Page 1

The essential guide

Motion & Drives

2011

Page 2

Lexium 32

Inspired by Simplicity

Altivar 32

More than 150 application-specifi c

functions

The Altivar 32 range of variable speed drives controls

asynchronous and synchronous motors rated from 0.18 to 15 kW

operating in open loop mode in complex machines:

• Compact, vertical and slim format (45 mm)

• Integrated function blocks for creating simple control system

functions (timers, counters, comparators, etc.)

• Machine safety functions integrated as standard (STO, SLS, SS1)

• Open design: communicates with most industrial networks

For more information, see page 18

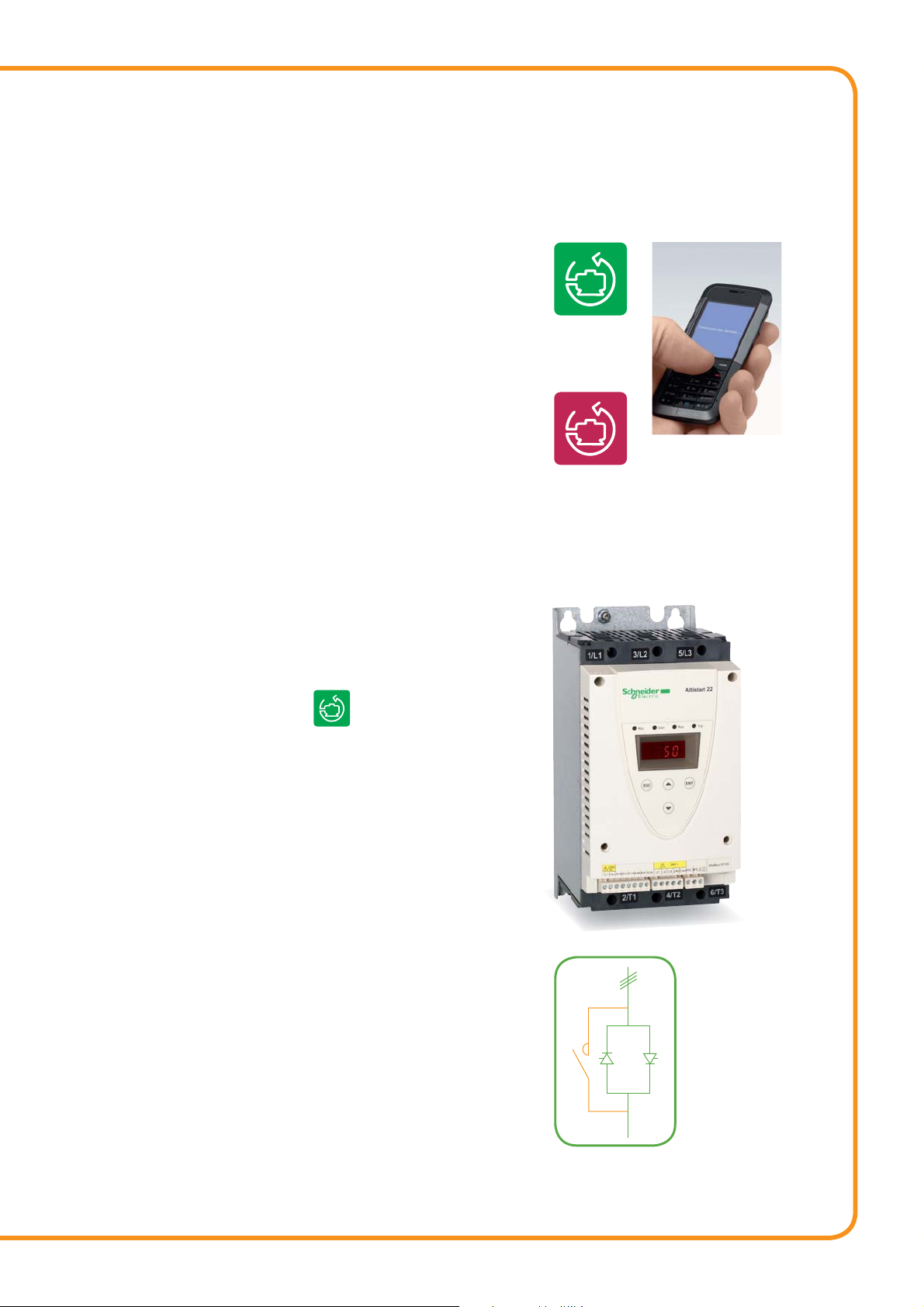

The Lexium 32 servo drive range (0.15 to 7 kW) is a drive system

designed for applications where high precision and dynamic

positioning are critical:

• Suitable for packaging, materials processing (cutting, turning,

milling, etc.) and handling, printing and textile applications

• 3 servo drive families and two types of servo motor available

• Simplifi ed engineering: motor sizing, CAD and cabinet drawings,

support for PLCopen libraries and SoMove setup software

• Integrated “Safe Torque Off” function

• Quick integration: wide selection of fi eldbus modules

For more information, see page 44

Ultra slim and ultra powerful

Practical and innovative, the Altivar 32 and Lexium 32 ranges can help

reduce the size of your enclosures by as much as 40%.

• Extra slim book format

• Easy to confi gure and setup with SoMove software

• Packed with common software tools, accessories and functions

• Homogeneous mounting and wiring systems

• High-performance communication system

• Built-in Bluetooth as standard

• Can be confi gured with the power off in its original packaging:

confi gurations can be transferred remotely via mobile phone using

SoMove Mobile software

Page 3

SoMove and SoMove Mobile

User-friendly and effi cient

SoMove is a common setup software tool for PCs, designed for

Schneider Electric’s latest motor control devices.

• Available as a free download from www.schneider-electric.com,

SoMove allows you to prepare drive confi guration fi les and set

parameters, while making maintenance easier.

• Compatible with communication tools, such as Multi-Loader,

Simple Loader, remote display terminals, etc.

SoMove Mobile is an application for mobile phones:

• Remote confi guration or modifi cation of Altivar 32 variable speed

drives, Lexium 32 servo drives and many products from the

TeSys range

• File and data exchange via Bluetooth, USB, e-mail, MMS, etc.

For more information, see page 50

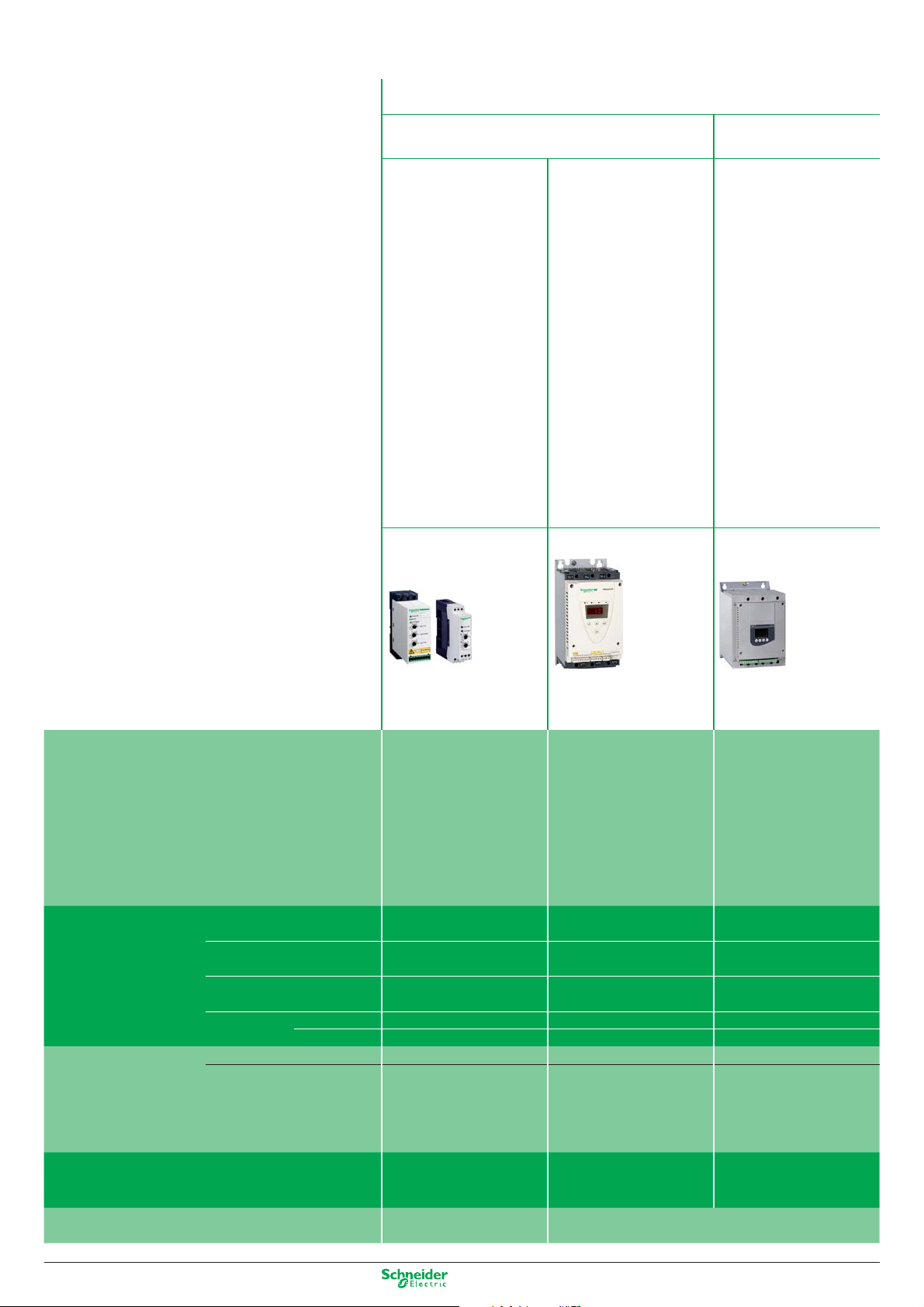

Altistart 22

Integrated bypass function

The Altistart 22 range of compact soft start/soft stop units for

pumps and fans is designed for infrastructure and industrial

applications.

• Integrated bypass function for controlled starting and stopping,

using both voltage and torque, of three-phase squirrel cage

asynchronous motors

• Power ratings between 4 and 400 kW

With the Altistart 22 range driving your applications, you can:

• Cut your operating costs

• Reduce the number of components you need to manage

(multifunction products)

• Control temperature rises due to its low heat dissipation

• Simplify wiring (6 cables instead of 12)

• Protect your electrical installation

• Save space in your enclosures with a fully equipped product

For more information, see page 10

3 controlled

phases

Page 4

Altivar 212 for HVAC*

Save up to 70% on your energy bills**

Designed for pumps, fans and compressors, the new generation of

Altivar 212 drives optimises the performance of motors rated from

0.75 to 75 kW (1 to 100 hp).

• A wealth of integrated application-specifi c functions (sleep/

wake-up, smoke extraction, etc.)

• Advanced performance management for your installations

(service continuity)

• Instant overview of energy consumption

• Fault detection ensures work can be carried out quickly

• Preventive maintenance: fault alarms, operating time, etc.

• Connection to the supervision network via embedded protocols

for effective building management

• Uses tools such as Multi-Loader, remote graphic display

terminal, Bluetooth, etc. to install, confi gure and visualise your

installation

Altivar 212, variable

speed drive

dedicated to HVAC

*HVAC: Heating, Ventilation and Air Conditioning

**compared to a conventional solution with valves

For more information, see page 15

Altivar 61Q and Altivar 71Q

A rugged water-cooled range

Altivar Q variable speed drives are suitable for applications in very

dusty or corrosive atmospheres, such as tunnels, mines or marine

environments, or in small rooms without air conditioning.

• Reduced noise

• Corrosion-resistant

• Saves energy as there is no need for air conditioning

• Rugged

• Easy to install

• Low maintenance (stainless steel pipes), ensuring a long

service life

• High-performance: high torque at low speed

• 3 sizes designed to cover a wide range of power ratings

(90 to 800 kW)

• CE, UL, CSA and Marine certifi cations

For more information, see page 23 and 32

Altivar 61Q with

water cooling

system

Page 5

Motion & Drives

This document is a selection of

the top selling products.

Soft starters and variable speed drives

Selection guide ............................................................................................................... 3 and 7

Starters

Altistart 01 ........................................................................................................................ 8 and 9

Altistart 22 .....................................................................................................................10 and 11

Altistart 48 .................................................................................................................... 12 and 13

Drives

Altivar 12 .................................................................................................................................. 14

Altivar 212 ................................................................................................................................ 15

Altivar 312 ................................................................................................................................ 16

Altivar 31C ................................................................................................................................ 17

Altivar 32 .................................................................................................................................. 18

Altivar 61, 61Q, 61 Plus ................................................................................................... 19 to 25

Specific cards and extension for pumping and ventilation machines ........................... 26 and 27

Altivar 71, 71Q, 71 Plus ................................................................................................... 28 to 34

Altivar Lift .................................................................................................................................. 35

Specific cards and extension for complex and high power machines .......................... 36 and 37

Accessories and options (Altistart et Altivar) ............................................... 38 and 39

Controllers, drives, motors and linear motion axes

Selection Guide ............................................................................................................. 40 to 42

Motion Controller Lexium LMC ........................................................................................ 43

Servo drives, servo motors Lexium 32 and accessories ............................. 44 to 51

Lexium 32 servo drives

Lexium BMH and Lexium BSH servo motors

Stepper Drives and Stepper Motors Lexium SD ....................................................... 52

Lexium SD2/Lexium SD3 stepper drives

Lexium BRS2/Lexium BRS3 stepper motors

Integrated Drives Lexium IL ..................................................................................... 53 to 55

Lexium ILA/ILE/ILS/ILT/ILP

Single axes and multi-axis Systems Linear Motion .................................... 56 and 57

Lexium PAS/CAS/TAS/MAX

1

Page 6

The Altistart, Altivar and Lexium ranges

increase the effi ciency of your machines,

reduce their energy consumption and

optimise their kinematics.

Easy to install, offering intuitive

programming and extensive communication options, they are easily integrated

into your control system architectures.

Altistart and Altivar

Use Altistart soft starters to start your motors smoothly

and so protect the mechanics of your equipment.

With the Altivar range of

variable speed drives,

you save energy and

manage the speed of

your motors to optimise and enhance

productivity in your

installations.

Lexium

Controllers, drives, motors and

linear positioning axes:

Schneider Electric offers a

complete range of motion

control products and solu-

tions suitable for even the most

specialised applications. Designed with

maximum simplicity in mind throughout a machine’s entire

service life, the Lexium range reduces costs and optimises

productivity.

2

Page 7

Selection guide

Starters - Low voltage

Simple machines

Complex machines/

Special machines

CApplications:

Compressors, fans,

pumps, conveyors, car

wash gantries, etc.

CApplications:

Pumps, fans, turbines,

compressors, conveyors,

conveyor belts, lifting

screws, escalators, etc.

CApplications:

Pumps, high inertia

fans and machines,

compressors, conveyors,

agitators, mixers,

escalators, etc.

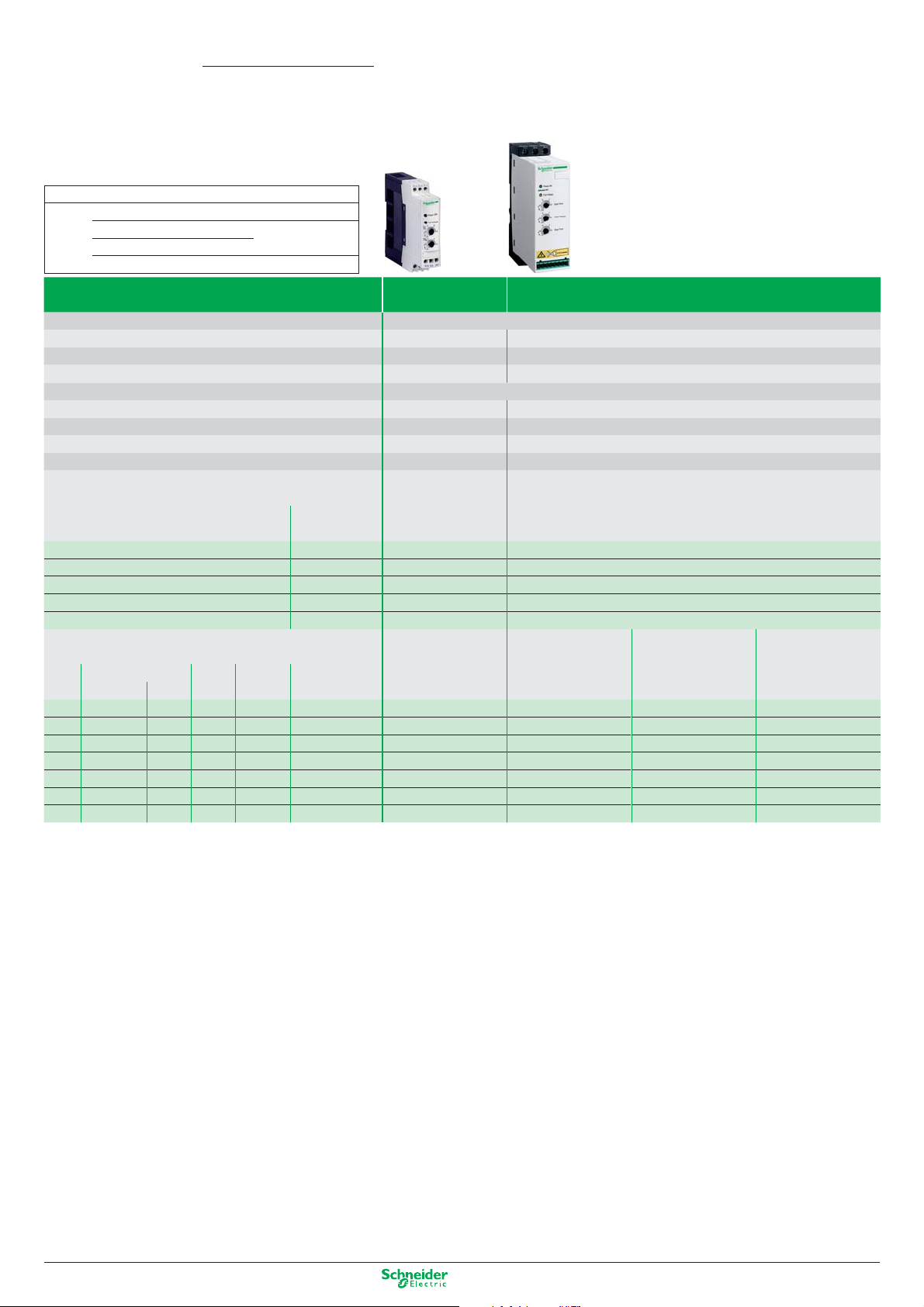

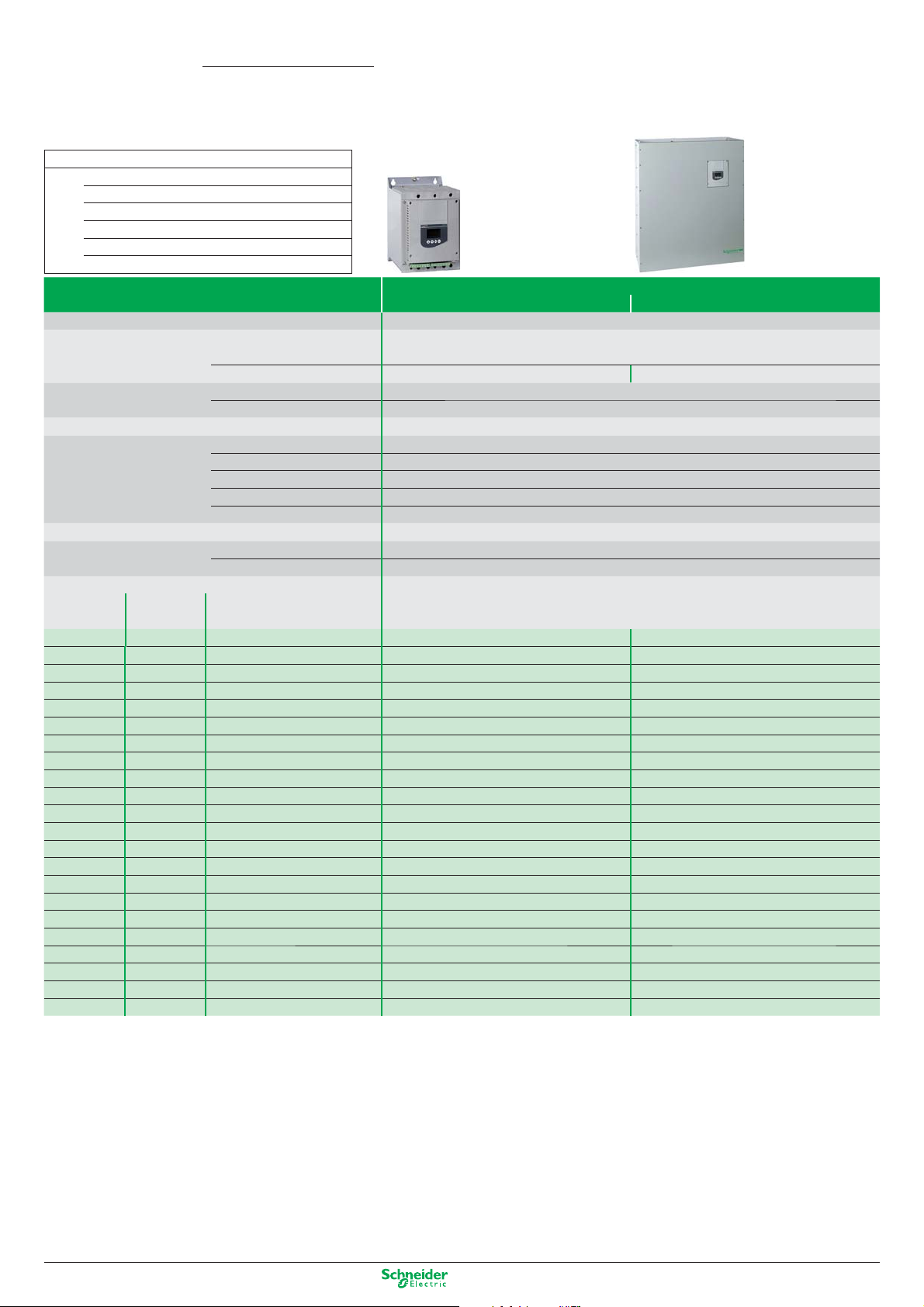

Altistart 01 Altistart 22 Altistart 48

Soft start and

Soft start/soft stop units

Description • Compact

• Simple: easy mounting,

wiring and adjustment

• Effi cient: Current peaks

limitation on starting, reduction

of mechanical shocks, increased

service life for your machines

• Energy saving

Technical information Power range for

50…60 Hz supply

Voltage Single-phase 110…480 V Three-phase 208…600 V Three-phase 208…690 V

Drive/Output frequency – – –

Motor type Asynchronous Yes Yes Yes

Synchronous No No No

Communication Integrated – Modbus Modbus

As an option Can be used with TeSys U

0.37...15 kW 4... 400 kW 4...1200 kW

Three-phase 110…480 V Three-phase 230…440 V

motor starter-controller to

create a complete motor

starter solution

Soft start/soft stop units

• Innovative with its integrated

Bypass contactor for motors up

to 315 kW

• Cost-effective

• Compact dimensions

• Quick setup

• Protection of motor and

starter

• Energy saving

• 3 controlled phases

– DeviceNet, Fipio, P

Soft start/soft stop units

• Torque control system:

controlled torque, prevention of

pressure surges and limiting of

temperature rises

• Simple: quick setup

• Protection of motor and

starter: thermal protection,

phase loss detection, locked

rotor detection

• Energy saving

Ethernet

ROFIBUS DP,

Standards and certifi cations IEC/EN 60947-4-2, C-Tick, CSA,

UL, CE

Intended use Buildings, Simple machines. Machines, Infrastructures and Buildings

IEC/EN 60947-4-2, C-Tick, CSA,

UL, CE, GOST, CCC

Class A EMC

Other versions: please consult our Customer Care Centre.

IEC/EN 60947-4-2, C-Tick, CSA,

UL, CE, DNV, GOST, CCC, NOM,

SEPRO and TCF

Classes A and B EMC

3

Page 8

Selection guide

Standard drives - Low voltage

Simple machines

CApplications:

• Simple machines for

industry (small handling

applications, packaging,

pumps, fans, etc.)

• Simple consumer

machines (access barriers,

C Applications:

Simple industrial machines

(material handling

and packaging, textile

machines, special

machines, pumps and

fans).

C Applications:

Simple industrial

machines (material

handling and packaging,

textile machines, special

machines, pumps and

fans).

rotating advertising

hoardings, medical beds,

treadmills, dough mixers,

etc.)

• Other types of application:

- Mobile machines and

small appliances equipped

with a power socket

- Applications which

traditionally use other

solutions (2-speed DC

motors, mechanical drives,

etc.).

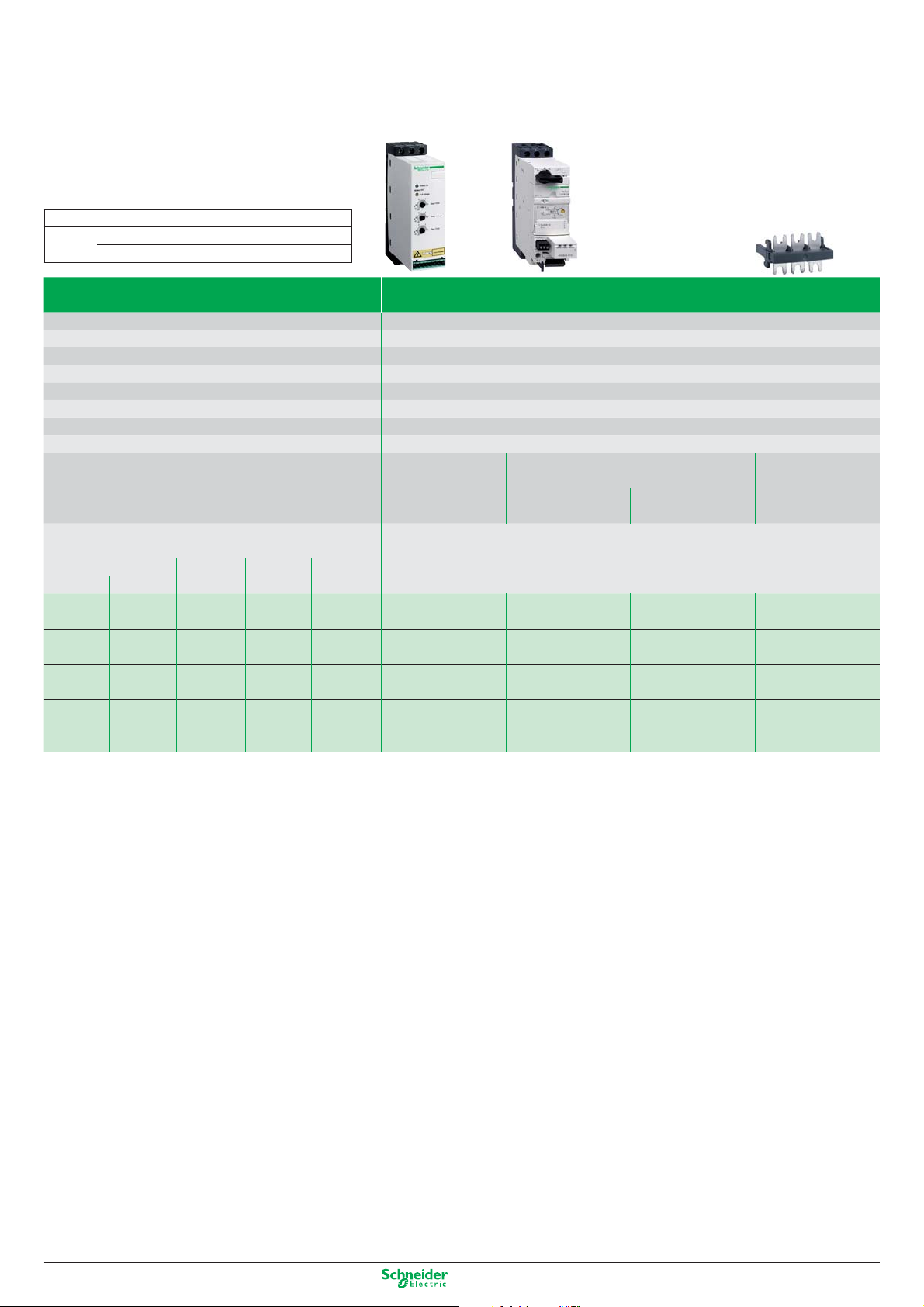

Altivar 12 Altivar 312 Altivar 31C IP55

Variable speed drives for small

machines with 240 V three-phase

asynchronous motor

Description • Compact

• Easy to set up

(Plug & Play)

• Reliable, cost-effective

solution for compact machines

Technical information Power range for

50…60 Hz supply

Voltage Single-phase 100…240 V

Drive/Output frequency

Motor type Asynchronous Yes Yes Yes

Synchronous No No No

Communication Integrated Modbus Modbus and CANopen Modbus and CANopen

As an option – CANopen Daisy chain,

0.18...4 kW 0.18...15 kW 0.18...15 kW

Three-phase 200…240 V

0.5…400 Hz 0.5…500 Hz 0.5…500 Hz

Variable speed drives for threephase asynchronous motors

• Open: large number of

communication cards available

as options

• User-friendly: simplified

interface

• Autotuning:

maximum performance

Single-phase 200…240 V

Three-phase 200…600 V

DeviceNet, P

Modbus TCP, Fipio

ROFIBUS DP,

Variable speed drives for threephase asynchronous motors for

machines in harsh environments.

• Rugged even in the most hostile

environments:

- Installed as close as possible to

the motor

- Integrated functions for applications

requiring IP55 degree of protection

- Modbus and CANopen

communication protocols

• Flexibility to adapt to each machine:

- Customisable depending on the

model

- Easy configuration

Single-phase 200…240 V

Three-phase 380…500 V

DeviceNet, Ethernet TCP/IP,

Fipio, PROFIBUS DP

Standards and certifications IEC/EN 61800-5-1, IEC/EN 61800-3 (environments 1 and 2,

categories C1 to C3)

CE, UL, CSA, C-Tick, GOST, NOM

Intended use Machines

Other versions: please consult our Customer Care Centre.

4

IEC/EN 61800-5-1, IEC/EN

61800-3 (environments 1 and 2,

categories C1 to C3)

CE, UL, CSA, C-Tick, GOST

Page 9

Complex machines

Complex machines/

Special machines

Pumps and

Fans

C Applications:

Industrial machines:

hoisting, packaging,

material handling,

special machines (woodworking machines, metal

processing machinery,

etc.).

C Applications:

High performance

applications:

• Material handling

• Hoisting

• Wood-working machines

• Process machinery

• Textile machines

• Packaging

C Applications:

High performance

applications:

• Material handling

• Hoisting

• Wood-working machines

• Process machinery

• Textile machines

• Packaging

C Applications:

Range specifi cally for high

performance pumps and

fans for the industrial and

building markets.

C Applications:

Pumping and ventilation

machines in harsh

environment

Altivar 32 Altivar 71 Altivar 71Q Altivar 61 Altivar 61Q

Variable speed drives for

asynchronous motors and

open-loop synchronous motors

• Compact: "Book" format

Integrated Safety function com-

•

pliant to IEC 61508 SIL3 and PL-e

• Open: communication cards

available as options

• Integrated programmable

logic functions

• Simple setup

· Energy saving : Control of

energy effi cient permanent

magnet synchr onous motors

0.18...15 kW 0.37...630 kW 90...630 kW 0.37...800 kW 110…800 kW

Single-phase 200…240 V

Three-phase 380…480 V

0.1…599 Hz 0…599 Hz up to 37 kW /

Yes Yes Yes Ye s Yes

Yes Ye s Yes Yes Ye s

Modbus and CANopen Modbus and CANopen Modbus et CANopen Modbus and CANopen Modbus et CANopen

EtherNet/IP, Modbus TCP,

ROFIBUS DP V1, EtherCAT,

P

Devicenet

IEC/EN 61800-5-1, IEC/EN 61800-3

(environments 1 and 2, Categories

C2 and C3), UL508C, EN 954-1

Category 3, ISO/EN 13849-1/- 2

Category 3 (PLd), IEC 61800-5-2, IEC

61508 (parts 1&2) level SIL1 SIL2 SIL3,

draft standard EN 50495E, CE, UL,

CSA, C-Tick, GOST, NOM.

Machines Machines, industrial processes

For three-phase synchronous

and asynchronous motors.

Constant torque applications.

• Wide range

• Quick start-up and easy

diagnostics: multi-language

graphic display terminal

• Open to most industrial

communication buses

• Integrated safety functions

• Motor control: high-

performance in open-loop and

closed loop mode

Single-phase 200…240 V

Three-phase 200…690 V

200…240V and 380…480V

0…500 Hz for the rest of the range

Modbus TCP, Fipio,

Modbus/Uni-Telway, Modbus

Plus, EtherNet/IP, DeviceNet,

P

ROFIBUS DP, PROFIBUS DP V1,

NTERBUS S, CC-Link,

I

IEC/EN 61800-3, EN 55011,

EN 55022, CSA, UL, C-TICK,

CE, NOM, DNV, GOST

and infrastructures

Water-cooled variable speed

drives for three-phase synchronous and asynchronous motors.

Constant torque applications.

• Improved robustness with

water cooling

• Effi cient cooling system reduced

need of air conditioning

• Long time operation without

maintenance

• Excellent protection against

corrosion due to stainless steel

cooling pipes

• Very high starting torque for

frequent start-up applications

Three-phase 380...480 V

Three-phase 500…690 V

0…500 Hz 0.1…599 Hz up to 37 kW /

Modbus TCP, Fipio, Modbus/UniTelway, Modbus Plus, EtherNet/IP,

DeviceNet, PROFIBUS DP, PROFIBUS

DP V1, I

NTERBUS S, CC-Link,

IEC/EN 61800-3, EN 55011, EN

55022, CSA, UL, C-TICK, CE,

NOM, DNV, GOST

Machines, industrial processes

or infrastructures

Variable speed drives for threephase asynchronous motors.

Variable torque applications.

• Wide range

• Easy setup and diagnostics

with the multi-language graphic

display terminal

• Open to the main

communication buses

Single-phase 200…240 V

Three-phase 200…690 V

200…240V and 380…480V

0.1…500 Hz for the rest of the range

Modbus TCP, Fipio, Modbus/UniTelway, Modbus Plus, EtherNet/IP,

DeviceNet, PROFIBUS DP, PROFIBUS

DP V1,

INTERBUS

Lonworks, METASYS N2, APOGEE FLN P1, BACnet

IEC/EN 61800-3, EN 55011,

EN 55022, CSA, UL, C-TICK,

CE, NOM, DNV, GOST

Buildings and infrastructures Building or infrastructures

S, CC-Link,

Other versions: please consult our Customer Care Centre.

Water-cooled variable speed

drives for three-phase asynchronous and synchronous motors.

Variable torque applications

• Improved robustness with

water cooling

• Effi cient cooling system reduced

need of air conditioning

• Prolonged maintenance-free

operational life

• Excellent protection against

corrosion due to stainless steel

cooling pipes

Three-phase 380...480 V

Three-phase 500…690 V

0.1…500 Hz

HVAC protocols

METASYS N2,APOGEE FLN P1

Industrial protocols: Modbus TCP,

Modbus/Uni-Telway, Fipio, Modbus Plus,

PROFIBUS DP, PROFIBUS DP V1, DeviceNet,

Ethernet IP, CC-Link,

IEC/EN 61800-3, EN 55011, EN

55022, CSA, UL, C-TICK, CE,

NOM, DNV, GOST

: LonWorks, BACnet,

INTERBUS

5

Page 10

Selection guide

Specialized drives - Low voltage

HVAC Lifts

C Applications:

Range specifically for HVAC applications

C Applications:

Lifts

(heating, ventilation, air conditioning) in

buildings.

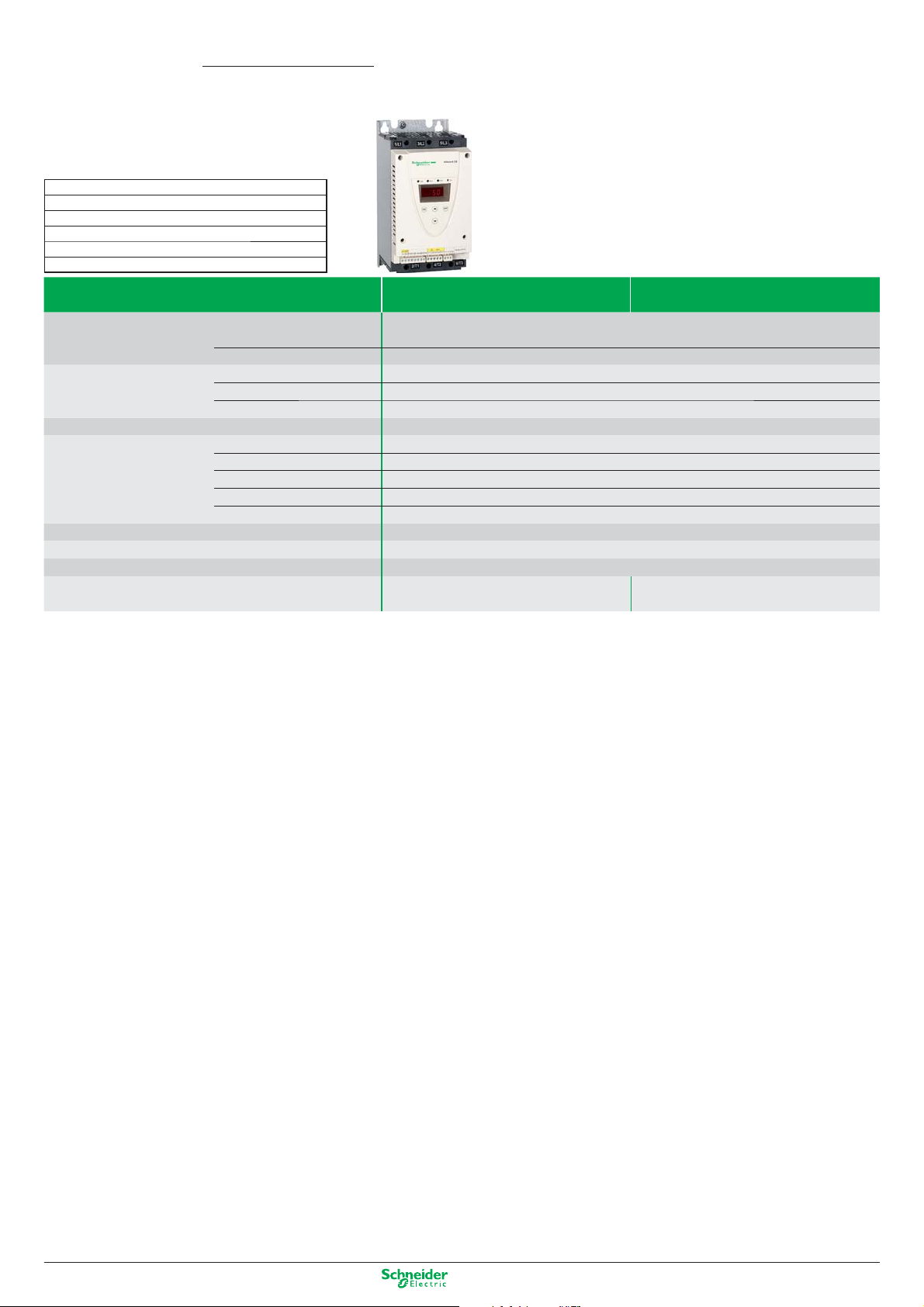

Altivar 212 Altivar LIFT

Variable speed drives for three-phase asynchronous motors.

Variable torque building HVAC applications.

Variable speed drives for lifts.

Description

Technical information Power range for

50…60 Hz supply

Voltage Three-phase 200…480 V Single-phase 200…240 V

Drive/Output frequency

Number of quadrants

Cooling system — —

Protection class — —

Motor type Asynchronous Yes Yes

Synchronous No No

Communication Integrated Modbus, METASYS N2, APOGEE FLN P1, BACnet Modbus and CANopen

As an option Lonworks

• Compact size: side-by-side mounting

• Simplicity : Dedicated HVAC functions and remote

graphic keypad option

• Openness : Integrated communications for building management systems

• EMC filters built-in

• Reduction of the total harmonic distortion

THDI<30%

• Protection class: IP21 and IP55

0.75…75 kW 4…22 kW

0.5…200 Hz 0...599 Hz

——

• Quick start-up and easy diagnostics with the

multi-language graphic display terminal and dedica-

ted Lift configuration menu.

• Dedicated Lift functions for greater comfort and

safety

• High-performance motor control in open-loop

and closed loop mode

Three-phase 200…480 V

Modbus TCP, Fipio, Modbus/Uni-Telway, Modbus

Plus,EtherNet/IP, DeviceNet, PROFIBUS DP,

PROFIBUS DP V1,

INTERBUS

S, CC-Link

Standards and certifications IEC/EN 61800-3, EN 55011,

EN 55022, CSA, UL, C-TICK, CE, NOM

Intended use Buildings Machines

6

IEC/EN 61800-3, EN55011,

EN 55022, CSA, UL, C-TICK, CE, NOM et EN81-1

(chap 12.7.3)

Other versions: please consult our Customer Care Centre.

Page 11

Integrated variable speed control solutions

Pumps and Fans

Low voltage

C Applications:

• Fans

• Pumps

• Compressors

• Screw feeders

Pumps and Fans

Medium voltage

C Applications:

• Energy: fans, pumps, turbine

starters

• Oil and gas: pumps,

compressors, air blowers,

extruders

• Mines and Minerals:

conveyors, crushers, fans,

pumps

• Water treatment: pumps,

Complex machines/Special

machines Low voltage

C Applications:

• Fans

• Pumps

• Compressors

• Screw feeders

Complex machines/Special

machines Medium voltage

C Applications:

• Energy: fans, pumps, turbine

starters

• Oil and gas: pumps,

compressors, air blowers,

extruders

• Mines and Minerals: conveyors,

crushers, fans, pumps

• Water treatment: pumps,

air blowers.

air blowers.

Altivar 61 Plus Altivar 1100 Altivar 71 Plus Altivar 1000

High power low voltage variable speed drives

for buildings and infrastructures.

Variable torque

A simple, open range:

• Greater fl exibility: numerous possible

options and communication on most industrial

networks

• Easy confi guration

• Ready to use

Maximum safety: the Altivar Plus range has

a cooling system and components that have

been tested in extreme conditions.

Time savings on:

• Creating quotes

• Placing orders

• Installation and start-up

90…2400 kW 0.3…10.5 MW 90…2000 kW 0.5…10 MW

Three-phase 380…690 V 3,3 kV

0.1…500 Hz Standard : 0,2…60 Hz

2 and 4 2 2 and 4 2 and 4

Air or water cooled Air cooled Air or water cooled Air or water cooled

IP23/IP54

IP55 (water cooled)

Yes Ye s Yes Ye s

Yes No Yes No

Modbus and CANopen PROFIBUS, Modbus Modbus and CANopen Ethernet, PROFIBUS, Modbus

Modbus TCP, Fipio, Modbus/Uni-Telway, Modbus

Plus, EtherNet/IP, DeviceNet, PROFIBUS DP,

PROFIBUS DP V1,

METASYS N2, APOGEE FLN P1, BACnet

IEC/EN 61800-5-1, IEC/EN 61800-3

(environments 1 and 2), IEC/EN 61000-4-2,

-4-3, -4-5, -4-6 (level 3), IEC/EN 61000-4-4

(level 4), IEC/EN 60529, IEC 60721-3-3 class

3C2 and 3S2, CE. DNV, GOST

Buildings and infrastructures Infrastructures Machines, industrial processes

INTERBUS

S, CC-Link,

Lonworks,

Medium voltage variable speed

drives for asynchronous motors

(quotation on request)

Environmentally-friendly and Costeffective:

• Perfect integration in the line supply

• No disturbance of the motor and the

driven load

• High effi ciency

Easy to install and set up

Compact

6,6 kV

10 kV

Option : 0,2…120 Hz

IP31

IP41 (option)

Ethernet, Devicenet, CANopen, etc. Modbus TCP, Fipio, Modbus/Uni-Telway,

IEC/EN 61800-5-1, IEC/EN 61800-4,

IEC/EN 61800-3 (environnements 1

and 2, catégories C1 to C3), IEEE

519, IEC/EN 60204-11 and

IEC/EN 60529

High power low voltage variable speed drives

for industry.

Constant torque

A simple, open range:

• Greater fl exibility: numerous possible

options and communication on most industrial

networks

• Easy confi guration

• Ready to use

Maximum safety: the Altivar Plus range has

a cooling system and components that have

been tested in extreme conditions.

Time savings on:

• Creating quotes

• Placing orders

• Installation and start-up

Three-phase 380…690 V 2.4 kV

0…500 Hz Standard: 5…70 Hz

IP23/IP54

IP55 (water cooled)

Modbus Plus, EtherNet/IP, DeviceNet,

PROFIBUS DP, PROFIBUS DP V1,

INTERBUS S, CC-Link

IEC/EN 61800-5-1, IEC/EN 61800-3 (environments 1 and 2), IEC/EN 61000-4-2,

-4-3, -4-5, -4-6 (level 3), IEC/EN 61000-4-4

(level 4), IEC/EN 60529, IEC 60721-3-3 class

3C2 and 3S2, CE. DNV and GOST

and infrastructures

Medium voltage variable speed drives

for asynchronous motors (quotation on

request)

High effi ciency

For use in harsh environments

Open to all communication networks

3.3 kV

Option: 5…140 Hz

IP41 (air cooled)

IP54 (water cooled)

Devicenet, CANopen

IEC/EN 61800-5-1, IEC/EN 61800-4,

IEC/EN 61800-3 (environments 1 and 2,

categories C1 to C3), CE

Machines, industrial processes

and infrastructures

Other versions: please consult our Customer Care Centre.

7

Page 12

Altistart 01

0.37…15 kW

Dimensions (in mm) width x height x depth

ATS01 N103FT/N106 FT 22.5 x 100 x 100.4

N109FT/N112 FT/N125 FT

N206pp/N209pp/N212pp

N222pp/N232pp 45 x 154 x 130.7

45 x 124 x 130.7

Simple machines

Starters

Type Soft start units Soft start/soft stop units

Motor power 0.37 to 11 kW 0.75 to 15 kW

Degree of protection IP20

Reduction of current peaks 2 controlled phases 2 controlled phases

Adjustable starting time 1…5 s 1…10 s

Adjustable deceleration time No: freewheel stop Yes: 1... 10 s

Adjustable breakaway torque 30…80% of DOL motor starting torque

Logic inputs

Logic outputs – 1 logic output

Relay outputs – 1 relay output

Control supply voltage

Supply voltage

Motor power

230 V Nominal current

kW (IcL)

0.37 3 A ATS01N103FT

0.75 6 A ATS01N106FT

1.1 9 A ATS01N109FT

1.5 12 A ATS01N112FT

2.2 25 A ATS01N125FT

Supply voltage

Motor power

210 V 230 V 400 V 460 V Nominal current

HP kW HP kW HP (IcL)

– 0.37-0.55 0.5/– 1.1 0.5-1.5 3 A ATS01N103FT – – –

0.5 0.75-1.1 1-1.5 2.2-3 2-3 6 A ATS01N106FT ATS01N206LU ATS01N206QN ATS01N206RT

11.5 2 4 5 9 A ATS01N109FT ATS01N209LU ATS01N209QN ATS01N209RT

1.5 2.2 3 5.5 7.5 12 A ATS01N112FT ATS01N212LU ATS01N212QN ATS01N212RT

– 4-5.5 5-7.5 7.5-11 10-15 22 A – ATS01N222LU ATS01N222QN ATS01N222RT

7.5-9-11

2-3 3-4-5.5 5-7.5

– 7.5 10 15 20 32 A – ATS01N232LU ATS01N232QN ATS01N232RT

10-15 25A ATS01N125FT – – –

–

110... 220 VAC ± 10%, 24 VDC ± 10%

Single-phase 110…230 V

Three-phase 110…480 V Three-phase 200…240 V Three-phase 380…415 V Three-phase 440…480 V

3 logic inputs (start, stop and startup boost)

Built into the starter

8

Other versions: please consult our Customer Care Centre.

Page 13

Starters with TeSys model U

Dimensions (in mm) width x height x depth

ATSU01 N206LT/N209LT/N212LT 45 x 124 x 130.7

N222LT/N232LT 45 x 154 x 130.7

Type Soft start/soft stop units

Motor power 0.75 to 15 kW

Degree of protection IP20

Reduction of current peaks Yes

Adjustable starting and stopping times 1…10 s

Adjustable breakaway torque

Logic inputs 3 logic inputs (start, stop and startup boost)

Logic outputs 1 logic output

Relay outputs 1 relay output

Control supply voltage 24 VDC, 100 mA, ± 10%

References

model U

Supply voltage Three-phase 200…480 V

Motor power

230 V 400 V 460 V

kW HP kW HP

0.75 1 1.5 2 6 A ATSU01N206LT LUB12 LUCp05BL VW3G4104

1.1 1.5 2.2/3 3 6 A ATSU01N206LT LUB12 LUCp12BL

1.5 2 – 5 9 A ATSU01N209LT LUB12 LUCp12BL VW3G4104

– – 4 – 9 A ATSU01N209LT LUB12 LUCp12BL

2.2 3 5.5 7.5 12 A ATSU01N212LT LUB12 LUCp12BL VW3G4104

3 – – – 12 A ATSU01N212LT LUB32 LUCp18BL

4 5 7.5 10 22 A ATSU01N222LT LUB32 LUCp18BL VW3G4104

5.5 7.5 11 15 22 A ATSU01N222LT LUB32 LUCp32BL

7.5 10 15 20 32 A ATSU01N232LT LUB32 LUCp32BL VW3G4104

(1) To compose your reference, replace p in the reference with: «A» for a standard control unit, «M» for a multifunction unit and «B» for an advanced unit.

Nominal

current (IcL)

30.... 80% of DOL motor starting torque

Soft start/soft stop

units

TeSys starter-controller Power connector

Power base Control unit (1) between ATSU and

TeSys model U

Other versions: please consult our Customer Care Centre.

9

Page 14

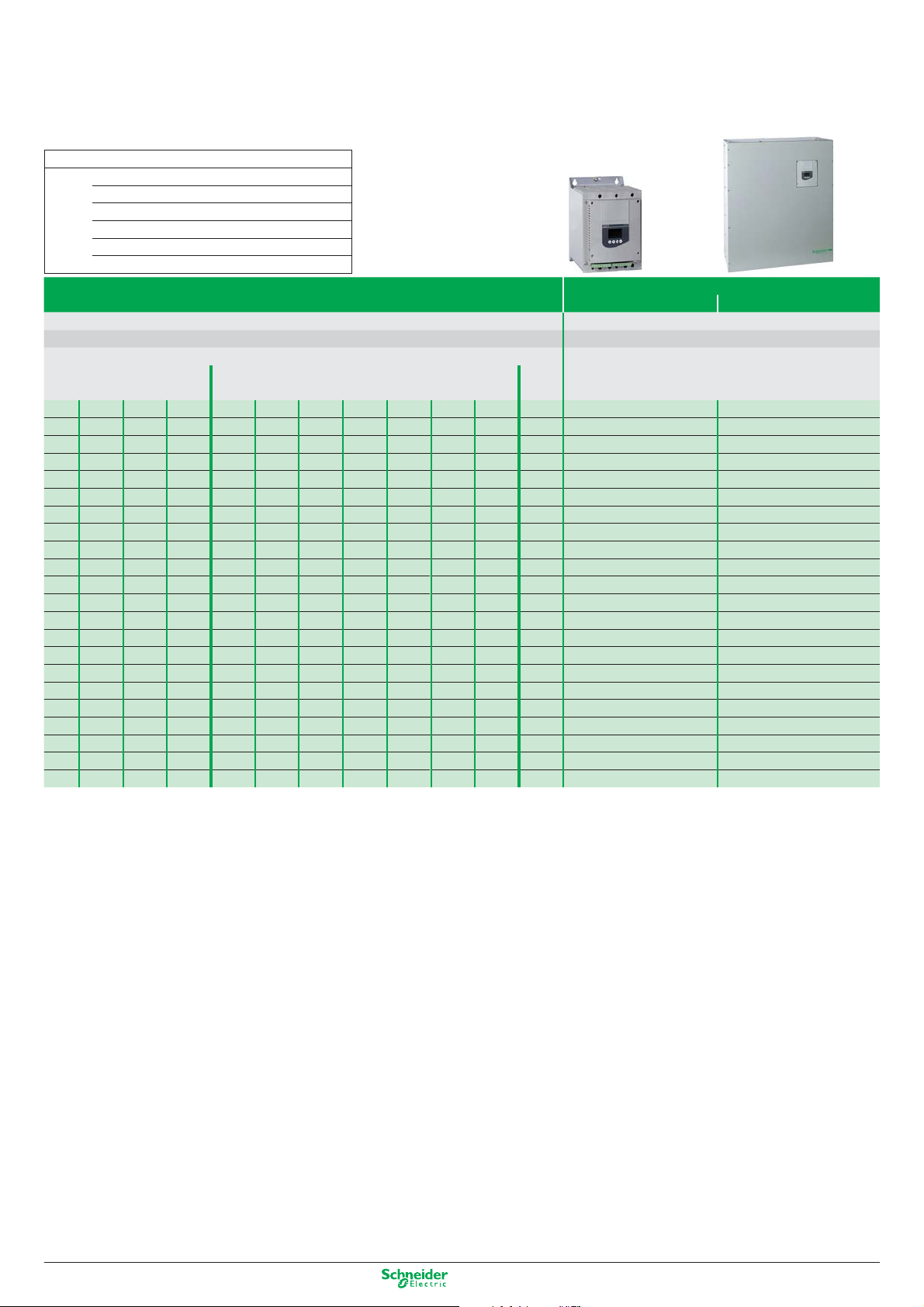

Altistart 22

4…400 kW

Dimensions (en mm) width x height x depth

Size A: 130 x 265 x 169

Size B: 145 x 295 x 207

Size C: 150 x 356 x 229

Size D: 206 x 425 x 299

Size E: 304 x 455 x 340

Simple machines

Soft start/soft stop units

Supply voltage Three-phase 208…600 V Three-phase 230…440 V

Protection Degree of protection IP20: for ATS 22D17pppD88 starters

IP00: for ATS 22C11pppC59 starters (protection of terminals available as an option)

Motor thermal protection Class 10, 20 or 30

Drive Number of controlled phases 3

Types of control Confi gurable voltage ramp, torque ramp

Operating cycle Standard

Functions Integrated Bypass contactor

Number of I/O Analog inputs 1 PTC probe

Logic inputs 3

Logic outputs –

Analog outputs –

Relay outputs 2

Dialogue Integrated display terminal, SoMove Lite setup software

Communication Integrated Modbus

Standards and certifi cations IEC/EN 6 0947-4-2, class A EMC, CE, UL, CSA, C-Tick, GOST, CCC

Motor connection Possible to connect the starter in the motor delta

connection

10

Other versions: please consult our Customer Care Centre.

Page 15

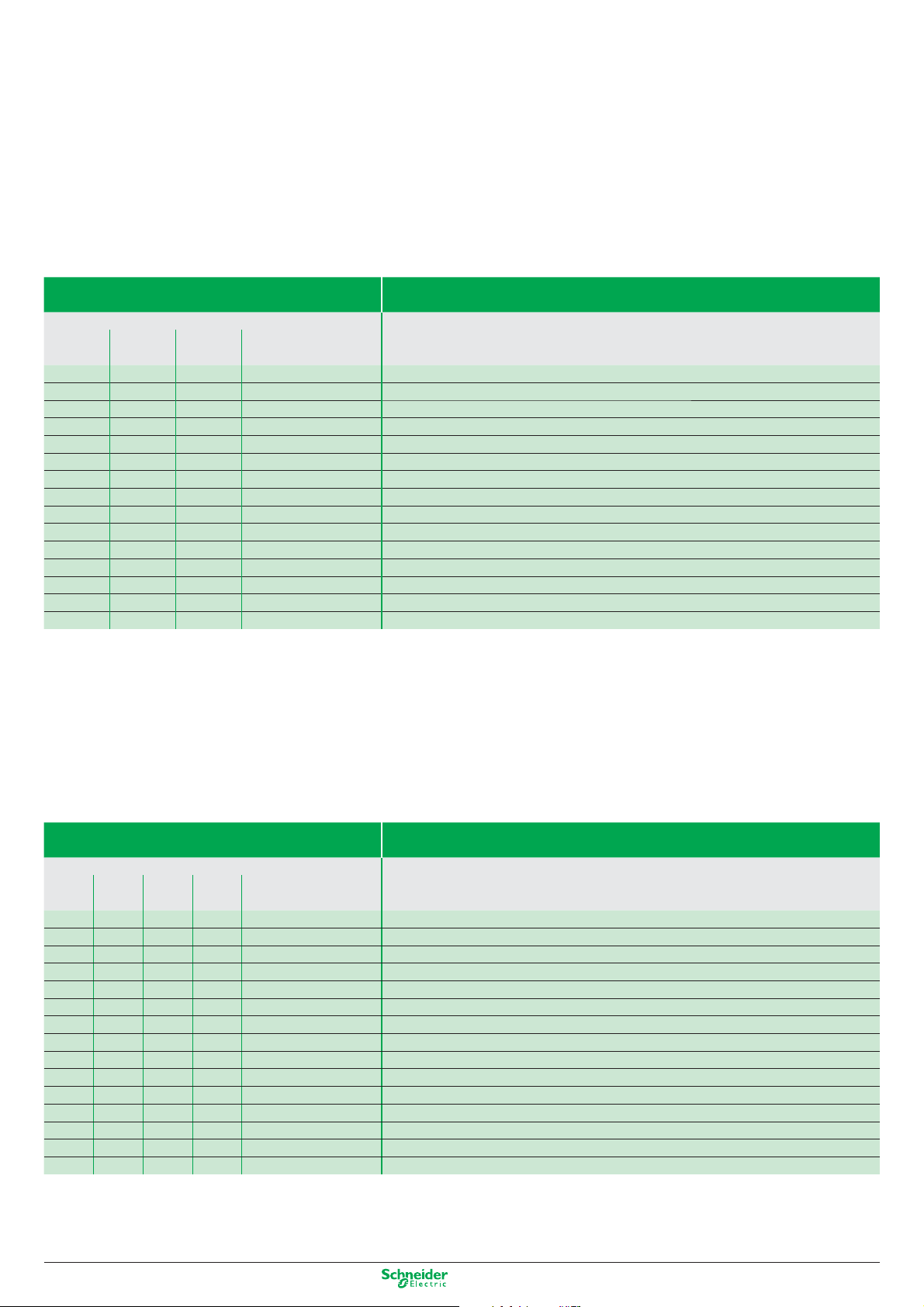

Connection in the motor power supply line Soft start/soft stop unit 230…440 V - 50/60 Hz

Motor

Power indicated on rating plate

230 V 400 V 440 V Nominal current

kW kW kW starter (IcL) Reference Size

4 7.5 7.5 17 ATS22D17Q Size A

7.5 15 15 32 ATS22D32Q Size A

11 22 22 47 ATS22D47Q Size A

15 30 30 62 ATS22D62Q Size B

18.5 37 37 75 ATS22D75Q Size B

22 45 45 88 ATS22D88Q Size B

30 55 55 110 ATS22C11Q Size C

37 75 75 140 ATS22C14Q Size C

45 90 90 170 ATS22C17Q Size C

55 110 110 210 ATS22C21Q Size D

75 132 132 250 ATS22C25Q Size D

90 160 160 320 ATS22C32Q Size D

110 220 220 410 ATS22C41Q Size D

132 250 250 480 ATS22C48Q Size E

160 315 355 590 ATS22C59Q Size E

Connection in the motor power supply line Soft start/soft stop unit 230…600 V - 50/60 Hz

Motor

Power indicated on rating plate

230 V 400 V 440 V 500 V Nominal current

kW kW kW kW starter (IcL) Reference Size

4 7.5 7.5 9 17 ATS22D17S6 Size A

7.5 15 15 18.5 32 ATS22D32S6 Size A

11 22 22 30 47 ATS22D47S6 Size A

15 30 30 37 62 ATS22D62S6 Size B

18.5 37 37 45 75 ATS22D75S6 Size B

22 45 45 55 88 ATS22D88S6 Size B

30 55 55 75 110 ATS22C11S6 Size C

37 75 75 90 140 ATS22C14S6 Size C

45 90 90 110 170 ATS22C17S6 Size C

55 110 110 132 210 ATS22C21S6 Size D

75 132 132 160 250 ATS22C25S6 Size D

90 160 160 220 320 ATS22C32S6 Size D

110 220 220 250 410 ATS22C41S6 Size D

132 250 250 315 480 ATS22C48S6 Size E

160 315 355 400 590 ATS22C59S6 Size E

The Altistart 22 soft start/soft stop unit is also available with a 110 VDC control power supply, reference ATS22…S6U

Other versions: please consult our Customer Care Centre.

11

Page 16

Altistart 48

4…1200 kW

Dimensions (in mm) width x height x depth

ATS48 D17Q to D47Q Size A: 160 x 275 x 190

D62Q to C11Q Size B: 190 x 290 x 235

C14Q to C17Q Size C: 200 x 340 x 265

C21Q to C32Q Size D: 320 x 380 x 265

C41Q to C66Q Size E: 400 x 670 x 300

C79Q to M12Q Size F: 770 x 890 x 315

Pumping and ventilation machines

Soft start/soft stop units

Supply voltage Three-phase 230…415 V (1)

Type of application Standard Severe (2)

Starter control supply voltage 220…415 V

Protection Degree of protection IP20: ATS48D17p to ATS48C11p starters

IP00: ATS48C14p to ATS48M12p starters

Motor thermal protection Class 10 Class 20 and 30

EMC Class A On all starters

Class B On all starters up to 170 A

Starting mode Torque control (patented TCS: Torque Control System)

I/O Analog inputs 1 PTC probe

Logic inputs 4 logic inputs, 2 of which are configurable

Logic outputs 2 configurable logic outputs

Analog outputs 1 analog output

Relay outputs 3 relay outputs, 2 of which are configurable

Dialogue Integrated or remote display terminal (in option), PowerSuite software workshop

Communication Integrated Modbus

As an option DeviceNet, Ethernet, Fipio, P

Motor power

230 V 400 V Nominal current

kW kW (IcL)

3 5.5 12 A – ATS48D17Q Size A

4 7.5 17 A ATS48D17Q Size A ATS48D22Q Size A

5.5 11 22 A ATS48D22Q Size A ATS48D32Q Size A

7.5 15 32 A ATS48D32Q Size A ATS48D38Q Size A

9 18.5 38 A ATS48D38Q Size A ATS48D47Q Size A

11 22 47 A ATS48D47Q Size A ATS48D62Q Size B

15 30 62 A ATS48D62Q Size B ATS48D75Q Size B

18.5 37 75 A ATS48D75Q Size B ATS48D88Q Size B

22 45 88 A ATS48D88Q Size B ATS48C11Q Size B

30 55 110 A ATS48C11Q Size B ATS48C14Q Size C

37 75 140 A ATS48C14Q Size C ATS48C17Q Size C

45 90 170 A ATS48C17Q Size C ATS48C21Q Size D

55 110 210 A ATS48C21Q Size D ATS48C25Q Size D

75 132 250 A ATS48C25Q Size D ATS48C32Q Size D

90 160 320 A ATS48C32Q Size D ATS48C41Q Size E

110 220 410 A ATS48C41Q Size E ATS48C48Q Size E

132 250 480 A ATS48C48Q Size E ATS48C59Q Size E

160 315 590 A ATS48C59Q Size E ATS48C66Q Size E

– 355 660 A ATS48C66Q Size E ATS48C79Q Size F

220 400 790 A ATS48C79Q Size F ATS48M10Q

250 500 1000 A ATS48M10Q Size F ATS48M12Q Size F

355 630 1200 A ATS48M12Q Size F –

(1) Possible to connect the starter in the motor delta connection

(2) Starting time greater than 30 seconds (fans, high inertia machines and compressors)

ROFIBUS DP

Size F

12

Other versions: please consult our Customer Care Centre.

Page 17

Soft start/soft stop units

Dimensions (in mm) width x height x depth

ATS48 D17Y to D47Y Size A: 160 x 275 x 190

D62Y to C11Y Size B: 190 x 290 x 235

C14Y to C17Y Size C: 200 x 340 x 265

C21Y to C32Y Size D: 320 x 380 x 265

C41Y to C66Y Size E: 400 x 670 x 300

C79Y to M12Y Size F: 770 x 890 x 315

Supply voltage Three-phase 208…690 V (1)

Type of application Standard Severe (2)

Starter control supply voltage 110…230 V

Characteristics Identical to 230…415 V starters

Motor power

208 V 230 V 460 V 575 V 230 V 400 V 440 V 500 V 525 V 660 V 690 V

HP kW

2 3 7.5 10 3 5.5 5.5 7.5 7.5 9 11 12 A – ATS48D17Y Size A

3 5 10 15 4 7.5 7.5 9 9 11 15 17 A ATS48D17Y Size A ATS48D22Y Size A

5 7.5 15 20 5.5 11 11 11 11 15 18.5 22 A ATS48D22Y Size A ATS48D32Y Size A

7.5 10 20 25 7.5 15 15 18.5 18.5 22 22 32 A ATS48D32Y Size A ATS48D38Y Size A

10 – 25 30 9 18.5 18.5 22 22 30 30 38 A ATS48D38Y Size A ATS48D47Y Size A

–1530401122223030373747 AATS48D47Y Size A ATS48D62Y Size B

15 20 40 50 15 30 30 37 37 45 45 62 A ATS48D62Y Size B ATS48D75Y Size B

20 25 50 60 18.5 37 37 45 45 55 55 75 A ATS48D75Y Size B ATS48D88Y Size B

25 30 60 75 22 45 45 55 55 75 75 88 A ATS48D88Y Size B ATS48C11Y Size B

30 40 75 100 30 55 55 75 75 90 90 110 A ATS48C11Y Size B ATS48C14Y Size C

40 50 100 125 37 75 75 90 90 110 110 140 A ATS48C14Y Size C ATS48C17Y Size C

50 60 125 150 45 90 90 110 110 132 160 170 A ATS48C17Y Size C ATS48C21Y Size D

60 75 150 200 55 110 110 132 132 160 200 210 A ATS48C21Y Size D ATS48C25Y Size D

75 100 200 250 75 132 132 160 160 220 250 250 A ATS48C25Y Size D ATS48C32Y Size D

100 125 250 300 90 160 160 220 220 250 315 320 A ATS48C32Y Size D ATS48C41Y Size E

125 150 300 350 110 220 220 250 250 355 400 410 A ATS48C41Y Size E ATS48C48Y Size E

150 – 350 400 132 250 250 315 315 400 500 480 A ATS48C48Y Size E ATS48C59Y Size E

– 200 400 500 160 315 355 400 400 560 560 590 A ATS48C59Y Size E ATS48C66Y Size E

200 250 500 600 – 355 400 – – 630 630 660 A ATS48C66Y Size E ATS48C79Y Size F

250 300 600 800 220 400 500 500 500 710 710 790 A ATS48C79Y Size F ATS48M10Y Size F

350 350 800 1000 250 500 630 630 630 900 900 1000 A ATS48M10Y Size F ATS48M12Y Size F

400 455 1000 1200 355 630 710 800 800 – – 1200 A ATS48M12Y Size F –

(1) Starter connection in the motor delta connection: up to 500 V only, add "S316" at the end of the reference

(2) Starting time greater than 30 seconds (fans, high inertia machines and compressors)

Nominal

current

(IcL)

Other versions: please consult our Customer Care Centre.

13

Page 18

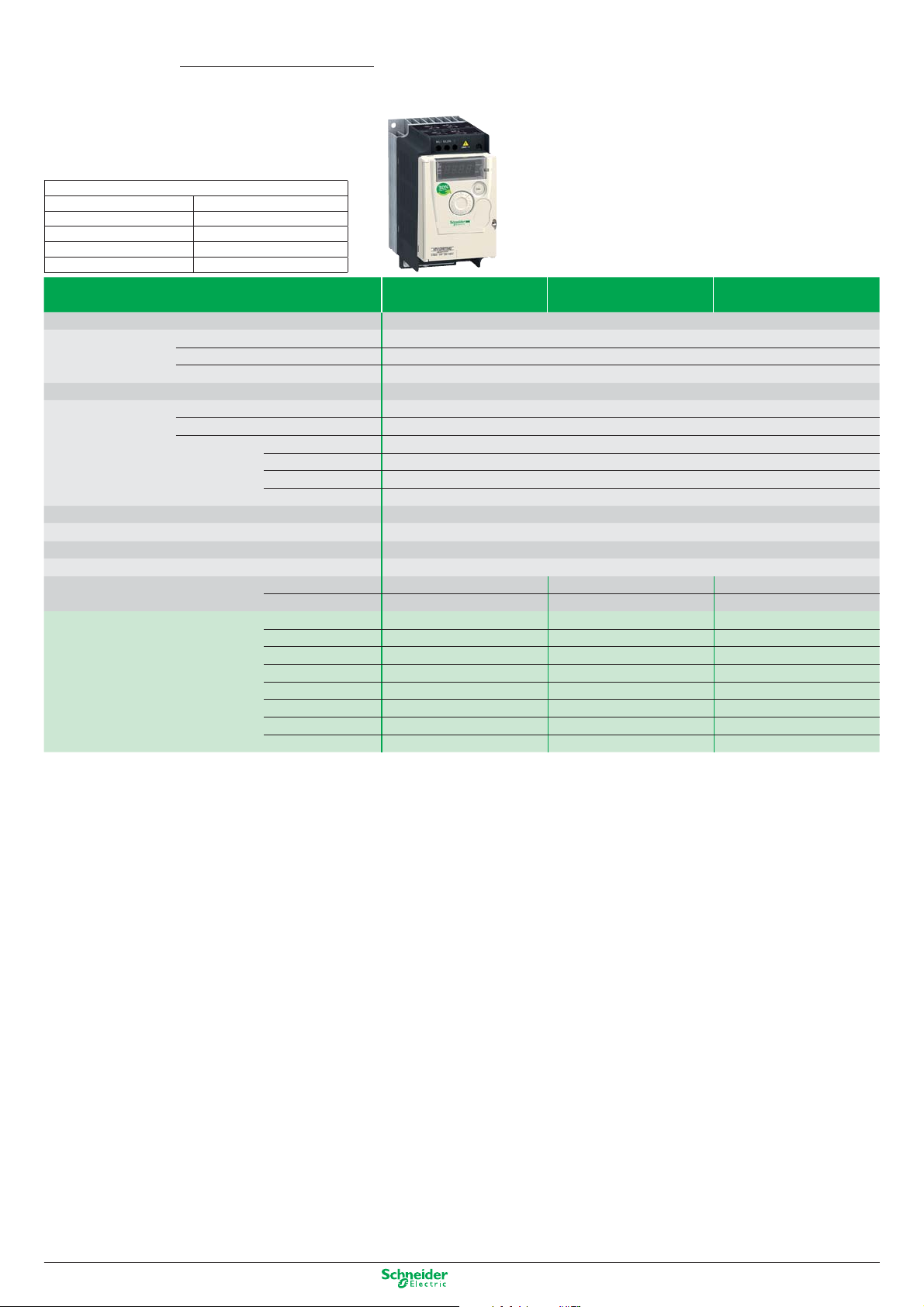

Altivar 12

0.18…4 kW

Dimensions (in mm) width x height x depth

1C1: 72 x 143 x 102.2 2F3: 105 x 143 x 131.2

1C2: 72 x 143 x 102.2 3F3: 140 x 184 x 141.2

1C3: 72 x 143 x 121.2

2C1: 105 x 142 x 156.2

2C2: 105 x 142 x 156.2

Simple machines

Ultra-compact drives

Type of drive Single-phase Single-phase Three-phase

Supply voltage 120 V 240 V 240 V

Degree of protection IP20

Drive Output frequency 0.5… 400 Hz

Type of control Asynchronous motor U/F, sensorless flux vector control, quadratic U/F

Transient overtorque 150…170

Speed range 1 to 20

Functions Number of functions 40

Number of preset speeds 8

Number of I/O Analog inputs 1 configurable analog input

Logic inputs 4 assignable logic inputs

Analog outputs 1 configurable analog output

Relay outputs 1 protected relay logic output

Dialogue

Communication Integrated Modbus

Cards (available as an option)

Reduction of current harmonics

EMC filter Integrated C1 EMC

As an option

Motor power kW/HP 0.18/0.25 ATV12H018F1 (1) 1C1 ATV12H018M2 (1) (2) 1C2 ATV12H018M3 (1) 1C3

0.37/0.5 ATV12H037F1 1C1 ATV12H037M2 (2) 1C1 ATV12H037M3 1C3

0.55/0.75 – ATV12H055M2 (2) 1C2 –

0.75/1 ATV12H075F1 2C1 ATV12H075M2 (2) 1C2 ATV12H075M3 1C3

1.5/2 – ATV12HU15M2 (2) 2C2 ATV12H015M3 2F3

2.2/3 – ATV12HU22M2 (2) 2C2 ATV12H022M3 2F3

3/3 – – ATV12H030M3 3F3

4/5 – – ATV12H040M3 3F3

(1) Because of the low heat dissipation, the ATV12H018.. is only supplied on a base plate

(2) Also exists as a multipack

Integrated or remote display terminal, SoMove software workshop, or mobile phone via Bluetooth

©

14

Other versions: please consult our Customer Care Centre.

Page 19

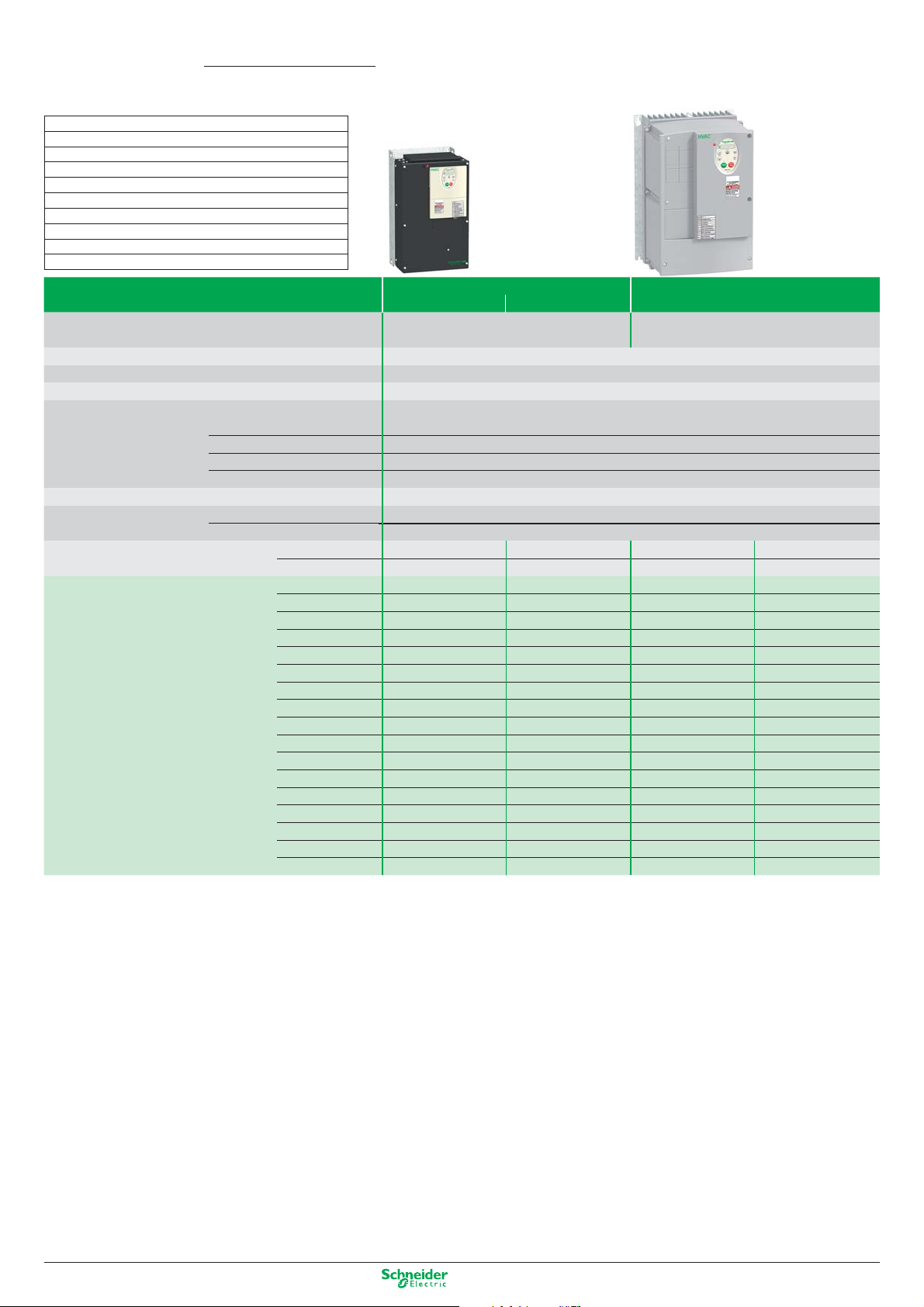

Altivar 212

0.75…75 kW

Building

Drives for HVAC applications

Dimensions (in mm) width x height x depth

IP21 IP55

T1A: 107 x 143 x 150 T1: 215 x 297 x 192

T2A: 142 x 184 x 150 T2: 230 x 340 x 208

T3A: 180 x 232 x 170 T3: 290 x 560 x 315

T4A: 245 x 329.5 x 190 T4: 310 x 665 x 315

T5A: 240 x 420 x 214 T5: 284 x 720 x 315

T6A: 320 x 630 x 290 T5: 284 x 880 x 343

T7A: 240 x 550 x 266 T5: 362 x 1000 x 364

T8A: 320 x 630 x 290

Type of drive IP21 IP55

Supply voltage Three-phase 200…240 V 380…480 V

Degree of protection IP21 and IP41 on the upper part

Output frequency 0.5…200 Hz

Type of control

Speed range 1 to 10

I/O Analog inputs 1 switch-confi gurable current or voltage analog input and 1 voltage analog input, confi gurable as a PTC

Logic inputs 3 programmable logic inputs

Analog outputs 1 switch-confi gurable current or voltage analog output

Relay outputs 2 relay logic outputs

Dialogue

Communication

(see page 4/11)

EMC fi lter Integrated – C2 EMC C2 EMC C1 EMC

Motor power kW/HP 0.75/1 ATV212H075M3X T1A ATV212H075N4 T1A ATV212W075N4 T1 ATV212W075N4C T1

(1) Drive with local controls, Run/Stop, Loc/Rem. keys

(2) For references ATV212HD22N4 and ATV212HD30N4, please refer to the Schneider Electric catalogue.

(3) PC Software is available as a free download from www.schneider-electric.com

Integrated Modbus, APOGEE FLN P1, Metasys N2, BACnet

As an option LonWorks

Available as an option C2 EMC C1 EMC – –

1.5/2 ATV212HU15M3X T1A ATV212HU15N4 T1A ATV212WU15N4 T1 ATV212WU15N4C T1

2.2/3 ATV212HU22M3X T1A ATV212HU22N4 T1A ATV212WU22N4 T1 ATV212WU22N4C T1

3/– ATV212HU30M3X T2A ATV212HU30N4 T2A ATV212WU30N4 T2 ATV212WU30N4C T2

4/5 ATV212HU40M3X T2A ATV212HU40N4 T2A ATV212WU40N4 T2 ATV212WU40N4C T2

5.5/7.5 ATV212HU55M3X T3A ATV212HU55N4 T2A ATV212WU55N4 T2 ATV212WU55N4C T2

7.5/10 ATV212HU75M3X T3A ATV212HU75N4 T3A

11/15 ATV212HD11M3X T4A ATV212HD11N4 T3A

15/20 ATV212HD15M3X T4A ATV212HD15N4 T4A

18.5/25 ATV212HD18M3X T4A ATV212HD18N4 T4A

22/30 – ATV212HD22N4S T4A – –

22/30 ATV212HD22M3X T5A ATV212HD22N4 (2) T5A

30/40 ATV212HD30M3X T6A ATV212HD30N4 (2) T5A

37/50 – ATV212HD37N4 T7A ATV212WD37N4 T6 ATV212WD37N4C T6

45/60 – ATV212HD45N4 T7A ATV212WD45N4 T6 ATV212WD45N4C T6

55/75 – ATV212HD55N4 T8A ATV212WD55N4 T7 ATV212WD55N4C T7

75/100 – ATV212HD75N4 T8A ATV212WD75N4 T7 ATV212WD75N4C T7

Kn2 quadratic ratio, sensorless fl ux vector control, voltage/frequency ratio (2 points), energy saving ratio

probe input

Integrated display terminal with local controls (1) or remote display terminal or PC software (3)

380…480 V

IP55 drive available in two manufacturing variants,

ATV212W…N4 C1 EMC or ATV212W…N4C C2 EMC

ATV212WU75N4

ATV212WD11N4

ATV212WD15N4

ATV212WD18N4

ATV212WD22N4

ATV212WD30N4

T2 ATV212WU75N4C T2

T3 ATV212WD11N4C T3

T3 ATV212WD15N4C T3

T4 ATV212WD18N4C T4

T5 ATV212WD22N4C T5

T5 ATV212WD30N4C T5

Other versions: please consult our Customer Care Centre.

15

Page 20

Altivar 312

0.18…15 kW

Dimensions (in mm) width x height x depth

X 145 X 122 T 6: 107 X 143 X 152

T 1: 72

T 2: 72

X 145 X 132 T 7: 142 X 184 X 152

X 145 X 132 T 8: 180 X 232 X 172

T 3: 72

X 145 X 142 T 9: 245 X 330 X 192

T 4: 72

T 5: 105

X 143 X 132

Simple industrial machines

High performance drives

Type of drive Single-phase 240 V Three-phase 240 V Three-phase 500V Three-phase 600V

Supply voltage

Degree of protection IP20

Drive Output frequency 0.5…500 Hz

Type of control Asynchronous motor Standard (voltage / frequency) - Performance (sensorless flux vector control)

Transient overtorque 170 ... 200% of the nominal motor torque

Speed range 1 to 50

Functions Number of functions 50

Number of preset speeds 16

Number of I/O Analog inputs 3

Logic inputs 6

Analog outputs 1

Logic outputs –

Relay outputs 2

Dialogue Integrated 4-digit display, remote terminals (IP54 or IP65), Altivar 61/71 remote graphic display terminal

with integrated EMC filters

Energy saving ratio

without EMC filter

with integrated EMC filters

without EMC filter

Communication Integrated Modbus and CANopen

As an option CANopen Daisy chain, Modbus TCP, DeviceNet, P

Reduction of current harmonics

EMC filter Integrated C2 EMC

As an option C1 EMC – – –

Motor power kW/HP 0.18/0.25 ATV312H018M2 T3 ATV312H018M3 T1 – –

0.37/0.5 ATV312H037M2T3ATV312H037M3 T1 ATV312H037N4 T5 –

0.55/0.75 ATV312H055M2 T4 ATV312H055M3 T2 ATV312H055N4 T5 –

0.75/1 ATV312H075M2 T4 ATV312H075M3 T2 ATV312H075N4 T6 ATV312H075S6 T6

1.1/1.5 ATV312HU11M2 T6 ATV312HU11M3 T5 ATV312HU11N4 T6 –

1.5/2 ATV312HU15M2 T6 ATV312HU15M3 T5 ATV312HU15N4 T6 ATV312HU15S6 T6

2.2/3 ATV312HU22M2

3/- – ATV312HU30M3 T7 ATV312HU30N4 T7 –

4/5 – ATV312HU40M3 T7 ATV312HU40N4 T7 ATV312HU40S6 T7

5.5/7.5 – ATV312HU55M3 T8 ATV312HU55N4 T8 ATV312HU55S6 T8

7.5/10 – ATV312HU75M3 T8 ATV312HU75N4 T8 ATV312HU75S6 T8

11/15 – ATV312HD11M3 T9 ATV312HD11N4 T9 ATV312HD11S6 T9

15/20 – ATV312HD15M3 T9 ATV312HD15N4 T9 ATV312HD15S6 T9

(1) C2 up to 4 kW

(2) Supplied with integrated C3 EMC filter

External as an option

(2)

T7 ATV312HU22M3 T6 ATV312HU22N4 T7 ATV312HU22S6 T7

ROFIBUS DP, Fipio

Integrated C2(1) or C3 EMC

External as an option

16

Other versions: please consult our Customer Care Centre.

Page 21

Altivar 31C

0.18…15 kW

Dimensions (in mm) width x height x depth

Size 1: 210 x 240 x 163 / Size 2: 215 x 297 x 192

Size 3: 230 x 340 x 208 / Size 4: 320 x 512 x 282

Size 5: 440 x 625 x 282

Simple machines

Enclosed IP55 drives

Supply voltage Single-phase 200…240 V Three-phase 380…500 V

Degree of protection IP55

Description Enclosure equipped with an Altivar 31 drive with external heatsink. Removable covers for adding 1

switch-disconnector or 1 circuit-breaker, 3 buttons and/or LEDs, 1 potentiometer

Motor power kW/HP 0.18/0.25 ATV31C018M2 Size 1 –

0.37/0.5 ATV31C037M2 Size 1 ATV31C037N4 Size 2

0.55/0.75 ATV31C055M2 Size 1 ATV31C055N4 Size 2

0.75/1 ATV31C075M2 Size 1 ATV31C075N4 Size 2

1.1/1.5 ATV31CU11M2 Size 2 ATV31CU11N4 Size 2

1.5/2 ATV31CU15M2 Size 2 ATV31CU15N4 Size 2

2.2/3 ATV31CU22M2 Size 3 ATV31CU22N4 Size 3

3/– – ATV31CU30N4 Size 3

4/5 – ATV31CU40N4 Size 3

5.5/7.5 – ATV31CU55N4 (1) Size 4

7.5/10 – ATV31CU75N4 (1) Size 4

11/15 – ATV31CD11N4 (1) Size 5

15/20 – ATV31CD15N4 (1) Size 5

(1) Drive in metal enclosure without cover.

Other versions: please consult our Customer Care Centre.

17

Page 22

Altivar 32

0.18…15 kW

Dimensions (in mm) width x height x depth

T1: 45 x 317 x 245

T2: 60 x 317 x 245

T4: 150 x 308 x 232 (EMC plate installed)

T4: 150 x 232 x 232 (EMC plate not installed)

T5: 180 x 404 x 232 (EMC plate installed)

T5: 180 x 330 x 232 (EMC plate not installed)

Complex machines

Compact drives

Type of drive Single-phase Three-phase

240 V with integrated EMC fi lter 500 V with integrated EMC fi lter

Degree of protection

Drive Output frequency

Type of control Asynchronous motor

Synchronous motor

Transient overtorque

Speed range

Functions Number of functions

Number of I/O Analog inputs

Logic inputs

Analog outputs

Logic outputs

Relay outputs

Dialogue

Communication Integrated

As an option

Reduction of current harmonics

EMC fi lter Integrated

As an option

Motor power kW HP

0.18 1/4 ATV32H018M2 T1 –

0.37 1/2 ATV32H037M2 T1 ATV32H037N4 T1

0.55 3/4 ATV32H055M2 T1 ATV32H055N4 T1

0.75 1 ATV32H075M2 T1 ATV32H075N4 T1

1.1 11/2 ATV32HU11M2 T2 ATV32HU11N4 T1

1.5 2 ATV32HU15M2 T2 ATV32HU15N4 T1

2.2 3 ATV32HU22M2 T2 ATV32HU22N4 T2

3- – ATV32HU30N4 T2

45 – ATV32HU40N4 T2

5.5 71/2 – ATV32HU55N4 T4

7.5 10 – ATV32HU75N4 T4

11 15 – ATV32HD11N4 T5

15 20 – ATV32HD15N4 T5

IP20

0.1…599 Hz

Standard (voltage/frequency)

Performance (sensorless fl ux vector control)

Pump/fan (Kn² quadratic ratio)

Energy saving ratio

Profi le for open loop synchronous motor

170...200% of the nominal motor torque

1 to 50

150

3 - Response time : 3ms, resolution 10 bits

6 - Response time : 8 ms, confi gurable in PTC and IN pwm

1 - Updating time : 2 ms

1 - Sampling time : 2 ms, confi gurable as voltage (0-10 V) or current (0-20 mA)

2

4-digit display, remote display terminal (IP54 or IP55), remote graphic display terminal, SoMove setup

software and SoMove Mobile application for mobile phone.

Modbus and CANopen - Bluetooth® link

DeviceNet, P

C2 EMC

C1 EMC

ROFIBUS DP V1, EtherNet/IP, Modbus TCP, EtherCat

18

Other versions: please consult our Customer Care Centre.

Page 23

Altivar 61

0.37…800 kW

Dimensions (in mm) width x height x depth

T2 : 130 x 230 x 175 T3 : 155 x 260 x 187

T4 : 175 x 295 x 187 T5A : 210 x 295 x 213

T5B : 230 x 400 x 213 T6 : 240 x 420 x 236

T7A : 240 x 550 x 266 T7B : 320 x 550 x 266

T8 : 320 x 630 x 290 T9 : 320 x 920 x 377

T10 : 360 x 1022 x 377 T11 : 340 x 1190 x 377

T12 : 440 x 1190 x 377 T13 : 595 x 1190 x 377

T14 : 890 x 1390 x 377 T15 : 1120 x 1390 x 377

Type of drive

Supply voltage

Degree of protection IP20 for unprotected drives and IP41 on the upper part

Drive Output frequency 0.1…599 Hz up to 37 kW; 0.1…500 Hz from 45 to 800 kW

Type of control Asynchronous motor

Synchronous motor Vector control without speed feedback

Transient overtorque 120…130% of the nominal drive current for 60 seconds

Speed range 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds 16

Number of I/O Analog inputs 2…4/Logic inputs 6…20

Dialogue Remote graphic display terminal, SoMove setup software (3)

Communication Integrated Modbus and CANopen

As an option HVAC protocols: LonWorks, BACnet, METASYS N2, APOGEE FLN P1

Cards (available as an option) Multi-pump cards, I/O extension cards, “Controller Inside” programmable card

Reduction of current harmonics DC choke integrated or supplied with the drive or AFE Altivar (Active Front End)

EMC fi lter Integrated C2 EMC C2 EMC up to 7.5 kW C2 EMC up to 4 kW

As an option C1 EMC C1 EMC C1 EMC

Motor power kW/HP 0.37/0.5 ATV61H075M3 T2 – –

0.75/1 ATV61HU15M3 T2 ATV61H075M3 T2 ATV61H075N4

1.5/2 ATV61HU22M3 T3 ATV61HU15M3 T2 ATV61HU15N4

2.2/3 ATV61HU30M3 T3 ATV61HU22M3 T3 ATV61HU22N4

3/– ATV61HU40M3 (1) T3 ATV61HU30M3 T3 ATV61HU30N4

4/5 ATV61HU55M3 (1) T4 ATV61HU40M3 T3 ATV61HU40N4

5.5/7.5 ATV61HU75M3 (1) T5A ATV61HU55M3 T4 ATV61HU55N4

7.5/10 – ATV61HU75M3 T5A ATV61HU75N4

11/15 – ATV61HD11M3X

15/20 – ATV61HD15M3X

18.5/25 – ATV61HD18M3X

22/30 – ATV61HD22M3X

30/40 – ATV61HD30M3X

37/50 – ATV61HD37M3X

45/60 – ATV61HD45M3X

55/75 – ATV61HD55M3X

75/100 – ATV61HD75M3X

90/125 – ATV61HD90M3X

110/150 – – ATV61HC11N4

132/200 – – ATV61HC13N4

160/250 – – ATV61HC16N4

220/350 – – ATV61HC22N4

250/400 – – ATV61HC25N4

315/500 – – ATV61HC31N4

400/600 – – ATV61HC40N4

500/700 – – ATV61HC50N4

630/900 – – ATV61HC63N4

(1) Must be used with a line choke, refer to the Schneider Electric catalogue.

(2) Drive supplied without EMC fi lter

(3) SoMove setup software : available from 2011. Altivar 61 is also supported by Powersuite software workshop.

Pumping and ventilation machines

Drives for industry and infrastructure

Single-phase

200…240 V

Kn2 quadratic ratio, fl ux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), energy saving ratio

Analog outputs 1…3/Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Industrial protocols: Modbus TCP Daisy Chain, Modbus/Uni-Telway, EtherNet/IP, EtherCAT,

DeviceNet, P

ROFIBUS DP V0 and V1, INTERBUS, CC-Link

Three-phase

200…240 V

Three-phase

380…480 V

C3 EMC from 5.5 to 630 kW

from 0.75 to 630 kW

(2)

T5B ATV61HD11N4

(2)

T5B ATV61HD15N4

(2)

T6 ATV61HD18N4

(2)

T6 ATV61HD22N4

(2)

T7B ATV61HD30N4

(2)

T7B ATV61HD37N4

(2)

T7B ATV61HD45N4

(2)

T9 ATV61HD55N4

(2)

T9 ATV61HD75N4

(2)

T10 ATV61HD90N4

T2

T2

T2

T3

T3

T4

T4

T5A

T5B

T5A

T6

T7A

T7A

T8

T8

T8

T9

T9

T10

T11

T12

T13

T13

T14

T14

T15

For all other variants, please refer to the Schneider Electric catalogue.

Other versions: please consult our Customer Care Centre.

19

Page 24

Altivar 61

0.37…800 kW

Dimensions (in mm) width x height x depth

T6 : 240 x 420 x 236

T8 : 320 x 630 x 290

T11 : 340 x 1190 x 377

T13 : 595 x 1190 x 377

T15 : 1120 x 1390 x 377

Type of drive

Supply voltage

Degree of protection IP20 and IP41 on the upper part

Drive Output frequency 0.1…599 Hz up to 37 kW; 0.1…500 Hz from 45 to 800 kW

Type of control Asynchronous motor

Synchronous motor Vector control without speed feedback

Transient overtorque 120…130% of the nominal drive current for 60 seconds

Speed range 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds 16

Number of I/O Analog inputs 2…4/Logic inputs 6…20

Dialogue Remote graphic display terminal, SoMove setup software (1)

Communication Integrated Modbus and CANopen

As an option HVAC protocols: LonWorks, BACnet, METASYS N2, APOGEE FLN P1

Cards (available as an option) Multi-pump cards, I/O extension cards, “Controller Inside” programmable card

Reduction of current harmonics DC choke integrated or supplied with the product or AFE Altivar (Active Front End)

EMC fi lter Integrated C3 EMC

Motor power kW/HP

(1) SoMove setup software : available from 2011. Altivar 61 is also supported by Powersuite software workshop.

500 V 575 V 690 V

kW HP kW

2.2 3 3 ATV61HU30Y T6

3–4ATV61HU40Y T6

4 5 5.5 ATV61HU55Y T6

5.5 7.5 7.5 ATV61HU75Y T6

7.5 10 11 ATV61HD11Y T6

11 15 15 ATV61HD15Y T6

15 20 18.5 ATV61HD18Y T6

18.5 25 22 ATV61HD22Y T6

22 30 30 ATV61HD30Y T6

30 40 37 ATV61HD37Y T8

37 50 45 ATV61HD45Y T8

45 60 55 ATV61HD55Y T8

55 75 75 ATV61HD75Y T8

75 100 90 ATV61HD90Y T8

90 125 110 ATV61HC11Y T11

110 150 132 ATV61HC13Y T11

132 – 160 ATV61HC16Y T11

160 200 200 ATV61HC20Y T11

200 250 250 ATV61HC25Y T13

250 350 315 ATV61HC31Y T13

315 450 400 ATV61HC40Y T13

400 550 500 ATV61HC50Y T15

500 700 630 ATV61HC63Y T15

630 800 800 ATV61HC80Y T15

Pumping and ventilation machines

Drives for industry and infrastructure

Three-phase

500...690 V

Kn2 quadratic ratio, fl ux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), energy saving ratio

Analog outputs 1…3/Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Industrial protocols: Modbus TCP Daisy Chain, Modbus/Uni-Telway, EtherNet/IP, EtherCAT,

DeviceNet, P

ROFIBUS DP V0 et V1, INTERBUS, CC-Link

For all other variants, please refer to the Schneider Electric catalogue.

20

Other versions: please consult our Customer Care Centre.

Page 25

Altivar 61

0.75…90 kW

Dimensions (in mm) width x height x depth

ATV61W…

:

235 x 490 x 272 TD : 310 x 665 x 315

TA2

:

235 x 490 x 286 TE : 284 x 720 x 315

TA3

TB : 255 x 525 x 286 TF : 284 x 880 x 343

:

290 x 560 x 315 TG : 362 x 1000 x 364

TC

Pumping and ventilation machines

IP54 drives

Type of drive Three-phase 380…480 V

Degree of protection Type 12 (1) / IP54

Drive Output frequency 0.1…599 Hz up to 37 kW; 0.1…500 Hz from 45 to 800 kW

Type of control Asynchronous motor

Synchronous motor Vector control without speed feedback

Transient overtorque 120…130% of the nominal drive current for 60 seconds

Speed range 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds

Number of I/O Analog inputs 2…4/Logic inputs 6…20

Dialogue Remote graphic display terminal, SoMove setup software (2)

Communication Integrated Modbus and CANopen

As an option HVAC protocols: LonWorks, BACnet, METASYS N2, APOGEE FLN P1

Cards (available as an option) Multi-pump cards, I/O extension cards, “Controller Inside” programmable card

Reduction of current harmonics Integrated DC choke

EMC fi lter Integrated C2 EMC

As an option – –

Motor power kW/HP 0.75/1 ATV61W075N4 TA2 ATV61E5075N4 TA2

1.5/2 ATV61WU15N4 TA2 ATV61E5U15N4 TA2

2.2/3 ATV61WU22N4 TA2 ATV61E5U22N4 TA2

3/– ATV61WU30N4 TA3 ATV61E5U30N4 TA3

4/5 ATV61WU40N4 TA3 ATV61E5U40N4 TA3

5.5/7.5 ATV61WU55N4 TB ATV61E5U55N4 TB

7.5/10 ATV61WU75N4 TB ATV61E5U75N4 TB

11/15 ATV61WD11N4 TC ATV61E5D11N4 TC

15/20 ATV61WD15N4 TD ATV61E5D15N4 TD

18.5/25 ATV61WD18N4 TD ATV61E5D18N4 TD

22/30 ATV61WD22N4 TE ATV61E5D22N4 TE

30/40 ATV61WD30N4 TF ATV61E5D30N4 TF

37/50 ATV61WD37N4 TF ATV61E5D37N4 TF

45/60 ATV61WD45N4 TG ATV61E5D45N4 TG

55/75 ATV61WD55N4 TG ATV61E5D55N4 TG

75/100 ATV61WD75N4 TG ATV61E5D75N4 TG

90/125 ATV61WD90N4 TG ATV61E5D90N4 TG

Drive with integrated C1 fi lter: add the letter C at the end of the reference For example, ATV61W075N4 becomes ATV61W075N4C

For other variants, please refer to the Schneider Electric catalogue.

(1) For ATV61W... range only.

(2) SoMove setup software : available from 2011. Altivar 61 is also supported by Powersuite software workshop.

Kn2 quadratic ratio, fl ux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), energy saving ratio

16

Analog outputs 1…3/Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Industrial protocols: Modbus TCP Daisy Chain, Modbus/Uni-Telway, EtherNet/IP, EtherCAT,

DeviceNet, P

ROFIBUS DP V0 and V1, INTERBUS, CC-Link

Other versions: please consult our Customer Care Centre.

21

Page 26

Altivar 61

0.37…800 kW

Drive Kit

ATV61HC11N4 VW3A9541

ATV61HC13N4 VW3A9542

ATV61HC16N4 VW3A9543

ATV61HC22N4 VW3A9544

ATV61HC25N4 VW3A9545

ATV61HC31N4

ATV61HC25N4 VW3A9546

ATV61HC31N4

ATV61HC40N4 VW3A9547

ATV61HC50N4

ATV61HC63N4 VW3A9548

VW3A7102 braking unit VW3A9549

Additional empty enclosure (600 mm)

Additional empty enclosure (800 mm)

Pumping and ventilation machines

IP54 Altivar 61 kit with preassembled enclosure

VW3A9550

VW3A9551

22

Other versions: please consult our Customer Care Centre.

Page 27

Altivar 61Q

110…800 kW

Dimensions (in mm) width x height x depth

T11 : 330 x 950 x 377

T13 : 585 x 950 x 377

T15 : 1110 x 1150 x 377

Type of drive

Supply voltage

Degree of protection Sideways and front IP31 - Top IP20 - Bottom IP00

Drive Output frequency 0.1...500Hz

Type of control Asynchronous motor

Synchronous motor Vector control without speed feedback

Transient overtorque 120…130% of the nominal drive current for 60 seconds

Speed range 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds

Number of I/O Analog inputs 2…4/Logic inputs 6…20

Dialogue Remote graphic display terminal, SoMove setup software (2)

Communication Integrated Modbus and CANopen

As an option HVAC protocols: LonWorks, BACnet, METASYS N2, APOGEE FLN P1

Cards (available as an option) Multi-pump cards, I/O extension cards, “Controller Inside” programmable card

Reduction of current harmonics Optional AC choke, Altivar AFE (Active Front End)

EMC filter Integrated C3 EMC

As an option C1 EMC

Motor power kW/HP 110/150 ATV61QC11N4 T11 –

132/200 ATV61QC13N4 T11 –

160/250 ATV61QC16N4 T11 –

200/300 ATV61QC20N4 T13 –

250/400 ATV61QC25N4 T13 –

315/500 ATV61QC31N4 T13 –

400/600 ATV61QC40N4 T15 –

500/700 ATV61QC50N4 T15 –

630/900 ATV61QC63N4 T15 –

Pumping and ventilation machines

Water-cooled drives for harsh environments

Three-phase

380...480 V

Kn2 quadratic ratio, flux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), energy saving ratio

16

Analog outputs 1…3/Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Industrial protocols: Modbus TCP, Modbus/Uni-Telway, Fipio, Modbus Plus, Profbus DP,

Profbus DP V1, DeviceNet, EthernetIP, CC-Link, I

Three-phase

500...690 V

NTERBUS

500 V 575 V 690 V

KWHPKW

110 150 132

132 – 160

160 200 200

200 250 250

250 350 315

315 450 400

400 550 500

500 700 630

630 800 800

(1) SoMove setup software : available during 2011. Altivar 61 also works with the PowerSuite software workshop.

–

–

–

–

–

–

–

–

–

ATV61QC13Y T11

ATV61QC16Y T11

ATV61QC20Y T11

ATV61QC25Y T13

ATV61QC31Y T13

ATV61QC40Y T13

ATV61QC50Y T15

ATV61QC63Y T15

ATV61QC80Y T15

Other versions: please consult our Customer Care Centre.

23

Page 28

Altivar 61 Plus

90…2400 kW

Dimensions (in mm) width x height x depth

ATV61EXC2C…

:

616 x 2159 x 659

E1

E2

:

816 x 2159 x 659

:

1016 x 2159 x 659

E3

E4

:

1220 x 2159 x 659

Pumping and ventilation machines

Solutions in IP23 and IP54 ready-assembled enclosures

Enclosure types Three-phase 380…480 V - 500 V - 690 V

(1)

Degree of protection IP23, IP54

Drive Output frequency 0.1…599 Hz up to 37 kW; 0.1…500 Hz from 45…2400 kW

Type of control Asynchronous motor

Synchronous motor Vector control without speed feedback

Transient overtorque 120…130% of the nominal drive current for 60 seconds

Speed range 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds

Number of I/O Analog inputs 2…4/Logic inputs 6…20

Dialogue Remote graphic display terminal, SoMove setup software (2)

Communication Integrated Modbus and CANopen

As an option HVAC protocols: LonWorks, BACnet, METASYS N2, APOGEE FLN P1

Cards (available as an option) Multi-pump cards, I/O extension cards, “Controller Inside” programmable card

Reduction of current harmonics DC choke or Integrated AC choke, variant 12 pulse, AFE Altivar (Active Front End)

EMC fi lter Integrated C3 EMC

Equipment A wide range of options listed in the catalogue provides add-ons for the standard offer as required.

Kn2 quadratic ratio, fl ux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), energy saving ratio

16

Analog outputs 1…3/Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Industrial protocols: Modbus TCP, Modbus/Uni-Telway, EtherNet/IP, EtherCAT, DeviceNet,

ROFIBUS DP V0 and V1, INTERBUS, CC-Link.

P

As well as the options listed in the catalogue, it is possible to customise the equipment. Just contact our

teams of experts directly.

- Water cooling solution

- Integration of specifi c options

IP23 Three-phase

380…415 V

kW/HP Dimensions kW Dimensions kW Dimensions

– 90 ATV61 EXC2D90N E1 –

110/150 ATV61EXC2C11N4 E1 110 ATV61 EXC2C11N E1 110 ATV61 EXC2C11Y E1

132/200 ATV61EXC2C13N4 E1 132 ATV61 EXC2C13N E1 132 ATV61 EXC2C13Y E1

160/250 ATV61EXC2C16N4 E1 160 ATV61 EXC2C16N E1 160 ATV61 EXC2C16Y E1

220/350 ATV61EXC2C22N4 E1 200 ATV61 EXC2C20N E2 200 ATV61 EXC2C20Y E1

250/400 ATV61EXC2C25N4 E2 250 ATV61 EXC2C25N E2 250 ATV61 EXC2C25Y E2

315/500 ATV61EXC2C31N4 E2 315 ATV61 EXC2C31N E2 315 ATV61 EXC2C31Y E2

400/600 ATV61EXC2C40N4 E3 400 ATV61 EXC2C40N E4 400 ATV61 EXC2C40Y E2

500/700 ATV61EXC2C50N4 E3 500 ATV61 EXC2C50N E4 500 ATV61 EXC2C50Y E4

630/900 ATV61EXC2C63N4 E4 630 ATV61 EXC2C63N E4 630 ATV61 EXC2C63Y E4

(1) The Altivar 61 range in ready-assembled enclosure consists of: an ATV61H… drive, a switch and fast-acting fuses, an IP65 remote mounting kit for graphic display terminal

(2) SoMove setup software : available from 2011. Altivar 61 is also supported by Powersuite software workshop.

Three-phase

500 V

Three-phase

690 V

800 ATV61 EXC2C80Y E4

IP23 offer available up to 2400 kW. For ratings above 800 kW, please consult your Regional Sales Offi ce.

24

Other versions: please consult our Customer Care Centre.

Page 29

Altivar 61 Plus

90…2400 kW

Dimensions (in mm) width x height x depth

ATV61EX…

E5 : 616 x 2264 x 659 E9 : 616 x 2359 x 659

E6 : 816 x 2264 x 659 E10 : 816 x 2359 x 659

E7 : 1016 x 2264 x 659 E11 : 608 x 2359 x 659

E8 : 1216 x 2264 x 659 E12 : 808 x 2359 x 6590

E13 : 1008 x 2359 x 659

E14 : 1208 x 2359 x 659

IP54 (1) Three-phase

380…415 V

Compact floor-standing enclosure kW/HP Dimensions kW Dimensions kW Dimensions

110/150 ATV61EXC5C11N4 E5 110 ATV61EXC5C11N E5 110 ATV61EXC5C11Y E5

132/200 ATV61EXC5C1 3N4 E5 132 ATV61EXC5C13N E5 132 ATV61EXC5C13Y E5

160/250 ATV61EXC5C16N4 E5 160 ATV61EXC5C16N E5 160 ATV61EXC5C16Y E5

220/350 ATV61EXC5C22N4 E5 200 ATV61EXC5C20N E6 200 ATV61EXC5C20Y E5

250/400 ATV61EXC5C25N4 E6 250 ATV61EXC5C25N E6 250 ATV61EXC5C25Y E6

315/500 ATV61EXC5C31N4 E6 315 ATV61EXC5C31N E6 315 ATV61EXC5C31Y E6

400/600 ATV61EXC5C40N4 E7 400 ATV61EXC5C40N E8 400 ATV61EXC5C40Y E6

500/700 ATV61EXC5C50N4 E7 500 ATV61EXC5C50N E8 500 ATV61EXC5C50Y E8

630/900 ATV61EXC5C63N4 E8 630 ATV61EXC5C63N E8 630 ATV61EXC5C63Y E8

(1) The IP54 offer is available for power ratings up to 800 kW. For higher power ratings up to 2400 kW, consult your customer care centre.

Pumping and ventilation machines

Solutions in IP23 and IP54 ready-assembled enclosures

Three-phase

500 V

– 90 ATV61EXC5D90N E5 –

Three-phase

690 V

800 ATV61EXC5C80Y E8

IP54 (2) Three-phase

380…415 V

Separate air flow kW/HP Dimensions kW Dimensions kW Dimensions

– 90 ATV61EXS5D90N E11 –

110/150 ATV61EXS5C11N4 E9 110 ATV61EXS5C11N E11 110 ATV61EXS5C11Y E11

132/200 ATV61EXS5C13N4 E9 132 ATV61EXS5C13N E11 132 ATV61EXS5C13Y E11

160/250 ATV61EXS5C16N4 E9 160 ATV61EXS5C16N E11 160 ATV61EXS5C16Y E11

220/350 ATV61EXS5C22N4 E9 200 ATV61EXS5C20N E12 200 ATV61EXS5C20Y E11

250/400 ATV61EXS5C25N4 E10 250 ATV61EXS5C25N E12 250 ATV61EXS5C25Y E12

315/500 ATV61EXS5C31N4 E10 315 ATV61EXS5C31N E12 315 ATV61EXS5C31Y E12

400/600 ATV61EXS5C40N4 E13 400 ATV61EXS5C40N E14 400 ATV61EXS5C40Y E12

500/700 ATV61EXS5C50N4 E13 500 ATV61EXS5C50N E14 500 ATV61EXS5C50Y E14

630/900 ATV61EXS5C63N4 E14 630 ATV61EXS5C63N E14 630 ATV61EXS5C63Y E14

(2) The IP54 offer with separate air flow is available for power ratings upt o 800 kW. For higher power ratings up to 2400 kW, consult your customer care centre.

Three-phase

500 V

Three-phase

690 V

800 ATV61EXS5C80Y E14

Other versions: please consult our Customer Care Centre.

25

Page 30

Altivar 61

0.37…2400 kW

Pumping and ventilation machines

I/O extension and specific cards

Type of card I/O extension

Logic Extended

Description 1 relay logic output (“C/O” contact)

4 x 24 VDC positive or negative logic inputs

2 x 24 VDC open collector positive or negative logic

outputs

1 input for PTC probes

Reference VW3A3201 VW3A3202

1 x 0…20 mA differential current analog input

1 software-configurable voltage (0…10 VDC) or

current (0…20 mA) analog input

2 software-configurable voltage (±10V, 0…10 VDC)

or current (0…20 mA) analog inputs

1 relay logic output (“C/O” contact)

4 x 24 VDC positive or negative logic inputs

2 x 24 VDC open collector positive or negative logic

outputs

1 input for PTC probes

1 frequency control input

"Controller Inside" programmable card

Type of card Programmable “Controller Inside”

Description

Reference VW3A3501

10 logic inputs, 2 of which can be used for 2 counters or 4 of which can be used for 2 incremental encoders

2 analog inputs, 6 logic outputs, 2 analog outputs, a master port for the CANopen bus, a PC port for

programming with the PS 1131 software workshop.

Multi-pump cards

Type of card Multi-pump

Description The pump switching card ensures compatibility of

applications developed on the Altivar 38.

Reference VW3A3502

Description The VWA3503 “Water Solution” card can be used

to support all multi-pump applications.

Reference VW3A3503

26

This card is specific to pump switching.

It ensures optimum flow for an impeccable quality of service.

Its algorithm both saves energy and prolongs equipment service life.

This card offers all the functions needed to manage a pumping, booster, irrigation station, etc with the

operational safety of a control and monitoring system.

Other versions: please consult our Customer Care Centre.

Page 31

Accessories and options

Braking resistors

The network braking unit can be used to restore the following to the

line supply:

p The energy from the motor

p The energy from the motors controlled by several drives connected

on the same DC bus

Type of drive Three-phase

Supply voltage 200…240 V 50/60 Hz 380…480 V 50/60 Hz

ATV61H075M3 VW3A7701 –

ATV61HU15M3, HU22M3 VW3A7702 –

ATV61HU30M3, HU40M3 VW3A7703 –

ATV61HU55M3, HU75M3 VW3A7704 –

ATV61HD11M3X VW3A7705 –

ATV61HD15M3X VW3A7706 –

ATV61HD18M3X, HD22M3X VW3A7707 –

ATV61HD30M3X VW3A7708 –

ATV61HD37M3X, HD45M3X VW3A7709 –

ATV61HD55M3X, HD75M3X VW3A7713 –

ATV61HD90M3X VW3A7714 –

ATV61H075N4…HU40N4, ATV61W075N4…WU55N4, – VW3A7701

ATV61W075N4C…WU55N4C

ATV61HU55N4, HU75N4, ATV61WU75N4, WD11N4, – VW3A7702

ATV61WU75N4C, WD11N4C

ATV61HD11N4, HD15N4, ATV61WD15N4, WD18N4, – VW3A7703

ATV61WD15N4C, WD18N4C

ATV61HD18N4…HD30N4, ATV61WD22N4…WD37N4, – VW3A7704

ATV61WD22N4C…WD37N4C

ATV61HD37N4, ATV61WD45N4, WD45N4C – VW3A7705

ATV61WD55N4…WD90N4, ATV61WD55N4C…WD90N4C – VW3A7706

ATV61HD45N4…HD75N4 – VW3A7707

ATV61HD90N4, HC11N4 – VW3A7710

ATV61HC13N4, HC16N4, E5C16N4 – VW3A7711

ATV61HC22N4 – VW3A7712

ATV61HC25N4 – VW3A7715

ATV61HC31N4 – VW3A7716

ATV61HC40N4, HC50N4, E5C50N4 – VW3A7717

ATV61HC63N4 – VW3A7718

Other accessories (see references in the Schneider Electric Catalogue)

> Resistance braking units (integrated in ATV61 drives up to 220 kW)

> Additional EMC input filters

> AC line chokes

> Optional DC chokes

> Passive filters

> Sinus filters

> Motor chokes

> Altivar AFE (Active Front End)

> Regenerative network braking unit

Other versions: please consult our Customer Care Centre.

27

Page 32

Altivar 71

0.37…630 kW

Dimensions (in mm) width x height x depth

T2 : 130 x 230 x 175 T3 : 155 x 260 x 187

T4 : 175 x 295 x 187 T5A : 210 x 295 x 213

T5B : 230 x 400 x 213 T6 : 240 x 420 x 236

T7A : 240 x 550 x 266 T7B : 320 x 550 x 266

T8 : 320 x 630 x 290 T9 : 320 x 920 x 377

T10 : 360 x 1022 x 377 T11 : 340 x 1190 x 377

T12 : 440 x 1190 x 377 T13 : 595 x 1190 x 377

T14 : 890 x 1390 x 377 T15 : 1120 x 1390 x 377

Complex, high-power machines

High performance drives

Type of drive Single-phase Three-phase Three-phase

Supply voltage 200…240 V (3) 200…240 V (3) 380…480 V (3)

Degree of protection IP20 for unprotected drives and IP41 on the upper part

Drive Output frequency 0…599 Hz up to 37 kW - 0…500 Hz from 45…630 kW

Type of control Asynchronous motor Flux vector control with or without sensor, voltage/frequency ratio (2 or 5 points), ENA System

Synchronous motor Vector control with and without speed feedback (4)

Transient overtorque 220% of nominal motor torque for 2 seconds, and 170% for 60 seconds

Speed range 1…1000 in closed loop mode with encoder feedback, 1…100 in open loop mode

Functions Number of functions > 150

Number of preset speeds 16

Number of I/O Analog inputs 2…4

Logic inputs 6…20

Analog outputs 1…3

Logic outputs 0…8

Relay outputs 2…4

Safety input 1

Dialogue Remote graphic display terminal, SoMove setup software (5)

Communication Integrated Modbus and CANopen

As an option Modbus TCP, Modbus/Uni-Telway, EtherNet/IP, EtherCAT, DeviceNet, P

NTERBUS, CC-Link.

I

Cards (available as an option)

Reduction of current harmonics DC choke integrated or supplied with the product or Altivar AFE (Active Front End ).

EMC fi lter Integrated C2 EMC up to 4 kW, C3 EMC from 5,5 to 500 kW

As an option C1 EMC from 0.75 to 500 kW

Motor power kW/HP 0.37/0.5

0.75/1

1.5/2

2.2/3

3/–

4/5

5.5/7.5

7.5/10

11/15

15/20

18.5/25

22/30

30/40

37/50

45/60

55/75

75/100

90/125

110/150

132/200

160/250

200/300

220/350

280/450

315/500

355/–

500/700

(1) Must be used with a line choke, Refer to the Schneider Electric catalogue.

(2) Drive supplied without EMC fi lter.

(3) A three-phase 380...480 V range on base plate is available from 0.75 to 11 kW. Please refer to the Schneider Electric catalogue.

(4) Vector control with speed feedback for synchronous motors is supported by the S383 variant of the Altivar 71.

(5) SoMove setup software : available from 2011. Altivar 71 is also supported by Powersuite software workshop.

Encoder interface cards, I/O extension cards, “Controller Inside” programmable card

ATV71H075M3 T2 ATV71H037M3 T2 –

ATV71HU15M3 T2 ATV71H075M3 T2 ATV71H075N4 T2

ATV71HU22M3 T3 ATV71HU15M3 T2 ATV71HU15N4 T2

ATV71HU30M3 T3 ATV71HU22M3 T3 ATV71HU22N4 T2

ATV71HU40M3 (1) T3 ATV71HU30M3 T3 ATV71HU30N4 T3

ATV71HU55M3 (1) T4 ATV71HU40M3 T3 ATV71HU40N4 T3

ATV71HU75M3 (1) T5A ATV71HU55M3 T4 ATV71HU55N4 T4

– ATV71HU75M3 T5A ATV71HU75N4 T4

– ATV71HD11M3X (2) T5B ATV71HD11N4 T5A

– ATV71HD15M3X (2) T5B ATV71HD15N4 T5B

– ATV71HD18M3X (2) T6 ATV71HD18N4 T5B

– ATV71HD22M3X (2) T6 ATV71HD22N4 T6

– ATV71HD30M3X (2) T7B ATV71HD30N4 T7A

– ATV71HD37M3X (2) T7B ATV71HD37N4 T7A

– ATV71HD45M3X (2) T7B ATV71HD45N4 T8

– ATV71HD55M3X (2) T9 ATV71HD55N4 T8

– ATV71HD75M3X (2) T10 ATV71HD75N4 T8

––ATV71HD90N4 T9

––ATV71HC11N4 T10