Samsung Color Laser Printer The keynote of Product

High Performance /

High Quality Muti-path CLBP

- Model : only CLP 350N

- Speed(Color/Mono) : 5/20ppm(A4). 5/19ppm(Let)

- Printing resolution : 2,400 x 600 dpi

- Emulation : PCL6/PS3

- Memory expansion => Max.128MB

- Processor : 300MHz

- Interface : IEEE 802.3,Ethernet(10/100Mbps)

Wireless: Not Supported

- Toner Cartridge :

4K Toner(K), 2K toner(C, M, Y each)

- Printer Life : 200,000 pages

Monthly Max. Duty : 25,000 pages/month

CLP-350N

Manual

SERVICE

Basic Model :CLP-350N

CLP-350N

CLP-350N/XAA

1. Precautions

1.1 Safety Warning 1-1

1.2 Caution for safety

1-2

1.3 ESD Precautions

1-5

2. Product Specification

2.1 Product Specifications 2-1

2.1.1 Product Overview

2-1

2.1.2 Specifications

2-2

2.1.3 Model Comparison Table

2-7

2.2 System Overview

2-8

2.2.1 System Structure

2-8

2.2.2 Main PBA Description

2-14

2.2.3 CRUM

2-24

2.2.4 General Description

2-26

3. Disassembly and Reassembly

3.1 Precautions When Replacing Parts 3-2

3.1.1 Precautions when assembling and disassembling

3-2

3.1.2 Precautions when handling PBA

3-2

3.2 Parts for Maintenance and Repair

3-3

3.2.1 Replacement interval for parts with a limited life

3-3

3.2.2 Printer Cleaning

3-4

3.3 Information Related in Disassembly and Assembly

3-5

3.3.1 Special Service Parts

3-5

3.3.2 Screws Used in the Printer

3-6

3.4 Disassembly Procedure

3-10

3.4.1 Cover Unit

3-10

Contents

3.4.2 Fuser Unit 3-12

3.4.3 LSU Unit

3-13

3.4.4 HVPS Board

3-13

3.4.5 Main Board

3-14

3.4.6 Drive Unit

3-14

3.4.7 SMPS Board

3-15

3.4.8 Transfer Unit

3-15

4. Alignment & Troubleshooting

4.1 Alignment and Adjustments 4-1

4.1.1 Control Panel

4-1

4.1.2 Function

4-2

4.1.3 Jam Removal

4-6

4.1.4 Sample Pattern

4-9

4.1.5 Periodic Defective Image

4-10

4.1.6 How to use EDC (Engine Diagnostic Control) Mode

4-11

4.1.7 Error Message

4-17

4.1.8 ITB Unit Reset

4-18

4.2 Troubleshooting

4-20

4.2.1 Procedure of Checking the Symptoms

4-20

4.2.2 Troubleshooting Checklist

4-21

4.2.3 Solving General Printing Problems

4-22

4.2.4 Solving Print Quality Problems

4-32

4.2.5 Common Windows Problems

4-50

4.2.6 Common Macintosh Problems

4-51

4.2.7 Common Linux Problems

4-52

4.2.8 Major Problems Trouble shooting

4-56

5. Exploded Views & Parts List

Continued

5.1 Main 5-2

5.2 Cover Unit

5-4

5.3 Top Cover

5-6

5.4.1 Rear Cover

5-8

5.4.2 Transfer Unit

5-10

5.5 Frame

5-12

5.6 LSU Cover

5-16

5.7 Fuser Ass'y

5-18

5.8 Main Drive

5-20

5.9 Cartridge-Transfer

5-24

5.10 Cartridge-Drum

5-27

5.11 Toner BK

5-29

5.12 Toner CMY

5-31

5.13 Cassette

5-33

5.14 SCF-Frame

5-35

5.15 SCF Cassette

5-39

6. System Diagram

6.1 Block Diagram 6-1

6.2 Connection Diagram

6-2

6.2.1 Main Layout

6-2

6.2.2 Power

6-3

6.2.3 Imaging, ITB Unit

6-4

6.2.4 HVPS, LSU

6-5

6.2.5 SCF, OPE, BLDC

6-6

6.2.6 Sensor, Clutch, Solenoid

6-7

7. Reference Information

7.1 Tools for Troubleshooting 7-1

Continued

Continued

7.2 Acronyms and Abbreviations 7-2

7.3 Select a location for the printer

7-4

7.4 A4 ISO 19752 Standard Pattern

7-5

Precautions

Samsung Electronics

Service Manual

1-1

1

1

1. Precautions

In order to prevent accidents and to prevent damage to the equipment please read the precautions listed

below carefully before servicing the printer and follow them closely.

1.1 Safety Warning

(1) Only to be serviced by appropriately qualified service engineers.

High voltages and lasers inside this product are dangerous. This printer should only be serviced by a suitably

trained and qualified service engineer.

(2) Use only Samsung replacement parts

There are no user serviceable parts inside the printer. Do not make any unauthorized changes or

additions to the printer, these could cause the printer to malfunction and create electric shock or fire hazards.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for

Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product

conforming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The

laser system and printer are designed so there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The

reflected beam, although invisible, can damage your eyes. When using this product, these basic safety

pre-cautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET.

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D’OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE L’ESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDGÅ UDSAETTELSE FOR STRÅLNING.

ADVARSEL. - USYNLIG LASERSTRÅLNING NÅR DEKSEL

ÅPNES. STIRR IKKE INN I STRÅLEN.

UNNGÅ EKSPONERING FOR STRÅLEN.

VARNING - OSYNLIG LASERSTRÅLNING NÄR DENNA DEL

ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN. STRÅLEN ÄR FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA NÄKYMÄTTÖMÄLLE LASER-

SÄTEILYLLE ÄLÄ KATSO SÄTEESEEN.

Samsung Electronics

Service Manual

Precautions

1-2

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

Please keep toner cartridges away from children. The toner powder contained in the toner cartridge may be harmful and

if swallowed you should contact a doctor.

1.2.2 Electric Shock and Fire Safety Precautions

Failure to follow the following instructions could cause electric shock or potentially cause a fire.

(1) Use only the correct voltage, failure to do so could damage the printer and potentially cause a fire or electric

shock.

(2) Use only the power cable supplied with the printer. Use of an incorrectly specified cable could cause the cable

to overheat and potentially cause a fire.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could lead to

a fire.

(4) Do not allow water or other liquids to spill into the printer, this can cause electric shock. Do not allow paper

clips, pins or other foreign objects to fall into the printer these could cause a short circuit leading to an electric

shock or fire hazard..

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock. When

servicing the printer remove the power plug from the wall socket.

(6) Use caution when inserting or removing the power connector. The power connector must be inserted com-

pletely otherwise a poor contact could cause overheating possibly leading to a fire. When removing the power

connector grip it firmly and pull.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply round corners or otherwise

damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat and

cause a fire or exposed cables could cause an electric shock. Replace a damaged power cable immediately,

do not reuse or repair the damaged cable. Some chemicals can attack the coating on the power cable,

weakening the cover or exposing cables causing fire and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should be

repaired immediately. Take care not to cut or damage the power cable or plugs when moving the machine.

(9) Use caution during thunder or lightening storms. Samsung recommend that this machine be disconnected from

the power source when such weather conditions are expected. Do not touch the machine or the power cord if it

is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the printer in a clean well ventilated location. Do not position the machine

near a humidifier. Damp and dust build up inside the machine can lead to overheating and cause a fire.

(11) Do not position the printer in direct sunlight. This will cause the temperature inside the printer to rise possibly

leading to the printer failing to work properly and in extreme conditions could lead to a fire.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it could

make contact with a high voltage conductor inside the machine and cause an electric shock.

Precautions

Samsung Electronics

Service Manual

1-3

1.2.3 Handling Precautions

The following instructions are for your own personal safety, to avoid injury and so as not to damage the printer

(1) Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could cause

the printer to tip or fall.

(2) The printer contains many rollers, gears and fans. Take great care to ensure that you do not catch your fingers,

hair or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the printer which if

spilled could get into the machine and cause damage or a shock or fire hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidifier or heater. Damage could be caused to the printer in such areas.

(5) Do not place candles, burning cigarettes, etc. on the printer, these could cause a fire.

1.2.4 Assembly / Disassembly Precautions

Replace parts carefully, always use Samsung parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the printer or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if the

mainboard is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect printer interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or temperature

rating are correct.

(5) When removing or re-fitting any parts do not use excessive force, especially when fitting screws into plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the OPC Drum

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to fluorescent or incandescent room

lighting. Exposure for as little as 5 mins can damage the surface’s photoconductive properties and will result

in print quality degradation. Take extra care when servicing the printer. Remove the OPC Drum and store it in

a black bag or other lightproof container. Take care when working with the covers(especially the top cover)

open as light is admitted to the OPC area and can damage the OPC Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

Samsung Electronics

Service Manual

Precautions

1-4

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to cool

down before disassembly.

(2) Do not put finger or hair into the rotating parts.

When operating a printer, do not put hand or hair into the rotating parts (Paper feeding entrance, motor, fan,

etc.). If do, you can get harm.

(3) When you move the printer.

This printer weighs 14.8kg including Consumables. Use safe lifting and handling techniques. Back injury could

be caused if you do not lift carefully.

(4) Ensure the printer is installed safely.

The printer weighs 14.8Kg, ensure the printer is installed on a level surface, capable of supporting its weight.

Failure to do so could cause the printer to tip or fall possibly causing personal injury or damaging the printer.

(5) Do not install the printer on a sloping or unstable surface. After installation, double check that the printer is stable.

Precautions

Samsung Electronics

Service Manual

1-5

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by

static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as

aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing

together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

Product specification and feature

Service Manual

2-1

Samsung Electronics

2

2

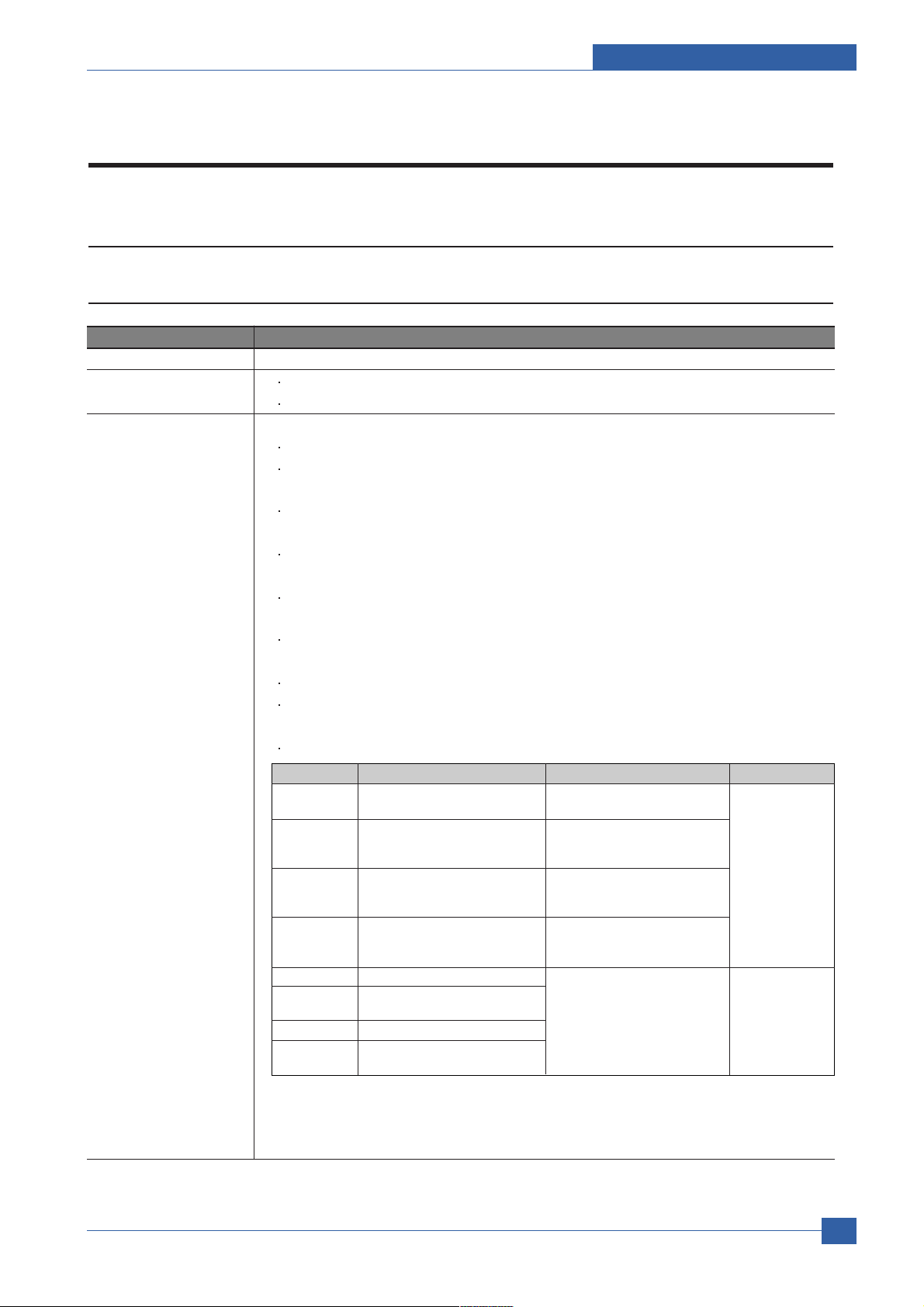

Item Descriptions

Basic Model CLP-350N

Maket of Sales

Main Target : Reseller

Black only Function(Saving money)

Main Specification 1.Speed

Up to 20 ppm in A4 (19 ppm in Letter)

Up to 5 ppm in A4 (5 ppm in Letter)

2.Printing Resolution

Native 600 x 600 dpi standard

3.Processor

CHORUSm (300Mhz), Proprietary SOC

4.Printer Language Emulations

SPL-Color, PCL6, PS3

5.Memory

The controller has 128 MB SDRAM and 16 MB flash ROM on Board

6.Interfaces

One USB port

One 10/100 BaseT network connector

7.Control Panel

No LCD, 1 keys and 5 LEDs

2. Product specification and feature

2.1 Product Specifications

2.1.1 Product Overview

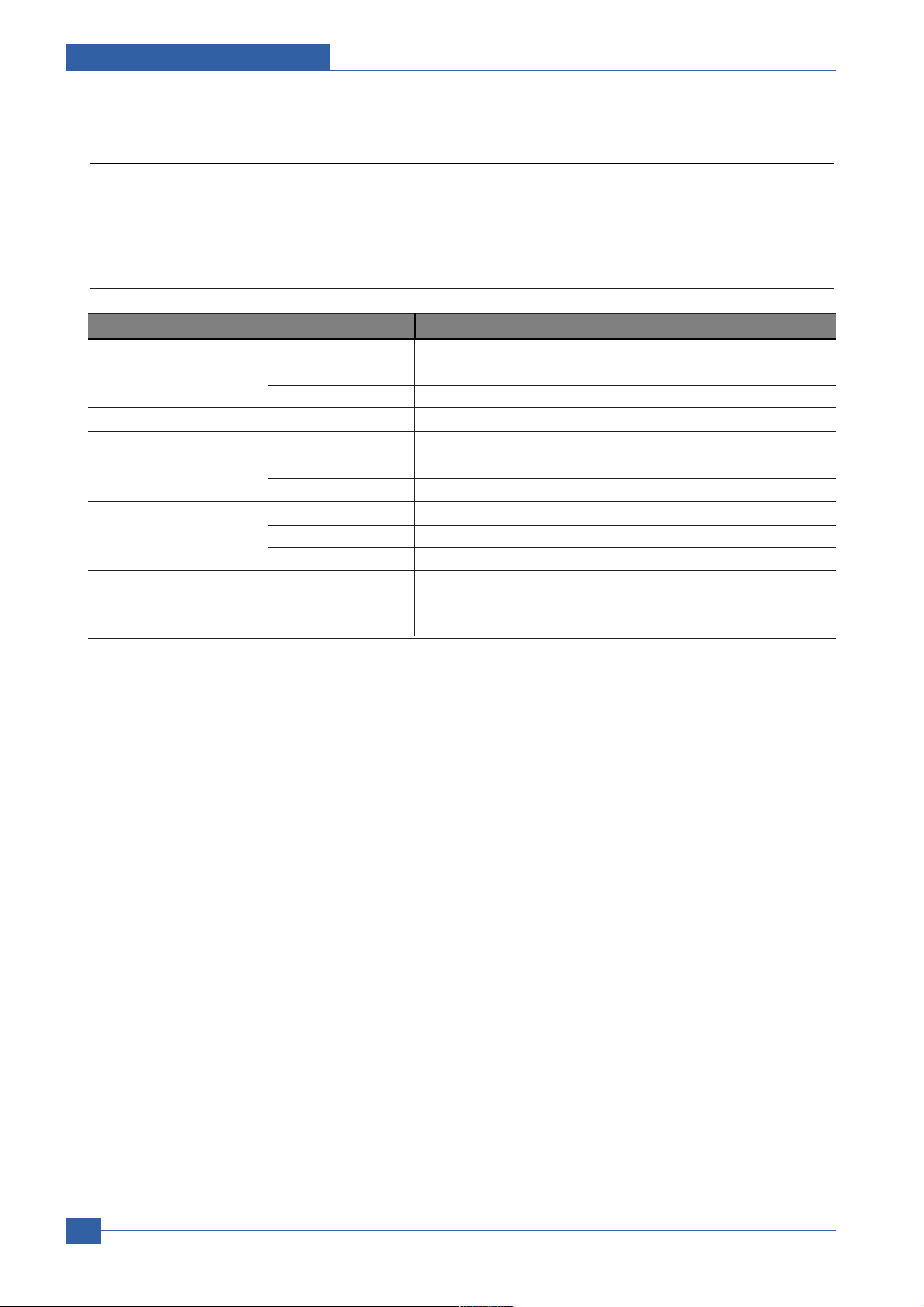

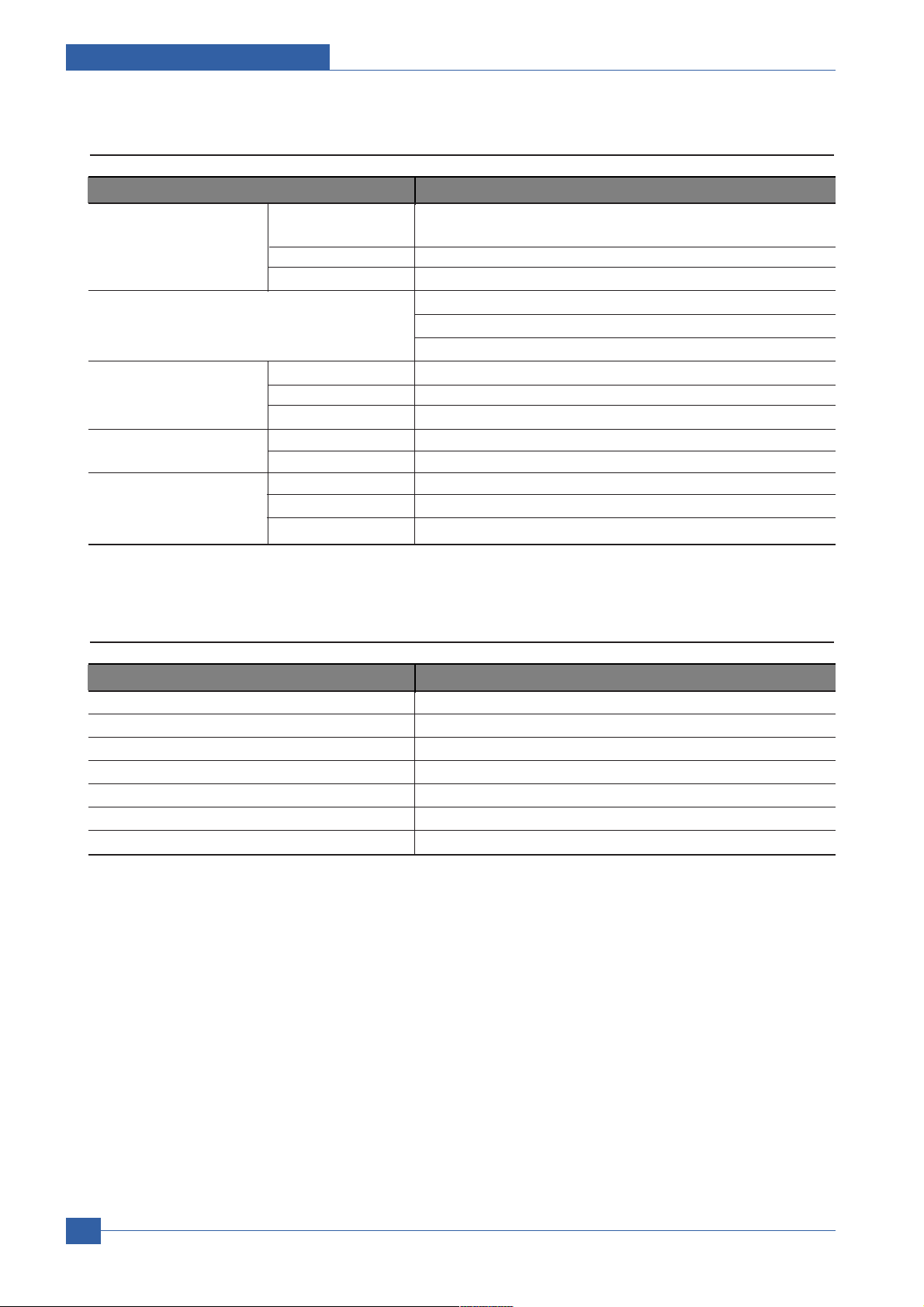

Item(s) Pages Printed Part number Remark

Black toner Approx. Initial : 4,000 pages* CLP-K350A

cartridge Sales : 4,000 pages*

Color toner Approx. 2000 pages* CLP-C350A : Cyan

cartridges CLP-M350A : Magenta

CLP-Y350A : Yellow

Imaging unit Approx. 20,000 black CLP-R350A

pages or approx.

12,500 color pages

Waste toner Approx. 5,000 images** CLP-W350A

container or Approx. 1,250 pages

(fulll color Std. ISO 19752 image)

Pick-up roller Approx. 50,000 pages Contact a service

Fuser unit Approx. 80,000 black pages representative

or 40,000 color pages

T2 roller Approx. 100,000 pages

ITB Approx. 100,000 black pages

or 25,000 color pages

* Average A4-/letter-sized page count based on Std. ISO 19752 of individual colors on each page. Usage

conditions and print patterns may cause results to vary.

** Image counts based on one color on each page. If you print documents in full color (Cyan, Magenta,

Yellow, Black), the life of this item will be reduced by 25%.

User

Replacement

Engineer

Replacement

Service Manual

Product specification and feature

2-2

Samsung Electronics

2.1.2 Specifications

Specifications are correct at the time of printing. Product specifications are subject to change without

notice. See below for product specifications.

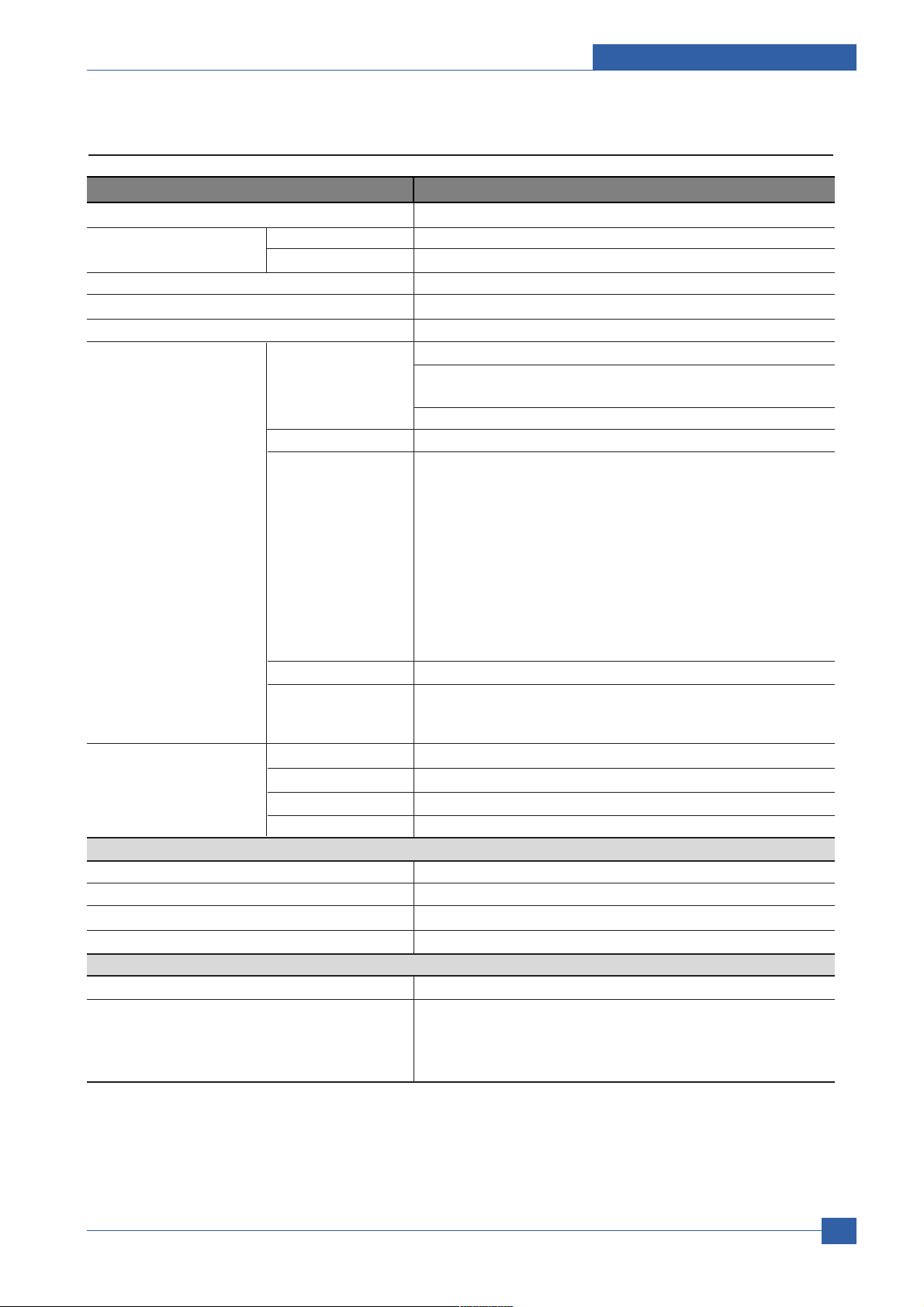

2.1.2.1 General Specifications

Engine Speed Simplex Up to 20 ppm in A4 (19 ppm in Letter)

Up to 5 ppm in A4 (5 ppm in Letter)

Duplex N/A

Warmup time Less than 38 sec

FPOT (B&W) From Ready Less than 14 sec

From Idle Less than 48 sec

From Coldboot Less than 50 sec

FPOT (Color) From Ready Less than 24 sec

From Idle Less than 58 sec

From Coldboot Less than 60 sec

Resolution Optical 600 x 600 dpi

Support

MAX: 2400 x 600 dpi effective output, 1200 x 600 dpi (default),

600 x 600 dpi(Color & B&W)

Item CLP-350N

Product specification and feature

Service Manual

2-3

Samsung Electronics

2.1.2.2 Controller & S/W

MPU Samsung CHORUSm 300MHz

Memory Std. 128 MB

Max. 256 MB

Memory Expansion 128 MB

Printer Languages SPL-C (Samsung Printer Language Color)

Fonts 45 Scalable, 1 Bitmap, 136 Postscript3

Driver Supporting OS Windows 2000/XP/2003/Vista/98/Me/NT 4.0

Various Linux OS including Red Hat 8.0~9.0, Mandrake 9.2~10.1,

SuSE 8.2~9.2 and Fedora Core 1~4

Mac OS 10.3 ,10.4

Default Driver SPL-C (Samsung Printer Language Color), PCL6, PS3

Driver feature Watermark

Overlay

N-up printing

Poster printing

Traymanual duplex

Quality(1200 dpi, 1200dpi class, 600 dpi)

Color mode (Color, Gray scale)

Color spec.

application color matiching

Device color

Black only status in Status monitor

WHQL Windows 2000/XP/2003/Vista

Language Localization

Korean, English, French, German, Italian, Spanish, Russian,

Dutch, E.Portuguese, Finish, Swedish, Norwegian, Danish,

S.Chinese, T.Chinese, Polish, Hungarian, Czech

Application RCP USB / Network

Smart Panel Yes(USB / Network, Install Default)

Network Management

Set IP, Web SyncThru 4.5 (SWS)

SmarThru4 SmartThru 4 (Windows only)

Interface

Parallel N/A

USB USB 2.0

Network Ethernet 10/100 Base TX

Wireless N/A

Network Interface

Protocol TCP/IP, DLC/LLC, IPP, SNMP

Network OS Microsoft Windows 2000/XP/2003 Microsoft and above Driver

Vista, Mac OS 10.3 or higher (TCP/IP only)Mac OS 9 available

Various Linux OS including Red Hat, Caldera, Debian, Mandrake,

Slackware, SuSE and Turbo Linux Novell not available

Item CLP-350N

Service Manual

Product specification and feature

2-4

Samsung Electronics

2.1.2.3 Paper Handling

Standard Capa. 150-sheet Semi Cassette Tray

Max. Capa. 150 sheets @ 75g/

Printing Max. Size 216 x 356mm (8.5" x 14")

Min. Size 76 x 127 mm (3" x 5")

Margin(T/B/L/R) 4 mm, 4 mm, 4 mm, 4 mm

Optional Cassette Tray

Capacity 250 sheets @ 75g/

Media sizes 148 x 210 mm(A4) ~ 216 x 356 mm(Legal)

Media types Plain paper, Cotton, Colored, Preprinted, Recycled

Media weight 60 to 90g/

Size sensor N/A

User Interface No Indicator

Sensing Photo Sensor

Output Stacking

Capacity FaceUp N/A

FaceDown 100 sheets @ 75g/

Output Full sensing N/A

Duplex

Supporting Manual

Throughput N/A

Media sizes N/A

Media types N/A

Media weight N/A

Item CLP-350N

Product specification and feature

Service Manual

2-5

Samsung Electronics

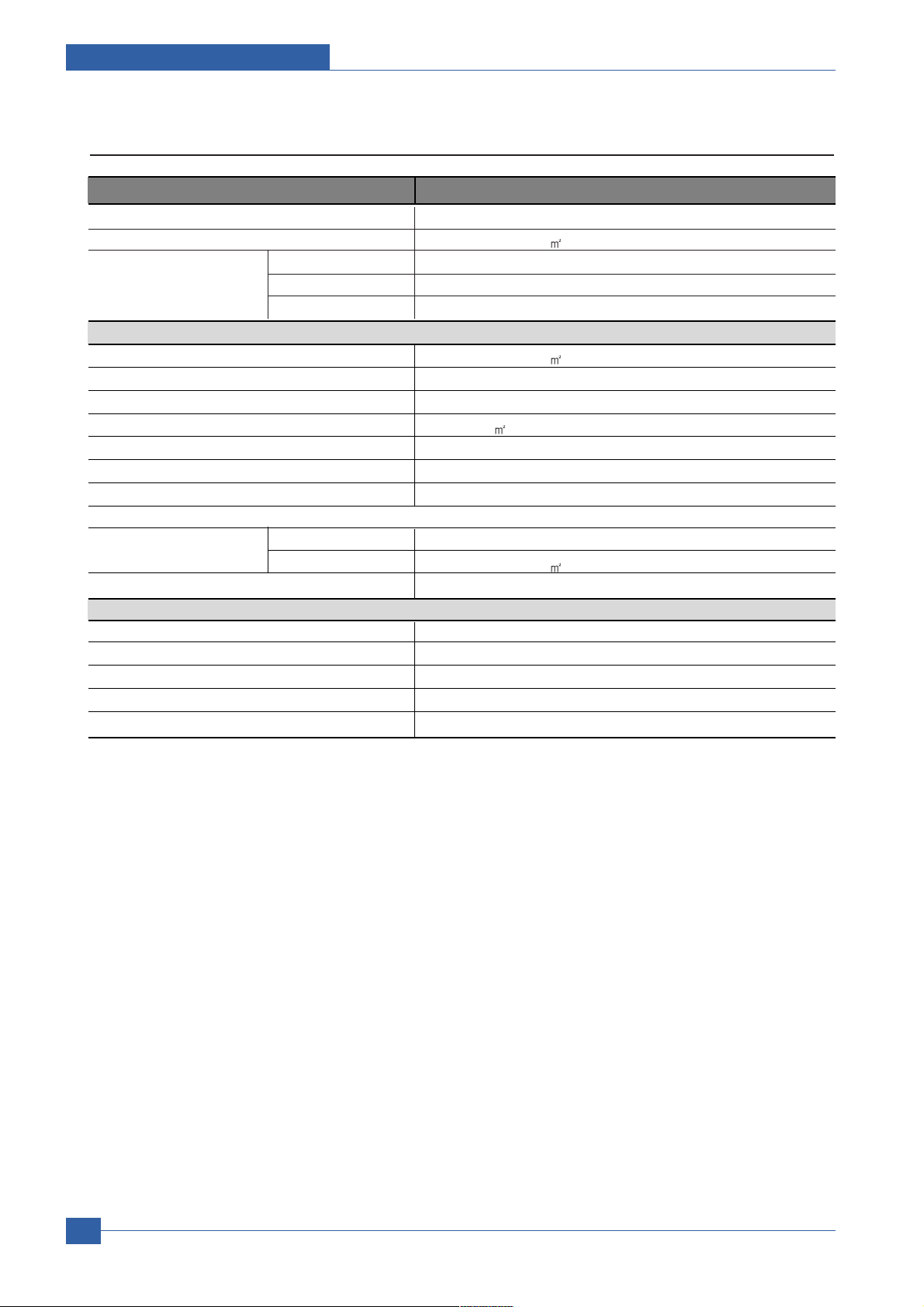

2.1.2.4 Consumables

CRU

No. of CRUs 6 (C/M/Y/K toner, Imaging Unit, Waste toner container)

K toner cartridge: CLP-K350A

C toner cartridge: CLP-C350A

M toner cartridge: CLP-M350A

Y toner cartridge: CLP-Y350A

Imaging unit : CLP-R350A

Waste toner container: CLP-W300A

Toner Black 4,000 A4/Letter pages, at Std. ISO 19752, Semi glossy

Color 2,000 A4/Letter pages, at Std. ISO 19752, Semi glossy

Key Unique, Electronic key(S-CRUM)

Life detect Sensor (Y)Remain % (90% : warning,100%: empty,

120% : hardstop)

Imaging Kit(OPC+Deve) Yield Approx. 20K black pages (or 12.5K color pages)

Key Unique, Electronic key(CRUM)

Sensor None, that would be traced via software

Replace method 6 steps for install/replacing

Waste Toner Container Yield 1,

250 sheets (Full Color

Std. ISO 19752

Image) or 5,000 images, Full Sensor

Key N/A

FRU

No. of FRUs 4 (ITB, Fuser, T2 roller, Pick-up roller)

ITB Yield Approx. 100,000 black pages (or 25,000 color pages)

Key None

Sensor None

Fuser Yield 80,000 sheets B&W or 40,000 sheets Color

Key None

T2 Roller Yield 100,000 sheets, Replacable

Key None

Pick-up Roller Yield 50,000 sheets, Replacable

Key None

Item CLP-350N

Item CLP-350N

Service Manual

Product specification and feature

2-6

Samsung Electronics

2.1.2.5 Environment

2.1.2.6 Options

Memory 128 MB

Second Cassette 250 sheet SCF

PostScript Built-in

Network Built-in

Wireless Network N/A

Hard Disk N/A

Duplex Unit N/A

Acoustic Noise Level Printing Less than 48.0 dBA (Color printing)

(Sound Power/Pressure)

Less than 49.0 dBA (B/W printing)

Standby Less than 35 dBA

Sleep Background noise level

Input Voltages 110-120 VAC, 50/60Hz

220-240 VAC, 50/60Hz

Power Switch

Power Consumption Ready Less than 80w

AVG. Less than 400W

Sleep/Power Off Less than 10W /Less than

Dimension(W x D x H) Set 390 X 418.8 X 269.5 mm (15.4" x 16.5" x 10.6")

Set Packing 531 X 525 X 443 mm ( 20.9" x 20.7" x 17.4" )

Weight

Set (with consumables)

14.8 kg

Set Packing 18.5 kg

Consumable 3.5 kg(Imaging Unit)

Item CLP-350N

Product specification and feature

Service Manual

2-7

Samsung Electronics

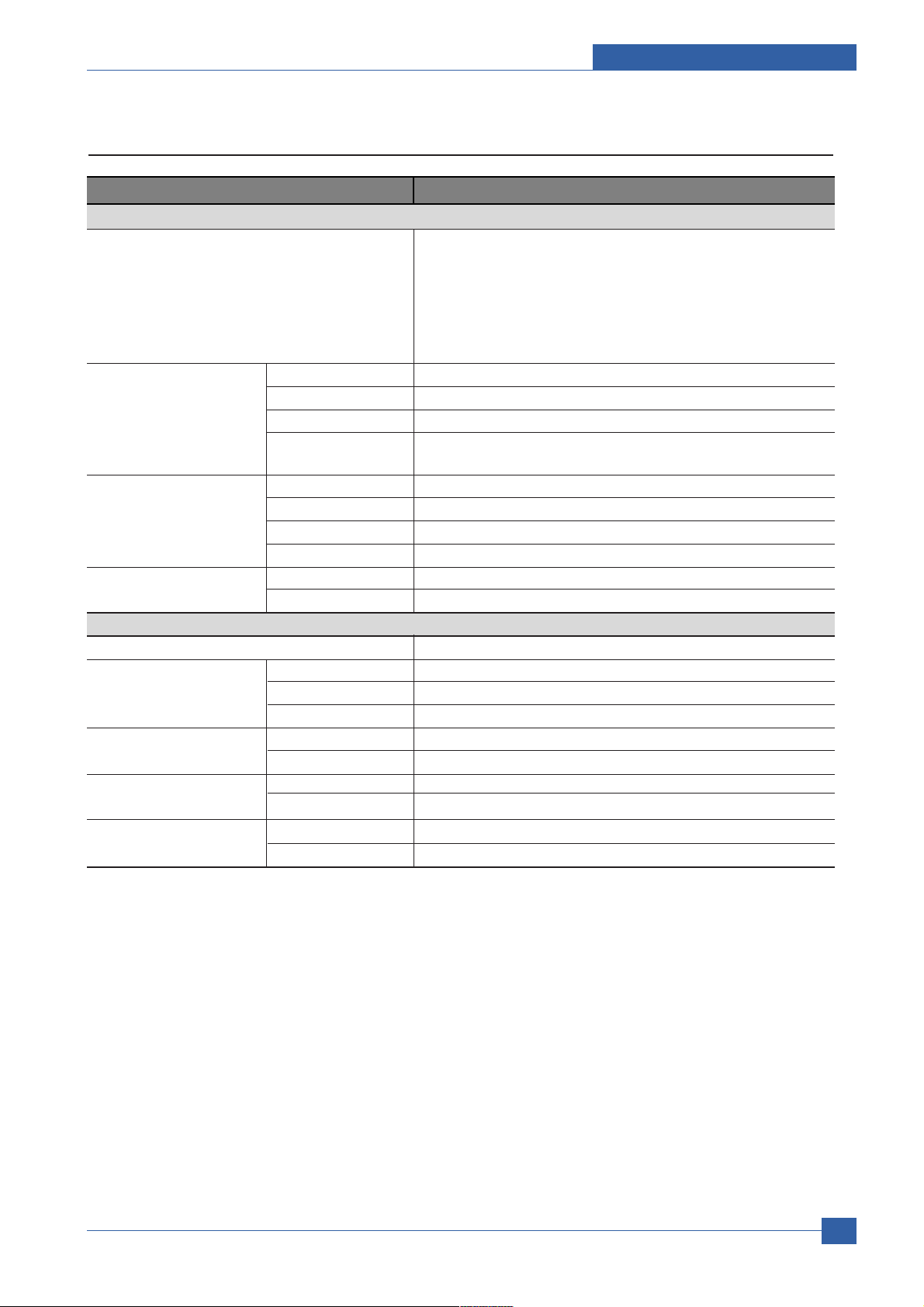

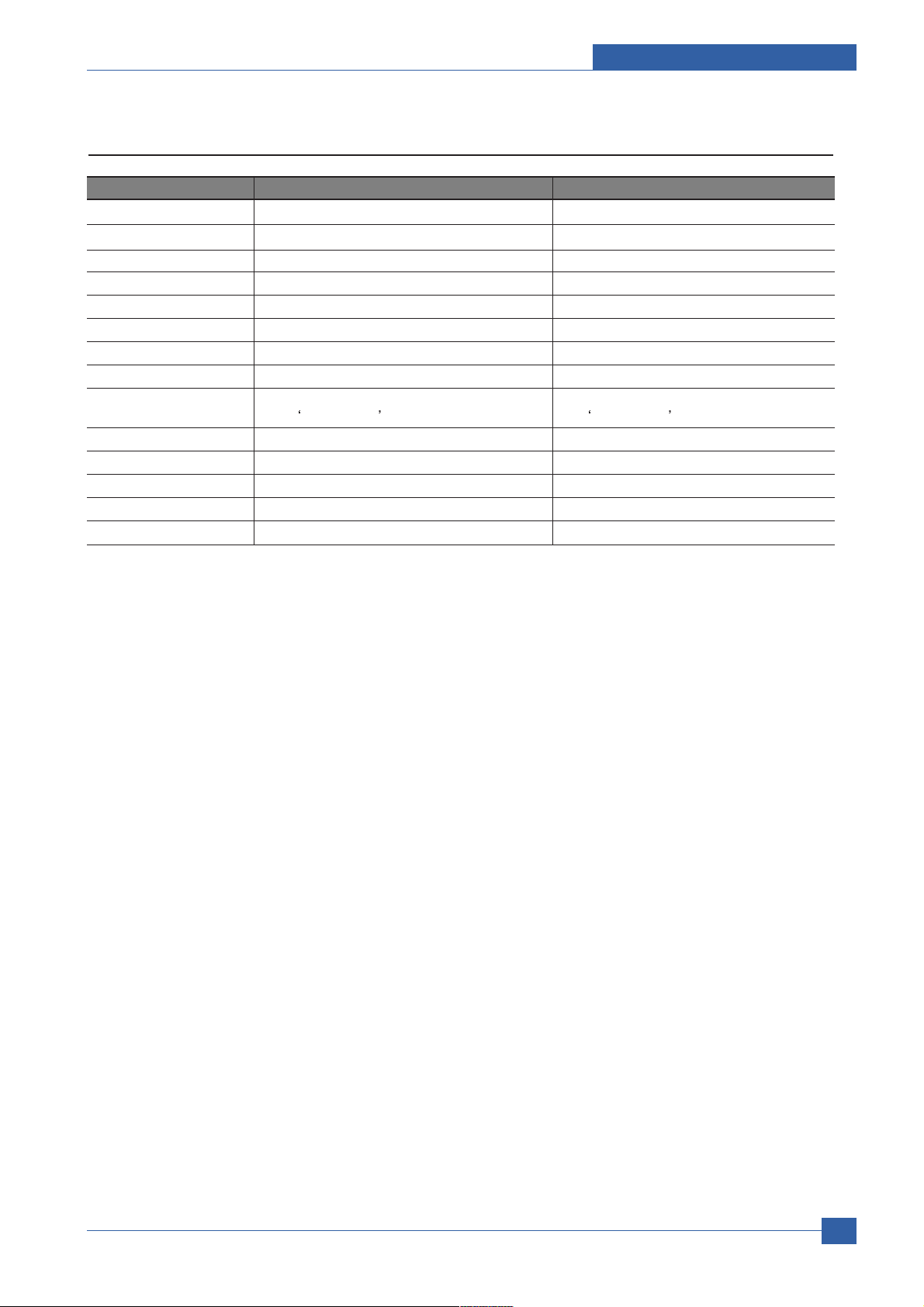

2.1.3 Model Comparison Table

Item Magicolor 2400W CLP-350N

Print Method: Electro photographic laser Electro photographic laser

Print Speed: 5 ppm colour/ 20 ppm monochrome 5 ppm colour/ 19 ppm monochrome

Resolution: 2400 x 600 ; 1200 x 600 ; 600 x 600 2400 x 600 dpi class

First page print: 12 sec monochrome, 21 sec colour 14 sec monochrome, 24 sec colour

Warm-up time: 49 seconds 38 seconds

Processor Type: Special ASIC 48 MHz ChorusM 300MHz

Memory: 32 MB RAM 128 MB (expandable up to 256 MB)

Printer Emulations: GDI GDI, PCL6, PS3

Standard Interfaces: USB 2.0 (High Speed) supporting USB 2.0 (High Speed) supporting

MS

Plug and Play MS Plug and Play

OS Compatibility Windows XP / 2000 / ME / 98 SE Windows XP/2K/2003/ME/98/Longhorn

Standard Paper In: 200-sheet Multi-purpose Tray 150-sheet Cassette Tray

Standard Paper Out: 200-sheet Face-down Output Tray 100-sheet Face-down Output Tray

Dimensions (WxDxH): 395 x 430 x 341 (mm) 390 x 418.8 x 269.5 (mm)

Weight: with consumables 20 kg; with consumables 14.8 kg

Service Manual

Product specification and feature

2-8

Samsung Electronics

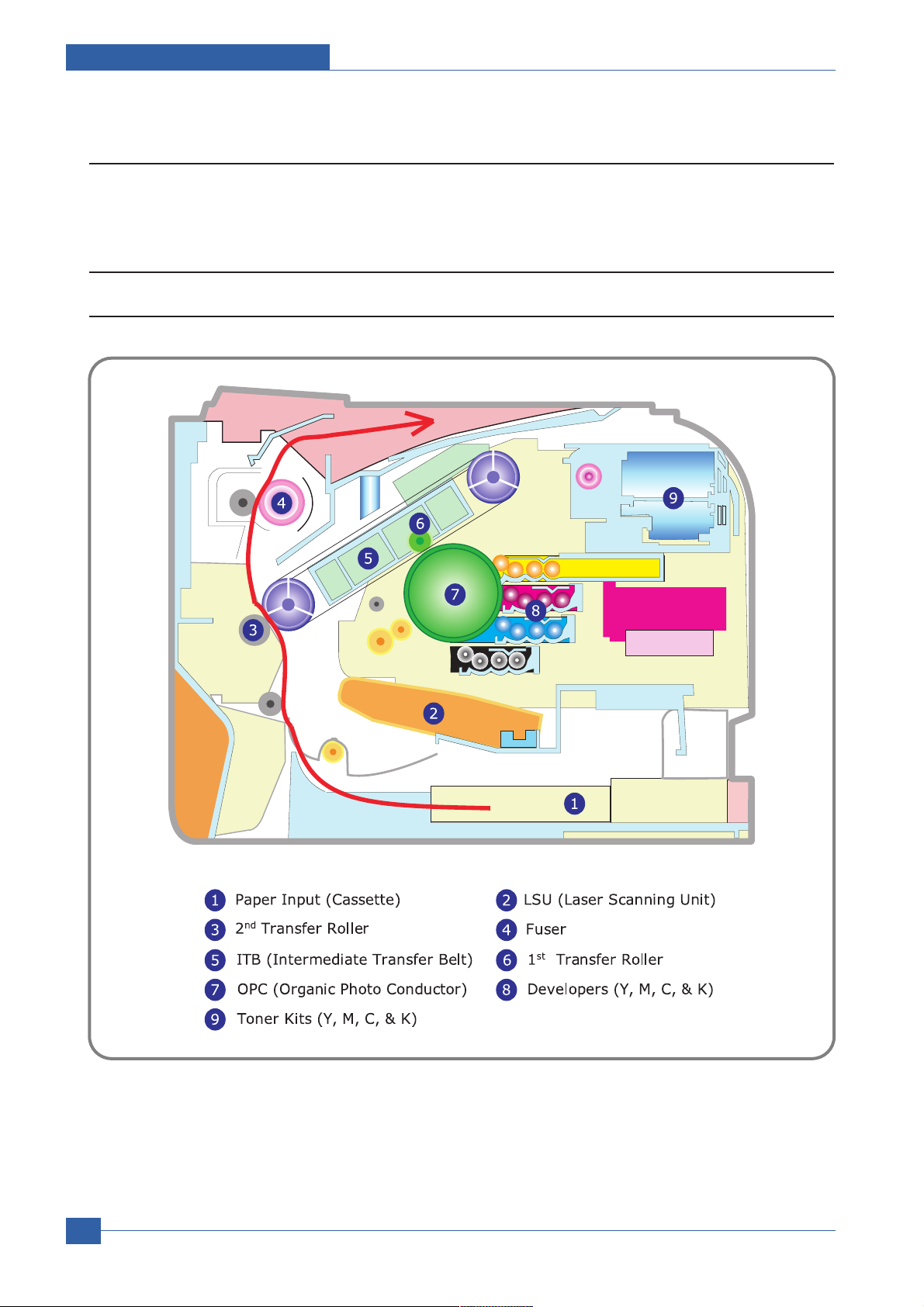

2.2 System Overview

This chapter describes the functions and operating principles of the main components.

2.2.1 System Structure

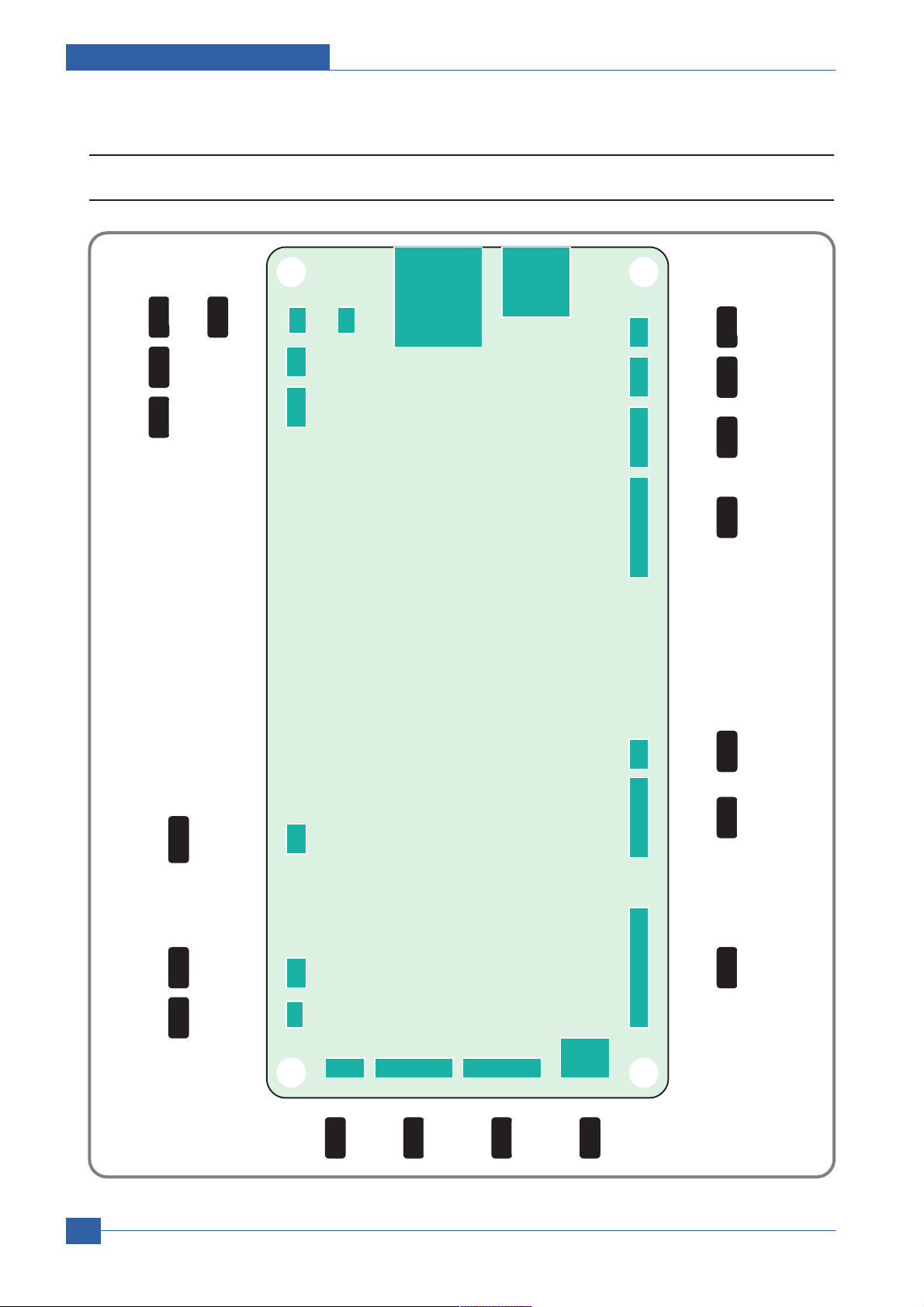

2.2.1.1 Main Parts of System

Product specification and feature

Service Manual

2-9

Samsung Electronics

Cassette

Feeding Method : Cassette Type

Feeding Standard : Center Loading

Feeding Capacity : Cassette 150 Sheets(75g/ , 20lb Paper Standard)

No Manual Feeder

Paper Detecting Sensor : Photo Sensor (Empty, Registration, Exit)

Paper Size Sensor : None

LSU(Laser Scan Unit)

Consisted of LD(Laser Diode) and Polygon Motor Control.

2ndTransfer Ass y

The life span: Print over 100,000 sheets (in 15~30 )

Specification: Similar to CLP-300 Series

Fuser Ass y

Heat Lamp : New Part - Knuckle Type

Heat Roller : Similar to CLP-500 Series

2 Pressure Roller : One is similar to HummingBird, the Other is a new added part comparing with

other Fuser

Thermistor - Temperature-Measuring Device

Thermostat - Critical Temperature-Detecting Device

& ITB(Intermediate Transfer Belt) & 1st Transfer Roller

The life span: Print over 60,000 Images

The ITB unit includes 1st Transfer Roller

& OPC(Organic Photo-Conductor) & Developer

The life span: Print over 50,000 Images (Both)

Imagine Unit consists of 4 kinds of Developer , OPC, and Deve. Main Frame

Toner Kits

The life span: Color -> 2000 images (Std. ISO 19752 Print-Out)

Black -> 4000 images (Std. ISO 19752 Print-Out)

Driver Ass y

It is a power delivery unit by gearing

By driving the motor, it supplies the power to the feeding unit, the fusing unit, and the distributing unit.

The Main Motor is similar to CLP-300 Series Main Motor.

Error Phenomenon

Polygon Motor Error The Rotation of Polygon Motor can not reach stable

Hsync Error Though the rotation of Polygon Motor reach stable, the sig-

nal of Hsync is not occurred

Service Manual

Product specification and feature

2-10

Samsung Electronics

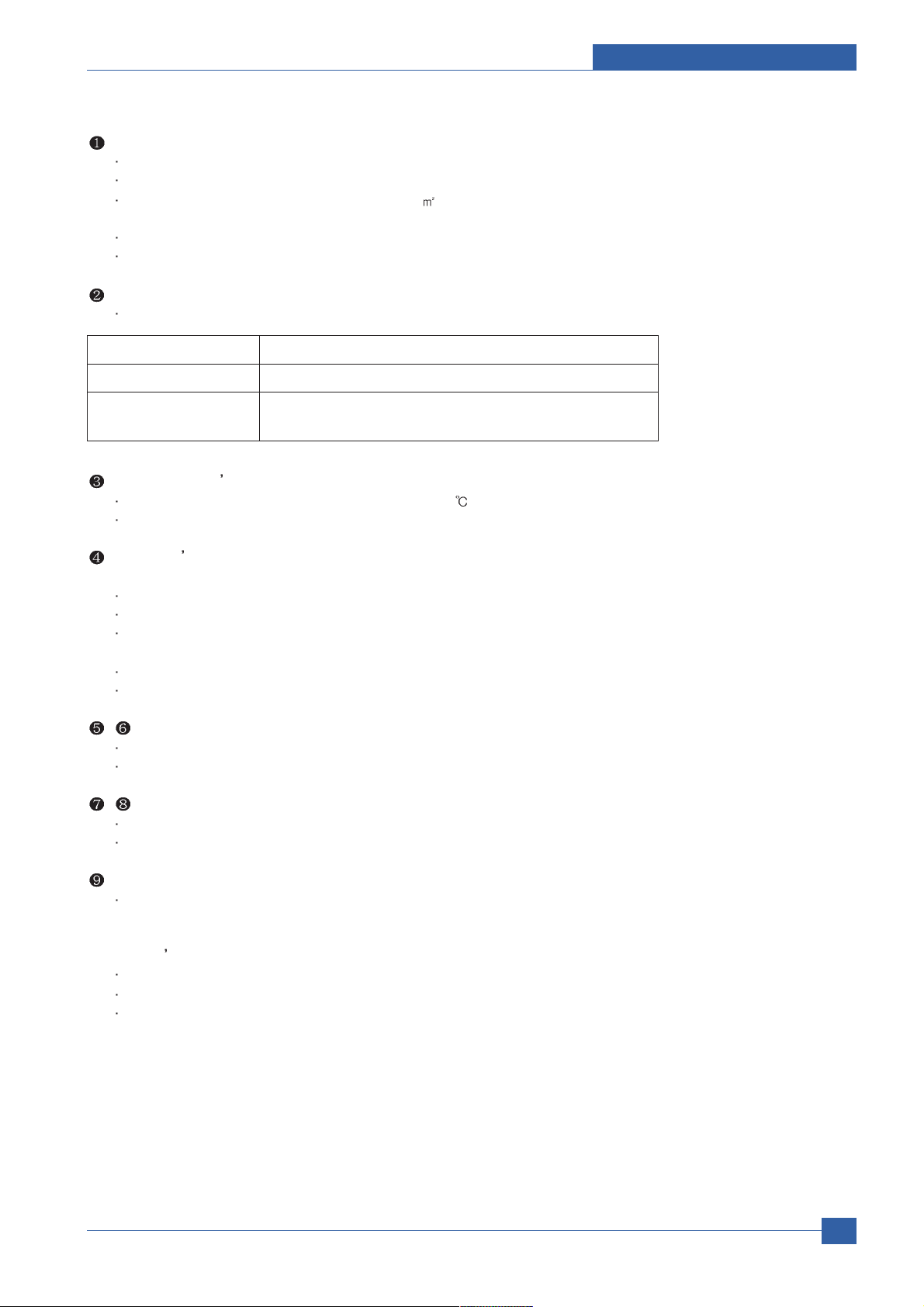

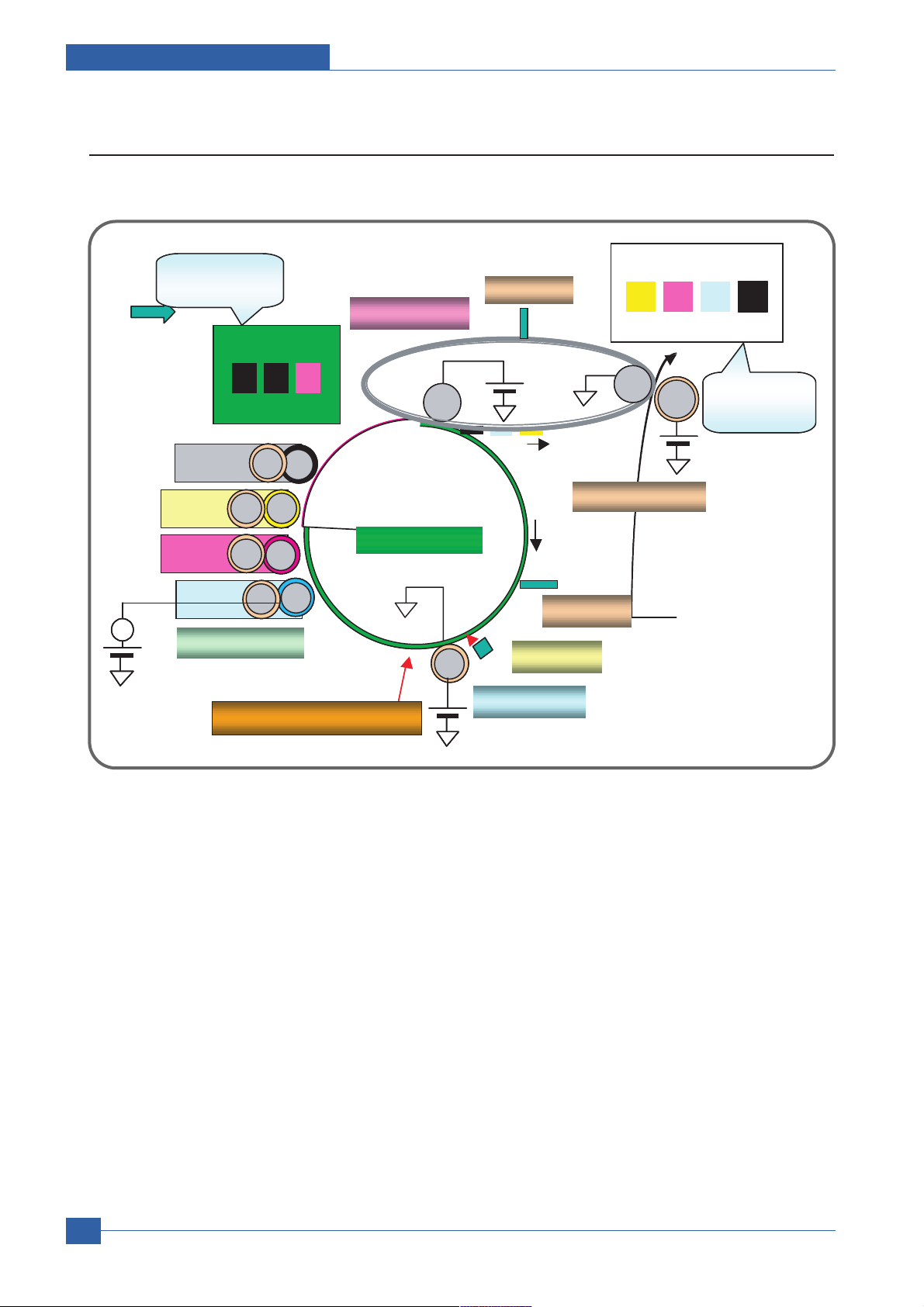

2.2.1.2 EP Process

- Structure of EP Process

Charger

Developer

Laser Scanning Unit

OPC

ITB Unit

Eraser

Blade

Blade

Media Path

P2: Image

on Media

P1: Image

on OPC

~

Charger

Developer

Laser Scanning Unit

OPC

ITB Unit

Eraser

Blade

Blade

Media Path

P2: Image

on Media

P1: Image

on OPC

~~

Product specification and feature

Service Manual

2-11

Samsung Electronics

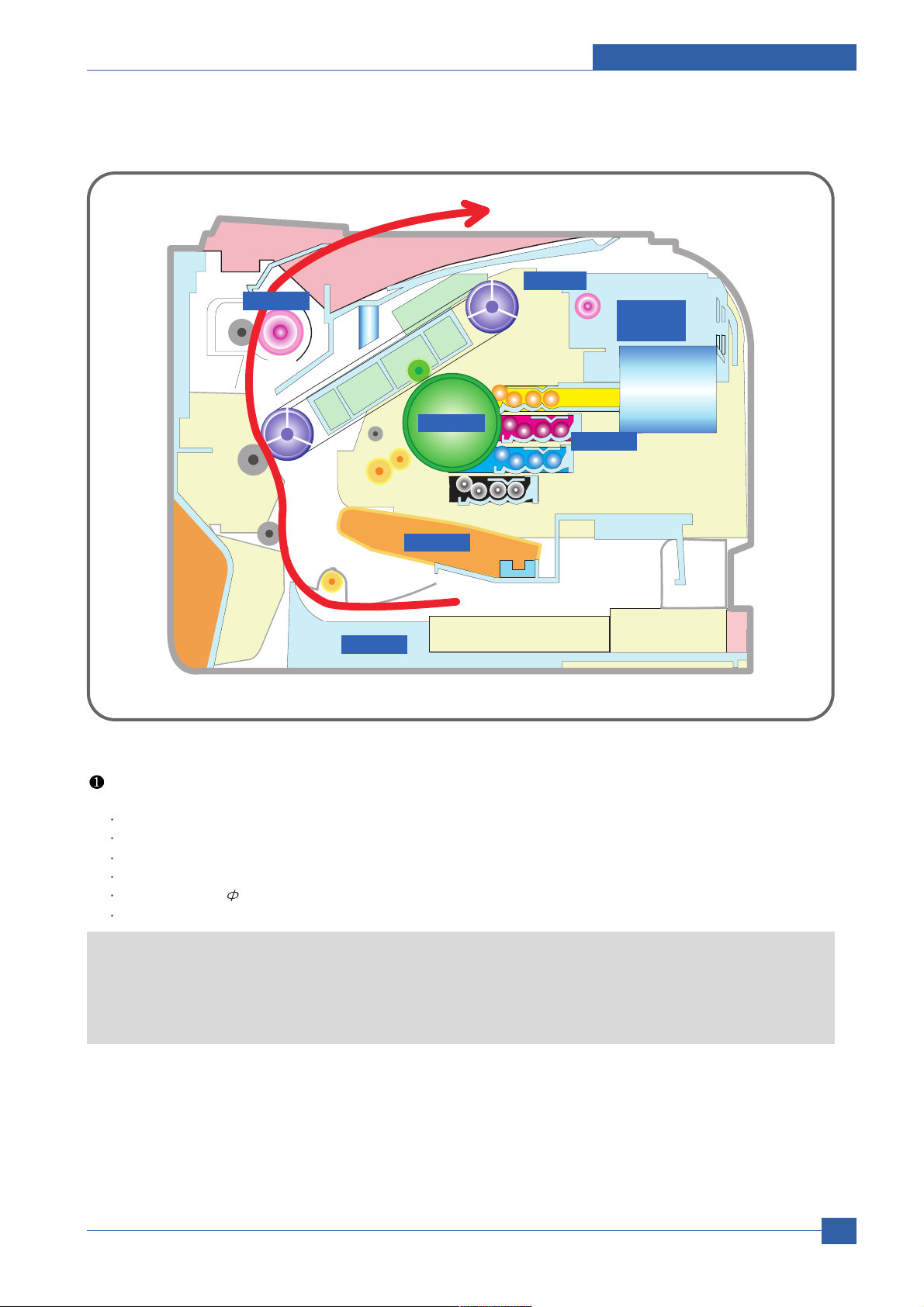

- System Outline

Paper path

Exit

ITB

OPC

LSU

Cassette

Toner

Cartridge

Dev-Y

Dev-M

Dev-C

Dev-K

Dev-Y

Dev-M

Dev-C

Dev-K

Fuser

Charging

Conductive Roller charging

Applied voltage : -1.1kV

Charge acceptance : -520V

OPC coating thickness : 21um

OPC diameter : 60mm

Eraser system

1. Organic Photoconductor is charged to uniform voltage by conductive roll charging method

2. No ozone is produced because corona is not used

3. Charger roll is cleaned with cleaning roll

4. Toner remained on OPC after T1 process is cleaned by cleaning blade and retrieved into waste toner

box by auger and belt driving mechanism

Service Manual

Product specification and feature

2-12

Samsung Electronics

Exposing

One polygon motor ( 6 facet )

Single beam LD (1ea)

LD wavelength : 785nm

Polygon motor rpm : 29685

LSU energy : 0.25uJ/cm^2

OPC exposed potential : -50V

1. Exposing is implemented by laser striking on to OPC with uniform potential

2. Laser beam is modulated according to image to be printed that is from PC

3. Latent Image is formed on OPC, which is developed with toner

Developing

Non-magnetic, mono component

Non-contact development

Developing bias : DC + AC

AC peak to peak : 1.5 ~ 2.0kV

Roller diameter : 10mm

Process speed ratio : 1.2 (OPC=1.0)

Color order : Y -> M -> C -> K

1. Only latent image formed by exposing process is developed with toner

2. AC + DC Voltage is being used to develop toner into latent image on OPC because non-contact

developing method is adopted

3. Y, M, C, and K Images are sequentially developed onto OPC and transferred onto Intermediate

Transfer Belt (hereafter ITB) to form a color image on ITB

4. Toner Bottles are used to supply toner into developer compartment

5. Toner level is being sensed to control toner supply from toner bottle to developer

Transfer 1

Multi-pass transfer

Indirect transfer

Transfer voltage : 0.5 ~ 2.0kV (controllable)

Roller diameter : 14mm

Transfer unit life : 100K images

1. Developed Image on OPC is transferred onto ITB by T1 Process

2. T1 Voltage is positive which attract toner to ITB

3. 4 times of T1 process is required to make a color image on ITB, which means multi-pass process

4. ITB has a hole as a fiducial mark for timing. Engine control for color image is synchronous with it,

ITB Home Sensing Signal

Product specification and feature

Service Manual

2-13

Samsung Electronics

Transfer 2

Indirect transfer

Transfer voltage : 1 ~ 4.0kV (controllable)

Roller diameter : 18.6mm

Transfer unit life : 100 K images

1. Color image formed on ITB is transferred onto media by T2 process

2. T2 voltage is also positive to get color image moved onto media

3. Toner remained on ITB after T2 process is cleaning by ITB cleaning blade and collected and

4. Transported and retrieved into waste toner box by auger and belt driving system

5. T2 Roll is engaged when color image is being transferred onto media. Otherwise it is disengaged. Clutch is

used for driving T2 Roll engagement and disengagement

Fusing

3 Roll system

-> short warm-up time (38sec)

Post Pressure Roll

1. Color Image on media is melted down and fixed into media by fusing process

Service Manual

Product specification and feature

2-14

Samsung Electronics

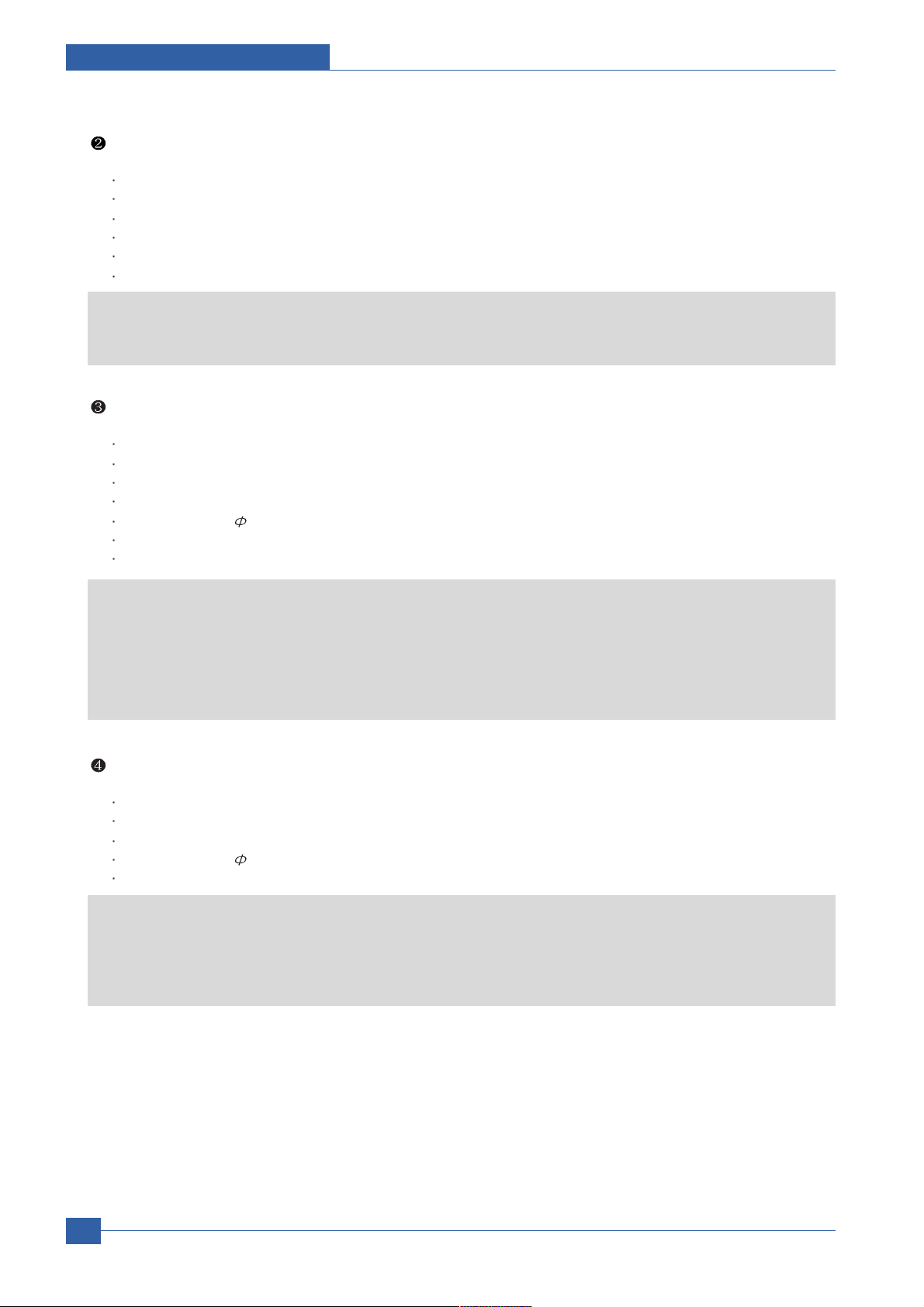

2.2.2 Main PBA Description

2.2.2.1 Main Controller PBA

CN2 CN3

CN1 CN5 CN6

CN17 CN21 CN22CN16

USB

RJ45

CN8

CN20CN19

CN14

CN18

CN13

CN11

CN9

DEVE_

HOME

DEV_

SOL

ITB_

CLUTCH

CN24

Fan

PANEL

SMPS

COVER

OPEN

HVPS

SCF

LSU

DEVE&

ITB

REG&

EMPTY

REGI

CLUTCH

PICKUP

BLDC

T2_

CLUTCH

FUSER

FUSER

CLUTCH

Product specification and feature

Service Manual

2-15

Samsung Electronics

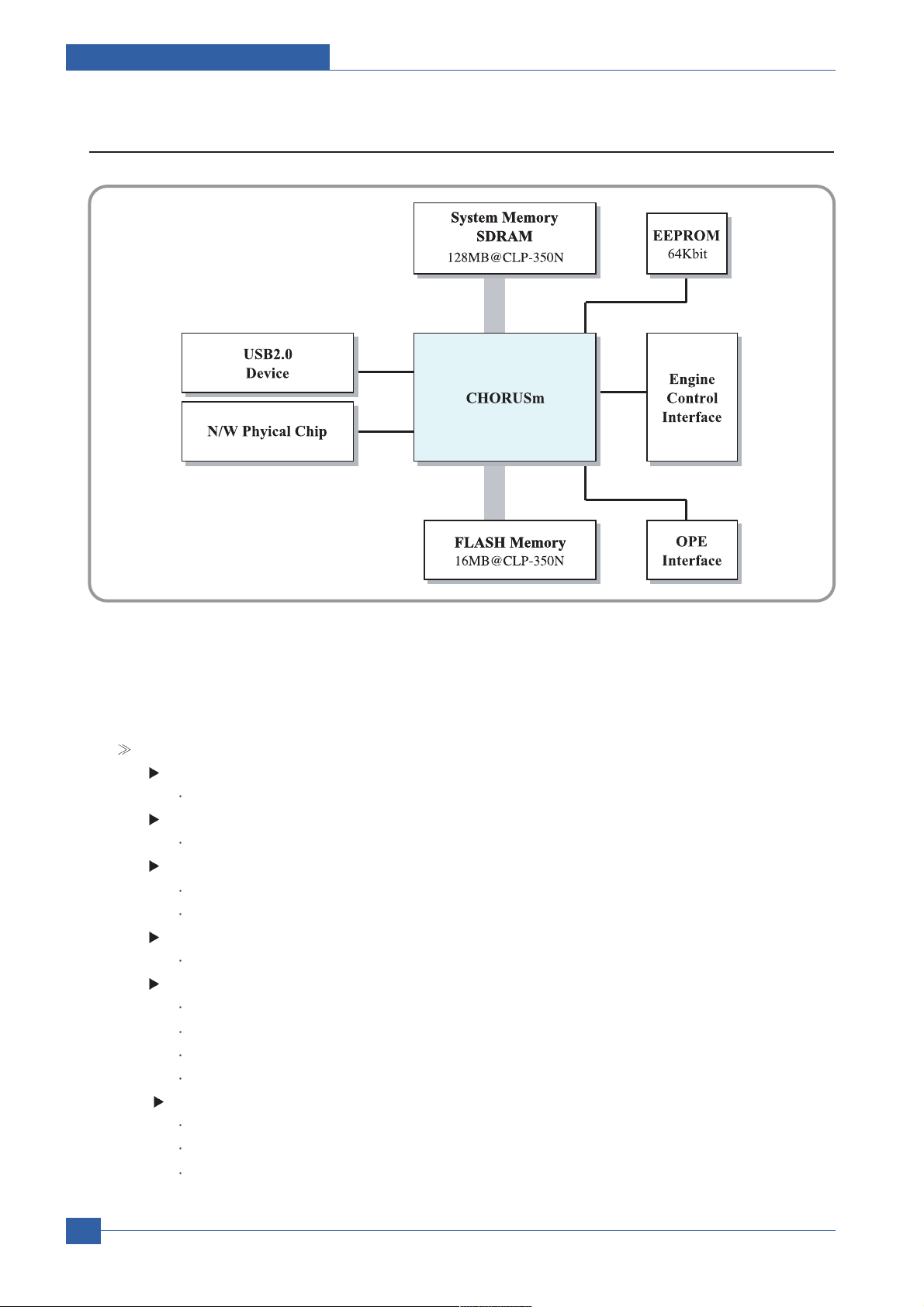

2.2.2.2 Main PBA

Service Manual

Product specification and feature

2-16

Samsung Electronics

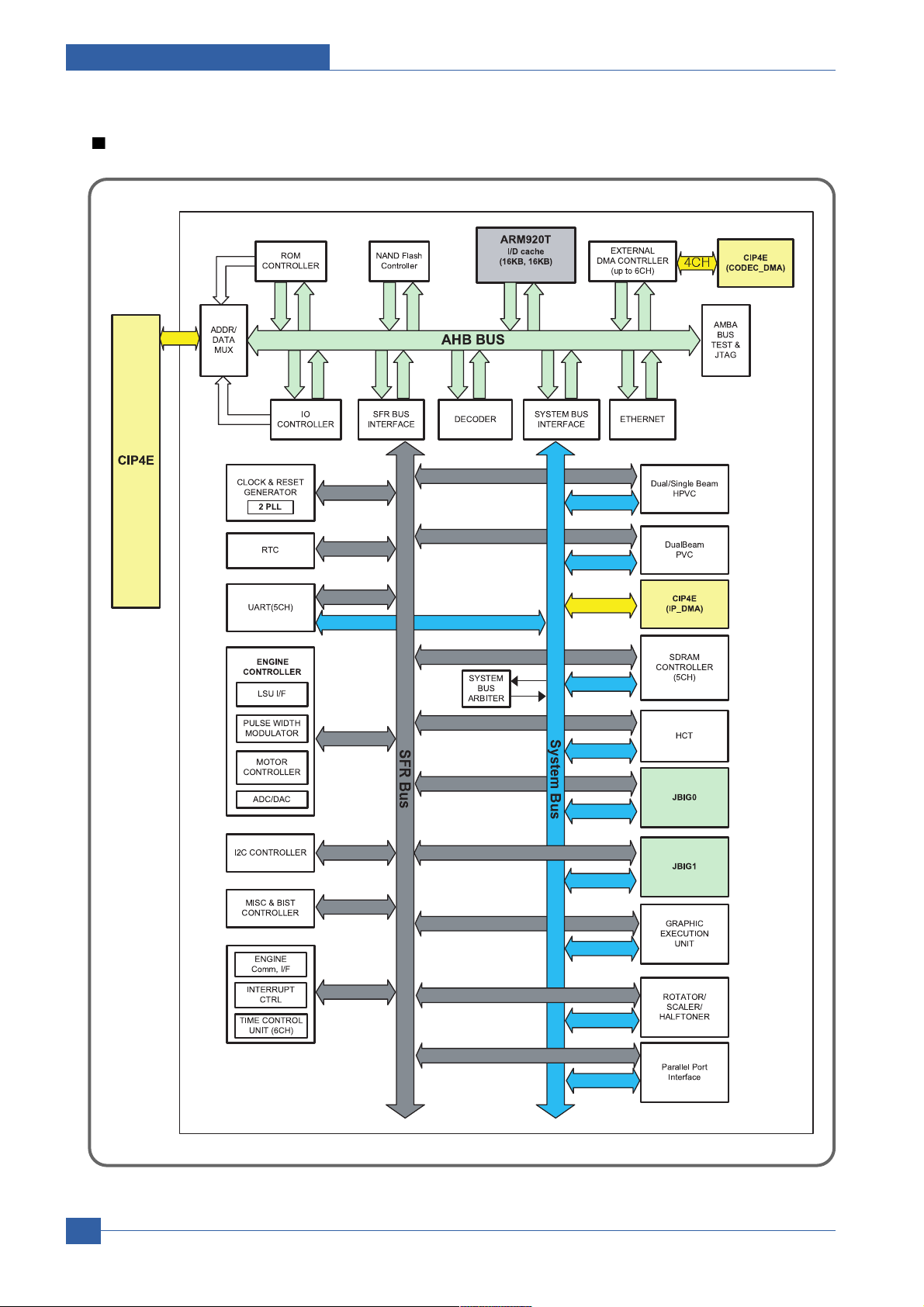

1) CHORUSm

CHORUSm involves in itself the functions to control ARM Processor Core and various H/W devices.

CHORUSm, therefore, controls Main PBA and all engine mechanism, processing the print job received from

host and enabling the engine to print image.

Function

Process

0.13um Technology

Package

496 PBGA

CPU Core

ARM 920T - 300MHz

Cache : I-Cache 16KB, D-Cache 16KB

System Bus

32-bit width, 100MHz

SDRAM Controller

32-bit width, 100MHz operation

5 Banks, Up to 128MB Address space per Bank

Programmable Timing to Control SDRAM A.C Characteristics

Support Self Refresh for Data Retention

ROM Controller

32-bit width, 4 Banks, Up to 16MB Address space per Bank

Burst Capability

Programmable Timing per Bank

2.2.2.3 Main PBA Description

Product specification and feature

Service Manual

2-17

Samsung Electronics

IO Controller

6 Channels, Up to 16MB Address space per Bank

Programmable Timing per Bank

DMA Controller

6 Channels General Purpose DMA

HPVC Controller

Hyper Printer Video Controller

High Performance DMA-based Interface to Printer Engine

Support Dual/Single Beam LSU, LVDS Video Output

Support A3, 1200dpi

UART Controller

5 Channels Indepenent Full Duplex UART

Interrupt Controller

Support 6 External Interrupts

Support 26 Internal Interrupts

Timer Controller

6 System Timers and Watch Dog Timer for S/W Trap

Scanner Controller

300/400/600/1200dpi CIS/CCD Interface

Color/Mono grey image, Binary image scan support

600dpi Color/Mono Copy support

Image Processing for High-End MFP,Digital Copier

MH/MR/MMR CODEC for Fax

Scan image : A4 1200dpi processing

Copy image : A4 600dpi processing

MAC Controller

10/100Mbps

Full IEEE 802.3 compatibility

PPI Controller

IEEE1284 compliant parallel port interface

DMA-Based or Interrupt-Based operation

GEU Controller

Graphic Engine Unit for Banding support of Printer Language

Scan Line Buffer, Polygon Filling

CODEC Controller

2 Channels JBIG Encoding and Decoding

I2C Controller

1 Channel, Operated at max frequency 400kHz

RTC Controller

Engine Controller

LSU Control and Interface Unit

2 Channels STEP Motor Control Unit

8 Channels PWM Control Unit

8 Channels ADC Control Unit

2 Channels DAC Control Unit

Service Manual

Product specification and feature

2-18

Samsung Electronics

CHORUSm (Internal Block Diagram)

Product specification and feature

Service Manual

2-19

Samsung Electronics

2) System Memory Block

Memory saves program and video data and print jobs received from host. Its volume is 64MB with network

function.

It has separate device for 128MB extension. SDRAM is used, driven at width of 32-bit and 100MHz, and

controlled by memory controller built in CHORUSm.

3) Flash Memory Block

Flash memory is the space used for saving program. Its volume is 16MB with network function. It has no

separate device for extension. NOR type flash memory is used and accessed at 32-bit width burst, being

controlled by the ROM controller built in CHORUSm.

4) USB2.0 Device Block

This block supports USB2.0 high speed (480Mbps). ISP1582 of Philips company is used and connected to the

IO Bus of CHORUSm at 16-bit, controlled by IO controller built in CHORUSm. Through this I/O port it receives

print job from host.

5) Network Block

This block has 10/100Mbps wired network function and is controlled by MAC controller built in CHORUSm. It is

connected to host through physical layer chip outside, and thus receives print job from host. BCM5241 is used

for physical layer chip.

6) EEPROM Block

System EEPROM is controlled by the I2C controller built in CHORUSm, connected to the other non-volatile

memory on I2C bus. It works at the speed of 400KHz. This system EEPROM contains all drive information and

production information necessary for the operation of printer. Its size is 64K-bit.

7) OPE Control

The panel is driven in the form of PIO by GPIO controller built in CHORUSm. OPE consists of one key and four

monochrome LED, and one dual LED.

8) LSU Control

Laser Scanning Unit is controlled by LSU controller built in CHORUSm. It makes use of all functions such as

Polygon Mirror Motor Control necessary for driving LSU and Synchronized Signal Generation Control, and

helps to scan laser beam on the photosensitive drum to form latent image.

9) BLDC Control

It is controlled by BLDC controller built in CHORUSm. It controls the drive of printer mechanism and helps it to

be

driven at an equal speed.

10) Sensors Control

GPIO controller built in CHORUSm collects the status of all sensors. According to this status of sensors, it

controls printer mechanism to help normal printing. There are sensors such as Paper Empty Sensor,

Registration Sensor and Developer Home Sensor, etc.

Service Manual

Product specification and feature

2-20

Samsung Electronics

11) Clutches Control

GPIO Controller built in CHORUSm controls all clutches, which help printer to do print job normally. There are

clutches such as Paper Pick-up Clutch, Registration Clutch, Developer Home Clutch, ITB Clutch, T2 Clutch,

Fuser Clutch, Developer Toner Supply Clutch, etc.

12) PWM Control

PWM Controller built in CHORUSm controls the parts that require PWM for normal printing, such as BLDC

drive speed and HVPS high voltage level, etc.

13) ADC Control

It is controlled by ADC Controller built in CHORUSm, and is used for perception of charged voltage and

current, 1st and 2nd transfer voltage and current, fusing temperature, used-up toner and toner amount, and

interior temperature, etc.

14) DAC Control

It is controlled by DAC Controller built in CHORUSm and used to set standard level of light amount of LSU

Laser Diode.

Loading...

Loading...