SEW Eurodrive MOVITRAC 07 User Manual

Edition

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

MOVITRAC® 07 Communication

06/2003

Manual

10565310 / EN

SEW-EURODRIVE

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1 Important Notes................................................................................................. 4

2 Introduction .......................................................................................................5

2.1 Technical data........................................................................................... 5

2.2 MOVILINK® and system bus....................................................................5

2.3 Fieldbus .................................................................................................... 8

3 Installation ......................................................................................................... 9

3.1 System bus (SBus) installation ................................................................. 9

4 System Bus Communication Slave............................................................... 11

4.1 Data exchange with a slave via MOVILINK®.......................................... 11

4.2 Setting parameters via the SBus.............................................................15

4.3 Project planning example for SBus......................................................... 18

5 System Bus Communication Master.............................................................20

5.1 MOVITRAC® 07 as MOVILINK® master................................................20

5.2 Data exchange via profile-independent variable telegrams....................23

5.3 Programming of the data exchange in LOGODrive ................................31

6 Unit Profile....................................................................................................... 32

6.1 Scaling of process data........................................................................... 32

6.2 Definition of the control word...................................................................33

6.3 Connection of control commands............................................................33

6.4 Setpoint cascade ....................................................................................38

6.5 Status word definition.............................................................................. 40

7 Operation and Service....................................................................................43

7.1 Startup SBus...........................................................................................43

7.2 Return codes for parameter setting.........................................................44

8 Monitoring Functions......................................................................................46

8.1 Timeout error .......................................................................................... 46

9 Bus Diagnostics.............................................................................................. 47

9.1 Diagnostics of process input data and output data.................................47

10 Parameter List ................................................................................................ 49

10.1 Explanation of the table header ..............................................................49

10.2 Conversion index ....................................................................................50

10.3 Complete parameter list, sorted by parameter numbers......................... 51

11 Index.................................................................................................................57

Manual – MOVITRAC® 07 Communication

3

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Important Notes

1 Important Notes

Handbuch

• This manual does not replace the detailed operating instructions!

• Installation and startup only by trained personnel observing applicable acci-

dent prevention regulations and the MOVITRAC

Documentation

Bus systems

• Read this manual carefully before you install or operate the MOVITRAC® 07 frequency inverter with communication link.

• We assume that you are familiar the the MOVITRAC

reading this manual.

• Consult the existing documentation. It is a prerequisite for trouble-free operation and

fulfillment of any warranty claims.

General safety notes on bus systems:

This communication system will make it possible for you to match the MOVITRAC

to the specifics of your application. As with all bus systems, there is a danger of invisible,

external (as far as the inverter is concerned) modifications to the parameters, which give

rise to changes in the inverter behavior. This may result in unexpected (not uncontrolled,

though!) system behavior.

®

07 operating instructions!

®

07 system manual prior to

®

unit

Safety and warning notes

Observe the safety and warning notes contained in this documentation!

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Harmful situation

Possible consequences: Damage to the unit and the environment.

Tips and useful information.

4

Manual – MOVITRAC® 07 Communication

2 Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The units of the MOVITRAC® 07 series are available in standard and LOGODrive design.

Units in standard design can only be operated as slaves. The master functions are not

available in this unit.

2.1 Technical data

System Bus

(SBus)

Standard CAN specification 2.0 parts A and B

Baud rate either 125, 250, 500 or 1000 kbaud, factory setting 500 kbaud

ID range 0 ... 2047

Address can be set with parameter P813: 0 ... 63

Number of process

data words

Cable length depending on the baud rate, max. 320 m

Number of stations max. 64

fixed setting: 3 PD

Introduction

Technical data

2

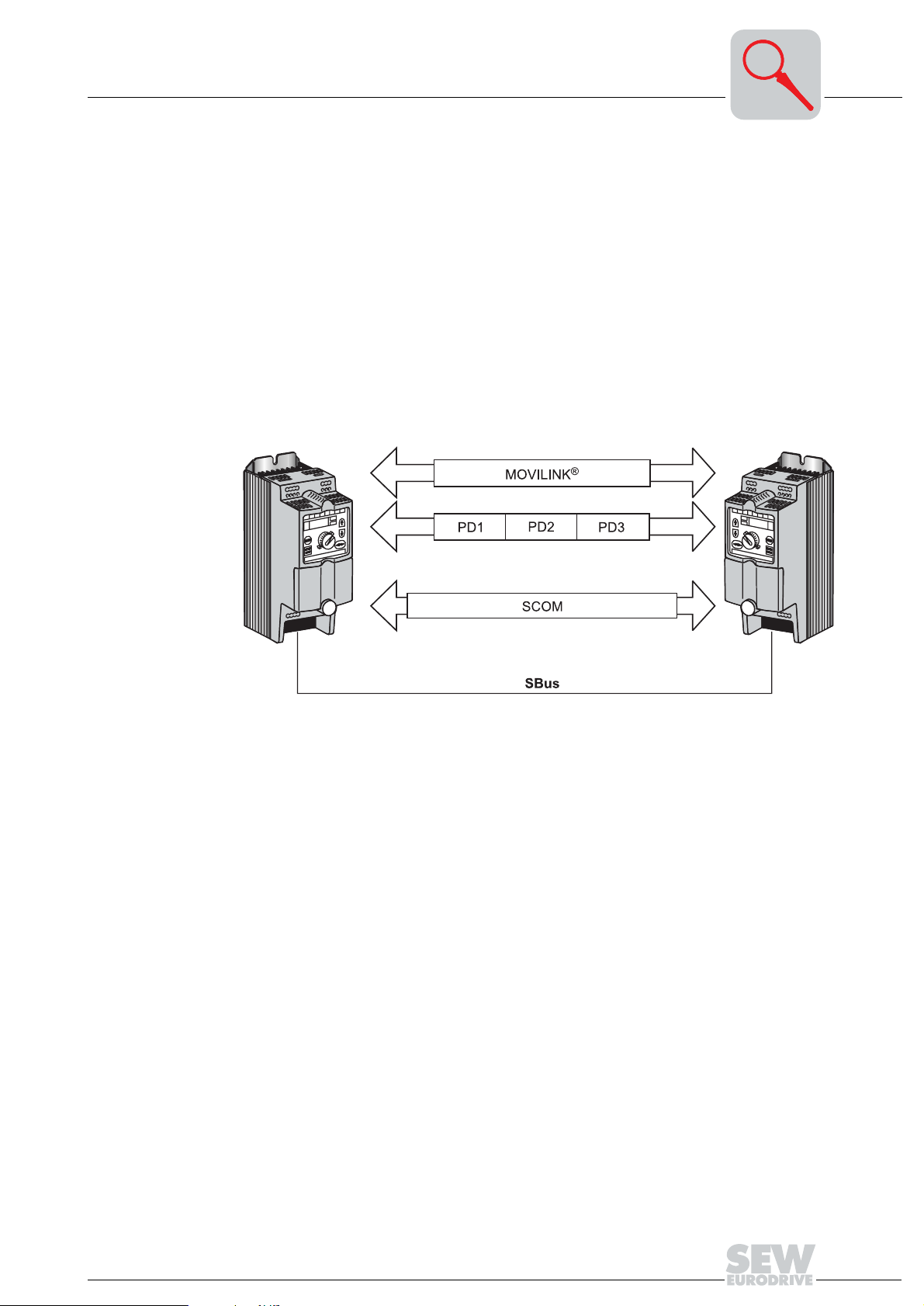

2.2 MOVILINK® and system bus

MOVILINK® profile

The MOVILINK® profile is an SEW-specific profile.

®

The MOVILINK

profile makes for the data exchange between a higher-level master

and several SEW inverters. Masters may take the form of programmable logic controllers, PCs or even SEW inverters with PLC functions (units with IPOS

bus gateways). SEW inverters usually function as slaves in the bus system.

®

The MOVILINK

profile offers the following functions:

• Automation

– Drive control

– Parameter setting of the drives

•Startup

• Visualization

®

The MOVILINK

profile does not depend on any specific transmission medium. This fact

makes the functions described in the MOVILINK

sion as well as transmission via a fieldbus system.

plus®

or UFx field-

®

profile available for serial transmis-

Manual – MOVITRAC® 07 Communication

5

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

MOVILINK® and system bus

Features

The MOVILINK® profile has a range of functions comparable to other fieldbus systems,

such as:

•PROFIBUS

• INTERBUS

• CANopen

• DeviceNet

®

The MOVILINK

• Access to all drive parameters and functions in SEW inverters. The profile will help

you manage the following tasks:

–Startup

–Service

– Diagnostics

– Visualization

– Automation

• In addition, the MOVILINK

– Fast process data exchange

– Comprehensive parameter access

– Network management

• The MOVITOOLS startup and diagnostic tools use the MOVITOOLS

communication with the inverter.

profile offers the following functions:

®

profile offers the following services:

®

profile for

System bus

(SBus)

The SBus is a CAN bus according to the CAN specification 2.0, parts A and B. The SBus

supports all services offered by the MOVILINK

exchange IPOS

MOVITRAC

The SBus controls the inverter via the fast process data.

You can specify the following setpoints with the process data telegrams:

• Setpoint speed

• Integrator time

• Acceleration/deceleration

You can specify the following drive functions with the process data telegrams:

• Enable

• Controller inhibit

• Standard stop

• Rapid stop

plus®

variables via the SBus regardless of the profile.

®

07 offers digital access to all drive parameters and functions via the SBus.

®

SEW unit profile. In addition, you can

6

Manual – MOVITRAC® 07 Communication

Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

MOVILINK® and system bus

You can read back the following actual values from the inverter with the process data

telegrams:

• Actual speed

• Current

•Unit state

• Error code

• Reference signals

®

You can generate applications with the MOVILINK

parameters in the higher-level automation device. This setup eliminates the need for

manual parameter setting of the inverter.

plus®

IPOS

with other MOVILINK

via IPOS

provides the MOVLNK command to exchange parameter and process data

plus®

and control other units. Only LOGODrive units can serve as masters.

®

stations. As a result, MOVITRAC® 07 can operate as the master

profile that store all important drive

2

Variable telegrams

Figure 1: Variants of SBus communication

05886AXX

Using the SBus requires additional monitoring functions such as time monitoring (SBus

timeout time) or special emergency off concepts.

®

The MOVITRAC

07 inverter offers numerous diagnostic options for startup and service

purposes.

The MOVITOOLS software offers a more convenient diagnostic option:

You can set all drive parameters and display the bus and unit status in detail with the

SHELL and STATUS programs.

You can monitor the data exchange with the bus monitor or use the control mode to pre-

set the data exchange.

The cyclical and acyclical exchange of variables via SBus offers an interface for the exchange of variables between several MOVITRAC

®

07 units. You can also perform profile-specific partial implementations for non-SEW units. These non-SEW units may support the CANopen or other protocol.

Manual – MOVITRAC® 07 Communication

7

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.3 Fieldbus

Introduction

Fieldbus

You can use the UFx11A fieldbus gateways to integrate the MOVITRAC® 07 into the

following fieldbus systems:

• PROFIBUS-DP

• INTERBUS

• DeviceNet

• CANopen

You can connect several inverters to the UFx11A fieldbus gateway via the SBus. The

UFx11A fieldbus gateway connects the fieldbus and SBus.

Figure 2: System overview fieldbus master – UFx11A – inverter

8

05929AXX

Manual – MOVITRAC® 07 Communication

3 Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.1 System bus (SBus) installation

Installation

System bus (SBus) installation

3

Figure 3: System bus connection MOVITRAC® 07

S12 = System bus terminating resistor

SC11 = System bus high

SC12 = System bus low

SC21 = System bus high

SC22 = System bus low

GND = System bus reference

SBus MOVITRAC® 07: Connect the communication terminals to SC11/SC12. SC21/

SC22 is only active when S12 = OFF.

Cable specification

Shield contact

• Use a 2-core twisted and shielded copper cable (data transmission cable with shield

comprising copper braiding). The cable must meet the following specifications:

– Cable cross section 0.75 mm

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

Suitable cables include CAN bus or DeviceNet cables.

• Connect the shield at either end to the electronics shield clamp of the inverter or the

master control and ensure the shield is connected over a large area. Also connect

the ends of the shield to GND.

2

(AWG 18)

05987AXX

Manual – MOVITRAC® 07 Communication

9

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation

System bus (SBus) installation

Cable length

Terminating

resistor

• The permitted total cable length depends on the baud rate setting of the SBus

(P816):

– 125 kbaud → 320 m (1,056 ft)

– 250 kbaud → 160 m (528 ft)

– 500 kbaud → 80 m (264 ft)

– 1000 kbaud → 40 m (132 ft)

• Switch on the system bus terminating resistor (S12 = ON) at the start and end of the

system bus connection. Switch off the terminating resistor on the other units (S12 =

OFF).

• There must not be any potential displacement between the units connected using the

SBus. Take suitable measures to avoid a potential displacement, such as connecting

the unit ground connectors using a separate lead.

10

Manual – MOVITRAC® 07 Communication

System Bus Communication Slave

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Data exchange with a slave via MOVILINK®

4 System Bus Communication Slave

4

4.1 Data exchange with a slave via MOVILINK

CAN bus identifier

Communication via MOVILINK® incorporates the data exchange of parameter and process data telegrams. The MOVITRAC

this process. Only LOGODrive units can serve as masters.

As slave, the unit can receive and answer parameter and process data messages via

the SBus.

Communication with a master control works with different telegrams types. These types

of telegrams can be divided into two categories:

• Process data telegrams

• Parameter telegrams

On the SBus, it is necessary to differentiate between these various types of telegrams

by means of the identifiers (ID). You create the ID of an SBus telegram by indicating the

telegram type and the SBus address. Set the SBus address using parameters P813 or

P814. P813 is the SBus address while P814 is the SBus group address.

The CAN bus identifier consists of 11 bits. The 11 bits of the identifier form three groups:

• Function (bits 0 ... 2)

• Address (bits 3 ... 8)

• Process data/parameter data switch (bit 9)

®

®

07 unit can communicate as master or slave in

Table 1: CAN identifier for SBus in MOVILINK® profile

543210

↓↓↓↓↓↓

0X XXX

Bit109876543210

Address Function

0 = process data telegram

1 = parameter data telegram

Reserved = 0

Bit 9 distinguishes between process and parameter data telegrams. Bit 10 is reserved

and must be 0. The address of parameter and process data telegrams includes the

SBus address (P813) of the unit that is addressed by a request; the address of group

parameter and group process data telegrams includes the SBus group address (P814).

Manual – MOVITRAC® 07 Communication

11

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Bus Communication Slave

Data exchange with a slave via MOVILINK®

Creating the identifiers

Process data telegrams

The following table shows the relationship between the type of telegram and the address

when creating the identifiers for SBus MOVILINK

Identifier Telegram type

8 × SBus address + 3 Process output data telegram (PO)

8 × SBus address +4 Process input data telegram (PI)

8 × SBus group address + 6 Group process output data telegram (GPO)

8 × SBus address + 512 + 3 Parameter request telegram

8 × SBus address + 512 +4 Parameter response telegram

8 × SBus group address + 512 + 6 Group parameter request telegram

®

telegrams:

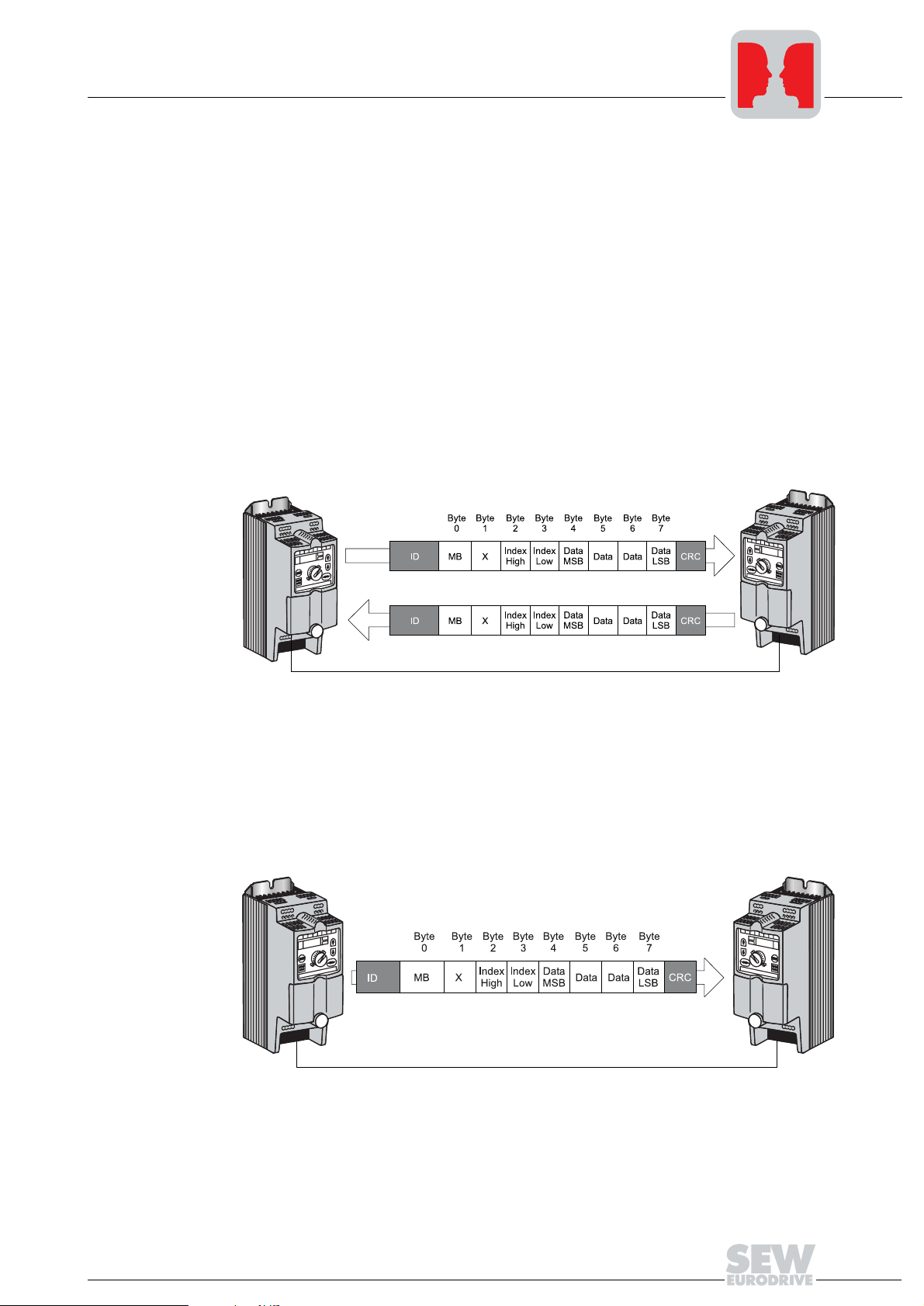

Process data telegrams are comprised of a process output and a process input data

telegram. The process output data telegram is sent from the master to a slave; it contains the setpoint values for the slave. A process input data telegram is sent from the

slave to the master after receipt of the process output telegram; it contains the actual

values of the slave.

The fixed setting for the number of process data is "3 process data words."

The resulting CAN telegram always includes 6 byte user data.

Group process

data telegram

Figure 4: Process data telegrams

05887AXX

The group process data telegram is sent from the master to one or more slaves with the

same SBus group address. Its structure is the same as the process output data telegram. Use this telegram to send the same setpoint values to several slaves that share

the same SBus group address. The slaves do not respond to the telegram.

05890AXX

Figure 5: Group process data telegram

12

Manual – MOVITRAC® 07 Communication

System Bus Communication Slave

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Data exchange with a slave via MOVILINK®

4

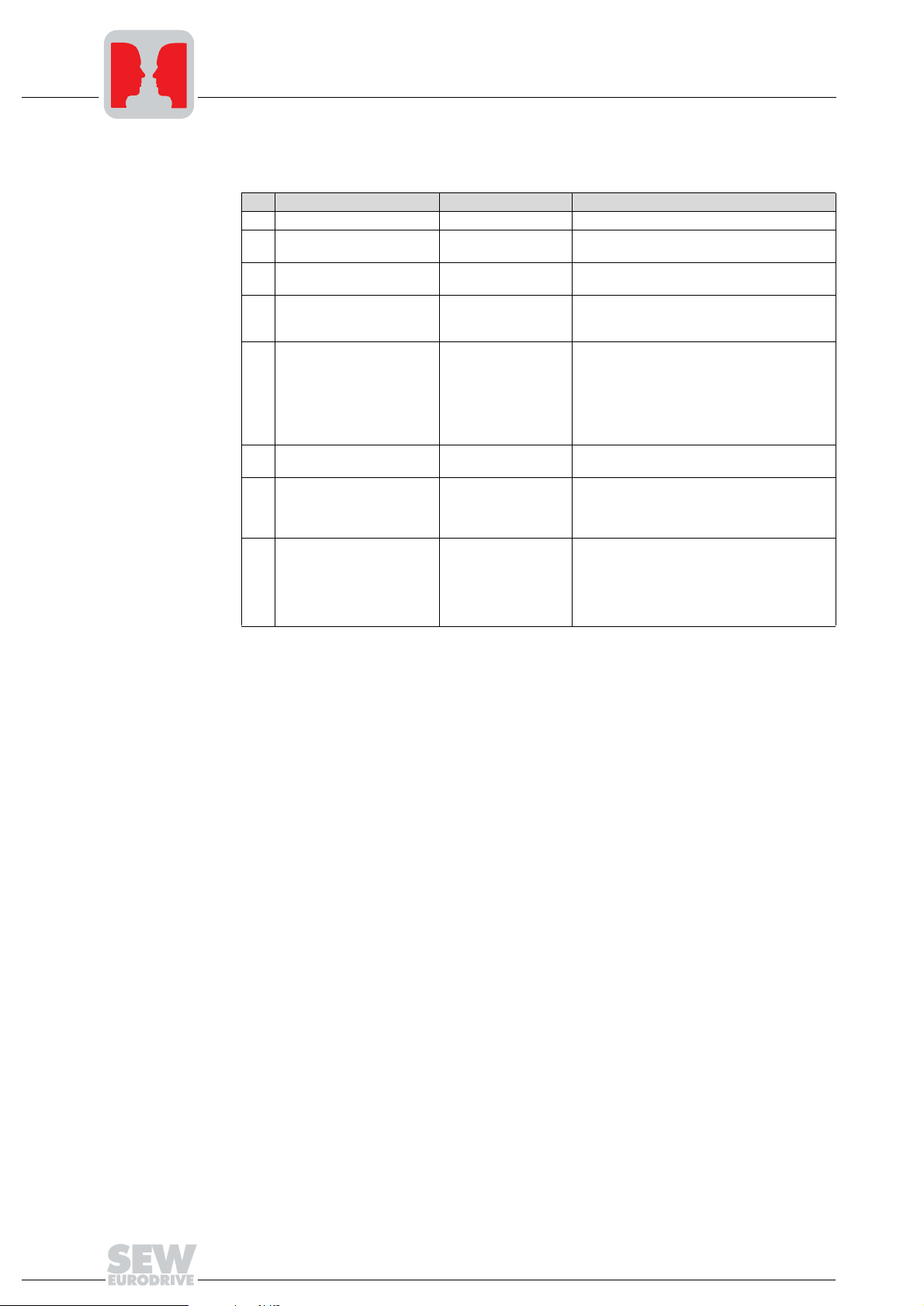

Parameter telegrams

Parameter telegrams are made up of a parameter request telegram and a parameter response telegram.

The master sends the parameter request telegram to read or write a parameter value. It

has the following components:

• Management byte

• Index high byte

• Index low byte

• Four data bytes

The management byte indicates the service that is to be performed. The index indicates

the parameter for which the service will be performed. The four data bytes contain the

numerical value to be read or written.

The resulting CAN telegram always includes 8 byte user data.

The slave sends the parameter response telegram in response to the parameter request

telegram sent by the master. The request and response telegrams have the same structure.

Group parameter

telegram

Figure 6: Parameter telegrams

05889AXX

MB = Management byte

X = Reserved

The master sends the group parameter telegram to one or more slaves with the same

SBus group address. Its structure is the same as the parameter request telegram. You

can only write parameters of the slave units with this telegram. The slaves do not respond to the telegram.

05888AXX

Figure 7: Group parameter telegram

MB = Management byte

X = Reserved

Manual – MOVITRAC® 07 Communication

13

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Bus Communication Slave

Data exchange with a slave via MOVILINK®

Parameter settings

The following parameters have to be set on the MOVITRAC® 07 for communication via

the SBus:

Par. Name Setting Meaning

100 Setpoint source SBus The inverter gets its setpoint from the SBus.

101 Control signal source SBus

813 SBus address 0...63

814 SBus group address 0...63

815 SBus timeout delay 0...650 s

816 SBus baud rate

870

PO1 setpoint description

871

PO2 setpoint description

872

PO3 setpoint description

873

PI1 actual value description

874

PI2 actual value description

875

PI3 actual value description

876

PO data enable

125/250/500/1000

kbaud

Factory setting:

CTRL. WORD 1

SPEED

NO FUNCTION

Factory setting:

STATUS WORD 1

SPEED

NO FUNCTION

ON

The inverter gets its control commands from

the SBus.

Setting of the SBus address used for the

exchange of parameter and process data.

Setting of the SBus group address for the

receipt of group parameter data and group process data.

Set the monitoring time for data transmission

via the system bus with P815. MOVITRAC

reacts with the error response 'rapid stop/fault'

if there is no data traffic via the system bus for

the time period set in P815. No monitoring of

data transmission via the system bus takes

place when P815 is set to the value 0.

The transmission speed of the SBus is set.

The content of the process output data words

PO1/PO2/PO3 is defined. This step is necessary so that the MOVITRAC

the appropriate setpoints.

The content of the process input data words

PI1/PI2/PI3 is defined. This step is necessary

so that the MOVITRAC

appropriate actual values. The process data

must be enabled for the unit to accept the setpoints.

®

07 can allocate

®

07 can allocate the

®

07

14

Manual – MOVITRAC® 07 Communication

System Bus Communication Slave

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.2 Setting parameters via the SBus

The MOVITRAC® 07 inverter supports the MOVILINK® parameter channel with the

SBus.

Setting parameters via the SBus

4

Services

Structure of the

parameter telegram

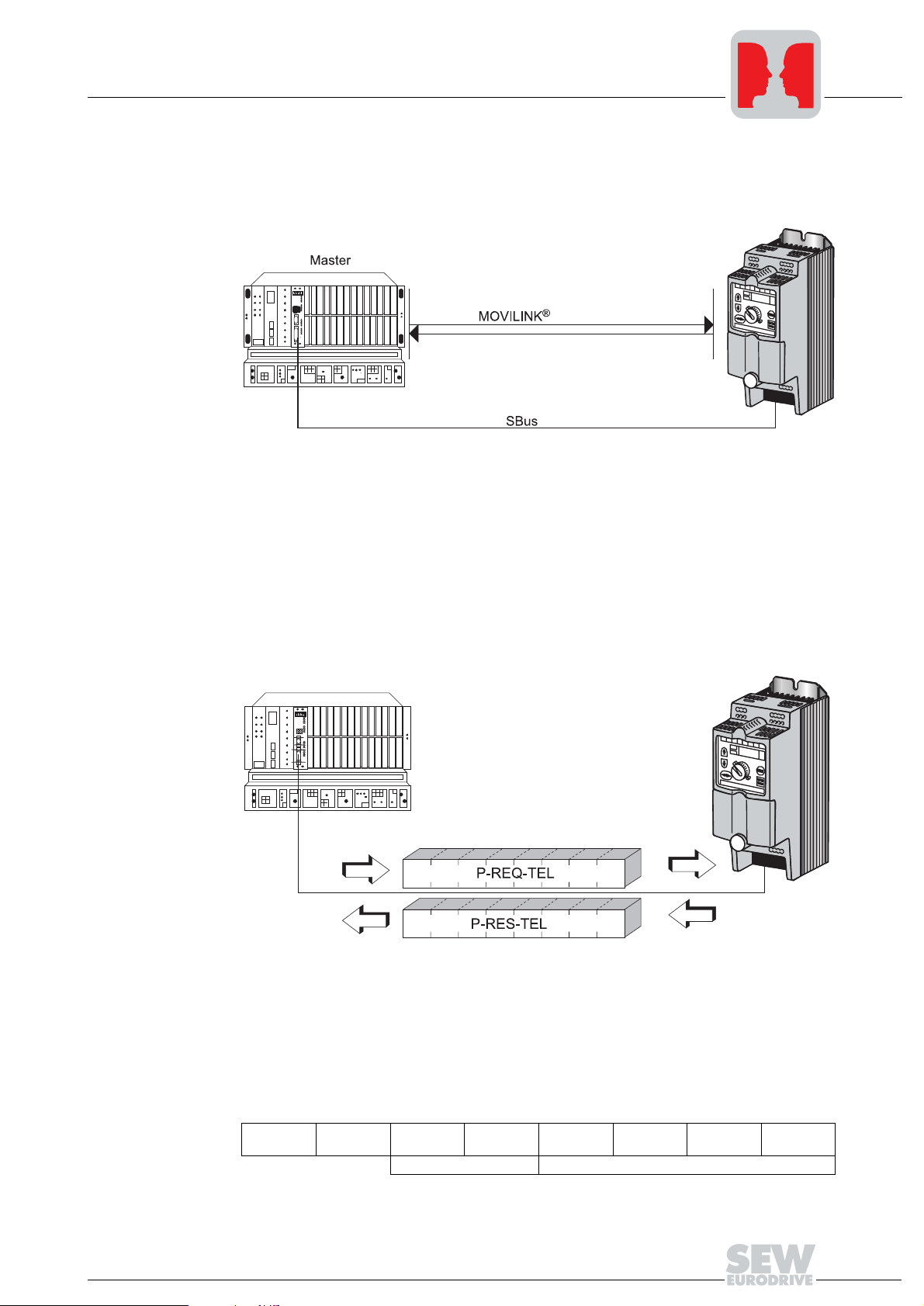

Figure 8: Services available via the SBus

05891AXX

The inverter parameters are read and written via the SBus with the MOVILINK® parameter channel services of the application layer (layer 7 of the ISO/OSI model for communication).

Parameter setting of field devices via fieldbus systems requires functions and services

such as READ and WRITE for reading and writing of parameters. The parameter telegram in the MOVILINK

®

profile serves such a purpose. The parameter data can be read

and written via parameter telegrams.

Figure 9: Parameter telegram for SBus

P-REQ-TEL = Parameter-Request-Telegram

P-REQ-TEL = Parameter-Response-Telegram

The following table shows the structure of the parameter telegram. In principle, it is

made up of a management byte, an index word and four data bytes.

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Manage-

ment

Manual – MOVITRAC® 07 Communication

Reserved Index high Index low Data MSB Data Data Data LSB

Parameter index 4 byte data

05892AXX

15

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Bus Communication Slave

Setting parameters via the SBus

Byte 0: Management of the parameter telegram

The entire parameter setting sequence is coordinated with byte 0: "Management". This

byte provides important service parameters such as service identifier, data length, version and status of the service performed. The following table shows that bits 0 ... 3 include the service identifier and define the service to be performed. Bit 4 and bit 5 specify

the data length in bytes for the WRITE service. This setting should be 4 bytes for all SEW

inverters.

• Bit 6 = 0: Asynchronous response (must be set to zero)

Status bit 7 indicates whether it was possible to carry out the service properly or if there

were errors.

Byte 0: Management

MSB LSB

Bit:7654321 0

Service identifier:

0000 = No service

0001 = Read parameter

0010 = Write parameter

0011 = Write parameter volatile

0110 = Read default

1000 = Read attribute

Data length:

11 = 4 bytes

= 0

Byte 1

Bytes 2 and 3:

Index addressing

Byte 4 ... 7: Data

range

Status bit:

0 = No error during execution of service

1 = Error during execution of service

Byte 1 should be considered reserved and must be set to 0x00.

Byte 2: Index high and byte 3: Index low determines the parameter read or written via

the fieldbus system. The parameters of an inverter are addressed with a uniform index

regardless of the connected fieldbus system.

The data are located in byte 4 to byte 7 of the parameter telegram. This means up to 4

bytes of data can be transmitted per service. The data are always entered with right-justification so that byte 7 contains the least significant data byte (Data LSB) while byte 4

is the most significant data byte (Data MSB).

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Manage-

ment

Reserved Index high Index low Data MSB Data Data Data LSB

High byte 1 Low byte 1 High byte 2 Low byte 2

High word Low word

Double word

16

Manual – MOVITRAC® 07 Communication

System Bus Communication Slave

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Setting parameters via the SBus

4

Successful execution of service

Incorrect execution of a service

Return codes for

parameter setting

The successful execution of a service is indicated by a status bit not set in the management byte. Byte 4 ... 7 of the parameter response telegram contain the data corresponding to the service.

An incorrect execution of a service is indicated by setting the status bit in the management byte. If the status bit indicates an error, the error code is entered in structured form

in the data range (byte 4 ...7) of the parameter telegram.

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Manage-

ment

Reserved Index high Index low Error class Error code

Add. code

high

Add. code

low

↓

Status bit = 1: Incorrect execution of a service

The return codes sent to the parameter-setting master in case of an incorrect execution

of a service include detailed information concerning the cause of the error. These return

codes are usually structured according to DIN 19245 T2. The system distinguishes between the following elements:

• Error class

• Error code

• Additional code

The operating instructions and the system manual include a description of the errors.

Special cases

• Errors in parameter settings

An incorrect code was entered in the management byte during execution of a read

or write service via SBus.

®

In this case, the MOVITRAC

Code (dec) Meaning

Error class: 5 Service

Error code: 5 Illegal value

Add. code

high:

Add. code low: 0–

0–

07 firmware prompts the following return code:

Manual – MOVITRAC® 07 Communication

17

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Bus Communication Slave

Project planning example for SBus

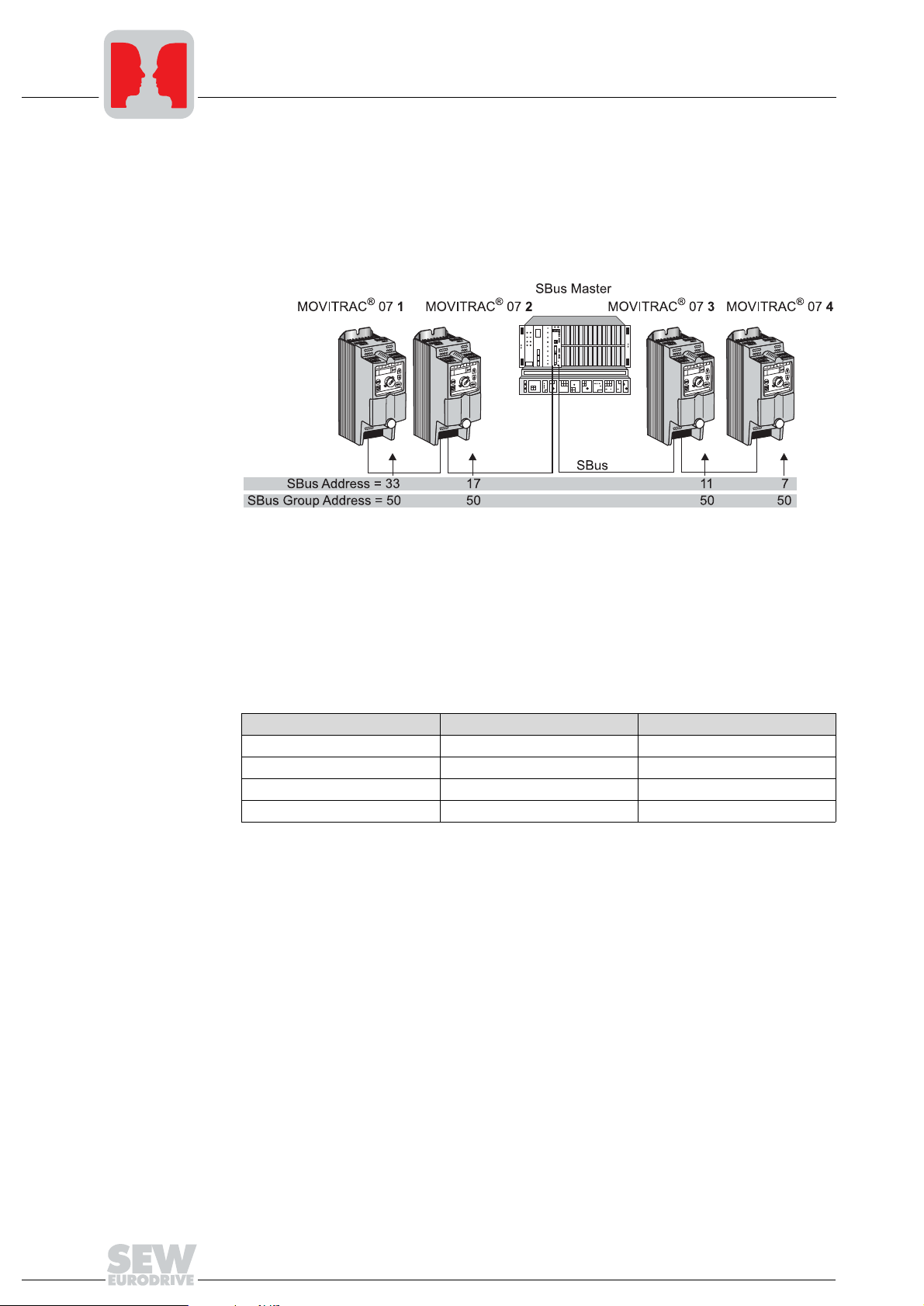

4.3 Project planning example for SBus

Specifications

Settings

The following settings have to be made:

• Four inverters

• Process data length 3

• Baud rate 500 kbit/s

05895AXX

Figure 10: Sample for project planning

Use parameter P816 to set the required SBus baud rate on all inverters. All inverters

must be set to the same baud rate. The factory setting for the baud rate is 500 kbaud.

The fixed setting for the number of process data on the SBus is "3 process data words."

Then use parameter P813 to set the SBus address on each inverter. In this example,

the SBus address is assigned to the inverters according to the following table:

Inverters SBus address SBus group address

1 33

2 17

3 11

4 7

dec

dec

dec

dec

50

50

50

50

dec

dec

dec

dec

You will realize that there is no prescribed sequence for setting of the SBus address. Do

not assign the addresses several times; two drive inverters must not share the same

SBus address.

In addition, the terminating resistor must also be switched on at the ends of the cable.

Do this by setting the S12 DIP switch on inverters 1 and 4 to ON. The terminating resistors must be switched off on all other stations, such as inverters 2 and 3 and the SBus

master control.

18

Manual – MOVITRAC® 07 Communication

Loading...

Loading...