TAC I/NETTM

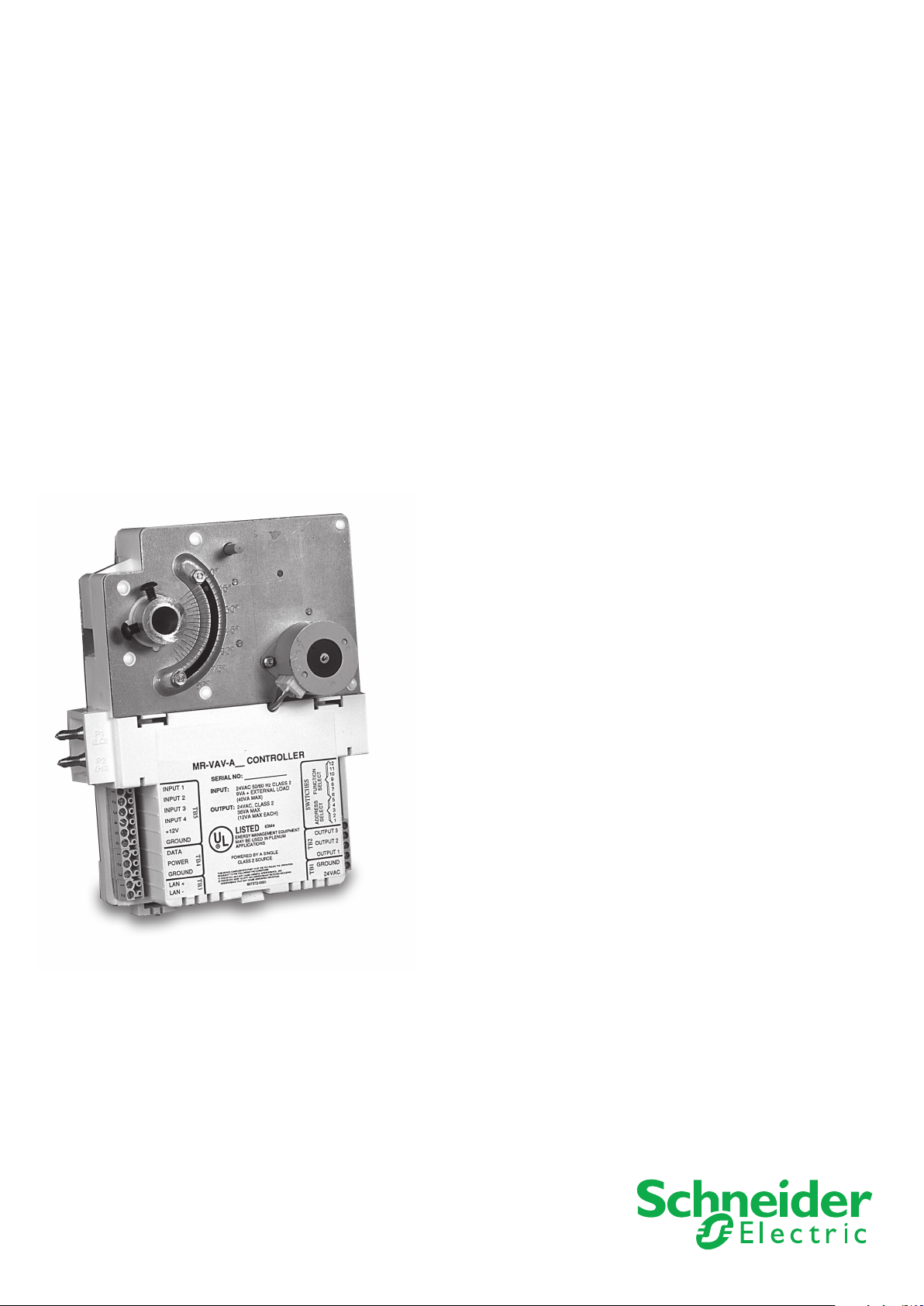

MR-VAV-AX

Application Specific MicroRegulator

TAC’s MR-VAV-AX Application Specific MicroRegulatorTM has an

extensive range ofpre-engineered VAV control sequences, which

combined with a fully integrated actuator and airflow transducer,

makes it a low “Total Installed Cost” solution for most VAV

terminal unit control applications.

TM

TAC I/NET MR-VAV-AX

Application Specific MicroRegulator

Features

An intelligent I/STATTM interface for

independent local control and an interface

to a TAC I/NET

System are standard options.

TM

Distributed Control

02

PRODUCT AT A GLANCE

• Full y Integr ated Actuato r, Ai rflow Tran sducer

and Controller in a single, low profile package.

• Standalone and Networked Applications

• Extensive VAV Control Sequences:

– Two Stage Heating, Multiple Modes

– Series/Parallel Fan

– Local/Remote Occupancy Override

– Local/Remote Central Plant Heat or Morning

Warm-up Control

– Loc al/Rem ote Shut Down O verride

(fire, failure, etc.)

– Indoor Air Quality Airflow Setpoint Override

– Demand Control Setpoint Override

– Mi nimum a nd Maximum Airfl ow Param eters

for heating and cooling

• Complete “Out-of-the-Box” Installation,

Configuration and Commissioning

– DI P Switc h Confi guratio n and N etwork

Addressing with Local/Remote Override

– Completely mount and secure with one box

screw and two damper shaft screws

– Travel Limit Settings

– Automatic calibration of Airflow and

Temperature Sensors

– Autoconfiguration of Heating Stages

– “Prove It” function for Performance

Verification

– Automatic Database Distribution for

Networked Configurations

– Default Parameter Values

(continued)

Operation

The MR-VAV-AX has been designed to minimize

the total installation, setup, configuration and

commissioning costs typically associated with

VAV controllers.

Installation costs have been reduced by

integrating the actuator, airflow transducer and

controller into a single, low profile, plenum-rated

package that can be completely mounted and

secured with one box screw and two damper shaft

screws.

Setup costs have been reduced by the

provision of DIP switches that can be set during

installation and before power is applied. For most

applications, default parameters will allow the

controller to run immediately from startup based on

these switch settings.

The MR-VAV-AX is also supplied with an

extensive range of pre-engineered and tested

control sequences and therefore, no application

programming is required. All configuration

parameters are pre-installed with the most typical

default values. However, they can be overwritten

either by an I/STAT, an M/STAT (a portable I/

STAT) or the Operator Station PC. Heating stage

setpoints, proportional bands and delays are

automatically calculated and set in the controller

based on the controller setup selection.

Commissioning costs have been reduced

by the use of several automated processes.

Airflow conversion parameters are automatically

calculated once the box duct diameter and the

manufacturer’s K-factor are entered. By measuring

and entering the low and high airflow values for the

box, automatic calibration of the installed airflow

transducer is then performed. Automatic calibration

of the temperature sensor is also initiated once a

measured value is entered into the controller.

TAC I/NET MR-VAV-AX

Application Specific MicroRegulator

03

Features

– Co nfigura tion an d Commi ssioni ng by

I/STAT, M/STAT or PC

– Auto-rescaling of velocity transducer in

low flow applications

– Self-Test Diagnostics

• I/STAT and M/STAT Support Standard

– Local Display - 3 Digit & Decimal

– Local Point Control - Analog or Digital

– Local Override & Setpoint Adjustment

– Service Mode for Commissioning

and Calibration

– User-Defined Passwords

• Slide/STAT Support Standard

– Slide Setpoint Override

– Occupancy Override

– Integral Port for M/STAT Connection

• Inputs

– Integrated Airflow Transducer

– Thermistor or Discrete

• Low Voltage Triac Outputs for

– Series/Parallel Fan Control

– First Stage Heater Control (Two Position,

Frequency Modulated, Pulse Width

Modulated or Floating Control Modes)

– Se cond St age Hea ter Control

(Two Position Control only)

– Integrated Actuator

(continued)

Dimensional Drawing

A “Prove It” function allows a complete verification

of the control sequence from an I/STAT or M/STAT.

Once initiated, the space temperature is placed in

Test Mode and can be “increased” or “decreased”

by the buttons on the I/STAT.

value is changed through the control range, the

I/STAT displays the airflow values and the state

of the fan and auxiliary heating. This allows

confirmation of the thermodynamic process from

end to end.

Schneider Electric

As the temperature

TAC I/NET MR-VAV-AX

Application Specific MicroRegulator

04

Features

Finally, in a networked environment, the database

for the MicroController Interface or an I/SITE LAN

can be automatically generated by an upload of

all the data in the connected Application Specific

MicroRegulators. This database can also include a

unique eight-character name for each controller as

part of each point descriptor.

In a standalone configuration, the controller

provides auxiliary inputs for VAV Shutdown (e.g.

fire alarm), Occupancy Override (e.g. Timer, Pushbutton or Occupancy Sensor) and Central Plant

Heat or Morning Warm-Up Override (e.g. contacts

from a central plant).

In a network environment, these signals can be

provided locally for the standalone mode or via

the network. If these inputs are not used for local

override signals, then they can be designated as

“free” and used for any auxiliary input condition

monitoring desired in a networked environment

(e.g. supply air temperature). This is also applicable

to any unused outputs. They can become

available for control applications resident in the

MCI or I/SITE LAN (e.g. lighting control).

A networked environment of MR-VAV-AX

controllers can provide an extensive range of

global interlocks. These include Demand Mode

setpoint override, Central Plant Heat/Morning

Warm-up, Smoke Control (purge and isolate),

Indoor Air Quality (IAQ), Minimum Airflow setpoint

override, Temperature Setpoint override and

Occupancy override.

(continued)

Model N umber Description

MR-VAV -AX Applic ation Specific M icroRegulato r, 1 I/STAT Port, Integrate d

Airflo w Transduce r, 4 Thermis tor or Discrete Inp uts,

3 Low Voltage Triac Out puts, Integrate d Actuator, 24Vac

TCON 147 Applic ation Specific M icroRegulato r Installation G uide

TCON1 48 Application Sp ecific MicroRe gulator Insta llation Sheet

TCON1 49 Application Sp ecific MicroRe gulator Pocket Gui de

Also, the current damper actuator position is

continuously calculated and available as an Analog

Output value that is a percentage of full damper

stroke. This eliminates the need for expensive

feedback potentiometers and analog voltage

controlled (0-10 Vdc) damper actuators. This

analog output point can be overridden either

manually from an operator station or automatically

via an application program in the MCI or I/SITE

LAN and the actuator driven to any desired

absolute position.

The controller can also provide an analog value of

the current controller loading as a percentage value

of full load for both cooling and heating modes.

This value can be used in the networked system

to provide an accurate signal to the central plant

controllers of actual system load requirements.

hneider Electric

Sc

TAC I/NET MR-VAV-AX

Application Specific MicroRegulator

Specifications

MR-VAV-A X

05

Communication Ports

Microregulator Lan

RS-485, 9600 baud, asynchronous, polling.

Network Wiring Requirements

MR LAN Length

5000 ft (1500 m)

Cable Supported

Twisted pair, shielded. 24 AWG or larger,

30pF/ft or less between conductors,

55pF/ft or less conductor to shield,

85 to 150 Ohm impedance.

Belden 9841 or equivalent

Processor

Processor

Zilog 86C193

Memory

EPROM: 32Kbytes

RAM: 464Bytes

NOVRAM: 4096Bytes.

Physical Description

Dimensions

7.75˝ L x 6.25˝ W x 2.5˝ H

(19.7 cm x 15.9 cm x 6.3 cm).

Enclosure

Meets UL94-5V UL flammability

for plenum applications.

Power Requirements

24Vac, +10%, 50/60 Hz

(9VA, plus triac load, 4A fused)

Operating Temperature

32°F to 122°F (0°C to 50°C)

Operating Humidity

10-90% RH, non-condensing

Software

Point Capacity

20 resident points. Hardware (external)

points are a function of model selected

and software (internal) points activated.

Input/Output

Space Sensor Input

Supports I/STAT, Slide/STAT

or 10K Ohm NTC Thermistor

(Dale 1M1002-C3)

Accuracy: 1°F (0.6°C)

Resolution: 0.32°F (0.18°C) @ 77°F (25°C)

Inputs

May be either thermistor or discrete per

the following specifications.

Analog Inputs

10K Ohm NTC Thermistor

(Dale 1M1002-C3)

Accuracy: 1%

Resolution: 0.4% Span

A/D Digital Filtering: Median value filter

and 60 Hz notch filter

Calibration Coefficients: Factory set in

NOVRAM, field adjustable, 6 individual pairs

Digital Inputs

Dry contact input

Contact Excitation: 5V @ 0.5 mA

Discrete Outputs

Low Voltage Triac: 24Vac @ 0.5A maximum

(voltage sourcing), fused

Point Scan Interval

1-255 seconds

hneider Electric

Sc

TAC I/NET MR-VAV-AX

Application Specific MicroRegulator

06

Specifications

(continued)

MR-VAV-A X

Velocity Pressure Input

Operating Range:

0.0 to 1’’ of W.C. (0 to 250Pa)

Sensitivity: 0.0029’’W.C.

(0.73Pa) below midscale and

0.0049’’W.C. (1.10Pa) above midscale.

Tubing Connections:

Barb fittings for 0.170˝ (4.3 mm) I.D. FRPE

polyethylene tubing or 0.25˝ O.D./0.125˝ I.D.

6.3 mm/3.2 mm) tygon tubing

Tubing Length: 4 ft (1.2 m)

maximum each tube

Actuator Outputs

Torque Rating: 53 lb-in (6 Nm)

Stroke: Fully adjustable from 0° to 95°

Timing: 2 sec/degree rotation (60 Hz),

2.4 sec/degree rotation (50Hz)

Position Indication: Visual Indication

Provided Manual Override: Push-button

clutch release to allow manual positioning

of damper

Damper Linkage: 0.5’’D (12.7 mm) round

shaft extending a minimum of 1’’ (25 mm)

from the box, 3/8’’ shaft adapter optional.

Terminations

Terminal Blocks

Removable screw terminal connectors

Indications

LEDs

MR LAN activity (transmitting & receiving -

each channel), test mode (microprocessor

check, EPROM check, NOVRAM check)

Dip Switch

SW1- 5: Address (0 to 31)

SW6-12: Function Selection

Agency Approval

FCC Part 15

UL916 Energy Management

Equipment UL94-5V UL

Requirements for Plenum Application

MicroRegulator Interface (MRI)

Available Platforms

7792 MRI

7793 MCI

7798 I/SITE LAN

All brand names, trademarks and registered trademarks are the property

without notice.

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

Schneider Electric

of their respective owners. Information contained within this document is subject to change

May 2006 pdw

© 200 6-2009 Schneider Electric. All rights reserved.

Loading...

Loading...