Page 1

PowerLogic™ Series 800 Power Meter

PM810, PM820, PM850, & PM870

User Guide

63230-500-225A2

03/2011

Page 2

Page 3

63230-500-225A2 PowerLogicTM Series 800 Power Meter

DANGER

WARNING

CAUTION

CAUTION

3/2011

HAZARD CATEGORIES AND SPECIAL SYMBOLS

Read these instructions carefully and look at the equipment to become familiar with the

device before trying to install, operate, service, or maintain it. The following special

messages may appear throughout this bulletin or on the equipment to warn of potential

hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an

electrical hazard exists which will result in personal injury if the instructions are not

followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, can result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, can result in minor or moderate injury.

CAUTION, used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, can result in property

damage.

NOTE: Provides additional information to clarify or simplify a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

CLASS A FCC STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense. This Class A digital apparatus complies with Canadian

ICES-003.

© 2011 Schneider Electric. All Rights Reserved.

iii

Page 4

PowerLogicTM Series 800 Power Meter 63230-500-225A2

3/2011

iv

© 2011 Schneider Electric. All Rights Reserved.

Page 5

63230-500-225A2 PowerLogicTM Series 800 Power Meter

3/2011 Contents

Contents

Chapter 1—Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Topics Not Covered In This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

What is a Power Meter? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Power Meter Hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Box Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Chapter 2—Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Chapter 3—Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Power Meter Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

How the Buttons Work - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Changing Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Menu Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Power Meter Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Power Meter Resets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Power Meter Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Chapter 4—Metering Capabilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Real-Time Readings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Power Factor Min/Max Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Power Factor Sign Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Demand Readings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Energy Readings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Energy-Per-Shift (PM810 with PM810LOG) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Power Analysis Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Chapter 5—Input/Output Capabilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Digital Inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Demand Synch Pulse Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Relay Output Operating Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Solid-state KY Pulse Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Fixed Pulse Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Calculating the Kilowatthour-Per-Pulse Value - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Analog Inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Analog Outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Chapter 6—Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Basic Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Basic Alarm Groups - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Setpoint-driven Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Priorities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Viewing Alarm Activity and History - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Types of Setpoint-controlled Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Scale Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Scaling Alarm Setpoints - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Alarm Conditions and Alarm Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Advanced Alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Advanced Alarm Groups - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Alarm Levels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Viewing Alarm Activity and History - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Alarm Conditions and Alarm Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Chapter 7—Logging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Memory Allocation for Log Files - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Alarm Log - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Maintenance Log - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Data Logs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Billing Log - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

© 2011 Schneider Electric. All Rights Reserved.

v

Page 6

TM

PowerLogic

Contents 3/2011

Series 800 Power Meter 63230-500-225A2

Chapter 8—Waveform Capture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Waveform Capture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Waveform Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

How the Power Meter Captures an Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

Channel Selection in PowerLogic Software - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

Chapter 9—Disturbance Monitoring (PM870) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -65

About Disturbance Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -65

Capabilities of the PM870 During an Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -67

Chapter 10—Maintenance and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - -69

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

Power Meter Memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

Identifying the Firmware Version, Model, and Serial Number - - - - - - - - - - - - - - - - -70

Viewing the Display in Different Languages - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

Technical Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

Appendix A—Instrument Transformer Wiring: Troubleshooting Tables - - - - - - - - 73

Using This Appendix - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -73

Section I: Common Problems for 3-Wire and 4-Wire Systems - - - - - - - - - - - - - - - -74

Section II: 3-Wire System Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -75

Section III: 4-Wire System Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - -76

Field Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -78

Appendix B—Register List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

Register List Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

About Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

How Date and Time are Stored in Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - -80

How Signed Power Factor is Stored in the Register - - - - - - - - - - - - - - - - - - - - - - - -80

Supported Modbus Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -81

Resetting Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -81

Appendix C—Using the Command Interface- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Overview of the Command Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -83

Operating Outputs from the Command Interface - - - - - - - - - - - - - - - - - - - - - - - - - -86

Using the Command Interface to Change Configuration Registers - - - - - - - - - - - - -86

Conditional Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -87

Incremental Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -88

Setting Up Individual Harmonic Calculations - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

Changing Scale Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -90

Enabling Floating-point Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

Appendix D—Advanced Power Quality Evaluations - - - - - - - - - - - - - - - - - - - - - - - 93

Power Quality Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -93

SEMI-F47/ITI (CBEMA) Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -93

EN50160:2000 Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -95

How Evaluation Results Are Reported - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -95

Possible Configurations Through Register Writes - - - - - - - - - - - - - - - - - - - - - - - - -96

Evaluation During Normal Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -96

Evaluations During Abnormal Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -97

Operation with PQ Advanced Enabled - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -99

Advanced Power Quality Evaluation System Configuration

and Status Registers [EN50160 and SEMI-F47/ITI (CBEMA)] - - - - - - - - - - - - - - - -99

EN50160 Evaluation Data Available Over a Communications Link - - - - - - - - - - - - 101

Setting Up PQ Advanced Evaluation from the Display - - - - - - - - - - - - - - - - - - - - -104

Glossary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

Terms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

Abbreviations and Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -107

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 109

vi

© 2011 Schneider Electric. All Rights Reserved.

Page 7

63230-500-225A2 PowerLogicTM Series 800 Power Meter

3/2011 Chapter 1—Introduction

Chapter 1—Introduction

This user guide explains how to operate and configure a PowerLogic™ Series 800 Power

Meter. Unless otherwise noted, the information contained in this manual refers to the

following power meters:

• Power meter with integrated display

• Power meter without a display

• Power meter with a remote display

Refer to “Power Meter Parts and Accessories” on page 5 for all models and model

numbers. For a list of supported features, see “Features” on page 7.

NOTE: The power meter units on the PM810, PM810U, and the PM810RD are functionally

equivalent.

Topics Not Covered In This Manual

Some of the power meter’s advanced features, such as on-board data logs and alarm log

files, can only be set up via the communications link using PowerLogic software. This

power meter user guide describes these advanced features but does not explain how to set

them up. For information on using these features, refer to your software’s online help or

user guide.

What is a Power Meter?

A power meter is a multifunction, digital instrumentation, data acquisition and control

device. It can replace a variety of meters, relays, transducers, and other components. This

power meter is equipped with RS485 communications for integration into any power

monitoring/control system and can be installed at multiple locations within a facility.

These are true rms meters, capable of exceptionally accurate measurement of highly

non-linear loads. A sophisticated sampling technique enables accurate measurements

through the 63rd harmonic

➀

. You can view over 50 metered values, plus minimum and

maximum data, either from the display or remotely using software. Table 1 – 1 summarizes

the readings available from the power meter.

Table 1–1: Summary of power meter instrumentation

Real-time Readings Power Analysis

• Current (per phase, residual, 3-Phase)

• Voltage (L–L, L–N, 3-Phase)

• Real Power (per phase, 3-Phase

• Reactive Power (per phase, 3-Phase

• Apparent Power (per phase, 3-Phase

• Power Factor (per phase, 3-Phase

• Frequency

• THD (current and voltage)

Energy Readings Demand Readings

• Accumulated Energy, Real

• Accumulated Energy, Reactive

• Accumulated Energy, Apparent

• Bidirectional Readings

• Reactive Energy by Quadrant

• Incremental Energy

• Conditional Energy

➀ Individual harmonics are not calculated in the PM810. The PM810 with PM810LOG, and the PM820,

calculate distortion to the 31st harmonic. The PM850 and PM870 calculate distortion to the 63rd harmonic.

• Displacement Power Factor (per phase, 3-Phase

• Fundamental Voltages (per phase)

• Fundamental Currents (per phase)

• Fundamental Real Power (per phase)

• Fundamental Reactive Power (per phase)

• Unbalance (current and voltage)

•Phase Rotation

• Current and Voltage Harmonic Magnitudes and

Angles (per phase)

• Sequence Components

• Demand Current (per phase present, 3-Phase

avg.)

• Average Power Factor (3-Phase total)

• Demand Real Power (per phase present, peak)

• Demand Reactive Power (per phase present,

peak)

• Demand Apparent Power (per phase present,

peak)

• Coincident Readings

• Predicted Power Demands

➀

© 2011 Schneider Electric. All Rights Reserved.

1

Page 8

PowerLogicTM Series 800 Power Meter 63230-500-225A2

Bottom View

Back View

Chapter 1—Introduction 3/2011

Power Meter Hardware

Power Meter With Integrated Display

Figure 1–1: Parts of the Series 800 Power Meter with integrated display

1

2

3

4

5

6

8

Table 1–2: Parts of the Series 800 Power Meter with integrated display

No. Part Description

1 Control power supply connector Connection for control power to the power meter.

2 Voltage inputs Voltage metering connections.

3 I/O connector KY pulse output/digital input connections.

4 Heartbeat LED A green flashing LED indicates the power meter is ON.

5 RS-485 port (COM1)

6 Option module connector Used to connect an option module to the power meter.

7 Current inputs Current metering connections.

8 Integrated display Visual interface to configure and operate the power meter.

The RS-485 port is used for communications with a monitoring and

control system. This port can be daisy-chained to multiple devices.

7

2

© 2011 Schneider Electric. All Rights Reserved.

Page 9

63230-500-225A2 PowerLogicTM Series 800 Power Meter

Bottom View

Back View

3/2011 Chapter 1—Introduction

Power Meter Without Display

Figure 1–2: Parts of the Series 800 Power Meter without display

3

4

2

1

5

6

Table 1–3: Parts of the Series 800 Power Meter without display

No. Part Description

1 Control power supply connector Connection for control power to the power meter.

2 Voltage inputs Voltage metering connections.

3 I/O connector KY pulse output/digital input connections.

4 Heartbeat LED A green flashing LED indicates the power meter is ON.

5 RS-485 port (COM1)

6 Option module connector Used to connect an option module to the power meter.

7 Current inputs Current metering connections.

The RS-485 port is used for communications with a monitoring and

control system. This port can be daisy-chained to multiple devices.

7

© 2011 Schneider Electric. All Rights Reserved.

3

Page 10

PowerLogicTM Series 800 Power Meter 63230-500-225A2

2

3

1

TX/RX

4 5 6 87

PM8RDA Top View

Chapter 1—Introduction 3/2011

Power Meter With Remote Display

NOTE: The remote display kit (PM8RD) is used with a power meter without a display. See

“Power Meter Without Display” on page 3 for the parts of the power meter without a display.

Figure 1–3: Parts of the remote display and the remote display adapter

Table 1–4: Parts of the remote display

No. Part Description

1 Remote display adapter (PM8RDA)

2 Cable CAB12 Connects the remote display to the remote display adapter.

3 Remote display (PM8D) Visual interface to configure and operate the power meter.

4 Communications mode button Use to select the communications mode (RS232 or RS485).

5 Communications mode LED

6 RS232/RS485 port

7 Tx/Rx Activity LED The LED flashes to indicate communications activity.

8 CAB12 port

Provides the connection between the remote display and the

power meter. Also provides an additional RS232/RS485

connection (2- or 4-wire).

When lit, the LED indicates the communications port is in RS232

mode.

This port is used for communications with a monitoring and control

system. This port can be daisy-chained to multiple devices.

Port for the CAB12 cable used to connect the remote display to

the remote display adapter.

4

© 2011 Schneider Electric. All Rights Reserved.

Page 11

63230-500-225A2 PowerLogicTM Series 800 Power Meter

3/2011 Chapter 1—Introduction

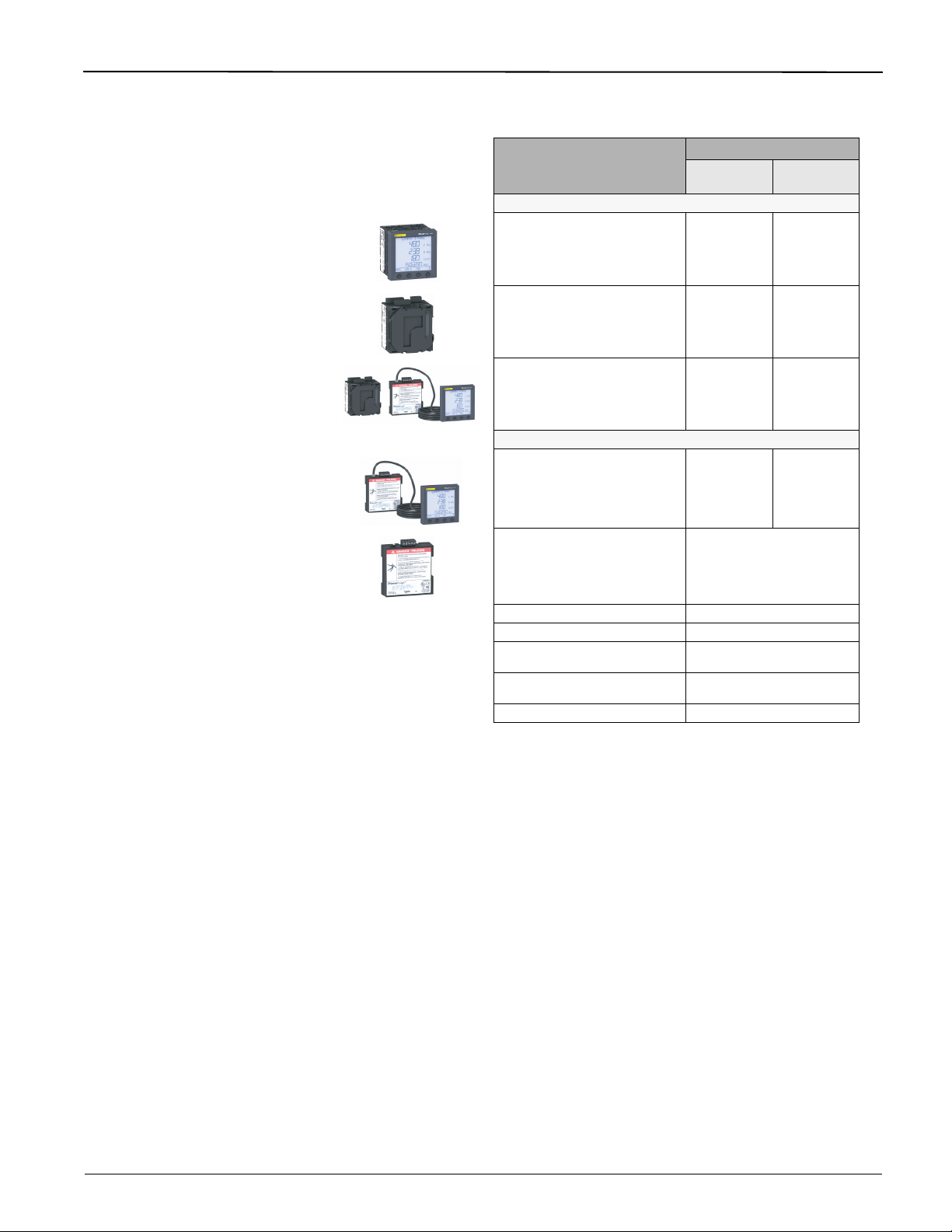

Power Meter Parts and Accessories

Table 1–5: Power Meter Parts and Accessories

Description

Power meters

Power meter with integrated display

Power meter without display

Power meter with remote display

Accessories

Remote display with remote display

adapter

Remote display adapter PM8RDA

Square D

PM810

PM820

PM850

PM870

PM810U

PM820U

PM850U

PM870U

PM810RD

PM820RD

PM850RD

PM870RD

PM8RD PM8RDMG

Model Number

Schneider

Electric

➀

➁

➂

➃

➀

➁

➂

➃

➀

➁

➂

➃

PM810MG

PM820MG

PM850MG

PM870MG

PM810UMG

PM820UMG

PM850UMG

PM870UMG

PM810RDMG

PM820RDMG

PM850RDMG

PM870RDMG

➀

➁

➂

➃

➀

➁

➂

➃

➀

➁

➂

➃

Input/Output modules PM8M22, PM8M26, PM8M2222

PM810 logging module PM810LOG

Cable (12 feet) extender kit for

displays

Retrofit gasket (for 4 in. round hole

mounting)

CM2000 retrofit mounting adapter PM8MA

➀ The power meter units for these models are identical and support the

same features (see “Features” on page 7).

➁ The power meter units for these models are identical and support the

same features (see “Features” on page 7).

➂ The power meter units for these models are identical and support the

same features (see “Features” on page 7).

➃ The power meter units for these models are identical and support the

same features (see “Features” on page 7).

RJ11EXT

PM8G

© 2011 Schneider Electric. All Rights Reserved.

5

Page 12

PowerLogicTM Series 800 Power Meter 63230-500-225A2

Chapter 1—Introduction 3/2011

Box Contents

Table 1–6: Box contents based on model

Model Description Box Contents

• Power Meter with integrated display

• Hardware kit (63230-500-16) containing:

— Two retainer clips

Power Meter with Integrated Display

Power Meter without Display

Power Meter with Remote Display

— Template

— Plug set

— Terminator MCT2W

• Power Meter installation guides (EN, FR, ES, DE)

• Power Meter specification guide

• Power Meter without display

• Hardware kit (63230-500-16) containing:

— Two retainer clips

— Template

— DIN Slide (installed at factory)

— Plug set

— Terminator MCT2W

• Power Meter installation guides (EN, FR, ES, DE)

• Power Meter specification guide

• Power Meter without display

• Remote display (PM8D)

• Remote display adapter (PM8RDA)

• Hardware kit (63230-500-16) containing:

— Two retainer clips

— Template

— DIN Slide (installed at factory)

— Plug set

— Terminator MCT2W

• Hardware kit (63230-500-96) containing:

— Communication cable (CAB12)

— Mounting screws

• Hardware kit (63230-500-163) containing:

— Com 2 RS-485 4-wire plug

— Crimp connector

• Power Meter installation guides (EN, FR, ES, DE)

• Power Meter specification guide

6

© 2011 Schneider Electric. All Rights Reserved.

Page 13

63230-500-225A2 PowerLogicTM Series 800 Power Meter

3/2011 Chapter 1—Introduction

Features

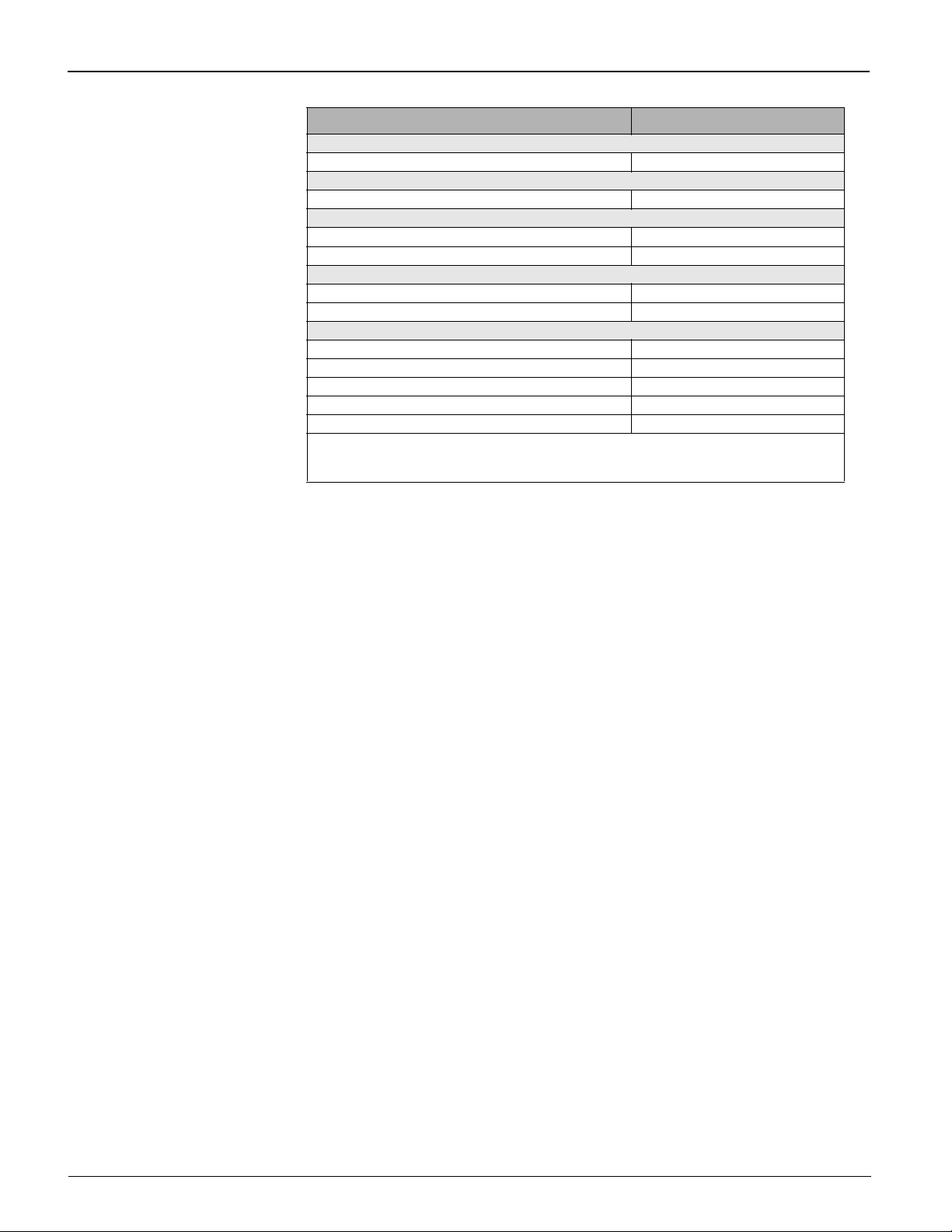

Table 1–7: Series 800 Power Meter Features

PM810 PM820 PM850 PM870

True rms metering to the 63rd harmonic (3) (3)

Accepts standard CT and PT inputs

600 volt direct connection on voltage inputs

High accuracy — 0.075% current and voltage (typical conditions)

Min/max readings of metered data

Input metering (five channels) with PM8M22, PM8M26, or PM8M2222

installed

Power quality readings — THD

Downloadable firmware

Easy setup through the integrated or remote display (password protected)

Setpoint-controlled alarm and relay functions

On-board alarm logging

Wide operating temperature range: –25° to +70°C for the power meter

unit

Communications:

On-board: one Modbus RS485 (2-wire)

PM8RD: one configurable Modbus RS232/RS485 (2- or 4-wire)

Active energy accuracy: ANSI C12.20 Class 0.2S and IEC 62053-22

Class 0.5S

Non-volatile clock (1)

On-board data logging (2) 80 KB 800 KB 800 KB

Real-time harmonic magnitudes and angles (I and V):

To the 31st harmonic

To the 63rd harmonic

Waveform capture

Standard

Advanced

EN50160 evaluations

NOTE: The PM850 performs EN50160 evaluations based on

standard alarms, while the PM870 performs EN50160 evaluations

based on disturbance alarms.

ITI (CBEMA) and SEMI-F47 evaluations

NOTE: The PM870 performs ITI (CBEMA) and SEMI-F47

evaluations based on disturbance alarms.

Current and voltage sag/swell detection and logging — — —

(1) The Time Clock in the PM810 with PM810LOG is non-volatile. However, it is volatile in the PM810.

The on-board data logging memory in the PM810 with PM810LOG is 80 KB, but it is not available in the PM810.

(2)

(3) The PM810 with PM810LOG and the PM820 monitor distortion to the 31st harmonic. Harmonic distortion is not

monitored in the PM810.

(3)

—

—

——

———

—

—

—

—

—

—

Firmware

This user guide is written to be used with firmware version 11.xx and above. See

“Identifying the Firmware Version, Model, and Serial Number” on page 70 for instructions

on how to determine the firmware version. To download the latest firmware version, follow

the steps below:

1. Using a web browser, go to http://www.Schneider-Electric.com.

2. Locate the Search box in the upper right corner of the home page.

3. In the Search box enter “PM8”.

4. In the drop-down box click on the selection “PM800 series”.

5. Locate the downloads area on the right side of the page and click on

6. Click on the applicable firmware version title (i.e. “PowerLogic Series 800 Power Meter

7. Download and run the “xxx.exe” firmware upgrade file provided.

© 2011 Schneider Electric. All Rights Reserved.

“Software/Firmware”.

Firmware version 12.100”).

7

Page 14

PowerLogicTM Series 800 Power Meter 63230-500-225A2

Chapter 1—Introduction 3/2011

8

© 2011 Schneider Electric. All Rights Reserved.

Page 15

63230-500-225A2 PowerLogicTM Series 800 Power Meter

DANGER

3/2011 Chapter 2—Safety Precautions

Chapter 2—Safety Precautions

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical

practices. For example, in the United States, see NFPA 70E.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this equipment,

disconnect all sources of electric power. Assume that all circuits are live until they

have been completely de-energized, tested, and tagged. Pay particular attention to

the design of the power system. Consider all sources of power, including the

possibility of backfeeding.

• Turn off all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Beware of potential hazards and carefully inspect the work area for tools and

objects that may have been left inside the equipment.

• Use caution while removing or installing panels so that they do not extend into the

energized bus; avoid handling the panels, which could cause personal injury.

• The successful operation of this equipment depends upon proper handling,

installation, and operation. Neglecting fundamental installation requirements may

lead to personal injury as well as damage to electrical equipment or other property.

• Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which

the power meter is installed, disconnect all input and output wires to the power

meter. High voltage testing may damage electronic components contained in the

power meter.

• Always use grounded external CTs for current inputs.

Failure to follow these instructions will result in death or serious injury.

© 2011 Schneider Electric. All Rights Reserved.

9

Page 16

TM

PowerLogic

Series 800 Power Meter 63230-500-225A2

Chapter 2—Safety Precautions 3/2011

10

© 2011 Schneider Electric. All Rights Reserved.

Page 17

63230-500-225A2 PowerLogicTM Series 800 Power Meter

ABCD

E

G

HIK

L

M

J

F

PLSD110097

3/2011 Chapter 3—Operation

Chapter 3—Operation

This section explains the features of the power meter display and the power meter setup

procedures using this display. For a list of all power meter models containing an integrated

display or a remote display, see Table 1 –5 on page 5.

Power Meter Display

The power meter is equipped with a large, back-lit liquid crystal display (LCD). It can

display up to five lines of information plus a sixth row of menu options. Figure 3–1 shows

the different parts of the power meter display.

Figure 3– 1: Power Meter Display

A. Type of measurement

B. Screen title

C. Alarm indicator

D. Maintenance icon

E. Bar chart (%)

F. Units (A, V, etc.)

G. Display more menu items

H. Menu item

I. Selected menu indicator

J. Button

K. Return to previous menu

L. Values

M. Phase

How the Buttons Work

The buttons are used to select menu items, display more menu items in a menu list, and

return to previous menus. A menu item appears over one of the four buttons. Pressing a

button selects the menu item and displays the menu item’s screen. When you have

reached the highest menu level, a black triangle appears beneath the selected menu item.

To return to the previous menu level, press the button below

items in a menu list, press the button below

NOTE: Each time you read “press” in this manual, press and release the appropriate button

beneath the menu item. For example, if you are asked to “Press PHASE,” you would press

the button below the PHASE menu item.

###: (see Figure 3 – 1).

1;. To scroll through the menu

Changing Values

When a value is selected, it flashes to indicate that it can be modified. A value is changed

by doing the following:

Menu Overview

• Press + (plus) or - (minus) to change numbers or scroll through available options.

• If you are entering more than a single-digit number, press <-- to move to the next

higher numeric position.

• To save your changes and move to the next field, press OK.

Figure 3–2 on page 12, shows the first two levels of the power meter menu. Level 1

contains all of the top level menu items. Selecting a Level 1 menu item takes you to the

corresponding Level 2 menu items. Additional menu levels may be provided, depending on

the specific meter features and options.

NOTE: Press ###: to scroll through all menu items on a given level.

© 2011 Schneider Electric. All Rights Reserved.

11

Page 18

TM

PHASE I - DMD UNBAL

PWR (PQS) PHASE P - DMD

TRUE DISPL

V L-L (U) V L-N (V) I

MINMX AMPS (I) VOLTS (U-V) UNBAL PWR (PQS) PF HZ (F) THD V THD I

ACTIV HIST

DATE TIME LANG COMMS (COM) METER ALARM I/O PASSW TIMER ADVAN

AMPS (I)

VOLTS (U-V)

PWR (PQS)

ENERG (E)

PF

HZ (F)

THD

MINMX

ALARM

I/O

RESET

SETUP

DIAG

HARM

METER ENERG (E) DMD MINMX MODE TIMER

CONTR

MAINT

TIMER

PM8M2222

COMM1

COMM2

PM8RD

D OUT D IN A OUT A IN

METER REG CLOCK

1

3

2

D OUT [Digital KY Out]

D IN [Digital In]

A OUT [Analog Out]

A IN [Analog In]

PM8M2222

PM8M2222, PM8M26, and PM8M22

4

4

4

1

V L-L (U) V L-N (V) I

V L-L (U) V L-N (V)

Wh VAh VARh INC

LEVEL 1

LEVEL 2

PowerLogic

Series 800 Power Meter 63230-500-225A2

Chapter 3—Operation 3/2011

Figure 3–2: Abbreviated List of PM800 Menu Items in IEEE (IEC) Mode

© 2011 Schneider Electric. All Rights Reserved.

➀ Available on the PM810 only when an optional Power Meter Logging Module (PM810LOG) is installed. Available on all other PM800 Series models.

➁ Available with some models.

➂ Both IEC and IEEE modes are available. Depending on the mode selected, menu labels will be different. See “Display Mode Change” on page 24 to select the

desired mode.

➃ The PM810 has a volatile clock. The PM810 with an optional Power Meter Logging Module (PM810LOG), and all other PM800 Series models, have a non-volatile

clock.

12

Page 19

63230-500-225A2 PowerLogicTM Series 800 Power Meter

!

!

""!

PLSD110218

3/2011 Chapter 3—Operation

Power Meter Setup

Power meter setup is typically performed by using the meter’s front panel display. To

configure a power meter without a display, you will need a means of communication

between the power meter and your computer. Additionally, you will need to install

PowerLogic Meter Configuration Software or PowerLogic ION Setup Software on your

computer. These can be downloaded from the Schneider’s www.Schneider-Electric.com

website.

Power meter setup is performed through the meter’s maintenance (MAINT) option. Refer to

Figure 3–2 on page 12. Setup features may be programmed individually or in any order. To

access the Setup features, follow these steps:

SETUP MODE Access

1. Press ###: to scroll through the Level 1 menu until you see MAINT.

2. Press MAINT.

3. Press SETUP.

4. Enter your password, then press OK. The SETUP MODE screen will be displayed.

NOTE: The default password is 0000.

5. Press

After programming a feature, you may continue through the remaining features by returning

to the SETUP MODE screen and pressing

Once you have selected the correct options for each setup parameter, press

SAVE CHANGES? prompt appears, then press YES. The meter will reset, briefly display

the meter info screen, then automatically return to the main screen.

Use the menu provided in Figure 3– 2 on page 12 to locate the setup features described in

the following topics:

###: to scroll through the setup features and select the one to be programmed.

###: to scroll to additional features.

1; until the

DATE Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press DATE.

4. Enter the MONTH number.

5. Press OK.

6. Enter the DAY number.

7. Press OK.

8. Enter the YEAR number.

9. Press OK.

10. Select how the date is displayed: M/D/Y,

11. Press OK to return to the SETUP MODE

12. Press

13. To verify the new settings, press MAINT >

NOTE: The clock in the PM810 is volatile. Each time the meter resets, the PM810 returns

to the default clock date/time of 12:00 AM 01-01-1980. See “Date and Time Settings” on

page 69 for more information. All other PM800 Series meters have a non-volatile clock

which maintains the current date and time when the meter is reset.

###: until DATE is visible.

Y/M/D, or D/M/Y).

screen.

1; to return to the main screen.

DIAG > CLOCK.

© 2011 Schneider Electric. All Rights Reserved.

13

Page 20

TM

#$

%&

'()

PLSD110227

PLSD110103

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

TIME Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press TIME.

4. Enter the HOUR.

5. Press OK.

6. Enter the MIN (minutes).

7. Press OK.

8. Enter the SEC (seconds).

9. Press OK.

10. Select how the time is displayed: 24H or

11. Press OK to return to the SETUP MODE

12. Press

13. To verify the new settings, press MAINT >

NOTE: The clock in the PM810 is volatile. Each time the meter resets, the PM810 returns

to the default clock date/time of 12:00 AM 01-01-1980. See “Date and Time Settings” on

page 69 for more information. All other PM800 Series meters have a non-volatile clock,

which maintains the current date and time when the meter is reset.

###: until TIME is visible.

AM/PM.

screen.

1; to return to the main screen.

DIAG > CLOCK.

LANG (Language) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press LANG.

4. Select the language: ENGL (English), FREN

5. Press OK.

6. At the SETUP MODE screen, continue

7. Press YES to save the changes.

###: until LANG is visible.

(French), SPAN (Spanish), GERMN (German),

or RUSSN (Russian).

programming additional setup features or

1; until you are asked to save changes.

press

*++

+*

14

© 2011 Schneider Electric. All Rights Reserved.

Page 21

63230-500-225A2 PowerLogicTM Series 800 Power Meter

,-(

.

PLSD110100

PLSD110106

3/2011 Chapter 3—Operation

COMMS (Communications) Setup

NOTE: If you are using PowerLogic software to set up the power meter, it is recommended

you set up the communications features first.

Refer to Table 3-1 for the meter’s default settings.

Table 3– 1: Communications Default Settings

Communications Setting Default

Protocol MB.RTU (Modbus RTU)

Address 1

Baud Rate 9600

Parity Even

The same procedure is used to program the settings for the COMMS, COMM 1, and

COMM 2 options.

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press COMMS (communications).

4. Select the required protocol: MB.RTU (Modbus

5. Press OK.

6. Enter the ADDR (power meter address).

7. Press OK.

8. Select the BAUD (baud rate).

9. Press OK.

10. Select the parity: EVEN, ODD, or NONE.

11. Press OK.

12. At the SETUP MODE screen, continue

13. Press YES to save the changes.

###: until COMMS (communications)

is visible.

RTU), Jbus, MB. A.8 (Modbus ASCII 8 bits),

MB. A.7 (Modbus ASCII 7 bits).

programming additional setup features or

1; until you are asked to save changes.

press

METER Setup

© 2011 Schneider Electric. All Rights Reserved.

CTs Setup

This feature allows the user to configure the CTs, PTs, system frequency, and system

wiring method.

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press METER.

4. Press CT.

5. Enter the PRIM (CT primary) number.

6. Press OK.

7. Enter the SEC. (CT secondary) number.

8. Press OK.

9. At the SETUP MODE screen, continue

10. Press YES to save the changes.

###: until METER is visible.

programming additional setup features or

1; until you are asked to save changes.

press

15

Page 22

TM

*

/

PLSD110112

PLSD110109

PLSD110324

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

PTs Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press METER.

4. Press PT.

5. Enter the SCALE value: x1, x10, x100, NO PT

6. Press OK.

7. Enter the PRIM (primary) value.

8. Press OK.

9. Enter the SEC. (secondary) value.

10. Press OK.

11. At the SETUP MODE screen, continue

12. Press YES to save the changes.

###: until METER is visible.

(for direct connect).

programming additional setup features or

1; until you are asked to save changes.

press

HZ (System Frequency) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press METER.

4. Press

5. Press HZ.

6. Select the frequency.

7. Press OK.

8. At the SETUP MODE screen, continue

9. Press YES to save the changes.

###: until METER is visible.

###: until HZ is visible.

programming additional setup features or

1; until you are asked to save changes.

press

!0)#1(#$2

3

04

SYS (System Type) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press METER.

4. Press ###: until SYS is visible.

5. Press SYS.

6. Select your system (SYS) type (D) based on

7. Press OK.

8. At the SETUP MODE screen, continue

9. Press YES to save the changes.

###: until METER is visible.

the number of wires (A), the number of CTs (B),

and the number of voltage connections (either

direct connect or with PT) (C).

programming additional setup features or

1; until you are asked to save changes.

press

5!

A

B

C

D

6

!

16

© 2011 Schneider Electric. All Rights Reserved.

Page 23

63230-500-225A2 PowerLogicTM Series 800 Power Meter

..

+

*

*

PLSD110212

PLSD110311

3/2011 Chapter 3—Operation

ALARM (Alarms) Setup

There is an extensive list of meter error conditions

which can be monitored and cause an alarm.

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press ALARM.

4. Press

5. Press EDIT.

6. Select to ENABL (enable) or DISAB (disable)

7. Press OK.

8. Select the PR (priority): NONE, HIGH, MED, or

9. Press OK.

10. Select how the alarm values are displayed:

11. Enter the PU VALUE (pick-up value).

12. Press OK.

13. Enter the PU DELAY (pick-up delay).

14. Press OK.

15. Enter the DO VALUE (drop-out value).

16. Press OK.

17. Enter the DO DELAY (drop-out delay).

18. Press OK.

19. Press

20. Press

21. At the SETUP MODE screen, continue

22. Press YES to save the changes.

###: until ALARM is visible.

<- or -> to select the alarm option you

want to edit.

the alarm.

LOW.

ABSOL (absolute value) or RELAT (percentage

relative to the running average).

1; to return to the alarm summary

screen.

1; to return to the SETUP MODE screen.

programming additional setup features or

1; until you are asked to save changes.

press

..

+

*!

+

*!

© 2011 Schneider Electric. All Rights Reserved.

17

Page 24

TM

PLSD110221

PLSD110224

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

I/O (Input/Output) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press I/O.

4. Press D OUT for digital output or D IN for digital

5. Press EDIT.

6. Select the I/O mode based on the I/O type and

7. Depending on the mode selected, the power

8. Press OK.

9. Select EXT. (externally controlled via

10. Press

11. At the SETUP MODE screen, continue

12. Press YES to save the changes.

###: until I/O is visible.

input, or press A OUT for analog output or A IN

for analog input. Use the ###: button to scroll

through these selections.

NOTE: Analog inputs and outputs are available

only with the PM8222 option module.

the user selected mode: NORM., LATCH,

TIMED, PULSE, or END OF.

meter will prompt you to enter the pulse weight,

timer, and control.

communications) or ALARM (controlled by an

alarm).

1; to return to the SETUP MODE screen.

programming additional setup features or

1; until you are asked to save changes.

press

!

*

/

PASSW (Password) Setup

1. Perform steps 1 through 5 of the SETUP MODE

2. Press

3. Press PASSW.

4. Enter the SETUP password.

5. Press OK.

6. Enter the DIAG (diagnostics) password.

7. Press OK.

8. Enter the ENERG (energy reset) password.

9. Press OK.

10. Enter the MN/MX (minimum/maximum reset)

11. Press OK.

12. At the SETUP MODE screen, continue

13. Press YES to save the changes.

Access procedure on page 11.

###: until PASSW (password) is visible.

password.

programming additional setup features or

1; until you are asked to save changes.

press

6

+

+

"/

18

© 2011 Schneider Electric. All Rights Reserved.

Page 25

63230-500-225A2 PowerLogicTM Series 800 Power Meter

.+

5

PLSD110257

PLSD110203

3/2011 Chapter 3—Operation

TIMER (Operating Time Threshold) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until TIMER is visible.

3. Press TIMER.

4. Enter the 3-phase current average.

NOTE: The power meter begins counting the

operating time whenever the readings are equal

to or above the average.

5. Press OK.

6. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

7. Press YES to save the changes.

ADVAN (Advanced) Power Meter Setup Features

The Advanced Feature set contains several items which need to be programmed. To

access these features, follow these steps:

After programming a feature, you may continue through the remaining features by returning

to the SETUP MODE screen and pressing ###: to scroll to additional features.

Once you have selected the correct options for each setup parameter, press

SAVE CHANGES? prompt appears, then press YES. The meter will reset, briefly display

the meter info screen, then automatically return to the main screen.

1;

until the

ROT (Phase Rotation) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press ADVAN.

4. Press ###: until ROT (phase rotation) is visible.

5. Press ROT.

6. Select the phase rotation: ABC or CBA.

7. Press OK.

8. At the SETUP MODE screen, continue

9. Press YES to save the changes.

###: until ADVAN (advanced setup) is

visible.

programming additional setup features or

1; until you are asked to save changes.

press

'7-78'

© 2011 Schneider Electric. All Rights Reserved.

19

Page 26

TM

+!

.*

PLSD110197

PLSD110206

PLSD110209

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

E-INC (Incremental Energy Interval) Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until ADVAN (advanced setup) is

visible.

3. Press ADVAN.

4. Press

###: until E-INC (incremental energy) is

visible.

5. Press E-INC.

6. Enter the INTVL (interval). Range is 00 to 1440.

7. Press OK.

8. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

9. Press YES to save the changes.

THD Calculation Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until ADVAN (advanced setup) is

visible.

3. Press ADVAN.

4. Press

###: until THD is visible.

5. Press THD.

6. Select the THD calculation: FUND or RMS.

7. Press OK.

8. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

9. Press YES to save the changes.

-9$(9-78'

:(

VAR/PF Convention Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until ADVAN (advanced setup) is

visible.

3. Press ADVAN.

4. Press

###: until PF is visible.

5. Press PF.

6. Select the Var/PF convention: IEEE or IEC.

7. Press OK.

8. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

9. Press YES to save the changes.

0';#78'

8###

20

© 2011 Schneider Electric. All Rights Reserved.

Page 27

63230-500-225A2 PowerLogicTM Series 800 Power Meter

PLSD110200

* *+>

PLSD110215

PLSD110231

3/2011 Chapter 3—Operation

Lock Resets Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until ADVAN (advanced setup) is

visible.

9'$<#=#7=>

3. Press ADVAN.

4. Press

###: until LOCK is visible.

5. Press LOCK.

6. Select Y (yes) or N (no) to enable or disable

resets for PK.DMD, ENERG, MN/MX, and

METER.

!

+

?"@A

#7#)

7. Press OK.

8. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

9. Press YES to save the changes.

Alarm Backlight Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press ADVAN.

4. Press ###: until BLINK is visible.

5. Press BLINK.

6. Enter ON or OFF.

7. Press OK.

8. At the SETUP MODE screen, continue

9. Press YES to save the changes.

###: until ADVAN (advanced setup) is

visible.

programming additional setup features or

1; until you are asked to save changes.

press

Bar Graph Setup

© 2011 Schneider Electric. All Rights Reserved.

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

###: until ADVAN (advanced setup) is

visible.

3. Press ADVAN.

4. Press

###: until BARGR is visible.

5. Press BARGR.

6. Press AMPS or PWR.

7. Select AUTO or MAN. If MAN is selected, press

OK and enter the %CT*PT and KW (for PWR)

or the %CT and A (for AMPS).

8. Press OK.

9. At the SETUP MODE screen, continue

programming additional setup features or

1; until you are asked to save changes.

press

10. Press YES to save the changes.

-)B)-C=$-9#

6

21

Page 28

TM

'D#)0+

.*

*

PLSD110232

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

PQ Advanced Evaluation Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press ADVAN.

4. Press

5. Press PQADV.

6. Select ON.

7. Press OK.

8. Change the nominal voltage (NOM V) value if

9. Press OK to return to the SETUP MODE

10. At the SETUP MODE screen, continue

11. Press YES to save your changes and reset the

###: until ADVAN (advanced setup) is

visible.

###: until PQADV is visible.

desired (the default is 230).

screen.

programming additional setup features or

1; until you are asked to save changes.

press

power meter.

4;-

.

Power Demand Configuration Setup

1. Perform steps 1 through 5 of the SETUP MODE

Access procedure on page 11.

2. Press

3. Press ADVAN.

4. Press ###: until DMD is visible.

5. Press DMD (P-DMD, I-DMD).

6. Select the demand configuration. Choices are

7. Press OK.

8. Enter the INTVL (interval) and press OK.

9. Enter the SUB-I (sub-interval) and press OK.

10. At the SETUP MODE screen, continue

11. Press YES to save the changes.

###: until ADVAN (advanced setup) is

visible.

COMMS, RCOMM, CLOCK, RCLCK, IENGY,

THERM, SLIDE, BLOCK, RBLCK, INPUT, and

RINPUT.

programming additional setup features or

1; until you are asked to save changes.

press

22

© 2011 Schneider Electric. All Rights Reserved.

Page 29

63230-500-225A2 PowerLogicTM Series 800 Power Meter

>

!

PLSD110285

+!>

!

<.E

<.E

<6E

PLSD110280

3/2011 Chapter 3—Operation

Power Meter Resets

The Power Meter Resets Feature set contains several items. After resetting a feature, you

may continue through the remaining features by returning to the RESET MODE screen and

pressing

press 1; until the display returns to the main screen.

Initialize the Power Meter

Initializing the power meter resets the energy

readings, minimum/maximum values, and

operating times. To initialize the power meter,

follow these steps:

1. Press ###: to scroll through the Level 1 menu

2. Press MAINT.

3. Press RESET.

4. Press

5. Press METER.

6. Enter the password (the default is 0000).

7. Press YES to initialize the power meter and to

8. At the RESET MODE screen, continue

NOTE: We recommend initializing the power meter

after you make changes to any of the following:

CTs, PTs, frequency, or system type.

###: to scroll to additional features. Once you have reset the specific features,

until you see MAINT.

###: until METER is visible.

return to the RESET MODE screen.

resetting additional features or press

you return to the main screen.

1; until

Accumulated Energy Readings Reset

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press RESET.

4. Press

5. Press ENERG.

6. Enter the password (the default is 0000).

7. Press YES to reset the accumulated energy

###: until ENERG is visible.

readings and to return to the RESET MODE

screen.

© 2011 Schneider Electric. All Rights Reserved.

23

Page 30

TM

PLSD110281

PLSD110282

0*>

4

PLSD110283

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

Accumulated Demand Readings Reset

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press RESET.

4. Press

5. Press DMD.

6. Enter the password (the default is 0000).

7. Press YES to reset the accumulated demand

###: until DMD is visible.

readings and to return to the RESET MODE

screen.

>

<6F<

<

<

!

<.F

Minimum/Maximum Values Reset

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press RESET.

4. Press

5. Press MINMX.

6. Enter the password (the default is 0000).

7. Press YES to reset the minimum/maximum

###: until MINMX is visible.

values and to return to the RESET MODE

screen.

"/>

!

Display Mode Change

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press RESET.

4. Press

5. Press MODE.

6. Press IEEE (default for Square D branded

NOTE: Resetting the mode changes the menu

labels, power factor conventions, and THD

calculations to match the standard mode selected.

To customize the mode changes, see the register

list.

###: until MODE is visible.

power meters) or IEC (default for Schneider

Electric branded power meters) depending on

the operating mode you want to use.

24

© 2011 Schneider Electric. All Rights Reserved.

Page 31

63230-500-225A2 PowerLogicTM Series 800 Power Meter

PLSD110284

*

+ *

PLSD110191

3/2011 Chapter 3—Operation

Accumulated Operating Time Reset

Power Meter Diagnostics

1. Press

2. Press MAINT.

3. Press RESET.

4. Press

5. Press TIMER.

6. Enter the password (the default is 0000).

7. Press YES to reset the accumulated operating

To view the power meter’s model, firmware version, serial number, read and write registers,

or check the health status, you must access the HEALTH STATUS screen.

After viewing a feature, you may continue through the remaining features by returning to

the HEALTH STATUS screen and selecting one of the other options.

Once you have viewed the specific features, press

screen.

###: to scroll through the Level 1 menu

until you see MAINT.

###: until TIMER is visible.

time and to return to the RESET MODE screen.

NOTE: The accumulated days, hours, and

minutes of operation are reset to zero when you

press YES.

>

!

1;

until the display returns to the main

!

HEALTH STATUS screen

NOTE: The wrench icon and the health status code

display when a health problem is detected. For

code 1, set up the Date/Time (see “DATE Setup”

and “TIME Setup” on pages 11 and 12). For other

codes, contact technical support.

© 2011 Schneider Electric. All Rights Reserved.

25

Page 32

TM

0

G

*

.

.

PLSD110094d

PLSD110194

PLSD110327

PowerLogic

Chapter 3—Operation 3/2011

Series 800 Power Meter 63230-500-225A2

View the Meter Information

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press DIAG (diagnostics) to open the HEALTH

STATUS screen.

4. On the HEALTH STATUS screen, press

METER (meter information).

5. View the meter information.

6. Press

7. Press

NOTE: The wrench icon and the health status code

display when a health problem is detected. For

code 1, set up the Date/Time (see “DATE Setup”

and “TIME Setup” on pages 11 and 12). For other

codes, contact technical support.

###: to view more meter information.

1; to return to the HEALTH STATUS

screen.

Read and Write Registers

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press DIAG (diagnostics) to open the HEALTH

STATUS screen.

4. On the HEALTH STATUS screen, Press REG

(register).

5. Enter the password (the default is 0000).

6. Enter the REG. (register) number that contains

the data you want to monitor.

The register content will be displayed in both

HEX (hexadecimal) and DEC (decimal) values.

7. Press

NOTE: For more information about using registers,

see Appendix C—Using the Command Interface

on page 83.

1; to return to the HEALTH STATUS

screen.

"6+

+

/

26

View the Meter Date and TIme

1. Press ###: to scroll through the Level 1 menu

until you see MAINT.

2. Press MAINT.

3. Press DIAG (diagnostics) to open the HEALTH

STATUS screen.

4. On the HEALTH STATUS screen, press

CLOCK (current date and time).

5. View the date and time.

6. Press

1; to return to the HEALTH STATUS

screen.

© 2011 Schneider Electric. All Rights Reserved.

H

.

.

G

Page 33

63230-500-225A2 PowerLogicTM Series 800 Power Meter

3/2011 Chapter 4—Metering Capabilities

Chapter 4—Metering Capabilities

Real-Time Readings

The power meter measures currents and voltages, and reports in real time the rms values

for all three phases and neutral. In addition, the power meter calculates power factor, real

power, reactive power, and more.

Table 4–1 lists some of the real-time readings that are updated every second along with

their reportable ranges.

Table 4–1: One-second, Real-time Readings

Real-time Readings Reportable Range

Current

Per-Phase

Neutral

3-Phase Average

% Unbalance

Voltage

Line-to-Line, Per-Phase

Line-to-Line, 3-Phase Average

Line-to-Neutral, Per-Phase

Line-to-Neutral, 3-Phase Average

% Unbalance

Real Power

Per-Phase

3-Phase Total

Reactive Power

Per-Phase

3-Phase Total

Apparent Power

Per-Phase

3-Phase Total

Power Factor (True)

Per-Phase

3-Phase Total

Power Factor (Displacement)

Per-Phase

3-Phase Total

Frequency

45–65 Hz

350–450 Hz

0 to 32,767 A

0 to 32,767 A

0 to 32,767 A

0 to 100.0%

0 to 1,200 kV

0 to 1,200 kV

0 to 1,200 kV

0 to 1,200 kV

0 to 100.0%

0 to ± 3,276.70 MW

0 to ± 3,276.70 MW

0 to ± 3,276.70 MVAR

0 to ± 3,276.70 MVAR

0 to ± 3,276.70 MVA

0 to ± 3,276.70 MVA

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

23.00 to 67.00 Hz

350.00 to 450.00 Hz

© 2011 Schneider Electric. All Rights Reserved.

27

Page 34

TM

PowerLogic

Chapter 4—Metering Capabilities 3/2011

Series 800 Power Meter 63230-500-225A2

Min/Max Values for Real-time Readings

When certain one-second real-time readings reach their highest or lowest value, the power

meter saves the values in its non-volatile memory. These values are called the minimum

and maximum (min/max) values.

The power meter stores the min/max values for the current month and previous month.

After the end of each month, the power meter moves the current month’s min/max values

into the previous month’s register space and resets the current month’s min/max values.

The current month’s min/max values can be reset manually at any time using the power

meter display or PowerLogic software. After the min/max values are reset, the power meter

records the date and time. The real-time readings evaluated are:

• Min/Max Voltage L-L • Min/Max Reactive Power Total

• Min/Max Voltage L-N • Min/Max Apparent Power Total

• Min/Max Current • Min/Max THD/thd Voltage L-L

• Min/Max Voltage L-L, Unbalance • Min/Max THD/thd Voltage L-N

• Min/Max Voltage L-N, Unbalance • Min/Max THD/thd Current

• Min/Max Total True Power Factor • Min/Max Frequency

• Min/Max Total Displacement Power

Factor

• Min/Max Real Power Total • Min/Max Current, Neutral

NOTE: Min/Max values for Vng and In are not available from the display. Use the display to

read registers (see “Read and Write Registers” on page 26) or use PowerLogic software.

For each min/max value listed above, the power meter records the following attributes:

• Date/Time of minimum value • Date/Time of maximum value

• Minimum value • Maximum value

• Phase of recorded minimum value • Phase of recorded maximum value

• Min/Max Voltage N-ground

(see the note below)

(see the note below)

NOTE: Phase of recorded min/max only applies to multi-phase quantities.

NOTE: There are two ways to view the min/max values. 1- Use the power meter display to

view the min/max values since the meter was last reset. 2- Use PowerLogic software to

view a table with the instantaneous min/max values for the current and previous months.

Power Factor Min/Max Conventions

All running min/max values, except for power factor, are arithmetic minimum and maximum

values. For example, the minimum phase A-B voltage is the lowest value in the range 0 to

1200 kV that has occurred since the min/max values were last reset. In contrast, because

the power factor’s midpoint is unity (equal to one), the power factor min/max values are not

true arithmetic minimums and maximums. Instead, the minimum value represents the

measurement closest to -0 on a continuous scale for all real-time readings -0 to 1.00 to +0.

The maximum value is the measurement closest to +0 on the same scale.

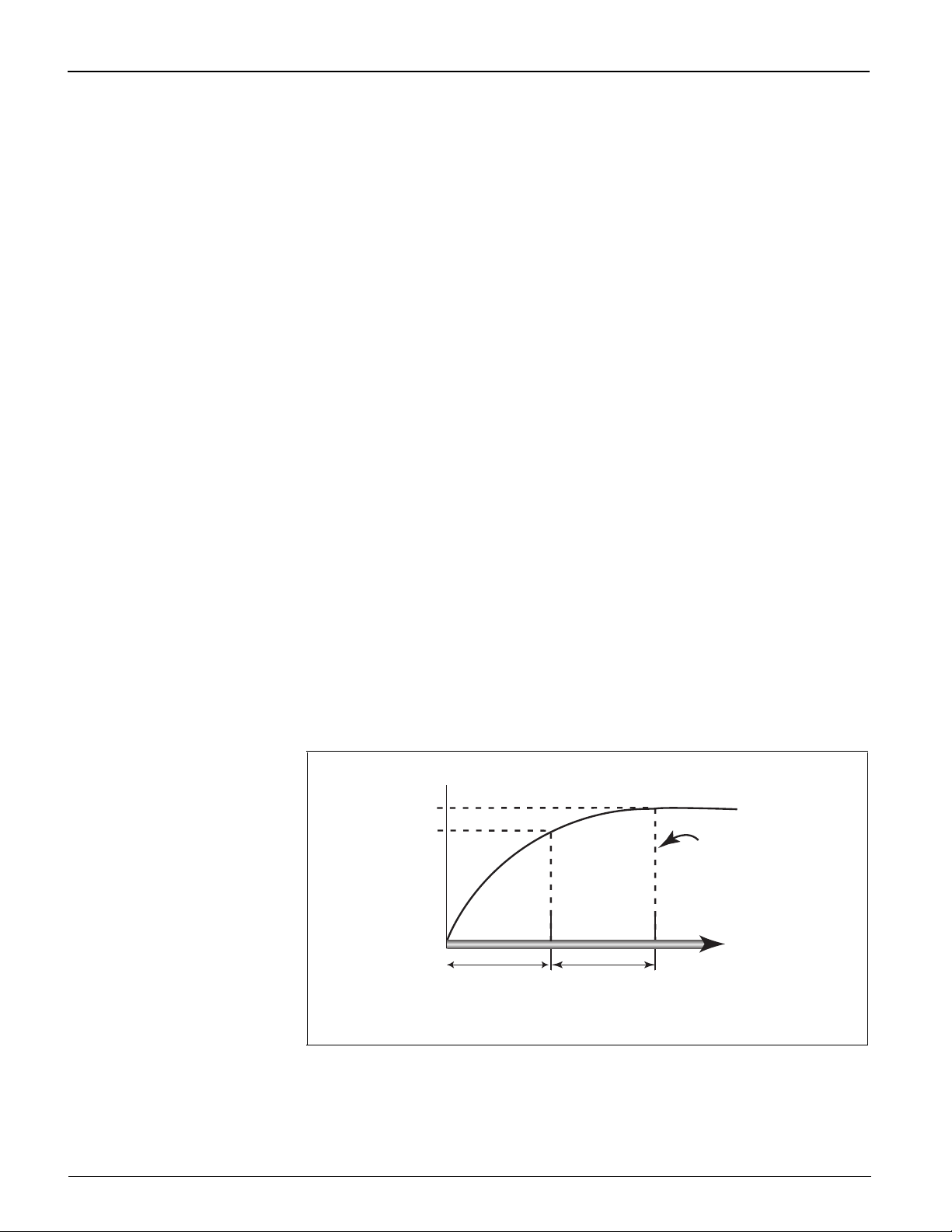

Figure 4–1 shows the min/max values in a typical environment in which a positive power

flow is assumed. In the figure, the minimum power factor is -0.7 (lagging) and the maximum

is 0.8 (leading). Note that the minimum power factor need not be lagging, and the maximum

power factor need not be leading. For example, if the power factor values ranged from

-0.75 to -0.95, then the minimum power factor would be -0.75 (lagging) and the maximum

power factor would be -0.95 (lagging). Both would be negative. Likewise, if the power factor

ranged from +0.9 to +0.95, the minimum would be +0.95 (leading) and the maximum would

be +0.90 (leading). Both would be positive in this case.

28

© 2011 Schneider Electric. All Rights Reserved.

Page 35

63230-500-225A2 PowerLogicTM Series 800 Power Meter

1.00

.4

.4

.6

.8

.6

.8

+0

.2

-0

.2

Minimum

Power Factor

-.7 (lagging)

Range of Power

Factor Value

Unity

Maximum

Power Factor

.8 (leading)

Lead

(+)

Lag

(–)

NOTE: Assumes a positive power flow

Real

Power

In

watts negative (–)

vars positive (+)

power factor (–)

watts positive (+)

vars positive (+)

power factor (+)

watts negative (–)

vars negative (–)

power factor (–)

watts positive (+)

vars negative (–)

power factor (+)

IEC Power Factor Sign Convention

Reverse

Power Flow

Normal

Power Flow

Reactive

Power In

Quadrant

2

Quadrant

1

Quadrant

3

Quadrant

4

watts negative (–)

vars positive (+)

power factor (+)

watts positive (+)

vars positive (+)

power factor (–)

watts negative (–)

vars negative (–)

power factor (–)

watts positive (+)

vars negative (–)

power factor (+)

Reactive

Power In

Real

Power

In

IEEE Power Factor Sign Convention

Reverse

Power Flow

Normal

Power Flow

Quadrant

2

Quadrant

1

Quadrant

3

Quadrant

4

)(#0

)*

*

I

I

I

I

The power

factor sign is

visible next to

the power

factor reading.

3/2011 Chapter 4—Metering Capabilities

Figure 4–1: Power factor min/max example

An alternate power factor storage method is also available for use with analog outputs and

trending. See “Using the Command Interface” on page 83 for the applicable registers.

Power Factor Sign Conventions

The power meter can be set to one of two power factor sign conventions: IEEE or IEC. The

Series 800 Power Meter defaults to the IEEE power factor sign convention. Figure 4– 2

illustrates the two sign conventions. For instructions on changing the power factor sign

convention, refer to “ADVAN (Advanced) Power Meter Setup Features” on page 19.

© 2011 Schneider Electric. All Rights Reserved.

Figure 4–2: Power factor sign convention

Figure 4–3: Power Factor Display Example

29

Page 36

TM

PowerLogic

Series 800 Power Meter 63230-500-225A2

Chapter 4—Metering Capabilities 3/2011

Demand Readings

The power meter provides a variety of demand readings, including coincident readings and

predicted demands. Table 4–2 lists the available demand readings and their reportable

ranges.

Table 4–2: Demand Readings

Demand Readings Reportable Range

Demand Current, Per-Phase, 3Ø Average, Neutral

Last Complete Interval

Peak

Average Power Factor (True), 3Ø Total

Last Complete Interval

Coincident with kW Peak

Coincident with kVAR Peak

Coincident with kVA Peak

Demand Real Power, 3Ø Total

Last Complete Interval

Predicted

Peak

Coincident kVA Demand

Coincident kVAR Demand

Demand Reactive Power, 3Ø Total

Last Complete Interval

Predicted

Peak

Coincident kVA Demand

Coincident kW Demand

Demand Apparent Power, 3Ø Total

Last Complete Interval

Predicted

Peak

Coincident kW Demand

Coincident kVAR Demand

0 to 32,767 A

0 to 32,767 A

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

–0.002 to 1.000 to +0.002

0 to ± 3276.70 MW

0 to ± 3276.70 MW

0 to ± 3276.70 MW

0 to ± 3276.70 MVA

0 to ± 3276.70 MVAR

0 to ± 3276.70 MVAR

0 to ± 3276.70 MVAR

0 to ± 3276.70 MVAR

0 to ± 3276.70 MVA

0 to ± 3276.70 MW

0 to ± 3276.70 MVA

0 to ± 3276.70 MVA

0 to ± 3276.70 MVA

0 to ± 3276.70 MW

0 to ± 3276.70 MVAR

Demand Power Calculation Methods

Demand power is the energy accumulated during a specified period divided by the length of

that period. How the power meter performs this calculation depends on the method you

select. To be compatible with electric utility billing practices, the power meter provides the

following types of demand power calculations:

• Block Interval Demand

• Synchronized Demand

• Thermal Demand

The default demand calculation is set to sliding block with a 15 minute interval. You can set

up any of the demand power calculation methods using PowerLogic software.

30

© 2011 Schneider Electric. All Rights Reserved.

Page 37

63230-500-225A2 PowerLogicTM Series 800 Power Meter

PLSD110131

Demand value is the

average for the last

completed interval

Demand value is

the average for

the last

completed

interval

Demand value is

the average for

the last

completed

interval

Time

(sec)

Time

(min)

Time

(min)

Calculation updates

every 15 or 60

seconds

Calculation updates at

the end of the interval

Calculation updates at the end of

the sub-interval (5 minutes)

Sliding Block

Fixed Block

Rolling Block

15-minute interval

15-minute interval

15-minute interval 15-min

15-minute interval

3/2011 Chapter 4—Metering Capabilities

Block Interval Demand

In the block interval demand method, you select a “block” of time that the power meter uses

for the demand calculation. You choose how the power meter handles that block of time

(interval). Three different modes are possible:

• Sliding Block. In the sliding block interval, you select an interval from 1 to 60 minutes

(in 1-minute increments). If the interval is between 1 and 15 minutes, the demand

calculation updates every 15 seconds. If the interval is between 16 and 60 minutes, the

demand calculation updates every 60 seconds. The power meter displays the demand

value for the last completed interval.

• Fixed Block. In the fixed block interval, you select an interval from 1 to 60 minutes (in

1-minute increments). The power meter calculates and updates the demand at the end

of each interval.

• Rolling Block. In the rolling block interval, you select an interval and a sub-interval.

The sub-interval must divide evenly into the interval. For example, you might set three

5-minute sub-intervals for a 15-minute interval. Demand is updated at each sub-

interval. The power meter displays the demand value for the last completed interval.

Figure 4–4 below illustrates the three ways to calculate demand power using the block

method. For illustration purposes, the interval is set to 15 minutes.

Figure 4–4: Block Interval Demand Examples

15 30 45

60 . . .

15 30 45

15

20 35 4025

30 45

© 2011 Schneider Electric. All Rights Reserved.

31

Page 38

TM

PowerLogic

Chapter 4—Metering Capabilities 3/2011

Series 800 Power Meter 63230-500-225A2

Synchronized Demand

The demand calculations can be synchronized by accepting an external pulse input, a

command sent over communications, or by synchronizing to the internal real-time clock.

• Input Synchronized Demand. You can set up the power meter to accept an input such

as a demand synch pulse from an external source. The power meter then uses the

same time interval as the other meter for each demand calculation. You can use the

standard digital input installed on the meter to receive the synch pulse. When setting up

this type of demand, you select whether it will be input-synchronized block or inputsynchronized rolling block demand. The rolling block demand requires that you choose

a sub-interval.

• Command Synchronized Demand. Using command synchronized demand, you can

synchronize the demand intervals of multiple meters on a communications network. For

example, if a PLC input is monitoring a pulse at the end of a demand interval on a utility

revenue meter, you could program the PLC to issue a command to multiple meters

whenever the utility meter starts a new demand interval. Each time the command is

issued, the demand readings of each meter are calculated for the same interval. When

setting up this type of demand, you select whether it will be command-synchronized

block or command-synchronized rolling block demand. The rolling block demand

requires that you choose a sub-interval. See Appendix C—Using the Command