M580

PHA83350 11/2020

M580

BMENUA0100 OPC UA Embedded

Module

Installation and Configuration Guide

Original instructions

11/2020

PHA83350.02

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 PHA83350 11/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1 BMENUA0100 Module Characteristics. . . . . . . . . . . . . . 15

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Standards and Certifications. . . . . . . . . . . . . . . . . . . . . . 23

Standards and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMENUA0100 Module Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMENUA0100 Firmware Compatibility with

EcoStruxure™ Control Expert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 BMENUA0100 Functional Description . . . . . . . . . . . . . . 27

3.1 Cybersecurity Operating Mode Settings . . . . . . . . . . . . . . . . . . . . . . .

Cybersecurity Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 OPC UA Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMENUA0100 OPC UA Server Operating Characteristics . . . . . . . . .

OPC UA Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMENUA0100 OPC UA Server Stack Services . . . . . . . . . . . . . . . . .

BMENUA0100 OPC UA Server Stack Data Access Services. . . . . . .

BMENUA0100 OPC UA Server Stack Discovery and Security Services

BMENUA0100 OPC UA Server Stack Publish and Subscribe Services

BMENUA0100 OPC UA Server Stack Transport Services . . . . . . . . .

3.3 Discovering PAC Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mapping Control Expert PAC Variables to OPC UA Data Logic

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Hot Standby and Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Server Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Supported Architectures . . . . . . . . . . . . . . . . . . . . . . . . . 61

Supported BMENUA0100 Module Configurations. . . . . . . . . . . . . . . .

Isolated Control Network with M580 Hot Standby PACs . . . . . . . . . . .

Non-Isolated Flat Network with M580 Hot Standby . . . . . . . . . . . . . . .

Flat Network with Multiple M580 Standalone CPUs and Single SCADA

16

18

22

24

25

26

28

28

34

35

37

39

40

42

44

48

49

49

53

53

62

64

66

68

PHA83350 11/2020 3

Flat Network with Multiple M580 Standalone CPUs and Redundant

SCADA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flat Network with M580 Hot Standby CPUs and Redundant SCADA .

Hierarchical Network featuring Multiple M580 Standalone CPUs

Connected to Control Network and Redundant SCADA . . . . . . . . . . .

Hierarchical Network with Multiple M580 Hot Standby CPUs and

Redundant SCADA Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

72

74

76

Chapter 5 Commissioning and Installation . . . . . . . . . . . . . . . . . . . . 79

Commissioning Checklist for the BMENUA0100 Module. . . . . . . . . . .

Commissioning the BMENUA0100 Module . . . . . . . . . . . . . . . . . . . . .

Installing the BMENUA0100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

80

81

84

Chapter 6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.1 Configuring the BMENUA0100 Cybersecurity Settings . . . . . . . . . . . .

Introducing the BMENUA0100 Web Pages . . . . . . . . . . . . . . . . . . . . .

Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certificates Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuring the BMENUA0100 in Control Expert. . . . . . . . . . . . . . . . .

Configuring IP Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Network Time Service. . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Agent Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Configuring M580 CPU Settings for OPC UA Client - Server

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring M580 CPU Security Settings . . . . . . . . . . . . . . . . . . . . . .

88

89

93

96

101

108

110

112

113

116

119

122

122

Chapter 7 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

LED Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMENUA0100 Derived Data Type (DDT) . . . . . . . . . . . . . . . . . . . . . .

Configuring the READ_DDT Elementary Function. . . . . . . . . . . . . . . .

OPC UA Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Syslog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Diagnostic Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

124

128

133

137

140

144

145

146

Chapter 8 Optimizing BMENUA0100 Performance. . . . . . . . . . . . . . 147

Optimizing BMENUA0100 Performance . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the BMENUA0100 Module . . . . . . . . . . . . . . . . . . . .

148

151

4 PHA83350 11/2020

Chapter 9 Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

EcoStruxure™ Automation Device Maintenance Tool . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A CPU Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

OPC UA Server to CPU Connections . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B IPSEC Windows Scripts . . . . . . . . . . . . . . . . . . . . . . . . . 159

IKE/IPSEC Windows Firewall Configuration Scripts . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

153

155

157

159

163

165

PHA83350 11/2020 5

6 PHA83350 11/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

PHA83350 11/2020 7

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

BEFORE YOU BEGIN

Do not use this product on machinery lacking effective point-of-operation guarding. Lack of

effective point-of-operation guarding on a machine can result in serious injury to the operator of

that machine.

UNGUARDED EQUIPMENT

Do not use this software and related automation equipment on equipment which does not have

point-of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

This automation equipment and related software is used to control a variety of industrial processes.

The type or model of automation equipment suitable for each application will vary depending on

factors such as the control function required, degree of protection required, production methods,

unusual conditions, government regulations, etc. In some applications, more than one processor

may be required, as when backup redundancy is needed.

Only you, the user, machine builder or system integrator can be aware of all the conditions and

factors present during setup, operation, and maintenance of the machine and, therefore, can

determine the automation equipment and the related safeties and interlocks which can be properly

used. When selecting automation and control equipment and related software for a particular

application, you should refer to the applicable local and national standards and regulations. The

National Safety Council's Accident Prevention Manual (nationally recognized in the United States

of America) also provides much useful information.

In some applications, such as packaging machinery, additional operator protection such as pointof-operation guarding must be provided. This is necessary if the operator's hands and other parts

of the body are free to enter the pinch points or other hazardous areas and serious injury can occur.

Software products alone cannot protect an operator from injury. For this reason the software

cannot be substituted for or take the place of point-of-operation protection.

Ensure that appropriate safeties and mechanical/electrical interlocks related to point-of-operation

protection have been installed and are operational before placing the equipment into service. All

interlocks and safeties related to point-of-operation protection must be coordinated with the related

automation equipment and software programming.

WARNING

8 PHA83350 11/2020

NOTE: Coordination of safeties and mechanical/electrical interlocks for point-of-operation

protection is outside the scope of the Function Block Library, System User Guide, or other

implementation referenced in this documentation.

START-UP AND TEST

Before using electrical control and automation equipment for regular operation after installation,

the system should be given a start-up test by qualified personnel to verify correct operation of the

equipment. It is important that arrangements for such a check be made and that enough time is

allowed to perform complete and satisfactory testing.

EQUIPMENT OPERATION HAZARD

Verify that all installation and set up procedures have been completed.

Before operational tests are performed, remove all blocks or other temporary holding means

used for shipment from all component devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Follow all start-up tests recommended in the equipment documentation. Store all equipment

documentation for future references.

Software testing must be done in both simulated and real environments.

Verify that the completed system is free from all short circuits and temporary grounds that are not

installed according to local regulations (according to the National Electrical Code in the U.S.A, for

instance). If high-potential voltage testing is necessary, follow recommendations in equipment

documentation to prevent accidental equipment damage.

Before energizing equipment:

Remove tools, meters, and debris from equipment.

Close the equipment enclosure door.

Remove all temporary grounds from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

WARNING

PHA83350 11/2020 9

OPERATION AND ADJUSTMENTS

The following precautions are from the NEMA Standards Publication ICS 7.1-1995 (English

version prevails):

Regardless of the care exercised in the design and manufacture of equipment or in the selection

and ratings of components, there are hazards that can be encountered if such equipment is

improperly operated.

It is sometimes possible to misadjust the equipment and thus produce unsatisfactory or unsafe

operation. Always use the manufacturer’s instructions as a guide for functional adjustments.

Personnel who have access to these adjustments should be familiar with the equipment

manufacturer’s instructions and the machinery used with the electrical equipment.

Only those operational adjustments actually required by the operator should be accessible to

the operator. Access to other controls should be restricted to prevent unauthorized changes in

operating characteristics.

10 PHA83350 11/2020

About the Book

At a Glance

Document Scope

This manual describes the features and use of the M580 BMENUA0100 Ethernet communication

module with embedded OPC UA server.

NOTE: The specific configuration settings contained in this guide are intended to be used for

instructional purposes only. The settings required for your specific configuration may differ from the

examples presented in this guide.

Validity Note

This document is valid for an M580 system when used with EcoStruxure™ Control Expert 15.0 or

later.

The technical characteristics of the devices described in the present document also appear online.

To access the information online:

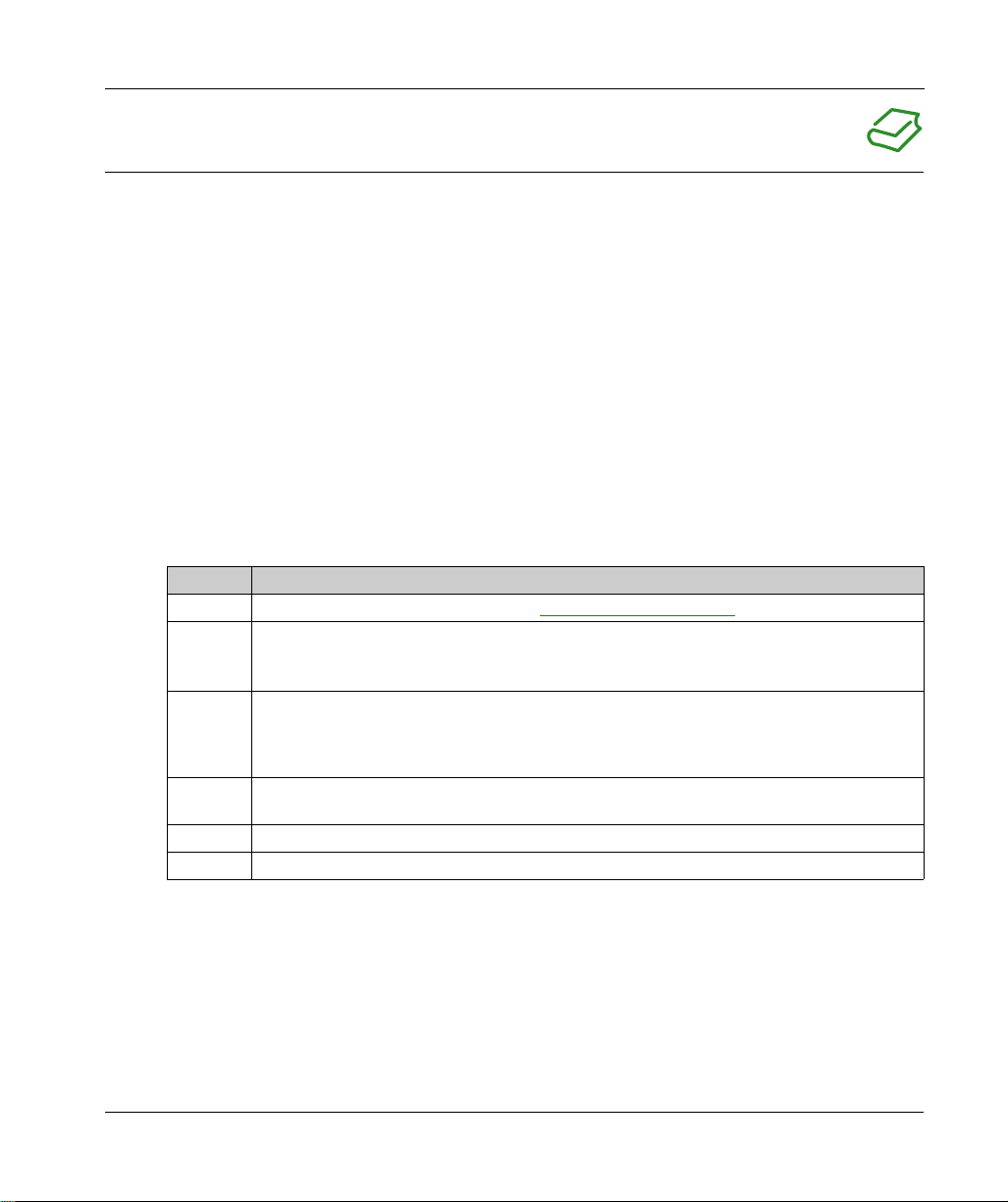

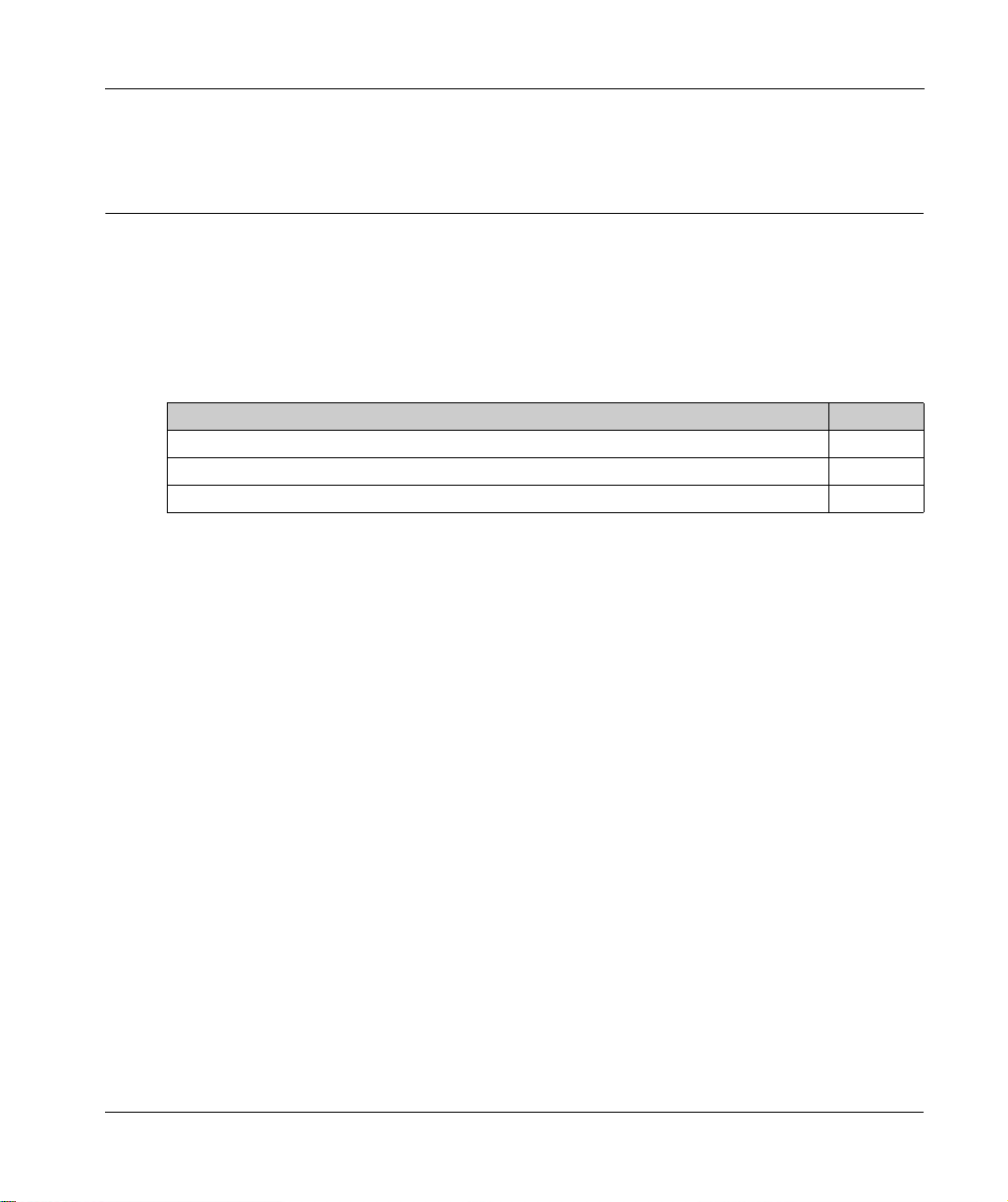

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

3 If you entered a reference, go to the Product Datasheets search results and click on the

4 If more than one reference appears in the Products search results, click on the reference that

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

www.schneider-electric.com

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and click

on the product range that interests you.

interests you.

.

*

).

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

PHA83350 11/2020 11

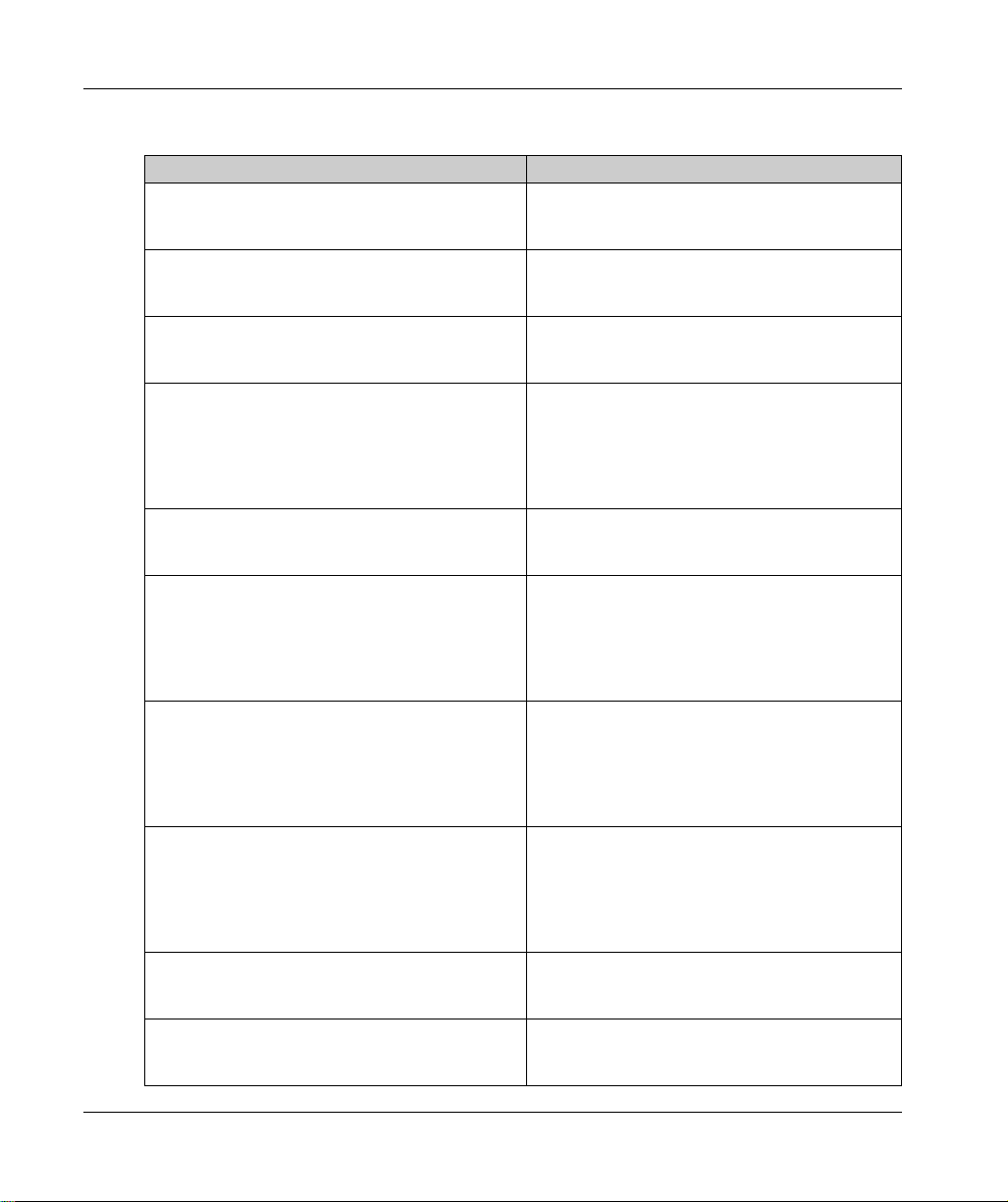

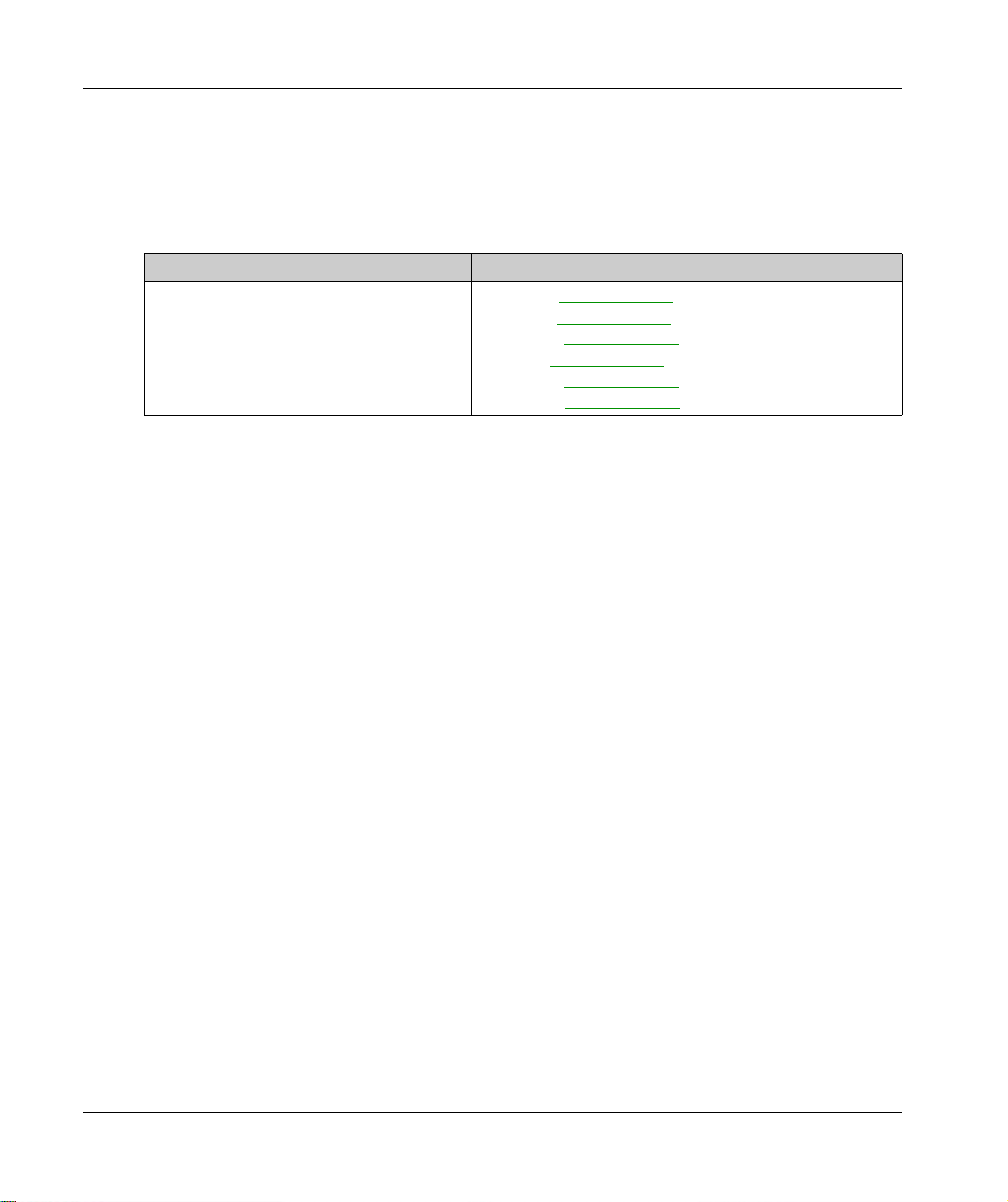

Related Documents

Title of documentation Reference number

Modicon M580 Standalone, System Planning Guide

for Frequently Used Architectures

Modicon M580, System Planning Guide for Complex

Topologies

Modicon M580 Hot Standby, System Planning Guide

for Frequently Used Architectures

Modicon M580, M340, and X80 I/O Platforms,

Standards and Certifications

M580 BMENOS0300, Network Option Switch,

Installation and Configuration Guide

Modicon M580, Hardware, Reference Manual EIO0000001578 (English),

Modicon M580, RIO Modules, Installation and

Configuration Guide

Modicon M580, Change Configuration on the Fly,

User Guide

Modicon X80, Discrete Input/Output Modules, User

Manual

Modicon X80, BMXEHC0200 Counting Module, User

Manual

HRB62666 (English), HRB65318 (French),

HRB65319 (German), HRB65320 (Italian),

HRB65321 (Spanish), HRB65322 (Chinese)

NHA58892 (English), NHA58893 (French),

NHA58894 (German), NHA58895 (Italian),

NHA58896 (Spanish), NHA58897 (Chjnese)

NHA58880 (English), NHA58881 (French),

NHA58882 (German), NHA58883 (Italian),

NHA58884 (Spanish), NHA58885 (Chinese)

EIO0000002726 (English),

EIO0000002727 (French),

EIO0000002728 (German),

EIO0000002730 (Italian),

EIO0000002729 (Spanish),

EIO0000002731 (Chinese)

NHA89117 (English), NHA89119 (French),

NHA89120 (German), NHA89121 (Italian),

NHA89122 (Spanish), NHA89123 (Chinese)

EIO0000001579 (French),

EIO0000001580 (German),

EIO0000001582 (Italian),

EIO0000001581 (Spanish),

EIO0000001583 (Chinese)

EIO0000001584 (English),

EIO0000001585 (French),

EIO0000001586 (German),

EIO0000001587 (Italian),

EIO0000001588 (Spanish),

EIO0000001589 (Chinese),

EIO0000001590 (English),

EIO0000001591 (French),

EIO0000001592 (German),

EIO0000001594 (Italian),

EIO0000001593 (Spanish),

EIO0000001595 (Chinese)

35012474 (English), 35012475 (German),

35012476 (French), 35012477 (Spanish),

35012478 (Italian), 35012479 (Chinese)

35013355 (English), 35013356 (German),

35013357 (French), 35013358 (Spanish),

35013359 (Italian), 35013360 (Chinese)

12 PHA83350 11/2020

Title of documentation Reference number

Grounding and Electromagnetic Compatibility of PLC

Systems, Basic Principles and Measures, User

Manual

EcoStruxure™ Control Expert, Program Languages

and Structure, Reference Manual

EcoStruxure™ Control Expert, System Bits and

Words, Reference Manual

EcoStruxure™ Control Expert, Operating Modes 33003101 (English), 33003102 (French),

EcoStruxure™ Control Expert, Installation Manual 35014792 (English), 35014793 (French),

Web Designer for FactoryCast User Manual 35016149 (English), 35016150 (French), 35016151

Modicon Controllers Platform Cyber Security,

Reference Manual

33002439 (English), 33002440 (French),

33002441 (German), 33003702 (Italian),

33002442 (Spanish), 33003703 (Chinese)

35006144 (English), 35006145 (French),

35006146 (German), 35013361 (Italian),

35006147 (Spanish), 35013362 (Chinese)

EIO0000002135 (English),

EIO0000002136 (French),

EIO0000002137 (German),

EIO0000002138 (Italian),

EIO0000002139 (Spanish),

EIO0000002140 (Chinese)

33003103 (German), 33003104 (Spanish),

33003696 (Italian), 33003697 (Chinese)

35014794 (German), 35014795 (Spanish),

35014796 (Italian), 35012191 (Chinese)

(German), 35016152 (Italian), 35016153 (Spanish),

35016154 (Chinese)

EIO0000001999 (English),

EIO0000002001 (French),

EIO0000002000 (German),

EIO0000002002 (Italian),

EIO0000002003 (Spanish),

EIO0000002004 (Chinese)

You can download these technical publications and other technical information from our website

at

www.schneider-electric.com/en/download

PHA83350 11/2020 13

.

14 PHA83350 11/2020

M580

BMENUA0100 Module Cha racteristics

PHA83350 11/2020

BMENUA0100 Module Cha racteristics

Chapter 1

BMENUA0100 Module Characteristics

Introduction

This chapter describes the BMENUA0100 Ethernet communications module with embedded OPC

UA server.

What Is in This Chapter?

This chapter contains the following topics:

Module Features 16

Module Description 18

Module LEDs 22

Topic Page

PHA83350 11/2020 15

BMENUA0100 Module Characteristics

Module Features

Introduction

The Modicon BMENUA0100 OPC UA server module brings high performance OPC UA capabilities

to Modicon M580 ePAC systems.

OPC UA is a modern, secure, open, reliable communications platform for industrial

communications, designed to be flexible and scalable from resource constrained IoT sensors in

the field through to enterprise grade servers hosted in the data center or the cloud. Beyond

connecting and moving data around, OPC UA defines a comprehensive information model for

publishing and managing meta-information and system context to simplify automation engineering

and systems integration.

In realizing a communications standard for modern, connected industrial operations, OPC UA

provides a common link between connected products in the field, automation and edge controllers,

and enterprise applications and analytics. As such it is designed to be compatible with modern IT

and security infrastructure such as firewalls, VPNs and proxies. OPC UA scales for both functional

requirements and bandwidth.

Features

The BMENUA0100 module includes an OPC UA server and an embedded Ethernet switch. It is

Included in the Control Expert Hardware Catalog in the Communication module group,

The BMENUA0100 brings the following features to the Modicon M580 platform:

General:

Direct and optimized access to Control Expert data dictionary for simple mapping between

Control Expert and OPC UA variables

Support for Hot Standby configurations via OPC UA Redundancy

Compatibility with M580 Safety systems as a type 1 non-interfering module as defined by TÜV

Rheinland.

Seamless Ethernet backplane communications.

DHCP/FDR client for downloading stored (non-cybersecurity) configuration settings.

NTP time server

Multiple diagnostic methods, including LEDs

variables and data items

SNMP

(see page 145)

Firmware Upgrade via the EcoStruxure™ Maintenance Expert (see page 133) tool.

Firmware integrity checking.

Hardware secured storage.

(see page 116)

(see page 49)

and client synchronization.

(see page 124)

(see page 137)

, Syslog

, and secure web pages

.

, DDT

(see page 140)

(seepage146)

(see page 53)

(see page 128)

, Modbus

(see page 144)

(see page 129).

.

, OPC_UA

,

16

PHA83350 11/2020

BMENUA0100 Module Characteristics

Cybersecurity:

Secure communications via HTTPS, OPC UA (optional), and IPSEC (optional).

Module-level OPC UA security

The ability to control inbound and outbound communication flow by enabling and disabling

communication services

IPSEC

(see page 99)

based on a pre-shared key (PSK) for securing services such as SNMPv1,

(see page 96)

(seepage97)

configurable via HTTPS.

.

Modbus/TCP, Syslog, and NTPv4.

NOTE: The BMENUA0100 supports main mode IPSEC, not aggressive mode. An IPSEC

channel can be opened by either the BMENUA0100 server or a remote OPC UA client. On a

PC client, IPSEC is supported and validated on Windows 7, 10 and Windows server 2016

systems.

Authentication management:

Role based access control (RBAC) and user authentication

(see page 108)

for HTTPS and

OPC UA clients.

Certificates

(see page 101)

for OPC UA client application entities.

M580 communication module features include:

DHCP/FDR client for downloading stored non-cybersecurity configuration settings.

Direct and optimized access to Control Expert data dictionary, for mapping Control Expert

variables to OPC UA server variables

Ethernet backplane port for Ethernet communication over the local main Ethernet rack.

X Bus backplane port for 24 Vdc power and rack addressing.

NTP time server

Compatibility with Hot Standby configurations via OPC UA Redundancy

Safety configuration as a type 1 non-interfering module as defined by TÜV Rheinland.

Multiple diagnostic methods, including LEDs

variables and data items

SNMP

(see page 119)

Firmware Upgrade via the EcoStruxure™ Maintenance Expert

Hardware secured storage.

Integrity checking of firmware.

(see page 116)

(see page 137)

, and secured web pages

(see page 49)

and client synchronization.

(see page 124)

, Syslog

.

, DDT

(see page 140)

(see page 143)

(see page 53)

(see page 128)

, Modbus

(see page 144)

.

(see page 153)

.

, OPC_UA

tool.

,

PHA83350 11/2020 17

BMENUA0100 Module Characteristics

Module Description

Introduction

Schneider Electric offers two Ethernet communication modules with an embedded OPC UA server

for communication with OPC UA clients, including SCADA:

BMENUA0100 module for standard environments.

BMENUA0100H module for harsh environments.

The module can be installed only in an Ethernet slot, on a main, local Ethernet rack. Refer to the

Supported BMENUA0100 Module Configurations (see page 62)

topic

supported module placements, including the maximum number of BMENUA0100 modules that can

be placed into a rack.

Physical Description

This figure shows the external features of the BMENUA0100 module:

for a description of

18

1 LED array

2 Control port with Ethernet link and activity LEDs

3 Ethernet backplane port

4 X Bus backplane port

5 Cybersecurity operating mode rotary selector switch

Refer to the topic LED Diagnostics

(see page 124)

for information on reading module LEDs.

PHA83350 11/2020

If the Ethernet control port is not enabled, use the stopper that ships with each module to help

prevent debris from entering the control port:

External Ports

The BMENUA0100 module includes the following external ports:

Port Description

Control port The control port is the single port located on the front of the BMENUA0100 module. Its features

BMENUA0100 Module Characteristics

include:

When the control port is enabled, it is the exclusive interface for OPC UA communications.

Operating speed up to 1 Gb/s. When operating at the speed of:

1 Gb/s, use only CAT6 copper shielded twisted four-pair cables.

10/100 Mb/s, use CAT5e or CAT6 copper shielded twisted four-pair cables.

Dual IP stack that supports both IPv4 (32 bit) and IPv6 (128 bit) IP addressing:

Both IPv4 and IPv6 are configured for the module.

IPv6 configuration can be static or dynamic (via SLAAC).

IPv4 default setting

(see page 113)

is auto-assigned based on the module MAC address,

if an IP address is not configured.

Secure access to the OPC UA server via both IPv4 and IPv6 protocols.

HTTPS secure protocol (over IPv4) for firmware upgrade

configuration

NTPv4 secure protocol support.

IPsec-provided security for non-secure services, including SNMPv1, Modbus TCP, and

(seepage88)

.

(see page 153)

and cybersecurity

Syslog.

PHA83350 11/2020 19

BMENUA0100 Module Characteristics

Port Description

Ethernet

backplane

port

X Bus

backplane

port

The BMENUA0100 Ethernet backplane port supports the IPv4 (32 bit) protocol. When the

control port is disabled, the backplane port can support OPC UA communications. the

backplane port includes the following features:

Operating speed up to 100 Mb/s.

Modbus TCP IPv4 Ethernet connectivity to the CPU:

The Ethernet backplane port is the exclusive port for Modbus diagnostics.

Exclusive port for non-cybersecurity configuration (IP, NTPv4, SNMPv1), by:

Control Expert v14.1 and later

FDR/DHCP server

If the control port is disabled, the Ethernet backplane port provides secure access to the

OPC UA server via the IPv4 protocol, and supports the following services:

HTTPS secure protocol for firmware upgrade

configuration

NTPv4, SNMPv1 and Syslog.

The BMENUA0100 module uses X Bus backplane communication to:

Receive 24 Vdc power.

Discover the rack and slot address of the BMENUA0100 module.

NOTE: No other communication is performed via the X Bus backplane port of the

BMENUA0100 module.

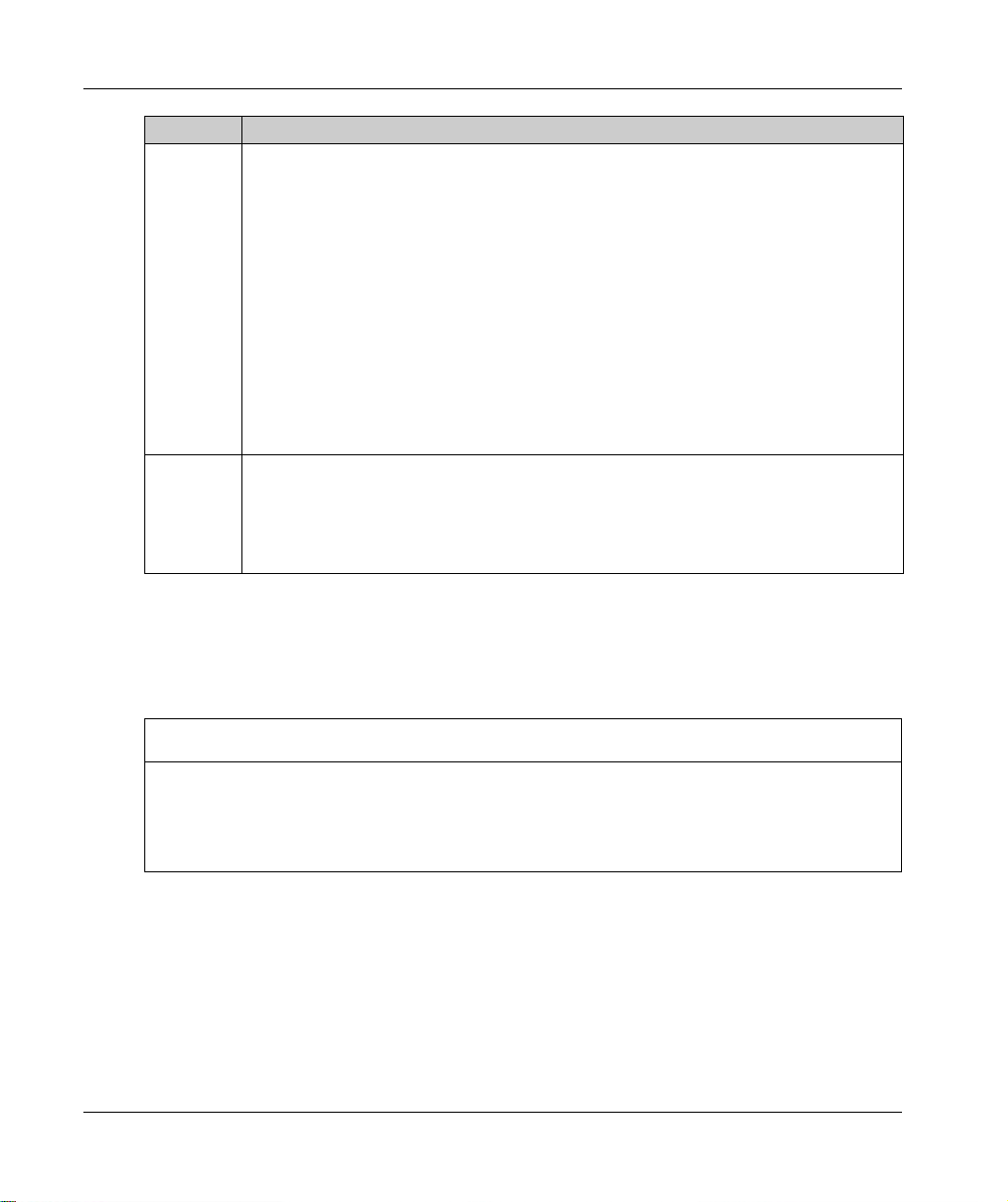

Rotary Switch

A three-position rotary switch is located on the back of the module. Use only the small, plastic

screwdriver that ships with the module to change the switch position and configure a cybersecurity

operating mode for the module.

(seepage88)

(see page 153)

.

and cybersecurity

20

NOTICE

RISK OF UNINTENDED OPERATION

Use only the small, plastic screwdriver that ships with the module to change the rotary switch

position. Using a metal screwdriver can damage the switch, rendering it inoperable.

Failure to follow these instructions can result in equipment damage.

PHA83350 11/2020

BMENUA0100 Module Characteristics

The positions on the rotary switch are:

The settings are:

Secured mode

Standard mode

Security Reset

NOTE:

The rotary switch is not accessible when the module is placed on the rack.

In a Hot Standby system, verify that the BMENUA0100 module rotary switch positions – in both

the primary and the standby local main racks – are the same. The system does not automatically

perform this check for you.

Refer to the description of cybersecurity operating modes

(seepage28)

for information on each

rotary switch position setting.

PHA83350 11/2020 21

BMENUA0100 Module Characteristics

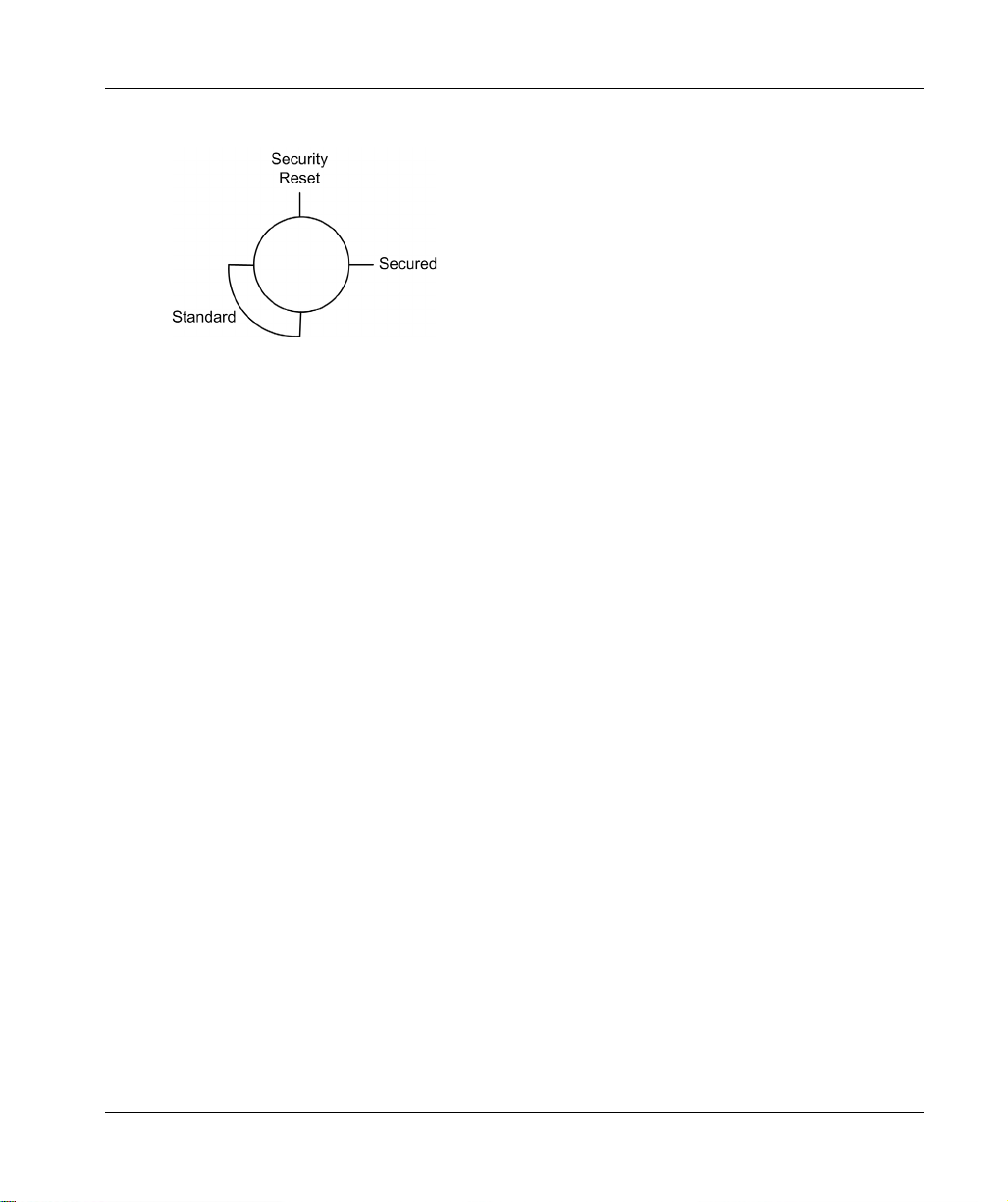

Module LEDs

LED Display

A 7-LED display panel is located on the front of the BMENUA0100 module:

The LEDs display information about the module as follows:

LED Describes the state of the module:

RUN Operating condition.

ERR Detected errors.

UACNX OPC UA connections.

BS Backplane port.

NS Control port.

SEC Cybersecurity condition.

BUSY Data dictionary status

Refer to the LED Diagnostics topic

diagnose the state of the BMENUA0100 module.

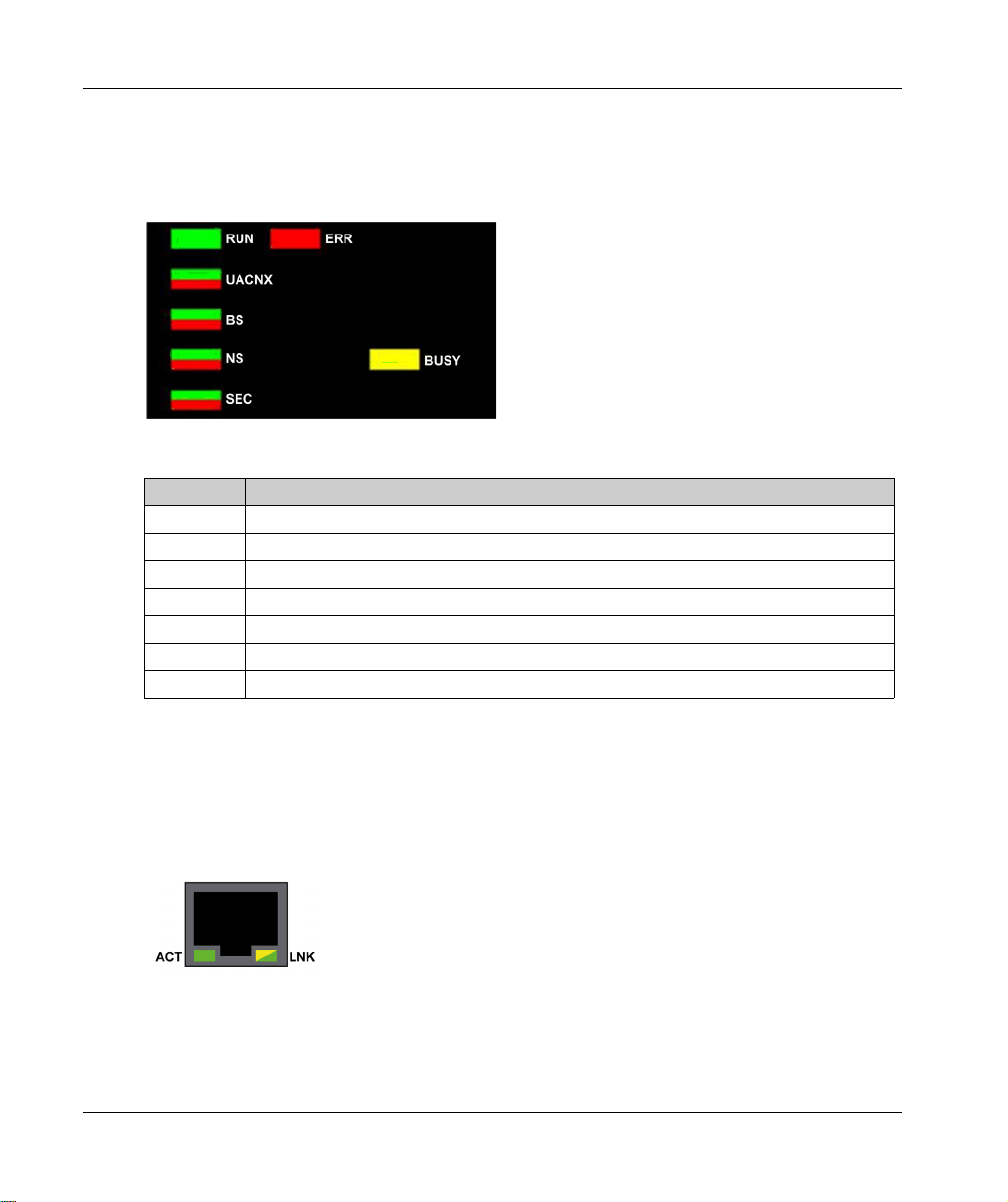

Control Port LEDs

The control port, on the front of the module, presents two LEDs describing the state of the Ethernet

link over the port:

The ACT LED indicates the presence of Ethernet activity on the port.

The LNK LED indicates the existence of an Ethernet link and the link speed.

Refer to the LED Diagnostics topic

LEDs to diagnose the state of the BMENUA0100 module control port.

22

(see page 124)

(see page 127)

for information on how to use these LEDs to

for information on how to use the control port

PHA83350 11/2020

M580

Standards and Certificat ions

PHA83350 11/2020

Standards and Certificat ions

Chapter 2

Standards and Certifications

Overview

This chapter describes the standards and certifications that apply to the BMENUA0100 Ethernet

communications module with embedded OPC UA server.

What Is in This Chapter?

This chapter contains the following topics:

Standards and Certifications 24

BMENUA0100 Module Standards 25

BMENUA0100 Firmware Compatibility with EcoStruxure™ Control Expert 26

Topic Page

PHA83350 11/2020 23

Standards and Certifications

Standards and Certifications

Download

Click the link that corresponds to your preferred language to download standards and certifications

(PDF format) that apply to the modules in this product line:

Title Languages

Modicon M580, M340, and X80 I/O Platforms,

Standards and Certifications

English:

French:

German:

Italian:

Spanish:

Chinese:

EIO0000002726

EIO0000002727

EIO0000002728

EIO0000002730

EIO0000002729

EIO0000002731

24

PHA83350 11/2020

BMENUA0100 Module Standards

Agency Requirements

The BMENUA0100 OPC UA embedded Ethernet communication module conforms to the following

agency standards:

Marking Requirement

OPC UA V1.03: OPC Unified Architecture machine to machine communication protocol.

K3/C3 – K3/C2 nuclear certification; Cx certification validates overall quality level of the

PAC system, application, and with respect to our processes (to provide traceability,

development process and mastering, maturity in our overall quality management…); K3

deals with climatic or mechanical constraints, and consists of full environmental tests

under specific mechanical constraints.

Standards and Certifications

PHA83350 11/2020 25

Standards and Certifications

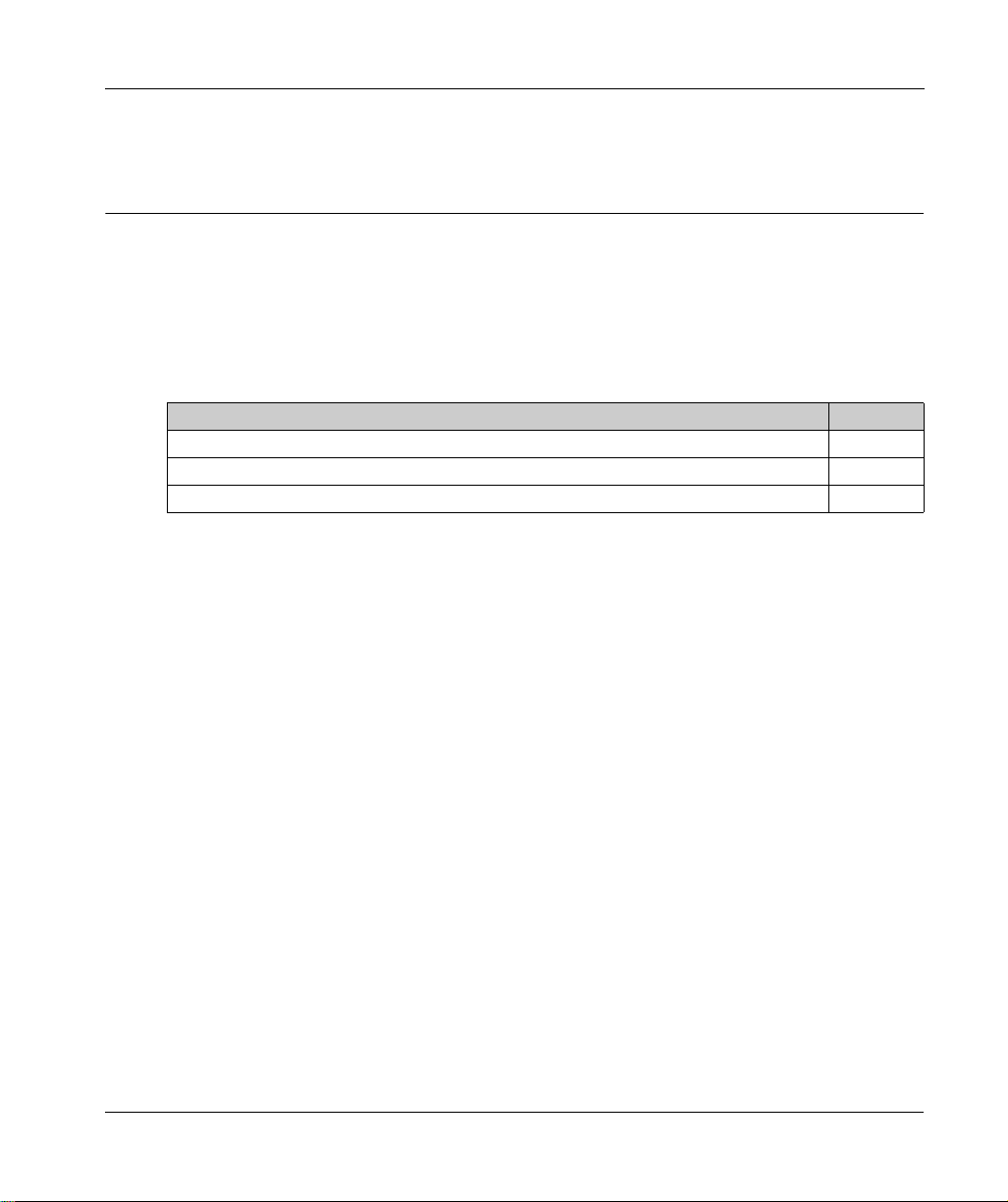

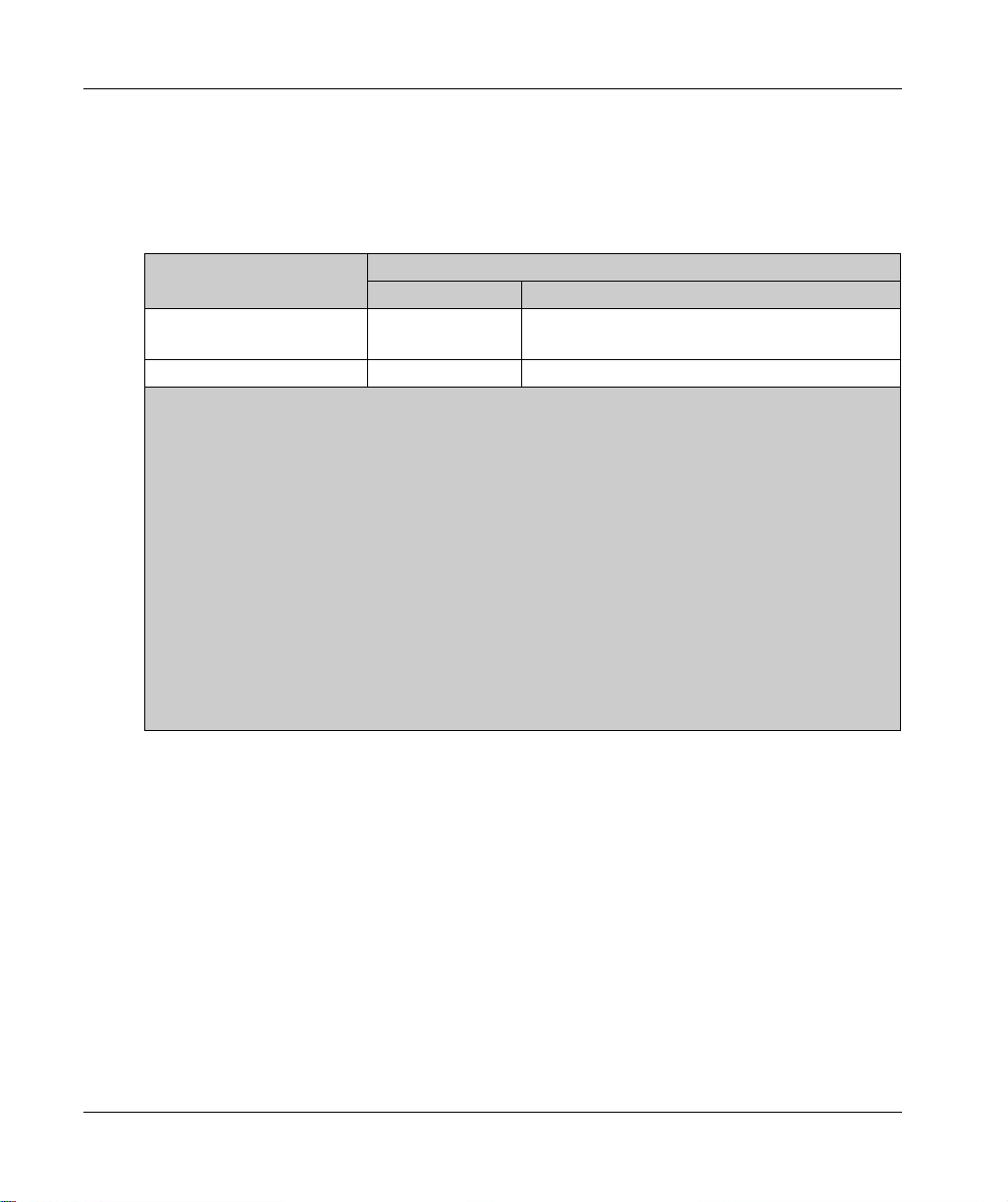

BMENUA0100 Firmware Compatibility with EcoStruxure™ Control Expert

Compatibility

Applications created with EcoStruxure™ Control Expert software are compatible with

BMENUA0100 module firmware as follows:

BMENUA0100 Firmware

Version

1.01 Fully compatible Only legacy features of firmware version 1.01 are

1.10 Fully compatible Fully compatible

1. If a BMENUA0100 module with firmware version 1.01 receives an application generated with

EcoStruxure™ Control Expert V15 where:

configure fast monitoring is Activated (in the IPConfig tab

implemented.

IPv4 is de-activated for the control port, the module control port will be configured with the IPv4 address

that appears grayed-out in the IPConfig tab for the module.

EcoStruxure™ Control Expert Software Version

14.0 15.0

supported by software

(seepage114)

1, 2, 3

), this setting will not be

NOTE: The grayed-out IPv4 address can be the most recently user-input IPv4 address, or the IPv4

address automatically input by the EcoStruxure™ Control Expert software (172.16.12.1) if no IPv4

address was previously entered.

NTP

(see page 118)

indicate NTP is operational when the NTP service actually is not operational.

2. If two BMENUA0100 modules with firmware version 1.01 are configured in a Hot Standby rack with

EcoStruxure™ Control Expert V15, the limitations described in the preceding items also apply to these

modules.

3. If SNMP is enabled in Control Expert, include the IPv4 address of the SNMP manager in the SNMP tab for

the BMENUA0100 module

has been configured with an IPv6 address, the module web pages mistakenly

(see page 119)

so that the SNMP manager can access the SNMP MIB.

26

PHA83350 11/2020

M580

Functional Description

PHA83350 11/2020

BMENUA0100 Functional Description

Chapter 3

BMENUA0100 Functional Description

Introduction

This chapter describes the supported functions of the BMENUA0100 Ethernet communications

module with embedded OPC UA server.

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

3.1 Cybersecurity Operating Mode Settings 28

3.2 OPC UA Services 34

3.3 Discovering PAC Variables 49

3.4 Hot Standby and Redundancy 53

PHA83350 11/2020 27

Functional Description

Cybersecurity Operatin g Mode Settings

Section 3.1

Cybersecurity Operating Mode Settings

Cybersecurity Operating Modes

Introduction

The BMENUA0100 module can be configured to operate in either Secured or Standard mode. The

3-position rotary selector switch on the back of the module determines the operating mode.

The three rotary switch positions are:

Secured mode

Standard mode

Security Reset

NOTE:

The module’s default, out-of-the-box configuration, is the Secured mode.

You can view the current position of the rotary switch in the Home page

module web pages.

Because the rotary selector switch is not accessible while the module is on the rack, the switch

position can be changed only when the module is powered off and removed from the rack. After a

new switch position is selected, the module can be re-inserted into the rack and power applied.

NOTE: Use only the small, plastic screwdriver that ships with the module

the switch position and configure a cybersecurity operating mode.

(see page 93)

(seepage20)

of the

to change

28

PHA83350 11/2020

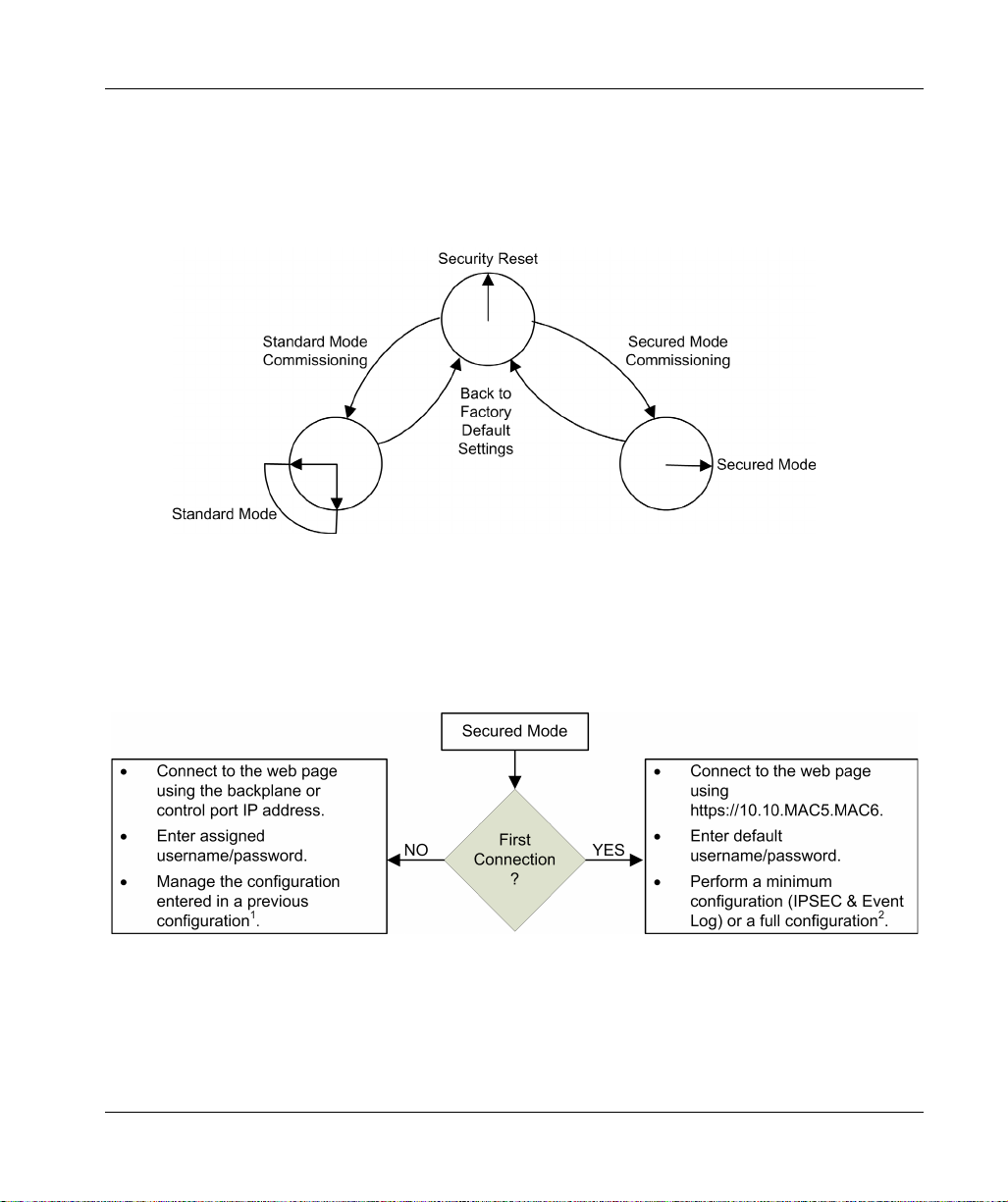

Changing Operating Mode

Each time you switch the cybersecurity operating mode from Secured mode to Standard mode, or

from Standard mode to Secured mode, perform a Security Reset operation

configuring the new mode.

The position of the rotary switch determines the operating state of the module, as follows:

A new (out-of-the-box factory default) module, or a module for which a Security Reset has been

performed, can be commissioned for either Standard mode

(seepage81)

operations.

The process for configuring the module for Secured mode operations varies, depending on

whether you are connecting to the module configuration settings for the first time after performing

a security reset:

(see page 82)

Functional Description

(see page 83)

before

or Secured mode

1 For information about managing the configuration, refer to the configuration chapter.

2 For information on performing a configuration on first connection, refer to the topic Secured Mode

Commissioning

PHA83350 11/2020 29

(seepage81)

.

(see page 87)

Functional Description

Secured Mode

When operating in Secured mode, the module will not engage in process communications – over

either the control port or the backplane port – until valid cybersecurity settings have been

configured. After Secured mode has been configured, you can configure cybersecurity settings

using the module web pages

either the backplane or control ports. In Secured mode, the module supports the level of

cybersecurity that is specified in the cybersecurity configuration. Only after cybersecurity settings

have been configured, can IP address, NTP client, and SNMP agent settings

configured using the Control Expert configuration software.

Standard Mode

When operating in Standard mode, module communications can begin immediately. Cybersecurity

settings are not required and cannot be configured. Only the IP address and other settings

available in Control Expert can be configured.

Security Reset

The Security Reset command restores the out-of-the-box factory default configuration settings. It

deletes any existing cybersecurity configuration, white lists, certificates, and role based access

control settings. While the process of restoring factory default settings is ongoing, the RUN LED

continues blinking green. After completion of process, the RUN LED turns to solid green, and all

services are disabled. To complete the security reset, either cycle power (off, then on) to the

BMENUA0100 module, or physically remove the module from the rack (which turns off power) then

re-insert the module into the rack (which turns power back on).

This setting can be made using either the rotary switch or the web pages (when operating in

Secured mode):

If set via rotary switch: the module ceases to be functional until the module is removed from the

rack, the rotary switch is re-set to either the Secured or Standard position, and the module is

again placed on the rack. The necessary configuration(s) will need to be applied.

If set via the web pages: upon completion of the process cycle power (off / on) to – or hot swap

– the module in Standard or in Secured mode. Both the cybersecurity and IP address settings

need to be configured.

NOTE: After a Security Reset of the BMENUA0100 module, the following conditions apply to the

module:

No device certificates are preserved.

All services are disabled except for HTTPS, which is used to create the cybersecurity

configuration via the control port.

Factory default settings are applied, including:

Username / Password default settings

IP address default setting of 10.10.MAC5.MAC6

(seepage88)

, which can be accessed via the HTTPS protocol over

(see page 31)

(see page 113)

(see page 112)

.

.

be

30

PHA83350 11/2020

Functional Description

Default Username / Password Combination

The default username / password combination depends on the cybersecurity operating mode

setting:

Secured mode: admin / password

Standard mode: installer / Inst@ller1

Functions Supported by Secured and Standard Operating Modes

The following functions are supported by the BMENUA0100 module in Secured and Standard

modes:

Security Mode Standard mode Secured mode

Control port Disable Enable Disable Enable

Ethernet port Backplane Backplane Control port Backplane Backplane Control port

OPC UA Comm Yes No Yes Yes No Yes

Security

Settings (

None – None None, Sign,

3

)

Sign&Encrypt

(default value)

User

authentication

No

authentication

(anonymous)

–No

authentication

(anonymous)

Operator,

Engineer,

No authentication

(anonymous)

SNMP V1

NTP V4

1

Yes (

)Yes (

Client only (

1

1

)Yes (

) Client (1),

Server

1

)Yes (

Yes,

Client only (

Client only (*)

1

)

1

)Yes (

Event Log No No No Yes Yes Yes

IPSec No No No No No Yes for Modbus,

Web CS Config

No No No Yes Yes Yes

change

(HTTPS)

1. Configurable with Control Expert.

2. NTP V4 can be configured to be transported outside IPSec tunnel.

3. For both Standard and Secured cybersecurity operating modes, if Security Settings is set to

authentication (i.e. the User Identifier token types OPC UA setting

(see page 100)

4. To provide Control Expert with online access to the CPU or Device Network, configure the PC (on which Control

Expert is installed) with an IP address on the same subnet as the BMENUA0100 module control port, and use the

BMENUA0100 module control port IP address as the PC gateway IP address. In this case, no IP address of the

PC can be on the same subnet as the BMENUA0100 module backplane port.

– None, Sign,

Sign&Encrypt

(default value)

– Operator,

Engineer,

No authentication

(anonymous)

1

)Yes (

1

),

Client (

Server

1

)

Yes,

Client only (

SNMP V1,

NTP V4 (

2

Syslog (IPSec

enabled by

default)

None

, there is no user

is set to

Anonymous.

)

1

)

) and

PHA83350 11/2020 31

Functional Description

Security Mode Standard mode Secured mode

Control port Disable Enable Disable Enable

Ethernet port Backplane Backplane Control port Backplane Backplane Control port

User

– – – Admin Admin Admin

authentication

Network

Services Comm

server

Enable/Disable

If supported,

always

enabled (refer

above)

If

supported,

always

enabled

(refer

If supported,

always

enabled (refer

above)

All services are

configurable

(disabled by

default)

All services

are

configurable

(disabled by

default)

All services are

configurable

(disabled by

default)

above)

Web Diagnostic

Yes Yes Yes Yes Yes Yes

(Home and

Diagnostic

pages only)

User

authentication

Installer

(default

credentials)

Installer

(default

credentials)

Installer

(default

credentials)

Admin, Operator,

Engineer,

Installer

Admin,

Operator,

Engineer,

Admin, Operator,

Engineer,

Installer

Installer

Firmware

upgrade

Yes Yes Yes Yes Yes Yes, if HTTPS

enabled

(HTTPS)

User

authentication

Filtering: CPU to

CPU Data Flows

(Modbus)

Installer

(default

credentials)

Installer

(default

credentials)

Installer

(default

credentials)

– – Forward of

Modbus data

flow from CPU

(always

enabled)

Installer Installer Installer

– – Forward of

Modbus data flow

from CPU

(disabled by

default)

1. Configurable with Control Expert.

2. NTP V4 can be configured to be transported outside IPSec tunnel.

3. For both Standard and Secured cybersecurity operating modes, if Security Settings is set to

authentication (i.e. the User Identifier token types OPC UA setting

(see page 100)

is set to

None

, there is no user

Anonymous.

)

4. To provide Control Expert with online access to the CPU or Device Network, configure the PC (on which Control

Expert is installed) with an IP address on the same subnet as the BMENUA0100 module control port, and use the

BMENUA0100 module control port IP address as the PC gateway IP address. In this case, no IP address of the

PC can be on the same subnet as the BMENUA0100 module backplane port.

32

PHA83350 11/2020

Functional Description

Security Mode Standard mode Secured mode

Control port Disable Enable Disable Enable

Ethernet port Backplane Backplane Control port Backplane Backplane Control port

Filtering: Control

Expert Data

Flows to CPU

only (FTP, EIP,

Explicit,

Modbus, Ping)

Filtering: Control

Expert Data

Flows to Device

Network

(including CPU)

(FTP, EIP,

Explicit,

Modbus, Ping)

via IPv4 only

– – Forward of

4

– – Forward of

4

Control Expert

data flows

from Control

Network to

CPU only

(always

enabled)

4

Control Expert

data flows

from Control

Network to

Device

Network

(always

enabled)

– – Forward of

Control Expert

data flows from

Control Network

to CPU only

(disabled by

4

default)

– – Forward of

Control Expert

data flows from

Control Network

to Device

Network (disabled

by default)

1. Configurable with Control Expert.

2. NTP V4 can be configured to be transported outside IPSec tunnel.

3. For both Standard and Secured cybersecurity operating modes, if Security Settings is set to

authentication (i.e. the User Identifier token types OPC UA setting

(see page 100)

is set to

None

, there is no user

Anonymous.

)

4. To provide Control Expert with online access to the CPU or Device Network, configure the PC (on which Control

Expert is installed) with an IP address on the same subnet as the BMENUA0100 module control port, and use the

BMENUA0100 module control port IP address as the PC gateway IP address. In this case, no IP address of the

PC can be on the same subnet as the BMENUA0100 module backplane port.

PHA83350 11/2020 33

Functional Description

OPC UA Services

Section 3.2

OPC UA Services

Introduction

This section describes the services supported by the OPC UA server embedded in the

BMENUA0100 module.

What Is in This Section?

This section contains the following topics:

BMENUA0100 OPC UA Server Operating Characteristics 35

OPC UA Server 37

BMENUA0100 OPC UA Server Stack Services 39

BMENUA0100 OPC UA Server Stack Data Access Services 40

BMENUA0100 OPC UA Server Stack Discovery and Security Services 42

BMENUA0100 OPC UA Server Stack Publish and Subscribe Services 44

BMENUA0100 OPC UA Server Stack Transport Services 48

Topic Page

34

PHA83350 11/2020

BMENUA0100 OPC UA Server Operating Characteristics

Limitations

The maximum:

Number of nodes that can be published in the BMENUA0100 OPC UA Server data access

Address space is 100000 nodes.

Memory amount that can be allocated to the BMENUA0100 OPC UA Server is 4GB.

NOTE: If either limit is exceeded, the server Address Space state enters into a

state.

NOTE: The time needed to establish time subscription may significantly depend on the number of

items and the number of connected clients.

Other limitations, the context in which they occur, and their consequences if exceeded are set forth

below:

Limit Value OPCUA Service Service Parameter Effects

Cumulative

Session

Count

Minimum

Session

Timeout

Cumulative

Session

timeout

Maximum

Cumulative

Subscription

Count

Minimum

Publishing

Interval

Maximum

Publishing

Interval

Maximum

Subscription

Lifetime

1. If Fast Monitoring is disabled.

2. If Fast Monitoring is enabled.

3. If Fast Monitoring is disabled, and the server is configured with:

a sampling interval of at least 1 second, and

a publishing interval of at least 1 second.

10

30 s

3600 s

40

250 ms

20 ms

10 s

300 s

CreateSession

CreateSession

CreateSubscription

CreateSubscription

1

CreateSubscription

2

CreateSubscription

CreateSubscription

(Not Applicable)

Requested SessionTimeout revisedSession Timeout

Requested SessionTimeout revisedSession Timeout

(Not Applicable)

Requested Publishing

Interval

Requested Publishing

Interval

Min(Requested Publishing

Interval, 3600000) *

Requested LifetimeCount

Bad_TooManySessions

result code

Bad_TooManySubscriptions

service result code

revisedPublishingInterval

revisedPublishingInterval

revisedLifetimeCount

Functional Description

LimitsExceeded

s e r v i c e

PHA83350 11/2020 35

Functional Description

Limit Value OPCUA Service Service Parameter Effects

Maximum

Notifications

Per Publish

12500

CreateSubscription

maxNotificationsPerPublish Notifications maximum capacity

is thus (1000/

revisedPublishingInterval) *

1000 notifications per second.

Minimum

Sampling

Interval

Maximum

Message

125 ms

20 ms

100

1

CreateMonitoredtems

2

CreateMonitoredtems

MonitoringParameters.

SamplingInterval

MonitoringParameters.

QueueSize

revisedSampling Interval

revisedQueueSize

Queue Size

Maximum

Cumulative

Monitored

50000

2000

CreateMonitoredtems

2

(Not Applicable)

Bad_TooManyMonitoredItems

service result code

3

Items Count

Maximum

4– – –

Subscriptions

Per Session

Maximum

25000 – – –

Monitored

Items Count

Per

Subscription

1. If Fast Monitoring is disabled.

2. If Fast Monitoring is enabled.

3. If Fast Monitoring is disabled, and the server is configured with:

a sampling interval of at least 1 second, and

a publishing interval of at least 1 second.

36

PHA83350 11/2020

OPC UA Server

Introduction

The primary purpose of the BMENUA0100 Ethernet communication module is to provide an

OPC UA communication channel over Ethernet between M580 CPUs and OPC UA clients. The

data of the M580 CPU is mapped to variables in the BMENUA0100 module, and made available

to OPC UA clients via a high performance OPC UA server communication stack embedded in the

BMENUA0100 module. OPC UA clients connect to the embedded OPC UA server stack using IP

address of the BMENUA0100 module's control port or backplane port, thereby establishing a client

server connection. The BMENUA0100 module is able to handle a maximum of ten (10)

simultaneous OPC UA client connections for firmware version 1.1 (or three (3) simultaneous

OPC UA client connections for firmware version 1.0).

NOTE: The terms of each connection between an OPC UA client and the OPC UA server

embedded in the BMENUA0100 module are determined by the client, which sets the attributes of

the connection between the client and server.

The OPC UA server stack embedded in the BMENUA0100 module consists of functionalities

defined by the following terms:

Profile: a full-featured definition of functionality that comprises other profiles, facets,

conformance groups, and conformance units.

Facet: defines a partial functionality.

Conformance Group: a collection of conformance units.

Conformance Unit: a specific service, for example, read, write, and so forth.

Functional Description

BMENUA0100 Supported Profile

The BMENUA0100 module supports the Embedded 2017 UA Server Profile. As stated in the OPC

Foundation web site, this profile:

is a FullFeatured Profile that is intended for devices with more

than 50 MBs of memory and a more powerful processor. This Profile builds upon the Micro

Embedded Device Server Profile. The most important additions are: support for security via the

Security Policies and support for the Standard DataChange Subscription Server Facet. This Profile

also requires that Servers expose all OPC-UA types that are used by the Server including their

components and their super-types.

" For more information, refer tot he OPC Foundation website at:

http://opcfoundation.org/UA-Profile/Server/EmbeddedUA2017.

PHA83350 11/2020 37

Functional Description

BMENUA0100 Supported Facets

The BMENUA0100 module supports the following Facets:

Server Category → Facets → Core Characteristics:

Core 2017 Server Facet (

Server Category → Facets → Data Access:

ComplexType 2017 Server Facet (

Profile/Server/ComplexTypes2017

Data Access Server Facet (

Embedded DataChange Subscription Server Facet (

Profile/Server/EmbeddedDataChangeSubscription

Server Category → Facets → Generic Features:

Method Server Facet (

Security Category → Facets → Security Policy:

Basic128RSA15 (

Basic256 (

Basic256Sha256 (

Transport Category → Facets → Client-Server:

UA-TCP- UA-SC UA-Binary (

uabinary

http://opcfoundation.org/UA/SecurityPolicy#Basic256

)

The following topics discuss the services, related to the above-referenced facets, that are

supported by the BMENUA0100 module.

http://opcfoundation.org/UA-Profile/Server/Core2017Facet

http://opcfoundation.org/UA-

)

http://opcfoundation.org/UA-Profile/Server/DataAccess

http://opcfoundation.org/UA-

)

http://opcfoundation.org/UA-Profile/Server/Methods

)

http://opcfoundation.org/UA/SecurityPolicy#Basic128Rsa15

)

http://opcfoundation.org/UA/SecurityPolicy#Basic256Sha256

http://opcfoundation.org/UA-Profile/Transport/uatcp-uasc-

)

)

)

)

38

PHA83350 11/2020

BMENUA0100 OPC UA Server Stack Services

Supported OPC UA Services

The BMENUA0100 module OPC UA server stack supports the following service sets and services:

Service Set Services

Attribute

Discovery

MonitoredItem

SecureChannel

Session

Subscription

View

Read

Write

FindServers

GetEndpoints

CreateMonitoredItems

ModifyMonitoredItems

DeleteMonitoredItems

SetMonitoringMode

OpenSecureChannel

CloseSecurechannel

CreateSession

ActivateSession

CloseSession

CreateSubscription

ModifySubscription

DeleteSubscription

SetPublishingMode

SetMonitoringMode

Publish

Republish

Browse

BrowseNext

TranslateBrowsePathToNodeIds

RegisterNodes

UnregisterNodes

Functional Description

NOTE: For a description of these service sets and services, refer to the document

Architecture Specification Part 4: Services (Release 1.04)

PHA83350 11/2020 39

.

OPC Unified

Functional Description

BMENUA0100 OPC UA Server Stack Data Access Services

Supported Data Access Services

Data access by the BMENUA0100 module embedded OPC UA server stack is enabled by its

support of the following facets and related services:

Data Access Server Facet

ComplexType 2017 Server Facet

Core 2017 Server Facet

NOTE: In the following facet descriptions, italicized text indicates a direct quote of the OPC

Foundation source material. Click on the links below and use the

Architecture Profile Reporting Visualization Tool

Core 2017 Server Facet

The Core 2017 Server Facet

tation. The core functionality includes the ability to discover endpoints, establish secure

communication channels, create Sessions, browse the AddressSpace and read and/or write to

Attributes of Nodes. The key requirements are: support for a single Session, support for the Server

and Server Capabilities Object, all mandatory Attributes for Nodes in the AddressSpace, and

authentication with UserName and Password. For broad applicability, it is recommended that

Servers support multiple transport and security Profiles

http://opcfoundation.org/UA-Profile/Server/Core2017Facet

The BMENUA0100 module embedded OPC UA server stack supports the following conformance

units in the Core 2017 Server Facet:

View Service Set, includes the following groups and services:

View Basic: includes the Browse and the BrowseNext services.

View TranslateBrowsePath: includes the TranslateBrowsePathsToNodeIds service.

View Register Nodes: includes the RegisterNodes and UnregisterNodes services as a way

to optimize access to repeatedly used Nodes in the Server's OPC UA AddressSpace.

Attribute Service Set, includes the following groups and services:

Attribute read: includes the Read service, which supports reading one or more attributes of

one or more Nodes, including support of the IndexRange parameter to read a single element

or a range of elements when the Attribute value is an array.

Attribute Write values: includes the Write Value service, which supports writing one or more

values to one or more Attributes of one or more Nodes.

Attribute Write Index: includes the Write Index service, which supports the IndexRange for

writing to a single element or a range of elements when the Attribute value is an array and

partial updates is allowed for this array.

defines the core functionality required for any UA Server implemen

to access a description of each facet.

. For a full description of this facet, refer to

.

OPC Foundation Unified

-

40

PHA83350 11/2020

Data Access Server Facet

The Data Access Server Facet

industrial automation data. This model defines standard structures for analog and discrete data

items and their quality of service. This Facet extends the Core Server Facet which includes support

of the basic AddressSpace behaviour

http://opcfoundation.org/UA-Profile/Server/DataAccess

ComplexType 2017 Server Facet

The ComplexType 2017 Server Facet

structured data, i.e. data that are composed of multiple elements such as a structure and where

the individual elements are exposed as component variables. Support of this Facet requires the

implementation of structured DataTypes and Variables that make use of these DataTypes. The

Read, Write and Subscriptions service set shall support the encoding and decoding of these

structured DataTypes. As an option the Server can also support alternate encodings, such as an

XML encoding when the binary protocol is currently used and vice-versa

this facet, refer to

http://opcfoundation.org/UA-Profile/Server/ComplexTypes2017

Functional Description

specifies the support for an Information Model used to provide

. For a full description of this facet, refer to

.

extends the Core Server Facet to include Variables with

. For a full description of

.

PHA83350 11/2020 41

Functional Description

BMENUA0100 OPC UA Server Stack Discovery and Security Services

Introduction

The BMENUA0100 module embedded OPC UA server stack supports both discovery and security

services.

To connect to the OPC UA server in the BMENUA0100 module, an OPC UA client requires

information describing the server, including its network address, protocol, and security settings.

OPC UA defines a set of discovery features a client can use to obtain this information.

The information needed to establish a connection between an OPC UA client and an OPC UA

server is stored in an endpoint. An OPC UA server can possess several endpoints, each

containing:

Endpoint URL (network address and protocol), for example:

For IPv4: opc.tcp://172.21.2.30:4840, where:

- opc.tcp = protocols

- 172.21.2.30 = IPv4 address

- 4840 = opcua-tcp port number configured in Control Expert

For IPv6: opc.tcp://[2a01:cb05:431:f00:200:aff:fe02:a0a]:50000, where:

- opc.tcp = protocols

- [2a01:cb05:431:f00:200:aff:fe02:a0a] = IPv6 address

- 50000 = opcua-tcp port number configured in Control Expert

Security Policy (including a set of security algorithms and key length)

Message Security Mode (security level for exchanged messages)

User Token Type (server supported types of user authentication)

One or more OPC UA servers can exist. In the case of multiple servers, a discovery server can be

used to provide information regarding each server. Individual servers can register with the

discovery server. Clients can request a list of some or all of the available servers from the discovery

server and use the GetEndpoints service to acquire connection information from an individual

server.

42

PHA83350 11/2020

The BMENUA0100 module supports several discovery and security services, including:

Discovery Service Set

SecureChannel Service Set

Session Service Set

The decision to enable or disable services depends on the cybersecurity policy you decide to

implement for the server.

Discovery Service Set

The BMENUA0100 OPC UA server stack supports the Discovery Service Set, which is

incorporated in the Core 2017 Server Facet

module, the supported services include:

FindServers: As implemented in the BMENUA0100 module OPC UA server stack, this service

finds all servers only on the local OPC UA server.

GetEndpoints: Returns the Endpoints supported by a server and all of the configuration

information required to establish a SecureChannel and a Session. Can provide a filtered

Endpoints return list, based on profiles.

SecureChannel Service Set

The BMENUA0100 OPC UA server stack supports the SecureChannel Service Set, which includes

the following services:

OpenSecureChannel: Opens or renews a SecureChannel that provides confidentiality and

integrity for the exchange of messages during a session. This Service requires the OPC UA

server stack to apply the various security algorithms to the messages as they are sent and

received.

CloseSecureChannel: Terminates a SecureChannel.

(seepage40)

Functional Description

. As implemented in the BMENUA0100

Session Service Set

The BMENUA0100 OPC UA server stack supports the Session Service Set, which is incorporated

in the Core 2017 Server Facet

(see page 40)

. As implemented in the BMENUA0100 module, the

supported services include:

CreateSession: After creating a SecureChannel with the OpenSecureChannel service, a client

uses this service to create a session. The server returns two values which uniquely identify the

session:

A sessionId, which is used to identify the session in the audit logs and in the server's

AddressSpace.

An authenticationToken, which is used to associate an incoming request with a session.

ActivateSession: Used by the client to specify the identity of the user associated with the

session. It cannot be used to change the session user.

CloseSession: Terminates a session.

NOTE: For the CreateSession and ActivateSession services, if the SecurityMode = None then:

1. The Application Certificate and Nonce are optional.

2. The signatures are null/empty.

PHA83350 11/2020 43

Functional Description

BMENUA0100 OPC UA Server Stack Publish and Subscribe Services

Subscriptions

Instead of permanently reading information by polling, the OPC UA protocol includes the Subscription

function. This function enables the OPC UA high performance stack embedded in the BMENUA0100

module to provide publish/subscribe services, which are used when the module connects to remote

devices.

An OPC UA client can subscribe to one or more selected nodes and let the server monitor these

items. Upon the occurrence of a change event, for example a change in value, the server notifies the

client of the change. This mechanism significantly reduces the quantity of data that is transferred. This

reduces bandwidth consumption and is the recommended mechanism for reading information from

an OPC UA server.

An OPC UA client can subscribe to the multiple types of information that an OPC UA server provides.

The subscription groups together these varying types of data, called Monitored Items, to form a single

collection of data called a Notification.

A subscription must:

Consist of at least one Monitored Item.

Be created within the context of a Session, which is created within the context of a

Secure Channel.

NOTE: The subscription can be transferred to another session.

The service sets involved in a client subscription are described below:

Subscriptions and Overruns

In some cases, where there exists a large number of subcription requests, the OPC UA server

attempts to obtain data from the CPU in an amount greater than the CPU or the BMENUA0100

module can handle in the specified publishing interval. In this case, the execution time for

subscription requests will be automatically extended – and the next subscription execution

postponed – until all requests can be completed.

When setting a publishing interval, consider the number of clients and client requests the server

needs to handle. When determining the number of client requests, confirm that all clients are

operating online. In this regard, note that some clients can take 2 minutes or more to come online

after startup.

NOTE: A publishing interval equal to twice the sampling interval is recommended.

44

PHA83350 11/2020

Change Events

A client can subscribe to a data change event, which is triggered by a change to the value attribute

of a variable, as a Monitored Item.

The configurable subscription settings, their sequence and roles, are described below:

The following three settings determine how Monitored Items are added to a subscription:

Sampling Interval: the sampling time interval set for each Monitored Item in the subscription.

This is the frequency by which the server checks the data source for changes. For a single

Variable item, the Sampling Interval can be smaller (i.e. faster) than the period between

notifications to the client. In this case, the OPC UA Server may queue the samples and publish

the complete queue. In extreme cases, the server will revise (i.e. slow) the Sampling Interval so

that the data source will not experience excessive queuing load that may be caused by the

sampling itself.

NOTE: If OPC UA queuing of data samples is supported, the queue size (i.e., the maximum

number of values which can be queued) can be configured for each monitored item. When the

data is delivered (published) to the client, the queue is emptied. In case of a queue overflow,

the oldest data is discarded and replaced by new data.

Filter: a collection of several criteria used to identify which data changes or events are reported,

and which should are blocked.

Monitoring Mode: used to enable or disable data sampling and reporting.

The following two settings apply to the Subscription itself:

Publishing Interval: The period after which notifications collected in the queues are delivered to

the client in a Notification Message (Publish Response). The OPC UA Client must confirm that

the OPC UA server has received enough Publish Tokens (Publish Requests), so that whenever

the Publish Interval elapsed and a notification is ready to send, the server uses such a token

and sends the data within a Publish Response. In case that there is nothing to report (e.g. no

values have changed) the server will send a KeepAlive notification to the Client, which is an

empty Publish, to indicate that the server is still alive.

Publish Enabled: Enables and disables the sending of the Notification Message.

Functional Description

PHA83350 11/2020 45

Functional Description

Embedded DataChange Subscription Server Facet

The Embedded DataChange Subscription Server Facet

data change notifications within subscriptions. It includes limits which minimize memory and

processing overhead required to implement the Facet. This Facet includes functionality to create,

modify and delete Subscriptions and to add, modify and remove Monitored Items. As a minimum

for each Session, Servers shall support one Subscription with up to two items. In addition, support

for two parallel Publish requests is required. This Facet is geared for a platform such as the one

provided by the Micro Embedded Device Server Profile in which memory is limited and needs to

be managed.

For a full description of this facet, refer to

Profile/Server/EmbeddedDataChangeSubscription

This facet supports the following services:

Monitored Item Service Set

Subscription Service Set

Monitored Item Service Set

The Monitored Item Service Set supports the following services:

CreateMonitoredItems: An asynchronous call used to create and add one or more

MonitoredItems to a subscription.

ModifyMonitoredItems: an asynchronous call to modify monitored items. This service is used to

modify MonitoredItems of a subscription. Changes to the MonitoredItem settings shall be

applied immediately by the server. They take effect as soon as practical.

DeleteMonitoredItems: an asynchronous call to delete monitored items. This service is used to

remove one or more MonitoredItems of a subscription. When a MonitoredItem is deleted, its

triggered item links are also deleted.

SetMonitoringMode: an asynchronous call to set the monitoring mode for a list of

MonitoredItems. This service is used to set the monitoring mode for one or more

MonitoredItems of a subscription. Setting the mode to DISABLED causes all queued

notifications to be deleted.

specifies the minimum level of support for

http://opcfoundation.org/UA-

.

46

PHA83350 11/2020

Subscription Service Set

The Subscription Service Set supports the following services:

CreateSubscription: an asynchronous call to create a subscription.

ModifySubscription: an asynchronous call to modify a subscription. The server immediately

applies changes to the subscription, and changes take effect as soon as practical.

DeleteSubscription: an asynchronous call to delete one or more subscriptions belonging to the

client session. Successful completion of this service deletes all Monitored Items associated with

the subscription.

Publish: This Service is used for two purposes: to acknowledge the receipt of Notification-

Messages for one or more subscriptions, and to request the server to return a

NotificationMessage or a keep-alive message.

Republish: an asynchronous republish call to get lost notifications. This service requests the

subscription to republish a NotificationMessage from its retransmission queue. If the server

does not have the requested message in its retransmission queue, it returns an error response.

SetPublishingMode: an asynchronous call to enable sending of Notifications on one or more

subscriptions.

Functional Description

PHA83350 11/2020 47

Functional Description

BMENUA0100 OPC UA Server Stack Transport Services

Support for the UA-TCP UA-SC UA-Binary Facet

The BMENUA0100 module supports the UA-TCP UA-SC UA-Binary transport facet. (For

additional information, refer to the online description at

Profile/Transport/uatcp-uasc-uabinary

.)

This transport facet defines a combination of network protocols, security protocols, and message

encoding that is optimized for low resource consumption and high performance. It combines the

simple TCP-based network protocol UA-TCP 1.0 with the binary security protocol UA-SecureConversation 1.0 and the binary message encoding UA-Binary 1.0.

Data that passes between an OPC UA client and the BMENUA0100 module embedded OPC UA

server uses the TCP protocol, and is binary coded in accordance with the OPC UA Binary File

Format.

NOTE: The OPC UA Binary File Format replaces the XML UA-Nodeset Schema from the OPC

Foundation. It improves performance and memory consumption. It does not require an XML

parser.

http://opcfoundation.org/UA-

48

PHA83350 11/2020

Functional Description

Discovering PAC Varia bles

Section 3.3

Discovering PAC Variables

Mapping Control Expert PAC Variables to OPC UA Data Logic Variables