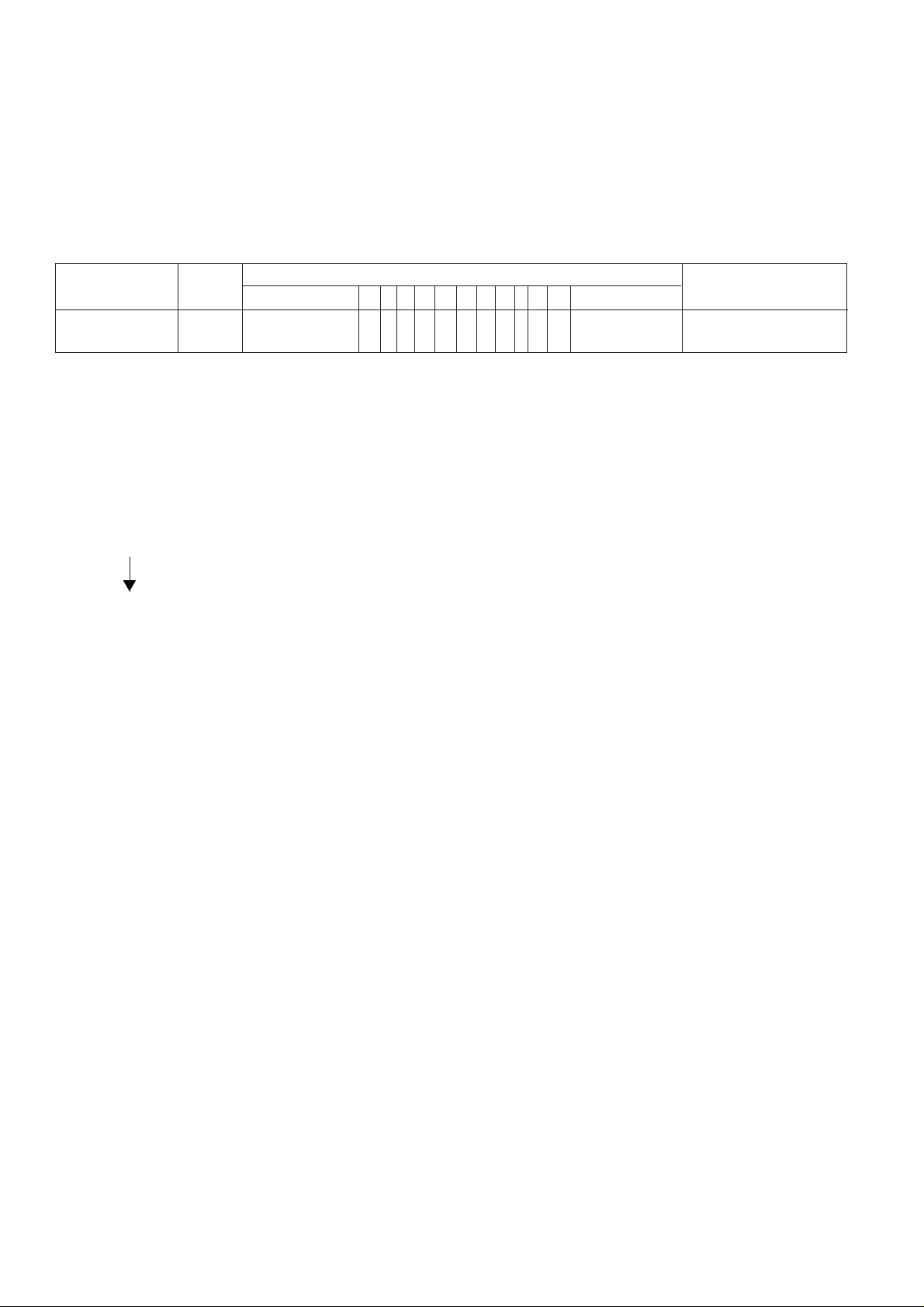

Table 24. TEST-TuSet preset frequencies

BAND

U.S.A.CH

1 % FM 87.5 MHz

2 FM108.0 MHz

3 FM FM 90.0 MHz

4 FM106.0 MHz

5 FM 98.0 MHz

6 % AM 530 kHz

7 AM1720 kHz

8 AM AM 600 kHz

9 AM1400 kHz

10 AM 990 kHz

11-40

Extension cable

Type

1. 33 Pin extension QCNWN6931AFZZ

flat cable, 500mm

Part No.

Unused channels are indicated with "_".

'%' indicates the last channel for each band.

All FM bands are preset to FM monaural.

CNP1

33

33

1

1

33Pin extension flat cable

QCNWN6931AFZZ

33

1

CNP901

1

33

CD PWB-C

MAIN PWB-A

Figure 24

ERROR MESSAGE LIST

CD error messages

Errors

Messages

Pickup mechanism error E-CD01 Slide motor operation error (PU-IN SW detection NG)

Tray error E-CD20 Tray open/close operation error

Changer mechanism error E-CD10 Changer mechanism operation error

TUNER error messages

Errors

Messages

Relation to RDS WEAK SIG When switching to an EON station,

EON reception impossible it cannot be received due to weak signal.

PLL UN LOCK Frequency Reception error or PLL control error

indicator

flashing

Remarks

Remarks

TAPE error messages

Errors

Messages

You tried to record on a tape 'PROTECTED'

removing the recording

prevention tabs.

TAPE mechanism error E-TA01 Mechanism initialize abnormal end

– 24 –

Remarks

Page 25

NOTES ON SCHEMA TIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

REF. NO DESCRIPTION POSITION POSITIONREF. NO DESCRIPTION

NSW1 PICKUP IN ON—OFF

SW701 POWER ON—OFF

SW705 OPEN/CLOSE ON—OFF

SW710 PANEL OPEN/CLOSE ON—OFF

SW711 VOLUME DOWN ON—OFF

SW712 VOLUME UP ON—OFF

SW720 CD 1 EJECT ON—OFF

SW721 CD 2 EJECT ON—OFF

SW722 CD 3 EJECT ON—OFF

SW723 CD 4 EJECT ON—OFF

SW724 CD 5 EJECT ON—OFF

SW725 CD 6 EJECT ON—OFF

SW730 CD 1 PLAY ON—OFF

SW731 CD 2 PLAY ON—OFF

SW732 CD 3 PLAY ON—OFF

SW733 CD 4 PLAY ON—OFF

SW734 CD 5 PLAY ON—OFF

SW735 CD 6 PLAY ON—OFF

SW750 RECORD PAUSE ON—OFF

SW751 CLEAR ON—OFF

SW752 MEMORY ON—OFF

SW753 FAST REVERSE ON—OFF

SW755 FAST FORWARD ON—OFF

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

( ) indicates AM

< > indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

SW756 PLAY/PAUSE ON—OFF

SW758 STOP ON—OFF

SW761 AUX ON—OFF

SW762 TUNER ON—OFF

SW763 TAPE ON—OFF

SW764 CD ON—OFF

SW770 PLAY MODE ON—OFF

SW772 EQUALIZER MODE ON—OFF

SW773 X-BASS ON—OFF

SW774 DISPLAY ON—OFF

SW776 MENU ON—OFF

SW778 ENTER ON—OFF

SWB101 DISC DETECT 1 ON—OFF

SWB102 DISC DETECT 2 ON—OFF

SWB103 DISC DETECT 3 ON—OFF

SWB104 MODE 1 ON—OFF

SWB105 MODE 2 ON—OFF

SWB106 MODE 3 ON—OFF

SWB107 MODE 4 ON—OFF

SWB108 MODE 5 ON—OFF

SWB109 TRAY 1 ON—OFF

SWB110 TRAY 2 ON—OFF

CD-CH1000

FRONT

VIEW

ECB

(S)(G)(D)

(1) (2) (3)

2SA1015 GR

2SA562 Y

2SB561 C

2SB562 C

2SC1740 R

DTC363 TS

KRA102 M

KRA107 M

KRC102 M

TYPES OF TRANSISTOR AND LED

KRC104 M

KRC107 M

KTA1046 Y

KTC2026

KTC3194 Y

KTC3203 Y

KTA1266 GR

KTC3199 GR

FRONT

VIEW

BCE

2SD2012

– 25 –

FRONT

VIEW

HLMP1700

K5052C

K5052UL

L1154GDA

1 2 3

SVC211C

SVC348S

Page 26

CD-CH1000

R

C

C

FM

MUTE

LEVEL

T306

ANTENNA

SWITCHING

Q351

VR351

10K(B)

VD301

AM

A_+B

TUN_L

TUN_R

X351

456kHz

T306

(FM/AM)

13 12

MO/ST

PHASE

14

L-CH OUT

15

R-CH OUT

PHASE

MPX IN

16

17

18

19

20

21

22

23

24

IF OUT

MPX

VCC

VCO

FM DET

IC303

STEREO

LA1832S

SD

FM IF DET./FM MPX./AM IF

GND

FM/AM OUT

AM LOW CUT

AM IF IN

VSM

AM RF IN

FM AFC

REG

AM OSC IN

AM MIX OUT

AM OSC OUT

FM IF IN

AM OSC.

VD303

SVC211C

VSM

11

10

9

CF351

FM IF

8

SWITCHING

A_+B

Q360

D_GND

C2B_CE

C2B_CL

C2B_DO

C2B_DI

7

6

5

4

CF352

3

1

2

AM IF

T351

AM IF

3

2

A_+B

1

+B

ST IND

IF IN

IO2

NC

AM IN

FM IN

VDD

PD

AIN

IC302

AOUT

VSS

X OUT

X352

4.5MHz

11

10

MO/ST

MUTE

9

8

MW

7

FM

6

DO

CL

5

DI

4

LC72131

3

CE

2

NC

1

X IN

SWITCHING

IC302

LC72131

PLL(TUNER)

Q371

C2B_CL

C2B_DI

C2B_CE

C2B_DO

T312

CF302

FM IF

10.7MHz

3

1

FM IF

12

13

14

15

16

17

18

19

2

+B

20

21

22

VT_CK

TP301

BAND

PASS

FILTER

FM/AM

LOOP

ANTENNA

BF301

CNP303

AM

FM

IC301

TA7358AP

3

2

1

9

8

T311

7

6

5

4

3

2

FM FRONT END

1

3

1

2

2

3

1

FM OSC.

Q302

OSC BUFF

VD302

SVC211C

+B

L312

FM RF

Figure 26 BLOCK DIAGRAM (1/6)

– 26 –

R-

L-

P

Page 27

CD-CH1000

TO MICOM SECTION

C2B_DO

AUX_SEL

VSM

X

W

Y

V

NC

VSM

D_GND

C2B_DO

C2B_CL

C2B_DI

C2B_CE

IC102

BA3126N

HAED

SELECTOR

1

2

3

4

5

SWITCHING

Q101

C2B_DI

C2B_CE

U

T

Q102

D_GND

C2B_CL

R

S

9

8

7

+B

6

S-MUTE

CD-R_SEL

Q

O

NC

PB_MUTE

Q508

IC502

LC75341

AUDIO

PROCESSOR

L-CH

CD_R

TUNER_R

TAPE_R

AUX_R

R_CH

+B

13

14

15

16

17

18

19

20

21

22

23

24

R1

R2

R3

R4

RSEL0

RIN

RTRE

RBASS

ROUT

VREF

VDD

CLK

n

A_GND

TAPE_R

CD_R

A_GND

CD_L

JK501

AUX IN

A_GND

R_CH

A_GND2

L_CH

A_GND

A_-B

A_+B

CNP102

m

l

SECTION

TO MICOM

k

j

i

h

g

TO MICOM SECTION

f

e

d

c

b

a

TO MICOM SECTION

1

2

3

4

5

CNS940

6

7

8

FROM MAIN PWB

Q507

TAPE_L

REC_R-CH

-B

8

4

5

7

+

–

6

+

–

–

+

+

–

–

2

CD

TUNER

DECK

AUX

IC502

+

+

–

+

+

–

CCB

INTERFACE

1

NJM4558M

+

MOTOR DRIVER

3

REC_L-CH

L1

L2

L3

+

–

–

L4

–

LSEL0

LIN

LTRE

LBASS

LOUT

VSS

CE

DI

IC503

12

TUNER_L

11

TAPE_L

10

9

8

REC_L-CH

7

6

5

4

3

2

1

CD_L

AUX_L

AUX_R

REC_L-CH

R-CH

L-CH

SYSTEM MUTE

Q502

R_CH

REC_L-CH

+B

Q509

SWITCHING

Q501

TAPE_L-CH

TAPE_R-CH

REC_R-CH

REC_L-CH

REC_MUTE

REC_CONT

REC_BIAS

Q120

REC MUTE

Q119

REC MUTE

ERASE

HEAD

R-CH

L-CH

RECORD/

PLAYBACK

HEAD

1

2

3

4

5

6

7

CNP101

ERASE

1

M_GND

2

T2_R1

3

T2_R2

4

A_GND

5

T2_L2

6

T2_L1

7

R-CH

R-CH

22

L-CH

3

–

+

Hich=T1

+

–

21

112K

112K

4

24

23

2

1

19

20

IC101

5

6

IC101

AN7345K

PLAYBACK AND

RECORD/PLAY BACK

AMP.

Figure 27 BLOCK DIAGRAM (2/6)

– 27 –

18 17

7

16

–

56K

+

Hich=CHROME

+

56K

–

8

9

15

ALC

10

14

RIPPLE

Nor/CrO2

ALC

11

+B

13

Vcc

GND

12

BIAS OSC.

Q114

SWITCHING

Q116

M_+10V

Q115

A_+10V

A_GND

BIAS_GND

A

B

C

D

TO POWER SECTION

Page 28

CD-CH1000

L

7

C

H

H

H

P

C

C

D

D

D

D

D

+B

TO CD PWB

CNP901

NC

NC

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

FH_C-SW_B

FH_C-SW_A

FH_A-SW_E

FH_A-SW_D

FH_A-SW_C

FH_A-SW_B

FH_A-SW_A

FH_T-SW_A

FH_T-SW_B

FH_T-SW_C

CD_RES

CD_CCE

CD_BUCK

CD_BUS3

CD_BUS2

CD-RW

CD_BUS1

T-MO_REV

CD_BUS0

T-MO_FOR

CD_L

PU-IN

A_GND

C-MO_REV

CD_R

C-MO_FOR

CD_GND

CD_GND

CD_+B

CD_+B

SOLENOID DRIVER

Q905

Q906

+B

X901

8MHz

32.768kHz

Q901

+B

X902

30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10

LCD E

31

32

TIMER LCD

33

BACK LED CONT

SYS MUTE

34

C FUTA CL

35

C FUTA OP

36

VDD

37

X2

38

X1

39

VSS

40

XT2

41

XT1

42

RESET

43

REMOCON

44

JOG-A

45

JOG-B

46

SYS STOP

47

48

PROTECT

49

50

AVDD A

51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78

+B

+B

1

3

IC905

2

IC905

KIA7042AP

RESET

Vref 0

KEY 0

LCD DB6

LCD DB5

LCD DB4

30 LCD R/W

29 LCD RS

28 POWER RLY

27 N.C.

26 LCD DB7

MICROCOMPUTER

49 SP RLY

50 POWER KEY

KEY 4

KEY 3

KEY 2

KEY 1

CLK

LCK2

LCK1

TEST/Vpp

IC901

IX0353AW

SYSTEM

LEVEL_L

LEVEL_R

VSM

AVSS

DATA

+B

SPAN

CD MUTE

AVref1

CE

DEST_IN

CST SW

CAM SW

B-FP SW

A-FP SW

3 REC BIAS

2 REC

1 PB MUTE

83 FH T-SW C

82 FH T-SW B

81 FH T-SW A

TUNER DI

TUNER DO

TUNER CL

9 8 7 6 5 4 3

VDD

T-SOL

REC

T-MOTOR

RUN PULSE

DEST_OUT1

DEST_OUT2

CD

CD

FH

FH

FH A-SW E

LCD-RW

LCD-E

FH A-SW D

VO

F

FH

F

F

C

C

C

C

C

FH A-SW C

+B

+B

SOL

SOLENOID

PLAY

SWITCH

M

TAPE

MOTOR

+

–

SENSOR OUT

CASSETTE

SWITCH

+SOL

PLAY SW

+MTR

+5V SENSOR

–COM

CST_SW

F_REC

FFC970

1

1

2

3

4

NC

5

6

NC

7

8

9

10

11

11

CNP970

1

11

10

9

8

7

6

5

4

3

2

1

11

RUN PULSE

Q907

+B

Q908

RUN_PUL

CAM-SW

+B

MOTOR DRIVER

MOTOR

Q909

+5V

CST-SW

SIDE-A

CD_L

A_GND

CD_R

g

h

i

TO AUDIO SECTION

+B

O

PB_MUTE

CD-R_SEL

Q

AUX_SEL

C2B_DO

C2B_CE

C2B_DI

VSM

CD_MUTE

PXYUVWT

TO AUDIO SECTION

C2B_CL

S-MUTE

D_GND

A_+B

Sdfc

R

TO AUDIO SECTION

A_-B

R_CH

A_GND

L_CH

A_GND2

a

b

A_GND

A_GND

A_+10V

A_+10V

R CH

L CH

1 2 3 4 5 6 7 8 9

TO POWER

PWB

CNP806

CD_+B

CD_+B

CD_GND

CD_GND

10 11 12 13 14 15

+B

M_GND

M_GND

M_+B

M_+B

Figure 28 BLOCK DIAGRAM (3/6)

– 28 –

Page 29

CD-CH1000

CD

GND

7 6 5 4 3 2 1

T-SOL

REC MUTE

T-MOTOR

FH M B-

DEST_OUT1

DEST_OUT2

FH M B+

FH M A-

FH A-SW E

LCD-E

FH M A+

CD PICK IN

CD RW

CD RESET

CD BUS0

CD BUS1

CD BUS2

CD BUS3

CD BUCK

CD CCE

FH C-SW A

FH C-SW B

FH A-SW B

FH A-SW D

FH A-SW C

74 75 76 77 78 79 80

VSS

FH A-SW A

REMOTE

SENSOR

LED731

RX701

1

Q708

+B

+B

3 2

+B

KEY0

JOG701

JOG DIAL

REMOCON

POW_KEY

POW_IND

CNS720

A_+B

1

D_+B

2

D_GND

3

4

5

6

DATA

7

CK

8

LCK

9

KEY1

10

11

LED781

LED782

SW750~SW753,

SW755,SW756,SW758

SW761~SW764

SW770,

SW772~SW774,

SW776,SW778

+B

VDD

VSS

1

DATA

2

CLK

3

LCK

4

NC

5

NC

6

NC

7

NC

8

CD-R_SEL

9

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

SW12

SW11

SW10

SW9

SW8

SW7

SW5

+B

18

OE

17

+B

16

15

14

13

12

11

10

IC912

BU2092F

INPUT/OUTPUT

EXPANDER

Q725

Q723

Q724

LED758

LED759

LED_1

LED_2

LED757

LED_3

Q722

LED756

LED_4

IC702

INPUT/OUTPUT

EXPANDER

BU2092F

18

VDD

__

17

OE

Q11

16

Q10

15

Q9

14

Q8

13

12

Q7

Q6

11

Q5

10

Q721

Q720

LED755

LED_5

VSS

DATA

CLOCK

LCK

IC702

+B

+B

LED754

LED_6

1

2

3

4

Q0

5

Q1

6

Q2

7

Q3

8

Q4

9

LED_1

LED_2

LED_3

LED_4

LED_5

+B

LED_EG

SW701

POWER

+B

CNS770

7

6

5

4

3

2

1

SW710,

SW730~SW735

SW711,SW712,

SW720~SW725

LED773~

LED776

A_+B

KEY2

KEY3

KEY4

D_GND

JOG-A

JOG-B

KIA7805P

VOLTAGE REGULATOR

+B

1

IC913

2

+B

_

9

M_+B

CD_+B

CD_+B

M_GND

M_GND

10 11 12 13 14 15

6

M_+B

BI960

TO POWER

IC913

3

FAN

PROTECT

SP_RLY

SP_RLY

SP_DET

FAN_CTL

UN_SW 5V

1 2 3 4 5 6 7 8

CNP807

PWB

D_GND

D_GND

POWER_RLY

A_-B

AC_RLY CTL

BI950

LEVEL_R

Q955

+B

+B

TAPE_R

A_GND

REC_LCH

REC_RCH

REC_MUTE

REC_CONT

REC_BIAS

8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

TO POWER PWB

CNP102

Q954

TAPE_L

BI940

CNS940

REC_RCH

REC_LCH

TAPE_L

TAPE_R

m

j

l

TO AUDIO SECTION

k

A_GND

m

IC701

TA7291S

LOADING

MOTOR DRIVER

IC701

1 2 3 4 5 6 7 8 9

PNL_CL

D_+B

PNL_OP

P_CONT

+B

1

+B

2

3

4

5

6

7

8

9

10

11

CNP934

1

2

3

4

5

6

+B

7

DIMMER

A +B

D GND

D +B

SCL

SDA

OPEN_SW

CLOSE_SW

MOTOR_+

MOTOR_–

PANEL MOTOR

CNP931

A_+B

D_+B

D_GND

REMOCON

POW_KEY

POW_IND

DATA

CK

LCK

KEY1

KEY0

JOG-B

JOG-A

D_GND

KEY4

KEY3

KEY2

A_+B

Q707

D_GND

M

MO700

CONTROL

LED701 ~ LED709,

LED716 ~ LED724

CNP701

1

2

3

4

5

SW705

1

5

VLCD

VSS

VDD

OPEN/CLOSE

LCD720

LCD DISPLAY

Figure 29 BLOCK DIAGRAM (4/6)

– 29 –

Page 30

CD-CH1000

Q200

MO200

FAN

M

MOTOR

+

Q212

FAN MOTOR

DRIVER

Q210

RY202

Q209

RY201

JK701

HEADPHONES

SO201

-

+

-

+

-

+

-

+

M+10V

SP L-CH

GND

SP L-CH

SP L-CH

GND

SP L-CH

SP R-CH

GND

SP R-CH

SP R-CH

GND

SP R-CH

MAIN

SUB

WOOFER

MAIN

SO201

SPEAKER

TERMINALS

RY801

F807

5A 125V

AC POWER

SUPPLY

CORD

AC 120V,

60Hz

15

14

+

–

13

Ch2

12

11

Out

10

Ch2

–Vcc

9

8

+Vcc

IC202

POWER AMP.

STK40204(2Ch)

Out

7

Ch2

6

5

4

–

+

Ch1

NC

3

2

1

15

14

+

–

13

Ch2

12

Q211

Q208

Q207

Q203

-B

+B

Q204

Q206

Q205

T801

MAIN POWER TRANSFOMER

F803

F806

F805

D816

4A 125V

+B

4A 125V

-B

HIGH

+B

5A 125V

D817

TF

F804

5A 125V

F808

2.5A 125V

-B

+B

LOW

VOLTAGE

REGULATOR

Q806

-B

T802

SUB POWER

TRANSFORMER

+B

D815

IC808

KIA7805AP

REGULATOR

CONSTANT VOLTAGE

D812

+B

IC808

+B

Q807

D807

D804

-B

-B

+B

F801

2.5A 125V

D806

D805

RELAY

DRIVER

D814

D813

1

2

3

MICON +5V

11

Out

10

Ch2

–Vcc

9

8

IC201

+Vcc

POWER AMP.