Page 1

Drive Technology \ Drive Automation \ System Integration \ Services

Fieldbus Gateway UFF41B

DeviceNet and PROFIBUS DP

Edition 02/2009

16756428 / EN

Manual

Page 2

SEW-EURODRIVE – Driving the world

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

1 General Information ............................................................................................... 6

1.1 Using the manual........................................................................................... 6

1.2 Structure of the safety notes .......................................................................... 6

1.3 Rights to claim under limited warranty........................................................... 7

1.4 Exclusion of liability........................................................................................ 7

1.5 Copyright notice............................................................................................. 7

2 Safety Notes ......................... .................................................................................. 8

2.1 Other applicable documentation .................................................................... 8

2.2 General safety notes for bus systems............................................................ 8

2.3 Safety functions ............... ... ... ... ..................................................................... 8

2.4 Hoist applications....................................................................... ... ... ... .... ... .... 8

2.5 Product names and trademarks.......................................................... .... ....... 8

2.6 Waste disposal............................................................................................... 9

3 Introduction .......................................................................................................... 10

3.1 Content of the manual............................ ...................................................... 10

3.2 Characteristics ............................................................................................. 10

3.2.1 Process data exchange .................................................................... 10

3.2.2 Parameter access ............................................................................. 10

3.2.3 Monitoring functions .......................................................................... 11

4 Assembly and Installation Instructions ............................................................. 12

4.1 Installation options of the UFF41B fieldbus gateway................................... 12

4.2 Voltage supply ............................................................................................. 13

4.2.1 Voltage supply in the MOVIAXIS

4.2.2 Voltage supply in the UOH21B gateway housing ............................. 15

4.3 Connecting inverters and engineering PC ................................................... 16

4.3.1 Functional description of the terminals, DIP switches

and LED of the UFF41B option ......................................................... 16

4.3.2 Connecting CAN 1 system bus (connector X33) /

CAN 2 (terminal X32) ........................................................................ 17

4.3.3 Connecting SBUS

4.3.4 Ethernet interface terminal (terminal X37) ........................................ 21

4.3.5 Pin assignment X37 (Ethernet for engineering) ................................ 22

4.4 Status LED of the UFF41B fieldbus gateway............................................... 23

4.5 DIP switch S1 default IP address................................................................. 24

4.5.1 TCP / IP addressing and subnetworks .............................................. 24

4.6 SD memory card type OMG4.B ................................................................... 26

4.7 Connecting the UFF41B fieldbus gateway to a DeviceNet network............. 27

4.7.1 Pin assignment X30D (DeviceNet) ................................................... 27

4.7.2 Bus termination ................................................................................. 28

4.7.3 Setting the DIP switches ................................................................... 28

4.7.4 Status LED in DeviceNet operation .................................................. 30

4.8 Connecting the UFF41B fieldbus gateway to a PROFIBUS network........... 32

4.8.1 Pin assignment X30P (PROFIBUS) .................................................. 32

4.8.2 Status LED in PROFIBUS operation ................................................. 34

4.9 Shielding and routing bus cables................................................................. 35

plus

system bus (terminal X36) ............................. 21

®

master module ........................... 13

5 Configuring the UFx41B Fieldbus Gateway and the Inverter........................... 36

5.1 Description of the gateway functions ........................................................... 36

5.1.1 Introduction ....................................................................................... 36

5.1.2 Autosetup .......................................................................................... 36

5.1.3 Customized configuration ................................................................. 38

5.1.4 Configuring fieldbus gateway and slave units ................................. .. 39

5.1.5 Data backup ...................................................................................... 41

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

3

Page 4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.2 Startup procedure ........................................................................................ 44

5.2.1 Checking hardware installation and communication settings ........... 44

5.2.2 Establishing an engineering connection ........................................... 44

5.2.3 Configuring the fieldbus gateways ........................... ......................... 46

5.2.4 Last settings in the slave units .......................................................... 47

5.2.5 Monitoring and controlling process data ........................................... 49

5.2.6 Saving inverter data in the fieldbus gateway and

using MOVITOOLS

5.2.7 E rror processing and status messages ............................................. 54

6 Configuration and Startup on DeviceNet Fieldbus........................................... 57

6.1 Validity of EDS files for the UFF41B option ................................................. 57

6.2 Configuring PLC and master (DeviceNet scanner)...................................... 58

6.3 Project planning examples in RSLogix5000.................................. ... ... ......... 61

6.3.1 UFF41B fieldbus gateway with 16 process data ............................... 61

6.3.2 Access to UFF41B fieldbus gateway parameters ............................. 64

6.3.3 A ccess to unit parameters of lower-level units .................................. 67

7 DeviceNet Operating Characteristics................................................................. 70

7.1 Process data exchange ............................................................................... 70

7.2 The Common Industrial Protocol (CIP)........................................................ 73

7.2.1 CIP object directory .......................................................................... 73

7.3 Return codes of the parameterization via explicit messages....................... 82

7.4 Terms and definitions................................................................................... 86

®

MotionStudio ................................................... 52

8 Configuration and Startup on the PROFIBUS DP-V1 Fieldbus................... ... .. 87

8.1 Configuring a PROFIBUS DP master .......................................................... 87

9 PROFIBUS DP-V1 Operating Characteristics ............................... ...... ... ... .... ... .. 92

9.1 Process data exchange with the UFF41B fieldbus gateway........................ 92

9.2 PROFIBUS DP timeout................................................................................ 93

10 Functions of PROFIBUS DP-V1........................................................................... 94

10.1 Introduction to PROF IBUS DP- V1 ............................. ... ............................... 94

10.1.1 Class 1 master (C1 master) ............................................................. 95

10.1.2 Class 2 master (C2 master) ............................................................. 95

10.1.3 Data sets (DS) ............................... ... ... ... ... .... ... ... ............................ 95

10.1.4 DP-V1 services .............................. .................................................. 96

10.1.5 DP-V1 alarm handling ...................................................................... 96

10.2 Features of SEW fieldbus inte rfa ce s.......... .................................................. 97

10.3 Structure of the DP-V1 parameter channel.................................................. 98

10.3.1 Parameterization procedure via data set 47 .................................. 100

10.3.2 DP-V1 master processing sequence .............................................. 101

10.3.3 Addressing connected inverters ..................................................... 102

10.3.4 MOVILINK

10.3.5 PROFIdrive parameter orders ........................................................ 107

10.4 Configuring a C1 master............................................................................ 112

10.4.1 Operating mode (DP-V1 mode) ..................................................... 112

10.4.2 Example program for SIMATIC S7 ................................................. 113

10.4.3 Technical data of DP-V1 for UFF41B fieldbus gateway ................. 114

10.4.4 Error codes of the DP-V1 services .... ... .......................................... 115

®

parameter requests .................................................... 103

4

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

11 Operating MOVITOOLS® MotionStudio............... ............................................. 116

11.1 About MOVITOOLS

11.1.1 Tasks ... .......................................................................................... 116

11.1.2 Establishing communication with units ........................................... 116

11.1.3 Executing functions with the units .................................................. 116

11.2 First steps .................................................................................................. 117

11.2.1 Starting the software and creating a project ................................... 117

11.2.2 Establishing communication and scanning the network ................. 117

11.3 Communication mode................................................................................ 118

11.3.1 Overview .......... .... ... ... ... .... ............................................................. 118

11.3.2 Selecting communication mode (online or offline) ......................... 119

11.4 Communication via USB (direct)................................................................ 120

11.4.1 Connect the unit with the PC using USB connection cables .......... 120

11.4.2 Installing the driver ......................................................................... 121

11.4.3 Configuring USB communication ................................................... 121

11.4.4 USB communication parameters ................................................... 123

11.5 Communication via Ethernet...................................................................... 124

11.5.1 Connecting the unit with the PC via Ethernet ................................. 124

11.5.2 Configuring the communication channel via Ethernet .................... 125

11.5.3 Setting communication parameters for SMLP ................................ 126

11.6 Communication via PROFIBUS DP/DP-V1................................................ 128

11.6.1 Communication via C2 master ....................................................... 128

11.6.2 Additionally required hardware and software ................................. 129

11.6.3 Parameterize C2 master with SIMATIC NET ................................. 130

11.6.4 Configuring communication via PROFIBUS ................................... 133

11.6.5 Communication parameters for PROFIBUS DP/DP-V1 ................. 135

11.7 Executing function s with the units.............................................................. 136

11.7.1 Parameterizing units in the parameter tree .................................... 136

11.7.2 Reading/changing unit parameters ................................................ 136

11.7.3 Starting up the units (online) .......................................................... 137

11.8 Special configura tion an d dia g no stic s tool s ..................... ... .... ................... 138

®

MotionStudio ................................. ... .... ................... 116

12 Troubleshooting................................................................................................. 139

12.1 Error messages of the fieldbus gateway.................................................... 139

12.1.1 General errors of the fieldbus gateway .......................................... 140

12.1.2 Error during process data processing ............................................ 141

12.1.3 Error during unit replacement ......................................................... 142

12.2 Diagnostic procedure for operation on DeviceNet ..................................... 143

12.3 Diagnostic procedure for operation on PROFIBUS DP-V1........................ 145

13 Technical Data.................................................................................................... 146

13.1 General technical data............................................................................... 146

13.2 UFF41B fieldbus gateway.......................................................................... 147

13.3 Bus connection .......................................................................................... 148

13.4 Dimension drawings................................................................................... 149

13.4.1 Dimension drawing for fieldbus gateway UFF41B / UOH21B ........ 149

13.4.2 Dimension drawing MOVIAXIS

14 Appendix............................................................................................................. 151

14.1 Parameter access to lower-level units via DeviceNet ................................ 151

14.2 Parameter access to lower-level units via PROFIBUS DP-V1................... 152

14.3 Parameter access to lower-level units via engineering interfaces ............. 153

15 Index.................................................................................................................... 154

®

master module MXM / UFF41B . 150

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

5

Page 6

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

General Information

Using the manual

1 General Information

Manual

1.1 Using the manual

The manual is part of the product and contains important information on operation and

service. The manual is written for all employees who assemble, install, startup, and

service the product.

The manual must be accessible and legible. Make sure that persons responsible for the

system and its operation, as well as persons who work independently on the unit, have

read through the manual carefully and understood it. If you are unclear about any of the

information in this documentation, or if you require further information, contact SEWEURODRIVE.

1.2 Structure of the safety notes

The safety notes in this manual are structured as follows:

Pictogram SIGNAL WORD

Type and source of danger.

Possible consequence(s) if the safety notes are disregarded.

• Measure(s) to prevent the danger.

Pictogram Signal word Meaning Consequences if

disregarded

Example:

General danger

Specific danger,

e.g. electric shock

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

environment

TIP Useful information or tip.

Simplifies the handling of the

drive system.

6

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 7

Rights to claim under limited warranty

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the manual. Therefore, read the manual

before you start operating the device!

1.4 Exclusion of liability

You must comply with the information in the manual and the documentation of the units

connected to the fieldbus gateway to ensure safe operation and to achieve the specified

product characteristics and performance features. SEW-EURODRIVE assumes no

liability for injury to persons or damage to equipment or property resulting from nonobservance of the operating instructions. In such cases, any liability for defects is

excluded.

1.5 Copyright notice

© 2008 - SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

General Information

1

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

7

Page 8

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Notes

Other applicable documentation

2 Safety Notes

2.1 Other applicable documentation

• Installation and startup only by trained personnel observing the relevant accident

prevention regulations and the following documents:

– "MOVIDRIVE

– "MOVITRAC

– "MOVIAXIS

• Read through these documents carefully before you commence installation and

startup of the UFF41B fieldbus gateway.

• As a prerequisite to fault-free operation and fulfillment of warranty claims, you must

adhere to the information in the documentation.

2.2 General safety notes for bus systems

This communication system lets you adjust inverters and servo inverters to a variety of

different applications. As with all bus systems, there is a danger of invisible, external (as

far as the inverter is concerned) modifications to the parameters which give rise to

changes in the unit behavior. This may result in unexpected (not uncontrolled) system

behavior.

®

®

®

" operating instructions

MDX60B/61B" operating instructions

B" operating instructions

2.3 Safety functions

The inverters and servo drives are not allowed to perform any safety functions unless

they are subordinate to other safety systems. Use higher-level safety systems to ensure

protection of equipment and personnel.

For safety applications, ensure that the information in the following publications is

observed: "Safe Disconnection for MOVIDRIVE

2.4 Hoist applications

MOVIDRIVE® MDX60B/61B, MOVITRAC® B and MOVIAXIS® must not be used as a

safety device in hoist applications.

Use monitoring systems or mechanical protection devices as safety equipment to avoid

possible damage to property or injury to people.

2.5 Product names and trademarks

The brands and product names contained within this manual are trademarks or registered trademarks of the titleholders.

®

B / MOVITRAC® B / MOVIAXIS®".

8

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 9

2.6 Waste disposal

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Observe the applicable national regulations.

Dispose of the following materials separately in accordance with the country-specific

regulations in force, as:

• Electronics scrap

• Plastic

• Sheet metal

• Copper

Safety Notes

Waste disposal

2

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

Content of the manual

3 Introduction

3.1 Content of the manual

This user manual describes how to:

• Connect the UFF41B fieldbus gateway to MOVIDRIVE

• Startup MOVIDRIVE

• Startup the UFF41B fieldbus gateway with the DeviceNet and PROFIBUS DP-V1

• Configure the DeviceNet master with EDS files.

• Configure the PROFIBUS DP-V1 master using GSD files.

3.2 Characteristics

The powerful, universal fieldbus interfaces of the UFF41B option enable you to use the

option to connect to higher-level automation systems via DeviceNet and PROFIBUS

DP-V1.

and to the MOVIAXIS

fieldbus systems.

®

®

servo inverter.

®

B, MOVITRAC® B and MOVIAXIS® for gateway operation.

B, MOVITRAC® B inverters

3.2.1 Process data exchange

The UFF41B fieldbus gateway allows for digital access to most parameters and functions via the DeviceNet and PROFIBUS interfaces. Control is performed via fast, cyclic

process data. Via this process data channel, you can enter setpoints and trigger various

control functions, such as enable, normal stop, rapid stop, etc. At the same time you can

also use this channel to read back actual values, such as actual speed, current, unit

status, error number or reference signals. In DeviceNet operation, process data are

exchanged with polled I/O and bit-strobe I/O. In PROFIBUS operation, they are exchanged via I/O data in the master.

3.2.2 Parameter access

In DeviceNet operation, the parameters of the inverter are set solely via explicit

messages.

In PROFIBUS operation, the PROFIBUS DP-V1 parameter mechanisms lets you

access any device information.

10

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 11

3.2.3 Monitoring functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Using a fieldbus system requires additional monitoring functions, for example, time

monitoring of the fieldbus (fieldbus timeout) or rapid stop concepts. You can determine,

for instance, which fault responses should be triggered in the event of a bus error. The

parameters for the fault response can be set in the servo inverter / inverter. A rapid stop

is useful for many applications. This is why the fieldbus gateway will stop the lower-level

drives in the event of a fieldbus timeout. As the range of functions for the control terminals is also guaranteed in fieldbus mode, you can continue to implement rapid stop

concepts using the servo inverters/inverters connected to the fieldbus gateway.

Introduction

Characteristics

3

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

11

Page 12

4

EURODRIVE

X35

X36

X37

Version

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

S1

L1 L2 L3 L5

XM

L4

UFF41B

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

X35

X36

X37

Version

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

S1

L1 L2 L3L5

XM

L4

UFF41B

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

X26

1

23456

7

X24

H1

H2

MOVIAXIS

T1

T1

MOVIAXIS®MXM UFF41B/ UOH21B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

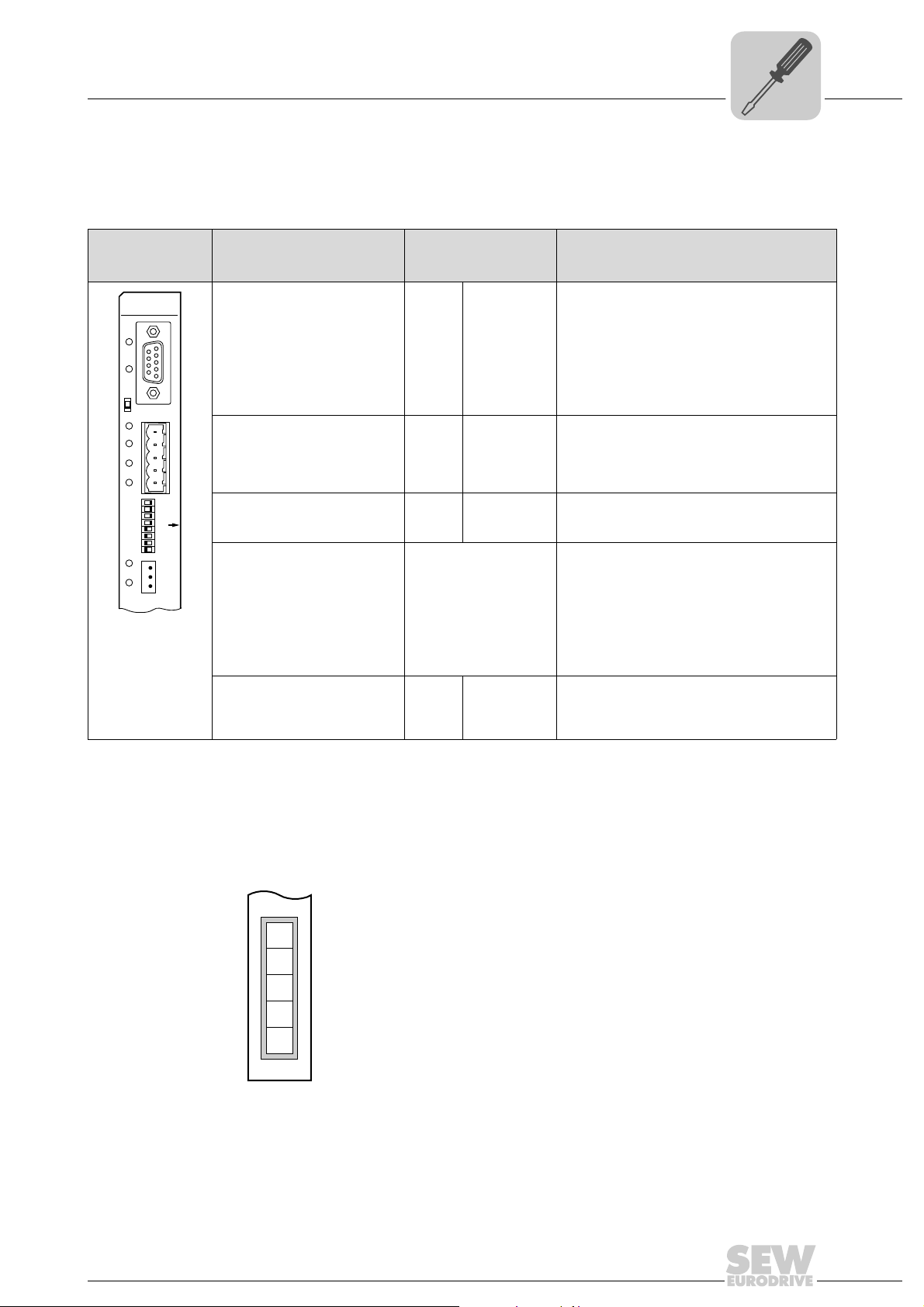

Assembly and Installation Instructions

Installation options of the UFF41B fieldbus gateway

4 Assembly and Installation Instructions

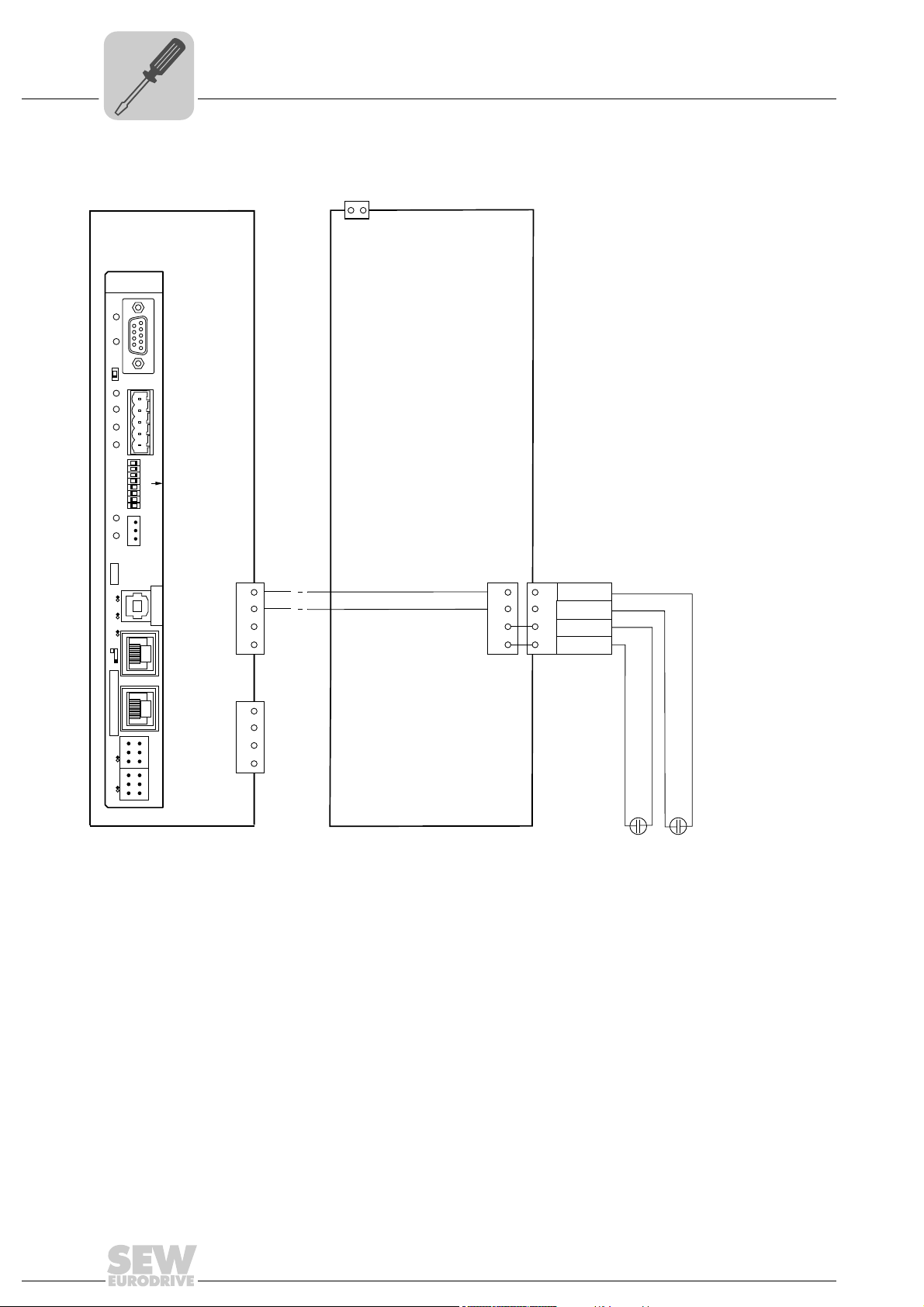

This chapter contains information on the assembly and installation of the UFF41B fieldbus gateway in a MOVIAXIS

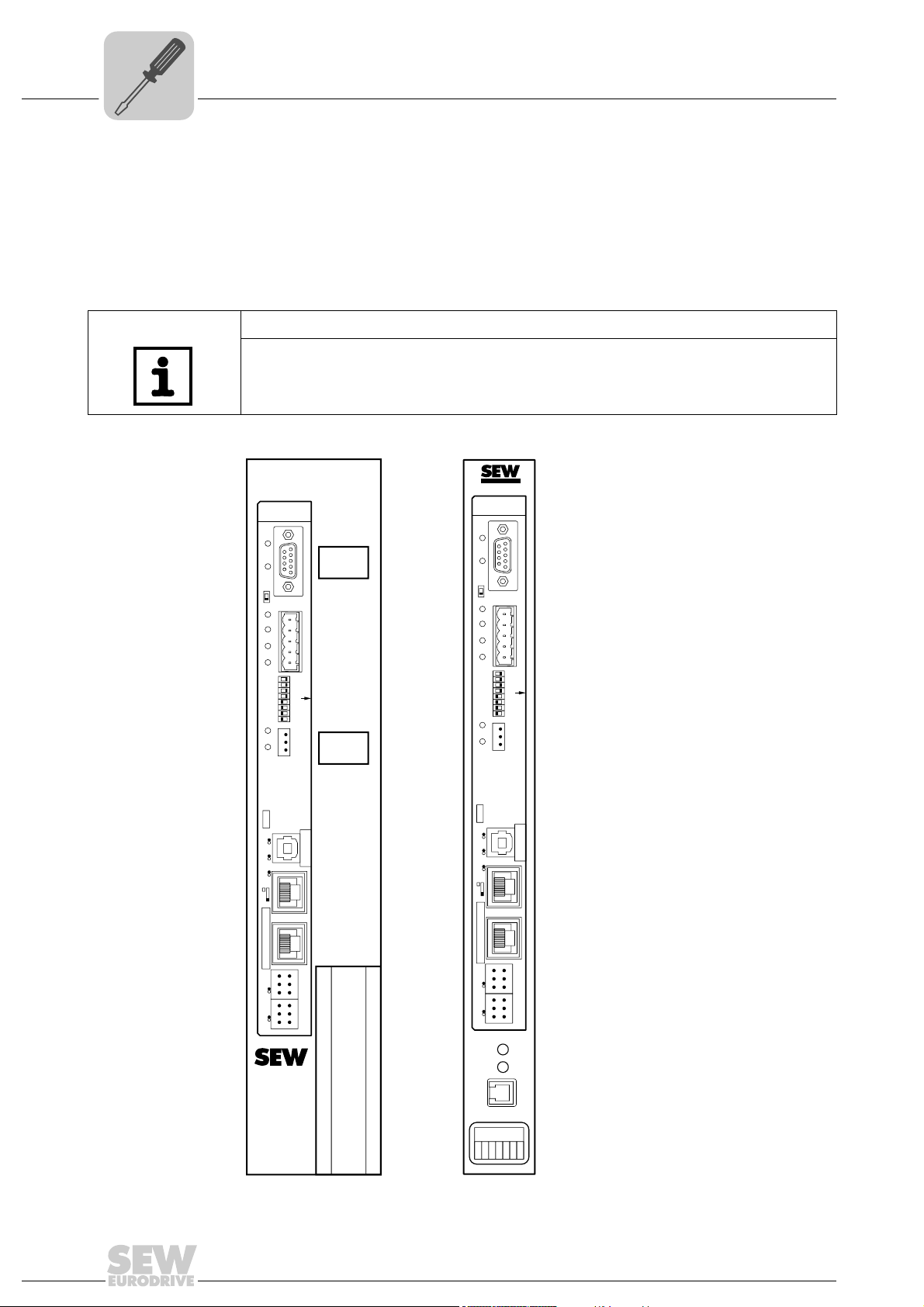

4.1 Installation options of the UFF41B fieldbus gateway

Observe the following installation instructions:

TIP

Only SEW-EURODRIVE is allowed to install/remove the UFF41B fieldbus gateway

into/from a MOVIAXIS

®

master module MXM or in an UOH21B gateway housing.

®

master module MXM and an UOH21B gateway housing.

64421AXX

12

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 13

4.2 Voltage supply

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Voltage supply, system bus and fieldbus interfaces as well as the engineering interface

are located at different potential levels (see chapter 13.1).

Assembly and Installation Instructions

Voltage supply

4

4.2.1 Voltage supply in the MOVIAXIS

®

master module

TIP

The MOVIAXIS® master module MXM provides additional connections that are

described in the following section.

Functional description of the terminals, X5a/X5b (MOVIAXIS

MOVIAXIS® master

module MXM

1

X5b

2

3

4

1

X5a

2

3

4

59233AXX

• The terminals X5a and X5b are connected in parallel. In this way, the voltage supply

of the MOVIAXIS

below to X5a. With connection to X5a, further modules can be connected via X5b

(e.g. supply module, axis module). The voltage supply for the brake (X5a/b:3, 4) is

fed through the MOVIAXIS

• The UFF41B fieldbus gateway can be supplied from the MOVIAXIS

power supply (MXS) or from an external voltage source. To do so, connect X5

between the individual units.

• If the UFF41B fieldbus gateway is connected with DC 24 V from the MOVIAXIS

switched-mode power supply, the functioning of the option is maintained after disconnection from the power supply. This is the case if the DC link voltage is maintained or an external DC 24 V supply is present from the MOVIAXIS

power supply.

Designation Terminal Function

X5b connector X5b:1

Terminal X5a X5a:1

®

master module can be provided from the right to X5b or from

X5b:2

X5b:3

X5b:4

X5a:2

X5a:3

X5a:4

®

master module.

®

master module)

DC 24 V

DGND

DC 24 V

BGND

DC 24 V

DGND

DC 24 V

BGND

Voltage supply for control electronics

E

Reference potential for control

electronics

B

Voltage supply for brake

Reference potential for brake

connection

Voltage supply for control electronics

E

Reference potential for control

electronics

B

Voltage supply for brake

Reference potential for brake

connection

®

switched-mode

®

switched-mode

®

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

13

Page 14

4

MOVIAXIS®

master module MXM

2

X5b

1

DC 24V

E

DGND

3

DC 24V

B

4 BGND

DC 24 V for

brake supply

DC 24 V supply

for control electronics

+-+-

X16

-

+

DC 24 V external

X5a

2

1

3

4

X5a

2

1

3

4

X5b

2

1

3

4

MOVIAXIS®

switched-mode

power supply MXS

X35

X36

X37

Version

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X

32

X33

S1

L1 L2 L3L5

XM

L4

UFF41B

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L

18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

T1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Wiring diagram

Assembly and Installation Instructions

Voltage supply

14

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

64424AEN

Page 15

Assembly and Installation Instructions

X24

H1

H2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

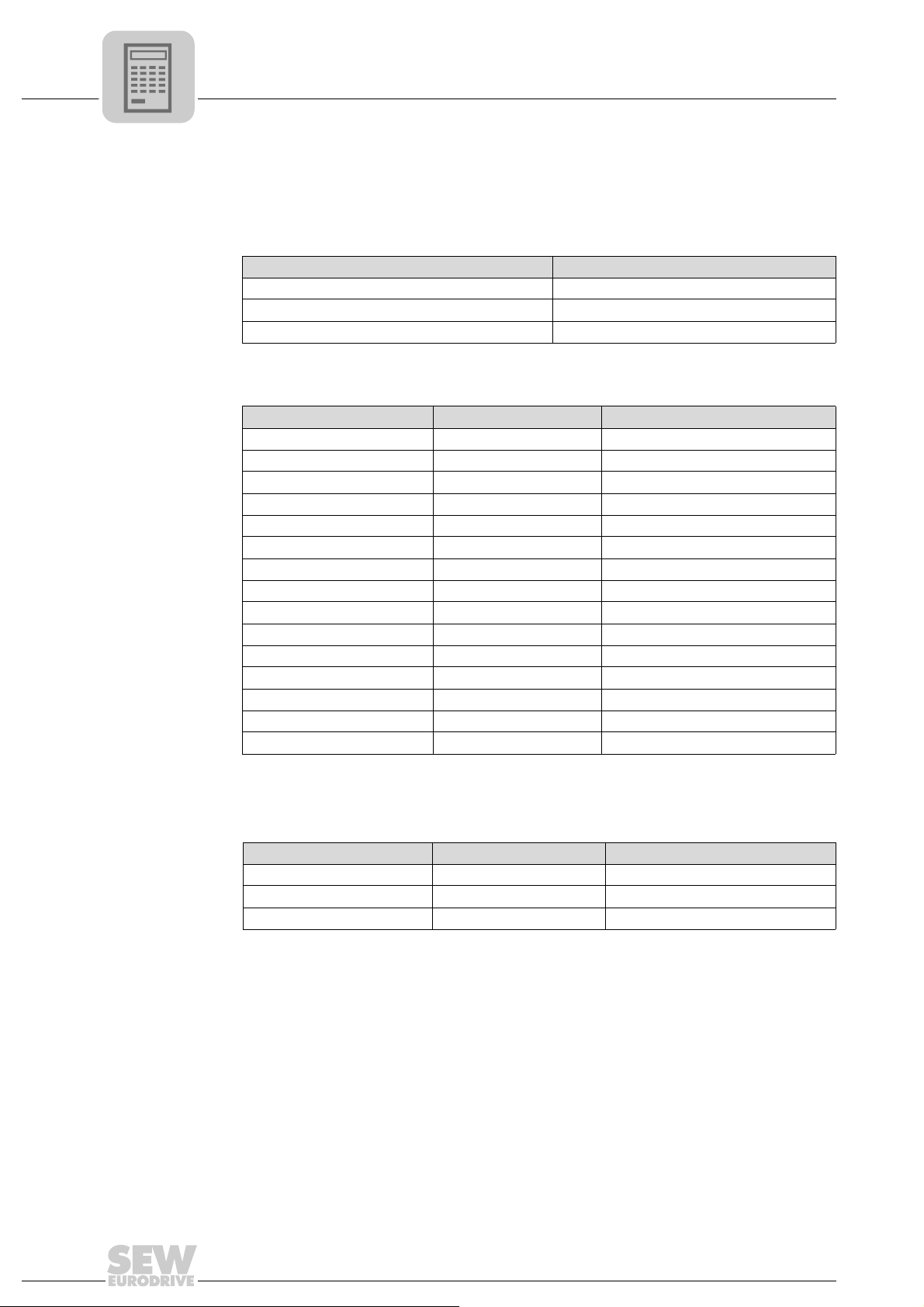

4.2.2 Voltage supply in the UOH21B gateway housing

Description of the terminals and LED functions

Voltage supply

4

Front view

MOVITRAC

compact controller

Side view

compact controller

X26

2345671

®

B /

58905AXX

58906AXX

X26:1

X24:2

X24:3

X24:4

X26:5

X26:6

X26:7

LED

Terminal

H2

X24:4

X24:3

X24:2

X24:1

CAN1H

CAN1L

DGND

Reserved

Reserved

DGND

DC 24 V

Function

Reserved

Reserved

No function.

Engineering cannot be

performed using X24.

System bus CAN 1 high

System bus CAN 1 low

Reference potential control/CAN1

-

Reference potential for UFF41B

Voltage supply for controller

Designation

LED H1

Connector X24:

RJ10 socket

Designation Terminal Function

Connector X26:

CAN 1 and voltage supply

(plug-in terminal)

Connection of CAN 1 system bus / voltage supply (terminal X26)

The connections for CAN 1 (X26:1/2/3 and connector X33) are connected in parallel.

The UFF41B fieldbus gateway is supplied with voltage in the UOH21B gateway housing

via X26:6/7.

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

15

Page 16

4

UFF41B

X35

X36

X37

Version

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

S1

L1 L2 L3L5

XM

L4

T1

UFR41B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting inverters and engineering PC

4.3 Connecting inverters and engineering PC

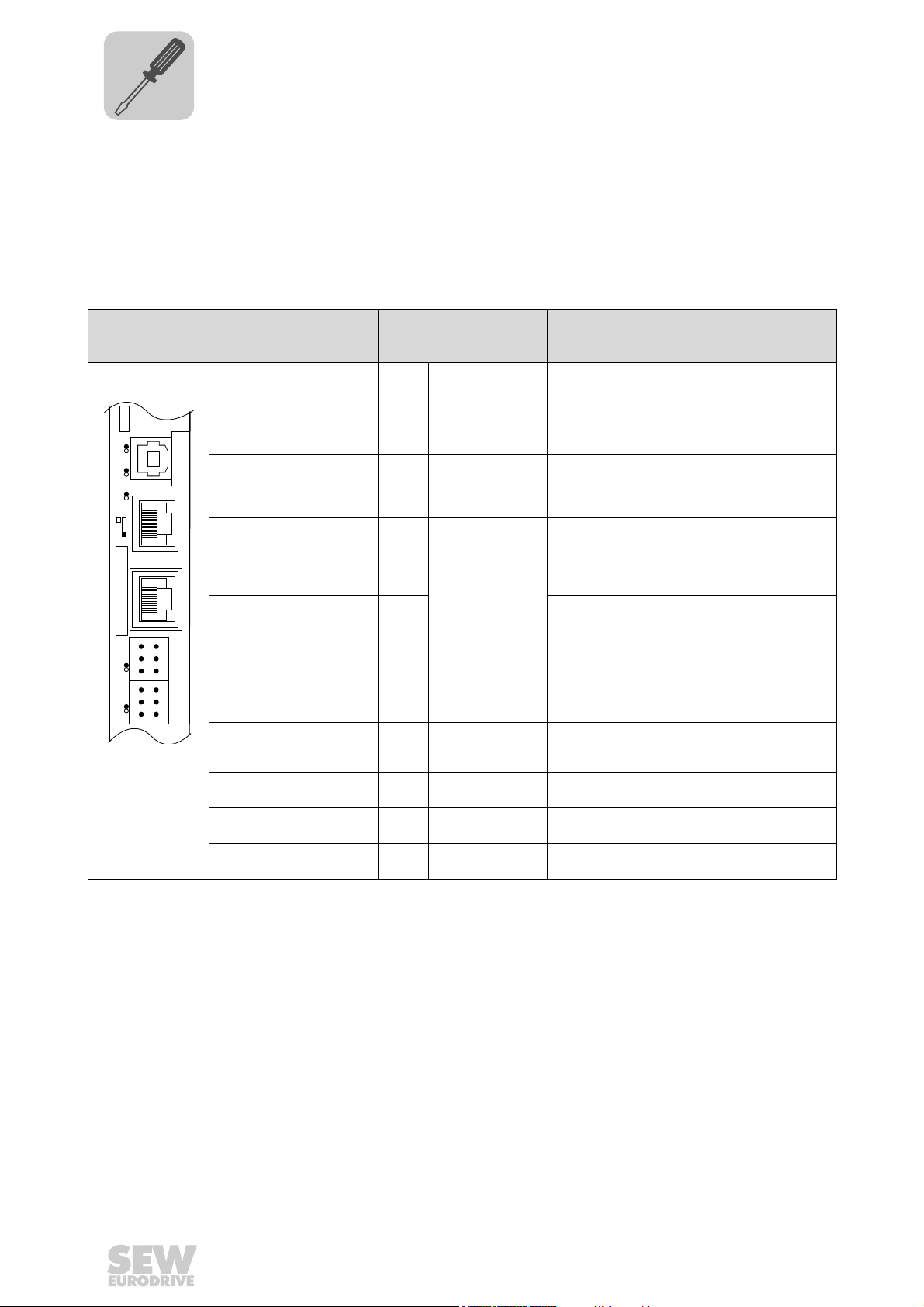

4.3.1 Functional description of the terminals, DIP switch es and LEDs of the UFF41B option

Connectors, LEDs and DIP switches in the upper part of the UFF41B fieldbus gateway

allow for connection to the fieldbus systems DeviceNet (see section "Connecting the

UFF41B fieldbus gateway to a DeviceNet network") and PROFIBUS-DP (see section

"Connecting the UFF41B fieldbus gateway to a PROFIBUS network").

Front view

UFF41B fieldbus

gateway

64418AXX

LED

Designation

DIP switch

Terminal

LED LED 1

LED 2

LED 3

LED 4

LED 5

Terminal X35:

USB connection

X35:1

X35:2

X35:3

X35:4

Terminal X36:

X36

Connection of an

EtherCAT based

system bus (RJ45 socket)

Terminal X37:

X37 Ethernet for engineering

Ethernet connection

(RJ45 socket)

Terminal X32:

System bus CAN 2

(electrically isolated)

X32:1

X32:2

X32:3

(plug-in terminals)

Terminal X33:

System bus CAN 1

(plug-in terminals)

X33:1

X33:2

X33:3

DIP switch S1

Memory card M1

Button T1

CAN 1 status

CAN 2 status

Program status

Gateway status

Gateway error

USB+5 V

USBUSB+

DGND

Standard Ethernet

assignment

BZG_CAN 2

CAN 2H

CAN 2L

DGND

CAN 1H

CAN 1L

To p

Bottom

Function

Status of CAN 1 system bus

Status of CAN 2 system bus

Status of gateway program

Status of gateway firmware

Status of gateway error (see section "Error

messages of the fieldbus gateway")

DC 5 V voltage supply

Signal USBSignal USB+

Reference potential

plus

System bus SBUS

(in preparation)

Reference potential for system bus CAN 2

System bus CAN 2 high

System bus CAN 2 low

Reference potential for system bus CAN 1

System bus CAN 1 high

System bus CAN 1 low

Default IP address (192.168.10.4)

IP parameter from SD memory card

Memory for firmware, gateway application, gateway configuration, and inverter parameters

For Bootloader update

(see section "SD memory card OMG4.B")

16

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 17

Assembly and Installation Instructions

UFF41B

DGND

MDX60B/61B

X12

SC11

2

1

3

SC12

UFR41B

X31X32X33

1

2

3

1

2

3

1

2

3

2

3

1

ON OFF

S12

X45

X46

1

23456HL

FSC11B

MOVITRAC® B

S1

OFF

ON

7

S2

X44

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting inverters and engineering PC

4.3.2 Connecting CAN 1 system bus (terminal X33) / CAN 2 (terminal X32 )

Do not connect more than 64 units to the CAN 1 or CAN 2 system bus. The system bus

supports the address range 0 to 63.

TIPS

• The CAN 1 system bus is not electrically isolated. Therefore, it is recommended to

use the CAN 1 (X33 or X26 with UFF41B/UOH21B) interface to connect inverters

via the system bus in the control cabinet. Set the P881 SBus address parameter in

increasing order to values 1 - 16 if the slave unit is connected to CAN 1 or the fieldbus gateway.

• The CAN 2 system bus is electrically isolated. Therefore, preferably use interface

CAN 2 (X32) for connecting field units or units in other control cabinets. Set the

P881 SBus address parameter in increasing order to values 17 - 34 if the unit is

connected to CAN 2 or the fieldbus gateway.

4

The CAN system bus supports transmission systems compliant with ISO 11898. For

detailed information on the CAN system bus, refer to the "MOVIDRIVE

®

Communication

and Fieldbus Device Profile" manual. You can order this manual from SEWEURODRIVE.

®

Wiring diagram for MOVIDRIVE

B, MOVITRAC® B on CAN 1 system bus

64714AXX

Cable specification • Use a 2 x 2-core twisted and shielded copper cable (data transmission cable with

braided copper shield). Clamping without conductor end sleeves is possible in accordance with IEC 60999. The cable must meet the following specifications:

2

– Cable cross-section 0.2 to 1.0 mm

(AWG 24 - AWG 18)

– Cable resistance 120 Ω at 1 MHz

Cable length • The permitted total cable length depends on the baud rate setting of the system bus:

– Capacitance per unit length ≤ 40 pF/m at 1 kHz

Suitable cables include CAN bus or DeviceNet cables.

– 125 kBaud → 500 m

– 250 kBaud → 250 m

– 500 kBaud → 100 m

– 1000 kBaud → 40 m

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

17

Page 18

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting inverters and engineering PC

Terminating

resistor

• Switch on the system bus terminating resistor at the start and end of the CAN system

bus connection (MOVIDRIVE

S1 = ON). For all other devices, switch off the terminating resistor (MOVIDRIVE

DIP switch S12 = OFF; MOVITRAC

way is, for example, located at the end of the CAN 2 system bus, you have to connect

a terminating resistor of 120 Ω between pins X32:2 and X32:3 (for CAN 1: Terminating resistor betwee

n pins X33:2 and X33:3).

®

B, DIP switch S12 = ON; MOVITRAC® B, DIP switch

®

B, DIP switch S1 = OFF). If the fieldbus gate-

®

B,

CAUTION

•There must not be any potential displacement between the units connected via the

CAN 2 system bus.

•There must not be any potential displacement between the units connected via the

CAN 1 system bus.

• Take suitable measures to avoid potential displacement, such as connecting the

unit ground connectors using a separate cable.

18

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 19

Assembly and Installation Instructions

0

1

0

1

0

1

0

1

0

1

0

1

[1]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting inverters and engineering PC

Wiring diagram for MOVIAXIS® on CAN 1 system bus

4

[1] Terminating resistor

Overview of system connection cables

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Type Part number Description

CAN system cable 0819 692 3

CAN1 connection cable,

750 mm, RJ45-RJ45

CAN1 connection cable,

3000 mm, RJ45-RJ45

CAN2 adapter cable 1810 1607

CAN2 connection cable 1810 1585

CAN2 connection cable 1810 1593

System cable UFF41B gateway CAN 1 post connector (or CAN 2) to MOVIAXIS

supply/regenerative power module CAN 1 system bus RJ45, length: 750 mm

0819 7261

0819 8993

CAN1 connection cable between MOVIAXIS

system, length: 750 mm

CAN1 connection cable between MOVIAXIS

system, length: 3000 mm

CAN2 post connector between master module and CAN2 SUB-D9 MOVIAXIS

length: 500 mm

CAN2 SUB-D9 MOVIAXIS

modules

CAN2 SUB-D9 MOVIAXIS

®

and CAN2 SUB-D9 MOVIAXIS®, to connect 3 axis

®

and CAN2 SUB-D9 MOVIAXIS®, to connect 4 axis

®

axis system and MOVIAXIS® axis

®

axis system and MOVIAXIS® axis

modules

Terminating resistor CAN 2 1810 1615 Terminating resistor for CAN 2 connections between axis modules

64784AXX

®

®

,

19

Page 20

4

X46

ON

OFF

S

2

S

1

1

2

3

4

5

6

7

0

1

0

1

0

1

X12

MOVIAXIS

®

MOVITRAC

®

MOVIDRIVE

®

123

MOVITRAC

®

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting inverters and engineering PC

Wiring diagram for MOVIAXIS®, MOVIDRIVE® B and MOVITRAC® B on CAN 1 system bus

Overview of system connection cables

Type Part number Description

20

CAN1 connection cable,

750 mm, RJ45 litz wire

CAN1 connection cable,

3000 mm, RJ45 litz wire

0819 7288

0819 7563

CAN connection cable MOVIAXIS

length: 750 mm

CAN connection cable MOVIAXIS

length: 3000 mm

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

®

axis system to MOVIDRIVE® and MOVITRAC®,

®

axis system to MOVIDRIVE® and MOVITRAC®,

64783AXX

Page 21

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting inverters and engineering PC

4

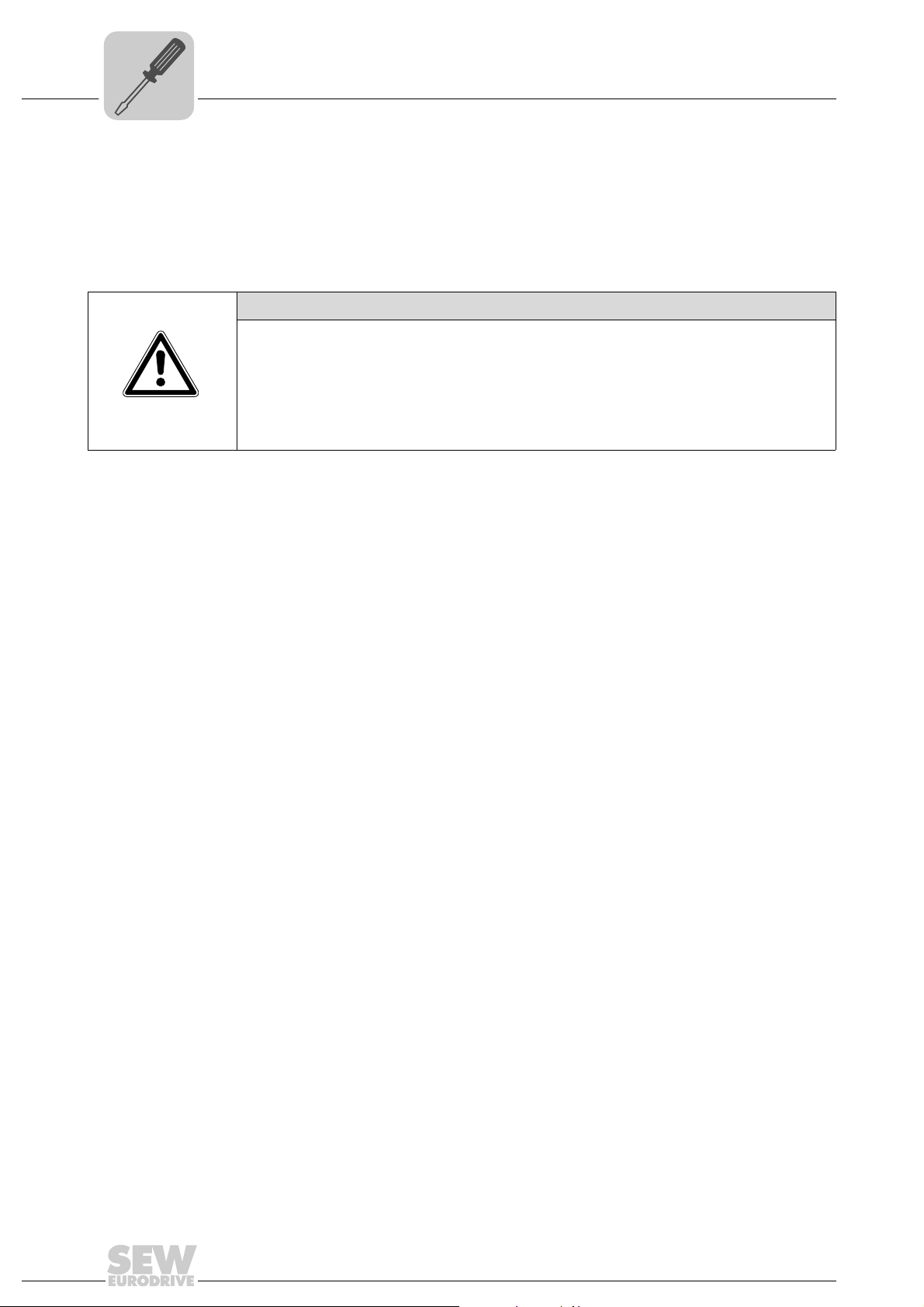

4.3.3 Connecting SBUS

plus

system bus (terminal X36)

Terminal X36 is intended for connecting a system bus based on EtherCAT (SBUS

4.3.4 Ethernet interface terminal (terminal X37)

You can connect an engineering PC to the Ethernet interface (terminal X37).

UFF41B

X35

342

1

Version

X36

S1

X37

1

1

XM L4

2

2

X32X33

3

3

1

1

2

2

3

3

L1 L2 L3L5

plus

).

64420AXX

The Ethernet interface (X37) supports auto crossing auto negotiation for baud rate and

duplex mode. The IP parameters are defined depending on DIP switch S1 (see section

"DIP switches S1 default IP address").

In addition to the engineering access via terminal X37, there is another engineering

access via PROFIBUS (see section "Operation of MOVITOOLS

®

MotionStudio").

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

21

Page 22

4

[3]

[2]

[1]

2

3

6

1

[6]

AB

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting inverters and engineering PC

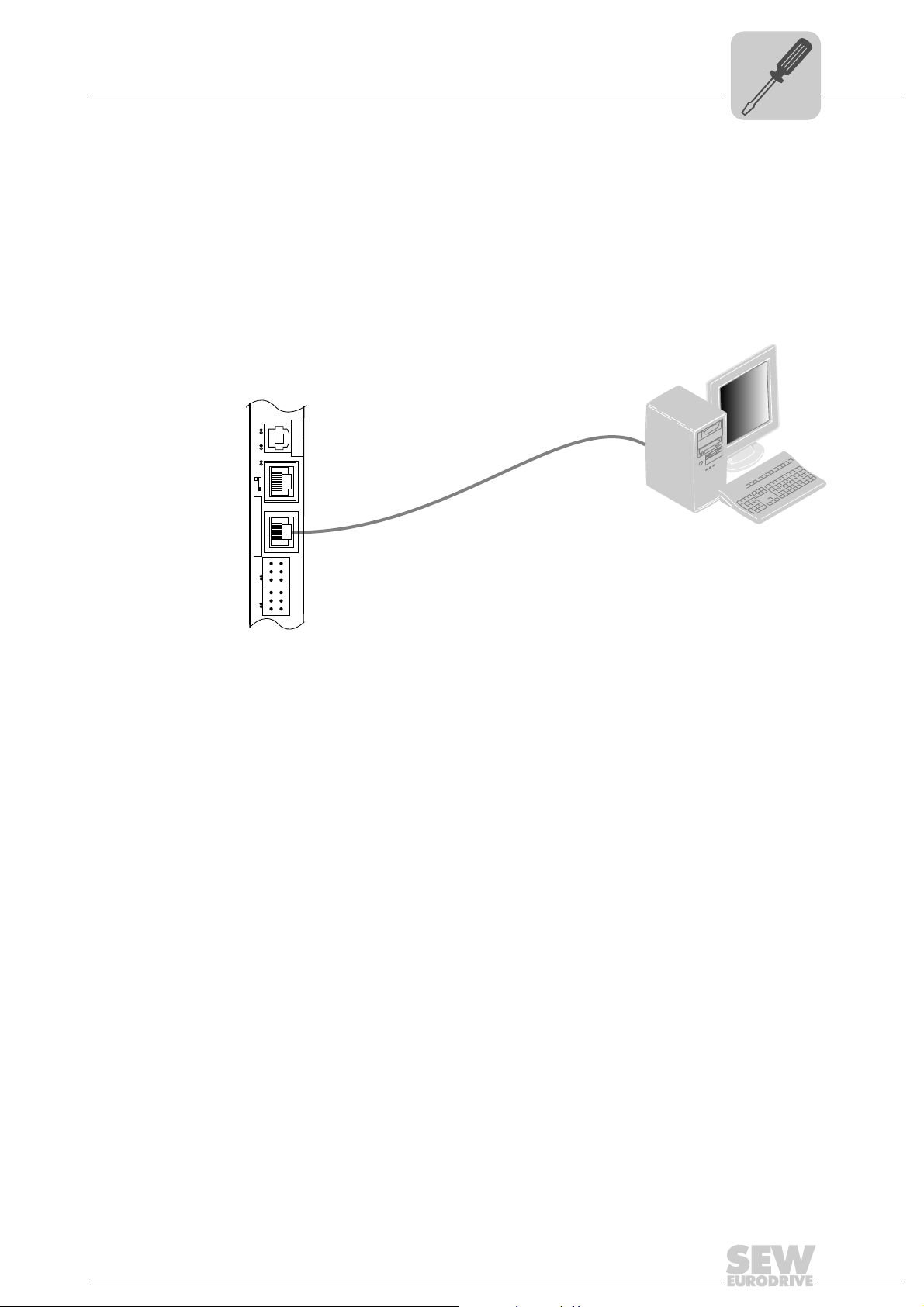

4.3.5 Pin assignment X37 (Ethernet for engineering)

Use prefabricated, shielded RJ45 plug connectors compliant with IEC 11801 edition 2.0,

category 5.

Figure 1: Pin assignment of an RJ45 plug connector

A = Front view

B = View from back

[1] Pin 1 TX+ Transmit Plus

[2] Pin 2 TX- Transmit Minus

[3] Pin 3 RX+ Receive Plus

[6] Pin 6 RX- Receive Minus

Connecting UFF41B fieldbus gateway to Ethernet

To connect UFF41B to the Ethernet, connect the Ethernet interface X37 (RJ45 plug

connector) to the other network stations using a category 5, class D twisted-pair cable

in accordance with IEC 11801 edition 2.0. The interface supports auto crossing and high

auto negotiation for baud rate and duplex mode.

TIP

According to IEC 802.3, the maximum cable length for 10/100 MBaud Ethernet

(10BaseT / 100BaseT), e.g. between two network stations, is 100 m.

54174AXX

22

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 23

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Status LED of the UFF41B fieldbus gateway

4.4 Status LED of the UFF41B fieldbus gateway

4

LED L1 (CAN 1

status)

LED L2 (CAN 2

status)

The LED L1 indicates the status of the CAN 1 system bus.

Status of the L1

LED

Orange The CAN 1 system bus is initialized.

Green The CAN 1 system bus is initialized.

Flashing green

(0.5 Hz)

Flashing green

(1 Hz)

Red The CAN 1 system bus is off (BUS-

Flashing red

(1 Hz)

Diagnostics Remedy

The CAN 1 system bus is currently in

SCOM suspend mode.

The CAN 1 system bus is currently in

SCOM On mode.

OFF).

Warning on the CAN 1 system bus. 1. Check and correct the cabling of the

-

1. Check and correct the cabling of the

CAN 1 system bus.

2. Check and correct the baud rate set

for the CAN 1 system bus.

3. Check and correct the terminating

resistors of the CAN 1 system bus.

CAN 1 system bus.

2. Check and correct the baud rate set

for the CAN 1 system bus.

The LED L2 indicates the status of the CAN 2 system bus.

Status of the L2

LED

Orange The CAN 2 system bus is initialized. -

Green The CAN 2 system bus is initialized. -

Flashing green

(0.5 Hz)

Flashing green

(1 Hz)

Red The CAN 2 system bus is off (BUS-

Flashing red

(1 Hz)

Diagnostics Remedy

The CAN 2 system bus is currently in

SCOM suspend mode.

The CAN 2 system bus is currently in

SCOM On mode.

OFF).

Warning on the CAN 2 system bus. 1. Check and correct the cabling of the

-

-

1. Check and correct the cabling of the

CAN 2 system bus.

2. Check and correct the baud rate set

for the CAN 2 system bus.

3. Check and correct the terminating

resistors of the CAN 2 system bus.

CAN 2 system bus.

2. Check and correct the baud rate set

for the CAN 2 system bus.

LED L3 (program

status)

LED L3 indicates the status of the gateway program.

Status of L3 Diagnostics Remedy

Green Gateway program is running. -

Off No gateway program is loaded. Load a gateway program into the controller.

Flashing orange

(1 Hz)

Program has stopped. Bootloader update required (see section

"SD memory card type OMG4.B")

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

23

Page 24

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

DIP switch S1 default IP address

LED 4 (PLC

status)

LED L4 indicates the firmware status of the fieldbus gateway.

Status of the L4 LED Diagnostics Remedy

Flashing green

(1 Hz)

Red • No SD card plugged in.

Flashing orange

(1 Hz)

The firmware of the fieldbus gateway

is running properly.

• File system of the SC card corrupt

Program has stopped. Bootloader update required (see section

-

"SD memory card type OMG4.B")

LED L5 (user) LED L5 is lit up red if the gateway program has detected an error and if this error can

only be eliminated after diagnostics with MOVITOOLS

®

MotionStudio.

4.5 DIP switch S1 default IP address

With DIP switch S1, you can set a default IP address for the Ethernet connection (X37).

The set IP address is applied in the next boot process.

S1 switch setting Meaning

Top IP p a r a m e t e r :

Bottom The IP parameters defined on the memory card of the UFF41B gateway are used.

• IP address: 192.168.10.4

• Subnet mask: 255.255.255.0

• Standard gateway: 1.0.0.0

The IP parameters for engineering interface X37 are entered in the file "...\System\NetConfig.cfg" in section "Ethernet 2". You can adjust the file using a text

editor (e.g. Notepad).

4.5.1 TCP / IP addressing and subnetworks

Introduction The settings for the address of the IP protocol are made using the following parameters:

• MAC address

• IP address

• Subnet mask

• Standard gateway

The addressing mechanisms and subdivision of the IP networks into sub-networks are

explained in this chapter to help you set the parameters correctly.

MAC address The MAC address (Media Access Controller) is the basis for all address settings. The

MAC address is a worldwide unique 6-byte value (48 bits) assigned to the Ethernet

device. SEW Ethernet devices have the MAC address 00-0F-69-xx-xx-xx. The MAC

address is difficult to handle for larger networks. This is why freely assignable IP

addresses are used.

IP address The IP address is a 32 bit value that uniquely identifies a station in the network. An IP

address is represented by four decimal numbers separated by decimal points.

Example: 192.168.10.4

24

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 25

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

DIP switch S1 default IP address

Each decimal number stands for one byte (= 8 bits) of the address and can also be

represented using binary code (see following table).

Byte 1 Byte 2 Byte 3 Byte 4

11000000 . 10101000 . 00001010 . 00000100

The IP address comprises a network address and a station address (see following

table).

Network address Station address

192.168.10 4

The part of the IP address that denotes the network and the part that identifies the

station is determined by the network class and the subnetwork mask.

Station addresses cannot consist of only zeros or ones (binary) because they represent

the network itself or a broadcast address.

Network classes The first byte of the IP address determines the network class and as such represents

the division into network addresses and station addresses.

4

Subnetwork

mask

Value range

Byte 1

0 - 127 A 10.1.22.3 10 = Network address

128 - 191 B 172.16.52.4 172.16 = Network address

192 - 223 C 192.168.10.4 192.168.10 = Network address

Network class

Complete network address

(Example)

Meaning

1.22.3 = Station address

52.4 = Station address

4 = Station address

This rough division is not sufficient for a number of networks. They also use an explicit,

adjustable subnetwork mask.

A subnetwork mask is used to divide the network classes into even finer sections. The

subnetwork mask is represented by four decimal numbers separated by decimal points,

in the same way as the IP address.

Example: 255.255.255.128

Each decimal number stands for one byte (= 8 bits) of the subnetwork mask and can

also be represented using binary code (see following table).

Byte 1 Byte 2 Byte 3 Byte 4

11111111 . 11111111 . 11111111 . 1 0000000

If you compare the IP addresses with the subnetwork masks, you see that in the binary

representation of the subnetwork mask all ones determine the network address and all

the zeros determine the station address (see following table).

Byte 1 Byte 2 Byte 3 Byte 4

IP address

Subnet mask

decimal 192 . 168. . 10 . 129

binary 11000000 . 10101000 . 00001010 . 10000001

decimal 255 . 255 . 255 . 128

binary 11111111 . 11111111 . 11111111 . 10000000

The class C network with the address 192.168.10. is further subdivided into

255.255.255.128 using the subnetwork mask. Two networks are created with the

address 192.168.10.0 and 192.168.10.128.

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

25

Page 26

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Standard gateway The standard gateway is also addressed via a 32-bit address. The 32-bit address is rep-

Assembly and Installation Instructions

SD memory card type OMG4.B

The following station addresses are permitted in the two networks:

• 192.168.10.1 - 192.168.10.126

• 192.168.10.129 - 192.168.10.254

The network stations use a logical AND operation for the IP address and the subnetwork

mask to determine whether there is a communication partner in the same network or in

another network. If the communication partner is in a different network, the standard

gateway is addressed for passing on the data.

resented by four decimal numbers separated by decimal points.

Example: 192.168.10.1

The standard gateway establishes a connection to other networks. In this way, a network station that wants to address another station can use a logical AND operation with

the IP address and the subnetwork mask to decide whether the desired station is located

in the same network. If this is not the case, the station addresses the standard gateway

(router), which must be part of the actual network. The standard gateway then takes on

the job of transmitting the data packages.

4.6 SD memory card type OMG4.B

The SD memory card type OMG4.B is required for operating the UFF41B fieldbus gate-

Bootloader

update

way and contains the firmware, the gateway program, and the gateway configuration.

With a MOVIAXIS

terization in case an axis needs to be replaced.

The SD memory card type OMG4.B is included in the scope of delivery of the UFF41B

fieldbus gateway.

Only use type OMG4.B memory cards in a UFF41B fieldbus gateway.

When the LEDs L3 and L4 flash orange at a 1 Hz frequency after power-on, a bootloader

update is required. Proceed as follows:

• Do not switch off the power supply during the entire process.

• Press the reset button T1 on the front of the UFF41B fieldbus gateway for 3 seconds.

When the bootloader update starts, only LED 4 is flashing.

• The bootloader update has been successful when L4 flashes green.

®

axis module, it is also used for data backup and automatic parame-

26

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 27

Assembly and Installation Instructions

UFF41B

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting the UFF41B fieldbus gateway to a DeviceNet network

4.7 Connecting the UFF41B fieldbus gateway to a DeviceNet network

The following sections describes the terminals, DIP switches, and LEDs relevant for

DeviceNet fieldbus operation.

4

Front view

UFF41B fieldbus

gateway

64775AXX

LED

Designation

DIP switch

Terminal

LED LED 18

LED 17

LED 16

LED 15

LED 14

LED 13

LED 12

LED 11

Terminal X30D:

DeviceNet

(plug-in terminals)

X30D:1

X30D:2

X30D:3

X30D:4

X30D:5

DIP switch S2

S2 To p

Switching between PROFIBUS

and DeviceNet

For operation via DeviceNet:

DIP switch

for setting

the MAC ID and the baud rate

Terminal X38:

CAN for safety-relevant

communication

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

X38:1

X38:2

X38:3

(plug-in terminals)

Mod/Net

Polled I/O

Bit-strobe I/O

BUSFAULT

-

-

VCAN_L

DRAIN

CAN_H

V+

Bottom

Function

LEDs 17 and 18 are reserved for PROFIBUS.

LED 18 is lit orange: UFF41B option is being

initialized

The two-color LEDs 13 to 16 indicate the current

status of the fieldbus interface and the DeviceNet

system.

Reserved

Reserved

0V24

CAN_L

DRAIN

CAN_H

24 V

Fieldbus interface PROFIBUS (X30P) active

Fieldbus interface DeviceNet (X30D) active

The DIP switches 20 - 25 are used to set the

MAC ID (Media Access Control Identifier). The

MAC ID represents the node address (address

range 0 - 63)

Baud rate setting

Baud rate setting

Reserved

Reserved

Reserved

4.7.1 Pin assignment X30D (DeviceNet)

The assignment of connecting terminals is described in the DeviceNet specification

(Volume I, Appendix A).

DFD11B

UFF41B

1

2

3

4

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

5

X30D

The UFF41B option is opto-decoupled on the driver side in accordance with the

DeviceNet specification (Volume I, Chapter 9). This means the CAN bus driver must be

powered with 24 V voltage via the bus cable. The cable to be used is also described in

the DeviceNet specification (Volume I, Appendix B). The connection must be made

according to the color code specified in the following table.

61612BXX

27

Page 28

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting the UFF41B fieldbus gateway to a DeviceNet network

Pin no. Signal Meaning Color coding

1V- 0V24 BK

2CAN_L CAN_L BU

3 DRAIN DRAIN blank

4CAN_H CAN_H WH

5V+ 24 V RD

UFF41B and

DeviceNet

connection

According to the DeviceNet specification, a linear bus structure without or with very short

droplines is required.

The maximum permitted cable length depends on the baud rate setting:

Baud rate Maximum cable length

500 kBaud 100 m

250 kBaud 250 m

125 kBaud 500 m

4.7.2 Bus termination

In order to avoid disruptions in the bus system due to reflections, each DeviceNet segment must be terminated with 120 Ω bus terminating resistors at the first and last physical station. Connect the bus terminating resistor between connections 2 and 4 of the

bus plug.

4.7.3 Setting the DIP switches

TIP

De-energize the UFF41B fieldbus gateway before you change the DIP switch settings.

The DIP switch settings are adopted during initialization only.

UFF41B

0

2

1

2

2

2

ON

3

2

4

2

5

2

6

2

7

2

64419AXX

20-25 = MAC ID setting

6-27

2

= Baud rate setting

Setting the MAC IDThe MAC ID (Media Access Control Identifier) is set on the UFF41B option using DIP

switches 2

0

- 25 in a binary coded manner. The MAC ID represents the node address

of the UFF41B. The UFF41B supports the address range 0 - 63.

28

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 29

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting the UFF41B fieldbus gateway to a DeviceNet network

4

Setting the baud

rate

The baud rate is set using DIP switches 26 and 27.

DIP switch

6

2

0 0 125 kBaud

1 0 250 kBaud

0 1 500 kBaud

11Invalid

7

2

Baud rate

A maximum of 64 DeviceNet data words can be exchanged between the DeviceNet

module and the UFF41B option. The number is set using the DeviceNet scanner.

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

29

Page 30

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting the UFF41B fieldbus gateway to a DeviceNet network

4.7.4 Status LED in DeviceNet operation

The UFF41B fieldbus gateway has four two-color LEDs for diagnostic of the DeviceNet

system; they indicate the current status of the UFF41B and the DeviceNet system. The

unit status corresponding to the status of the LED is described in chapter "Error

diagnostics".

Designation Abbreviation Complete LED designation

L16 MOD/NET Module/Network status

L15 PIO Polled I/O

L14 BIO Bit-strobe IO

L13 BUS FAULT BUS FAULT

LED

LED L16

(Mod/Net)

The function of the L16 LED (Mod/Net = Module/Network Status) described in the

following table is specified in the DeviceNet specification.

Status of the

L16 LED

Off Not switched on/offline • Unit is offline

Flashing green

(1 s cycle)

Lights up green Online, operational mode

Flashing red

(1 s cycle)

Red light Critical fault or critical link

Status Meaning

• Unit performs DUP MAC check

• Unit is switched off

Online and in operational

mode

and connected

Minor fault or connection

timeout

failure

• The unit is online and no connection has been

established

• DUP-MAC check performed successfully

• A connection has not yet been established with a

master

• Missing, incorrect or incomplete configuration

•Online

• Connection to a master has been established

• Connection is active (established state)

• A correctable fault has occurred

• Polled I/O and/or bit strobe I/O connections are in the

timeout status

• DUP-MAC check has detected an error

• A correctable fault has occurred

•BusOff

• DUP-MAC check has detected an error

L15 LED (PIO) The L15 (Polled I/O) LED monitors the polled I/O connection.

Status of the

L15 LED

Flashing green

(125 ms cycle)

Off Not switched on / offline

Flashing green

(1 s cycle)

Lights up green Online, operational mode

Flashing red

(1 s cycle)

Red light Critical fault or critical link

30

Status Meaning

DUP-MAC check Unit is performing DUP-MAC check

but not DUP-MAC check

Online and in operational

mode

and connected

Minor fault or connection

timeout

failure

• Unit is offline

• Unit is switched off

• Unit is online

• DUP-MAC check performed successfully

• A polled IO connection is being established with a

master (configuring state)

• Missing, incorrect or incomplete configuration

•Online

• A polled I/O connection has been established

(established state)

• Invalid baud rate set via DIP switches

• A correctable fault has occurred

• Polled I/O connection is in timeout status

• A fault that cannot be remedied has occurred

•BusOff

• DUP-MAC check has detected an error

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 31

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting the UFF41B fieldbus gateway to a DeviceNet network

L14 LED (BIO) The L14 (bit-strobe I/O) LED monitors the bit-strobe I/O connection.

4

L13 LED (BUS

FAULT)

Status of the

L14 LED

Flashing green

(125 ms cycle)

Off Not switched on / offline

Flashing green

(1 s cycle)

Lights up green Online, operational mode

Flashing red

(1 s cycle)

Red light Critical fault or critical link

Status Meaning

DUP-MAC check Unit is performing DUP-MAC check

but not DUP-MAC check

Online and in operational

mode

and connected

Minor fault or connection

timeout

failure

• Unit is offline

• Unit is switched off

• Unit is online

• DUP-MAC check performed successfully

• A BIO connection is being established with a master

(configuring state)

• Missing, incorrect or incomplete configuration

•Online

• A BIO connection has been established (established

state)

• Invalid number of process data is set via DIP switches

• A correctable fault has occurred

• Bit-strobe I/O connection is in timeout state

• A fault that cannot be remedied has occurred

•BusOff

• DUP-MAC check has detected an error

The L13 (BUS-OFF) LED indicates the physical status of the bus node.

Status of the

L13 LED

Off NO ERROR The number of bus errors is in the normal range (error

Flashing red

(125 ms cycle)

Flashing red

(1 s cycle)

Red light BUS ERROR • BusOff state

Yellow light POWER OFF External voltage supply has been turned off or is not

Status Meaning

active status).

The unit is performing a DUP-MAC check and cannot

send any messages because no other stations are

BUS WARNING

connected to the bus (error passive state)

The number of physical bus errors is too high. No more

error telegrams are actively written to the bus (error

passive state).

• The number of physical bus errors has increased

despite a switch to the error-passive state. Access to

the bus is switched off.

connected.

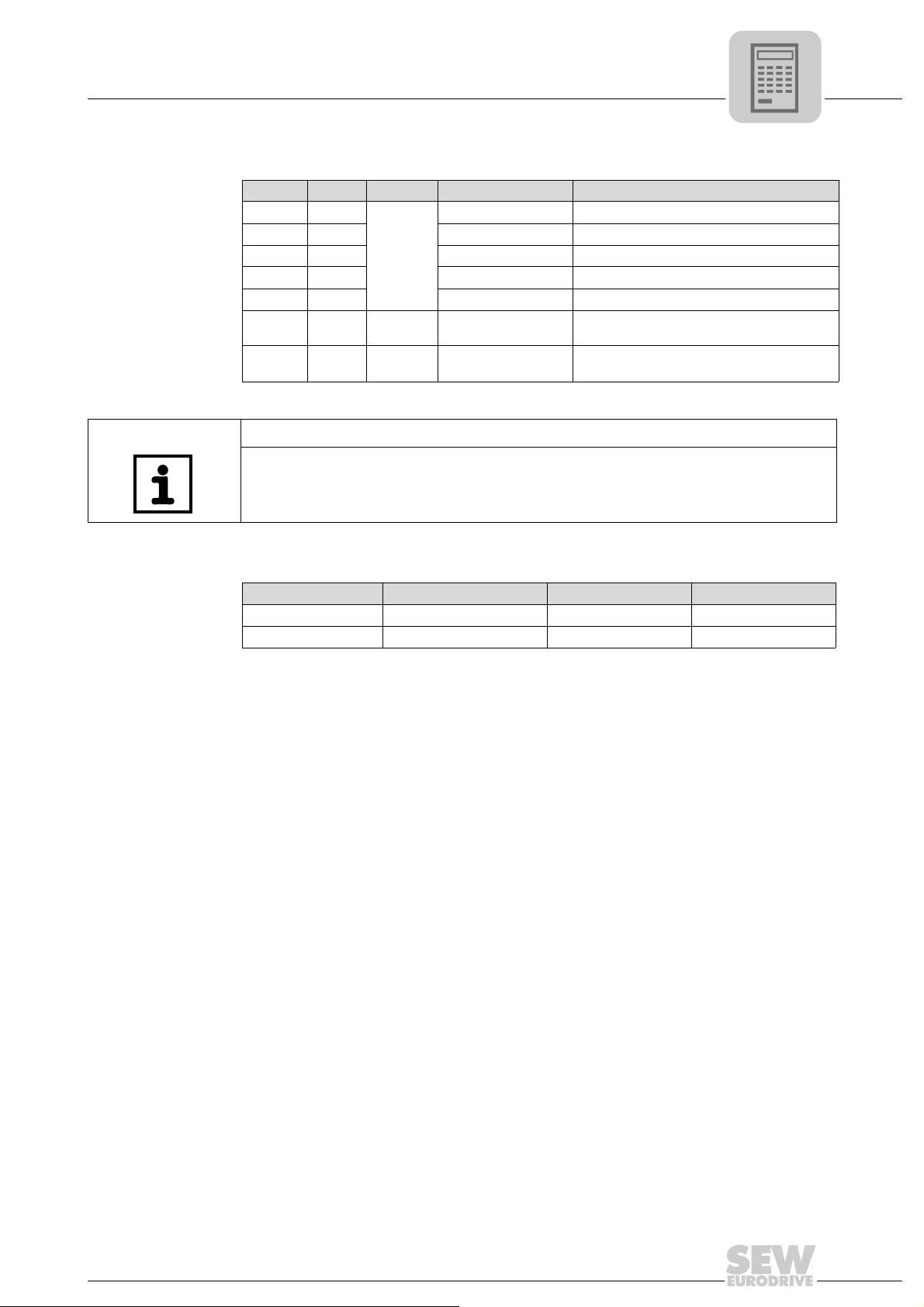

Power-UP test A power-up test of all LEDs is performed once the drive inverter has been switched on.

The LEDs are switched on in the following sequence:

Time [ms] LED L16 MOD/NET LED L15 PIO LED L14 BIO LED L13 BUS FAULT

0

250

500 Off

750 Off

1000 Off Off

1250 Off Off

1500 Off Off Off

1750 Off Off Off

2000 Off Off Off Off

Green Off Off Off

Red Off Off Off

Green Off Off

Red Off Off

Green Off

Red Off

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Green

Red

31

Page 32

4

UFF41B

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

RxD/TxD-P

3

1

5

9

6

8

4

5

6

9

VP (P5V/100mA)

DGND (M5V)

DGND (M5V)

CNTR-P

RxD/TxD-N

[3]

[1]

[2]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting the UFF41B fieldbus gateway to a PROFIBUS network

4.8 Connecting the UFF41B fieldbus gateway to a PROFIBUS network

The following sections describe the terminals, DIP switches, and LEDs relevant for

PROFIBUS operation.

Front view

UFF41B fieldbus

gateway

64422AXX

LED

Designation

DIP switch

Terminal

LED LED 18

LED 17

LED 12

LED 11

Terminal X30P:

PROFIBUS

(Sub-D9)

X30P:9

X30P:8

X30P:7

X30P:6

X30P:5

X30P:4

X30P:3

X30P:2

X30P:1

DIP switch S2

S2 To p

Switching between

PROFIBUS and DeviceNet

For PROFIBUS mode: DIP

switch for setting

the PROFIBUS station

address

Terminal X38:

CAN for safety-relevant

communication

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

X38:1

X38:2

X38:3

(plug-in terminals)

Run PROFIBUS

Fault PROFIBUS

-

-

GND (M5V)

RxD/TxD-N

N.C.

VP (P5V/100 mA)

GND (M5V)

CNTR-P

RxD/TxD-P

N.C.

N.C.

Bottom

Function

Status of PROFIBUS communication

Status of PROFIBUS bus electronics

Reserved

Reserved

Reference potential for PROFIBUS

Signal receive transmit negative

Terminal unassigned

DC+5 V potential for bus terminator

Reference potential for PROFIBUS

PROFIBUS control signal for repeater

Signal receive transmit positive

Terminal unassigned

Terminal unassigned

Fieldbus interface PROFIBUS (X30P) active

Fieldbus interface DeviceNet (X30D) active

Significance: 1

Significance: 2

Significance: 4

Significance: 8

Significance: 16

Significance: 32

Significance: 64

In PROFIBUS operation without function

Reserved

Reserved

Reserved

4.8.1 Pin assignment X30P (PROFIBUS)

Connection to the PROFIBUS system is made using a 9-pin sub D plug according to

IEC 61158. The T-bus connection must be made using a plug with the corresponding

configuration. The following figure shows the PROFIBUS connector that is connected to

X30P of the UFF41B fieldbus gateway.

32

[1] 9-pin D-sub connector

[2] Signal line, twisted

[3] Conductive connection over a large area is necessary between plug housing and

the shield

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

61766AXX

Page 33

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Connecting the UFF41B fieldbus gateway to a PROFIBUS network

4

UFF41B gateway

and PROFIBUS

connection

As a rule, the UFF41B fieldbus gateway is connected to the PROFIBUS system using a

shielded twisted-pair cable. Observe the maximum supported transmission rate when

selecting the bus connector.

The twisted-pair cable is connected to the PROFIBUS connector at pin 3 (RxD/TxD-P)

and pin 8 (RxD/TxD-N). Communication takes place using these two pins. The RS485

signals RxD/TxD-P and RxD/TxD-N must all be connected to the same contacts in all

PROFIBUS stations. Else, the bus components cannot communicate via the bus

medium.

The PROFIBUS interface sends a TTL control signal for a repeater or fiber optic adapter

(reference = pin 9) via pin 4 (CNTR-P).

Baud rates

greater than 1.5

The UFF41B fieldbus gateway with baud rates > 1.5 MBaud can only be operated with

special 12-MBaud PROFIBUS connectors.

MBaud

Bus termination When the UFF41B fieldbus gateway is located at the start or end of a PROFIBUS

segment and when there is only one PROFIBUS cable connected to the UFF41B fieldbus gateway, you must use a plug with an integrated bus terminating resistor.

Switch on the bus terminating resistors for this PROFIBUS connector.

0

Setting the

station address

To set the PROFIBUS station address, use DIP switches 2

7

gateway. DIP switch 2

has no function in PROFIBUS operation.

- 26 on the UFF41B fieldbus

The UFF41B fieldbus gateway supports the address range 0 - 125.

UFF41B

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

ON

64419AXX

The default setting for the station address is 4:

0

→ Significance: 1 × 0 = 0

2

1

2

→ Significance: 2 × 0 = 0

2

2

→ Significance: 4 × 1 = 4

3

→ Significance: 8 × 0 = 0

2

4

2

→ Significance: 16 × 0 = 0

5

2

→ Significance: 32 × 0 = 0

6

→ Significance: 64 × 0 = 0

2

Any change of the PROFIBUS station address during ongoing operation does not take

effect immediately. You have to switch the supply voltage of UFF41B off and then on

again for the changes to take effect.

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

33

Page 34

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Instructions

Connecting the UFF41B fieldbus gateway to a PROFIBUS network

4.8.2 Status LED in PROFIBUS operation

The UFF41B fieldbus gateway has two two-color LEDs for diagnostic of the PROFIBUS

system. They indicate the current status of the UFF41B and the PROFIBUS system. The

unit status corresponding to the status of the LED is described in chapter "Error

diagnostics".

LED L17 (FAULT

PROFIBUS)

LED L18 (RUN

PROFIBUS)

LED L17 (FAULT PROFIBUS) indicates that communication via the PROFIBUS inter-

face is working properly.

Status of the

L17 LED

Off • The UFF41B fieldbus gateway exchanges

Red • Connection to the DP master has failed.

Flashing red

(1 Hz)

Diagnostics Remedy

data with the PROFIBUS-DP master (data

exchange status).

• The UFF41B fieldbus gateway does not

detect the PROFIBUS baud rate.

• Bus interruption has occurred.

• PROFIBUS-DP master not in operation.

• The UFF41B fieldbus gateway does not

detect the baud rate. However, the DP

master does not address the UFF41B

fieldbus gateway.

• The UFF41B fieldbus gateway was not

configured in the DP master or was configured incorrectly.

-

• Check the PROFIBUS connection on

the unit.

• Check project planning of the

PROFIBUS DP master.

• Check all the cables in the

PROFIBUS network.

• Check and correct the PROFIBUS

station address set in the UFF41B

fieldbus gateway and in the configuration software of the DP master.

• Check and correct the configuration

of the DP master.

• Use the GSD file SEW_600D.GSD

with the designation Adv.Gateway

UFF for configuration.

LED L18 (RUN PROFIBUS) indicates the proper functioning of the PROFIBUS electron-

ics (hardware).

Status of the

L18 LED

Green • PROFIBUS hardware OK. -

Flashing

green

(1 Hz)

Orange • UFF41B option is being initialized. -

Diagnostics Remedy

• The PROFIBUS station address set on

the DIP switches exceeds 125. If the

PROFIBUS station address is set to a

value greater than 125, the UFF41B fieldbus gateway will use PROFIBUS station

address 4.

1. Check and correct the PROFIBUS

station address on the DIP switches.

2. Switch on all drive inverters again.

The modified PROFIBUS address

will only take effect after a restart.

34

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

Page 35

Assembly and Installation Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.9 Shielding and routing bus cables

Only use shielded cables and connection elements that meet the requirements of

category 5, class D according to IEC 11801 edition 2.0.

Correct shielding of the bus cable attenuates electrical interference that can occur in

industrial environments. The following measures ensure the best possible shielding:

• Manually tighten the mounting screws on the connectors, modules, and equipotential

bonding conductors.

• Use only connectors with a metal housing or a metallized housing.

• Connect the shielding in the connector over a wide surface area.

• Apply the shielding of the bus line on both ends.

• Route signal and bus cables in separate cable ducts. Do not route them parallel to

power cables (motor leads).

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding close to each

other using the shortest possible route.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

Shielding and routing bus cables

4

CAUTION

In case of fluctuations in the earth potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according in accordance with relevant

VDE regulations in such a case.

Manual – Fieldbus Gateway UFF41B DeviceNet and PROFIBUS DP

35

Page 36

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the UFx41B Fieldbus Gateway and the Inverter

Description of the gateway functions

5 Configuring the UFx41B Fieldbus Gateway and the Inverter

5.1 Description of the gateway functions

5.1.1 Introduction

With the UFF41B and UFR41B fieldbus gateways, SEW-EURODRIVE offers innovative

solutions for integrating SEW inverter technology in fieldbus systems.

For this purpose, process data of the higher-level control in the fieldbus gateway are

processed and sent via CAN (SBus) to the devices connected to the fieldbus gateway.

Type UFx41B fieldbus gateways can transmit up to 64 process data (PD) from the

fieldbus to up to 16 lower-level slave units. The data length per slave unit is limited to 16

process data.

Two different unit configurations are supported:

• Autosetup configuration

For automatic configuration of the fieldbus gateway and connected devices.