Page 1

CompactNSX

DOCA0140EN-01 01/2020

Compact NSX

Circuit Breakers and Switch-Disconnectors 100630 A

User Guide

01/2020

DOCA0140EN-01

www.se.com

Page 2

The information provided in this documentation contains general descriptions and/or technical character

istics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

-

2 DOCA0140EN-01 01/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Compact NSX Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Compact NSX Circuit Breaker Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EcoStruxure Power Commission Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

De-Energizing the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Circuit Breaker With Toggle Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Face Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening, Closing, and Resetting the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Circuit Breaker With Rotary Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Face Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening, Closing, and Resetting the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing a Circuit Breaker With Direct Rotary Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking a Circuit Breaker With Direct Rotary Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing a Circuit Breaker With Extended Rotary Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking a Circuit Breaker With Extended Rotary Handle . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Motor-Operated Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Face Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening, Closing, and Resetting a Circuit Breaker With Motor Mechanism . . . . . . . . . . . . .

Opening, Closing, and Resetting Circuit Breakers With Communicating Motor Mechanism.

Locking the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Compact NSX Installation Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Plug-in Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Withdrawable Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Compact NSX Electrical Auxiliary Devices . . . . . . . . . . . . . . . . . . . . . . . . . 65

Electrical Auxiliary Device Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indication Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDx Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDTAM Module (Micrologic 2 M and 6 E-M). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BSCM Breaker Status Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NSX Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Insulated NSX Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Auxiliaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Compact NSX Trip Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.1 Fault Currents and Trip Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Currents in Electrical Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Against Overcurrents in Electrical Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Against Ground Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection for Motor-Feeders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

11

17

19

20

22

24

25

26

28

29

31

32

34

36

37

40

42

44

45

47

50

51

54

58

64

66

70

71

74

76

79

81

83

86

87

88

89

91

93

DOCA0140EN-01 01/2020 3

Page 4

4.2 TM-D, TM-G Thermal-Magnetic and MA Magnetic Trip Units . . . . . . . . . . . . . . . . . . . . . . . .

Thermal-Magnetic Trip Unit Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM-D Thermal-Magnetic Trip Unit for 1P and 2P Circuit Breakers . . . . . . . . . . . . . . . . . . . .

TM-D Thermal-Magnetic Trip Unit for 3P and 4P Circuit Breakers up to 63 A. . . . . . . . . . . .

TM-D Thermal-Magnetic Trip Unit for 3P and 4P Circuit Breakers from 80 A to 250 A . . . .

TM-G Thermal-Magnetic Trip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MA Magnetic Trip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Vigi Earth-Leakage Protection Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vigi Earth-Leakage Protection Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Micrologic Electronic Trip Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics of Micrologic Electronic Trip Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 2 Electronic Trip Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 4 Electronic Trip Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 1.3 M Electronic Trip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 2 M Electronic Trip Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 2 G Electronic Trip Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micrologic 2 AB and 4 AB Electronic Trip Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Maintenance Interfaces for Micrologic Trip Units . . . . . . . . . . . . . . . . . . . . . 137

Micrologic Maintenance Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pocket Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand-Alone USB Maintenance Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

USB Maintenance Interface Connected to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Compact NSX Circuit Breakers Operation . . . . . . . . . . . . . . . . . . . . . . . . . 147

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining the Circuit Breaker During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responding to a Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Fixed Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug-in / Withdrawable Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDx Module With Micrologic 2, 4, 5, 6, and 7 Trip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDTAM Module With Micrologic M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B Additional Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Compact NSX100-250 - Distribution Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX100-250 - Motor-Feeder Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX400-630 - Distribution Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX400-630 - Motor-Feeder Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX100-630 - Reflex Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact NSX100-630 - Limitation Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

96

97

99

100

101

104

106

108

108

111

112

118

122

127

129

132

134

138

139

141

144

148

153

155

157

159

162

165

170

172

174

178

184

185

186

187

188

191

4 DOCA0140EN-01 01/2020

Page 5

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

DOCA0140EN-01 01/2020 5

Page 6

CYBERSECURITY SAFETY NOTICE

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND CONFIDENTIALITY

Change default passwords at first use to help prevent unauthorized access to device settings,

controls, and information.

Disable unused ports/services and default accounts to help minimize pathways for malicious

attackers.

Place networked devices behind multiple layers of cyber defenses (such as firewalls, network

segmentation, and network intrusion detection and protection).

Use cybersecurity best practices (for example, least privilege, separation of duties) to help prevent

unauthorized exposure, loss, modification of data and logs, or interruption of services.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

6 DOCA0140EN-01 01/2020

Page 7

At a Glance

Document Scope

Validity Note

Related Documents

About the Book

The aim of this guide is to provide users, installers and maintenance personnel with the technical

information needed to operate Compact NSX circuit breakers and switch-disconnectors in compliance with

the IEC/EN standards.

This guide applies to Compact NSX circuit breakers and switch-disconnectors.

The information contained in this guide is likely to be updated at any time. Schneider Electric strongly

recommends that you have the most recent and up-to-date version available on

electric.com

Title of Documentation Reference Number

Compact NSX & NSXm Catalogue LVPED217032EN

Compact NSX Micrologic 5/6/7 Electronic Trip Units - User Guide DOCA0141EN

Compact NSX - Modbus Communication Guide DOCA0091EN

Enerlin'X IO - Input/Output Application Module for One IEC Circuit

Breaker - User Guide

Enerlin'X IFE - Ethernet Interface for One IEC Circuit Breaker - User

Guide

ULP System (IEC Standard) - User Guide DOCA0093EN

.

DOCA0141ES

DOCA0141FR

DOCA0141ZH

DOCA0091ES

DOCA0091FR

DOCA0091ZH

DOCA0055EN

DOCA0055ES

DOCA0055FR

DOCA0055ZH

DOCA0084EN

DOCA0084ES

DOCA0084FR

DOCA0084ZH

DOCA0093ES

DOCA0093FR

DOCA0093ZH

www.schneider-

You can download these technical publications and other technical information from our website at

https://www.se.com/ww/en/download/ .

Trademark Notice

All trademarks are owned by Schneider Electric Industries SAS or its affiliated companies.

DOCA0140EN-01 01/2020 7

Page 8

8 DOCA0140EN-01 01/2020

Page 9

CompactNSX

Compact NSX Circuit Breakers

DOCA0140EN-01 01/2020

Compact NSX Circuit Break ers

Chapter 1

Compact NSX Circuit Breakers

What Is in This Chapter?

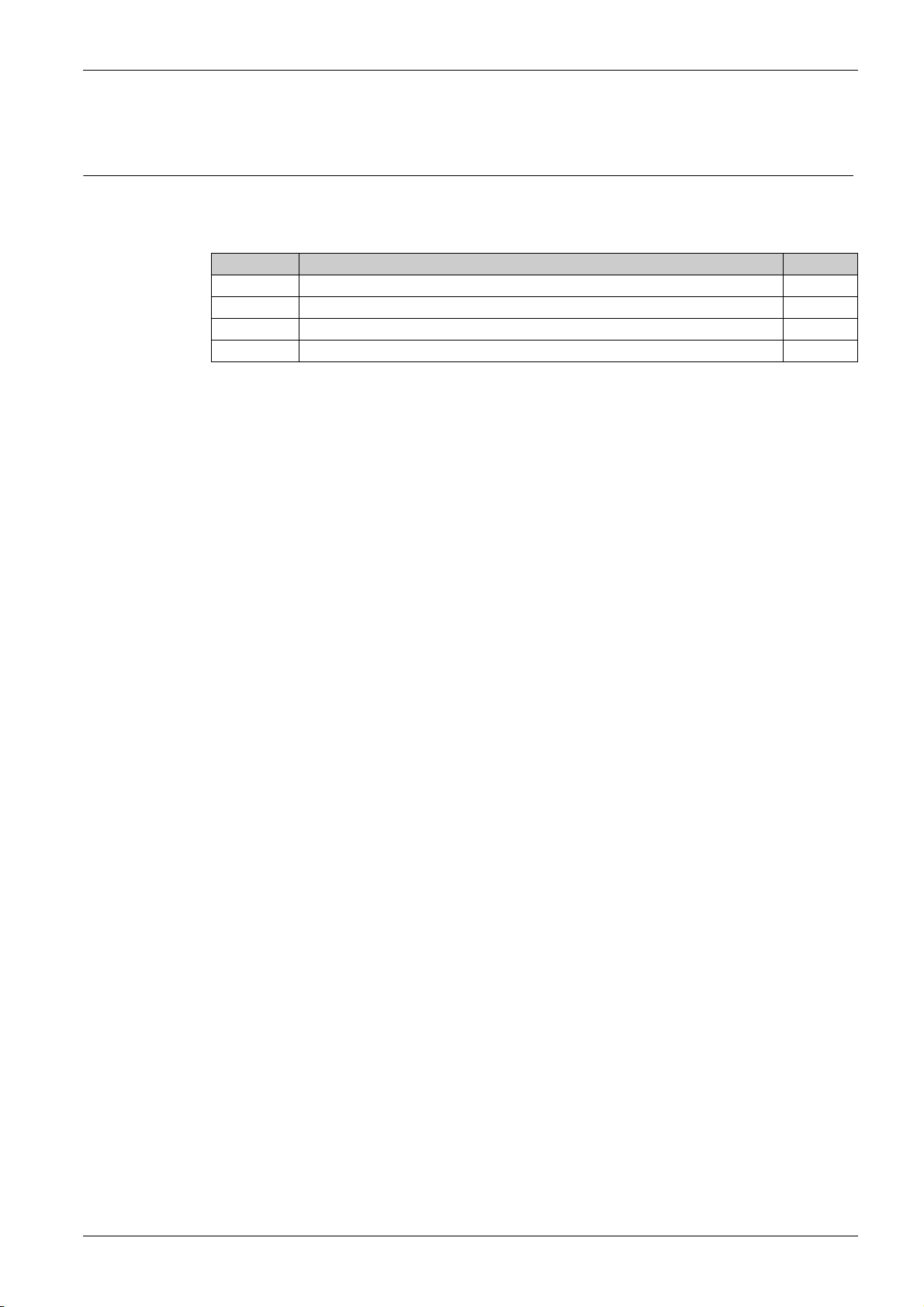

This chapter contains the following sections:

Section Topic Page

1.1 Compact NSX Circuit Breaker Presentation 10

1.2 Circuit Breaker With Toggle Handle 24

1.3 Circuit Breaker With Rotary Handle 31

1.4 Motor-Operated Circuit Breakers 44

DOCA0140EN-01 01/2020 9

Page 10

Compact NSX Circuit Breakers

CompactNSX Circuit Breaker Presentation

Section 1.1

Compact NSX Circuit Breaker Presentation

What Is in This Section?

This section contains the following topics:

Compact NSX Range 11

Operating the Circuit Breaker 17

EcoStruxure Power Commission Software 19

De-Energizing the Circuit Breaker 20

Environmental Conditions 22

Topic Page

10

DOCA0140EN-01 01/2020

Page 11

Compact NSX Range

Description

The Compact NSX alternating current (AC) range consists of

Circuit breakers and switch-disconnectors operating on alternating current:

1-pole circuit breakers from 16 to 250 A, up to 240 Vac

2-pole circuit breakers from 16 to 160 A, up to 690 Vac

3 and 4-pole circuit breakers and switch-disconnectors from 16 to 630 A, up to 690 Vac

A set of standard accessories and auxiliaries shared with the Compact NSX DC range

The Compact NSX range covers the following applications:

Electrical distribution protection

Special protection for receivers (for example, motors, transformers) or generators

The Compact NSX range is compliant with the following standards:

IEC/EN 60947-2 for circuit breakers

IEC/EN 60947-3 for switch-disconnectors

IEC/EN 60947-2 and IEC/EN 60947-4-1 for motor protection circuit breakers

UL 60947-4-1 for motor protection circuit breakers

CSA-C22.2 No.60947-4-1-14 for motor protection circuit breakers

Convention

In this guide, the term

circuit breaker

Compact NSX Circuit Breakers

covers circuit breakers and switch-disconnectors.

DOCA0140EN-01 01/2020 11

Page 12

Compact NSX Circuit Breakers

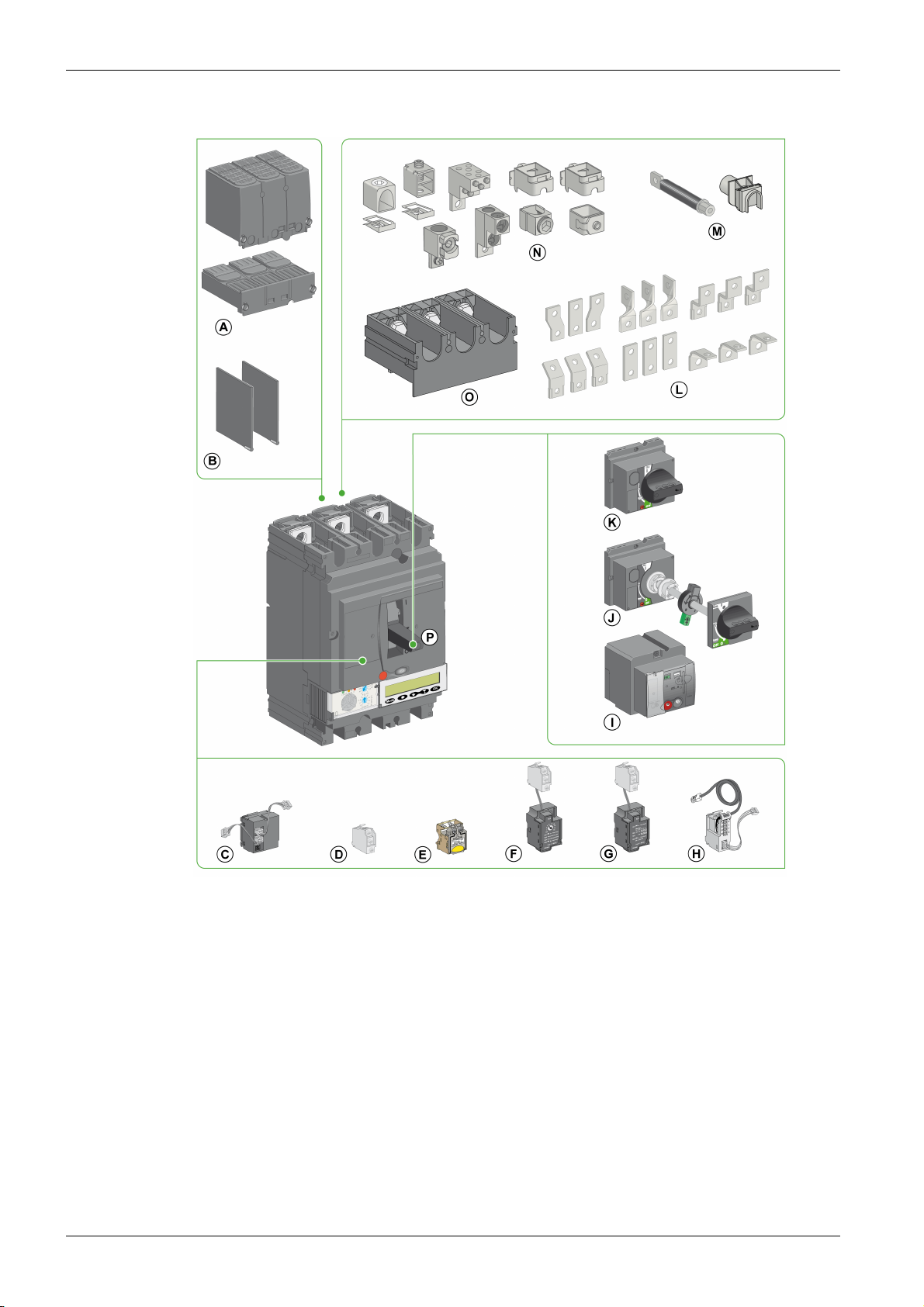

Fixed Circuit Breaker

12

A Sealable terminal shields

B Interphase barriers

C BSCM module

D Indication contact

E Voltage release

F SDTAM module

G SDx module

H NSX cord

I Motor mechanism

J Extended rotary handle

K Direct rotary handle

L Terminal extensions

M Rear connectors

N Cable connectors

O One-piece spreader

P Toggle handle

DOCA0140EN-01 01/2020

Page 13

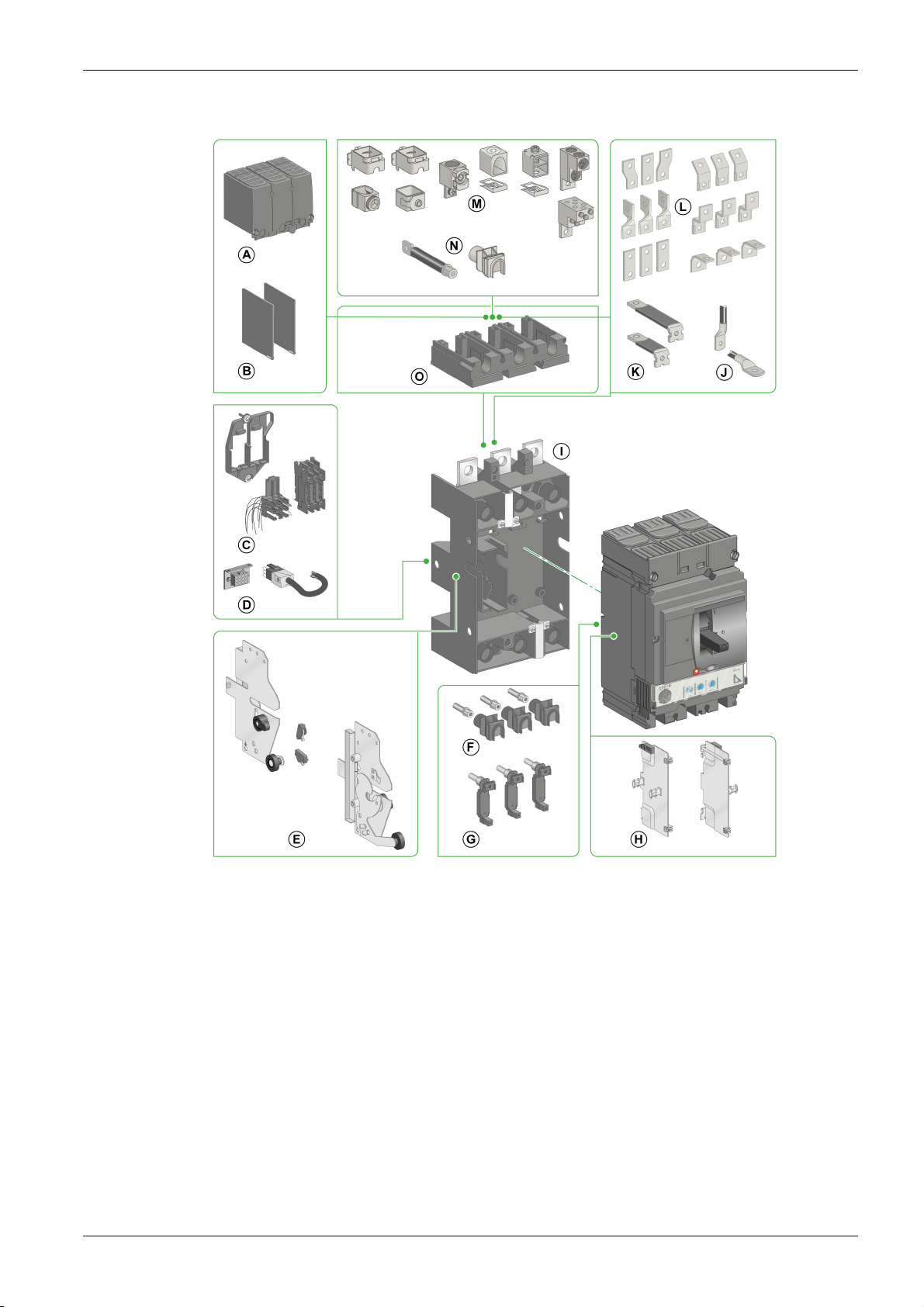

Withdrawable or Plug-in Circuit Breaker

Compact NSX Circuit Breakers

A Sealable long terminal shields for plug-in base

B Interphase barriers

C Automatic withdrawable auxiliary connector

D Manual auxiliary connector

E Chassis side plate for withdrawable circuit breaker

F Power connections

G Power connections for circuit breaker with Vigi module

H Circuit-breaker side plate

I Circuit-breaker plug-in base

J Lugs

K Rear connectors

L Terminal extensions

M Cable connectors

N Rear connectors

O Adapter

DOCA0140EN-01 01/2020 13

Page 14

Compact NSX Circuit Breakers

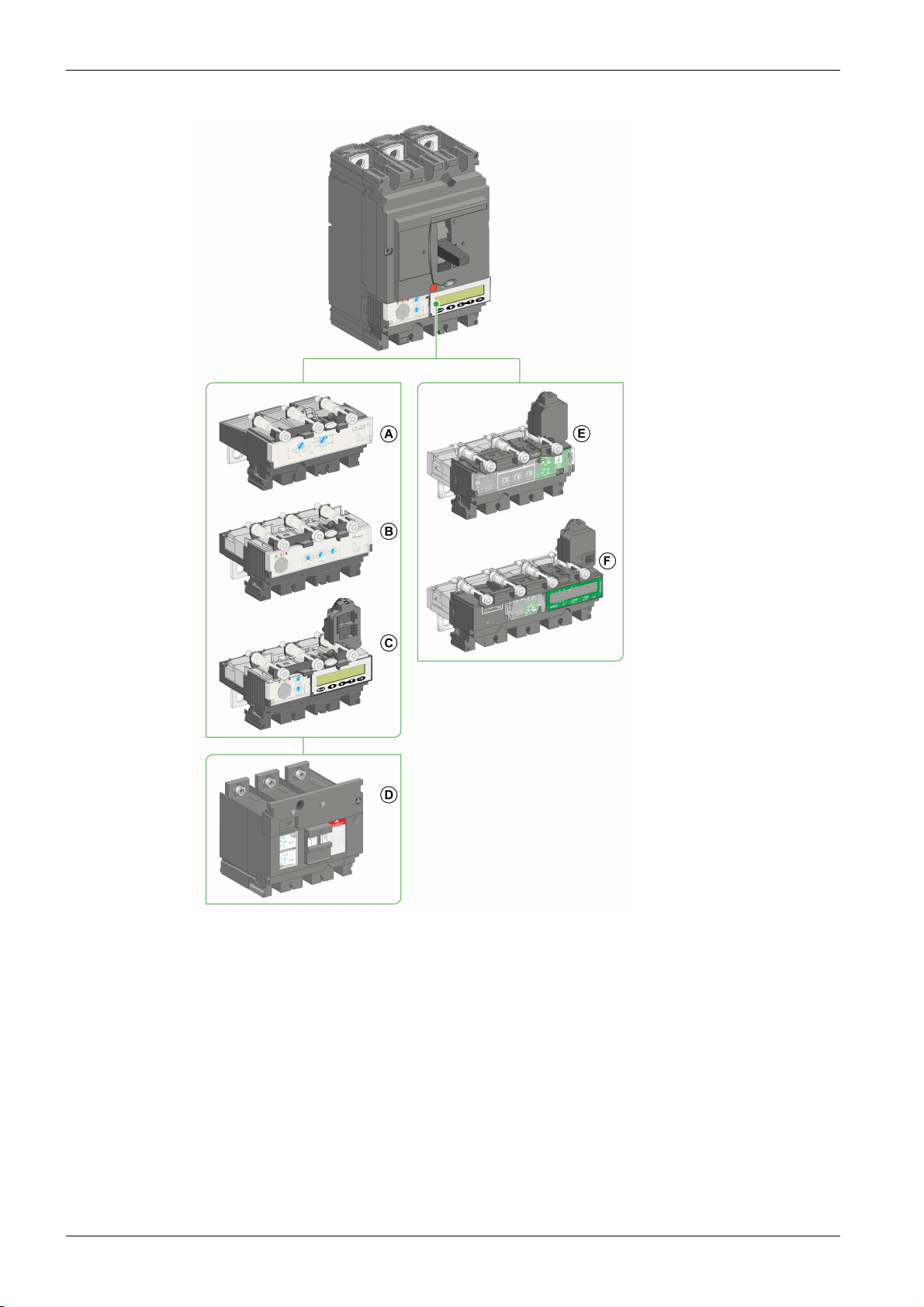

Trip Units and Trip Unit Accessories

14

A TM-D, TM-G, or MA trip unit

B Micrologic 1 or 2 trip unit

C Micrologic 5 or 6 trip unit

D Vigi module for additional earth-leakage

protection

E Micrologic 4 trip unit with earth-leakage

protection

F Micrologic 7 trip unit with earth-leakage

protection

DOCA0140EN-01 01/2020

Page 15

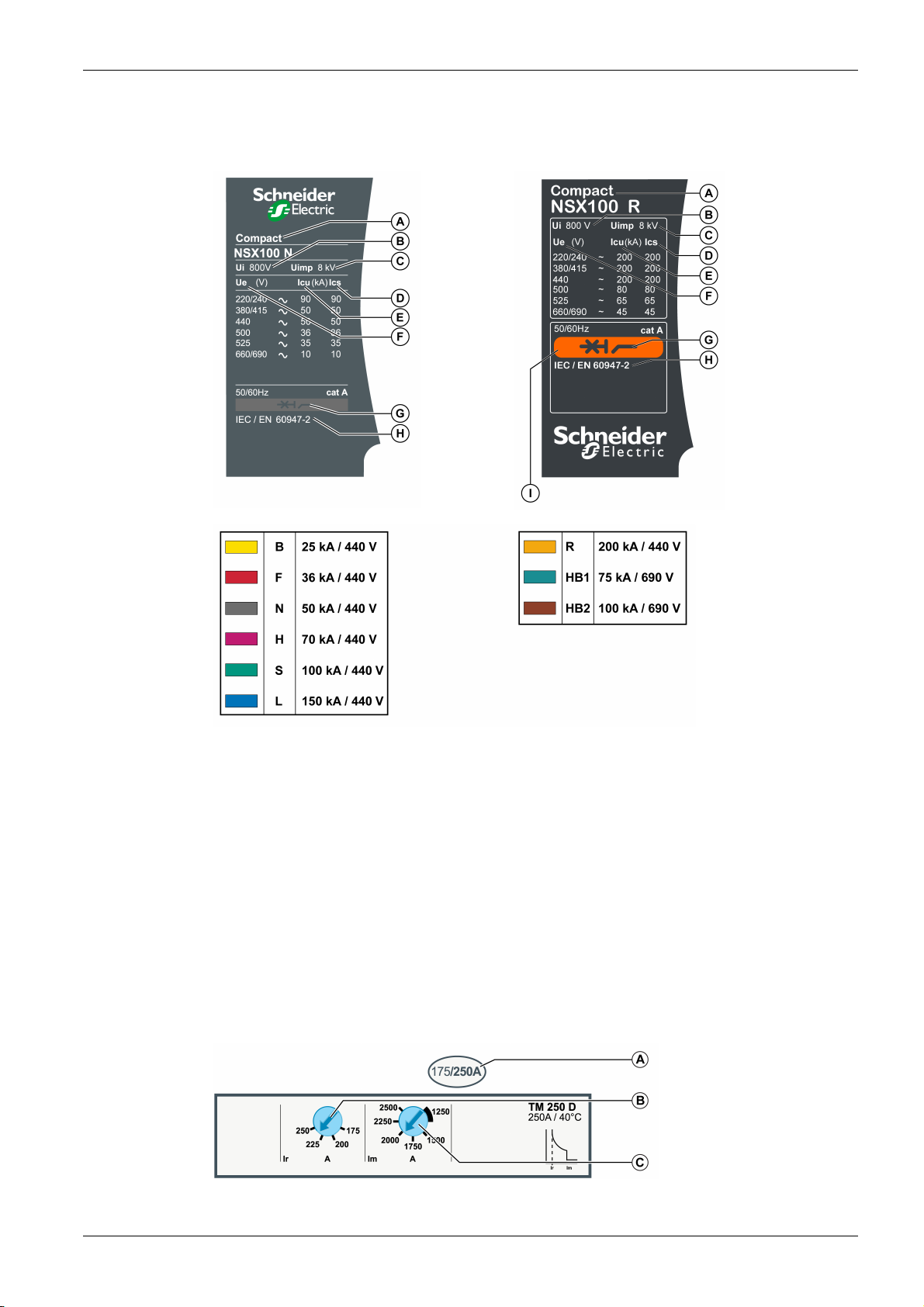

Identification

Compact NSX Circuit Breakers

The faceplate on the front of the circuit breaker identifies the circuit breaker and its characteristics.

The faceplate depends on the breaking performances:

Dial Settings

A Device size and rated current

B Ui: rated insulation voltage

C Uimp: rated impulse withstand voltage

D Ics: rated service short-circuit breaking capacity

E Icu: rated ultimate short-circuit breaking capacity

F Ue: rated operational voltage

G Type of device: circuit breaker or switch-disconnector, suitable for isolation

H Standards

I Color code indicating breaking performance

NOTE: R, HB1, and HB2 breaking performances are not compatible with Micrologic 4 and 7 trip units.

NOTE: For extended rotary handles, open the door to view the faceplate label.

The dial positions on the front of the trip unit set the circuit breaker pickup settings.

Example 1: TM-D thermal-magnetic trip unit

A Setting range for TM-D

thermal-magnetic trip unit

B Adjustment dial for the

thermal protection pickup Ir

C Adjustment dial for the

magnetic protection pickup

Im (for TM-D 200/250 only)

DOCA0140EN-01 01/2020 15

Page 16

Compact NSX Circuit Breakers

Example 2: Micrologic 2 and Micrologic 4 electronic trip units

Trip Unit Settings

For Micrologic 5, 6, and 7 electronic trip units, read all settings on the display unit. For more information,

refer to

A Trip unit adjustment range

B Adjustment dials for the

long-time protection pickup

Io and Ir

C Adjustment dial for the

short-time protection pickup

Isd

D Adjustment dial for the

earth-leakage current

pickup IΔn

E Adjustment dial for the

earth-leakage time delay Δt

DOCA0141EN, Compact NSX Micrologic 5/6/7 Electronic Trip Units - User Guide

.

16

DOCA0140EN-01 01/2020

Page 17

Compact NSX Circuit Breakers

Operating the Circuit Breaker

Circuit Breaker Operating Control Accessories

The following table shows the operating control accessories compatible with the Compact NSX circuit

breakers. For more information, refer to

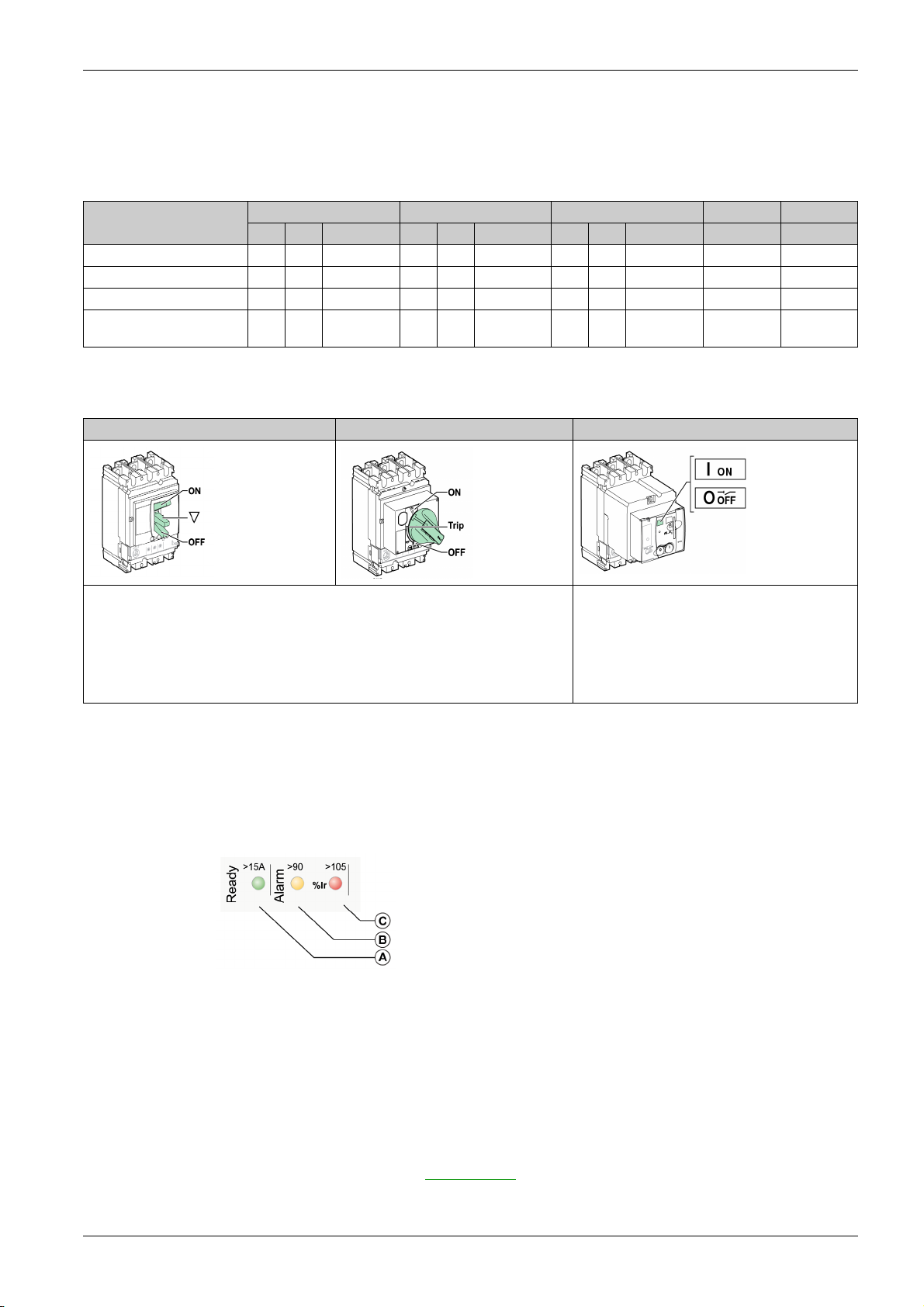

Operating control accessory NSX100 NSX160 NSX250 NSX400 NSX630

1P 2P 3P/4P 1P 2P 3P/4P 1P 2P 3P/4P 3P/4P 3P/4P

Toggle handle ✔ ✔ ✔ ✔ ✔ ✔ ✔ – ✔ ✔ ✔

Rotary handle – – ✔ – – ✔ – – ✔ ✔ ✔

Motor mechanism – – ✔ – – ✔ – – ✔ ✔ ✔

Communicating motor

mechanism

––✔ ––✔ ––✔ ✔ ✔

Handle Position

The handle position indicates the state of the circuit breaker:

Toggle handle Rotary handle Motor mechanism

Compact NSX & NSXm Catalogue

.

I (ON): Circuit breaker closed.

Closed manually.

O (OFF): Circuit breaker open.

Opened manually.

Trip or Tripped: Circuit breaker tripped.

Tripped by the protection (trip unit or trip auxiliaries), the push-to-trip button, or the

USB maintenance interface.

Load Indication

Circuit breakers equipped with a Micrologic trip unit provide precise information of the state of the circuit

breaker or the installation. This information can be used for the management and maintenance of the

installation.

For example, if the pre-alarm or alarm indicator is lit, performing load shedding may prevent tripping due

to circuit breaker overload.

A The Ready LED (green) blinks slowly when the electronic trip unit is ready to provide protection.

B The overload pre-alarm LED (orange) shows a steady light when the load exceeds 90% of the Ir setting.

C The overload alarm LED (red) shows a steady light when the load exceeds 105% of the Ir setting.

I (ON): Circuit breaker closed (in Auto or Manu

mode).

O (OFF): Circuit breaker open or tripped (in

Auto or Manu mode).

Remote Indication

Information is available remotely:

From the indication contacts

By using a communication network

These indication auxiliaries can be installed on site.

For more information about the remote indication and communication options, refer to the summary tables

of auxiliaries

User Guide

DOCA0140EN-01 01/2020 17

(see page 66)

.

and to

DOCA0141EN, Compact NSX Micrologic 5/6/7 Electronic Trip Units -

Page 18

Compact NSX Circuit Breakers

Remote Electrical Stop Command

The remote electrical stop command can be given by electrical control auxiliaries regardless of the control

type in use.

To obtain a remote electrical stop command, use:

An MX shunt trip release, or

An MN undervoltage trip release, or

An MN undervoltage trip release with time-delay unit (the time-delay unit overcomes the problem of

micro-cuts).

For more information about the electrical control auxiliaries, refer to the relevant topic

NOTE: It is advisable to test operation of the remote electrical stop commands at regular intervals (every

six months).

(seepage83)

.

18

DOCA0140EN-01 01/2020

Page 19

Compact NSX Circuit Breakers

EcoStruxure Power Commission Software

Overview

EcoStruxure

EcoStruxure Power Commission software helps you to manage a project as part of testing, commissioning,

and maintenance phases of the project life cycle. The innovative features in it provide simple ways to

configure, test, and commission the smart electrical devices.

EcoStruxure Power Commission software automatically discovers the smart devices and allows you to add

the devices for an easy configuration. You can generate comprehensive reports as part of Factory

Acceptance Test and Site Acceptance Test to replace your heavy manual work. Additionally, when the

panels are under operation, any change of settings made can be easily identified by a yellow highlighter.

This indicates the difference between the project and device values, and hence provides a system

consistency during the operation and maintenance phase.

EcoStruxure Power Commission software enables the configuration of the following circuit breakers,

modules, and accessories:

Circuit breaker ranges Modules Accessories

Masterpact MTZ circuit breakers

Masterpact NT/NW circuit breakers

Compact NS circuit breakers

PowerPact P- and R-frame circuit breakers

Compact NSX circuit breakers

PowerPact H-, J- and L-frame circuit

breakers

(1) For FDM121 display, only the firmware and language download are supported.

TM

Power Commission is the new name of Ecoreach software.

Micrologic X control unit

Communication interface modules: IFM

interface, IFE interface, IFE server, and EIFE

interface

ULP modules: IO module

Micrologic trip units

Communication interface modules: BCM

module, CCM module, BCM ULP module, IFM

interface, IFE interface, IFE server

ULP modules: IO module, FDM121 display

Micrologic trip units

Communication interface modules: BSCM

(1)

module, IFM interface, IFE interface, IFE server

ULP modules: IO module, FDM121 display

(1)

M2C output module

M2C and M6C output modules

SDTAM and SDx output modules

Key Features

For more information, refer to the

EcoStruxure Power Commission Online Help

EcoStruxure Power Commission software is available at

www.se.com

.

EcoStruxure Power Commission software performs the following actions for the supported devices and

modules:

Create projects by device discovery

Save the project in the EcoStruxure Power Commission cloud for reference

Upload settings to the device and download settings from the device

Compare the settings between the project and the device

Perform control actions in a secured way

Generate and print the device settings report

Perform a communication wiring test on the entire project and generate and print test report

View the communication architecture between the devices in a graphical representation

View the measurements, logs, and maintenance information

Export Waveform Capture on Trip Event (WFC)

View the status of device and IO module

View the alarm details

Buy, install, remove, or retrieve the Digital Modules

Check the system firmware compatibility status

Update to the latest device firmware

Perform force trip and automatic trip curve tests

DOCA0140EN-01 01/2020 19

Page 20

Compact NSX Circuit Breakers

De-Energizing the Circuit Breaker

Isolation Capacity

Compact NSX circuit breakers offer positive contact indication and are suitable for isolation in accordance

with standards IEC/EN 60947-1 and 2. The O (OFF) position of the actuator is sufficient to isolate the

circuit breaker concerned.

The following marking on the faceplate label indicates that the circuit breaker is capable of isolation:

To confirm this capability, standards IEC/EN 60947-1 and 2 require specific shock withstand tests.

Compact NSX circuit breakers can be locked in the O (OFF) position to allow work to be carried out with

the power off in accordance with installation rules. The circuit breaker can only be locked in the open

position if the circuit breaker is in the O (OFF) position.

NOTE: Locking a Compact NSX circuit breaker in the open position is sufficient to isolate the circuit

breaker.

The locks depend on the type of actuator:

For circuit breakers with toggle handles, refer to the locking accessories

For circuit breakers with rotary handles, refer to how to lock the circuit breaker with direct rotary handle

(see page 37)

For circuit breakers with motor mechanisms, refer to how to lock the circuit breaker

Maintenance and Servicing Work on Installation

and how to lock the circuit breaker with extended rotary handle

(see page 29)

(see page 42)

(see page 51)

.

.

.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See

NFPA 70E or CSA Z462 or local equivalent.

This equipment must only be installed and serviced by qualified electrical personnel.

Turn off all power supplying this equipment before working on or inside equipment.

Always use a properly rated voltage sensing device to confirm that power is off.

Replace all devices, doors, and covers before turning on power to this equipment.

Repair the installation immediately if an insulation fault occurs during operation.

Failure to follow these instructions will result in death or serious injury.

Turn off all power supplying the equipment before working on or inside equipment. For a partial powering

down of the installation, the installation and safety rules require clearly labeling and isolating the feed being

worked on.

Maintenance Work Following Fault Trip

HAZARD OF CLOSING ON ELECTRICAL FAULT

Do not close the circuit breaker again without first inspecting and, if necessary, repairing the downstream

electrical equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

20

The fact that a protection has tripped does not remedy the cause of the fault detected on the downstream

electrical equipment.

The following table describes the procedure to be followed after a fault trip:

Step Action

1 Isolate the feed before inspecting the downstream electrical equipment.

2 Look for the cause of the detected fault.

3 Inspect and, if necessary, repair the downstream equipment.

4 Inspect the equipment in the event of a short-circuit trip.

5 Close the circuit breaker again.

DOCA0140EN-01 01/2020

Page 21

For more information about troubleshooting and restarting following a fault, refer to what to do in the event

of a trip

Checking the Settings

Checking settings does not require any particular precautions. The checks must be carried out by a

qualified person.

Testing the Circuit Breaker

HAZARD OF NUISANCE TRIPPING

Protection tests must be done by qualified electrical personnel.

Failure to follow these instructions can result in injury or equipment damage.

When testing circuit breaker trip mechanisms, precautions must be taken:

To avoid disrupting operations.

To avoid inappropriate actions or tripping of alarms.

For example, tripping the circuit breaker with the push-to-trip button or the LTU test software can lead to

inappropriate fault indications or corrective actions (such as switching to a replacement power source).

(see page 155)

Compact NSX Circuit Breakers

.

CAUTION

Setting the Trip Unit

WARNING

HAZARD OF NUISANCE TRIPPING OR FAILURE TO TRIP

Protection setting adjustments must be done by qualified electrical personnel.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Modifying trip unit settings requires a thorough knowledge of the installation and safety rules.

DOCA0140EN-01 01/2020 21

Page 22

Compact NSX Circuit Breakers

Environmental Conditions

Ambient Temperature

The ambient temperature refers to the temperature of the air immediately surrounding the circuit breaker.

Operation temperature

–25 to +70 °C (–13 to +158 °F): Normal operating temperature

NOTE: The minimum operating temperature for the earth-leakage fault indicator on the Micrologic 4

trip unit is -15 °C (5°F). Between -15 and -5 °C (5 and 23 °F), and when operating the device with an

earth leakage fault and a very low load compared to the trip unit rating In, the earth leakage indicator

may not work correctly (fault indication or reset).

–35 to –25 °C (–31 to –13 °F): Commissioning possible

Storage temperature

–50 to +85 °C (–58 to +185 °F): Without Micrologic trip unit

–40 to +85 °C (–40 to +185 °F): With liquid crystal Micrologic trip unit

Extreme Atmospheric Conditions

Compact NSX circuit breakers are designed to operate in industrial atmospheres as defined in standard

IEC/EN 60947-2 for the highest level of pollution (level 3).

They are tested for extreme storage conditions according to the following standards:

Standard Title

IEC/EN 60068-2-2 Dry heat, severity level +85 °C (+185 °F)

IEC/EN 60068-2-1 Dry cold, severity level –55 °C (–67 °F)

IEC/EN 60068-2-30 Damp heat, cyclic

IEC/EN 60068-2-52 Salt-mist test

To obtain the best use from the circuit breakers, install them in properly ventilated switchboards where

excessive dust is not a problem.

Vibration

Compact NSX circuit breakers are tested against vibration.

temperature +55 °C (+131 °F)

relative humidity 95 %

22

Conformity tests are carried out in accordance with standard IEC/EN 60068-2-6 at the levels of severity

required by the merchant shipping regulatory bodies (IACS, Veritas, Lloyd namely):

2 Hz to 13.2 Hz with an amplitude of +/- 1 mm (+/- 0.04 in)

13.2 Hz to 100 Hz at a constant acceleration of 0.7 g

DOCA0140EN-01 01/2020

Page 23

Electromagnetic Disturbances

Compact NSX circuit breakers are immune to electromagnetic disturbance.

They comply with the requirements of the electromagnetic compatibility (EMC) standard:

Standard Title

IEC/EN 60947-2 appendixes F and J Overcurrent protection tests

IEC/EN 60947-2 appendixes B and J Specific tests for earth-leakage protection

Check for compliance with EMC standards by testing for immunity to:

Overvoltages produced by the operation of electromagnetic switchgear.

Overvoltages produced by atmospheric disturbance that pass through the electrical network (for

example, lightning).

The use of apparatus emitting radio waves (such as radio transmitters, walkie-talkies, or radar).

Electrostatic discharges produced by the operators themselves.

Conformity with EMC standards as described above helps to ensure that:

The circuit breaker operates correctly in a disturbed environment:

Without nuisance tripping.

In accordance with the trip time.

There is no disturbance to any type of industrial or commercial environment.

Compact NSX Circuit Breakers

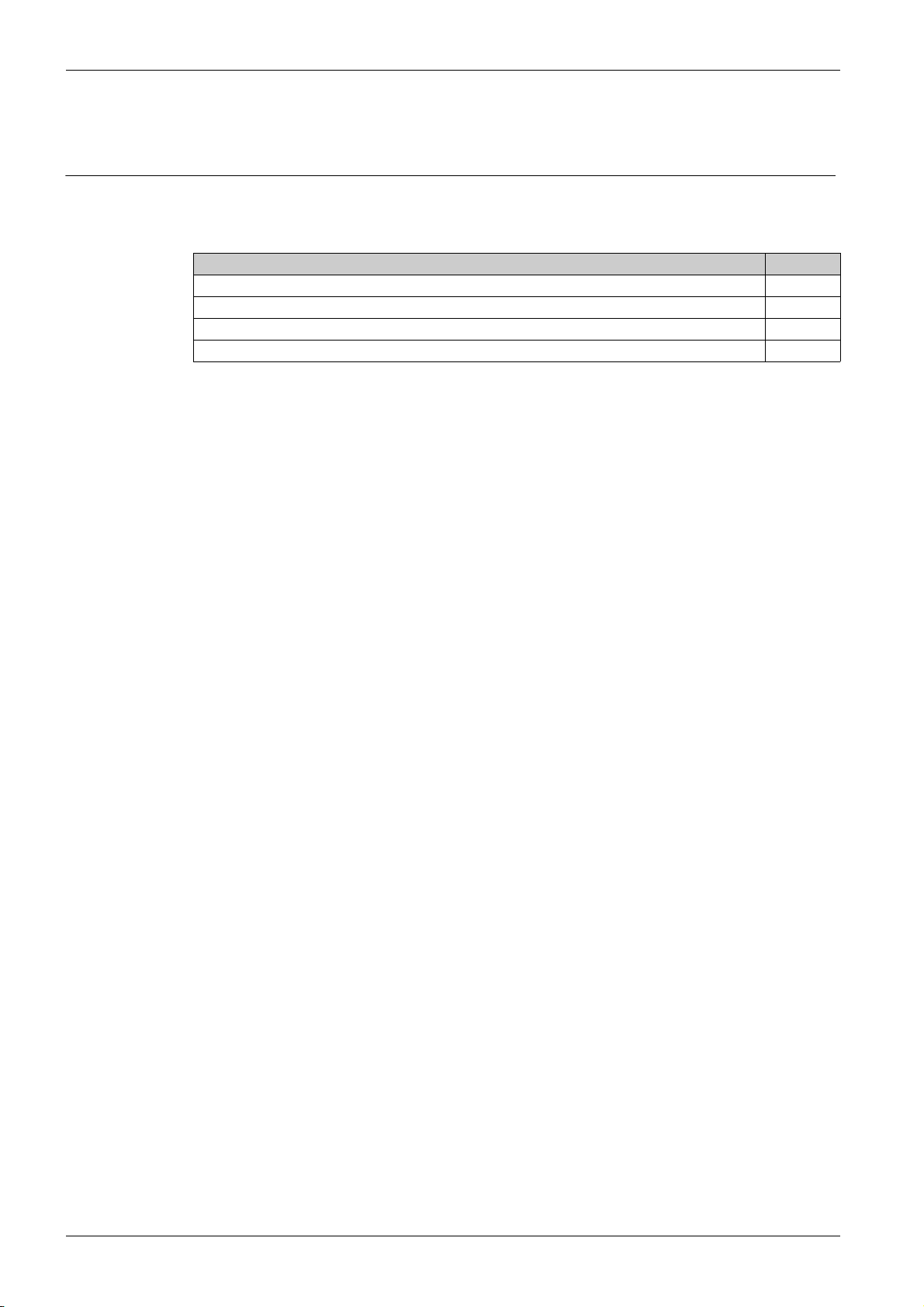

Altitude

Compact NSX circuit breakers are designed to operate within specification at altitudes of up to 2,000 m

(6,600 ft).

Above 2,000 m (6,600 ft) modifying the characteristics of the surrounding air (dielectric strength, cooling

capacity) causes derating as follows:

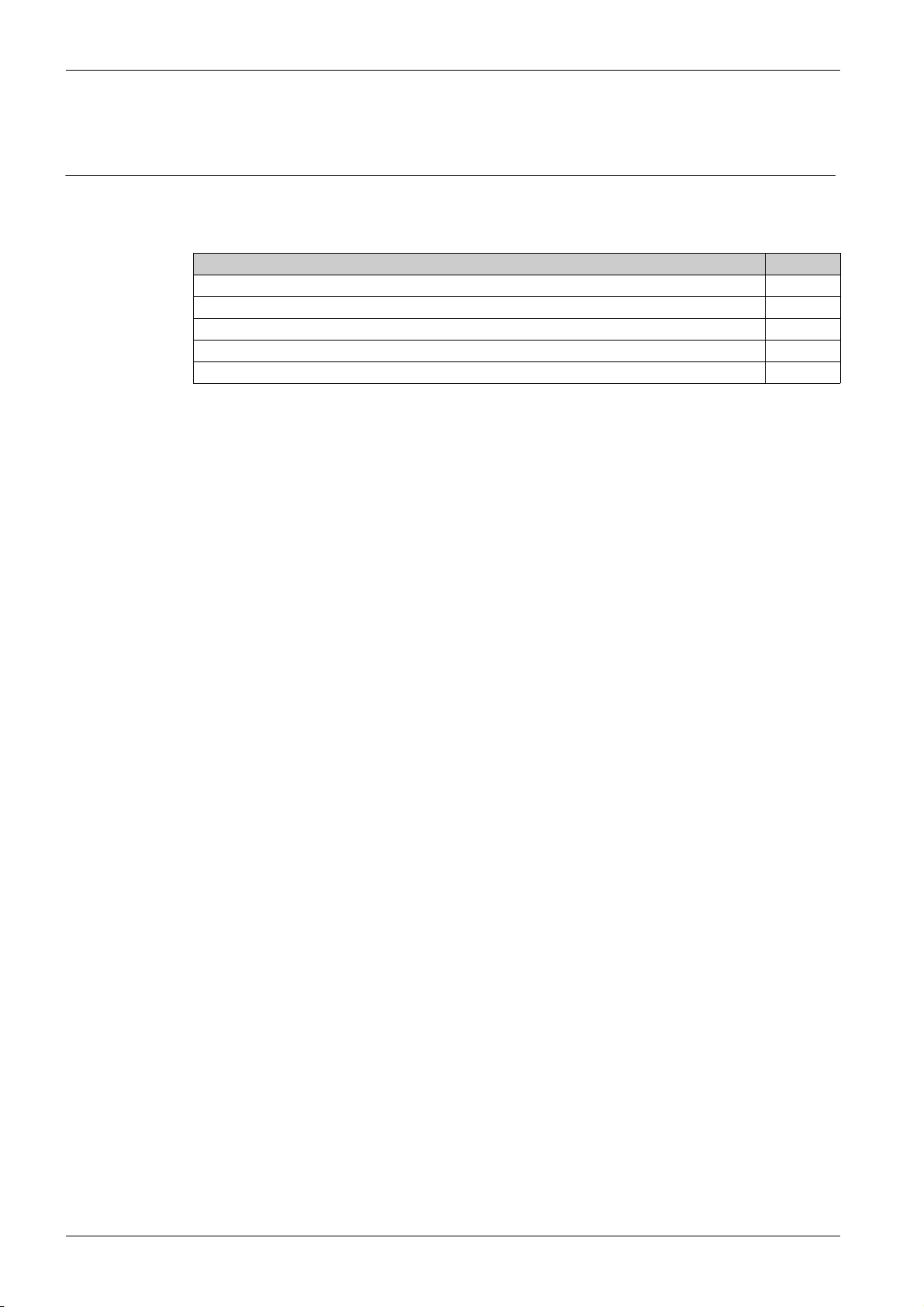

Altitude (m/ft) < 2,000 m

(6,600 ft)

Maximum operating voltage (V) 690 590 520 460

Rated thermal current (A) at 40 °C (104 °F) In 0.96 x In 0.93 x In 0.9 x In

3,000 m

(9,800 ft)

4,000 m

(13,000 ft)

5,000 m

(16,500 ft)

DOCA0140EN-01 01/2020 23

Page 24

Compact NSX Circuit Breakers

Circuit Breaker With Toggle Handle

Section 1.2

Circuit Breaker With Toggle Handle

What Is in This Section?

This section contains the following topics:

Front Face Description 25

Opening, Closing, and Resetting the Circuit Breaker 26

Testing the Circuit Breaker 28

Locking the Circuit Breaker 29

Topic Page

24

DOCA0140EN-01 01/2020

Page 25

Front Face Description

Front Face

Compact NSX Circuit Breakers

A Faceplate

B Toggle handle for opening, closing, and resetting

C Push-to-trip button

D Trip unit setting range

E Trip unit

F Trip unit adjustment dials

For more information about trip units, refer to the related description

(see page 85)

.

DOCA0140EN-01 01/2020 25

Page 26

Compact NSX Circuit Breakers

Opening, Closing, and Resetting the Circuit Breaker

Opening and Closing Locally

To close the circuit breaker, move the toggle handle from the O(OFF) position to the I(ON) position.

To open the circuit breaker, move the toggle handle from the I(ON) position to the O (OFF) position.

Resetting After a Trip on Electrical Fault

The circuit breaker has tripped on electrical fault, the toggle handle has moved from the I(ON) position to

the Trip position.

WARNING

HAZARD OF CLOSING ON ELECTRICAL FAULT

Do not close the circuit breaker again without first inspecting and, if necessary, repairing the downstream

electrical equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The fact that a circuit breaker has tripped does not remedy the cause of the fault detected on the

downstream electrical equipment.

26

DOCA0140EN-01 01/2020

Page 27

Compact NSX Circuit Breakers

To reset after a fault trip:

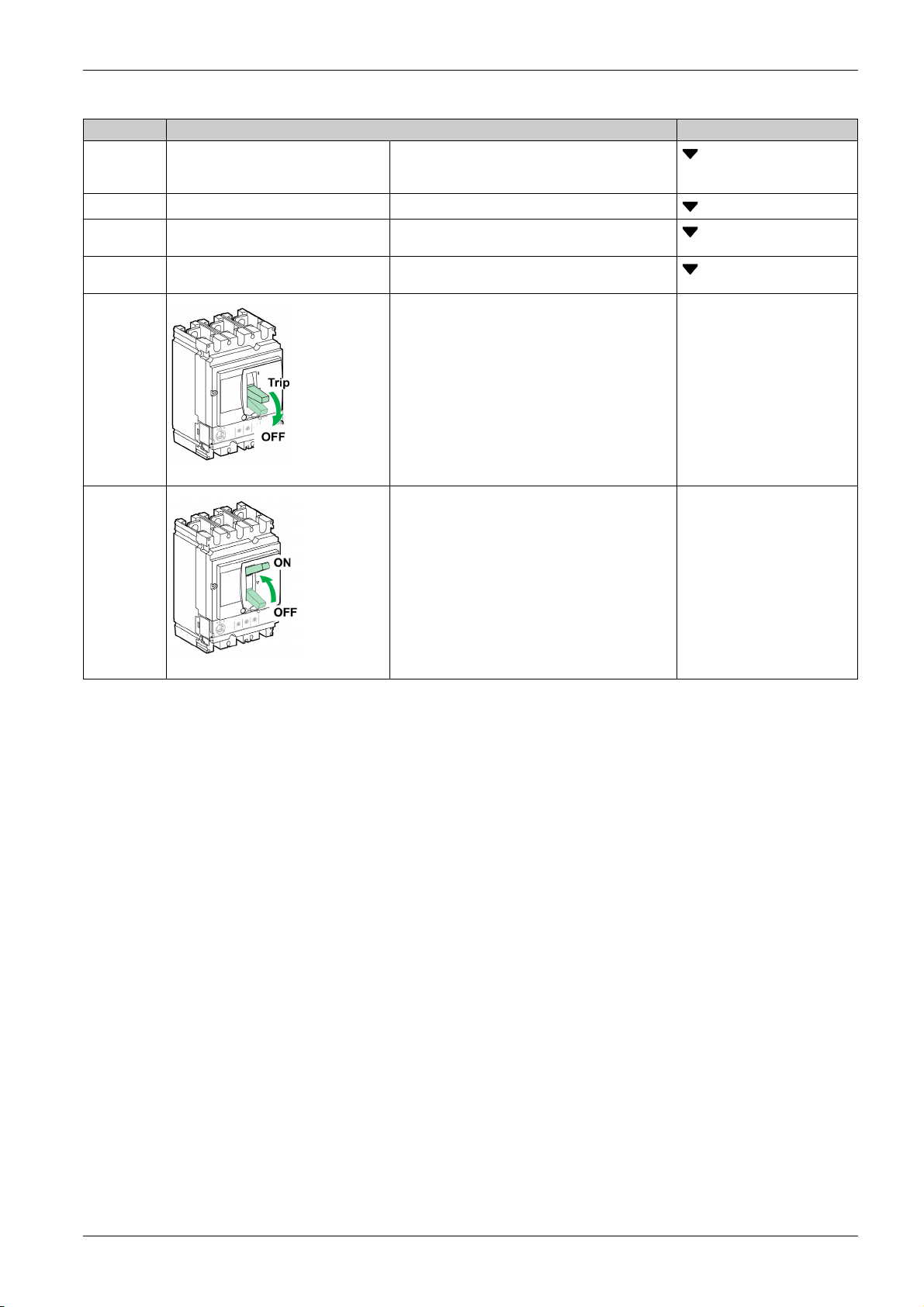

Step Action Position

1 – Isolate the feed (refer to maintenance and servicing

work on installation

inspecting the downstream electrical equipment.

2 – Look for the cause of the detected fault.

3 – Inspect and, if necessary, repair the downstream

equipment.

4 – Inspect the equipment in the event of a short-circuit

trip.

5 Reset the circuit breaker by moving the toggle

handle to O(OFF).

(see page 20)

) before

O (OFF)

6 Close the circuit breaker by moving the toggle

handle to I(ON).

I(ON)

DOCA0140EN-01 01/2020 27

Page 28

Compact NSX Circuit Breakers

Testing the Circuit Breaker

Push-to-Trip Procedure

CAUTION

HAZARD OF NUISANCE TRIPPING

Circuit breaker tests must only be done by qualified electrical personnel.

Failure to follow these instructions can result in injury or equipment damage.

When testing the trip mechanism take precautions against:

Disrupting operations

Activating inappropriate alarms

Triggering unwanted actions

For example, tripping the circuit breaker with the push-to-trip button can lead to inappropriate fault

indications or corrective actions (such as switching to an alternate power source).

Follow these steps to test the trip mechanism:

Step Action Position

1 Close the circuit breaker. I (ON)

2 Press the push-to-trip button to trip the

circuit breaker.

3 Move the toggle handle to the

O(OFF) position to reset the circuit

breaker.

4 Move the toggle handle to the I(ON)

position to close the circuit breaker.

O(OFF)

I(ON)

28

DOCA0140EN-01 01/2020

Page 29

Locking the Circuit Breaker

Locking Accessories

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When the circuit breaker toggle handle is locked in the (O) OFF position, always use a properly rated

voltage sensing device to confirm that power is off before working on equipment.

Failure to follow these instructions will result in death or serious injury.

Use locking accessories to lock the toggle handle in the I(ON) or O (OFF) position.

Accessory Padlocks

Compact NSX Circuit Breakers

DANGER

Accessory that is part of the case Use up to 3 padlocks (not supplied) 5–8 mm

(0.2–0.3 in) in diameter

Accessory that is detachable Use up to 3 padlocks (not supplied) 5–8 mm

NOTE: Locking the toggle handle in the I(ON) position does not disable the circuit breaker protection

functions. If there is an electrical fault, the circuit breaker trips without altering its performance. When

unlocked, the toggle handle moves to the Trip position. To return the circuit breaker to service, refer to how

to open, close, and reset the circuit breaker

(see page 26)

(0.2–0.3 in) in diameter

.

DOCA0140EN-01 01/2020 29

Page 30

Compact NSX Circuit Breakers

Sealing Accessories

Use sealing accessories to prevent circuit breaker operations.

Seal Prohibited operations

Escutcheon mounting screw

Dismantling the escutcheon

Accessing the auxiliaries

Dismantling the trip unit

Transparent protective cover

Altering trip unit settings

Accessing the test port for the trip

units

Mounting screw for terminal shields Accessing the power connection

(protection against direct contact)

30

DOCA0140EN-01 01/2020

Page 31

Circuit Breaker With Rotary Handle

Section 1.3

Circuit Breaker With Rotary Handle

What Is in This Section?

This section contains the following topics:

Front Face Description 32

Opening, Closing, and Resetting the Circuit Breaker 34

Testing a Circuit Breaker With Direct Rotary Handle 36

Locking a Circuit Breaker With Direct Rotary Handle 37

Testing a Circuit Breaker With Extended Rotary Handle 40

Locking a Circuit Breaker With Extended Rotary Handle 42

Compact NSX Circuit Breakers

Topic Page

DOCA0140EN-01 01/2020 31

Page 32

Compact NSX Circuit Breakers

Front Face Description

Front Face with Direct Rotary Handle

The circuit breaker operating controls, operation indicators, settings, and locking mechanisms for the direct

rotary handle are on the front of the circuit breaker.

There are two models of rotary handle:

Black handle for standard applications

Red handle on yellow bezel for machine control applications

A Faceplate

B Direct rotary handle for opening, closing, and

resetting

C Push-to-trip button

D Trip unit

E Trip unit adjustment dials

For more information about trip units, refer to the related description

(see page 85)

.

32

DOCA0140EN-01 01/2020

Page 33

Front Face with Extended Rotary Handle

For circuit breakers with an extended rotary handle:

The circuit breaker operating controls are on the door escutcheon.

The operation indicators and settings are only accessible when the door is open

The locking mechanisms are on the circuit breaker (optional) and on the door escutcheon (door closed)

(see page 42)

.

There are two models of extended rotary handle:

Black handle for standard applications

Red handle on yellow bezel for machine control applications

Cabinet door open Cabinet door closed

Compact NSX Circuit Breakers

A Faceplate

B Open door shaft operator

C Push-to-trip button

D Trip unit

E Trip unit adjustment dials

F Extended rotary handle for opening, closing, and resetting

For more information about trip units, refer to the related description

(see page 85)

.

DOCA0140EN-01 01/2020 33

Page 34

Compact NSX Circuit Breakers

Opening, Closing, and Resetting the Circuit Breaker

Opening and Closing Locally

To close the circuit breaker, turn the rotary handle clockwise from the O (OFF) position to the I(ON)

position.

To open the circuit breaker, turn the rotary handle counterclockwise from the I(ON) position to the

O(OFF) position.

Resetting After a Trip on Electrical Fault

The circuit breaker has tripped on electrical fault, the rotary handle has moved from the I(ON) position to

the Trip position.

WARNING

HAZARD OF CLOSING ON ELECTRICAL FAULT

Do not close the circuit breaker again without first inspecting and, if necessary, repairing the downstream

electrical equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The fact that a circuit breaker has tripped does not remedy the cause of the fault detected on the

downstream electrical equipment.

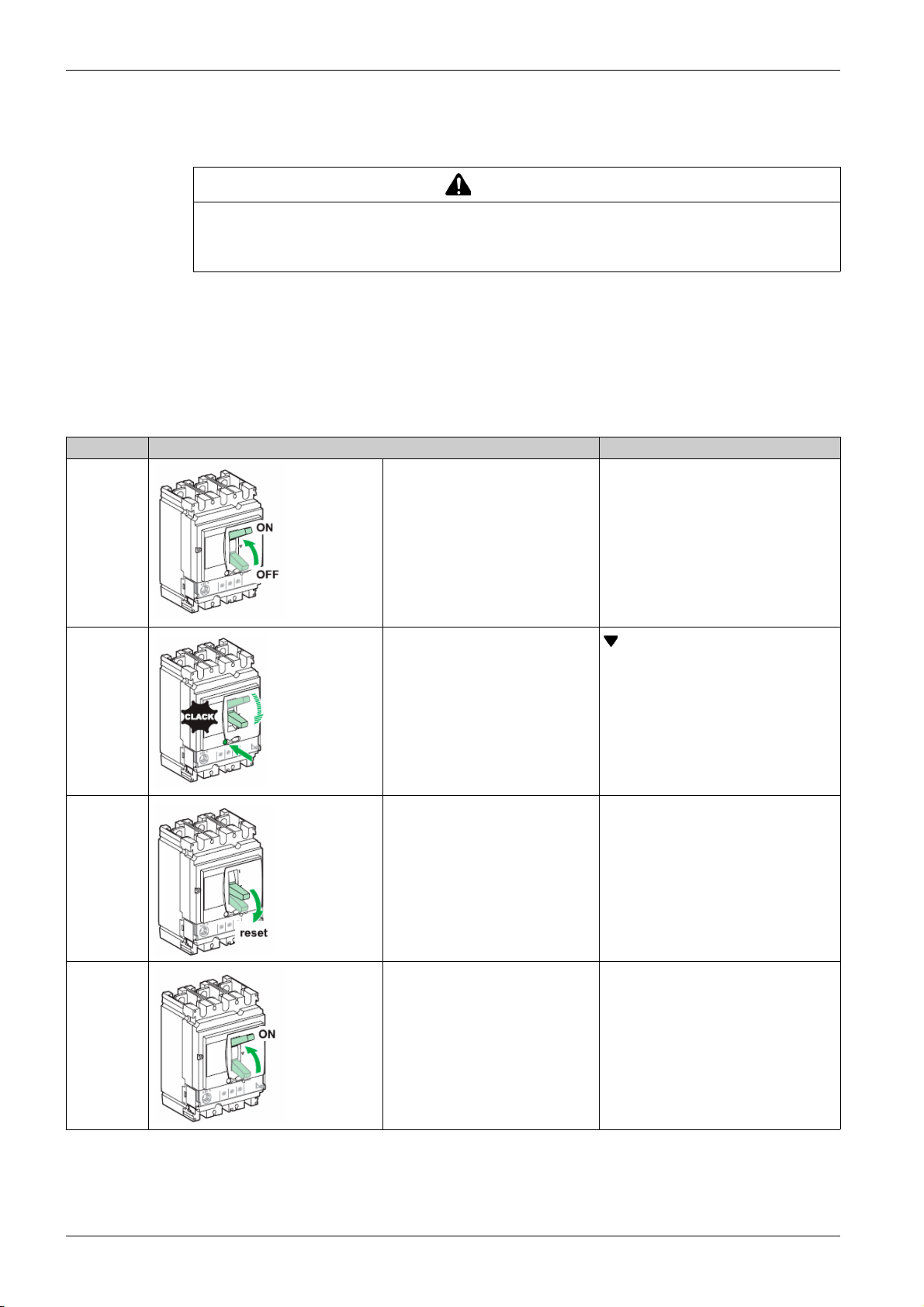

To reset after a fault trip:

Step Action Position

1 – Isolate the feed

equipment.

2 – Look for the cause of the detected fault. Trip

3 – Inspect and, if necessary, repair the downstream equipment. Trip

4 – Inspect the equipment in the event of a short-circuit trip. Trip

(see page 20)

before inspecting the downstream electrical

Trip

34

DOCA0140EN-01 01/2020

Page 35

Compact NSX Circuit Breakers

Step Action Position

5 Reset the circuit breaker by turning the rotary handle counterclockwise from

O(OFF)

the Trip position to O(OFF).

6 Close the circuit breaker by turning the rotary handle clockwise to I(ON). I(ON)

DOCA0140EN-01 01/2020 35

Page 36

Compact NSX Circuit Breakers

Testing a Circuit Breaker With Direct Rotary Handle

Push-to-Trip Procedure

CAUTION

HAZARD OF NUISANCE TRIPPING

Circuit breaker tests must only be done by qualified electrical personnel.

Failure to follow these instructions can result in injury or equipment damage.

When testing the trip mechanism, take precautions against:

Disrupting operations

Activating inappropriate alarms

Triggering unwanted actions

For example, tripping the circuit breaker with the push-to-trip button can lead to inappropriate fault

indications or corrective actions (such as switching to an alternate power source).

Follow these steps to test the trip mechanism:

Step Action Comment

1 Close the circuit breaker. I (ON)

2 Press the push-to-trip button: the

circuit breaker trips.

3 Turn the rotary handle

counterclockwise to the O(OFF)

position. The circuit breaker is open.

4 Turn the rotary handle clockwise from

the O(OFF) position to the I(ON)

position. The circuit breaker is closed.

Trip

O(OFF)

I (ON)

36

DOCA0140EN-01 01/2020

Page 37

Locking a Circuit Breaker With Direct Rotary Handle

Locking Accessories

Lock handle with up to three padlocks (not supplied) or a keylock.

Accessory Padlocks

Padlocking (standard) only in the O(OFF) position. Lock handle with up to three padlocks (not

supplied) with shackle diameters of 5–8 mm (0.2–

0.3 in).

Compact NSX Circuit Breakers

Padlocking (after modification to the rotary handle

during installation) in the two positions I(ON) and

O(OFF).

Keylocking with a Profalux® or Ronis® lock

(optional).

The circuit breaker can be locked in the O(OFF)

position only or in the O(OFF) and I(ON) position,

depending on the bolt chosen.

Lock handle with up to three padlocks (not

supplied) with shackle diameters of 5–8 mm (0.2–

0.3 in).

A Profalux or Ronis lock can be installed on site.

Keylocking can be used at the same time as

padlocking.

NOTE: Locking the rotary handle in the I(ON) position does not disable the circuit breaker protection

functions. If there is an electrical fault, the circuit breaker still trips. When unlocked, the handle moves to

the Trip position. To return the circuit breaker to service, follow the resetting instructions

(see page 34)

.

Door Locking (MCC Function)

Further options are offered with the direct rotary handle in the MCC function.

When the circuit breaker is in the I(ON) position, the direct rotary handle locks the door in the closed

position.

DOCA0140EN-01 01/2020 37

Page 38

Compact NSX Circuit Breakers

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Only qualified persons are authorized to disable the door lock.

Failure to follow these instructions will result in death or serious injury.

Temporarily disable this lock to open the door when the circuit breaker is in the I(ON) position.

Disabling this lock requires modifying the rotary handle. Refer to the instruction sheets on the Schneider

Electric website:

GHD16292AA

GHD16320AA

If the lock has been disabled, the following direct rotary handle functions are inoperative:

Door locking

Preventing the circuit breaker from being closed when the door is open

DANGER

, Direct rotary handle for Compact NSX100-250

, Direct rotary handle for Compact NSX400-630

Preventing Circuit Breaker Closing When the Door Is Open

The door locking device can also help to prevent the direct rotary handle from being moved to the I(ON)

position when the door is open.

Sealing Accessories

Use sealing accessories to prevent circuit breaker operations.

Seal Prohibited operations

Escutcheon mounting screw

Transparent protective cover

Dismantling the escutcheon

Accessing the auxiliaries

Dismantling the trip unit

Altering trip unit settings

Accessing the test port for the trip units

38

DOCA0140EN-01 01/2020

Page 39

Compact NSX Circuit Breakers

Seal Prohibited operations

Mounting screw for terminal shields Accessing the power connection (protection

against direct contact)

DOCA0140EN-01 01/2020 39

Page 40

Compact NSX Circuit Breakers

Testing a Circuit Breaker With Extended Rotary Handle

Push-to-Trip Procedure

CAUTION

HAZARD OF NUISANCE TRIPPING

Circuit breaker tests must only be done by qualified electrical personnel.

Failure to follow these instructions can result in injury or equipment damage.

When testing the trip mechanism take precautions against:

Disrupting operations

Activating inappropriate alarms

Triggering unwanted actions

For example, tripping the circuit breaker with the push-to-trip button can lead to inappropriate fault

indications or corrective actions (such as switching to an alternate power source).

There is no push-to-trip button on the door of a circuit breaker with a front extended rotary handle. To check

the trip mechanism, the door must first be opened.

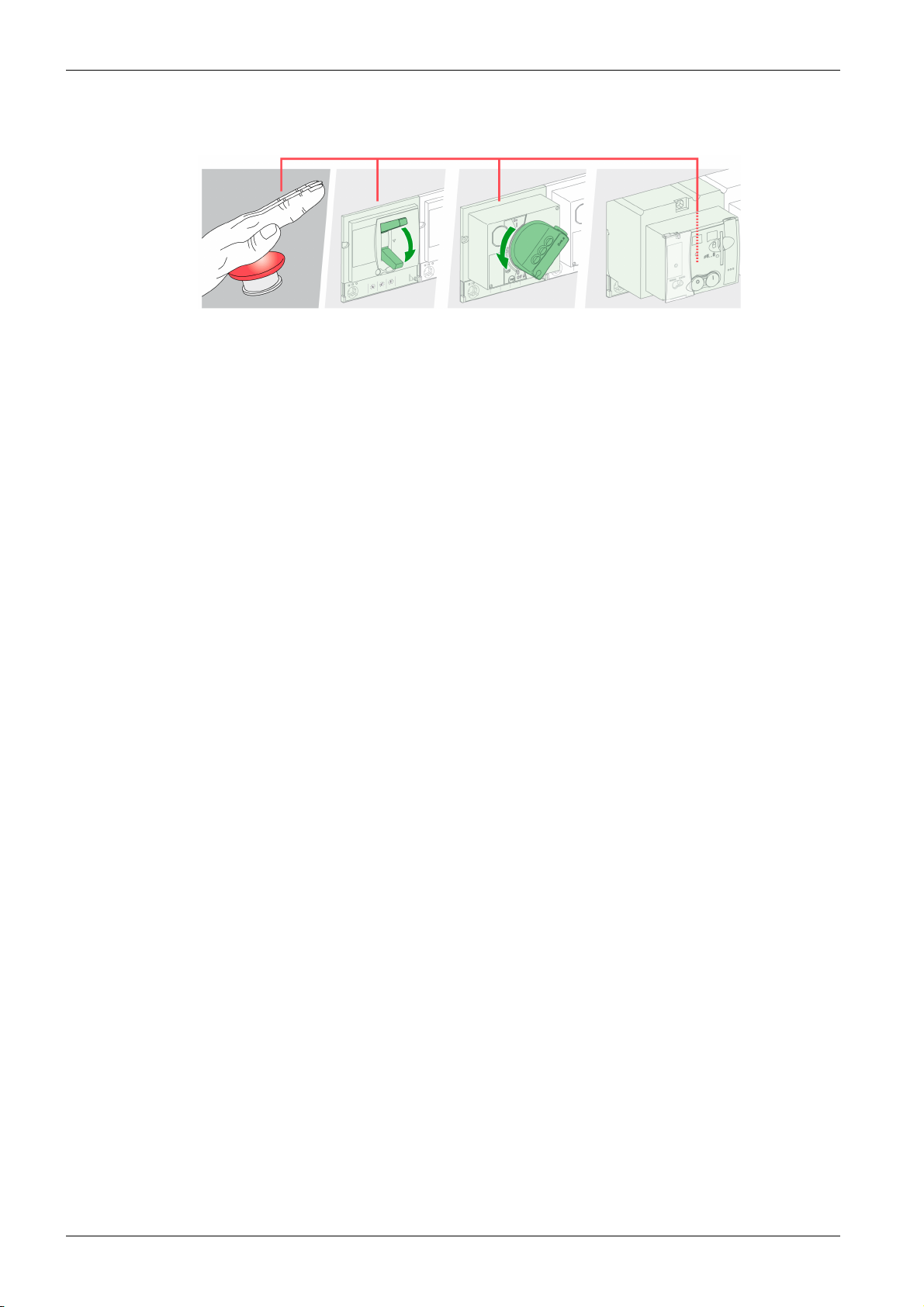

Follow these steps to test the trip mechanism:

Step Action Position

1 Switch the circuit breaker to the open O(OFF) position. Open the door. O(OFF)

2 Turn the circuit breaker from the O(OFF) position to the I(ON) position,

using one of the following tools:

An open door shaft operator (LV426937).

A flat wrench, taking care not to damage the extension shaft or its

surface treatment.The extension shaft is a hollow rectangular

tube,15 x 10 mm (0.59 x 0.39 in).

The circuit breaker is ready for the test.

3 Press the push-to-trip button. The circuit breaker trips. Trip

4 Use a special tool (refer to step 2) to turn the extension shaft

counterclockwise and switch the circuit breaker from the Trip position to

the O(OFF) position. The circuit breaker is in the open position.

I(ON)

O(OFF)

40

DOCA0140EN-01 01/2020

Page 41

Compact NSX Circuit Breakers

Step Action Position

5 Close the door. –

DOCA0140EN-01 01/2020 41

Page 42

Compact NSX Circuit Breakers

Locking a Circuit Breaker With Extended Rotary Handle

Locking Accessories

The extended rotary handle offers several locking functions to:

Prevent the rotary handle being operated.

Prevent the door being opened.

Some locking functions can be disabled on different adaptations.

The handle can be locked with up to three padlocks (not supplied) or keylock.

Accessory Padlocks

Padlocking (standard) in the O (OFF) position.

Padlocking the rotary handle in the O(OFF)

position does not prevent the door from

opening.

Lock rotary handle with up to three padlocks

(not supplied) with shackle diameters of 5–

8 mm (0.2–0.3 in).

Padlocking (after modification to the rotary

handle during installation) in the two positions

I(ON) and O(OFF).

There is a choice of two options when locking

the rotary handle in the I(ON) position:

Standard with the door opening locked.

As an option, door is not interlocked, and

locking the rotary handle does not stop the

door from opening.

Keylocking with a Profalux® or Ronis® lock

(optional).

The lock is mounted on the case inside the

switchboard.

Lock the circuit breaker in the O(OFF) position

only or in the O(OFF) and I(ON) positions

depending on the bolt chosen.

Lock rotary handle with up to three padlocks

(not supplied) with shackle diameters of 5–

8 mm (0.2–0.3 in).

A Profalux or Ronis lock can be installed on

site. Keylocking can be used at the same time

as padlocking.

NOTE: Locking the rotary handle in the I(ON) position does not disable the circuit breaker protection

functions. If there is an electrical fault, the circuit breaker still trips. When unlocked, the rotary handle

moves to the Trip position. To return the circuit breaker to service, follow the resetting instructions

(see page 34)

.

Door Locking (MCC Function)

The extended rotary handle locks the door in the I(ON) position as standard.

42

DOCA0140EN-01 01/2020

Page 43

Compact NSX Circuit Breakers

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Only qualified persons are authorized to disable the door lock.

Failure to follow these instructions will result in death or serious injury.

Temporarily disable this lock to open the door when the circuit breaker is in the I(ON) position.

Disabling this lock requires modifying the rotary handle. Refer to the instruction sheets on the Schneider

Electric website:

GHD16292AA

GHD16320AA

Example: An application includes a circuit breaker for a switchboard incoming supply and several receiver

circuit breakers with extended rotary handles installed behind the same door. Locking the door with a single

rotary handle (incoming supply circuit breaker) simplifies maintenance work on the switchboard.

, Extended rotary handle for Compact NSX100-250

, Extended rotary handle for Compact NSX400-630

Key-Operated Locking Procedure

Keylocking can be done with circuit breaker in either the O (OFF) position or the I(ON) position.

Step Action (circuit breaker in the O (OFF) position) Action (circuit breaker in the I (ON) position)

1 Open the door. Open the door by disabling the door locking device if necessary.

2 Use the keylock mounted on the case inside the switchboard to

lock the rotary handle.

3 Close the door. Close the door, disabling the door locking device if necessary.

Use the keylock mounted on the case inside the switchboard to

lock the rotary handle.

Sealing Accessories

The sealing accessories for circuit breakers with extended rotary handles are identical to those for circuit

breakers with direct rotary handles

(see page 37)

.

DOCA0140EN-01 01/2020 43

Page 44

Compact NSX Circuit Breakers

Motor-Operated Circuit Breakers

Section 1.4

Motor-Operated Circuit Breakers

What Is in This Section?

This section contains the following topics:

Front Face Description 45

Opening, Closing, and Resetting a Circuit Breaker With Motor Mechanism 47

Opening, Closing, and Resetting Circuit Breakers With Communicating Motor Mechanism 50

Locking the Circuit Breaker 51

Topic Page

44

DOCA0140EN-01 01/2020

Page 45

Front Face Description

Front Face

The main controls, operation indicators, settings, and locking mechanisms are on the front of an

electrically-operated circuit breaker (with motor mechanism).

Compact NSX Circuit Breakers

A Faceplate

B Charging handle

C Keylocking in O(OFF) position (option available for Compact NSX400-630 only)

D Sealing accessory

E Main contacts position indicator

F Spring-charged and ready-to-close indicator

G Padlocking in O(OFF) position

H Closing (I(ON)) and opening (O(OFF)) pushbuttons

I Manual/automatic operating mode selector

J Trip unit

Main Contacts Position Indicator

Indicator Description

NOTE: Use the SD or SDE auxiliary contact to distinguish the Trip position from the O (OFF) position.

Spring-Charged and Ready-to-Close Indicator

Indicator Description

The circuit breaker is closed.

The circuit breaker is open or tripped.

Closing spring charged

Closing spring discharged

NOTE: The closing spring only provides the necessary energy for circuit breaker closing. The circuit

breaker mechanism supplies the energy for tripping.

DOCA0140EN-01 01/2020 45

Page 46

Compact NSX Circuit Breakers

Manu/Auto Selector

The Manu/Auto button selects the operating mode:

In automatic operating mode, only electrical commands are executed.

In manual operating mode, all electrical commands are disabled.

46

DOCA0140EN-01 01/2020

Page 47

Opening, Closing, and Resetting a Circuit Breaker With Motor Mechanism

Introduction

The motor mechanism can open and close a circuit breaker remotely with electrical commands. There are

many applications:

Automation of electrical distribution to optimize operating costs

Normal/standby source changeover: changes over to a replacement source to improve continuity of

service

Load shedding/reconnection to optimize tariff-based contracts

CAUTION

HAZARD OF REPEATED CLOSING ON ELECTRICAL FAULT

Do not modify the wiring diagrams for the motor mechanism.

Failure to follow these instructions can result in injury or equipment damage.

Compact NSX Circuit Breakers

Wire the motor mechanism in strict accordance with the motor mechanism wiring diagram in the Appendix

(see page 161)

.

In automatic operating mode, wiring the SDE contact helps to prevent the circuit breaker from resetting

automatically on an electrical fault. For more information about the SDE contact, refer to the indication

contacts

(seepage70)

.

Manual Operation: Opening, Closing, and Resetting Locally

Move the selector to the Manu position.

Cycle of operation:

Manual Operation Description

Check that the spring-charged indicator is on charged (A). If not, reset the circuit breaker.

Step Action Comment

1

Close the circuit breaker by pressing the closing pushbutton .

2 Open the circuit breaker by pressing the opening pushbutton .When the circuit breaker is open:

3 Reset the circuit breaker: recharge the closing spring by operating

the charging handle (eight times).

DOCA0140EN-01 01/2020 47

When the circuit breaker is closed:

The contact position indicator (B) changes to

I(ON).

The spring-charged indicator (C) changes to

discharged.

The contact position indicator (D) changes to

O(OFF).

The spring-charged indicator (E) stays on

discharged.

When the circuit breaker is ready to be closed:

The contact position indicator (F) stays on

O(OFF).

The spring-charged indicator (A) changes to

charged.

Page 48

Compact NSX Circuit Breakers

Automatic Operation: Opening, Closing, and Resetting Remotely

Move the selector to the Auto position.

Cycle of operation:

Automatic Operation Description

Step Action Comment

1 Close the circuit breaker by sending a close (ON) command. When the circuit breaker is closed:

2 Open the circuit breaker by sending an open (OFF) command. When the circuit breaker is open:

3 Recharge the stored energy control by using one of the three reset

modes, depending on the wiring diagram:

Automatic reset

Remote reset by using the pushbutton

Manual reset by operating the charging handle

The contact position indicator (A) changes to

I(ON).

The spring-charged indicator (B) changes to

discharged.

The contact position indicator (C) changes to

O(OFF).

The spring-charged indicator (D) stays on

discharged.

The circuit breaker is ready to be closed:

The contact position indicator (E) stays on

O(OFF).

The spring-charged indicator (F) changes to

charged.

Resetting After a Trip on Electrical Fault

Resetting after a trip on electrical fault can only be done locally. When operating in automatic mode, return

to manual operation to reset the circuit breaker.

HAZARD OF CLOSING ON ELECTRICAL FAULT

Do not close the circuit breaker again without first inspecting and, if necessary, repairing the downstream

electrical equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The fact that a protection has tripped the circuit breaker does not remedy the cause of the fault detected

on the downstream electrical equipment.

WARNING

48

DOCA0140EN-01 01/2020

Page 49

Compact NSX Circuit Breakers

To reset after a fault trip:

Step Action

1 Isolate the feed

(see page 20)

2 With selector on Manu, operate the charging handle 8 times to reset the circuit breaker in ready-to-close position.

Result: The spring-charged indicator changes to charged (B) and the internal mechanism goes from the Trip position to the

O(OFF) position (A).

3 Lock the circuit breaker.

4 Look for the cause of the detected fault.

5 Inspect and, if necessary, repair the downstream equipment.

6 Inspect the equipment in the event of a short-circuit trip.

7 Reset and close the circuit breaker.

before inspecting the downstream electrical equipment.

DOCA0140EN-01 01/2020 49

Page 50

Compact NSX Circuit Breakers

Opening, Closing, and Resetting Circuit Breakers With Communicating Motor Mechanism

Introduction

Manage the communicating motor mechanism with the communication network.

For this function, it is necessary to:

Install a Breaker Status Control Module (BSCM)

Use a communicating motor mechanism.

(see page 77)

and the NSX cord

(see page 79)

Connect the BSCM module to the communication network with the NSX cord:

To receive closing, opening, and reset commands.

To transmit the circuit breaker states: O(OFF), I(ON), Tripped by SDE.

NOTE: The communicating motor mechanism has a specific reference. For more information, refer to

Compact NSX & NSXm Catalogue

The BSCM module can be configured using EcoStruxure Power Commission software.

.

(see page 19)

The schematic for the communicating motor mechanism in the BSCM module can be configured. It must

be created in strict accordance with the simplified schematic shown in the appendix

(see page 170)

CAUTION

HAZARD OF REPEATED CLOSING ON ELECTRICAL FAULT

Do not modify the wiring diagrams for the motor mechanism.

Failure to follow these instructions can result in injury or equipment damage.

.

.

Manual Operation: Opening, Closing, and Resetting Locally

The process is the same as the standard motor mechanism.

Automatic Operation: Opening, Closing, and Resetting Remotely

The process is the same as the standard motor mechanism.

Resetting After a Trip on Electrical Fault

Without modifying the factory configuration, the process is the same as the standard motor mechanism

(see page 48)

.

Reconfiguration of the BSCM module using EcoStruxure Power Commission software

authorizes remote resetting after a trip on electrical fault on a circuit breaker with communicating motor

mechanism.

(see page 78)

50

DOCA0140EN-01 01/2020

Page 51

Locking the Circuit Breaker

Locking Accessories

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When the circuit breaker toggle handle is locked in the (O) OFF position, always use a properly rated

voltage sensing device to confirm that power is off before working on equipment.

Failure to follow these instructions will result in death or serious injury.

Lock the mechanism with up to three padlocks (not supplied) or a keylock.

Both locking methods can be used at the same time.

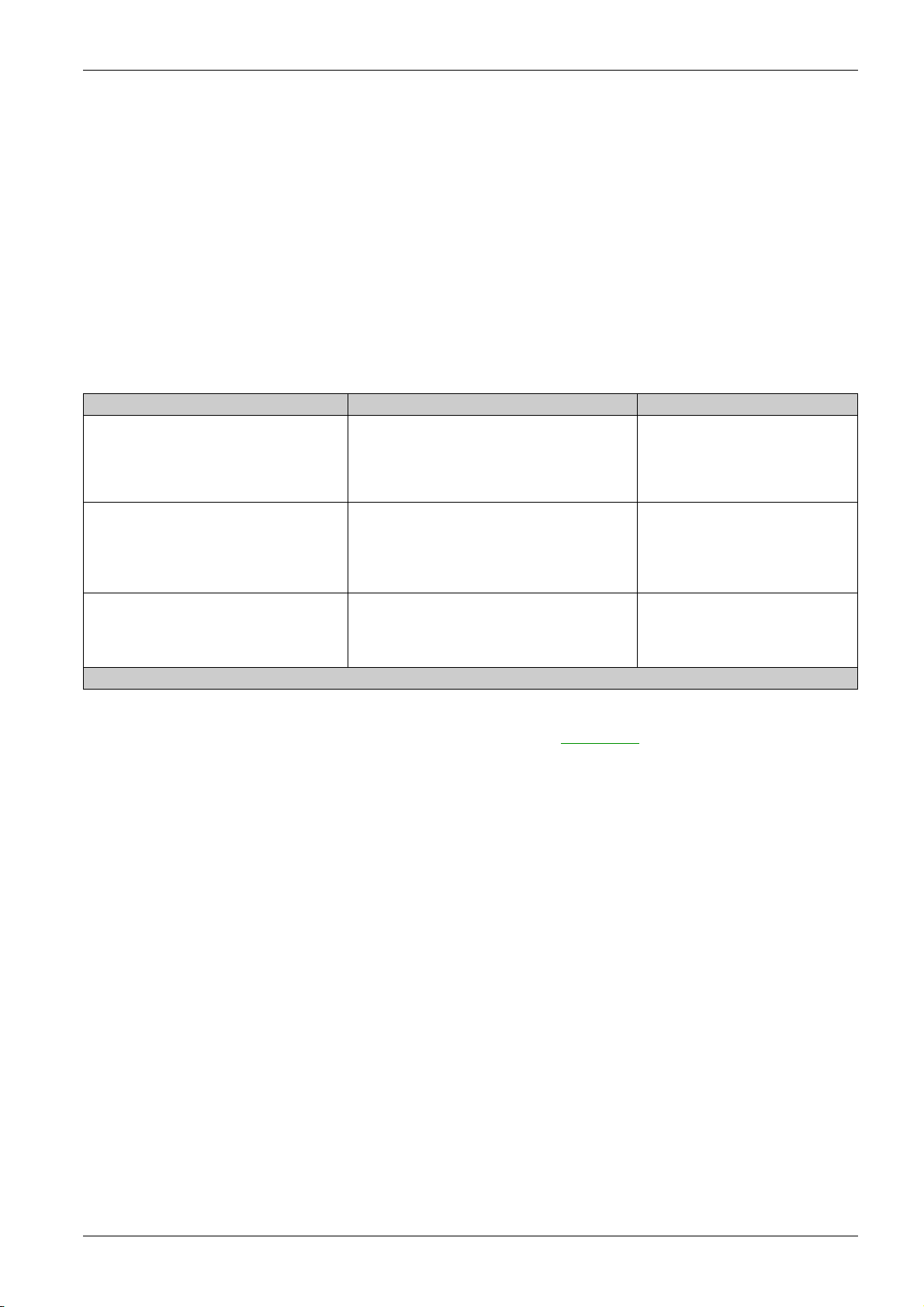

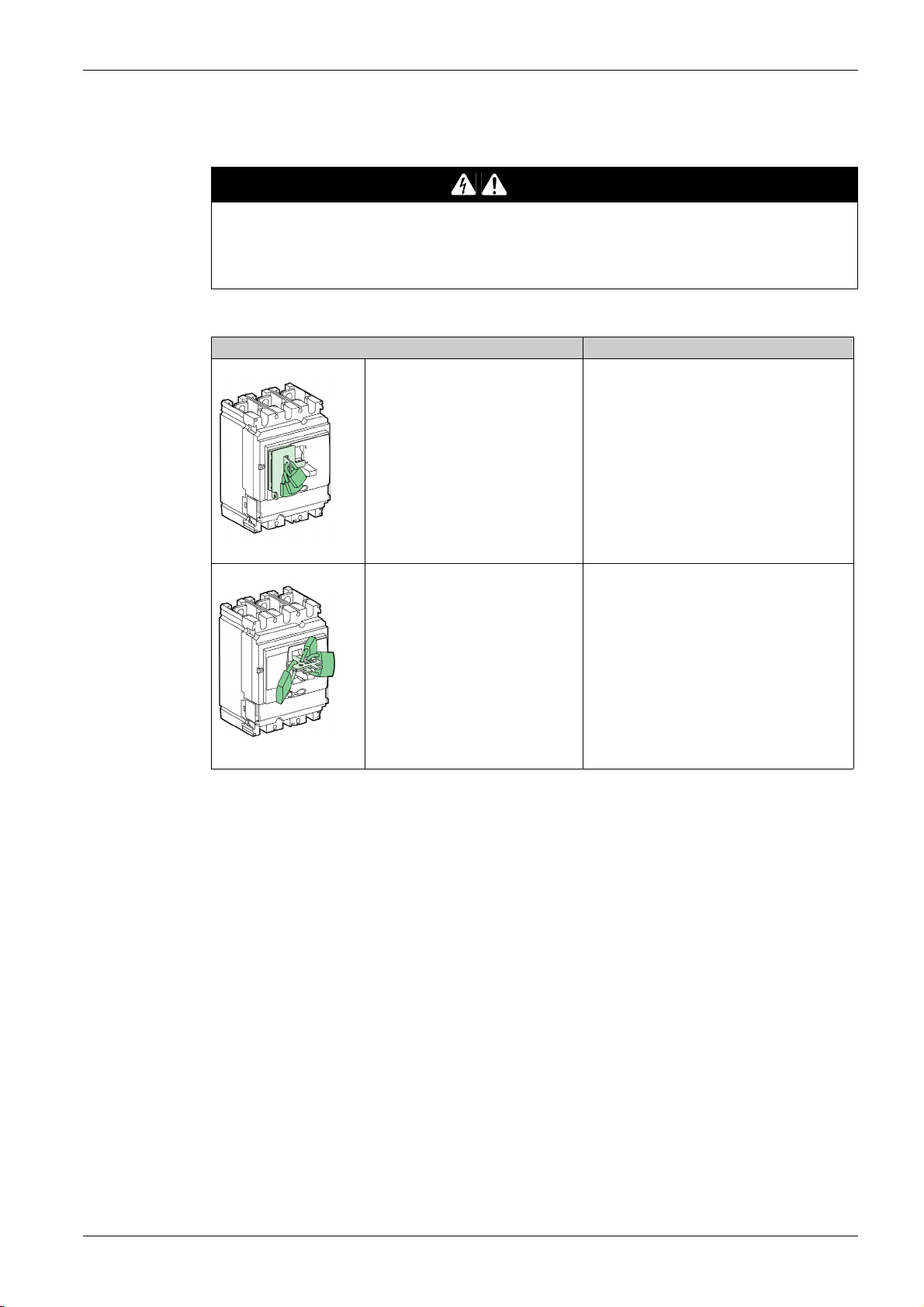

Step Action Comment Result

1 Switch the circuit breaker to the

O (OFF) position.

2 Pull out the tab –

–

Compact NSX Circuit Breakers

3 Lock the tab using:

Up to three padlocks 5-8 mm (0.2-

0.3 in) in diameter.

A keylock (optional).

The circuit breaker is locked.

No commands in Auto mode or

Manu mode are executed.

Sealing Accessories

Use sealing accessories to prevent circuit breaker operations.

Seal Prohibited operations

Motor mechanism mounting screw

Transparent cover for the motor

mechanism

Dismantling the escutcheon

Accessing the auxiliaries

Dismantling the trip unit

Accessing the manual/automatic

selector (depending on its position,

manual operation

(1)

operation is disabled).

, or automatic

Transparent protective cover for the trip

units

Altering any settings and accessing the

test port.

(1) In this case no local operations are possible.

DOCA0140EN-01 01/2020 51

Page 52

Compact NSX Circuit Breakers

Seal Prohibited operations

Mounting screw for terminal shields Accessing the power connection

(protection against direct contact)

(1) In this case no local operations are possible.

52

DOCA0140EN-01 01/2020

Page 53

CompactNSX

CompactNSX Installation Accessories

DOCA0140EN-01 01/2020

Compact NSX Instal lation Accessories

Chapter 2

Compact NSX Installation Accessories

What Is in This Chapter?

This chapter contains the following topics:

Plug-in Circuit Breaker 54

Withdrawable Circuit Breaker 58

Accessories 64

Topic Page

DOCA0140EN-01 01/2020 53

Page 54

Compact NSX Installation Accessories

Plug-in Circuit Breaker

Introduction

Plug-in base circuit breakers make it possible to:

Extract and/or rapidly replace the circuit breaker without having to touch the connections on the base

Allow for the addition of future circuits by installing bases that will be equipped with a circuit breaker at

a later date

Isolate the power circuits when the circuit breaker is mounted on or through a panel. It acts as a barrier

for the connections of the plug-in base. Insulation is made complete by the mandatory short terminal

shields on the circuit breaker

The following types of circuit breaker can be installed in a plug-in base:

3P and 4P circuit breakers

Circuit breakers with toggle handle, direct rotary handle, or extended rotary handle

Motor-operated circuit breakers

Circuit breakers with Vigi module

The plug-in circuit breaker is made up of the fixed circuit breaker and a plug-in kit, which includes:

Plug-in base

Power connections

Short terminal shields

Safety trip interlock

Disconnecting the Circuit Breaker

(see page 56)

.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See

NFPA 70E, CSA Z462, NOM-029-STPS, or local equivalent.

This equipment must only be installed and serviced by qualified electrical personnel.

The circuit breaker must be in the O (OFF) position.

Do not use tools to disconnect or connect the circuit breaker.

Failure to follow these instructions will result in death or serious injury.

Follow this procedure to disconnect the circuit beaker:

Step Action

1 Switch the circuit breaker to the O(OFF) position.

2 Remove both mounting screws.

54

DOCA0140EN-01 01/2020

Page 55

Step Action

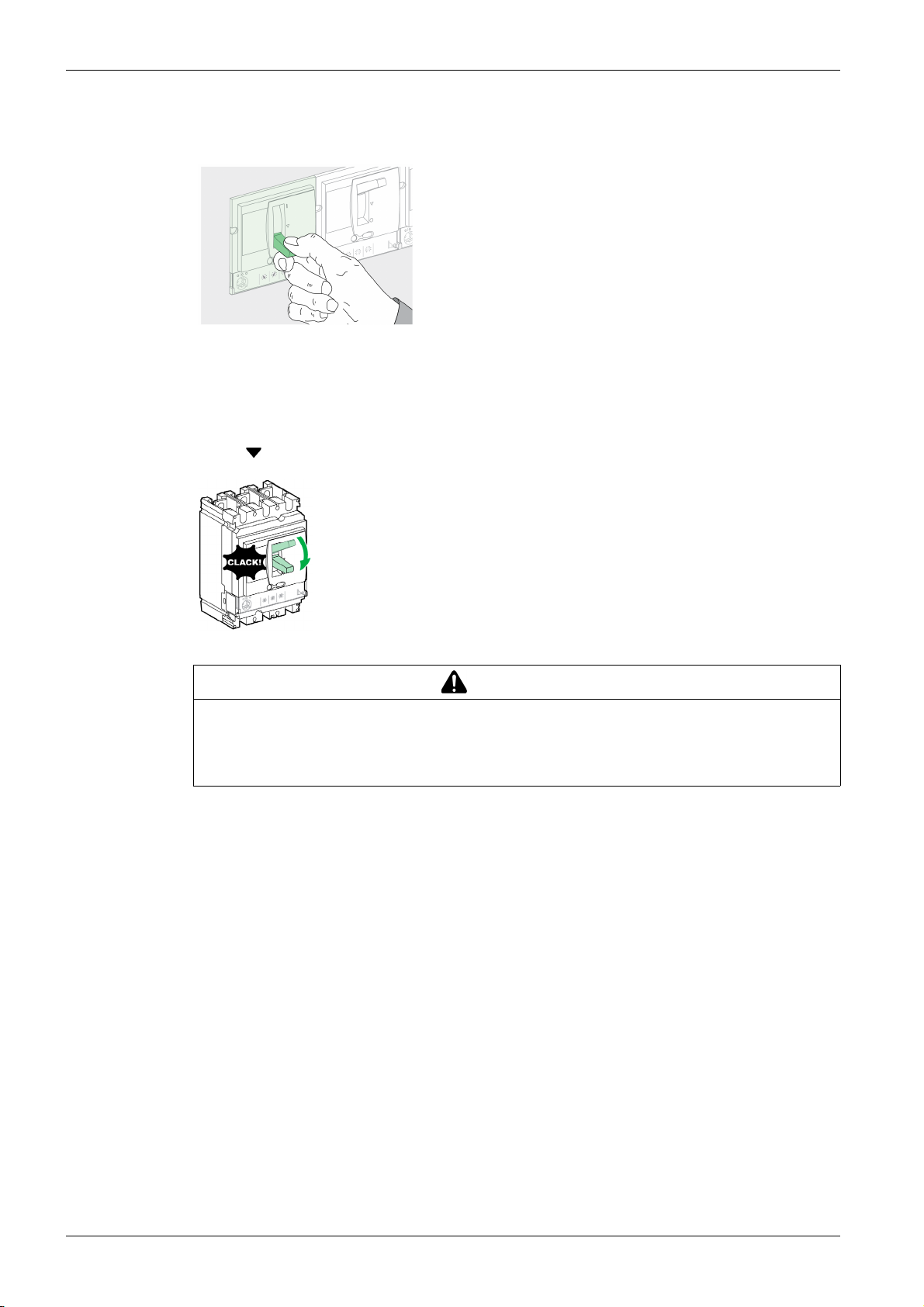

3 Pull out the circuit breaker, keeping it horizontal.

NOTE:

The auxiliary circuits automatically disconnect because of the connectors located on the base and at

the rear of the circuit breaker.

Open the circuit breaker before disconnecting it. If the circuit breaker is in the closed I(ON) position

when disconnecting, a pre-trip mechanism trips the circuit breaker before the pins are disconnected.

Connecting the Circuit Breaker

Compact NSX Installation Accessories

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See

NFPA 70E, CSA Z462, NOM-029-STPS, or local equivalent.

This equipment must only be installed and serviced by qualified electrical personnel.

The circuit breaker must be in the O (OFF) position.

Do not use tools to disconnect or connect the circuit breaker.

Failure to follow these instructions will result in death or serious injury.

Follow this procedure to connect the circuit beaker:

Step Action

1 Switch the circuit breaker to the O(OFF) position.

2 Connect the circuit breaker.

DOCA0140EN-01 01/2020 55

Page 56

Compact NSX Installation Accessories

Step Action

3 Replace both mounting screws. Tighten the screws to a

NOTE:

The auxiliary circuits automatically connect because of the connectors located on the base and at the

rear of the circuit breaker.

Open the circuit breaker before connecting it. If the circuit breaker is in the closed I(ON) position when

connecting, the pre-trip mechanism trips the circuit breaker before the pins are connected.

Protection Against Direct Contact With Power Circuits

The following table shows plug-in circuit breaker configurations with the corresponding protection indices

(IP):

torque of 2.5 N•m (22.1 lb-in).

Configuration Protection

index

IP20 Built-in plug-in base:

IP40 Built-in plug-in base and circuit breaker with terminal shields.

Description

Without circuit breaker

With circuit breaker without terminal shields

56

IP40 Plug-in base with adapter, terminal shields and blanking plate without

circuit breaker:

The adapter enables the use of all the connection accessories of the

fixed circuit breaker. It is required to equip the plug-in circuit breaker

with long and short terminal shields and interphase barriers.

Terminal shields are mandatory for plug-in circuit breakers. Short

terminal shields are supplied in the plug-in kit. They can be replaced by

long terminal shields available as an option.

The blanking plate is not supplied by Schneider Electric.

DOCA0140EN-01 01/2020

Page 57

Compact NSX Installation Accessories

Configuration Protection

index

IP40 Plug-in base with adapter and terminal shields, and circuit breaker with

For more information about configurations and installation, consult the instruction sheets on the Schneider

Electric website:

GHD16276AA

GHD16316AA

, Plug-in base for Compact NSX100-250

, Plug-in base for Compact NSX400-630

Description

terminal shields.

DOCA0140EN-01 01/2020 57

Page 58

Compact NSX Installation Accessories

Withdrawable Circuit Breaker

Introduction

In addition to the advantages provided by a plug-in base, installation of the circuit breaker on a chassis

facilitates handling. Withdrawable chassis circuit breakers offer three positions, with transfer from one to

the other after mechanical unlocking:

Connected: the power circuits are connected.

Disconnected: the power circuits are disconnected, the circuit breaker can be operated to check

auxiliary operation.

Removed: the circuit breaker is free and can be removed from the chassis.

The following types of circuit breaker can be installed in a chassis:

3P and 4P circuit breakers

Circuit breakers with toggle handle, direct rotary handle, or extended rotary handle

Motor-operated circuit breakers

Circuit breakers with Vigi module

The withdrawable circuit breaker is made up of:

The fixed circuit breaker

A plug-in kit

Two chassis side plates for the plug-in base

Two chassis side plates for the circuit breaker

Disconnecting the Circuit Breaker

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See

NFPA 70E, CSA Z462, NOM-029-STPS, or local equivalent.

This equipment must only be installed and serviced by qualified electrical personnel.

The circuit breaker must be in the O (OFF) position.

Do not use tools to disconnect or connect the circuit breaker.

Failure to follow these instructions will result in death or serious injury.

Follow this procedure to disconnect the circuit breaker:

Step Action

1 Switch the circuit breaker to the O(OFF)

2 Move both locking levers down as far as

position.

they can go.

58

DOCA0140EN-01 01/2020

Page 59

Compact NSX Installation Accessories

Step Action

3 Push down both operating handles at the

same time until you hear a double-click from

the locking levers (as the locking levers

return to their original position).

The circuit breaker is disconnected.

NOTE:

The auxiliary circuits can be:

Automatically disconnected because of the connectors located on the chassis and at the rear of the

circuit breaker.

Left connected for a circuit breaker with a manual auxiliary connector.

Open the circuit breaker before disconnecting it. If the circuit breaker is in the closed I(ON) position

when disconnecting, a safety mechanism ensures that the poles open automatically by tripping the

circuit breaker before the pins disconnect.

Removing the Circuit Breaker

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See