Page 1

Drive Technology \ Drive Automation \ System Integration \ Services

Addendum to the Operating Instructions

MOVITRAC

Servo Module for MOVITRAC

Edition 09/2011 19352026 / EN

®

LTX

®

LTP-B

Page 2

SEW-EURODRIVE—Driving the world

Page 3

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Contents

1 Important Notes........... ... .......................................... ... ........................................ 5

1.1 Use of this documentation ......................................................................... 5

1.2 Structure of the safety notes................................... ... ... ... .... ... .................... 5

1.3 Rights to claim under limited warranty........................................................ 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright notice.......................................................................................... 7

1.6 Other applicable documentation................................................................. 7

1.7 Product names and trademarks.................................................................. 7

2 Unit Design .......................................................................................................... 8

2.1 MOVITRAC

2.2 Unit designation .......................................................................................... 8

3 Mechanical Installation....................................................................................... 9

3.1 Installing MOVITRAC

3.2 Removing MOVITRAC

4 Electrical Installation ........................................................................................ 11

4.1 Overview of signal terminals for keypad mode ......................................... 12

4.2 Overview of signal terminals for terminal mode (internal ramp

control of the LTP without controller/gateway).......................................... 14

4.3 Overview of signal terminals for third-party controllers........................... .. 16

4.4 Overview of signal terminals for SEW controllers..................................... 19

4.5 Overview of signal terminals for SEW gateways ...................................... 21

4.6 Overview of relay terminals and X13 ...................................................... 23

5 Startup................................................................................................................ 24

5.1 User interface............ .... ... ... .......................................... ............................ 24

5.2 Simple startup of MOVITRAC

5.3 Software.................................................................................................... 37

5.4 Control loop optimization in different operating modes............................. 38

6 Parameters......................................................................................................... 43

6.1 LTX-specific parameters (level 1) ............................................................. 43

6.2 P1-14 extended parameter access........................................................... 44

6.3 P1-15 binary input function selection, LTX-specific parameters............... 44

6.4 P1-16 motor type ...................................................................................... 46

6.5 P1-17 Smart Servo operation ................................................................... 47

6.6 P1-21 Stiffness.......................................................................................... 47

6.7 P1-22 motor load inertia............. ... ... ... .... ... ... ... ......................................... 48

6.8 P2-01 preset speed 1.................... .......................................... .................. 48

6.9 P2-05 preset speed 5.................... .......................................... .................. 48

6.10 P2-06 preset speed 6....................... ... .... ... ... ... ....... ... ... ... .... ... ... ... ... .... ... .. 48

6.11 P2-21 display scaling factor...................................................................... 48

6.12 LTX function parameter set (level 3)......................................................... 49

®

LTX ....................................................................................... 8

®

LTX........................................................................ 9

®

LTX.................................................................... 10

®

LTX .......................................... ............... 26

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

3

Page 4

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

7 Technical Data and Dimension Sheets ........................................................... 56

7.1 Environment.............................................................................................. 56

7.2 Technical data X14 application connection............................................... 56

7.3 Mass moment of inertia values for CMP motors in the

Smart Servo Package............................................................................... 56

7.4 MOVITRAC

Index................................................................................................................... 58

®

LTX dimension drawing ..................................................... 57

4

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 5

1 Important Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Use of this documentation

The documentation is part of the product and contains important information about installation, startup, operation and service. The documentat ion is written for all employees

who install, startup, and service this product.

The documentation must be accessible and legi ble. Make sure that persons responsible

for the system and its operation, as well as persons wh o work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

Unless the information in the documentation is adhered to, it will be impossible to

ensure:

• Trouble-free operation

• Fulfillment of any rights to claim under guarantee

Important Notes

Use of this documentation

1

Consequently, read the operating instructions before you start working with the

unit!

The operating instructions contain important information about servicing. Therefore,

keep the operating instructions close to the unit.

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to propert y, an d ot he r no te s.

Signal Word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal

WARNING Possible dangerous situation Severe or fatal

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its environ-

INFORMATION Useful information or tip: Simplifies

injuries

injuries

ment

the handling of the drive system.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

5

Page 6

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.2.2 Structure of the section safety notes

Important Notes

Structure of the safety notes

The section safety notes do not apply to a specific action, but to several actions pertaining to one subject. The pictograms used indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Nature and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the hazard.

This is an example of a section safety note:

WARNING

Falling of suspended loads.

Severe or fatal injuries.

• Do not stand under the suspended load.

• Secure the danger zone.

1.2.3 Structure of the embedded safety notes

The embedded safety notes are directly integrated in the instructions just before the

description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the hazard.

This is an example of an embedded safety note:

• DANGER Risk of crushing if the drive restarts unintentionally.

Severe or fatal injuries.

– De-energize the drive.

– Secure the drive against unintended restart.

6

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 7

Rights to claim under limited warranty

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3 Rights to claim under limited warranty

Important Notes

1

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the MOVITRAC

tion. Read the documentation before you start working with the unit!

Make sure that the documentation is available to persons responsible for the system and

its operation as well as to persons who work independently on the unit. You must also

ensure that the documentation is legible.

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of the documentation. In such cases,

any liability for defects is excluded.

1.5 Copyright notice

© 2011 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or a ny other use of the whole or an y

part of this documentation is strictly prohibited.

®

LTP-B documenta-

1.6 Other applicable documentation

This document supplements the MOVITRAC® LTP-B Operating Instructions. Only use

this document in connection with the MOVITRAC

1.7 Product names and trademarks

The brands and product names contained within this publica tion are tradema rks or registered trademarks of the titleholders.

®

LTP-B Operating Instructions.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

7

Page 8

2

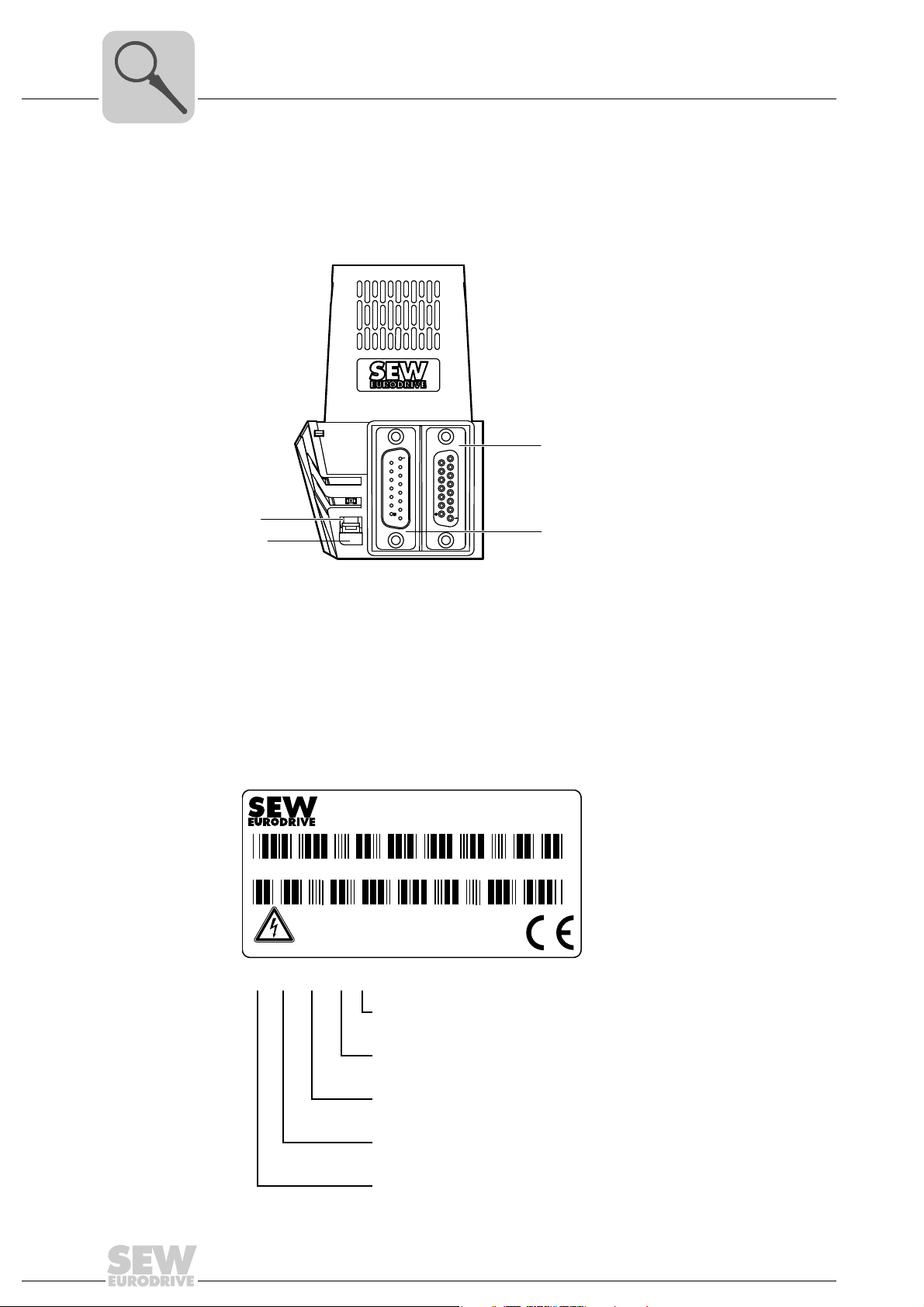

LTX-H1A

LTX Servomodule

Serial No.: 00655685402020

18239226

Read User

guide before

installation

or servicing

Firmware: 0.00

Packed in the UK

CAUTION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Unit Design

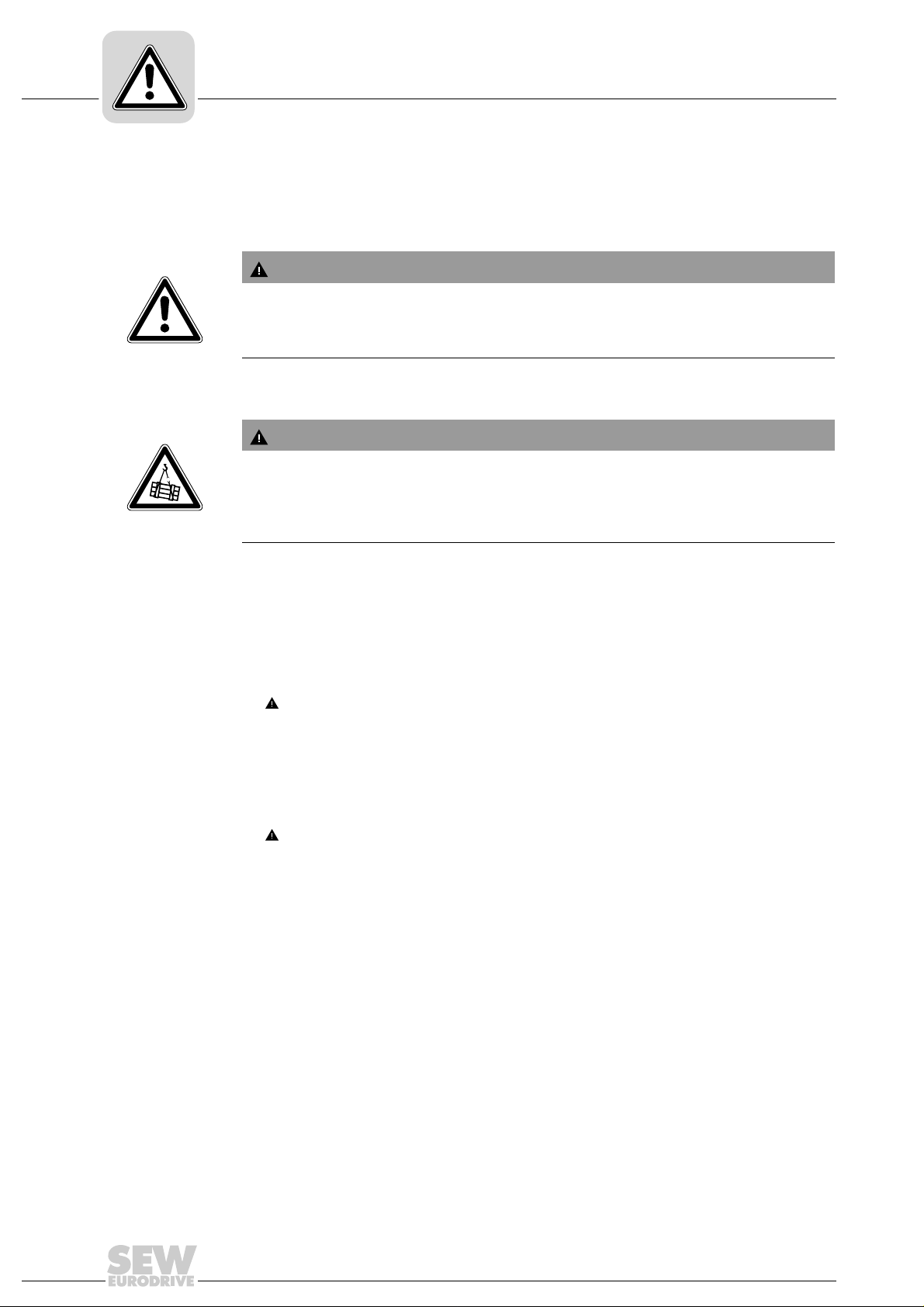

2.1 MOVITRAC® LTX

Unit Design

MOVITRAC® LTX

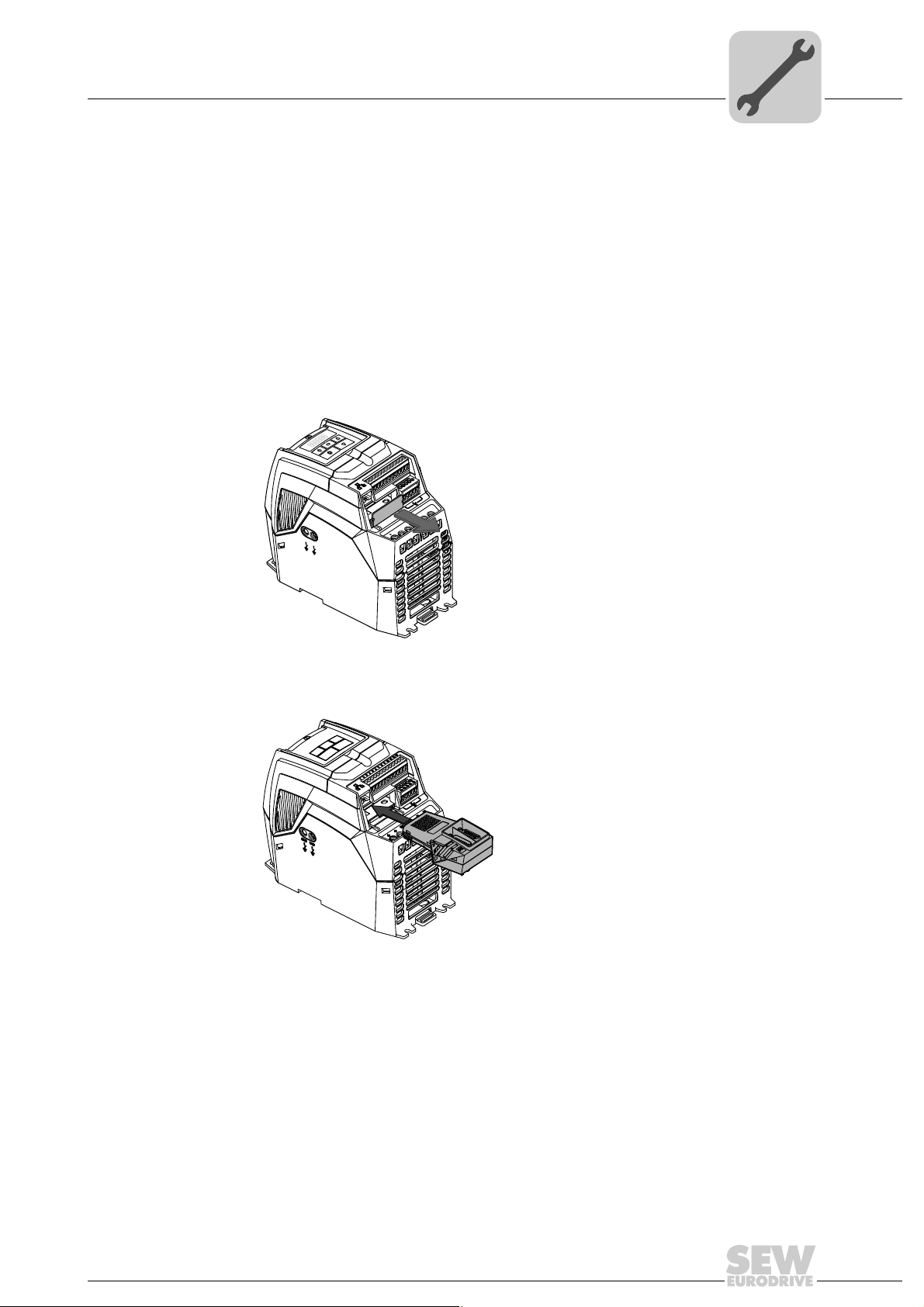

The following figure shows the MOVITRAC® LTX servo module:

[1]

[3]

[4]

[1] X14 Application connector

[2] X13 Motor feedback connector

[3] Detent nose

[4] Retaining button

2.2 Unit designation

2.2.1 Sample nameplate

[2]

3575503499

LT X- H1A

Production status

Variant

Secondary functionality H = Hiperface

8

Primary functionality X = Servo module

Indicator for the LT option module

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 9

3 Mechanical Installation

MOVITRAC

®

LTP-B

1

2

3

4

5

6

7

8

9

10

11

12

13

18

14

16

W

V

BR

EMC

VAR

+

17

15

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

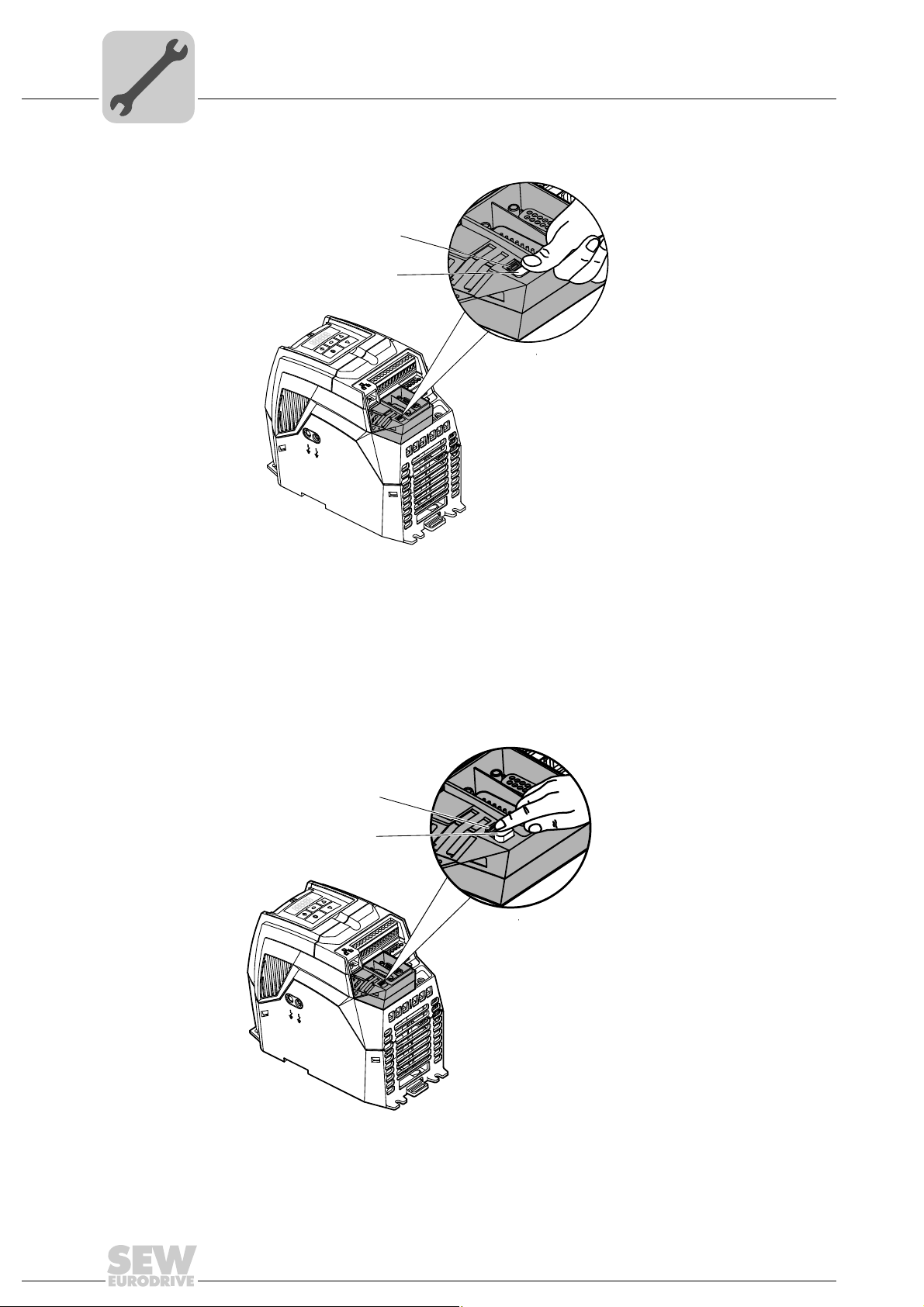

• INFORMATION

Motor cables can only be connected when the MOVITRAC

plugged because some motor connections may be covered by the LTX module.

3.1 Installing MOVITRAC® LTX

To convert MOVITRAC® LTP-B into MOVITRAC® LTX, carry out the following steps:

1. Remove the protective cover from the LTX slot.

Mechanical Installation

Installing MOVITRAC® LTX

®

LTX module is not

3

3577877003

2. Carefully insert the LTX servo module into the slot. Make sure you insert the LTX

module evenly to prevent the pins from being damaged.

3551073931

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

9

Page 10

3

MOVITRAC

®

LTP-B

1

2

3

4

5

6

7

8

9

10

11

12

13

1

8

14

16

W

V

BR

EMC

VAR

+

17

15

[2]

[1]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Mechanical Installation

Removing MOVITRAC® LTX

3. Secure the LTX servo module by pressing the retaining button [1].

[1] Retaining button

[2] Detent nose

3.2 Removing MOVITRAC® LTX

To unlock the LTX servo module, push the detent nose [2] in the direction of the slot to

release the retaining button [1].

[2]

[1]

LTP-B

®

MOVITRAC

EMC

VAR

8

7

6

5

4

3

2

1

3579840267

13

12

11

10

9

8

1

17

16

15

14

W

V

BR

+

10

3579838347

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 11

4 Electrical Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

This chapter illustrates the wiring of the following connections:

• Main terminals

• Relay terminals

• Motor encoder X13

• Application connection X14

The wiring of the main terminals and the application con nection depends o n the operating mode of the drive. The drive offers the following operating modes:

• Keypad mode

• Terminal mode

• External control mode

• SEW controller mode

• Operation via gateway

Electrical Installation

4

Proper functioning requires wiring according to the respective operating mode. The

wiring options are therefore described in different sub-ch apters.

We strongly recommend to perform a simple startup first as this chapter refers to the

respective sub-chapter regarding the wiring according to the selected operating mode.

The connection X13 for the motor encoder and the r elay terminals are wired in the same

way for all operating modes. This is why the wiring is only described once for those two

connections.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

11

Page 12

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for keypad mode

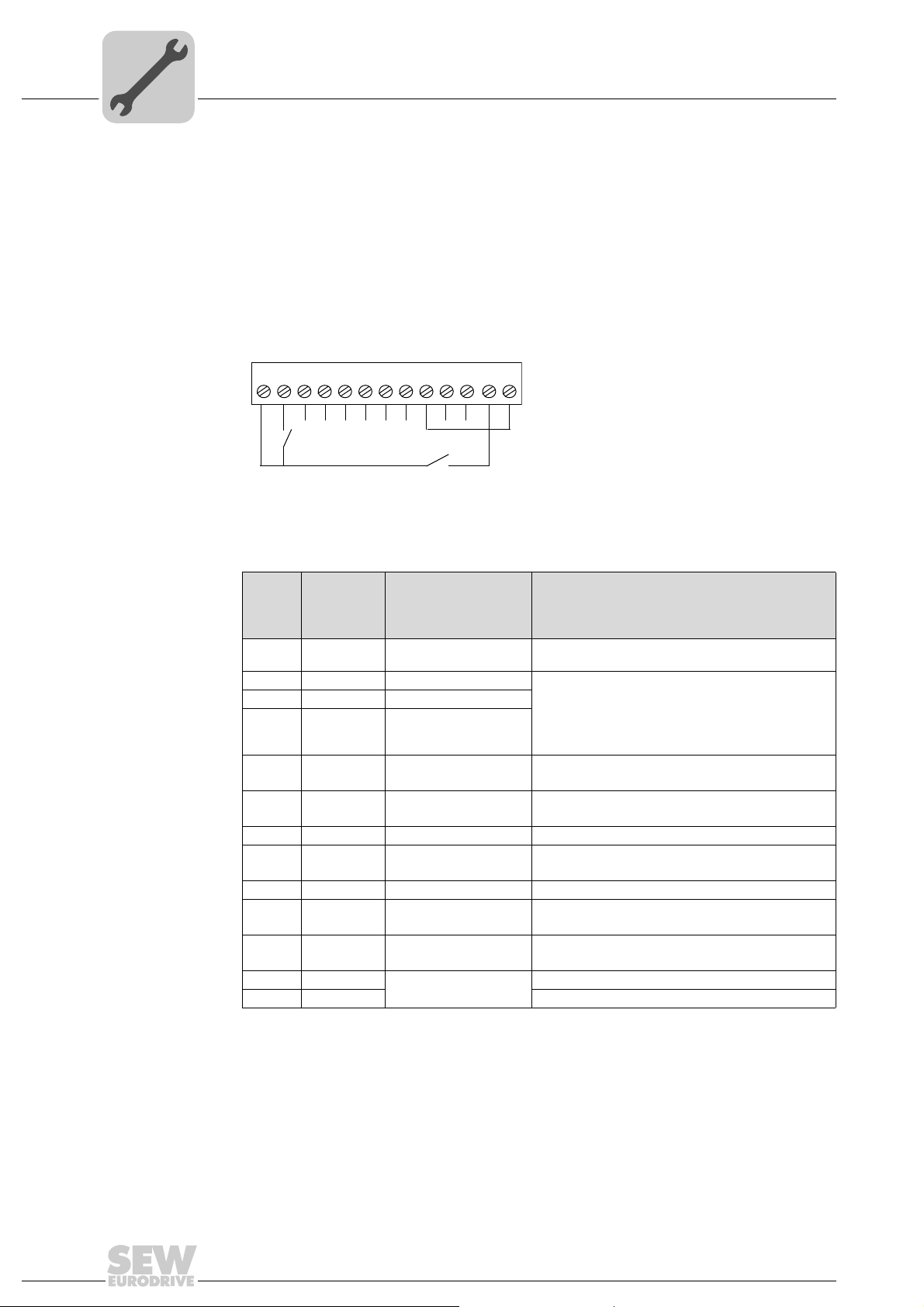

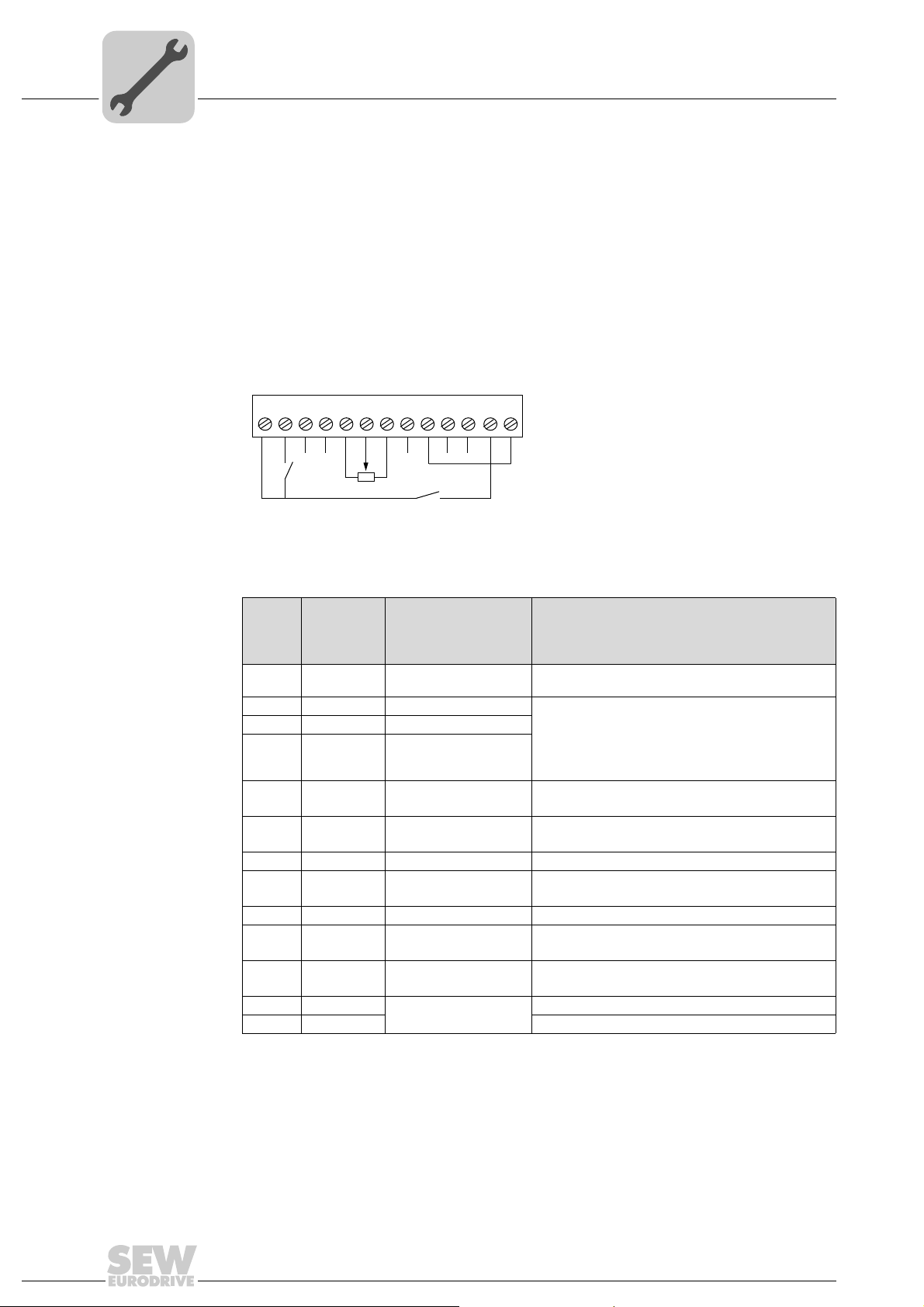

4.1 Overview of signal terminals for keypad mode

4.1.1 Main terminals

IP20 and IP55

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AI 2 / DI 5

1 234 56789101112 13

3614563083

AO 2 / DO 2

PSE+

PSE–

The signal terminal block is equipped with the following signal connections:

Terminal

1) Do not connect any cables

Signal Function

no.

1 +24 V Output +24 V reference

2 DI1 Enable Positive logic

3DI2 n.s.

4DI3 n.s.

5 +10 V n.s.

6 AI1 / DI4 n.s.

7 0 V 0 V reference potential 0 V reference potential (Pot. supply –)

8 AO1 / DO1 n.s.

9 0 V 0 V reference potential 0 V reference potential

10 AI2 / DI5 n.s.

11 AO2 / DO2 n.s.

12 PSE + Output stage enable +24 V must be connected to PSE+

13 PSE– GND must be connected to PSE–

P1-12 =1

P1-15 =1

(pre-assigned)

voltage

1)

1)

1)

1)

1)

1)

1)

Description

Ref. for the activation of DI1 – DI3 (max. 100 mA)

"Logic 1" input voltage range: DC 8 – 30 V

"Logic 0" input voltage range: DC 0 – 2 V

Compatible with PLC requirement if 0 V is connected

to terminal 7 or 9.

10 V ref. for analog input

(Pot. supply +, 10 mA max., 1 kΩ min.)

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

12

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 13

Overview of signal terminals for keypad mode

9

15

1

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

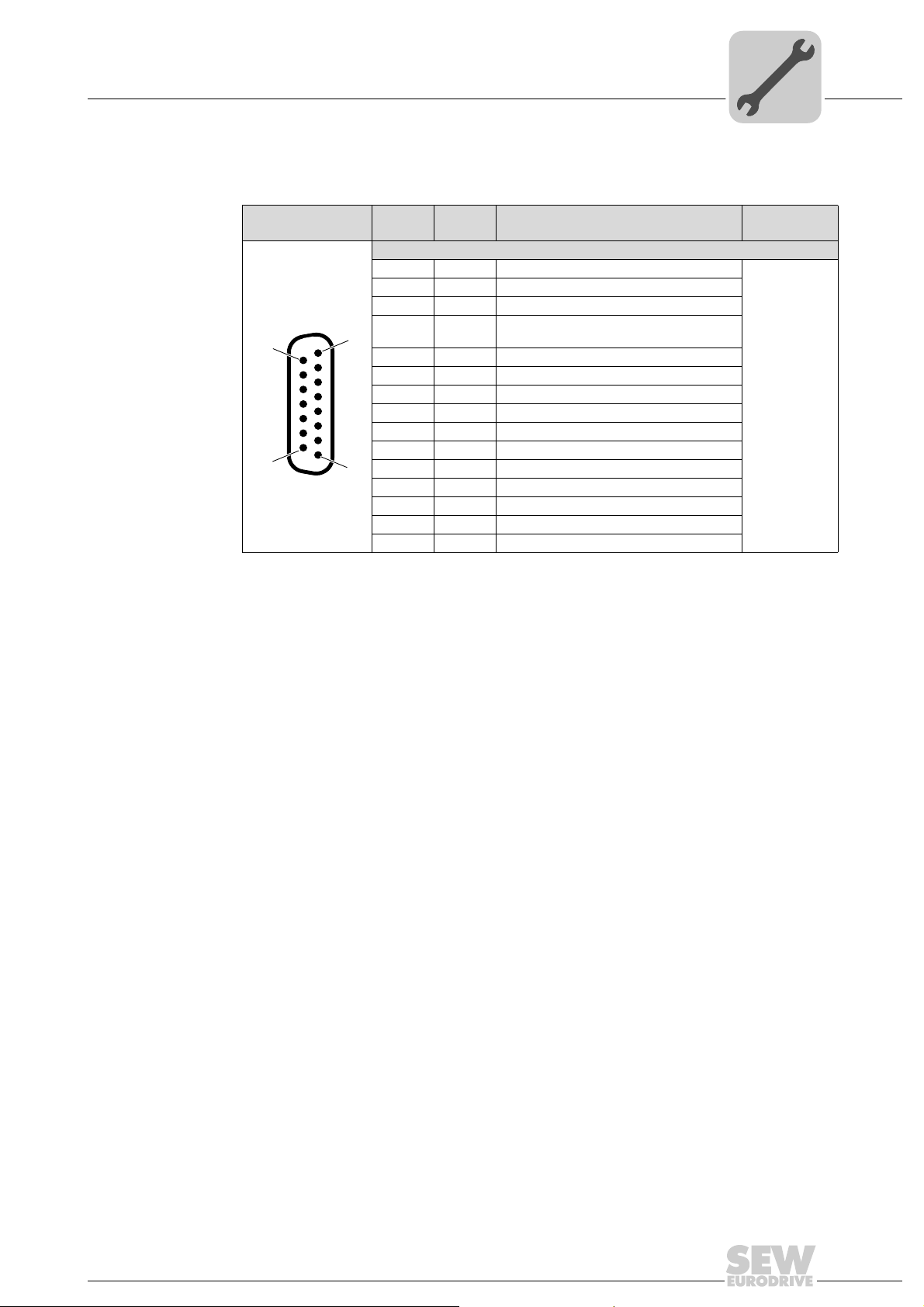

4.1.2 Application connection assignment X14

Electrical Installation

4

Terminal

no.

Signal Function

P1-17 = 1 (pre-assigned)

1)

1

1)

2

DI11 n.s.

DI12 n.s.

2)

31)DI13 n.s.

DI14 /

1)

4

1)

5

1)

6

1)

7

1)

8

n.s.

AI11

PI1 n.s.

/PI1 n.s.

PI2 n.s.

/PI2 n.s.

9An.s.

10 /A n.s.

11 B n.s.

12 /B n.s.

13 Z n.s.

14 /Z n.s.

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

15 0 V

1) Terminal assignment depends on parameter settings

2) Do not connect any cables

Connector type

X14

D-sub 15-pole

(male)

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

13

Page 14

4

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AO 2 / DO 2

PSE+

PSE–

AI 2 / DI 5

1 234 56789101112 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for terminal mode (internal ramp control of the

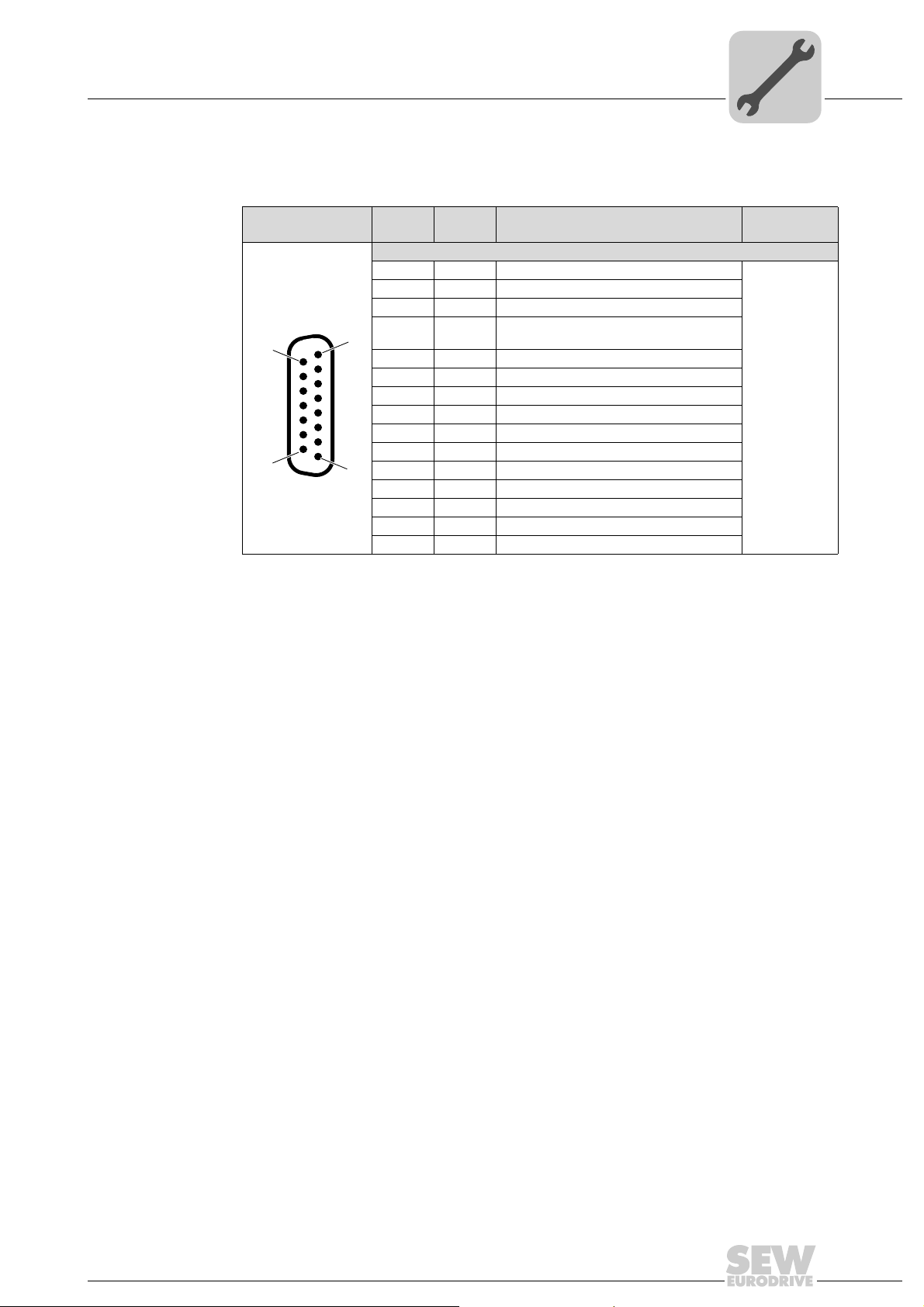

4.2 Overview of signal terminals for terminal mode (internal ramp control of the

LTP without controller/gateway)

4.2.1 Main terminals

IP20 and IP55

3616350731

The signal terminal block is equipped with the following signal connections:

Terminal

1) Do not connect any cables

Signal Function

no.

1 +24 V Output +24 V reference

2 DI1 Enable Positive logic

3DI2 n.s.

4DI3 n.s.

5 +10 V Output +10 V reference

6 AI1 / DI4 Analog input (12 bit)

7 0 V 0 V reference potential 0 V reference potential (Pot. supply –)

8 AO1 / DO1 n.s.

9 0 V 0 V reference potential 0 V reference potential

10 AI2 / DI5 n.s.

11 AO2 / DO2 n.s.

12 PSE + Output stage enable +24 V must be connected to PSE+

13 PSE– GND must be connected to PSE–

P1-12 =0

P1-15 =1

(pre-assigned)

voltage

1)

1)

voltage

reference speed

1)

1)

1)

Description

Ref. for the activation of DI1 – DI3 (max. 100 mA)

"Logic 1" input voltage range: DC 8 – 30 V

"Logic 0" input voltage range: DC 0 – 2 V

Compatible with PLC requirement if 0 V is connected

to terminal 7 or 9.

10 V ref. for analog input

(Pot. supply +, 10 mA max., 1 kΩ min.)

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

14

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 15

Electrical Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Overview of signal terminals for terminal mode (internal ramp control of the

4.2.2 Application connection assignment X14

4

15

Terminal

no.

9

1

8

Signal Function

P1-17 = 1 (pre-assigned)

1)

1

1)

2

DI11 n.s.

DI12 n.s.

2)

31)DI13 n.s.

DI14 /

1)

4

1)

5

1)

6

1)

7

1)

8

n.s.

AI11

PI1 n.s.

/PI1 n.s.

PI2 n.s.

/PI2 n.s.

9An.s.

10 /A n.s.

11 B n.s.

12 /B n.s.

13 Z n.s.

14 /Z n.s.

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

15 0 V

1) Terminal assignment depends on parameter settings

2) Do not connect any cables

Connector type

X14

D-sub 15-pole

(male)

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

15

Page 16

4

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AO 2 / DO 2

PSE+

PSE–

AI 2 / DI 5

1 234 56789101112 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for third-party controllers

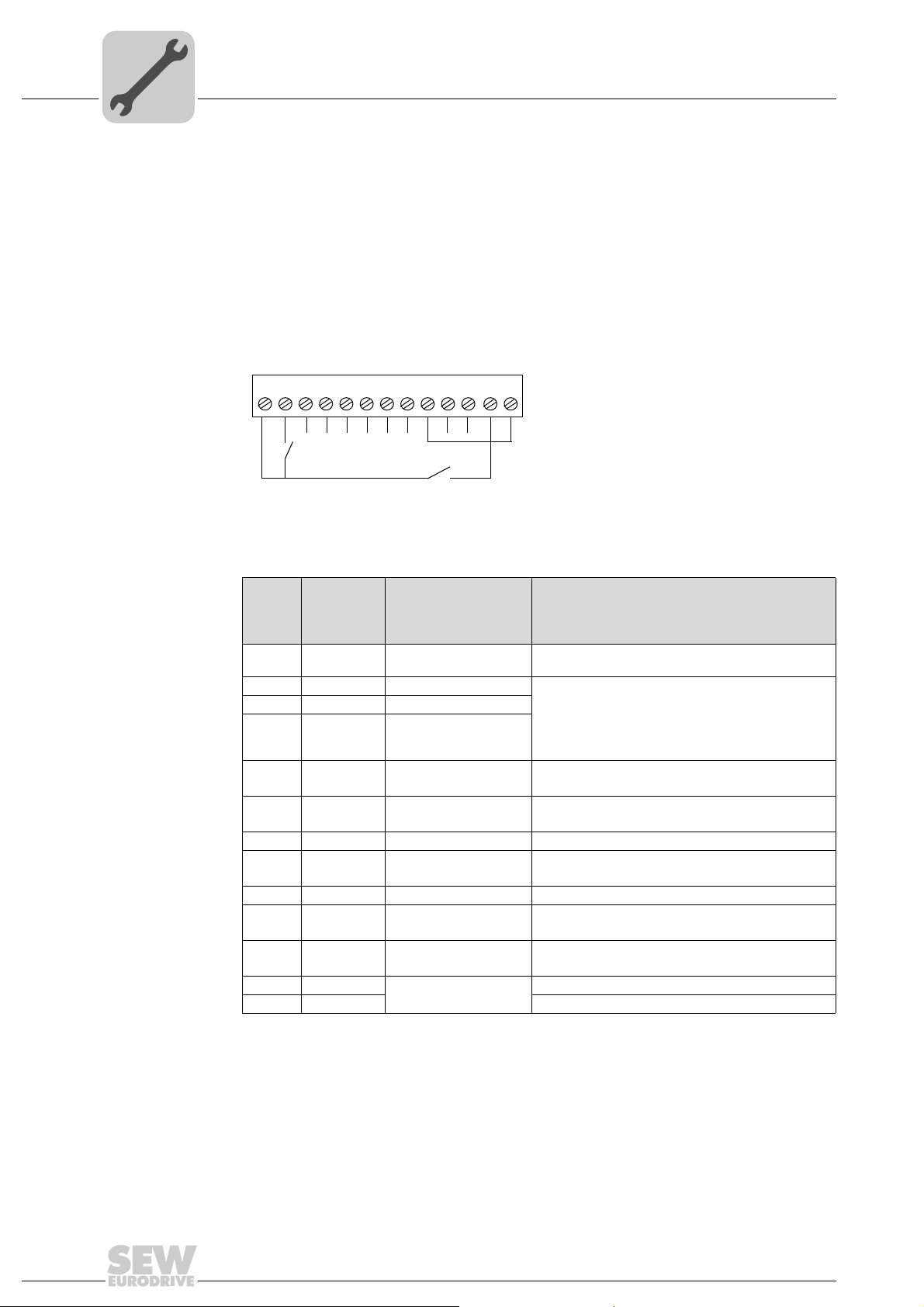

4.3 Overview of signal terminals for third-party controllers

4.3.1 Main terminals

IP20 and IP55

3614563083

The signal terminal block is equipped with the following signal connections:

Terminal

1) Do not connect any cables

Signal Function

no.

1 +24 V Output +24 V reference

2 DI1 Enable Positive logic

3DI2 n.s.

4DI3 n.s.

5 +10 V n.s.

6 AI1 / DI4 n.s.

7 0 V 0 V reference potential 0 V reference potential (Pot. supply –)

8 AO1 / DO1 n.s.

9 0 V 0 V reference potential 0 V reference potential

10 AI2 / DI5 n.s.

11 AO2 / DO2 n.s.

12 PSE + Output stage enable +24 V must be connected to PSE+

13 PSE– GND must be connected to PSE–

P1-12 =0

P1-15 =1

(pre-assigned)

voltage

1)

1)

1)

1)

1)

1)

1)

Description

Ref. for the activation of DI1 – DI3 (max. 100 mA)

"Logic 1" input voltage range: DC 8 – 30 V

"Logic 0" input voltage range: DC 0 – 2 V

Compatible with PLC requirement if 0 V is connected

to terminal 7 or 9.

10 V ref. for analog input

(Pot. supply +, 10 mA max., 1 kΩ min.)

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

16

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 17

Overview of signal terminals for third-party controllers

9

15

1

8

9

15

1

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.3.2 Application connection assignment X14

±10 V reference

potential and

encoder simulation

1) Terminal assignment depends on parameter settings

Terminal

no.

1

2

3

4

5

6

7

8

10 /A Encoder simulation output /A

11 B Encoder simulation output B

12 /B Encoder simulation output /B

13 Z Encoder simulation Z

14 /Z Encoder simulation /Z

15 0 V

Electrical Installation

Signal Function

P1-17 =5

1)

DI11 – Limit switch left

1)

DI12 – Limit switch right

1)

DI13 Fast reference cam for referencing input

DI14 /

1)

AI11

1)

1)

/PI1 –

1)

1)

/PI2 –

9 A Encoder simulation output A

Fast + – 10 V reference speed signal

input

PI1 –

PI2 –

Function

P1-17 =6

X14

4

Connector

type

D-sub 15-pole

(male)

Interface pulse /

direction or A/B

phase

1) Terminal assignment depends on parameter settings. Input is RS422-compliant and not HTL-capable

(connection of 24 V signals not possible). Maximum voltage of –10 to 15 V between PI1, /PI1, PI2, /PI2

and 0 V. Nominal operation level DC ± 6 V differential and min. DC ± 2 V differential.

2) Do not connect any cables

Terminal Signal Function

P1-17 =5

1)

1

DI11 –

1)

DI12 –

2

1)

3

DI13 –

DI14 /

1)

4

AI11

1)

5

1)

6

/PI1 Input \pulse Input \A phase

1)

7

1)

/PI2 Input \direction Input \B phase

8

9An.s.

10 /A n.s.

11 B n.s.

12 /B n.s.

13 Z n.s.

14 /Z n.s.

15 0 V

–

PI1 Input pulse Input A phase

PI2 Input direction Input B phase

2)

2)

2)

2)

2)

2)

X14

Function

P1-17 =6

Connector

type

D-sub 15-pole

(male)

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

17

Page 18

4

A

[1]

B

[1]

t1t

2

– 2.5 V

– 2.5 V

+ 2.5 V

+ 2.5 V

≥ 2.5 μs ≥ 2.5 μs

A

[1]

B

[1]

– 2.5 V

– 2.5 V

+ 2.5 V

+ 2.5 V

≥ 2.5 μs ≥ 2.5 μs

t1t

2

≥ 2.5μs ≥ 2.5 μs

Pulse

[2]

t

v

" low "

– 2.5 V

+ 2.5 V

+ 2.5 V

– 2.5 V

+ 2.5 V

Direction

[2]

t

ON

PULSE

[2]

≥ 2.5 μs ≥ 2.5 μs

t

v

– 2.5 V

+ 2.5 V

– 2.5 V

t

ON

Direction

[2]

+ 2.5 V

" high "

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for third-party controllers

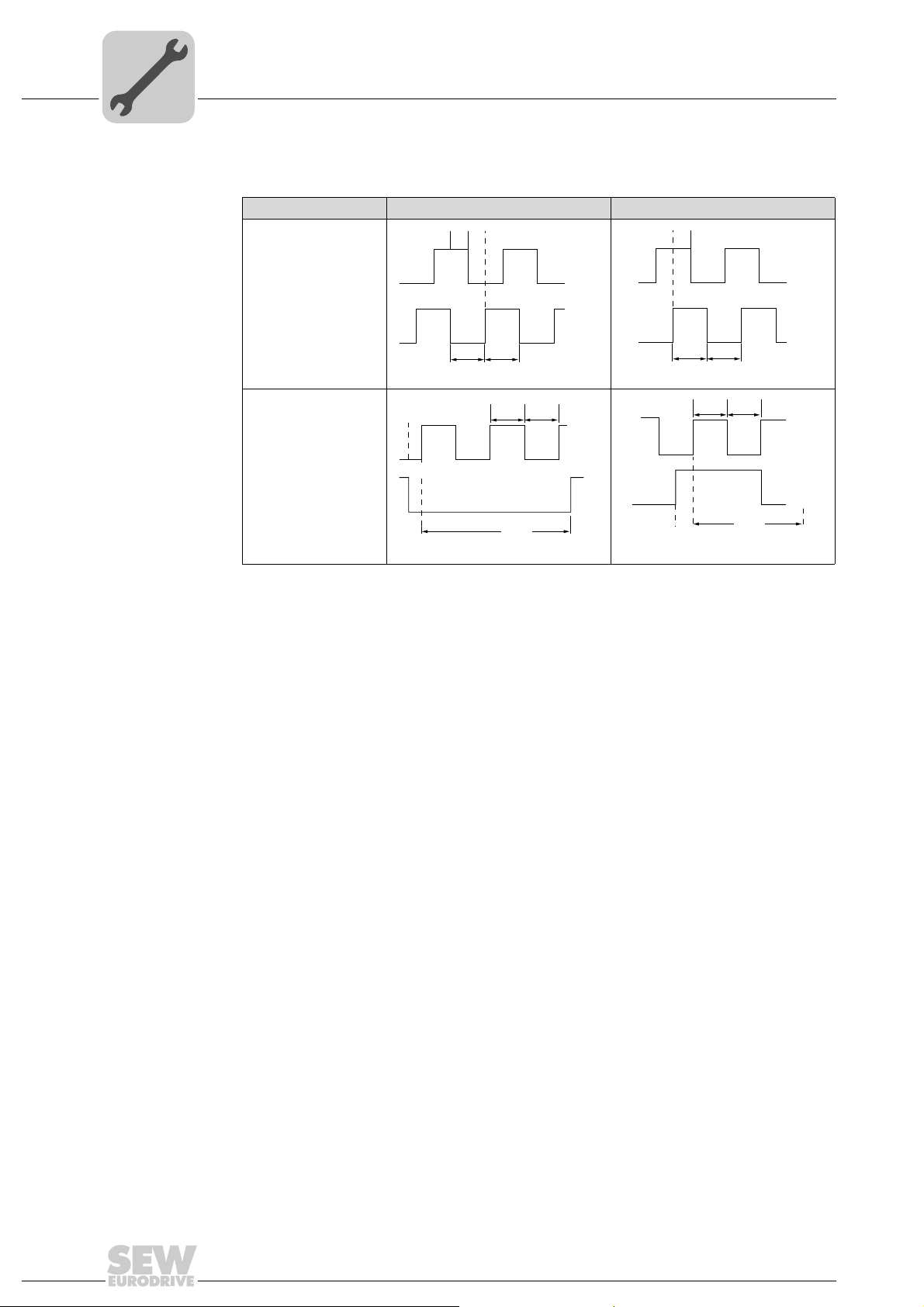

The following illustration shows the motor behavior according to the setting of parameter

P1-17 and the signal sequence.

P1-17 Negative direction (CCW) Positive direction (CW)

Input A/B phase

P1-17 =8

Input pulse/direction

P1-17 =7

[1] The displayed signals A or B are the resulting signals/voltage values between A (PI1) and /A (/PI1)

or B (PI2) and /B (/PI2).

[2] The displayed signals pulse and direction are the resulting signals/voltage values between pulse

(PI1) and /pulse (/PI1) or direction (PI2) and /direction (/PI2).

t

, t2t1/t2 ≥ 1.25 ±10 %

1

tv ≥ 0.5 µs

t

v

t

ONtON

≥ 100 µs

18

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 19

Electrical Installation

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AO 2 / DO 2

PSE+

PSE–

AI 2 / DI 5

1 234 56789101112 13

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AO 2 / DO 2

PSE+

PSE–

AI 2 / DI 5

1 234 56789101112 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Overview of signal terminals for SEW controllers

4.4 Overview of signal terminals for SEW controllers

4.4.1 Main terminals

IP20 and IP55 profile 1 IP55 and IP66 profile 2

3616834059 3616835979

4

The signal terminal block is equipped with the following signal connections:

Terminal no.

1) Do not connect any cables

Signal Function

Profile 1

P1-12 = set automatically

P1-15 = set automatically

1 +24 V Output +24 V ref-

2 DI1 Start Start Positive logic

3DI2 Reset Reset

4 DI3 Reference cam Reference cam

5 +10 V n.s.

6 AI1 / DI4 n.s.

7 0 V 0 V reference

8 AO1 / DO1 n.s.

9 0 V 0 V reference

10 AI2 / DI5 n.s.

11 AO2 / DO2 n.s.

12 PSE + Output stage

13 PSE– GND must be connected to PSE–

erence voltage

1)

1)

potential

1)

potential

1)

1)

enable

Function

Profile 2

Output +24 V

reference voltage

1)

n.s.

Limit switch + 0–10V, 0–20mA, 4–20mA

0 V reference

potential

1)

n.s.

0 V reference

potential

Limit switch – 0–10V, 0–20mA, 4–20mA

1)

n.s.

Output stage

enable

Description

Ref. for the activation of DI1 – DI3

(max. 100 mA)

"Logic 1" input voltage range:

DC 8 – 30 V

"Logic 0" input voltage range:

DC 0 – 2 V

Compatible with PLC requirement if 0

V is connected to terminal 7 or 9.

10 V ref. for analog input

(Pot. supply +, 10 mA max., 1 kΩ

min.)

"Logic 1" input voltage range:

DC 8 – 30 V

0 V reference potential (Pot. supply –)

0 – 10 V, 20 mA analog

24 V, 20 mA digital

0 V reference potential

"Logic 1" input voltage range:

DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

+24 V must be connected to PSE+

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

19

Page 20

4

9

15

1

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for SEW controllers

4.4.2 Application connection assignment X14

Terminal

no.

Signal Function

P1-17 = 1 (pre-assigned)

1)

1

DI11 n.s.

1)

DI12 n.s.

2

1)

3

DI13 Touch probe 1

DI14 /

1)

4

AI11

1)

PI1 n.s.

5

1)

6

/PI1 n.s.

1)

7

PI2 n.s.

1)

8

/PI2 n.s.

9An.s.

10 /A n.s.

11 B n.s.

12 /B n.s.

13 Z n.s.

14 /Z n.s.

2)

2)

Touch probe 2

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

15 0 V

1) Terminal assignment depends on parameter settings

2) Do not connect any cables

Connector

type

X14

D-sub 15-pole

(male)

20

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 21

Electrical Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Overview of signal terminals for SEW gateways

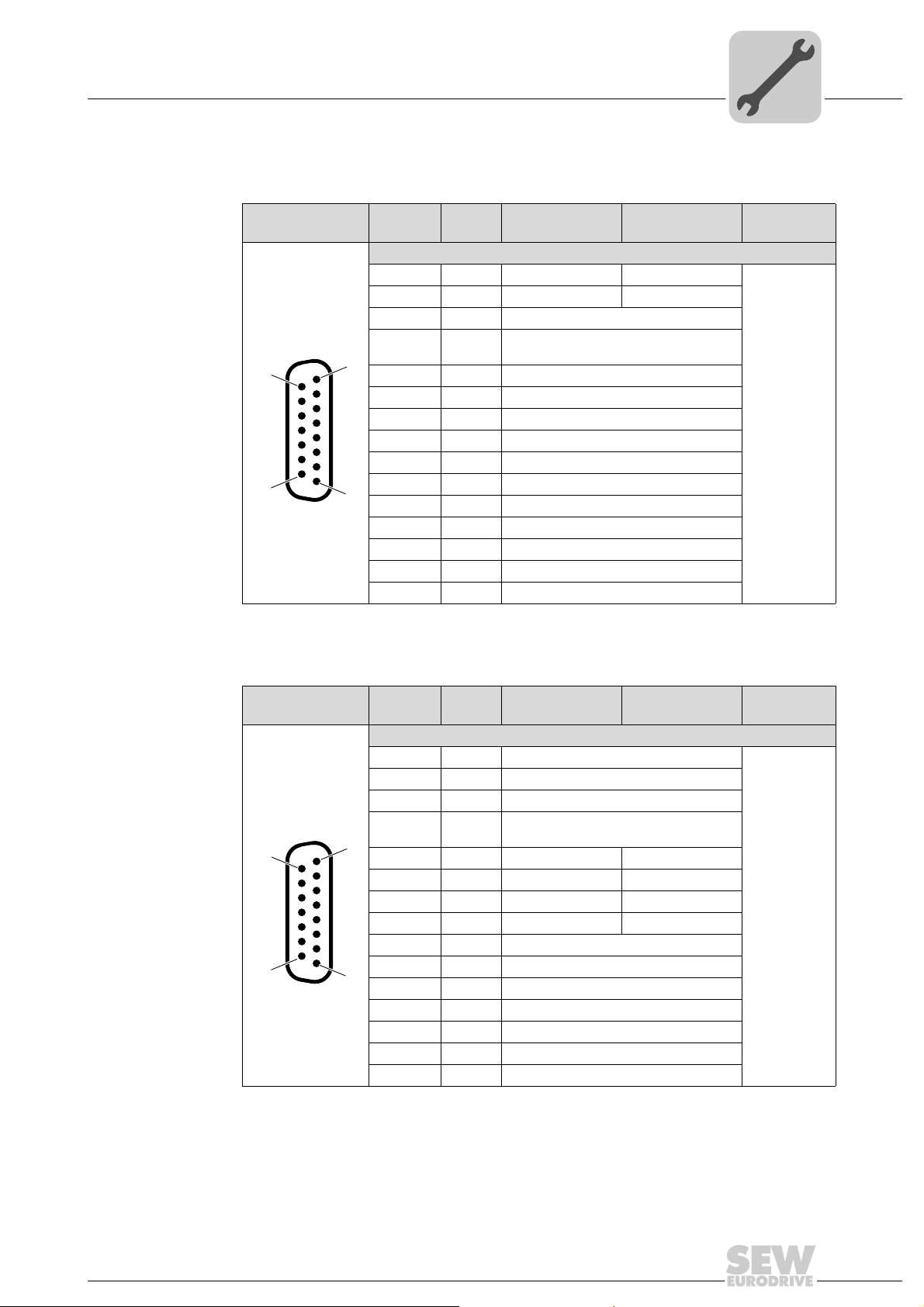

4.5 Overview of signal terminals for SEW gateways

4.5.1 Main terminals

IP20 and IP55

+24 V

DI 1

DI 2

DI 3

+10 V

AI 1 / DI 4

0 V

AO 1 / DO 1

0 V

AO 2 / DO 2

PSE+

AI 2 / DI 5

1 234 56789101112 13

PSE–

3614563083

4

The signal terminal block is equipped with the following signal connections:

Terminal no.

1) Do not connect any cables

Signal Function

P1-12 =0

P1-15 =1

(pre-assigned)

1 +24 V Output +24 V reference

2 DI1 Enable Positive logic

3DI2 n.s.

4DI3 n.s.

5 +10 V n.s.

6 AI1 / DI4 n.s.

7 0 V 0 V reference potential 0 V reference potential (Pot. supply –)

8 AO1 / DO1 n.s.

9 0 V 0 V reference potential 0 V reference potential

10 AI2 / DI5 n.s.

11 AO2 / DO2 n.s.

12 PSE + Output stage enable +24 V must be connected to PSE+

13 PSE– GND must be connected to PSE–

voltage

1)

1)

1)

1)

1)

1)

1)

Description

Ref. for the activation of DI1 – DI3 (max. 100 mA)

"Logic 1" input voltage range: DC 8 – 30 V

"Logic 0" input voltage range: DC 0 – 2 V

Compatible with PLC requirement if 0 V is connected

to terminal 7 or 9.

10 V ref. for analog input

(Pot. supply +, 10 mA max., 1 kΩ min.)

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

0–10V, 0–20mA, 4–20mA

"Logic 1" input voltage range: DC 8 – 30 V

0 – 10 V, 20 mA analog

24 V, 20 mA digital

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

21

Page 22

4

9

15

1

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Electrical Installation

Overview of signal terminals for SEW gateways

4.5.2 Application connection assignment X14

Terminal

Signal Function Connector

no.

1)

1

DI11 n.s.

1)

DI12 n.s.

2

1)

3

DI13 n.s.

DI14 /

1)

4

AI11

1)

5

PI1 n.s.

1)

6

/PI1 n.s.

1)

7

PI2 n.s.

1)

8

/PI2 n.s.

9An.s.

10 /A n.s.

11 B n.s.

12 /B n.s.

13 Z n.s.

14 /Z n.s.

n.s.

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

15 0 V

1) Terminal assignment depends on parameter settings

2) Do not connect any cables

type

X14

D-sub 15-pole

(male)

22

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 23

Overview of relay terminals and X13

9

15

1

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.6 Overview of relay terminals and X13

4.6.1 Relay terminal overview for all operating modes

Relay output 1

14 15 16 17 18

Electrical Installation

Reference potential

Relay output 1 NO

Relay output 2

Reference potential

Relay output 1 NC

Relay output 2 NO

4

3003612555

Terminal

no.

14 Relay output 1 reference Relay contact (AC 250 V / DC 30 V @ 5 A)

15 Relay output 1 NO

16 Relay output 1 NC

17 Relay output 2 reference

18 Relay output 2 NO

Signal Description

4.6.2 Connection assignment X13 motor encoder for all operating modes

Terminal

no.

1 Signal track A (cos+)

2 Signal track B (sin+)

1)

3n.s.

4DATA+

5 n.s.

6KTY–

1)

7 n.s.

8DGND

9 Signal track A_N (cos–)

10 Signal track B_N (sin–)

11 n.s.

12 DATA–

13 n.s.

14 KTY +

15 Us

1) Do not connect any cables

1)

Function Connector type

X13

D-sub 15-pole

(female)

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

23

Page 24

5

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5Startup

5.1 User interface

5.1.1 Keypad

Startup

User interface

®

Each MOVITRAC

ating and setting-up the drive without any further devices.

The keypad has 5 keys with the following functions:

LTP-B is equipped with a keypad as standard that allows for oper-

Start (execute)

Stop/reset • Stops the motor

Navigate • Shows real-time information

Up • Increases the speed in real-time mode

Down • Decreases the speed in real-time mode

• Enables the motor

• Reverses the direction of rotation if bidirectional keypad mode is activated

• Acknowledges an error

• Press and hold to enable/disable parameter edit mode

• Saves parameter changes

• Increases the parameter values in parameter edit mode

• Decreases the parameter values in parameter edit mode

If the parameters are set to the factory settings, the "Start" and "Stop" keys of the keypad

are disabled. In order to enable the "Start" and "Stop" keys of the keypad, P1-12 must

be set to 1 or 2, see operating instructions for MOVITRAC

®

LTP-B, chapter "Parameter

group 1: Standard parameters".

The parameter edit menu can only be accessed via the "Navigate" key. Press and hold

the key (> 1 s) to switch between the parameter edit menu and th e real-time display (operating state of the drive/speed). Press this key briefly (< 1 s) to switch between the operating speed and operating current of the running drive.

[1]

LT

®

[4]

[2]

MOVITRAC

[5]

[3]

[1] Display [4] Navigate

[2] Start [5] Up

[3] Stop/reset [6] Down

[6]

2933664395

• NOTE

To restore the factory settings, pr ess th e "Up" , "Do wn" an d "Stop/ rese t" keys s imul-

taneously for > 2 s. "P-deF" is displayed.

Press the "Stop/reset" key again to confirm the change and to reset the inverter.

24

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 25

Extended key combinations

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

User interface

I

5

00

Function The device dis-

Quick parameter

group selection

Selection of the

lowest group

parameter

Set the parameter

to the lowest value

Changing individual

digits of a parameter value

1) Parameter group access must be activated by setting P1-14 to "101".

plays...

Px-xx "Navigate" + "Up" keys The next higher parame-

1)

Px-xx "Navigate" + "Down"

Px-xx "Up" + "Down" keys The first parameter of

Numerical value

(when changing a

parameter value)

Numerical value

(when changing a

parameter value)

Press... Result Example

keys

"Up" + "Down" keys The parameter is set to

"Stop/reset" + "Navigate" keys

ter group is selected

The next lower parameter group is selected

a

group is selected

the lowest value

The individual parameter digits can be changed

• "P1-10" is displayed

• Press the "Navigate" + "Up"

keys

• Now, "P2-01" is displayed

• "P2-26" is displayed

• Press the "Navigate" + "Down"

keys

• Now, "P1-01" is displayed

• "P1-10" is displayed

• Press the "Up" + "Down" keys

• Now, "P1-01" is displayed

When changing P1-01:

• "50.0" is displayed

• Press the "Up" + "Down" keys

• Now "0.0" is displayed

When setting P1-10:

• "0" is displayed

• Press the "Stop/reset" + "Navigate" keys

• Now "_0" is displayed

• Press the "Up" key

• Now "10" is displayed

• Press the "Stop/reset" + "Navigate" keys

• Now "_10" is displayed

• Press the "Up" key

• Now "110" is displayed

etc.

5.1.2 Display

A six-digit 7-segment display is integrated in each drive. It can be used to monitor drive

functions and set parameters.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

25

Page 26

5

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

5.2 Simple startup of MOVITRAC® LTX

The following figure shows the MOVITRAC® LTP-B without and with inserted LTX servo

module.

[1]

L1/L L2/N L3

L1/L L2/N L3

[2]

[3]

[4]

LTP-B

®

MOVITRAC

LTP-B

®

MOVITRAC

[5]

[6]

+

BR U V W

+

BR U V W

[8]

[7]

[9]

[11]

[10]

[1] Supply system terminals [8] Detent

[2] Quick aid [9] Push button

[3] Display [10] X14 application connection

[4] Keypad [11] X13 Motor encoder connection

[5] Main terminals

[6] Relay terminals

[7] Connection for motor and brake chopper

26

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 27

Simple startup of MOVITRAC® LTX

CMP

Motor

PE U V W

123

4

131415

BMV

DC 24 V

K11

(AC-3)

D

–

+

C

14 15 16 17 18

+

––

+

[6]

[7]

[12]

(1)

(2)

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.2.1 Basic wiring and settings prior to operating mode-specific startup

• Connect the CMP motor with a pre-fabricated SEW motor cable to the motor connection terminals [7].

• If you want to connect a CMP brak emotor, use a pre-fabricated SEW brakemotor

cable and a BMV brake rectifier. The brake must be wired according to the following

wiring diagram.

Startup

5

3783241355

[6] Relay terminals

[7] Connection for motor and brake chopper

[12] Optionally integrated motor brake

• Connect the motor encoder to the motor encoder connection X13 [11] of the LTX

device with a pre-fabricated SEW encoder cable.

• WARNING Danger due to unintended restart.

The motor might restart when the inverter is connected to the supply.

– Regardless of the selected operating mode, the contacts 12 and 13 of the main

terminals [5] must be interrupted.

• Connect the inverter to the supply system by wiring the supply terminals [1].

• Turn on the inverter.

• Restore the factory settings of the inverter, if required (press the "Stop", "Up" and

"Down" keys for 5 s until "P-Def" is displayed). Confirm with the "Stop" key.

• Check whether the correct CMP motor is displayed in the parameter P1-16.

• If P1-16 = "in-syn", or if there is no access, the motor encoder does not have a valid

electronic nameplate. Without valid electronic nameplate, the motor type must be set

manually.

Setting the motor type manually:

•Set P1-14 to "1" for free access to parameters P1-16 to P1-22

•Set P1-16 to the connected motor type.

•Set P1-18 to "1" to activate the thermal motor protection KTY.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

• INFORMATION

Only motors of the Smart Servo Package are supported.

27

Page 28

5

P

J

J

ext

mot

122−=

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

• Once the correct motor has been set, either automatically or manually, the motor

startup is completed.

• The motor overload protection is set to "250%" to provide a high overload torque.

• If you use an SEW encoder cable, the KTY thermistor is connected by default in o rder

to provide for thermal motor protection.

• Contacts 12 and 13 of the main termin als [5] are wired according to the selected

operating mode. Now you can enable the drive. For information on the electrical

installation depending on the respective operating mode refer to chapter "Electrical

Installation" (page 11) or to the following chapters that illustrate the correct wiring

according to the operating mode.

– "Keypad mode (P1-12 = 1 or 2)" (page 29)

– "Terminal mode (basic setting) P1-12 = 0 fur LTP-internal ramp control" (page 29)

– "Linking and startup with different controllers (third-party controller and SEW

controller)" (page 30)

• WARNING Danger of electric shock.

Improper wiring my cause danger due high voltages when the motor or the drive is

enabled.

– Check the wiring according to:

• the selected operating mode

• the installation and wiring notes in chapter "Electrical Installation"

• the installation and wiring notes in chapter "Electrical Installation" in the

"MOVITRAC

®

LTP-B" operating modes.

• INFORMATION

All motors of the Smart Servo Package can be operated with standard parameter

settings of the inverter for speed and position control. You can change parameter P1-

22 for initial simple control loop optimization. Parameter P1-22 represents the

relation between total inertia (J

ext

= J

Load

+ J

Gear unit

) and motor inertia (J

mot

/ Jb

For further optimization options regar ding speed and position control, refer to chapter

"Control loop optimization in different operating modes" (page 38).

For further information regarding the motor iner tia, refer to chapter "Ma ss moment of

inertia of the CMP motors in the Smart Servo Package" (page 56).

mot

).

28

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 29

5.2.2 Keypad mode (P1-12 = 1 or 2)

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

For operation in keypad mode:

• As the electrical installation depends on the respective operating mode, chapter

"Overview of signal terminals for keypad mode" (page 12) provides wiring information.

•Set P1-12 to "1" (uni-directional) or "2" (bi-directional).

• Connect a wire break or a switch between terminal 1 and 2 to the user term inal block

in order to enable the drive.

• Press the "Start" key. The drive is enabled with 0.0 Hz.

• Press the "Up" key to increase the speed or the "Down" key to decrease the speed.

• To stop the drive, press the "Stop/reset" key.

• Press the "Start" key again to resume the original speed.

If bi-directional mode is enabled (P1-12 = 2), the direction is reversed by pressing the

"Start" key.

Startup

Simple startup of MOVITRAC® LTX

5

• INFORMATION

The required target speed can be set by pressing the "Stop/reset" key in standstill.

By then pressing the "Start" key, the drive moves along a ramp until it has reached

this speed.

5.2.3 Terminal mode (basic setting) P1-12 = 0 fur LTP-internal ramp control

For operation in keypad mode (basic setting):

• As the electrical installation depends on the respective operating mode, chapter

"Overview of signal terminals for termin al mode " (page 14) provides wiring information.

• P1-12 must be set to "0" (basic setting).

• Connect a switch between terminals 1 and 2 on the user terminal block.

• Connect a potentiometer (1 – 10 k) between terminals 5, 6 and 7, the slidin g co ntact

is connected to pin 6.

• Provide for a connection between terminals 1 and 2 in order to enable the drive.

• Set the speed using the potentiometer.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

29

Page 30

5

startup modes

startup tools

External control mode

Keypad

Manually

Pulse/direction; ± 10V

w. encoder simulation

Velocity control

CCU

configurable control unit

User-programmable

MS

(PLCEditor)

e.g. bus positioning

Gateway

(DFP-UOH...)

MOVI-PLC®

Motion and logic controller

Keypad

MS

(Drive Startup)

Keypad

MS

(Gateway Configurator)

SEW gateway modeSEW controller mode

Keypad

SD card

MS

(Drive Startup)

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

5.2.4 Linking and startup with different controllers (third-party controller and SEW controller)

Third-party

controller mode

9007202885779467

Third-party controllers, SEW controllers and gateway operation are described in the

following chapters.

For operation in third-party controller mode:

Setting motor limits (applies to all third-party controller modes):

• Set parameter P1-01 to the upper limit of the required motor spe ed (N

[rpm]). If

max

the values are displayed in Hz, set the rated speed of the motor in P1-10 to the r ated

speed of the connected motor. P1-01 also represents the possible ma xim u m sp ee d

in analog mode with ± 10 V, if DC 10 V are connected. (For all Smart Servo Package

motors, P1-10 should show 4500 rpm). For a detailed description of this parameter,

refer to the MOVITRAC

•Set P1-03 to the required acceleration ramp that specifies the time in seconds, the

®

LTP-B operating instructions.

output frequency increases from 0 to 50 Hz (AccRamp [s]). The 6-pole CMP motors

of the Smart Servo Package require an output frequency of 150 Hz for a speed of

3000 rpm, for example. You ha ve to set P1-03 to 0.33 s to specify an acceleration

ramp of 3000 rpm/s. For a detailed description of this parameter, refer to the

®

MOVITRAC

•Set P1-04 to the required deceleration/stop ramp that specifies the time in seconds,

the output frequency decreases from 50 to 0 Hz (DecRamp [s]). Proceed as with P1-

LTP-B operating instructions.

03.

30

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 31

Startup

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Simple startup of MOVITRAC® LTX

Operation with ±10 V interface with analog input on the main terminal strip

(sampling cycle = 16 ms)

•Set P1-14 to 201 to access the parameters of the LTX-specific parameter group 8.

•Set P1-15 to one of the possible operating modes: 22, 23, 24 or 25.

For a detailed description of this parameter, refer to chapter "1- 15 function selection

digital inputs, LTX-specific parameters" (page 44). You can use an analog setpoint

for velocity specification at the first analog input of the main terminal strip.

•Set P1-12 to 0 (terminal control, default setting).

• If using the analog input, set P2-30 to –10 to +10 V for bipolar voltage input at the

analog input. For a detailed description of this parameter, refer to the MOVITRAC

LTP-B operating instructions.

• Use parameter P8-01 to set the scaling factor for the incremen tal encoder simulation.

For a detailed description of this parameter, refer to chapter "P8-01 simulated

encoder scaling" (page 49)

• CAUTION unexpected drive response possible.

Risk of crushing

5

®

If functions (e.g. the analog input) are set in parameter P1-15 and activated in

parameter P1-17, the input on the X14 connector has priority and the signal assignments on parameter P1-15 are overwritten or deactivated.

The wrong use of parameters P1-15 and P1-17 in conjunction with the inputs of the

terminals of X14 can cause uncontrolled movements or malfunctions of the drive.

The required electric installation of the signal terminals depends on the selected

operating mode. A wiring that does not suit the respective operating mode, can

cause uncontrolled movements or malfunctions of the drive.

– Wire the signal terminals according to chapter "Overview of signal terminals for

third-party controllers" (page 16) and/or check the existing wiring accordingly.

– Perform the parameterization of P1-15 and P1-17 according to the operating

mode.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

31

Page 32

5

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

Operation with ±10 V interface with fast analog input on the LTX servo module

(sampling cycle = 4 ms)

You should use the servo module inputs predominantly if you require reference cams or

a fast analog input or a stepper motor control. This will also enable the pulse/direction

control or the encoder input function.

•Set P1-14 to 201 to access the parameters of the LTX-specific parameter group 8.

•Set P1-15 to one of the possible operating modes: 22, 23, 24 or 25.

For a detailed description of this parameter, refer to chapter "1- 15 function selection

digital inputs, LTX-specific parameters" (page 44).

•Set P1-12 to 0 (terminal control, default setting).

•Set P1-17 to one of the possible operating modes: 5 or 6.

For a detailed description of the parameter, refer to chapter "P1-17 Smart Servo

operation" (page 47).

• If using the analog input, set P2-30 to –10 to +10 V for bipolar voltage input at the

analog input.

®

For a detailed description of this parameter, refer to the MOVITRAC

ing instructions.

LTP-B operat-

• Use parameter P8-01 to set the scaling factor for the encoder simulation.

For a detailed description of this parameter, refer to chapter "P8-01 simulated

encoder scaling" (page 49)

• CAUTION unexpected drive response possible.

Risk of crushing

If functions (e.g. the analog input) are set in parameter P1-15 and activated in

parameter P1-17, the input on the X14 connector has priority and the signal assignments on parameter P1-15 are overwritten or deactivated.

The wrong use of parameters P1-15 and P1-17 in conjunction with the inputs of the

terminals of X14 can cause uncontrolled movements or malfunctions of the drive.

The required electric installation of the signal terminals depends on the selected

operating mode. A wiring that does not suit the respective operating mode, can

cause uncontrolled movements or malfunctions of the drive.

– Wire the signal terminals according to chapter "Overview of signal terminals for

third-party controllers" (page 16) and/or check the existing wiring accordingly.

– Perform the parameterization of P1-15 and P1-17 according to the operating

mode.

32

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 33

Startup

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Simple startup of MOVITRAC® LTX

Operation with pulse/direction or A, /A, B, /B (stepper motor control interface) on

the server module

• CAUTION potential unexpected movement of the motor.

Risk of crushing

– Perform a reference travel prior to enabling the drive with stepper motor control

(P4-01 = 5, PM-Motor, position control). This is to align actual position and

setpoint position. Without reference travel, the motor might move unexpectedly

directly after it has been enabled.

– We recommend to consult SEW-EURODRIVE before you activate jog mode in

the current unit variant as jog mode causes a lag error that has to be processed

by the position controller once the "jog signal" has be en removed. This may cause

unexpected movements.

If jog mode is used, reset or deactivate the lag error and/or the lag erro r m onitoring prior to an initial enable.

The servo module inputs are used predominantly if you require reference ca ms or a fast

analog input or a stepper motor control. This will also enable the pulse/direction control

or the encoder input function.

5

•Set P1-14 to 201 to access the parameters of the LTX-specific parameter group 8.

•Set P1-15 to one of the possible operating modes: 22, 23, 24 or 25.

For a detailed description of this parameter, refer to chapter "1- 15 function selection

digital inputs, LTX-specific parameters" (page 44).

•Set P1-12 to 0 (terminal control, default setting).

• Use parameter P8-02 to set the scaling factor for the input pulses that represent a

motor revolution.

For a detailed description of this parameter, refer to chapter "P8-02 pulses per

revolution for input pulse/direction A/B phase" (page 49).

•Set P4-01 to 5 (PM Motor, position control).

•Set P1-17 to one of the possible operating modes: 7 or 8.

For a detailed description of the parameter, refer to chapter "P1-17 Smart Servo

operation" (page 47).

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

33

Page 34

5

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

• CAUTION unexpected drive response possible.

Risk of crushing

If functions (e.g. the analog input) are set in parameter P1-15 and activated in

parameter P1-17, the input on the X14 connector has priority and the signal assignments on parameter P1-15 are overwritten or deactivated.

The wrong use of parameters P1-15 and P1-17 in conjunction with the inputs of the

terminals of X14 can cause uncontrolled movements or malfunctions of the drive.

The required electric installation of the signal terminals depends on the selected

operating mode. A wiring that does not suit the respective ope rating mode can cause

uncontrolled movements or malfunctions of the drive.

– Wire the signal terminals according to chapter "Overview of signal terminals for

third-party controllers" (page 16) and/or check the existing wiring accordingly.

– Perform the parameterization of P1-15 and P1-17 according to the operating

mode.

• WARNING Danger of electric shock.

Improper wiring my cause danger due high voltages when the motor or the drive is

enabled.

– Check the wiring according to:

• the selected operating mode

• the installation and wiring notes in chapter "Electrical Installation"

• the installation and wiring notes in chapter "Electrical Installation" in the

"MOVITRAC

• INFORMATION

For further information on the drive adaption, refer to chapter "Con trol loop optimiza-

tion for gateway mode" (page 42).

®

LTP-B" operating modes.

34

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 35

Startup

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Simple startup of MOVITRAC® LTX

SEW control mode For operation with an SEW controller with CCU or MOVI-PLC® (setup via the

"Drive startup" wizard):

• Set the required drive address in P1-19 (1 – 63).

• Set the required baud rate in P1-20 (125, 250, 500, 1000 kBaud). For CCU mode,

the baud rate must be set to 500 kBaud.

®

• For a detailed description of these two parameters, refer to the MOVITRAC

operating instructions.

®

• The network view of MOVITOOLS

junction with the SEW controller. Click right to open the context menu and select

"DriveStartUpLTX". Perform a network scan with MOVITOOLS

• Follow the instructions and perform all the required settings in the "Drive startup"

software in MOVITOOLS

• CAUTION As the electrical installation depends on the respective operating mode,

chapter "Overview of signal terminals for SEW controllers" (pag e 19) provides wiring

information.

• WARNING Danger of electric shock.

Improper wiring my cause danger due high voltages when the motor or the drive is

enabled.

– Check the wiring according to:

®

MotionStudio.

MotionStudio shows the LTX inverters in con-

®

MotionStudio.

LTP-B

5

• the selected operating mode

• the installation and wiring notes in chapter "Electrical Installation"

• the installation and wiring notes in chapter "Electrical Installation" in the

"MOVITRAC

• INFORMATION

For further information on the drive adaption, refer to chapter "Con trol loop optimiza-

tion for gateway mode" (page 42).

®

LTP-B" operating modes.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

35

Page 36

5

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Simple startup of MOVITRAC® LTX

SEW gateway

mode

For operation with direct fieldbus connection (via gateway):

Setting motor limits

®

[rpm]). If

max

LTP-B

®

LTP-B

For a detailed description of the following parameters, refer to the MOVITRAC

operating instructions.

• Set parameter P1-01 to the upper limit of the required motor spe ed (N

the values are displayed in Hz, set the rated speed of the motor in P1-10 to the r ated

speed of the connected motor. P1-01 also displays the possible maximum speed in

gateway mode. Scaling: 0x4000 = 100 % of the maximum speed as set in P-01.

Values above 0x4000 or below 0xC000 are limited to 0x4000 / 0xC000. (For all

Smart Servo Package motors, P1-10 should show 4500 rpm).

•Set P1-03 to the required acceleration ramp that specifies the time in seconds, the

output frequency increases from 0 to 50 Hz (AccRamp [s]). The 6-pole CMP motors

of the Smart Servo Package require an output frequency of 150 Hz for a speed of

3000 rpm, for example. You ha ve to set P1-03 to 0.33 s to specify an acceleration

ramp of 3000 rpm/s.

•Set P1-04 to the required deceleration/stop ramp that specifies the time in seconds,

the output frequency decreases from 50 to 0 Hz (DecRamp [s]). See P1-03 (above)

for a scaling example.

Setting the control source

®

• Set parameter P1-12 to "5", i.e. control via SBus MOVILINK

way. For a detailed description of this parameter, refer to the MOVITRAC

operating instructions.

and thus via the gate-

Setting the communication parameters

For a detailed description of the following parameters, refer to the MOVITRAC

operating instructions.

•Set P1-14 to "101" for extended parameter access.

• Set the required drive address in P5-01 (1

• Set the required baud rate in P5-02 (125, 250, 500

the baud rate must be set to 500 "kBaud".

•Set P5-05 to the required "Communication failure response".

– 0 = error and coast to a stop

1 = error and stop via a ramp

2 = stop via a ramp, no error

3 = preset speed 8

– 63).

, 1000 kBaud). For gateway mode,

®

LTP-B

36

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 37

Startup

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Software

•Set P5-06 to the required "Communication failure time monitoring" (0.0 – 1.0 – 5.0 s).

This determines the time in seconds after which the inverter performs the response

set in P5-05. With "0.0 s", the invert er maintains the actual speed even if the communication fails.

• Use P5-07 to specify the use of "externa l or internal ramps". You can use this parameter to enable internal or external ramp control. With the enable signal, the inverter

follows the external ramps that are specified via the MOVILINK

(PO3).( 0 = Inhibit

• CAUTION As the electrical installation depends on the respective operating mode,

chapter "Overview of signal terminals for SEW gateways" (page 21) provides wiring

information.

• WARNING Danger of electric shock.

Improper wiring my cause danger due high voltages when the motor or the drive is

enabled.

– Check the wiring according to:

• the selected operating mode

, 1 = Enable).

®

process data

5

• INFORMATION

5.3 Software

5.3.1 Modbus control

Modbus control is not possible when using the LTX module.

• the installation and wiring notes in chapter "Electrical Installation"

• the installation and wiring notes in chapter "Electrical Installation" in the

"MOVITRAC

For further information on the drive adaption, refer to chapter "Con trol loop optimization for gateway mode" (page 42).

®

LTP-B" operating instructions.

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

37

Page 38

5

P

J

J

ext

mot

122−=

Scaling encoder simulation

P8-01 = 1, 2, 4, 8

Actual position (Hiperface)Encoder simulation

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Control loop optimization in different operating modes

5.4 Control loop optimization in different operating modes

5.4.1 Control loop optimization with third-party controllers

±10 V reference

potential and

encoder simulation

Setting speed control

You can use P1-22 to optimize the control response of the motor. Parameter P1-22

represents the relation between total inertia (J

(J

mot

/ J

bmot

).

• INFORMATION

For further information regarding the motor iner tia, refer to chapter "Ma ss moment of

inertia of the CMP motors in the Smart Servo Package" (page 56).

If the control accuracy is not sufficient, you can optimize the stiffness (P1-21). The

stiffness parameter (P1-22) sets an adequate ratio for the speed control parameters

(P4-03, P4-04). Most applications do not require an additional optimization of

parameters P4-03 or P4-04.

ext

= J

Load

+ J

Gear unit

) and motor inertia

Reference speed

Speed control loop

-

Actual speed

(Hiperface)

P1-22 = J

P1-21 = stiffness

ext

/ J

mot

Acceleration

-

3626204555

3626278155

38

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 39

Startup

P

J

J

ext

mot

122−=

Position control task (1 ms task speed)

Derivation

Position control

P8-06 = 1 %

-

+

Velocity

control

-

Derivation

-

Acceleration

Scaling:

P8-02 = 4, 8,

16 – 65536

in steps of 2

x

Step/direction or

A/B phase encoder

P4-01 = 5 PM motor position control

Velocity

pre-control

Reference speed

Acceleration

pre-control

Actual position

(Hiperface)

Actual speed

(Hiperface)

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Control loop optimization in different operating modes

5

Interface pulse /

direction (A/B

phase)

Setting speed control

You can use P1-22 to optimize the control response of the motor. Parameter P1-22

represents the relation between total inertia (J

(J

mot

/ J

bmot

).

ext

= J

Load

+ J

Gear unit

) and motor inertia

• INFORMATION

For further information regarding the motor iner tia, refer to chapter "Ma ss moment of

inertia of the CMP motors in the Smart Servo Package" (page 56).

If the control accuracy is not sufficient, you can optimize the stiffness (P1-21). The

stiffness parameter (P1-22) sets an adequate ratio for the speed control parameters

(P4-03, P4-04). Most applications do not require an additional optimization of

parameters P4-03 or P4-04.

Reference speed

-

Speed control loop

P1-22 = J

P1-21 = stiffness

ext

/ J

mot

Acceleration

-

Actual speed

(Hiperface)

3626204555

Setting position control

Position control (P4-01 = 5) must be activated for pulse/direction and A/B encoder

signals.

3626206475

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

39

Page 40

5

P

J

J

ext

mot

122−=

Position control task (1 ms task speed)

Derivation

Position control

P8-06 = 1 %

-

+

-

Derivation

-

Acceleration

Velocity

pre-control

Reference speed

Acceleration

pre-control

Actual position

(Hiperface)

Actual speed

(Hiperface-Ableitung)

SBus position value

every 5 - 15 ms

Speed control loop

P1-22 =

J

ext

/ J

mot

P1-21 = stiffness

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Control loop optimization in different operating modes

5.4.2 Control loop optimization with SEW controllers

Setting the control response

You can use P1-22 to optimize the control response of the motor. Parameter P1-22

represents the relation between total inertia (J

(J

mot

/ J

bmot

).

• INFORMATION

For further information regarding the motor iner tia, refer to chapter "Ma ss moment of

inertia of the CMP motors in the Smart Servo Package" (page 56).

If the control accuracy is not sufficient, you can optimize the stiffness (P1-21). The

stiffness parameter (P1-22) sets an adequate ratio for the speed control parameters

(P4-03, P4-04). Most applications d o not requ ire an additional optimization of parameters P4-03 or P4-04.

ext

= J

Load

+ J

Gear unit

) and motor inertia

40

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

3626208395

Page 41

Control response

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

setting with "Drive

startup"

Startup

Control loop optimization in different operating modes

5

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

41

Page 42

5

P

J

J

ext

mot

122−=

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Startup

Control loop optimization in different operating modes

5.4.3 Control loop optimization for gateway mode

Setting speed control

You can use P1-22 to optimize the control response of the motor. Parameter P1-22

represents the relation between total inertia (J

(J

mot

/ J

bmot

).

• INFORMATION

For further information regarding the motor iner tia, refer to chapter "Ma ss moment of

inertia of the CMP motors in the Smart Servo Package" (page 56).

If the control accuracy is not sufficient, you can optimize the stiffness (P1-21). The

stiffness parameter (P1-22) sets an adequate ratio for the speed control parameters

(P4-03, P4-04). Most applications d o not requ ire an additional optimization of parameters P4-03 or P4-04.

ext

= J

Load

+ J

Gear unit

) and motor inertia

Reference speed

Speed control loop

-

Actual speed

(Hiperface)

P1-22 = J

P1-21 = stiffness

ext

/ J

mot

Acceleration

-

3626204555

42

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 43

6 Parameters

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Parameters

LTX-specific parameters (level 1)

6

This chapter describes the LTX parameters. Also observe the parameter description in

®

the operating instructions for MOVITRAC

plement the parameters of MOVITRAC

eters that change if you use MOVITRAC

LTP-B. The parameters described her e com-

®

LTP-B. Further, this chapter describes param-

®

LTX. The factory setting is underlined.

6.1 LTX-specific parameters (level 1)

Parameters

P1-16 Motor type In-Syn

P1-17 Servo module I/O

P1-18 Motor thermistor

P1-19 Inverter address 0 – 125 1 Global inverter address setting

P1-20 SBus baud rate 125, 250, 500, 1000 kBaud 500 kBd Expected SBus baud rate setting.

P1-21 Stiffness 0 0 Reserved

P1-22 Load inertia 0 – 400 10 Inertia ratio between motor and connected

1) Only drives with 400 V

Description Section Default

Syn

40M / 40M bP

50S / 50S bP

50M / 50M bP

50L / 50L bP

63S / 63S bP

63M / 63M bP

63L / 63L bP

1)

gEArF2

1)

gEArF4

function selection

selection

0 – 6 1 Determines the function of the servo module

0 Disabled 0 Thermal motor protection with KTY enabled.

1KTY

setting

In-Syn For motor setting (CMP and MOVIGEAR

Explanation

This parameter is set automatically when

Hiperface

the LTX encoder card.

When using a permanent magnet motor in FI

operation, P1-16 does not have to be

changed. In this case P4-01 determines the

motor type (Autotune required).

I/O.

See chapter "P1-17 Smart Servo mode"

(Mirror parameter of P5-01.)

(Mirror parameter of P5-02.)

load can be specified in the inverter. This

value can usually remain set to the default

value 10. However, it is used by the control

algorithm as pre-control value for CMP/PM

motors in order to provide the optimal torque/

current for the acceleration of the load. This is

why the exact setting of the inertia ratio

improves the response characteristics and the

dynamics of the system.

In a closed control loop, the value is calculated

as follows:

If you do not know the value, keep the default

setting "10".

®

encoder information is read-in via

J

P1-22 =

total load

M0

Motor

10

x

2

s

®

).

5

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

43

Page 44

6

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Parameters

P1-14 extended parameter access

6.2 P1-14 extended parameter access

Setting range: 0 – 30000

This parameter allows access to the non-standard parameter groups (parameters P1-

01 – P1-15). Access is possible if the following values are valid.

• 0 / P1-01–P1-15

• 1 / P1-01–P1-22

• 101 /P1-01 – P5-08

• 201/ P1-01 – P8-15

6.3 P1-15 binary input function selection, LTX-specific parameters

Setting range: 0 – 1 – 25

P1-15 = 22, 23, 24 and 25 are intended for MOVITRAC

mend to use them only in conjunction with a third-party PLC. This requires terminal

control (P1-12 =0).

®

LTX exclusively. We recom-

P1-15 Binary input 1 Binary input 2 Binary input 3 Analog input 1 Analog input 2

1 O: Controller inhibit

C: Enable

22 O: Normal mode

C: Reference cam

23 O: Normal mode

C: Reference cam

24 O: Controller inhibit

C: Enable

25 O: Controller inhibit

C: Enable

O: Forward

C: Backward

O: Normal mode

C: Jog speed +

O: Limit switch +

C: Normal mode

O: Normal mode

C: Jog speed +

O: Limit switch +

C: Normal mode

O: Selected speed

setpoint

C: Preset speed 1, 2

O: Normal mode

C: Jog speed –

O: Limit switch –

C: Normal mode

O: Normal mode

C: Jog speed –

O: Limit switch –

C: Normal mode

Analog speed ref. 1 O: Preset speed 1

C: Preset speed 2

Speed setpoint O: Normal mode

C: Reference travel start

Speed setpoint O: Normal mode

C: Reference travel start

Speed setpoint O: Normal mode

C: Reference cam

Speed setpoint O: Normal mode

C: Reference cam

44

Addendum to the Operating Instructions – MOVITRAC® LTX Servo Module

Page 45

Parameters

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

P1-15 binary input function selection, LTX-specific parameters

• If a function set in P1-15 is also set in P1-17 (servo module input), the servo module