Page 1

INTERBUS UFI11A Fieldbus Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Edition

06/2002

Manual

1052 5114 / EN

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

1 Overview of the System.................................................................................... 4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Unit Structure ....................................................................................................5

2.1 Front view ................................................................................................. 5

3 Installation and Operation with Autosetup.....................................................6

3.1 Installation notes ....................................................................................... 6

3.2 Setting the inverter parameters............................................................... 10

3.3 Autosetup................................................................................................ 10

3.4 Configuring the fieldbus master .............................................................. 11

3.5 Starting the inverters............................................................................... 12

4 Installation and Operation with a PC............................................................. 13

4.1 Installation notes ..................................................................................... 13

4.2 PC connection......................................................................................... 17

4.3 Setting the inverter parameters............................................................... 17

4.4 Startup software...................................................................................... 17

4.5 Configuring the fieldbus master .............................................................. 18

4.6 Starting the inverters............................................................................... 19

5 INTERBUS Interface........................................................................................20

5.1 Startup of the INTERBUS master ........................................................... 20

5.2 Configuring the INTERBUS interface...................................................... 28

5.3 Examples of DIP switch settings for process data and

PCP communication in Autosetup mode................................................. 31

5.4 Control via INTERBUS............................................................................ 34

5.5 PCP interface.......................................................................................... 35

5.6 Return codes for parameter setting......................................................... 44

5.7 Autosetup................................................................................................ 46

6 Error Response ...............................................................................................48

6.1 Fieldbus timeout...................................................................................... 48

6.2 SBus timeout........................................................................................... 48

6.3 Unit errors ............................................................................................... 48

7 Diagnostic LEDs.............................................................................................. 49

7.1 States of the LEDs UL, RC, BA, TR and RD........................................... 49

8 DIP Switches.................................................................................................... 51

9 Application examples .....................................................................................52

9.1 Control via process data ......................................................................... 52

9.2 Parameter setting via the PCP interface................................................. 52

9.3 Representation of the coding examples.................................................. 53

9.4 Sequence of a parameter setting process .............................................. 53

9.5 Reading of an UFI parameter.................................................................. 54

9.6 Writing of UFI11A or drive parameters via object 8288 .......................... 55

9.7 Reading of UFI11A or drive parameters via object 8288 ........................ 56

10 Parameter List ................................................................................................. 58

11 List of Errors....................................................................................................59

12 Technical Data................................................................................................. 61

13 Dimensions...................................................................................................... 62

14 Index................................................................................................................. 63

Manual – Fieldbus Interface INTERBUS UFI11A

3

Page 4

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Overview of the System

1 Overview of the System

The UFI11A INTERBUS fieldbus interface serves as a gateway for connecting one or

more MOVIDRIVE, MOVIDRIVEcompact or MOVITRAC 07 inverters to INTERBUS. Several inverters can be connected to the INTERBUS UFI11A interface via the SBus. The

INTERBUS UFI11A interface provides the translation between the INTERBUS and the

SBus.

Copying data

4

Fig. 1: Overview of the system: INTERBUS master – UFI11A – inverter

The UFI11A settings can be copied with the UBP11A parameter module from UFI11A

to UFI11A. For safety reasons, all inverters connected to the UFI11A must be turned off

when writing data.

Manual – Fieldbus Interface INTERBUS UFI11A

05373AXX

Page 5

2Unit Structure

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.1 Front view

Unit Structure

2

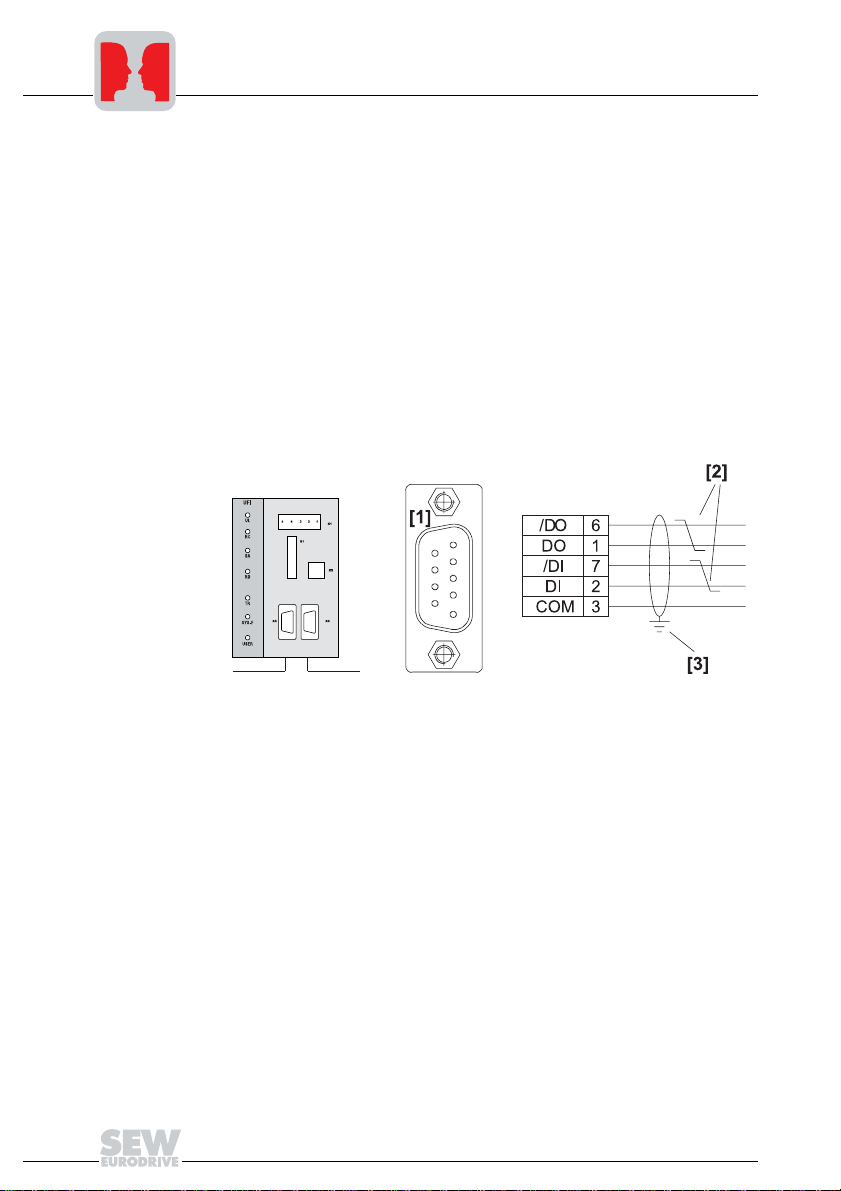

Fig. 2: Arrangement of LEDs, connectors and DIP switches

X1 SBus and 24 V connection

X2 Diagnostic interface

X3 INTERBUS remote in (incoming remote bus)

X4 INTERBUS remote out (outgoing remote bus)

S1 DIP switches

UL Logic voltage

RC Incoming remote bus OK

BA Bus mode active

RD Outgoing remote bus switched off

TR Parameter data exchange via PCP channel

SYS-F System fault

USER Expert mode

Manual – Fieldbus Interface INTERBUS UFI11A

05405AXX

5

Page 6

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with Autosetup

3 Installation and Operation with Autosetup

3.1 Installation notes

Mounting

Pin assignment

The unit can be mounted using the integrated DIN rail mounting option or directly onto

a switch cabinet wall using the four holes integrated into the back wall of the housing. In

the latter case, the two retaining screws for the DIN rail mounting must be removed.

Basically, there are no restrictions regarding positioning in relation to the inverters to be

connected (e.g. MOVITRAC

length and the fact that the UFI11A must be the first or last node on the system bus

(SBus).

The UFI11A must have additional HF-compliant grounding if the DIN rail mounting option is used in conjunction with SBus cables more than 1 m in length.

The UFI11A fieldbus interface is equipped with a 9-pin sub D male connector for the incoming bus signal and a 9-pin sub D female connector for the outgoing bus signal according to EN 50170.

®

07). In laying out the system, consider the maximum cable

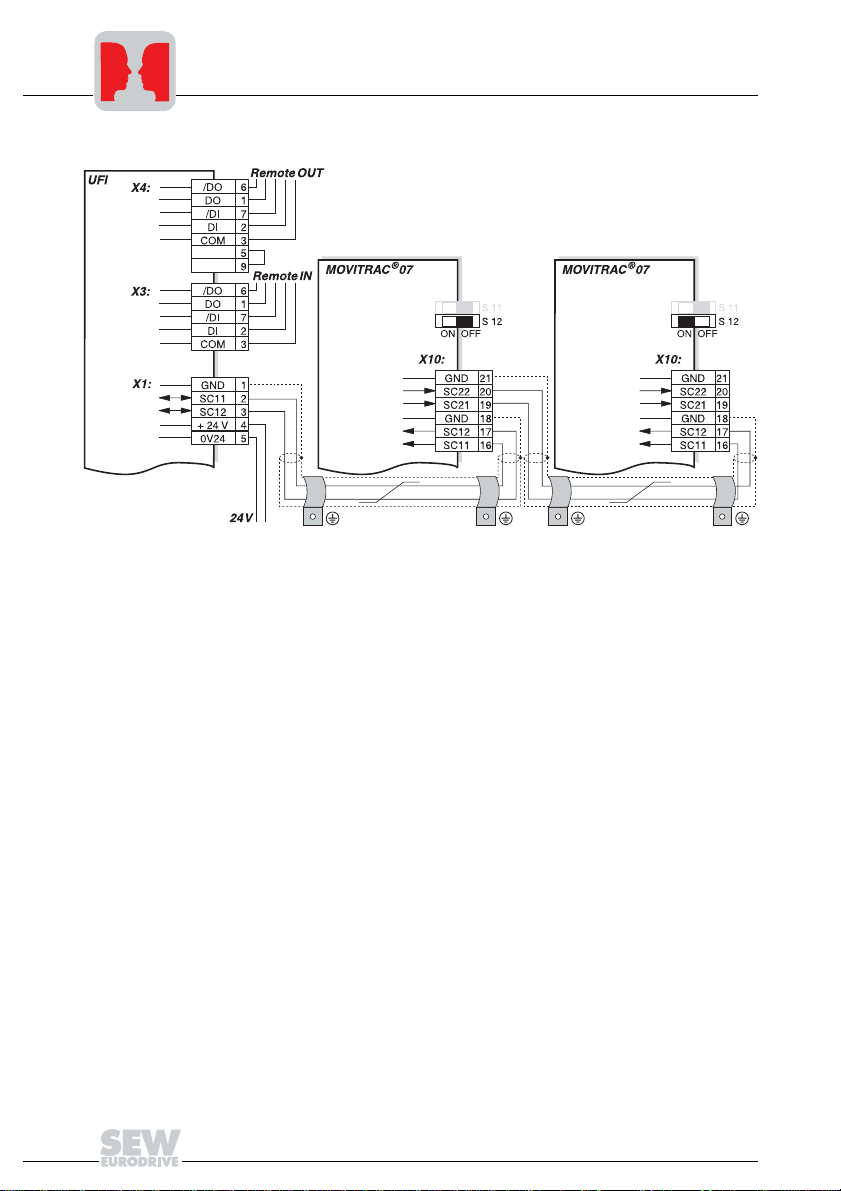

Fig. 3: Pinout of the 9-pin sub D male connector X3 to EN 50170 ([1] = 9-pin sub D male

connector; [2] = Signal lines twisted pair; [3] = Conductive connection between the

connector housing and the shield)

6

Manual – Fieldbus Interface INTERBUS UFI11A

05406AXX

Page 7

Installation and Operation with Autosetup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3

Fig. 4: Pinout of the 9-pin sub D female connector X4 to EN 50170 ([1] = 9-pin sub D female

connector; [2] = Signal lines twisted pair; [3] = Conductive connection between the

connector housing and the shield; [4] = Jumper)

As a rule, the fieldbus interface is connected to the INTERBUS system using a twisted,

shielded cable. The shield of the INTERBUS cable must be connected on both ends, for

example on the plug housing. Note the maximum supported transmission rate when you

are selecting the bus connector.

The cable is connected to the INTERBUS plug using pins 6 and 1 (/DO and DO) and

pins 7 and 2 (/DI and DI). Communication takes place via these contacts. The RS-485

signals /DO and DO as well as /DI and DI must have the same contacts on all INTERBUS stations. Otherwise, communication via the bus will not function.

05374AXX

Manual – Fieldbus Interface INTERBUS UFI11A

7

Page 8

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with Autosetup

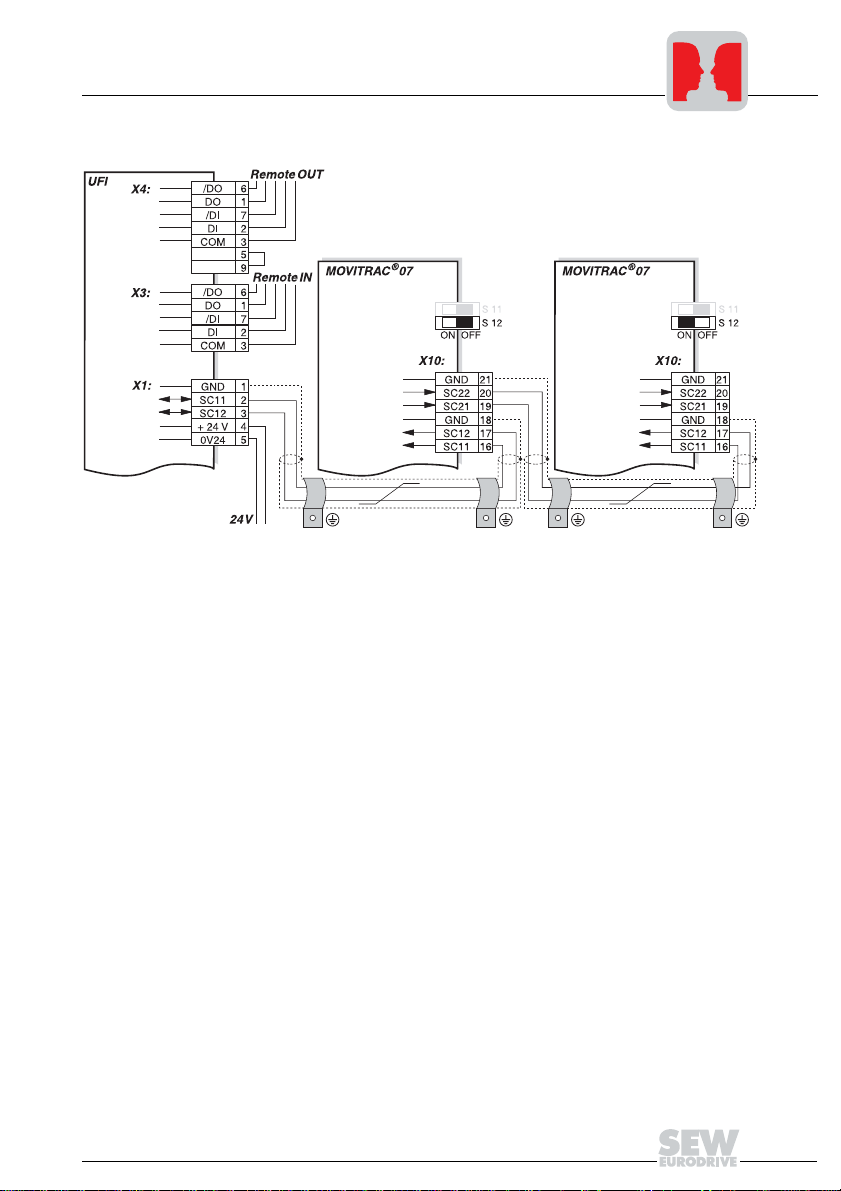

Connection

Fig. 5: System bus connection

UFI11A

COM = RS-485 reference

/DO = Data out inverted

DO = Data out

/DI = Data in inverted

DI = Data in

GND = System bus reference

SC11 = System bus high

SC12 = System bus low

Notes on SBus configuration:

• Use a twisted and shielded copper cable (data transmission cable with braided cop-

• The permitted total cable length depends on the baud rate setting of the SBus:

05375AXX

MOVITRAC® 07

GND = System bus reference

SC22 = System bus outgoing low

SC21 = System bus outgoing high

SC12 = System bus incoming low

SC11 = System bus incoming high

S12 = System bus terminating resistor

per shield). Connect the shield at both ends to the electronics shield clamp of MOVI-

®

07 or the UFI11A and ensure a large area of contact between the shield and

TRAC

clamp. Also connect the ends of the shield to GND. The cable must meet the following specifications (CAN bus or DeviceNet cables are suitable, for example):

2

–Conductor cross section 0.75 mm

(AWG18)

–Cable resistance 120 Ω at 1 MHz

–Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

–250 kbaud: 160 m (528 ft)

–500 kbaud: 80 m (264 ft)

–1000 kbaud: 40 m (132 ft)

8

Manual – Fieldbus Interface INTERBUS UFI11A

Page 9

Installation and Operation with Autosetup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

• Switch on the system bus terminating resistor (S1 2 = ON) of the node end of the system bus. Switch off the terminating resistor on the other units (S12 = OFF). The

UFI11A fieldbus interface must always be the first or last node on the system bus. It

has an integrated terminating resistor.

• There must not be any potential difference between the units connected to the SBus.

Take suitable measures such as connecting each unit’s ground lug to a central

grounding point in the cabinet to avoid potential differences.

• Point-to-point cabling is not permitted.

3

24 V connection

Shielding and

routing of the bus

cables

An external 24 VDC voltage supply must be connected to terminals X1:4 and X1:5.

The voltage range for the 24 VDC voltage supply is 18 – 30 V. The current consumption

of the UFI11A fieldbus interface is 300 mA.

The INTERBUS interface supports RS-485 transmission technology and requires the

cable type specified as the physical medium for INTERBUS. This cable must be a shielded, twisted-pair cable with 3 x 2 cores.

Having the bus cable correctly shielded eliminates parasitic interference which can occur in an industrial environment. The following measures ensure the best possible shielding:

• Finter-tighten the retaining screws of plugs, modules and equipotential bonding conductors.

• Use only connectors with a metal housing or a metallized housing.

• Maximize the contact area between the shield and the connector housing.

• Shield the bus cable on both ends.

• Do not route the signal and bus cables in parallel with the power cables (motor

leads); use separate cable ducts if possible.

• Only use grounded-metal cable trays in industrial environments.

• Join the signal cables and the associated equipotential bonding together at closely

spaced intervals by the shortest route.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely adjacent to available grounding surfaces.

In the event of fluctuations in the ground potential, a compensating current may flow

along the shield which is connected at both ends and to the ground potential (PE). In this

case, make adequate provision for equipotential bonding in accordance with the relevant VDE regulations.

Manual – Fieldbus Interface INTERBUS UFI11A

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with Autosetup

3.2 Setting the inverter parameters

The settings can be entered using the inverter control panel. Refer to the inverter operating instructions for more information.

• Switch on the voltage supply for the UFI11A and all connected inverters.

• Set an individual SBus address (P813) on the inverters. Recommendation: Assign

the addresses starting from address 1 and working in ascending order according to

the arrangement of inverters in the switch cabinet. Do not assign address 0 since this

is used by the UFI11A.

• Check the SBus baud rate (P816, factory setting = 500 kbaud).

• Set the Setpoint source (P100) to SBus (value 10).

• Set the Control signal source (P101) to SBus (value 3).

• Set the terminal assignment of the binary inputs. The value 0 is recommended for

P60- in MOVITRAC

–DI01 CW/STOP (applied to 24 V, enable CW direction of rotation)

–DI02 CCW/STOP (applied to 24 V, enable CCW direction of rotation)

–DI03 FIX SETPT SW.OV(not connected)

–DI04 n11/n21 (not connected)

–DI05 n12/n22 (not connected)

–Program the unused terminals to "NO FUNCTION" if you are using a MOVIDRIVE

or MOVIDRIVE compact.

• Important: If you need to set P815 SBus timeout delay for MOVITRAC

only possible using a PC. The default value is 0, which means timeout monitoring is

switched off. Set P815 to the value 1 s.

3.3 Autosetup

Switch on the Autosetup function using the DIP switch on the UFI11A. The function is

active for as long as the SYS-FLT LED is flashing briefly with a long interval between

flashes. The LED stays off after the scanning process if at least one inverter has been

detected.

ted by switching the DIP switch off and on again. The SYS-FLT LED remains on following Autosetup if no inverter is detected. In this case, check the cabling of the SBus, the

terminating resistors of the SBus, the voltage supply to the inverters and the SBus

address settings (P813).

The Autosetup DIP switch must stay switched on.

®

07. This corresponds to the following assignment:

Autosetup can be reactiva-

®

07, this is

®

10

Manual – Fieldbus Interface INTERBUS UFI11A

Page 11

Installation and Operation with Autosetup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4 Configuration of the fieldbus master

You will find detailed information in the section "INTERBUS interface."

• Set the required process data length via DIP switches 1 ... 5. You will need three process data words for each drive inverter connected to the UFI11A. That means you

will have to set 9 words in case you are operating three MOVITRAC

change in the DIP switch settings will become active after turning the UFI11A off and

on again.

• Start the "CMD Tool" project planning software for your INTERBUS interface.

• Enter the bus setup via "Configuration frame / Read in" or "Read in configuration

frame."

• Assign program addresses of the control program to the INTERBUS process data of

the inverters. This assignment takes place via the context menu "Process data" or

"Process data manager."

• Enhance the control program by the data exchange with the UFI11A.

®

07 units. A

3

Manual – Fieldbus Interface INTERBUS UFI11A

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with Autosetup

3.5 Starting the inverters

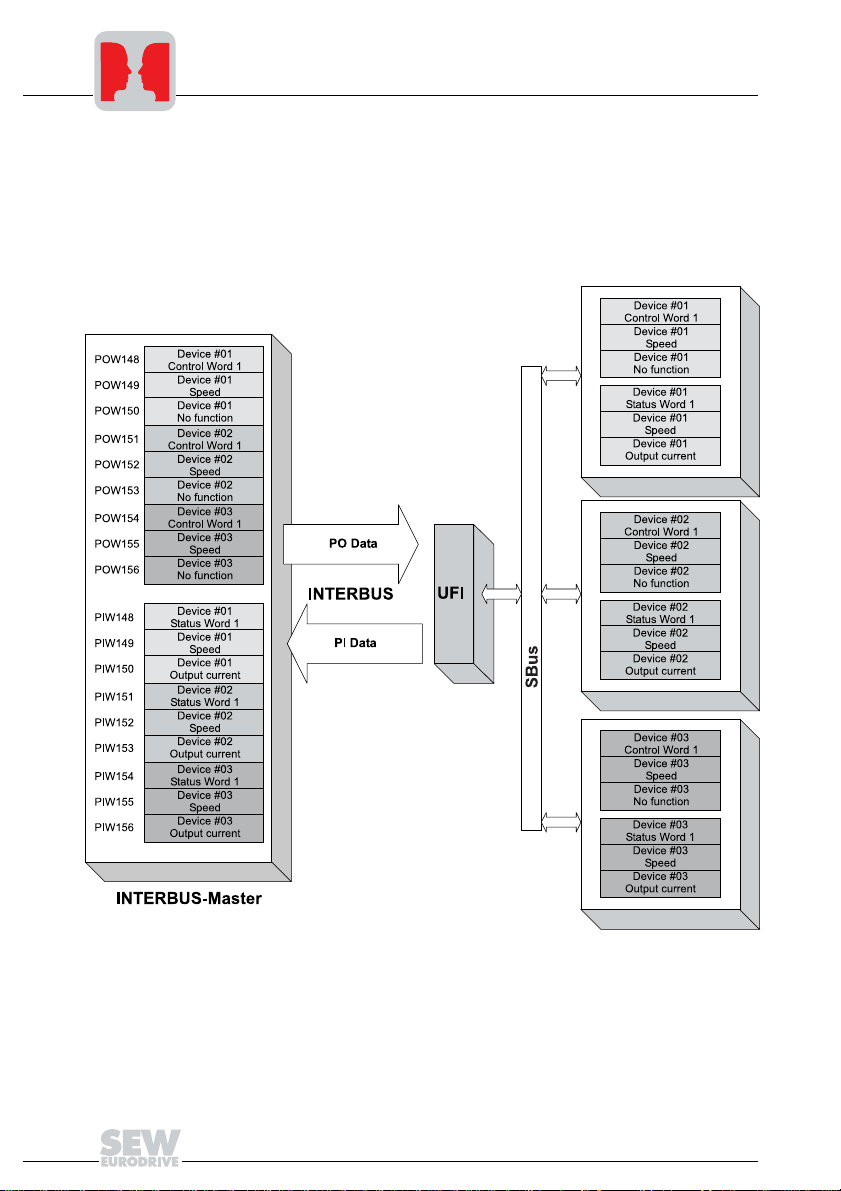

You can operate up to eight inverters on the INTERBUS via one UFI11A. The INTERBUS master and the UFI11A will exchange setpoints and actual values of all inverters

connected to the UFI11A in contiguous data packages. It is important for you to know

where a particular inverter is located in the data package (process image). The relationship is shown in the following illustration:

Fig. 6: Data exchange INTERBUS master – UFI11A – inverter

You can enable the inverter by writing the value 0006h in the corresponding control

word. You can enter the speed setpoint in the following word; it is scaled with 0.2 1/min

per digit.

12

05431AXX

Manual – Fieldbus Interface INTERBUS UFI11A

Page 13

Installation and Operation with a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4 Installation and Operation with a PC

4.1 Installation notes

Mounting

Pin assignment

The unit can be mounted using the integrated DIN rail mounting option or directly onto

a switch cabinet wall using the four holes integrated into the back wall of the housing. In

the latter case, the two retaining screws for the DIN rail mounting must be removed.

Basically, there are no restrictions regarding positioning in relation to the inverters to be

connected (e.g. MOVITRAC

length and the fact that the UFI11A must be the first or last node on the system bus

(SBus).

The UFI11A must have additional HF-compliant grounding if the DIN rail mounting option is used in conjunction with SBus cables more than 1 m in length.

The UFI11A fieldbus interface is equipped with a 9-pin sub D male connector for the incoming bus signal and a 9-pin sub D female connector for the outgoing bus signal.

®

07). In laying out the system, consider the maximum cable

4

Fig. 7: Pinout of the 9-pin sub D male connector X3 to EN 50170 ([1] = 9-pin sub D male

connector; [2] = Signal lines twisted pair; [3] = Conductive connection between the

connector housing and the shield)

Manual – Fieldbus Interface INTERBUS UFI11A

05406AXX

13

Page 14

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

Fig. 8: Pinout of the 9-pin sub D female connector X4 to EN 50170 ([1] = 9-pin sub D female

connector; [2] = Signal lines twisted pair; [3] = Conductive connection between the

connector housing and the shield; [4] = Jumper)

As a rule, the fieldbus interface is connected to the INTERBUS system using a twisted,

shielded cable. The shield of the INTERBUS cable must be connected on both ends, for

example on the plug housing. Note the maximum supported transmission rate when you

are selecting the bus connector.

The cable is connected to the INTERBUS plug using pins 6 and 1 (/DO and DO) and

pins 7 and 2 (/DI and DI). Communication takes place via these contacts. The RS-485

signals /DO and DO as well as /DI and DI must have the same contacts on all INTERBUS stations. Otherwise, communication via the bus will not function.

05374AXX

14

Manual – Fieldbus Interface INTERBUS UFI11A

Page 15

Connection

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

4

Fig. 9: System bus connection

UFI11A

COM = RS-485 reference

/DO = Data out inverted

DO = Data out

/DI = Data in inverted

DI = Data in

GND = System bus reference

SC11 = System bus high

SC12 = System bus low

Notes on SBus configuration:

• Use a twisted and shielded copper cable (data transmission cable with braided cop-

• The permitted total cable length depends on the baud rate setting of the SBus:

05375AXX

MOVITRAC® 07

GND = System bus reference

SC22 = System bus outgoing low

SC21 = System bus outgoing high

SC12 = System bus incoming low

SC11 = System bus incoming high

S12 = System bus terminating resistor

per shield). Connect the shield at both ends to the electronics shield clamp of MOVI-

®

07 or the UFI11A and ensure a large area of contact between the shield and

TRAC

clamp. Also connect the ends of the shield to GND. The cable must meet the following specifications (CAN bus or DeviceNet cables are suitable):

2

–Conductor cross section 0.75 mm

(AWG18)

–Cable resistance 120 Ω at 1 MHz

–Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

–250 kbaud: 160 m (528 ft)

–500 kbaud: 80 m (264 ft)

–1000 kbaud: 40 m (132 ft)

Manual – Fieldbus Interface INTERBUS UFI11A

15

Page 16

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

• Switch on the system bus terminating resistor (S1 2 = ON) of the node end of the system bus. Switch off the terminating resistor on the other units (S12 = OFF). The

UFI11A fieldbus interface must always be the first or last node on the system bus. It

has an integrated terminating resistor.

• There must not be any potential difference between the units connected to the SBus.

Take suitable measures such as connecting each unit’s ground lug to a central

grounding point in the cabinet to avoid potential differences.

• Point-to-point cabling is not permitted.

24 V connection

Shielding and

routing of the bus

cables

An external 24 VDC voltage supply must be connected to terminals X1:4 and X1:5.

The voltage range for the 24 VDC voltage supply is 18 – 30 V. The current consumption

of the UFI11A fieldbus interface is 300 mA.

The INTERBUS interface supports RS-485 transmission technology and requires the

cable type specified as the physical medium for INTERBUS. This cable must be a shielded, twisted-pair cable with 3 x 2 cores.

Having the bus cable correctly shielded eliminates parasitic interference which can occur in an industrial environment. The following measures ensure the best possible shielding:

• Finter-tighten the retaining screws of plugs, modules and equipotential bonding conductors.

• Use only connectors with a metal housing or a metallized housing.

• Maximize the contact area between the shield and the connector housing.

• Shield the bus cable on both ends.

• Do not route the signal and bus cables in parallel with the power cables (motor

leads); use separate cable ducts if possible.

• Only use grounded-metal cable trays in industrial environments.

• Join the signal cables and the associated equipotential bonding together at closely

spaced intervals by the shortest route.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely adjacent to available grounding surfaces.

In the event of fluctuations in the ground potential, a compensating current may flow

along the shield which is connected at both ends and to the ground potential (PE). In this

case, make adequate provision for equipotential bonding in accordance with the relevant VDE regulations.

16

Manual – Fieldbus Interface INTERBUS UFI11A

Page 17

Installation and Operation with a PC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.2 PC connection

The UFI11A is equipped with a 4-pole RJ12 socket on the front. The option UWS21A

with item no. 8230773 establishes the connection to a COM interface on your PC. Connect the desired COM of the PC with the UWS21A via the enclosed serial cable. The

UWS21A will be connected with the UFI11A via the enclosed RJ11 cable.

4.3 Setting the inverter parameters

The settings can be entered using the inverter control panel. Refer to the inverter operating instructions for more information.

• Switch on the voltage supply for the UFI11A and all connected inverters.

• Set an individual SBus address (P813) on the inverters. Recommendation: Assign

the addresses starting from address 1 and working in ascending order according to

the arrangement of inverters in the switch cabinet. Do not assign address 0 since this

is used by the UFI11A.

4.4 Startup software

• Install the MOVITOOLS software package as of version 2.70 on your PC.

• Start the software. Select the COM to which the UFI11A has been connected and

press the "Update“ button. The UFI11A should appear at address 0 and the connected inverters on the following addresses. In case you do not see an entry in the window, please check the COM interface and the connection via the UWS21. If you only

see the UFI11A as an entry in the window, please check the SBus cabling and the

terminating resistors.

• Select the UFI11A and start the UFx Configurator.

• Select the menu item "New configuration of fieldbus node.“

• Select your project path and name. Press the "Next" button.

• Press the "Update“ button. You should now see all inverters connected to the

UFI11A. You can customize the configuration with the "Insert“, "Edit“ and "Delete“

buttons. Press the "Next" button.

• Press the "Autoconfiguration“ button. You will now see the process image for the

UFI11A in your control. The process data length is displayed at the bottom. This value is important for the configuration of the fieldbus master. Press the "Next" button."

• Save the project data and press the "Download“ button. If you experience problems

with the download, you have probably set the DIP switch to AUTOSETUP. You need

to turn off the autosetup feature when configuring with a PC.

4

Manual – Fieldbus Interface INTERBUS UFI11A

17

Page 18

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation and Operation with a PC

• You can see the data being exchanged between fieldbus master and UFI11A with

the process data monitor.

• You will have to enable the unit via the terminals to control the inverter via fieldbus.

You have already connected the terminals. Select the first inverter with address 1 in

the window "Connected units" to check the pinout and start "Shell." Make the following settings for the pinout of the MOVITRAC

• Repeat this step for all inverters listed in the window "Connected units."

4.5 Configuration of the fieldbus master

You will find detailed information in the section "INTERBUS interface."

• Set the required process data length via DIP switches 1 ... 5. You will need three process data words for each drive inverter connected to the UFI11A. That means you

will have to set 9 words in case you are operating three MOVITRAC

change in the DIP switch settings will become active after turning the UFI11A off and

on again.

®

07:

®

07 units. A

• Start the "CMD Tool" project planning software for your INTERBUS interface.

• Enter the bus setup via "Configuration frame / Read in" or "Read in configuration

frame."

• Assign program addresses of the control program to the INTERBUS process data of

the inverters. This assignment takes place via the context menu "Process data" or

"Process data manager."

• Enhance the control program by the data exchange with the UFI11A.

18

Manual – Fieldbus Interface INTERBUS UFI11A

Page 19

4.6 Starting the inverters

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

You can operate up to eight inverters on the INTERBUS via one UFI11A. The INTERBUS master and the UFI11A will exchange setpoints and actual values of all inverters

connected to the UFI11A in contiguous data packages. It is important for you to know

where a particular inverter is located in the data package (process image). The relationship can be seen in the process data monitor of the UFx Configurator.

You can enable the inverter by writing the value 0006h in the corresponding control

word. You can enter the speed setpoint in the following word; it is scaled with 0.2 1/min

per digit.

Installation and Operation with a PC

4

Manual – Fieldbus Interface INTERBUS UFI11A

19

Page 20

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

5 INTERBUS Interface

5.1 Startup of the INTERBUS master

Project planning of the UFI11A in the INTERBUS interface module with the "CMD Tool"

(CMD = Configuration-Monitoring-Diagnostics) project planning software takes place in

two steps. In the first step, you will set up the bus structure. The second step involves a

station description and address entry of process data.

Configuring the

bus structure

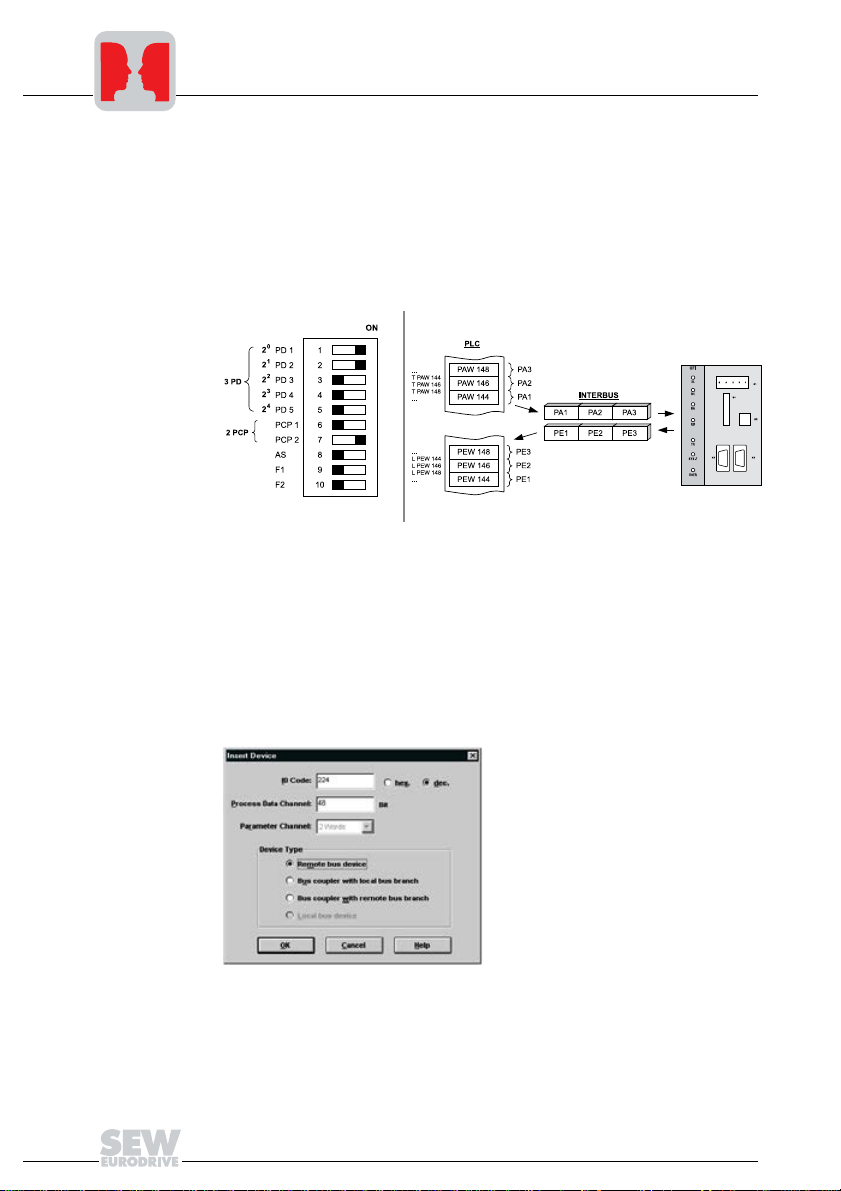

Fig. 10: Project planning example for 3PD + 2PCP

The following illustrations show the CMD Tool settings for a UFI11A configured with 3PD

+ 2PCP according to Fig. 10 on the input/output addresses 144...149 of the control.

Off-line configuration: Insert with ID code

You can configure the bus structure with the CMD Tool on-line or off-line. In the off-ine

status, the drive inverter will be configured with the menu item "Edit / Insert with ID code"

in the CMD tool. In this mode, you will have to enter the ID code, process data channel

and device type according to Fig. 11.

Fig. 11: Off-line configuration with the CMD Tool

05654AXX

05653AXX

20

Manual – Fieldbus Interface INTERBUS UFI11A

Page 21

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Not all combinations are available. You will find the valid settings in the following table.

The insert with ID Code has to correspond to the setting of DIP switches 6 and 7. The

process data channel setting has to correspond to the setting of DIP switches 1-5. Any

conflicting settings will prevent operation of the INTERBUS. See also the section on configuration of the Interbus interface via DIP switches.“

5

ID Code 3 dez (03 hex) No parameter channel PCP

Process data

channel:

ID Code 227 dez (E3 hex) Parameter channel PCP: 1 word

Process data

channel:

Program setting Function

16 Bit 1 process data word (1 PD)

32 Bit 2 process Data Words (2 PD)

48 Bit 3 process data words (3 PD)

64 Bit 4 process data words (4 PD)

80 Bit 5 process data words (5 PD)

96 Bit 6 process data words (6 PD)

112 Bit 7 process data words (7 PD)

128 Bit 8 process data words (8 PD)

144 Bit 9 process data words (9 PD)

160 Bit 10 process data words (10 PD)

192 Bit 12 process data words (12 PD)

224 Bit 14 process data words (14 PD)

256 Bit 16 process data words (16 PD)

384 Bit 24 process data words (24 PD)

16 Bit 1 process data word (Param + 1 PD)

32 Bit 2 process data words (Param + 2 PD)

48 Bit 3 process data words (Param + 3 PD)

64 Bit 4 process data words (Param + 4 PD)

80 Bit 5 process data words (Param + 5 PD)

96 Bit 6 process data words (Param + 6 PD)

112 Bit 7 process data words (Param + 7 PD)

128 Bit 8 process data words (Param + 8 PD)

144 Bit 9 process data words (Param + 9 PD)

176 Bit 11 process data words (Param + 11PD)

218 Bit 13 process data words (Param + 13 PD)

240 Bit 15 process data words (Param + 15 PD)

368 Bit 23 process data words (Param + 23 PD)

Manual – Fieldbus Interface INTERBUS UFI11A

21

Page 22

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

ID Code 224 dez (E0 hex) Parameter channel PCP: 2 words

Process data

channel:

ID Code 225 dez (E1 hex) Parameter channel PCP: 4 words

Process data

channel:

Program setting Function

16 Bit 1 process data word (Param + 1 PD)

32 Bit 2 process data words (Param + 2 PD)

48 Bit 3 process data words (Param + 3 PD)

64 Bit 4 process data words (Param + 4 PD)

80 Bit 5 process data words (Param + 5 PD)

96 Bit 6 process data words (Param + 6 PD)

112 Bit 7 process data words (Param + 7 PD)

128 Bit 8 process data words (Param + 8 PD)

160 Bit 10 process data words (Param + 10 PD)

192 Bit 12 process data words (Param + 12 PD)

224 Bit 14 process data words (Param + 14 PD)

352 Bit 22 process data words (Param + 22 PD)

384 Bit 24 process data words (Param + 24 PD)

16 Bit 1 process data word (Param + 1 PD)

32 Bit 2 process data words (Param + 2 PD)

48 Bit 3 process data words (Param + 3 PD)

64 Bit 4 process data words (Param + 4 PD)

80 Bit 5 process data words (Param + 5 PD)

96 Bit 6 process data words (Param + 6 PD)

128 Bit 8 process data words (Param + 8 PD)

160 Bit 10 process data words (Param + 10 PD)

192 Bit 12 process data words (Param + 12 PD)

320 Bit 20 process data words (Param + 20 PD)

352 Bit 22 process data words (Param + 22 PD)

On-line configuration: Configuration frame / Read in

You can initially install the INTERBUS system completely and then set the DIP switches

of the UFI11A. The entire bus structure (configuration frame) can then be read in via the

CMD Tool. All stations will be automatically identified with their set data length.

22

Manual – Fieldbus Interface INTERBUS UFI11A

Page 23

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Insert device

description

You can create an individual device description for the UFI11A in the INTERBUS system

to clearly identify and describe the INTERBUS stations. The following entries are of importance in this instance:

In the fields "Manufacturer Name" and "Device Type" you must enter the

– Manufacturer Name: SEW-EURODRIVE

– Device Type: UFI

so that the drive can be configured via the INTERBUS interface module (Fig. 12) with a

management PC from the management level.

Fig. 12: Device description for UFI

05655AXX

Select "Remote Bus" as interface type.

Manual – Fieldbus Interface INTERBUS UFI11A

23

Page 24

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

As of CMD Tool version 4.50, you can copy your own ICO files in the directory

".\IBSCMD\Pict32\" (Fig. 13) for easier identification of the drive inverter. You will find

the "INTERBUS description files for CMD Tool" under "Software / Movitrac" on the SEW

homepage.

Fig. 13: Linking device description with ICO files

03716AXX

24

Manual – Fieldbus Interface INTERBUS UFI11A

Page 25

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Parameter

channel

Assigning process data

The following settings of the parameter channel will become necessary if you want to

use the PCP channel for configuring the UFI11A or a drive inverter connected to the

UFI11A:

• Message Lengths / Transmit / Receive: 243 bytes each

• Supported Parameter Channel Services (Standard): Read / Write

Fig. 14: Setting the parameter channel (PCP)

You assign the INTERBUS process data of the drive inverters to the program addresses

of the control system with the context menu "Process Data."

03717AXX

Fig. 15: Assignment of INTERBUS process data and PLC program addresses

Manual – Fieldbus Interface INTERBUS UFI11A

05657AXX

25

Page 26

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

Testing the PCP

connection

You can use the MONITOR mode of the CMD Tool to test the PCP connection to the

UFI. The following illustrations demonstrate the PCP test. You are basically establishing

a PCP connection with this method and read the parameter list (object directory) stored

in the device. Change the CMD Tool to the "Monitoring" operating state.

Fig. 16: Change the CMD Tool to the "MONITO-

RING“ operating state

Click on the UFI to which you would like to establish a PCP connection. Open the context menu with the right mouse button and select the menu item "Device Parameterization".

05658AXX

Fig. 17: Testing the PCP device parameterization

26

Manual – Fieldbus Interface INTERBUS UFI11A

Page 27

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Activate the menu item "Device / Read Parameter List" in the window "Device Parameterization.“

5

Fig. 18: Window for device parameterization via CMD Tool

The configuration of the PCP channel is correct if the device parameters are now read

in. You can cancel the read-in process. If you receive an error message instead of the

progression bar, check the PCP configuration and assignment of the CRs. You may

want to format the parameterization memory of the interface module once again and write the current project once again into the parameterization memory. Repeat the configuration of the interface module and the sequence for testing the PCP connection.

Fig. 19: CMD Tool reads in device parameters, indicating that the

PCP communication is ok

03713AXX

03722AXX

Manual – Fieldbus Interface INTERBUS UFI11A

27

Page 28

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

5.2 Configuration of the INTERBUS interface

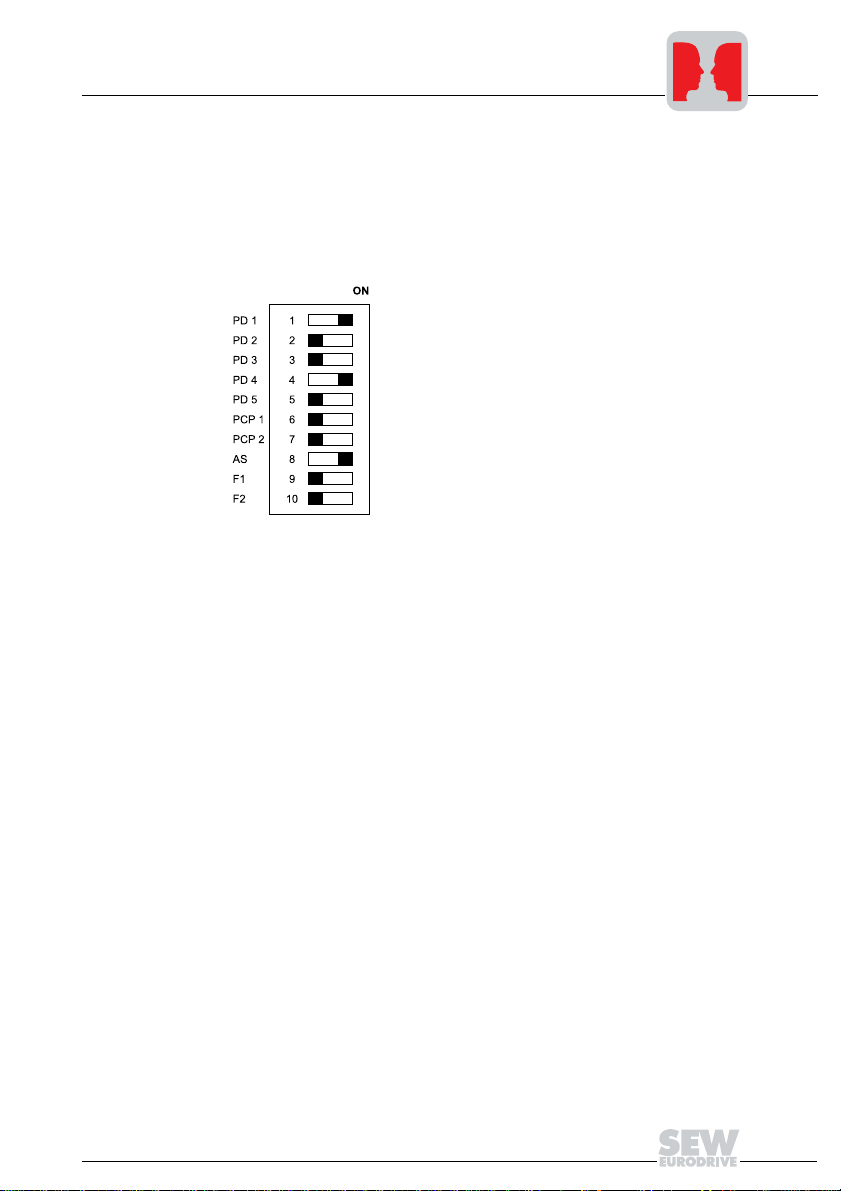

Under the cover plate, there is a DIP switch for setting the INTERBUS data length of the

fieldbus interface. The process data length can be set to a maximum of 24 words using

switches S1-1 to S1-5. The PCP length can be set using switches S1-6 and S1-7. PCP

is the parameter channel of the INTERBUS and is used for setting the parameters of the

UFI11A and the connected inverters.

Fig. 20: UFI11A DIP

switches

The process data channel is the means by which the connected inverters are controlled

and their status read. Since all data of the connected inverters are transmitted by the

INTERBUS, you will have to enter the sum of the process data lengths of all individual

inverters. In Autosetup, this means three words per inverter.

Fig. 21 shows an example setting of six process data words for two inverters. The value

of each switch in determining the process data length is shown on the right.

Fig. 21: Process data words

05376AXX

05377AXX

28

Manual – Fieldbus Interface INTERBUS UFI11A

Page 29

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

A maximum of 3PDs can be assigned to one station on the SBus.

The PCP channel can be set to 0, 1, 2, or 4 words. At least one word must be set to

enable parameter data to be exchanged. Higher settings increase the transmission

speed. Fig. 8 shows the possible settings for the PCP channel.

5

Fig. 22: Possible settings for PCP words

Note that if the total of process data and PCP words exceeds 10 words , you must select

a value equal to or greater than your required data length from the following settings:

0 – 10 words set directly, 12 words, 14 words, 16 words, 24 words and 26 words.

Manual – Fieldbus Interface INTERBUS UFI11A

05378AXX

29

Page 30

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

Use the following table for the valid settings. You can also refer to the example settings

given below if you are operating the fieldbus interface in Autosetup mode.

Number of process data words 0 PCP words 1 PCP word 2 PCP words 4 PCP words

1 XXXX

2 XXXX

3 XXXX

4 XXXX

5 XXXX

6 XXXX

7 XXX

8 XXXX

9XX

10 X X X

11 X

12 X X X

13 X

14 X X

15 X

16 X

17

18

19

20 X

21

22 XX

23 X

24 X X

De-energize the UFI11A before adjusting the DIP switch settings. The settings of DIP

switches S1-1 to S1-7 are only read during the power-up initialization.

The UFI11A signals the "Microprocessor not ready" ID code (38h) if the settings of DIP

switches S1-1 to S1-7 are invalid.

30

Manual – Fieldbus Interface INTERBUS UFI11A

Page 31

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.3 Examples of DIP switch settings for process data and PCP communication in

Autosetup mode

1 inverter

(3 process data

words)

3 process data words are set. 0, 1, 2 and 4 PCP words can be set using DIP switches

PCP1 and PCP2.

5

2 inverters

(6 process data

words)

3 inverters

(9 process data

words)

6 process data words are set. 0, 1, 2 and 4 PCP words can be set using DIP switches

PCP1 and PCP2.

9 process data words are set. 0 and 1 PCP word can be set using DIP switches PCP1

and PCP2.

Manual – Fieldbus Interface INTERBUS UFI11A

31

Page 32

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

4 inverters

(12 process data

words)

5 inverters

(15 process data

words)

6 inverters

(18 process data

words)

12 process data words are set. 0, 2 and 4 PCP words can be set using DIP switches

PCP1 and PCP2.

15 process data words are set. Only 1 PCP word can be set using DIP switches PCP1

and PCP2.

20 process data words are set. 4 PCP words must be set using DIP switches PCP1 and

PCP2.

32

Manual – Fieldbus Interface INTERBUS UFI11A

Page 33

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

7 inverters

(21 process data

words)

8 inverters

(24 process data

words)

22 process data words are set. 2 and 4 PCP words can be set using DIP switches PCP1

and PCP2.

24 process data words are set. 0 and 2 PCP words can be set using DIP switches PCP1

and PCP2.

Manual – Fieldbus Interface INTERBUS UFI11A

33

Page 34

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

5.4 Control via INTERBUS

Data exchange between the INTERBUS master and the UFI11A takes place using the

I/O area. The process data for all inverters connected to the UFI11A are located in a

contiguous block in this area.

If there is more than one inverter, the associated process data words are appended at

the end (see Fig. 23). The number of process data words per inverter is 3 words with

Autosetup.

The inverters are located in ascending (SBus) address sequence with their associated

process data lengths in the process image, for example an inverter with address 1 and

3 words, then an inverter with address 2 and 3 words, then an inverter with address 3

and 2 words, etc.

POW318

POW316

POW314

POW312

POW310

POW308

[1]

PIW318

PIW316

PIW314

PIW312

PIW310

PIW308

Fig. 23: Representation of the INTERBUS data in the PLC address area ([1] = PLC address area

/ U/f = Inverter)

PO 3

PO 2

PO 1

PO 3

PO 2

PO 1

UFI

PI 3

PI 2

PI 1

PI 3

PI 2

PI 1

PO 1

PO 2

PO 3

U/f!1 U/f!2

PI 2

PI 1

PI 3

PO 1

PI 1

PO 2

PI 2

PO 3

PI 3

50394AXX

34

Manual – Fieldbus Interface INTERBUS UFI11A

Page 35

5.5 PCP interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The UFI11A fieldbus interface offers a standardized interface for parameter setting

using the "Peripherals Communication Protocol" (PCP). This communications channel

gives you full access to the parameters of the UFI11A fieldbus interface and the drive

parameters of the inverters connected to the UFI11A.

Overview of basic

structure

PCP services

The PCP channel must be set to one, two or four words using the DIP switches on the

UFI11A to enable access to the parameter values of the UFI11A fieldbus interface or the

inverter. Changing the number of PCP words varies the access speed to parameter values via the PCP channel. The PCP interface is implemented using PCP version 3.0 in

the UFI11A.

The UFI11A fieldbus interface supports the PCP services shown in Fig. 10. However,

only the following services are relevant for setting parameters:

• Establishing the connection (Initiate)

• Reading of parameter values (Read)

• Writing of parameter values (Write)

• Cancelling the connection (Abort)

INTERBUS Interface

5

Fig. 24: PCP services supported by the UFI11A fieldbus interface

Manual – Fieldbus Interface INTERBUS UFI11A

05389AXX

35

Page 36

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

Establishing the

communications

link with "Initiate"

Canceling the

communications

link with "Abort"

Reading parameter values with

"Read"

Writing parameter

values with "Write"

Parameters in the

object list

The "Initiate" PCP service establishes a communication link for exchanging parameters

between an INTERBUS master and the UFI11A fieldbus interface. The connection is always established from the INTERBUS master. Various arrangements relating to the

communication link are checked during establishment of the connection, such as supported PCP services, user data length, etc. The fieldbus interface responds with a positive initiate response if the connection is established successfully. If the connection can

not be established, then the arrangements for the communications link on the INTERBUS master do not match those on the fieldbus interface. The fieldbus interface responds with an initiate error response. In this case, compare the configured communications relationship list in the INTERBUS master with that in the fieldbus interface.

As a rule, an attempt to re-establish an existing communication link leads to an abort.

The communication link is then dropped, which means the "Initiate" PCP service must

be run a third time in order to re-establish the communication connection.

The "Abort" PCP service cancels an existing communications link between the INTERBUS master and the fieldbus interface. Abort is an unconfirmed PCP service and can be

triggered either from the INTERBUS master or from the fieldbus interface.

The "Read" PCP service gives the INTERBUS master read access to all communication

objects (drive parameters) of the fieldbus interface. All drive parameters and their coding

are presented in detail in the Fieldbus Unit Profile documentation and the list of MOVID-

®

parameters.

RIVE

The "Write" PCP service gives the INTERBUS master write access to all parameters of

the fieldbus interface. The fieldbus interface generates a write error response if incorrect

access is made to a parameter (e.g. the value written is too large). Precise information

is given relating to the cause of the error.

The "Read" and "Write" PCP services give the INTERBUS master access to all parameters defined in the object list of the UFI11A. All the parameters of the fieldbus interface

which can be accessed via the bus system are described as communication objects in

the static object list of the UFI11A. All objects in the static object list are addressed using

indices. The following table shows the structure of the object list of the UFI11A.

36

Manual – Fieldbus Interface INTERBUS UFI11A

Page 37

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The index range is subdivided into three logical areas. The UFI11A parameters are

addressed using indices 8300 – 8313dec. Indices below 8300dec can be used for accessing parameters which are not contained in the object list, or for addressing parameters which are found on an inverter connected to the UFI11A.

Parameter index

(decimal)

8288 Variable data channel with acyclical routing (UFI11A and parameters of the con-

8296 Download parameter block

8297 Last PCP index

8299 MOVILINK parameter channel acyclical (only UFI11A parameters can be rea-

8300 – 8313 UFI11A parameters

8314 – 9999 Parameters of the UFI11A or of an inverter connected to the UFI11A which can

> 10000 Table, program and variable memory of the UFI11A or an inverter connected to

Name of the communication object

nected inverters can be reached)

ched)

be addressed via object 8288.

the UFI11A. These parameters can be addressed with object 8288.

5

Object description

of the UFI11A or

drive parameters

The parameters of the connected inverters are described in detail in the SEW document

"Parameter List." In addition to the parameter index, additional information about coding,

the range of values and the meaning of the parameter data is provided. The object description in the object list is identical for all parameters. Even read-only parameters are

given the Read all/Write all attribute in the object list because the inverter undertakes

the corresponding check itself and sends back a return code if necessary. The following

table shows the object description of all parameters.

Index: 8300 ... 8313

Object code: 7 (simple variable)

Data type index : 10 (octet string)

Length: 4

Local address:

Password:

Access groups:

Access rights: Read all/Write all

Name[16]: -

Extension length: -

Manual – Fieldbus Interface INTERBUS UFI11A

37

Page 38

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

"Variable data

channel with acyclical routing"

object

This object enables you to address all the parameters of the UFI11A itself and the connected inverters. The object contains a selection option for the subchannel and address

information for selecting the target unit. It contains information about the data length and

frame type and an acyclical MOVILINK parameter channel. The required service and

data value are specified here. The length is fixed at 12 bytes.

Octet 0 1 2 3 4 5 6 7 8 9 10 11

Meaning Subchan-

Fine structure Subchan-

Coarse structure

nel

nel

Routing information MOVILINK parameter channel acyclical

Subaddress

Subaddress

Frame

type

Frame

type

Data

length

Data

length

Admin Re-

served

Admin Re-

served

Index

Index

Low

Data

MSB

High

Parameter index 4 bytes data

Data Data Data

The subchannel determines to which interface the data will be directed. The setting 0

addresses the parameters of the UFI11A and the subaddress is of no importance. The

setting 1 on the subchannel addresses the standard interface (the SBus in case of the

UFI11A).

The subaddress byte allows selection of the target unit. If you want to address the parameters of a drive inverter connected to the UFI11A via SBus, you will enter the SBus

address of the respective drive inverter.

The frame type must be set to 86hex (only acyclical parameter data). The data length

for this frame type is fixed at 8 bytes.

Variable data

channel performs a

write service

If a write service is performed via the data channel (e.g. write parameter or write parameter volatile), the UFI11A responds with the current service confirmation when the service has been performed. The corresponding error code is returned if the write service

is not successful.

This method offers the advantage that the write services are processed simply by sending a WRITE "MOVILINK parameter channel" once and evaluating the "write confirmation." The following table shows how write services are performed via the variable data

channel.

Control (master) UFI11A fieldbus interface

1. Initiate the service coded in the parameter channel by means of a WRITE to the "MOVILINK parameter

channel cyclical" object.

WRITE 8288 (parameter channel)

LSB

Service confirmation (OK/error code)

The WRITE service coded in the parameter channel is performed and the service confirmation is returned directly as the response.

38

Manual – Fieldbus Interface INTERBUS UFI11A

Page 39

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Variable data

channel performs a

read type service

A PCP WRITE service has to be performed before a parameter can be read via the data

channel. The PCP WRITE service defines where the UFI11A data should be available.

A read service must take place on the variable data channel in order for these data to

get to the master. As a result, a PCP WRITE and a PCP READ are always required for

performing read services via the variable data channel. The following table shows how

read services are performed via the variable data channel.

Control (master) UFI11A fieldbus interface

1. Initiate the service coded in the parameter channel by means of a WRITE to the "MOVILINK parameter

channel cyclical" object.

2. READ "MOVILINK parameter channel cyclical" and evaluation of the service confirmation in the parameter channel.

WRITE 8288 (parameter channel)

OK

READ 8288 (parameter channel)

Data = Parameter channel with result

1. Reception is confirmed immediately, the data channel is evaluated and the requested service performed.

2. Service confirmation is entered in the data channel and can be evaluated by READ

access in the master.

The "variable data channel with acyclical routing" object is only handled locally on the

fieldbus interface and is defined as in the following table.

Index: 8288

Object code: 11 (string variable)

Data type index : 10 (octet string)

Length: 11

Local address:

Password:

Access groups:

Access rights: Read all/Write all

Name[16]: -

Extension length: -

Manual – Fieldbus Interface INTERBUS UFI11A

39

Page 40

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

"Download parameter block"

object

The "download parameter block" object enables up to 38 drive parameters of the

UFI11A or an inverter connected to the UFI11A to be written at the same time with only

one write service. This object gives you the opportunity to set the parameters of the inverter in the startup phase, by calling the write service only once. In general, only a few

parameters vary from application to application so that this parameter block with its max.

38 parameters is sufficient for almost all applications. The user data area is defined as

38 x 6 + 2 bytes = 230 bytes (byte format). The following table shows the structure of

the "download parameter block" object.

Octet Meaning Note

0 Address Target address: 0 or 254 for the UFI11A or SBus address of the

1 Number of parameters 1 – 38 parameters

2 Index high

3 Index low

4 Data MSB

5Data

6Data

7 Data LSB

8 Index high

223 Data LSB

224 Index high

225 Index low

226 Data MSB

227 Data

228 Data

229 Data LSB

target inverter

1st parameter

2nd parameter... ...

38th parameter

The "download parameter block" object is only handled locally on the fieldbus interface

and is defined as in the following table.

Index: 8296

Object code: 7 (simple variable)

Data type index : 10 (octet string)

Length: 230

Local address:

Password:

Access groups:

Access rights: Write all

Name[16]: -

Extension length: -

40

Manual – Fieldbus Interface INTERBUS UFI11A

Page 41

Example

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

"Last PCP index"

object

INTERBUS Interface

The WRITE service on the "download parameter block" object starts a parameterization

mechanism on the UFI11A. This writes all the parameters specified in the user data area

of the object one after the other in the UFI11A itself or a connected inverter and therefore

sets the parameters of the UFI11A or the inverter. The UFI11A is addressed using

address 0. An inverter connected to the UFI11A is addressed using its SBus address.

The write service is terminated with a positive write response once the download parameter block has been processed successfully (i.e. all parameters transferred by the INTERBUS fieldbus interface have been written). A negative write response is returned in

case of an error. The return code contains more detailed information about the type of

error, as well as the number of the parameter (no. 1 – 38) where the error occurred (see

example).

Write error response for an error when writing the 11th parameter:

Error class: 8 Other

Error code: 0 Other

Additional code high: 11dec Error when writing parameter 11

Additional code low: 15hex Value too large

Note the following points when using the download parameter block:

• Do not perform a factory setting within the download parameter block!

• All parameters written after the parameter lock has been activated will be rejected.

This object is 4 bytes long and, when read access is executed, it returns the numerical

value of the last index which can be addressed directly using the PCP services. PCP

accesses to indices greater than this numerical value must be made using the "MOVILINK parameter channel with acyclical routing" object. Access is also possible using object 8299 "MOVILINK parameter channel acyclical" if the parameters of the UFI11A are

to be addressed.

Index: 8297

Object code: 7 (simple variable)

Data type index : 10 (octet string)

Length: 4

Local address:

Password:

Access groups:

Access rights: Read all

Name[16]: -

Extension length: -

5

Manual – Fieldbus Interface INTERBUS UFI11A

41

Page 42

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

MOVILINK parameter channel

acyclical

Parameter channel performs a

write service

The "MOVILINK parameter channel acyclical" object is 8 bytes long and contains the

MOVILINK parameter channel. This object can be used for acyclical parameter accesses, i.e. the inverter processes the service coded in the parameter channel every time

a WRITE service is received on this object.

The handshake bit is not evaluated! The following table shows the structure of the "MOVILINK parameter channel acyclical."

Octet 01234567

Meaning Admin Re-

Note Admin Re-

served

served

Index

Index

Data

high

Parameter index 4 bytes data

low

Data Data Data

MSB

LSB

There are two different procedures involved in setting the drive inverter parameters via

the acyclical MOVILINK parameter channel:

• Parameter channel performs a write service

• Parameter channel performs a read service

If a write service is performed via the acyclical parameter channel (e.g. write parameter

or write parameter volatile), the UFI11A responds with the current service confirmation

when the service has been performed. The appropriate error code is returned if the write

access is not successful.

This method offers the advantage that the write services are processed simply by sending a WRITE "MOVILINK parameter channel" once and evaluating the "write confirmation". The following table shows how write services are performed via the acyclical MOVILINK parameter channel.

Control (master) UFI11A fieldbus interface

1. Initiate the service coded in the parameter channel by means of a WRITE to the "MOVILINK parameter

channel cyclical" object.

WRITE 8299 (parameter channel)

Service confirmation (OK/error code)

The WRITE service coded in the parameter channel is performed and the service confirmation is returned directly as the response.

42

Manual – Fieldbus Interface INTERBUS UFI11A

Page 43

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Parameter channel performs a

read type service

A PCP WRITE service must be performed before a parameter can be read via the parameter channel. The PCP WRITE service defines where the UFI11A data should be

available. A read service must take place on the acyclical parameter channel in order

for these data to get to the master. As a result, a PCP WRITE and a PCP READ are

always required for performing read services via the parameter channel. The following

table shows how read services are performed via the acyclical MOVILINK parameter

channel.

Control (master) UFI11A fieldbus interface

1. Initiate the service coded in the parameter channel by means of a WRITE to the "MOVILINK parameter

channel cyclical" object.

2. READ "MOVILINK parameter channel cyclical" and evaluation of the service confirmation in the parameter channel.

WRITE 8299 (parameter channel)

OK

READ 8299 (parameter channel)

Data = Parameter channel with result

1. Reception is confirmed immediately, the parameter channel is evaluated and the requested service performed.

2. Service confirmation is entered in the parameter channel and can be evaluated by

READ access in the master.

The acyclical MOVILINK parameter channel is only handled locally on the fieldbus interface and is defined as in the following table.

Index: 8299

Object code: 7 (simple variable)

Data type index : 10 (octet string)

Length: 8

Local address:

Password:

Access groups:

Access rights: Read all/Write all

Name[16]: -

Extension length: -

Manual – Fieldbus Interface INTERBUS UFI11A

43

Page 44

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

5.6 Return codes for parameter setting

Different return codes will be sent back to the master used for parameter setting in case

of inccorrect parameters. These codes will give the user a detailed insight into the reason for an error. The return codes are usually structured according to EN 50170 with

the following elements:

•Error class

•Error code

• Additional code

These return codes apply to all communication interfaces of the UFI11A.

Error class

Error code

The element "Error class" classifies the type of error. The following error classes are

listed according to EN 50170.

Class (hex) Designation Meaning

1 vfd-state Status error of the virtual field device

2 application-reference Error in application program

3 definition Definition error

4 resource Resource error

5 service Error during service execution

6 access Access error

7 ov Error in object directory

8 other Other error (see Additional code)

Except for error class 8 = Other error, the error class is generated by the communication

software of the fieldbus card in case of communication problems. Return codes generated by the inverter system are all classified as error class 8 = Other error. You will get a

more detailed analysis of the error with the element "Additional code."

The element "Error code" gives you more detailed information on the reason for the error

within the "Error class" and is generated by the communication software of the fieldbus

card in case of communication problems. Error code = 0 (other error code) is the only

error code that has been defined for error class 8 = Other error. You will find detailed

information for this error in "Additional code."

44

Manual – Fieldbus Interface INTERBUS UFI11A

Page 45

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Additional code

Special case

"Internal

communication

error"

The "Additional code" contains all SEW-specific return codes for incorrect parameter

setting of the drive inverters. These codes are sent back to the master as "Error class 8

= Other error." Table 2 lists all possible codes for the additional code.

Add. code

high (hex)

00 00 No error

00 10 Incorrect parameter index

00 11 Function/parameter not available

00 12 Read access only

00 13 Parameter block is active

00 14 Factory setting is active

00 15 Value too large for parameter

00 16 Value too small for parameter

00 17 No option card available for this function/parameter

00 18 Error in system software

00 19 Parameter access via RS485 process interface on X13 only

00 1A Parameter access via RS485 diagnostics interface only

00 1B Limited-access parameter

00 1C Requires controller inhibit

00 1D Invalid parameter value

00 1E Factory setting has been activated

00 1F Parameter was not saved in EEPROM

00 20 Parameter cannot be changed with enabled output stage

Add. code low

(hex)

Meaning

The return code listed in the following table will be generated in case of a communication

error between option card and inverter system. The PCP service transmitted via fieldbus

may not have been executed and should be repeated. In case this error occurs frequently, the drive inverter will have to be turned off and on again to start a new initialization.

Error class: 6 Access

Error code: 2 Hardware problem

Add. code high: 0 -

Add. code low: 0 -

Code (dez) Meaning

Manual – Fieldbus Interface INTERBUS UFI11A

45

Page 46

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INTERBUS Interface

Error correction

Extension of the

Additional code

Extension of the

special return

codes

5.7 Autosetup

Repeat the read or write service. If the error occurs once again, turn off the drive inverter

completely and turn it on again. Please consult the SEW Electronics Service If this error

occurs permanently.

00 23h Parameter may only be changed in IPOS program "Stop"

00 24h Parameter may only be changed with Autosetup turned off

Error class: 06 Access

Error code: 01 Object does not exist

Add. code high: 0 -

Add. code low: 0 -

Remedy: You are trying to exchange parameters with a drive inverter and have not configured a parameter channel.

You can start up the UFI11A without a PC with the Autosetup function. It is activated with

the Autosetup DIP switch. Turning on the Autosetup DIP switch will execute the function

The DIP switch will have to stay turned on afterwards.

once.

cuted once again by turning the switch off and on again. Upon activation of the

Autosetup feature, the UFI11A automatically searches for inverters on the lower-level

SBus and indicates this activity with a brief blinking of the SYS-FLT LED. Each inverter

on the SBus must be assigned a unique SBus address (P813). To avoid confusion with

data assignments, it is recommended to assign the addresses from address 1 ans working in ascending order according to the arrangement of inverters in the control cabinet.

The process image on the fieldbus side will be extended by three words for each located

inverter. The SYS-FLT LED stays on if no inverters are found. A maximum of eight inverters can be configured. The figure shows the process image for three inverters with

three words in the process output data and process input data. Following the search, the

UFI11A cyclically exchanges three process data words with each connected inverter.

The process output data are collected from the fieldbus, divided into blocks of three and

sent. The process input data are read by the inverters, assembled and sent to the fieldbus master.

Autosetup has to be executed only once. The detected configuration will be saved in the

non-volatile memory. See section "Installation and operation without PC."

Important: Execute Autosetup again in case you change the process data assignment

of the inverters connected to the UFI11A, because the UFI11A saves these values once

only during Autosetup. Likewise, the process data assignments (P860 ... P865) of the

connected inverters must not be altered dynamically either, for example by an IPOS program, following Autosetup.

Code (dez) Meaning

The function can be exe-

46

Manual – Fieldbus Interface INTERBUS UFI11A

Page 47

INTERBUS Interface

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Fig. 25: Data exchange INTERBUS master – UFI11A – inverter

Manual – Fieldbus Interface INTERBUS UFI11A

05431AXX

47

Page 48

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6 Error Response

6.1 Fieldbus timeout

6.2 SBus timeout

6.3 Unit errors

Error Response

Switching off the fieldbus master or a wire break in the fieldbus cabling leads to a fieldbus timeout in the UFI11A. The connected inverters are set to a safe status by zeros

being sent on the process output data. This corresponds to a rapid stop on control word

1. The fieldbus timeout error is self-resetting, meaning the inverters will begin receiving

the current process output data from the master immediately after fieldbus communication is re-established. This error response can be deactivated using P831 on the

UFI11A.

If one or more inverters on the Sbus can no longer be addressed by the UFI11A, the

UFI11A enters error code 91, "System error," in status word 1 of the corresponding inverter. The SYS-FLT LED lights up and the error is also displayed via the diagnostic interface. P815 SBus timeout delay must be set to a value other than 0 on the inverter if

it is to stop. The error is self-resetting on the UFI11A, meaning the current process data

are exchanged again immediately after communication resumes.

UFI11A fieldbus interfaces detect a range of hardware defects and respond with an inhibit condition. Refer to the list of errors for the exact error responses and measures to

remedy the problem. A hardware defect means error 91 is entered in the process input

data of the fieldbus in status word 1 of all inverters. The SYS-FLT LED on the UFI11A

then flashes evenly. The exact error code is displayed in the status of the UFI11A using

the diagnostic interface of MOVITOOLS.

48

Manual – Fieldbus Interface INTERBUS UFI11A

Page 49

7 Diagnostic LEDs

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The UFI11A INTERBUS interface has 7 diagnostic LEDs.

• LED "UL" (green) Logic voltage

• LED "RC" (green) Incoming remote bus OK

• LED "BA" (green) Bus mode active

• LED "RD" (yellow) Outgoing remote bus switches off

• LED "TR" (green) Parameter data exchange via PCP channel

• LED "SYS-FAULT"(red) for displaying system errors and operating conditions of the

• LED "USER" (green) for application-specific diagnostics in expert mode

7.1 States of the LEDs UL, RC, BA, TR and RD

LED UL "U-Logic"

(green)

LED RC "Cable

Check" (green)

LED BA "Bus

Active" (green)

LED RD "Remote

Bus Disable"

(red)

Status Meaning Remedy

on Supply voltage of bus electro-

off Supply voltage of bus electro-

Status Meaning Remedy

on Incoming remote bus connec-

off Incoming remote bus connec-

Status Meaning Remedy

on Data transmission via INTER-

off No data transmission; INTER-

Status Meaning Remedy

on Outgoing remote bus turned off -

off Outgoing remote bus not turned off -

nics is present

nics is missing

tion is ok

tion is faulty

BUS active

BUS has been stopped

UFI11A

-

Check the 24V voltage supply of the UFI11A.

-

Check the incoming remote bus connection.

-

Check the incoming remote bus cable. Use the diagnostics

display of the INTERBUS interface module (master) for

additional error localization.

Diagnostic LEDs

7

Manual – Fieldbus Interface INTERBUS UFI11A

49

Page 50

7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

LED TR "Transmit" (green)

LED TR "Transmit" (yellow or

red)

LED "SYSFAULT" (red)

LED "USER"

(green)

Diagnostic LEDs

Status Meaning Remedy

The LED TR corresponds in the color green according to the Interbus standard.

off No PCP communication -

green PCP communication active or INTERBUS start (parameter access via

Status Meaning Remedy

The LED TR signals system-internal states with the colors yellow and red that usually do not occur during

INTERBUS operation.

off or

green

flashing

yellow

steady red Incorrect DIP switch configuration selected,

flashing

red

Status Meaning

OFF Standard operating status. The UFI11A is exchanging data with the connected inver-

FLASHES 1 x

briefly with long

pause

FLASHES regularly UFI11A is in error status. If you started the UFI11A using the Autosetup DIP switch,

ON The UFI11A is not exchanging data with the connected inverters. Either is has not

Statuts Meaning

OFF Standard operating status. The "USER“ LED is reserved for expert mode.

INTERBUS PCP channel)

Standard operation (see table for TR = green) -

Inverter is in initialization phase -

no INTERBUS operation possible.

Incorrect DIP switch configuration or defective INTERBUS option card, no INTERBUS

operation possible.

ters.

Autosetup has been selected using the DIP switch and the UFI11A is currently setting up its configuration. If this status lasts for more than one minute, turn off the

Autosetup mode and turn it on again. Replace the module if the behavior persists.

turn the UFI11A off and on again. If the LED is still on, restart Autosetup by turning

the DIP switch off and on again. If you started the UFI11A with MOVITOOLS, you

will see an error message in the status window. Consult the corresponding error

description.