Page 1

Product

Environmental

Profile

Altivar 21

22 to 75 kW – IP54 range

Page 2

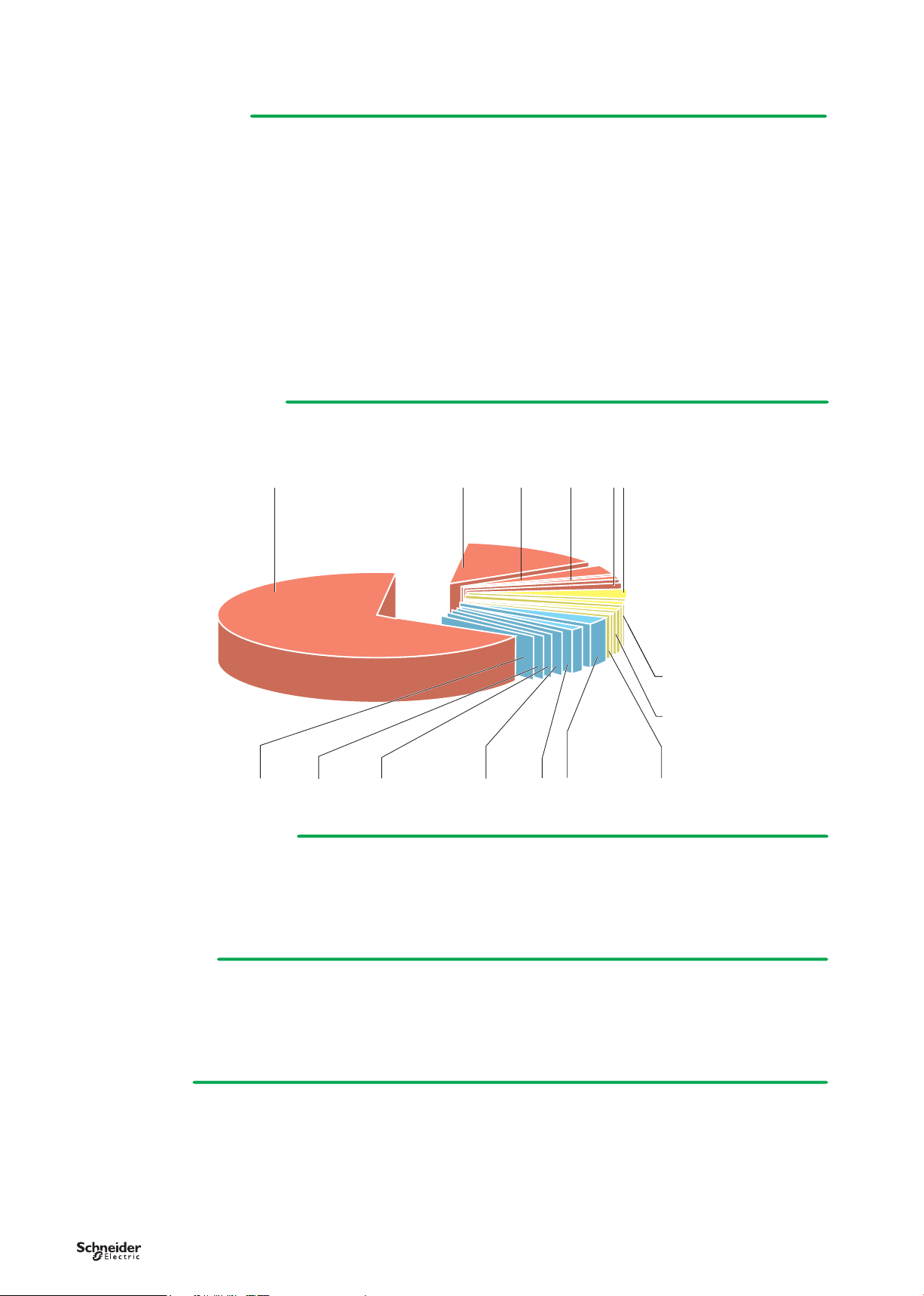

Steel

68.7 %

Aluminium alloys

14.59 %

Brass

3.64 %

Copper

1.04 %

Tin

0.03 %

Polyamide 66

1.2 %

Polycarbonate

0.54 %

PBT

0.48 %

Polyvinyl

chloride

0.43 %

Through-hole

electronic

components

3.37 %

Epoxy resin

printed Circuit

1.5 %

Others

1.97 %

Ferrite

1.24 %

EPDM

0.7 %

Surface-mounted

components

0.57 %

Product Environmental Prole - PEP

Product Overview

The main function of the Altivar 21 range is control and rotation speed variation of an

asynchronous electric motor, mainly for HVAC applications.

This range comprises products from 0.75 to 75 kW, operating at voltages from 200 and 480 V,

single or three-phase.

The representative product used for carrying out assessment is the complete Altivar 21 of

rating 22 kW 400 V (ref ATV21WD22N4).

It is representative of the entire ATV21 22 to 75 kW IP54 range. Other products of the range

are produced using the same technology and on the same production process.

Environmental assessment was carried out conforming to standard ISO 14040

"Environmental management: life cycle assessment, principle and framework".

This assessment takes account of product life cycle stages.

Constituent materials

Weight of products in the range is from 29000 g to 88000 g. It is 29168 g

excluding packaging for the Altivar 21 - 22 kW 400 V assessed.

Constituent materials are broken down as follows:

Substance assessment

Manufacturing

Distribution

Products of this range are designed in conformity with the requirements

of the RoHS directive (European Directive 2002/95/EC of 27 January

2003) and do not contain, or in the authorised proportions, lead, mercury,

cadmium, chromium hexavalent, ame retardant (polybromobiphenyles

PBB, polybromodiphenylthers PBDE) as mentioned in the Directive.

This range is manufactured on a Schneider Electric production site

operating to an ISO 14001 certied environmental management system.

Constant process improvement enables reduction by an average 5 % of

annual energy consumption of the site.

Complete waste sorting enables achievement of a recovery rate of 99 %.

Packaging has been designed with a view to reducing its weight and

volume, respecting the packaging directive of the European Union.

The weight of packaging of the 14970 g, consisting of cardboard, wood

and steel (recyclable materials).

Product distribution ows are optimised by location of local distribution

centres in close proximity to market areas.

Page 3

Product Environmental Prole - PEP

Utilization

Products of the Altivar 21 - 22 to 75 kW IP54 range present no

environmental stress requiring particular use precautions (noise,

emissions, etc.).

Electrical energy consumed depends on product installation and use

conditions.

Power consumed varies from 632 W to 1953 W. It is 632 W for the Altivar

21 - 22 kW 400 V and represents less than 3 % of total power through the

product.

End of life

At end-of-life, products of the Altivar 21 range can either be dismantled or

ground to recover maximum value of the various constituent materials.

Recovery potential is greater than 89 %.

This percentage consists of ferrous metals, copper and aluminium alloys

and marked plastics.

Products of this range also include electronic cards to be extracted and

directed towards specialised processing channels.

End-of-life data is detailed in the product end-of-life sheet.

Environmental impacts

Life cycle assessment (LCA) was produced using EIME (Environmental

Impact and Management Explorer) software, version 1.6 and its database

version 5.4.

Product use duration is estimated as 10 years and the electrical energy

model used is the European model.

Scope of assessment is the Altivar 21 – 22 kW 400 V IP54.

Environmental impacts have been assessed on phases of Manufacturing

(M) including conversion of raw materials, Distribution (D) and Use (U).

Presentation of the environmental impacts

Environmental indicators

S = M + D + U M D U

Raw Material Depletion

Energy Depletion MJ

Water depletion

Global Warming

Ozone Depletion g≈CFC-11

Air Toxicity

Photochemical Ozone Creation

Air acidication

Water Toxicity

Water Eutrophication

Hazardous waste production kg

Unit ATV21 IP54 22 kW 400 V SE (1.000 unit)

Y-1

3

dm

g≈CO

3

m

g≈C2H

+

g≈H

3

dm

g≈PO

-12

1.18 10

3.55 105

4

4.80 10

7

2

2.24 10

2.78

9

4.61 10

3

4

4

7.93 10

3.79 10

1.83 10

6.08 10

3.19 10

3

6

2

2

-13

8.64 10

2.94 10

1.99 10

2.25 10

3.77 10

6.30 10

1.23 10

3

3

5

-2

7

2

2.40 10

4.44 10

1.26 10

1.01 10

2.39 10

3.56 10

10.8

41.6 2.69

5

5.34 10

5.22 10

2

2.97 10

1.05

1.71 2.38 10

-16

2

2

4

-3

6

3

-1

Life cycle assessment has shown that Use phase (phase U) has the

greatest impact on the majority of environmental indicators.

Assessment also shows that indicators of this phase are highly inuenced

by the "product thermal dissipation" parameter.

3.15 10

3.52 105

4.59 104

2.21 107

2.74

4.54 109

7.80 103

3.75 103

1.30 10

85.6

3.17 102

-13

6

Page 4

Product Environmental Prole - PEP

System approach

As the product of the range are designed in accordance with the RoHS

Directive (European Directive 2002/95/EC of 27 January 2003),

they can be incorporated without any restriction within an assembly or

an installation submitted to this Directive.

N.B.: please note that the environmental impacts of the product depend on the use and

installation conditions of the product.

Impacts values given above are only valid within the context specied and cannot be directly

used to draw up the environmental assessment of the installation.

Glossary

Raw Material Depletion (RMD) This indicator quanties the consumption of raw materials during the life

cycle of the product. It is expressed as the fraction of natural resources

that disappear each year, with respect to all the annual reserves of

the material.

Energy Depletion (ED) This indicator gives the quantity of energy consumed, whether it be from

fossil, hydroelectric, nuclear or other sources.

This indicator takes into account the energy from the material produced

during combustion. It is expressed in MJ.

Water Depletion (WD) This indicator calculates the volume of water consumed, including

drinking water and water from industrial sources. It is expressed in dm3.

Global Warming (GW) The global warming of the planet is the result of the increase in

the greenhouse effect due to the sunlight reected by the earth’s surface

being absorbed by certain gases known as "greenhouse-effect" gases.

The effect is quantied in gram equivalent of CO2.

Ozone Depletion (OD) This indicator denes the contribution to the phenomenon of

the disappearance of the stratospheric ozone layer due to the emission

of certain specic gases. The effect is expressed in gram equivalent

of CFC-11.

Photochemical Ozone Creation (POC) This indicator quanties the contribution to the "smog" phenomenon

(the photochemical oxidation of certain gases which generates ozone)

and is expressed in gram equivalent of ethylene (C2H4).

Air Acidication (AA) The acid substances present in the atmosphere are carried by rain.

A high level of acidity in the rain can cause damage to forests.

The contribution of acidication is calculated using the acidication

potentials of the substances concerned and is expressed in mode

equivalent of H+.

Hazardous Waste Production (HWP) This indicator calculates the quantity of specially treated waste created

during all the life cycle phases (manufacturing, distribution and utilization).

For example, special industrial waste in the manufacturing phase, waste

associated with the production of electrical power, etc.

It is expressed in kg.

Registration No.: SCHN-2011-107-V0 Programme information: www.pep-ecopassport.org

PEP in compliance with PEPecopassport according to PEP-AP0011 rules

ACV rules are available from PEP editor on request

Schneider Electric Industries SAS

35, rue Joseph Monier

CS30323

F - 92506 Rueil Malmaison Cedex

RCS Nanterre 954 503 439

Capital social 896 313 776 €

www.schneider-electric.com

ENVPEP070203EN

Published by: Schneider Electric

We are committed to safeguarding

our planet by "Combining

innovation and continuous

improvement to meet the new

environmental challenges".

© 2010 - Schneider Electric - All rights reserved

04-2010

Loading...

Loading...