SEA SWING 2 DG User Manual

®

Sistemi Elettronici |

|

|

di Apertura Porte e Cancelli |

Italiano |

|

International registered trademark n. 804888 |

||

|

||

|

|

|

|

English |

|

|

|

|

SWING 2 DG R2F |

Français |

|

|

||

Español |

||

|

(Cod. 23021096 - 23021110 - 33001165/75/80)

CENTRALE ELETTRONICA PER 1 O 2 MOTORI A 230V/115V ELECTRONIC CONTROL UNIT FOR 1 OR 2 230V/115V MOTORS ARMOIRE DE COMMANDE POUR 1 OU 2 MOTEURS EN 230V/115V CENTRAL ELECTRÓNICA PARA 1 O 2 MOTORES A 230V/115V

SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. +39 0861 588341 r.a. Fax +39 0861 588344

www.seateam.com

seacom@seateam.com

67411725 |

Rev.04 - 06/2015 |

®

English |

SWING 2 DG R2F |

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

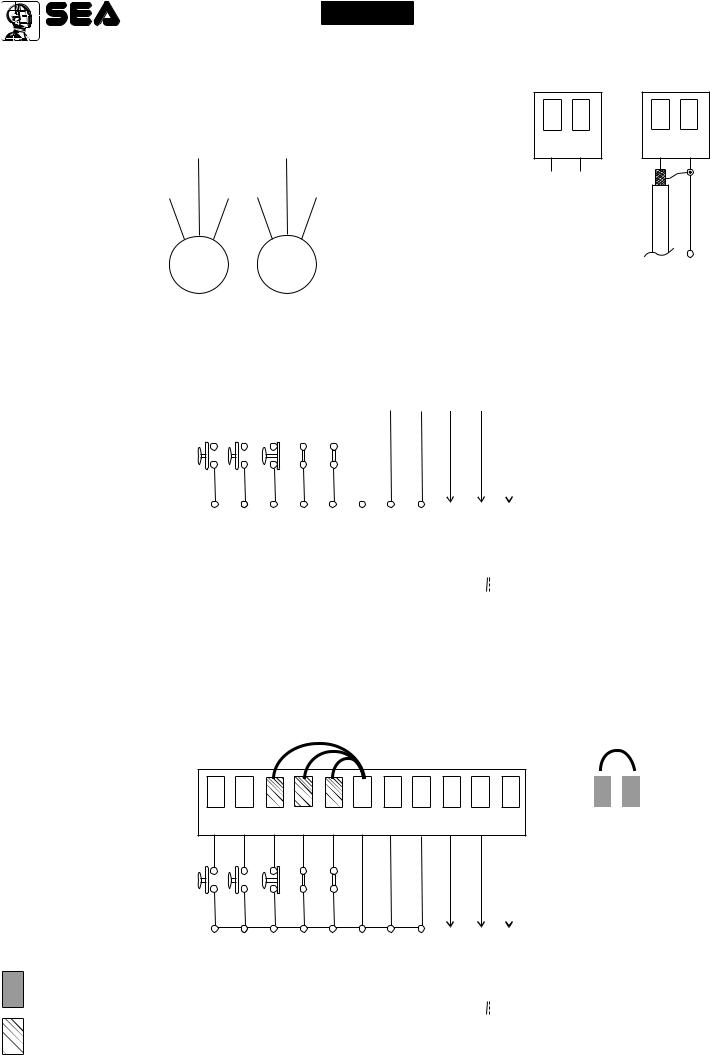

COMPONENTS

TECHNICAL SPECIFICATIONS

Control unit power supply: 230 Vac 50/60 Hz - 115Vac 50/60 Hz

Absorption in stand by: 30 mA

Environment temperature : -20°C  +50°C

+50°C

Specifications of external enclosure: 183 X 238 X 120 - Ip55

JOLLY-JOLLY2

LE CARD

|

- |

+ |

M2 |

|

ENCON |

|

|

1011 |

I3 I4 |

1 |

2 |

|

9 |

GND |

|

7 8 |

I1 I2 |

||

POT |

DS1 |

|

||

|

|

|

|

|

CNP |

|

|

5 6 |

D2 P12 |

|

|

|

4 |

P02 |

|

|

|

3 |

P11 |

CN1 |

|

|

1 2 |

P01 D1 |

|

|

|

|

M1 |

120 mm

CN3 |

|

|

|

|

F2 |

|

|

|

|

|

|

TR1 |

|

|

CN2 |

|

|

|

164 |

|

R2 |

F1 |

|

|

|

|

|

mm |

|

|

|

|

|

|

R1 |

|

|

|

|

CN1 |

|

T2 |

CN7 |

RECEIVER RX |

|

T1 |

|

CNF |

|

|

|

|

|

|

JOLLY |

UP |

|

CNA |

|

CN4 |

DOWN |

DS |

|

|

|

|

|

||

|

|

CNS |

|

|

EXP |

|

|

||

|

|

|

||

CN5 |

OK |

|

CNP |

|

|

|

|

||

CN6 |

|

CNI |

|

|

|

|

|

|

|

CN1 = Input/output connectors

CN2 = Motors, capacitors and courtesy light connector

CN3 = Power supply connector

CN4 = Flash led and electrolock connector

CN5 = Safety edge connector

CN6 = Limit switch connector

CN7 = Connector antena

CNP = Programming connector

CNA = Receiver module connector RX

CNS = Fix receiver connector

CNI = Plug-in receiver connector

EXP = Expansion module connector/LE Card

JOLLY = Jolly - Jolly 2 connector

DS = Programming display

OK = Programming button

DOWN = Programming button

UP = Programming button

T1 = Motors piloting Triac

T2 = Motors piloting Triac

R1 = Motors comand relay

R2 = Courtesy light comand relay

F1 = Accessories 1A fuse

F2 = 6.3AT fuse on 230V/10AT on 115V

TR1 = Power transformer

23

®

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

CONNECTIONS

CN3 CN2 CN4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N L |

|

1 2 3 4 5 6 7 8 |

|

|

20 21 |

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Motor 1 Neutral |

|

Motor 1 Opening |

|

|

|

|

|

Motor 1 Closing Motor 2 Neutral |

|

|

Motor 2 Opening |

|

|

|

|

|

Motor 2 Closing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Not connected |

|

Neutral |

|

Line |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flash N |

|

Flash |

|

|

|

Flash Light |

Electrolock (12V 15VA max) |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

M1 M2

CN1

SWING 2 DG R2F

CN5 CN7

22 23 |

24 |

25 |

|

Common |

Edge 1 |

|

|

|

|

Antenna |

Common |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

10 |

11 12 |

13 14 15 16 |

17 |

18 19 |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start |

START Ped. |

Stop |

Photocell 1 |

Photocell 2 |

Common |

Common |

Common |

24V |

AUX 500mA max) |

Test |

|

|

|

|

|

|

|

|

|

(24V |

|

JUMPERS

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (Photocells and Stop) except the SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs” menu without need to repeat the programming (page 36).

Obligatory jumper without accessory connection.

Optional

CN1

9 10 11 12 13 14 15 16 17 18 19

Start |

START Ped. |

Stop |

Photocell 1 |

Photocell 2 |

Common |

Common |

Common |

24V |

AUX 500mA max) |

Test |

|

|

|

|

|

|

|

|

|

(24V |

|

|

|

|

|

|

CN5 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

22 |

23 |

|

|||||

|

|

|

|

|

|

|

|

|

Common |

|

Edge 1 |

||||

The herein reported f u n c t i o n s a r e available starting from revision 016.

24

®

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

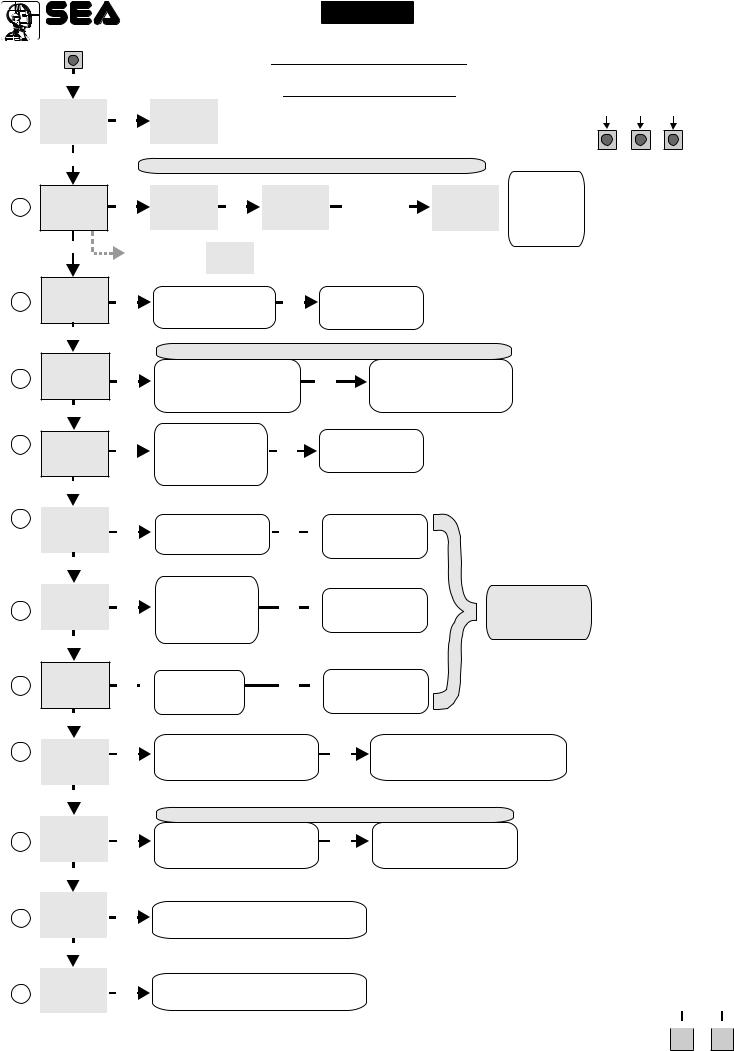

PROGRAMMING

UP

QUICK START

|

MENU |

SEA |

|

MENU |

SEA |

|

SET |

OK |

SET |

||

1 |

LANGUAGE |

ITALIANO |

|||

|

|

|

|

|

|

UP

Skip this step if you do not want to program a transmitter

SEA

MENU SET

2

TRANSMITTERS

|

UP |

|

|

|

SEA |

SET |

|

|

MENU |

||

3 |

MOTOR |

||

|

UP |

|

|

|

SEA |

SET |

|

|

MENU |

||

4 |

ONE SINGLE |

||

|

LEAF |

|

|

|

UP |

|

|

|

SEA |

SET |

|

5 |

MENU |

||

REVERSE |

|||

|

|||

|

MOTOR |

||

UP

|

SEA |

SET |

|

|

SEA |

SET |

|

Press the |

MENU |

SEA |

|

|

MENU |

|

|

MENU |

|

button of the |

SET |

||||

OK |

START |

|

|

OK |

PRESS |

|

|

STORED |

|||

|

|

|

|

TX to be |

|||||||

|

|

|

|

|

BUTTON |

|

|||||

|

|

|

|

|

|

|

stored |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check if a receiver has |

|

|

||||

|

|

|

MENU SET |

|

|

|

|||||

If on the display |

|

|

SEA |

|

|

|

|

|

|

|

|

|

RECEIVER |

|

been connceted |

|

|

|

|||||

appears the item: |

|

|

|

|

|

||||||

|

MISSING |

|

(see page 23) |

|

|

|

|||||

|

Choose the type of |

|

|

|

|||||||

OK |

OK |

To confirm and return |

|

|

|||||||

motor with |

|

|

|||||||||

|

|

|

|

|

|

|

|

to main menu |

|

|

|

UP or DOWN

Skip this step if you are working in double leaf mode

With UP or DOWN choose

OK

ON only if in single leaf mode (Motor 1)

Choose ON with UP or DOWN

OK if you want to reverse OK the direction of

the motor rotation

OK |

To confirm and return |

|

to the main menu |

Per confermare e tornare

al Menu principale

SWING 2 DG R2F

PROGRAMMING

BUTTONS

UP DOWN OK

OK to exit Menu or press the button of the next TX to be stored

6 |

SEA |

SET |

MENU |

||

LOGIC |

|

|

(See |

|

|

page 26) |

|

|

|

UP |

|

|

|

|

|

SEA |

SET |

|

MENU |

|

7 |

PAUSE TIME |

|

|

|

|

UP

SEA

MENU SET

8START IN PAUSE

|

UP |

|

|

|

|

|

|

|

SEA |

SET |

|

9 |

MENU |

||

PROGRAM- |

|||

(See |

|||

page 24) |

MING |

|

|

|

UP |

|

|

|

|

|

|

|

SEA |

SET |

|

|

MENU |

||

10 |

TEST START |

||

|

|

|

|

UP

With UP or DOWN OK choose

the desired logic

With UP or DOWN OK choose a delay for automatic closing

OK

With UP or DOWN Choose ON

With UP or DOWN Choose ON

OK

To confirm and return to main menu

To confirm and return to main menu

OK

To confirm and return to main menu

To confirm and return to main menu

OK

To confirm and return to main menu

To confirm and return to main menu

Skip this step

if you want to work

in half-automatic

logic

OK |

With UP or DOWN choose ON |

OK |

At the end of the selflearning |

the control unit returns automatically |

|||

|

to start times learning |

|

to the main menu |

|

|

|

|

|

The gate will execute a CLOSING-OPENING-CLOSING CYCLE |

||

|

Skip this step if a TX has already been stored |

||

OK |

With |

OK |

To confirm and return to |

UP or DOWN Choose |

|||

|

ON to start test |

|

main menu |

|

SEA |

SET |

|

|

|

MENU |

|

Press OK to return to the |

|

15 |

END |

|

OK |

|

|

display of the inputs state. |

|||

|

|

|

|

|

|

|

|

|

|

|

UP |

|

|

|

|

|

|

|

|

|

SEA |

SET |

|

|

|

MENU |

|

|

|

16 |

SPECIAL |

OK |

Press OK to enter the special menu. |

|

|

MENU |

|

|

|

ALL OTHER PARAMETERS HAVE DEFAULT SETTINGS WHICH ARE USEFUL FOR THE 90% OF THE APPLICATIONS

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S. DOWN UP

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S. DOWN UP

25

® |

|

|

English |

|

SWING 2 DG R2F |

|||

Sistemi Elettronici |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

di Apertura Porte e Cancelli |

|

|

|

|

|

|

|

|

International registered trademark n. 804888 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

MENU FUNCTIONS TABLE SWING 2 DG R2F |

|

|

|

||||

MENU |

|

SET |

|

Description |

|

Default |

Set value |

|

|

|

|

|

|

|

|

|

|

|

Italiano |

Italian |

|

|

|

|||

|

English |

English |

|

|

|

|||

1 - LANGUAGE |

Français |

French |

|

Italiano |

|

|||

|

Español |

Spanish |

|

|

|

|||

|

Dutch |

Olandese |

|

|

|

|||

|

Start |

|

|

Start |

|

|

|

|

|

Pedestrian Start |

Pedestrian Start |

|

|

|

|||

|

External module |

External module |

|

|

|

|||

|

Stop |

|

|

Stop |

|

Start |

|

|

|

|

|

|

Storing of a command |

|

|

||

|

|

|

|

|

|

|

||

2 - TRANSMITTERS |

Unloch |

for unlocking an |

|

Pedestrian |

|

|||

|

|

|

electric brake |

|

|

|||

|

|

|

|

|

Start |

|

||

|

Delete a transmitter |

Delete single transmitter |

|

|

||||

|

|

|

|

|||||

|

Clear memory |

Delete transmitter memory |

|

|

||||

|

|

|

|

Transfers the stored |

|

|

|

|

|

Move to eep |

transmitters on the control |

|

|

|

|||

|

unit to the external EEPROM |

|

|

|||||

|

|

|

|

|

|

|||

|

|

|

|

(MEM) if inserted. |

|

|

|

|

|

Hydraulic |

Hydraulic |

|

|

|

|||

|

Sliding |

Sliding |

|

|

|

|||

3 - MOTOR |

Reversible sliding gate |

Reversible sliding gate |

|

Mechanic |

|

|||

|

Mechanic |

Mechanic |

|

|

|

|||

|

Kougar |

Kougar motor |

|

|

|

|||

4 - ONE SINGLE |

Off |

|

|

Disabled |

|

Off |

|

|

|

|

|

In ON activates single leaf |

|

||||

LEAF * |

On |

|

|

|

||||

|

|

mode (Motor 1) |

|

|

|

|||

|

|

|

|

|

|

|

||

5 - REVERSE MOTOR |

Off |

|

|

Synchronized right motor |

Off |

|

||

On |

|

|

Synchronized left motor |

|

|

|||

|

|

|

|

|

|

|||

|

Automatic |

Automatic |

|

|

|

|||

|

Open-stop-close-stop-open |

Step by step type 1 |

|

|

|

|||

6 - LOGIC |

Open-stop-close-open |

Step by step type 2 |

|

Automatic |

|

|||

2 buttons |

Two buttons |

|

|

|||||

(See page 28) |

|

|

|

|||||

|

Safety |

Safety |

|

|

|

|||

|

Dead man |

Dead man |

|

|

|

|||

|

Off |

|

|

OFF |

|

|

|

|

7 - PAUSE TIME |

|

|

(semi-automatic logics) |

|

Off |

|

||

1 240 |

|

Setting from 1s to 4min. |

|

|

||||

|

|

|

|

|

||||

8 - START IN PAUSE |

Off |

|

|

In pause start is not acceped |

Off |

|

||

On |

|

|

In pause start is accepted |

|

||||

|

|

|

|

|

||||

9 - PROGRAMMING |

Off |

On |

Times learning start |

|

Off |

|

||

(See page 27) |

|

|

||||||

|

|

|

|

|

|

|

|

|

10 - TEST START |

Off |

On |

Start command |

|

Off |

|

||

15 - END

Press OK to return to the display of the firmware version and to the one of inputs state.

16 - SPECIAL MENU |

Press OK to enter the special menu. |

Note 1: The * indicates that the default value or the menu may change depending on the selected motor type.

26

®

English |

SWING 2 DG R2F |

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

WORKING TIMES SELF LEARNING

The control unit is pre-set with the default settings, to start the control unit with the

DEFAULT settings just keep pressed the UP and DOWN buttons at the same time power

supplying the control unit the display shows the message “Init”.

The DEFAULT settings are shown in the Menues table.

WORKING TIMES SELFLEARNING THROUGH IMPULSES

ATTENTION: This procedure is potentially dangerous and should only be performed by qualified people in safety conditions.

NOTE: The card is preset with the standard working times, therefore the automation can be started even without the times programming, simply by adjusting the timing on the display (see default times).

In this procedure all used N.C. contacts must be kept closed.

1)Turn off electricity, release the motors and manually position the leaves on halfway. Reset the mechanical lock.

2)Connect the control board to the power supply

3)Select on the on-board display or JOLLY programmer, the type of motor that you are using as indicated in the dispaly management (“Mechanic-Hydraulic”, etc).

4)If necessary also set the operation logic and the other parameters. If you want to program with a transmitter, store a transmitter before programming.

5)Select 9-PROGRAMMING on the display, press OK and than one of the UP or DOWN buttons.

(If the motor starts in opening, remove and re-put power supply, select on the display 5-REVERSE MOTOR. And through the UP and DOWN button put it on ON, or if you have the Jolly programmer, activate the motor exchange function. )

6)At this point the gate will start the following cycle: CLOSING M2 - CLOSING M1 - OPENING M1 - OPENING M2 - CLOSING M2 - CLOSING M1. During cycle, to store the respective stops, press UP or DOWN or START at every point of stop of the leaf.

7)The self-learning is done.

SELFLERNING OPERATION TIME WITH ENCODER / POTENTIOMETER

When an encoder is installed, it is necessary to select “On” in the 32-ENCODER menu, when the potentiometer is installed, it is necessary to select “Potentiometer” in the 32-ENCODER menu. Start programming and make sure that leaf 2 starts as first in closing. The gate will automatically execute the following cycle: CLOSING M2 - CLOSING M1 - OPENING M1 - OPENING M2 - CLOSING M2 - CLOSING M1.

Note: For stop detection sensitivity setting refer to the special menu.

Note 2: With the potentiometer you can also make the learning giving impulses as described under point 6 of the preceding paragraph.

LEARNING WITH LIMIT SWITCH (Only on version with limit switch)

When limit switches are mounted, the gate executes automatically the follwing cycle: CLOSING M2 - CLOSING M1 - OPENING M1 - OPENING M2 - CLOSING M2 - CLOSING M1.

Before starting the learning, make sure( through the test menu), that the relative limit switches of every leaf and every opening are employed.

Exe: For the M2 motor closing the limit switch M2 in closing must be employed.

27

®

English |

SWING 2 DG R2F |

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

FUNCTION LOGIC

AUTOMATIC LOGIC

A start impulse opens the gate. A second impluse during the opening will not be accepted. A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semiautomatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item 8-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

SECURITY LOGIC

A start impulse opens the gate. A second impulse during opening reverses the movement. A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semiautomatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item 8-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 1 LOGIC

The start impulse follows the OPEN-STOP-CLOSE-STOP-OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semiautomatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item 8-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 2 LOGIC

The start impulse follows the OPEN-STOP-CLOSE -OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semiautomatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item 8-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

DEAD MAN LOGIC

The gate opens as long as the START button of opening is pressed; releasing it the gate stops. The gate closes as long as the button connected to the PEDESTRIAN START is pressed; releasing it the gate stops. To execute complete opening and/or closing cycles the related pushbuttons must be constantly pressed.

2 PUSHBUTTONS LOGIC

One start opens, one pedestrian start closes. In opening the closing will not be accepted. In closing a start command reopens, a pedestrian start command (closes) will be ignored.

28

®

English |

SWING 2 DG R2F |

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

SPECIAL MENU

PRESS AT THE SAME TIME FOR 5 SECONDS TO ENTER OR TO EXIT THE SPECIAL MENU

DOWN UP

SPECIAL MENU FUNCTIONS TABLE SWING 2 DG R2F

For entering into the special menu move on one of the menu and press the UP and DOWN buttons at the same time for 5 s. For exiting the special menu press END or move on one of the menu and press the UP and DOWN buttons at the same time for 5 s.

|

MENU SP |

|

SET |

Description |

Default |

Set value |

|

|

|

|

|

|

|

26 - LEAF DELAY IN |

Off |

6 |

Setting from OFF to |

1,5 |

|

|

|

OPENING * |

6 seconds |

|

|||

|

|

|

|

|

||

27 - LEAF DELAY IN |

Off |

20 |

Setting from OFF to |

2,5 |

|

|

|

CLOSING * |

20 seconds |

|

|||

|

|

|

|

|

||

|

|

|

|

M1 opening torque |

|

|

28 - OPENING TORQ 1 * |

10 100 |

Note: with hydraulic motors |

75 |

|

||

|

|

|

|

the torque will be on 100% |

|

|

|

|

|

|

M1 closing torque |

|

|

29 - CLOSING TORQ 1 * |

10 100 |

Note: with hydraulic motors |

75 |

|

||

|

|

|

|

the torque will be on 100% |

|

|

|

|

|

|

M2 opening torque |

|

|

30 - OPENING TORQ 2 * |

10 100 |

Note: with hydraulic motors |

75 |

|

||

|

|

|

|

the torque will be on 100% |

|

|

|

|

|

|

M2 closing torque |

|

|

31 - CLOSING TORQ 2 * |

10 100 |

Note: with hydraulic motors |

75 |

|

||

|

|

|

|

the torque will be on 100% |

|

|

|

|

|

|

In ON enables the |

|

|

32 - ENCODER * |

On |

|

Encoder, in OFF |

Off |

|

|

|

|

|

|

it's disabled |

|

|

|

47 - ENCODER PAR.1 * |

xxx. |

|

Encoder impulses during operation |

||

|

|

(Motor 1). |

|

|

||

|

|

|

|

|

|

|

|

48 - ENCODER TOT.1 * |

xxx. |

|

Encoder impulses stored in programming |

||

|

|

(Motor 1). |

|

|

||

|

|

|

|

|

|

|

|

49 - ENCODER PAR.2 * |

xxx. |

|

Encoder impulses during operation |

||

|

|

(Motor 2). |

|

|

||

|

50 - ENCODER TOT.2 * |

xxx. |

|

Encoder impulses stored in programming |

||

|

|

(Motor 2). |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Enables the reading of |

|

|

32 - ENCODER * |

Potentiometer |

the potentiometer with |

Off |

|

||

|

|

|

|

LE card. |

|

|

|

|

|

|

Reports the current position |

|

|

|

|

|

|

of the potentiometer on the |

|

|

|

51 - I.PAR.M1 * |

- - - - - - - - |

leaf of motor 1. |

|

|

|

|

This parameter is useful for |

|

|

|||

|

|

|

|

seeing if the potentiometer |

|

|

|

|

|

|

is read correctly. |

|

|

|

|

|

|

Reports the impulses |

|

|

|

52 - I.AP.M1 * |

- - - - - - - - |

stored by the control unit |

|

|

|

|

when the leaf of motor 1 |

|

|

|||

|

|

|

|

is fully open. |

|

|

|

|

|

|

Reports the impulses stored |

|

|

|

53 - I.CH.M1 * |

- - - - - - - - |

by the control unit when the |

|

|

|

|

|

|

|

leaf of motor 1is fully close. |

|

|

29

®

English |

SWING 2 DG R2F |

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

|

MENU SP |

SET |

Description |

|

|

|

|

|

|

|

Reports the current position |

|

|

|

of the potentiometer on the |

|

54 - I.PAR.M2 * |

|

leaf of motor 2. |

|

- - - - - - - - |

This parameter is useful for |

|

|

|

|

seeing if the potentiometer |

|

|

|

is read correctly. |

|

|

|

Reports the impulses |

|

55 - I.AP.M2 * |

- - - - - - - - |

stored by the control unit |

|

when the leaf of motor 2 |

||

|

|

|

is fully open. |

|

|

|

Reports the impulses |

|

56 - I.CH.M2 * |

- - - - - - - - |

stored by the control unit |

|

when the leaf of motor 2 |

||

|

|

|

is fully close. |

|

|

|

In ON enables the |

32 - ENCODER * |

Off |

Encoder, in OFF |

|

|

|

|

it's disabled |

Default |

Set value |

|

|

|

|

|

|

|

|

Off

|

65 - OPENING TIME |

xxx.s |

|

Indicates the working times selflearning |

|||

|

MOTOR1 |

in opening and closing (Motor 1). |

|||||

|

|

|

|||||

|

66 - CLOSING TIME |

xxx.s |

With UP or DOWN it is possible to increase |

||||

|

MOTOR1 |

or reduce the working times. |

|

|

|||

|

|

|

|

|

|||

|

67 - OPENING TIME |

xxx.s |

Indicates the working times selflearning |

||||

|

MOTOR2 |

in opening and closing (Motor 2). |

|||||

|

|

|

|||||

|

68 - CLOSING TIME |

xxx.s |

With UP or DOWN it is possible to increase |

||||

|

MOTOR2 |

or reduce the working times. |

|

|

|||

|

|

|

|

|

|||

|

|

10% (Fast intervention) |

Adjusts the intervention time |

|

|

|

|

33 - OPENING SENSITIVITY |

99% (Slow intervention) |

of the Encoder / Potentiometer |

|

Off |

|

||

on Motor 1 in opening |

|

|

|||||

|

MOTOR1 * |

|

|

|

|

||

|

Off (Intervention excluded) |

Disabled |

|

|

|

||

|

|

|

|

|

|||

|

|

10% (Fast intervention) |

Adjusts the intervention time |

|

|

|

|

34 - CLOSING SENSITIVITY |

99% (Slow intervention) |

of the Encoder / Potentiometer |

|

Off |

|

||

|

MOTOR1 * |

|

|

on Motor 1 in closing |

|

|

|

|

Off (Intervention excluded) |

Disabled |

|

|

|

||

|

|

|

|

|

|||

|

|

10% (Fast intervention) |

Adjusts the intervention time |

|

|

|

|

35 - OPENING SENSITIVITY |

of the Encoder / Potentiometer |

|

|

|

|||

99% (Slow intervention) |

|

Off |

|

||||

|

MOTOR2 * |

on Motor 2 in opening |

|

|

|||

|

|

Off (Intervention excluded) |

Disabled |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10% (Fast intervention) |

Adjusts the intervention time |

|

|

|

|

36 - CLOSING SENSITIVITY |

99% (Slow intervention) |

of the Encoder / Potentiometer |

|

Off |

|

||

on Motor 2 in closing |

|

|

|||||

|

MOTOR2 * |

|

|

|

|

||

|

Off (Intervention excluded) |

Disabled |

|

|

|

||

|

|

|

|

|

|||

38 - POT. THRESHOLD |

|

|

Adjusts the threshold of the |

|

|

|

|

|

|

potentiometer intervention. |

|

|

|

||

|

OPENING 1 * |

|

|

|

|

|

|

|

|

|

The parameter self- |

|

|

|

|

39 - POT. THRESHOLD |

|

|

determines in learning but |

|

|

|

|

|

|

can also be adjusted later. |

|

|

|

||

|

CLOSING 1 * |

|

|

|

|

|

|

|

1 100 |

|

The lower the value, the |

|

|

|

|

40 - POT. THRESHOLD |

|

|

slower will be the response |

|

|

|

|

|

|

of the potentiometer. |

|

|

|

||

|

OPENING 2 * |

|

|

|

|

|

|

|

|

|

The parameter can be set |

|

|

|

|

|

|

|

|

|

|

|

|

41 - POT. THRESHOLD |

|

|

as maximum threshold at |

|

|

|

|

|

|

the value read on the |

|

|

|

||

|

CLOSING 2 * |

|

|

|

|

|

|

|

|

|

DEBUG VPI, VP2 menu. |

|

|

|

|

|

|

|

|

|

|

|

|

30

Loading...

Loading...