Page 1

Gearmotors \ Industrial Gear U nits \ Dri ve Ele ctroni cs \ Dr ive Aut omat ion \ Servi ces

Fieldbus Interface DFE24B

EtherCAT

Edition 05/2007

11571810 / EN

M

anual

Page 2

SEW-EURODRIVE – Driving the world

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

1 Important Notes...................................................................................................... 6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Explanation of symbols.................................................................... ... .... ... ... . 6

1.2 Integral part of the product............................................................................. 6

1.3 Note on the documentation........................................ ... ... ... .... ... .................... 6

1.4 Liability for defects .... ... .... ... ............................................. .............................. 7

1.5 Product names and trademarks.................................... ... ... .... ... ... ................. 7

1.6 Waste disposal............................................................................................... 7

2 Safety Notes ................ ... ... ... .... ............................................. ................................. 8

2.1 Preliminary information .................................................................................. 8

2.2 General safety notes...................................................................................... 8

2.2.1 General safety notes for bus systems.................................................. 8

2.3 Transportation / putting into storage .............................................................. 8

2.4 Assembly / installation.................................................................................... 9

2.5 Startup / operation ......................................................................................... 9

3 Introduction .......................................................................................................... 10

3.1 Content of this manual ................................................................................. 10

3.2 Additional documentation.................... ... .... ... ... ... ......................................... 10

3.3 Features....................................................................................................... 10

3.3.1 MOVIDRIVE

®

, MOVITRAC®B and EtherCAT .................................. 10

3.3.2 Access to all information.................................................................... 11

3.3.3 Cyclic data exchange via EtherCAT ................................................. 11

3.3.4 Acyclic data exchange via EtherCAT ................................................ 11

3.3.5 Configuration of the EtherCAT option card........................................ 11

3.3.6 Monitoring functions........................................................................... 12

3.3.7 Diagnostics ........................................................................................ 12

3.3.8 Fieldbus monitor ................................................................................ 12

4 Assembly and Installation Notes........................................................................ 13

®

4.1 Installing option card DFE24B in MOVIDRIVE

MDX61B........................... 13

4.1.1 Before you begin................................................................................ 13

4.1.2 Basic procedure for installing and removing an option card .............. 14

4.2 Installing option card DFE24B in MOVITRAC

®

B........................................ 15

4.2.1 SBus connection................................................................................ 15

4.2.2 System bus connection...................................................................... 16

4.3 Installing the UOH11B gateway housing...................................................... 18

4.4 Connection and terminal description of the DFE24B option ........................ 19

4.5 Pin assignment ............................................................................................ 20

4.6 Shielding and routing bus cables................................................................. 21

4.7 Bus termination............................................................................................ 21

4.8 Setting the station address . ... ... .... ............................................. .................. 21

4.9 Operating displays of the DFE24B option..................................... ... ... ......... 2 2

4.9.1 EtherCAT LEDs ................................................................................. 22

4.9.2 Gateway LED..................................................................................... 24

Manual – Fieldbus Interface DFE24B EtherCAT

3

Page 4

5 Configuration and Startup................................. ... ... ... ......................................... 25

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.1 Validity of the XML files for DFE24B............................................................ 25

5.2 Configuring the EtherCAT master for MOVIDRIVE

5.2.1 XML for operation in MOVIDRIVE

®

B................................................ 25

®

B with the XML file..... 25

5.2.2 Configuration procedure .................................................................... 26

®

5.2.3 PDO configuration for operation in MOVIDRIVE

5.3 Configuring the EtherCAT master for MOVITRAC

............................. 27

®

B / gateway

with XML file................................................................................................. 35

5.3.1 XML files for operation in MOVITRAC

®

B and

gateway housing UOH11B ................................................................ 35

5.3.2 Configuration procedure .................................................................... 35

®

5.3.3 PDO configuration for DFE24B gateway for MOVITRAC

B............. 36

5.3.4 Auto setup for gateway operation ...................................................... 41

®

5.4 Setting the MOVIDRIVE

5.5 Setting the MOVITRAC

MDX61B drive inverter ....................................... 42

®

frequency inverter................................................ 43

6 EtherCAT Operating Characteristics.................................................................. 45

6.1 Controlling the MOVIDRIVE

6.1.1 Control example in TwinCAT with MOVIDRIVE

6.1.2 EtherCAT timeout (MOVIDRIVE

6.1.3 Fieldbus timeout response (MOVIDRIVE

6.2 Controlling the MOVITRAC

6.2.1 Control example in TwinCAT with MOVITRAC

®

MDX61B drive inverter ..................... ... .... ... .. 45

®

MDX61B) ..................................... 48

®

B (Gateway) frequency inverter..................... 49

®

MDX61B ............... 46

®

MDX61B)........................ 48

®

B (gateway) ........... 50

6.2.2 SBus timeout ..................................................................................... 51

6.2.3 Unit faults........................................................................................... 51

6.2.4 DFE24B fieldbus timeout in gateway operation ................................. 52

6.3 Configuration via EtherCAT ........................................................................ 52

6.3.1 SDO READ and WRITE services ...................................................... 52

6.3.2 Example of reading a parameter in TwinCAT via EtherCAT.............. 53

6.3.3 Example of writing a parameter in TwinCAT via EtherCAT ............... 55

6.4 Configuration return codes........................................................................... 56

6.4.1 Elements............................................................................................ 56

6.4.2 Error class.......................................................................................... 56

6.4.3 Error code .......................................................................................... 56

6.4.4 Additional code .................................................................................. 57

6.4.5 List of the error codes for SDO services ............................................ 57

7 Motion Control via EtherCAT ............................................................................. 58

7.1 Introduction to EtherCAT .... ... ... .... ... ............................................. ............... 58

7.1.1 Velocity mode .................................................................................... 61

7.1.2 Position mode .................................................................................... 62

®

7.2 Settings in MOVIDRIVE

B with MOVITOOLS® MotionStudio.................... 63

7.2.1 Settings for velocity mode.................................................................. 63

7.2.2 Settings for position mode ................................................................. 65

7.3 Settings in EtherCAT master........................................................................ 67

7.3.1 Settings for velocity mode.................................................................. 67

7.3.2 Settings for position mode ................................................................. 68

7.4 Example in TwinCAT.................................................................................... 69

7.4.1 Velocity mode .................................................................................... 71

4

Manual – Fieldbus Interface DFE24B EtherCAT

Page 5

8 Operating MOVITOOLS® MotionStudio via EtherCAT...................................... 74

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

8.1 Introduction .................................................................................................. 74

8.2 Required hardware ...................................................................................... 75

8.3 Required software........................................................................................ 75

8.4 Installation.................................................................................................... 75

8.5 Configuring the mailbox gateway................................................................. 76

8.6 Network settings on the engineering PC...................................................... 76

8.7 Configuring the SEW communication server ............................................... 78

8.7.1 Establishing communication .............................................................. 78

8.7.2 Procedure .......................................................................................... 78

8.8 Automatic search for connected units (unit scan)........................................ 80

8.9 Activating online mode................................................................................. 81

8.10 Familiar problems during the operation of MOVITOOLS

®

MotionStudio..... 81

9 Error Diagnostics................................................................................................. 82

9.1 Diagnostic procedures ................................................................................. 82

9.2 List of errors................................................................................................. 85

10 Technical Data...................................................................................................... 86

10.1 Option DFE24B for MOVIDRIVE

10.2 Option DFE24B for MOVITRAC

®

MDX61B................................................ 86

®

B and

Universal Gateway Housing UOH11B ......................................................... 87

11 Index...................................................................................................................... 88

Manual – Fieldbus Interface DFE24B EtherCAT

5

Page 6

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Important Notes

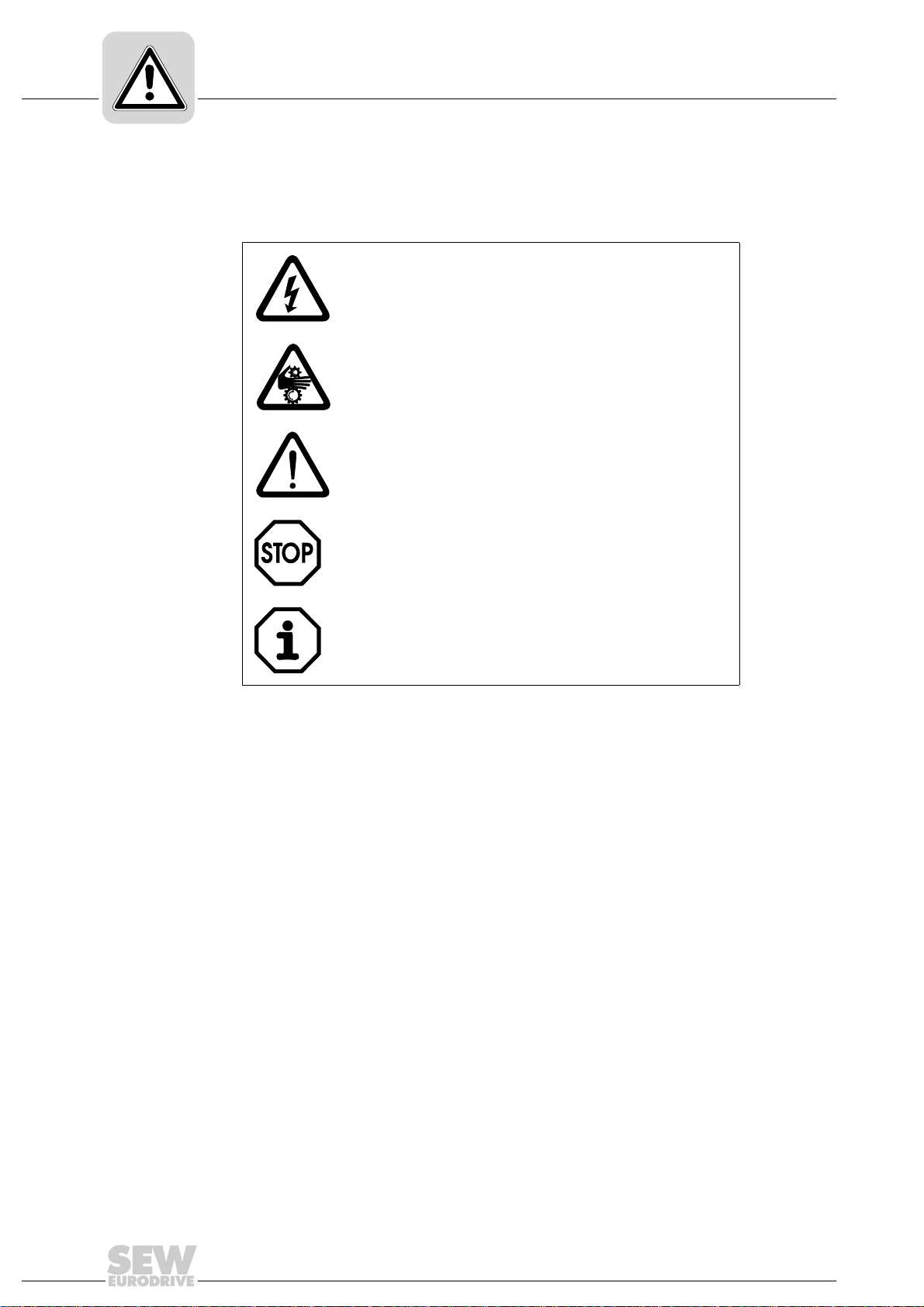

Explanation of symbols

1 Important Notes

Manual

1.1 Explanation of symbols

Always observe the safety and warning information in this documentation.

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard.

Possible consequences: Severe or fatal injuries.

Hazardous situation.

Possible consequences: Slight or minor injuries.

Harmful situation.

Possible consequences: Damage to the unit and the

environment.

Tips and useful information.

1.2 Integral part of the product

This manual is an integral part of the DFE24B EtherCAT fieldbus interface and contains

important notes on operation and service.

1.3 Note on the documentation

• You must adhere to the documentation to ensure:

– Fault-free operation

– Fulfillment of any rights to claim under limited warranty

• Therefore, make sure you read this manual carefully before you install and startup

frequency inverters with the DFE24B EtherCAT option card.

• This manual assumes that the user has access to and is familiar with the

MOVIDRIVE

MDX60B/61B and MOVITRAC® B system manuals.

®

and MOVITRAC® documentation, in particular the MOVIDRIVE

®

6

Manual – Fieldbus Interface DFE24B EtherCAT

Page 7

1.4 Liability for defects

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Incorrect handling or any action performed that is not specified in this manual could

impair the properties of the product. In this case, you lose any right to claim under limited

warranty against SEW-EURODRIVE GmbH & Co KG.

1.5 Product names and trademarks

The brands and product names in this manual are trademarks or registered trademarks

of the titleholders.

1.6 Waste disposal

Please follow the current national regulations.

Dispose of the following materials separately in accordance with the country-specific

regulations in force:

• Electronics scrap

• Plastics

• Sheet metal

• Copper

etc.

Important Notes

Liability for defects

1

Manual – Fieldbus Interface DFE24B EtherCAT

7

Page 8

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Safety Notes

Safety Notes

Preliminary information

Only install and startup the DFE24B EtherCAT fieldbus interface in accordance

with the relevant accident prevention regulations and the MOVIDRIVE

MDX60B/61B and MOVITRAC® B operating instructions.

2.1 Preliminary information

The following safety notes refer to the use of the DFE24B EtherCAT fieldbus

interface.

Please also observe the supplementary safety notes in the individual sections of

this manual.

2.2 General safety notes

Never install damaged products or take them into operation.

Submit a complaint to the shipping company immediately in the event of damage.

®

2.2.1 General safety notes for bus systems

This communication system allows you to adjust the MOVIDRIVE® drive inverter to your

specific application very accurately. As with all bus systems, there is a danger of

invisible, external (as far as the inverter is concerned ) modifications to the parameters which give rise to changes in the inverter behavior . This may result in unexpected (not uncontrolled) system behavior.

2.3 Transportation / putting into storage

Inspect the shipment for any damage that may have occurred in transit as soon

as you receive the delivery. Inform the shipping company immediat ely. Do not

operate the product if it is damaged.

Use suitable, sufficiently rated handling equipment if necessary.

Possible damage caused by incorrect storage!

Store the unit in a dry, dust-free room if it is not to be installed straight away.

8

Manual – Fieldbus Interface DFE24B EtherCAT

Page 9

2.4 Assembly / installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Follow the instructions in section 4, "Assembly and Installation Notes."

2.5 Startup / operation

Follow the instructions in section 5, "Configuration and Startup."

Safety Notes

Assembly / installation

2

Manual – Fieldbus Interface DFE24B EtherCAT

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

Content of this manual

3 Introduction

3.1 Content of this manual

This user manual describes how to:

• install the DFE24B EtherCAT option card in the MOVIDRIVE

inverter

• use the DFE24B EtherCAT option card in the MOVITRAC

in the UOH11B gateway housing

• startup MOVIDRIVE

• startup MOVITRAC

• configure the EtherCAT master using XML files

• operate MOVITOOLS

3.2 Additional documentation

®

®

MDX61B on the EtherCAT fieldbus system

®

B on the EtherCAT gateway

®

MotionStudio via EtherCAT.

®

MDX61B drive

B frequency inverter and

3.3 Features

3.3.1 MOVIDRIVE

For information on how to connect MOVIDRIVE® simply and effectively to the EtherCAT

fieldbus system, in addition to this user manual on the EtherCAT option, you should

request the following documentation on fieldbus technology:

•"MOVIDRIVE

•MOVITRAC

The "MOVIDRIVE

manual describe the fieldbus parameters and their coding, and explains the whole range

of control concepts and application options in the form of brief examples.

The "MOVIDRIVE

parameters that can be read or written via the various communication interfaces, such

as system bus, RS485 and also via the fieldbus interface.

The MOVIDRIVE® MDX61B drive inverter and the MOVITRAC®B frequency inverter

enable you to use the DFE24B option to connect to higher-level automation systems via

EtherCAT using its powerful, universal fieldbus interface.

®

, MOVITRAC®B and EtherCAT

®

Fieldbus Unit Profile" manual

®

B system manual

®

Fieldbus Unit Profile" manual and the MOVITRAC®B system

®

Fieldbus Unit Profile" manual contains a list of all drive inverter

The unit behavior of the inverter that forms the basis of EtherCAT operation is referred

to as the unit profile. It is independent of any particular fieldbus and is therefore a

uniform feature. This feature allows the user to develop drive applications independent

of the fieldbus in operation. This makes it much easier to change to other bus systems,

such as DeviceNet (option DFD).

10

Manual – Fieldbus Interface DFE24B EtherCAT

Page 11

3.3.2 Access to all information

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

Features

3

MOVIDRIVE

the EtherCAT interface. The drive inverter is controlled via fast, cyclic process data. You

can use this process data channel to enter setpoints (e.g. setpoint speed, ramp generator time for acceleration/deceleration, etc.) and to trigger various drive functions such

as enable, controller inhibit, normal stop, rapid stop, etc. At the same time you can use

this channel to read back actual values from the drive inverter, such as the actual speed,

current, unit status, fault number and reference signals.

3.3.3 Cyclic data exchange via EtherCAT

Process data is usually exchanged cyclically between the EtherCAT master and the

MOVIDRIVE

configuration of the EtherCAT master.

3.3.4 Acyclic data exchange via EtherCAT

The EtherCAT specification defines acyclical READ/WRITE services that are transferred together with the telegrams during ongoing cyclical bus operation without impacting on the performance of the process data communication via EtherCAT.

Read and write access to the drive parameters is enabled via SDO (Service Data

Object) services that are implemented according to CoE (CANopen over EtherCAT) or

VoE (Vendor-specific over EtherCAT) services.

This parameter data exchange enables you to implement applications in which all the

important drive parameters are stored in the higher-level programmable controller, so

that there is no need to make parameter settings manually on the drive inverter itself.

®

MDX61B offers digital access to all drive parameters and functions via

®

B and MOVITRAC® B inverters. The cycle time is specified during the

3.3.5 Configuration of the EtherCAT option card

The EtherCAT option card is designed so that all fieldbus-specific settings are made

during startup of the EtherCAT system. This process enables the drive inverter to be

integrated and operated in the EtherCAT environment within a very short period of time.

EtherCAT

Master

Ethernet

Header

Frame

Header

EtherCAT

SEW

Drive

Header

EtherCAT

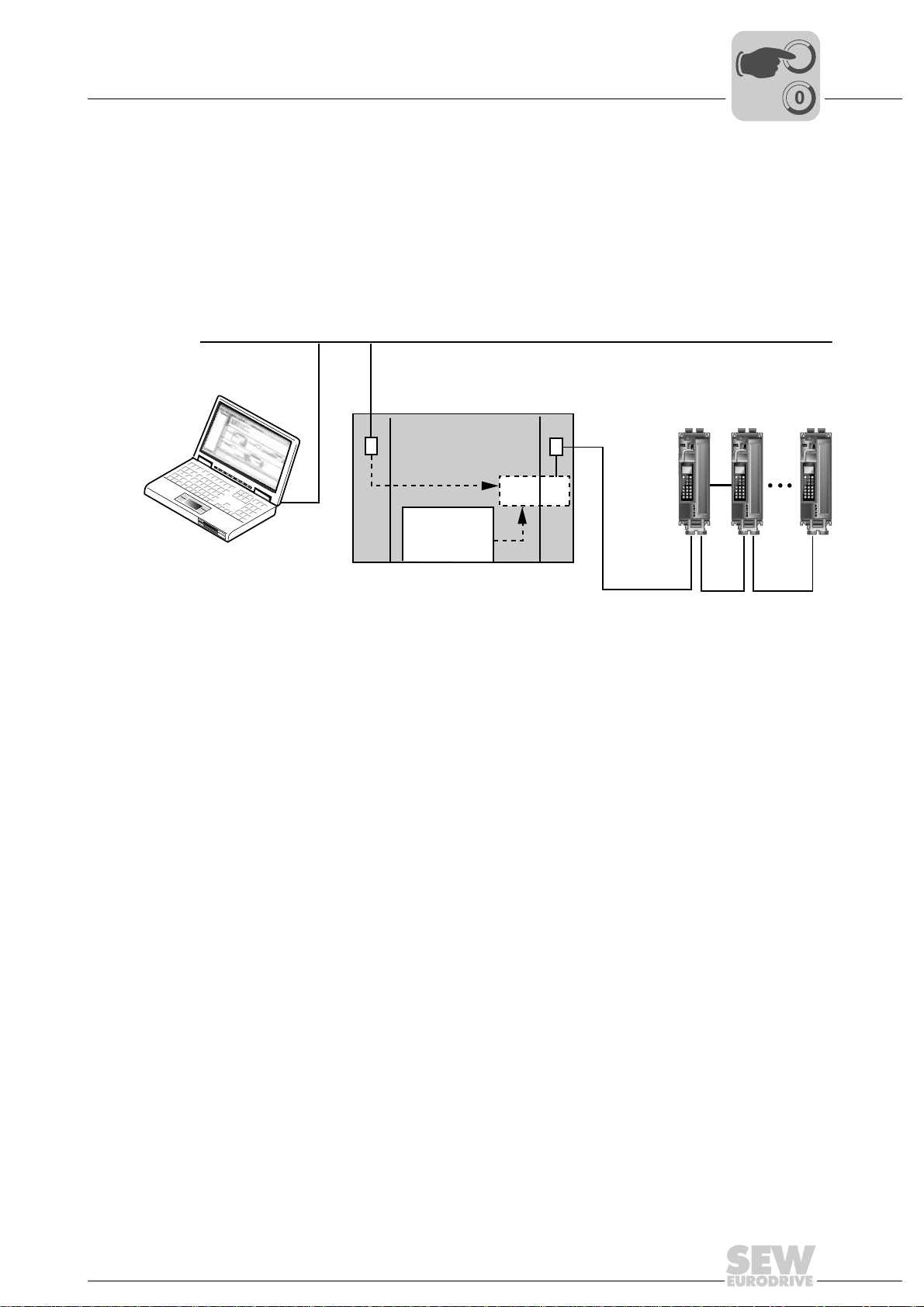

Figure 1: EtherCAT with MOVIDRIVE

Data

®

Drive

Drive 1

SEW

Drive 2 Drive 3

SEW

Drive

I/O

...

FCS

61211AXX

Manual – Fieldbus Interface DFE24B EtherCAT

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.3.6 Monitoring functions

3.3.7 Diagnostics

Introduction

Features

Using a fieldbus system requires additional monitoring functions for the drive

technology, for example, cycle time monitoring of the fieldbus (fieldbus timeout) or rapid

stop concepts. You can, for example, adapt the monitoring functions of MOVIDRIVE

/MOVITRAC

of the drive inverter’s fault responses should be triggered in the event of a bus error. It

is a good idea to use a rapid stop function for many applications. However you can also

freeze the last setpoints so that the drive continues to operate with the most recently

valid setpoints (for example, conveyor belt). As the functions of the control terminals are

still active in fieldbus operation, you can still implement fieldbus-independent

emergency stop concepts via the drive inverter terminals.

The MOVIDRIVE

number of diagnostic options for startup and service. For example, you can use the

integrated fieldbus monitor to control setpoint values sent from the higher-level

controller and the actual values.

®

B specifically to your application. You can determine, for instance, which

®

B drive inverter and MOVITRAC®B frequency inverter both offer a

®

B

3.3.8 Fieldbus monitor

Furthermore, you are supplied with a variety of additional information about the status

of the fieldbus option card. In conjunction with the MOVITOOLS

ware, the fieldbus monitor function offers you an easy-to-use diagnostic tool for setting

all drive parameters (including the fieldbus parameters) and for displaying the fieldbus

and device status information in detail.

®

MotionStudio PC soft-

12

Manual – Fieldbus Interface DFE24B EtherCAT

Page 13

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing option card DFE24B in MOVIDRIVE® MDX61B

4 Assembly and Installation Notes

4

This section provides you with information on assembly and installation for the DFE24B

option card in MOVIDRIVE

housing.

®

MDX61B, MOVITRAC® B and the UOH11B gateway

4.1 Installing option card DFE24B in MOVIDRIVE® MDX61B

Only SEW-EURODRIVE personnel may install or remove option cards for

MOVIDRIVE

• Users may only install and remove options cards for MOVIDRIVE

to 6.

• The DFE24B option is powered with voltage via MOVIDRIVE

supply is not required.

4.1.1 Before you begin

The DFE24B option card must be installed in the fieldbus slot.

Read the following notes before installing or removing the option card:

• Disconnect the inverter from the power. Switch off the DC 24 V and the supply

voltage.

• Take appropriate measures (discharge strap, conductive shoes, etc.) to protect the

option card from electrostatic charge before touching it.

• Before installing the option card, remove the keypad and the front cover (→

MOVIDRIVE

• After installing the option card, replace the front cover and the keypad (→

MOVIDRIVE

• Keep the option card in its original packaging until immediately before you are ready

to install it.

• Hold the option card by its edges only. Do not touch any subassemblies.

®

MDX61B size 0.

®

MDX60B/61B operating instructions, Sec. "Installation").

®

MDX60B/61B operating instructions, Sec. "Installation").

®

MDX61B sizes 1

®

B. A separate voltage

Manual – Fieldbus Interface DFE24B EtherCAT

13

Page 14

4

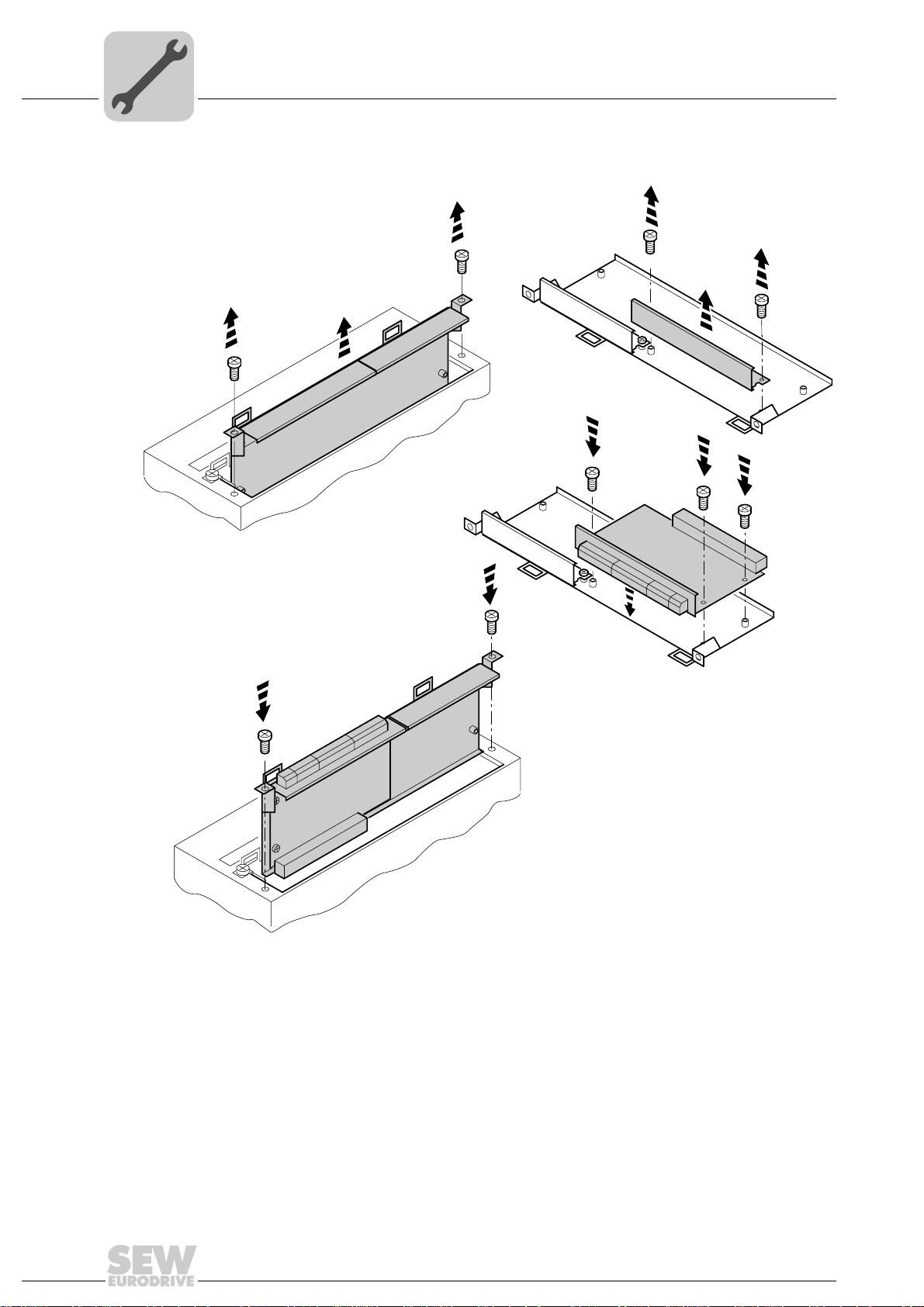

4.1.2 Basic procedure for installing and removing an option card

Assembly and Installation Notes

Installing option card DFE24B in MOVIDRIVE® MDX61B

1.

1.

2.

2.

3.

3.

3.

4.

4.

Figure 2: Installing an option card in MOVIDRIVE® MDX61B sizes 1 to 6

1. Remove the two retaining screws holding the card retaining bracket. Pull the card

retaining bracket out evenly from the slot (do not twist!).

2. Remove the 2 retaining screws from the black cover plate on the card retaining

bracket. Remove the black cover plate.

3. Position the option card onto the retaining bracket so that the 3 retaining screws fit

into the corresponding holes on the card retaining bracket.

4. Insert the retaining bracket with the installed option card into the slot, pressing

slightly so it is seated properly. Secure the card retaining bracket with the two retaining screws.

5. To remove the option card, follow the instructions in reverse order.

60039AXX

14

Manual – Fieldbus Interface DFE24B EtherCAT

Page 15

Assembly and Installation Notes

Installing option card DFE24B in MOVITRAC® B

4.2 Installing option card DFE24B in MOVITRAC® B

•MOVITRAC® B does not require any special firmware status.

• Only SEW-EURODRIVE personnel may install or remove options cards into

MOVITRAC

4.2.1 SBus connection

®

B.

4

DC 24 V

[1]

[2]

MOVITRAC® B

DFE 24B

RUN

ERR

X44

S1

S2

ON

OFF

FSC11B

X46

X45

7

23456HL ⊥

1

X12

1

2

3

+

=

24V IO

–

GND

4

5

6

7

8

9

01

AS

F1

EtherCAT

INX30OUTX31

OUTX31

H1

H2

X24

X26

1234567

[1] Terminating resistor activated, S1 = ON

[2] DIP switch S2 (reserved), S2 = OFF

• DFE24B has an integrated SBus terminating resistor and must always be installed at

the start of the SBus line.

• DFE24B always has the address 0.

X46 X26

X46:1 X26:1 SC11 SBus +, CAN high

X46:2 X26:2 SC12 SBus –, CAN low

X46:3 X26:3 GND, CAN GND

X46:7 X26:7 DC 24 V

X12

X12:8 DC 24 V input

X12:9 GND reference potential for binary inputs

Manual – Fieldbus Interface DFE24B EtherCAT

61212AXX

15

Page 16

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing option card DFE24B in MOVITRAC® B

For simple cabling, the DFE24B option can be provided with DC 24 V voltage at X26.7

from X46.7 of MOVITRAC

When powering option DFE24B through MOVITRAC

provided with DC 24 V voltage at terminals X12.8 and X12.9.

4.2.2 System bus connection

S1

ON

OFF

X44

FSC11B

X46

X45

23456HL⊥

1

MOVITRAC® B

S2

7

DFE 24B

RUN

ERR

01

AS

F1

EtherCAT

INX30OUTX31

OUTX31

®

B.

®

B, MOVITRAC®B itself must be

X12

1

2

3

4

5

6

7

8

9

DC 24 V

+

=

-

24V IO

GND

Figure 3: System bus connection

DFE24B

GND = System bus reference

SC11 = System bus high

SC12 = System bus low

H1

H2

X24

X26

1234567

MOVITRAC® B

S1

S2

ON

OFF

X44

FSC11B

X46

X45

23456HL ⊥

1

7

MOVITRAC® B

GND = System bus reference

SC22 = System bus low, outgoing

SC21 = System bus high, outgoing

SC12 = System bus low, incoming

SC11 = System bus high, incoming

S12 = System bus terminating resistor

MOVITRAC® B

S1

ON

OFF

X44

FSC11B

X46

X45

23456HL ⊥

1

61073AXX

S2

7

16

Manual – Fieldbus Interface DFE24B EtherCAT

Page 17

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing option card DFE24B in MOVITRAC® B

Please note:

• If available, use a 2 x 2 core twisted and shielded copper cable (data transmission

cable with braided copper shield). Apply the shield at both ends to the electronics

shield clamp of MOVITRAC

the shield ends additionally to GND. The cable must meet the following specifications:

– Core cross section 0.25 ... 0.75 mm

– Line resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m at 1 kHz

Suitable would be CAN bus or DeviceNet cable.

• The permitted total cable length depends on the baud rate setting of the SBus:

– 250 kBaud: 160 m

– 500 kBaud: 80 m

– 1000 kBaud:40 m

• Connect the system bus terminating resistor (S1 = ON) at the end of the system bus

connection. Switch off the terminating resistor on the other units (S1 = OFF). The

DFE24B gateway has a permanently installed terminating resistor and must always

be located at the beginning or end of the system bus line.

• Star like bus structure is not permitted.

®

B over a large area. When using a 2-core cable connect

2

(AWG23 ... AWG18)

4

• There must not be any potential displacement between the units connected with the

SBus. Take suitable measures to avoid potential displacement, e.g. by connecting

the unit ground connectors using a separate lead.

Manual – Fieldbus Interface DFE24B EtherCAT

17

Page 18

4

V

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the UOH11B gateway housing

4.3 Installing the UOH11B gateway housing

SC11 Systembus +, CAN high

SC12 Systembus -, CAN low

GND, CAN GND

SEW Drive

UOH11B

DFE 24B

RUN

ERR

01

AS

F1

EtherCAT

INX30OUTX31

OUTX31

X24

X26

23456

1

H1

H2

7

DC+24

GND

X26

X26:1 SC11 System bus +, CAN high

X26:2 SC12 System bus -, CAN low

X26:3 GND, CAN GND

X26:6 GND, CAN GND

X26:7 DC 24 V

The gateway housing is powered with DC 24 V at X26.

61074AXX

18

Manual – Fieldbus Interface DFE24B EtherCAT

Page 19

Assembly and Installation Notes

Connection and terminal description of the DFE24B option

4.4 Connection and terminal description of the DFE24B option

Part number EtherCAT interface type DFE24B: 1821 126 7

4

The option "EtherCAT interface type DFE24B" is only possible in conjunction with

MOVIDRIVE

Plug the DFE24B option into the fieldbus slot.

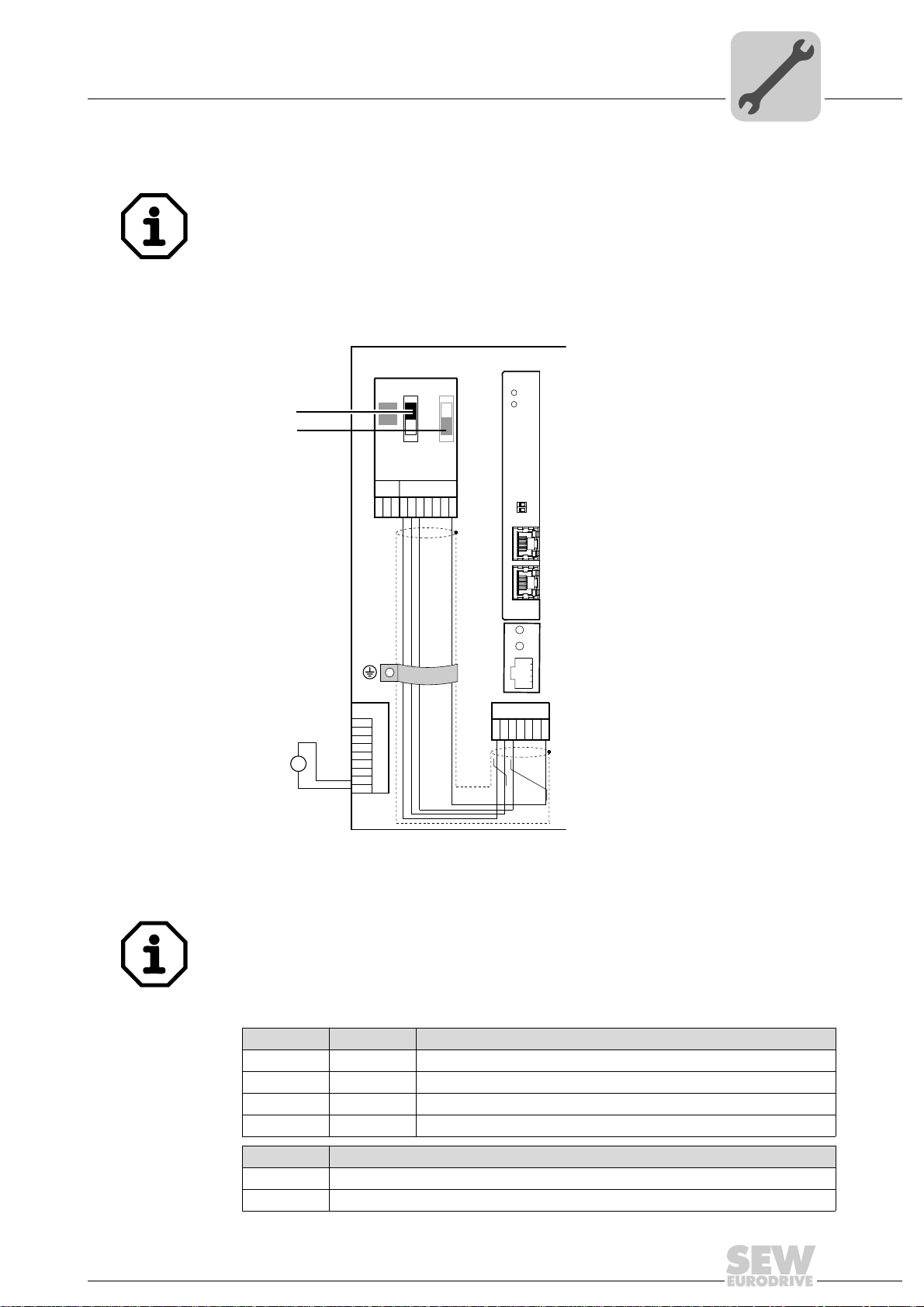

Front view of DFE24B Description

DFE 24B

RUN: EtherCAT operation LED

RUN

ERR

01

AS

F1

(orange/green)

ERR: EtherCAT error LED (red)

DIP switch AS

®

MDX61B, not with MDX60B.

DIP

switches

Terminal

F1

Function

Shows the operating status of bus electronics and

communication.

Displays EtherCAT errors.

Auto setup for gateway operation

Reserved

EtherCAT

INX30OUTX31

OUTX31

Front view in

MOVITRAC

UOH11B

®

H1

H2

X24

58083AXX

B and

LED Link/Activity (green)

X30 IN: Incoming EtherCAT

connection

LED Link/Activity (green)

X31 OUT: Outgoing EtherCAT

connection

Description Function

LED H1 (red)

LED H2 (green)

X24 X terminal

Shows that the EtherCAT connection with the preceding unit is available/active.

Shows that the EtherCAT connection with the following unit is available/active.

System error (only for gateway functionality)

Reserved

RS485 interface for diagnostics via PC and

MOVITOOLS

®

MotionStudio

58129AXX

Manual – Fieldbus Interface DFE24B EtherCAT

19

Page 20

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.5 Pin assignment

Assembly and Installation Notes

Pin assignment

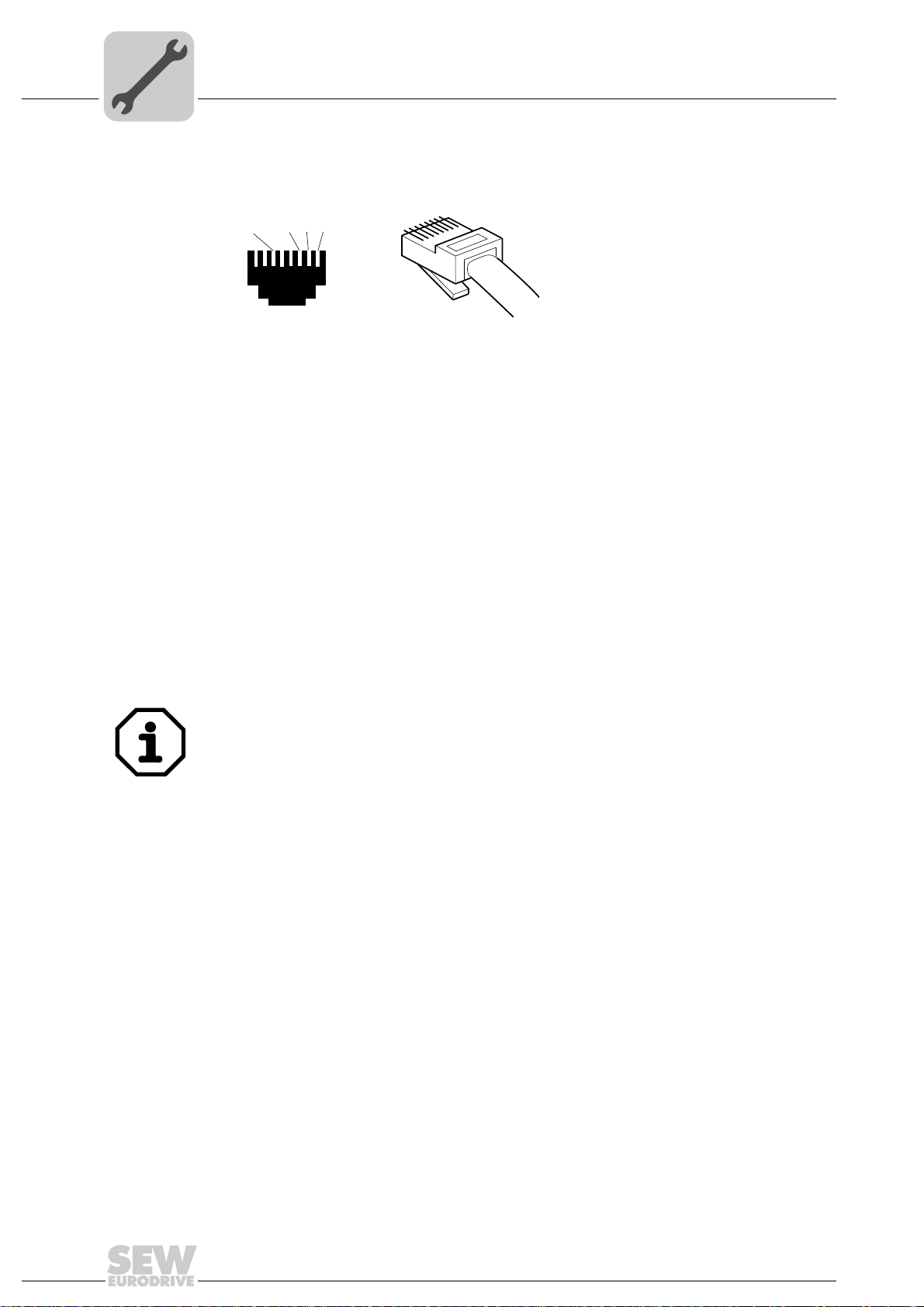

Use prefabricated, shielded RJ45 plug connectors to IEC11801 edition 2.0, category 5.

[1]

[2]

[3]

[6]

AB

Figure 4: Pin assignment of an RJ45 plug connector

A = Front view

B = View from back

[1] Pin 1 TX+ Transmit Plus

[2] Pin 2 TX– Transmit Minus

[3] Pin 3 RX+ Receive Plus

[6] Pin 6 RX– Receive Minus

6

3

2

1

54174AXX

DFE24B EtherCAT

connection

Option DFE24B is equipped with two RJ45 connectors for a linear bus structure. The

EtherCAT master is connected (if necessary, via additional EtherCAT slaves) to X30 IN

(RJ45) with a shielded, twisted-pair cable. Additional EtherCAT units are then

connected via X31 OUT (RJ45).

In accordance with IEC 802.3, the maximum permitted cable length for 100 MBaud

Ethernet (100BaseT), e.g. between two DFE24B units, is 100 m.

20

Manual – Fieldbus Interface DFE24B EtherCAT

Page 21

4.6 Shielding and routing bus cables

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Only use shielded cables and connection elements that also meet the requirements of

category 5, class D according to IEC 11801 edition 2.0.

Correct shielding of the bus cable attenuates electrical interference that can occur in

industrial environments. The following measures ensure the best possible shielding:

• Manually tighten the mounting screws on the connectors, modules, and equipotential

bonding conductors.

• Use only connectors with a metal housing or a metallized housing.

• Connect the shielding in the connector over a wide surface area.

• Apply the shielding of the bus line on both ends.

• Route signal and bus cables in separate cable ducts. Do not route them parallel to

power cables (motor leads).

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding close to each

other using the shortest possible route.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

Assembly and Installation Notes

Shielding and routing bus cables

4

In case of fluctuations in the ground potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according in accordance with relevant

VDE regulations in such a case.

4.7 Bus termination

Bus termination (e.g. with bus terminating resistors) is not necessary. If no further device

is connected to an EtherCAT slave, it recognizes this automatically.

4.8 Setting the station address

EtherCAT devices from SEW-EURODRIVE do not have an address that can be set on

the unit. The units are detected by their position in the bus structure and are assigned

an address by the EtherCAT master. The addresses can be displayed, for example,

using the DBG60B keypad (parameter P093).

Manual – Fieldbus Interface DFE24B EtherCAT

21

Page 22

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Operating displays of the DFE24B option

4.9 Operating displays of the DFE24B option

4.9.1 EtherCAT LEDs

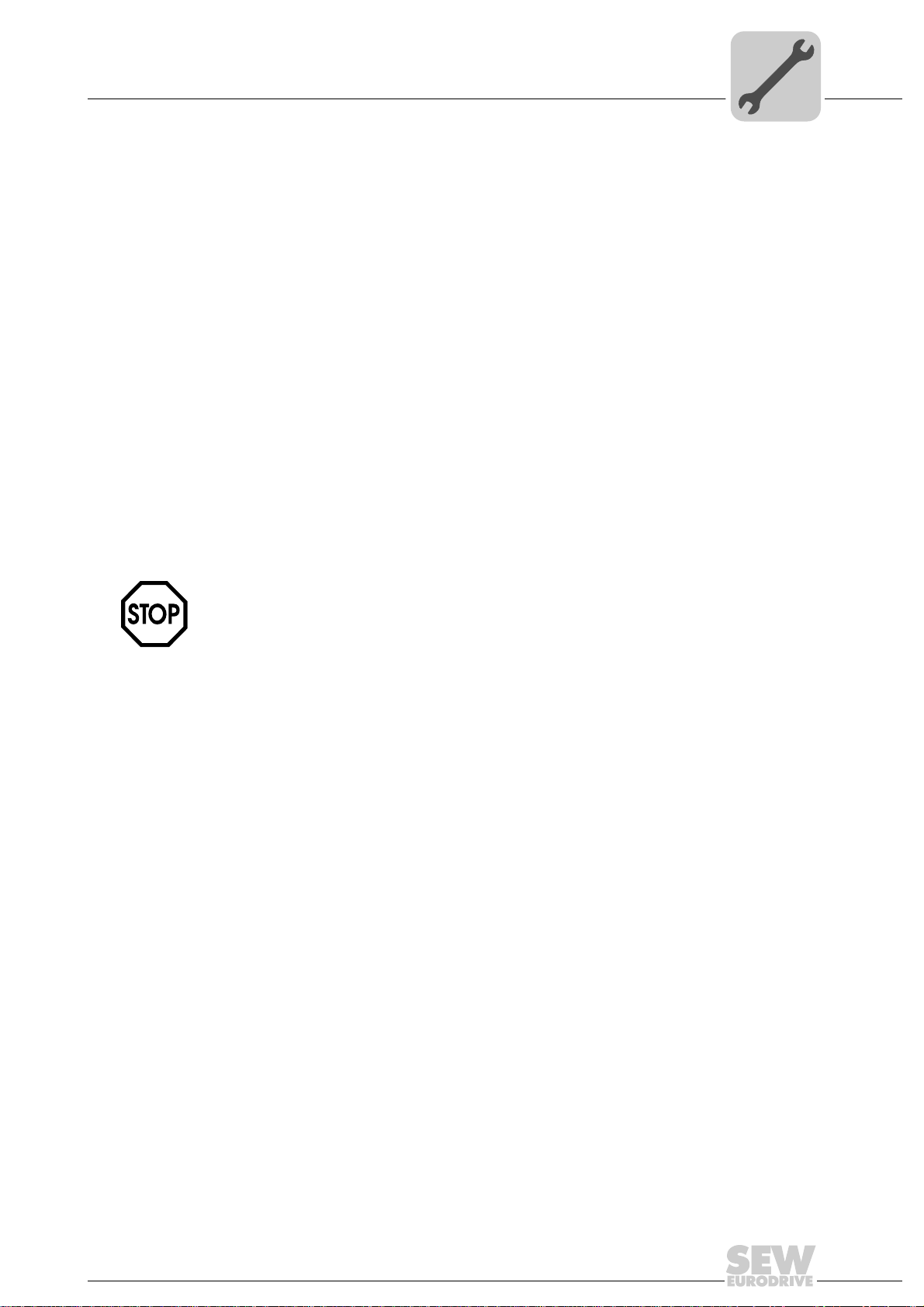

There are two LEDs on the DFE24B EtherCAT option card that display the current status

of the DFE24B option and the EtherCAT system.

DFE24B

RUN

ERR

61070AXX

LED RUN

(green/orange)

The RUN LED (green/orange) signals the status of option DFE24B.

Status State Description

Off INIT Option DFE24B is in the state INIT.

Flashing

green

Lights up

once (green)

Green OPERATIONAL Option DFE24B is in the state OPERATIONAL.

Flickering

green

Flashing

orange

PRE-OPERATIONAL Option DFE24B is in the state PRE-OPERATIONAL.

SAFE-OPERATIONAL Option DFE24B is in the state SAFE-OPERATIONAL.

INITIALISATION or

BOOTSTRAP

NOT CONNECTED Option DFE24B has been switched on but has not yet been

• Option DFE24B is booting and has not yet reached the state

INIT.

• Option DFE24B is in the state BOOTSTRAP. The firmware

is being downloaded.

addressed by an EtherCAT master.

LED ERR (red) The ERR LED (red) signals an error on EtherCAT.

Status Error Description

Off No error EtherCAT communication of the DFE24B option is in the

Flickering Boot error A boot error has been detected. The state INIT was achieved,

Flashing Invalid configuration General configuration error.

Lights up

once

Lights up

twice

Lights up

three times

Lights up

four times

On PDI watchdog timeout A PDI watchdog timeout occurs.

Unrequested change

in status

Application watchdog

timeout

Reserved -

Reserved -

operating state.

but the "Change" parameter in the AL status register has been

set to "0x01:change/error".

The slave application has changed the EtherCAT state automatically. The "Change" parameter in the AL status register has

been set to "0x01:change/error".

A watchdog timeout occurred in the application.

22

Manual – Fieldbus Interface DFE24B EtherCAT

Page 23

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Operating displays of the DFE24B option

Definition of the display statuses

Display Definition Time profile

On Display is always switched on.

Off Display is always switched off.

Flickering Display switches on and off at a

frequency of 10 Hz.

Lights up briefly

once

The display lights up briefly, followed

by on off phase.

Flashing Display switches on and off at a

frequency of 2.5 Hz (200 ms on,

200 ms off).

Lights up once The display lights up once (200 ms),

followed by a longer off phase

(1000 ms).

Lights up twice The display lights up twice in succes-

sion, followed by on off phase.

Lights up three

times

Lights up four

times

The display lights up three times in

succession, followed by on off phase.

The display lights up four times in

succession, followed by on off phase.

50ms

on

off

50ms

50ms

on

off

on

200ms 200ms

off

on

200ms 1s

off

on

200ms 1s

off

on

200ms

off

on

200ms

off

200ms 200ms

200ms 200ms

200ms 200ms

4

58094AXX

58095AXX

58096AXX

58097AXX

58100AXX

1s200ms 200ms

58101AXX

1s200ms 200ms 200ms 200ms

58102AXX

Manual – Fieldbus Interface DFE24B EtherCAT

23

Page 24

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Operating displays of the DFE24B option

LED Link/Activity

(green)

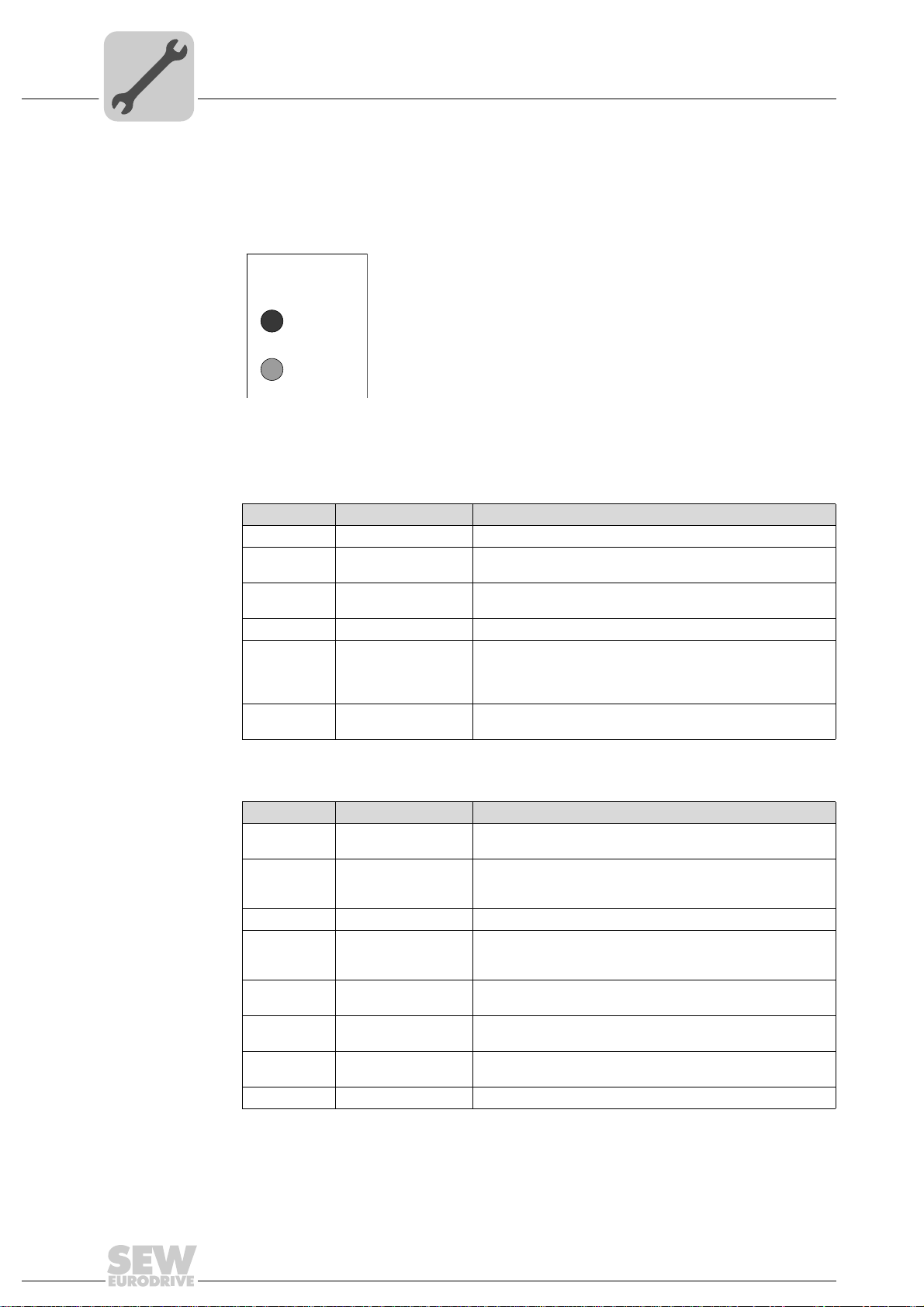

4.9.2 Gateway LED

LEDs for the

gateway communication status

Each EtherCAT connection has a "Link/Activity" LED for the incoming EtherCAT cable

(X30) and the outgoing EtherCAT cable (X31). They signal whether the EtherCAT

connection to the preceding (X30) or following (X31) unit is available / active.

INX30OUTX31

LED"Link/Activity"

OUTX31

61195AXX

H1

H2

X24

58129axx

LED H1 Sys-Fault (red) Only for gateway function

Status State Description

Red System error Gateway not configured or one of the drives

Off SBus ok Gateway is configured correctly

Flashes Bus scan Bus is being checked by the gateway

is inactive

LED H2 (green) is reserved at present.

X terminal X24 is the RS485 interface for diagnostics via PC and MOVITOOLS

®

Motion-

Studio.

24

Manual – Fieldbus Interface DFE24B EtherCAT

Page 25

Validity of the XML files for DFE24B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5 Configuration and Startup

This section provides you with information on configuration for the EtherCAT master and

startup of the drive inverter for fieldbus operation.

The current version of the XML file for the DFE24B control card is available on the SEW

homepage under the heading "Software."

5.1 Validity of the XML files for DFE24B

Configuration and Startup

I

5

00

The XML file is needed when DFE24B is used as a fieldbus option in MOVIDRIVE® B

and as a gateway in MOVITRAC

Do not change or expand the entries in the XML file. SEW assumes no liability for

inverter malfunctions caused by a modified XML file!

®

B or a gateway housing (UOH11B).

5.2 Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

5.2.1 XML for operation in MOVIDRIVE® B

An XML file (SEW_DFE24B.XML) is available for configuring the EtherCAT master.

Copy this file to a folder in the configuration software.

Refer to the manuals for the appropriate configuration software for details on this

procedure.

The XML files standardized by the EtherCAT Technology Group (ETG) can be read by

all EtherCAT masters.

Manual – Fieldbus Interface DFE24B EtherCAT

25

Page 26

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Configuration and Startup

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

00

5.2.2 Configuration procedure

Proceed as follows to configure MOVIDRIVE

1. Install (copy) the XML file according to the specifications of your configuration software. Once the file has been installed correctly, the device appears next to the slave

stations (under SEW EURODRIVE → Drives) with the designation

MOVIDRIVE+DFE24B.

2. Use the [Insert] menu item to add the device to the EtherCAT structure. The address

is assigned automatically. You can give the device a name to make it easier to

identify.

3. Select the process data configuration required for your application (see section

5.2.3).

4. Connect the I/O or periphery data to the input and output data of the application

program.

Once configuration is complete, you can start EtherCAT communication. The LEDs

RUN and ERR indicate the communication status of option DFE24B (see section 4.9

"Operating displays of the DFE24B option").

®

B with EtherCAT fieldbus interface:

26

Manual – Fieldbus Interface DFE24B EtherCAT

Page 27

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

I

5

00

5.2.3 PDO configuration for operation in MOVIDRIVE

In the CoE (CANopen over EtherCAT) variant, EtherCAT uses the process data objects

(PDO) defined in the CANopen standard for cyclical communication between master

and slave. CANopen Standard distinguishes between the process data objects Rx

(Receive) and Tx (Transmit).

Rx process data

objects

Tx process data

objects

Rx process data objects (Rx-PDO) are received by the EtherCAT slave. They transfer

process output data (control values, setpoints, digital output signals) from the EtherCAT

master to the EtherCAT slave.

Tx process data objects (TX-PDO) are returned from the EtherCAT slave to the

EtherCAT master. They transfer process input data (actual values, status, digital input

information, etc.).

In the DFE24B operating mode of MOVIDRIVE

for cyclical process input and output data.

• OutputData1 (Standard 10 PO)

Static PDO with 10 cyclical process output data words that are connected in fixed

configuration with the standard process data of MOVIDRIVE

Fieldbus Unit Profile" manual).

®

®

B, two different PDO types can be used

®

B (→ "MOVIDRIVE

®

• OutputData2 (Configurable PO)

Configurable PDO with up to 10 cyclical process output data words (16 Bit) and up

to 8 cyclical system variables (32 Bit) that can be configured as required and

connected to various process data of the drive inverter.

• InputData1 (Standard 10 PI)

Static PDO with 10 cyclical process input data words that are connected in fixed

configuration with the standard process data of MOVIDRIVE

Fieldbus Unit Profile" manual).

• InputData2 (Configurable PI)

Configurable PDO with up to 10 cyclical process input data words (16 Bit) and up to

8 cyclical system variables (32 Bit) that can be configured as required and connected

to various process data of the drive inverter.

®

B (→ "MOVIDRIVE

®

Manual – Fieldbus Interface DFE24B EtherCAT

27

Page 28

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Configuration and Startup

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

00

List of the possible process data objects (PDO) for DFE24B MOVIDRIVE® B

Index Size Name Mapping Sync manager Sync unit

1600hex

(5632dec)

1602hex

(6656dec)

1A00hex

(5632dec)

1A02hex

(6658dec)

20 bytes OutputData1 (Standard 10 PDO) Fixed

2 ... 52 bytes OutputData2 (Configurable PO) - 2 0

20 bytes InputData1 (Standard 10 PI) Fixed

2 ... 52 bytes InputData2 (Configurable PI) - 3 0

content

20

30

content

Ethernet

Header

Frame

Header

EtherCAT

Header

Data ... FCS

Drive

EtherCAT

Master

acycl. Mailbox

Communication

EtherCAT

cycl. InputData1

(Standard 10 PI)

Figure 5: Use of the process data objects OutputData1 and InputData1

cycl. OutputData1

(Standard 10 PO)

acycl. Mailbox

Communication

SEW

Drive

61221AXX

28

Manual – Fieldbus Interface DFE24B EtherCAT

Page 29

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

Static PDO for 10

cyclic process

data words

PO 1 PO 2 PO 3 PO 4 PO 5 PO 6 PO 7 PO 8 PO 9 PO 10

acycl. Mailbox

Communication

cycl. OutputData1

(Standard 10 PO)

I

5

00

Fixed assignments of the configured process

output data for

PDO OutputData1

MOVIDRIVE

Proces s D at a 1...3 or

®

plus

IPOS

®

Process Data 1...3

IPOS

MOVIDRIVE

®

plus

Proces s D at a 4...10

®

61223AXX

Figure 6: Assignment of standard process output data for OutputData1

The process output data transferred with OutputData1 are assigned according to the following table. The process output data PO1 ... PO3 can be connected with various

process data (control words, setpoints) using the process data configuration in the

MOVIDRIVE

process output data PO4 ... PO10 are only available in IPOS

Index.Subindex Offset in PDO Name Data type Size in bytes

3DB8.0hex

(15800.0dec)

3DB9.0hex

(15801.0dec)

3DBA.0hex

(15802.0dec)

3DBB.0hex

(15803.0dec)

3DBC.0hex

(15804.0dec)

3DBD.0hex

(15805.0dec)

3DBE.0hex

(15806.0dec)

3DBF.0hex

(15807.0dec)

3DC0.0hex

(15808.0dec)

3DC1.0hex

(15809.0dec)

®

B drive inverter (→ "MOVIDRIVE® Fieldbus Unit Profile" manual). The

0.0 PO1 UINT

2.0 PO2 UINT

4.0 PO3 UINT

6.0 PO4 UINT

8.0 PO5 UINT

10.0 PO6 UINT

12.0 PO7 UINT

14.0 PO8 UINT

16.0 PO9 UINT

18.0 PO10 UINT

plus®

.

2

Manual – Fieldbus Interface DFE24B EtherCAT

29

Page 30

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Fixed assignment

of the configured

process input data

for PDO

InputData1

I

Configuration and Startup

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

00

MOVIDRIVE

Proces s D at a 1...3 or

®

plus

IPOS

PI 1 PI 2 PI 3 PI 4 PI 5 PI 6 PI 7 PI 8 PI 9 PI 10

®

Process Data 1...3

IPOS

MOVIDRIVE

®

plus

Proces s D at a 4...10

®

cycl. InputData1

(Standard 10 PI)

acycl. Mailbox

Communication

61226AXX

Figure 7: Assignment of the standard process input data for PDO InputData1

The process input data transferred with InputData1 are assigned according to the

following table. The process input data PI1 ... PI3 can be connected with various process

data (status words, actual values) using the process data configuration in the

MOVIDRIVE

process input data PI4 ... PI10 are only available in IPOS

Index.Subindex Offset in PDO Name Data type Size in bytes

3E1C.0hex

(15900.0dec)

3E1D.0hex

(15901.0dec)

3E1E.0hex

(15902.0dec)

3E1F.0hex

(15903.0dec)

3E20.0hex

(15904.0dec)

3E21.0hex

(15905.0dec)

3E22.0hex

(15906.0dec)

3E23.0hex

(15907.0dec)

3E24.0hex

(15908.0dec)

3E25.0hex

(15909.0dec)

®

B drive inverter (→ "MOVIDRIVE® Fieldbus Unit Profile" manual). The

0.0 PI1 UINT

2.0 PI2 UINT

4.0 PI3 UINT

6.0 PI4 UINT

8.0 PI5 UINT

10.0 PI6 UINT

12.0 PI7 UINT

14.0 PI8 UINT

16.0 PI9 UINT

18.0 PI10 UINT

plus®

.

2

If fewer than 10 process data words are to be transferred, or if the PDO mapping is to

be adjusted, the configurable PDOs are to be used instead of the static PDO.

30

Manual – Fieldbus Interface DFE24B EtherCAT

Page 31

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

I

5

00

Configurable PDO

for up to 8 IPOS-

plus®

variables and

10 process data

words

The process data transferred with OutputData2 and InputData2 can be configured as required with process data information according to the following table. 32-bit variables of

type DINT and standard process data PO1 ... PO10 and PI1 ... PI10 can be configured.

In this way, the PDO can be configured to suit any application.

Ethernet

Header

EtherCAT

Figure 8: Use of the configurable PDO OutputData2, InputData2

Frame

Header

Master

EtherCAT

EtherCAT

Header

Data

acycl. Mailbox

Communication

cycl. InputData2

(Configurable PI)

Drive

cycl. OutputData2

(Configurable PO)

acycl. Mailbox

Communication

SEW

Drive

...

61230AXX

FCS

acycl. Mailbox

Communication

PO1 PO2 PO106. Variable 7. Variable

1. Variable

max. 10 Process Data

PO1..10 (UINT)

cycl. OutputData2

(Configurable PO)

max. 8 IPOS

Variables (D INT)

plus

®

Figure 9: Configurable PDO mapping for OutputData2

max. 10 Process Data

PI1..10 (UINT)

PI1 PI102. Variable 8. Variable1. Variable 7. Variable

max. 8 IPOS

Variables (D INT)

cycl. InputData2

(Configurable PI)

plus

acycl. Mailbox

Communication

8. Variable

61232AXX

®

Figure 10: Configurable PDO mapping for InputData2

Manual – Fieldbus Interface DFE24B EtherCAT

61237AXX

31

Page 32

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

I

Configuration and Startup

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

00

Assignment of the

configurable

process input and

output data for

PDO OutputData2

and InputData2

The maximum amount of configurable PDO OutputData2 and InputData2 data is

• 10 process data words (type UINT)

plus®

• 8 IPOS

Index.Subindex Name Data

2AF8.0hex

(11000.0dec)

2CBD.0hex

(11453.0dec)

2CBE.0hex

(11454.0dec)

2CBF.0hex

(11455.0dec)

2CC0.0hex

(11456.0dec)

2CD1.0hex

(11473.0dec)

2CD2.0hex

(11474dec)

2CD3.0hex

(11475.0dec)

2CD6.0hex

(11478.0dec)

2CD7.0hex

(11478.0dec)

2CD8.0hex

(11480.0dec)

2CD9.0hex

(11481.0dec)

2CDA.0hex

(11482.0dec)

2CDB.0hex

(11483.0dec)

2CDC.0hex

(11484.0dec)

2CE4.0hex

(11492.0dec)

2CE7.0hex

(11495.0dec)

2CEB.0hex

(11499.0dec)

2CEC.0hex

(11500.0dec)

2CED.0hex

(11501.0dec)

2CEE.0hex

(11502.0dec)

2CEF.0hex

(11503dec)

variables (type DINT)

Size in

type

Template IposVar (0...1023)

ModuloCtrl

(H453)

ModTagPos

(H454)

ModActPos

(H455)

ModCount

(H456)

StatusWord

(H473)

Scope474 Direct Scope variable

Scope475

H475)

AnaOutIPOS2

(H478)

AnaOutIPOS

(H479)

OptOutIPOS

(H480)

StdOutIPOS

(H481)

OutputLevel

(H482)

InputLevel

(H483)

ControlWord

(H484)

TargetPos

(H492)

LagDistance

(H495)

SetpPosBus

(H499)

TpPos2_VE

(H500)

TpPos1_VE

(H501)

TpPos2_Abs

(H502)

TpPos1_Abs

(H503)

DINT 4 4

bytes

Read

Write

Access attribute

Template for IPOS

Control word of the Modulo function

Modulo target position

Modulo actual position

Modulo counter value

IPOS status word

Direct Scope variable

Analog output 2 option DIO11B

Analog output option DIO11B

Optional digital outputs

Standard digital outputs

Status of the digital outputs

Status of the digital inputs

®

IPOSplus

Target position

Lag distance

Bus position setpoint

Touch probe position 2 virtual

encoder

Touch probe position 1 virtual

encoder

Touch probe position 2

Touch probe position 1

control word

plus®

variables

32

Manual – Fieldbus Interface DFE24B EtherCAT

Page 33

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

I

5

00

Index.Subindex Name Data

2CF0.0hex

(11504.0dec)

2CF1.0hex

(11505.0dec)

2CF2.0hex

(11506.0dec)

2CF3.ohex

(11507.0dec)

2CF4.0hex

(11508.0dec)

2CF5.0hex

(11509dec)

2CF6.0hex

(11510.0dec)

2CF7.0hex

(11511.0dec)

3DB8.0hex

(15800.0dec)

3DB9.0hex

(15801.0dec)

3DBA.0hex

(15802.0dec)

3DBB.0hex

(15803.0dec)

3DBC.0hex

(15804.0dec)

3DBD.0hex

(15805.0dec)

3DBE.0hex

(15806.0dec)

3DBF.0hex

(15807.0dec)

3DC0.0hex

(15808.0dec)

3DC1.0hex

(15801.0dec)

3E1C.0hex

(15900.0dec)

3E1D.0hex

(1590010dec)

3E1E.0hex

(15902.0dec)

3E1F.0hex

(15903.0dec)

3E20.0hex

904.0dec)

(15

3E21.0hex

(15905.0dec)

3E22.0hex

(15906.0dec)

3E23.0hex

(15907.0dec)

3E24.0hex

(15908.0dec)

3E25.0hex

(15909.0dec)

TpPos2_Ext

(H504)

TpPos2_Mot

(H505)

TpPos1_Ext

(H506)

TpPos1_Mot

(H507)

ActPos_Mot16

bit (H508)

ActPos_Abs

(H509)

ActPos_Ext

(H510)

ActPos_Mot

(H511)

PO1

PO2 Standard process output data word

PO3 Standard process output data word

PO4 Standard process output data word

PO5 Standard process output data word

PO6 Standard process output data word

PO7 Standard process output data word

PO8 Standard process output data word

PO9 Standard process output data word

PO10 Standard process output data word

PI1 Standard process input data word

PI2 Standard process input data word

PI3 Standard process input data word

PI4 Standard process input data word

PI5 Standard process input data word

PI6 St

PI7 Standard process input data word

PI8 Standard process input data word

PI9 Standard process input data word

PI10 Standard process input data word

type

DINT 4 4

UINT 2 2

Size in

bytes

Read

Write

Access attribute

Touch probe position 2 external

Touch probe position 2 motor

encoder

Touch probe position 1 external

Touch probe position 1 motor

Actual position motor 16 Bit

Actual position absolute encoder

Actual position external encoder

X14

Actual position motor encoder

Standard process output data word

PO1

PO2

PO3

PO4

PO5

PA6

PO7

PO8

PO9

PO10

PI1

PI2

PI3

PI4

PI5

andard process input data word

PI6

PI7

PI8

PI9

PI10

Manual – Fieldbus Interface DFE24B EtherCAT

33

Page 34

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

I

Configuration and Startup

Configuring the EtherCAT master for MOVIDRIVE® B with the XML file

00

Plausibility of the configuration of process data objects:

• In the freely configurable process data objects OutputData2 and InputData2, cyclical

process output data PO1 ... 10 cannot be inserted when OutputData1 or InputData1

is configured at the same time.

• Multiple configuration of process data objects is not possible.

• Only standard process data objects PO1 ... PO10, PI1 ... PI10 or IPOS

(indices 11000.0 ... 12023.0) can be configured as process data.

plus®

variables

34

Manual – Fieldbus Interface DFE24B EtherCAT

Page 35

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

00

5.3 Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

This section describes the configuration of the EtherCAT master with MOVITRAC® B

and the DFE24B gateway / UOH11B.

I

5

5.3.1 XML files for operation in MOVITRAC

An XML file (SEW_DFE24B.XML) is available for configuring the EtherCAT master.

Copy this file to a folder in the configuration software.

Refer to the manuals for the appropriate configuration software for details on this

procedure.

The XML files standardized by the EtherCAT Technology Group (ETG) can be read by

all EtherCAT masters.

5.3.2 Configuration procedure

Proceed as follows to configure MOVITRAC

1. Install (copy) the XML file according to the specifications of your configuration software. Once the file has been installed correctly, the device appears next to the slave

stations (under SEW EURODRIVE → Drives) with the designation DFE24B-

Gateway.

2. Use the [Insert] menu item to add the device to the EtherCAT structure. The address

is assigned automatically. You can give the device a name to make it easier to

identify.

3. Connect the I/O or periphery data to the input and output data of the application

program.

®

B and gateway housing UOH11B

®

/ gateways with the EtherCAT interface:

Once configuration is complete, you can start EtherCAT communication. The LEDs

RUN and ERR indicate the communication status of option DFE24B (see section 4.9

"Operating displays of the DFE24B option").

Manual – Fieldbus Interface DFE24B EtherCAT

35

Page 36

EURODRIVE

EURODRIVE

EURODRIVE

EURODRIVE

EURODRIVE

EURODRIVE

EURODRIVE

EURODRIVE

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Configuration and Startup

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

00

5.3.3 PDO configuration for DFE24B gateway for MOVITRAC® B

In the DFE24B gateway operating mode for MOVITRAC

®

B, one PDO each is used for

cyclical process input and output data.

• OutputData1 (Standard 24 PO)

Static PDO with 24 cyclical process output data words that are connected in fixed

configuration with the process data of a maximum of 8 MOVITRAC

®

B connected to

the gateway.

• InputData1 (Standard 24 PI)

Static PDO with 24 cyclical process input data words that are connected in fixed

configuration with the process data of a maximum of 8 MOVITRAC

®

B connected to

the gateway.

List of the possible PDO for the DFE24B gateway:

Index Size Name Mapping Sync manager Sync unit

1601hex

(5633dec)

1A01hex

(5633dec)

48 bytes OutputData1 (Standard 24 PO) Fixed

content

48 bytes InputData1 (Standard 24 PI) Fixed

content

20

30

Ethernet

Header

EtherCAT

Master

EtherCAT

Frame

Header

EtherCAT

Header

Data

acycl. Mailbox

Communication

cycl. InputData1

(Standard 24 PI)

Unit = SBus-Address: 1 2 3 4 5 6 7 8

Drive

cycl. OutputData1

(Standard 24 PO)

acycl. Mailbox

Communication

B

®

EURODRIVEEURODRIVE

MOVITRAC

EURODRIVEEURODRIVE

EURODRIVEEURODRIVE

EURODRIVEEURODRIVE

DFE 24B

AS

F1

EtherCAT

INX30OUTX31

OUTX31

... FCS

RUN

ERR

01

EURODRIVEEURODRIVE

EURODRIVEEURODRIVE

EURODRIVEEURODRIVE

EURODRIVEEURODRIVE

Figure 11: Data exchange (PDO OutputData1, InputData1) with EtherCAT master

36

Manual – Fieldbus Interface DFE24B EtherCAT

61242AXX

Page 37

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

Assignment of the fixed configured process output data (PDO 1)

I

5

00

acycl. Mailbox

Communication

PO1 PO2 PO3 PO4 PO5 PO6 PO22 PO23 PO24

Dr i ve 1

PO1...PO3

cycl. OutputData1

(Standard 10 PO)

Dr i ve 2

PO1...PO3

Dr i ve 8

PO1...PO3

61239AXX

Figure 12: Assignment of standard process output data for OutputData1

The process output data transferred with OutputData1 are assigned according to the following table. For each inverter, the process output data PO1 ... PO3 can be connected

with various process data (control words, setpoints) using the process data configuration in the MOVITRAC

Index.Subindex Offset in PDO Name Assignment Data type Size in bytes

3DB8.0hex

(15800.0dec)

3DB9.0hex

(15801.0dec)

3DBA.0hex

(15802.0dec)

3DBB.0hex

(15803.0dec)

3DBC.0hex

(15804.0dec)

3DBD.0hex

(15805.0dec)

3DBE.0hex

(15806.0dec)

3DBF.0hex

(15807.0dec)

3DC0.0hex

(15808.0dec)

3DC1.0hex

(15809.0dec)

3DC2.0hex

(15810.0dec)

3DC3.0hex

(15811.0dec)

3DC4.0hex

(15812.0dec)

3DC5.0hex

(15813.0dec)

3DC6.0hex

(15814.0dec)

®

B drive inverter (→ "MOVITRAC® B" operating instructions).

0.0 PO1 Drive 1 PO1

2.0 PO2 Drive 1 PO2

4.0 PO3 Drive 1 PO3

6.0 PO4 Drive 2 PO1

8.0 PO5 Drive 2 PO2

10.0 PO6 Drive 2 PO3

12.0 PO7 Drive 3 PO1

14.0 PO8 Drive 3 PO2

16.0 PO9 Drive 3 PO3

18.0 PO10 Drive 4 PO1

0.0 PO11 Drive 4 PO2

2.0 PO12 Drive 4 PO3

4.0 PO13 Drive 5 PO1

6.0 PO14 Drive 5 PO2

8.0 PO15 Drive 5 PO3

UINT 2

Manual – Fieldbus Interface DFE24B EtherCAT

37

Page 38

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

I

Configuration and Startup

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

00

Index.Subindex Offset in PDO Name Assignment Data type Size in bytes

3DC7.0hex

(15815.0dec)

3DC8.0hex

(15816.0dec)

3DC9.0hex

(15817.0dec)

3DCA.0hex

(15818.0dec)

3DCB.0hex

(15819.0dec)

3DCC.0hex

(15820.0dec)

3DCD.0hex

(15821.0dec)

3DCE.0hex

(15822.0dec)

3DCF.0hex

(15823.0dec)

10.0 PO16 Drive 6 PO1

12.0 PO17 Drive 6 PO2

14.0 PO18 Drive 6 PO3

16.0 PO19 Drive 7 PO1

18.0 PO20 Drive 7 PO2

18.0 PO21 Drive 7 PO3

18.0 PO22 Drive 8 PO1

18.0 PO23 Drive 8 PO2

18.0 PO24 Drive 8 PO3

UINT 2

38

Manual – Fieldbus Interface DFE24B EtherCAT

Page 39

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

Assignment of the fixed configured process input data (PDO 1)

I

5

00

Drive 1

PI1...PI3

PI1 PI2 PI3 PI4 PI5 PI6 PI22 PI23 PI24

Dr i ve 2

PI1...PI3

cycl. InputData1

(Standard 10 PI)

Drive 8

PI1...PI3

acycl. Mailbox

Communication

61240AXX

Figure 13: Assignment of the standard process input data for InputData1

The process input data transferred with InputData1 are assigned according to the

following table. The process input data PI1 ... PI3 can be connected with various process

data (status words, actual values) using the process data configuration in the

MOVITRAC

Index.Subindex Offset in PDO Name Assignment Data type Size in bytes

3E1C.0hex

(15900.0dec)

3E1D.0hex

(15901.0dec)

3E1E.0hex

(15902.0dec)

3E1F.0hex

(15903.0dec)

3E20.0hex

(15904.0dec)

3E21.0hex

(15905.0dec)

3E22.0hex

(15906.0dec)

3E23.0hex

(15907.0dec)

3E24.0hex

(15908.0dec)

3E25.0hex

(15909.0dec)

3E26.0hex

(15910.0dec)

3E27.0hex

(15911.0dec)

3E28.0hex

(15912.0dec)

3E29.0hex

(15913.0dec)

3E2A.0hex

(15914.0dec)

®

B drive inverter (→ "MOVITRAC® B" operating instructions).

0.0 PI1 Drive 1 PI1

2.0 PI2 Drive 1 PI2

4.0 PI3 Drive 1 PI3

6.0 PI4 Drive 2 PI1

8.0 PI5 Drive 2 PI2

10.0 PI6 Drive 2 PI3

12.0 PI7 Drive 3 PI1

14.0 PI8 Drive 3 PI2

16.0 PI9 Drive 3 PI3

18.0 PI10 Drive 4 PI1

20.0 PI11 Drive 4 PI2

22.0 PI12 Drive 4 PI3

24.0 PI13 Drive 5 PI1

26.0 PI14 Drive 5 PI2

28.0 PI15 Drive 5 PI3

UINT 2

Manual – Fieldbus Interface DFE24B EtherCAT

39

Page 40

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

I

Configuration and Startup

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

00

Index.Subindex Offset in PDO Name Assignment Data type Size in bytes

3E2B.0hex

(15915.0dec)

3E2C.0hex

(15916.0dec)

3E2D.0hex

(15917.0dec)

3E2E.0hex

(15918.0dec)

3E2F.0hex

(15919.0dec)

3E30.0hex

(15920.0dec)

3E31.0hex

(15921.0dec)

3E32.0hex

(15922.0dec)

3E33.0hex

(15923.0dec)

30.0 PI16 Drive 6 PI1 UINT 2

32.0 PI17 Drive 6 PI2

34.0 PI18 Drive 6 PI3

36.0 PI19 Drive 7 PI1

38.0 PI20 Drive 7 PI2

40.0 PI21 Drive 7 PI3

42.0 PI22 Drive 8 PI1

44.0 PI23 Drive 8 PI2

46.0 PI24 Drive 8 PI3

40

Manual – Fieldbus Interface DFE24B EtherCAT

Page 41

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Configuring the EtherCAT master for MOVITRAC® B / gateway with XML file

5.3.4 Auto setup for gateway operation

The auto setup function can be used to startup DFE24B as a gateway without a PC. The

function is activated using the DIP switch Auto-Setup (see section 4.4 on page 19) .

Setting the DIP switch Auto-Setup (AS) from OFF to ON position causes the function to

be executed once. The Auto-Setup DIP switch must then remain in ON position.

The function can be reactivated by turning the DIP switch off and back on again.

First, the DFE24B searches on the lower-level SBus for SEW drives. This process is indicated by the LED H1 (system error) flashing briefly. For this purpose, different SBus

addresses must be set for the drive inverters (P881). We recommend assigning the

addresses beginning with address 1 in ascending order based on the arrangement of

inverters in the control cabinet. The process image on the fieldbus side is expanded by

three words for each detected drive inverter.

The LED H1 remains lit if no drive inverter is located. A total of up to 8 drive inverters is

taken into account.

After the search is completed, the DFE24B cyclically exchanges 3 process data words

with each connected drive inverter. The process output data is taken from the fieldbus,

divided into blocks of three and transmitted. The drive inverters read the process input

data, put it together and send it to the fieldbus master.

The cycle time of SBus communication is 2 ms per station.

For an application with 8 inverters on the SBus, the cycle time for the process data

update will be 8 x 2 ms = 16 ms.

I

5

00

If you change the process data assignment of the drive inverters connected to DFE24B,

you must activate Auto-Setup again because the DFE24B saves these values only once

during Auto-Setup. At the same time, the process data assignments of the connected

drive inverters may not be changed dynamically after Auto-Setup.

Manual – Fieldbus Interface DFE24B EtherCAT

41

Page 42

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Configuration and Startup

Setting the MOVIDRIVE® MDX61B drive inverter

00

5.4 Setting the MOVIDRIVE® MDX61B drive inverter

The following settings must be made for simple fieldbus operation.

11638AXX

®

However, to control the MOVIDRIVE

switch the drive inverter to control signal source (P101) and setpoint source (P100) =

FIELDBUS. The FIELDBUS setting means the drive inverter parameters are set for

control and setpoint entry via EtherCAT. The MOVIDRIVE

responds to the process output data transmitted from the PLC.

The parameters of the MOVIDRIVE

CAT without any further settings once the EtherCAT option card has been installed. For

example, all parameters can be set by the master programmable controller after poweron.

B drive inverter via EtherCAT, you must first

®

B drive inverter now

®

B drive inverter can be set straight away via Ether-

42

Manual – Fieldbus Interface DFE24B EtherCAT

Page 43

Configuration and Startup

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Setting the MOVITRAC® frequency inverter

Activation of the control signal source and setpoint source FIELDBUS is signaled to the

machine controller using the "Fieldbus mode active" bit in the status word.

For safety reasons, you must also enable the MOVIDRIVE

terminals for control via the fieldbus system. Consequently, you must wire and program

the terminals in such a way that the inverter is enabled via the input terminals. The

simplest way of enabling the inverter on the terminal side is to set the DIØØ input

terminal (Function /CONTROLLER INHIBIT) to a +24 V signal and to program the input

terminals DIØ1 ... DIØ7 to NO FUNCTION.

The whole procedure for starting up the MOVIDRIVE

connection is described in sections 6 and 7.

5.5 Setting the MOVITRAC® frequency inverter

I

00

®

B drive inverter at the

®

B drive inverter with EtherCAT

5

Manual – Fieldbus Interface DFE24B EtherCAT

11639AXX

43

Page 44

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

I

Configuration and Startup

Setting the MOVITRAC® frequency inverter

00

To control the MOVITRAC® B frequency inverter via EtherCAT, you must first switch the

inverter to Control signal source (P101) and Setpoint source (P100) = SBus. The SBus

setting means the MOVITRAC

transfer from the gateway. The MOVITRAC

process output data transmitted from the PLC.

To ensure that the MOVITRAC

is interrupted, set the SBus1 timeout time (P883) to a value other than 0 ms. We

recommend a value between 50 and 200 ms.

Activation of the control signal source and setpoint source SBus is signaled to the

machine controller using the "SBus mode active" bit in the status word.

For safety reasons, you must also enable the frequency inverter at the terminals for

control via the fieldbus system. Consequently, you must wire and program the terminals

in such a way that the inverter is enabled via the input terminals. The simplest way of

enabling the frequency inverter on the terminal side is to set the DIØØ input terminal

(function CW/STOP) to a +24 V signal and to program the other input terminals to NO

FUNCTION.

®

B frequency inverter parameters are set for setpoint

®