Page 1

Page 2

Electrical Connections

Power input, running with full load MGF350V-24FP, MG350V-24M,

Power input, holding MGF350V-24FP, MG350V-24M,

Internal power supply type MGF350V-24FP, MG350V-24M,

Input signal impedance

(MG350V-24M, MGF350V-24MP)

Input Signal Auto Calibration

(MGF350V-24FP, MG350V-24M,

MGF350V-24MP)

Floating Control Signal

(MG350V-24F, MGF350V-24FP)

Floating Input Signal Minimum Pulse

Width (MG350V-24F)

Position Feedback Output Signal

(MGF350V-24FP, MGF350V-24MP)

Conduit Connection Removable 1/2” conduit opening plate

Electrical Connections Removable terminal block, AWG 12 … 24, meets the requirements of cUL without the need of an

MGF350V-24MP

MG350V-24F 24 Vac, ±20% (Class 2 power supply), 50/60 Hz, 5 VA, 20 … 29

MGF350V-24MP

MG350V-24F Actuator is unpowered when it is holding

MGF350V-24MP

MG350V-24F full wave

MG350V-24M and MGF350V-24MP 2 … 10 Vdc and 0 … 10 Vdc >100 kOhms

MGF350V-24MP 4 … 20 mA, 500 Ohms

Automatic span calibration to precisely match the stroke length of the valve (with a minimum stroke of

1/8” (3.2 mm) and a maximum stroke of 21/32” (16.5 mm).

SPST center off (floating) control contacts or one or two SPST control contacts, minimum rating of

250 mA at 24 V or one or two triacs must be able to switch 250 mA at 24 Vac,

1,100 Ohms input impedance

100 msec

2 … 10 Vdc and 0 … 5 Vdc, 0.5 mA (field selectable)

electrical earth ground connection

24 Vac, ±20% (Class 2 power supply), 50/60 Hz, 7.2 VA, 20 …

29 Vdc, 3.5 W

Vdc, 3.5 W

24 Vac, ±20% (Class 2 power supply), 50/60 Hz, 1.2 VA (24FP

0.7W, 24M 0.4W, 24MP 0.5W)

half wave

Installation Instruction

Mechanical

Linkage Linkage for 1/2” … 2” VB-7000 and 1/2” … 1-1/4” obsolete VB-9000 Globe Valves included with actuator

Manual Override 3 mm hex wrench (not included with actuator), “tee” handle style recommended

Mechanical Valve Position Indicator Graduated position indicator showing open to close with end point indicators

Electrical Valve Status Indication Tri-color LED status indication for motion indication, calibration, and alarm notification

Speed MG350V-24 and MG350V-24M: 0.295” (7.5 mm) per minute

Force MG350V-24F and MG350V-24M: 78 lbf (350 N) force

Enclosure Plenum rated per UL 2043

Yoke Rugged die cast aluminum

Weight 1.6 lbs.

MG350V-24F does not include the calibration and alarm indication

MGF350-24FP and MGF350V-24MP: 0.59” (15 mm) per minute

MGF350-24FP and MGF350V-24MP: 67 lbf (300 N) force

Environmental

Operating Temperature Range For fluid temperatures up to 266 °F (130 °C): 23 … 131 °F (-5 … 55 °C)

Shipping and Storage Temperature

Range

Operating Humidity Range 5 … 95% non condensing

Location NEMA 2 (IP 53) with proper mounting orientation

Noise Level ≤30 dB (A) @ 1 meter

For fluid temperatures up to 281 °F (138 °C): 23 … 127 °F (-5 … 53 °C)

For fluid temperatures up to 340 °F (171 °C): 23 … 115 °F (-5 … 46 °C)

For fluid temperatures up to 400 °F (204 °C): 23 … 102 °F (-5 … 39 °C)

-40 … 158 ˚F (-40 … 70 ˚C)

© 2017 Schneider Electric. A ll righ ts rese rved. All tr ademar ks are ow ned by Sc hneide r Electric Indu stries SAS or i ts affiliated companies. Februa ry, 2019 tc

Docume nt Number: F-278 52-11

Page 3

Page 4

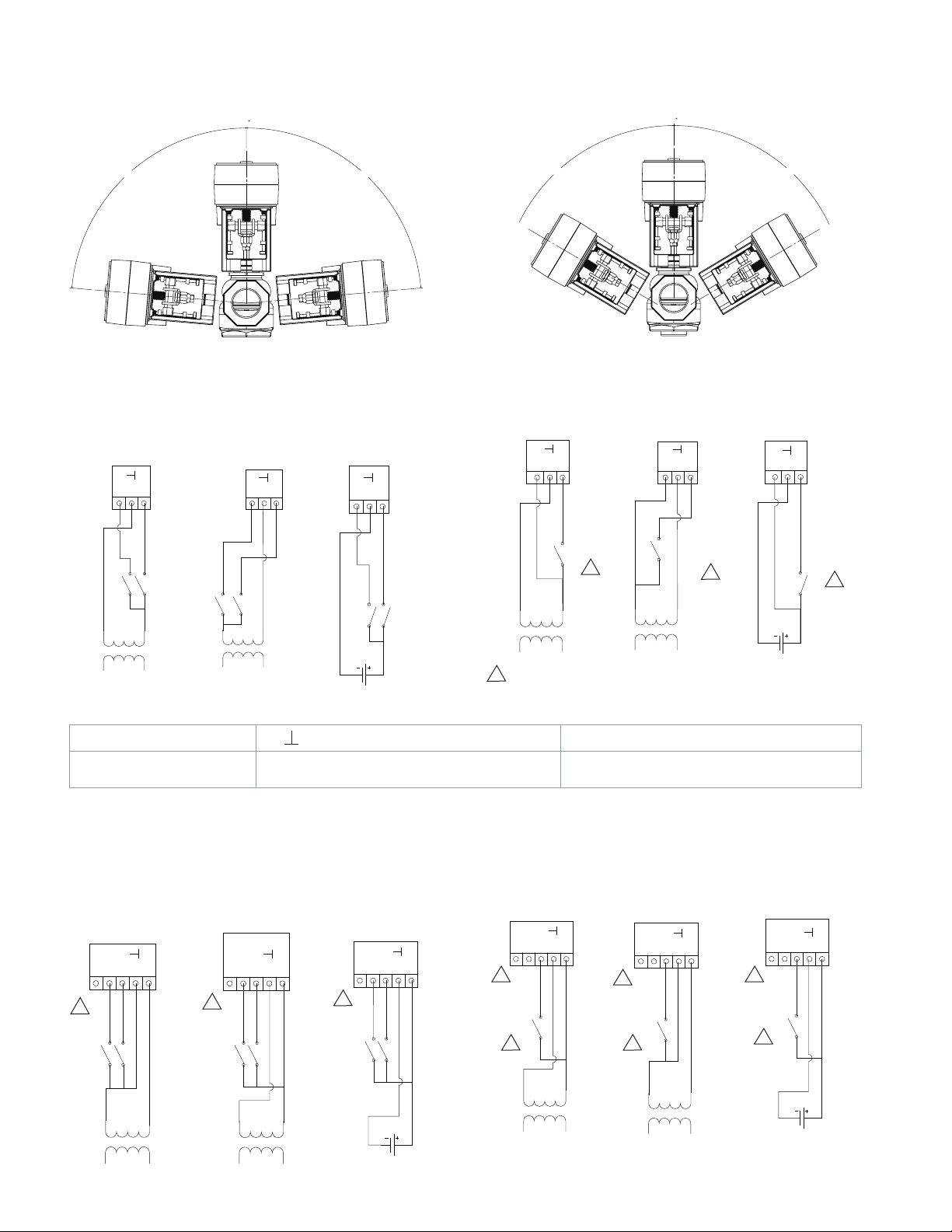

IP51 and NEMA Type 2 Allowable Mounting Orientation IP53 and NEMA Type 2 Allowable Mounting Orientation

0

0

Installation Instruction

85° 85°

Wiring

MG350V-24F Three Wire Floating Wiring

24 VAC

Floating Sourcing

Y1

24

Y2

24H24G

MG350V-24F Terminals

Y1

Extends the actuator linkage

and lowers the valve stem

24 VAC

Floating Sinking

Y1

24

24H24G

Floating Sourcing

Y2

24

24 Vac neutral or 24 Vdc common (Ref) for 24 Vac

sourcing and 24 Vdc, 24 Vac hot for 24 Vac sinking

24 VDC

Y1

24

Y2

60° 60°

MG350V-24F Two Position (On/Off) Wiring

24 VAC Two

Position Sourcing

Y1

24

Y2

24H24G

1

24 VAC Two

Position Sinking

Y1

24

Y2

24H24G

24 VDC24 Ref

1

With a two-position (on/o) wire connection Y2 closed (powered)

retracts the linkage and raises the valve stem. Y2 open (unpowered)

extends the linkage and lowers the valve stem.

Y2

Retracts the actuator linkage and raises the valve

stem

24 VDC Two

Position Sourcing

1

Y1

24

Y2

1

24 VDC24 Ref

NOTE: The MG350V-24F actuator is powered by Y1 and/or Y2. If both Y1 and Y2 are powered at the same time, then the actuator retracts linkage and raises the stem.

MGF350V-24FP Three Wire Floating with Position Output

Signal Wiring

24 VAC

Floating Sinking

UY2Y1

24

24~

1

24H24G

© 2017 Schneider Electric. A ll righ ts rese rved. All tr ademar ks are ow ned by Sc hneide r Electric Indu stries SAS or i ts affiliated companies. Februa ry, 2019 tc

Docume nt Number: F-278 52-11

24 VAC

Floating Sourcing

UY2Y1

24

24~

1

24H24G

24 VDC

Floating Sourcing

UY2Y1

24

24~

1

24 VDC24 Ref

MGF350V-24FP PWM with Position Output Signal Wiring

24 VAC Modulating

PWM Sourcing

UY2Y1

24

24~

1

PWM

2

24H24G

24 VAC Modulating

PWM Sinking

UY2Y1

24

24~

1

PWM

2

24H24G

24 VDC

Modulating PWM

UY2Y1

24

1

PWM

2

24~

24 VDC24 Ref

Page 5

Page 6

Page 7

DIP Switch Settings

MGF350V-24FP

Switch 1 Switch 2 Switch 3 Switch 4

Function Not Used Position Feedback Output

ON Position

(Switch up)

OFF Position

(Switch down)

1

The PWM input signal configuration responds to a timed pulsed signal (consisting of a leading and trailing edge) with a period between the minimum pulse width

setting (0.1 or 0.59 sec depending upon the setting of switch 3) and the maximum pulse width setting (25.5 or 2.93 sec depending upon the setting of switch 3). The

actuator responds to the width of the pulse relative to the pulse width span selected by switch 3. For example, if switch 3 is OFF, the actuator proportionally responds

to pulses between 0.59 sec and 2.93. sec. Thus, if the actuator receives a pulse consisting of a leading and trailing edge for 1.37 sec, the actuator positions the valve

stem to 33.3% because 1.37 sec is 33.3% between 0.59 and 2.93 sec. When setup for the PWM mode, the actuator responds to the last pulse signal received even if

the actuator is moving when the pulse is received.

Not Used 0 … 5 Vdc Output Signal 0.1 … 25.5 sec

Not Used 2 … 10 Vdc Output Signal 0.59 … 2.93 sec

Signal Selection

MG350V-24M

Switch 1 Switch 2 Switch 3* Switch 4

Function Not Used Not Used Input Signal Action Voltage Input Signal

ON Position (Switch up) Not Used Not Used Reverse Acting - a decrease in input signal extends the

OFF Position (Switch down) Not Used Not Used Direct Acting - an increase in input signal extends the

valve linkage and lowers the valve stem

valve linkage and lowers the valve stem

PWM Input Signal Range Selection,

only valid if Switch 4 is ON

1

1

Floating or PWM Input Selection

PWM Input Signal

Floating Input Signal

Range

2 … 10 Vdc

0 … 10 Vdc

Installation Instruction

MGF350V-24MP

Switch 1 Switch 2 Switch 3 * Switch 4

Function Selects internal 500 Ohm resistor for 4 …

ON Position

(Switch up)

OFF Position

(Switch

down)

* Switch 3: Direct Acting: 0% (0 Vdc (0...10 mode), or 2 Vdc (2...10 mode) = fully Retracted. 100% (10 Vdc) = fully Extended.

Reverse Mode: 0% (0 Vdc (0...10 mode), or 2 Vdc (2...10 mode) = fully Extended 100% (10 Vdc) = fully Retracted.

20 mA input signals, this also selects a 2

… 10 Vdc input signal (overriding switch 4

when it is in the ON position)

Internal 500 Ohm resistor connected for 4

… 20 mA input signal

Internal 500 Ohm resistor not connected 2 … 10 Vdc Output

Position Feedback

Output Signal Selection

0 … 5 Vdc Output

Signal

Signal

Input Signal Action Voltage Input Signal

Reverse Acting - a decrease

in input signal extends the

actuator linkage and lowers the

valve stem

Direct Acting - an increase

in input signal extends the

actuator linkage and lowers the

valve stem

Range, only valid if

Switch 1 is OFF

2 … 10 Vdc

0 … 10 Vdc

DIP Switch Operation

The MGF350V-24FP, MG350V-24M, and MGF350V-24MP actuators have a DIP switch block located under the cover to the left of

the wiring terminal. The MG350V series actuators are shipped with all their DIP switches in the OFF (down) position. If any DIP

switch is changed while the actuator is unpowered, it recognizes the DIP switch change the next time the actuator is powered,

initiates its calibration sequence, and then controls according to the latest DIP switch setting. If a DIP switch is changed while the

actuator is powered, it recognizes the DIP switch change, initiates its calibration sequence after 15 seconds, and then controls according to the latest DIP switch setting.

Auto-Calibration Operation

MGF350V-24FP, MG350V-24M (no position output signal), MGF350V-24MP actuators with DIP switches have an auto-calibration

program. Auto-calibration occurs the first time the actuator is mounted to the valve and powered, as well as any time a DIP switch

is changed. During the auto-calibration procedure, the actuator strokes the valve full stem down (actuator linkage extended) to

full stem up (actuator linkage retracted) in order to identify the two end of travel points. The input signal is then spanned to match

this travel distance. The valve calibration data is stored in permanent memory, and the actuator resumes normal operation from its

input signal.

© 2017 Schneider Electric. A ll righ ts rese rved. All tr ademar ks are ow ned by Sc hneide r Electric Indu stries SAS or i ts affiliated companies. Februa ry, 2019 tc

Docume nt Number: F-278 52-11

Page 8

Installation Instruction

During the calibration process, the actuator’s LED provides indication of calibration status, and the actuator’s position output signal indicates that it is in calibration mode. See the LED Operation section for more details. If the actuator is unable to calibrate, it

provides an LED status error. After the actuator has calibrated and is powered after a power failure, the actuator strokes the valve

full stem up (actuator linkage retracted), and then responds to its control signal.

The auto-calibration process can also be manually initiated by changing any DIP switch. If a DIP switch is changed while the actuator is unpowered, it recognizes the DIP switch change the next time the actuator is powered, initiates its calibration sequence,

and then controls according to the latest DIP switch setting. If a DIP switch is changed while the actuator is powered it recognizes

the DIP switch change, initiates its calibration sequence after 15 seconds, and then controls according to the latest DIP switch

setting.

Power Up Operation

The MGF350V-24FP, MG350V-24M, and MGF350V-24MP actuators remain in their last commanded position with no power applied. When power is applied, the actuator strokes the valve stem full up (actuator linkage retracted). While the actuator is retracting to its retracted position, its position feedback output signal (for MGF350V-24FP and MG350V-MP models only) remains at 0.4

Vdc (if Switch 2 is OFF) or 0 Vdc (if Switch 2 is ON). After the valve stem reaches its full up position (actuator linkage retracted),

the actuator then positions the valve in accordance to its control input signal and the position output signal indicates the valve

stem position.

The MG350V-24F actuators remains in their last commanded position with no power applied. When power is applied, the actuator

operates in accordance to its input control signals to retract or extend the valve stem.

Positioning and Sensitivity

The MG350 series actuators include a built-in microprocessor that provides accurate motor control and overload protection at all

of its stroke positions. The microprocessor constantly monitors the rotation of the stepper motor and stops the pulses to the motor

when it senses a stall condition. The proportional MG350V-24M and MGF350V-24MP actuators include a 1% positioning sensitivity

and “a change of direction” algorithm with a wider 2.5% sensitivity to accurately follow the proportional control signal while not

responding unnecessarily to electric noise and control input instability. The floating MGF350V-24FP accumulates repeated small

drive open and drive closed commands and positions the valve when the commands are consistently in the same direction to

provide accuracy while not responding unnecessarily to electric noise and control input instability.

Manual Override Operation

Use the manual override to manually position the actuator

when it is not powered. The actuator stays in the selected position until powered. After power is applied, the actuator strokes

the valve full stem up (actuator linkage retracted), then positions the valve according to its control input signal. The manual

override accepts a 3 mm allen wrench. Press firmly (depressing the wrench downward approximately 1/8” (3 mm) into the

actuator) and continue to hold the wrench in the depressed

position, then turn the wrench CCW to extend the actuator

spindle, lowering the valve stem, or CW to retract the actuator

spindle, raising the valve stem. It takes approximately 3 …

3-1/2 manual override wrench turns to fully stroke the valve

stem (each manual override turn moves the valve stem about

5/32” (4 mm).

Note: If the allen wrench is not seated properly or if the user

does not press firmly downward, it will not engage, and the

wrench may spin inside the nut.

3 mm allen wrench

(not included with the

actuator)

Manual Override

LED

viewing

port

© 2017 Schneider Electric. A ll righ ts rese rved. All tr ademar ks are ow ned by Sc hneide r Electric Indu stries SAS or i ts affiliated companies. Februa ry, 2019 tc

Docume nt Number: F-278 52-11

Page 9

LED Operation

MGF350V-24FP, MG350V-24M, and MGF350V-24MP Normal Operation LED Status

LED

Blinking Pattern

Orange

Green

Red

Orange

Orange Green Red

Cycles on

for 1/3 sec

Blinks once

every sec

Green -

1

See the Auto-Calibration Operations section for a complete explanation on the Auto-calibration process

MG350V-24F Normal Operation LED Status

LED

Blinking

Pattern

Orange

Green -

Orange Green Red

Blinks once

every sec

LED Color

Cycles on for

1/3 sec

- -

Blinks once

every sec

LED Color

- -

Blinks once

every sec

Cycles

on for

1/3 sec

-

Function Description

During calibration, the three LED colors flash until

Auto-Calibration Mode

1

the calibration is complete (orange, green, red,

repeated). The actuator’s position output signal is 0.4

Vdc during the calibration process (MGF350V-24FP

and MGF350V-24MP models only).

Indicates the actuator linkage is extending,

which lowers the valve stem

Indicates the actuator linkage is retracting,

Blinks every second when the actuator is moving

which raises the valve stem

Function Description

Indicates the actuator linkage is extending, which lowers the valve

stem

Indicates the actuator linkage is retracting, which raises the valve

stem

Installation Instruction

Blinks every second when the

actuator is moving

MGF350V-24FP, MG350V-24M, and MGF350V-24MP Alarm LED Operation

LED

Blinking Pattern

Each color cycles

on for 1/3 sec

LED

Color

Orange

Green

Red

Description Recommended Actions Alarm Type

During calibration the three LED colors flash

until the calibration is complete (orange,

Wait for the calibration process to finish Auto-Calibration

3

Mode

green, red, repeated). The actuator’s

position output signal is 0.4 Vdc during the

calibration process (MGF350V-24FP and

MGF350V-24MP models only).

Solid Red Travel during calibration revealed inad-

equate output stroke.

Check freedom of valve stem movement

and proper linkage connection, replace

Critical

1

actuator if necessary

3 seconds On,

1 second Off

Red Unexpected stalling Check for freedom of valve stem move-

ment and proper linkage connection,

Maintenance 1.0 Vdc

possible debris on the valve body, and for

proper DIP switch setup

6 seconds On,

1 second Off

Red Out of range 2 … 10 Vdc/4 … 20 mA input

signal

Check the input signal range: underrange

(below 2 Vdc) for MG350V-24M, and

Low Priority 1.3 Vdc

MGF350V-24MP when configured for a 2

… 10 Vdc input signal (DIP switch 4 ON)

Solid Red Actuator fault Replace actuator Critical

1

The actuator does not move the valve stem when a Critical Alarm is present. It does continue to position the valve if a Maintenance or Low Priority Alarm is present.

2

The Position Feedback Output Signal Override Voltage is valid for the MGF350V-24FP and MGF350V-24MP models only when configured for a 2 … 10 Vdc position

1

output signal (DIP switch 2 OFF). The Position Feedback Output Signal Override Voltage overrides the normal 2 … 10 Vdc output voltage that indicates the valve stem

position. The Position Feedback Output Signal Override Voltages do not occur when the position output signal is configured for 0 … 5 Vdc output range (DIP switch 1

OFF).

3

See the Auto-Calibration Operations section for a complete explanation on the Auto-Calibration process.

Position Feedback

1

Output Signal

Override Voltage

0.4 Vdc

0.7 Vdc

1.6 Vdc

2

© 2017 Schneider Electric. A ll righ ts rese rved. All tr ademar ks are ow ned by Sc hneide r Electric Indu stries SAS or i ts affiliated companies. Februa ry, 2019 tc

Docume nt Number: F-278 52-11

Page 10

Page 11

Loading...

Loading...