Page 1

MicroLogic™ 5 and 6 Electronic Trip

r

c

i

Mcigolo

E

2

.5

r

I

%

A

03

>

0

3

>

0

11

>

.

9

2

9

.

3

9

.

4

9

.

5

9

.

1

89

.

7

9

.

6

9

.

Ir

)

o

Ix(

5.

1

2

5.

2

3

4

0

1

8

6

5

d

s

I

)

r

I

x

(

Units—User Guide

Unidades de disparo electrónico MicroLogic™

5 y 6—Guía de usuario

MC

Déclencheurs électroniques MicroLogic

5

et 6—Guide de l’utilisateur

Instruction Bulletin / Boletín de instrucciones /

Directives d’utilisation

48940-312-01

Rev. 05, 01/2020

Retain for future use. / Conservar para uso futuro. / À conserver pour usage ultérieur.

™

Page 2

Page 3

MicroLogic™ 5 and 6 Electronic Trip Units—

r

c

i

Mcigolo

E

2

.5

r

I

%

A

03

>

0

3

>

0

11

>

.

9

2

9

.

3

9

.

4

9

.

5

9

.

1

89

.

7

9

.

69

.

Ir

)

o

Ix(

5.

1

2

5.

2

3

4

0

1

8

6

5

d

s

I

)

r

I

x

(

User Guide

for PowerPact™ H-, J-, and L-Frame Circuit Breakers

Instruction Bulletin

48940-312-01

Rev. 05, 01/2020

Retain for future use.

ENGLISH

™

Page 4

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide —

DANGER

WARNING

CAUTION

NOTICE

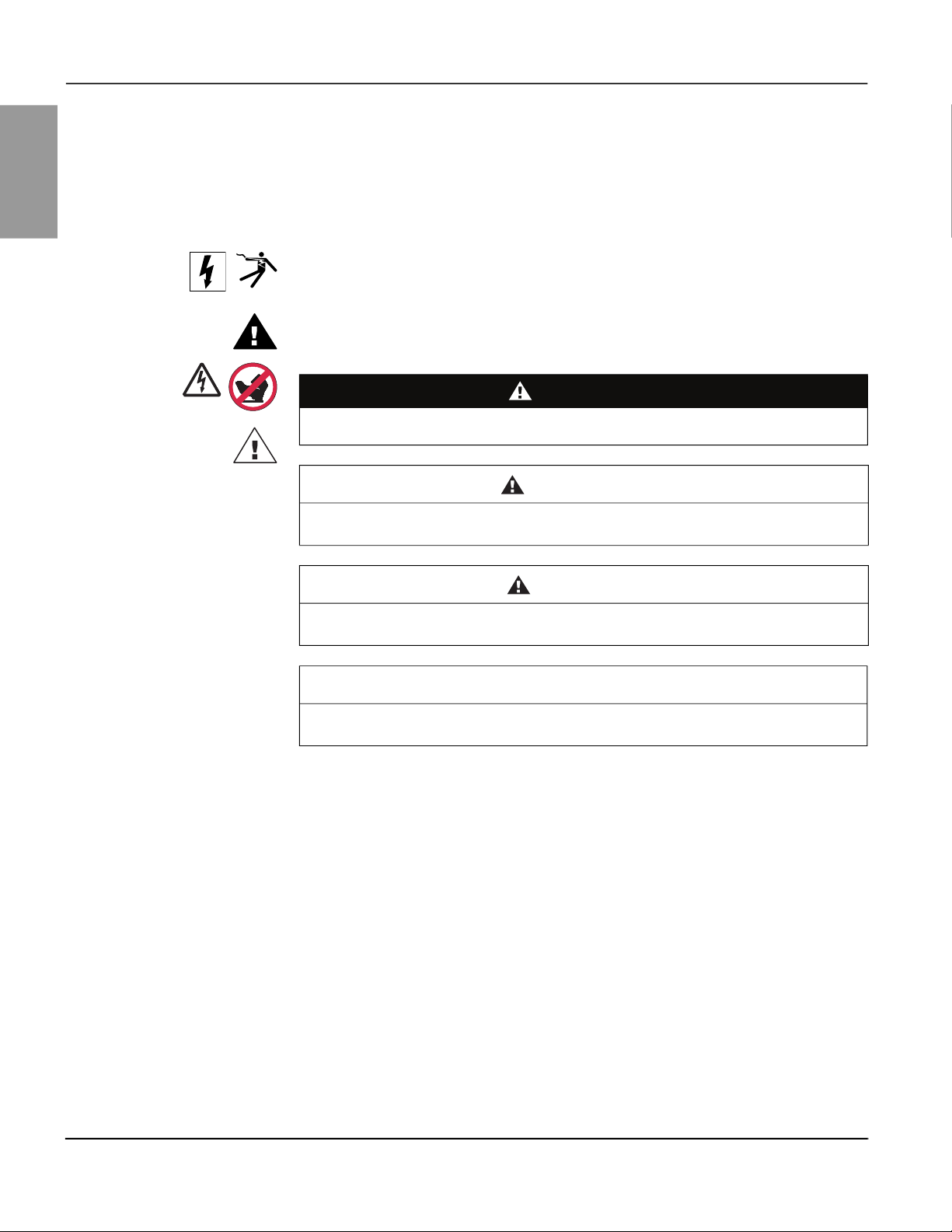

Hazard Categories and Special Symbols

ENGLISH

Read these instructions carefully and look at the equipment to become familiar with

the device before trying to install, operate, service or maintain it. The following

special messages may appear throughout this bulletin or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that

an electrical hazard exists which will result in personal injury if the instructions are

not followed.

ANSI

IEC

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, can result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, can result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury. The safety

alert symbol is not used with this signal word.

Please Note

FCC Notice

2-EN

NOTE: Provides additional information to clarify or simplify a procedure.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense. This Class A digital apparatus complies with Canadian ICES-003.

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 5

Table of Contents MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Table of Contents

SECTION 1:GENERAL INFORMATION ........................................................................................................ 7

Introduction ...................................................................................................... 7

In Rating ........................................................................................................... 8

Control Power .................................................................................................. 9

Backlighting ...................................................................................................... 9

Trip Unit Installation ......................................................................................... 9

Trip Unit Sealing ............................................................................................ 10

MicroLogic Trip Unit Layout ........................................................................... 11

Trip Unit Face .......................................................................................... 11

Navigation Principles ..................................................................................... 13

Lock/Unlock the Settings ......................................................................... 13

Trip Unit Modes ....................................................................................... 13

Mode Selection ........................................................................................ 14

Readout Mode ............................................................................................... 14

ENGLISH

Energy Meter Readout (MicroLogic E) ........................................................... 19

Protection Function Readout ................................................................... 22

Neutral Status Readout Mode ................................................................. 22

Setting Mode .................................................................................................. 23

Setting Using a Dial ................................................................................. 23

Setting Using the Keypad ........................................................................ 23

Presetting a Protection Function .............................................................. 27

Setting a Protection Function ................................................................... 28

SECTION 2:ELECTRICAL DISTRIBUTION PROTECTION .................................................................. 29

Protection Functions ...................................................................................... 29

Setting the Protection .............................................................................. 29

Reflex Tripping ......................................................................................... 29

Selective Coordination ................................................................................... 30

Mission Critical Circuit Breakers .................................................................... 30

Long-Time Protection ..................................................................................... 31

Setting the Long-Time Protection ............................................................ 31

Ir Pickup Setting Values ........................................................................... 31

tr Time Delay Setting Values ................................................................... 32

Thermal Image ......................................................................................... 32

Conductor Heat Rise and Tripping Curves .............................................. 33

Thermal Memory ...................................................................................... 33

Short-Time Protection .................................................................................... 33

Setting the Short-Time Protection ............................................................ 34

Isd Pickup Setting Values ........................................................................ 34

tsd Time Delay Setting Values ................................................................. 34

I2t ON/OFF .............................................................................................. 34

Instantaneous Protection ............................................................................... 35

Setting the Instantaneous Protection ....................................................... 35

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

3-EN

Page 6

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Table of Contents

Ii Pickup Setting Values ........................................................................... 36

ENGLISH

Ground-Fault Protection ................................................................................. 36

Setting the Ground-Fault Protection ........................................................ 36

Ig Pickup Setting Values .......................................................................... 37

tg Time Delay Setting Values ................................................................... 37

I2t ON/OFF Function ............................................................................... 37

Ground-Fault Protection Test ................................................................... 37

Neutral Protection .......................................................................................... 38

Operation ................................................................................................. 38

Setting the Neutral Protection .................................................................. 39

Neutral Protection Setting Value .............................................................. 39

Selection of the ENCT Option .................................................................. 39

Zone Selective Interlocking (ZSI) ................................................................... 41

Example of ZSI Operation ....................................................................... 41

ZSI Wiring ................................................................................................ 41

ZSI Connection ........................................................................................ 42

Testing the ZSI ........................................................................................ 43

SECTION 3:METERING FUNCTION .......................................................................................................... 44

Real-Time Measurements .............................................................................. 44

Instantaneous Values .............................................................................. 44

Measuring the Neutral Current ................................................................. 44

Measuring the Phase-to-Neutral Voltages ............................................... 44

Calculating the Average Current and Average Voltage ........................... 45

Measuring the Current and Voltage Phase Unbalances .......................... 45

Maximum/Minimum Values ...................................................................... 46

Resetting Maximum/Minimum Values ...................................................... 46

Calculating Demand Values (MicroLogic E) .................................................. 47

Demand Value Models ............................................................................ 47

Metering Window ..................................................................................... 47

Fixed Metering Window .......................................................................... 47

Sliding Metering Window ......................................................................... 48

Synchronized Metering Window .............................................................. 48

Quadratic Demand Value (Thermal Image) ............................................. 48

Arithmetic Demand Value ........................................................................ 48

Peak Demand Value ................................................................................ 48

Resetting Peak Demand Values .............................................................. 49

Power Metering (MicroLogic E) ...................................................................... 49

Principle of Power Metering ..................................................................... 49

Calculation Based on Neutral Conductor ................................................. 50

Distributed Neutral ................................................................................... 50

Power Sign and Operating Quadrant ....................................................... 51

Power Supply ........................................................................................... 51

Power Calculation Algorithm .................................................................... 51

Energy Metering (MicroLogic E) .................................................................... 53

Principle of Energy Calculation ................................................................ 53

Partial Energy Meters .............................................................................. 53

Energy Meters ......................................................................................... 54

Selecting Energy Calculation ................................................................... 54

Resetting Energy Meters ......................................................................... 54

4-EN

Harmonic Currents ......................................................................................... 55

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 7

Table of Contents MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Origin and Effects of Harmonics .............................................................. 55

Definition of a Harmonic .......................................................................... 55

RMS Currents and Voltages .................................................................... 56

Acceptable Harmonic Levels ................................................................... 56

Metering Energy Quality Indicators (MicroLogic E) ........................................ 58

Current THD ............................................................................................ 58

Voltage THD ............................................................................................ 59

Distortion Power D ................................................................................... 59

Power Factor PF and Cos φ Measurement (MicroLogic E) ........................... 60

Power Factor PF ...................................................................................... 60

Cos φ ....................................................................................................... 60

Power Factor PF and Cos φ When

Harmonic Currents are Present ............................................................... 60

Sign for the Power Factor PF and Cos φ ................................................. 61

Managing the Power Factor PF and Cos φ:

Minimum and Maximum Values ......................................................................62

Monitoring the Cos φ and Power Factor PF Indicators ............................ 62

Selecting the Sign Convention for the

Cos φ and Power Factor PF .................................................................... 63

Measurements ............................................................................................... 63

Accuracy .................................................................................................. 63

Real-Time Measurements .............................................................................. 64

SECTION 4:ALARMS .......................................................................................................... 68

Alarms Associated with Measurements ......................................................... 68

Alarm Setup ............................................................................................. 68

Alarm Priority Level .................................................................................. 68

Alarm Activation Conditions ..................................................................... 69

Overvalue Condition ................................................................................ 69

Undervalue Condition .............................................................................. 69

Equality Condition .................................................................................... 70

Management of Time Delays (Overvalue or Undervalue Conditions) ..... 70

ENGLISH

Alarms on a Trip, Failure, and Maintenance Event ........................................ 71

Alarm Setup ............................................................................................. 71

Alarm Priority Level .................................................................................. 71

Tables of Alarms ............................................................................................ 72

Operation of SDx Module Outputs Assigned to Alarms ................................. 75

SDx Module Output Operating Modes ..................................................... 75

Acknowledgment of Latching Mode ......................................................... 76

SECTION 5:REMOTE SETTING UTILITY (RSU) SOFTWARE ............................................................ 78

Function Setting ............................................................................................. 78

Using the RSU Software .......................................................................... 78

User Profiles ............................................................................................ 79

Offline Mode ............................................................................................ 79

Online Mode ............................................................................................ 79

Software Configuration Tabs ................................................................... 80

Saving and Printing .................................................................................. 81

Protection Functions ...................................................................................... 81

Setting the Protection Functions .............................................................. 81

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

5-EN

Page 8

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Table of Contents

Presetting the Protection Functions by a Dial .......................................... 81

ENGLISH

Metering Setup ............................................................................................... 82

Alarm Setup ................................................................................................... 84

Setting the SDx Module Output Functions ..................................................... 85

SECTION 6:MICROLOGIC TRIP UNIT INDICATORS ............................................................................ 87

LED Indication ................................................................................................ 87

Local Indicator ......................................................................................... 87

Operation of the Ready LED .................................................................... 87

Operation of Pre-Alarm and Alarm LEDs

(Electrical Distribution Protection) ............................................................ 88

Indication on the MicroLogic Display ............................................................. 88

Stacking Screens ..................................................................................... 88

Indication Screens Cause and Response ...................................................... 89

Values According to IEC Convention ....................................................... 91

Setting the Cos φ Alarms According to IEEE Convention ....................... 92

Setting the SDx Outputs .......................................................................... 93

Acknowledging the Out1 Screen ............................................................. 93

SECTION 7:THE COMMUNICATION NETWORK .................................................................................... 94

Circuit Breaker Communication ..................................................................... 94

Remote Readout of the Circuit Breaker Status ........................................ 94

Remote Readout of the Measurements ................................................... 94

Remote Readout of the Operating Assistance Information ...................... 94

Circuit Breaker Remote Control ............................................................... 95

History and Time-Stamped Information ......................................................... 95

History ...................................................................................................... 95

Time-Stamped Information ...................................................................... 95

Maintenance Indicators .................................................................................. 95

BSCM Counters ....................................................................................... 95

MicroLogic Trip Unit Counters ................................................................. 95

6-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 9

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

200

175

125

150

100

80

70

250

225

8

6

4

5

3

2

1.5

12

10

Ii

45

40

30

35

25

20

15

60

50

10

8

4

6

3

1.5

15

12

Ii (x In)

2

5.3 A

Micrologic

Ir tr Isd tsd Ii(xIn)

Ii (x In)

225

125

2

3

4

6

5

8

10

12

150

175

200

250

300

350

400

1.5

Ir (A)

Section 1— General Information

Introduction

MicroLogic 5 and 6 electronic trip units provide:

• Adjustable tripping functions on electronic trip circuit breakers

• Protection for the electrical distribution system or specific applications

• Metering of instantaneous and demand values

• Kilowatt-hour metering

• Operating information (such as peak demand values, customized alarms, or

operation counters)

• Communication

ENGLISH

MicroLogic 5.2 A trip unit

Front faces of MicroLogic trip unit

The product name specifies the protection provided by the trip unit.

MicroLogic 6.2 A-W

Type of Protection

0—Molded case switch (L-frame circuit breaker only)

1—Magnetic only motor circuit protection (L-frame circuit breaker only)

2—Standard motor circuit protection

3—Standard UL protection (LI or LSI), no display

5—Selective protection (LSI), with display

6—Selective protection plus ground-fault protection for equipment (LSIG), with display

Frame Size

2—150/250 A

3—400/600 A

Type of Measurement

A—Provides protection plus ammeter measurements

E—Provides protection plus energy measurements

S—Provides LSI protection with fixed long time delay and fixed short time delay

W—Mission Critical (Selective)

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

7-EN

Page 10

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

I

s

d(

x

I

r)

8

6

2

3

4

5

7

1

01

.

5

Micrologic

5.2E

A

I

r tr

I

sd ts

d

l

i

(x

l

n

)

N

1

/

A

2

/

B

3

/

C

OK

M

ode

30

Ready

>

1

5

A

Alarm

%

I

r

>9

0

>

1

0

5

36

2

8

1

8

2

0

2

3

2

5

3

2

4

0

I

r

(

A

)

Mic

I

s

d(

x

1

.

5

0

1

2

3

4

5

9

8

7

6

0

1

2

3

4

5

9

8

7

6

3.

2

Micr

o

lo

g

ic

5.1

2

5

.2

3

4

0

1

8

6

5

.9

2

9

.

3

9

.

4

9

.

5

9

.

1

89

.

7

9

.

69

.

0

0

1

0

1

1

5

2

1

0

4

1

0

6

1

0

5

2

52

2

0

02

5

7

1

I

r

d

s

I

dsI

)

r

I

x

(

I

r

)

o

I

x(

o

I

)

A

(

r

I

%

A

0

3

>

0

3>

0

1

1

>

In=250A

MicroLogic trip units can be configured to communicate with other devices. For

ENGLISH

information on the UTA Tester and Modbus™ Interface Module (IFM), see the

product catalog and the circuit breaker user guide.

Modbus™ Interface

Module (IFM)

UTA Tester

Front Display Module

(FDM121)

PowerPact™ H-frame

circuit breaker equipped

with a MicroLogic trip unit,

BSCM, and NSX Cord

For complete information on available circuit breaker models, frame sizes,

interrupting ratings, and trip units, see the product catalog.

This manual describes operation of the MicroLogic 5 and 6 trip units.

In Rating

For additional information see the following user guides available on the Schneider

Electric™ website:

• Bulletin 48940-310-01: MicroLogic™ 1, 2, and 3 Electronic Trip Units—User

Guide.

• Bulletin DOCA0088EN: FDM121—Display for LV Circuit Breaker —User Guide

• Bulletin DOCA0037EN: FDM128—Display For 8 LV Devices—User Guide

To access the website go to:

http://www.schneider-electric.com

For application assistance, please call 1-888-778-2733.

The trip unit In value (A) is visible on the front face of the circuit breaker when the

trip unit is installed. The trip unit In rating (in amperes) is the trip unit maximum

value.

A

For MCP versions, the Full Load Amp (FLA) range is displayed

Example:

250 A trip unit

• Sensor rating I

8-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

= 250 A

n

Page 11

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Control Power

The current through the circuit breaker provides power to operate the MicroLogic trip

unit, maintaining protection if the trip unit is not externally powered.

Backlighting

An optional external 24 Vdc power supply for the MicroLogic trip unit is available

for:

• Modifying the setting values when the circuit breaker is open

• Displaying measurements when the circuit breaker is closed but current

through the circuit breaker is low (15–50 A depending on the rating

• Continuing to display the reason for the trip and the breaking current when the

circuit breaker is open

Without the optional external 24 Vdc power supply, the MicroLogic trip unit only

functions when the circuit breaker is closed. When the circuit breaker is open or the

current through the circuit breaker is low, the MicroLogic trip unit has no power and

the display switches off.

The external 24 Vdc power supply is available to the trip unit when it is connected

to another module in the ULP system (Modbus Interface Module (IFM), Front

Display Module (FDM121), or UTA Tester).

When the MicroLogic trip unit is not connected to a ULP module, it can be

connected directly to an external 24 Vdc power supply using the optional 24 Vdc

supply terminal block.

When the MicroLogic trip unit is powered by an external 24 Vdc power supply, the

trip unit display has white backlighting that is:

ENGLISH

Trip Unit Installation

• Low intensity continuously

• High intensity for 1 minute after pressing one of the keypad buttons

The display backlighting is:

• Deactivated if the temperature exceeds 149°F (65°C)

• Reactivated once the temperature drops back below 140°F (60°C)

On trip units powered by the pocket tester, the display unit is not backlit.

The trip unit is designed for ease of field installation and replacement (for circuit

breakers which offer this capability):

• No connections to make

• Installable with a standard Torx T25 driver

• A mechanical cap ensures trip unit compatibility

• Torque limiting screws ensure secure mounting

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

9-EN

Page 12

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

ENGLISH

For installation information, see the instruction bulletin shipped with the FieldInstallable Trip Unit (FITU).

NOTE: After installation, the screw heads are accessible so the trip unit can be

removed if necessary.

Trip Unit Sealing

The transparent cover on MicroLogic trip units is sealable.

• A sealed cover prevents modification of the protection settings.

• A sealed cover prevents access to the test port.

• The protection settings and measurements can still be read on the keypad.

10-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 13

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Ii (x In)

35

15

2

3

4

8

6

10

12

15

20

25

30 40

45

50

60

1.5

225

200

175

5

4

3

2

1.5

6

8

10

12

250

Ir (A)

125

150

100

80

70

Ii (x In)

Micrologic

5.2 A

MicroLogic Trip Unit Layout

Trip Unit Face

Use the display screen and keypad on the trip unit to set the trip unit options and

check system measurements. See “Navigation Principles” on page 13 for more

information.

ENGLISH

A

B

C

D

E

A. Indication LEDs: • shows the trip unit operational state

• vary in meaning depending on the trip unit type.

1. Ready LED (green): Blinks slowly when the electronic trip unit is ready to provide protection.

2. Overload pre-alarm LED (orange): Lights when the load exceeds 90% of the I

3. Overload alarm LED (red): Lights when the load exceeds 105% of the I

1

2

3

B. Test Port

Use the test port for:

— connecting a pocket tester for local testing of the MicroLogic trip unit

— connecting the UTA tester for testing, setting the MicroLogic trip unit, and

for installation diagnostics.

C. Dials and Microswitch

A. Indication LEDs

B. Test port

C. Dials for presetting protection

functions and microswitch for locking

protection setting

D. LCD display

E. Navigation keypad

setting.

r

setting.

r

A

B

A. Pickup (Ir) preset dial (distribution trip unit only)

Sets the maximum continuous current level of the circuit breaker. If current exceeds this value, circuit

breaker trips after the preset time delay.

B. Instantaneous (I

) preset dial (distribution trip unit only)

i

Sets the instantaneous trip pickup value setting for the phases and for the neutral (trip unit with

ENCT option and neutral protection active).

C. Microswitch to lock/unlock the protection settings

C

The trip unit face has two dials for presetting protection functions and a microswitch

for locking/unlocking the protection settings. For distribution trip units, the dials are

for setting long-time and instantaneous protection.

Long-time protection:

• protects equipment against overloads

• is standard on distribution trip units

• uses true rms measurement

Instantaneous protection:

• protects equipment against fault currents

• is standard on distribution trip units

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

11-EN

Page 14

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

OK

• has pickup value setting for the phases and for the neutral (trip unit with ENCT

ENGLISH

option and neutral protection active)

• uses true rms measurement

Trip units are shipped with the long-time pickup switch set at the maximum setting

and all other trip unit switches set at their lowest settings. All advanced protection

settings are turned “off.”

D. LCD display

1. Five pictograms: Metering, Readout, Protection, Setting, Lock.

How pictograms are combined defines the mode

2. Up arrow points to protection function currently being set

3. List of protection functions according to the MicroLogic trip unit type

4. Value of the measured quantity

5. Unit of the measured quantity

6. Navigation arrows

7. Down arrow(s) point to the selected phase(s), neutral, or the ground

8. Phases (1/A, 2/B, 3/C), neutral (N) and ground

An LCD display provides information necessary to use the trip unit. The list of

protection functions varies according to the MicroLogic trip unit type.

On MicroLogic trip units powered by an external 24 Vdc power supply, the trip unit

display has white backlighting that is:

• low intensity continuously

• high intensity for 1 minute after pressing any of the keys on the keypad

• deactivated if the temperature exceeds 149°F (65°C)

• reactivated once the temperature drops back below 140°F (60°C)

NOTE: On trip units powered by the pocket tester, the display unit is not backlit.

E. Navigation keypad Use the 5-button keypad for navigation.

Button Description

Mode

Mode: Selecting the mode

Scroll: Scrolling navigation

Back: Navigation back (metering) or - (setting the protection functions)

Forward: Navigation forward (metering) or + (setting the protection functions)

OK: Confirmation

Screensaver The screensaver displays the instantaneous current passing through the most

heavily loaded phase (Instantaneous measurement readout mode).

The MicroLogic display automatically reverts to a screensaver:

12-EN

• In padlock locked mode, 20 seconds after the last action on the keypad

• In padlock unlocked mode, 5 minutes after the last action on the keypad or

dials

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 15

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

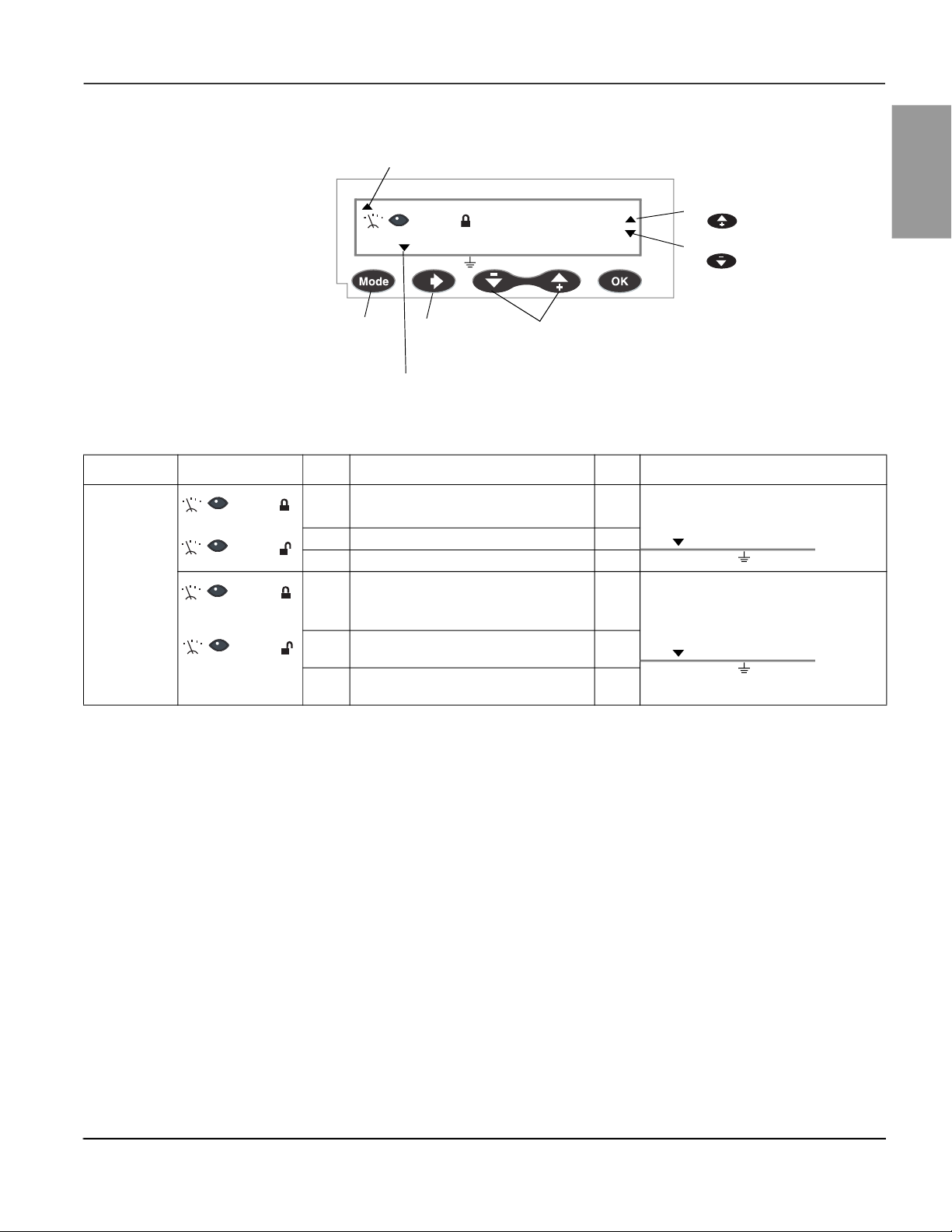

Navigation Principles

Lock/Unlock the Settings

Table 1 – Protection Settings

Display Description

Padlock locked. The protection settings are locked.

Padlock unlocked. The protection settings are unlocked.

The protection settings are locked when the transparent cover is closed and sealed

to prevent access to the adjustment dials and the locking/unlocking microswitch.

A pictogram on the display indicates whether the protection settings are locked:

To unlock the protection settings:

1. Open the transparent cover

2. Press the lock/unlock microswitch or turn either adjustment dial

To lock the protection settings, press the lock/unlock microswitch again.

The protection settings also lock automatically five minutes after pressing a button

on the keypad or turning one of the dials on the MicroLogic trip unit.

ENGLISH

Trip Unit Modes

Information displays on the MicroLogic trip unit are based on its mode. The modes

available depend on:

• Whether the settings are locked

• The trip unit version

A combination of pictograms define the mode:

Metering

Readout

Protection

Setting

Lock

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

13-EN

Page 16

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Table 2 – Possible Modes

ENGLISH

Pictograms Mode Accessible

• Instantaneous measurement readout

or

• Kilowatt hour meter readout and reset

Mode Selection

Readout Mode

Max Reset? OK

or

Max Reset? OK

Select mode by successive presses on the button:

Peak demand readout and reset

Protection function readout

Protection function setting

Neutral status readout

Neutral status setting

Mode

• The modes scroll cyclically.

• Press the lock/unlock microswitch to switch between readout mode and setting

mode.

NOTE: When the Readout icon is visible, protection settings cannot be

altered.

Press the button successively to scroll through the metering screens.

Mode

Scrolling is cyclical.

14-EN

Use the , and navigation buttons to select the metering screen for

each of the phases:

The down indication arrow indicates the phase relating to the measurement value

displayed.

N 1/A 2/B 3/

Indicating arrows on two phases indicates that phase-to-phase value is being

measured:

N 1/A 2/B 3/

Indicating arrows on three phases indicates total power is being measured:

N 1/A 2/B 3/

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 17

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Figure 1 – Readout Screen

Up arrow indicates

function being measured.

Ir tr Isd tsd Ii (x

A

200

N 1/A 2/B 3/

Possible to press

button

the

Possible to press

button

the

ENGLISH

Use to select

measurement

readout mode

Use to select

phase screen is

measuring

Down arrow indicates phase

being measured.

Use to select

measurement to display

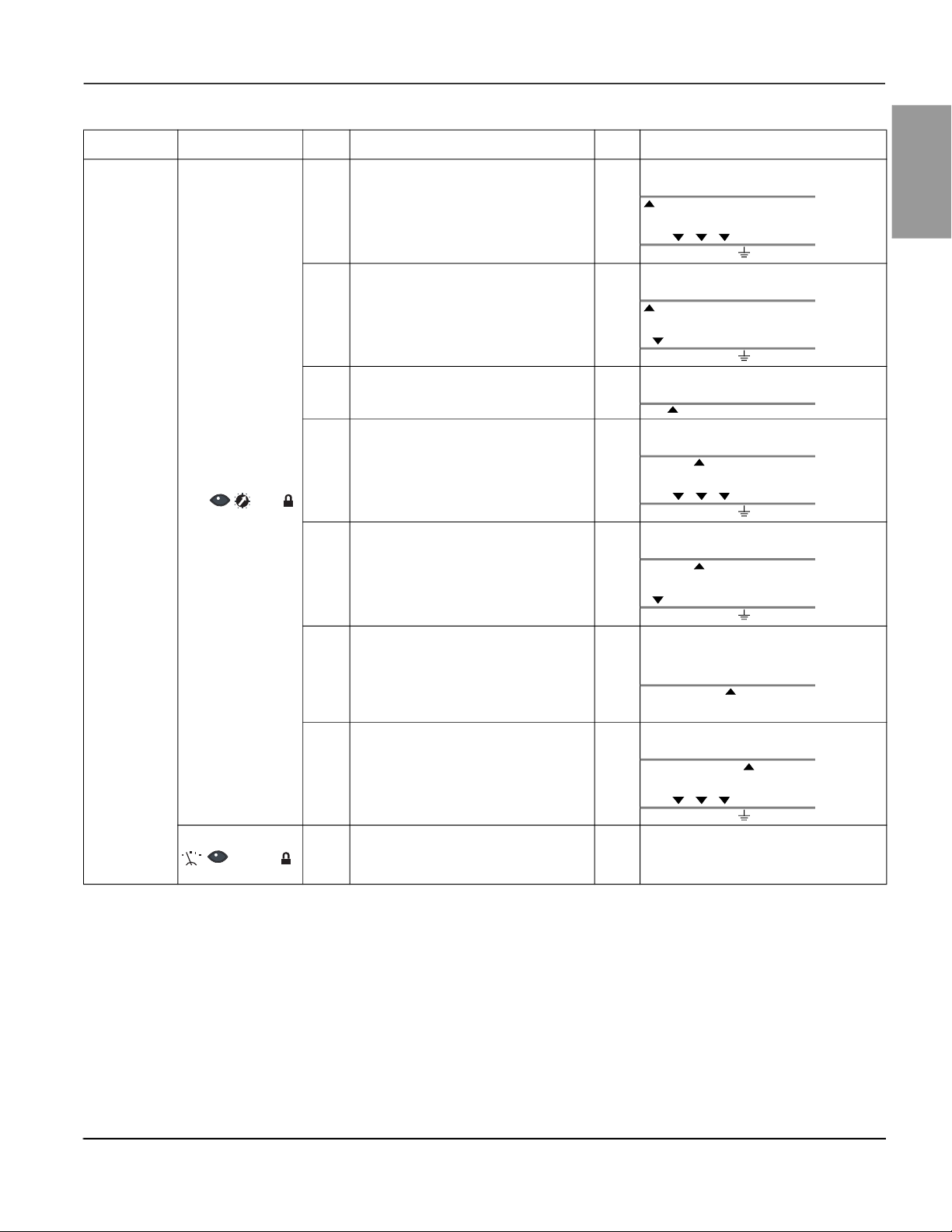

Table 3 – Metering Screens

Trip Unit Mode Order Screen Description Unit Arrows

MicroLogic A

(Ammeter)

or

Max Reset? OK

or

Max Reset? OK

Readout as instantaneous rms value of the:

1

• Three phase currents I

2 • Ground-fault current (MicroLogic 6) % I

3 • Neutral current IN (with ENCT option) A

Readout and resetting of the:

4

• Maximum I

currents

• Maximum ground-fault current

5

6

(MicroLogic 6 trip unit)

• Maximum I

(with ENCT option)

i max

max for the neutral current

N

, IB, and IC A

A

for the three phase

The down arrow indicates the conductor

(phase, neutral, or ground) corresponding

to the value shown.

g

N 1/A 2/B 3/

The down arrow indicates the conductor

A

(phase, neutral, or ground) corresponding

to the value shown.

% I

g

N 1/A 2/B 3/

A

Continued on next page

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

15-EN

Page 18

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Table 3 – Metering Screens (continued)

ENGLISH

Trip Unit Mode Order Screen Description Unit Arrows

MicroLogic E

(Energy)

or

Max Reset? OK

or

Max Reset? OK

Readout as instantaneous rms value of the:

1

• Three phase currents A, B, and C A

• Ground-fault current (MicroLogic 6 trip

2

unit)

3 • Neutral current IN (with ENCT option) A

Readout as instantaneous rms value of the:

• Phase-to-phase voltages V

4

VCA

• Phase-to-neutral voltages V

, VBC, and

AB

, VBN,

AN

and VCN (with ENVT option)

5 Readout of the total active power P

Readout of the total apparent power S

6

the three phase conductors.

7 Readout of the total reactive power Q

Readout and resetting of the active energy

8

meter E

Readout and resetting of the apparent

9

energy meter E

Readout and resetting of the reactive

10

energy meter E

p

s

q

kW

tot

in

tot

kvar

tot

The down arrow indicates the conductor

(phase, neutral, or ground) corresponding

to the value shown.

% I

g

N 1/A 2/B 3/

The down arrow indicates the conductor

(phase, neutral, or ground) corresponding

V

to the value shown.

N 1/A 2/B 3/

kVA

kWh,

MWh

kVAh,

MVAh

kvarh,

Mvarh

or

Max Reset? OK

or

Max Reset? OK

11 Readout of the phase rotation —

Readout and resetting of the:

12

• Maximum I

• Maximum ground-fault current

13

14

(MicroLogic 6 trip unit)

• Maximum I

(with ENCT option)

for the 3 phase currents

i max

for the neutral current

N max

% I

Readout and resetting of the:

• Maximum V

15

• Maximum V

phase voltages

for the three phase-to-

ij max

for the three phase-

iN max

to-neutral voltages (with ENVT option)

Readout and resetting of the maximum

16

P

of the active power

max

Readout and resetting of the maximum

17

S

of the apparent power kVA

max

Readout and resetting of the maximum

18

of the reactive power kvar

Q

max

kW

kVA

kvar

A

The down arrow indicates the conductor

(phase, neutral, or ground) corresponding

to the value shown.

g

N 1/A 2/B 3/

A

The down arrows indicate the phases

between which the maximum V

V

N was measured.

N 1/A 2/B 3/

The down arrows indicate the three phase

conductors.

N 1/A 2/B 3/

Continued on next page

L-L or L-

max

16-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 19

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Table 3 – Metering Screens (continued)

Trip Unit Mode Order Screen Description Unit Arrows

MicroLogic 5

LSI: Protection

Function

Readout

Screens

I

—Long-time protection pickup value for

r

1

the phases

)—Long-time protection pickup value

I

r(IN

for the neutral (trip unit with ENCT option

2

and neutral protection active)

—Long-time protection time delay value

t

r

4

5

6

)

(at 6 I

r

—Short-time protection pickup value for

I

sd

the phases

) —Short-time protection pickup value

I

sd(IN

for the neutral (trip unit with ENCT option

and neutral protection active)

—Short-time protection time delay value

t

sd

The time delay is for the I2t inverse time

curve protection:

7

• ON: I

• OFF: I

I

setting for the phases and for the neutral

8

(trip unit with ENCT option and neutral

2

t function active

2

t function not active

—Instantaneous protection pickup value

i

protection active).

Neutral status (with ENCT option):

9

• N—Neutral protection active

• noN—Neutral protection not active

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrow indicates the neutral.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii (x In)

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrow indicates the neutral.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii (x In)

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

— —

Continued on next page

function.

r

function.

r

function.

r

function.

sd

function.

sd

function.

sd

function.

i

ENGLISH

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

17-EN

Page 20

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Table 3 – Metering Screens (continued)

ENGLISH

Trip Unit Mode Order Screen Description Unit Arrows

function.

r

function.

r

function.

r

sd

sd

sd

function.

g

MicroLogic 6

LSIG:

Protection

Function

Readout

Screens

I

—Long-time protection pickup value for

r

1

the phases

I

)—Long-time protection pickup value

r(IN

2

for the neutral (trip unit with ENCT option

and neutral protection active)

t

—Long-time protection time delay value

r

4

5

6

)

(at 6 I

r

I

—Short-time protection pickup value for

sd

the phases

)—Short-time protection pickup value

I

sd(IN

for the neutral (trip unit with ENCT option

and neutral protection active)

—Short-time protection time delay value

t

sd

The time delay is for the I

curve protection:

7

• ON: I

• OFF: I

I

setting for the phases and for the neutral

8

(trip unit with ENCT option and neutral

2

t function active

2

t function not active

—Instantaneous protection pickup value

i

2

t inverse time

protection active).

9 I

—Ground-fault protection pickup value A A

g

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrow indicates the neutral.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii Ig tg

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrow indicates the neutral.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii Ig tg

The up arrow indicates the Ii function.

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three phases.

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

The down arrows indicate the three phases.

function.

function.

function.

18-EN

N 1/A 2/B 3/

t

—Ground-fault protection time delay

g

value

The time delay is for the I

10

curve protection:

• ON: I

• OFF: I

2

t function active

2

t function not active

2

t inverse time

The up arrow indicates the t

s

Ir tr Isd tsd Ii Ig tg

function.

g

Neutral status (with ENCT option):

11

• N—Neutral protection active

• noN —Neutral protection not active

— —

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 21

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Energy Meter Readout (MicroLogic E)

Energy meters change measurement unit automatically:

• For active energy, E

, displayed in kWh from 0 to 9999 kWh then in MWh

p

• For reactive energy, Eq, displayed in kvarh from 0 to 9999 kvarh then in Mvarh

• For apparent energy, E

, displayed in kVAh from 0 to 9999 kVAh then in MVAh

s

When energies are in MWh, Mkvarh, or MVAh, the values display on four digits.

The MicroLogic trip unit incorporates the option of full energy meter readout.

NOTE: The energy meter can be reset with the padlock locked or unlocked. Table

4 shows the padlock locked.

Table 4 – Example of Full Energy Readout (MicroLogic E)

Step Readout Value Action Using Display

Reading Full Energy Values

Ir tr Isd tsd Ii (x In)

1

2

Current in most

heavily loaded

phase

Energy

with Reset

option showing

Select the readout and reset the energy meter

mode (main screen displayed).

Select the E

The value displayed is 11.3 MWh (in the

example), which corresponds to 10 MWh +1300

kWh (approximately).

active energy meter.

p

Mode

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

N 1/A 2/B 3/

Reset? OK

229

11.3

ENGLISH

A

MWh

3

4

Specific

energy

measurement

Energy

normal

display

Specify the measurement.

The value displayed is 1130 kW. (In the example

the full energy meter value is 11300 kWh)

Return to the energy meter normal display.

The display reverts automatically after 5

minutes.

Ir tr Isd tsd Ii (x In)

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In

Reset? OK

N 1/A 2/B 3/

1130

11.3

Continued on next page

kWh

kWh

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

19-EN

Page 22

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Mode

Mode

Table 4 – Example of Full Energy Readout (MicroLogic E) (continued)

ENGLISH

Resetting Full Energy Readout

Ir tr Isd tsd Ii (x In)

Current in most

1

heavily loaded

phase

Energy with

2

Reset option

showing

3 Reset option lit

4 OK

Select the measurement readout and reset

energy meter mode (main screen displayed).

Select the energy meter to reset.

Enter the reset.

The OK pictogram blinks.

Confirm the reset.

The confirmation OK displays for 2 seconds.

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

OK

OK

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

229

1458

1458

A

kWh

kWh

OK

Resetting Peak Demand Values

1 Main screen

Peak demand

2

with Reset option

showing

3 Reset option lit

4 OK

Select the Readout and reset peak demand

value mode

Select the peak demand to reset.

Enter the reset.

The OK pictogram blinks.

Confirm the reset.

The confirmation OK display for 2 seconds.

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

OK

OK

Max Reset?

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

Max Reset?

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

243

435

435

A

V

V

OK

20-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 23

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

OK

OK

Table 5 – Example of Ground-Fault Protection Readout (MicroLogic 6)

Step Readout Value Action Using Display

Reading Measurement Values

Current in most

1

heavily loaded

phase

2 Ground-fault current

Select the Instantaneous measurement readout

mode (the display is the most heavily loaded

phase, in this example Phase B).

Read the value of current in Phase B.

Select the ground-fault current measurement

screen (the value is a % of the I

Ground-Fault Protection Test (MicroLogic 6)

setting).

g

Mode

Ir tr Isd tsd Ii Ig tg

N 1/A 2/B 3/

Ir tr Isd tsd Ii Ig tg

OK

N 1/A 2/B 3/

A

229

%

17

ENGLISH

Current in most

1

heavily loaded

phase

Peak demand with

2

Reset option

showing

3 Reset option lit

4 OK

Access the ground-fault protection test function by

pressing OK.

The tESt pictogram appears and the OK pictogram

blinks.

Prompt the ground-fault protection test by pressing

OK.

The circuit breaker trips. The ground-fault

protection trip screen is displayed.

Acknowledge the ground-fault trip screen by

pressing OK.

The Reset OK pictogram blinks.

Confirm by pressing OK again

The confirmation OK displays for 2 seconds.

Mode

Ir tr Isd tsd Ii Ig tg

OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii Ig tg

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii Ig tg

Reset? OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii Ig tg

N 1/A 2/B 3/

tESt

triP

triP

OK

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

21-EN

Page 24

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Mode

Mode

Protection Function Readout

ENGLISH

Select a protection function using the mode key. This selection is only possible in

Readout mode (when the padlock is locked).

• Scrolling is cyclical.

• The up arrow indicates the selected protection function. (For the neutral

protection functions, the down arrow which points to N replaces the up arrow.)

Example: I

Ir tr Isd tsd Ii (x In)

pickup selected

r

Table 6 – Example of Protection Function Readout

Readout

Step

1

2

3

Value

Long-time

protection I

pickup setting

value in

amperes.

Long-time

protection t

time delay

setting value in

seconds.

The short-time

protection I

pickup setting

value in

amperes.

Action Using Display

Select the Protection function readout mode

r

(main screen displayed).

The long-time protection I

in amperes.

r

Select the long-time protection tr time delay.

sd

Select the short-time protection I

pickup setting value

r

pickup

sd

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

110

A

s

8.0

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

A

715

N 1/A 2/B 3/

Neutral Status Readout Mode

NOTE: The Neutral status readout mode is dedicated to this function. Navigation is

therefore limited to the Mode key.

Table 7 – Example of Neutral Status Readout

Readout

Step

1

22-EN

Value

Neutral status is

displayed

Action Using Display

Select the Neutral status readout mode.

The neutral status value is displayed:

• N—Neutral protection active (with ENCT

option declared)

• noN—Neutral protection not active (without

ENCT option or with ENCT option not

declared)

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

noN

Page 25

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

CAUTION

Setting Mode

Setting Using a Dial

Figure 2 – Protection

Switches

150

175

125

100

A

80

70

3

B

2

1.5

Ir (A)

4

Ii (x In)

200

5.2 A

225

250

5

6

8

10

12

Micrologic

HAZARD OF NO PROTECTION OR NUISANCE TRIPPING

Modifying the protection functions must be done only by qualified electrical

personnel.

Failure to follow these instructions can result in injury or equipment

damage.

The protection function settings can be set:

• By a dial and fine-tuned on the keypad for the main protection functions

• On the keypad for all protection functions

The up arrow on the display indicates the protection function currently being set.

Use a dial to set (or preset) the Ir (A) and Ii (B) pickups.

Turning a dial results simultaneously in:

• Selection of the screen for the protection function assigned to the dial

• Unlocking (if necessary) the padlock (the navigation interface is in protection

function setting mode)

• Setting the protection function assigned to the dial to the value indicated on the

dial and on-screen.

ENGLISH

Setting Using the Keypad

Use the keypad to fine-tune the protection function.

• The setting value cannot exceed that indicated by the dial.

• All the protection function settings are accessible on the keypad.

Press the button successively to scroll through the protection function

Mode

screens. Scrolling is cyclical.

Navigate through the protection function settings with the , and

navigation buttons.

• Use the button to select the function to set:

— The up arrow indicates the selected function

— The down arrow indicates phase. Multiple down arrows indicate all phases

set to the same value (except for the neutral protection setting)

— Scrolling is cyclical

• Set the protection functions on the keypad with the and buttons.

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

23-EN

Page 26

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Figure 3 – Protection Function Screen

ENGLISH

Up arrow indicates

selected function.

Ir tr Isd tsd Ii (x

200

N 1/A 2/B 3/

A

Possible to press

button

the

Possible to press

button

the

Confirmation of Setting

Use to select

protection

function screen

Use to select

function to set

Down arrow

indicates phase.

Use to select

measurement to display

The value of a protection function set on the keypad must be:

1. Entered by pressing the OK key once (the OK pictogram blinks on the display)

2. Then confirmed by pressing the OK key again (the text OK displays for

2 seconds)

NOTE: Setting using a dial does not require any enter/confirm action.

24-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 27

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

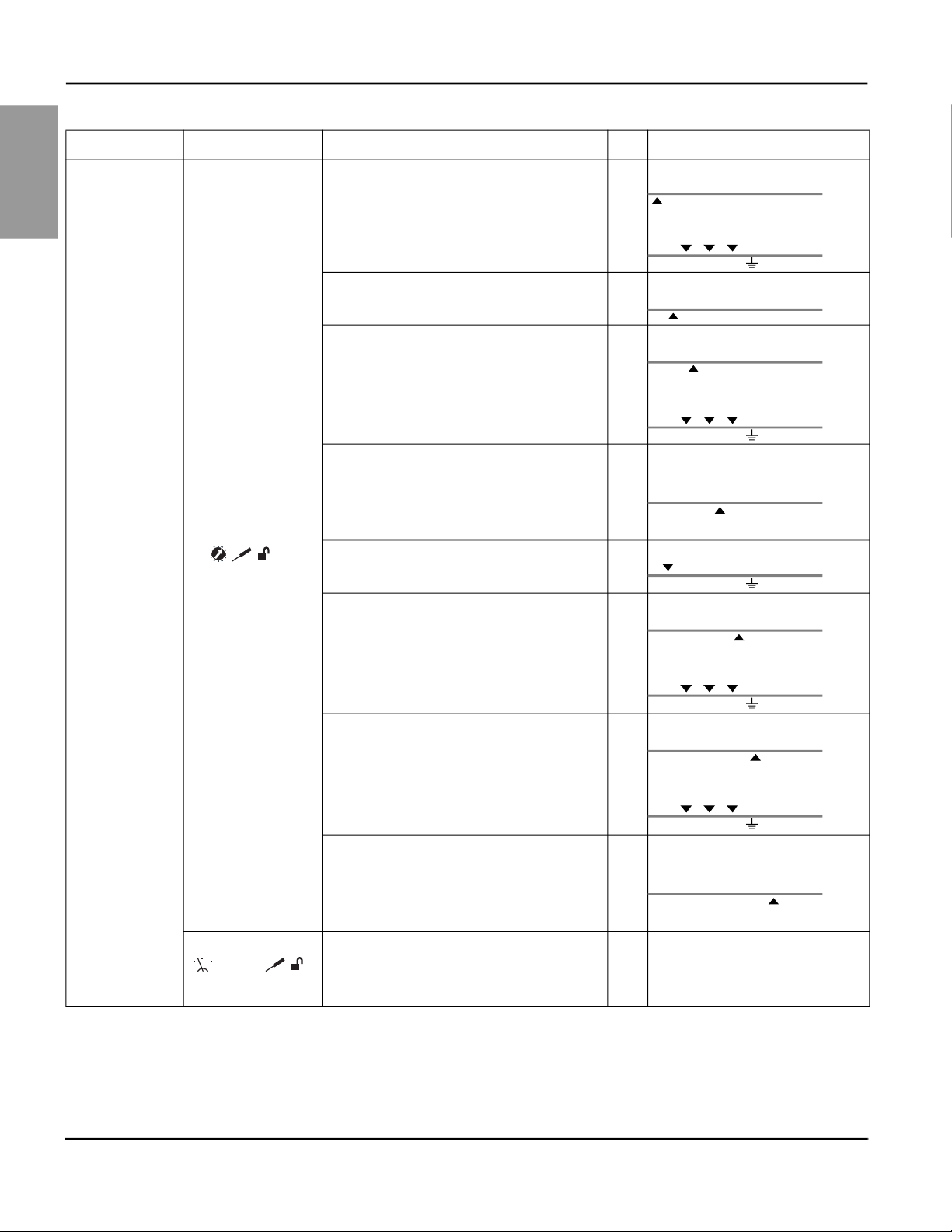

Table 8 – List of Protection Function Setting Screens

Trip Unit Mode Screen Description Unit Arrows

I

—Long-time protection pickup setting for the

r

phases

Preset by a dial

—Long-time protection time delay setting (at 6 Ir) s

t

r

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

The up arrow indicates the t

Ir tr Isd tsd Ii (x In)

function.

r

function.

r

ENGLISH

MicroLogic 5 LSI

—Short-time protection pickup setting for the

I

sd

phases

Preset by a dial

—Short-time protection time delay setting

t

sd

Activation of the I2t inverse time curve short-time

protection:

2

• ON: I

• OFF: I

I

N

t function active

2

t function not active

—Protection pickup setting for the neutral (trip

unit with ENCT option and neutral protection

active)

—Instantaneous protection pickup value setting

I

i

for the phases and for the neutral (trip unit with

ENCT option and neutral protection active).

Activation of neutral status (trip unit with ENCT

option):

• N: Neutral protection active

• noN: Neutral protection not active

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii (x In)

The down arrow indicates the neutral.

A

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii (x In)

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

— —

Continued on next page

function.

sd

function.

sd

function.

i

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

25-EN

Page 28

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Table 8 – List of Protection Function Setting Screens (continued)

ENGLISH

Trip Unit Mode Screen Description Unit Arrows

The up arrow indicates the I

—Long-time protection pickup setting for the

I

r

phases

Preset by a dial

t—Long-time protection time delay setting s

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

The up arrow indicates the t

Ir tr Isd tsd Ii Ig tg

function.

r

function.

r

MicroLogic 6 LSIG:

I

—Short-time protection pickup setting for the

sd

phases

—Short-time protection time delay setting

t

sd

The time delay is for the I

2

t inverse time curve

protection:

2

• ON: I

• OFF: I

I

N

t function active

2

t function not active

—Protection pickup setting for the neutral (trip

unit with ENCT option and neutral protection

active)

—Instantaneous protection pickup setting for the

I

i

phases and for the neutral (trip unit with ENCT

option and neutral protection active).

I—Ground-fault protection pickup setting

Preset by a dial

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

The up arrow indicates the t

s

Ir tr Isd tsd Ii Ig tg

The down arrow indicates the neutral.

A

N 1/A 2/B 3/

The up arrow indicates the I

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three

phases.

N 1/A 2/B 3/

The up arrow indicates the Ig function.

Ir tr Isd tsd Ii Ig tg

A

The down arrows indicate the three

phases.

function.

sd

function.

sd

function.

i

26-EN

N 1/A 2/B 3/

t

—Ground-fault protection time delay setting

g

The time delay is for the I2t inverse time curve

protection:

2

• ON: I

• OFF: I

t function active

2

t function not active

The up arrow indicates the t

s

Ir tr Isd tsd Ii Ig tg

function.

g

Activation of neutral status (trip unit with ENCT

option):

• N—Neutral protection active

• noN—Neutral protection not active

— —

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 29

Section 1—General Information MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Presetting a Protection Function

Table 9 illustrates presetting and setting the long-time protection Ir pickup on a

MicroLogic trip unit 5.2 rated 250 A:

Press the button to scroll through the metering screens.

Mode

Press the , and navigation buttons to select the metering screen for

each of the phases:

Table 9 – Example of Presetting a Protection Function Using a Dial

Step Action Using Display

Set the Ir dial to the maximum value (the padlock unlocks

1

2

4

automatically).

The down arrows indicate all 3 phases (the setting is identical

on each phase).

Turn the I

Presetting is complete:

• If the pickup setting value is correct (in this case, 175 A), exit

• If the pickup setting value is not suitable, fine-tune it on the

Set the exact value required for I

(in increments of 1 A).

dial to the setting above the value required.

r

the setting procedure (no enter keystroke is required).

keypad.

on the keypad

r

16

17

14

10

14

10

Ir (A)

16

Ir (A)

25

17

25

20

22

20

22

12

11

12

11

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

OK

ENGLISH

A

250

A

175

A

170

Ir tr Isd tsd Ii (x In)

5

6

Enter the reset.

The OK pictogram blinks.

Confirm the reset.

The confirmation OK displays for 2 seconds.

OK

OK

OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

170

A

OK

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

27-EN

Page 30

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 1—General Information

Mode

Setting a Protection Function

ENGLISH

Table 10 illustrates setting the long-time protection tr time delay on a MicroLogic

5.2 trip unit:

Press the button to scroll through the screens.

Mode

Press the , and navigation buttons to select the screen for each of

the phases:

Table 10 – Example of Setting a Protection Function Using the Keypad

Step Action Using Display

Ir tr Isd tsd Ii Ig tg

1

2 Select the protection function setting mode.

3 Select the t

If the locked pictogram is displayed, unlock the

protection settings.

function: the up arrow moves under tr.

r

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

A

229

A

170

s

0.5

4 Set the t

5 Enter the setting (the OK pictogram blinks).

6

Confirm the setting.

The confirmation OK displays for 2 seconds.

value required on the keypad.

r

Ir tr Isd tsd Ii (x In)

s

OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

OK

OK

OK

N 1/A 2/B 3/

Ir tr Isd tsd Ii (x In)

N 1/A 2/B 3/

8.0

s

8.0

OK

28-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 31

Section 2—Electrical Distribution Protection MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

1

5

4

3

2

7

6

10

9

8

In=400A

Section 2— Electrical Distribution Protection

MicroLogic 5 and 6 trip units provide protection against overcurrents and groundfault currents for commercial or industrial applications.

When choosing the protection characteristics to use, take account of:

• Overcurrents (overloads and short-circuits) and potential ground-fault currents

• Conductors than need protection

• The presence of harmonic currents

• Coordination between the devices

• Mission Critical trip units with enhanced selectivity have a “W” in the trip unit

number (for example, 3.2W or 3.2S-W)

Protection Functions

Functions are reviewed in detail on the following pages.

Table 11 – Protective Functions Trip Curve

Protective Functions Trip Curve No Function Description

1 I

n

2 I

r

3 t

r

4 I

sd

5 t

sd

2

6 I

t ON/OFF Short-time protection I2t curve in ON or OFF position A A

7 I

i

8 I

g

9 t

g

2

10 I

t ON/OFF

Sensor rating N N

Long-time protection pickup A A

Long-time protection time delay A A

Short-time protection pickup A A

Short-time protection time delay A A

Instantaneous protection pickup A A

Ground-fault protection pickup — A

Ground-fault protection time delay — A

Ground-fault protection I2t curve in ON or OFF

position

ENGLISH

MicroLogic Trip Unit

5 6

— A

A = Adjustable

N = Not Adjustable

— = Not Available

Setting the Protection

Reflex Tripping

To set the protection functions:

• On the MicroLogic trip unit, use the preset dials (depending on the protection

function and the MicroLogic type) and the keypad.

• With the communication option, use the RSU software under the Basic

protection tab.

For more information about using the RSU software to set the protection function,

see “Setting the Protection Functions” on page 81.

In addition to the devices integrated in the MicroLogic trip units, the PowerPact™ Lframe circuit breakers have reflex protection. This system breaks very high fault

currents by mechanically tripping the device with a “piston” actuated directly by the

pressure produced in the circuit breaker from a short circuit. This piston operates

the opening mechanism, resulting in ultra-fast circuit breaker tripping.

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

29-EN

Page 32

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 2—Electrical Distribution Protection

Selective Coordination

ENGLISH

Figure 4 – Coordination Trip Curves

Q

Q

2

1

Q

1

Q

2

Selective coordination between the upstream and downstream devices is essential

to optimize continuity of service. The large number of options for setting the

protection functions on MicroLogic 5 and 6 trip units improves the natural

coordination between circuit breakers.

Schneider Electric provides trip curves for each circuit breaker and tables showing

UL Listed series-rated circuit breakers. Trip curves can be found on our website:

http://www.schneider-electric.us

In the search box, type “PowerPact H, J, L”. Click on “PowerPact H/J/L Frame

Molded Case Circuit Breakers”, then click on the “Documents and Downloads” tab.

The user guides and trip curves are found within this tab.

For assistance, please call 1-888-778-2733.

Mission Critical Circuit Breakers

The PowerPact J- and L-Frame Mission Critical circuit breakers deliver high levels

of selective coordination with the QO™ family of miniature circuit breakers and the

ED, EG, and EJ circuit breakers in a flexible design that can be easily configured

for a variety of applications. These circuit breaker can be equipped with 5.2A-W,

5.2E-W, 6.2A-W, 5.3A-W, 6.3A-2, and 6.3E-2 MicroLogic trip units.

The mission critical trip units have the same settings and trip curves as the

standard trip units as described in this document.

For more information see catalog 0611CT1001 PowerPact H-, J-, and L-Frame

Circuit Breakers on the Schneider Electric website.

30-EN

© 2011–2020 Schneider Electric All Rights Reserved 48940-312-01

Page 33

Section 2—Electrical Distribution Protection MicroLogic™ 5 and 6 Electronic Trip Units—User Guide

Tripping curve:

In

I

r

t

r

In=250A

t

r

I

r

6 I

r

Long-Time Protection

Figure 5 – Long-Time Protection Curve

In = Trip unit setting range: Minimum setting/maximum setting - trip unit

rating

I

n

Ir = Long-time protection pickup

= Long-time protection time delay

t

r

Long-time protection on MicroLogic 5 and 6 trip units protect electrical distribution

applications against overload currents. It is identical for MicroLogic 5 and 6 trip units.

2

Long-time protection is I

t IDMT (Inverse Definite Minimum Time):

ENGLISH

• It incorporates the thermal image function.

• It is set with the I

Setting the Long-Time Protection

Set the Ir pickup:

• Using the MicroLogic trip unit I

tune the value

• With the communication option, preset using the I

unit and fine-tune the setting using the RSU software

Set the time delay t

• Using the keypad on the MicroLogic trip unit

• With the communication option, set using the RSU software

Ir Pickup Setting Values

The long-time protection tripping range is 1.05–1.20 Ir.

The default Ir pickup setting value is the maximum dial position In.

Use the keypad to fine-tune the setting, in increments of 1 A:

• The setting range maximum is the preset value of the dial.

• The range minimum is the minimum preset value (for the 400 A rating, the

setting range minimum is 125 A).

Example:

A MicroLogic 5.2 trip unit rated I

• The minimum preset value is 70 A

• The keypad fine-tuning range is 70–150 A

pickup and the tr trip time delay.

r

dial to preset the value and the keypad to fine-

r

:

r

= 250 A is preset using the dial at 150 A:

n

dial on the MicroLogic trip

r

© 2011–2020 Schneider Electric All Rights Reserved48940-312-01

31-EN

Page 34

MicroLogic™ 5 and 6 Electronic Trip Units—User Guide Section 2—Electrical Distribution Protection

2

5

3

2

5

A

B

11

4

The setting value displayed is the value of the trip time delay for a current of 6 Ir.

ENGLISH

Table 12 – Preset Values of I

(A)

r

In Rating

60 A 15 A 20 A 25 A 30 A 35 A 40 A 45 A 50 A 60 A

100 A 35 A 40 A 45 A 50 A 60 A 70 A 80 A 90 A 100 A

150 A 50 A 60 A 70 A 80 A 90 A 100 A 110 A 125 A 150 A

250 A 70 A 80 A 100 A 125 A 150 A 175 A 200 A 225 A 250 A

400 A 125 A 150 A 175 A 200 A 225 A 250 A 300 A 350 A 400 A

600 A 200 A 225 A 250 A 300 A 350 A 400 A 450A 500 A 600 A

tr Time Delay Setting Values

The default tr time delay setting value is 0.5 (minimum value) that is, 0.5 seconds at

6 I

Table 13 shows the value of the trip time delay (in seconds) according to the

current in the load for the setting values displayed on-screen.

The accuracy range is -20%/+0%.

Table 13 – Preset Values of tr (seconds)

Current in the

Load

1.5 t

6 t

7.2 t

Preset Values of I

Depending on the Trip Unit In Rating and the Dial

r

Position