Page 1

CANopen UFO11A Fieldbus Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Edition

11/2002

Manual

1054 1217 / EN

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

1 Unit Structure ....................................................................................................4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Front view ................................................................................................. 4

2 Installation and Operation without a PC.........................................................5

2.1 Installation notes ....................................................................................... 5

2.2 Setting the inverter parameters (MOVITRAC® 07)................................... 8

2.3 Autosetup.................................................................................................. 8

2.4 Setting the UFO DIP switches................................................................... 9

3 Installation and Operation with a PC............................................................. 10

3.1 Installation notes ..................................................................................... 10

3.2 Setting the inverter parameters (MOVITRAC® 07)................................. 13

3.3 Startup software...................................................................................... 14

3.4 Setting the UFO DIP switches................................................................. 14

4 CANopen Interface..........................................................................................15

4.1 Configuring the CANopen interface ........................................................ 15

4.2 SYNC object ........................................................................................... 23

4.3 Emergency object ................................................................................... 24

4.4 Guarding and heartbeat .......................................................................... 26

4.5 Parameter access via SDOs................................................................... 28

5 Error Response ...............................................................................................30

5.1 Fieldbus timeout...................................................................................... 30

5.2 SBus timeout........................................................................................... 30

5.3 Unit errors ............................................................................................... 30

6 LEDs................................................................................................................. 31

6.1 COMM LED............................................................................................. 31

6.2 GUARD LED ........................................................................................... 31

6.3 STATE LED ............................................................................................ 31

6.4 BUS-F LED ............................................................................................. 32

6.5 SYS-F LED ............................................................................................. 32

6.6 USER LED .............................................................................................. 32

7 DIP Switches.................................................................................................... 33

7.1 CANopen address................................................................................... 33

7.2 Baud rate of the CANopen bus ............................................................... 34

7.3 Number of process data items to be transmitted via the CANopen bus . 34

7.4 Autosetup................................................................................................ 35

7.5 DIP switch F1.......................................................................................... 35

8 Using the Interface..........................................................................................36

9 Object List........................................................................................................ 38

10 Parameter List ................................................................................................. 43

11 List of Errors.................................................................................................... 44

12 Technical Data................................................................................................. 45

13 Dimensions...................................................................................................... 46

14 Index................................................................................................................. 47

Startup of UFO11A fieldbus interface:

• without PC: section 2

• with PC: section 3

Manual – UFO11A Fieldbus Interface

3

Page 4

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1 Unit Structure

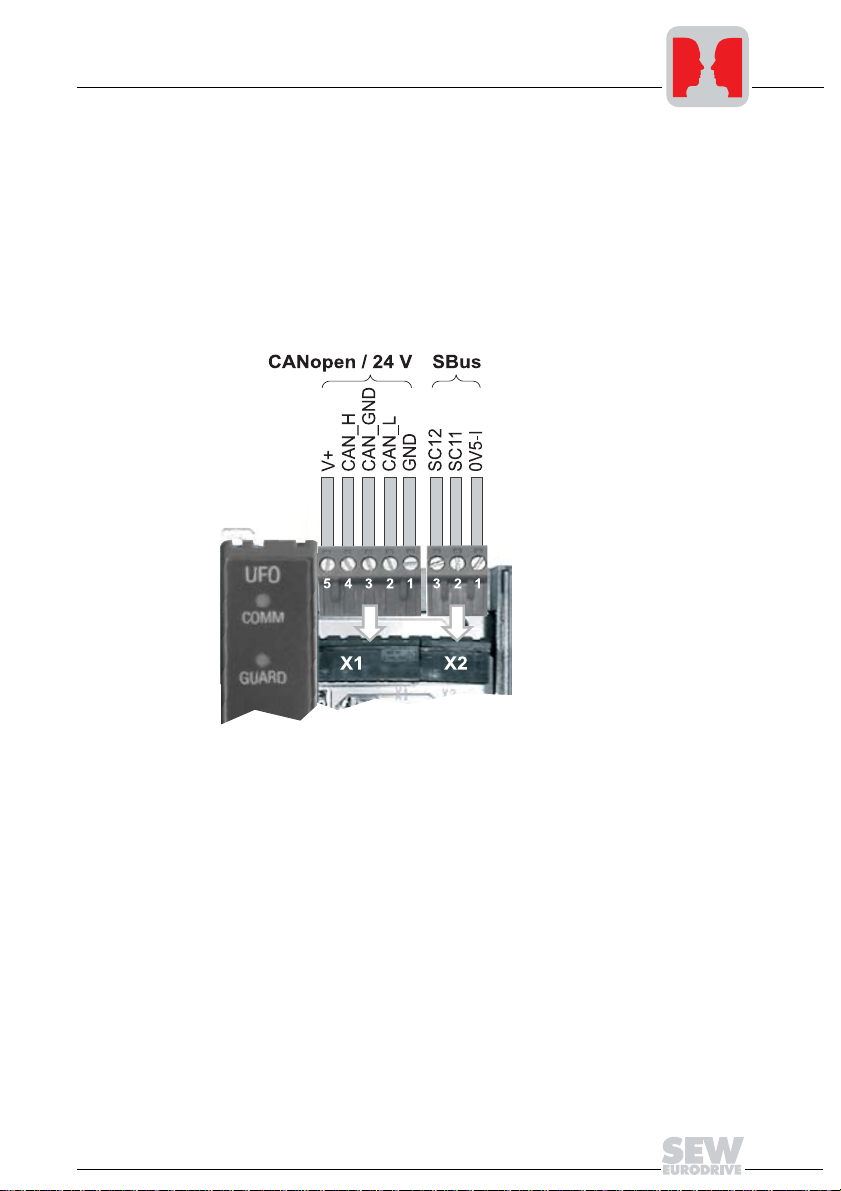

1.1 Front view

Unit Structure

Fig. 1: Arrangement of LEDs, connectors and DIP switches

X1 CANopen and electrical power supply

X2 SBus

X3 Diagnostic interface

S1 DIP switch

S2 DIP switch

COMM Communication on the CANopen interface

GUARD Status display for timeout on the CANopen bus

STATE CANopen operating status of the UFO11

BUS-F Bus fault on the CANopen interface

SYS-F System fault

USER Expert mode

4

05790AXX

Manual – UFO11A Fieldbus Interface

Page 5

Installation and Operation without a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Installation and Operation without a PC

2.1 Installation notes

Mounting

Pin assignment

The unit can be mounted using the pre-installed DIN rail mounting option or directly onto

a switch cabinet wall using the four holes integrated into the back wall of the housing.

Basically, there are no restrictions regarding positioning in relation to the inverters to be

connected (e.g. MOVITRAC

®

07). In laying out the system, consider the maximum cable

length and the fact that the gateway must be the first or last node on the system bus

(SBus).

2

Fig. 2: Pinout

Supply voltage

X1:5: V+

X1:1: GND

Manual – UFO11A Fieldbus Interface

CANopen

X1:4: CAN_H

X1:3: CAN_GND

X1:2: CAN_L

05789AXX

SBus

X2:3: SC12

X2:2: SC11

X2:1: 0V5-I

5

Page 6

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without a PC

System bus

connection

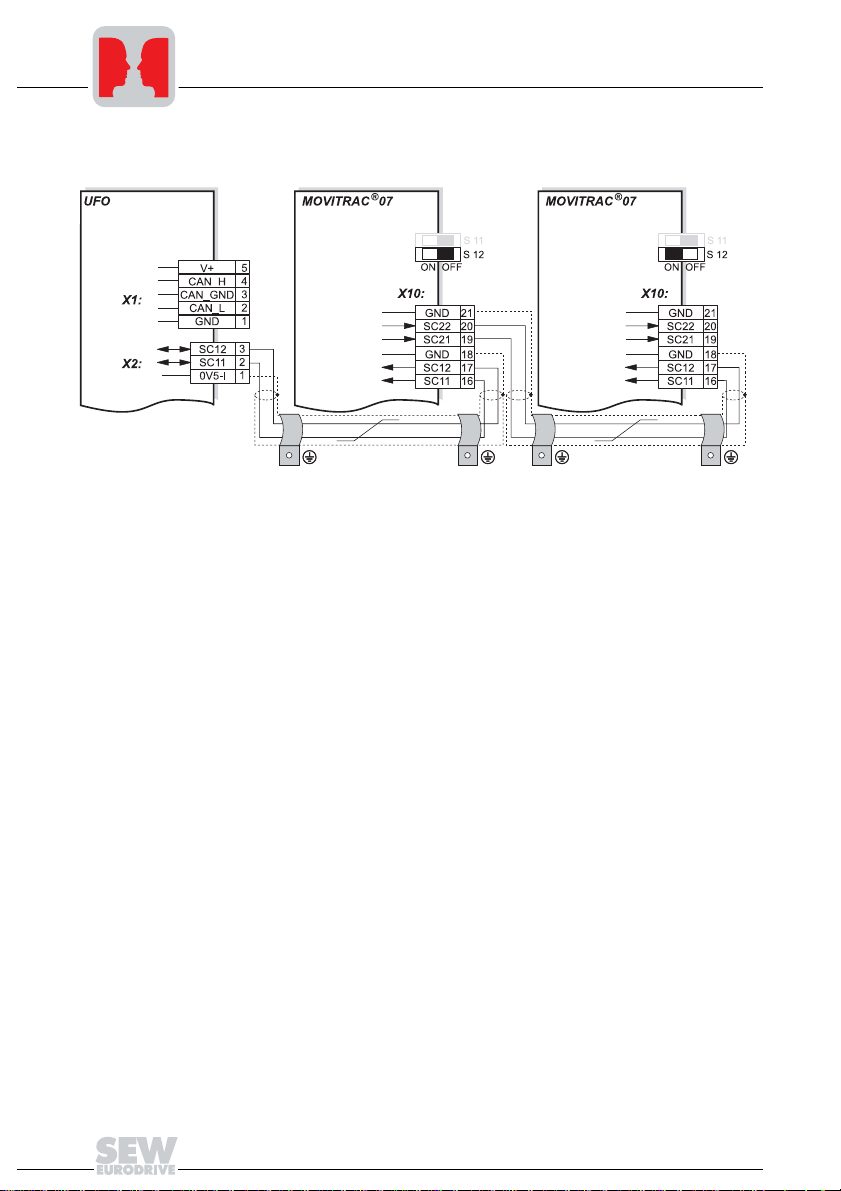

Fig. 3: System bus connection

UFO11A

V+ = Supply voltage

CAN_H = CAN bus high

CAN_GND = CAN bus reference

CAN_L = CAN bus low

0V5-I = System bus reference

SC11 = System bus high

SC12 = System bus low

Please note:

• Use a 2-core twisted and shielded copper cable (data transmission cable with

• The permitted total cable length depends on the baud rate setting of the SBus:

05791AXX

MOVITRAC® 07

GND = System bus reference

SC22 = System bus outgoing low

SC21 = System bus outgoing high

SC12 = System bus incoming low

SC11 = System bus incoming high

S12 = System bus terminating resistor

braided copper shield). Connect the shield at either end to the electronics shield

clamp of MOVITRAC

®

07 or the UFO11A and also connect the ends of the shield to

GND/0V5-I. The cable must meet the following specifications (CAN bus or DeviceNet

cables are suitable, for example):

– Conductor cross section 0.75 mm

2

(AWG18)

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

– 125 kbaud: 320 m (1056 ft)

– 250 kbaud: 160 m (528 ft)

– 500 kbaud: 80 m (264 ft)

– 1000 kbaud: 40 m (132 ft)

6

Manual – UFO11A Fieldbus Interface

Page 7

Installation and Operation without a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

• Switch on the system bus terminating resistor (S12 = ON) of the node end of the

system bus. Switch off the terminating resistor on the other units (S12 = OFF). The

UFO11A gateway must always be the first or last node on the system bus. It has an

integrated terminating resistor.

• There must not be any potential difference between the units connected to the SBus.

Take suitable measures such as connecting each unit’s ground lug to a central

grounding point in the cabinet to avoid potential differences.

• Point-to-point cabling is not permitted.

2

Shielding and

routing of the bus

cables

The CANopen interface supports RS-485 transmission technology and requires the

cable type A to EN 50170 specified as the physical medium for CANopen. This cable

must be a shielded, twisted-pair two-core cable.

In practice, cables such as the Unitronic BUS CAN 2 × 2 × 0.22 made by Lapp have

proven effective even under harsh conditions. The CAN signals are carried along one

pair of conductors. The other pair of conductors is used for CAN ground and any supply

voltage which is also carried. Yellow – CAN high / Green – CAN low / Brown – CAN

GND.

This setup offers the advantage that the necessary compensating current of the bus

drivers does not have to be carried along the shield. As a result, no parasitic EMC

interference is carried into the shield and ultimately the electronics.

Having the bus cable correctly shielded cuts out parasitic interference which can occur

in an industrial environment. The following measures ensure the best possible shielding:

• Finger-tighten the retaining screws of plugs, modules and equipotential bonding

conductors.

• Use only connectors with a metal housing or a metallized housing.

• Maximize the contact area between the shield and the connector housing.

• Shield the bus cable on both ends.

• Do not route the signal and bus cables in parallel with the power cables (motor

leads); use separate cable ducts if possible.

• Use only grounded metal cable trays in industrial environments.

• Join the signal cables and the associated equipotential bonding together at closely

spaced intervals by the shortest route.

• Avoid using plug connections to extend bus cables.

• Route the bus cables closely adjacent to available grounding surfaces.

In the event of fluctuations in the ground potential, a compensating current may flow

along the shield which is connected at both ends and to the ground potential (PE). In this

case, make adequate provision for equipotential bonding in accordance with the

relevant VDE regulations.

Bus termination

Manual – UFO11A Fieldbus Interface

No bus termination is provided on the UFO electronics. External bus termination must

be used if the UFO module is used as the first or last unit in the CANopen branch. To do

this, connect the supplied 120 Ω resistor between CAN high and CAN low (terminals

X1:2 and X1:4) as well.

7

Page 8

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation without a PC

2.2 Setting the inverter parameters (MOVITRAC® 07)

• Switch on the voltage supply for the UFO and all connected inverters.

• Set an individual SBus address (P813) on the inverters. Recommendation: Assign

the addresses starting from address 1 and working in ascending order according to

the arrangement of inverters in the switch cabinet. Do not assign address 0 since this

is used by the UFO.

• Set the setpoint source (P100) to SBus (value 10 on MOVITRAC

• Set the control signal source (P101) to SBus (value 3 on MOVITRAC

• Set the terminal assignment of the binary inputs (P60-). Set unrequired binary inputs

to "No function." For safety reasons, the inverter must be enabled on the terminal

side. Refer to the appropriate unit documentation for information about this. For

MOVITRAC

following assignment:

– DI01 CW/STOP (applied to 24 V, enable CW direction of rotation)

– DI02 CCW/STOP (no function)

– DI03 FIX SETPT SW.OV (not connected)

– DI04 n11/n21 (not connected)

– DI05 n12/n22 (not connected)

• Set the SBus timeout delay (P815) to a value other than 0, for example 1 s, to

activate the monitoring process.

• If necessary, change the default values of the process data assignments (P870 –

P875). This step must be performed before Autosetup (see Sec. "Autosetup").

®

07, parameter P60- can be set to the value 0. This corresponds to the

2.3 Autosetup

You can start up the UFO without a PC with the Autosetup function. It is activated with

the Autosetup DIP switch. Turning on the Autosetup DIP switch will execute the function

once. The function can be executed once again by turning the switch off and on again.

Upon activation of the Autosetup feature, the UFO automatically searches for inverters

on the lower-level SBus and indicates this activity with a brief blinking of the SYS-F LED.

Each drive inverter on the SBus must be assigned a unique SBus address (P813). To

avoid confusion with data assignments, it is recommended to assign the addresses from

address 1 and working in ascending order according to the arrangement of inverters in

the control cabinet. The process image on the fieldbus side will be extended by three

words for each located inverter. The SYS-FLT LED stays on if no drive inverters are

found. A maximum of eight inverters can be configured. Following the search, the UFO

cyclically exchanges three process data words with each connected drive inverter. The

process output data are collected from the fieldbus, divided into blocks of three and sent.

The process input data are read by the drive inverters, assembled and sent to the fieldbus master.

®

07).

®

07).

8

Manual – UFO11A Fieldbus Interface

Page 9

Installation and Operation without a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Autosetup has to be executed only once. The detected configuration will be saved in the

non-volatile memory. Important: Execute Autosetup again in case you change the

process data assignment of the drive inverters connected to the UFO, because the UFO

saves these values once only during Autosetup. Likewise, the process data

assignments of the connected drive inverters must not be altered dynamically either, for

example by an IPOS program, following Autosetup. Failure to comply with this

instruction could prevent a fault response if there is a fieldbus timeout.

2.4 Setting the UFO DIP switches

• For project planning, set an individual CANopen address using the DIP switches on

the UFO (see Sec. "DIP Switches"). Address 0 is not permitted in CANopen.

• Set the DIP switches for the number of process data items (see Sec. "DIP Switches").

The following applies: Number of process data items = Number of connected

inverters times 3.

• Set the DIP switch for the baud rate of the CANopen bus (see Sec. "DIP Switches").

Changes to the DIP switches do not come into effect until the UFO has been switched

off and on.

2

Manual – UFO11A Fieldbus Interface

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

3 Installation and Operation with a PC

3.1 Installation notes

Mounting

Pin assignment

The unit can be mounted using the pre-installed DIN rail mounting option or directly onto

a switch cabinet wall using the four holes integrated into the back wall of the housing.

Basically, there are no restrictions regarding positioning in relation to the inverters to be

connected (e.g. MOVITRAC

length and the fact that the gateway must be the first or last node on the system bus

(SBus).

®

07). In laying out the system, consider the maximum cable

05789AXX

SBus

X2:3: SC12

X2:2: SC11

X2:1: 0V5-I

Manual – UFO11A Fieldbus Interface

10

Fig. 4: Pinout

Supply voltage

X1:5: 24 V

X1:1: 0 V

CANopen

DC

DC

X1:4: CAN H

X1:3: CAN GND

X1:2: CAN L

Page 11

System bus

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

connection

Installation and Operation with a PC

3

Fig. 5: System bus connection

UFO11A

V+ = Supply voltage

CAN_H = CAN bus high

CAN_GND = CAN bus reference

CAN_L = CAN bus low

0V5-I = System bus reference

SC11 = System bus high

SC12 = System bus low

Please note:

• Use a 2-core twisted and shielded copper cable (data transmission cable with

• The permitted total cable length depends on the baud rate setting of the SBus:

05095AXX

MOVITRAC® 07

GND = System bus reference

SC22 = System bus outgoing low

SC21 = System bus outgoing high

SC12 = System bus incoming low

SC11 = System bus incoming high

S12 = System bus terminating resistor

braided copper shield). Connect the shield at both ends to the electronics shield

clamp of MOVITRAC

®

07 or the UFO11A and ensure a large area of contact

between the shield and the clamp. Also connect the ends of the shield to GND/0V5I. The cable must meet the following specifications (CAN bus or DeviceNet cables

are suitable):

– Core cross section 0.75 mm

2

(AWG18)

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

– 125 kbaud: 320 m (1056 ft)

– 250 kbaud: 160 m (528 ft)

– 500 kbaud: 80 m (264 ft)

– 1000 kbaud: 40 m (132 ft)

Manual – UFO11A Fieldbus Interface

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

• Switch on the system bus terminating resistor (S12 = ON) at the end of the system

bus. Switch off the terminating resistor on the other units (S12 = OFF). The UFO11A

gateway must always be the first or last node on the system bus. It has an integrated

terminating resistor.

• There must not be any potential difference between the units connected to the SBus.

Take suitable measures such as connecting each unit’s ground lug to a central

grounding point in the cabinet to avoid potential differences.

• Point-to-point cabling is not permitted.

Shielding and

routing of the bus

cables

The CANopen interface supports RS-485 transmission technology and requires the

cable type A to EN 50170 specified as the physical medium for CANopen. This cable

must be a shielded, twisted-pair two-core cable.

In practice, cables such as the Unitronic BUS CAN 2 × 2 × 0.22 made by Lapp have

proven effective even under harsh conditions. The CAN signals are carried along one

pair of conductors. The other pair of conductors is used for CAN ground and any supply

voltage which is also carried. Yellow – CAN high / Green – CAN low / Brown – CAN

GND.

This setup offers the advantage that the necessary compensating current of the bus

drivers does not have to be carried along the shield. As a result, no parasitic EMC

interference is carried into the shield and ultimately the electronics.

Having the bus cable correctly shielded cuts out parasitic interference which can occur

in an industrial environment. The following measures ensure the best possible shielding:

• Finger-tighten the retaining screws of plugs, modules and equipotential bonding

conductors.

• Use only connectors with a metal housing or a metallized housing.

• Maximize the contact area between the shield and the connector housing.

• Shield the bus cable on both ends.

• Do not route the signal and bus cables in parallel with the power cables (motor

leads); use separate cable ducts if possible.

• Use only grounded metal cable trays in industrial environments.

• Join the signal cables and the associated equipotential bonding together at closely

spaced intervals by the shortest route.

• Avoid using plug connections to extend bus cables.

• Route the bus cables closely adjacent to available grounding surfaces.

In the event of fluctuations in the ground potential, a compensating current may flow

along the shield which is connected at both ends and to the ground potential (PE). In this

case, make adequate provision for equipotential bonding in accordance with the

relevant VDE regulations.

Bus termination

12

No bus termination is provided on the UFO electronics. External bus termination must

be used if the UFO module is used as the first or last unit in the CANopen branch. To do

this, connect the supplied 120 Ω resistor between CAN high and CAN low (terminals

X1:2 and X1:4) as well.

Manual – UFO11A Fieldbus Interface

Page 13

Installation and Operation with a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3

UWS21A

• The UFO is equipped with a 4-pol phone jack on its front panel. The UWS21A option

with part no. 8230773 establishes the connection to a COM interface on your PC.

Connect the desired COM of the PC with the UWS21A via the enclosed serial cable.

Connect the UWS21A to the UFO using the supplied phone cable.

Fig. 6: UWS connection

3.2 Setting the inverter parameters (MOVITRAC® 07)

• Switch on the voltage supply for the UFO and all connected inverters.

• Set an individual SBus address (P813) on the inverters. Recommendation: Assign

the addresses starting from address 1 and working in ascending order according to

the arrangement of inverters in the switch cabinet.

05901AXX

Do not assign address 0 since this is used by the UFO!

Manual – UFO11A Fieldbus Interface

13

Page 14

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.3 Startup software

Installation and Operation with a PC

• Install the MOVITOOLS® software package on your PC.

• Start the software. Select the COM port to which the UFO is connected and press the

"Update" button. The UFO should appear at address 0 and the connected inverters

on the following addresses. In case you do not see an entry in the window, please

check the COM interface and the connection via the UWS21. If you only see the UFO

as an entry in the window, please check the SBus cabling and the terminating

resistors.

• Select the UFO and start the startup software for the fieldbus gateway.

• Select the menu item "New configuration of fieldbus node."

• Enter your project path and name. -> Next

• Press the "Update" button. You should now see all inverters connected to the UFO.

You can customize the configuration with the "Insert", "Edit" and "Delete" buttons.

-> Next

• Press the "Autoconfiguration" button. You will now see the process image for the

UFO in your control. The process data length is displayed at the bottom. This value

is important for configuration of the fieldbus master. -> Next

• Save the project data and click the "Download" button. If you experience problems

with the download, you have probably set the DIP switch to AUTOSETUP. You need

to turn off the autosetup feature when configuring with a PC.

• You can see the data being exchanged between fieldbus master and UFO with the

process data monitor.

• You will have to enable the unit via the terminals to control the inverters via fieldbus.

You have already connected the terminals DI01 and DI02 (MOVITRAC

the first inverter with address 1 in the window "Connected units" to check the pinout.

• Repeat this step for all inverters listed in the window "Connected units."

®

07). Select

3.4 Setting the UFO DIP switches

• For project planning, set an individual CANopen address using the DIP switches on

the UFO (see Sec. "DIP Switches"). Address 0 is not permitted in CANopen.

• Set the DIP switches for the number of process data items (see Sec. "DIP Switches").

The following applies: Number of process data items = Number of connected

inverters times 3.

• Set the DIP switch for the baud rate of the CANopen bus (see Sec. "DIP Switches").

Changes to the DIP switches do not come into effect until the UFO has been switched

off and on.

14

Manual – UFO11A Fieldbus Interface

Page 15

4 CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.1 Configuring the CANopen interface

General features of the CANopen interface of the UFO:

• 0 to 8 RX PDOs

• 0 to 8 TX PDOs

• Various transmission modes for the PDOs

• Length of the PDOs can be configured dynamically

•1 SDO

• Emergency message

• COB IDs for SYNC, emergency and PDOs can be configured dynamically.

• Heartbeat producer & consumer

• Guarding protocol

CANopen Interface

4

Unit states and

NMT services

The UFO supports what is referred to as the "minimum capability device". This means

the following states are supported: "pre-operational", "operational" and "prepared". In

"pre-operational" status, the device can only communicate via SDOs (see also Sec.

"CANopen Interface" / "Parameter access via SDOs"). PDOs and SDOs can be

exchanged in "operational" status; neither SDOs nor PDOs can be exchanged in

"stopped" status.

Following switch-on, the CANopen option card is always automatically in the "preoperational" status.

Fig. 7: Status diagram for CANopen devices

05772AXX

Manual – UFO11A Fieldbus Interface

15

Page 16

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

The states can be changed at any time by services referred to as NMT services.

The possible commands in this case are:

• (6) Node_Start indication

• (7) Node_Stop indication

• (8) Enter_Pre-Operational_State indication

• (10) Reset_Node indication: This command resets the entire inverter and the UFO

activates the default settings in the object list.

• (11) Reset_Communication: This command triggers a reset of the communication

parameters in the object list.

• (12) Initialization complete – automatically changes to "pre-operational"

The CAN respective telegrams have the following structure:

NMT service COB ID Byte 1 Byte 2

Node_Start 0x0000 0x01 Node ID

Node_Stop 0x0000 0x02 Node ID

Enter_Pre-Operational_State 0x0000 0x80 Node ID

Reset_Node 0x0000 0x81 Node ID

Reset_Communication 0x0000 0x82 Node ID

In this case, node ID corresponds to the address set in the DIP switches (see Sec. "DIP

Switches"). In addition, the value "0" is permitted for the node ID here; in this case, all

CANopen devices are addressed.

NMT services are not confirmed by the slave.

Process data

exchange

16

Up to 8 inverters can be connected to the gateway. A maximum of 3 process words

(process output data items, PO for short) are sent from the UFO to each inverter and 3

process input words (PI for short) are sent from each inverter to the UFO. This means

the UFO is provided with a 24 word process data buffer (48 bytes) for the POs and a 24

word buffer for the PIs.

The buffer for the POs is located at index 15800 ... 15823 (subindex 0) and the buffer

for the PIs at index 15900 ... 15923 (subindex 0).

RX PDOs can be written to the PO buffer by the control. A maximum of 4 words can be

transmitted by each PDO in the CANopen profile. This means at least 6 RX PDOs are

necessary to transmit 24 process data items from the control to the UFO.

However, a maximum of 4 default RX PDOs are defined in CANopen DS301 V4.02. You

can assign the COB IDs of the PDOs dynamically from the control to avoid conflicts with

the COB IDs on the CANopen bus.

Manual – UFO11A Fieldbus Interface

Page 17

CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

In addition, it may be desirable under special circumstances for the 24 process data

items to be transmitted with mutual or partially mutual consistency. Consistent

transmission can be achieved using a SYNC telegram and by configuring the

corresponding RX PDOs to "SYNC" transmission mode.

It is possible to send process data subject to event control, which means only whenever

they have changed. This is done to reduce bus traffic and to avoid having to transmit 24

PDs cyclically.

Up to 8 RX PDOs are provided in the UFO to transmit the POs for each connected

inverter in a separate RX PDO. The length of an RX PDO can be adapted if only 1 PO

(control word) is sent to the inverter instead of 3 POs.

It goes without saying that the TX PDOs can be configured in the same way as the RX

PDOs described above.

4

Configuration of

the COB IDs

In its initializing status, the UFO defines the COB IDs according to the settings of the DIP

switches (see Sec. "DIP Switches").

If more than 4 PDOs are activated with the DIP switches, the UFO also uses the default

COB IDs of the CANopen slave address 64 + (own slave address).

If only slaves with addresses < 65 are connected to the CANopen bus, no bus conflicts

can occur, even when 8 RX and 8 TX PDOs are used. If the system contains slaves with

addresses > 64, an individual check must be made to see whether the COB IDs need to

be changed by the CANopen master.

The COB IDs should be changed in the pre-operational unit status (see Sec. "CANopen

Interface"). Although it is also possible to change the COB IDs in the operational status,

the CAN controller is temporarily separated from the bus. This means process data

losses may occur in the operational status.

The COB IDs for TX PDO1..8 can be changed using object 1800(hex) – 1807(hex),

subindex 1.

The COB IDs for RX PDO1..8 can be changed using object 1400(hex) – 1407(hex),

subindex 1. This is a 32-bit word. Its basic structure is explained in the tables "Structure

of the PDO COB ID entry" and "Description of the PDO COB ID entry."

Identifier range 0 ... 28 can only be changed if bit 31 is set at the same time (COB ID

invalid). New values are only accepted in the identifier range if they have an 11-bit ID

(i.e. bit 29 is never allowed to be set) and if the ID has not already been assigned to

another PDO or the emergency object (see Sec. "CANopen Interface" / "Emergency

object").

In TX PDOs, bit 30 (RTR not allowed) must always be 0 and it must always be set in RX

PDOs.

Manual – UFO11A Fieldbus Interface

17

Page 18

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure of the

PDO COB ID entry

Description of the

PDO COB ID entry

CANopen Interface

UNSIGNED32

MSB LSB

Bits 31 30 29 28 ... 11 10 ... 0

11-bit ID 0/1 0/1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 11-bit identifier

29-bit ID 0/1 0/1 1 29-bit identifier

Bits Value Meaning

31 (MSB 0 PDO exists / is valid

1 PDO does not exist / is not valid

30 0 RTR allowed in this PDO

1 RTR not allowed in this PDO

29 0 11-bit ID (CAN 2.0A)

1 29-bit ID (CAN 2.0B)

28 ... 11 0 If bit 29 = 0

X If bit 29 = 1: Bits 28 ... 11 of 29-bit COB ID

10 ... 0 (LSB) X Bits 10 ... 0 of COB ID

18

Manual – UFO11A Fieldbus Interface

Page 19

Changing the

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PDO length

CANopen Interface

4

Fig. 8: Standard division of the UFO process data buffer

In initializing status, the UFO specifies the mapping and the length of all TX and RX

PDOs as 3 process data items.

Manual – UFO11A Fieldbus Interface

05773AXX

19

Page 20

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

The number of process data items in the PDOs should be changed in the preoperational unit status (see Sec. "CANopen Interface"). Although it is also possible to

make such changes in the operational status, the CAN controller is temporarily

separated from the bus. This means process data losses may occur in the operational

status.

Fig. 8 shows the classic division of the process data buffer in the UFO following an

Autosetup (see Sec. "Installation and Operation without a PC" / "Autosetup"). The

number of process data items which are transmitted in a PDO and the number of

process data items which are transmitted to the corresponding inverter via the SBus are

completely independent of one another. When Autosetup is selected, 3 POs and 3 PIs

are always provided on the SBus for each connected inverter. The UFx Configurator

makes it possible to set other configurations (see Sec. "Using the Interface"). As a rule,

this configuration will enable 90 % of all applications to work satisfactorily.

Fig. 9 illustrates how a control word and the speed are transmitted in an RX PDO using

PDO1. In a second RX PDO, the ramp for the inverter with SBus address 2 is

transmitted. This method allows a reduced bus traffic if the ramp is to be transmitted

much less frequently than the control word and the setpoint speed.

Fig. 9: 2 PDOs for 1 MOVITRAC® 07

20

Manual – UFO11A Fieldbus Interface

05774AXX

Page 21

CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Fig. 10 shows a possible configuration in which only two or one process data items are

transmitted via the SBus rather than three. RX PDO1 was configured with two process

data items and RX PDO2 with one process data item to give a consistent and logical

assignment to PDOs.

4

Transmission

mode

TX PDO

Fig. 10: Consistent assignment of PDOs to the individual inverters

The number of process data items transferred with the individual PDOs is defined for RX

PDO1 ... 8 by object 1600(hex) ... 1607(hex), subindex 0 and for TX PDO1 ... 8 with

object 1A00(hex) ... 1A07(hex), subindex 0. Possible values are in the range 0 ... 4. 0

corresponds to a PDO which does not transmit any process data, 4 corresponds to a

PDO which transmits 4 process data items (8 bytes). The important peripheral condition

in this case is that the total of all process data transmitted in RX PDOs is not to exceed

24 and the total of all process data transmitted in the TX PDOs is not to exceed 24. The

mapping is automatically recalculated and defined by the UFO. The UFO always

assumes that RX PDO1 ... 8 are mapped in succession into the PO buffer and TX PDO1

... 8 are mapped in succession into the PI buffer.

It is possible to select from various transmission modes for each TX PDO and for each

RX PDO:

The transmission modes for TX PDO1 ... 8 can be changed using object 1800(hex) ...

1807(hex), subindex 2. This is an 8-bit value.

• Event-driven and synchronous (value 0): The corresponding TX PDO is always sent

following the next SYNC pulse whenever a process data item has changed.

05775AXX

Manual – UFO11A Fieldbus Interface

21

Page 22

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

• Cyclical and synchronous (value 1 ... 240): After every 1st ... 240th SYNC pulse

(depending on the value), the TX PDO is sent regardless of whether the content of

the TX PDOs has changed or not. Every PDO has transmission mode = 1 after

leaving initialized status.

• Proprietary (value 254): For this mode, the corresponding RX PDO must also be set

to transmission mode 254. The TX PDO is always sent whenever the corresponding

RX PDO is received. In this case, the process data takeover is completely

asynchronous, i.e. unrelated to the SYNC pulses. Example: RX PDO2 and TX PDO2

have transmission mode 254. A TX PDO2 is sent immediately after a valid RX PDO2

is received (valid means the length is not too short).

• Event-driven and asynchronous (value 255): Whenever a value of the TX PDO

changes, this is sent by the UFO. Warning: This setting results in very considerable

bus traffic if the TX PDO is used for sending speed, current, position or other rapidly

changing parameters. The inhibit time can be used for restricting the bus traffic

deterministically for such TX PDOs.

Transmission modes 241 ... 253 are reserved and cannot be selected.

See Sec. "CANopen Interface" / "SYNC object" for information about the SYNC pulse.

The default setting is 1 (synchronous on each SYNC pulse).

RX PDO

The transmission modes for RX PDO1 ... 8 can be changed using object 1400(hex) ...

1407(hex), subindex 2. This is an 8-bit value.

• Synchronous (value 0 ... 240): The data of the RX PDO are transferred into the PO

buffer of the UFO when the next SYNC pulse is received (it does not matter whether

the value is 0 or 240). This transmission process allows several PDOs to be sent from

the master to the UFO and then transferred into the PO buffer of the UFO using a

SYNC pulse at the same time and with mutual consistency.

• Proprietary (value 254): For this mode, the corresponding RX PDO must also be set

to transmission mode 254. The TX PDO is always sent whenever the corresponding

RX PDO is received. In this case, the process data takeover is completely

asynchronous, i.e. unrelated to the SYNC pulses. Example: RX PDO2 and TX PDO2

have transmission mode 254. A TX PDO2 is sent immediately after a valid RX PDO2

is received (valid means the length is not too short).

• Event-driven and asynchronous (value 255): Whenever an RX PDO arrives, it is

always accepted and passed on.

Transmission modes 241 ... 253 are reserved and cannot be selected.

See Sec. "CANopen Interface" / "SYNC object" for information about the SYNC pulse.

The default setting is 1 (synchronous on each SYNC pulse).

22

Manual – UFO11A Fieldbus Interface

Page 23

CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4

Inhibit time

4.2 SYNC object

Changing the

COB ID of the

SYNC object

Structure of the

SYNC COB ID

entry

The inhibit time is a blocking time for TX PDOs. The inhibit time for a TX PDO starts after

the object is sent. The object is not allowed to be sent again on the CANopen bus until

the inhibit time has elapsed. The inhibit time is entered in 0.0001 s, i.e. 10000

corresponds to 1 s. The maximum inhibit time is 6.5535 s.

The UFO processes inhibit times with a resolution of 1.0 ms, i.e. the value 15

(corresponding to an inhibit time of 1.5 ms) is treated as 2 ms.

The inhibit time cannot be changed unless the corresponding PDO is marked as

"invalid" (index 1800(hex) ... 1807(hex), subindex 1, bit 31 = 1, see Sec. "Configuration

of the COB IDs").

The SYNC object transfers process data of several PDOs into the UFO data buffer or

sends them in a mutually consistent way at a defined point in time. All PDOs to be

synchronized with the SYNC object have to be operated in transmission mode 0 ... 240.

If the transmission mode of a TX PDO is 4, the UFO sends this TX PDO after every 4th

SYNC pulse. The situation is different with RX PDOs: These accept the PDO data on

every SYNC pulse.

In initializing status, the UFO defines the COB ID of the SYNC object as 0080 hex.

The COB ID should be changed in the pre-operational unit status (see Sec. "CANopen

Interface"). Although it is also possible change the COB ID in the operational status, the

CAN controller is temporarily separated from the bus. This means process data losses

may occur in the operational status.

The UFO is only a SYNC consumer and only works with 11-bit COB IDs. Consequently,

bit 30 and bit 29 must always be 0. The structure of the COB ID and the meaning of the

individual bits are explained in the tables "Structure of the SYNC COB ID entry" and

"Description of the SYNC COB ID entry".

The COB ID is addressed as unsigned long via index 1005hex, subindex 0.

UNSIGNED32

MSB LSB

Bits 31 30 29 28 ... 11 10 ... 0

11-bit ID X 0/1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 11-bit identifier

29-bit ID X 0/1 1 29-bit identifier

Manual – UFO11A Fieldbus Interface

23

Page 24

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

Description of the

SYNC COB ID

entry

4.3 Emergency object

Bits Value Meaning

31 (MSB) X No influence

30 0 Unit does not generate SYNC message

29 0 11-bit ID (CAN 2.0A)

28 ... 11 0 If bit 29 = 0

10 ... 0 (LSB) X Bits 10 ... 0 of SYNC COB ID

1 Unit does generate SYNC message

1 29-bit ID (CAN 2.0B)

X If bit 29 = 1: Bits 28 ... 11 of 29-bit SYNC COB ID

The emergency object is always sent once by the UFO when a fault is detected and

once again when this fault is no longer present.

The UFO sends an EMCY object in response to the following faults:

• An inverter sets the error bit in its status word.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

10hex FFhex Error register

(object 1000hex)

0 Status word 1 of

the inverter, low

Status word 1 of

the inverter,

high

0 SBus addr. of

the inverter

• The UFO sets the error bit in its status word.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0 FFhex Error register

(object 1000hex)

0 Status word 1 of

the UFO, low

Status word 1 of

the UFO, high

0 SBus addr. of

the inverter

• The inverter is only running in 24 V backup mode, there is no voltage for the rotating

field.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0 31hex Error register

(object 1000hex)

0000SBus addr. of

• The CAN controller has lost telegrams from the CANopen bus because the receive

queue has overrun.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

24

10hex 81hex Error register

(object 1000hex)

00000

Manual – UFO11A Fieldbus Interface

the inverter

Page 25

COB ID of the

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

emergency object

Structure of the

identifier entry

EMCY

Description of the

SYNC COB ID

entry

CANopen Interface

• The CAN controller is in the error-passive status (see Sec. "LEDs" / "BUS-F LED").

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

20hex 81hex Error register

(object 1000hex)

• The CAN controller was in the bus off status (see Sec. "LEDs" / "BUS-F LED").

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

40hex 81hex Error register

(object 1000hex)

• The lifeguarding protocol was activated but not served within the timeout time.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

30hex 81hex Error register

Bits 31 30 29 28 ... 11 10 ... 0

11-bit ID 0/1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 11-bit identifier

29-bit ID 0/1 0 1 29-bit identifier

Bits Value Meaning

31 (MSB 0 EMCY exists / is valid

30 0 reserved (always 0)

29 0 11-bit ID (CAN 2.0A)

28 ... 11 0 If bit 29 = 0

10 ... 0 (LSB) X Bits 10 ... 0 of COB ID

(object 1000hex)

UNSIGNED32

MSB LSB

1 EMCY does not exist / is not valid

1 29-bit ID (CAN 2.0B)

X If bit 29 = 1: Bits 28 ... 11 of 29-bit COB ID

00000

00000

00000

4

Manual – UFO11A Fieldbus Interface

25

Page 26

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

In initializing status, the UFO defines the COB ID of the EMCY object as 0080hex +

slave address.

The COB ID should be changed in the pre-operational unit status (see Sec. "CANopen

Interface"). Although it is also possible to change the COB ID in the operational status,

the CAN controller is temporarily separated from the bus. This means process data

losses may occur in the operational status.

Bit 29 must always be 0 because the UFO only works with 11-bit COB IDs. The structure

of the COB ID and the meaning of the individual bits are explained in the tables

"Structure of the EMCY identifier entry" and "Description of the EMCY COB ID entry".

If the UFO is not to send any EMCY object, the EMCY object can be deactivated by

setting bit 31 to 1.

The COB ID is addressed as unsigned long via index 1014hex, subindex 0.

Inhibit time of the

EMCY object

The inhibit time of the emergency object on the CANopen bus is specified as

unsigned16 (2 bytes) via index 1015hex, subindex 0. This value is 0 when the UFO exits

initialized status, i.e. there is no inhibit time.

The inhibit time is defined as a multiple of 0.0001 s, i.e. the value 3000 corresponds to

an inhibit time of 300 ms.

4.4 Guarding and heartbeat

Lifetime

The UFO supports two kinds of timeout monitoring (nodeguarding). First, the network

master can check whether the individual nodes are still ready to operate. To do this, a

nodeguarding object with RTR bit set must be sent to the nodes (example for node ID

"3"):

If the node is ready, it responds with a corresponding nodeguarding object which returns

the current readiness status and a toggle bit:

The toggle bit changes between 0 and 1 with every telegram. The network master can

use the response to determine whether the CANopen participants are still in their

original status or whether the status has changed due to a fault.

In initializing status, the UFO defines the COB ID for nodeguarding as 0700hex +

CANopen address.

In the second type of lifeguarding, the CANopen slaves check their NMT master. It is

possible to set a timeout time for this in milliseconds using the indices 0x100C ("guard

time") and 0x100D ("lifetime factor"). This timeout time is calculated as the product of

lifetime factor and guard time. Timeout times shorter than 5 ms are rejected. The second

type of nodeguarding is only active if a timeout time other than 0 is set (i.e. lifetime factor

0 and guard time 0). All process data words in the UFO are set to zero if no node event

is triggered by the master within the timeout time.

26

Manual – UFO11A Fieldbus Interface

Page 27

CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Refer to the appropriate operating instructions to see how the inverters connected to the

UFO via the SBus react to zero value setpoints and control words. Also, an

EMERGENCY object is placed on the CAN bus.

The GUARD LED lights up with a steady light to indicate that nodeguarding has been

activated.

The timeout time set by the control can be read out from P819 using the diagnostic

interface and MOVITOOLS. However, it is not to be changed using MOVITOOLS, but

instead only by the control using CANopen objects 0x100C and 0x100D:

Nodeguarding is active in all operating states from the first time a node is received from

the master.

4

Heartbeat

The UFO is a heartbeat producer. The time interval in which heartbeats are produced

can be set using index 1017hex, subindex 0 by means of an unsigned16 value. This

value corresponds to the heartbeat in ms, i.e. 3000 means that a heartbeat is sent every

3 s. The default value after exiting initialized status is 0, i.e. the heartbeat is deactivated.

If the guarding protocol is active, simultaneous use of the heartbeat protocol is not

allowed.

The UFO can monitor another heartbeat producer at the same time. An unsigned32

value in index 1016hex, subindex 1 sets the node to be monitored and the monitoring

time.

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x600 +

NodeID =

0x603

ID for SDO Expedited

0x423 0x16 0x10 0x01 Time in ms 0x01 –

Index

Index

Sub-

upload

low

high

index

Time low Time

high

0x7F

Nodes Re-

0x00

served

The monitoring time must have a larger value than the time interval set for the heartbeat

on the monitored node. If the heartbeat protocol is active then simultaneous use of the

lifetime mechanism is not allowed.

Manual – UFO11A Fieldbus Interface

27

Page 28

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen Interface

4.5 Parameter access via SDOs

SDOs and their

services

Example: "Device

type" read access

SDOs (service data objects) are used for setting parameters and reading out the

configuration. These SDOs are capable of transmitting large volumes of data, but they

are relatively slow. The following services can be applied to the SDOs in order to send

SDOs from or to the UFO:

• Multiplexed download domain (write access)

• Initiate domain download protocol

• Multiplexed upload domain (read access)

• Initiate domain upload pro tocol

• Abort domain transfer (for any protocol errors that may occur)

The

normal transfer

others are uploaded using the

The response time to a download or upload is not specified and also depends on the

system load, i.e. the bus traffic and the number of incoming PDOs.

Refer to Sec. "Object List" and the MOVIDRIVE

parameters, their indices and subindices.

In this example, a read access is made to the "Device type" entry in the unit with

CANopen address = 3 set on the DIP switches:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x600 +

NodeID =

0x603

ID for SDO Expedited

The control must send an "initiate multiplexed upload domain" protocol for read access.

This protocol provides for all CAN telegrams being 8 bytes long.

The option card responds with:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x580 +

NodeID =

0x583

ID for SDO Expedited

1) This value only applies to the printed telegram. This value may change depending on the data type in the

case of other indices, see CANopen DS301.

• Expedited transfer

• Normal transfer (data block length > 4 bytes)

• Expedited transfer

• Normal transfer (data block length > 4 bytes)

is only implemented for uploading objects 0x1008 – 0x100A; all

expedited transfer

0x40 0x00 0x10 0x00 0x00 0x00 0x00 0x00

upload

0x43

upload

Index low Index high Subindex Value unimportant

1)

0x00 0x10 0x00 0x2D 0x01 0x00 0x00

Index

Index

low

high

because they are 4 bytes long at most.

®

Fieldbus Unit Profile for the

Sub-

Re-

Re-

index

sponse

low

sponse

Response

Response

high

28

Manual – UFO11A Fieldbus Interface

Page 29

CANopen Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4

Example: Write

access

Incorrect

performance of

service

A similar example is the write access to index 0x100C, subindex 0x00 (guard time). This

entry is set to the value 10000 ms (0x2710)

The control sends an "expedited download" request first:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x600 +

NodeID =

0x603

ID for SDO Expedited

1) This value only applies to the printed telegram. This value may change depending on the data type in the

case of other indices, see CANopen DS301.

1)

0x2B

download

0x0C 0x10 0x00 0x10 0x27 0x00 0x00

Index

Index

Sub-

Val ue

low

high

index

low

Val ue

high

Filler

byte

Filler

byte

The CANopen option card responds if implementation was successful (the CANopen

option card checks the index, subindex, write permission, data type and, if necessary,

whether the sent value is permitted):

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x580 +

NodeID =

0x583

ID for SDO Expedited

1) This value only applies to the printed telegram. This value may change depending on the data type in the

case of other indices, see CANopen DS301.

1)

0x60

download

0x00 0x10 0x00 0x00 0x00 0x00 0x00

Index

Index

Sub-

low

high

index

Value unimportant

The DFO11A sends an abort telegram in case of a fault. The abort telegram contains an

error code which describes the cause of the fault.

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x580 +

NodeID =

0x583

ID for SDO SDO abort Index

0x80 0x00 0x10 0x00

Index

high

Subindex

low

Add.

code low

Add. code

high

Error

code

Error

class

SEW-specific fault codes are described in [Inverter parameter settings] / [Return codes

for parameterization] of the MOVIDRIVE

®

Fieldbus Unit Profile. All other fault codes are

specified in the CANopen Communication Profile DS301, Sec. 9.2.2.

Access to SEW

unit parameters

The UFO parameters can be accessed using parameter access (from index 206Chex)

with subindex 0. The parameters of the inverters connected via the SBus can be

accessed using parameter access (from index 206Chex) with subindex ≠ 0. In this case,

the subindex should be set to the same value as the SBus address of the connected

inverter.

Example: Access index 8300, subindex 0 to read the software version of the UFO.

Access index 8300, subindex 2 to read the software version of the top MOVITRAC

in Fig. 8.

Manual – UFO11A Fieldbus Interface

®

07

29

Page 30

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Error Response

5 Error Response

5.1 Fieldbus timeout

5.2 SBus timeout

5.3 Unit errors

In case the the timeout monitoring has been set and activated for the CANopen fieldbus,

switching off the fieldbus master or a wire break in the fieldbus cabling leads to a fieldbus

timeout in the UFO. The connected drive inverters are set to a safe status by zeros being

sent on the process output data. This corresponds to a rapid stop on control word 1. The

fieldbus timeout error is self-resetting, meaning the drive inverters will begin receiving

the current process output data from the master immediately after fieldbus communication is re-established. This error response can be deactivated using P831 on the UFO.

If one or more inverters on the Sbus can no longer be addressed by the UFO, the UFO

enters error code 91, "System error," in status word 1 of the corresponding drive inverter. The SYS-F LED lights up and the error is also displayed via the diagnostic interface.

P815 SBus timeout delay must be set to a value other than 0 on the drive inverter if it is

to stop. The error is self-resetting on the UFO, meaning the current process data are exchanged again immediately after communication resumes.

UFO fieldbus interfaces detect a range of hardware defects and respond with an inhibit

condition. Refer to the list of errors for the exact error responses and measures to remedy the problem. A hardware defect means error 91 is entered in the process input data

of the fieldbus in status word 1 of all drive inverters. The SYS-F LED on the UFO then

flashes evenly. The exact error code is displayed in the status of the UFO using the diagnostic interface of MOVITOOLS.

30

Manual – UFO11A Fieldbus Interface

Page 31

6LEDs

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.1 COMM LED

6.2 GUARD LED

LEDs

The UFO CANopen interface has 6 diagnostic LEDs:

• "COMM" LED (green) for displaying module communication

• "LIFE" LED (green/red) for displaying the fieldbus timeouts

• "STATE" LED (green) for displaying the UFO module status

• "BUS-F" LED (red) for displaying bus faults

• "SYS-F" LED (red) for displaying system faults and operating conditions of the UFO

• "USER" LED (green) for application-specific diagnostics in expert mode

The COMM LED always flashes briefly whenever the UFO has sent a telegram or when

the UFO receives a telegram addressed to the UFO.

The GUARD LED displays the status of CANopen lifetime monitoring.

LED Meaning

Off CANopen timeout monitoring not activat ed for the UFO (object 0x100C = 0 and/or

On CANopen timeout monitoring activated for the UFO (object 0x100C0 and object

Flashes green

(1 s cycle)

object 0x100D=0). This is the default setting after switching on the unit.

0x100D0).

No more lifetime requests have been received by the CANopen master. The UFO is in

"fieldbus timeout" status.

6

6.3 STATE LED

The STATE LED displays the current NMT status of the UFO. The UFO supports

minimum boot up, i.e. the states "pre-operational", "operational" and "stopped" exist.

Status LED Meaning

Pre-operational Flashes

Operational On PDOs, SDOs and NMT services are processed.

Stopped Off The unit ignores all SDOs and PDOs. Only NMT telegrams are still

Manual – UFO11A Fieldbus Interface

(1 s cycle)

Only the unit parameters can be set (with SDOs); process data

(PDOs) are ignored. This status is adopted after switching on the

unit.

processed.

31

Page 32

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.4 BUS-F LED

6.5 SYS-F LED

LEDs

The BUS-F LED displays the physical status of the bus node.

Status LED Meaning

Error-active state Off The number of bus faults is in the normal range.

Error-passive state Flashes red

BusOff state Red The number of physical bus faults has continued to grow

(1 s cycle)

The number of physical bus faults is too high. No more error

telegrams are actively written to the bus.

despite the switch to the error-passive state. Access to the bus

is deactivated.

This fault can only be reset by a power-on reset.

6.6 USER LED

OFF Normal operating status. The UFO is exchanging data with the connected

FLASHES 1 x briefly

followed by a long

pause

FLASHES evenly The UFO is in fault status. If you started up the UFO using the Autosetup DIP

ON The UFO is not exchanging data with the connected inverters. Either it has not

inverters. Pre-requisite: The "STATE" LED must be on.

Autosetup has been selected using the DIP switch and the UFO is currently setting

up its configuration. Please switch Autosetup off and on again if this status

continues for longer than 1 minute. Replace the module if Autosetup does not

finish several times in a row.

switch, please switch the UFO off and on again. If the LED is still on, please restart

Autosetup by switching the DIP switch off and on again.

If you started up the UFO using MOVITOOLS, a fault message will be displayed in

the status window. Please refer to the appropriate fault description.

been configured or the connected inverters are not responding. Reconfigure the

UFO.

If you started up the UFO using Autosetup, please switch the Autosetup DIP

switch off and on again. If the LED stays on after Autosetup, please check the

cabling and the terminating resistors of the SBus as well as the inverter voltage

supply.

If you started up the UFO using MOVITOOLS, please click the "Update" button in

the Movitools Manager. All the inverters should be displayed in the "Connected

Inverters" window. If this is not the case, please check the cabling and the

terminating resistors of the SBus as well as the inverter voltage supply.

Reconfigure the UFO with MOVITOOLS if necessary.

Normal operating status; Off. The "USER" LED is reserved for expert mode.

32

Manual – UFO11A Fieldbus Interface

Page 33

7 DIP Switches

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DIP Switches

7

Fig. 11: DIP switches (factory setting)

The factory setting shown in Fig. 11 amounts to the following configuration:

• Baud rate 500 kbaud

• Slave ID 63

• 12 PD (corresponds to 4 default PDOs)

• Autosetup off

7.1 CANopen address

The CANopen address (NodeID) is set using DIP switches ID0 ... ID5. If a DIP switch is

"on," its value is 1; if it is "off," its value is 0.

The following formula applies:

CANopen address = ID0 + ID1 * 2 + ID2 * 4 + ID3 * 8 + ID4 * 16 + ID5 * 32

Example

For address 27, ID 5 must be off, ID4 on, ID3 on, ID2 off, ID1 on and ID0 on

Important! CANopen address 0 is not permitted. If ID0 ... ID5 are "off", this amounts to

an invalid CANopen configuration and the UFO cannot communicate via CANopen. This

is indicated by the STATE and GUARD LEDs flashing simultaneously when the UFO is

switched on.

05776AXX

Manual – UFO11A Fieldbus Interface

33

Page 34

7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DIP Switches

7.2 Baud rate of the CANopen bus

The baud rate is set using DIP switches DR0 and DR1.

125 kbaud Off Off

250 kbaud On Off

500 kbaud Off On

1 Mbaud On On

DR0 DR1

7.3 Number of process data items to be transmitted via the CANopen bus

You can use PD0 ... PD4 to determine how many PDOs the UFO makes available after

it exits the initializing status. Naturally, this PDO configuration can be overwritten by the

CANopen master.

The following table shows the length of the PDOs (in words, i.e. 2 bytes/word)

depending on the setting of the DIP switches. Here, PDO refers to both RX and TX

PDOs. "NA" stands for "not active", i.e. the COB ID of this PDO is still available for the

remainder of the CANopen system.

If a DIP switch is "on," its value is 1; if it is "off," its value is 0. The following formula

applies:

Number of PDs = PD0 + PD1 * 2 + PD2 * 4 + PD3 * 8 + PD4 * 16

If the number of PDs > 24 then the number of PDs is assumed to be 24.

No. of

PDO1 PDO2 PDO3 PDO4 PDO5 PDO6 PDO7 PDO8

PDs

0 NANANANANANA NANA

1 1 NANANANANANANA

2 2 NANANANANANANA

3 3 NANANANANANANA

431NANANANANANA

532NANANANANANA

633NANANANANANA

7331NANANANANA

8332NANANANANA

9333NANANANANA

103331NANANANA

113332NANANANA

123333NANANANA

1333331NANANA

1433332NANANA

1533333NANANA

16333331NANA

17333332NANA

18333333NANA

193333331NA

203333332NA

213333333NA

2233333331

2333333332

2433333333

34

Manual – UFO11A Fieldbus Interface

Page 35

The COB IDs occupied by the active PDOs are listed in the following tables. The

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CANopen address must be added to the COB IDs in the tables.

COB ID 200hex 300hex 400hex 500hex 240hex 340hex 440hex 540hex

COB ID 180hex 280hex 380hex 480hex 1C0hex 2C0hex 3C0hex 4C0hex

Important: If RX PDO 5 ... 8 or TX PDO 5 ... 8 are used, there must not be a participant

in the CANopen network with a node number equal to the node number of the UFO + 64.

7.4 Autosetup

The AS DIP switch activates Autosetup (see Sec. "Installation and Operation without a

PC" / "Autosetup") when it is switched from 0 to 1.

7.5 DIP switch F1

Currently, DIP switch F1 does not have a function assigned to it.

DIP Switches

RXPDO1 RXPDO2 RXPDO3 RXPDO4 RXPDO5 RXPDO6 RXPDO7 RXPDO8

TXPDO1 TXPDO2 TXPDO3 TXPDO4 TXPDO5 TXPDO6 TXPDO7 TXPDO8

7

Manual – UFO11A Fieldbus Interface

35

Page 36

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Using the Interface

8 Using the Interface

How to get online

Project planning /

startup

Example

Following the "Update" function in the MOVITOOLS Manager, all participants detected

on the system bus – inverters and gateways – are displayed. The gateway gives users

access to Status, Shell, Assembler and Compiler at all connected inverters.

MT Gateway supports project planning and startup of a UFO fieldbus node.

The bus configuration can either be planned offline or downloaded from the UFO online

and edited.

Before starting an MT Gateway session, it is a good idea to check that the

hardware Autosetup is switched off (DIP switch 8 set to off).

Before startup, make sure that there is no risk of injury to people or damage to

property if a bus error does occur (on the fieldbus or system bus).

Two modes are available for project planning/startup.

Autoconfiguration mode operates similarly to the hardware Autosetup. It works through

the participants one after the other starting from the lowest system bus address and

assigns 3 process output data items and 3 process input data items to each participant.

Autoconfiguration: 3 participants with addresses 10, 11 and 12 => 9 PDs

Fig. 12: Example of autoconfiguration

Process data assignment can be freely configured in expert mode ("Extras" menu).

Assignment is graphical to some extent (drag & drop).

36

Manual – UFO11A Fieldbus Interface

05037AEN

Page 37

Using the Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

8

Example

Participant 10, PO1 is configured

Fig. 13: Participant 10, PO1 is configured

Packing/bundling the process output data can look like this: PO1 ... PO3 are received

by all 3 participants (e.g. control word 1, speed setpoint, ramp).

The master receives 1 PD from each inverter as process input data (e.g. control word

2). Compared to Autosetup, this saves 6 process output words and 6 process input data

words in the master.

Avoid multiple assignment of process input data since it makes no sense.

05038AEN

Fig. 14: Multiple assignment

A CANopen telegram can contain up to 4 process data words (PO or PI). Consequently,

also pay attention to the assignment of individual telegrams during configuration. As a

result, PO1, PO2 and PO3 are transferred in one telegram in the Autosetup and PO4,

PO5 and PO6 in a second one.

Manual – UFO11A Fieldbus Interface

05039AXX

37

Page 38

9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Object List

9 Object List

Index Subindex Function Data type Default Access

0x1000 0 device type UNSIGNED32 0 ro

0x1001 0 error register UNSIGNED8 - ro

0x1002 0 manufacturer status register UNSIGNED32 - ro

0x1004 0 Number of PDOs supported UNSIGNED32 (See Sec. 7.3) ro

0x1005 0 Sync COB ID UNSIGNED32 0x80 rw

0x1008 0 manufacturer device name VISI.STRING UFO11A ro

0x1009 0 manufacturer hardware version VISI.STRING 8237328.XX ro

0x100A 0 manufacturer software version VISI.STRING 8243727.XX ro

0x100B 0 node ID UNSIGNED32 (See Sec. 7.1) ro

0x100C 0 guard time UNSIGNED16 0 rw

0x100D 0 lifetime factor UNSIGNED8 0 rw

0x100E 0 COB ID nodeguarding UNSIGNED32 = 0x700+NodeId ro

0x100F 0 number of SDOs supported UNSIGNED32 1 ro

0x1014 0 Emergency COB ID UNSIGNED32 = 0x080+NodeId rw

0x1015 0 Emergency inhibit time UNSIGNED16 0 rw

0x1016 0 Consumer heartbeat time UNSIGNED8 0 ro

0x1017 0 Heartbeat producer time UNSIGNED16 0 rw

0x1018 0 Identity object length UNSIGNED8 1 ro

0x1200 0 SDO server parameter UNSIGNED8 2 ro

0x1400 0 RX PDO1 communication parameter UNSIGNED8 2 ro

0x1401 0 RX PDO2 communication parameter UNSIGNED8 2 ro

0x1402 0 RX PDO3 communication parameter UNSIGNED8 2 ro

0x1403 0 RX PDO4 communication parameter UNSIGNED8 2 ro

0x1404 0 RX PDO5 communication parameter UNSIGNED8 2 ro

0x1405 0 RX PDO6 communication parameter UNSIGNED8 2 ro

0x1406 0 RX PDO7 communication parameter UNSIGNED8 2 ro

0x1407 0 RX PDO8 communication parameter UNSIGNED8 2 ro

1 Number of syn. PDOs supported UNSIGNED32 (See Sec. 4.1) ro

2 Number of asy. PDOs supported UNSIGNED32 ( --- " --- ) ro

1 Node ID + heartbeat time UNSIGNED32 0 rw

1 Identity UNSIGNED32 0x59 ro

1 COB ID client->server (RxSDO) UNSIGNED32 = 0x600+NodeId ro

2 COB ID server->client (TxSDO) UNSIGNED32 = 0x580+NodeId ro

1 COB ID UNSIGNED32 (See Sec. 7.3) rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

38

Manual – UFO11A Fieldbus Interface

Page 39

Object List

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Index Subindex Function Data type Default Access

0x1600 0 RX PDO1 mapping parameter UNSIGNED8 (See Sec. 4.1) rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1601 0 RX PDO2 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1602 0 RX PDO2 mapping parameter UNSIGNED8 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1603 0 RX PDO3 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1604 0 RX PDO4 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1605 0 RX PDO5 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1606 0 RX PDO6 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1607 0 RX PDO7 mapping parameter UNSIGNED8 - rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

0x1800 0 TX PDO1 communication parameter UNSIGNED8 3 ro

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

0x1801 0 TX PDO2 communication parameter UNSIGNED8 3 ro

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

0x1802 0 TX PDO3 communication parameter UNSIGNED8 3 ro

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

9

Manual – UFO11A Fieldbus Interface

39

Page 40

9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Index Subindex Function Data type Default Access

0x1803 0 TX PDO4 communication parameter UNSIGNED8 3 ro

0x1804 0 TX PDO5 communication parameter UNSIGNED8 3 ro

0x1805 0 TX PDO6 communication parameter UNSIGNED8 3 ro

0x1806 0 TX PDO7 communication parameter UNSIGNED8 3 ro

0x1807 0 TX PDO8 communication parameter UNSIGNED8 3 ro

0x1A00 0 TX PDO1 mapping parameter UNSIGNED8 - rw

0x1A01 0 TX PDO2 mapping parameter UNSIGNED8 - rw

0x1A02 0 TX PDO3 mapping parameter UNSIGNED8 - rw

0x1A03 0 TX PDO4 mapping parameter UNSIGNED8 - rw

0x1A04 0 TX PDO5 mapping parameter UNSIGNED8 - rw

0x1A05 0 TX PDO6 mapping parameter UNSIGNED8 - rw

0x1A06 0 TX PDO7 mapping parameter UNSIGNED8 - rw

Object List

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

1 COB ID UNSIGNED3 2 - rw

2 transmission type UNSIGNED8 1 rw

3 inhibit time UNSIGNED16 0 rw

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

1 first mapped object UNSIGNED32 - ro

2 second mapped object UNSIGNED32 - ro

3 third mapped object UNSIGNED32 - ro

4 fourth mapped object UNSIGNED32 - ro

40

Manual – UFO11A Fieldbus Interface

Page 41

Object List

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Index Subindex Function Data type Default Access

0x1A07 0 TX PDO8 mapping parameter UNSIGNED8 - rw

0x206c ...

0x5fff

0x3db8 0 PO data buffer, word 0 UNSIGNED32 0 ro

0x3db9 0 PO data buffer, word 1 UNSIGNED32 0 ro

0x3dba 0 PO data buffer, word 2 UNSIGNED32 0 ro