PLASMA DISPLAY TV

Chassis : F65A(P_HD)_B430

Model : PS42B430P2WXXH

SERVICE

Manual

PLASMA DISPLAY TV CONTENTS

1. Precaution

2. Product Specification

3. Disassembly & Reassembly

4. Troubleshooting

5. Exploded View & Part List

6. Wiring Diagram

PS42B430P2W

Refer to the service manual in the GSPN (see the rear cover) for the more information.

GSPN (Global Service Partner Network)

Area Web Site

North America service.samsungportal.com

Latin America latin.samsungportal.com

CIS cis.samsungportal.com

Europe europe.samsungportal.com

China china.samsungportal.com

Asia asia.samsungportal.com

Mideast & Africa mea.samsungportal.com

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. Apr. 2009

Printed in Korea

AA82-05791A

Table of Contents

Chapter 1 Precaution

■ 1-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

■ 1-2 Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■ 1-3 Static Electricity Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

■ 1-4 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Product Specification

■ 2-1 Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

■ 2-2 Specifications Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

■ 2-3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 Disassembly & Reassembly

■ 3-1 Overall Disassembly & Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Chapter 4 Troubleshooting

■ 4-1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

■ 4-2 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

■ 4-3 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Chapter 5 Exploded View & Part List

■ 5-1 PS42B430P2WXXH Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

■ 5-2 PS42B430P2WXXH Service Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Chapter 6 Wiring Diagram

■ 6-1 Overall Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1. Precaution

To avoid possible damage, electric shocks or exposure to radiation, follow the instructions below with regard to safety,

installation, service and ESD.

1-1 Safety Precautions

Precaution

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure there aren't any gaps between the front and

rear cover that anyone could insert they're fingers into

and receive any electrical shock. These gaps include

ventilation holes, cracks, etc.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁. In these cases, make sure that the device

is repaired before sending it back to the customer.

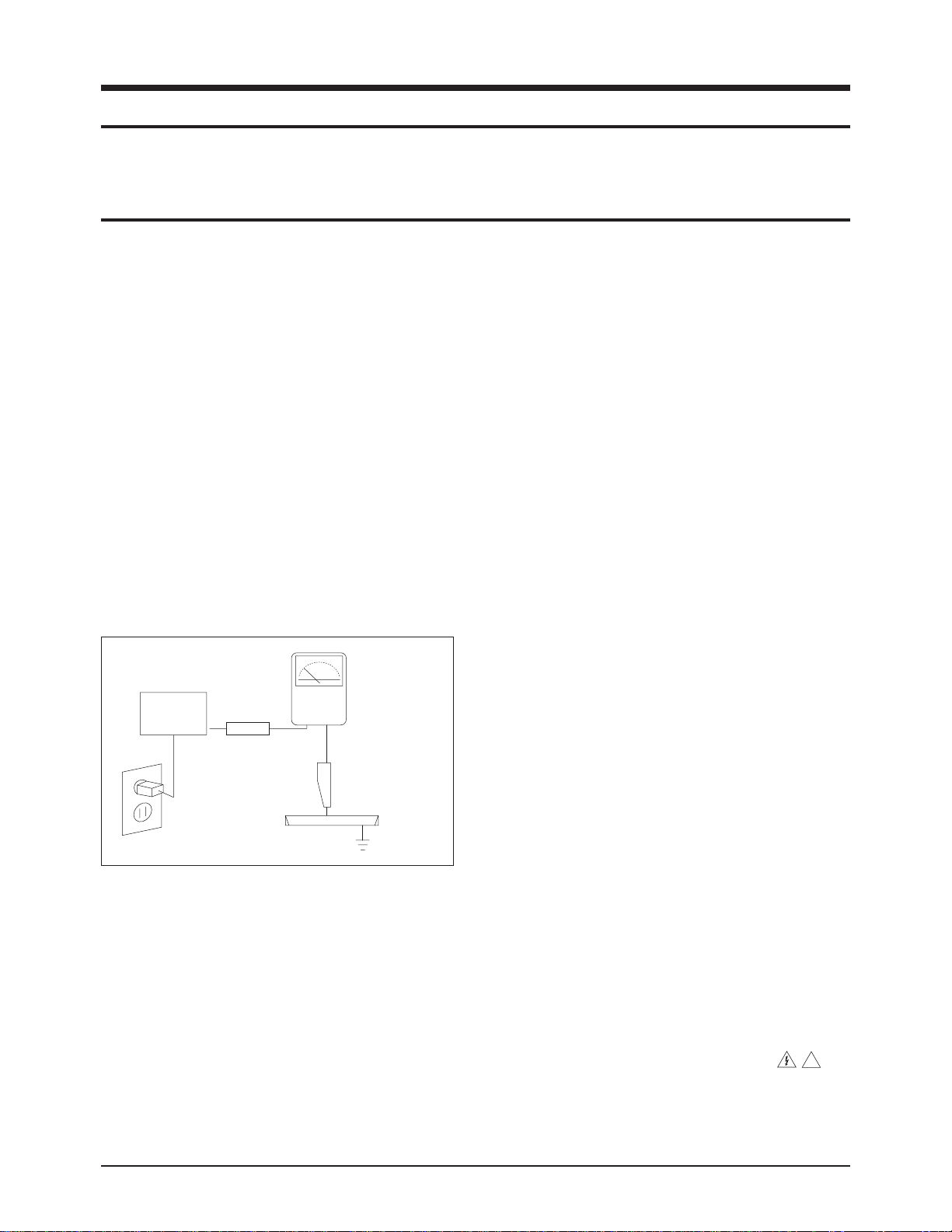

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transformer for

checking the leakage. Use only those current leakage

testers or mirroring systems that comply with ANSIC

101.1 and the Underwriter Laboratory's specifications

(UL1410, 59.7).

Fig. 1-1 AC Leakage Test

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

4. Ahigh voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons. Without

insulated transformers, the product can only be repaired

safely when the chassis is connected to the earth end of

the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the earth

ground. If the measurement is over 1.0V, unplug the AC

power cord and change the polarity before re-inserting it.

Measure the voltage between the chassis and the

ground again.

7. Some TV chassis are shipped with an additional

secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an

unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new immediately. When

any damage or overheating is detected, correct this

immediately and make a regular check of possible

errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages.

Keep the part or the lead away from any heat-emitting

materials.

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be marked with ( ).

!

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

Samsung Electronics 1-1

Precaution

1-2 Servicing Precautions

Warning 1: First carefully read the "Safety Instruction" in this service manual. When there is a conflict between the service and

the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

(UL / FCC ¡æ Refer to the Back Cabinet )

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts

should be installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so protect yourself by wearing gloves

during the repair.

11. Due to the nature of plasma display panels, partial afterimages may appear if a still picture is displayed on the

screen for a long period of time. This is caused by

brightness deterioration due to the storage effect of the

panel, and to prevent this from happening, we

recommend that the brightness and contrast are

reduced.

(e.g.) Contrast: 25, Brightness: 50

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the

insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

1-2 Samsung Electronics

1-3 Static Electricity Precautions

Precaution

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or assemblies. Alternatively,

wear a dischargeable wrist-belt. (Make sure to remove

any static electricity before connecting the power source

- this is a safety instruction for avoiding electric shock)

3. Remove the ESD assembly and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals. Such chemicals

will generate static electricity that causes damage to the

ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices. Most solder

removal devices do not support an anti-static feature.

Asolder removal device without an anti-static feature

can store enough static electricity to cause damage to

the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit assembly.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

CAUTION

These servicing instructions are for use by qualified

service personnel only.

To reduce the risk of electric shock do not perform any

servicing other than that contained in the operating

instructions unless you are qualified to do so.

Samsung Electronics 1-3

Precaution

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product.

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. Do not place the product in areas with poor ventilation

such as a bookshelf or closet. The increased internal

temperature may cause fire.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before repositioning the product.

Also check the antenna cable or the external connectors

if they are fully unplugged. Damage to the cord may

cause fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contact with the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. When connecting the RF antenna, check for a DTV

receiving system and install a separate DTV reception

antenna for areas with no DTV signal.

8. When installing the product, leave enough space (4")

between the product and the wall for ventilation

purposes. Arise in temperature within the product may

cause fire.

9. When moving a PDP with removable speakers, detach

the speakers first before moving the main body.

Moving the PDP main body without separating the

speakers may cause the speakers to detach, possibly

causing damage or injury.

1-4 Samsung Electronics

Disassembly & Reassembly

3. Disassembly & Reassembly

3-1 Overall Disassembly & Reassembly

!

Notice

- Be sure to separate the power cord before disassembling the unit.

- Discharge the capacitors first when separating PCB's with high capacity capacitors such as SMPS, X Main Board, YMain

Board, etc. (Aspark may be generated by the electric charge, and there is danger of electronic shock.)

- Check that the cables are properly connected referring to the circuit diagram when disassembling or assembling the unit

taking care not to damage the cables.

- Take care not to scratch the Glass Filter in the front.

- Assemble the boards in the reverse order of the disassembly.

- The plasma must be layed down on a flat padded surface for disassembly and reassembly.

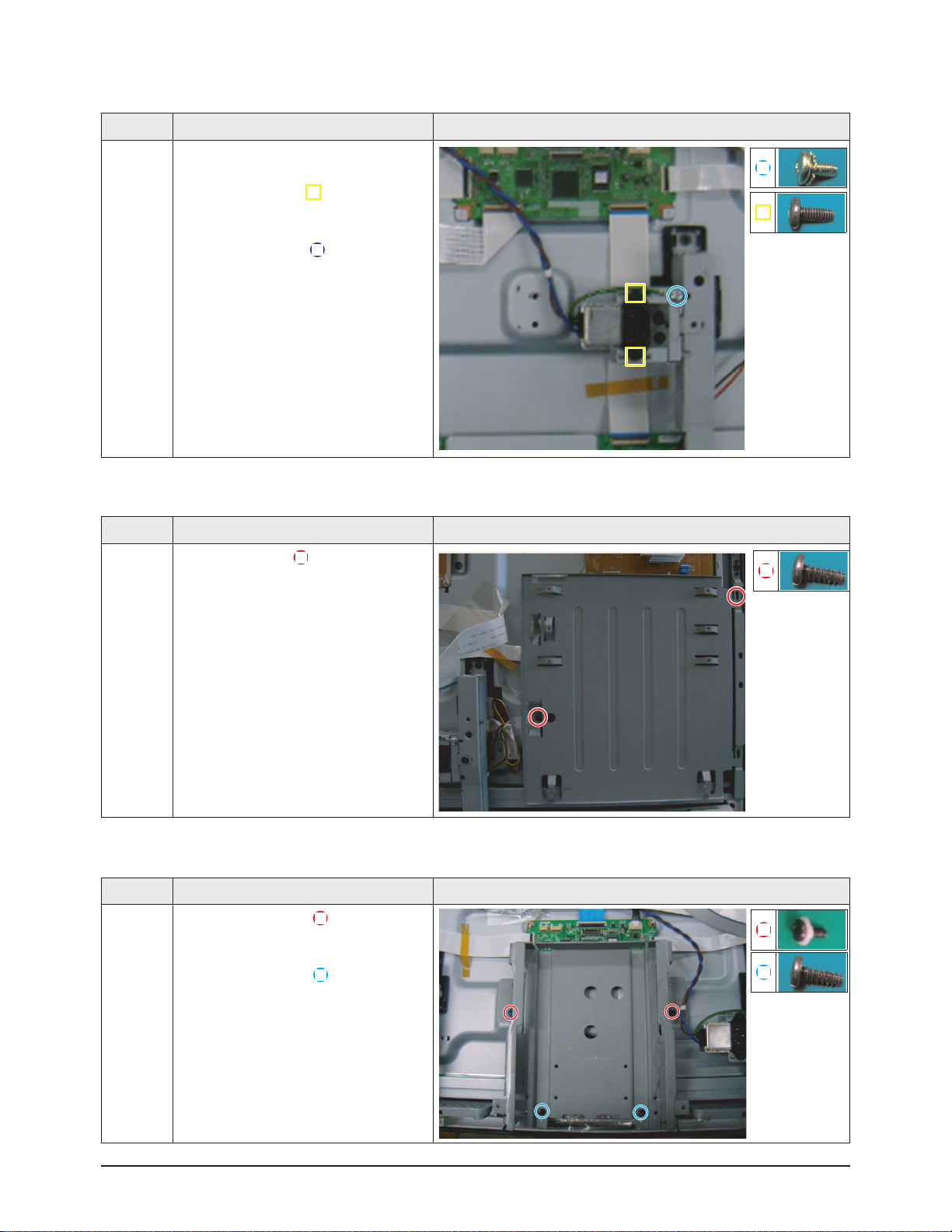

3-1-1 Separation of ASSY COVER P-REAR

Part Name Description Description Photo

Cover

Rear

① Remove 17 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove 6 screws. ( )

: PH,+,WSP,S,M4,L35,ZPC(BLK)

③ Remove the rear cover.

!

: Please lay the PDP unit face down on a

soft surface when removing the stand.

3-1-2 Separation of ASSY PCB MISC-MAIN

Part Name Description Description Photo

Main

Board

① Detach all connectors from the Main

Board.

② Remove 4 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the Main Board.

Samsung Electronics 3-1

Disassembly & Reassembly

3-1-3 Separation of FILTER-EMI AC LINE

Part Name Description Description Photo

FILTER-

EMI

AC LINE

① Detach connector from SMPS.

② Remove 2 screw. ( )

: PH,+,WWP,M3,L8,NI PLT

③ Remove 1 screws.( )

: BH,+,S,M4,L10,ZPC(BLK)

④ Separate FILTER-EMI AC LINE from

bracket.

3-1-4 Separation of BRACKET-PCB

Part Name Description Description Photo

Bracket

PCB

① Remove screw.( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove the BRACKET-PCB.

3-1-5 Separation of ASSY BRACKET

Part Name Description Description Photo

Bracket

① Remove 2 screws. ( )

: BH,+,PT,S Tite,M4,L10,ZPC(BLK)

② Remove 2 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

③ Remove Bracket.

3-2 Samsung Electronics

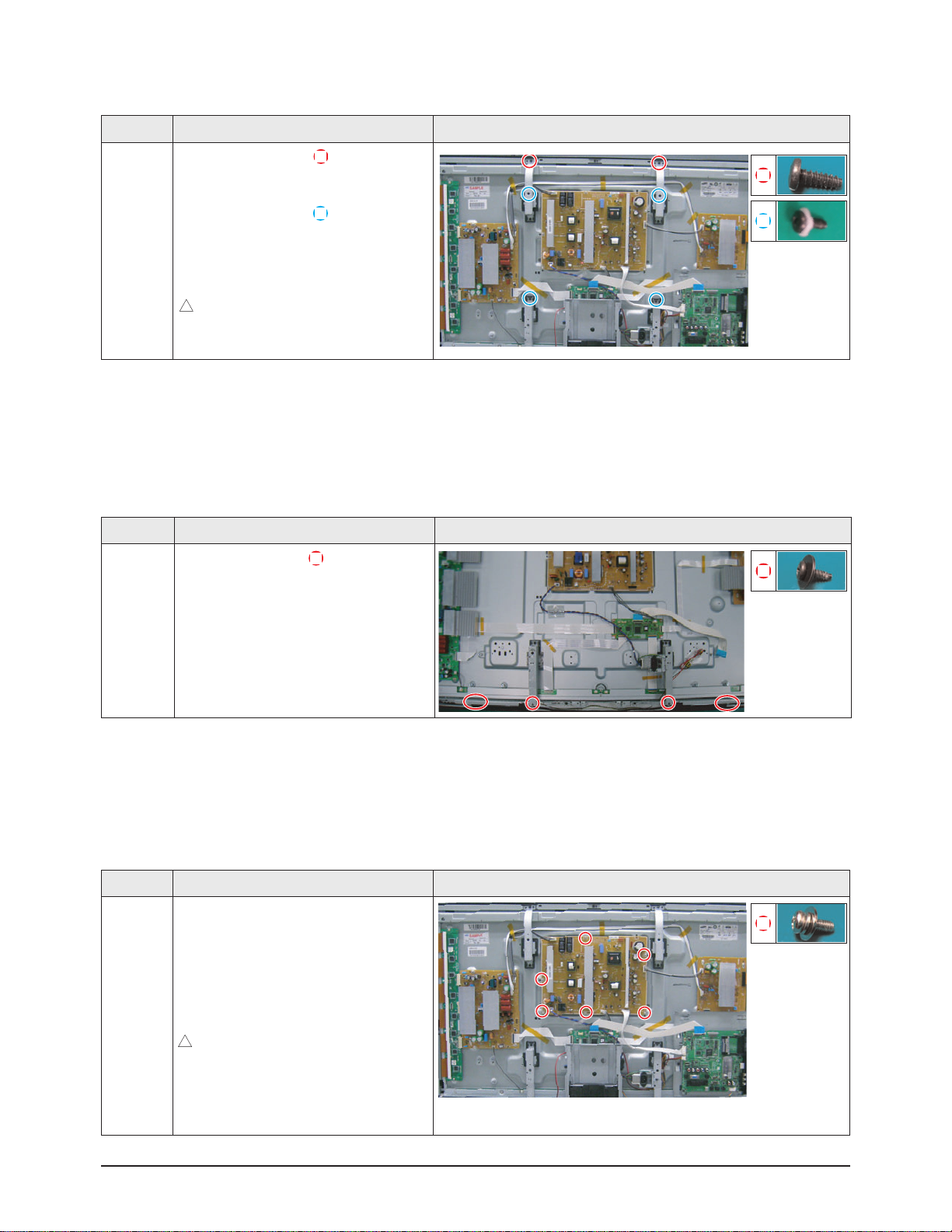

3-1-6 Separation of ASSY BRACKET P-WALL

Part Name Description Description Photo

Wall

Bracket

① Remove 2 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove 4 screws. ( )

: BH,+,S,M4,L10,ZPC(BLK)

③ Remove Wall Bracket.

!

: Please lay the PDP panel face down

on a soft surface when separating front

cover.

Disassembly & Reassembly

3-1-7 Separation of ASSY SPEAKER P

Part Name Description Description Photo

Speaker

① Remove 4 screws.( )

: BH,+,WP,B,M4.0,L3,ZPC(BLK),

SWRCH18A

② Remove the Speaker.

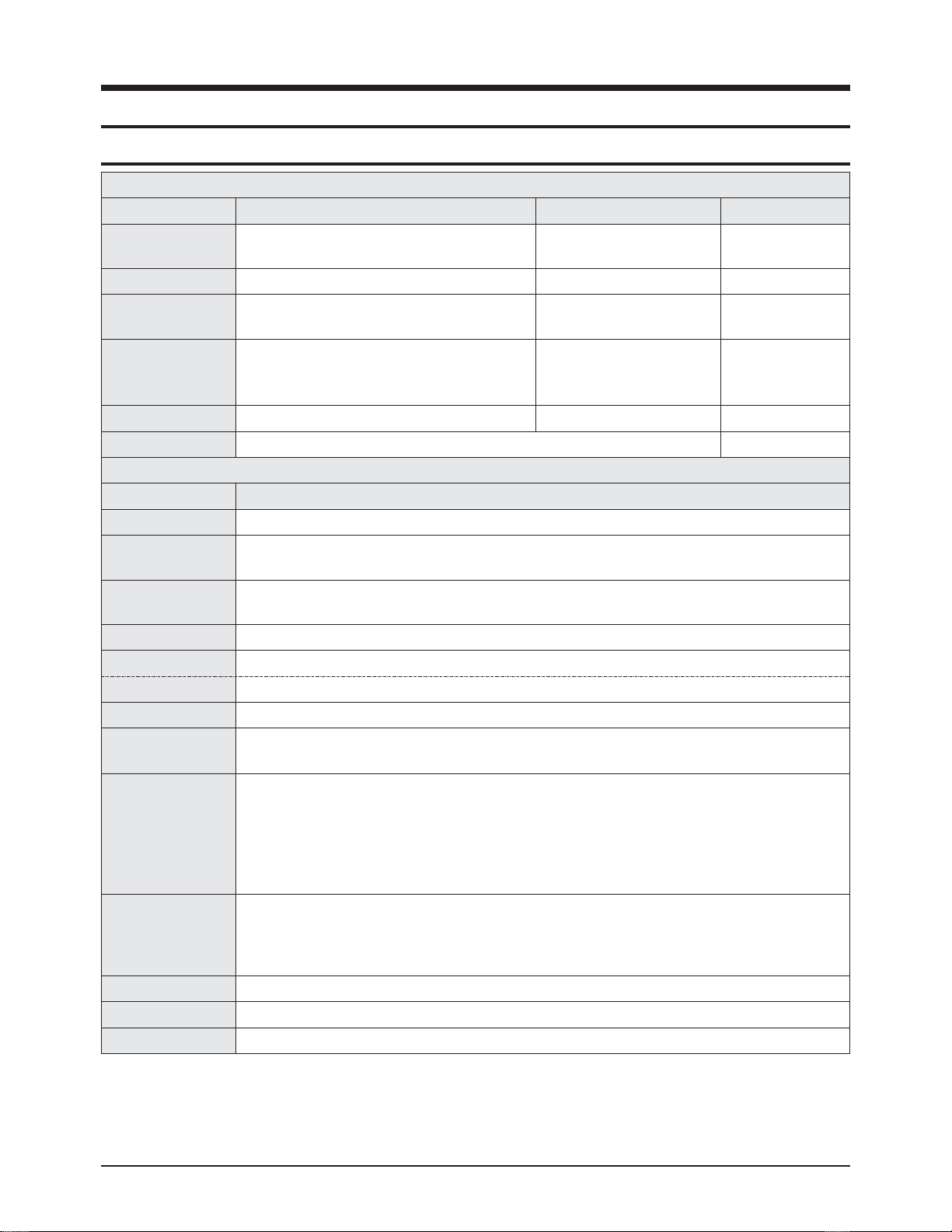

3-1-8 Separation of SMPS-PDP TV

Part Name Description Description Photo

SMPS

① Detach all connectors from the SMPS.

② Remove 6 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the SMPS.

!

: Wear gloves when handling the power

board as there may be some remaining

electrical charge in the capacitor.

Specifically, avoid touching any part of

the capacitor.

Samsung Electronics 3-3

Disassembly & Reassembly

3-1-9 Separation of ASSY PDP MODULE P-LOGIC MAIN BOARD

Part Name Description Description Photo

Logic

Board

① Detach all connectors from the Logic

Main Board.

② Remove 2 screws.

: WSP,PH,+,M3,L8,NI PLT

③ Remove the Logic Main Board.

3-4 Samsung Electronics

Disassembly & Reassembly

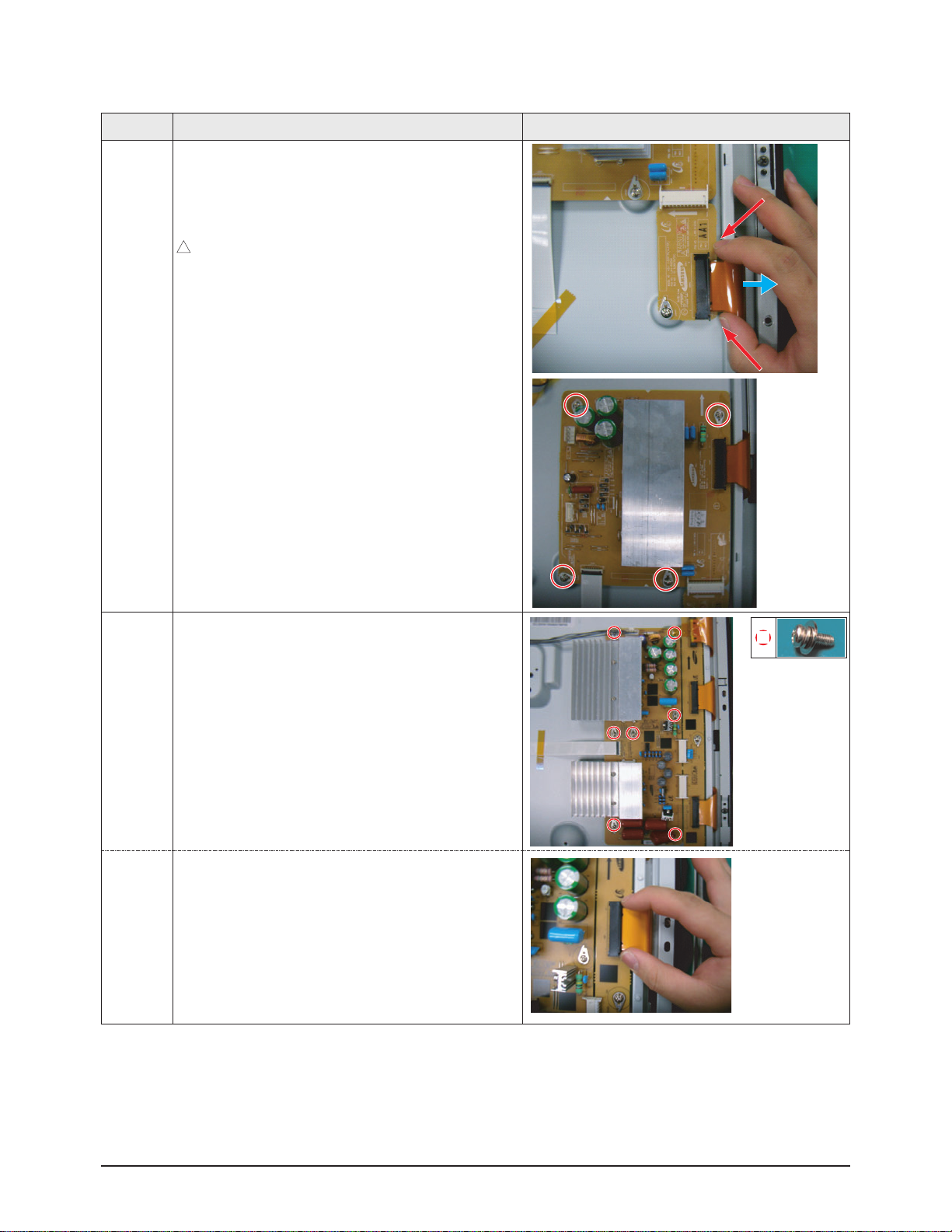

3-1-10 Separation of ASSY PDP MODULE P-X MAIN BOARD

Part Name Description Description Photo

Flat able

① Detach all Connectors from the X Main Board.

※ To separate the Flat Cable of the X-Board, press the

upper and the lower sides of the connector.

!

: Pinch the sides, but then push down in the ribbon, it

should slide out after that.

X-Main

Board

X-Main

Board

① Remove 7 screws.

: PH,+,WWP,M3,L8,NI PLT

② Remove the X-Main Board.

① Remove the X-Main Board.

Samsung Electronics 3-5

Disassembly & Reassembly

3-1-11 Separation of ASSY PDP MODULE P-Y MAIN BOARD

Part Name Description Description Photo

Flat Cable

① Detach the scan board connectors from the panel .

Y-Scan

Board

① Remove 2 screws.

: PH,+,WWP,M3,L8,NI PLT

3-1-12 Separation of ASSY PDP MODULE P-ADDRESS BUFFER BOARD

Part Name Description Description Photo

Buffer

board

shield

3-6 Samsung Electronics

① Remove 3 screws.

: PH,+,WWP,M3,L8,NI PLT

② Remove the still bar.

▶Before removing the still bar, you should

lift up the panel a little.

3-1-13 Separation of ASSY PANEL BRACKETS

Part Name Description Description Photo

Panel

Brackets

① Remove 7 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove the Side Panel Brackets.

Disassembly & Reassembly

Samsung Electronics 3-7

MEMO

3-8 Samsung Electronics

1. Precaution

To avoid possible damage, electric shocks or exposure to radiation, follow the instructions below with regard to safety,

installation, service and ESD.

1-1 Safety Precautions

Precaution

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure there aren't any gaps between the front and

rear cover that anyone could insert they're fingers into

and receive any electrical shock. These gaps include

ventilation holes, cracks, etc.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁. In these cases, make sure that the device

is repaired before sending it back to the customer.

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transformer for

checking the leakage. Use only those current leakage

testers or mirroring systems that comply with ANSIC

101.1 and the Underwriter Laboratory's specifications

(UL1410, 59.7).

Fig. 1-1 AC Leakage Test

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

4. Ahigh voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons. Without

insulated transformers, the product can only be repaired

safely when the chassis is connected to the earth end of

the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the earth

ground. If the measurement is over 1.0V, unplug the AC

power cord and change the polarity before re-inserting it.

Measure the voltage between the chassis and the

ground again.

7. Some TV chassis are shipped with an additional

secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an

unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new immediately. When

any damage or overheating is detected, correct this

immediately and make a regular check of possible

errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages.

Keep the part or the lead away from any heat-emitting

materials.

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be marked with ( ).

!

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

Samsung Electronics 1-1

Precaution

1-2 Servicing Precautions

Warning 1: First carefully read the "Safety Instruction" in this service manual. When there is a conflict between the service and

the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

(UL / FCC ¡æ Refer to the Back Cabinet )

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts

should be installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so protect yourself by wearing gloves

during the repair.

11. Due to the nature of plasma display panels, partial afterimages may appear if a still picture is displayed on the

screen for a long period of time. This is caused by

brightness deterioration due to the storage effect of the

panel, and to prevent this from happening, we

recommend that the brightness and contrast are

reduced.

(e.g.) Contrast: 25, Brightness: 50

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the

insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

1-2 Samsung Electronics

1-3 Static Electricity Precautions

Precaution

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or assemblies. Alternatively,

wear a dischargeable wrist-belt. (Make sure to remove

any static electricity before connecting the power source

- this is a safety instruction for avoiding electric shock)

3. Remove the ESD assembly and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals. Such chemicals

will generate static electricity that causes damage to the

ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices. Most solder

removal devices do not support an anti-static feature.

Asolder removal device without an anti-static feature

can store enough static electricity to cause damage to

the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit assembly.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

CAUTION

These servicing instructions are for use by qualified

service personnel only.

To reduce the risk of electric shock do not perform any

servicing other than that contained in the operating

instructions unless you are qualified to do so.

Samsung Electronics 1-3

Precaution

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product.

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. Do not place the product in areas with poor ventilation

such as a bookshelf or closet. The increased internal

temperature may cause fire.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before repositioning the product.

Also check the antenna cable or the external connectors

if they are fully unplugged. Damage to the cord may

cause fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contact with the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. When connecting the RF antenna, check for a DTV

receiving system and install a separate DTV reception

antenna for areas with no DTV signal.

8. When installing the product, leave enough space (4")

between the product and the wall for ventilation

purposes. Arise in temperature within the product may

cause fire.

9. When moving a PDP with removable speakers, detach

the speakers first before moving the main body.

Moving the PDP main body without separating the

speakers may cause the speakers to detach, possibly

causing damage or injury.

1-4 Samsung Electronics

Product Specification

2. Product Specification

2-1 Product Specification

Features

Block Specification Major IC Remark

RF Digital/Analog (DTV Built In)

PDP Module Samsung SDI U1P Module 42"HD New Module

Power

Video

Sound SRS TruSuround HD, Dolby Digital NTP3200 Optical Output

Cabinet B430 Design

Model PS42B430P2D

Screen Size 42 Inches (16:9)

Dimensions (WxHxD)

Weight

PC Resolution 1024 x 768 @ 60Hz

Power consumption 240W

Frequency Hsync 50Khz Vsync 50Khz

Voltage AC 100 ~ 240V, 50/60HZ

ANTENNAinput

VIDEO input

AUDIO input

Audio Output AUDIO (L/R)

Speaker Output 10W+10W (40dB+40dB)

New Features Anynet+

Samsung/Dong-yang electro

mechanics SMPS

NTSC 3.58, ATSC

HDMI

Component, PC

480i can be displayed on HDMI, however it is not contained in EDID data

*

Specification

1055.0 x 667.4 x 73 mm (without stand)

1055 x 728.2 x 316 mm (with stand)

24.3 kg (without stand)

28 kg (with stand)

※75Ω

COMPONENT - 480i/480p/720p/1080i/1080p

COMPONENT2 - 480i/480p/720p/1080i/1080p

HDMI1 : 480p/720p/1080i/1080p

HDMI2(DVI Compatible) - 480p/720p/1080i/1080p

COMPONENT - 480i/480p/720p/1080i/1080p

COMPONENT2 - 480i/480p/720p/1080i/1080pC

Tuner

DNOQ403SH151A SAMSUNG

SEMS12

ANTAIR IN

unbalanced

AV

AV

DVI

Samsung Electronics 2-1

Loading...

Loading...