Page 1

Modicon M172 Logic Co ntroller

EIO0000002015 02/2020

Modicon M172 Logic Controller

Hardware Guide

Original instructions

02/2020

EIO0000002015.04

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000002015 02/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part I Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 M172 Range Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Modicon M172 Logic Controller Offer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Range Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Modules Range Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Modules Range Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Display Range Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II Global Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Before Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Before Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Wiring Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

TM172•••07• / TM172•••18• Controllers Mounting Positions . . . . . . . . . . . . . . . . . . . . . . . . .

TM172•••28•• / TM172•••42•• Controllers Mounting Positions. . . . . . . . . . . . . . . . . . . . . . . .

TM172E••R Expansion Modules Mounting Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controllers and Expansion Modules Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top Hat Section Rail (DIN Rail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controllers and Expansion Modules Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172DCLWT•• Remote Display Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172DCLF• Remote Display Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III Controllers and Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Environmental Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 TM172P•••••• / TM172O••••• Controllers Description . . . . . . . . . . . . . . . . . 55

TM172P•G07R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172P••18• / TM172O••18• . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172P••28•• / TM172O••28R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172P••42•• / TM172O••42R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 TM172E••R Expansion Modules Description . . . . . . . . . . . . . . . . . . . . . . . 67

TM172E12R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172E28R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Electrical Characteristics and Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . 73

8.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fast Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regular Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Digital Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High voltage Relay SPST Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Voltage Solid-State Relay Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High voltage Relay SPDT Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

16

17

19

20

21

23

25

27

31

38

39

40

41

42

45

47

48

51

53

56

58

61

64

68

70

75

75

78

79

80

82

83

86

87

EIO0000002015 02/2020 3

Page 4

8.4 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NTC Analog Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistive Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input Used as Digital Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWM Open Collector Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Voltage (SELV) Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current ON/OFF Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN Expansion Bus Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

USB Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 RTC (Real-Time Clock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTC (Real-Time Clock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

TM172PD••••• / TM172OD•••• User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV Remote Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10 Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 11 TM172DCL•••• Remote Display Description. . . . . . . . . . . . . . . . . . . . . . . . . 125

TM172DCLWT••. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM172DCLF• . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 12 Electrical Characteristics and Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . 129

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Embedded Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Modbus Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part V Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 13 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Module Parameters Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Color Touchscreen Parameters Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part VI Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 14 EcoStruxure Machine Expert - HVAC software . . . . . . . . . . . . . . . . . . . . . . 167

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 15 Controller Connection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

First Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection with a PC Through Modbus SL/USB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection with a USB Memory Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection with a PC Through Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 16 Expansion and Remote Display Connection Types . . . . . . . . . . . . . . . . . . . 175

Connection Expansion Module and Remote display with a PC . . . . . . . . . . . . . . . . . . . . . . .

Chapter 17 BIOS Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Controller Update BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

89

90

93

94

95

96

97

98

99

100

101

102

103

104

105

109

111

112

115

115

117

117

119

121

123

126

127

130

131

132

133

136

138

152

161

165

167

170

172

173

174

175

177

179

4 EIO0000002015 02/2020

Page 5

Appendix A Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

NTC 10k beta 3435 Resistance Temperature Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NTC 10k-2 beta (25/50) 3977 Resistance Temperature Table . . . . . . . . . . . . . . . . . . . . . . .

Pt1000 Resistance Temperature Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

182

184

186

189

193

EIO0000002015 02/2020 5

Page 6

6 EIO0000002015 02/2020

Page 7

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

Qualification of Personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying parameter values and generally from mechanical, electrical, or electronic equipment. The

qualified person must be familiar with the standards, provisions, and regulations for the prevention of

industrial accidents, which they must observe when designing and implementing the system.

EIO0000002015 02/2020 7

Page 8

Intended Use

The products described or affected by this document, together with software, accessories, and options, are

controllers, intended for commercial HVAC machines according to the instructions, directions, examples,

and safety information contained in the present document and other supporting documentation.

The product may only be used in compliance with all applicable safety regulations and directives, the

specified requirements, and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application. Based

on the results, the appropriate safety-related measures must be implemented.

Since the product is used as a component in an overall machine or process, you must ensure the safety

of persons by means of the design of this overall system.

Operate the product only with the specified cables and accessories. Use only genuine accessories and

spare parts.

Any use other than the use explicitly permitted is prohibited and can result in unanticipated hazards.

Prohibited Use

Any use other than that expressed above under Permitted use is strictly prohibited.

The relay contacts supplied are of an electromechanical type and subject to wear. Functional safety

protection devices, specified in international or local standards, must be installed externally to this device.

Liability and Residual Risks

The liability of Schneider Electric is limited to the proper and professional use of this product under the

guidelines contained in the present and other supporting documents, and does not extend to damages

caused by (but not limited to):

Unspecified installation/use and, in particular, in contravention of the safety requirements of established

legislation or specified in this document;

Use on equipment which does not provide adequate protection against electrocution, water and dust in

the actual installation conditions;

Use on equipment in which dangerous components can be accessed without the use of specific tools;

Installation/use on equipment which does not comply with established legislation and standards.

Disposal

The appliance (or the product) must be disposed of separately in compliance with the local standards in

force on waste disposal.

8 EIO0000002015 02/2020

Page 9

At a Glance

Document Scope

Validity Note

Related Documents

About the Book

This document describes the Modicon M172 Logic controllers, expansion modules, remote displays, and

accessories, including installation and wiring information.

NOTE: Read and understand this document and all related documents

(seepage9)

operating, or maintaining your controller.

This document has been updated for the release of EcoStruxure Machine Expert - HVAC V1.2.

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

.

The technical characteristics of the devices described in the present document also appear online. To

access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

Title of documentation Reference number

EcoStruxure Machine Expert - HVAC software - Operating Guide

TM172 Optimized & Performance 7/18 IO Instruction Sheet

TM172 Performance 28/42 IO Instruction Sheet

TM172 Optimized & Performance Isolated 28/42 IO Instruction Sheet

TM172 Optimized & Performance Expansion 12/28 IO Instruction Sheet

TM172DCLW••• Display Color Touchscreen Instruction Sheet

TM172DCLF• Display Color Touchscreen Flush Mounting Instruction Sheet

.

EIO0000003412 (ENG)

QGH90428

NHA87740

PHA83703

QGH26895

QGH26896

PHA38669

before installing,

You can download these technical publications and other technical information from our website at

www.schneider-electric.com/en/download

.

EIO0000002015 02/2020 9

Page 10

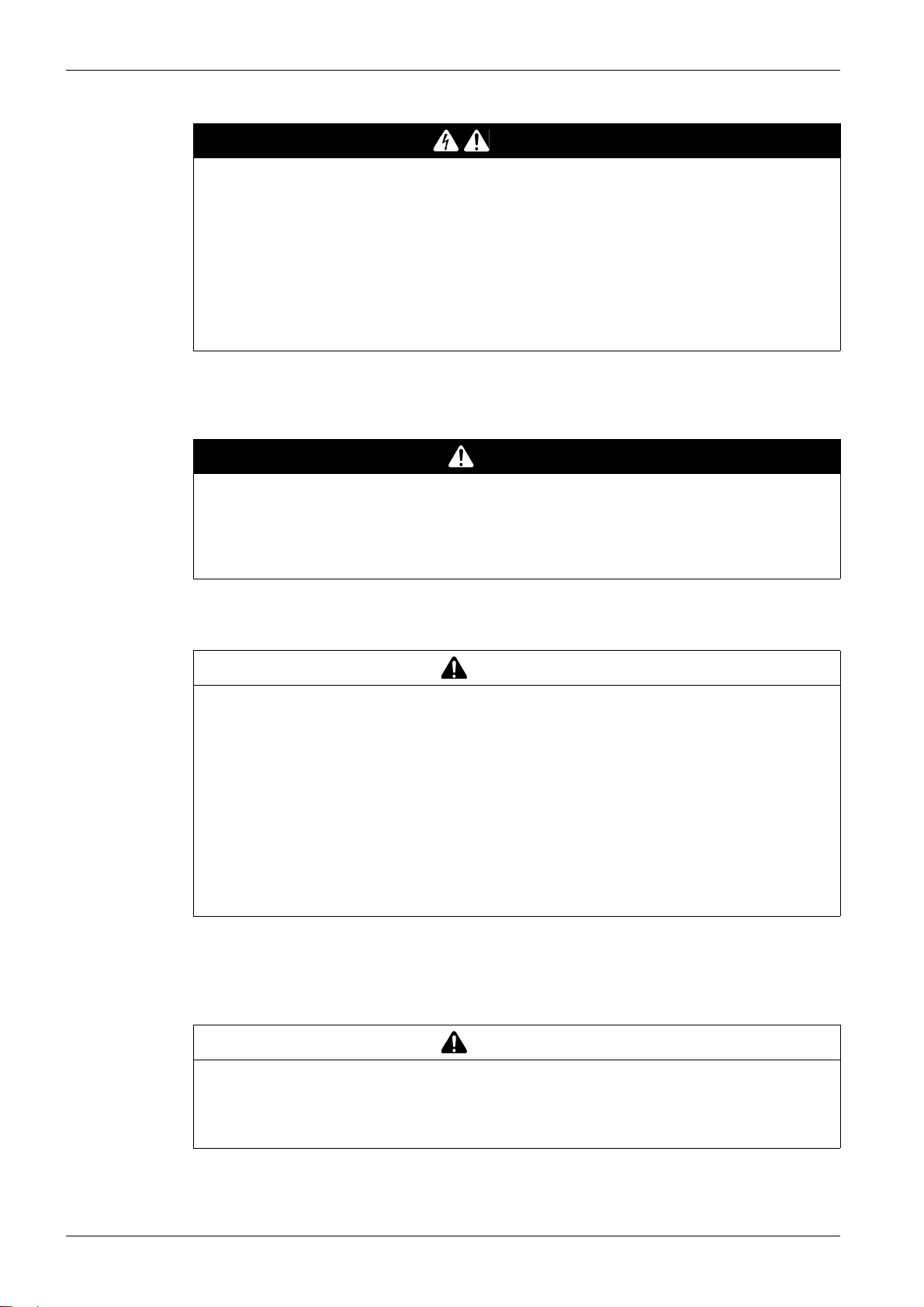

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any covers or

doors, or installing or removing any accessories, hardware, cables, or wires except under the specific

conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper

ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

This equipment has been designed to operate outside of any hazardous location, and exclusive of

applications that generate, or have the potential to generate, hazardous atmospheres. Only install this

equipment in zones known to be free, at all times, of hazardous atmospheres.

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Do not install and use this equipment in applications capable of generating hazardous atmospheres,

such as those applications employing flammable refrigerants.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

For information concerning the use of control equipment in applications capable of generating hazardous

materials, consult your local, regional, or national standards bureau or certification agency.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for certain critical control functions, provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop and overtravel stop, power outage

and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper operation

1

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest edition), "Safety

Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive

Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10 EIO0000002015 02/2020

Page 11

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or that

appear in or on the products themselves, are generally derived from the terms or definitions of international

standards.

In the area of functional safety systems, drives and general automation, this may include, but is not limited

to, terms such as

message, dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

safety, safety function, safe state, fault, fault reset, malfunction, failure, error, error

, etc.

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

In addition, terms used in the present document may tangentially be used as they are derived from other

standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

Finally, the term

zone of operation

is defined as it is for a

ISO 12100:2010

.

industrial control systems

may be used in conjunction with the description of specific hazards, and

hazard zone

or

danger zone

in the

Machinery Directive (2006/42/EC

) and

NOTE: The aforementioned standards may or may not apply to the specific products cited in the present

documentation. For more information concerning the individual standards applicable to the products

described herein, see the characteristics tables for those product references.

EIO0000002015 02/2020 11

Page 12

12 EIO0000002015 02/2020

Page 13

Modicon M172 Logic Controller

Overview

EIO0000002015 02/2020

Overview

Part I

Overview

EIO0000002015 02/2020 13

Page 14

Overview

14

EIO0000002015 02/2020

Page 15

Modicon M172 Logic Controller

M172 Range Overview

EIO0000002015 02/2020

M172 Range Overview

Chapter 1

M172 Range Overview

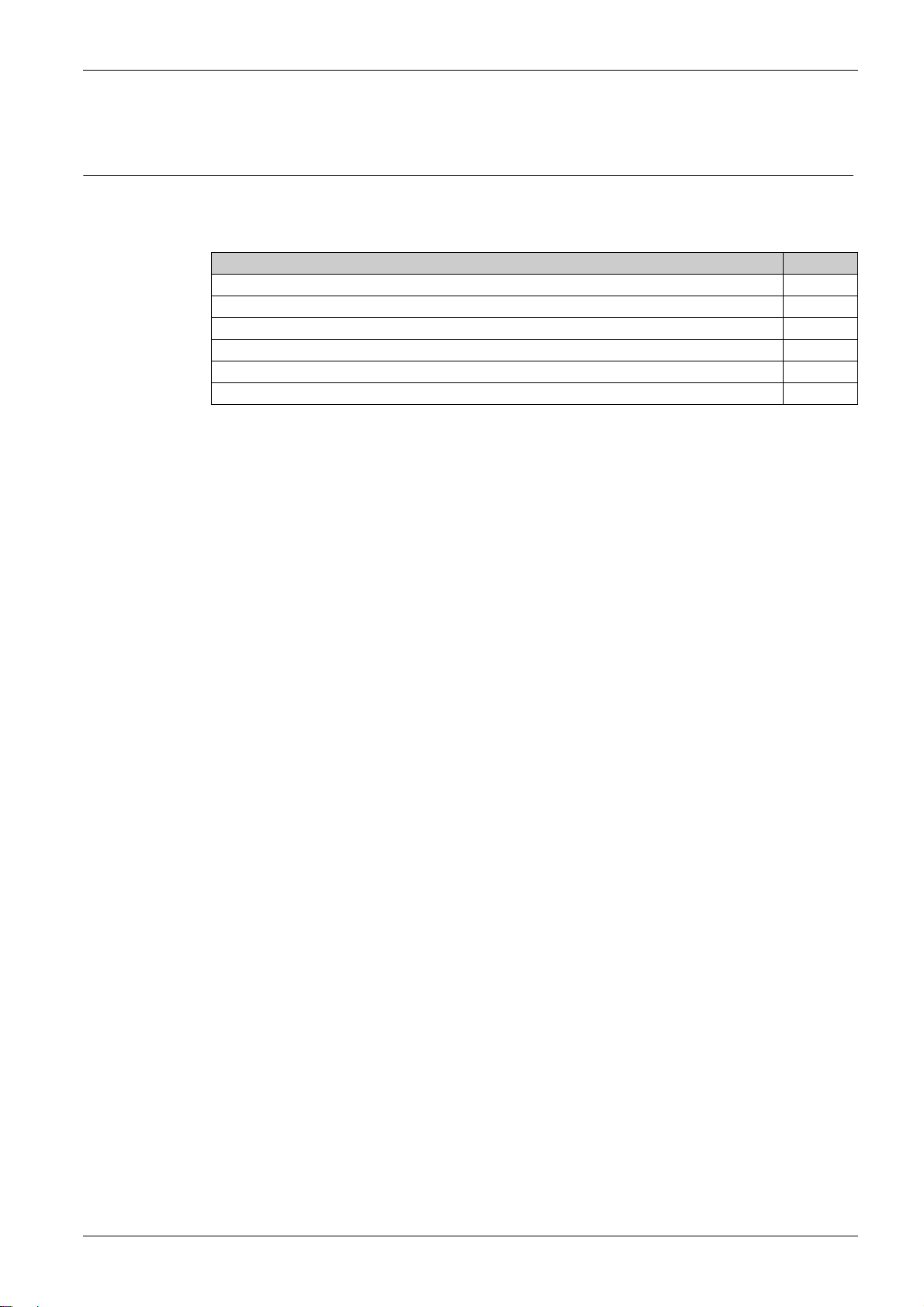

What Is in This Chapter?

This chapter contains the following topics:

Modicon M172 Logic Controller Offer Overview 16

Controller Range Overview 17

Expansion Modules Range Overview 19

Communication Modules Range Overview 20

Remote Display Range Overview 21

Accessories 23

Topic Page

EIO0000002015 02/2020 15

Page 16

M172 Range Overview

Modicon M172 Logic Controller Offer Overview

General Description

Modicon M172 Logic Controller are suitable for customized applications designed to control simple or

complex machines:

Air/water-cooled chiller

Rooftop unit

Heat pump

Compressor rack

Ventilation unit

The M172 offer is made of:

Controllers

Expansion modules

Communication modules

Remote displays

Accessories

Programming Software

In association with the controllers hardware, the EcoStruxure Machine Expert - HVAC development tool is

available to program and customize applications.

You can download EcoStruxure Machine Expert - HVAC - Programming Software for Modicon M171M172 Logic Controllers from

The use of several programming languages in accordance with IEC 61131-3 regulations (programming

standard for industrial control), makes it possible to develop new algorithms or entire programs easily,

which can then be uploaded to the M172 controllers via a PC and a Programming cable, helping to provide

confidentiality with appropriate security.

For more information, refer to Connection Types

(see page 17)

(see page 19)

(see page 20)

(see page 21)

(see page 23)

Schneider-electric web site download center

(seepage169)

.

.

16

EIO0000002015 02/2020

Page 17

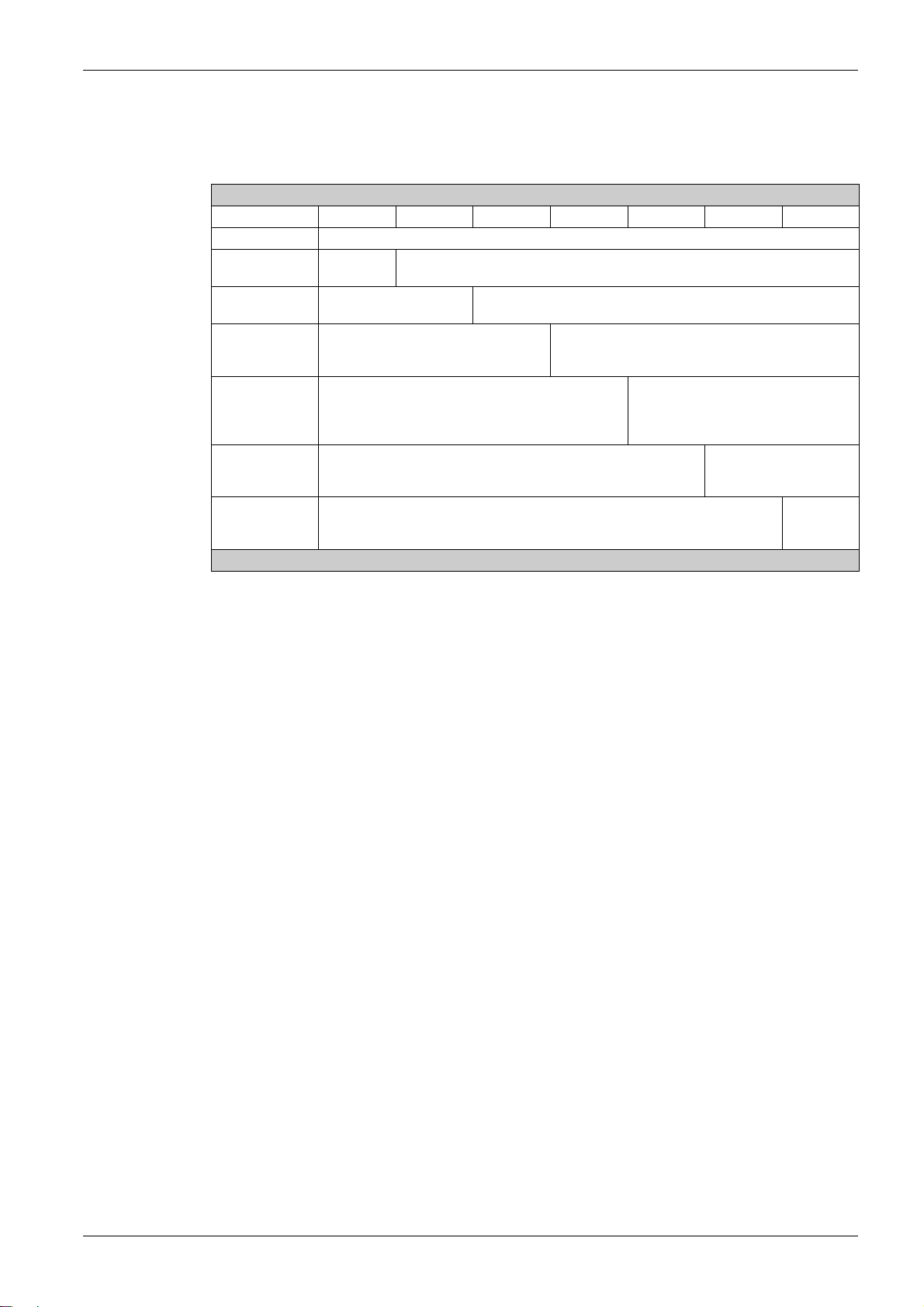

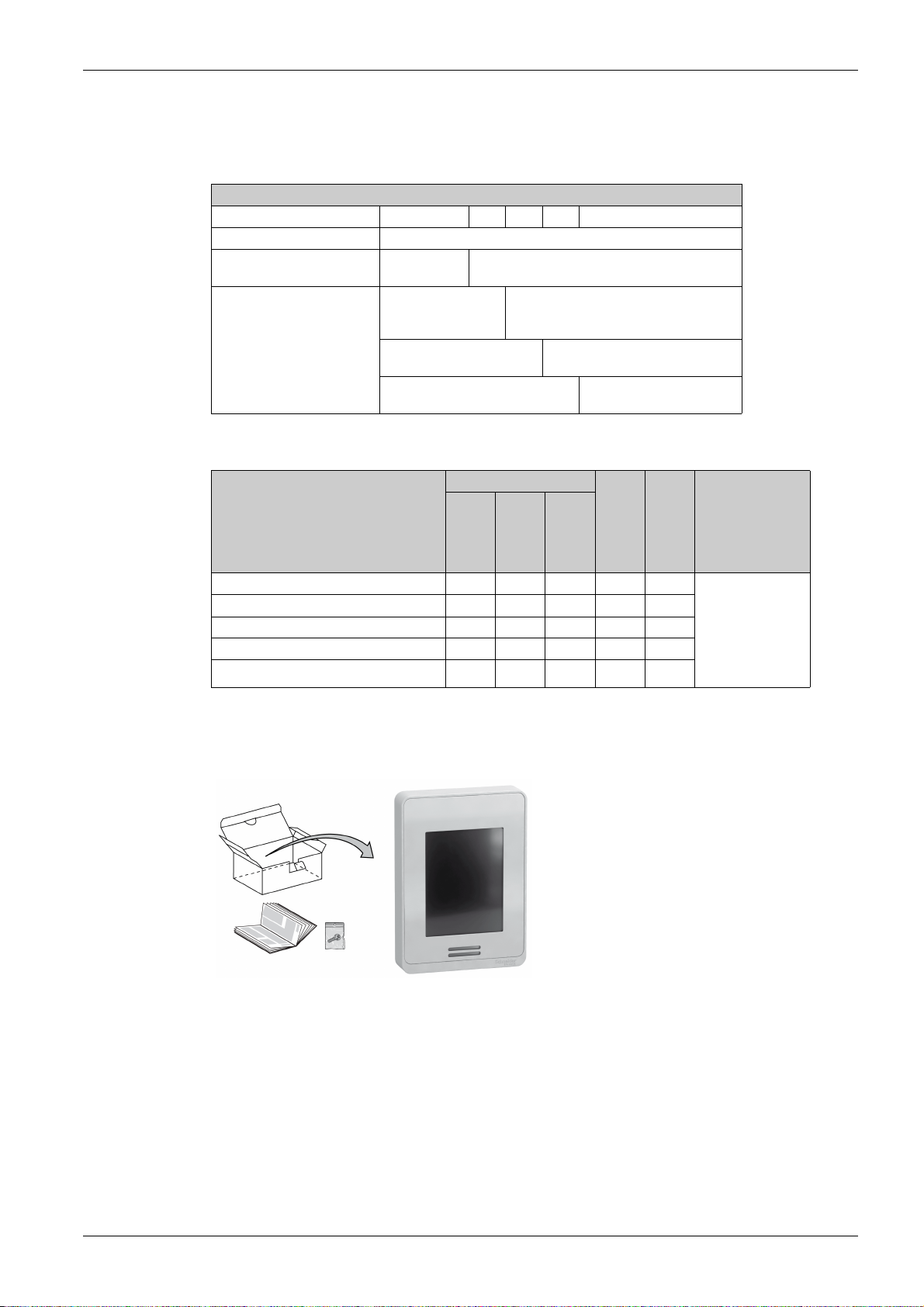

Controller Range Overview

Type Code

Controller type code:

Type code description

TM172PDG42R TM172 P D G 42 R I

Product family TM172

Complementary

product family

Physical feature B = Blind

Embedded

Communication

Number of I/O 7

Digital output type R = Relays

Power supply

isolation

(1) Only for 28 and 42 I/O

(1)

M172 Range Overview

P = Performance

O = Optimized

D = Built-in Display

G = RS-485 and Ethernet based communication

protocols

M = RS-485 based communication protocols

18

28

42

S = Solid State Relays

(SSR) and Relays

I = Power

Supply

Isolated

EIO0000002015 02/2020 17

Page 18

M172 Range Overview

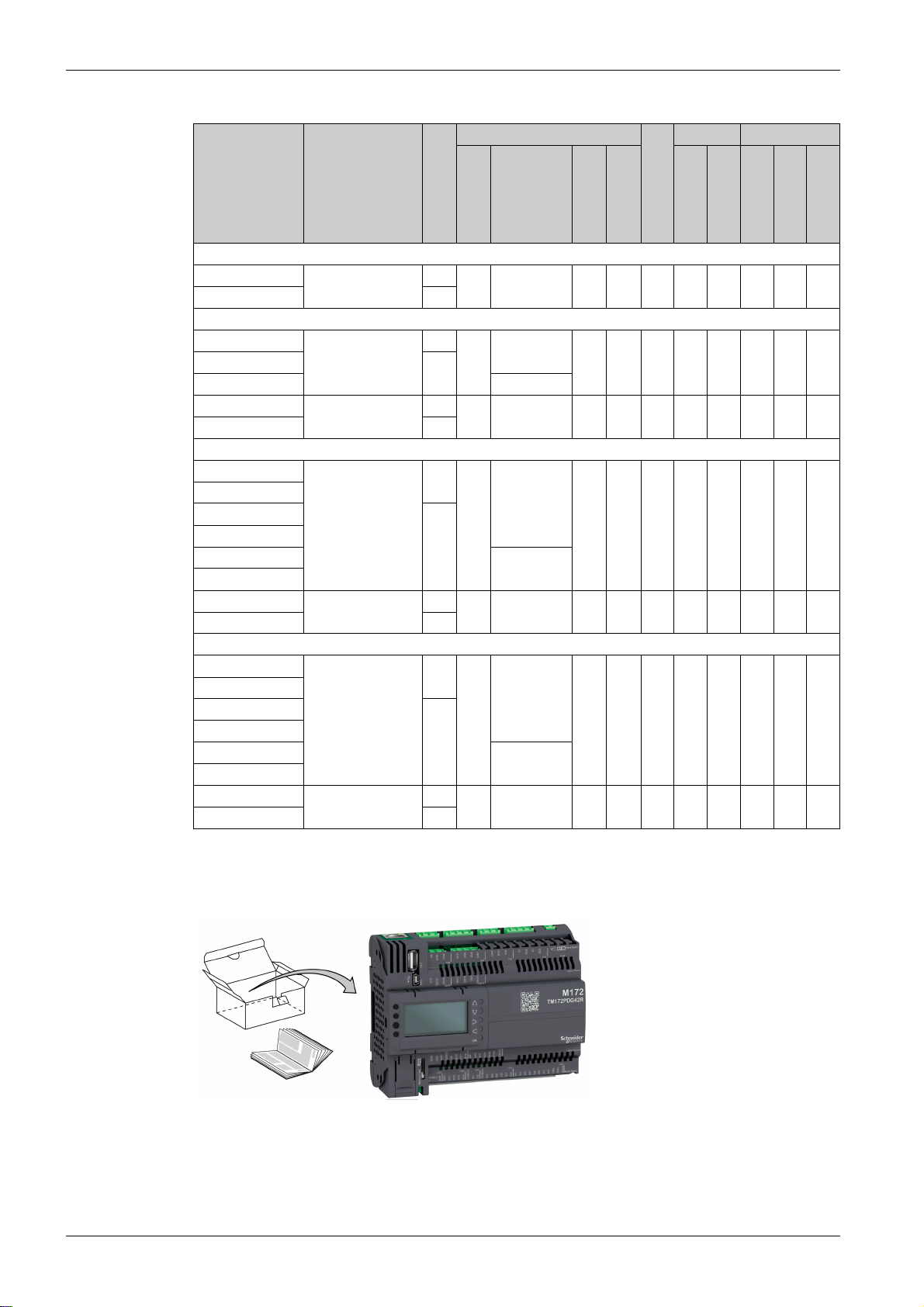

Controllers References

Reference Complementary

product family

Display

7 Inputs/Outputs

TM172PBG07R Performance - 2 3 2 0 ✓ ✓ ✓ ✓ ✓ ✓

TM172PDG07R ✓

18 Inputs/Outputs

TM172PBG18R Performance - 2 6 8 2 ✓ ✓ ✓ ✓ ✓ ✓

TM172PDG18R ✓

TM172PDG18S 4 + 2 SSR

TM172OBM18R Optimized - 2 6 8 2 - - ✓ ✓ - ✓

TM172ODM18R ✓

28 Inputs/Outputs

TM172PBG28R Performance - 8 8 8 4 ✓ ✓ ✓ ✓ ✓ ✓

TM172PBG28RI

TM172PDG28R ✓

TM172PDG28RI

TM172PDG28S 6 + 2 SSR

TM172PDG28SI

TM172OBM28R Optimized - 8 8 8 4 - - ✓ ✓ - ✓

TM172ODM28R ✓

42 Inputs/Outputs

TM172PBG42R Performance - 12 12 12 6 ✓ ✓ ✓ ✓ ✓ ✓

TM172PBG42RI

TM172PDG42R ✓

TM172PDG42RI

TM172PDG42S 10 + 2 SSR

TM172PDG42SI

TM172OBM42R Optimized - 12 12 12 6 - - ✓ ✓ - ✓

TM172ODM42R ✓

(see page 56)

(see page 58)

(see page 61)

(see page 64)

Inputs/Outputs

DI DO AI AO

USB Communication

Micro SD card

USB A

USB Mini-B

2 RS-485

1 Ethernet

1 CAN Exp. bus

The controller runs on 24 Vac/dc power supply.

TM172P•••••• / TM172O••••• Delivery Content

NOTE: Terminal blocks are not provided with the logic controllers and must be ordered separately

(see page 23)

18

EIO0000002015 02/2020

Page 19

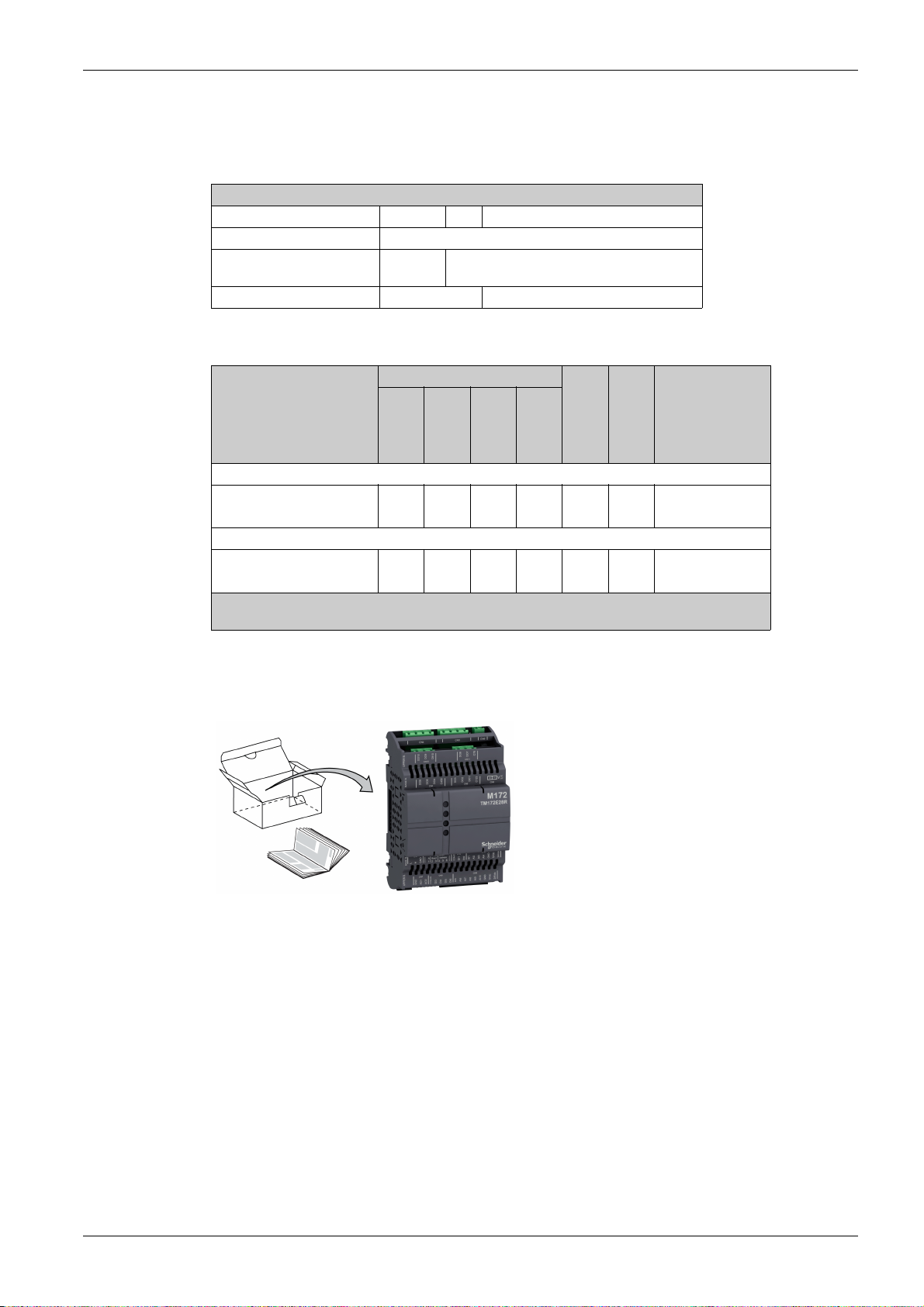

Expansion Modules Range Overview

Type Code

Expansion module type code:

Type code description

TM172E28R TM172E 28 R

Product family TM172E

Number of I/O 12

Digital output type R = Relays

Expansion Modules References

Reference Inputs/Outputs

12 Inputs/Outputs

TM172E12R 2 6 4 - ✓ ✓

28 Inputs/Outputs

TM172E28R 6 10 10 2 ✓ ✓

(1) For service only.

(2) Also compatible with TM171P controller range.

(see page 68)

(see page 70)

28

DI DO AI AO

1 CAN Exp. bus

(1)

Compatible

controllers

1 TTL

TM172P••••••

TM172O•••••

TM172P••••••

TM172O•••••

M172 Range Overview

(2)

(2)

(2)

(2)

The expansion modules run on 24 Vac/dc power supply.

TM172E••R Delivery Content

NOTE: Terminal blocks are not provided with the expansion modules and must be ordered separately

(see page 23)

EIO0000002015 02/2020 19

Page 20

M172 Range Overview

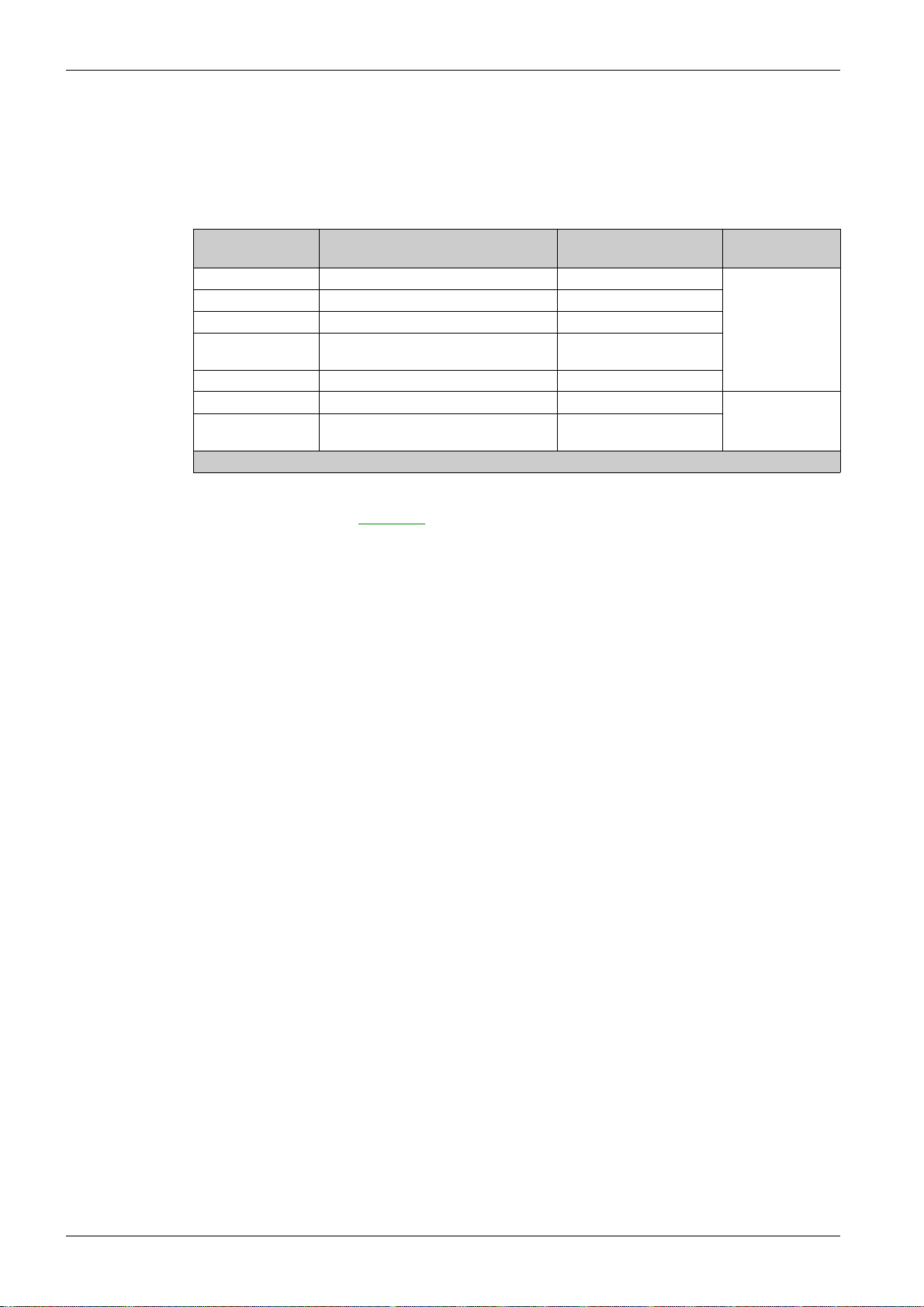

Communication Modules Range Overview

Overview

This section presents communication modules.

Communication Modules References

Reference Description Terminal type Compatible

TM171ACAN CAN 2 screw terminal blocks TM172P••••••

TM171ALON LonWorks 1 screw terminal block

TM171AMB Modbus SL (RS-485) 2 screw terminal blocks

TM171ARS232 RS-232 serial link, Relay output 1 SUB-D 9

TM171ARS485 Modbus SL, and BACnet MS/TP 2 screw terminal blocks

TM171AETH Ethernet, Modbus TCP, and BACnet/IP 1 RJ45

TM171AETHRS485 Ethernet, Modbus TCP, BACnet/IP,

Modbus SL, and BACnet MS/TP

(1) Also compatible with TM171P controller range.

For further information about communication modules, refer to the Modicon M171A Communication

Modules Instruction Sheet

EAV96007

controllers

TM172O•••••

1 screw terminal block

TM172O•••••

1 RJ45

2 screw terminal blocks

(1)

(1)

.

20

EIO0000002015 02/2020

Page 21

Remote Display Range Overview

Type Code

Remote display type code:

Type code description

TM172DCLWTHP TM172DCL W T H P

Product family TM172DCL

Mounting type W = Vertical mounting

Characteristics G = Gray color

Remote Displays References

M172 Range Overview

F = Flush mounting

W = White color

T = Temperature sensor

None

H = Relative humidity sensor

None

P = Presence sensor (PIR)

Reference Embedded sensors

TM172DCLWT

TM172DCLWTH

TM172DCLWTHP

TM172DCLFG

TM172DCLFW

The remote displays run on 24 Vac/dc power supply.

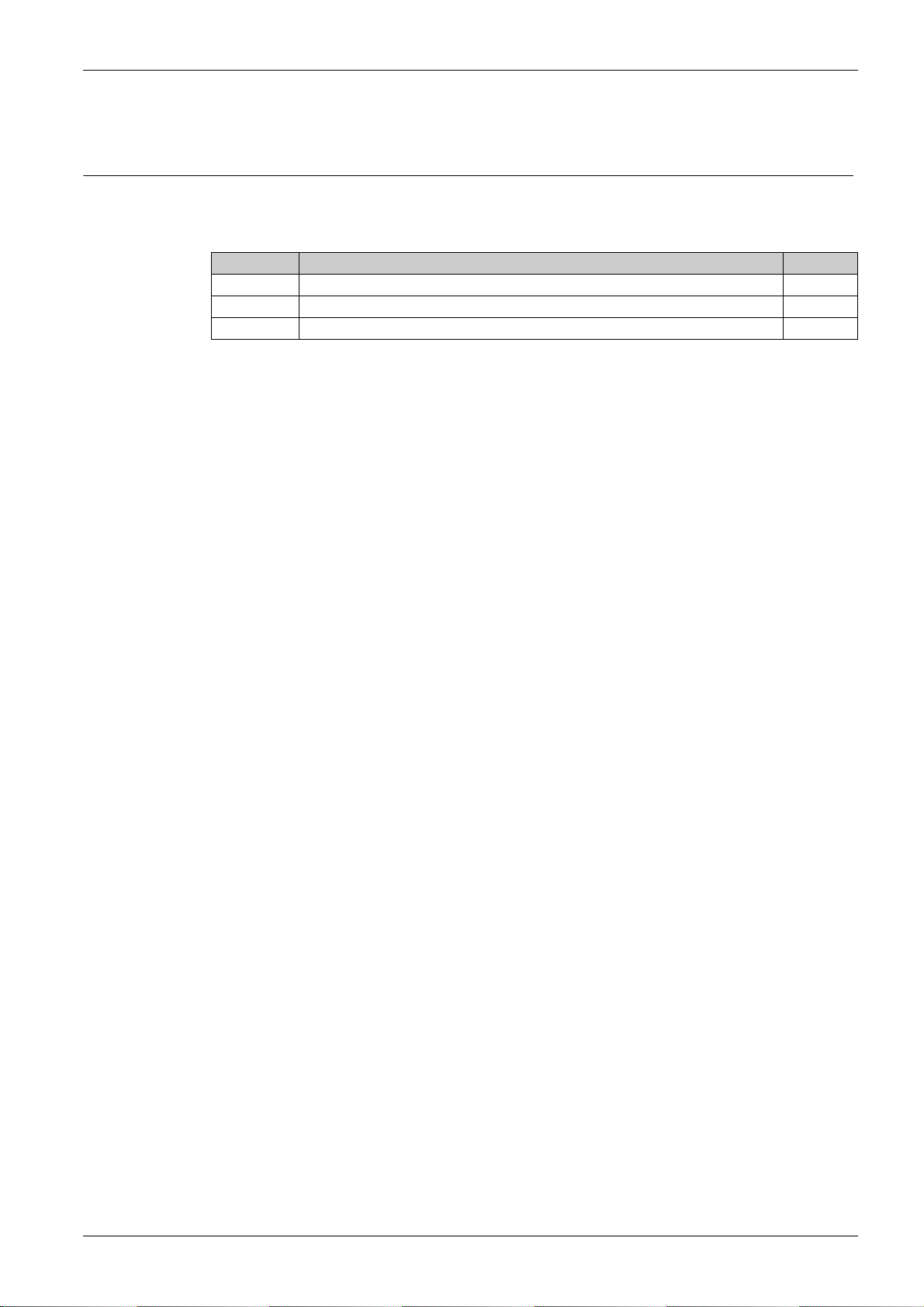

TM172DCLWT•• Delivery Content

(see page 126)

(see page 126)

(see page 126)

(see page 127)

(see page 127)

Compatible

controllers

Temperature

✓ - - ✓ ✓ TM172P••••••

✓✓ - ✓✓

✓✓✓✓✓

---✓✓

---✓✓

Humidity

Presence

1 RS-485

1 USB Micro-B

TM172O•••••

TM171P•••••

TM171O•••••

Third-party

Modbus SL

devices

EIO0000002015 02/2020 21

Page 22

M172 Range Overview

TM172DCLF• Delivery Content

22

EIO0000002015 02/2020

Page 23

Accessories

Overview

This section describes the accessories and sensors.

Mounting and Wiring Accessories References

Description Use Reference

TM172DCLF• vertical surface support

for display

12 clips-on lock To install the TM172•••••• controllers

Screw terminal blocks for wiring of controllers and

expansion modules

USB cable type A / Mini-B 1.8 m (5.9 ft) To connect a PC to a TM172••••••

DIN adapter for current transducer 3240202000 To install the current transducer on a

(see page 32)

M172 Range Overview

Gray To install a TM172DCLF• on a vertical

White TM172ABKPW

3 m (9.84 ft) TCSXCNAMUM3P

surface

and the expansion modules on a

panel surface

For TM172P•G07R

For TM172•••18•

For TM172•••28••

For TM172•••42••

For TM172E12R

For TM172E28R

controller

DIN Rail Top Hat

(see page 46)

(see page 56)

(see page 58)

(see page 61)

(see page 64)

(see page 68)

(see page 70)

(see page 172)

TM172ABKPG

TM172AP12PM

TM172ASCTB07

TM172ASCTB18

TM172ASCTB28

TM172ASCTB42

TM172ASCTB12E

TM172ASCTB28E

BMXXCAUSBH018

3240301000

Sensors References

Description Cable length Reference

NTC IP68 5x20 mm (0.79 in.) -50+110°C (122…+230°F) Gray

NTC IP67 6x15 mm (0.591 in.) -50…+110°C (-122…+230°F) Gray 1.5 m (4.9 ft) TM1STNTCRN61515

NTC FAST IP67 4x40 mm (1.57 in.) -50+110°C (-122…+230°F) Gray 1.5 m (4.9 ft) TM1STNTCSF44015

NTC IP68 6x20 mm (0.79 in.) -50+110°C (-122…+230°F) Gray 1.5 m (4.9 ft) TM1STNTCSN62015

NTC IP68 6x20 mm (0.79 in.) TPE with strap Gray 1.5 m (4.9 ft) TM1STNTCTN62015

NTC for inside air -40...+60°C (-40...+140°F) Wall mounting - TM1STNTCWN75750

Pt1000 IP68 6x20 mm (0.79 in.) -50…+110°C (-122…+230°F) Green 1.5 m (4.9 ft) TM1STPTTSN52015

Pt1000 IP68 5x20 mm (0.79 in.) -50…+110°C (-122…+230°F) Green 1.5 m (4.9 ft) TM1STPTTSN62015

Humidity Probe Outdoor Wall mounting

4...20 mA (%RH)

Humidity and Temperature Probe Outdoor Wall mounting

4...20 mA (%RH) + NTC (Temp)

Humidity and Temperature Probe Outdoor Wall mounting

4...20 mA (%RH) + 4...20 mA (Temp)

Humidity and Temperature Probe Outdoor Wall mounting,

Dewpoint Calculation

Modbus SL RS485

NTC Temperature Probe Outdoor Wall mounting - TM1STNTCW69755

8 pieces 1.5 m (4.9 ft) TM1STNTCRN52015

100 pieces TM1STNTCRN5201P

5 pieces 3 m (9.8 ft) TM1STNTCRN52030

50 pieces TM1STNTCRN5203P

4 pieces 5 m (16.4 ft) TM1STNTCRN52050

25 pieces TM1STNTCRN5205P

3 m (9.8 ft) TM1STNTCRN61530

5 m (16.4 ft) TM1STNTCRN61550

3 m (9.8 ft) TM1STNTCSF44030

3 m (9.8 ft) TM1STNTCSN62030

5 m (16.4 ft) TM1STNTCSN62050

3 m (9.8 ft) TM1STNTCTN62030

3 m (9.8 ft) TM1STPTTSN52030

5 m (16.4 ft) TM1STPTTSN52050

3 m (9.8 ft) TM1STPTTSN62030

- TM1SHC4

-TM1SHTCN4

-TM1SHTCC4

TM1SHTM4

EIO0000002015 02/2020 23

Page 24

M172 Range Overview

24

EIO0000002015 02/2020

Page 25

What Is in This Part?

Modicon M172 Logic Controller

Global Features

EIO0000002015 02/2020

Global Features

Part II

Global Features

This part contains the following chapters:

Chapter Chapter Name Page

2 Before Starting 27

3 Wiring Best Practices 31

4 Installation 37

EIO0000002015 02/2020 25

Page 26

Global Features

26

EIO0000002015 02/2020

Page 27

Before Starting

Before Starting

Modicon M172 Logic Controller

Before Starting

EIO0000002015 02/2020

Before Starting

Chapter 2

Before Starting

Read and understand this chapter before beginning the installation of your system.

Pay particular attention in conforming to any safety information, different electrical requirements, and

normative standards that would apply to your machine or process in the use of this equipment.

The use and application of the information contained herein require expertise in the design and

programming of automated control systems. Only you, the user, machine builder or integrator, can be

aware of all the conditions and factors present during installation and setup, operation, and maintenance

of the machine or process, and can therefore determine the automation and associated equipment and the

related safeties and interlocks which can be effectively and properly used. When selecting automation and

control equipment, and any other related equipment or software, for a particular application, you must also

consider any applicable local, regional or national standards and/or regulations.

Disconnecting Power

WARNING

REGULATORY INCOMPATIBILITY

Ensure that all equipment applied and systems designed comply with all applicable local, regional, and

national regulations and standards.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

All options and modules should be assembled and installed before installing the control system on a

mounting rail, onto a mounting plate or in a panel. Remove the control system from its mounting rail,

mounting plate or panel before disassembling the equipment.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any covers or

doors, or installing or removing any accessories, hardware, cables, or wires except under the specific

conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper

ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

Programming Considerations

The products described in this manual have been designed and tested using Schneider Electric

programming, configuration, and maintenance software products.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000002015 02/2020 27

Page 28

Before Starting

Operating Environment

This equipment has been designed to operate outside of any hazardous location, and exclusive of

applications that generate, or have the potential to generate, hazardous atmospheres. Only install this

equipment in zones known to be free, at all times, of hazardous atmospheres.

For information concerning the use of control equipment in applications capable of generating hazardous

materials, consult your local, regional, or national standards bureau or certification agency.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Do not install and use this equipment in applications capable of generating hazardous atmospheres,

such as those applications employing flammable refrigerants.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNINTENDED EQUIPMENT OPERATION

Install and operate this equipment according to the conditions described in the Environmental

Characteristics.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

28

EIO0000002015 02/2020

Page 29

Installation Considerations

UNINTENDED EQUIPMENT OPERATION

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Install and operate this equipment in an enclosure appropriately rated for its intended environment and

secured by a keyed or tooled locking mechanism.

Use the sensor and actuator power supplies only for supplying power to the sensors or actuators

connected to the module.

Power line and output circuits must be wired and fused in compliance with local and national regulatory

requirements for the rated current and voltage of the particular equipment.

Do not use this equipment in safety-critical machine functions unless the equipment is otherwise

designated as functional safety equipment and conforming to applicable regulations and standards.

Do not disassemble, repair, or modify this equipment.

Do not connect any wiring to unused connections, or to connections designated as No Connection

(N.C.).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTE: JDYX2 or JDYX8 fuse types are UL-recognized and CSA approved.

The M172 controllers are intended for Top Hat Section Rail (DIN rail) mounting, panel mounting, or wall

mounting.

Care must be taken to avoid damage from electrostatic sources when handling this equipment. In particular

exposed connectors and, in some cases, exposed printed circuit boards are exceptionally vulnerable to

electrostatic discharge.

Before Starting

WARNING

WARNING

UNINTENDED EQUIPMENT OPERATION DUE TO ELECTROSTATIC DISCHARGE DAMAGE

Keep equipment in the protective conductive packaging until you are ready to install the equipment.

Only install equipment in approved enclosures and / or locations that prevent casual access and

provide electrostatic discharge protection.

Use a conductive wrist strap or equivalent field force protective device attached to an earth ground

when handling sensitive equipment.

Always discharge yourself by touching a grounded surface or approved antistatic mat before handling

the equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

For more information about enclosures, refer to the definition found in IEC 1000-4-2.

EIO0000002015 02/2020 29

Page 30

Before Starting

30

EIO0000002015 02/2020

Page 31

Modicon M172 Logic Controller

Wiring Best Practices

EIO0000002015 02/2020

Wiring Best Practices

Chapter 3

Wiring Best Practices

Wiring Best Practices

Wiring Best Practices

The following information describes the wiring guidelines and associated best practices to be respected

when using a Modicon M172 Logic Controller.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any covers or

doors, or installing or removing any accessories, hardware, cables, or wires except under the specific

conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper

ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

DANGER

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for certain critical control functions, provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop and overtravel stop, power outage

and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest edition), "Safety

Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive

Systems" or their equivalent governing your particular location.

1

EIO0000002015 02/2020 31

Page 32

Wiring Best Practices

Wiring Guidelines

The following rules must be applied when wiring M172 offer product range:

I/O and communication wiring must be kept separate from the power wiring. Route these two types of

wiring in separate cable ducting.

Verify that the operating conditions and environment are within the specification values.

Use proper wire sizes to meet voltage and current requirements.

Use copper conductors (required).

Use twisted pair, shielded cables for analog, and/or fast I/O.

Use twisted pair, shielded cables for networks, and fieldbus.

Use shielded, properly grounded cables for all analog and high-speed inputs or outputs and

communication connections. If you do not use shielded cable for these connections, electromagnetic

interference can cause signal degradation. Degraded signals can cause the controller or attached modules

and equipment to perform in an unintended manner.

WARNING

UNINTENDED EQUIPMENT OPERATION

Use shielded cables for all fast I/O, analog I/O and communication signals.

Ground cable shields for all analog I/O, fast I/O and communication signals at a single point

Route communication and I/O cables separately from power cables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

.

1

Multipoint grounding is permissible if connections are made to an equipotential ground plane dimensioned

to help avoid cable shield damage in the event of power system short-circuit currents.

NOTE: Surface temperatures may exceed 60 °C (140 °F). Route primary wiring (wires connected to power

mains) separately and apart from secondary wiring (extra low voltage wiring coming from intervening

power sources). If that is not possible, double insulation is required such as conduit or cable gains.

Rules for Screw Terminal Block

The following table presents the cable types and wire sizes for a 5.08 mm (0.20 in.) or 5.00 mm (0.197 in.)

pitch screw terminal block:

The following table presents the cable types and wire sizes for a 3.81 mm (0.15 in.) or 3.50 mm (0.14 in.)

pitch screw terminal block:

32

The use of copper conductors is required.

EIO0000002015 02/2020

Page 33

LOOSE WIRING CAUSES ELECTRIC SHOCK

Tighten connections in conformance with the torque specifications.

Failure to follow these instructions will result in death or serious injury.

FIRE HAZARD

Use only the recommended wire sizes for the current capacity of the I/O channels and power supplies.

For relay output wiring up to 2 A, use conductors of at least 0.5 mm² (AWG 20) with a temperature

rating of at least 80 °C (176 °F).

For relay output wiring of 3 A, use conductors of at least 1.5 mm² (AWG 16) with a temperature rating

of at least 80 °C (176 °F).

For common conductors of relay output wiring of 9 A, or relay output wiring greater than 3 A, use

conductors of at least 2.0 mm² (AWG 12) with a temperature rating of at least 80 °C (176 °F).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Protecting Outputs from Inductive Load Damage

Depending on the load, a protection circuit may be needed for the relay outputs. Inductive loads using DC

voltages may create voltage reflections resulting in overshoot that will damage or shorten the life of output

devices.

Wiring Best Practices

DANGER

WARNING

CAUTION

OUTPUT CIRCUIT DAMAGE DUE TO INDUCTIVE LOADS

Use an appropriate external protective circuit or device to reduce the risk of inductive direct current load

damage.

Failure to follow these instructions can result in injury or equipment damage.

Choose a protection circuit from the following diagrams according to the power supply used. Connect the

protection circuit to the outside of the controller or relay output module.

If your controller or module contains relay outputs, these types of outputs can support up to 240 Vac.

Inductive damage to these types of outputs can result in welded contacts and loss of control. Each

inductive load must include a protection device such as a peak limiter, RC circuit or flyback diode.

Capacitive loads are not supported by these relays.

WARNING

RELAY OUTPUTS WELDED CLOSED

Always protect relay outputs from inductive alternating current load damage using an appropriate

external protective circuit or device.

Do not connect relay outputs to capacitive loads.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Protective circuit A: this protection circuit can be used for both AC and DC load power circuits.

C Value from 0.1 to 1 μF

R Resistor of approximately the same resistance value as the load

EIO0000002015 02/2020 33

Page 34

Wiring Best Practices

Protective circuit B: this protection circuit can be used for DC load power circuits.

Use a diode with the following ratings:

Reverse withstand voltage: power voltage of the load circuit x 10.

Forward current: more than the load current.

Protective circuit C: this protection circuit can be used for both AC and DC load power circuits.

In applications where the inductive load is switched on and off frequently and/or rapidly, verify that the

continuous energy rating (J) of the varistor exceeds the peak load energy by 20 % or more.

NOTE: Place protection devices as close to the load as possible.

Special Handling Considerations

Care must be taken to avoid damage from electrostatic sources when handling this equipment. In particular

exposed connectors and, in some cases, exposed printed circuit boards are exceptionally vulnerable to

electrostatic discharge.

UNINTENDED EQUIPMENT OPERATION DUE TO ELECTROSTATIC DISCHARGE DAMAGE

Keep equipment in the protective conductive packaging until you are ready to install the equipment.

Only install equipment in approved enclosures and / or locations that prevent casual access and

provide electrostatic discharge protection.

Use a conductive wrist strap or equivalent field force protective device attached to an earth ground

when handling sensitive equipment.

Always discharge yourself by touching a grounded surface or approved antistatic mat before handling

the equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

34

EIO0000002015 02/2020

Page 35

Analog Inputs-Probes

Wiring Best Practices

Temperature probes have no connection polarity and can be extended using a normal bipolar cable.

The extension of the probes wiring influences the electromagnetic compatibility (EMC) of the instrument

Verify the polarity for probes which have a specific connection polarity.

NOTICE

INOPERABLE EQUIPMENT

Verify all wiring connections before applying power.

Failure to follow these instructions can result in equipment damage.

Do not power any connected devices that are externally powered without also applying power to the M172.

NOTICE

INOPERABLE EQUIPMENT

Ensure that the controller has power applied when applying power to other connected and externally

powered devices.

Failure to follow these instructions can result in equipment damage.

Signal leads (probes, digital inputs, communication, and the electronic supply) must be routed separately

from power cables.

EIO0000002015 02/2020 35

Page 36

Wiring Best Practices

36

EIO0000002015 02/2020

Page 37

Modicon M172 Logic Controller

Installation

EIO0000002015 02/2020

Installation

Chapter 4

Installation

What Is in This Chapter?

This chapter contains the following topics:

TM172•••07• / TM172•••18• Controllers Mounting Positions 38

TM172•••28•• / TM172•••42•• Controllers Mounting Positions 39

TM172E••R Expansion Modules Mounting Positions 40

Controllers and Expansion Modules Clearances 41

Top Hat Section Rail (DIN Rail) 42

Controllers and Expansion Modules Installation 45

TM172DCLWT•• Remote Display Installation 47

TM172DCLF• Remote Display Installation 48

Topic Page

EIO0000002015 02/2020 37

Page 38

Installation

TM172•••07• / TM172•••18• Controllers Mounting Positions

Correct Mounting Position

TM172•••07• / TM172•••18• controllers must be mounted horizontally on a vertical plane as shown in the

figure below:

Incorrect Mounting Position

TM172•••07• / TM172•••18• controllers cannot be mounted neither vertically, nor horizontally backward:

38

EIO0000002015 02/2020

Page 39

TM172•••28•• / TM172•••42•• Controllers Mounting Positions

Correct Mounting Position

TM172•••28•• / TM172•••42•• controllers should be mounted horizontally on a vertical plane as shown in

the figure below:

Acceptable Mounting Position

TM172•••28R• / TM172•••42R• controllers can be mounted horizontally upward with a temperature

derating (maximum ambient temperature: 60 °C (140 °F)).

TM172PDG28SI / TM172PDG42SI controllers can be mounted horizontally upward with a temperature

derating (maximum ambient temperature: 55 °C (131 °F)).

Installation

Incorrect Mounting Position

TM172•••28•• / TM172•••42•• controllers cannot be mounted neither vertically, nor horizontally backward:

TM172PDG28S / TM172PDG42S controllers cannot be mounted horizontally upward:

EIO0000002015 02/2020 39

Page 40

Installation

TM172E••R Expansion Modules Mounting Positions

Correct Mounting Position

TM172E••R expansion modules must be mounted horizontally on a vertical plane or horizontally upward

as shown in the figure below:

Incorrect Mounting Position

TM172E••R expansion modules cannot be mounted neither vertically, nor horizontally backward:

40

EIO0000002015 02/2020

Page 41

Controllers and Expansion Modules Clearances

Minimum Clearances

UNINTENDED EQUIPMENT OPERATION

Place devices dissipating the most heat at the top of the cabinet and ensure adequate ventilation.

Avoid placing this equipment next to or above devices that might cause overheating.

Install the equipment in a location providing the minimum clearances from all adjacent structures and

equipment as directed in this document.

Install all equipment in accordance with the specifications in the related documentation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM172•••••• controllers and expansion modules have been designed as IP20 products and must be

installed in an enclosure appropriately rated for its intended environment and secured by a keyed or tooled

locking mechanism .

There are 3 types of clearances between:

The M172 device and the sides of the cabinet (including the panel door).

The M172 device terminal blocks and the wiring ducts. This distance reduces electromagnetic

interference between the controller and the wiring ducts.

The M172 device and other heat generating devices installed in the same cabinet.

The following figure shows the minimum clearances that apply to TM172•••••• references:

Installation

WARNING

EIO0000002015 02/2020 41

Page 42

Installation

Top Hat Section Rail (DIN Rail)

Dimensions of Top Hat Section Rail (DIN Rail)

You can mount the controller and expansion module on a 35 mm (1.38 in.) top hat section rail (DIN rail). It

can be attached to a smooth mounting surface or suspended from a EIA rack or mounted in a NEMA

cabinet.

Symmetric Top Hat Section Rails (DIN Rail)

The following illustration and table show the references of the top hat section rails (DIN rail) for the wallmounting range:

Reference Type Rail length (B)

NSYSDR50A A 450 mm (17.71 in.)

NSYSDR60A A 550 mm (21.65 in.)

NSYSDR80A A 750 mm (29.52 in.)

NSYSDR100A A 950 mm (37.40 in.)

The following illustration and table show the references of the symmetric top hat section rails (DIN rail) for

the metal enclosure range:

Reference Type Rail length (B-12 mm)

NSYSDR60 A 588 mm (23.15 in.)

NSYSDR80 A 788 mm (31.02 in.)

NSYSDR100 A 988 mm (38.89 in.)

NSYSDR120 A 1188 mm (46.77 in.)

42

EIO0000002015 02/2020

Page 43

Installation

The following illustration and table shows the references of the symmetric top hat section rails (DIN rail) of

2000 mm (78.74 in.):

Reference Type Rail length

NSYSDR200

NSYSDR200D

1

2

1 Unperforated galvanized steel

2 Perforated galvanized steel

A 2000 mm (78.74 in.)

A

EIO0000002015 02/2020 43

Page 44

Installation

Double-Profile Top Hat Section Rails (DIN Rail)

The following illustration and table show the references of the double-profile top hat section rails (DIN rails)

for the wall-mounting range:

Reference Type Rail length (B)

NSYDPR25 W 250 mm (9.84 in.)

NSYDPR35 W 350 mm (13.77 in.)

NSYDPR45 W 450 mm (17.71 in.)

NSYDPR55 W 550 mm (21.65 in.)

NSYDPR65 W 650 mm (25.60 in.)

NSYDPR75 W 750 mm (29.52 in.)

The following illustration and table show the references of the double-profile top hat section rails (DIN rail)

for the floor-standing range:

Reference Type Rail length (B)

NSYDPR60 F 588 mm (23.15 in.)

NSYDPR80 F 788 mm (31.02 in.)

NSYDPR100 F 988 mm (38.89 in.)

NSYDPR120 F 1188 mm (46.77 in.)

44

EIO0000002015 02/2020

Page 45

Controllers and Expansion Modules Installation

Overview

This section describes how to install and remove a TM172•••••• controller or expansion module from a top

hat section rail (DIN rail).

Installing on a Top Hat Section Rail (DIN Rail)

The following procedure describes how to install a controller or an expansion module on a top hat section

rail (DIN rail):

Step Action

1 Move the two spring docking devices to their standby position (use a screwdriver to press

against the relative compartments).

2 Position the top groove of the controller or the expansion modules on the top edge of the Top

Hat Section Rail (DIN rail).

3 Press the assembly against the Top Hat Section Rail (DIN rail).

4 Press the spring docking devices to put them into the locked position.

Installation

Removing from a Top Hat Section Rail (DIN Rail)

The following procedure describes how to remove a controller or an expansion module from a top hat

section rail (DIN rail):

Step Action

1 Remove the power from the controller or the expansion module.

2 Insert a flat screwdriver into the spring docking devices.

3 Pull down the spring docking device to move it to its standby position.

4 Pull the controller or the expansion module from the top hat section rail (DIN rail) from the

bottom.

EIO0000002015 02/2020 45

Page 46

Installation

Panel Installation

To install the controllers and expansion modules on a panel you must use clip-on locks.

NOTE: Upper clip-on locks are not provided with the logic controllers and must be ordered separately

(see page 23)

. Only one additional upper clip-on lock is necessary for TM172P•G07R, TM172•••18•, and

TM172E••R.

The following procedure shows how to install a TM172•••28•• or a TM172•••42•• controller on a panel using

the clip-on locks. The same procedure shall be followed for the TM172P•••••• / TM172O••••• / TM172E••R:

Step Action

1 Install the 2 upper clip-on locks

2 Move the 2 lower clip-on locks to their standby position

Mounting Holes Layout

3 Secure the device in position with 4 screws.

Refer to the mounting holes layout

TM172•••07•

TM172•••18•

TM172E••R

TM172•••28••

TM172•••42••

(see page 46)

.

46

EIO0000002015 02/2020

Page 47

TM172DCLWT•• Remote Display Installation

TM172DCLWT•• Panel installation

The TM172DCLWT•• remote display can be mounted horizontally or vertically on a vertical wall.

TM172DCLWT•• display incorporates a temperature sensor. To function correctly, air must circulate

through the product to accurately determine the temperature.

INACCURATE TEMPERATURE MEASUREMENT

Mount the TM172DCLWT•• in an upright, vertical (portrait) position when using the temperature sensor.

Failure to follow these instructions can result in equipment damage.

The following graphic and procedure explain how to install TM172DCLWT•• remote display on a wall:

Installation

NOTICE

Mounting Holes Layout

Mounting holes layout for TM172DCLWT••:

Step Action

1 Open unit by pulling on bottom side of the display(1)

2 Ensure correct side of base faces up

3 Pull cables 150 mm (5.90 in.) out from wall

4 Align base and mark location of two mounting holes on wall or panel (2)

5 Install anchors in wall (3)

6 Insert cable in central hole of base

7 Place rear cover on the wall and align it with mounting holes (4)

8 Insert screws in mounting holes on each side of base (5)

9 Strip each wire 6 mm (0.24 in.) from end

10 Insert each wire according to wiring chart

11 Gently push excess wiring back into hole

12 Gently align cover to top of base and snap in place from bottom (6)

13 Install the isolated screw connection for securing the plastic housing (7)

(see page 31)

EIO0000002015 02/2020 47

Page 48

Installation

TM172DCLF• Remote Display Installation

TM172DCLF• Wiring

The TM172DCLF• remote display must be wired prior to the mounting phase.

The following procedure explain how to wire a TM172DCLF• remote display:

Step Action

1 Open unit by pulling on bottom side of the display

2 Insert cable in central hole of base

3 Strip each wire 6 mm (0.24 in.) from end

4 Insert each wire according to wiring chart

5 Gently align cover to top of base and snap in place.

6 Install the 4 isolated screws connection for securing the plastic housing

(see page 31)

TM172DCLF• Panel Installation

The TM172DCLF• remote display can be mounted horizontally or vertically on a vertical panel.

The following procedure explain how to install a TM172DCLF• remote display on a panel:

Step Action

1 Make a hole using the mounting hole layout.

2 Pull cables 150 mm (5.90 in.) out from hole.

3 Wire the unit according to the wiring procedure.

4 Insert the unit in the hole (1).

5 Secure it with 4 panel mounting locks provided (2)(3).

48

EIO0000002015 02/2020

Page 49

TM172DCLF• Vertical Surface Installation

The TM172DCLF• remote display can be mounted horizontally or vertically on a vertical surface using

TM172ABKPG or TM172ABKPW accessory.

The following procedure explain how to install TM172DCLF• remote display on a vertical surface:

Step Action

1 Place the TM172ABKP• accessory.

2 Ensure correct side of TM172ABKP• faces up.

3 Pull cables 150 mm (5.90 in.) out from vertical surface if necessary.

4 Align TM172ABKP• and mark location of two mounting holes on the vertical surface.

5 Drill holes in the vertical surface (1).

6 Pull cables 150 mm (5.90 in.) out from a hole of TM172ABKP•.

7 Place TM172ABKP• on the vertical surface and align it with mounting holes.

8 Insert screws in mounting holes on each side of TM172ABKP• (2).

9 Wire the unit according to the wiring procedure.

10 Gently push excess wiring back into hole.

11 Gently snap in place TM172DCLF• into TM172ABKP• (3).

Installation

TM172DCLF• Top Hat Section Rail (DIN Rail) Installation

The TM172DCLF• remote display can be mounted horizontally on a top hat section rail (DIN rail).

The following procedure describes how to install a TM172DCLF• remote display on a top hat section rail

(DIN rail):

Step Action

1 Wire the unit according to the wiring procedure.

2 Position the top groove of the remote display on the top edge of the Top Hat Section Rail (DIN

rail) (1).

3 Press the assembly against the Top Hat Section Rail (DIN rail) (2) up to the locked position (3).

EIO0000002015 02/2020 49

Page 50

Installation

Mounting Holes Layout

Mounting hole layout for TM172DCLF•: with seals: without seals:

Mounting holes layout for TM172ABKPG or TM172ABKPW:

50

EIO0000002015 02/2020

Page 51

What Is in This Part?

Modicon M172 Logic Controller

Controllers and Expansion Modules

EIO0000002015 02/2020

Controllers and Expansion Modules

Part III

Controllers and Expansion Modules

This part contains the following chapters:

Chapter Chapter Name Page

5 Environmental Characteristics 53

6 TM172P•••••• / TM172O••••• Controllers Description 55

7 TM172E••R Expansion Modules Description 67

8 Electrical Characteristics and Wiring Diagrams 73

9 User Interface 119

EIO0000002015 02/2020 51

Page 52

Controllers and Expansion Modules

52

EIO0000002015 02/2020

Page 53

Modicon M172 Logic Controller

Environmental

EIO0000002015 02/2020

Environmental Characteristics

Chapter 5

Environmental Characteristics

Environmental Characteristics

Technical Data

The Modicon M172 Logic Controller offer components meet European Community (CE) requirements for

open equipment. You must install them in an enclosure or other location designed for the specific

environmental conditions and to minimize the possibility of unintended contact with hazardous voltages.

Use metal enclosures to improve the electromagnetic immunity of your M172 system. This equipment

meets CE requirements as indicated in the following tables.

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified within this chapter.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

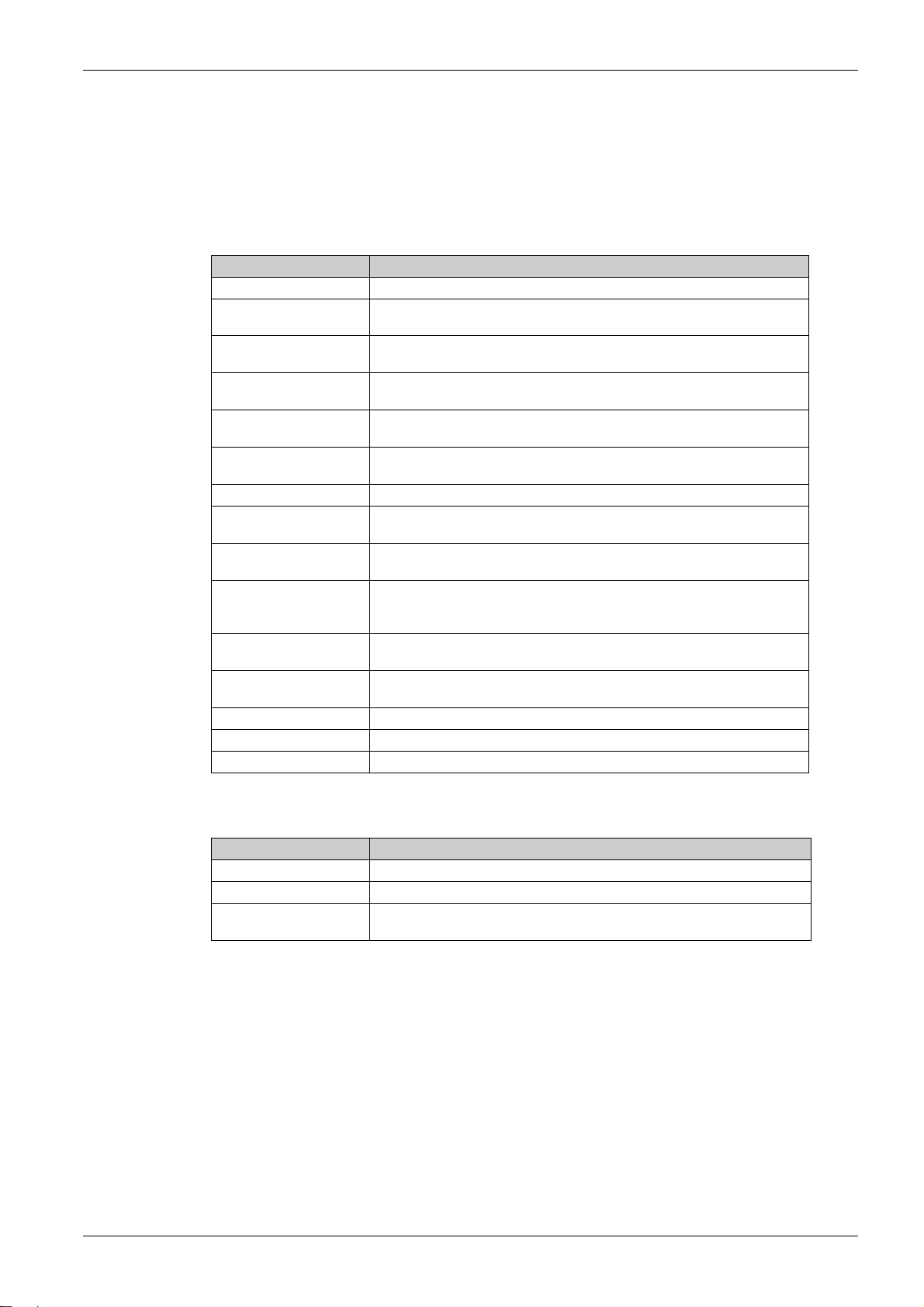

Controller and Expansion Modules Specifications

Characteristics Specification

The product complies with the

following harmonized

Standards

Construction of control Electronic automatic

Purpose of control Operating control

Mounting Top Hat Section Rail (DIN rail) ✓

Type of action 1.B ✓

Type of disconnection or

suspension for each circuit

Pollution degree 2 (normal) ✓

Over-voltage category II ✓

Rated impulse voltage 2500 V ✓

Period of electric stress on the

insulating parts

TM172E12R

TM172E28R

TM172PDG28S / TM172PDG42S

TM172P•G18R / TM172O•M18R

TM172O••28R

TM172PDG18S

TM172P•G07R

EN 60730-1 / EN 60730-2-9 ✓

Incorporated Control

(non-safety-related)

Optional panel mounting (with

accessories

1.Y -✓-✓-✓-✓-

Micro disconnection ✓

Long period, EN 60730 ✓

TM172O••42R

TM172PDG28SI

TM172PBG28RI / TM172PDG28RI

✓

✓

✓

TM172PDG42SI

TM172P•G28R / TM172P•G42R

TM172PBG42RI / TM172PDG42RI

EIO0000002015 02/2020 53

Page 54

Environmental

Characteristics Specification

TM172P•G07R

TM172PDG18S

TM172O••28R

TM172PDG28SI

TM172O••42R

TM172PDG42SI

TM172E12R

TM172E28R

TM172P•G28R / TM172P•G42R

TM172PBG42RI / TM172PDG42RI

TM172PDG28S / TM172PDG42S

Power supply 24 Vac (+/- 10 %) 50 Hz /

TM172P•G18R / TM172O•M18R

TM172PBG28RI / TM172PDG28RI

-✓

60 Hz

20…38 Vdc

(non-isolated)

24 Vac (+/- 10 %) 50 Hz /

✓60 Hz

20…38 Vdc

(isolated)

Power Consumption 20 VA / 10 W ✓ - ✓ -

21 VA / 11 W - ✓ -

23 VA / 12 W - ✓ -

24 VA / 15 W - ✓

25 VA / 14 W - ✓ -

35 VA / 15 W - ✓ -

Insulation class II ✓

Ambient operating temperature -20…55 °C (-4…131 °F) - ✓ - ✓ -

Ambient operating humidity

(2)

✓

(1)

-

-20…60 °C (-4…140 °F) ✓ -

-20…65 °C (-4…149 °F) -

✓

5…95 % ✓

✓

(2)

-

✓

(1)

-

-✓

✓

(3)

-

(non-condensing)

Ambient storage temperature -30…70 °C (-22…158 °F) ✓

Ambient storage humidity

5…95 % ✓

(non-condensing)

Temperature for ball pressure

125 °C (257 °F) ✓ - ✓

test

Insulation material group IIIa ✓

Fire-resistance category D ✓

Software class and structure A ✓

Digital outputs Refer to the label on the

✓

device

Degree of protection by

IP20 ✓

enclosure

(1) Limited to 55°C (131°F), if mounted other than horizontally on vertical plane.

(2) Limited to 60°C (140°F), if mounted other than horizontally on vertical plane.

(3) Limited to 60°C (140°F), if DO8 is active or if mounted other than horizontally on vertical plane.

54

EIO0000002015 02/2020

Page 55

Modicon M172 Logic Controller

TM172P•••••• / TM172O••••• Contro llers Description

EIO0000002015 02/2020

TM172P•••••• / TM172O••••• Controllers Description

Chapter 6

TM172P•••••• / TM172O••••• Controllers Description

What Is in This Chapter?

This chapter contains the following topics:

TM172P•G07R 56

TM172P••18• / TM172O••18• 58

TM172P••28•• / TM172O••28R 61

TM172P••42•• / TM172O••42R 64

Topic Page

EIO0000002015 02/2020 55

Page 56

TM172P•••••• / TM172O••••• Controllers Description

TM172P•G07R

Overview

Reference Description

TM172PBG07R M172 Performance Blind 7 I/Os Isolated

TM172PDG07R M172 Performance Display 7 I/Os Isolated

Physical Description

The following illustration presents the TM172P•G07R controller:

Number Name Description

1 CN6 DO3 High voltage relay digital output 250 Vac 3 A SPDT

CN9 DO1…DO2 High voltage relay digital output 250 Vac 3 A SPST

2 CN10 24 Vac/dc isolated power supply

3 CN5 Power out +24 Vdc power out for analog inputs, max current 100mA

+5 Vdc power out for ratiometric analog inputs, max current 40 mA

AI1…AI2 Analog inputs are configurable as

NTC resistive input or digital input

Current analog input

Voltage analog input

PTC resistive input

4 - Clip-on lock

6 CN3 DI1…DI2 Fast digital input, pulse/frequency counter up 2 kHz, opto-isolated

8 CN1 RS-485 serial port-2

CN19 RS-485 serial port-1

9 CN18 CAN expansion bus master

10 - Micro SD memory card slot

11 - Service battery door

12 -

13 - Communication module connector

14 -

15 -

16 CN16 USB type Mini-B female for PC connection

17 CN17 USB type A female for a mass storage device (FAT32)

18 CN20 Ethernet Modbus TCP/IP or BACnet IP

(1) Only for TM172•D•••••.

(2) 0-5 V Ratiometric: ratiometric range is 0.5 V to 4.5 V. Maximum current at +5 Vdc is 40 mA.

User interface - Display

User interface - LEDs

User interface - Keys

(see page 37)

(see page 109)

(see page 109)

(see page 117)

(see page 119)

(see page 119)

(see page 119)

(see page 75)

(see page 90)

(see page 105)

(see page 115)

(1)

(see page 20)

(1)

(1)

(see page 111)

(see page 111)

(see page 112)

(see page 87)

(see page 83)

:

(2)

(see page 79)

56

NOTE: The controller is delivered without removable screw terminal blocks

(see page 23)

EIO0000002015 02/2020

.

Page 57