Samsung DSR9400VIA Service manual

DIGITAL SATELLITE RECEIVER

DSR9400 FTA

DSR9400 EM VIA

SERVICE

1. Precautions

2. Operating Instructions

3. Software Upgrade and Installation

4. Troubleshooting

5. Exploded View and Parts List

6. Electrical Parts List

7. PCB Diagrams

8. Schematic Diagrams

Manual

DIGITAL SATELLITE RECEIVER CONTENTS

SERVICE MANUAL

DSR9400 (FTA, EM VIA)

ELECTRONICS

© Samsung Electronics Co., Ltd. NOV. 2002

Printed in Korea

MF82-00009A

Samsung Electronics 1-1

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all protective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

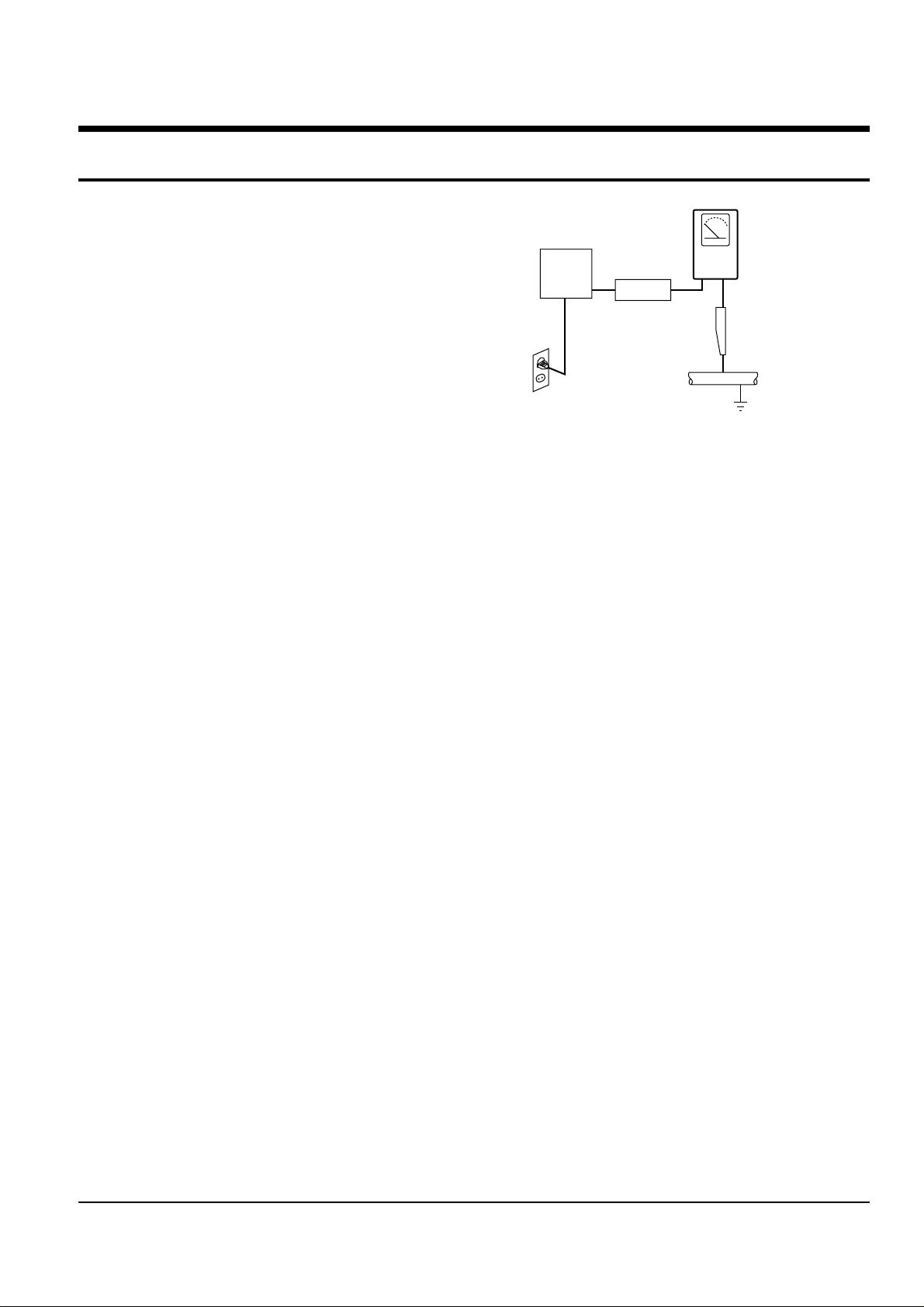

4. Leakage Current Hot Check (See Fig. 1-1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unit’s

AC switch first in the ON position and then OFF,

measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

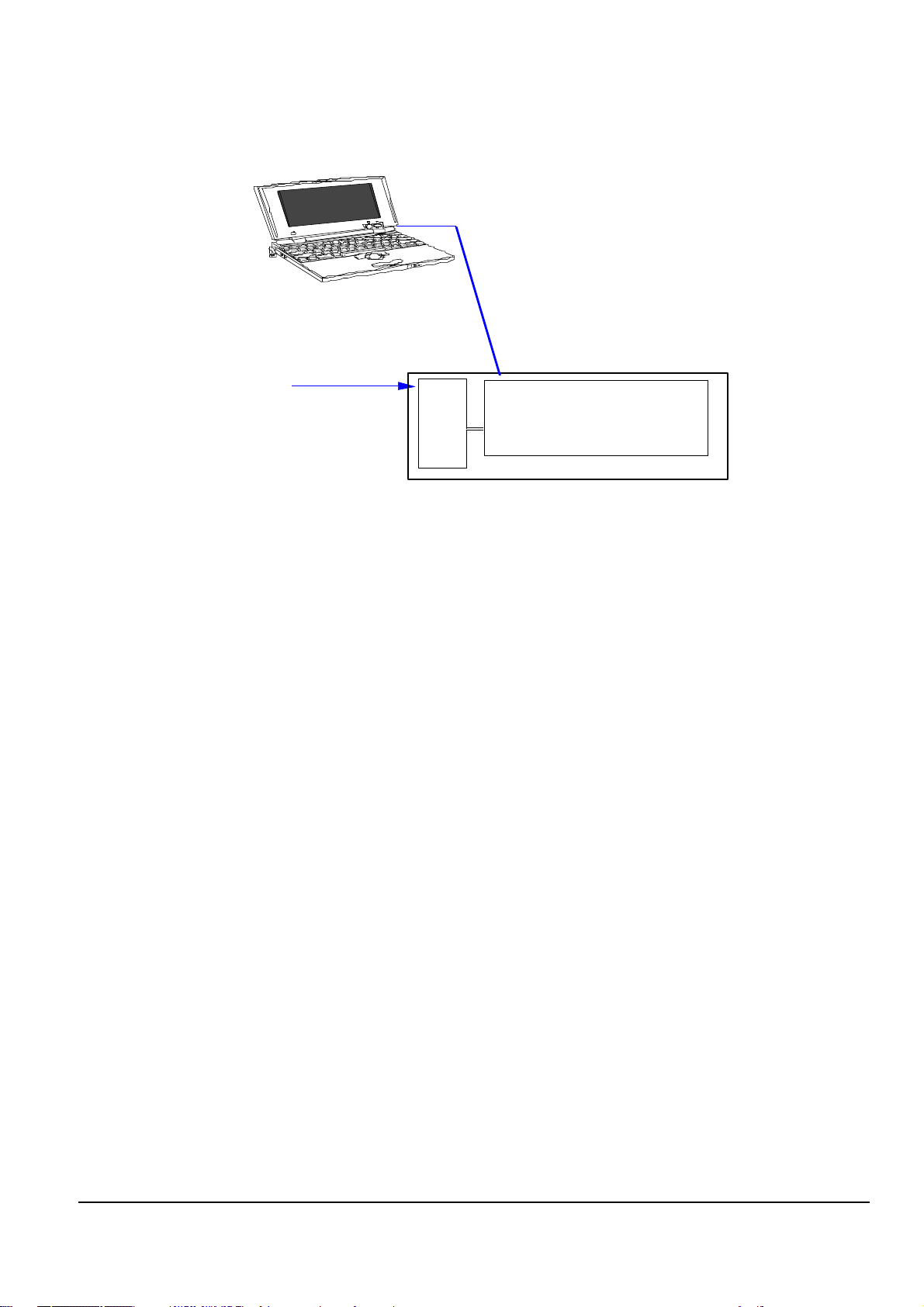

Fig. 1-1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Precautions

1-2 Samsung Electronics

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors.

Such alterations might create a safety hazard.

Also, any design changes or additions will void

the manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some “in-line” picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

“permanently attached” yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. Areplacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

Samsung Electronics 3-1

3. Software Upgrade and Installation

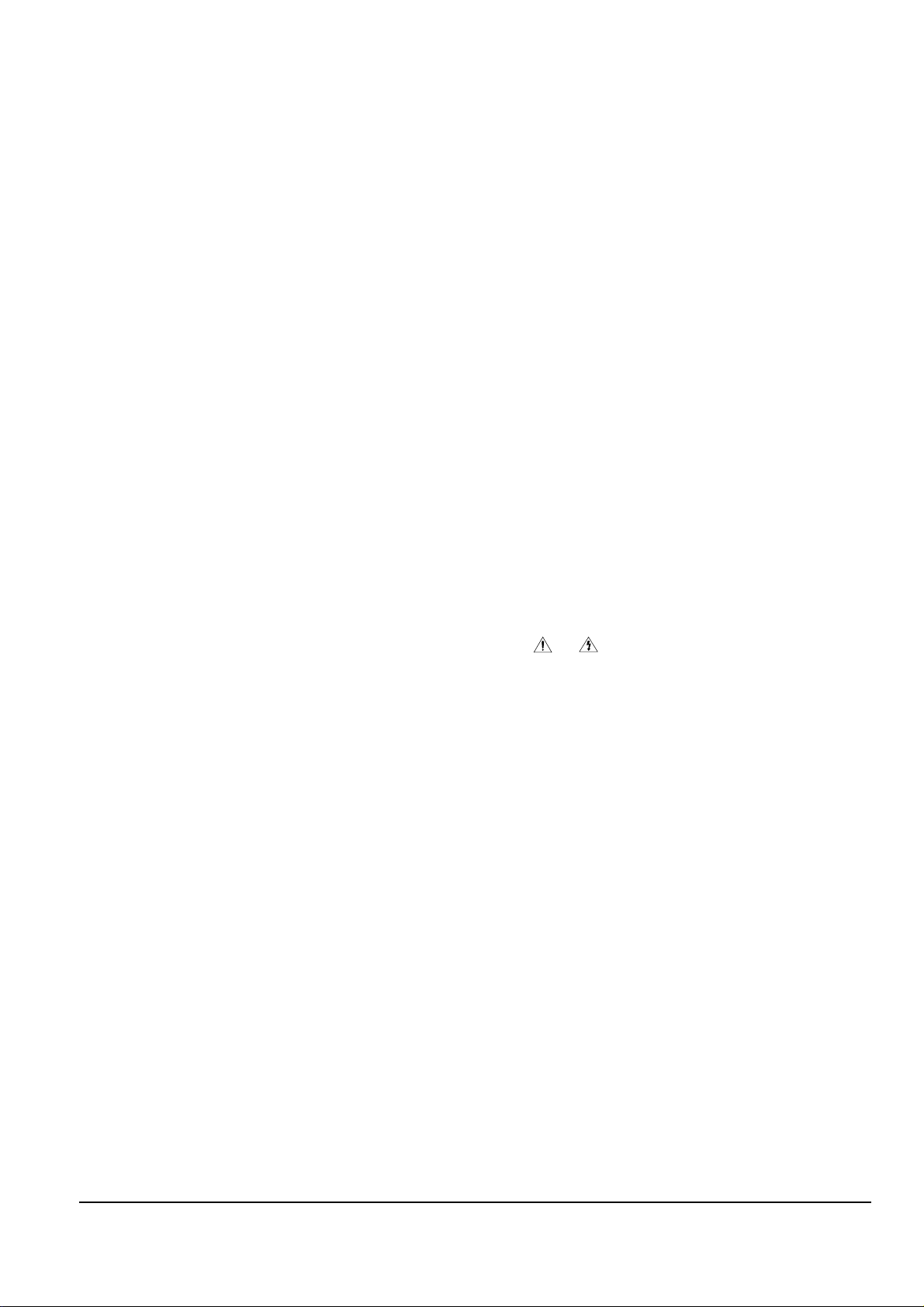

3-1 Flash Memory Writing process

How to input software after changing Boot software and replacing Flash Memory.

3-1-1 JPI Setting Manual

1) JPI exe Program : Setting ver R1.80

Make C:\STM\ST20R1.80 folder in C and copy exe file.

Execute setup file in C:\STM\ST20R1.80 folder.

2) PC Setting

Execute vppi set in bin folder, opening C:\STM\ST20R1.80\bin folder

Port type in vppi set up : Auto Detect -> EPP

Access Mode : after altering Synchronous -> Interrupt,

Click Apply and close “vppi set up”.

Open Regedit exe in Windows (O) : regedit

HKEY_LOCAL_MACHINE double click -> SYSTEM double click -> CURRENT CONTROL SET double

click -> SERVICES double click -> VxD double click

vppi set click -> *Access Mode : 0x00000002(2)

*Port Type : 0x00000003(3)

◆ Following line should be added at Autoexec.bat of PC.

SET ST20ROOT=C:\STM\ST20R1.80

SET STVM_HOME=C:\STM\ST20R1.80

SET TOOLSET=C:\STM\ST20R1.80

3) Caution

◆ When Defaulting in vppi set up (in case of not altering)

Access Mode : 0x00000003(3)

◆ Port Type : 0x00000000(0)

◆ When inputting boot program as JPI, following items should be

omitted in C:\windows\system.ini file[386Enh].

device=C:\ST20SWC\tools\vwrun.386

device=C:\ST20SWC\tools\vb045st.386

device=C:\ST20SWC\tools\vb008st.386

* If copied by PPI, above items should be included.

Software Upgrade and Installation

3-2 Samsung Electronics

3-1-2 Boot Software Input Process (Same Process in Main Software Installing)

<How to install software using JPI Adapter>

ΠPrepare PC and JPI, DSR 9400 as above figure.

´ Connect MAIN BOARD to JIG, JPI ADAPETER to JPI Port of MAIN PCB.

Then JP102(Jumper) Short of Main Board.

ˇ Approve a power source of POWER SUPPLY in the product set.

¨ Convert PC into MS-DOS MODE.

ˆ Execute C:\amd-boot\flash file name (SETTING UP ST20 DCU TOOLSET 1.6.2 SETTING END)

Ø After the power source of POWER SUPPLY OFF.

Then disassemble from JPI ADAPTER CONNECTER.

◆ SRF00902A (FTA) -> C:\amd-boot\flash boot_FTA_9400_1

◆ SRV10902A (EM VIA)-> C:\amd-boot\flash boot_VIACCESS_9400_1

“Message Check”

Program Start

Erased Block 65 OK!

Erased Block 66 OK!

Erased Block 67 OK!

Erased Block 68 OK!

Erased Block 69 OK!

received 65 block

entering fast mode programming sequence from C05e0000 to 7ffe0000

received 66 block

entering fast mode programming sequence from C05f0000 to 7fff0000

received 67 block

entering fast mode programming sequence from C05f8000 to 7fff8000

received 68 block

entering fast mode programming sequence from C05fa000 to 7fffa000

received 69 block

entering fast mode programming sequence from C05c0000 to 7fffc000

romtool : Operation Complete

Test Mode

JPIadapter

LPT1

220V AC

DC 9V

PC

Main PCB

DSR 9400

S

M

P

S

JPI Port

Fig. 3-1

Software Upgrade and Installation

Samsung Electronics 3-3

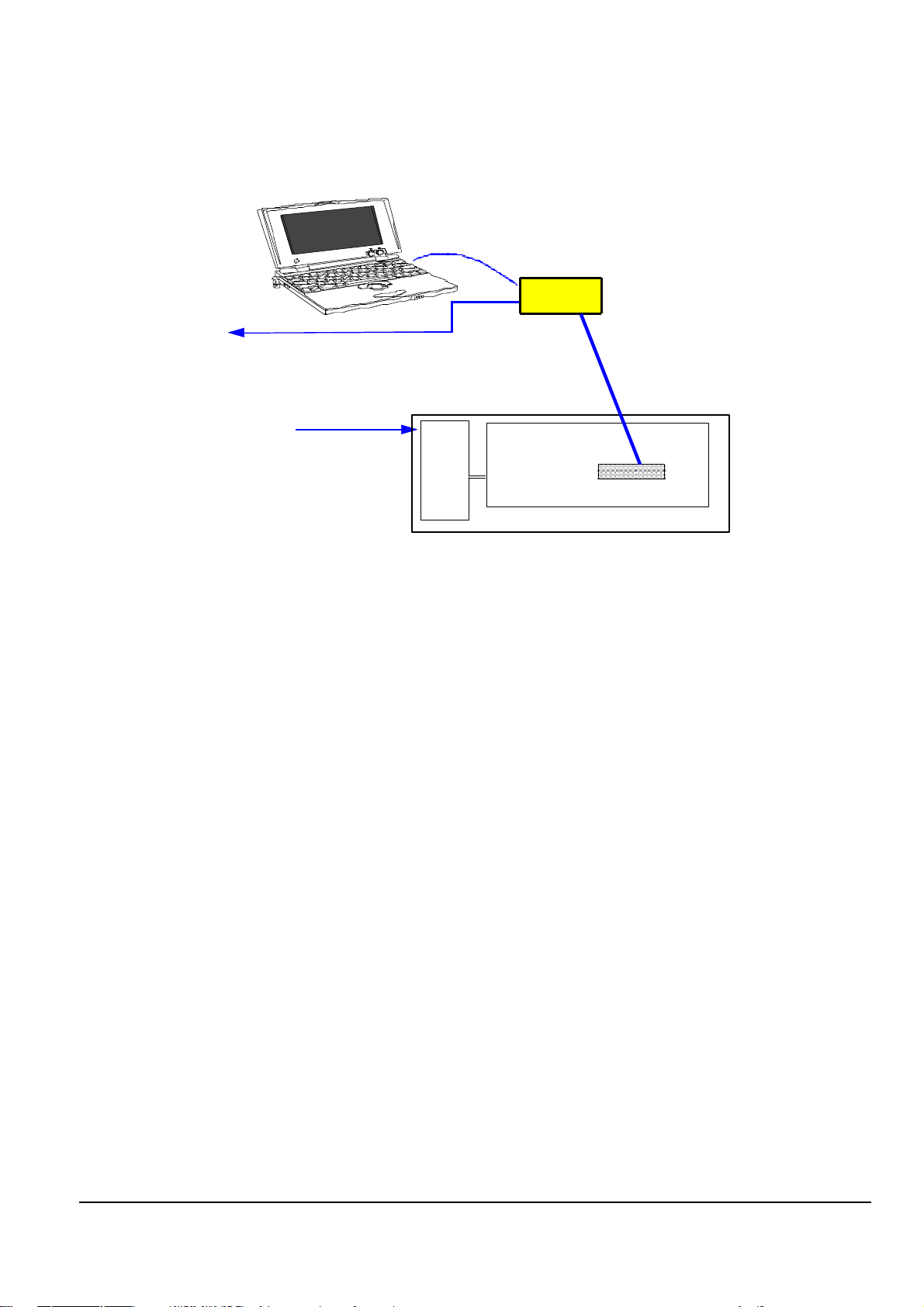

3-1-3 MAIN Software Install Process

ΠOpen DSR.TRM file while executing HYPERTERMINAL of PC.

Port : Select to COM 1 port currently used.

Baudrate : 115200

´ As Vol-up key of Front PCB presses, POWER(PLUG) ON.

◆ SRF00902A : Samsung Brand FTA Model

Loader version x. x

◆ SRV10902A : Samsung Brand EM VIACCESS Model

Loader version x. x

ˇ Send a file at Download ROM image. ( PROTOCOL : 1K XMODEM )

¨ Select Main Program (C:\main\DSR9400_2002_04_03_120_44D2.bin) by each kinds as selecting the File Send of

Transfer or Hyperterminal.

ˆ Check if the normal message appears.

COM1

220V AC

PC

Main PCB

DSR 9400

S

M

P

S

RS-232

Fig. 3-2

Software Upgrade and Installation

3-4 Samsung Electronics

MEMO

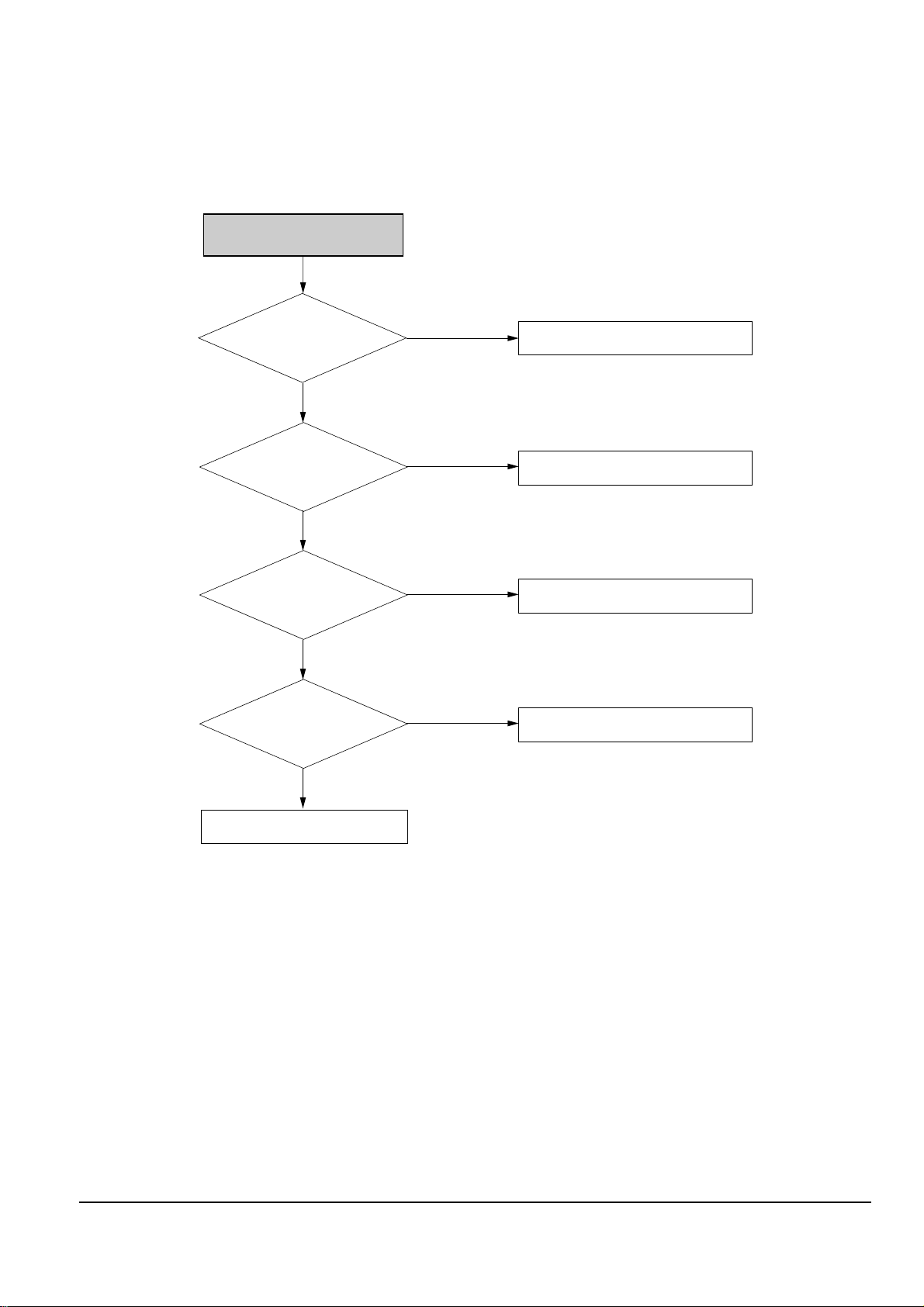

NO POWER (LED OFF)

Power switch and

power plug pin is

connected?

SMPS OK?

J301 (2, 5, 6, 7, 8, 9)

Check U901, U902

Connect switch and power Plug pin.

Yes

Yes

No

No

Check SMPS.

Front PCB ass'y is OK?

Yes

No

Check Front PCB ass'y.

U4(12, 13) signal?

: 27MHz CLK

No

Check X1.

Yes

R10 signal?

: 27MHz CLK

No

Check R10.

Yes

108MHz CLK is occurred

at R78, R79

Check U1

Yes

Yes

U4(8) signal?

: 27MHz CLK

No

Check U4.

Yes

No

Check U808.

Samsung Electronics 4-1

4. Troubleshooting

Troubleshooting

4-2 Samsung Electronics

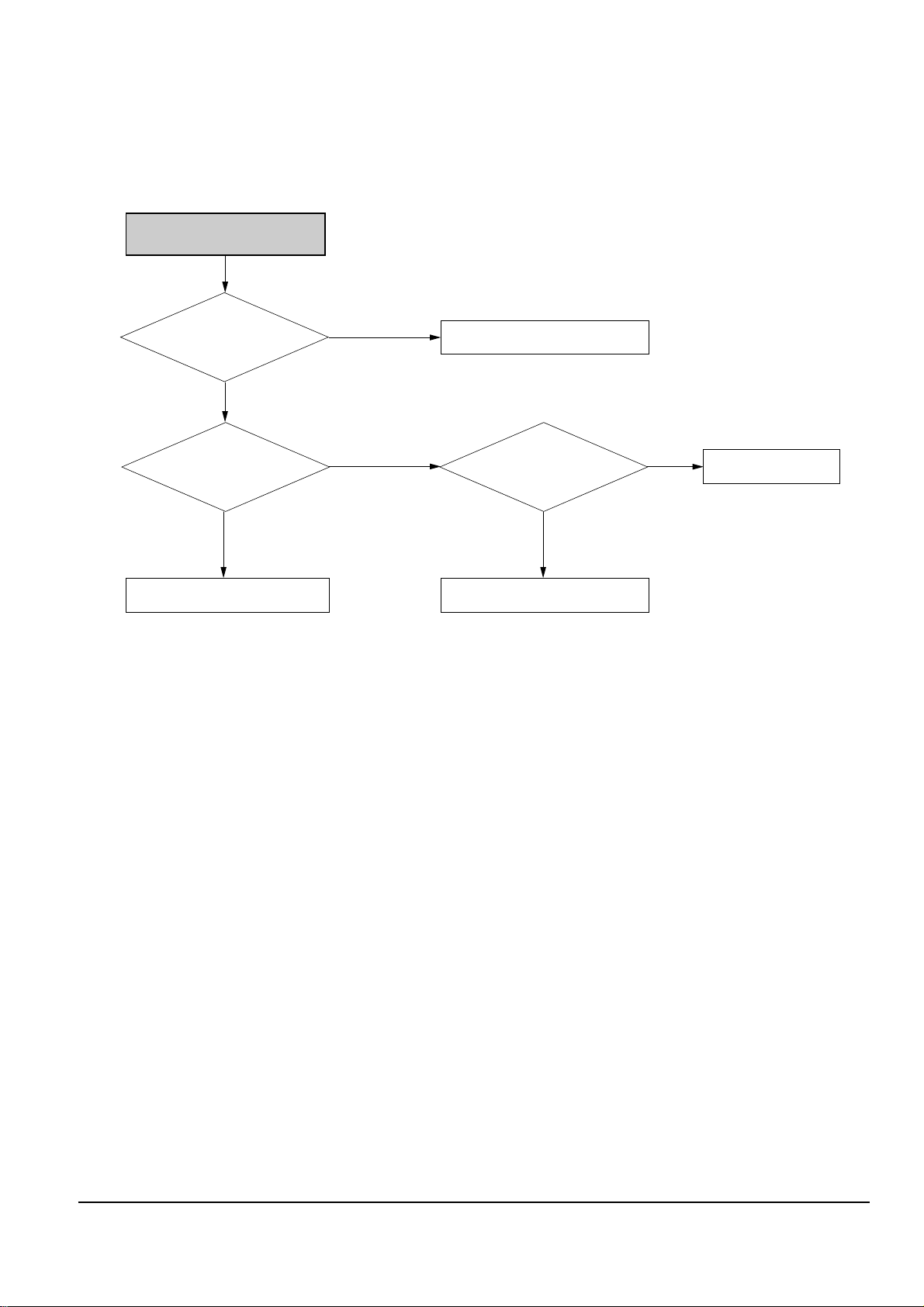

NO LOCKING

U305 (5) is High?

(5 Volts)

U305 (3) DC Voltage is

H : 17~19V , L : 12.5~14V?

Check U1.

Check LNB Power On/Off at Menu.

Yes

Yes

No

No

Check CHIC1, SMPS(11, 12).

U902 Input

voltage L809 : 5V,

U901 Input vloltage

BD804 : 3.3V

Yes

No

Check U301, U304.

U901 Data, Control

appear at R930 ~ R940

No

Check U901.

Yes

Troubleshooting

Samsung Electronics 4-3

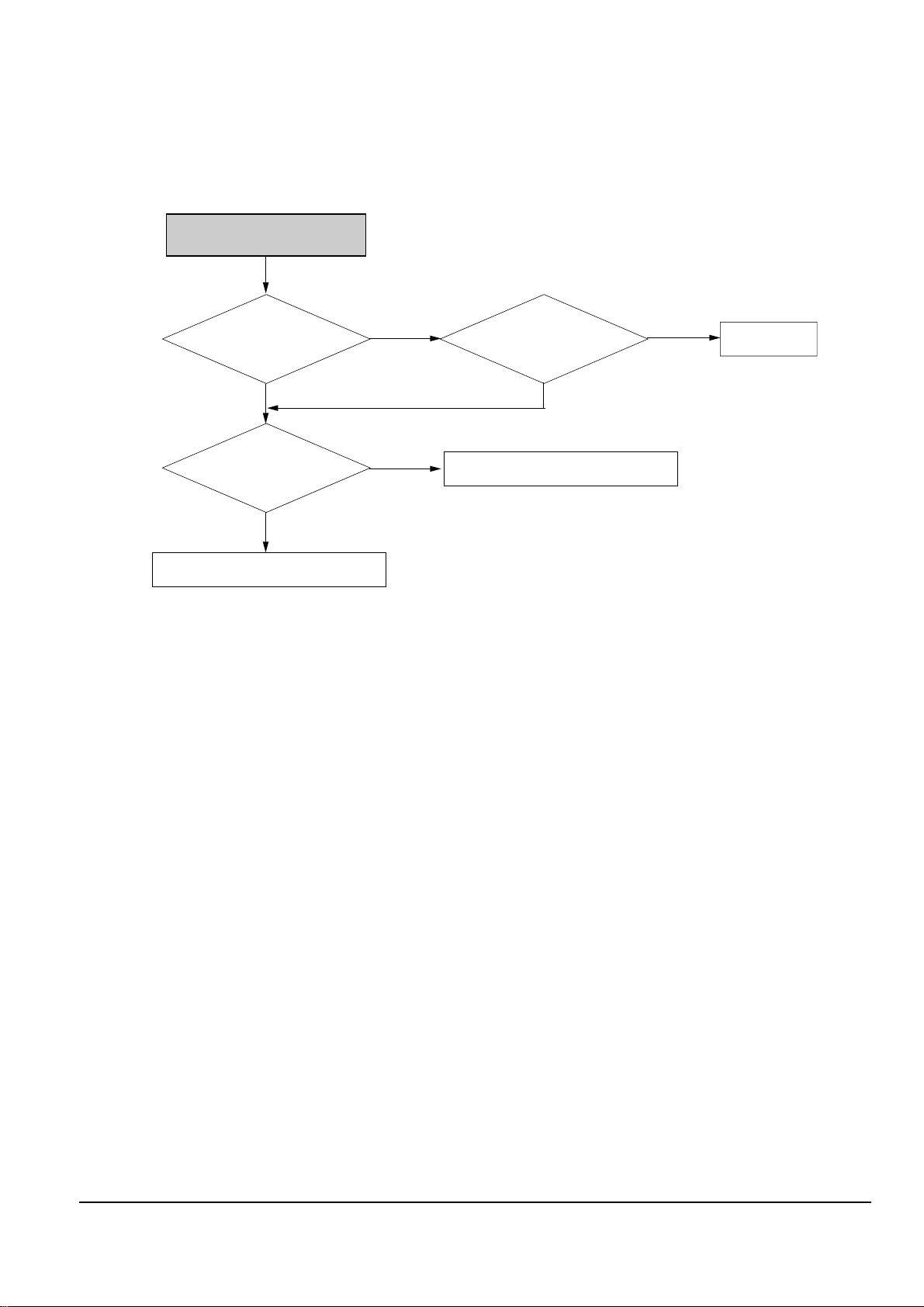

NO SPDIF OUTPUT

L602 is 5V?

Check L602, SMPS.

Yes

No

Check U1.

No

Data waveform

occur at U603(20)

U603(5, 6, 7, 8)

Data, CLK?

Yes

No

Check U603.

Yes

Check J600.

Troubleshooting

4-4 Samsung Electronics

NO VIDEO (TV SCART)

No

U800(4) Video signal ?

L804 Video signal ?

Yes

Yes

No

No

Check U1.

U800(44) Signal ?

Check R817.

Check U800.

Yes

Troubleshooting

Samsung Electronics 4-5

NO VIDEO (VCR SCART)

No

U800(4) Video signal ?

L804 Video signal ?

Yes

Yes

No

No

Check U1.

U800(44) Signal ?

Check R824.

Check U800.

Yes

Loading...

Loading...