Page 1

PROFIBUS DP-V1 UFP11A Fieldbus Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Edition

02/2004

Manual

11254416 / EN

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

1 System Overview ..........................................................................4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Unit Design ....................................................................................5

2.1 Front view .............................................................................5

3 Installation and Operation without PC........................................6

3.1 Installation notes ...................................................................6

3.2 Setting the inverter parameters............................................. 9

3.3 Autosetup............................................................................10

3.4 Project planning of the fieldbus master............................... 12

3.5 Starting the inverters...........................................................13

4 Installation and Operation with PC............................................14

4.1 Installation notes .................................................................14

4.2 Setting the inverter parameters........................................... 17

4.3 Startup software..................................................................17

4.4 Starting the inverters...........................................................18

5 PROFIBUS interface....................................................................19

5.1 Startup up PROFIBUS DP master ......................................19

5.2 Configuration of the PROFIBUS DP interface.....................19

5.3 Ident number.......................................................................25

5.4 Inverter control ....................................................................25

6 DP-V1 Functions..........................................................................27

6.1 Introduction to PROFIBUS DP-V1 ......................................27

6.2 Features of SEW drive inverters .........................................29

6.3 Structure of the DP-V1 parameter channel......................... 30

6.4 Project planning for a C1 master.........................................46

6.5 Appendix .............................................................................47

7 Error Responses .........................................................................54

7.1 Fieldbus timeout.................................................................. 54

7.2 SBUS timeout .....................................................................54

7.3 Device errors....................................................................... 54

8 LEDs.............................................................................................55

8.1 RUN ....................................................................................55

8.2 BUS-FAULT ........................................................................55

8.3 SYS-FAULT ........................................................................56

8.4 USER ..................................................................................56

9 DIP Switches................................................................................57

9.1 Setting the station address .................................................57

10 Operating the Interface...............................................................58

11 Appendix......................................................................................61

11.1 List of errors ........................................................................61

11.2 Technical data.....................................................................62

11.3 Dimension sheet .................................................................63

12 Index.............................................................................................64

Manual – PROFIBUS UFP11A Fieldbus Interface

3

Page 4

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Overview

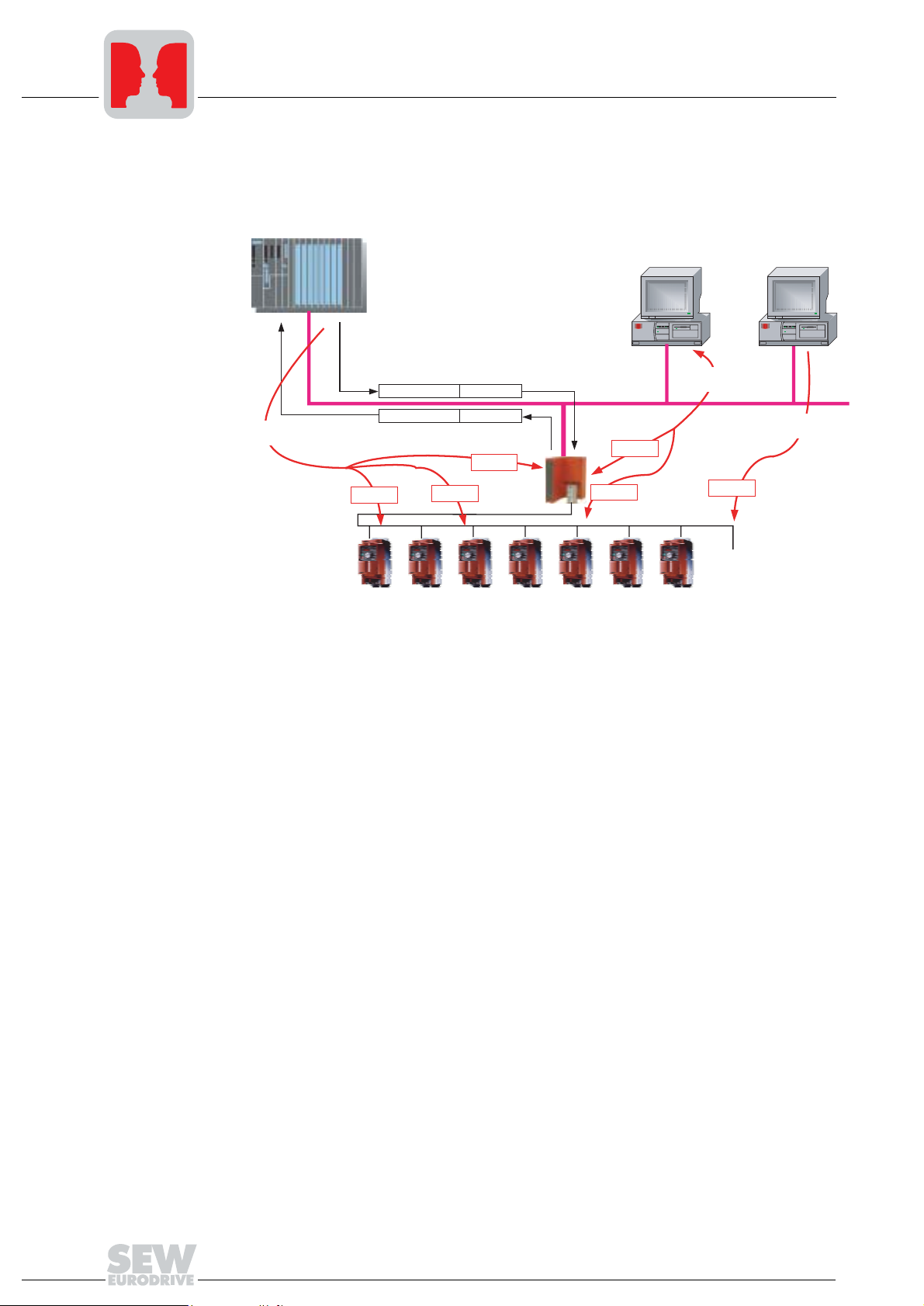

1 System Overview

Handbuch

The UFP11A PROFIBUS DP-V1 fieldbus interface is used for connecting inverters with

the PROFIBUS DP-V1. Several inverters can be connected to the UFP11A PROFIBUS

DP-V1 interface via the SBus. The UFP11A PROFIBUS interface establishes the

connection between PROFIBUS DP-VI and SBus.

C1-Master

UFP

PROFIBUS DP-V1

C2-Master

C2-Master

MOVITRAC

Figure 1: System overview DP-V1 master – UFP – inverter

®

07

53453AXX

4

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 5

2Unit Design

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

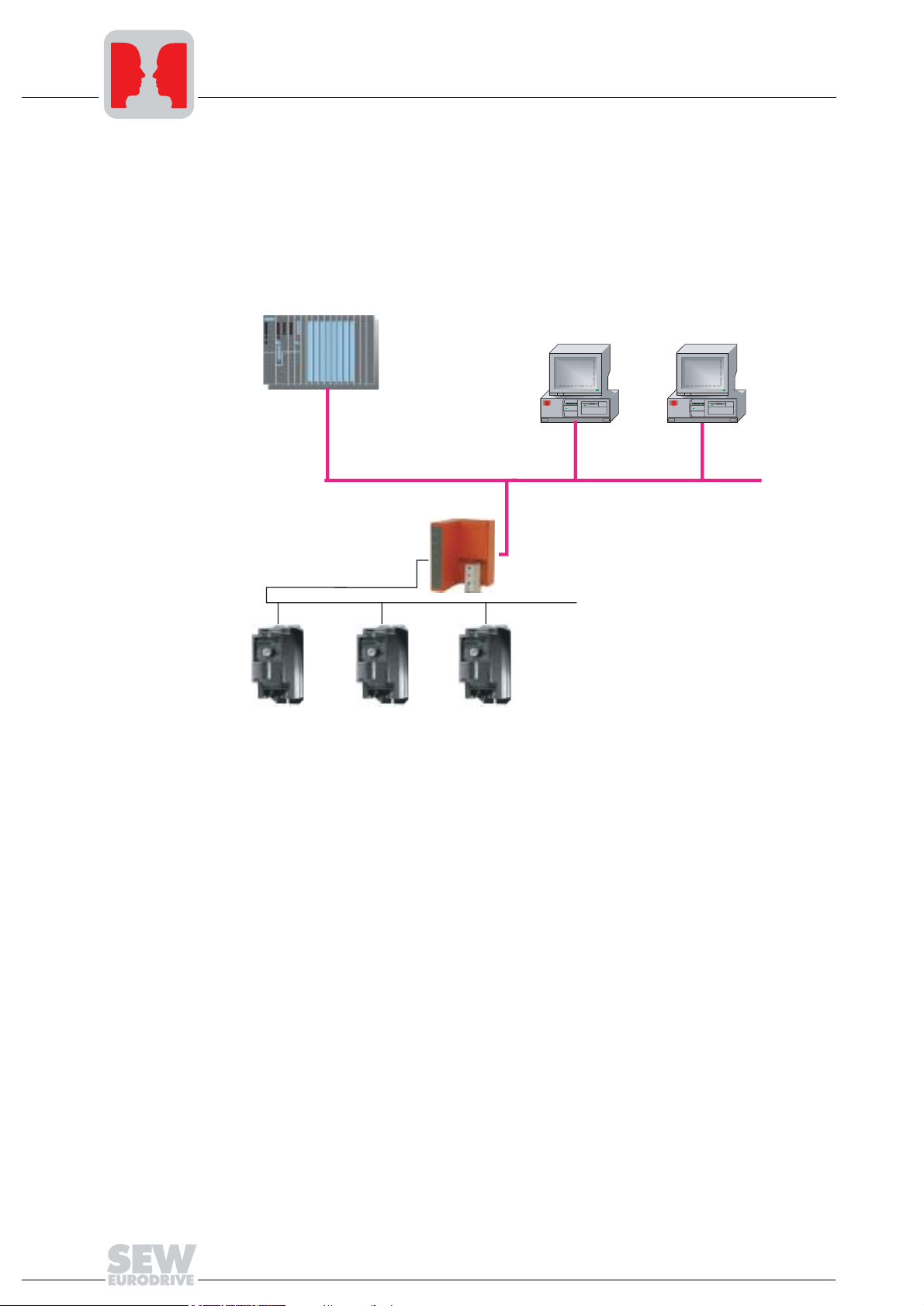

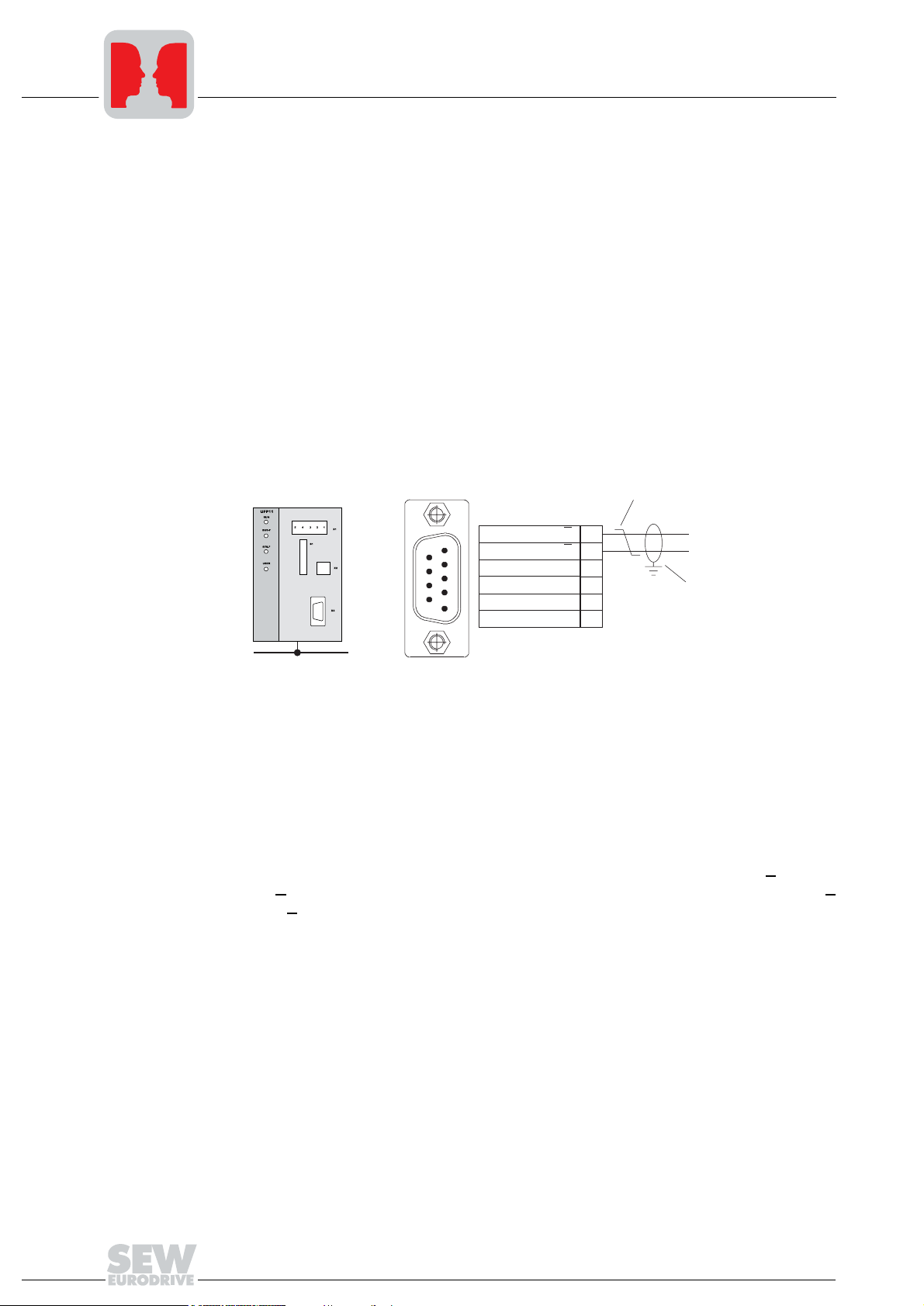

2.1 Front view

Unit Design

Front view

2

Figure 2: Arrangement of LEDs, connectors and DIP switches

X1 SBus and 24 V connector

X2 Diagnostic interface

X3 PROFIBUS

S1 DIP switch

RUN Operating status

BUS-F Bus fault

SYS-F System fault

USER Expert mode

Manual – PROFIBUS UFP11A Fieldbus Interface

04888AXX

5

Page 6

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without PC

Installation notes

3 Installation and Operation without PC

3.1 Installation notes

Installation

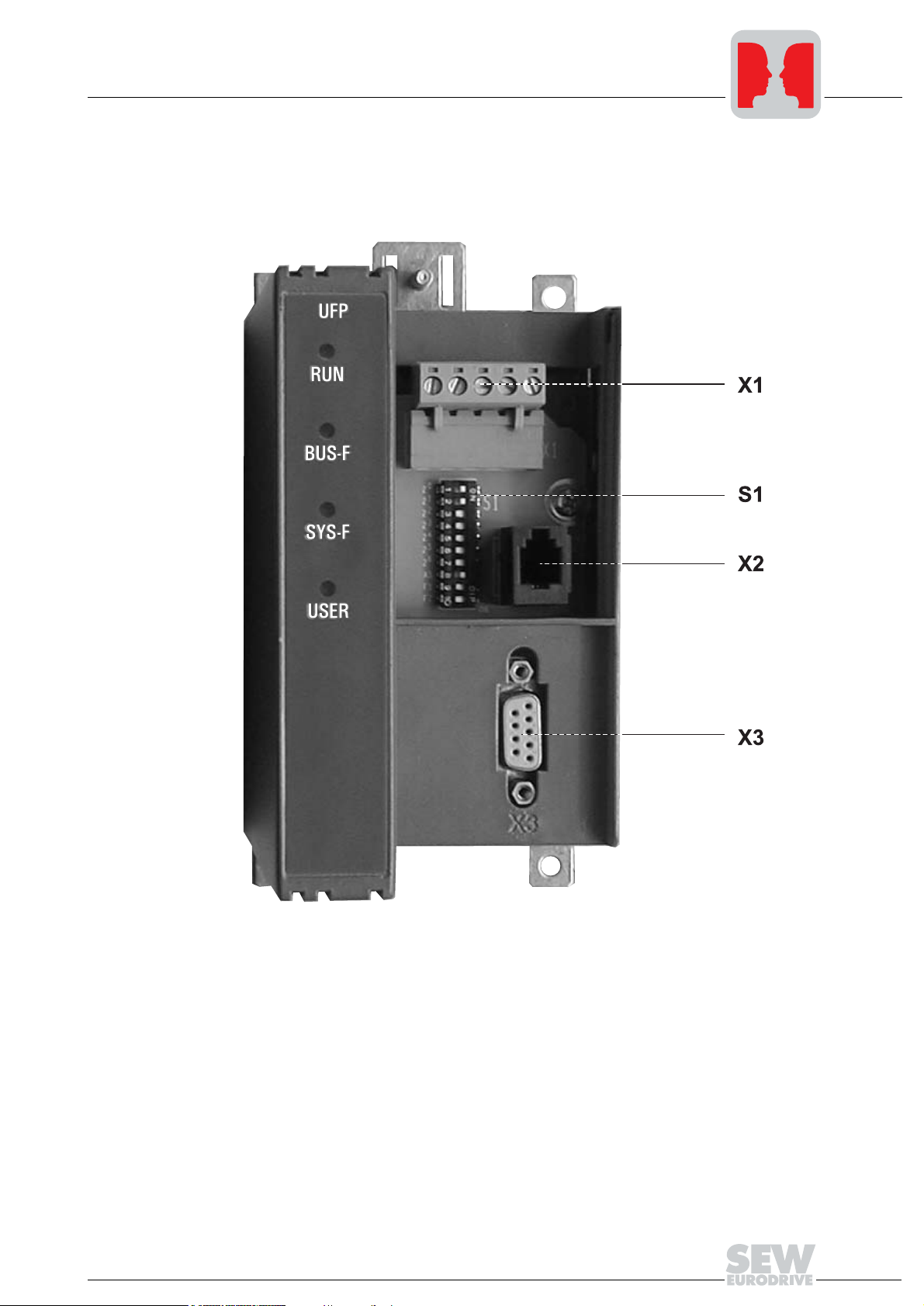

Pin assignment

The unit can be installed directly onto the wall of a control cabinet by using the preinstalled DIN rail mounting or the four drilled holes on the back of the housing. Basically,

there are no restrictions regarding the spatial arrangement of the units to be connected

(e.g. MOVITRAC

®

07). The maximum line length and the fact that the gateway must be

installed at the end or the beginning of the system bus (SBus) must be taken into

consideration. For this reason, we recommend you take the spatial aspects into

account.

The UFP must have additional HF-compliant grounding if the DIN rail mounting option

is used with SBus cables of more than 1 m in length.

The UFP11A fieldbus interface is connected to the PROFIBUS network by means of a

9-pin sub D connector in accordance with EN 50170. The T-bus connection must be

implemented with an appropriately designed plug.

[2]

[1]

RxD/TxD-P (B/ )B

RxD/TxD-N (A/ )A

CNTR-P

DGND (M5V)

VP (P5V)

DGND (M5V)

3

8

4

5

6

9

[3]

Fieldbus connector

Figure 3: Assignment of 9-pin sub D connector X3 according to EN 50170 ([1] = 9-pin sub D

connector; [2] = twisted signal lines; [3] = conductive connection between connector

housing and shielding)

01222DXX

The fieldbus interface is generally connected to the PROFIBUS system using a shielded

twisted-pair cable. The shielding of the PROFIBUS cable must be attached to both

sides, for example on the connector housing. Observe the maximum supported

transmission rate when selecting the bus connector.

The twisted-pair cable is connected to the PROFIBUS connector via pin 8 (A/A

3 (B/B

). Communication takes place via these two contacts. The RS-485 signals A/A

) and pin

and B/B must be contacted in the same way for all PROFIBUS stations. Otherwise, no

communication is possible via the bus medium.

The PROFIBUS interface sends a TTL control signal for a repeater or fiber optic adapter

(reference = pin 9) via pin 4 (CNTR-P).

6

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 7

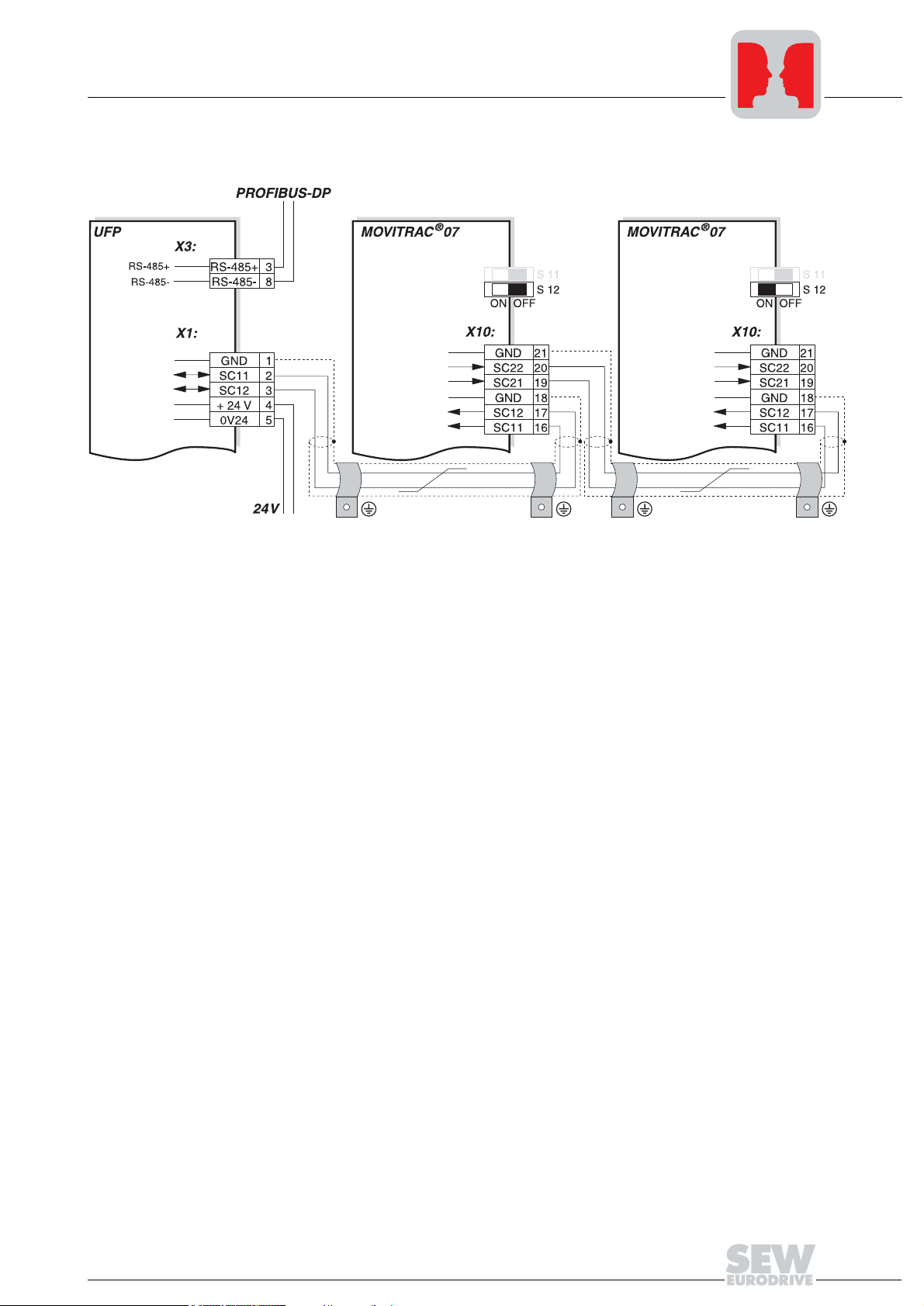

System bus connection

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without PC

Installation notes

3

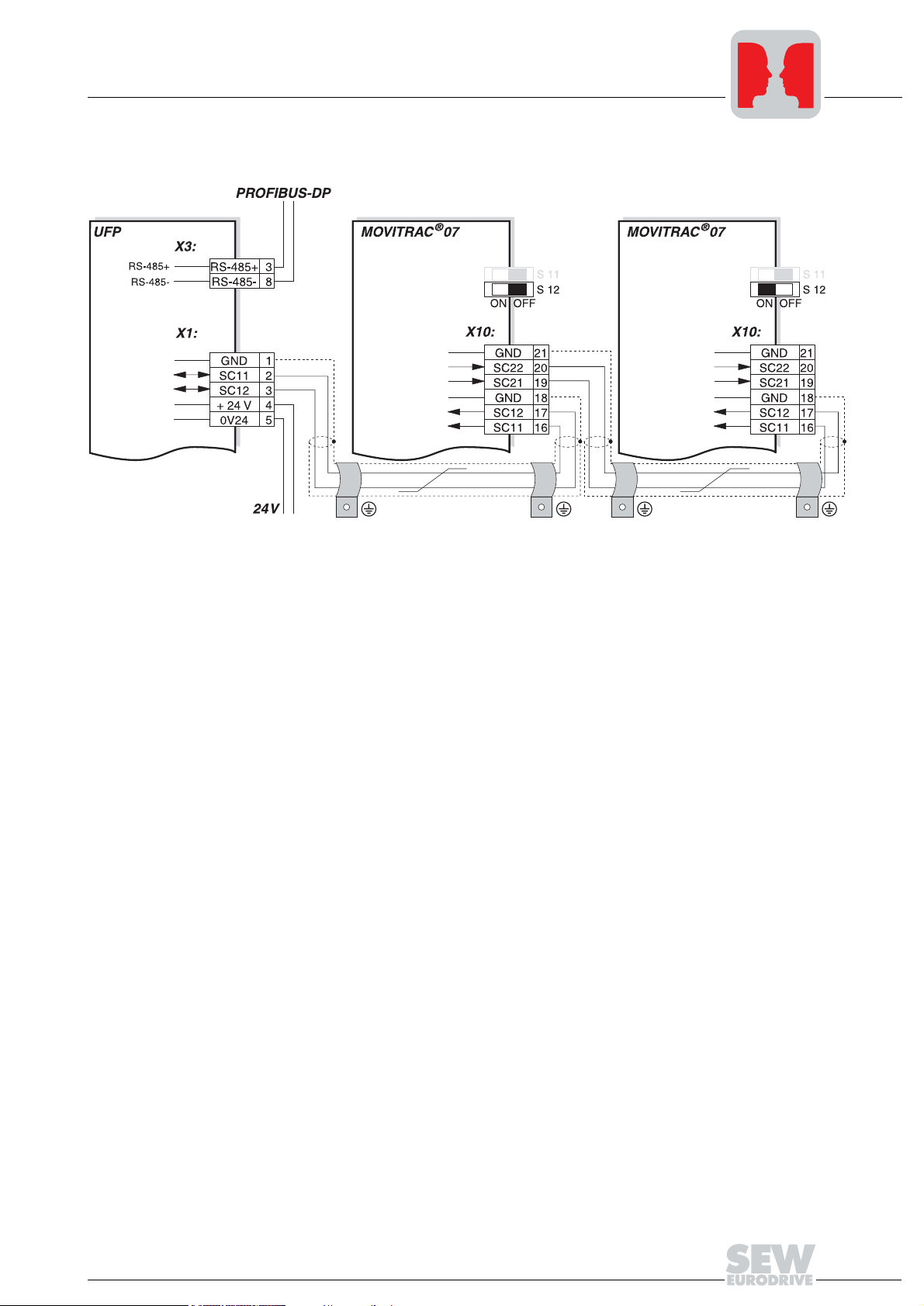

Figure 4: System bus connection

UFP

GND = System bus reference

SC11 = System bus high

SC12 = System bus low

Please note:

• Use a 2-core twisted and shielded copper cable (data transmission cable with

braided copper shield). Connect the shield with a wide-area contact at the electronics

terminal of MOVITRAC

The cable must meet the following specifications (CAN bus or DeviceNet cables are

suitable, for example):

– Core cross section 0.75 mm

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

• The approved total cable length depends on the specified SBus baud rate:

– 250 kbaud: 160 m (528 ft)

– 500 kbaud: 80 m (264 ft)

– 1000 kbaud: 40 m (132 ft)

MOVITRAC® 07

GND = System bus reference

SC22 = System bus low, outgoing

SC21 = System bus high, outgoing

SC12 = System bus low, incoming

SC11 = System bus high, incoming

S12 = System bus terminating resistor

®

07 or UFP11A and also connect the shield ends to GND.

2

(AWG18)

04848AXX

Manual – PROFIBUS UFP11A Fieldbus Interface

7

Page 8

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without PC

Installation notes

• Connect the system bus terminating resistor (S12 = ON) at the end of the system bus

connection. Disconnect the terminating resistor at the other devices (S12 = OFF).

The UFP11A gateway must always be connected either at the beginning or the end

of the system bus connection and feature a permanently installed terminating

resistor.

• There must not be any difference of potential between the units connected with the

SBus. Take suitable measures to avoid a difference of potential, such as connecting

the unit ground connectors using a separate line.

• Point-to-point wiring is not permitted.

24 V connection

Shielding and

routing of bus

cables

An external 24 V voltage supply must be connected to terminals X1:4 and X1:5.

The PROFIBUS interface supports the RS-485 communications protocol and requires

cable type A specified for PROFIBUS in accordance with EN 50170 as shielded twistedpair cable for the physical connection.

Correct shielding of the bus cable attenuates electrical interference that may occur in

industrial environments. The following measures ensure the best possible shielding:

• Tighten the mounting screws on the connectors, modules and equipotential bonding

conductors by hand.

• Use only connectors with metal housing or plated housing.

• Connect the shielding in the connector with the greatest possible surface area.

• Attach the shielding of the bus line on both sides.

• Do not route signal and bus cables parallel to power cables (motor leads). They must

be routed in separate cable ducts.

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding in close

proximity using the shortest way possible.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

In case of fluctuations in the earth potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according to relevant VDE regulations

in such a case.

8

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 9

Installation and Operation without PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Setting the inverter parameters

3

Bus termination

A bus termination is not provided on the UFP electronics. If the UFP module is used as

the first or last device of the PROFIBUS line, the bus termination has to be external. We

recommend PROFIBUS connectors with integrated bus termination that open the

continuing bus in case the bus termination is connected.

3.2 Setting the inverter parameters

The settings can be entered via the inverter keypad. Refer to the operating instructions

of the inverter for details.

• Connect the voltage supply for the UFx and all connected inverters.

• Set an individual SBus address (P813) at the inverters. Recommendation: Address

setting beginning with address 1 in ascending order based on the arrangement of

inverters in the control cabinet. Address 0 should not be assigned because it is used

by the UFx.

• Verify the SBus baud rate (P816, factory setting = 500 kbaud).

• Set the setpoint source (P100) to SBus (value 10).

• Set the control source (P101) to SBus (value 3).

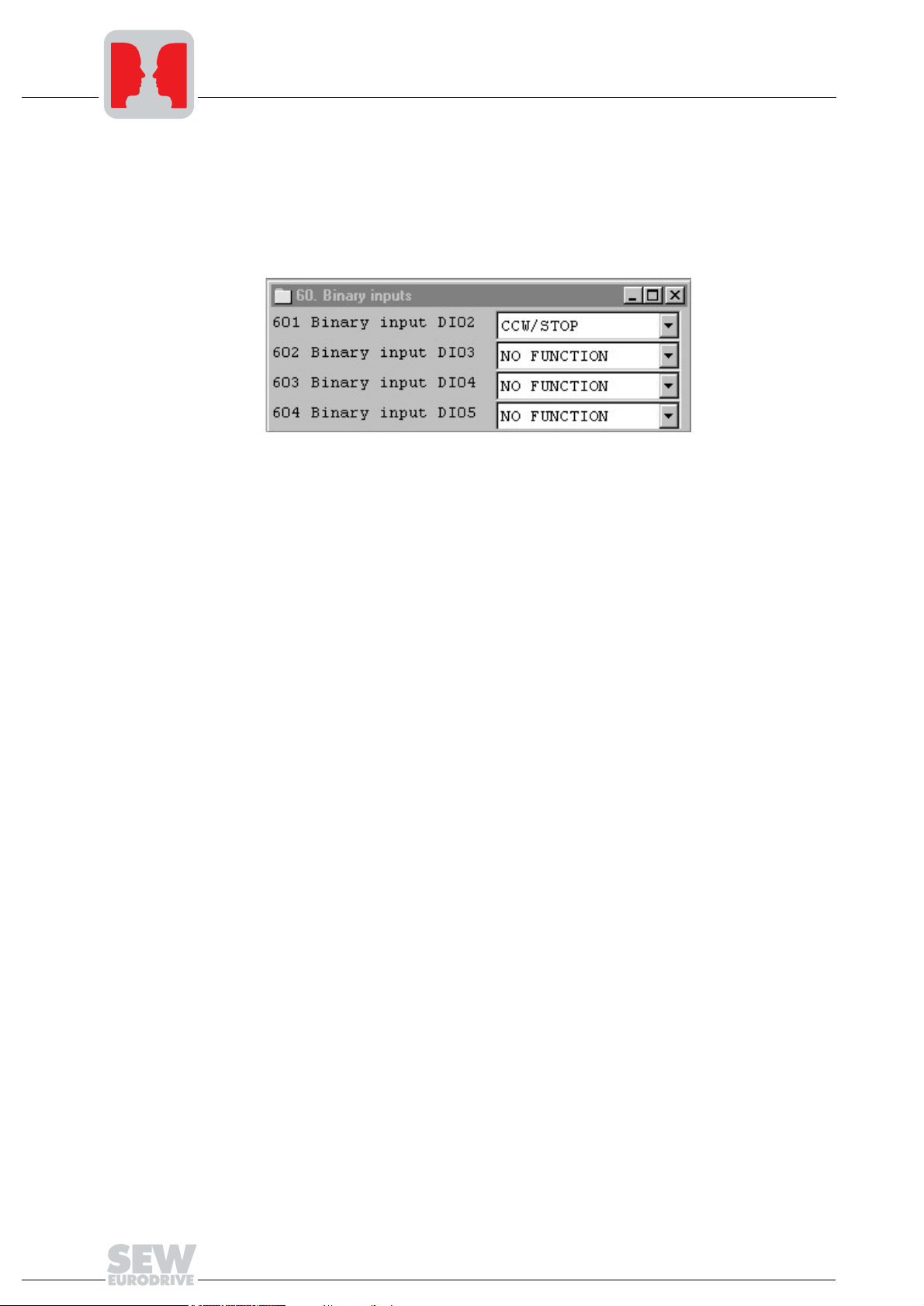

• Set the terminal assignment of the binary inputs. For MOVITRAC

recommended for P60-. This corresponds to the following assignment:

– DI01 CW/Stop (wired to 24 V, both directions of rotation enabled)

– DI02 CCW/Stop (no function)

– DI03 F.Setp. toggle(not wired)

– DI04 n11/n21 (not wired)

– DI05 n12/n22 (not wired)

– If you use a MOVIDRIVE

are not used to "No function."

• Important: For MOVITRAC

PC, if necessary. The default value is 0, which means timeout monitoring is

deactivated. Set P815 to the value 1 s.

®

07, the value 0 is

®

unit as inverter, you must program the terminals that

®

07, P815 SBus timeout interval can only be adjusted via

Manual – PROFIBUS UFP11A Fieldbus Interface

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.3 Autosetup

Installation and Operation without PC

Autosetup

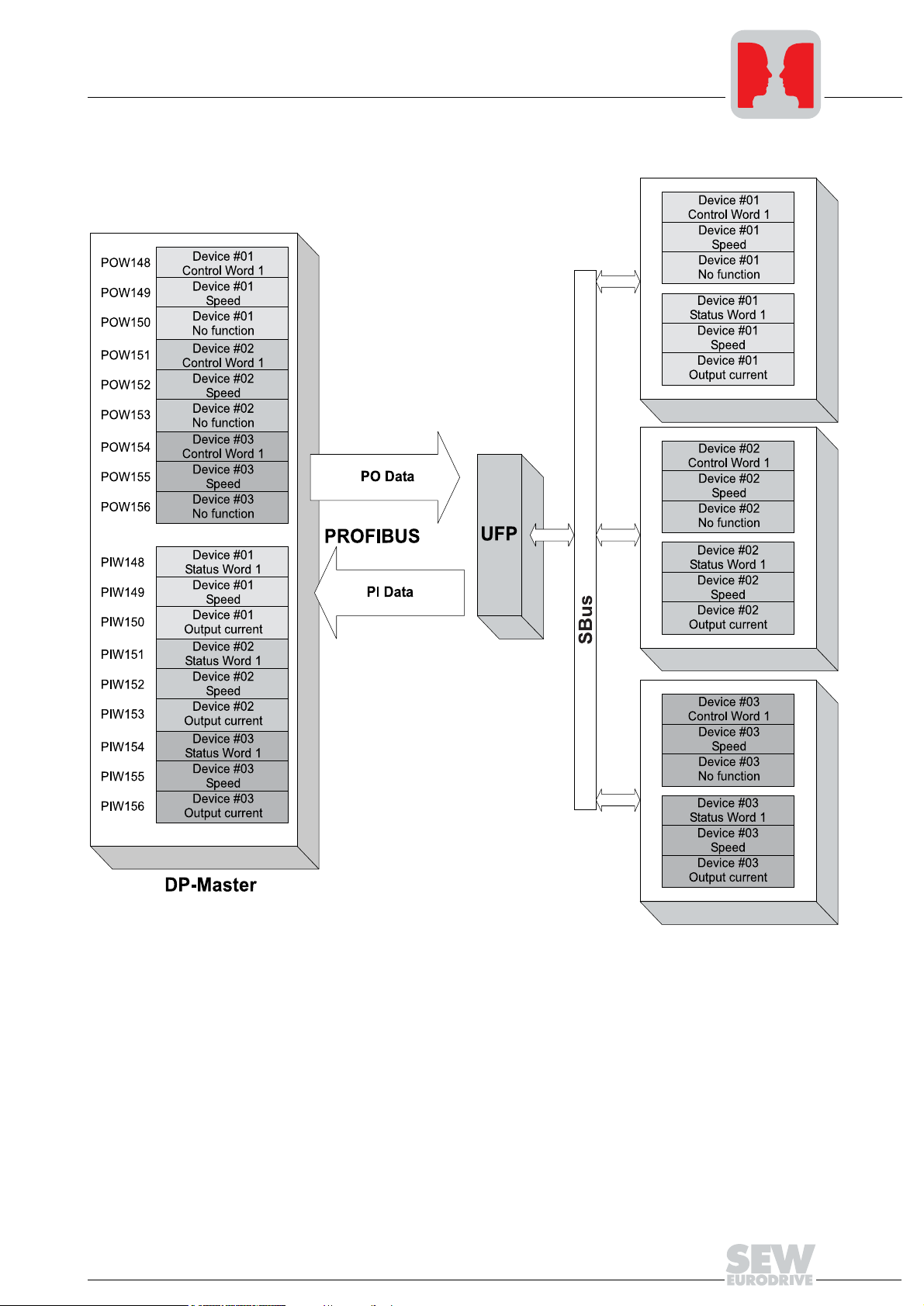

The Autosetup function allows startup of the UFx to be performed without a PC. Activate

the function via the Autosetup DIP switch. Switching on the Autosetup DIP switch

causes the function to be performed once.

in ON position.

again. First, the UFx searches the lower-level SBUS for drive inverters. This process is

indicated by the SYS-FAULT LED flashing briefly. For this purpose, different SBus

addresses must be set for the drive inverters (P813). We recommend assigning the

addresses beginning with address 1 in ascending order based on the arrangement of

inverters in the control cabinet. The process image on the fieldbus side is expanded by

three words for each detected drive inverter. If no inverter is detected, the SYS-FAULT

LED remains lit. A total of up to eight drive inverters is taken into account. The figure

shows the process image for three drive inverters with three words each of process

output data and process input data. After the search is complete, the UFx cyclically

exchanges three process data words with each connected drive inverter. The process

output data are fetched from the fieldbus, divided into blocks of three and transmitted.

The drive inverters read the process input data, put them together and send them to the

fieldbus master.

Important: If you change the process data assignment of the drive inverters connected

to the UFP, you have to activate Autosetup again because the UFP saves these values

only once during Autosetup. At the same time, the process data assignments of the

connected drive inverters may not be changed dynamically after Autosetup.

The function can be reactivated by turning the DIP switch off and back on

The Autosetup DIP switch must then remain

10

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 11

Installation and Operation without PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Autosetup

3

Figure 5: Data exchange DP-V1 master – UFP – inverter

Manual – PROFIBUS UFP11A Fieldbus Interface

04843AXX

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without PC

Project planning of the fieldbus master

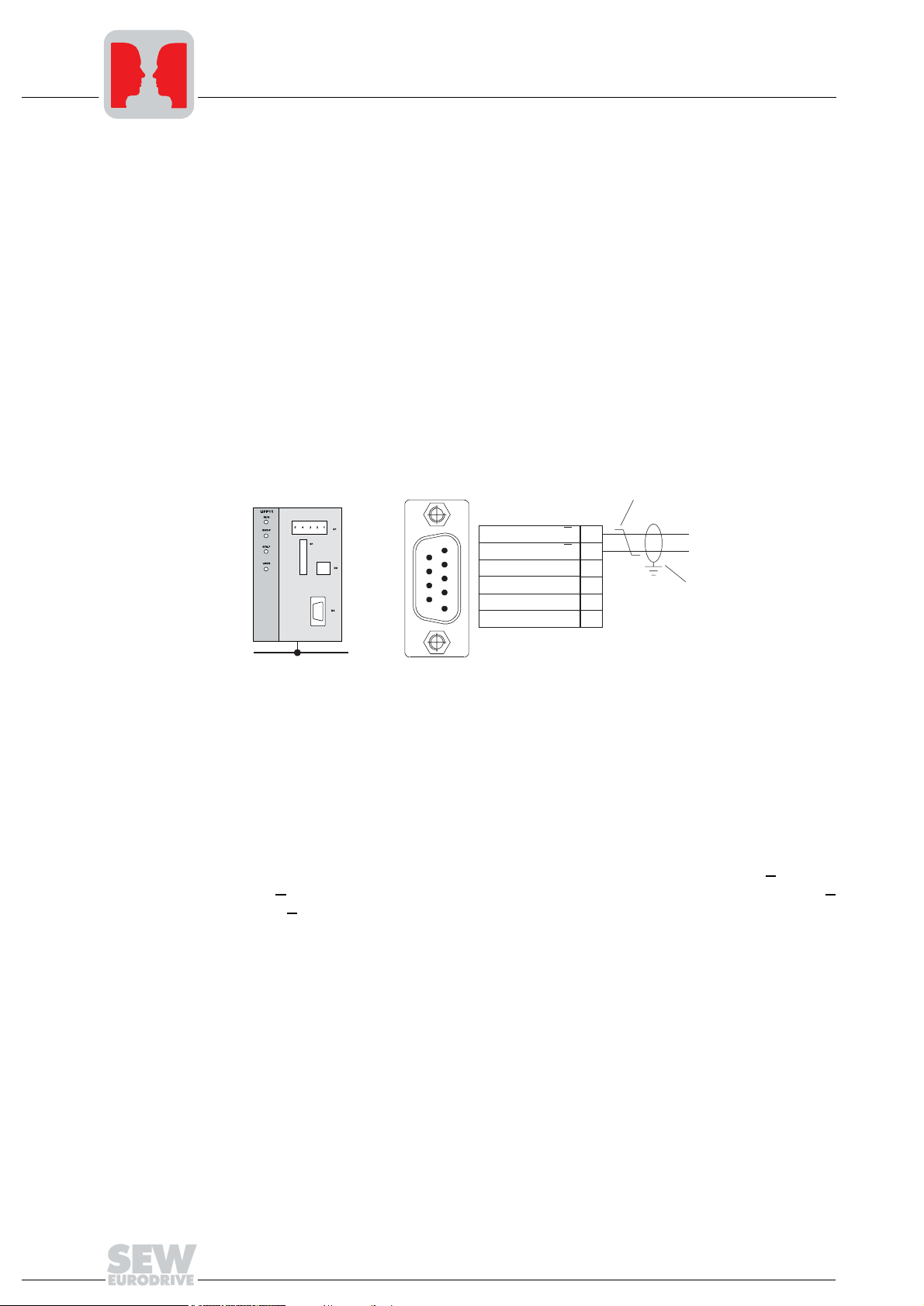

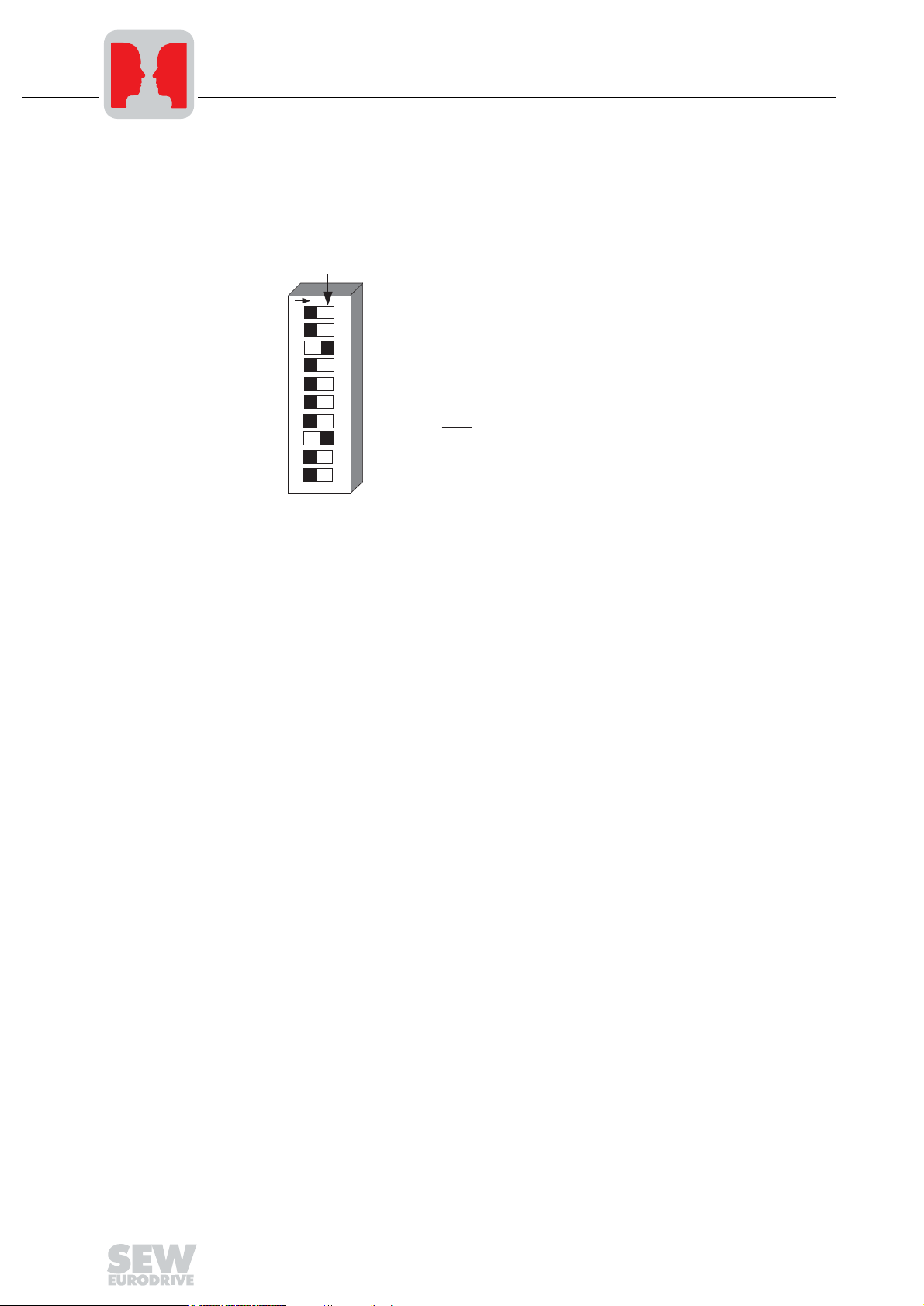

3.4 Project planning of the fieldbus master

• Set an individual PROFIBUS address using the DIP switches of the UFP for project

planning. The PROFIBUS address is set in binary form. A change of the PROFIBUS

address only becomes effective after switching the UFP off and on again.

X = on

1 2 3 4 5 6 7 8 9 10

2

2

2

2

2

2

2

AS

F1

F2

0

1

2

3

4

5

6

1: x 0 = +0

2: x 0 = +0

4: x 1 = +4

8: x 0 = +0

16: x 0 = +0

32: x 0 = +0

64: x 0 = +0

= 4

Figure 6: Setting the PROFIBUS station address

50341AXX

• The fieldbus master is configured using the GSD file (see appendix). The UFP is

addressed under the specified PROFIBUS address. The number of process data

words the fieldbus master uses to address the UFP depends on the number of

connected inverters. The process data width for an inverter is three words. If more

than one inverter is present, three words should be planned for each inverter. For

example, you have to configure nine words for three MOVITRAC

®

07 inverters.

• Example for STEP 7:

– Install the GDS file in the STEP 7 software.

– In HW config of the hardware catalog, insert the UFP at the PROFIBUS.

– Select the setting suitable for your application from the presented process data

configurations, for example "9PD", meaning nine process data words for three

inverters.

– Save the configuration.

– Expand your application program by the data exchange with the UFP. For this

purpose, use the system functions of S7 for consistent data exchange (SFC14

and SFC15).

– The BUS-FAULT LED of the UFP should be extinguished after saving the project,

loading it in the DP-V1 master and starting the DP-V1 master. If this is not the

case, check the connections and terminating resistors of the PROFIBUS and the

project planning, especially the PROFIBUS address in STEP 7.

12

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 13

3.5 Starting the inverters

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

You can operate up to eight inverters on the PROFIBUS using one UFP. The DP master

and the UFP exchange the setpoints and actual values of all inverters connected to the

UFP in coherent data packages. It is important for you to know which inverter is located

at which position of the data package (process image). Figure 5 shows the relationship.

The inverters are enabled by writing the value 0006h to the corresponding control

word 1. The speed setpoint can be specified with the following word. It is scaled with

0.2 1/min per digit.

For more information on the unit profile of MOVITRAC

07 Communication" manual.

Installation and Operation without PC

Starting the inverters

®

07, refer to the "MOVITRAC

3

®

Manual – PROFIBUS UFP11A Fieldbus Interface

13

Page 14

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with PC

Installation notes

4 Installation and Operation with PC

4.1 Installation notes

Installation

Pin assignment

The unit can be installed directly onto the wall of a control cabinet by using the preinstalled DIN rail mounting or the four drilled holes on the back of the housing. Basically,

there are no restrictions regarding the spatial arrangement of the units to be connected

(e.g. MOVITRAC

®

07). The maximum line length and the fact that the gateway must be

installed at the end or the beginning of the system bus (SBus) must be taken into

consideration. For this reason, we recommend you take the spatial aspects into

account.

The UFP must have additional HF-compliant grounding if the DIN rail mounting option

is used with SBus cables of more than 1 m in length.

The UFP11A fieldbus interface is connected to the PROFIBUS network by means of a

9-pin sub D connector in accordance with EN 50170. The T-bus connection must be

implemented with an appropriately designed plug.

[2]

[1]

RxD/TxD-P (B/ )B

RxD/TxD-N (A/ )A

CNTR-P

DGND (M5V)

VP (P5V)

DGND (M5V)

3

8

4

5

6

9

[3]

Fieldbus connector

Figure 7: Assignment of 9-pin sub D connector X3 according to EN 50170 ([1] = 9-pin sub D

connector; [2] = twisted signal lines; [3] = conductive connection between connector

housing and shielding)

01222DXX

The fieldbus interface is generally connected to the PROFIBUS system using a shielded

twisted-pair cable. The shielding of the PROFIBUS cable must be attached to both

sides, for example on the connector housing. Observe the maximum supported

transmission rate when selecting the bus connector.

The twisted-pair cable is connected to the PROFIBUS connector via pin 8 (A/A

3 (B/B

). Communication takes place via these two contacts. The RS-485 signals A/A

) and pin

and B/B must be contacted in the same way for all PROFIBUS stations. Otherwise, no

communication is possible via the bus medium.

The PROFIBUS interface sends a TTL control signal for a repeater or fiber optic adapter

(reference = pin 9) via pin 4 (CNTR-P).

14

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 15

System bus connection

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with PC

Installation notes

4

Figure 8: System bus connection

UFP

GND = System bus reference

SC11 = System bus high

SC12 = System bus low

Please note:

• Use a 2-core twisted and shielded copper cable (data transmission cable with

braided copper shield). Connect the shield with a wide-area contact at the electronics

terminal of MOVITRAC

The cable must meet the following specifications (CAN bus or DeviceNet cables are

suitable, for example):

– Core cross section 0.75 mm

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

• The approved total cable length depends on the specified SBus baud rate:

– 250 kbaud: 160 m (528 ft)

– 500 kbaud: 80 m (264 ft)

– 1000 kbaud: 40 m (132 ft)

MOVITRAC® 07

GND = System bus reference

SC22 = System bus low, outgoing

SC21 = System bus high, outgoing

SC12 = System bus low, incoming

SC11 = System bus high, incoming

S12 = System bus terminating resistor

®

07 or UFP11A and also connect the shield ends to GND.

2

(AWG18)

04848AXX

Manual – PROFIBUS UFP11A Fieldbus Interface

15

Page 16

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with PC

Installation notes

• Connect the system bus terminating resistor (S12 = ON) at the end of the system bus

connection. Disconnect the terminating resistor at the other devices (S12 = OFF).

The UFP11A gateway must always be connected either at the beginning or the end

of the system bus connection and feature a permanently installed terminating

resistor.

• There must not be any difference of potential between the units connected with the

SBus. Take suitable measures to avoid a difference of potential, such as connecting

the unit ground connectors using a separate line.

• Point-to-point wiring is not permitted.

24 V connection

Shielding and

routing of bus

cables

An external 24 V voltage supply must be connected to terminals X1:4 and X1:5.

The PROFIBUS interface supports the RS-485 communications protocol and requires

cable type A specified for PROFIBUS in accordance with EN 50170 as shielded twistedpair cable for the physical connection.

Correct shielding of the bus cable attenuates electrical interference that may occur in

industrial environments. The following measures ensure the best possible shielding:

• Tighten the mounting screws on the connectors, modules and equipotential bonding

conductors by hand.

• Use only connectors with metal housing or plated housing.

• Connect the shielding in the connector with the greatest possible surface area.

• Attach the shielding of the bus line on both sides.

• Do not route signal and bus cables parallel to power cables (motor leads). They must

be routed in separate cable ducts.

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding in close

proximity using the shortest way possible.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

16

In case of fluctuations in the earth potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according to relevant VDE regulations

in such a case.

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 17

Installation and Operation with PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Setting the inverter parameters

4

Bus termination

A bus termination is not provided on the UFP electronics. If the UFP module is used as

the first or last device of the PROFIBUS line, the bus termination has to be external. We

recommend PROFIBUS connectors with integrated bus termination that open the

continuing bus in case the bus termination is connected.

4.2 Setting the inverter parameters

The settings can be entered via the inverter keypad. Refer to the operating instructions

of the inverter for details.

• Connect the voltage supply for the UFx and all connected inverters.

• Set an individual SBus address (P813) at the inverters. Recommendation: Address

setting beginning with address 1 in ascending order based on the arrangement of

inverters in the control cabinet. Address 0 should not be assigned because it is used

by the UFx.

4.3 Startup software

• Install the MOVITOOLS software package version 2.70 or higher on your PC.

• Start the software. Select the COM to which the UFP is connected and press the

"Update" button. The UFP should appear at address 0 and the connected inverters

at the following addresses. If the window does not show an entry, check the COM

interface and the connection via UWS21. If the UFP is the only entry in the window,

check the SBus cabling and the terminating resistors.

• Select UFx and call up the startup software for the fieldbus gateway (UFx

configurator).

• Select the "Reconfigure fieldbus node" menu item.

• Select your project path and project name. Press the "Next" button.

• Press the "Update" button. All inverters connected to the UFP should be displayed

now. The configuration can be customized using the "Insert," "Change" and "Delete"

buttons. Press the "Next" button.

• Press the "Autoconfiguration" button. The process image for the UFP will now appear

in your controller. The process data width is shown at the bottom. This value is

important for the project planning of the fieldbus master. Press the "Next" button.

• Save the project data and press the "Download" button. The Autosetup DIP switch

must be in OFF position for this purpose.

Manual – PROFIBUS UFP11A Fieldbus Interface

17

Page 18

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with PC

Starting the inverters

• The data exchanged between fieldbus master and the UFP can be viewed with the

process data monitor.

• Enabling on the terminal side is required to control the inverters via fieldbus. You

have already wired the terminals. To check the terminal assignment, select the first

inverter with address 1 in the "Connected inverters" window and start Shell. For

MOVITRAC

• Repeat the previous step for all inverters displayed in the "Connected inverters"

window.

®

07, the terminal assignment should be set as follows:

4.4 Starting the inverters

You can operate up to eight inverters on the PROFIBUS using one UFP. The DP master

and the UFP exchange the setpoints and actual values of all inverters connected to the

UFP in coherent data packages. It is important for you to know which inverter is located

at which position of the data package (process image). The process data monitor

indicates the relationship in the project planning of the fieldbus gateway (UFx

configurator).

The inverters are enabled by writing the value 0006h to the corresponding control

word 1. The speed setpoint can be specified with the following word. It is scaled with

0.2 1/min per digit.

For more information on the unit profile of MOVITRAC

07 Communication" manual.

®

07, refer to the "MOVITRAC

®

18

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 19

5 PROFIBUS interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.1 Startup up PROFIBUS DP master

Supporting files for UFP are available in the Internet at sew-eurodrive web site.

• Observe the notes in the README.TXT file on the GSD disk.

• Install the GSD file according to the requirements of the project planning software for

the DP master. After successful installation, the "UFP" device appears in the list of

slave stations.

• Insert the interface module into the PROFIBUS structure under the name "UFP" and

assign the PROFIBUS address.

• Select the process data configuration required for your application (see next section).

• Enter the I/O or peripheral addresses for the configured data widths.

• Save the configuration.

• Expand your application program by the data exchange with the fieldbus interface.

In case of S7, use the system functions for consistent data exchange for this purpose

(SFC14 and SFC15).

• The BUS-FAULT LED of the fieldbus interface should extinguish after you have

saved the project, loaded it in the DP-V1 master and started the DP-V1 master. If this

is not the case, check the connections and terminating resistors of the PROFIBUS

and the project planning, especially the PROFIBUS address.

PROFIBUS interface

Startup up PROFIBUS DP master

5

5.2 Configuration of the PROFIBUS DP interface

General

information

The inverter must be given a specific DP configuration by the DP master to define type

and number of input and output data used for the transmission. You have the opportunity

to control the drives via process data and to read or write all parameters of the fieldbus

interface via parameter channel.

Manual – PROFIBUS UFP11A Fieldbus Interface

19

Page 20

5

c

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PROFIBUS interface

Configuration of the PROFIBUS DP interface

The figure shows a schematic view of the data exchange between automation device

8DP-V1 master), fieldbus interface (DP-V1 slave) and an inverter with process data

channel and parameter channel.

C1-Master

Process data

configuration

C2-Master

Cyclic OUT Data

Param PD

yclic DPV1

1-Services

Axis = 1

Axis = SBus-Address: 12345678

Param PD

Cyclic IN Data

Axis = 0

Axis = 3

Axis = 0

Axis = 5

Acyclic DPV1

C2-Services

PROFIBUS DPV1

Axis = 8

C2-Master

Acyclic DPV1

C2-Services

53129BXX

Figure 9: Data exchange with parameter data (Param) and process data (PD)

The fieldbus interface allows for different DP configurations for the data exchange

between DP master and fieldbus interface. The following table provides additional

details on all standard DP configurations of the fieldbus interfaces. The "Process data

configuration" column shows the name of the configuration. These texts also appear as

a selection list in your project planning software for the DP master. The DP

configurations column shows the type of configuration data sent to the fieldbus interface

while the link to PROFIBUS DP is being established. The configurations are determined

by the default process data width for SEW inverters of three process data words. In the

simplest case, the controller transmits three process data words to each inverter

connected to the fieldbus interface. The fieldbus interface then distributes these process

data words to the individual devices. The parameter channel is used for setting the

parameters of the UFP and is not passed on to the connected participants. The fieldbus

interface accepts 1 ... 24 process data words with and without parameter channel.

20

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 21

PROFIBUS interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuration of the PROFIBUS DP interface

The standard entries of the GSD file are based on the UFP Autosetup operating mode

and allow process data widths of 3PD ... 24PD according to 1 ... 8 inverters connected

to the fieldbus interface.

A maximum of 3PDs can be assigned to any SBus participant!

5

ONE module for all

drives

The process data are transmitted in one consistent data block for all inverters connected

to the fieldbus interface. Thus, only system functions SFC14 and SFC15 need to be

activated in Step 7.

UFP parameter +

ONE module

The configurations under "UFP parameter + ONE module" correspond to those listed

above. The parameter module that allows for a parameter setting of the UFP with eight

consistently transmitted bytes will be processed first. Refer to the "MOVITRAC

Communication" manual for information on the parameter channel.

One module per

drive

One consistent data block exists for each connected inverter. From the controller side,

this corresponds to the existing setup of several inverters with their own fieldbus

interface. System functions SFC14 and SFC15 need to be executed for each inverter in

Step 7.

UFP parameter +

One module per

drive

The configurations under "UFP parameter + One module" correspond to those listed

above. The parameter module which allows for a parameter setting of the fieldbus

interface using eight consistently transmitted bytes will be processed first. Refer to the

"MOVITRAC

®

07 Communication" manual for information on the parameter channel.

Drive parameters of connected MOVITRAC® 07 inverters can only be accessed using

the DP-V1 parameter services.

Process data

configuration

ONE module for all drives

AS 1 drive (3 PD) Control via 3 process data words 0 242

AS 2 drives (6 PD) Control via 6 process data words 0 245

AS 3 Drives (9 PD) Control via 9 process data words 0 248

AS 4 Drives

(12 PD)

AS 5 Drives

(15 PD)

AS 6 Drives

(18 PD)

AS 7 Drives

(21 PD)

AS 8 Drives

(24 PD)

Meaning / notes

Control via 12 process data words 0 251

Control via 15 process data words 0 254

Control via 18 process data words 0 192 209 209

Control via 21 process data words 0 192 212 212

Control via 24 process data words 0 192 215 215

Cfg0 Cfg1 Cfg2 Cfg3 Cfg4 Cfg5 Cfg6 Cfg7 Cfg8

®

07

Manual – PROFIBUS UFP11A Fieldbus Interface

21

Page 22

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PROFIBUS interface

Configuration of the PROFIBUS DP interface

Process data

configuration

UFP parameter + ONE module

AS 1 Drive

(Param + 3PD)

AS 2 Drives

(Param + 6PD)

AS 3 Drives

(Param + 9PD)

AS 4 Drives

(Param + 12PD)

AS 5 Drives

(Param + 15PD)

AS 6 Drives

(Param + 18PD)

AS 7 Drives

(Param + 21PD)

AS 7 Drives

(Param + 24PD)

One module per drive

AS 1 Drive

(1 x 3PD)

AS 2 Drives

(2 x 3PD)

AS 3 Drives

(3 x 3PD)

AS 4 Drives

(4 x 3PD)

AS 5 Drives

(5 x 3PD)

AS 6 Drives

(6 x 3PD)

AS 7 Drives

(7 x 3PD)

AS 8 Drives

(8 x 3PD)

Meaning / notes

Control via 3 process data words /

parameter setting via 8-byte

parameter channel

Control via 6 process data words /

parameter setting via 8-byte

parameter channel

Control via 9 process data words /

parameter setting via 8-byte

parameter channel

Control via 12 process data words

/ parameter setting via 8-byte

parameter channel

Control via 15 process data words

/ parameter setting via 8-byte

parameter channel

Control via 18 process data words

/ parameter setting via 8-byte

parameter channel

Control via 21 process data words

/ parameter setting via 8-byte

parameter channel

Control via 24 process data words

/ parameter setting via 8-byte

parameter channel

Control via 1x3 process data

words

Control via 2x3 process data

words

Control via 3x3 process data

words

Control via 4x3 process data

words

Control via 5x3 process data

words

Control via 6x3 process data

words

Control via 7x3 process data

words

Control via 8x3 process data

words

Cfg0 Cfg1 Cfg2 Cfg3 Cfg4 Cfg5 Cfg6 Cfg7 Cfg8

243 242

243 245

243 248

243 251

243 254

243 192 209 209

243 192 212 212

243 192 215 215

0 242

0 242 242

0 242 242 242

0 242 242 242 242

0 242 242 242 242 242

0 242 242 242 242 242 242

0 242 242 242 242 242 242 242

0 242 242 242 242 242 242 242 242

22

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 23

PROFIBUS interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuration of the PROFIBUS DP interface

5

Process data

configuration

UFP parameter + one module per drive

AS 1 Drive

(Param + 1 x 3PD)

AS 2 Drives

(Param + 2 x 3PD)

AS 3 Drives

(Param +3 x 3PD)

AS 4 Drives

(Param + 4 x 3PD)

AS 5 Drives

(Param + 5 x 3PD)

AS 6 Drives

(Param + 6 x 3PD)

AS 7 Drives

(Param + 7 x 3PD)

AS 8 Drives

(Param + 8 x 3PD)

Meaning / notes

Control via 1x3 process data

words / parameter setting via 8byte parameter channel

Control via 2x3 process data

words / parameter setting via 8byte parameter channel

Control via 3x3 process data

words / parameter setting via 8byte parameter channel

Control via 4x3 process data

words / parameter setting via 8byte parameter channel

Control via 5x3 process data

words / parameter setting via 8byte parameter channel

Control via 6x3 process data

words / parameter setting via 8byte parameter channel

Control via 7x3 process data

words / parameter setting via 8byte parameter channel

Control via 8x3 process data

words / parameter setting via 8byte parameter channel

Cfg0 Cfg1 Cfg2 Cfg3 Cfg4 Cfg5 Cfg6 Cfg7 Cfg8

243 242

243 242 242

243 242 242 242

243 242 242 242 242

243 242 242 242 242 242

243 242 242 242 242 242 242

243 242 242 242 242 242 242 242

243 242 242 242 242 242 242 242 242

"Universal module"

DP configuration

The "Universal Module" configuration (e.g. in STEP7) allows you to set the parameters

of the fieldbus interface deviating from the preset standard values of the GSD file. This

is useful in case you want to operate several inverters with different process data words

at the fieldbus interface.

You must observe the following conditions:

• Module 0 defines the parameter channel of the inverter. Entering 0 will switch off the

parameter channel; entering 243 will switch on the parameter channel with 8 bytes

length.

• The following modules determine the process data width of the fieldbus interface at

the PROFIBUS. The added process data width of all following modules must be

between 1 and 24 words. For safety reasons, the modules must be listed with data

integrity. Make sure that an inverter connected to the fieldbus interface is

represented by such a consistent module entry.

• The special identifier format is permitted.

Manual – PROFIBUS UFP11A Fieldbus Interface

23

Page 24

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PROFIBUS interface

Configuration of the PROFIBUS DP interface

The following figure shows the structure of the configuration data defined in EN 50170

(V2). These configuration data are transmitted to the inverter during the initial start of the

DP master.

Table 1: Format of the Cfg_Data identifier byte according to EN 50170 (V2)

7 / MSB 6 5 4 3 2 1 0 / LSB

Data length

0000 = 1 byte/word

1111 = 1 6 byte s/wor ds

Input/output

00 = special identifier formats

01 = input

02 = output

11 = input/output

Format

0 = byte structure

1 = word structure

Integrity over

0 = byte or word

1 = entire length

Data integrity

External

diagnostics

Note on Simatic S7

Master Systems

Note:

Use only the setting "Integrity over entire length" for data transmission!

Integral data are those data that must always be transmitted consistently between

automation device and inverter and may never be transmitted separately.

Data integrity is especially important for the transmission of positioning values or

complete positioning tasks. Inconsistent transmission may contain data from different

program cycles of the automation device and transfer undefined values to the inverter.

For PROFIBUS DP, the data communication always between automation device and

drive engineering is generally carried out with the setting "Data integrity over entire

length."

The fieldbus interface does not support external diagnostics. Error messages of the

individual inverters are indicated by the corresponding status words. Error states of the

fieldbus interface are also displayed on status word 1, for example, timeout of the SBus

connection to a participant.

Upon request, the fieldbus interface provides the standard diagnostics in accordance

with EN 50170 V2.

Diagnostic alarms may also be triggered by the PROFIBUS DP system in the DP master

even if external diagnostic generation is deactivated. As a result, the corresponding

operating blocks (e.g. OB84 for S7-400 or OB82 for S7-300) should always be created

in the controller.

24

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 25

5.3 Ident number

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Each DP master and DP slave must have an individual ident number assigned by the

PROFIBUS user group for unique identification of the connected unit. When the

PROFIBUS DP master is started up, it compares the ident numbers of the connected

DP slaves with the ident numbers configured by the user. The user data transfer will only

be activated after the DP master has ensured that the connected station addresses and

device types (ident numbers) correspond to the project planning data. This procedure

achieves a high degree of safety with respect to project planning errors.

The ident number for the UFP11A fieldbus interface is 6004

The ident number is defined as an unsigned 16-bit number (Unsigned16). The

PROFIBUS user group specified ident number 6004 hex (24580 dec) for the UFP11A

fieldbus interface.

5.4 Inverter control

The inverter is controlled via the process data channel which is one, two or three I/O

words in length. These process data words may mapped in the I/O or peripheral area of

the controller in case a programmable controller is used as DP master and can be

addressed as usual.

PROFIBUS interface

Ident number

hex.

5

POW318

POW316

POW314

POW312

POW310

POW308

[1]

PIW318

PIW316

PIW314

PIW312

PIW310

PIW308

Figure 10: Mapping of PROFIBUS data in the PLC address range ([1] = parameter channel / [2] =

PLC address range / U/f = inverter)

PO 3

PO 2

PO 1

PO 3

PO 2

PO 1

UFP

PI 3

PI 2

PI 1

PI 3

PI 2

PI 1

PO 1

PO 1

PO 2

PO 3

PO 2

PO 3

MOVITRACfi 07 1 MOVITRACfi 07 2

PI 2

PI 1

PI 3

PI 1

PI 2

PI 3

52996AXX

PO = process output data / PI = process input data

Additional information on programming and project planning can be found in the

README_GSD6004.PDF file included in the GSD file.

Manual – PROFIBUS UFP11A Fieldbus Interface

25

Page 26

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PROFIBUS interface

Inverter control

Control example

for Simatic S7

STEP7 programming example

The drive inverter is controlled via Simatic S7 in dependence of the selected process

data configuration, either directly via load and transfer commands or via the special

system functions

In principle, data lengths of 3 bytes or more than 4 bytes must be transmitted using

system functions SFC14 and SFC15.

Process data

configuration

1 PD Load/transfer commands

2 PD Load/transfer commands

3 PD ... 24 PD System functions SFC14/15 (length 6 .. 48 bytes)

Param +1 PD Parameter channel: System functions SFC14/15 (length 8 .. 48 bytes)

Param +2 PD Parameter channel: System functions SFC14/15 (length 6 .. 48 bytes)

Param + 3 PD ...

24 PD

The "README_GSD6004.PDF" file contains project planning and programming

examples for Simatic S7.

SFC 14 DPRD_DAT

STEP7 access via

Process data: Load/transfer commands

Process data: Load/transfer commands

Parameter channel: System functions SFC14/15 (length 6 .. 48 bytes)

Process data: System functions SFC14/15 (length 6 bytes)

and

SFC15 DPWR_DAT

.

26

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 27

6 DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.1 Introduction to PROFIBUS DP-V1

This chapter describes the functions and terms used for operating SEW drive inverters

on PROFIBUS DP-V1. Refer to the PROFIBUS user organization or visit

PROFIBUS website for extensive technical information on PROFIBUS DP-V1.

The PROFIBUS DP-V1 specification introduced new acyclical

the context of the PROFIBUS DP-V1 expansions. These acyclical services are inserted

into special telegrams during ongoing cyclical bus operation and thus ensure

compatibility between PROFIBUS DP (version 0) and PROFIBUS DP-V1 (Version 1).

The acyclical

between master and slave (drive inverter) than it would be possible to transfer in the

cyclical input or output data using the 8-byte parameter channel. The advantage of the

acyclical data exchange via DP-V1 lies in the minimum load on the cyclical bus

operation since DP-V1 telegrams are only added to the bus cycle if required.

The DP-V1 parameter channel provides two options for the user:

• The higher-level controller can access the entire inverter information of the SEW DPV1 slaves. This means not only cyclical process data but also unit settings can be

read, stored in the controller and modified in the slave.

• It is also possible to route the service and startup tool MOVITOOLS across the DPV1 parameter channel instead of using a proprietary RS-485 connection for this

purpose. After installing the MOVITOOLS software, detailed information will be

available in the ...\SEW\MOVITOOLS\Fieldbus folder.

The main features of PROFIBUS DP-V1 are explained below.

read/write

services can be used to exchange larger data quantities

DP-V1 Functions

Introduction to PROFIBUS DP-V1

read/write

6

services within

C1-Master

Acyclic DP-V1

C1-Services

Cyclic OUT Data

Param PD

Param PD

Cyclic IN Data

SEW

Drive

C2-Master

Acyclic DP-V1

C2-Services

PROFIBUS DP-V1

Acyclic DP-V1

C2-Services

C2-Master

53123AXX

Manual – PROFIBUS UFP11A Fieldbus Interface

27

Page 28

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Introduction to PROFIBUS DP-V1

Class 1 master

(C1 master)

Class 2 master

(C2 master)

Data sets (DS)

Different master classes are distinguished in a PROFIBUS DP-V1 network. The C1

master mainly performs the cyclical data exchange with the slaves. A typical C1 master

is a control system, such as a PLC, that exchanges cyclical process data with the slave.

If the DPV1 function has been activated via the GSD file, the acyclical connection

between C1 master and slave is established automatically when the cyclical connection

of the PROFIBUS-DP is being established. Only one C1 master can be operated in a

PROFIBUS DP-V1 network.

The C2 master itself does not perform cyclical data exchange with the slaves. Examples

for a typical C2 master are visualization systems or temporary installed programming

devices (Notebook / PC). The C2 master uses exclusively acyclical connections for the

communication with the slaves. The acyclical connections between C2 master and slave

are established by the

completed

with the slaves by means of

in a DP-V1 network. The number of C2 connections, which are established to a slave

simultaneously, are determined by the slave. SEW drive inverters support two parallel

C2 connections.

The user data transported via DP-V1 service are collected in a data set. Each data set

is uniquely represented through its length, a slot number and an index. The DP-V1

communication with the SEW drive inverter uses the structure of data set 47, which is

defined as DP-V1 parameter channel for drives starting with V3.1 in the PROFIdrive

profile drive engineering of the PROFIBUS user organization. Different access

procedures to the parameter data of the drive inverter are provided via this parameter

channel.

Initiate

Initiate

service. The connection is established after successfully

service. An established connection allows for cyclical data exchange

Read

or

Write

services. Several C2 masters can be active

DP-V1 services

DP-V1 alarm

handling

The DP-V1 expansions offer new services, which can be used for acyclical data

exchange between master and slave. The following services are provided:

C1 master Connection type: MSAC1 (master/slave acyclical C1)

Read Read data set

Write Write data set

C2 master Connection type: MSAC2 (master/slave acyclical C2)

INITIATE Establish C2 connection

ABORT Disconnect C2 connection

Read Read data set

Write Write data set

The DP-V1 specification not only defines acyclical services, but also includes expanded

alarm handling. Alarm handling distinguishes between different alarm types. As a result,

the unit-specific diagnostics via the DP-V1 service "DDLM_SlaveDiag" is not possible

anymore in DP-V1 operation. No DP-V1 alarm handling was defined for drive

engineering as the drive inverter generally transmits status informaton via cyclical

process data communication.

28

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 29

6.2 Features of SEW drive inverters

r

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The SEW fieldbus interfaces according to PROFIBUS DP-V1 have the same

communication features for the DP-V1 interface. Basically, the drives are controlled via

a C1 master according to the DP-V1 standard with cyclical process data. In the case of

cyclical data exchange, the C1 master (usually a PLC) can additionally use an 8-byte

parameter channel to perform parameter services with the UFP. The UFP cannot

access connected MOVITRAC

write services give the C1 master access to connected participants via the DP-V1 C1

channel.

Two C2 channels can be established in addition to these two parameter channels. The

first C2 master can use the C2 channel, for example, to read parameter data as

visualization. A second C2 master in the form of a notebook configures the drive using

MOVITOOLS.

DP-V1 Functions

Features of SEW drive inverters

®

07 drives via this parameter channel. The read and

6

C1-Master

8 Byte Param

DP:

DP:

PD

DP-V1 Interface

SEW PROFIBUS

Cyclic IN/Out

Process Data

Figure 11: DP-V1 parameter channels

Acyclic DP-V1

C1-Services

Drive System

Acyclic DP-V1

C2-Services

C1-Parameterbuffer

DP Parameterbuffer

cyclic

Parameterbuffer

C2-Master C2-Maste

PROFIBUS DP-V1

Acyclic DP-V1

C2-Services

C2-Parameterbuffer

C2-Parameterbuffer

53124AXX

Manual – PROFIBUS UFP11A Fieldbus Interface

29

Page 30

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

6.3 Structure of the DP-V1 parameter channel

On principle, the parameter setting of the drives to the PROFIdrive DPV1 parameter

channel of profile version 3.0 is implemented via data set index 47. The

is used to distinguish between parameter access based on PROFIdrive profile or via

SEW MoviLink services. The following table shows the possible codings of the individual

elements. The data set structure is the same for PROFIdrive and MoviLink access.

Request ID

entry

DP-V1

Read/Write

The following MoviLink services are supported:

• 8-byte MoviLink parameter channel with all the services supported by the drive

inverter such as

– Read parameter

– Write parameter

– Write parameter volatile

–etc.

PROFIdrive

Parameter Channel

DS47

SEW MoviLink

30

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 31

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

The following PROFIdrive services are supported:

• Reading (request parameter) individual parameters of the type

• Writing (change parameter) individual parameters of the type

Table 2: Elements of data set DS47

Field Data type Values

Request

Reference

Request ID Unsigned8 0x01 Request parameter (PROFIdrive)

Response ID Unsigned8 Response (+):

Axis Unsigned8 0x00 ... 0xFF Number of axis 0 ... 255

No. of parameters

Attributes Unsigned8 0x10 Value

Unsigned8 0x00 Reserved

0x01 ... 0xFF

0x02 Change parameter (PROFIdrive)

0x40 SEW MoviLink service

0x00 Reserved

0x01 Request parameter (+) (PROFIdrive)

0x02 Change parameter (+) (PROFIdrive)

0x40 SEW MoviLink service (+)

Response (–):

0x81 Request parameter (–) (PROFIdrive)

0x82 Change parameter (–) (PROFIdrive)

0xC0 SEW MoviLink service (–)

Unsigned8 0x01 ... 0x13 1 ... 19 DWORDs (240 DP-V1 data bytes)

double word

double word

6

For SEW MoviLink (Request ID = 0x40):

0x00 No service

0x10 Read Parameter

0x20 Write Parameter

0x30 Write Parameter volatile

0x40 ... 0xF0 Reserved

No. of Elements Unsigned8 0x00 for non-indexed parameters

Parameter Number

Subindex Unsigned16 0x0000 SEW: always 0

Format Unsigned8 0x43 Double word

No. of Values Unsigned8 0x00 ... 0xEA Quantity 0 ... 234

Error Value Unsigned16 0x0000 ... 0x0064 PROFIdrive error codes

Unsigned16 0x0000 ... 0xFFFF MoviLink parameter index

0x01 ... 0x75 Quantity 1 ... 117

0x44 Error

0x0080 + MoviLink-AdditionalCode Low

For SEW MoviLink 16 bit error value

Manual – PROFIBUS UFP11A Fieldbus Interface

31

Page 32

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

Procedure for

setting

parameters via

data set 47

Parameter access takes place with the combination of the DP-V1 services

Read

. The parameter setting service is transferred to the slave with

Write.req

Write

and

, followed

by slave-internal processing.

The master now sends a

master repeats the

Read.req

Read.req

responds with a positive response

to pick up the parameter setting response. The

if the

Read.res

Read.res

from the slave is negative. The slave

as soon as parameter processing in the

drive inverter is finished. The user data now contain the parameter setting response of

the parameter setting order that was previously sent with

Write.req

(see figure). This

mechanism applies to a C1 as well as a C2 master.

Master

Parameter

Request

PROFIBUS-DP-V1

Write.req DS47

with data (parameter request)

Write.res

without data

Read.req DS47

without data

Read.res(-)

without data

Slave (Drive)

Parameter

Request

Parameter

Processing

Read.req DS47

without data

Parameter

Response

Figure 12: Telegram sequence for parameter access via DP-V1

with data (parameter response)

Read.res(+)

Parameter

Response

53126AXX

32

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 33

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

6

Procedure for the

DP-V1 master

If the bus cycle time is short, the parameter response is queried earlier than the inverter

has completed the parameter access in the unit. As a result, the response data from the

inverter are not yet ready at this time. In this state, the inverter sends a negative

response on DP-V1 level with Error_Code _1 = 0xB5 (status fault). The DP-V1 master

must then send another request with above Read.req header until the drive inverter

sends a positive response.

Send Write.request

with Parameterdata

Check Write.

response

Send DS_Read.req

with Parameterdata

Read.

response

State

Conflict?

Write.response

Write.response

positive

yes

negative

no

Other Errors

or Timeout

no

Parameter transfer

ok, data available

yes

Parameter transfer

aborted with ERROR

53127AXX

Manual – PROFIBUS UFP11A Fieldbus Interface

33

Page 34

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

Addressing a

UFP with connected MOVIT-

®

RAC

07 units

The structure of the DS47 data set defines an axis element. With the setting

Axis = 0

the UFP is accessed directly. The SBus address of the corresponding inverter must be

entered in the axis element for addressing a connected MOVITRAC

C1-Master

Cyclic OUT Data

Param PD

Acyclic DP-V1

C1-Services

Axis = 1

Axis = SBus-Address: 12345678

Param PD

Cyclic IN Data

Axis = 0

Axis = 3

Axis = 0

Axis = 5

®

C2-Master

Acyclic DP-V1

C2-Services

07.

PROFIBUS DP-V1

Axis = 8

C2-Master

Acyclic DP-V1

C2-Services

53129BXX

,

MoviLink

parameter orders

The MoviLink parameter channel of the SEW drive inverters is directly mapped in the

structure of data set 47. The Request ID 0x40 (SEW MoviLink service) is used for the

exchange of MoviLink parameter setting orders. Parameter access with MoviLink

services usually takes place according to the structure described below. The typical

message sequence for data set 47 is used for this purpose.

Request ID: 0x40 SEW MoviLink Service

The actual service is defined by the data set element

Attribute

on the MoviLink

parameter channel. The high nibble of this element corresponds to the service nibble in

the management byte of the DPV0 parameter channel.

34

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 35

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

6

Example for reading a parameter via

MoviLink

The following tables show an example of the structure of the Write.request and Read.res

user data for reading an individual parameter via the MoviLink parameter channel.

Sending parameter order

The following tables show the coding of the user data for the

the DP-V1 header. The

Write.req

service is used to transfer the parameter setting order

Write.req

service including

to the drive inverter. The firmware version is read.

Table 3: Excerpt from the parameter list ("MOVITRAC® 07 Communication" manual)

Par.

Parameter

no.

0.. Display values

07. Unit data

070 Unit type 8301 206D 0 RO 0

071 Rated output current 8361 20A9 A –3 RO 0

076 Firmware basic unit 8300 206C 0 RO 0

Table 4: Write.request header for transferring the parameter order

Service: Write.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10 byte user data for parameter order

Table 5: Write.req USER DATA for MoviLink "read parameter"

Byte Field Value Description

0 Request Reference 0x01 Individual reference number for the parameter

1 Request ID 0x40 SEW MoviLink Service

2 Axis 0x01 Drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4 Attributes 0x10 MoviLink service “Read parameter”

5 No. of Elements 0x00 0 = access to direct value, no subelement

6..7 Parameter Number 0x206C MoviLink index 8300 = “firmware version”

8..9 Subindex 0x0000 Subindex 0

Index Unit/index

Dec Hex Abbr. Cv.

Access Default Meaning / value range

Example:

822609711 = 822 609 7.11

1822609011 = 822 609 X.11

setting order that is reflected in the parameter

response

Manual – PROFIBUS UFP11A Fieldbus Interface

35

Page 36

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

Requesting the parameter response

The following table shows the coding of the Read.req user data including the DP-V1

header.

Table 6: Read.req for requesting the parameter response

Service: Write.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10 byte user data for parameter order

Positive MoviLink parameter response

The table shows the Read.res USER DATA with the positive response data of the

parameter setting order. The parameter value for index 8300 (firmware version) is

returned as an example.

Table 7: DP-V1 header of the positive Read.response with parameter response

Service: Read.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10 byte user data in response buffer

Table 8: Positive response for MoviLink service

Byte Field Value Description

0 Response reference 0x01 Mirrored reference number from the parameter

setting order

1 Response ID 0x40 Positive MoviLink response

2 Axis 0x01 Mirrored drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4 Format 0x43 Parameter format: Double word

5 No. of values 0x01 1 value

6..7 Value Hi 0x311C Higher-order part of the parameter

8..9 Value Lo 0x7289 Lower-order part of the parameter

Decoding:

0x 311C 7289 = 823947913 dec

>> firmware version 823 947 9.13

36

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 37

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

6

Example for writing

a parameter via

MoviLink

The following tables show an example of the structure of the

Write

and

Read

services.

Speed 123 rpm (Ⳏ value 123 000) is to be written volatile to P160 internal value n11.

The MoviLink service

Table 9: Excerpt from the parameter list ("MOVITRAC® 07 Communication" manual)

Par.

Parameter

no.

16. Fixed setpoints 1

160 Internal setpoint n11 8489 2129 rps 66 N/RW 150000

161 Internal setpoint n12 8490 212A rps 66 N/RW 750000

Write Parameter volatile

Index Unit/index

Dec Hex Abbr. Cv.

is used for this purpose.

Access Default Meaning / value range

–5000000 ... –0, Step 200

0 ... 5000000, Step 200

–5000000 ... –0, Step 200

0 ... 5000000, Step 200

Send „Write parameter volatile“ order

Table 10: DP-V1 header of the Write.request with parameter order

Service: Write.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 16 16 byte user data for order buffer

Table 11: Write.req user data for MoviLink service "Write parameter volatile"

Byte Field Value Description

0 Request Reference 0x01 Individual reference number for the parameter

1 Request ID 0x40 SEW MoviLink Service

2 Axis 0x01 Drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4 Attributes 0x30 MoviLink service “Write parameter volatile”

5 No. of Elements 0x00 0 = access to direct value, no subelement

6..7 Parameter Number 0x2129 Parameter index 8489 = P160 n11

8..9 Subindex 0x0000 Subindex 0

10 Format 0x43 Double word

11 No. of values 0x01 Change 1 parameter value

12..13 Value HiWord 0x0001 Higher-order part of the parameter value

14..15 Value LoWord 0xE078 Lower-order part of the parameter value

setting order that is reflected in the parameter

response

After sending this Write.request, the Write.response is received. If there was no status

conflict in processing the parameter channel, a \positive Write.response occurs.

Otherwise, the status error is located in Error_code_1.

Manual – PROFIBUS UFP11A Fieldbus Interface

37

Page 38

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

Requesting the parameter response

The following table shows the coding of the Write.req USER DATA including the DP-V1

header.

Table 12: Read.req for requesting the parameter response

Field Value Description

Function_Num Read.req

Slot_Number X Slot_Number not used

Index 47 Index of data set

Length 240 Maximum length of response buffer in DP-V1 master

Positive response to “Write Parameter volatile”

Table 13: DP-V1 header of the positive Read.response with parameter response

Service: Read.response

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 4 12 byte user data in response buffer

Table 14: Positive response for MoviLink service „Write Parameter'

Byte Field Value Description

0 Response reference 0x01 Mirrored reference number from the parameter

setting order

1 Response ID 0x40 Positive MoviLink response

2 Axis 0x01 Mirrored drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

38

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 39

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

6

Negative parameter response

MoviLink return

codes for parameter setting for

DP-V1

The following table shows the coding of a negative response of a MoviLink service. Bit 7

is set in the Response ID if the response is negative.

Table 15: Negative response for MoviLink service

Service: Read.response

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 8 8 byte user data in response buffer

Byte Field Value Description

0 Response reference 0x01 Mirrored reference number from the parameter

1 Response ID 0xC0 Negative MoviLink response

2 Axis 0x01 Mirrored drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4Format 0x44 Error

5 No. of values 0x01 1 error code

6..7 Error value 0x0811 MoviLink return code

setting order

z. B. ErrorClass 0x08, Add. Code 0x11

(see the table MoviLink return codes for DP-V1)

The following table shows the return codes that are returned by the SEW DP-V1

interface in case of an error in the DP-V1 parameter access.

MoviLink

Return code (hex)

0x0810 Illegal index, parameter index does not exist in the unit

0x0811 Function/parameter not implemented

0x0812 Read access only

0x0813 Parameter lock is active

0x0814 Factory setting is active

0x0815 Value too large for parameter

0x0816 Value too small for parameter

0x0817 Required option card not installed

0x0818 Error in system software

0x0819 Parameter access via RS-485 process interface only

0x081A Parameter access via RS-485 diagnostic interface only

0x081B Parameter has access protection

0x081C Controller inhibit is required

0x081D Illegal value for parameter

0x081E Factory setting was activated

0x081F Parameter was not saved in EEPROM

0x0820 Parameter cannot be changed with output stage enabled / reserved

0x0821 Reserved

0x0822 Reserved

0x0823 Parameter may be changed at IPOS program stop only

0x0824 Parameter may only be changed with deactivated Autosetup

0x0505 Incorrect coding of management and reserved byte

0x0602 Communication error between inverter system and fieldbus option card

0x0502 Timeout of secondary connection (e.g. during reset or with Sys-Fault)

Description

Manual – PROFIBUS UFP11A Fieldbus Interface

39

Page 40

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DP-V1 Functions

Structure of the DP-V1 parameter channel

PROFIdrive

parameter orders

Example for reading a parameter via

PROFIdrive

The PROFIdrive parameter channel of SEW drive inverters is directly mapped in the

structure of data set 47. Parameter access with PROFIdrive services usually takes place

according to the structure described below. The typical message sequence for data

set 47 is used for this purpose. PROFIdrive only defines the two request IDs

Request ID:0x01Request Parameter (PROFIdrive)

Request ID:0x02Change Parameter (PROFIdrive)

That is why data access is limited compared to the MoviLink services.

The request ID = 0x02 = Change Parameter (PROFIdrive) results in a remanent write

access to the selected parameter. Consequently, the internal flash/EEPROM of the

inverter is written with each write access. Use the MoviLink service "Write Parameter

volatile" if parameters must be written cyclically at short intervals. With this service, you

alter the parameter values only in the RAM of the inverter.

The following tables show an example of the structure of the Write.request and Read.res

user data for reading an individual parameter via the MoviLink parameter channel.

Sending parameter order

The following tables show the coding of the user data for the Write.req service including

the DP-V1 header. The Write.req service is used to transfer the parameter setting order

to the drive inverter.

Table 16: Write.request header for transferring the parameter order

Service: Write.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10 byte user data for parameter order

Table 17: Write.req USER DATA for MoviLink "read parameter"

Byte Field Value Description

0 Request Reference 0x01 Individual reference number for the parameter

setting order that is reflected in the parameter

response

1 Request ID 0x01 Request parameter (PROFIdrive)

2 Axis 0x01 Drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4 Attributes 0x10 Access to parameter value

5 No. of Elements 0x00 0 = access to direct value, no subelement

6..7 Parameter Number 0x206C MoviLink index 8300 = “firmware version”

8..9 Subindex 0x0000 Subindex 0

40

Manual – PROFIBUS UFP11A Fieldbus Interface

Page 41

DP-V1 Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the DP-V1 parameter channel

Requesting the parameter response

The following table shows the coding of the Read.req user data including the DP-V1

header.

Table 18: Read.req for requesting the parameter response

Service: Read.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 240 Maximum length of response buffer in the DP-V1 master

Positive PROFIdrive parameter response

The table shows the Read.res user data with the positive response data of the

parameter setting order. The parameter value for index 8300 (firmware version) is

returned as an example.

Table 19: DP-V1 header of the positive Read.response with parameter response

Service: Read.request

Slot_Number 0 Random, (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10 byte user data in response buffer

Table 20: Positive response for MoviLink service

Byte Field Value Description

0 Response reference 0x01 Mirrored reference number from the parameter

setting order

1 Response ID 0x01 Positive response for „Request Parameter“

2 Axis 0x01 Mirrored drive number; 1 = SBus address

3 No. of parameters 0x01 1 parameter

4 Format 0x43 Parameter format: Double word

5 No. of values 0x01 1 value

6..7 Value Hi 0x311C Higher-order part of the parameter

8..9 Value Lo 0x7289 Lower-order part of the parameter

Decoding:

0x 311C 7289 = 823947913 dec

>> firmware version 823 947 9.13

6

Manual – PROFIBUS UFP11A Fieldbus Interface

41

Page 42

6