Page 1

Specification Sheet

MG350-24F

SmartX Globe Valve Actuator

Product Description

The MG350-24F is a compact electro-mechanical actuator

for controlling two-way and three-way Venta globe valves

V211, V211T, V241, V311, and V311T and V341.

The MG350-24F is a dual, 2 position / 3 point floating actuator within the SmartX Actuator family. The MG350 actuators

are primarily designed for applications where the demands

on speed and thrust are relatively small, such as:

• Mixing and injection heating circuits

• Small air handling systems

• Large Fan coil units

Specifications

Supply voltage

Power Consumption (50Hz),

full load Running 3.5 W

Transformer sizing 5.2 VA

Running Time 4 s/mm (Full stroke time,

Max. Stroke 21.5 mm

Force 350 N

Control

3 wire Floating

2 Position on/off

Minimum input pulse 100 msec

Ambient Temperature

Range

Ambient Operational Range

Storage temperature Range

Ambient humidity max . 95%

Protection rating IP 53 (vertically mounted)

Sound power level max. 30 dBA

24 Vac/dc ±20% 50/60 Hz

Venta Valves = 80 sec)

Dependant upon wiring, page 3

24 Vac/dc or 0V

NO or NC

–5…+55°C (for valve fluid

temperatures up to 130°C)

–40…+70°C

Features

• High Functionality

– Stable force control with stall protection

– Dual 3 Point floating and 2 position control.

– Sink or source floating control

– High Resolution PCBA and motor transmission for fine

valve plug position and excellent flow control.

• LED status indication

– Bi-color LED to indicate direction of movement when

under power.

• Removable terminal block and cable gland for ease of

installation.

• Compact Construction: Optimally designed to fit Venta

valves with 20mm Stroke.

Key Materials

Yoke

Housing

Standards/Directives

ElectroMagnetic Compatability [EMC]

Low voltage directive [LVD]

Restriction of Hazardous

Substances [RoHS2]

Heat

Humidity

Cold

Vibration

Manual Override 3 mm Hex (T style hand tool

Position indication Yoke position indicator with red and

blue position markers for hot and

cold pipe indication (green position

indicator for closed valve)

Cable Gland wire size 2.4 to 6.6 mm

Conduit hole M20

Weight (shipping) 0.36 kg

Aluminum

PBT/PC

2014/30/EU

2014/35/EU

2011/65/EC

IEC 60068-2-2

IEC 60068-2-3

IEC 60068-2-1

IEC 60068-2-6

recommend)

© 2016 Schne ider Ele ctric. All rights rese rved. All trademar ks are ow ned by Sch neider Electr ic Indust ries S AS or its affi liated co mpanie s. Januar y, 2019 tc

Docume nt Numbe r: F-279 80- 5

Page 2

Specification Sheet

180

Function

Actuator

The actuator utilizes a stepper motor to accurately position

the main spindle via a gearbox based on the command

received from the controller.

Control Signal

This MG350-24F SmartX Actuator series can be controlled

either by 3 wire floating (increase/decrease) switched either

between the 24 Vac/dc supply or by the 0V return. 2 position

control for the actuator to retract or extend (IN/OUT) proving

a normally open or normally closed valve is possible by configuring the wiring, see wiring diagrams on page 3.

Manual Operation

A 3mm hex key can be used to manually drive and position

the MG350 SmartX Actuator. Do not depress the hex key

during normal operation. The hex key is not supplied with the

actuator.

The Hex key should be depressed firmly to disengage the

main drive motor and continue to be depressed whilst rotating the key to adjust actuator position. It takes approximately

5 full rotations of the manual override to fully stroke the valve,

each manual override turn moves the valve stem about 4

mm. There may be a load click as the main drive motor reengages after a manual operation.

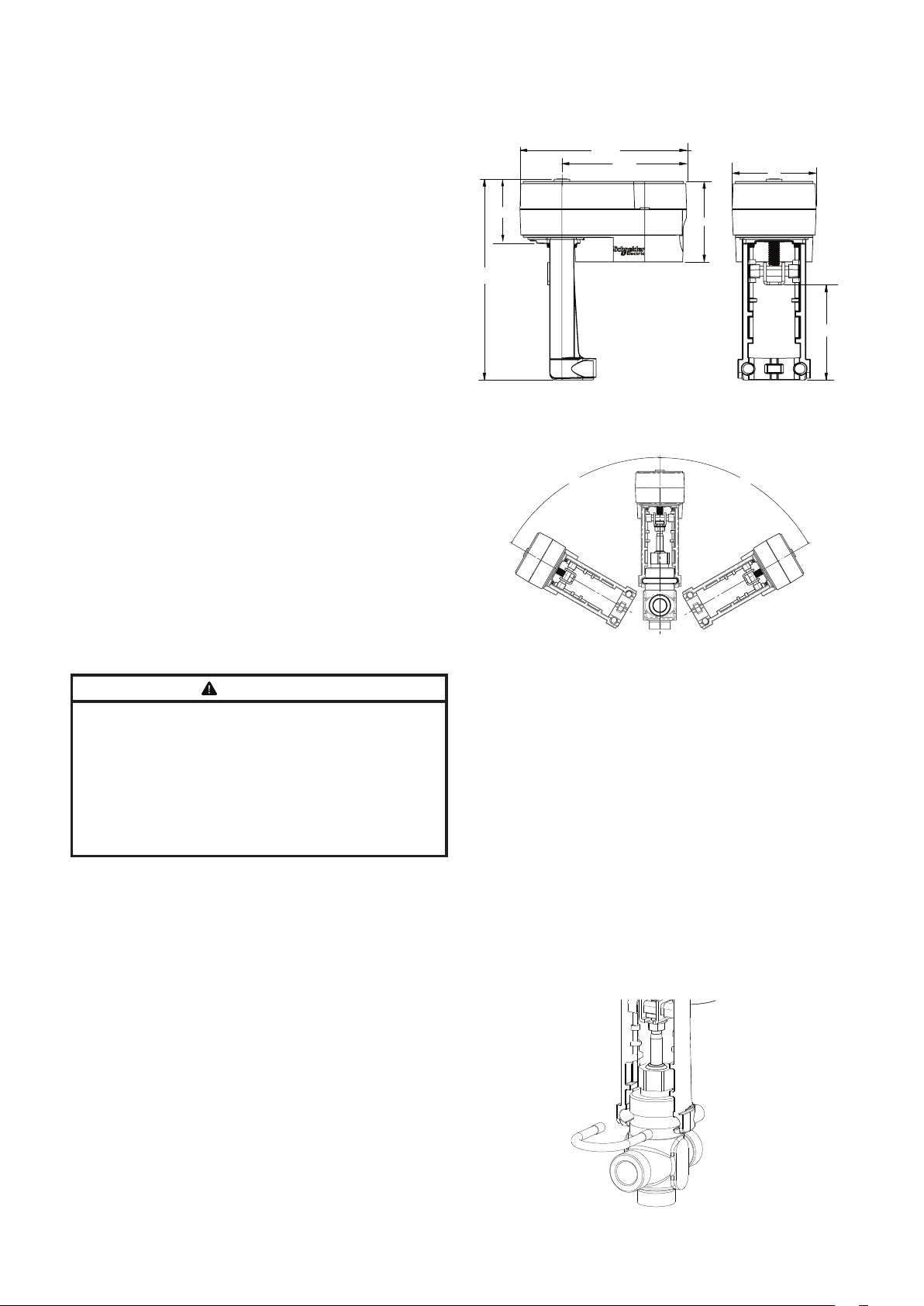

Dimensions (mm)

149

111

57

60°

75

72

85

0°

60°

Maintenance

The actuator is maintenance-free.

Mounting

WARNING

RISK OF BURNS OR FLYING PARTS

If the valve stem, spindle, or plug has been damaged, it may

blow out under pressure while servicing the actuator.

Isolate and depressurize the v

•

•

Manually check valve stem, spindle, or plug integrity by

moving it within the valve. If the part can be removed,

replace the valve assembly

Failure to follow these instructions may result in death or

serious injury.

Mount the actuator horizontally, vertically, or in any position in

between, but not upside down. If the media temperature is

above 120°C, install the actuator at an angle over the pipework to reduce the radiant heat influence.

For water ingress protection, do not mount actuators below

the horizontal plane of the valve. IP63 will be achieved with

a mounting orientation from vertical to 60 deg. IP51 will be

achieved to 85 deg.

alve before servicing.

.

Mounting the Actuator on the Venta Valve

A square nut is supplied with the actuator and is to be

mounted onto the top edge of the valve stem before the

actuator is mounted. The actuator is delivered so it is not

needed to operate the manual override to assemble the

product.

1.

Assemble the square nut to the top edge of the valve

stem leaving some clearance between this nut and the

flanged nut below.

2.

Position the valve stem by hand to align with the

actuator clasp.

3.

Slide the actuator onto the valve neck, aligning the

actuator clasp in between the square nut and flanged

nut.

4.

Push the actuator down to align and insert the U-bolt

brace; secure brace with the flanged nuts.

5.

Tighten the valve stem flanged nut.

Januar y, 2019 tc © 2 016 Schnei der Electric. A ll righ ts rese rved . All tra demar ks are own ed by Schn eider El ectri c Indust ries S AS or its a ffil iated co mpanie s.

Document Number: F-27980-5

Page 3

Specification Sheet

Colored Valve Limit Indicators

The colored end stop limits on the yoke are provided to show

the valve plug position according to the valve stroke. After

mounting the actuator, arrange the position and colour of the

limits as per the table below, discarding either the red or blue

as needed.

Squeeze the end stop limits either side of the actuator cross

bar and initiate a calibration sequence, the actuator will then

automatically push the end stop limits to the exact limits of

Terminal Block Connection

Y1

Extends the actuator

linkage and lowers the

valve stem

24

24 Vac/dc supply for

sinking

24 Vac neutral or

24 Vdc common for

sourcing

NOTE: The MG350-24F actuator is powered by Y1 and/or Y2. If both

Y1 and Y2 are powered at the same time, then the actuator retracts

linkage and raises the stem.

Wire Sizing

Cable type Maximum length Minimum cross sectional area

Power 100 m (328 ft) 1.5 mm2 (AWG 16)

Y2

Retracts the

actuator linkage

and raises the

valve stem

the valve stroke. It is recommended to set-up the colored

valve end stop limits according to the valve and media during commissioning.

Position the limits as follows:

Green end stop Closed valve

Red end stop Open heating circuit

Blue end stop Chilled water circuit

Direction of Operation

Y1

Y2

4 s/mm

Wiring

Three Wire Floating

24 VAC

Floating Sourcing

Y1

24

Y2

COM

24 Vac

Normal LED Operation

LED Color Blinking pattern Function

Orange light 0.3 sec,

Green light 0.3 sec,

every second

every second.

24 VAC

Floating Sinking

COM

Y1

24

Y2

24 Vac

Indicates actuator is extending, lowering

the valve stem to open the valve

Indicates actuator is retracting, lifting the

valve stem to close the valve

24 VDC

Floating Sourcing

Y1

24

24 Vdc

Return

Y2

24 Vdc

Two Position (On/Off)

24 VAC Two

Position Sourcing

Y1

24

Y2

24 Vac

24 VAC Two

Position Sinking

COMCOM

Y1

24

Y2

24 Vac

24 VDC Two

Position Sourcing

Y1

24

24 Vdc

Return

LED

Y2

24 Vdc

© 2016 Schne ider Ele ctric. All rights rese rved. All trademar ks are ow ned by Sch neider Electr ic Indust ries S AS or its affi liated co mpanie s. Januar y, 2019 tc

Docume nt Numbe r: F-279 80- 5

Page 4

Specification Sheet

Januar y, 2019 tc © 2 016 Schnei der Electric. A ll righ ts rese rved . All tra demar ks are own ed by Schn eider El ectri c Indust ries S AS or its a ffil iated co mpanie s.

Document Number: F-27980-5

Loading...

Loading...