Page 1

Page 2

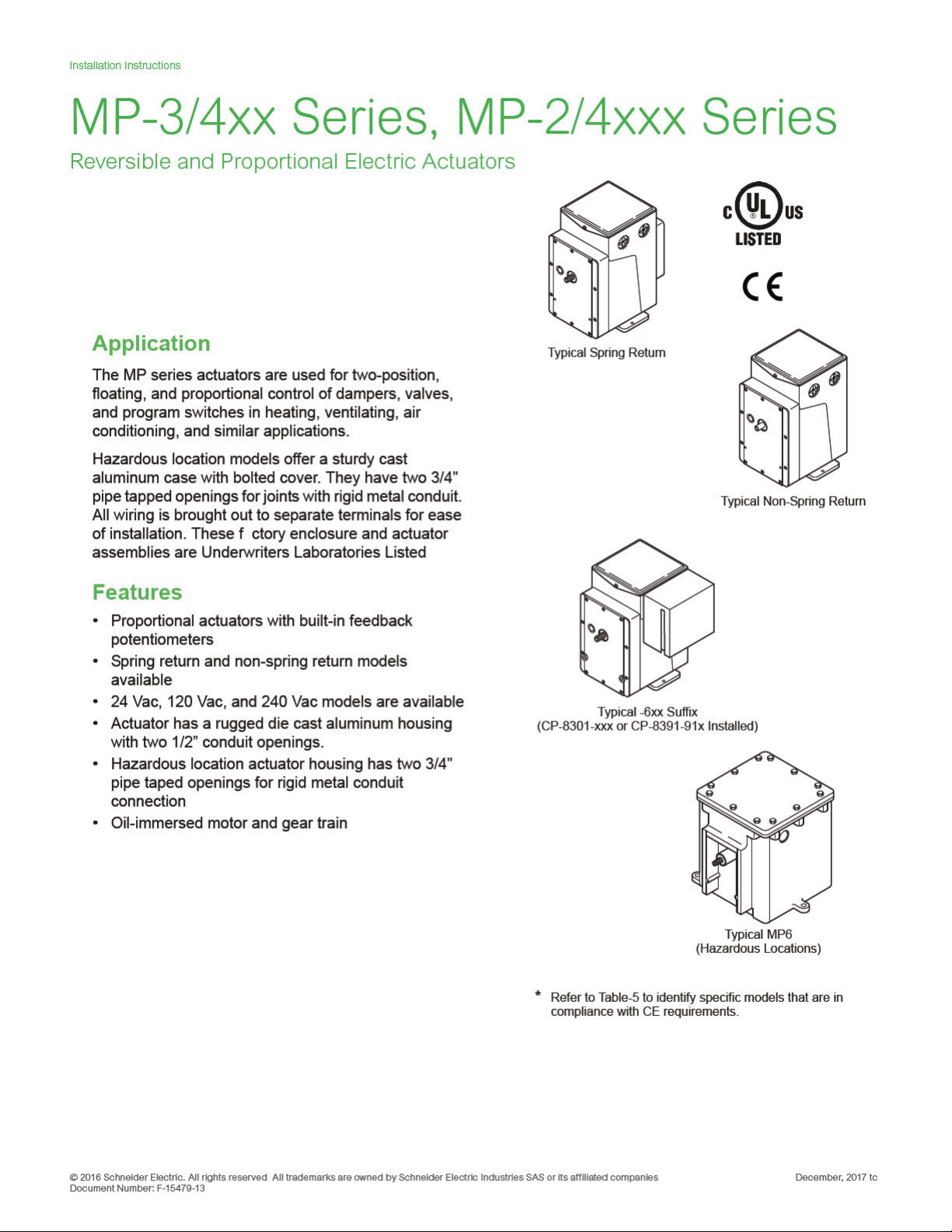

Installation Instructions

SPECIFICATIONS

Actuator Inputs

Input Control Signals: Refer to the actuator selection tables beginning on page 3 for input

control signal capability versus specific actuator models.

Floating, Requires one Single Pole Double Throw (SPDT) switch with floating (center

off) position rated at 0.9 amps @ 24 Vac or two Single Pole Single Throw (SPST)

switches rated at 0.9 amps @ 24 Vac.

Two-Position,

SPDT Requires snap acting switch rated at 0.9 amps @ 24 Vac.

ators. Switch must be rated to

Ω to

SPST Can be used with certain spring return actu

handle actuator power requirements.

Barber-Colman Microtherm, Proportional Electrical system with the following typical

controllers: PP-22x series, TP-1xx series, TP-2xx series, TP-3xx series, TP-4xx series,

TP-1xxx series, and TP-1xxxx series.

Standard Control of a single actuator.

Sequencing Control of two actuators in sequence.

Five-Position Used typically for adjustable minimum position (five positions) of an

economizer actuator.

Slidewire and Paralleling, Requires AE-504 paralleling relay. Refer to AE-504 Solid

State Paralleling Relay General Instructions F-16524. AE-504 accepts 100

Ω slidewires.

1000

Voltage Vdc, Requires CP-8301-xxx series of solid state actuator drives. Refer to

CP-8301 Solid State Actuator Drive General Instructions F-14940. Refer to the

actuator selection tables beginning on page 3.

Current mAdc, Requires CP-8391-xxx series of solid state actuator drives. Refer to the

actuator selection tables beginning on page 3.

Power Requirements: Refer to the actuator selection tables beginning on page 3 to

determine power requirements.

Connections:

MP-3xx, 4xx, 2xxx, 4xxx, Coded screw terminals.

Models with “-600” Suffix, Coded screw terminals except for input signal which are

color coded pigtails.

Actuator Outputs

Torque: Refer to the actuator selection tables beginning on page 3 to determine the

actuator torque rating.

Nominal Damper Area: Actuator selection should be made in accordance with the damper

manufacturer’s specifications.

Stroke (Degrees of Rotation), Refer to the actuator selection tables beginning on page

3 for information on degrees of rotation.

Auxiliary Switch, Refer to the actuator selection tables beginning on page 3 for the

models that include an auxiliary switch. Refer to Table-7 for ratings.

Spring Return: Refer to the actuator selection tables beginning on page 3 for models that

are spring return.

Environment

Ambient Temperature Limits:

Shipping and Storage, -40 to 160 °F (-40 to 71 °C).

Operating, -40 to 136 °F (-40 to 58 °C).

Humidity: 5 to 95% RH, non-condensing.

Locations: NEMA 1.

NEMA 4 for non-spring return actuators with AM-363.

Optional hazardous locations models.

Agency Listings:

US Standard UL 873, Underwriters Laboratories (File #E9429 XAPX, Temperature

ting and Regulating Equipment).

Indica

Canadian Standard C22.2 No. 24: Underwriters Laboratories (File #E429 Category

XAPX7, Temperature Indicating and Regulating Equipment).

European Community, EMC Directive (2004/108/EC). Low Voltage Directive

(2006/95/EC). Refer to Table-5 to identify specific models that are in compliance with CE

requirements.

Hazardous Location Models, UL file #E29291. Designed for use in hazardous

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Page 3

Installation Instructions

Actuator Drive General Instructions F-22453. The CP-8391-716 has an adjustable span of 4 to 16 mAdc (factory set for 16) and adjustable start

point of 2 to 16 mAdc (factory set for 4). The input signal on CP-8391-716 is optically isolated. Refer to

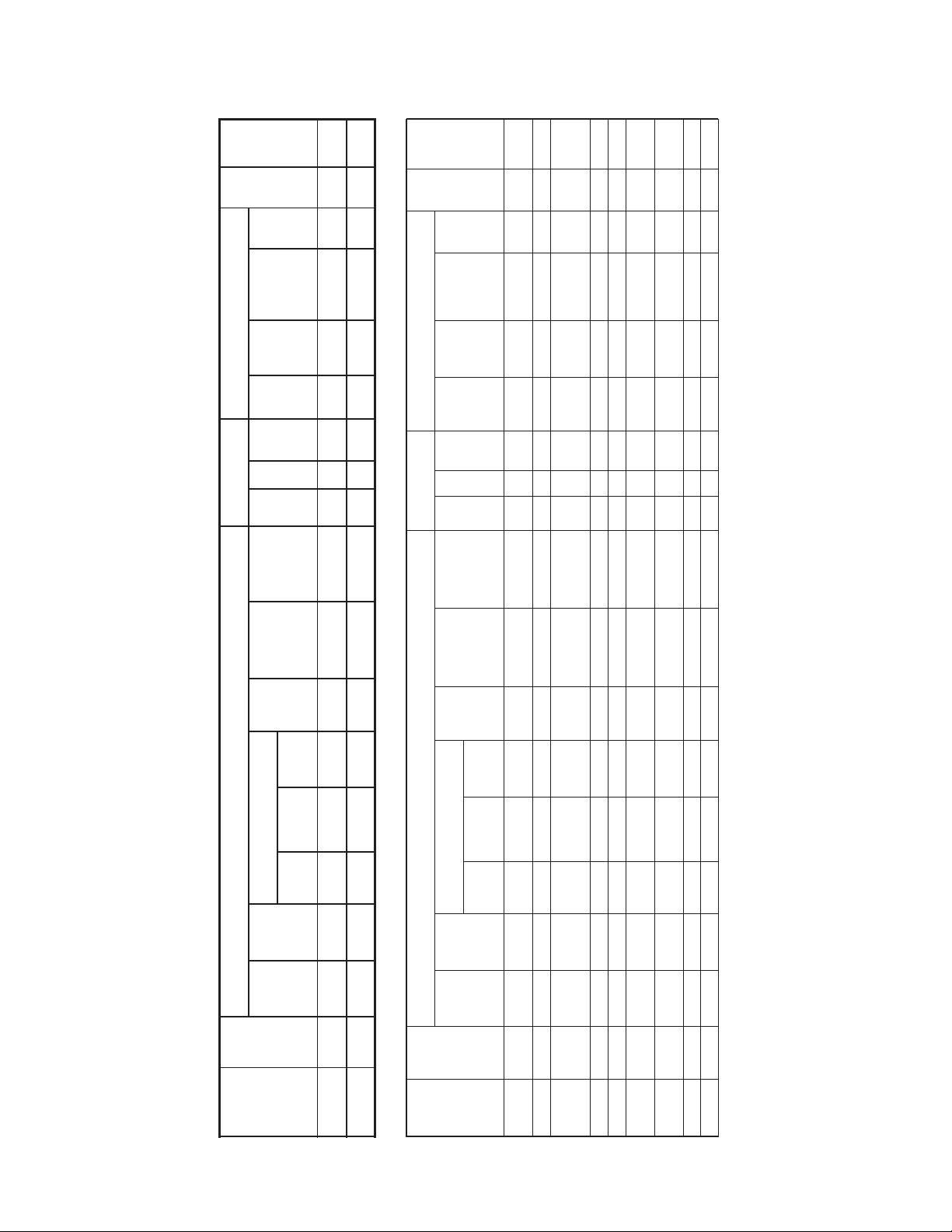

Table-1 MP-2xxx Series Model Chart

Table-2 MP-3xx Series Model Chart.

Input Control Signal External Wiri

MP-2113-500

MP-2150-500

Input Control Signal External Wi

a Typical Barber-Colman Microtherm Controllers: PP-22x Series; TP

b Units with a “-2-x” suffix, e.g. MP-xxxx-xxx-2-x, include a built-in transformer (used for Barber-Colman Microtherm or with AE

8 and Blue (12 Vac) to terminal 7. When these actuators are used with contro

transformer wired directly to potentiometer. To disconnect the transformer, remove the back plate of the actuator, disconnect and tape the transformer leads.

c Requires CP-8391-910.

d Requires CP-8391-716.

e Rotation adjustable 45 to 320

. Caution: On actuators with proportional inpu

f MP-371 models with the “-621” suffix are obsolete.

CP-8391-716 Electronic Actuator Drive

b

Trans-

Built-in

former

tch

Aux.

Swi

Spring

Return

tation

Ro

Degrees of

onds

Timing

Sec

(No Load)

(N-m)

Lb.-in.

Torque

Power

24 60 2.2 50 (5.6) 25 180 (nonAdj.) No SPDT –

Power Requirements Output Shaft

120 60 0.5 50 (5.6) 25 180 (non-Adj.) No SPDT Ye s

d

or

c

Figure-19

Figure-23

Figure-21

(CP-8391-913)

b

ransT

Built-in

former

itch

Aux.

Sw

Spring

Return

) CW SPDT –

) CW SPST –

e

e

Rotation

Degrees of

Output Shaft

Timing

Seconds

(No Load)

(N-m)

Lb.-in.

Torque

Requirements

24 60 2.5 50 (5.6) 90 180 (Adj.

Figure-19

(CP-8391-913)

24 60 2.5 50 (5.6) 90 180 (nonAdj.) CCW SPDT –

Figure-19

(CP-8391-913)

) No SPDT –

) No SPDT –

) No SPST –

e

24 60 2.2 220 (24.9) 130 180 (Adj.

Figure-19

(CP-8391-913)

) No None –

e

e

e

180 (Adj.

(Adj.)

130 to

1300

24 60 2.2 220 (24.9)

Figure-19

(CP-8391-913)

-504) with secondary leads wired externally to terminals 7 and 8 of the actuator. Red (24 Vac) to terminal

Figure-17

(CP-8301-024)

(AE-504)

Figure-14

Position)

Actuators

Figure-27 – Figure-5 Figure-7 – –

Figure-18

(CP-8301-120)

(AE-504)

Figure-15

Figure-29 – Figure-6 – – –

required Interface Module that must be purchased separately)

ring (and

135 to

a

(See Figure)

(Proportional Electric)

Barber-Colman Microtherm

or

2-Position

SPST

2-Position

ng

(See

Wiri

Internal

Part

Actuator

Voltage Vdc Current mAdc Vol ts Hz. Amps

1,000 Ω

Slidewire

Min

(Adj.

Position)

5-Position

wo

of T

Actuators

Sequencing

Standard

oating

SPDT

Fl

Spring

Return

Figure)

Number

Figure-17

Figure-14

(CP-8301-024)

(AE-504)

Figure-14

MP-367 Figure-32 – – – Figure-11 – – – – 24 60 2.5 50 (5.6) 90 180 (Adj.

MP-361 Figure-24 Figure-3 Figure-5 Figure-7 – –

locations N.E.C., Class 1, Groups C and D, and Class 2, Groups E, F, and G. Temperature code T6 for hazardous housing. Actuators in the

actuator selection tables below with “-600” suffix have the CP-8301-120 factory installed. All CP-8301s have a fixed span of 3 Vdc to drive the

actuator full stroke and a start point adjustable from 2 to 12 Vdc (factory set 6 Vdc).

Voltage Vdc Current mAdc Volts Hz. Amps

135 to

1,000 Ω

e Module that must be purchased separately)

(See Figure)

ng (and required Interfac

.

General Instructions F-21220.

The CP-8391-91x series have a fixed range of 4 to 20 mAdc to drive the actuator full stroke. Refer to CP-8391-910 Series 4 to 20 mA Electronic

Slidewire

a

(Adj. Min

5-Position

of Two

Sequencing

(Proportional Electric)

Barber-Colman Microtherm

Standard

DT

or

SP

Floating

2-Position

SPST

Spring

Return

2-Position

ng

(See

Wiri

Figure)

Internal

Part

Number

Actuator

F-15479-12 © Copyright 2012 Schneider Electric All Rights Reserved.

Figure-17

Figure-17

Figure-17

(CP-8301-024)

(AE-504)

MP-371 Figure-24 Figure-3 Figure-5 Figure-7 – –

(CP-8301-024)

(CP-8301-024)

(AE-504)

(AE-504)

Figure-14

Figure-14

llers other than Barber-Colman Microtherm or AE-504, disconnect the Red and Blue leads and tape off. Note: Models prior to “-2-x” suffix had

-1xx Series; TP-4xx Series; TP-101x Series; TP-103x Series; and TP-1xxxx Series.

MP-379 Figure-30 – – – – Figure-12 – – – 24 60 2.5 50 (5.6) 90 180 (nonAdj.) CCW None –

MP-381 Figure-24 – Figure-5 – – –

MP-377 Figure-32 – – – Figure-11 – – – – 24 60 2.5 50 (5.6) 90 180 (nonAdj.) CCW SPST –

MP-389 Figure-30 – – – – Figure-12 – – – 24 60 2.2 220 (24.9) 130 180 (Adj.

MP-382 Figure-24 – Figure-5 – – –

MP-387 Figure-32 – – – Figure-11 – – – – 24 60 2.2 220 (24.9) 130 180 (Adj.

t signals changing the rotation will affect the control, since the internal feedback potentiometer’s travel is fixed.

°

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 4

Installation Instructions

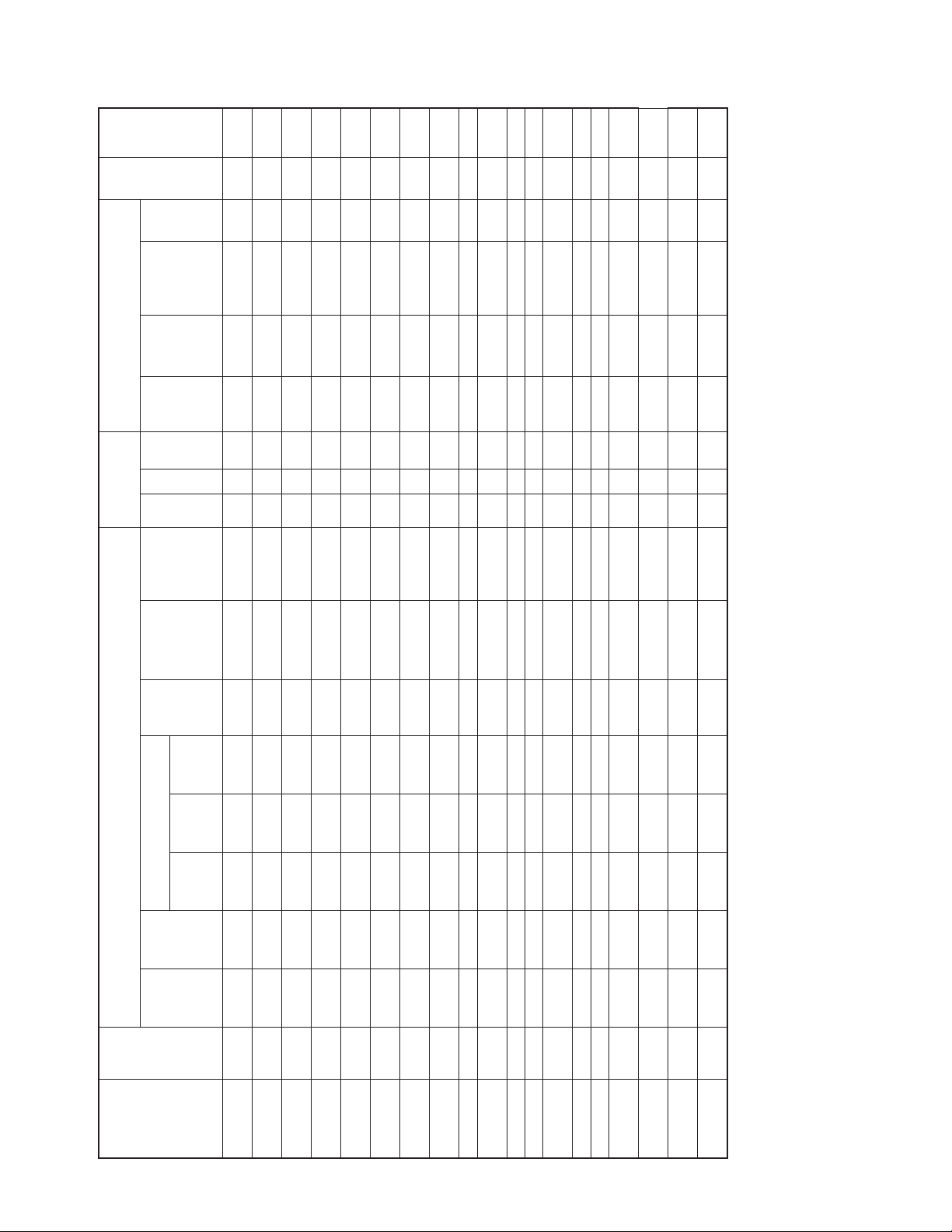

Table-3 MP-4xx Series Model Chart.

Actuator

Number

Input Control Signal External Wiring (and requ

MP-461-600

MP-471-600

MP-481-600

Footnotes for this table are listed on the following page.

b

ransT

Built-in

former

Aux.

Switch

Spring

Return

) No SPDT –

) No SPDT –

e

) No SPDT –

e

e

) No SPDT –

) No SPDT –

e

) No SPDT –

e

) No SPDT –

e

e

) CW SPDT –

) No SPDT –

e

) CW SPDT Ye s

e

e

) No None Ye s

) No SPDT –

e

e

) No SPDT Ye s

) No SPDT Ye s

) No SPDT Ye s

e

e

) No SPDT Ye s

e

e

ation

Rot

Degrees of

180 (Adj.

90 (Adj.

180 (Adj.

90 (Adj.

180 (Adj.

Output Shaft

Power

Requirements

e Module that must be purchased

a

ired Interfac

separately)

(See Figure)

conds

Timing

Se

(No Load)

-in.

(N-m)

Lb.

Torque

Vol ts Hz. Amps

mAdc

Current

Voltage Vdc

135 to

1,000 Ω

Slidewire

5-Position

ing

Sequenc-

(Adj.)

25 to 250

120 60 0.65 60 (6 8) 25 180 (Adj.

120 60 0.65 60 (6 8)

d

d

or

or

c

c

Figure-22

Figure-22

Figure-20

Figure-20

Figure-16

Figure-16

(CP-8301-120)

(CP-8301-120)

(Adj. Min

Position)

of Two

Actuators

c

or

Figure-20

Figure-16

120 60 0.65 60 (6 8) 13 90 (Adj.

d

Figure-22

(CP-8301-120)

13 to 130

or

c

Figure-20

Figure-16

120 60 0.65 60 (6 8)

d

(Adj.)

Figure-22

(CP-8301-120)

c

120 60 0.6 220 (24.9) 130 180 (Adj.

d

or

Figure-21

Figure-18

Figure-15

Figure-23

(CP-8301-120)

(AE-504)

130 to 1300

120 60 0.6 220 (24.9)

d

or

c

Figure-21

Figure-18

Figure-15

(Adj.)

Figure-23

(CP-8301-120)

(AE-504)

or

c

Figure-21

Figure-18

Figure-15

120 60 0.95 450 (50.9) 130 180 (Adj.

d

Figure-23

(CP-8301-120)

(AE-504)

(Adj.)

80 to 800

120 60 0.65 220 (24.9) 80 180 (Adj.

120 60 0.65 220 (24.9)

d

d

or

or

c

c

Figure-22

Figure-22

Figure-20

Figure-20

Figure-16

Figure-16

(CP-8301-120)

(CP-8301-120)

c

or

Figure-20

Figure-16

120 60 0.65 220 (24.9) 40 90 (Adj.

d

Figure-22

(CP-8301-120)

c

40 to 400

or

Figure-20

Figure-16

120 60 0.65 220 (24.9)

(Adj.)

d

Figure-22

(CP-8301-120)

120 60 0.6 50 (5.6) 90 180 (Adj.

d

or

c

– 120 60 0.6 50 (5.6) 90 180 (Adj.

Figure-23

Figure-21

f

Figure-18

(CP-8301-120)

(AE-504)

Figure-15

120 60 0.6 50 (5.6) 90 180 (non-Adj.) CCW SPDT Ye s

d

or

c

– 120 60 0.6 50 (5.6) 90 180 (non-Adj.) CCW SPDT –

Figure-23

Figure-21

f

Figure-18

(CP-8301-120)

(AE-504)

Figure-15

120 60 0.6 220 (24.9) 65 90 (Adj.

d

or

c

– 120 60 0.6 220 (24.9) 130 180 (Adj.

Figure-23

Figure-21

f

Figure-18

(CP-8301-120)

(AE-504)

Figure-15

(Proportional Electric)

Barber-Colman Microtherm

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Internal

Standard

or

oating

SPDT

Fl

2-Position

– Figure-6 – – –

Figure-26

g

MP-486 Figure-26 – Figure-6 – – –

MP-495

SPST

Spring

Return

2-Position

(See

Wiring

Figure)

Part

MP-421 Figure-25 – Figure-6 – – – –

MP-422 Figure-25 – Figure-6 – – – –

MP-424 Figure-25 – Figure-6 – – – –

MP-423 Figure-25 – Figure-6 – – – –

MP-451 Figure-25 – Figure-6 – – – –

MP-452 Figure-25 – Figure-6 – – – –

MP-453 Figure-25 – Figure-6 – – – –

Figure-25 – 1 5 – – – – Figure-16

MP-454 Figure-25 – Figure-6 – – – –

Figure-25 – – – – – – Figure-16

MP-465 Figure-26 Figure-4 Figure-6 Figure-9 – –

MP-470 Figure-31 – – – – Figure-13 – – – 120 60 0.6 50 (5.6) 90 180 (non-Adj.) CCW None Ye s

Figure-25 – – – – – – Figure-16

MP-485 Figure-26 – Figure-6 – – –

MP-475 Figure-26 Figure-4 Figure-6 Figure-9 – –

MP-483 Figure-26 – Figure-6 – – –

MP-480 Figure-31 – – – – Figure-13 – – – 120 60 0.6 220 (24.9) 130 180 (Adj.

Page 5

Installation Instructions

Table-4 MP-4xxx Series Model Chart.

Tabl e - 5 Actuator Part Numbers that are Compliant with CE

Actuator

Number

Input Control Signal External Wiring (and required Inte

MP5-4651

MP-4701

MP5-4751

MP-4851

MP5-4851

a Typical Barber-Colman Microtherm Controllers: PP-22x Series; TP-1

b Units with a “-2-x” suffix, e g. MP-xxx

terminal 8 and Blue (12 Vac) to terminal 7. When these actuat

transformer wired directly to potentiometer. To disconnect the tr

c Requires CP-8391-910.

d Requires CP-8391-716.

e Rotation adjustable 45 to 320

. Caution: On actuators with propor ional input signals changing the rotation will affect he control, since the internal feedb

f Integral solid state drive accepts 2-15 Vdc voltage.

g MP-495 is not rated for UL or CSA

b

Tra ns -

Built-in

former

Aux.

Switch

Spring

Return

Degrees of

) CW SPDT Yes

f

Rotation

) No SPDT Yes

) No SPDT Yes

f

f

Output Shaft

Timing

Seconds

(No Load)

(N-m)

Lb.-in.

Torque

ack potentiometer’s travel is fixed.

Power

Requirements

Vol ts Hz. Amps

240 50 0.25 50 (5.6) 108 180 (Adj.

d

or

c

240 50 0.25 50 (5.6) 108 180 (non-Adj ) CCW SPDT Yes

240 60 0.25 220 (24 9) 130 180 (Adj.

240 50 0.25 220 (24 9) 156 180 (Adj.

or

d

d

d

or

c

or

c

c

rface Module that must be purchased separately)

(See Figure)

mAdc

Current

Voltage Vdc

135 to

1,000 Ω

Slidewire

a

5-Position

Figure-23

Figure-21

Figure-18

(CP-8301-240)

(AE-504)

Figure-15

(Adj. Min

Position)

Figure-21

Figure-18

Figure-15

Figure-23

(CP-8301-240)

(AE-504)

Figure-21

Figure-18

Figure-15

Figure-23

(CP-8301-240)

(AE-504)

Figure-21

Figure-18

Figure-15

Figure-23

(CP-8301-240)

(AE-504)

xx Series; TP-4xx Series; TP-101x Series; TP-103x Series; and TP-1xxxx Series.

of Tw o

Actuators

Sequencing

(Proportional Electric)

ors are used with controllers other han Barber-Colman Micro herm or AE-504, disconnect the Red and Blue leads and tape off. Note: Models prior to “-2-x” suffix had

ansformer, remove the back plate of the actuator, disconnect and tape the transformer leads.

MP-361-0-0-2

MP-363-0-0-2

MP-367-0-0-2

MP-371-0-0-2

MP-377-0-0-2

MP-379-0-0-2

MP-381-0-0-2

MP-382-0-0-2

MP-383-0-0-2

MP-387-0-0-2

MP-389-0-0-2

MP-481-600-0-2

MP-481-691-0-2

MP-481-692-0-2

Barber-Colman Microtherm

Standard

2-Position

or

SPDT

Floating

x-xxx-2-x, include a built-in transformer (used for Barber-Colman Microtherm or with AE-504) wi h secondary leads wired externally to terminals 7 and 8 of he actuator. Red (24 Vac) to

SPST

Spring

Return

2-Position

(See

Wiring

Figure)

Internal

Figure-26 Figure-4 Figure-6 – – –

Figure-31 – – – – Figure-13 – – – 240 60 0.25 50 (5.6) 90 180 (non-Adj ) CCW None Yes

Figure-26 Figure-4 Figure-6 – – –

Figure-26 – Figure-6 – – –

Figure-26 – Figure-6 – – –

Part

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 6

Page 7

Page 8

Page 9

ACCESSORIES

Damper linkage accessories

AM-111 Crank arm for 5/16" (7.9 mm) diameter damper shaft

AM-112 Crank arm for 3/8" (9.5 mm) diameter damper shaft

AM-113 Crank arm for actuator or 1/2" (12.7 mm) diameter damper shaft

AM-115 Crank arm for 7/16" (11.1 mm) diameter damper shaft

AM-116 Splined crank arm for actuator

AM-122 Linkage connector, straight type

AM-123 Damper clip

AM-125 5/16" x 20" (7.9 mm x 0.5 m) damper rod

AM-125-048 5/16" x 48" (7.9 mm x 1.2 m) damper rod

AM-132 Ball joint connector

AM-161 Damper linkage kit

AM-161-1 Damper linkage kit

AM-301 90 degree mounting bracket

Miscellaneous actuator accessories

AM-321 Two step switch kit

AM-332 Potentiometer kit

AM-341 Four step switch kit

AM-342 Two step switch and potentiometer kit

AM-363 NEMA 4 gasket kit for non-spring return actuators only

Valve linkage for 50 lb.-in. minimum, 180 actuator

AV-329 Valve linkage for 2-1/2" and 3" VB-9323

AV-391 Valve linkage for 15 to 50 mm and 1/2" to 2” VB-72xx or VB-73xx (also valve

linkage for

obsolete 1/2” to 1-1/4" VB-92xx or VB-93xx)

AV-392 Valve linkage for obsolete 1-1/2" and 2" VB-92xx or VB-93xx

AV-395 Valve linkage for 65 and 80 mm VB-9215 or VB-9315, and 2-1/2" to 4" VB-9213 or

VB-9313

Valve linkage for 130 lb.-in. minimum, 180 actuator

AV-330 Valve linkage for 2-1/2" and 3" VB-9323

AV-352 Valve linkage for 2-1/2" to 6" VB-921x or VB-931x, 4" to 6" VB-9323

AV-393 Valve linkage for 15 to 50 mm and 1/2” to 2” VB-72xx or VB-73xx (also valve

linkage for

obsolete 1/2" to 1-1/4" VB-92xx or VB-93xx)

AV-394 Valve linkage for obsolete 1-1/2" and 2" VB-92xx or VB-93xx

AV-396 Valve linkage for 65 and 80 mm VB-9215 or VB-9315, and 2-1/2" to 4" VB-921x or

VB-931x

Valve Linkage for 50 lb.-in. MP6-xxx and MP7-xxx Hazardous Location Actuators

AV-291 Valve linkage for ½ to 2" VB-7xxx valves assemb

led with hazardous location

actuator assemblies.

AV-295 Valve linkage for 2½ to 3" VB-9xxx valves assembled with hazardous location

actuator assemblies.

Valve Linkage for 220 lb.-in. MP6-xxx and MP7-xxx Hazardous Location Actuators

AV-293 Valve linkage for ½ to 2" VB-7xxx valves assemb

led with hazardous location

actuator assemblies

AV-296 Valve linkage for 2½ to 3" VB-9xxx valves assembled with hazardous location

actuator assemblies

Installation Instructions

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 10

Installation Instructions

TYPICAL APPLICATIONS (wiring diagrams)

List of Figures

Figure-3 External Wiring for SPST Control of MP-361 and MP-371, 24 Vac

Actuators.

Figure-4 External Wiring for SPST Control of MP-465, MP-475, MP5-4651, and

Figure-5 External Wiring for SPDT (Snap Acting or Floating) Switch for Control of

Figure-6 External Wiring for SPDT (Snap Acting or Floating) Switch for Control of

Figure-7 Barber-Colman Microtherm Controller with 24 Vac Actuators – Standard

Figure-8 Barber-Colman Microtherm Controller with 24 Vac Actuators – Reversed

Figure-9 External Wiring of Barber-Colman Microtherm Controller with Line

Figure-10 External Wiring of Barber-Colman Microtherm Controller with Line

Figure-11 External Wiring for Barber-Colman Microtherm Controller with 24 Vac

Figure-12 External Wiring for Barber-Colman Microtherm Controller with

Figure-13 External Wiring for Barber-Colman Microtherm Controller with

Figure-14 External Wiring for Slidewire Controller with 24 Vac Actuators. page 18

Figure-15 External Wiring for Slidewire Controller with Line Voltage Actuator. page 18

Figure-16 External Wiring for CP-8301-120, Vdc Interface with Line Voltage

Figure-17 External Wiring for CP-8301-024, Vdc Interface with 24 Vac Actuators. page 20

Figure-18 External Wiring for CP-8301-120 and CP-8301-240, Vdc Interface with

Figure-19 External Wiring for CP-8391-913, 4 to 20 mAdc Interface with 24 Vac

Figure-20 External Wiring for CP-8391-910, 4 to 20 mAdc Interface with Line

Figure-21 External Wiring for CP-8391-910 and CP-8391-911, 4 to 20 mAdc

Figure-22 External Wiring for CP-8391-716, mAdc Interface with Line Voltage

Figure-23 External Wiring for CP-8391-716, mAdc Interface with Line Voltage

Figure-24 Internal Wiring for 24 Vac Actuator. page 24

Figure-25 Internal Wiring for Line Voltage Actuators. page 25

Figure-26 Internal Wiring for Line Voltage Actuator with Built-in Transformer. page 25

Figure-27 Internal Wiring for 24 Vac Actuator without Limit

Figure-28 Internal Wiring for Line Voltage Actuators without Limit Switches

Figure-29 Internal Wiring for Line Voltage Actuators without Limit Switches and

Figure-30 Internal Wiring for 24 Vac Five-Position Actuators. page 27

Figure-31 Internal Wiring for LIne Voltage Five-Position Actuators. page 28

Figure-32 Internal Wiring for 24 Vac Sequencing Actuators. page 28

MP5-4751 Line Voltage Actuators.

24 Vac Actuators MP-361, MP-371, MP-381, MP-382 and MP-2113-500.

Line Voltage Actuators.

Wiring Diagram.

(Cooling) Wiring Diagram.

Voltage Actuator – Standard Wiring.

Voltage Actuator – Reversed (Cooling) Wiring.

Sequencing Actuators.

Five-Position 24 Vac Actuators.

Five-Position Line Voltage Actuator.

Actuators without Internal Transformer.

Line Voltage Actuators with Internal Transformer.

Actuators.

Voltage Actuators without Internal Transformer.

Interface with Line Voltage Actuators with Internal Transformer.

Actuators without Internal Transformer.

Actuators with Internal Transformer.

Switches (Actuator is

Stall Type with Built-in Mechanical Stops).

(Actuator is Stall Type with Built-in Mechanical Stops.)

Built-in Transformer (Actuator is Stall Type with Built-in Mechanical

Stops).

page 11

page 11

page 12

page 12

Page 13

page 13

page 14

page 14

page 15

page 16

page 17

page 19

page 21

page 22

page 22

page 23

page 23

page 24

page 26

page 26

page 27

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Installation Instructions

Power Wiring All actuators include a barrier that separates the power wiring compartment from the low

voltage wiring compartment. Refer to Table-10 for allowable circuit class for the two wiring

compartments.

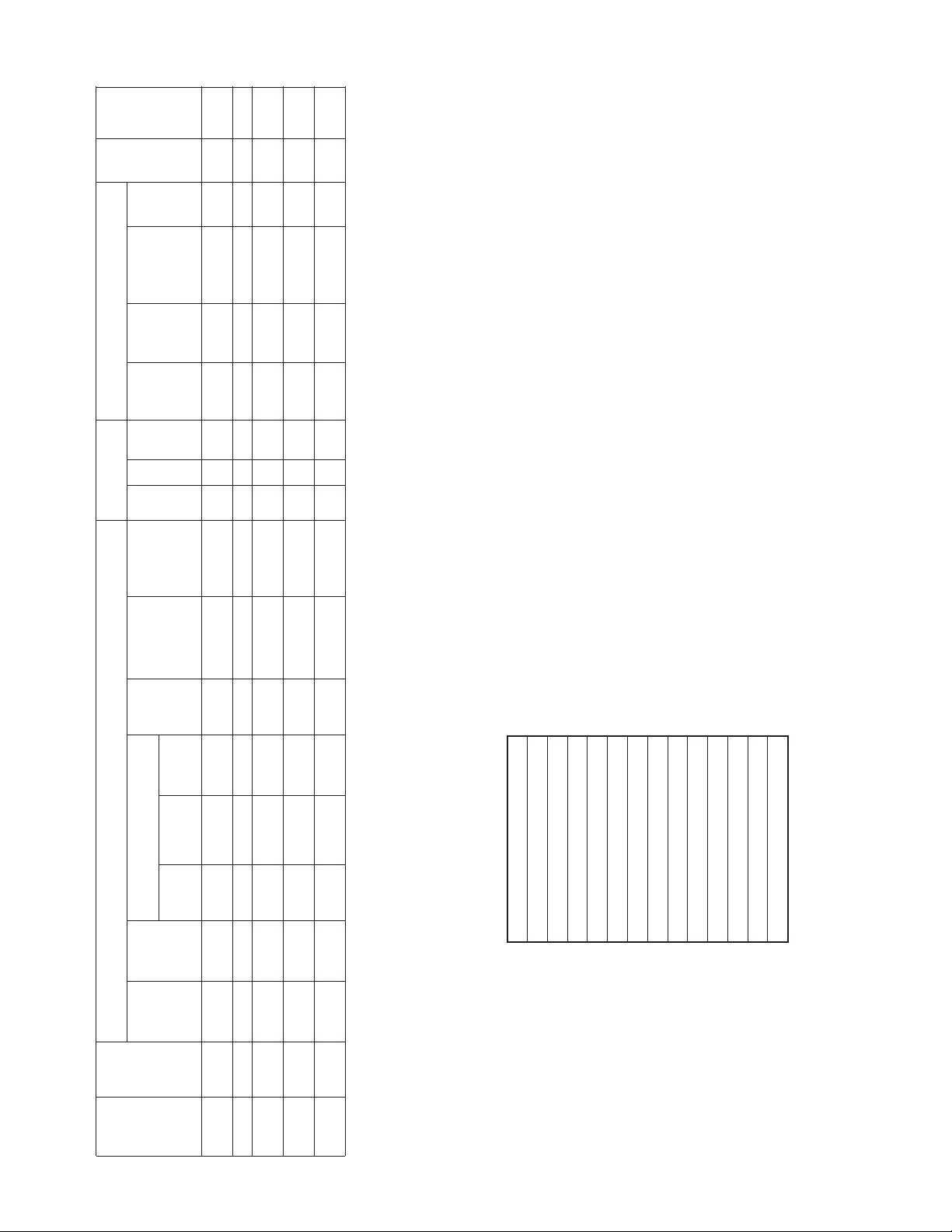

Table-10 Actuator Circuit Class.

Power Wiring Compartment Low Voltage Wiring Compartment

Typical Part Numbers

MP-361, MP-371,

81, MP-382,

MP-3

MP-2113-500

MP-421, MP-422,

23, MP-424,

MP-4

MP-451, MP-452,

MP-453, MP-454,

MP-461-600, MP-465,

MP-471-600, MP-475,

MP-481-600, MP-483,

MP-485, MP-486,

MP-495, MP-2150-500,

MP5-4651, MP5-4751,

MP-4851, MP5-4851

MP-367, MP-377,

MP-379, MP-389

MP-470, MP-480,

MP-38

MP-4701

7

Actuator

Description

Low Voltage

Proportional

Line Voltage

oportional

Pr

Low Voltage

Sequencing

Low Voltage

F

ive-Position

Line Voltage

Five-Position

Terminals (Function)

H&G (24 Vac Power)

1, 5, and 6

(Auxiliary Switch)

L1 and L2

oltage Power)

(Line V

1, 5, and 6

uxiliary Switch)

(A

H&G (24 Vac Power)

1, 5, and 6

Control Switches)

(

H&G (24 Vac Power)

6, 7, and 8

(Potentiometer)

H&G (24 Vac Power)

6, 7, and 8

Potentiometer)

(

Circuit Class for

Power Wiring Compartment

1.May be Class 2 circ

auxiliary switch is wired to

24 Vac or is not used.

2.Must be Class 1 circuit if

auxiliary switch is wired to line

voltage.

Must be Class 1 circuit.

May be Class 2 Circuit.

May be Class 2 Circuit.

Must be Class 1 Circuit.

uit if

Terminals (Function)

X, 2, and 3

(Control Circuit)

4, 7, and 8

(Potentiometer)

X, 2, and 3

(

Control Circuit)

4, 7, and 8

(Potentiometer)

X, 2, and 3

(

Control Circuit)

4, 7, and 8

(Potentiometer)

X, 1, 2, 3, 4, 5

(Control Circuit)

X, 1, 2, 3, 4, 5

(

Control Circuit)

Circuit Class

for Low

Voltage Wiring

Compartment

May be Class 2

Circuit.

May be Class 2

Circuit.

May be Class 2

Circuit.

May be Class 2

Circuit.

May be Class 2

Circuit.

Refer to Table-11 for selection of proper gage wire for

the length of wire run (one run has two

wires).

Table-11 Power Wire Selection.

Actuator Series Voltage

MP-36x, MP-37x 24 Vac

MP-38x 24 Vac

MP-42x

MP-445-304

MP-45x

MP-46x

MP-47x

MP-48x

MP-4xx1 240 Vac 14 3340 (1018)

120 Vac

120 Vac

Wire Size

(AWG)

14

12

10

14

12

10

14

12

10

14

12

10

Maximum

Run ft. (m)

115 (35)

180 (55)

285 (87)

130 (40)

205 (62)

325 (99)

810 (247)

1275 (388)

2040 (622)

1050 (320)

1660 (506)

2650 (808)

When multiple 24 Vac actuators are powered from the same transformer, the actuators must

be in phase. Connect the same transformer lead to the “G” terminal on all actuators and

same transformer lead to the “H” terminal on all actuators.

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Page 35

Control Wiring Refer to Figure-3 through Figure-23 for typical wiring of the actuators. Refer to the actuator

selection tables beginning on page 3, for an index of External Wiring Figures versus actuator

models and control signals. The requirements for the field control wiring are shown below.

SPST Control Signal

Refer to Figure-3 and Figure-4. Since the SPST switch is controlling the power to the

actuator, the control wiring is limited to the power wiring shown above.

SPDT Control Signal

Refer to Figure-5 and Figure-6. Use 18 gage wire for runs up to 1,000 ft. (305 m) between

the actuator and the SPDT switch. Use larger gage wires on longer runs.

Barber-Colman Microtherm Control

Refer to External Wiring Figure-7 through Figure-13. Use 18 gage wire for runs up to

1,000 ft. (305 m) between the actuator and the Barber-Colman Microtherm controller. Use

larger gage wires on longer runs.

135 to 1000 Ω Slidewire Control

Refer to External Wiring Figure-14 and Figure-15. Use 18 gage three-conductor twisted

leads (part number W-103 or equal) for runs up to 500 ft. (152 m) between the actuator and

the slidewire controller. Use larger gage wires for longer runs.

Voltage Vdc Control

Refer to External Wiring Figure-16 through Figure-18. Use 18 gage three-conductor twisted

leads (part number W-103 or equal) for runs up to 1,000 ft. (305 m) between the actuator

and the Vdc controller. Use larger gage wires for longer runs.

Installation Instructions

Caution: Use 18 gage three-conductor shielded cable (twisted) when it is necessary to

install the control leads in the same conduit with power wiring, or when high RFI/EMI

generating devices are near. Do not connect the shield to earth ground or any leads or

terminals.

Current mAdc Control

Refer to External Wiring Figure-19 through Figure-23. Use 18 gage two-conductor twisted

leads (part number W-102 or equal) for runs up to 500 ft. (152 m) between the actuator and

the slidewire controller. Use larger gage wires for longer runs.

Direct Digital Control (DDC)

DDC controllers may be used to control these actuators according to one of the methods

described below.

SPST Control

Refer to External Wiring Figure-5 and Figure-6. Requires two digital output points

programmed as a drive open, drive closed configuration. The digital output must be rated for

switching 0.9 amp at 24 Vac .

Voltage Vdc Control

Refer to External Wiring Figure-16, Figure-17, and Figure-18. Requires an analog output

from the DDC controller, programmed to provide the desired voltage range. Also requires a

CP-8301-120 electronic actuator drive between the DDC controller and the actuator.

Current mAdc Control

Refer to External Wiring Figure-19, Figure-20, and Figure-21. Requires an analog output

from the DDC controller, programmed to provide the desired current range (usually 4 to 20

mA). Also requires a CP-8391-913 electronic actuator drive between the DDC controller and

the actuator.

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 36

Page 37

Page 38

Page 39

CHECKOUT

After the entire system has been installed and the actuator has been powered up, the

following checks can be made for proper system operation.

GO, NO GO Test Slidewire Controller with 24 Vac Actuators

Refer to Figure-14.

1. Disconnect field wiring from Brown lead of AE-504 and terminals 7 and 8 of the actuator.

2. Apply 24 Vac power to terminals H and G of the actuator.

3. Short the Brown lead of AE-504 to terminal 7 of actuator and the actuator should rotate

CW to its limit.

4. Short the Brown lead of AE-504 to terminal 8 of actuator and the actuator should rotate

CCW to its limit.

5. If the unit passes steps 3 and 4, the actuator and the AE-504 are good. If the unit does

not pass steps 4 and 5, proceed to step 6.

6. Unhook the AE-504 leads from actuator terminals X, 2, and 3.

7. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

8. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

If the unit passes steps 7 and 8, the actuator is good and AE-504 is defective. If the unit does

not pass steps 7 and 8, the actuator is defective and the AE-504 may be good.

Installation Instructions

Slidewire Controller with Line Voltage Actuator

Refer to Figure-15.

1. Disconnect field wiring from Brown lead of AE-504 and terminals 7 and 8 of the actuator.

2. Apply proper AC power to terminals L1 and L2 of the actuator.

3. Short the Brown lead of AE-504 to terminal 7 of actuator and the actuator should rotate

CW to its limit.

4. Short the Brown lead of AE-504 to terminal 8 of actuator and the actuator should rotate

CCW to its limit.

5. If the unit passes steps 3 and 4, the actuator and the AE-504 are good. If the unit does

not pass steps 4 and 5, proceed to step 6.

6. Unhook the AE-504 leads from actuator terminals X, 2, and 3.

7. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

8. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

If the unit passes steps 7 and 8, the actuator is good and AE-504 is defective. If the unit does

not pass steps 7 and 8, the actuator is defective and the AE-504 may be good.

CP-8301-120, Vdc Interface with Line Voltage Actuators without Internal

Transformer

Refer to Figure-16.

1. Disconnect field wiring from Red, Yellow, and Blue leads of CP-8301-xxx.

2. Apply 120 Vac power to terminals L1 and L2 of the actuator.

3. Short the Yellow and Red leads of CP-8301-xxx and the actuator should rotate CW to

its limit, unless rewired to rotate CCW on an increase in input signal.

4. Short the Yellow and Blue leads of CP-8301-xxx and the actuator should rotate CCW to

its limit, unless rewired to rotate CCW on an increase in input signal.

5. If the unit passes steps 3 and 4, the actuator and the CP-8301-xxx are good. If the unit

does not pass steps 3 and 4, proceed to step 6.

6. Unhook the CP-8301-xxx leads from actuator terminals X, 2, and 3.

7. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 40

Installation Instructions

8. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

If the unit passes steps 7 and 8, the actuator is good and CP-8301-xxx is defective. If the

unit does not pass steps 7 and 8, the actuator is defective and the CP-8301-xxx may be

good.

CP-8301-024, Vdc Interface with 24 Vac Actuators

Refer to Figure-17.

1. Disconnect field wiring from Red, Yellow, and Blue leads of CP-8301-xxx.

2. Apply 24 Vac power to terminals H and G of the actuator.

3. Short the Yellow and Red leads of CP-8301-xxx and the actuator should rotate CW to

its limit, unless rewired to rotate CCW on an increase in input signal.

4. Short the Yellow and Blue leads of CP-8301-xxx and the actuator should rotate CCW to

its limit, unless rewired to rotate CCW on an increase in input signal.

5. If the unit passes steps 3 and 4, the actuator and the CP-8301-xxx are good. If the unit

does not pass steps 3 and 4, proceed to step 6.

6. Unhook the CP-8301-xxx leads from actuator terminals X, 2, and 3.

7. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

8. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

If the unit passes steps 7 and 8, the actuator is good and CP-8301-xxx is defective. If the

unit does not pass steps 7 and 8, the actuator is defective and the CP-8301-xxx may be

good.

CP-8301-120 and CP-8301-240, Vdc Interface with Line Voltage Actuators

with Internal Transformer

Refer to Figure-18.

1. Disconnect field wiring from Red, Yellow, and Blue leads of CP-8301-xxx.

2. Apply AC power to terminals L1 and L2 of the actuator.

3. Short the Yellow and Red leads of CP-8301-xxx and the actuator should rotate CW to

its limit, unless rewired to rotate CCW on an increase in input signal.

4. Short the Yellow and Blue leads of CP-8301-xxx and the actuator should rotate CCW to

its limit, unless rewired to rotate CCW on an increase in input signal.

5. If the unit passes steps 3 and 4, the actuator and the CP-8301-xxx are good. If the unit

does not pass steps 3 and 4, proceed to step 6.

6. Unhook the CP-8301-xxx leads from actuator terminals X, 2, and 3.

7. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

8. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

If the unit passes steps 7 and 8, the actuator is good and CP-8301-xxx is defective. If the

unit does not pass steps 7 and 8, the actuator is defective and the CP-8301-xxx may be

good.

CP-8391-xxx Series mAdc Interface

Refer to Figure-19 through Figure-23.

1. Unhook the CP-8391-xxx leads from actuator terminals X, 2, and 3.

2. Refer to specific actuator for power hook-ups.

3. Short actuator terminal X to 2 and the actuator should rotate CW to its limit.

4. Short actuator terminal X to 3 and the actuator should rotate CCW to its limit.

5. If the unit passes steps 3 and 4, the actuator is good.

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Page 41

Installation Instructions

Positioning the

Actuator with the

Controller

If the sensed media is within the controller’s setpoint range, the actuator can be positioned

by adjusting the controller setpoint up and down. Check for proper operation of the actuator

(valve or damper) while the actuator is being stroked.

Theory of Operation

Actuator variations are shown in Figure-24 through Figure-32. Refer to the actuator

selection tables beginning on page 3 to determine which Internal Wiring Figure applies to a

certain actuator.

The actuators are powered by shaded pole motors that are of the induction type, using what

is commonly know as a squirrel cage rotor. These motors, like all single phase induction

motors, must be provided with some means of starting. This is accomplished by the shading

coils in the poles of the motor and hence the name “Shaded Pole.” However, unlike most

single phase induction motors, the shading coils are also essential for running.

The field coil produces a magnetic field in the iron core (stator) and in the rotor. When

actuator terminal x is shorted to a terminal attached to CW shading coils, it causes a lag in

part of the field which provides the equivalent of a rotating field. This rotating field induces a

voltage and current in the rotor bars, and the attraction between the rotating field and these

current carrying bars pulls the rotor around with the field in a CW direction. When actuator

terminal x is shorted to a terminal attached to CCW shading coils, it operates the same

except it drives the actuator CCW. A voltage of 24 to 30 Vac with current of 9 amps is induced

in the shading coils in much the same manner as the secondary of a transformer.

© 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric Industr ies SAS or its af filiated companies . December, 2017 tc

Docume nt Number: F-15479 -13

Page 42

Installation Instructions

REPLACEMENT PARTS

Table-12 Potentiometer Kit.

Actuator

MP-xx0x-0-0-1

MP-xx0x-0-2-1

MP-xx1x-0-0-1 ADDA-902-2 100

MP-xx2x-0-0-1 ADDA-902-2 100

MP-xx3x-0-0-1

MP-xx3x-0-2-1

MP-xx4x-0-0-1

MP-xx4x-0-2-1

MP-xx5x-0-0-1

MP-xx5x-0-2-1

MP-xx6x-0-0-1

MP-xx6x-0-2-1

MP-xx7x-0-0-1 ADDA-902-4 50

MP-xx8x-0-0-1

MP-xx8x-0-2-1

MP-xx9x-0-0-1 ADDA-902-2 100

ADDA-902-2 100

ADDA-902-5 100

ADDA-902-5 100

ADDA-902-2 100

ADDA-902-2 100

ADDA-902-2 100

Table-13 Additional Potentiometer Kits.

Potentiometer Kits

Part No. Description

ADDA-902-6 500

ADDA-902-8 1000

ADDA-902-9 500

ADDA-902-10 1000

Potentiometer Kit

Part No. Description

Ω, 180°

Ω, 180°

Ω, 180°

Ω, 90°

Ω, 90°

Ω, 180°

Ω, 180°

Ω, 180°

Ω, 180°

Ω, 180°

Ω, 90°

Ω, 90°

Ω, 180°

Ω, 180°

MAINTENANCE

TROUBLESHOOTING

REPAIR

Regular maintenance of the total system is recommended to assure sustained, optimum

performance.

The actuators require a minimum of maintenance since the motor and gear train are

submerged in oil for continuous lubrication and cooling.

Refer to Section “GO, NO GO Test” on page 39.

None. Replace an inoperable actuator with a functional unit.

December, 2017 tc © 2016 Schne ider Ele ctric. All rights res erved. All t radema rks are owned by S chneider Electric In dustr ies SAS or its af filiated companies .

Document Number: F-15479-13

Page 43

Page 44

Page 45

Page 46

Loading...

Loading...