Page 1

Drive Technology \ Drive Automation \ System Integration \ Services

Assembly and Operating Instructions

Gear Units

R..7, F..7, K..7, K..9, S..7, SPIROPLAN

®

W

Edition 10/2013 20200544 / EN

Page 2

SEW-EURODRIVE—Driving the world

Page 3

Contents

Contents

1 General Information............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes......................................... ... ........................... 5

1.3 Rights to claim under warranty ................................................................... 6

1.4 Content of the documentation..................................................................... 6

1.5 Exclusion of liability..................................................................................... 6

1.6 Product names and trademarks.................................................................. 6

1.7 Copyright..................................................................................................... 6

2 Safety Notes ........................................................................................................ 7

2.1 Preliminary information ............................................................................... 7

2.2 General information ................................................................ ... ... .............. 7

2.3 Target group ............................................................................................... 8

2.4 Designated use............................................. ... ... .... ... ... ... .... ....................... 8

2.5 Other applicable documentation................................................................. 8

2.6 Transport/storage........................................................................................ 9

2.7 Setup........................................................................................................... 9

2.8 Startup/operation ........................................................................................ 9

2.9 Inspection/maintenance.............................................................................. 9

3 Gear Unit Structure........................................................................................... 10

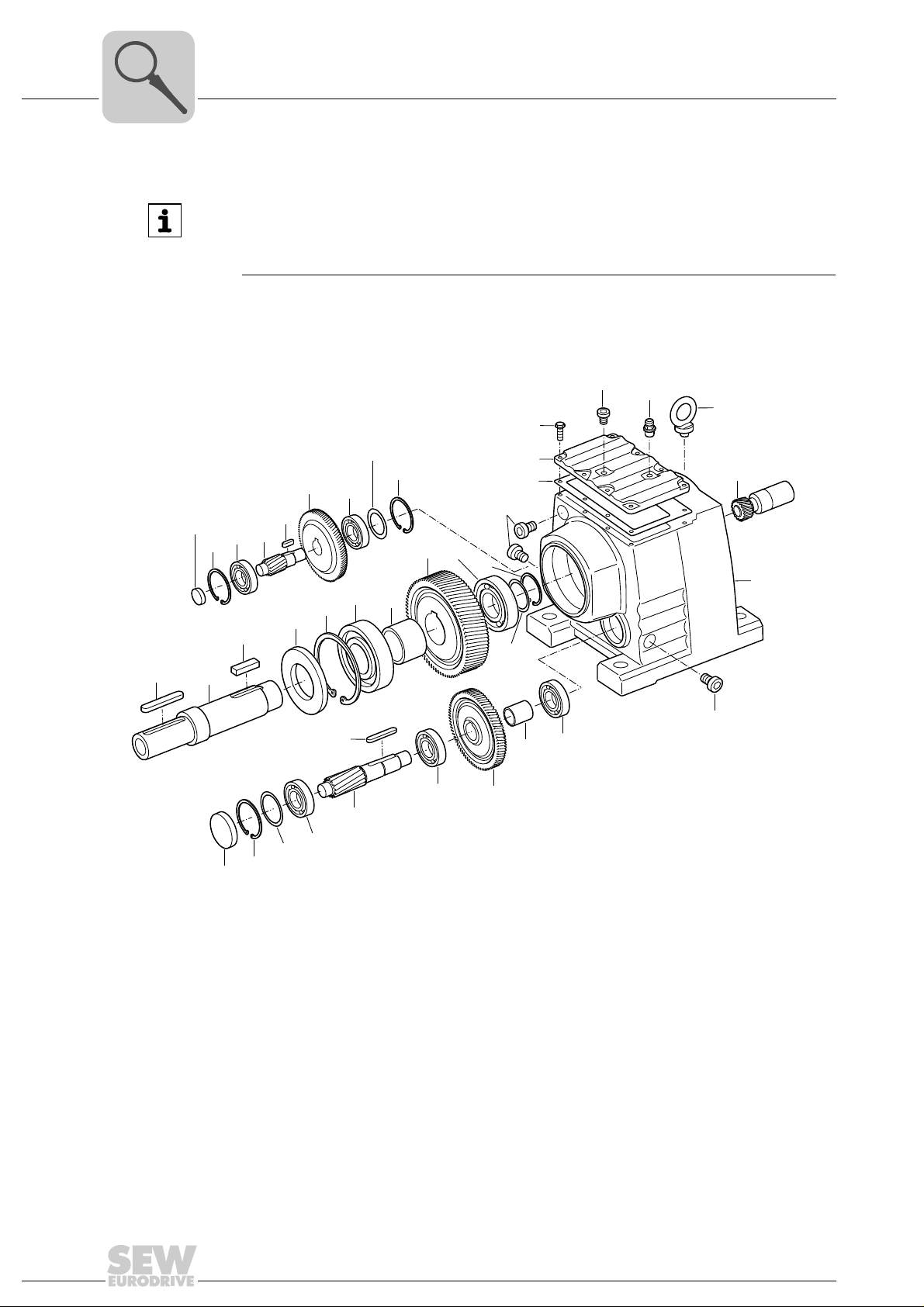

3.1 Basic structure of helical gear units .......................................................... 10

3.2 Basic structure of parallel-shaft helical gear units..................................... 11

3.3 Basic structure of helical-bevel gear units K..9......................................... 12

3.4 Basic structure of helical-bevel gear units K..37 – K..187........................ 13

3.5 Basic structure of helical-worm gear units ................................................ 14

3.6 Basic structure of SPIROPLAN

3.7 Basic structure of SPIROPLAN

3.8 Nameplate/type designation ............................ ... .... ... ... ... .... ... ... ... ... .... ... .. 17

4 Mechanical Installation..................................................................................... 18

4.1 Required tools/resources.......................................................................... 18

4.2 Installation requirements........................................................................... 19

4.3 Installing the gear unit............................................................................... 20

4.4 Gear units with solid shaft......................................................................... 27

4.5 Torque arms for shaft-mounted gear units................................................ 29

4.6 Shaft-mounted gear units with keyway or splined hollow shaft................. 32

4.7 Shaft-mounted gear units with shrink disk ................................................ 39

4.8 Shaft-mounted gear units with TorqLOC

4.9 Installing the protective cover ................................................................... 55

4.10 Coupling of AM adapters ................................. ... .... ... ... ... .... ... ... ... ... .... ... .. 57

4.11 AQ. adapter coupling ................................................................................ 61

4.12 EWH adapters............... ...... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ...... ... ... .... ... .. 64

4.13 AD input shaft assembly ........................................................................... 66

4.14 Accessory equipment................................................................................ 71

®

gear units W..10 – W..30...................... 15

®

gear units W..37 – W..47...................... 16

®

................................................ 43

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

3

Page 4

Contents

5 Startup................................................................................................................ 80

5.1 Checking the oil level................................................................................ 81

5.2 Pseudo-leakage at shaft seals.................................................................. 81

5.3 Helical-worm and SPIROPLAN

5.4 Helical/parallel-shaft helical/helical-bevel gear units................................. 83

5.5 Gear units with backstop........................................................................... 83

5.6 Components made of elastomers with fluorocarbon rubber ..................... 84

6 Inspection/Maintenance ................................................................................... 85

6.1 Preliminary work regarding gear unit inspection/maintenance ................. 85

6.2 Inspection/maintenance intervals.............................................................. 86

6.3 Lubricant change intervals........................................................................ 87

6.4 Inspection/maintenance for the AL / AM / AQ. / EWH adapter ................. 88

6.5 Inspection/maintenance for the AD input shaft assembly......................... 88

6.6 Inspection/maintenance for the gear unit.................................................. 89

7 Mounting Positions......................................................................................... 104

7.1 Designation of the mounting positions................................................. ... 104

7.2 Churning losses ...................................................................................... 105

7.3 Mounting position MX ............................................................................. 105

7.4 Universal mounting position M0.............................................................. 105

7.5 Mounting positions of SPIROPLAN

7.6 Key.......................................................................................................... 106

7.7 Helical gearmotors R ................................................................. ............. 107

7.8 Helical gearmotors RX........................................ .... ... ............................. 110

7.9 Parallel-shaft helical gearmotors F ......................................................... 112

7.10 Helical-bevel gearmotors K..................................................................... 115

7.11 Helical-worm gearmotors S..................................................................... 123

7.12 SPIROPLAN

®

W gearmotors. .... ... ... ... .... ... ... .......................................... 129

8 Technical Data................................................................................................. 135

8.1 Extended storage ................................................................................... 135

8.2 Lubricants ............................................................................................... 136

9 Malfunctions.................................................................................................... 145

9.1 Gear units ............................................................................................... 145

9.2 Adapters AM / AQ. / AL / EWH ............................................................... 146

9.3 AD input shaft assembly ......................................................................... 147

9.4 Customer service ................................................................................... 147

9.5 Disposal .................................................................................................. 147

®

W gear units .......... ... ... .... ... ... ... ... .... ... .. 82

®

gear units...................................... 106

10 Address list...................................................................................................... 148

Index................................................................................................................. 160

4

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 5

General Information

How to use this documentation

1

1 General Information

Gear Units R..7, F..7, K..7, K ..9, S..7, SPIROPLAN® W

1.1 How to use this documentation

The documentation is an integral part of the product and contains impo rtant information

on operation and service. The documentation is written for all employees wh o assemble,

install, start up, and service this product.

The documentation must be accessible and legi ble. Make sure that persons responsible

for the system and its operation, as well as persons wh o work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of signal words

The following table shows the graduation and meaning of the signal words for safety

notes, warnings regarding potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER! Imminent hazard Severe or fatal injuries

WARNING! Possible dangerous situation Severe or fatal injuries

CAUTION! Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its envi-

NOTE Useful information or tip: Simpli-

fies handling of the drive system.

ronment

1.2.2 Design of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to se veral actions per taining to one subject. The symbols used either indicate a general hazard or a specific

hazard.

This is the formal structure of a safety note for a specific section:

SIGNAL WORD!

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Design of the embedded safety notes

Embedded safety notes are directly integrated into the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD! Type and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the hazard.

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

5

Page 6

1

General Information

Rights to claim under warranty

1.3 Rights to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Therefore read the

documentation before you start working with the unit.

1.4 Content of the documentation

This document contains additional safety-related information and conditions for operation in safety-related applications.

1.5 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of the se operating instructions. In such

cases, any liability for defects is excluded.

1.6 Product names and trademarks

All product names in this documentation are trademarks or registered trademarks of

their respective titleholders.

1.7 Copyright

© 2013 – SEW-EURODRIVE. All rights reserved.

Unauthorized reproduction, modification, distribution or any other use of the whole or

any part of this documentation is strictly prohibited.

6

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 7

2 Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons a nd

damage to property. The operator must ensure that the basic safety notes a re read and

adhered to. Make sure that persons responsible for the system and its operation, as

well as persons who work independently on the unit, have read through the operating

instructions carefully and understood them. If you are unclear about any of the inform ation in this documentation or if you require further information, please contact SEWEURODRIVE.

2.1 Preliminary information

Safety Notes

Preliminary information

2

The following safety notes are primarily concerned with the use of th e followin g components: Gear unit series R..7, F..7, K..7, K..9, S..7, SPIRO PLAN

gearmotors, you must also observe the safety notes for motors in the correspondin g operating instructions.

Also observe the supplementary safety notes in the individual sections of this documentation.

2.2 General information

WARNING

Danger of fatal injury or risk of injury during the operation of motors or gearmotors

caused by live, bare (in the event of open connectors/terminal boxes) and movable or

rotating parts.

Risk of burns caused by hot surfaces

Severe or fatal injuries

• All work related to transport, storage, installation, assembly, connection, startup,

maintenance and repair may only be carried out by qualified personnel.

• For transport, storage, installation, assembly, connection, startup, maintenance

and repair it is important that you adhere to the information in the following documents:

– Warning and safety signs on the motor/gearmotor

– All the project planning documents, startup instructions and wiring diagrams re-

lated to the drive

– System-specific regulations and requirements

– National/regional regulations governing the safety and prevention of accidents

• Never install damaged products.

• Never operate or energize the unit without the necessary protection covers or

housing.

• Use the unit only for its intended purpose.

• Make sure the unit is installed and operated properly.

®

W. If you are using

INFORMATION

In the event of damage caused by transport, submit a complaint to the shipping company immediately.

This documentation provides additional information.

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

7

Page 8

2

2.3 Target group

Safety Notes

Target group

Any mechanical work may only be performed by adequately qualified person nel. Qualified personnel in the context of this documentation are persons familiar with the design,

mechanical installation, troubleshooting and servicing of the product who possess the

following qualifications:

• Training in mechanical engineering, e.g. as a mechanic or mechatronics technician

(final examinations must have been passed).

• They are familiar with these operating instructions.

Any electronic work may only be per form ed by adequately qualified electricians. Qualified electricians in the context of this documentation are persons familiar with electrical

installation, startup, troubleshooting and servicing of the product who possess the

following qualifications:

• Training in electrical engineering, e.g. as an electrician, electronics or mechatronics

technician (final examinations must have been passed).

• They are familiar with these operating instructions.

All work in further areas of transportation, stor age, operation and was te disposal must

only be carried out by persons who are trained appropriately.

All qualified personnel must wear appropriate protective clothing.

2.4 Designated use

The gear unit series R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W is intended for use in

industrial systems.

The gear units may only be used according to the specifications in the technical documentation from SEW-EURODRIVE as well as the specifications on the nameplate. They

fulfill the applicable standards and regulations.

When installed in machines, startup (i.e. start of designated operation) is prohibited until

it is determined that the machine complies with the local laws and directives. In the individual area of application, you must especially observe the Machinery Directive

2006/42/EC as well as the EMC Directive 2004/108/EC. The EMC test specifications

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-6 and EN 61000-6-2 form

the basis for this.

Use in potentially explosive atmospheres is prohibited unless specifically designated

otherwise.

2.5 Other applicable documentation

The following publications and documents have to be observed as well:

• "DR.71 – 225, 315 AC Motors" operating instructions for gearmotor s

• Operating instructions of any attached options

• "Gear Units" catalog or

• "Gearmotors" catalog

8

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 9

2.6 Transport/storage

Inspect the shipment for any damage that may have occurred in transit as soon as you

receive the delivery. Inform the shipping com pany immediately in the event of damage.

It may be necessary to preclude startup.

Tighten the eyebolts securely. They are designed to carry only the weight of the

motor/gearmotor; do not attach any additional loads.

The built-in lifting eyebolts comply with DIN 580. Always observe the loads and regulations listed in this standard. If the gearmotor is equipped with two eyebolts, then both

should be used for transportation. In this case, the tension force vector of the slings must

not exceed a 45° angle according to DIN 580.

Use suitable, sufficiently rated handling equipment if required. Reattach these in the

case of further transportation.

Store the motor/gearmotor in a dry, dust-free environment if it is not to be installed

straight away. You must not store the motor/gearmotor outdoors or on the fan guard.

The motor/gearmotor can be stored for up to 9 months without requiring any special

measures before startup.

Safety Notes

Transport/storage

2

2.7 Setup

NOTICE

Danger due to static overdetermination if gear units with foot (e.g. KA19/29B,

KA127/157B or FA127/157B) are mounted both via the torque arm and via the foot

plate.

Risk of injuries and damage to property.

• Especially with the KA.9B/T variant, it is not permitted to use the foot plates and the

torque arm at the same time.

• The KA.9B/T variant may only be mounted via torque arms.

• K.9 or KA.9B variants may only be mounted via the foot plate.

• If you want to use foot plates and torque arms for mounting, consult with SEW- EURODRIVE.

Observe the notes in the "Mechanical Installation" section.

2.8 Startup/operation

Check the oil level before startup as described in chapter Inspection/Maintenance

(page 85).

Check that the direction of rotation is correct in decoupled status. Listen out for unusual

grinding noises as the shaft rotates.

Secure keys for test mode without output elements. Do not deactivate monitoring and

protection equipment even in test mode.

Switch off the gearmotor if in doubt whenever changes occur in rela tion to normal o peration (e.g. increased temperature, noise, vibration). Determine the cause and contact

SEW-EURODRIVE, if required.

2.9 Inspection/maintenance

Observe the notes in chapter "Inspection/Maintenance".

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

9

Page 10

3

Gear Unit Structure

Basic structure of helical gear units

3 Gear Unit Structure

INFORMATION

The following figures are block diagrams. Their purpose is only to make it easier to assign components to the spare parts lists. Discrepancies may occur depending on the

gear unit size and version.

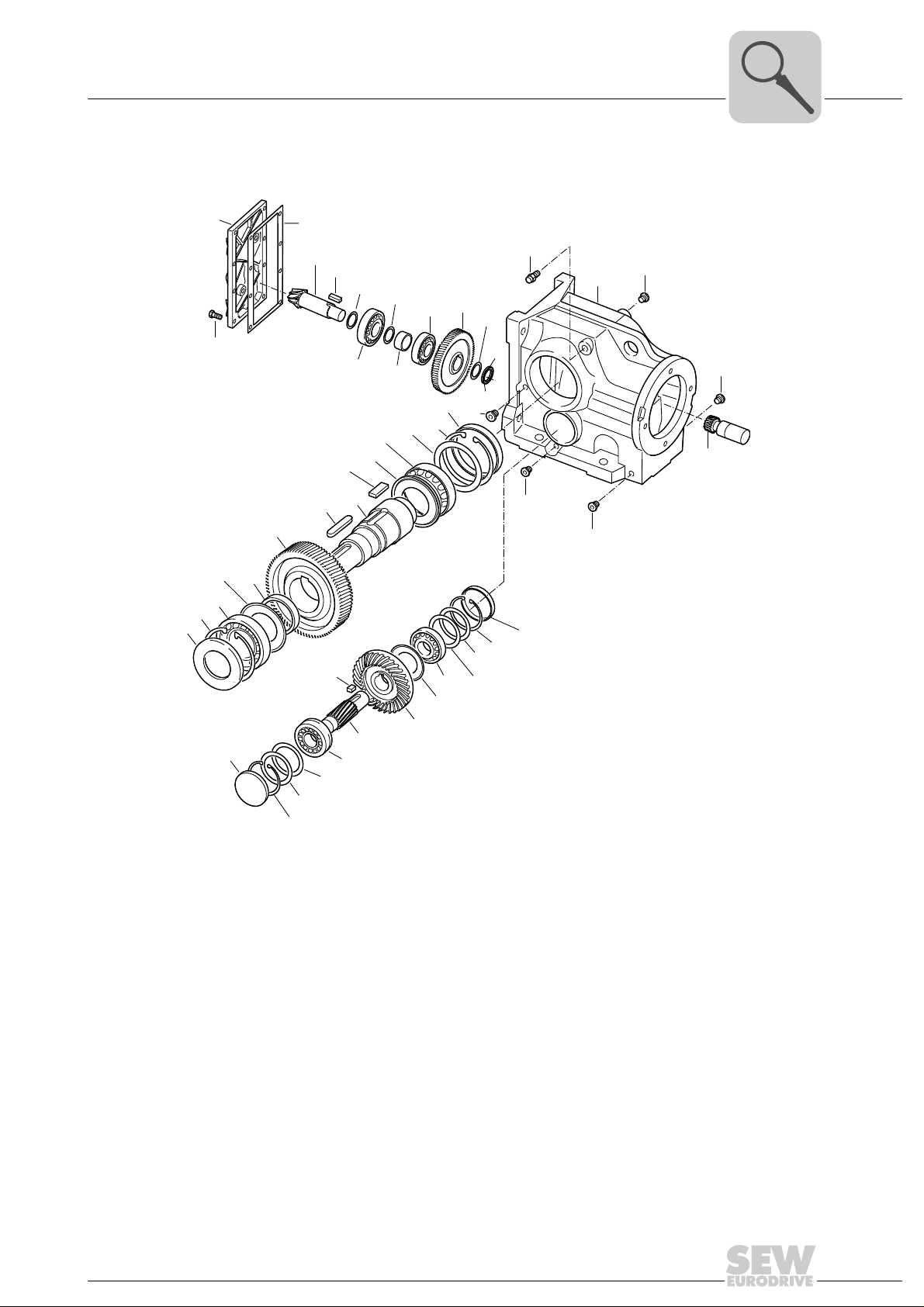

3.1 Basic structure of helical gear units

[8]

Pinion

[1]

Gear

[2]

Pinion shaft

[3]

Gear

[4]

Pinion shaft

[5]

Gear

[6]

Output shaft

[7]

Key

[8]

Oil seal

[9]

Rolling bearing bearing

[11]

Retaining ring

[12]

Spacer tube

[17]

[181]

[41]

[7]

[131]

[42]

[19]

[39]

[2]

[43]

[3]

[9]

[37]

[506]

[507]

[508]

Key

[19]

Breather valve

[20]

Gear unit housing

[22]

Eyebolt

[24]

Rolling bearing

[25]

Rolling bearing

[30]

Key

[31]

Spacer tube

[32]

Rolling bearing

[34]

Rolling bearing

[37]

Retaining ring

[39]

Retaining ring

[41]

[12]

[31]

[45]

[11]

[5]

[515]

[516]

[517]

[47]

[17]

[6]

[34]

[25]

[88]

[42]

[43]

[45]

[47]

[59]

[88]

[100]

[101]

[102]

[131]

[181]

[506]

[101]

[100]

[102]

[59]

[521]

[522]

[523]

[30]

[32]

[4]

Rolling bearing

Key

Rolling bearing

Retaining ring

Screw plug

Retaining ring

Inspection cover

Hex head screw

Gasket

Closing cap

Closing cap

Shim

[59]

[20]

[507]

[508]

[515]

[516]

[517]

[521]

[522]

[523]

[24]

[1]

[22]

[59]

19194251

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

10

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 11

Gear Unit Structure

[181]

[41]

[517]

[508]

[516]

[507]

[515]

[506]

[42]

[3]

[43]

[2]

[45]

[30]

[59]

[101]

[100]

[102]

[160]

[165]

[161]

[59]

[59]

[20]

[22]

[1]

[521]

[522]

[523]

[25]

[88]

[183]

[32]

[4]

[31]

[5]

[37]

[39]

[131]

[14]

[16]

[81]

[9]

[11]

[17]

[6]

[7]

[91]

[92]

[93]

[94]

[19]

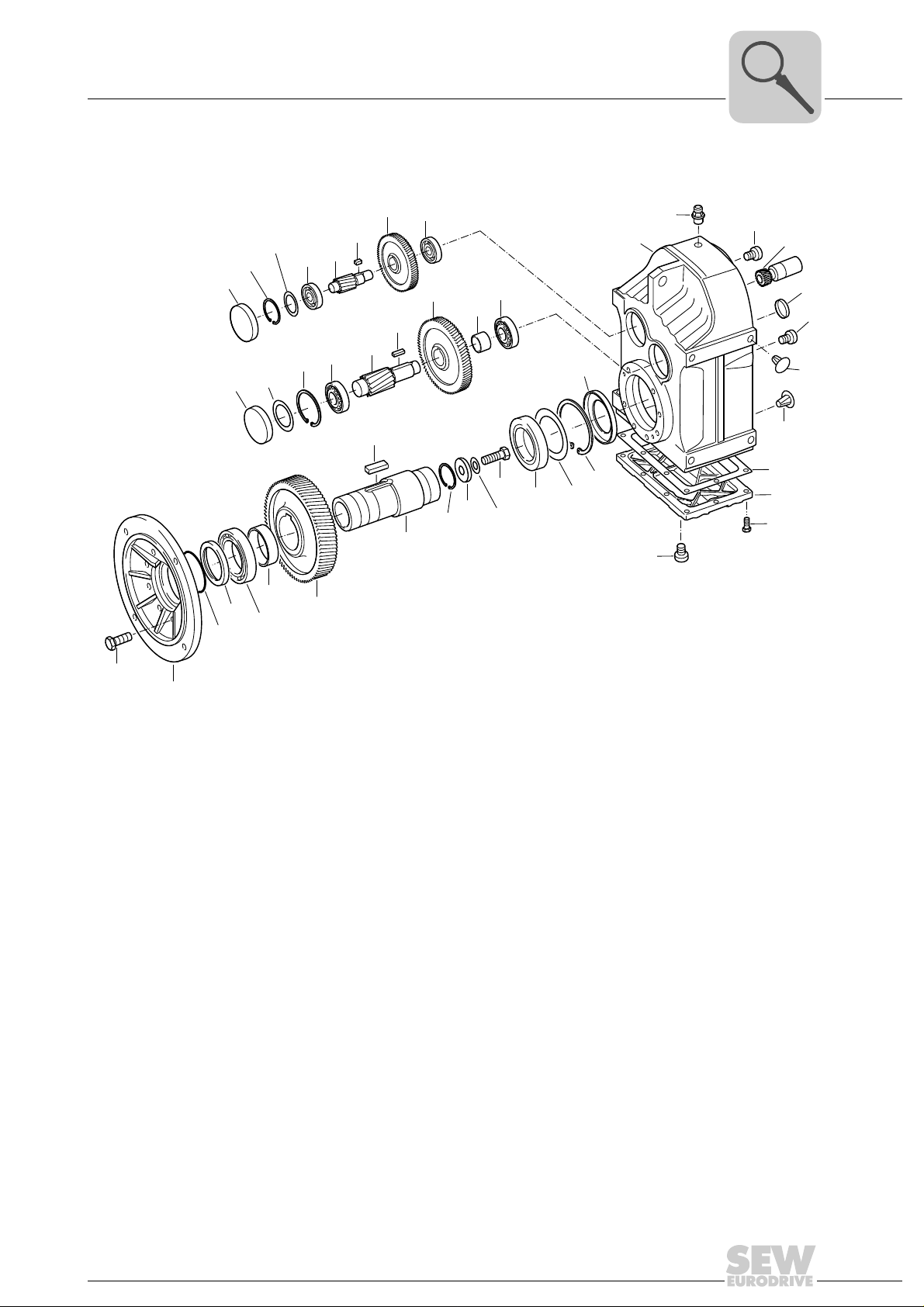

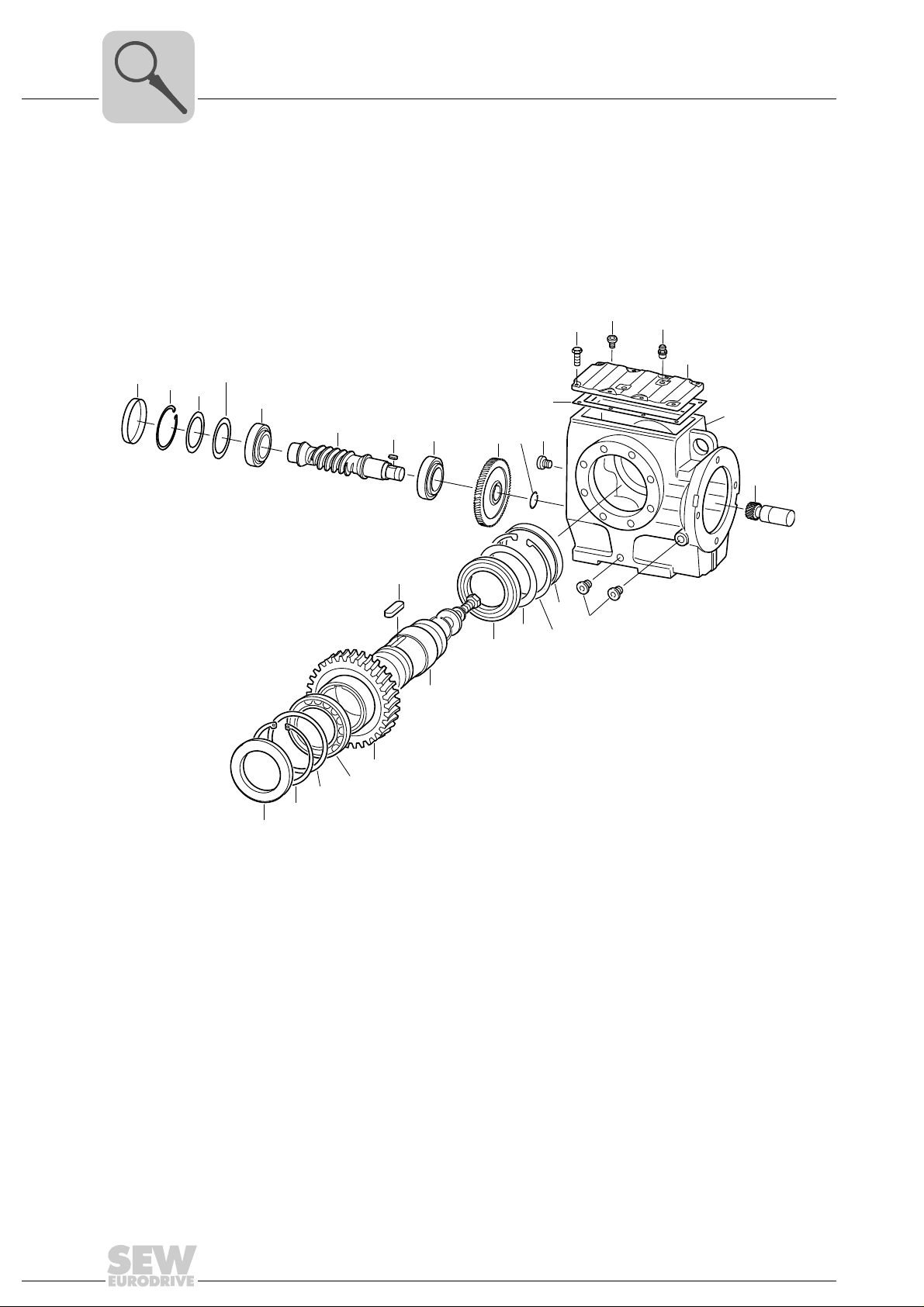

Basic structure of parallel-shaft helical gear units

3.2 Basic structure of parallel-shaft helical gear units

3

Pinion

[1]

Gear

[2]

Pinion shaft

[3]

Gear

[4]

Pinion shaft

[5]

Gear

[6]

[7]

[9]

[11]

[14]

[16]

[17]

[19]

[20]

Hollow shaft

Oil seal

Rolling bearing bearing

Hex head screw

Output flange

Spacer tube

Key

Breather valve

Gear unit housing

[22]

Rolling bearing

[25]

Rolling bearing

[30]

Key

[31]

Spacer tube

[32]

Rolling bearing

[37]

Retaining ring

[39]

Retaining ring

[41]

Rolling bearing

[42]

Key

[43]

Rolling bearing

[45]

Screw plug

[59]

Shield ring

[81]

Retaining ring

[88]

Retaining ring

[91]

Washer

[92]

Lock washer

[93]

Hex head screw

[94]

Inspection cover

[100]

Hex head screw

[101]

Gasket

[102]

Closing cap

[131]

Closing plug

[160]

Closing cap

[161]

Closing plug

[165]

Closing cap

[181]

Oil seal

[183]

[506]

[507]

[508]

[515]

[516]

[517]

[521]

[522]

[523]

19298059

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

11

Page 12

3

[9]

[12]

[518]

[519]

[520]

[11]

[17]

[36]

[24]

[1]

[29]

[26]

[44]

[115]

[163]

[530]

[531]

[532]

[2]

[45]

[141]

[42]

[536]

[537]

[538]

[43]

[5]

[150]

[7]

[80]

[183]

[48]

[8]

[7]

[19]

[59]

[159]

[88]

[521]

[522]

[523]

[25]

[6]

[167]

[59]

[22]

[106]

[20]

[89]

Gear Unit Structure

Basic structure of helical-bevel gear units K..9

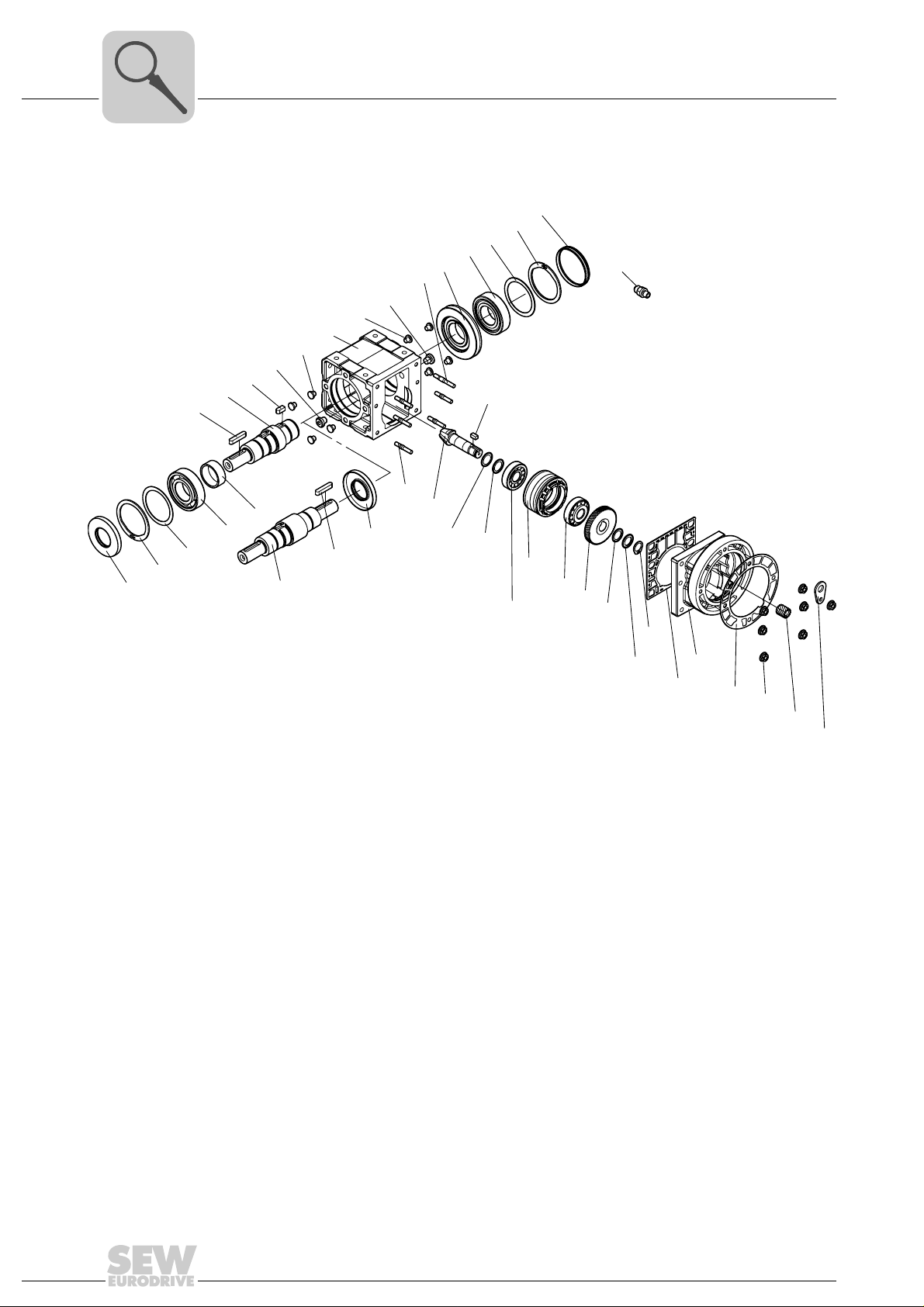

3.3 Basic structure of helical-bevel gear units K..9

Pinion

[1]

Gear

[2]

Pinion shaft

[5]

Gear

[6]

Output shaft

[7]

Key

[8]

Oil seal

[9]

Deep groove ball bearing

[11]

Retaining ring

[12]

Spacer tube

[17]

Key

[19]

Breather valve

[20]

Gear unit housing

[22]

Eyebolt

[24]

Deep groove ball bearing

[25]

[26]

[29]

[36]

[42]

[43]

[44]

[45]

[48]

[59]

[62]

[63]

Housing stage 1

Gasket

Stud

Tapered roller bearing

Key

Gasket

Tapered roller bearing

Supporting ring (only K..29)

Screw plug

Screw plug

Thread reduction

Key

[80]

Retaining ring

[88]

Closing cap

[89]

Stud

[106]

Retaining ring

[115]

Bushing

[141]

Hex nut

[150]

Closing plug

[159]

Supporting ring

[163]

Closing plug

[167]

Oil seal

[183]

Shim

[518]

Shim

[519]

[520]

[521]

[522]

[523]

[530]

[531]

[532]

[536]

[537]

[538]

7421610507

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

12

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 13

Gear Unit Structure

[100]

[102]

[3]

[101]

[43]

[538]

[535]

[537]

[534]

[536]

[533]

[42]

[119]

[45]

[2]

[20]

[22]

[59]

[59]

[59]

[59]

[1]

[114]

[113]

[116]

[89]

[59]

[88]

[521]

[522]

[523]

[25]

[84]

[19]

[8]

[7]

[6]

[17]

[83]

[11]

[12]

[9]

[37]

[5]

[4]

[30]

[135]

[542]

[543]

[544]

[133]

[132]

[161]

[31]

[506]

[507]

[508]

[137]

[39]

[131]

Basic structure of helical-bevel gear units K..37 – K..187

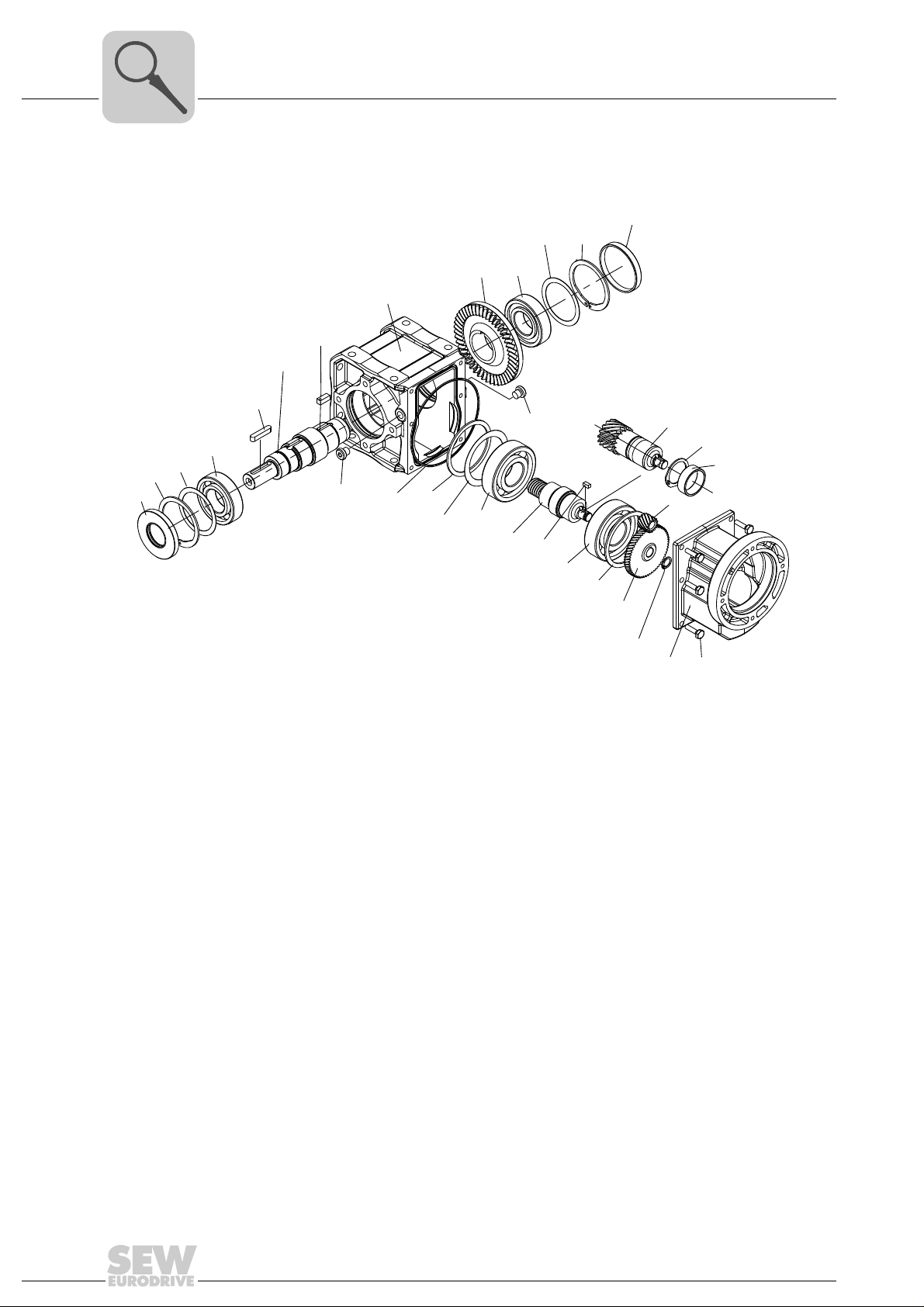

3.4 Basic structure of helical-bevel gear units K..37 – K..187

3

[25]

[30]

[31]

[37]

[39]

[42]

[43]

[45]

[59]

[83]

[84]

[88]

[89]

[100]

[101]

Pinion

[1]

Gear

[2]

Pinion shaft

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[11]

[12]

[17]

[19]

[20]

[22]

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Gear

Pinion shaft

Gear

Output shaft

Key

Oil seal

Rolling bearing bearing

Retaining ring

Spacer tube

Key

Breather valve

Gear unit housing

Rolling bearing

Rolling bearing

Key

Rolling bearing

Retaining ring

Rolling bearing

Key

Rolling bearing

Screw plug

Shield ring

Shield ring

Retaining ring

Closing cap

Inspection cover

Hex head screw

Gasket

[102]

Slotted nut

[113]

Lock washer

[114]

Threadlocker

[116]

Spacer tube

[119]

Closing cap

[131]

Retaining ring

[132]

Supporting ring

[133]

Shield ring

[135]

Closing cap

[161]

Shim

[506]

Shim

[507]

Shim

[508]

Shim

[521]

Shim

[521]

[522]

[523]

[533]

[534]

[535]

[536]

[537]

[538]

[542]

[543]

[544]

19301131

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

13

Page 14

3

[131]

[39]

[137]

[507]

[506]

[37]

[5]

[43]

[30]

[9]

[12]

[520]

[519]

[518]

[11]

[6]

[7]

[25]

[88]

[89]

[59]

[523]

[522]

[521]

[19]

[2]

[59]

[102]

[101]

[59]

[20]

[22]

[1]

[100]

[61]

Gear Unit Structure

Basic structure of helical-worm gear units

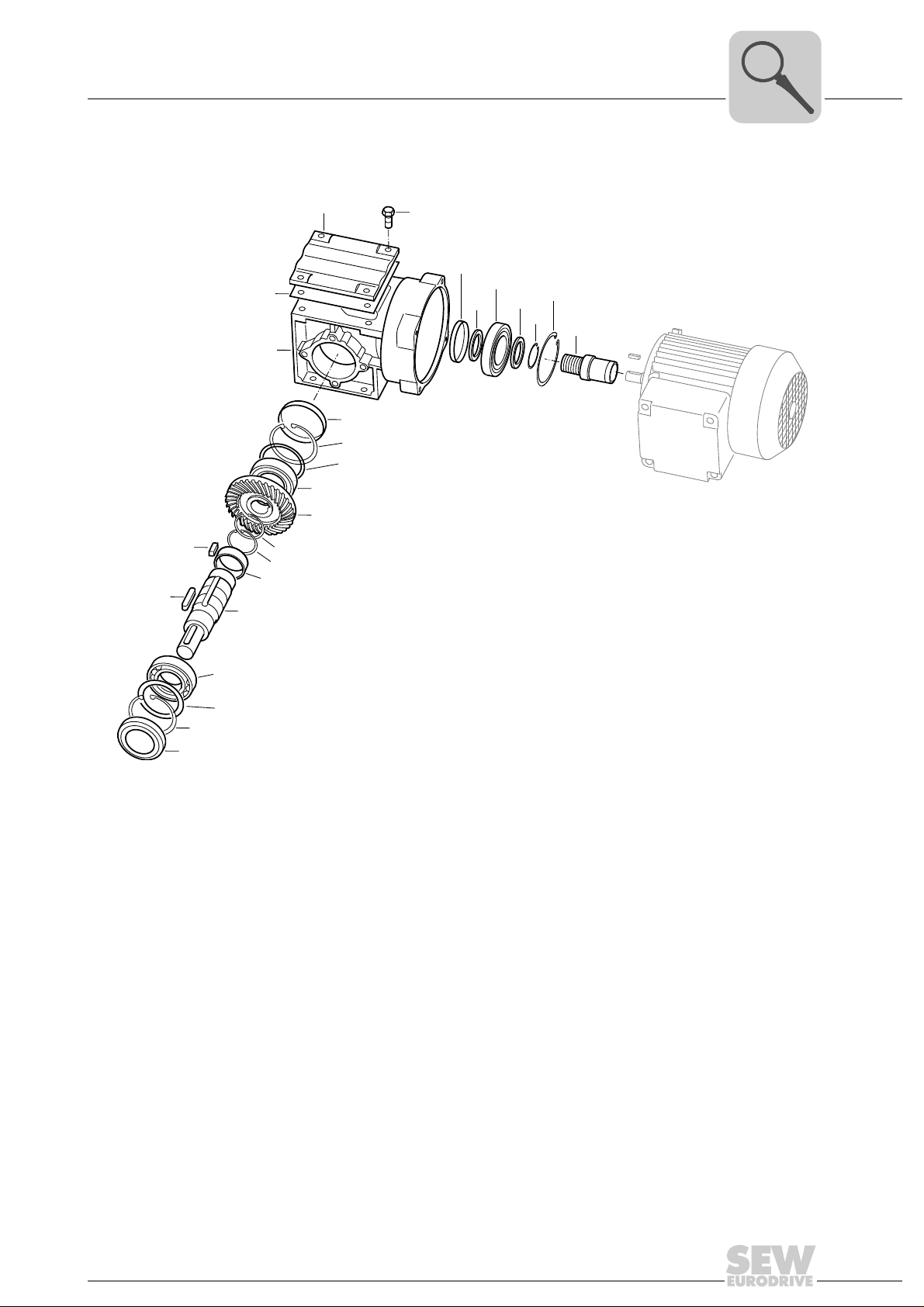

3.5 Basic structure of helical-worm gear units

Pinion

[1]

Gear

[2]

Worm gear

[5]

Worm gear

[6]

Output shaft

[7]

Oil seal

[9]

Rolling bearing bearing

[11]

Retaining ring

[12]

Key

[19]

Breather valve

[20]

Gear unit housing

[22]

Rolling bearing

[25]

Rolling bearing

[30]

Rolling bearing

[37]

Retaining ring

[39]

Key

[43]

Screw plug

[59]

Retaining ring

[61]

Retaining ring

[88]

Closing cap

[89]

Inspection cover

[100]

Hex head screw

[101]

Gasket

[102]

Closing cap

[131]

Supporting ring

[137]

Shim

[506]

Shim

[507]

[518]

[519]

[520]

[521]

[522]

[523]

19304203

Shim

Shim

Shim

Shim

Shim

Shim

14

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 15

Gear Unit Structure

[1]

[68]

[72]

[143]

[66]

[71]

[65]

[100]

[102]

[22]

[89]

[521]

[522]

[523]

[88]

[25]

[6]

[250]

[251]

[17]

[7]

[11]

[8]

[19]

[518]

[519]

[520]

[12]

[9]

[101]

Basic structure of SPIROPLAN® gear units W..10 – W..30

3.6 Basic structure of SPIROPLAN® gear units W..10 – W..30

3

Pinion

[1]

Gear

[6]

Output shaft

[7]

Key

[8]

Oil seal

[9]

Rolling bearing bearing

[11]

[12]

[17]

Retaining ring

Spacer tube

Key

[19]

[22]

[25]

[65]

[66]

[68]

[71]

[72]

Gear unit housing

Rolling bearing

Oil seal

Rolling bearing bearing

Retaining ring

Supporting ring

Retaining ring

[88]

[89]

[100]

[101]

[102]

[143]

[250]

[251]

Retaining ring

Closing cap

Inspection cover

Hex head screw

Gasket

Supporting ring

Retaining ring

Retaining ring

[518]

[519]

[520]

[521]

[522]

[523]

19307275

Shim

Shim

Shim

Shim

Shim

Shim

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

15

Page 16

3

Gear Unit Structure

Basic structure of SPIROPLAN® gear units W..37 – W..47

3.7 Basic structure of SPIROPLAN® gear units W..37 – W..47

[518]

[519]

[520]

[12]

[9]

Pinion

[1]

Gear

[2]

Pinion shaft

[5]

Gear

[6]

Output shaft

[7]

Key

[8]

Oil seal

[9]

Deep groove ball bearing

[11]

Retaining ring

[12]

Key

[19]

[11]

[8]

[19]

[7]

[59]

Gear unit housing

[22]

Deep groove ball bearing

[25]

Housing stage 1

[26]

Deep groove ball bearing

[30]

Key

[31]

Spacer tube

[32]

Retaining ring

[33]

Hex head screw

[36]

Deep groove ball bearing

[37]

O-ring

[44]

[22]

[44]

[133]

[506]

[6]

[37]

[59]

[61]

[88]

[89]

[133]

[137]

[506]

[518]

[519]

[520]

[521]

[522]

[523]

[25]

[59]

[5]

[31]

[30]

Screw plug

Retaining ring

Retaining ring

Closing cap

Shim

Shim

Shim

Shim

Shim

Shim

[88]

[137]

[2]

[89]

[61]

[26]

[5]

[1]

[521]

[522]

[523]

[33]

[32]

[36]

9007199860613387

Shim

Shim

Shim

16

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 17

3.8 Nameplate/type designation

76646 Bruchsal

na

Mamax

Nm

Memax

Nm

IM

i

kg

M1A

70,46

105

2700

r/min

1400/20

K87 AD4

Made in Germany

06415911

CLP HC 220 Synth. Öl / 3,71l

41

3.8.1 Nameplate

The following figure shows an example of a nameplate for a helical-bevel gear unit with

input cover:

Gear Unit Structure

Nameplate/type designation

4472018699

3

n

a

M

amax

M

emax

i Gear unit ratio

IM Mounting position

3.8.2 Type designation

Helical-bevel gear

units

A helical-bevel gear unit with AQ adapter has, for example, the following type designation:

[r/min] Maximum permitted output speed

[Nm] Maximum permitted output torque

[Nm] Maximum permitted input torque

K37/RAQA80/1

Variants

Flange classification

Adapter designation: e.g. for servomotors

- AQA: Adapter with keyway

- AQH: Adapter with clamping ring hub

Option: e.g. for servo gear units .../ R:

Reduced circumferential backlash

Gear unit size: e.g. B. 37

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Gear unit type: e.g. K

17

Page 18

4

Mechanical Installation

Required tools/resources

4 Mechanical Installation

4.1 Required tools/resources

• Set of wrenches

• If necessary, torque wrench for:

– Shrink disks

– Motor adapter AQH Or EWH

– Input shaft assembly with centering shoulder

• Mounting device

• Compensation elements (shims, spacing rings)

• Fasteners for input and output elements

• Lubricant (e.g. NOCO

®

Fluid)

• Bolt locking compound (for input shaft assembly with centering shoulder), e.g.

Loctite

Standard parts are not included in the delivery

4.1.1 Installation tolerances

Shaft end Flanges

Diameter tolerance in accordance with DIN 748

• ISO k6 for solid shafts with Ø ≤ 50 mm

• ISO m6 for solid shafts with Ø > 50 mm

• ISO H7 for hollow shafts

• Center bore in accordance with DIN 332, shape

DR

®

243

Centering shoulder tolerance to DIN 42948

• ISO j6 for b1 ≤ 230 mm

• ISO h6 with b1 > 230 mm

18

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 19

4.2 Installation requirements

CAUTION

Risk of injury due to protruding gear unit parts.

Minor injuries.

• Keep a sufficient safety distance to the gear unit/gearmotor.

NOTICE

Damage to the gear unit/gearmotor due to improper installation.

Possible damage to property

• Strictly adhere to the notes in this chapter.

Make sure that the following requirements are met before you start installing the unit:

• The drive has not been damaged during transportation or storage.

Mechanical Installation

Installation requirements

4

• The entries on the nameplate of the gearmotor match the voltage supply system.

• When the unit is installed in abrasive ambient conditions, protect the output end oil

seals against wear.

• The output shafts and flange surfaces must be completely free from anti-corrosion

agents, contamination or similar. Use a commercially available solvent for cleaning.

Do not expose the sealing lips of the oil se als to the solvent – damage to the material.

• For standard drives:

– Ambient temperature according to the technical documentation, nameplate and

lubricant table in section "Lubricants".

– No harmful oils, acids, gases, vapors, radiation etc. in the vicinity

• For special designs:

– The drive is designed in accordance with the ambien t conditions. Observe the in-

formation on the nameplate.

®

• For helical-worm/SPIROPLAN

– No large external mass moments of inertia which could ex ert a retrodriving load

on the gear unit.

– Self-locking with η’ (retrodriving) < 0.5;

Calculation : η’ = 2 – 1/η

• For servomotor mounting:

– Do not assemble the drive without having ensured that there will be sufficient ven-

tilation after installation to prevent heat build-up.

W gear units:

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

19

Page 20

4

Mechanical Installation

Installing the gear unit

4.3 Installing the gear unit

NOTICE

Danger due to static overdetermination if gear units with foot (e.g. KA19/29B,

KA127/157B or FA127/157B) are mounted both via the torque arm and via the foot

plate.

Risk of injuries and damage to property.

• Especially with the KA.9B/T variant, it is not permitted to use the foot plates and the

torque arm at the same time.

• The KA.9B/T variant may only be mounted via torque arms.

• K.9 or KA.9B variants may only be mounted via the foot plate.

• If you want to use foot plates and torque arms for mounting, consult with SEWEURODRIVE.

CAUTION

Improper installation may result in damage to the gear unit or gearmotor.

Possible damage to property.

• Protect the gear unit from direct cold air currents. Condensation may cause water

to accumulate in the oil.

• It is important that you observe the notes in this chapter.

CAUTION

Risk of trapping and crushing due to improper disassembly of heavy components.

Risk of injury.

• Remove the shrink disk properly.

• Work on the gear unit only when the machine is at a standstill. Secure the drive unit

against unintentional power-up.

The gear unit or gearmotor is only allowed to be installed in the specified mounting

position. Observe the information on the nameplate. SPIROPLAN

W10 – W30 are mounting position-independent.

The support structure must have the followin g fe at ur es :

• Level

• Vibration damping

• Torsionally rigid

The following table shows the ma ximally permit ted flatne ss defect for foot- an d flange-

mounting (guide values based on DIN ISO 1101) :

• Gear unit size ≤ 67: Max. 0.4 mm

• Gear unit size 77 – 107: Max. 0.5 mm

• Gear unit size 137 – 147: Max. 0.7 mm

• Gear unit size 157 – 187: Max. 0.8 mm

®

gear units of size

20

Do not tighten the housing legs and mounting flanges against one another and ensure

that you comply with the permitted overhung and axial loads. Observe chapter "Project

Planning" in the Gear unit/gearmotor catalog for calculating the permitted over hung and

axial loads.

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 21

Mechanical Installation

Installing the gear unit

Secure gearmotors using quality 8.8 screws.

Secure the following gearmotors using quality 10.9 screws:

• RF37, R37F with flange Ø = 120 mm

• RF37, RF47, R47F with flange Ø = 140 mm

• RF57, R57F with flange Ø = 160 mm

• FF, FAF, KF, KAF with flange Ø 250 mm

• and RZ37, RZ47, RZ57, RZ67, RZ77, RZ87

INFORMATION

When installing the gear unit, make sure that the oil level and drain plugs as well as

the breather plugs are easily accessible!

At the same time, also check that the oil fill corresponds to the specifications for the intended mounting position (see chapter "Lubricant fill quantities (page 139)" or refer to

the information on the nameplate). The gear units a re fi lled with the requ ired oil vol ume

at the factory. There may be slight deviations at the oil level plug as a result of the mounting position, which are permitted within the manufacturing tolerances.

Adjust the lubricant fill volumes and the positio n of the breather valve accordingly

in the event of a change of mounting position. Observe chapter "Lubricant fill quan-

tities" and chapter "Mounting Positions".

Consult the SEW customer service if you intend to change the mounting position of K

gear to M5 or M6 or between M5 and M6.

Please contact our SEW customer service if you want to change the mounting position

of size S47 – S97 helical-worm gear units to mounting position M2 or M3.

Use plastic inserts (2 – 3 mm thick) if there is a risk of electrochemical corrosion between

the gear unit and the driven machine. The material used must have an electrical leakage

resistance < 10

ample, cast iron and high-grade steel. Also fit the bolts with plastic wash ers. Ground the

housing additionally – use the grounding bolts on the motor.

9

Ω. Electrochemical corrosion can occur between various metals, for ex-

4

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

21

Page 22

4

Mechanical Installation

Installing the gear unit

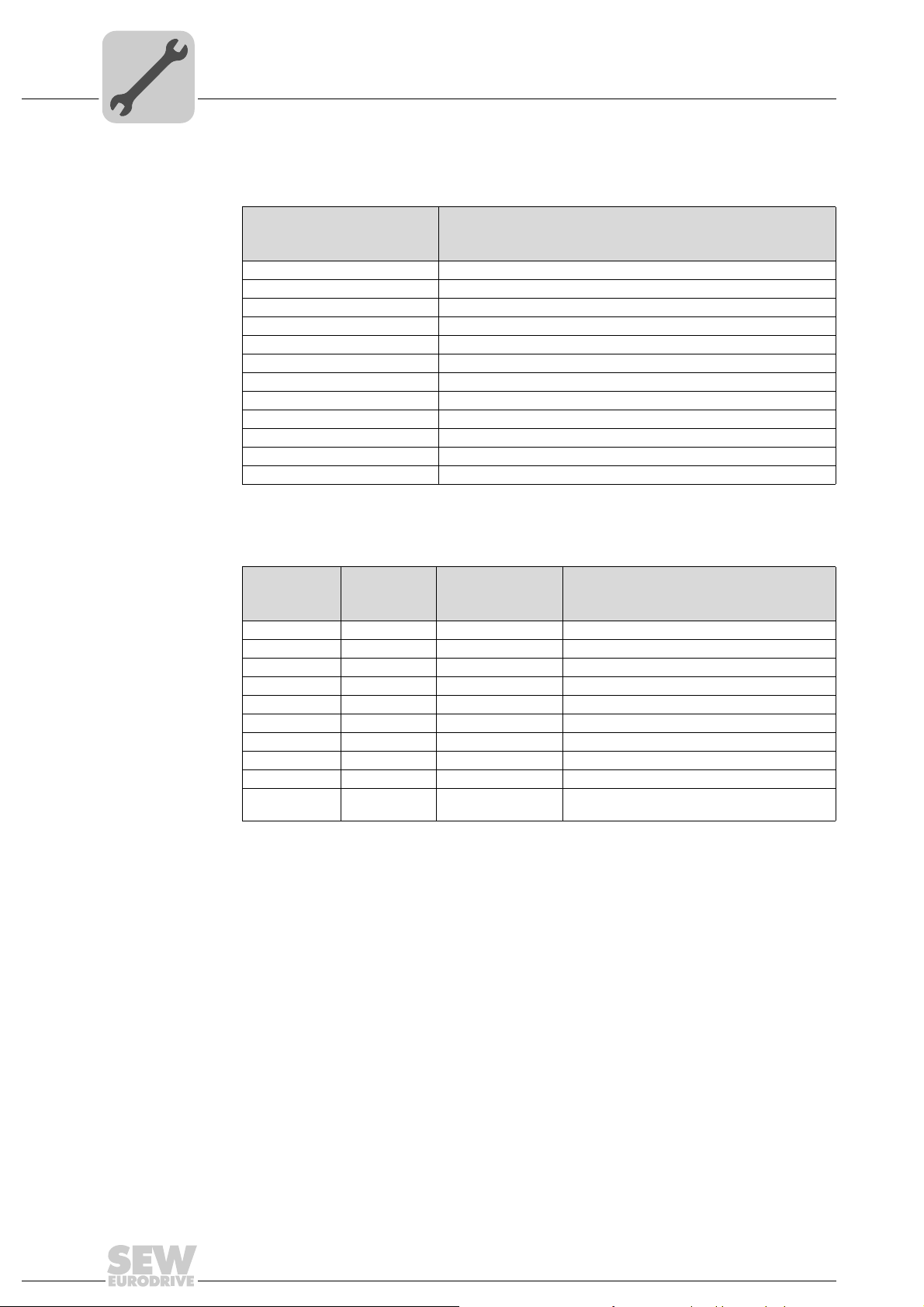

4.3.1 Tightening torques for retaining screws

Mount the gearmotors with the following tightening torques:

Bolt/nut

M6 11

M8 25

M10 48

M12 86

M16 210

M20 410

M24 710

M30 1450

M36 2500

M42 4600

M48 6950

M56 11100

Tightening torque screw / nut

Strength class 8.8

[Nm]

Mount the specified gearmotors in flange-mounted design with the following increased

tightening torques:

Flange Gear unit

120 RF37 M6 14

140 RF37, RF47 M8 35

160 RF57 M8 35

60ZR RZ37 M8 35

70ZR RZ47 M8 35

80ZR RZ57 M10 69

95ZR RZ67 M10 69

110ZR RZ77 M12 120

130ZR RZ87 M12 120

250

FF77, KF77,

FAF77, KAF77

Bolt/nut

M12 120

Tightening torque screw / nut

Strength class 10.9

[Nm]

22

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 23

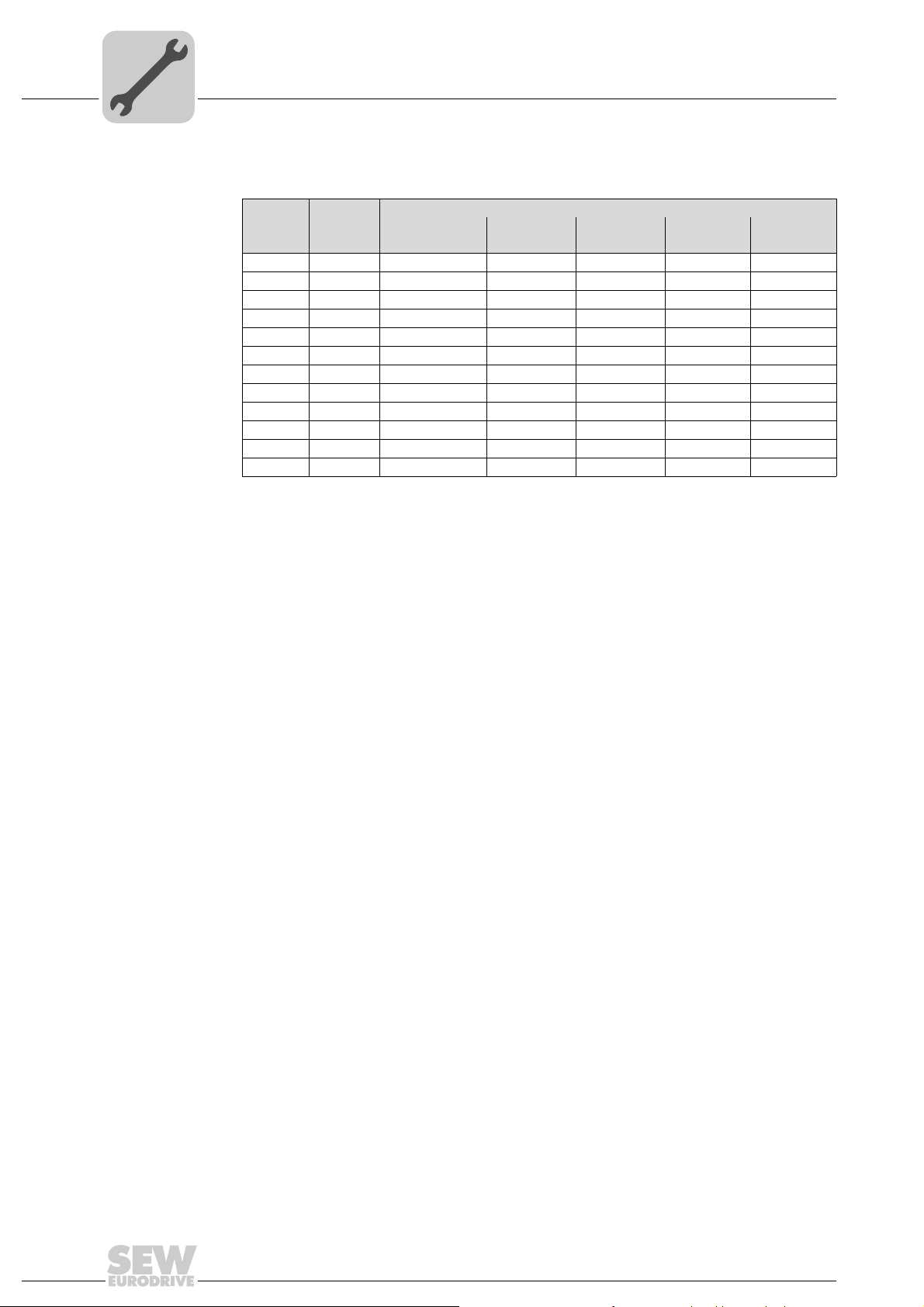

4.3.2 Gear unit mounting

INFORMATION

For gear units in foot/flange-mounted design in connection with VARIBLOC® variablespeed gear units, use quality 10.9 bolts and suitable washers for connecting the customer flange.

To improve the friction contact between flange and mounting surface, SEWEURODRIVE recommends anaerobic gaskets or an anaerobic glue.

Mechanical Installation

Installing the gear unit

4

Foot-mounted gear

units

Gear units with

B14 flange design

and/or hollow shaft

The following table shows the thread sizes of the foot-mounted g ear units depending on

the gear unit type and size:

Gear unit type

Screw

M6 07 19 10/20

M8 17/27/37 27/37 29 37 30/37/47

M10 57 47 37/47 47/57

M12 47/57/67 67 57/67 57/67 67

M16 77/87 77/87 77/87 77 77

M20 97 97/107 97 87 87

M24 107 107 97 97

M30 137 127 107/167

M36 147/167 157 127/157/187

R / R..F RX F /

FH..B / FA..B

K / KH..B /

KV..B / KA..B

S W

The following table shows the thread sizes of the ge ar units with B1 4 flan ge a nd/o r hollow shaft depending on the gear unit type and size:

Gear unit type

Screw RZ FAZ / FHZ KAZ /

KHZ / KVZ

M6 07/17/27 37 10/20/30

M8 37/47 27/37/47 37/47 47/57 37

M10 57/67 47

M12 77/87 57/67/77 57/67/77 67/77

M16 87/97 87/97 87/97

M20 107/127 107/127

M24 157 157

1) For W30 gear units mounted directly to a CMP motor or mounted via an EWH.. adapter, the thread size

is M8.

SA /

SAZ / SHZ

WA

1)

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

23

Page 24

4

Mechanical Installation

Installing the gear unit

Gear units with B5

flange

The following table shows the thread s izes of the gear units with B5 flange dependin g

on the gear unit type, size and flange diameter:

Gear unit type

Flange Ø

[mm]

80 M6 10

110 M8 20

120 M6 07/17/27 19 37 10/20/30/37

140 M8 07/17/27/37/47

160 M8 07/17/27/37/47 27/37 19/29/37 37/47 30/37/47

200 M10 37/47/57/67 47 29/47 57/67

250 M12 57/67/77/87 57/67 57/67 77

300 M12 67/77/87 77 77

350 M16 77/87/97/107 87 87 87

450 M16 97/107/137/147 97/107 97/107 97

550 M16 107/13 7/147/167 127 127

660 M20 147/167 157 157

Screw RF /

R..F / RM

FF /

FAF / FHF

KF / KAF /

KHF / KVF

SF /

SAF /SHF

WF / WAF

24

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 25

4.3.3 Installation in damp locations or outdoors

Drives are supplied in corrosion-resistant versions with a surface protection coating for

use in damp areas or outdoors. Repair any damage to the paint work (e.g. on the

breather valve or the eyebolts).

Mechanical Installation

Installing the gear unit

4

When mounting the motors onto AM, AQ adapters and to AR, AT start-up and friction

couplings, seal the flange areas with a suitable sealing compound, e.g. Loctite

Units installed outdoors must be protected from the sun. Suitable protective devices a re

required, such as covers or roofs. Avoid any heat accumulation. The operator must ensure that foreign objects do not impair the function of the gear unit (e.g. falling objects

or coverings).

4.3.4 Gear unit venting

The following gear units do not require venting:

• R..07 in mounting positions M1, M2, M3, M5 and M6

• R..17, R..27 and F..27 in mounting positions M1, M3, M5 and M6

• SPIROPLAN

• SPIROPLAN

• K..19, K..29 gear units in mounting positions M1, M2, M3, M5 and M6

SEW-EURODRIVE supplies all other gear units with the breath er valve installed and ac-

tivated according to the particular mounting position.

Exceptions:

1. SEW su pplies the following gear units with a screw plug on the vent hole provided:

M6

®

574.

®

W..10, W..20, W..30 gear units

®

W..37, W..47 gear units in mounting positions M1, M2, M3, M5 and

– Gear units with pivoted mounting positions, if possible

– Gear units for inclined mounting

The breather valve is located in the motor terminal box. Before startup, replace the

highest screw plug with the breather valve provided.

2. SEW supplies a breather valve in a plastic bag for mount-on gear units requiring

venting on the input side.

3. Enclosed gear units are supplied without a breather valve.

4. In some countries, the breather valve is installed, but not activated due to possible

pressure fluctuations during transport. In these cases, the breather valve must be activated by removing the transport protection as described in chapter "Activating the

breather valve".

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

25

Page 26

4

Mechanical Installation

Installing the gear unit

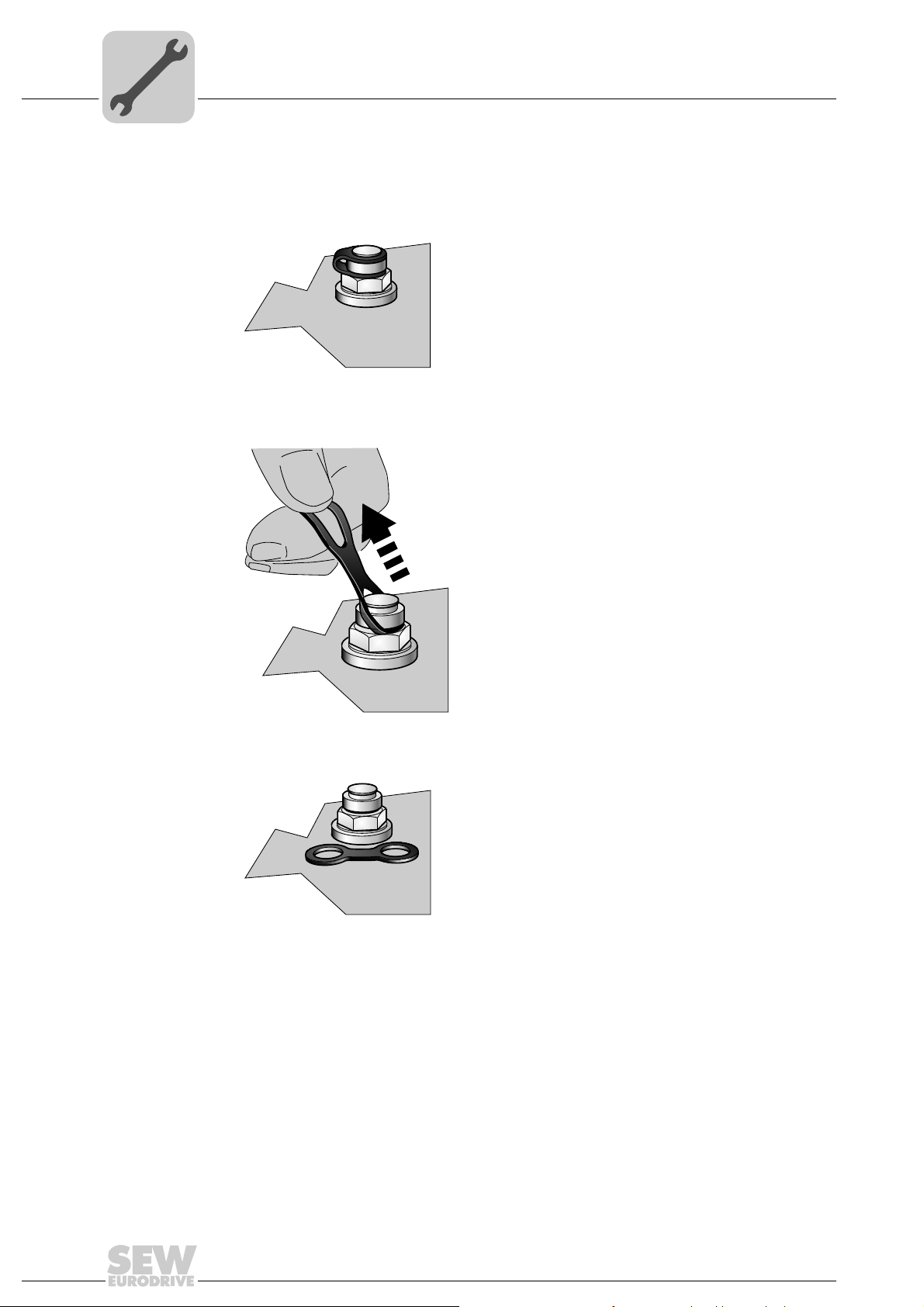

Activating the

breather valve

Check whether the breather valve is activate d. If the breather valv e has not been activated, you must remove the transportation protection device from the breather valve before starting up the gear unit.

1. Breather valve with transportation protection device

211319051

2. Remove transport fixture

211316875

3. Activated breather valve

211314699

26

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 27

4.3.5 Painting the gear unit

NOTICE

Breather valves and oil seals may be damaged during painting or re-painting.

Possible damage to property.

• Thoroughly cover the breather valves and the sealing lip of the oil seals with strips

prior to painting.

• Remove the strips after painting .

4.4 Gear units with solid shaft

4.4.1 Notes on installation

INFORMATION

Mounting is easier if you first apply lubricant to the output element or heat it up briefly

(to 80 - 100 °C).

Mechanical Installation

Gear units with solid shaft

4

4.4.2 Assembling input an d ou t pu t ele m en t s

NOTICE

Bearing, hosing or shaft may be damaged due to improper assembly.

Possible damage to property

• Assemble the input and output components only using a mounting device. Use the

center bore and the thread on the shaft end for positioning.

• Never force belt pulleys, couplings, pinions, etc. onto the shaft end by hitting them

with a hammer.

• In the case of belt pulleys, make sure the belt is tensioned correctly in accordance

with the manufacturer's instructions.

• Power transmission elements should be balanced after fitting and must not give

rise to any impermissible radial or axial forces (see the "Gearmotors" or "ExplosionProof Drives" catalog for permitted values).

Using a mounting

device

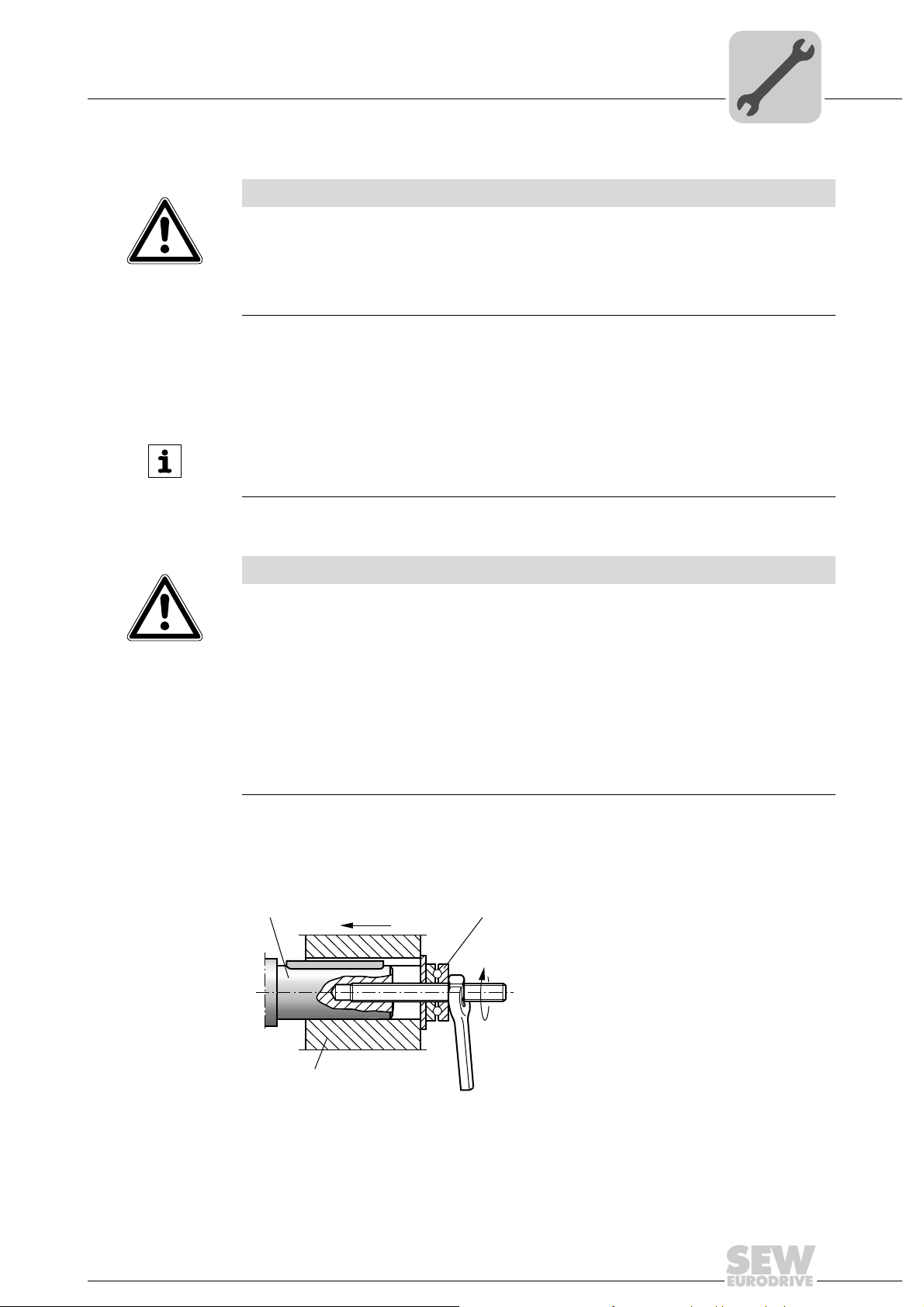

The following figure shows a mounting device for installing couplings or hubs on gear

unit or motor shaft ends. Should you be able to tighten the screw without any problems,

you may not need the thrust bearing on the mounting device.

[1]

[2]

[3]

211368587

[1] Gear unit shaft end

[2] Thrust bearing

[3] Coupling hub

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

27

Page 28

4

[A] [B]

[1]

[1]

a)

b) c)

Mechanical Installation

Gear units with solid shaft

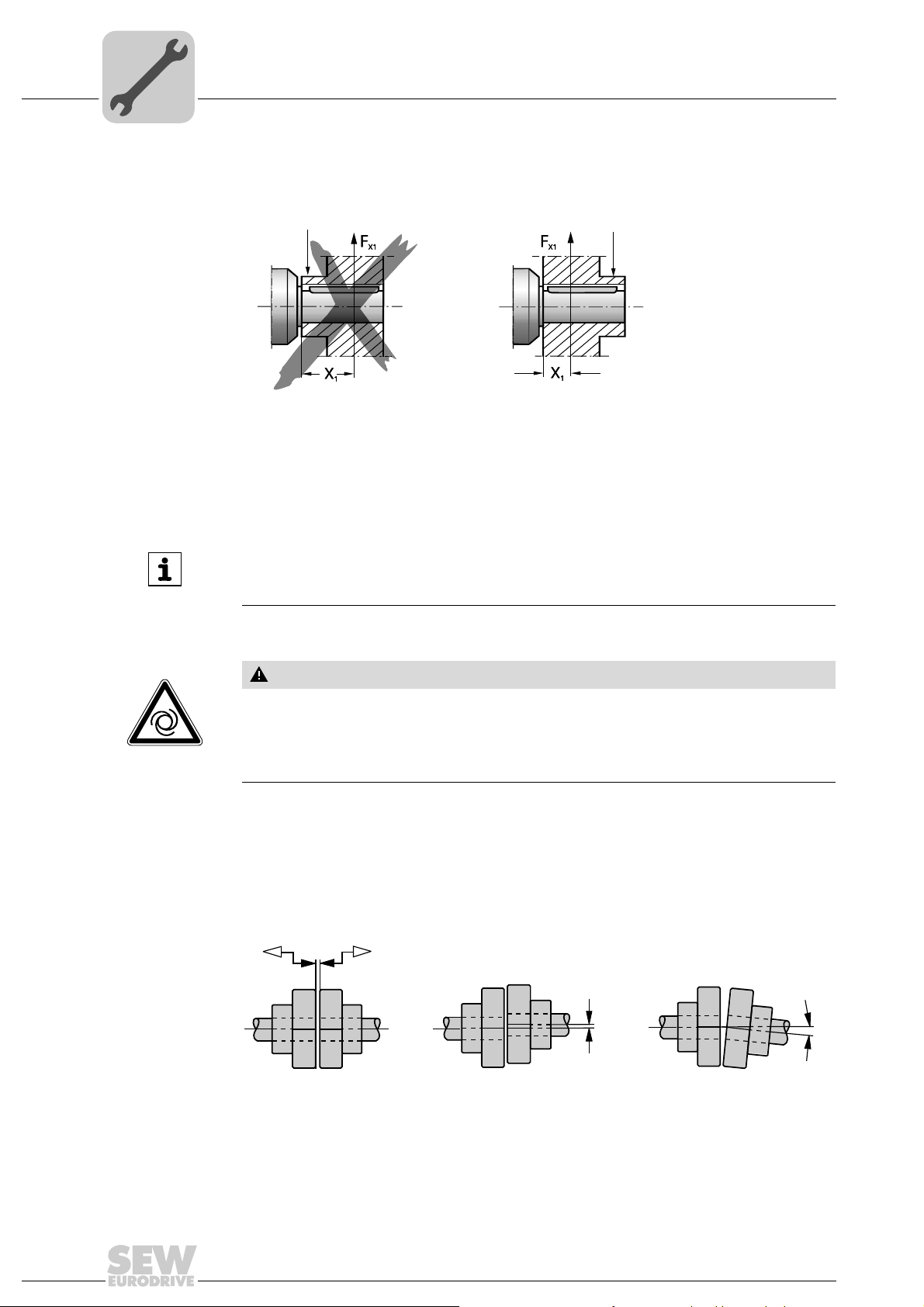

Avoiding excessive

overhung loads

Avoid high overhung loads by installing the gear or chain sprocket according to figure B

if possible.

211364235

[1] Hub

[A] Unfavorable

[B] Correct

INFORMATION

Mounting is easier if you first apply lubricant to the output element or heat it up briefly

(to 80 - 100 °C).

4.4.3 Mounting of couplings

CAUTION

Risk of injury due to moving drive elements, such as belt pulleys or couplings, during

operation.

Risk of jamming and crushing.

• Cover input and output components with a touch guard.

Adjust the following misalignments according to the coupling manufacturer's specifications when mounting couplings:

a) Maximum and minimum clearance

b) Axial offset

c) Angular offset

211395595

28

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 29

Torque arms for shaft-mounted gear units

c

a

øb

+0.5

ød

[1]

[2]

[3]

4.5 Torque arms for shaft-mounted gear units

NOTICE

Improper mounting may result in damage to the gear unit.

Possible damage to property.

• Do not place torque arms under strain when mounting.

• Use screws of quality 8.8 to fasten torque arms.

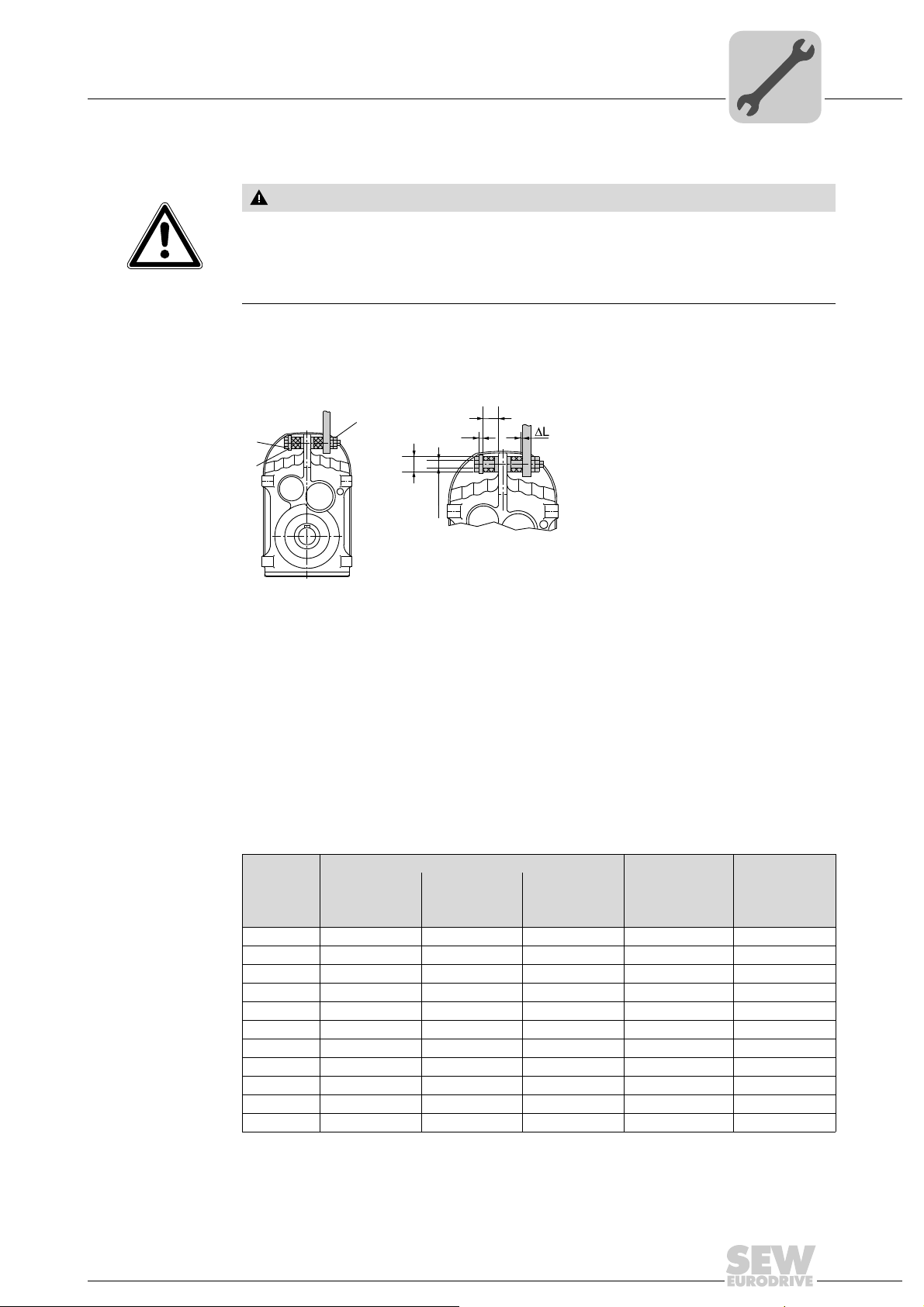

4.5.1 Parallel-shaf t he li ca l ge ar units

The following figure shows the torque arm for parallel-shaft helical gear units.

Mechanical Installation

4

9007199466107403

[1] Screw

[2] Washer

[3] Nut

Proceed as follows to mount the rubber buffers:

1. Use screws [1] and washers according to the following table.

2. Use two nuts to secure the screw connection [3].

3. Tighten the screw until the initial stress "∆ L" of the buffers is reached according to

the table.

Rubber buffer

Gear unit

F..27 /G 40 12.5 20 5 1

F..37 /G 40 12.5 20 5 1

F..47 /G 40 12.5 20 5 1.5

F..57 /G 40 12.5 20 5 1.5

F..67 /G 40 12.5 20 5 1.5

F..77 /G 60 21.0 30 10 1.5

F..87 /G 60 21.0 30 10 1.5

F..97 /G 80 25.0 40 12 2

F..107 /G 80 25.0 40 12 2

F..127 /G 100 32.0 60 15 3

F..157 /G 120 32.0 60 15 3

Diameter Inner

diameter

d [mm] b [mm] c [mm] a [mm] [mm]

Length

(loose)

Washer width ∆ L (taut)

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

29

Page 30

4

45°

[1]

Mechanical Installation

Torque arms for shaft-mounted gear units

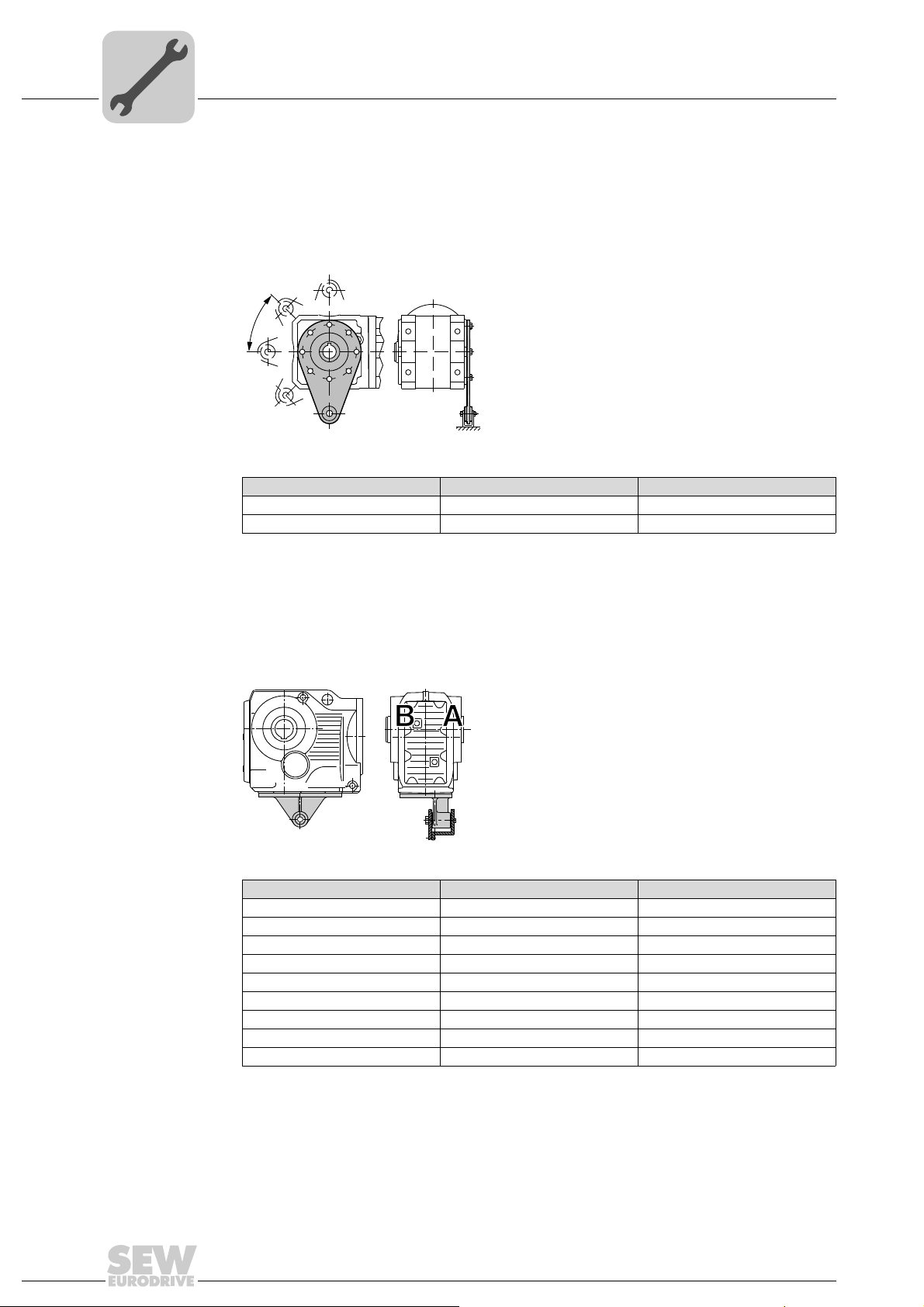

4.5.2 Helical-bevel gear units K..19 – 29

The following figure shows the torque arm for helical-bevel gear units KA19 – 29.

• Apply bearings to both sides of the bushing [1].

• Mount connection side B so that it mirrors A.

Gear unit Screws Tightening torque

K..19 /T 4 x M8 × 22 – 8.8 25 Nm

K..29 /T 4 x M8 × 22 – 8.8 25 Nm

7717631499

4.5.3 Helical-bevel gear units K..37 – 157

The following figure shows the toque arm for helical-bevel gear units.

• Apply bearings to both sides of the bushing [1].

• Mount connection side B so that it mirrors A.

Gear unit Screws Tightening torque

K..37 /T 4 × M10 × 25 – 8.8 48 Nm

K..47 /T 4 × M10 × 30 – 8.8 48 Nm

K..67 /T 4 × M12 × 35 – 8.8 86 Nm

K..77 /T 4 × M16 × 40 – 8.8 210 Nm

K..87 /T 4 × M16 × 45 – 8.8 210 Nm

K..97 /T 4 × M20 × 50 – 8.8 410 Nm

K..107 /T 4 × M24 × 60 – 8.8 710 Nm

K..127 /T 4 × M36 × 130 – 8.8 2.500 Nm

K..157 /T 4 × M36 × 130 – 8.8 2.500 Nm

[1]

211362059

30

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 31

4.5.4 Helical-worm gear units

[1]

45˚

[1]

The following figure shows the torque arm for helical-worm gear units.

• Apply bearings to both sides of the bushing [1].

Mechanical Installation

Torque arms for shaft-mounted gear units

211491723

4

4.5.5 SPIROPLAN

Gear unit Screws Tightening torque

S..37 /T 4 x M6 × 16 – 8.8 11 Nm

S..47 /T 4 x M8 × 20 – 8.8 25 Nm

S..57 /T 6 x M8 × 20 – 8.8 25 Nm

S..67 /T 4 x M12 × 25 – 8.8 86 Nm

S..77 /T 8 x M12 × 35 – 8.8 86 Nm

S..87 /T 8 x M16 × 35 – 8.8 210 Nm

S..97 /T 8 x M16 × 35 – 8.8 210 Nm

®

W gear units

®

The following figure shows the toque arm for SPIROPLAN

W gear units.

• Apply bearings to both sides of the bushing [1].

211489547

Gear unit Screws Tightening torque Nm

W..10 /T 4 x M6 × 16 - 8.8 11

W..20 /T 4 x M6 × 16 - 8.8 11

W..30 /T 4 x M6 × 16 - 8.8 11

W..37 /T 4 x M8 × 20 - 8.8 25

W..47 /T 4 x M10 × 25 - 8.8 48

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

31

Page 32

4

NOCO

FLUI

®

N

OC

O

FLU

I

®

A

[1]

[2]

[3]

[4]

[5]

Mechanical Installation

Shaft-mounted gear units with keyway or splined hollow shaft

4.6 Shaft-mounted gear units with keyway or splined hollow shaft

INFORMATION

Concerning the configuration of the customer shaft, please also refer to the design

notes in the gearmotors catalog.

4.6.1 Installation notes

®

1. Apply NOCO

fluid and thoroughly spread it.

2. Install the shaft and secure it axially

(installation is facilitated by using a mounting device).

Following a description of the three mounting types:

• 2A: Standard scope of delivery

• 2B: Installation/removal kit for customer shaft with contact shoulder

• 2C: Installation/removal kit for customer shaft without contact shoulder

2A: Installation with standard scope of delivery

211516171

211518347

[1] Short retaining screw (standard scope of delivery)

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Customer shaft

32

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 33

Mechanical Installation

B

C

Shaft-mounted gear units with keyway or splined hollow shaft

2B: Installation with SEW-EURODRIVE installation and removal kit (page 37)

– Customer shaft with contact shoulder

[1]

[2]

[3]

[4]

[5]

211520523

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Customer shaft with contact shoulder

4

2C: Installation with SEW-EURODRIVE installation and removal kit (page 37)

– Customer shaft without contact shoulder

[1]

[2]

[3]

[4]

[5]

[6]

211522699

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Spacer

[6] Customer shaft without contact shoulder

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

33

Page 34

4

Mechanical Installation

Shaft-mounted gear units with keyway or splined hollow shaft

3. Tighten the retaining screw to the appropriate torque (see table).

211524875

Screw Tightening torque [Nm]

M5 5

M6 8

M10/12 20

M16 40

M20 80

M24 200

INFORMATION

To avoid contact corrosion, we recommend that the customer shaft should additionally

be lathed down between the 2 contact surfaces.

34

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 35

Shaft-mounted gear units with keyway or splined hollow shaft

[1]

[2]

[3]

[4]

[5]

[6]

4.6.2 Information about disassembly

This description is only applicable when the gear unit was assembled using the installatio/removal kit (page 37) from SEW-EUROD RIVE. Observe section "Installation notes

(page 32)", 2B or 2C.

1. Loosen the retaining screw [1].

2. Remove parts [2] to [4] and, if fitted, the spacer tube [5].

Mechanical Installation

4

211527051

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Spacer

[6] Customer shaft

3. Insert the forcing disc [8] and the fixed nut [7] from the SEW-EURODRIVE installation/removal kit between the customer shaft [6] and the circlip [4].

4. Re -install the retaining ring [4].

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

35

Page 36

4

[1]

[4]

[7]

[8]

[6]

Mechanical Installation

Shaft-mounted gear units with keyway or splined hollow shaft

5. Screw the retaining screw [1] back in. Now you can force the gear unit off the shaft

by tightening the screw.

211529227

[1] Retaining screw

[4] Retaining ring

[6] Customer shaft

[7] Fixed nut

[8] Forcing disk

36

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 37

Shaft-mounted gear units with keyway or splined hollow shaft

[1]

[8]

[7]

[7]

[1]

4.6.3 SEW installation and removal kit

The SEW-EURODRIVE installation/removal kit can be ordered by quoting its part

number.

Mechanical Installation

4

211531403

[1] Retaining screw

[7] Fixed nut for disassembly

[8] Forcing disk

-0.5

-0.5

Type DH7

WA..10 16 M5 5 5 12 4.5 18 15.7 50 643 712 5

WA..20 18 M6 5 6 13.5 5.5 20.5 17.7 25 643 682 X

WA..20, WA..30, SA..37, WA..37, KA..19 20 M6 5 6 15.5 5.5 22.5 19.7 25 643 683 8

FA..27, SA..47, WA..47, KA..29 25 M10 5 10 20 7.5 28 24.7 35 643 684 6

FA..37, KA..37, SA..47, SA..57, WA..47, KA..29 30 M10 5 10 25 7.5 33 29.7 35 643 685 4

FA..47, KA..47, SA..57 35 M12 5 12 29 9.5 38 34.7 45 643 686 2

FA..57, KA..57, FA..67, KA..67, SA..67 40 M16 5 12 34 11.5 41.9 39.7 50 643 687 0

SA..67 45 M16 5 12 38.5 13.5 48.5 44.7 50 643 688 9

FA..77, KA..77, SA..77 50 M16 5 12 43.5 13.5 53.5 49.7 50 643 689 7

FA..87, KA..87, SA..77, SA..87 60 M20 5 16 56 17.5 64 59.7 60 643 690 0

FA..97, KA..97, SA..87, SA..97 70 M20 5 16 65.5 19.5 74.5 69.7 60 643 691 9

FA..107, KA..107 80 M20 5 20 75.5 21.5 85 79.7 70 106 8211 2

FA..107, KA..107, SA..97 90 M24 5 20 80 24.5 95 89.7 70 643 692 7

FA..127, KA..127 100 M24 5 20 89 27.5 106 99.7 70 643 693 5

FA..157, KA..157 120 M24 5 20 107 31 127 119.7 70 643 694 3

1) Retaining screw

[mm]

M1)C4

[mm]

C5

[mm]

C6

[mm]

U

[mm]

T

[mm]

-0.5

D3

[mm]

[mm]

L4

Part number of

installation/

removal kit

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

37

Page 38

4

Mechanical Installation

Shaft-mounted gear units with keyway or splined hollow shaft

INFORMATION

The SEW installation kit for attaching the customer shaft is a recommendation by

SEW-EURODRIVE. You must always check whether this design can compensate the

axial loads. In particular applications (e.g. mounting mixer shafts), a different design

may have to be used to secure the shaft axially. In these cases, customers can use

their own devices. However, you must ensure that these designs do no t cause p otential sources of combustion according to DIN EN 13463 (for example, impact sparks).

38

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 39

Shaft-mounted gear units with shrink disk

4.7 Shaft-mounted gear units with shrink disk

4.7.1 Assembly notes

NOTICE

Tightening the screws without installed shaft may result in the hollow shaft being

deformed.

Possible damage to property

• Only tighten the locking screws with the shaft installed.

1. Loosen the locking screws by a few turns (do not unscrew them completely!).

Mechanical Installation

4

AB

211533579

2. Carefully degrease the hollow shaft hole and the input shaft using a commercially

available solvent.

211535755

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

39

Page 40

4

Mechanical Installation

Shaft-mounted gear units with shrink disk

3. Ho llow shaft/input shaft after degreasing.

211537931

®

4. Apply NOCO

It is essential to make sure that the clamping area of the shrink disk is free from

grease. Never apply NOCO

may be able to get into the clamping area of the shr ink disk when the input shaft is

put on.

fluid to the input shaft in the area of the bushing.

®

fluid directly to the bushing. This is because the paste

40

211540107

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 41

Mechanical Installation

Shaft-mounted gear units with shrink disk

5. Install the input shaft.

– Make sure that the locking collars of the sh rink disk are installed in parallel to each

other.

– For gear unit housings with shaft shoulder:

Mount the shrink disk onto the stop on the shaft shoulder.

– For gear unit housings without shaft shoulder:

Install the shrink disk with a 1 to 2 mm distance from the gear unit housing.

– Tighten the locking screws by working round with the torque wrench seve ral times

from one screw to the next (not in diametrically opposite sequence).

The exact values for the tightening torques are shown on the shrink disk.

4

1-2mm

6. After installation, make sure the remaining gap between the outer rings is > 0 mm.

7. Grease the area around the shrink disk outside the hollow shaft to prevent corrosion.

s>0mm

211542283

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

41

Page 42

4

Mechanical Installation

Shaft-mounted gear units with shrink disk

4.7.2 Removal notes

4.7.3 Cleaning and lubrication

1. Loosen the locking screws one after the other by a quarter rotation to avoid tilting the

outer rings.

2. Unscrew the locking screws evenly one after the other. Do not remove the locking

screws completely.

3. Remove the shaft or pull the hub off the shaft. (Remove any rust that may have

formed between the hub and the end of the shaft beforehand.)

4. Remove the shrink disk from the hub.

There is no need to dismantle removed shrink disks before re-installing them.

Clean and lubricate the shrink disk if it is dirty.

Lubricate the tapered surfaces with one of the following solid lubricants:

Lubricant (Mo S2) Sold as

Molykote 321 (lube coat)

Molykote spray (powder spray)

Molykote G Rapid

Aemasol MO 19P

Aemasol DIO-sétral 57 N (lube coat)

Spray

Spray

Spray or paste

Spray or paste

Spray

Grease the locking screws with a multipurpose grease such as Molykote BR 2 or similar.

42

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 43

Mechanical Installation

NO

CO

FL

UID

®

Shaft-mounted gear units with TorqLOC

®

4

4.8 Shaft-mounted gear units with TorqLOC

®

4.8.1 Installation notes for customer shaft without contact shoulder

1. Clean the customer shaft and the inside of the hollow sha ft. Ensure that all traces of

grease or oil are removed.

2. Install the stop ring and the bushing on the customer shaft.

211941003

3. Mount the torque arm to the drive unit, observe chapter "Torque arms for shaftmounted gear units" (page 29).

5128549131

®

4. Apply NOCO

fluid on the bushing and spread it thoroughly.

211938827

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

43

Page 44

4

K..7

S.. / W.. / K..9

F..

Mechanical Installation

Shaft-mounted gear units with TorqLOC

5. Push the gear unit onto the customer shaft.

9007199466677643

6. Preassemble the torque arm (do not tighten the screws).

®

7. Push the busing onto the gear unit up to the stop.

9007199466686347

9007199466684171

44

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 45

Mechanical Installation

Shaft-mounted gear units with TorqLOC

8. Se cure the bushin g with the stop ring . Tigh ten the split ring on the bushing using the

appropriate torque as specified in the following table:

9007199466741899

®

4

Type Nickel-plated

[Standard]

KT / FT ST / WT Torque in Nm

-37 18 7.5

37 47 18 7.5

47 57 18 7.5

57, 67 67 35 18

77 77 35 18

87 87 35 18

97 97 35 18

107 – 38 38

127 – 65 65

157 – 150 150

Stainless steel

9. Make sure that all screws are loosened and slide the shrink disk onto the hollow

shaft.

9007199466744075

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

45

Page 46

4

Mechanical Installation

Shaft-mounted gear units with TorqLOC

10.Slide the counter bushing onto the customer shaft and into the hollow shaft

®

CO

NO

FLUID

9007199466746251

11.until the shrink disk is properly seated.

12.Tap lightly on the flange of the counter bushing to ensure that the socket is fitted

securely in the hollow shaft.

®

9007199466748427

13.Make sure that the customer shaft is seated in the counter bushing.

9007199466750603

46

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 47

Mechanical Installation

> 0 mm

s

> 0 mm

> 0 mm

Shaft-mounted gear units with TorqLOC

14.Manually tighten the screws of the shrink disk and ensure that the outer rings of the

shrink disk are parallel.

9007199466752779

15.Tighten the locking bolts by working round several times from one bolt to the next

(not in diametrically opposite sequence).

The exact values for the tightening torques are shown on the shrink disk.

®

4

> 0mm

9007199466754955

16.After installation, make su re the rem ainin g ga p be tween the outer rings is > 0 mm.

17.The remaining gap between counter bushing and hollow shaft end as well as bu shing

and stop ring must be > 0 mm.

9007201603402123

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

47

Page 48

4

Mechanical Installation

Shaft-mounted gear units with TorqLOC

18.Securely tighten the torque arm; observe chapter "Torque arm for shaft-mounted

gear units" (page 29).

5129142283

®

48

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 49

Mechanical Installation

0 mm

Shaft-mounted gear units with TorqLOC

4.8.2 Installation notes for customer shaft with contact shoulder

1. Clean the customer shaft and the inside of the hollow sha ft. Ensure that all traces of

grease or oil are removed.

5129572875

2. Mount the torque arm to the drive unit, observe chapter "Torque arms for shaftmounted gear units" (page 29).

®

4

5128549131

3. Slide the bushing onto the customer shaft.

2349377035

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

49

Page 50

4

NOCO

FL

UID

®

Mechanical Installation

Shaft-mounted gear units with TorqLOC

4. Apply NOCO® fluid on the bushing and spread it thoroughly.

2349367435

5. Push the gear unit onto the customer shaft.

®

5129650443

6. Make sure that all screws are loosened and slide the shrink disk onto the hollow

shaft.

212003083

50

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 51

Mechanical Installation

Shaft-mounted gear units with TorqLOC

7. Slid e the counter bushing onto the customer shaft and into the hollow shaft

®

CO

NO

FLUID

9007199466746251

8. until the shrink disk is properly seated.

9. Tap lightly on the flange of the counter bushing to ensure that the socket is fitted

securely in the hollow shaft.

®

4

9007199466748427

10.Make sure that the customer shaft is seated in the counter bushing.

9007199466750603

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

51

Page 52

4

> 0mm

> 0 mm

s

> 0 mm

> 0 mm

Mechanical Installation

Shaft-mounted gear units with TorqLOC

11.Manually tighten the screws of the shrink disk and ensure that the outer rings of the

shrink disk are parallel.

9007199466752779

12.Tighten the locking bolts by working round several times from one bolt to the next

(not in diametrically opposite sequence).

The exact values for the tightening torques are shown on the shrink disk.

®

9007199466754955

13.After installation, make su re the rem ainin g ga p be tween the outer rings is > 0 mm.

14.The remaining gap between counter bushing and hollow shaft end must be > 0 m m.

9007201603402123

52

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 53

Mechanical Installation

Shaft-mounted gear units with TorqLOC

15.Mount the torque arm and tighten it securely; observe chapter "Torque arms for

shaft-mounted gear units" (page 29).

5129142283

®

4

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

53

Page 54

4

4.8.3 Removal notes

Mechanical Installation

Shaft-mounted gear units with TorqLOC

®

CAUTION

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

1. Loosen the locking screws one after the other by a quarter rotation to

avoid tilting the outer rings.

212013963

2. Unscrew the locking bolts evenly one after the other.

Do not remove the locking screws completely.

3. Disma ntle the conical steel bushing.

If required, use the outer rings as pullers as follows:

– Remove all the locking screws.

– Screw the respective number of screws in the tapped holes of the shrink disk.

– Support the inner ring again st the gear unit housing.

– Pull off the conical steel bushing by tightening the screws.

4. Re move the gear unit from the shaft.

54

2903780235

5. Remove the shrink disk from the hub.

Assembly and Operating Instructions – Gear Units R..7, F..7, K..7, K..9, S..7, SPIROPLAN® W

Page 55

4.8.4 Cleaning and lubrication

There is no need to dismantle removed shrink disks before re-installing them.

Clean and lubricate the shrink disk if it is dirty.

Lubricate the tapered surfaces with one of the following solid lubricants:

Lubricant (Mo S2) Sold as

Molykote 321 (lube coat) Spray

Molykote spray (powder spray) Spray

Molykote G Rapid Spray or paste

Aemasol MO 19P Spray or paste

Aemasol DIO-sétral 57 N (lube coat) Spray

Grease the locking screws with a multipurpose grease such as Molykote BR 2 or similar.

4.9 Installing the protective cover

Mechanical Installation

Installing the protective cover

4

CAUTION

During operation, output components are in fast motion.

Risk of jamming and crushing.

• Disconnect the motor from the power supply before starting work and safeguard it