Page 1

Saitel DR

M556000002B / AB_AI

User Manual

This manual provides information for the assembly, wiring, configuration and

maintenance of the AB_AI module.

SE-M556-USR

Publication Date (3/2020)

Read carefully the information contained in this manual before assembly, installation and use of the

equipment.

www.schneider-electric.com

Page 2

20/03/2020

User Manual – AB_AI

R&D Digital Seville

01

20-03-2020

Initial edition

Easergy Builder User Manual

FTE-MSS-S856

HUe User Manual

SE-M588-USR

HU_A User Manual

SE-M551-USR

HU_B User Manual

SE-M552-USR

HU_AF User Manual

SE-M503-USR

Easergy Builder User Manual

FTE-MSS-S856

webAPP User Manual

FTE-WPP-S856

webTool user manual

FTE-MSW-S856

EOL Instructions

FTE-EOLI-M555

Baseline

HUe

11.06.08_7061

Baseline

HU_A/HU_AF

11.04.18_6825

Baseline

HU_B

02.03.01

Easergy Builder Tool

Core

1.5.9.1

AB_AI software

AB_AI.bin

01.07.07

Change Control

Rev Date Description

General Information

The Saitel platform and all its components have been developed in accordance to the requirements

for a quality management system, complying with the ISO 9001:2015 Norm.

Document nº: SE-M556-USR

Revision/Date: 01 / 20-03-2020

File: AB_AI – User Manual_EN_01.pdf

Retention period:

Reference Documents

User Manual Document Code

Permanent throughout its validation period + 3 years after its

cancellation.

Software Version in this Manual

The information in this manual is valid for the software versions listed below. This information is also valid for later

versions, although some parameters may change slightly:

RTU Software

Module

Module Version

Pag 2

Page 3

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Content

1 SAFETY & HEALTH .................................................................................................. 4

2 GENERAL DESCRIPTION OF AB_AI .................................................................... 15

3 PHYSICAL MOUNTING & INSTALLING ................................................................ 20

4 CONFIGURATION & MAINTENANCE .................................................................... 26

5 TECHNICAL SPECIFICATIONS TABLE ................................................................ 52

Pag 3

Page 4

20/03/2020

User Manual – AB_AI

R&D Digital Seville

1 Safety & Health

Pag 4

Page 5

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Content

1 SAFETY & HEALTH .................................................................................................. 4

INTRODUCTION ........................................................................................................ 6

INFORMATION OF SAFETY ................................................................................. 6

PRESENTATION ................................................................................................ 6

INTRODUCTION TO SAFETY ....................................................................................... 7

SYMBOLS AND LABELS ON THE EQUIPMENT ............................................................. 8

INSTALLATION, SETUP AND OPERATION ................................................................... 8

EARTHING ............................................................................................................. 10

ELECTRICAL SAFETY ...................................................................................... 10

FUNCTIONAL EARTH (EMC) ............................................................................ 11

HANDLING ELECTRONIC COMPONENTS .................................................................. 11

TECHNICAL SPECIFICATIONS FOR SAFETY .............................................................. 12

PROTECTIVE ELEMENTS ................................................................................. 12

ENVIRONMENTAL CONDITIONS ........................................................................ 12

STORAGE CONDITIONS ................................................................................... 12

TECHNICAL LABEL ................................................................................................. 13

PACKING AND UNPACKING ..................................................................................... 13

DECOMMISSIONING AND DISPOSAL ....................................................................... 13

Pag 5

Page 6

20/03/2020

User Manual – AB_AI

R&D Digital Seville

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or

NOTICE

NOTICE is used to address practices not related to physical injury. The safety alert symbol shall

Introduction

Information of Safety

Important information

Read these instructions carefully and look at the equipment to become familiar with the device

before trying to install, operate, service or maintain it. In this manual you can find different types of

messages associated with situations that have different level of risk for people and / or for the

equipment.

injury.

This symbol indicates "DANGER" or "WARNING". This symbol informs of an

electrical risk that will cause personal injuries if the instructions are not followed.

This symbol is associated to a safety alert. It is used to warn of possible personal

injury hazards. The user must follow all instructions or messages associated to this

symbol to avoid possible injuries.

serious injury.

not be used with this signal word.

To Keep in Mind

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is who fulfill with requirements in paragraph 1.2.

Presentation

This manual provides information for a safe handling, commissioning and testing. This Safety

chapter also includes descriptions of the labels on the equipment.

Documentation for equipment ordered from Schneider Electric is dispatched separately from

manufactured goods and may not be received at the same time. Therefore, this guide is provided

to ensure that printed information which may be present on the equipment is fully understood by

the recipient.

The technical data in this safety guide is typical only, see the technical data section of the user

manual for specific details of a particular equipment.

Pag 6

Page 7

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Before carrying out any work on the equipment the user should be familiar with the

THE EQUIPMENT.

WARNING

Before working with the terminal of connection, the device must be turned off and disconnected

of the feeding.

contents of this Safety chapter and the ratings on the equipment’s rating label.

THE SAFETY SECTION MUST BE READ BEFORE STARTING ANY WORK ON

Introduction to Safety

The information in this section is intended to get that equipment is properly installed and handled in

order to maintain it in safety conditions. It is assumed that everyone who will be associated with the

equipment will be familiar with the contents of that Safety section.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of the

equipment. Failure to observe warning notices, an incorrect or improper use may endanger

personnel and equipment and also cause personal injury or physical damage.

Proper and safe operation of the equipment depends on appropriate shipping and handling, proper

storage, installation and commissioning, and on careful operation, maintenance and servicing. For

this reason only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

• Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected.

• Have read and understood the information on the device and its user manual.

• Are able to safely perform switching operations in accordance with accepted safety engineering

practices and are authorized to energize and de-energize equipment and to isolate, ground,

and label it.

• Are trained in the care and use of safety apparatus in accordance with safety engineering

practices.

• Are trained in emergency procedures (first aid).

It is necessary to consider that the documentation of the device collects the instructions for its

installation, set up and operation. However, the manuals could not cover all the possible

circumstances neither include specific information on all the details.

In case of questions or specific problems, contact with his office of sales Schneider Electric or with

the center of attention to the customer and request the necessary information.

Pag 7

Page 8

20/03/2020

User Manual – AB_AI

R&D Digital Seville

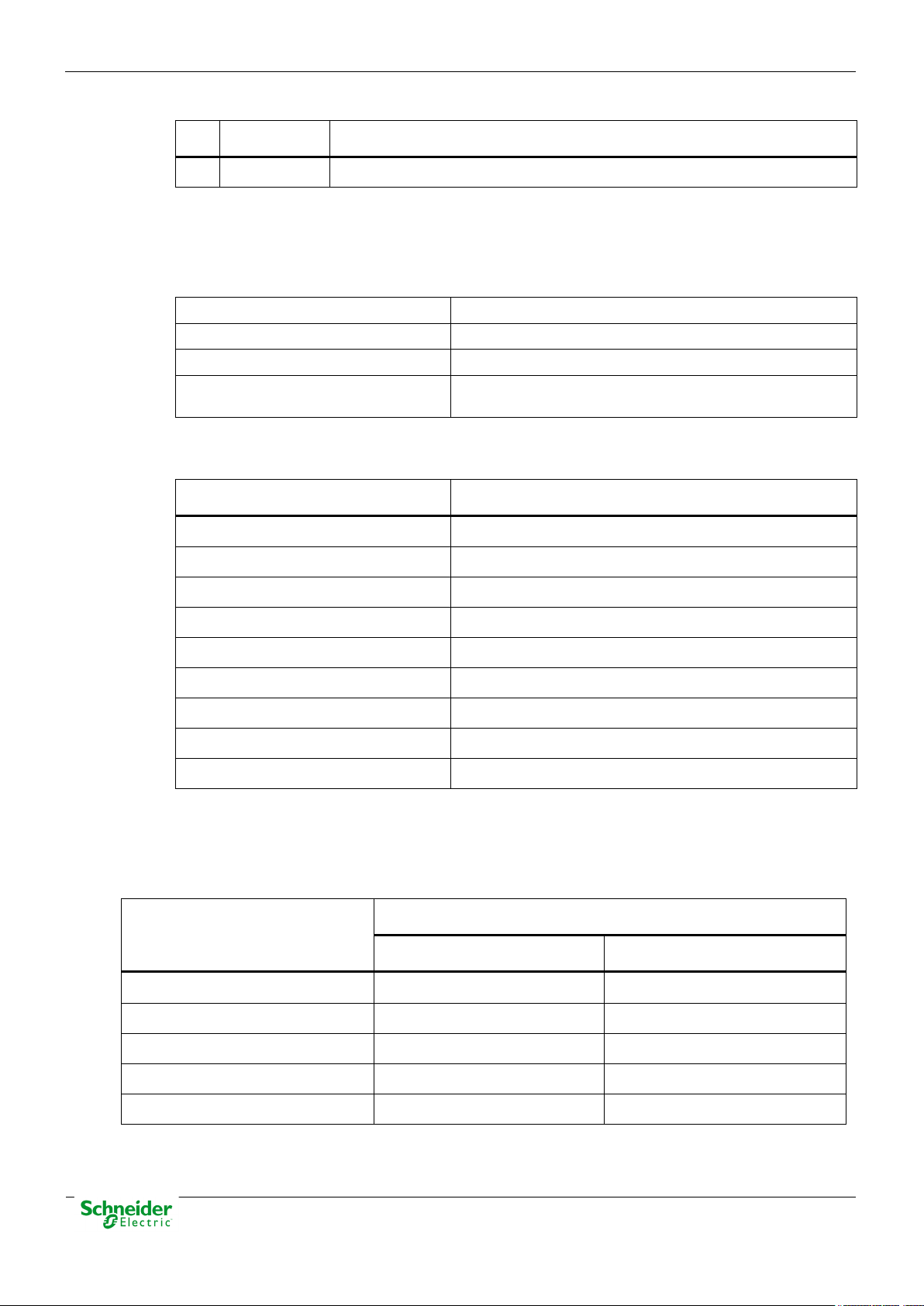

Symbol

Associated Text

Description

IEC symbol associated to a DANGER or

could cause damage to people or death.

Symbol associated with a risk alert. The user

equipment.

ANSY symbol associated to a DANGER or

Protective earth

Associated symbol to the protective ground

This symbol indicates that the equipment has

Electronic device.

This symbol indicates that, at the end of its life,

The equipment has been designed and

Symbol of direct voltage (VDC).

Alternate Voltage

Symbol of alternate voltage (VAC).

DANGER

Devices that handle dangerous tensions are marked with a sticker on the front label (size: 12,5

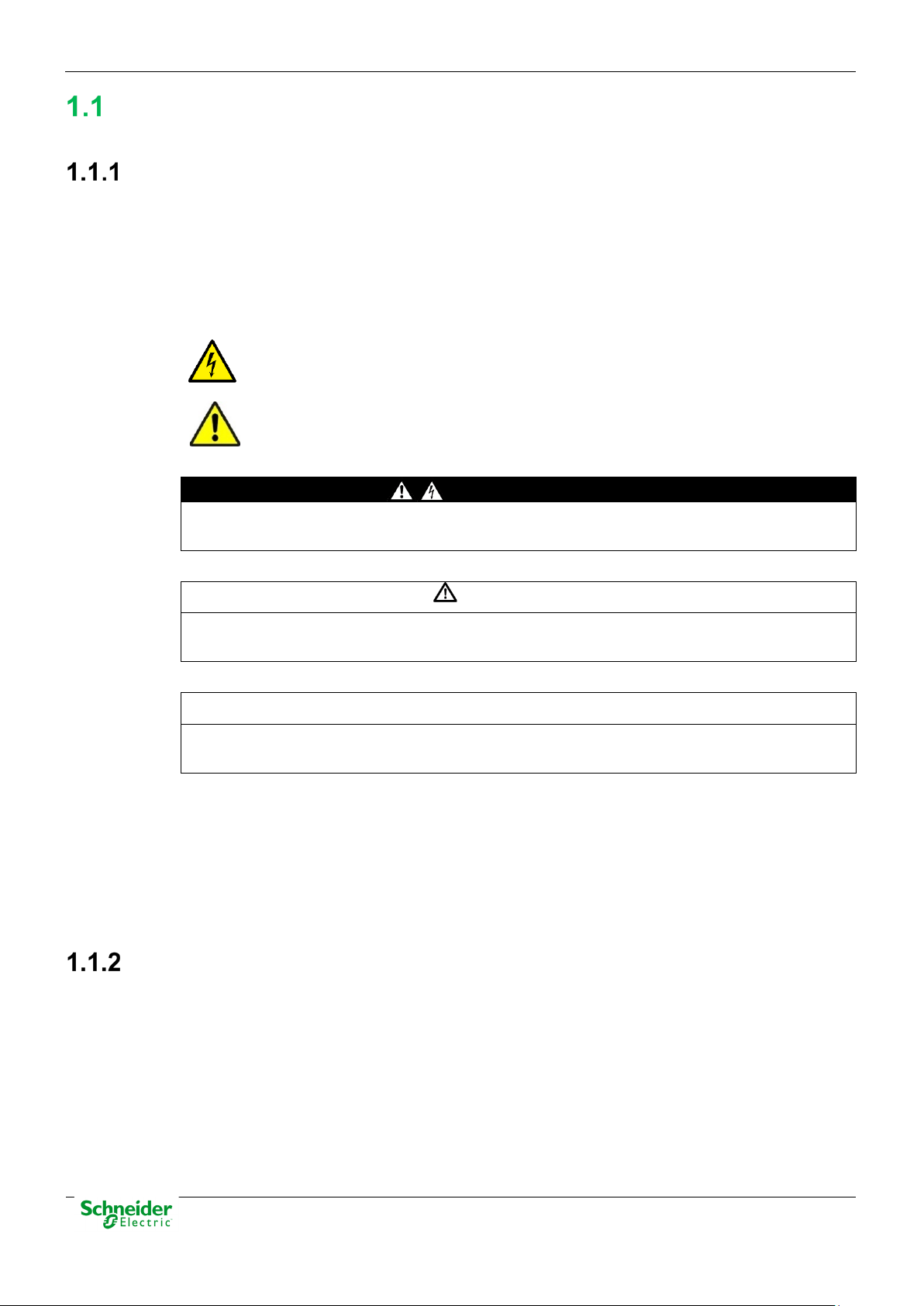

Symbols and Labels on the Equipment

Before the equipment is installed or commissioned, the user must understand the following

symbols, which may be used on the equipment or referred to in the user documentation:

Table 1 – Symbols

Possibility of electric

chock

Caution, read the

manual.

Possibility of electric

chock

WARNING message indicating that there is an

electrical risk. Failure to follow these instructions

must read the manual before handling the

WARNING message indicating that there is an

electrical risk. Failure to follow these instructions

could cause damage to people or death.

connection

CE Mark

Special instructions

must be follow for

discard it.

Compliant with

RoHS.

connection. See paragraph 1.5.1 in this manual.

been developed in compliance with all

applicable European Directives.

this module must be discarded according to the

WEEE Directive (Waste Electrical and Electronic

Equipment).

manufactured according to RoHS Directive

(Restriction of Hazardous Substances).

Direct Voltage

Installation, Setup and Operation

There are several acquisition blocks in Saitel DR that use high voltages (> 50 V). The user is

responsible to check that the characteristics of each device are adapted and convenient for his

installation. The user should read the instructions of installation before proceeding to the use or

maintenance of the devices.

Not following these instructions can be dangerous for the people and the devices.

mm). This label must be visible all the time while the module is installed on the DIN rail.

Pag 8

Page 9

User Manual – AB_AI

20/03/2020

R&D Digital Seville

WARNING

If this type of cabinet isn't available, a barrier must be installed in order to avoid an accidental

or even can damage to the people or devices.

INFORMATION

Terminals will not be accessible to the user directly once it has made the installation of the

The following products handle dangerous tensions:

• HU_AF: Advanced head unit with acquisition (P/N M503xx3x0x and P/N M503xx4x0x). For

other part numbers, depending on the voltage handled by the equipment connected to the

digital outputs (voltage > 50 V), this module must be marked with an electric risk label. It will

not be marked on factory.

• HU120: High-performance CPU with acquisition (P/N M590xx000x).

• AB_DI: Digital inputs module (P/N: M55520000x, M55530000x and M55540000x).

• AB_DIDO: Input and output digital module (P/N M5722x000x, M5723x000x and M5724x000x).

For other part numbers, depending on the voltage handled by the equipment connected to the

digital outputs (voltage > 50 V), this module must be marked with a electric risk label. It will not

be marked on factory.

• AB_AC: Direct measurements module (P/N M562x0000x).

• AB_DO: This module does not handle high voltages, it will not be marked at the factory. This

module must be marked to inform about the risk when some equipment that manage voltage

higher than 50 V are connected to digital outputs.

It is recommended to install the RTU inside a cabinet with a key. This cabinet only should be

opened by a qualified person.

contact with these dangerous elements. This barrier only should can be removed using a

special tool.

If the barrier has to be removed in order to access to equipment, personnel responsible for the

task must be sure that the barrier is installed again when the task is finished.

While the RTU is accessible for a user, all people must follow all instructions to prevent

electrical risk or discharges.

Not following these instructions can give like result that the device do not work properly

An electrical risk symbol with enough size must be included on the cabinet’s door or

on the barrier.

The following image shows an example:

Figure 1 – Barrier of protection for elements with dangerous voltages.

device. The cabinet will have to remain closed with key or the screen of installed protection.

The cabinet or installation must have a general switch placed just in the cable entry of the

installation (see paragraph 1.7.1)

Pag 9

Page 10

20/03/2020

User Manual – AB_AI

R&D Digital Seville

WARNING

Don’t use a liquid products of cleanliness due to the presence of active parts.

WARNING

that should be disconnected.

WARNING

All devices with high voltage must be disconnected before dismount a module from the DIN rail.

Earthing

For the cleaning of the device it is only necessary using a dry cloth by the surface when it detects

excessive presence of dust or any element deposited on the surface.

Because of the variety of uses of the product, the managers of the application and use of this

device of control will have to take the measures to ensure the fulfillment of all the requests of

security and provision of each application. The requests do reference to the applicable laws,

regulations, codes and standard.

Before energizer the device, it has to be placed to earth properly such as it indicates in sections

1.5.1 and 1.5.2.

When installing the device, ground is the first thing that should be connected and the last one

Saitel can need put to earth for two distinct needs:

• For purposes of electrical safety (Protective Earth, PE).

• Improve the behavior in EMC and derive perturbations to earth (functional Earth).

Electrical Safety

Only qualified personnel, with knowledge about hazards associate with electrical equipment is

allowed to install Saitel DR. In general, the installation will be following IEC 61010-1

recommendations in order to be compliant with this norm.

The DIN rail must be installed on a metallic surface. This metallic surface must have

available an M4 screw marked with this symbol. The ground of the cabinet or

installation must be connected to this screw, according to the norm IEC 61010-1.

Saitel DR modules have a metallic enclosure offering protection for isolation faults. Earthing is

done by the metal rail fixing clip.

A dedicated connection with green/yellow wire should be used to assure electric continuity to the

installation protective earth. Section of these wires must be enough in order to support 25 A

(ground bonding test).

Figure 2 – Yellow and Green cable for earthing.

The design and installation of the cabinet is responsible for compliance with all the existing

international and national electrical codes concerning protective grounding of any device.

Pag 10

Page 11

User Manual – AB_AI

20/03/2020

R&D Digital Seville

WARNING

According to Electrical Safety:

INFORMATION

The DIN rail must have terminals of earthing (of yellow and green color) necessary to connect

WARNING

The enclosure ONLY should be removed when is strictly necessary, because this action has a

• The screw for ground must be exclusive for this use.

• The power voltage must be supplied by a power supply that offers double or reinforced

insulation against dangerous voltages.

Functional Earth (EMC)

In this case the main rule is that the connection has to do with wires of the lower possible length to

the screen or connection of put to earth nearer. In this case the section of the driver is not notable,

is more, it advises that the use of flat wires or flexible conductive bands for a good behavior EMC.

the terminals of PE (if it is present).

Figure 3 – Terminal for functional earth (EMC).

All Saitel DR modules with power or polarization connector have an exclusive terminal for earthing

EMC. These modules are HU120, HUe, HU_B, HU_A, HU_AF, XU, AB_DO, AB_DIDO and

AB_SER with external polarization.

Figure 4 – Example of earthing for EMC.

Handling Electronic Components

Saitel is susceptible to receive electrostatic discharges during the handling. It is necessary to take

the usual measures to minimize this risk, since serious damage to the equipment can be caused,

which may not be detected immediately but which may affect the reliability of the product.

risk for the equipment:

• Before removing the enclosure, the operator must be equipotential with the equipment.

• Avoid touching the electronic. The board must be always manipulated for the edges.

• If the equipment has to be passed between two persons, both must be equipotential.

• Put the module always on an antistatic surface or on a surface equipotential with you.

• During the storage and transport, the module will remain in the packaging.

Pag 11

Page 12

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Not following these instructions can give like result that the device do not work properly

WARNING

The connection / disconnection switch must be installed in a fixed element (for example the wall

WARNING

This equipment has been designed ONLY for indoor use.

or even can damage to the people or devices.

Technical Specifications for Safety

Protective Elements

The cabinet's engineering and installation must include a general automatic switch next to the

cables' input in the cabinet; once the door is opened, high voltages must be interrupted inside. This

switch must be located at a place which is not accessible by a third person while the operator is

using the boards in the cabinet.

Moreover, the installation will incorporate a circuit breaker of 5A next to the cabinet protecting it

from possible overcurrent in the power supply.

Both switches will be labeled with the symbol O as "Off" and I as “On”.

of the cabinet) and it mustn’t break any earthing wire.

Environmental Conditions

The protection degree of the device is IP20.

If it is necessary for his use in some external surroundings, it has to mount in a cabinet or specific

accommodation that contributes a degree of protection IP54, protected against the dust and water.

The electronic cards of the modules will be able to be tropicalized or no according to the option of

setting chosen. The tropicalized used is the AVR80, of the company ABchimie. It can consult all the

technical information of this type of finishing in http://www.abchimie.com/

Other data to take into account about the environmental are:

• Altitude until 2000 m.

• Operation temperature range: Between -40 ºC and 70 ºC. (IEC 60068-2-1 and IEC 60068-2-2).

• Maximum relative humidity of 95%. (IEC 60068-2-30)

• Degree of pollution II. (IEC 61010-1)

• Overvoltage transitory until levels of Category II. (IEC 61010-1)

Storage Conditions

The continuous exhibition to some high levels of humidity during the storage can cause damages

to the electronic components and reduce the useful life of the device.

.

We recommend that, in the enclosure of storage, the relative humidity do not exceed 50%.

Once that the Saitel devices have been unpacked, recommend that they are energized inside the

three following months. When it installs an electrical device, it has to leave sufficient time for the

acclimatization to the temperature acclimatize of the environment, before the activation. Once the

equipment has been unpacked, it is recommended that it be energized within the following three

months.

Pag 12

Page 13

User Manual – AB_AI

20/03/2020

R&D Digital Seville

INFORMATION

On the “Technical data” zone, you can see relevant information about the input and output

the other elements, and each one must be recycled according to the local regulation.

•

•

•

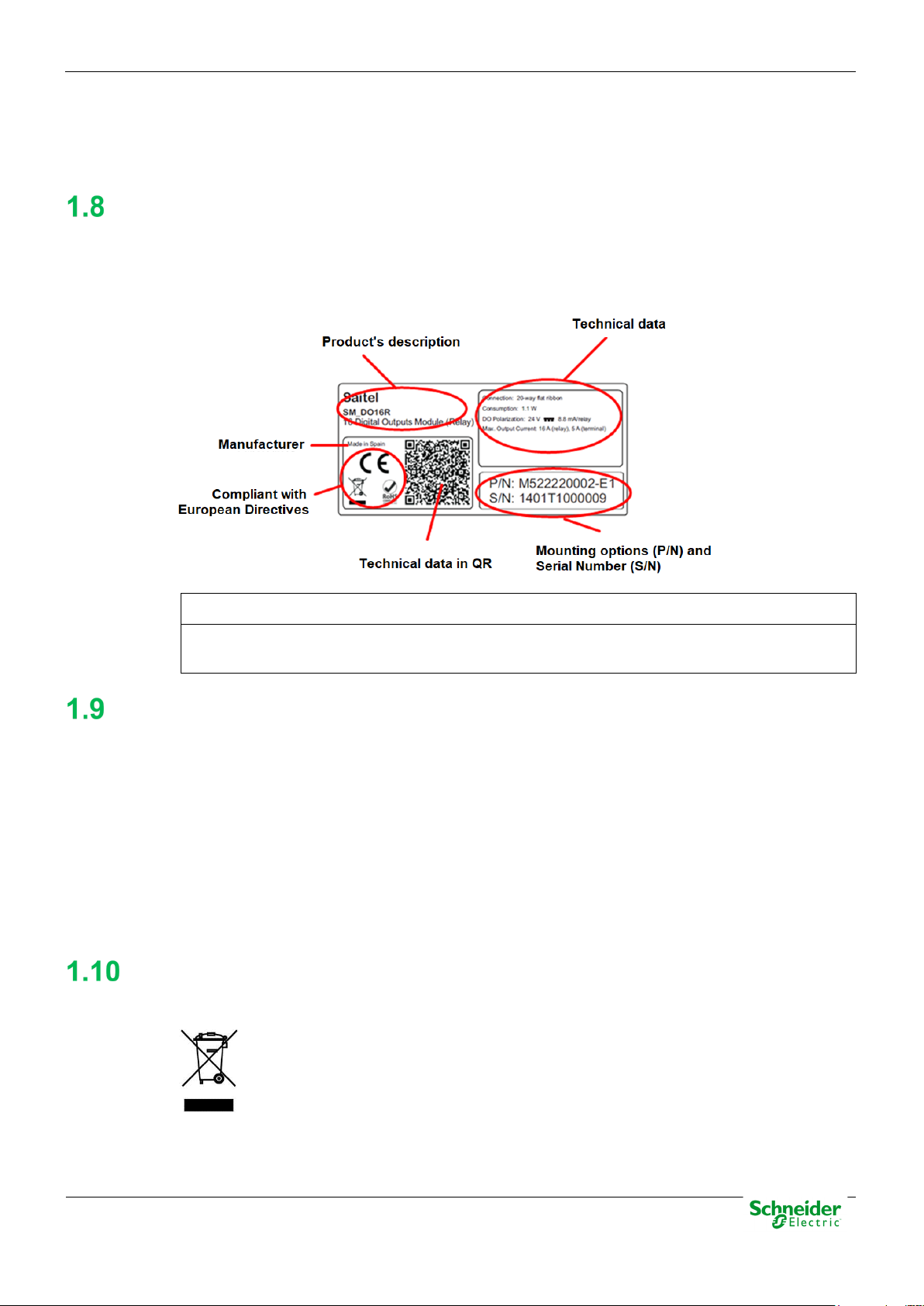

Technical Label

Each Saitel product includes a technical label with the following information:

Figure 5 – Technical label.

voltage in the module. Any voltage greater than 50 V must be consider as a high voltage.

Packing and Unpacking

All Saitel modules are packaged separately in their own carton box and shipped inside outer

packaging. Use special care when unpacking the device. Don’t use force.

The design revision and manufacturing options can be determined using the P/N included in the

packaging label on packaging.

After unpacking the device, inspect it visually to be sure it is in proper mechanical condition.

If the product needs to be shipped, the original packaging must be used, including foams and the

carton box. If the original packaging is no longer available, make sure that the packaging used is

according to ISO 2248 specifications for a drop height 1 m.

Decommissioning and Disposal

When the product is marked with this symbol, it means that, at the end of its life

cycle, you mustn't dispose the product together with habitual residues. To avoid the

possible damage to the environment or to the human health that represents the

uncontrolled elimination of residues, please, separate the battery (if there is one) of

•

•

Pag 13

Page 14

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Pag 14

Page 15

User Manual – AB_AI

20/03/2020

R&D Digital Seville

2 General Description of AB_AI

Pag 15

Page 16

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Content

2 GENERAL DESCRIPTION OF AB_AI .................................................................... 15

SAITEL DR PLATFORM ........................................................................................... 17

AB_AI FEATURES ................................................................................................. 17

INTERFACES .......................................................................................................... 18

HARDWARE ARCHITECTURE ................................................................................... 19

Pag 16

Page 17

User Manual – AB_AI

20/03/2020

R&D Digital Seville

WARNING

Please note Saitel DR does not support hot-swapping, that is, module replacements during

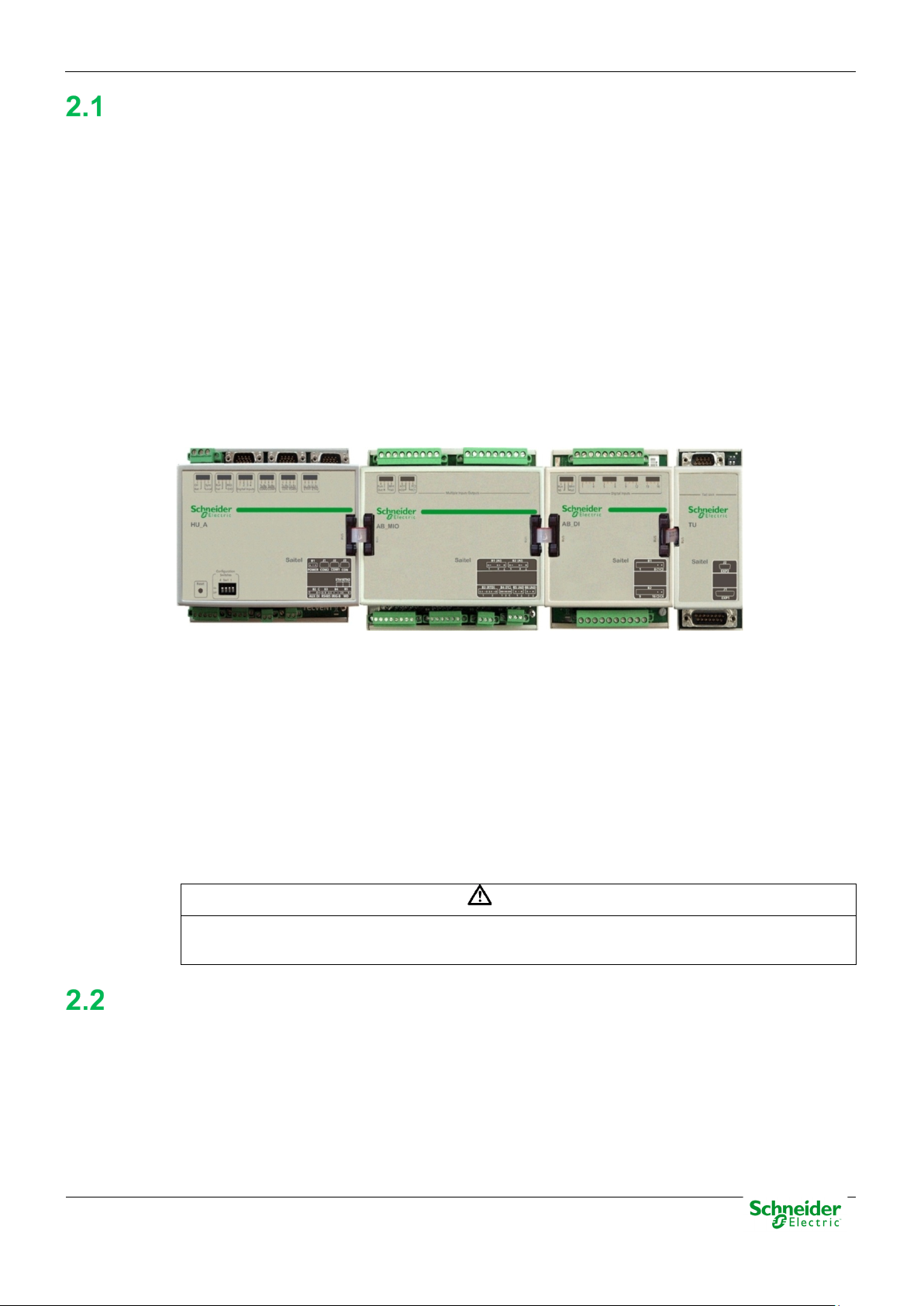

Saitel DR Platform

Saitel DR is a hardware platform by Schneider Electric. It consists of a set of equipment which

have been specifically designed for real-time control and automation applications. Saitel DR is a

high-technology platform which serves Schneider Electric’s business areas.

On this hardware platform, the Baseline Software Platform is installed. This software is used in

Saitel families (Saitel DP and Saitel DR) and other Schneider Electric products.

Other features identifying Saitel DR are:

• A DIN rail is used for the mechanical installation.

• The communication between the controls units integrated in a distributed system is mainly

established by Ethernet.

• The terminal blocks for field-connection are completely built into acquisition blocks.

Figure 6 – Saitel DR.

Saitel DR’s design has been optimized to meet the most demanding requirements of multiple

sectors:

• Safety and reliability requirements for power, gas and water supply, as well as sewage

treatment plants, etc.

• Compliance with electric safety, electromagnetic compatibility, and environmental standards.

• Centralized monitoring and control of geographically-distributed systems which support

hierarchical data acquisition and sharing networks.

• Local monitoring and control with data sharing capabilities of plant-distributed equipments.

• Quick troubleshooting, including the possibility of using programmable automation execution.

operation.

AB_AI Features

The main features of this module are:

• 8 analog inputs using 2 removable terminal blocks. Each terminal allows connecting 4 signals.

• The information is processed before transmitting it to the HU, to do so, it uses a high-resolution

sigma-delta converter.

• Processing of information includes:

Pag 17

Page 18

20/03/2020

User Manual – AB_AI

R&D Digital Seville

o Digital filtering.

o Scaling to engineering units.

o Range limits detection.

o Value change detection.

o Zero value cancellation

• The module is synchronized via a message received from the HU.

• 4 LED indicators are available on the front side.

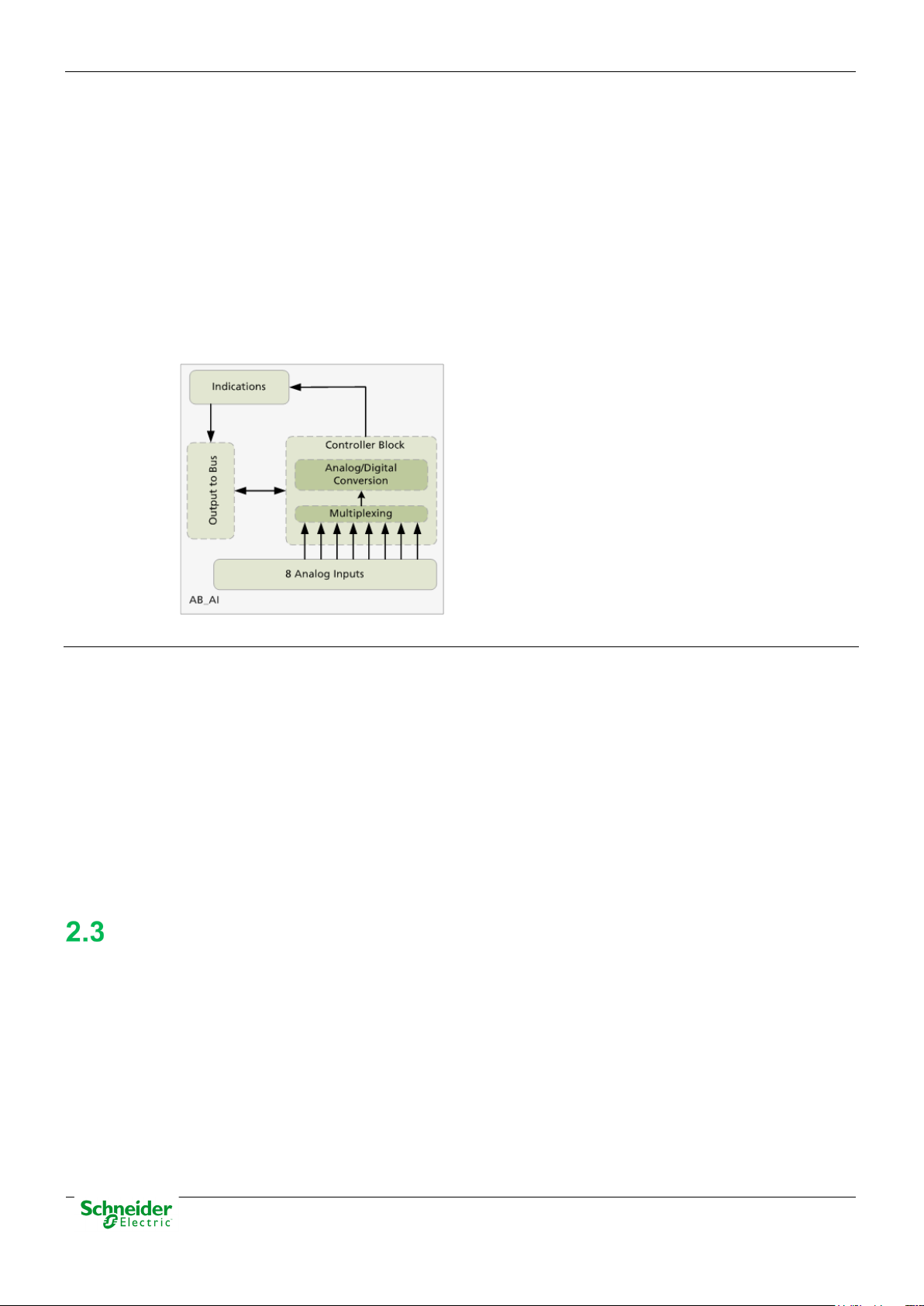

The diagram below illustrates the functional blocks integrated in the AB_AI module:

Figure 7 – Functional block diagram

Analog Inputs

Interfaces

The AB_AI has two terminal blocks labeled as B1 and B2 which allow the connection of 8 analog

inputs (4 per terminal block). The main features of these inputs are:

• Differential type.

• By default, all signals are ready for voltage, but they can be configured for currents using an

external resistor (250 Ω).

• 8-channel multiplexing.

• 16-bits sigma-delta converter.

• Accuracy better than 0.1% at 25 ºC.

• Protections against overvoltage.

Following interfaces are available in this module:

• 2 removable terminal block to connect one analog input.

• 4 LED indicators.

Figure 8 – AB_AI Module

Pag 18

Page 19

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Hardware Architecture

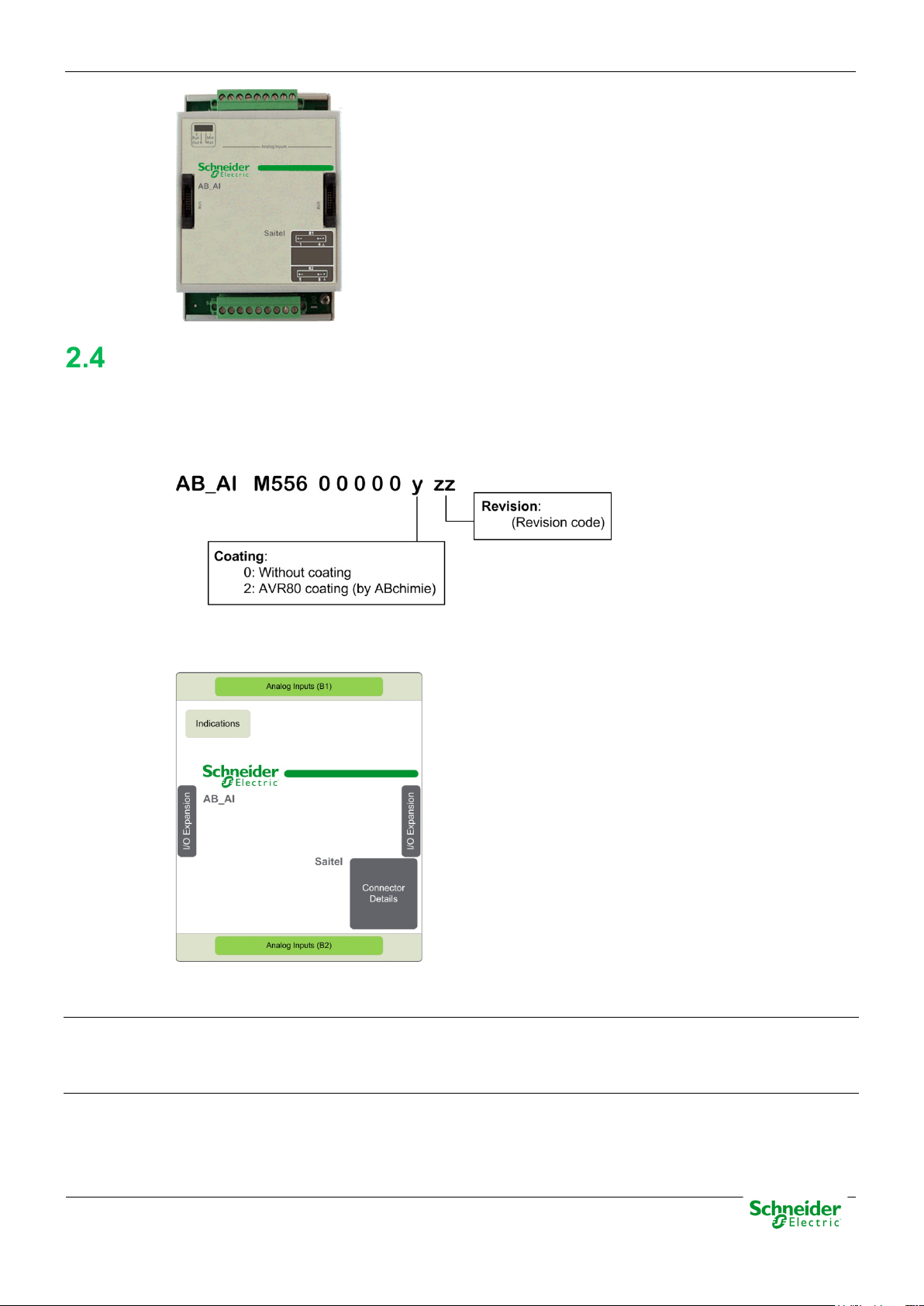

The following P/N describes all available ordering options for this module:

Figure 9 – AB_AI P/N description.

Indicators

The following figure illustrates the AB_AI hardware blocks diagram:

Figure 10 – AB_AI - Hardware block diagram

There are 4 LED indicators on the module’s front panel which provide information about the module

and the features

Analog Inputs (B1 and B2)

There are 4 analog inputs in each terminal. The first 8 pins (from left to right) are related to 4

analog inputs and the last one is used for ground connection.

Pag 19

Page 20

20/03/2020

User Manual – AB_AI

R&D Digital Seville

3 Physical Mounting & Installing

Pag 20

Page 21

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Content

3 PHYSICAL MOUNTING & INSTALLING ................................................................ 20

ITB INSTALLATION ................................................................................................. 22

HANDLING ...................................................................................................... 22

LOCATION IN THE ITB ..................................................................................... 22

POWER SUPPLY REQUIREMENTS .................................................................... 22

MOUNTING PROCEDURE ................................................................................. 22

WIRING AB_AI ...................................................................................................... 23

WIRING RECOMMENDATIONS .......................................................................... 24

ANALOG INPUT CONNECTION .......................................................................... 24

LED INDICATORS ................................................................................................... 25

Pag 21

Page 22

20/03/2020

User Manual – AB_AI

R&D Digital Seville

DANGER

Depending on the devices connected to the module AB_AI, could exist hazard of electric

WARNING

Electrostatic discharges may damage semi-conducive devices within the module.

WARNING

It is important to assure that handling is always done while the ITB elements are unpowered.

ITB installation

Handling

chock, electric arc or burns. For any of these cases, follow these instructions:

• Only qualified operator should install this equipment. Such work should be performed only

after reading this entire set of instructions and checking the technical characteristics of the

device.

• NEVER work alone.

• Turn off all power supplying this equipment before working on or inside it. Consider all

sources of power, including the possibility of back feeding.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Start by connecting the device to the protective ground and to the functional ground.

• Screw tight all terminals, even those not in use.

Failure to follow these instructions will result in death or serious injury.

To avoid electrostatic damage, the following precautions must be strictly followed:

• Do not touch the bus connector pins.

• If unused, keep the modules in the antistatic bag.

Location in the ITB

Saitel DR modules cannot be placed at any position in the ITB. Some of them, such as the head

unit, the termination (TU or BT), the expansion (XU) and the communications module (AB_SER)

must be installed in a specific position in the ITB.

All AB_AI modules will always be placed between two termination blocks. The type of termination

block will depend on the row position within the ITB (HU, TU, XU or BT).

Power Supply Requirements

The main power is supplied by the HU through the bus. The maximum power requirement for each

AB_AI module is:

1

• Main power supply: Basic consumption

Mounting Procedure

All Saitel DR modules have a DIN-rail bracket at the rear side that allows mounting on a DIN rail.

1

Basic consumption and Maximum current per signal values are indicated in the technical specifications table at

the end of this manual.

Pag 22

Page 23

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Figure 11 – Mount bracket on DIN rail.

The mounting procedure is described below:

• Switch off the power supply.

• Attach the module’s rear bracket on the upper DIN rail.

• Press the lower front panel gently until a click confirms that the bracket is fit on the rail.

• Verifying the module is anchored firmly to the rail, although lateral movement is possible.

Figure 12 –

Saitel DR module on a DIN rail.

The module is dismounted from the DIN rail as follows:

• Switch off the power supply.

• If necessary, disconnect the bridge(s) connecting the module to the system bus.

• Holding the module by the front panel, push the upper metal tab downward. The user can also pull the tab down

using for example a screwdriver as shown in the next figure.

• Figure 13 – Remove module.

•

•

• Pressing the tab, remove the module from the lower DIN rail.

• Once detached, the module can be removed easily.

Wiring AB_AI

The AB_AI analog inputs are differential, so there is no common terminal. Each terminal block

includes 4 pairs of signals which correspond to the 4 analog inputs.

Pag 23

Page 24

20/03/2020

User Manual – AB_AI

R&D Digital Seville

INFORMATION

Current inputs require a 250Ω resistor and a 0.1% precision between the two input

terminals.

This figure illustrates the pins arrangement in the AB_AI screw terminals:

Figure 14 – B1 and B2 terminal blocks wiring.

Wiring Recommendations

The following table shows several wiring recommendations for signals and polarization:

Analog inputs 7 mm

Analog Input Connection

Both B1 and B2 have 4 terminals for signals. The field inputs are voltage-free NO (Normally open)

contacts.

Figure 15 – B1 and B2 terminal blocks wiring.

2.5 mm²

13 AWG

0.5 Nm Copper

Type of wire

The 8 signals wiring in each terminal block is described below:

Figure 16 – Analog inputs wiring.

Pag 24

Page 25

User Manual – AB_AI

20/03/2020

R&D Digital Seville

LED

Status

Description

Recommended action

LED Indicators

The AB_AI module has the following indicators on the front panel:

Figure 17 – LED indicators.

Run

Out R

Fail

AB_AI LED provide the following information to the operator:

Table 1 - AB_AI - LED indicators meaning

Module working properly.

Module not in acquisition mode.

A signal is out of range. Check the range of the signals

Signals are in range.

Module not configured or in abnormal state.

No fault has been detected in configuration or

hardware.

Failure in EEPROM.

The module wasn’t included into the

configuration, the module doesn't have an

address or according to the loaded

configuration, the type of the module is wrong.

Check the configuration loaded in the HU. The

module must be addressed and with the

correct type (AB_AI).

Mnt

The module is in maintenance (Flashing,

addressing, ...)

The module is in operation.

Pag 25

Page 26

20/03/2020

User Manual – AB_AI

R&D Digital Seville

4 Configuration & Maintenance

Pag 26

Page 27

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Content

4 CONFIGURATION & MAINTENANCE .................................................................... 26

ITB CONFIGURATION .............................................................................................. 28

AB_AI CONFIGURATION ........................................................................................ 30

INFORMATION OF LOCAL ACQUISITION ............................................................. 31

AB_AI SIGNALS .............................................................................................. 32

LOCAL ACQUISITION COORDINATES ................................................................ 32

INFORMATION IN THE TABLE ANALOG .............................................................. 33

SIGNAL CALIBRATION ............................................................................................ 34

SIGNAL CALIBRATION USING A BASIC HU ........................................................ 34

SIGNAL CALIBRATION USING A HU_A OR HU_AF ............................................ 36

SIGNAL CALIBRATION USING A HUE ................................................................ 37

MAINTENANCE OF MODULE VIA WEB ..................................................................... 39

WEBAPP VS WEBTOOL .................................................................................. 39

USING WEBAPP ............................................................................................. 39

USING WEBTOOL ........................................................................................... 45

FIRMWARE UPDATE ............................................................................................... 49

Pag 27

Page 28

20/03/2020

User Manual – AB_AI

R&D Digital Seville

INFORMATION

To perform the operations described in this chapter, the user must be familiar with the Easergy

ITB configuration

Builder tool. Otherwise, please refer to the tool's manual.

In the Workspace of Easergy Builder, create a new RTU using button or pressing right button

of the mouse in an empty area of the rtus tree:

Figure 18 – Adding a new RTU.

Pressing button next to the graphical ITB, you can add, remove or change the I/O modules

included on the default configuration.

The user needs understand some basic concepts about Saitel DR before configuring the

acquisition:

• An ITB is a set of acquisition blocks connected to a CPU (HU).

• An Acquisition Block or AB is a Saitel DR input/output module.

• Each acquisition block is allocated to a unique address in the ITB, the Node Number; this

number identifies both the module and its type.

• The procedure AAP (Automatic Addressing Procedure) is performed by the operator

every time an AB module is added, deleted, replaced or moved inside the ITB. It can be

launched manually or automatically depending on the configuration switches of the HU

(consult user manual of the HU).

Figure 19 – ITB.

Pag 28

Page 29

User Manual – AB_AI

20/03/2020

R&D Digital Seville

The number between parentheses next to each module's name is the node number. You can

select an AB and use buttons to change its physical position.

When “Auto Address” box is checked (by default), if you reorder, add or delete an AB, all

addresses are automatically recalculated matching their physical position in the rail. Address

number 1 is assigned to the AB closest to the HU module (for HU_AF or HU_BI, address number 1

will be attached to the HU itself).

If “Auto Address” box is unchecked, modules will retain the allocated address, ignoring any

changes made. If rechecked, the following message will appear:

Figure 20 – Auto Address.

Select an AB (click on the AB image) and use button to remove it. Use button to add a new

AB. Select the type of AB in the following window:

Figure 21 – Adding an AB module.

If “Auto Address” is checked, you can add several AB at one time. This window allows selecting

the quantity of modules to be added. If “Auto Address” in unchecked, you only can add one AB

each time and you have to select the address to be assigned.

To create a new configuration, select RTU in the tree and pulse right button of the mouse or use

button.

Figure 22 – Adding a configuration.

Pag 29

Page 30

20/03/2020

User Manual – AB_AI

R&D Digital Seville

If the field "Create acquisition points defined in the RTU" is marked, all points of the local

acquisition of the acquisition blocks included in the default acquisition configuration associated with

the RTU will be included in coreDb.

For example, if a HUe has an ITB with an AB_AI module, if "Create acquisition points defined in

the RTU", 8 analog inputs signals will be included in the Analog table.

Finally, the new configuration will appear in the RTUs tree.

Access to the configuration edition clicking on the configuration name in the tree:

Figure 23 – Configuration edition

Double click on the claq Device open the window to configure/modify the ITB.

Selecting the module AB_AI, you can configure each field signal

Figure 24 – Changing the ITB configuration.

Other buttons in this window are explained in the user manual of Easergy Builder.

AB_AI Configuration

The local acquisition Device for Saitel DR is named “claq”. The main functionality of the Local

Acquisition Device Controller is supporting the communication between the inputs and the outputs

managed by the acquisition blocks and coreDb points.

The first step to configure the acquisition settings is to assure that the ITB in the graphical interface

is according to the system. Each module must be addressed according its position in the ITB.

Pag 30

Page 31

User Manual – AB_AI

20/03/2020

R&D Digital Seville

INFORMATION

The graphical interface does not take into account if the ITB is assembled in one or multiple

rows. The modules should always be added in the adequate order, regardless the number of

TU-XU modules that we have installed.

Figure 25 – Configuring local acquisition for Saitel DR.

Information of Local Acquisition

The following figure shows the relationship between the field information received by the AB_AI

module and the related points in coreDb:

Figure 26 – Field signals and points in coreDb.

Pag 31

Page 32

20/03/2020

User Manual – AB_AI

R&D Digital Seville

AB_AI signals

The following figure shows the configuration panel when the ITB is composed by an HUe and one

AB_AI module with address 1:

Figure 27 – AB_AI field signals.

Select the module in the ITB and all its field signals are shown (marked in red).

The first position of each row corresponds with the signal’s description (AI_PNT_1 ... AI_PNT_8).

In coreDb, each signal will be identified using its coordinate. (see paragraph 3.2.2).

Each signal has the following associated information:

• EMin: Minimum value expressed in field units (from -32768 to 32767).

• EMax: Maximum value expressed in field units (from -32768 to 32767).

• Rng: Voltage range expressed in engineering units (0/5 V, -5/5 V, 0/20 mA, -20/20 mA, and

4/20 mA).

• Filt: Mobile measuring filter (expressed as a percentage value, 0 - total filtering and 100 - no

filtering).

• Zero: Zero cancellation (expressed in scaled values)

Local Acquisition Coordinates

Each digital input is identified in coreDb by a name (it is stored in the field Description), but this

name is only used for information purpose. coreDb uses the signal’s coordinate in order to identify

a field signal.

A claq coordinate is a numerical identifier of 10 digits with the following structure:

Where:

• 1: First digit of the coordinate. In local acquisition signals, it must always be 1.

• XXX: Number that identifies the acquisition block. For the HUe signals, it will always be 000.

For the rest of the ABs, this number will correspond with the address of the module.

1XXXYYZZZZ

Pag 32

Page 33

User Manual – AB_AI

20/03/2020

R&D Digital Seville

• YY: Type of signal. For digital input could be:

o 02: Simple digital input.

o 03: Count.

o 07: Double digital input.

• ZZZZ: Position of the signal in the module.

Information in the Table Analog

Each AB_AI signal is associated to a coreDb register in the analog table using its claq coordinate

as source:

Figure 28 – Information of analogical inputs in CoreDb.

These points and other diagnostic points (D001_COMM_DIAG and D001_HW_DIAG) can be

created automatically when the module is included in the ITB, but they can be created manually

using the claq’s wizard.

In order to include a point manually, please create a new point, select claq as Source Device, click

right-button on the field Source Device and select Launch Point wizard:

Figure 29 – Point wizard.

Pag 33

Page 34

20/03/2020

User Manual – AB_AI

R&D Digital Seville

INFORMATION

Select the module in which it wants to create these points and then select the point to be created.

Only not created point will be shown in the list.

The following point can be added for a AB_AI module:

• Status, Source Coordinates:

o Diagnostics point:

• Analog, Source Coordinates:

o Analog Inputs: Analog inputs, depend on the configuration performed.

Signal Calibration

The AB_AI analog inputs are calibrated in factory. Nevertheless, the user may calibrate each signal

to meet the environment requirements.

COMM_DIAG: Status of the communication with the HU. 0 “Communication

FAIL”, 1 “Communication OK”.

HW_DIAG: Hardware diagnostic. 0 No problem detected, 1 Problem

detected in the hardware.

• The user must assure that the calibration device is similar to the device recommended by

Schneider Electric, in particular the calibrator Fluke 725. The device should be able to generate

voltages ranging from 0V to 10V with a precision lower than 0.1%.

• Signal calibration can be performed in the field, while the ITB is under a normal data acquisition

state. During calibration, all modules will operate normally, except for the module under calibration.

The calibration method depends on the HU type which controls the ITB. If the CPU is an advanced

HU (HU_A, HU_AF), Saitel Webtool is used to calibrate. If the CPU is a Hue, Saitel WebApp is

used. When the CPU module is a basic HU (HU_B), the calibration process is performed using the

console.

The calibration is done separately for each channel.

Signal Calibration Using a Basic HU

1. The user needs to connect the PC to the HU module through the CON port (console channel).

For further details about the connection, please refer to the CPU manual.

2. For each analog input, the user must execute the “claqCalAi N C” command, where N refers

tclao the AB_AI module's number within the ITB (can be obtained by entering the “claqShow”

command in the console) and C refers to the signal number within the module, where

1<=C<=8.

3. After executing the calibration command, for example on the 2

(signal 2) of the module number 1, the following message will appear:

nd

signal of the B1 terminal block

4. When the calibrator is connected to terminals AI2+ (red cable) and AI2- (black cable), the

system will wait for it to supply 0V. Then, the user needs to press any key. Subsequently, the

system asks the user to wait while specific calculations are made.

5. Once a 0V level is registered, the system requests a 5V level voltage to be injected and to

press any key:

Pag 34

Page 35

User Manual – AB_AI

20/03/2020

R&D Digital Seville

NOTICE

6. The system will repeat the operations and calculations for this voltage level. Once finished, it

will display a message to inform that the analog input has been calibrated:

The calibration values depend on the signal range assigned in the configuration tool (see section

3.2).

For example, if the input 1 of the AB_AI module, which is in the position 1, is configured in the

range 0/20 mA, the messages exchanged with the user during the calibration process are:

In the case of calibrating current inputs, it will be necessary to place a 250Ω resistor between the

positive and the negative pin, so that by injecting current with the calibrator, the voltage between

the two input terminals is lower than 5V.

Factory calibration values can be restored individually for each signal at any time. To do so,

execute the “claqRestCalAi N C” command, where N refers to the module number and C refers to

the signal number in the module. For example, to restore the factory values for the previous signal

(input 1), follow the procedure below:

• It should be noted that even if the signal is configured for current (0/20 mA), the factory

calibration is done for voltage values, and these are the retrieved values. Therefore, the resistor

tolerances, which convert current to voltage, are not calibrated.

• Schneider Electric recommends a 250Ω resistor with 0.1% tolerance in order to maximize the

resolution of the analog to digital converter

Pag 35

Page 36

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Signal Calibration Using a HU_A or HU_AF

If the CPU is a HU_A or HU_AF, to calibrate AB_AI, Saitel WebTool must be used.

In WebTool, go to Bins section and click on “claq”. You will see a table with the correspondent

signals.

Figure 30 – Saitel WebTool Menu.

For example, following picture shows a tab corresponding to an AB_AI module.

Figure 31 – Claq Device in Saitel WebTool.

To calibrate a specific AB_AI module, press “Calibrate” button on the table. Then, the following

screen appears:

Figure 32 – AB_AI module calibration.

Each input must be calibrated separately, by pressing the “Start” button which is associated to

each signal in the “Calibration” column.

Pag 36

Page 37

User Manual – AB_AI

20/03/2020

R&D Digital Seville

When calibration starts, the following message is shown:

When the calibrator is connected to terminals AI1+ (red cable) and AI1- (black cable), the system

will wait for the calibrator to supply 0 V. Then, press “Ok”. Subsequently, the system asks the user

to wait while the input is calibrated for 0 V.

Then, the following message is shown:

As described for the previous step, supply 5 V through the calibrator and then press “Ok”. The

system will start the calibration for this voltage level.

When the operation finishes, the following message will appear:

The calibration values depend on the signal range assigned in Easergy Builder.

Factory calibration values can be restored at any time for individual signals. To do so, press the

“Restore” button associated to the channel in the table. You will be prompted to confirm or cancel

the operation.

Signal Calibration Using a HUe

If the CPU is a HUe, to calibrate AB_AI, Saitel WebApp must be used. The recommended web

browser is Google Chrome (version 67.0.3396.99).

In WebApp, go to Maintenance section and click in “Acquisition”. You will see a table with the

correspondent signals. If the permissions set for the user allows it, these points van be calibrated.

Figure 33 – Saitel WebApp Menu.

Pag 37

Page 38

20/03/2020

User Manual – AB_AI

R&D Digital Seville

For example, following picture shows a tab corresponding to a AB_AI module. All its signals are

displayed with the value and quality information.

Figure 34 – AB_AI module calibration.

To start the calibration of an analog input, just click on the “calibrate” button for the signal to

calibrate. A window will pop with the instruction that the user must follow. Please take into account

that if the point has no good quality or it is blocked, calibration will not start.

Press “Yes” to continue or “No” to cancel the process.

If the analog point cannot be calibrated, following message will be shown:

Pag 38

Page 39

User Manual – AB_AI

20/03/2020

R&D Digital Seville

INFORMATION

WebApp has been designed to work only with cybersecurity brick. At now, it can be used only

Maintenance of Module via WEB

WebApp Vs WebTool

WebApp and Webtool are remote user interfaces for consulting, monitoring and maintenance

tasks. Once the username and password have been entered, you can access to the main window

and, depending on the web tool, several sections are available.

with HUe. HU_A and HU_AF use Webtool, while HU_B doesn’t allow a remote connection using

a webserver.

When use WebApp, the following message is shown previously to access the tool:

Figure 35 – Disclaimer information.

Please, read this information and take it into account.

In this manual, only the information about AB_AI is shown. For more information about these tools,

please, consult the user manual for each one.

Using WebApp

Saitel WebApp has an access control that allows differentiating the users who are able to connect.

To get the window access, please write https://< CPU IP address> in the navigation address bar.

Figure 36 – Access screen

Write the Username and Password in orfer to access the webAppp’s mains window:

Pag 39

Page 40

20/03/2020

User Manual – AB_AI

R&D Digital Seville

This screen contains 5 menus:

• Home

Home tab

• Monitoring & Control

• Diagnostic

• Maintenance

• Settings

Select Home in the main toolbar and the following information is shown.

Figure 37 – Home view.

Pag 40

Page 41

User Manual – AB_AI

20/03/2020

R&D Digital Seville

S

ome of this information can be filled in by the user.

• Device Information. It is possible to add the names of the operators who have used or

configured the equipment or a specific custom note that can be viewed each time a connectio

i

s established to this RTU. This information can be changed using button “Edit”, next to “Devic

i

nformation”.

• Location. The GPS coordinates for the RTU location (place, latitude, longitude, and altitude)

should be entered here by the installer. Location is not set automatically. The image must

i

ncluded manually by clicking button on the map.

be

n

e

• Image associated to the RTU. It could be useful to include a location map corresponding to t

G

PS coordinates. Use button on the graphic zone to do it.

• Notes. This zone allows the user to include notes that are shown to other users. Use butt

• Factory information: This zone shows the manufacturer, model and the version of t

software loaded on the HU module. Using button next to the text “Factory Information”, it is

also possible to include an image of the particular RTU or CPU for identification purposes.

This screen contains other menus:

• Monitoring & Control

• Diagnostic

• Maintenance

• Settings

This manual only includes relevant information for AB_AI. For more information about webApp,

please, consult the webApp user manual.

Monitoring and Control

This menu is used to monitor and control the information regarding to system status and coreDb

points.

t

oo add new notes.

he

on

he

Select “Monitoring & control System information” and the following information the system is

displayed or not depending on whether the corresponding monitoring point was included or not in

coreDb. In the following image, for each data, the supervision point that must be included in

coreDb is indicated in a blue square.

Pag 41

Page 42

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Figure 38 – Monitoring and Control view – System information

Please take into account that the correspondent supervision points must be installed, otherwise,

you will see a warning like the one in the example above (PLC information not available).

For an AB_AI module, the showed points are the followings:

Figure 39 – Monitoring and Control – Status.

Figure 40 – Monitoring and Control – Analog.

Pag 42

Page 43

User Manual – AB_AI

20/03/2020

R&D Digital Seville

For all types of points, each page has the same format. If the user locks the signal and click in

in the “value” column, the value of the correspondent signal can be changed.

If the user locks the signal and click in in the “quality” column, the value of the correspondent

signal can be changed.

Each code of quality bit has a different meaning. See next tables to know the description of each

one.

Table 2 - Local quality bits

Values (Hexadecimal) Description

0x00000000 OK

Pag 43

Page 44

20/03/2020

User Manual – AB_AI

R&D Digital Seville

NOTICE

If more than one error is detected for a signal, the hexadecimal value monitored for quality bits

been a carry on a counter or a roll-over. The value 0x00000003 would appear monitored.

Values (Hexadecimal) Description

0x00000001 There has been an overflow

0x00000002 There has been a carry on a counter or a roll-over.

0x00000004 There has been a counter adjustment.

0x00000008 Excessive changes in a digital input.

0x00000010 Locked Point (blocked)

0x00000020 Point manually replaced (manual)

0x00000040 The point has not yet been written into the database (No refresh)

0x00000080 Invalid value (Error)

0x00000100 The value of the item has exceeded Highest Limit Alarm.

0x00000200

The value of the item has exceeded High Limit Alarm.

0x00000400 The value of the point has fallen down of Low Limit Alarm.

0x00000800

The value of the point has fallen down of Lowest Limit Alarm.

0x00001000 Invalid time.

Table 3 - Quality bits from the Device

Values (Hexadecimal) Description

0x00000000 OK

0x00010000

0x00020000

0x00040000

0x00080000

0x00100000

0x00200000

There has been an overflow.

There has been a carry on a counter or a roll-over.

There has been a counter adjustment.

Excessive changes in a digital input.

Locked Point.

Point manually replaced.

0x00400000

0x00800000

The point has not yet been written into the database.

Invalid value.

0x10000000 Invalid time.

will result from the sum of all. For example:

0x00000001 indicates that an overflow has occurred and 0x00000002 indicates that there has

Pag 44

Page 45

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Using WebTool

Saitel Webtool is the tool used for maintenance and monitoring of Saitel RTUs which is supplied

with the baseline software platform. The values of all the coreDb signals in real-time can be

monitored through the Saitel Webtool as well as the quality data related to these values.

Saitel Webtool has an access control that allows differentiating the users who are able to connect.

To get the window access, please write https://< CPU IP address> in the navigation address bar.

If the browser has been correctly configured, and the remote equipment is connected to the PC,

the login window will prompt:

Figure 41 – Login window of Saitel Webtool.

nce the username and the password are introduced in the login window, the main workspace is

O

displayed:

Figure 42 – Initial screen of Saitel Webtool.

This window shows:

• Information about the user who opened the session (Login: admin).

• Button “Exit” in order to close the current session.

• It is possible to select the language through the field “Language”.

• The main menu is located on the left side of the screen. Each button gives access to all t

nformation of the RTU:

i

he

o Information: General information about the CPU configuration.

Pag 45

Page 46

20/03/2020

User Manual – AB_AI

R&D Digital Seville

o Monitoring: Gives access to the coreDb tables and the values for each register

and field.

o Bins: Gives access to the devices that have been configured in the RTU.

Information

o Network configuration: Gives information about the physical devices an

r

ooters.

Clicking Information on the main menu, you can see general information about the system.

The following real-time information can be monitored on this menu:

• System’s Configuration

• Hardware Status

• Synchronization Status

• Software Versions

• Figure 43 – Information section

d

Monitoring

The top area of the screen includes the following information for any signal type (go to “Monitoring

Status”, “Monitoring Command”, “Monitoring Analog” or “Monitoring Setpoint”):

For each kind of modules, the information will be included in different tables. In the case of the

AB_AI module, the information for the acquisition points can be found in the Status and Analog

screen.

In the status table, two signals are automatically created.

COMM_DIAG: CPU diagnosis communication variable. 0 the module cannot communicat

w

ith the CPU. 1 the module is communicating properly with the CPU.

e

HW_DIAG: Auto diagnosis hardware variable. 0 the module is correct. 1 the module has some

hardware problem.

Figure 44 – Status monitoring screen.

Pag 46

Page 47

User Manual – AB_AI

20/03/2020

R&D Digital Seville

NOTICE

If the value of the quality bit associated to the signal is “Unrefreshed” (0x00000040) or “Invalid”

(0x00000080), the signal value will be “???”.

In the analog table, the analog acquisition points can be monitored.

Figure 45 – Analog monitoring screen.

The information available for all types of signals is the following:

• Point name: Signal's name in coreDb.

• Value: Current value of the signal. This value is retrieved from the signal’s source and it is

updated in Saitel Webtool according to the refresh period specified in the RT field.

• QF: Current quality flags of the value displayed for this signal

Clinking in “Set”, the value and the quality flag can be modified.

Figure 46 – Set Value screen.

Pag 47

Page 48

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Each code of quality bit has a different meaning. See next tables to know the description of each

one.

Table 4 - Local quality bits

Values (Hexadecimal) Description

0x00000000 OK

0x00000001 There has been an overflow

0x00000002 There has been a carry on a counter or a roll-over.

0x00000004 There has been a counter adjustment.

0x00000008 Excessive changes in a digital input.

0x00000010 Locked Point (blocked)

0x00000020 Point manually replaced (manual)

0x00000040 The point has not yet been written into the database (No refresh)

0x00000080 Invalid value (Error)

0x00000100 The value of the item has exceeded Highest Limit Alarm.

0x00000200

The value of the item has exceeded High Limit Alarm.

0x00000400 The value of the point has fallen down of Low Limit Alarm.

0x00000800

The value of the point has fallen down of Lowest Limit Alarm.

0x00001000 Invalid time.

Table 5 - Quality bits from the Device

Values (Hexadecimal) Description

0x00000000 OK

0x00010000

0x00020000

There has been an overflow.

There has been a carry on a counter or a roll-over.

Pag 48

Page 49

User Manual – AB_AI

20/03/2020

R&D Digital Seville

NOTICE

If more than one error is detected for a signal, the hexadecimal value monitored for quality bits

been a carry on a counter or a roll-over. The value 0x00000003 would appear monitored.

0x00040000

0x00080000

0x00100000

0x00200000

0x00400000

0x00800000

0x10000000 Invalid time.

will result from the sum of all. For example:

0x00000001 indicates that an overflow has occurred and 0x00000002 indicates that there has

Firmware Update

There has been a counter adjustment.

Excessive changes in a digital input.

Locked Point.

Point manually replaced.

The point has not yet been written into the database.

Invalid value.

Once the ITB is configured, the HU module (HU_A or HU_B) already knows the type of acquisition

blocks that are been installed and their corresponding addresses.

To update the software of the AB_AI module, you need:

• A console connection with the HU.

• AB_AI module must be correctly addressed and working fine in the ITB (LED Run must be

blinking).

• AB_AI.bin file with the new version. This file must be available in the flash folder of the HU. If

not, you can contact Schneider Electric in order to ask for it. Use an SFTP client and transfer

this binary file into the HU flash folder.

The console tool can be executed using any commercial tool for serial or SSH connection. In this

manual, PuTTy software is used.

Open a serial connection as follow:

Figure 47 – Putty configuration.

Pag 49

Page 50

20/03/2020

User Manual – AB_AI

R&D Digital Seville

INFORMATION

If the baseline includes the cybersecurity brick, you need to login in the console with Installer.

for more information.

Module

File

Command

Description

INFORMATION

Console commands are case-sensitive, and quotation marks must be included.

SSH connection via Ethernet can be used too. More information about the console use in the HU

user manual. In the following picture, HUe is used as CPU:

Figure 48 – SSH connection.

No other user has permissions to execute this operation. Please, consult the HU user manual

If the file AB_AI.bin is available in the flash folder, use one of the following commands to upgrade

the software of AB_AI modules:

Table 6 – Upgrading AB_AI software.

All modules *.bin claqUpgrade “all” It updates all the acquisition AB

addressed in the ITB. You need to

use the adequate file for each block.

By position AB_AI.bin claqUpgrade “<position>” It updates the module AB_AI with

the <position> address.

AB_AI AB_AI.bin claqUpgrade “all AB_AI” It updates all the AB_AI modules

installed in the ITB.

Pag 50

Page 51

User Manual – AB_AI

20/03/2020

R&D Digital Seville

After running the command, the console will show some messages indicating the process status.

Finally, if no problem is found, we will have updated the firmware of the modules.

Pag 51

Page 52

20/03/2020

User Manual – AB_AI

R&D Digital Seville

5 Technical Specifications Table

Pag 52

Page 53

User Manual – AB_AI

20/03/2020

R&D Digital Seville

• ±20 mA / 0 - 20 mA / 4 - 20 mA

Ordering Options

CE Mark

LVD – Low Voltage Directive

Directive 2014/35/UE

EMC – Electromagnetic Compatibility

Directive 2014/30/UE

RoHS 2

Directive 2011/65/EU, according to RD 219/2013

Equipment

Verification of Lead, Cadmium, Mercury, Chrome

and Bromine

Cold - EN 60068-2-1:2007

-20ºC during 16h (100h)

Dry heat - EN 60068-2-2:2007

+80ºC during 16h (100h)

Damp heat - EN 60068-2-30:2005

25-60ºC with 95%RH during 24h

Features

Hardware Signal type. Differential

Input type Voltage from factory

Current, using an external resistor (250 Ω)

Converter 16-bits sigma-delta

Accuracy Better than 0.1% at 25 ºC

Input impedance 200 kΩ

Voltage tolerance in common mode > 15 V

Field connection. Terminal / Flat ribbon.

Consumption 0.6 W

Weight 427 g

Dimensions 129 x 94 x 60 mm

Protection Overvoltage

Software Processing Digital filtering.

Scaling to engineering units.

Range limits detection.

Value change detection.

Zero value cancellation.

Common mode rejection ratio. 90 dB

Parameterization Configurable range by channel:

• ±5 V

DC

/ 0 - 5 VDC.

Standards, Directives and

harmonized norms.

WEEE – Waste Electrical and Electronic

RoHS Directive 2011/65/UE

Environmental tests

Directive 2012/19/UE according to RD 110/2015

Pag 53

Page 54

20/03/2020

User Manual – AB_AI

R&D Digital Seville

EMC Directive

EN 60870-2-1 (1996)

IEC/TS 61000-6-5 (2015)

EN 55022:2006 + A1:2007

From 30 to 1000 MHz (Class A)

EN 55022:2006 + A1:2007

From 0.15 to 30 MHz (Class A)

EN 61000-4-2:2009

By air ±8 kV and by contact ±6 kV (Level 3)

EN 61000-4-3:2006 + A2:2010

From 80 to 2700 MHz (Level 3).

Power port: ±4 kV, 5kHz.

I/O ports: ±4 kV 5kHz (Level 4).

Power: ±4 kV symmetric and asymmetric (Level 4)

I/O: ±4 kV CM, ±2 kV DM

EN 61000-4-6:1996 + A1:2001

10 V

RMS

0.15-80MHz 80% AM (Level 3).

EN 61000-4-8:2010.

100 A/m, 1000 A/m 3s (Level 4).

EN 61000-4-16:1998

30V 50Hz, 300V 50Hz 1s (Level 4).

EN 61000-4-18:2007 + A1:2010

Tests according to

Emission

Immunity

Radiated emissions

Conducted emissions

Electrostatic discharges (ESD)

Radiated, radio-frequency, electromagnetic field

Fast transients common mode

EN61000-4-4:2012

Surges, line to line and line to ground

EN 61000-4-5:2006

RF common mode

Power frequency magnetic field

Power frequency common mode disturbances

Damped Oscillatory wave

Communications ports: ±4 kV 5kHz and 2.5kHz.

Power: ±4 kV, 5kHz.

Communications: ±4 kV CM, ±2 kV DM (Level 4).

Power, Communications and I/O:

1kV DM, 2.5kV CM (Level 4), (f=1MHz)

Pag 54

Page 55

User Manual – AB_AI

20/03/2020

R&D Digital Seville

Index of Figures

Figure 1 – Barrier of protection for elements with dangerous voltages. ....................................................................... 9

Figure 2 – Yellow and Green cable for earthing. ........................................................................................................ 10

Figure 3 – Terminal for functional earth (EMC). ......................................................................................................... 11

Figure 4 – Example of earthing for EMC. ................................................................................................................... 11

Figure 5 – Technical label. .......................................................................................................................................... 13

Figure 6 – Saitel DR. .................................................................................................................................................. 17

Figure 7 – Functional block diagram........................................................................................................................... 18

Figure 8 – AB_AI Module ............................................................................................................................................ 18

Figure 9 – AB_AI P/N description. .............................................................................................................................. 19

Figure 10 – AB_AI - Hardware block diagram ............................................................................................................ 19

Figure 11 – Mount bracket on DIN rail. ....................................................................................................................... 23

Figure 12 – Saitel DR module on a DIN rail. .............................................................................................................. 23

Figure 13 – Remove module. ..................................................................................................................................... 23

Figure 14 – B1 and B2 terminal blocks wiring. ........................................................................................................... 24

Figure 15 – B1 and B2 terminal blocks wiring. ........................................................................................................... 24

Figure 16 – Analog inputs wiring. ............................................................................................................................... 24

Figure 17 – LED indicators. ........................................................................................................................................ 25

Figure 18 – Adding a new RTU. ................................................................................................................................. 28

Figure 19 – ITB. .......................................................................................................................................................... 28

Figure 20 – Auto Address. .......................................................................................................................................... 29

Figure 21 – Adding an AB module. ............................................................................................................................. 29

Figure 22 – Adding a configuration. ............................................................................................................................ 29

Figure 23 – Configuration edition ................................................................................................................................ 30

Figure 24 – Changing the ITB configuration. ............................................................................................................. 30

Figure 25 – Configuring local acquisition for Saitel DR. ............................................................................................ 31

Figure 26 – Field signals and points in coreDb. ........................................................................................................ 31

Figure 27 – AB_AI field signals. .................................................................................................................................. 32

Figure 28 – Information of analogical inputs in CoreDb. ............................................................................................ 33

Figure 29 – Point wizard. ............................................................................................................................................ 33

Figure 30 – Saitel WebTool Menu. ............................................................................................................................. 36

Figure 31 – Claq Device in Saitel WebTool. ............................................................................................................... 36

Figure 32 – AB_AI module calibration. ....................................................................................................................... 36

Figure 33 – Saitel WebApp Menu. .............................................................................................................................. 37

Figure 34 – AB_AI module calibration. ....................................................................................................................... 38

Figure 35 – Disclaimer information. ............................................................................................................................ 39

Figure 36 – Access screen ......................................................................................................................................... 39

Figure 36 – Home view. .............................................................................................................................................. 40

Figure 38 – Monitoring and Control view – System information ................................................................................. 42

Pag 55

Page 56

20/03/2020

User Manual – AB_AI

R&D Digital Seville

Figure 39 – Monitoring and Control – Status. ............................................................................................................. 42

Figure 36 – Monitoring and Control – Analog. ............................................................................................................ 42

Figure 41 – Login window of Saitel Webtool. ............................................................................................................. 45

Figure 42 – Initial screen of Saitel Webtool. ............................................................................................................... 45