Page 1

TAC I/A Series

MicroNet BACnet VAV Controllers

MicroNet BACnet VAV Controllers MNB-Vx

The TAC I/A Series™ MicroNet™ BACnet™

VAV (Variable Air Volume) Controllers are

interoperable controllers with native BACnet MS/TP

communications support. All models incorporate: an

integral actuator with manual override; an integral,

patented, pressure transducer; three universal inputs;

Sensor Link (S-Link) support; LED status indication;

and over-the-shaft damper mounting. See the model

chart for optional features.

When programmed using WorkPlace Tech Tool, the

controllers provide a wide range of control strategies

for pressure-dependent and pressure-independent

terminal boxes with or without reheat capabilities.

The MicroNet BACnet VAV controllers can function

SPECIFICATIONS

HARDWARE

Dimensions

7-3/4 H x 6-1/4 W x 2-1/2 D in (197 x 159 x 63 mm).

Enclosure

Cover meets UL 94-5VA flammability ratings for

plenum application use.

Optional enclosure for conduit applications, conforms

to NEMA-1.

Mounting

Shaft mount.

Power Supply Input

20.4 to 30 Vac, 50/60 Hz.

Power Consumption

15 VA at 24 Vac plus DO loads.

AGENCY LISTINGS

US

FCC Part 15, Class A.

UL 916, File #E71385 Category PAZX

UL 864, Category UUKL, File #S5381 Smoke-Control

Equipment

Canadian

UL Listed to Canadian Safety Standards (CAN/CSA

22.2).

CUL Listed to Standards

ULC/ORD-C100-92 (Smoke Control System

Equipment) and CAN-ULC-S527 (Control Units for

Fire Alarm Systems)

Australian

Meets requirements to bear the C-Tick Mark.

BTL Listed

B-ASC

European Community

EMC Directive 89/336/EEC, EN61326

either in a standalone mode or as part of a BACnet

building automation system (BAS) network.

AMBIENT LIMITS

Operating Temperature

32 to 131 °F (0 to 55 °C).

Shipping and Storage Temperature

-40 to 160 °F (-40 to 71 °C).

Humidity

5 to 95% non-condensing.

WIRING TERMINALS)

Fixed Screw Terminals

Single AWG #14 (2.08 mm

#18 (0.823 mm

VELOCITY PRESSURE INPUT

Control Range

0.004 to 1.5 in. of W.C.

Over Pressure Withstand

±20 in. of W.C.

Accuracy

±5% at 1.00 in. of W.C. with laminar flow at 77 °F (25

°C) and suitable flow station.

Sensor Type

Self-calibrating flow sensor (differential pressure).

Tubing Connections

Barb fittings for 0.170 in. I.D. FRPE polyethylene

tubing or 1/4” O.D./0.125” I.D. Tygon® tubing (high

and low pressure taps).

Continued on next page.

2

) or smaller wires.

2

) wire or up to two AWG

1

Page 2

TAC I/A Series

MNB-Vx Controllers

2

Continued from first page.

Tubing Length

5 ft. (1.52 m) maximum, each tube.

INPUTS FROM MN-SX MICRONET SENSOR

Space Temperature

32 to 122 °F (0 to 50 °C).

Space Humidity

5 to 95% RH, non-condensing.

Local Setpoint

Adjustable within limits set by application

programming tool.

Override Pushbutton

For standalone occupancy control or occupancy

override.

Fan Operation and Speed Mode

On/off, speed (low/medium/high), or auto.

System Mode

Heat, cool, off, or auto.

Emergency Heat

Enable or disable.

UNIVERSAL INPUTS (3)

Universal Input characteristics are softwareconfigured to respond to one of the following input

types:

10 k ohm Thermistor with 11 k ohm Shunt

Resistor

Sensor operating range -40 to 250 °F (-40 to

121 °C), model TSMN-57011-850, TS-5700-850

series, or equivalent.

1 k ohm Balco

-40 to 250 °F (-40 to 121 °C), model TSMN-81011,

TS-8000 series, or equivalent.

1 k ohm Platinum

-40 to 240 °F (-40 to 116 °C), model TSMN-58011,

TS-5800 series, or equivalent.

1 k ohm Resistive

0 to 1500 ohms.

10 k ohm Resistive

0 to 10.5 k ohms.

Analog Voltage

Range 0 to 5 Vdc.

Analog Current

Range 0 to 20 mA, requires external 250 ohm shunt

resistor (AD-8969-202).

Digital

Dry switched contact; detection of closed switch

requires less than 300 ohms resistance; detection of

open switch requires more than 2.5 k ohms.

Standard Pulse Input

Minimum Rate

1 pulse per 4 minutes.

Maximum Rate

1 pulse per second.

ACTUATOR OUTPUTS

Torque Rating

53 lb-in. (6 N-m).

Stroke

Fully adjustable from 0° to 90°.

Timing

Approximately 3 minutes at 60 Hz (3.6 minutes at

50 Hz) for 90° rotation at 24 Vac.

Position Indication

Provides a visual indication of position.

Manual Override

Pushbutton to allow manual positioning of the

damper.

Damper Linkage

1/2 in. (12.75 mm) or 3/8 in. (9.5 mm) diameter round

shaft extending 7/8 in. (22.23 mm) minimum from

terminal box. 3/8 in. (9.5 mm) diameter shaft requires

AM-135 adapter kit.

DIGITAL OUTPUTS – TRIAC

DO1 plus DO2 Rating

24 VA total at 24 Vac, 50/60 Hz, high side switching.

DO3 Rating

12 VA at 24 Vac, 50/60 Hz, high side switching.

UNIVERSAL OUTPUT

0 to 20 mA

Output load from 80 to 550 ohms.

0 to 10 V

With external 500 ohms, 1/2 W, 1% resistor.

Capable of Driving Functional Devices RIBUI1C

Relay

UO configured for 0 to 20 mAdc, no external resistor.

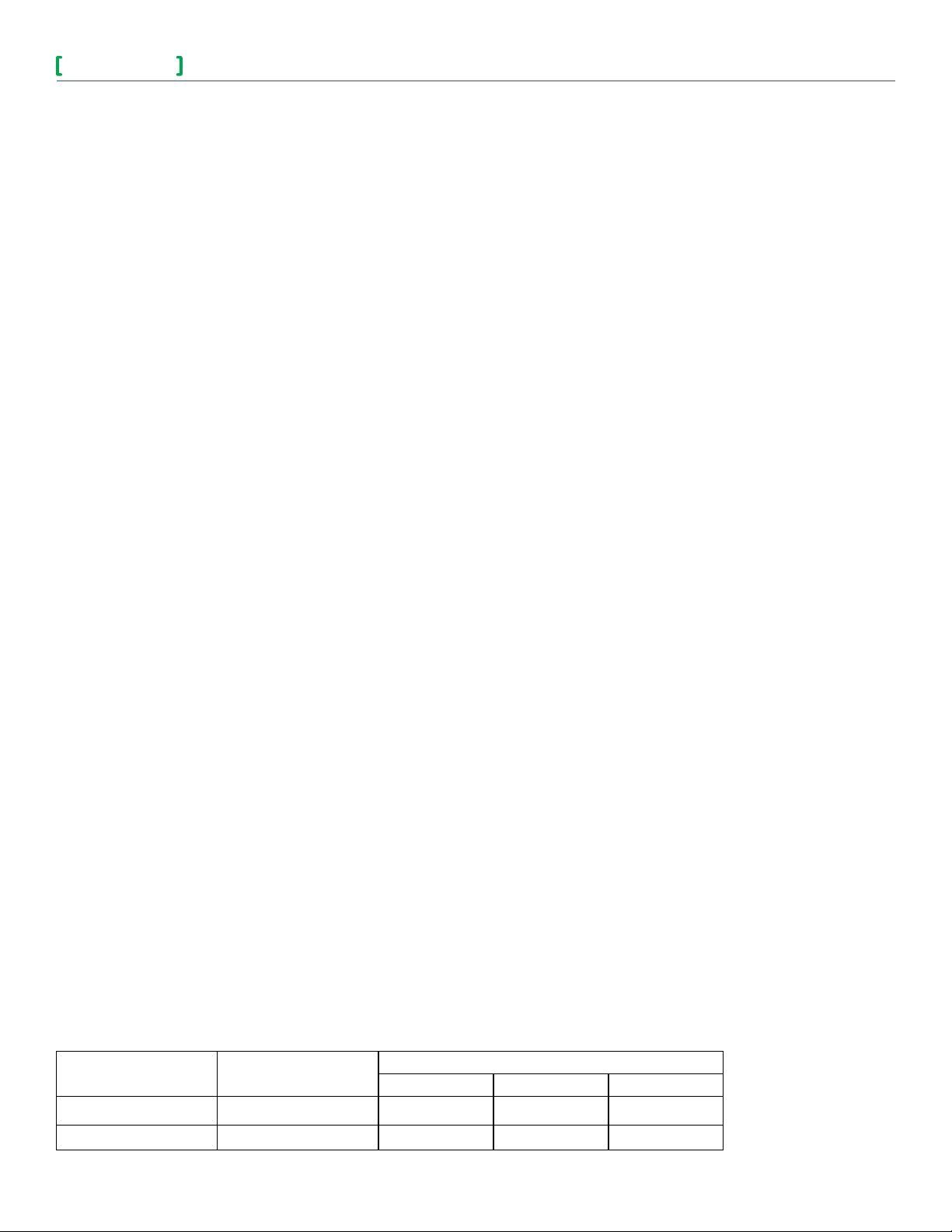

MODELS

Part Number Description

MNB-V1 Cooling only 3 — —

MNB-V2 Deluxe 3 1 3

Schneider Electric

F-27340-4

Inputs and Outputs

UI UO DO (Triac)

© 2009 Schneider Electric. All rights reserved.

September 200 9 tl

Page 3

TAC I/A Series

UO1*

COM*

UI1

COM

UI2

UI3

S-LK/COM

S-LK

MSTP +

MSTP –

SHLD

SW24H1* (DO1)

SW24H2* (DO2)

SW24H3* (DO3)

24H

24G (COM)

GND

MSTP RCV

MSTP XMT

STATUS

Physical

Address

MNB-V1 / -V2

Controllers

MS/TP Jack

Internal Triac

Switches (3)

* Asterisks indicate terminals that apply to the

MNB-V2 controller but not to the MNB-V1.

MNB-Vx Controllers

FEATURES

The MicroNet BACnet VAV controllers’ sequence•

of operation and BACnet image are fully

programmable using WorkPlace Tech Tool. The

controllers can be applied to all common VAV

configuration and reheat control strategies.

Capability to function in standalone mode or as•

part of a BACnet building automation network.

Air balancing performed via BACnet, using VAV•

Flow Balance software, through direct connection

or over the network.

Integral MS/TP jack for direct connection of PC•

with WorkPlace Tech Tool and Flow Balance tool.

Integrated packaging with actuator, pressure•

transducer, and controller.

Integral actuator features manual override and•

travel limit stops for easy set up and adjustment.

Optional plenum-rated enclosure for use if wiring•

to flexible conduit is required.

MS/TP DIP switch addressable.•

Isolated EIA-485 (formerly RS-485) transceiver for•

MS/TP communications.

3

MS/TP baud rate selection from 9.6 up to 76.8•

kbaud.

LED indication of MS/TP communication activity•

and controller status.

Firmware upgradeable over the network.•

Support for S-Link Sensor.•

Damper position feedback to the BACnet BAS via•

integral hall effect sensor.

Stable flow control down to 0.004 in. W.C.•

differential pressure.

Provides flow balancing for networked and•

standalone VAV controllers. Features include:

Local network control. –

Damper and fan adjustment. –

Setpoint monitoring and adjustment. –

Flow validation and calibration (1, 2, or 3 point –

calibration).

Sequence, calibration, and control setpoint –

logs.

COMMUNICATIONS

BACnet Networks

The MicroNet BACnet VAV controllers incorporate

an isolated EIA-485 (formerly RS-485) transceiver for

BACnet MS/TP communications at 9.6 up to 76.8

kbaud using standard MS/TP wiring methods. Up to

128 MicroNet BACnet controllers can be connected

to an MS/TP sub-net without repeaters.

S-Link

The Sensor Link (S-Link) communications wiring

provides power and a communication interface

for one MN-Sx TAC I/A Series MicroNet sensor.

The various MN-Sx sensors can provide room

temperature, room humidity, setpoint adjustment,

and occupancy override. This connection uses twowire, unshielded cable and is not polarity sensitive.

Maximum S-Link bus length is 200 ft (61 m).

BACn e t COMPLIANCE

BACnet Application Specific Controller (B-ASC).

OPTIONS

MNA-FLO-1

MicroNet Enclosure, used if wiring to flexible conduit

is required

S-Link Sensors

Temperature and Humidity Wall Sensors with Digital

Communication

TSMN Series

Room Temperature Sensors

Schneider Electric

F-27340-4

BACnet is a registered trademark of

ASHRAE. ASHRAE does not endorse,

approve, or test products for

compliance with ASHRAE standards.

Compliance of listed products to the

requirements of ASHRAE Standard 135 is the

responsibility of BACnet International (BI). BTL is a

registered trademark of BI.

VAV CONTROLLER TERMINALS

© 2009 Schneider Electric. All rights reserved.

September 200 9 tl

Page 4

TAC I/A Series

Network

Controller

One to Eight

TMicroNet BACnet

MNB-1000-15

Remote I/O Modules

Remote I/O Trunk

S-Link

Sensor

MicroNet BACnet

MNB-1000

Plant Controller

BACnet MS/TP Communications Bus

S-Link

Sensor

MicroNet BACnet

MNB-300

Unitary Controller

S-Link

Sensor

MicroNet BACnet

MNB-300

Unitary Controller

S-Link

Sensor

MicroNet BACnet

MNB-70

Zone Controller

S-Link

Sensor

MicroNet BACnet

MNB-V1 or V2

VAV Controller

S-Link

Sensor

MicroNet BACnet

MNB-V1 or V2

VAV Controller

MicroNet BACnet

MNB-1000

Plant Controller

BACnet MS/TP Communications Bus

PC Workstation

with WorkPlace

Tech Tool

Software Suite

PC Workstation

with WorkPlace

Tech Tool

Software Suite

S-Link

Sensor

MicroNet BACnet

MNB-300

Unitary Controller

S-Link

Sensor

MicroNet BACnet

MNB-70

Zone Controller

S-Link

Sensor

MicroNet BACnet

MNB-V1

Cooling Controller

S-Link

Sensor

MicroNet BACnet

MNB-V2

Deluxe Controller

Ethernet TCP/IP and BACnet/IP

Remote I/O

Module

Remote I/O

Module

Remote I/O

Module

MNB-Vx Controllers

TAC I/A SERIES BACNET TOPOLOGY

4

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider Electric. This document reflects the visual identit y of Schneider Electric, however there

remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate corporate brand changes.

All brand names, trademarks and registered trademarks are the property of their respective owners. Infor mation contained within this document is subject to change without notice.

All rights reserved.

Schneider Electric

F-27340-4 September 200 9 tl

© 2009 Schneider Electric. All rights reserved.

Loading...

Loading...