Page 1

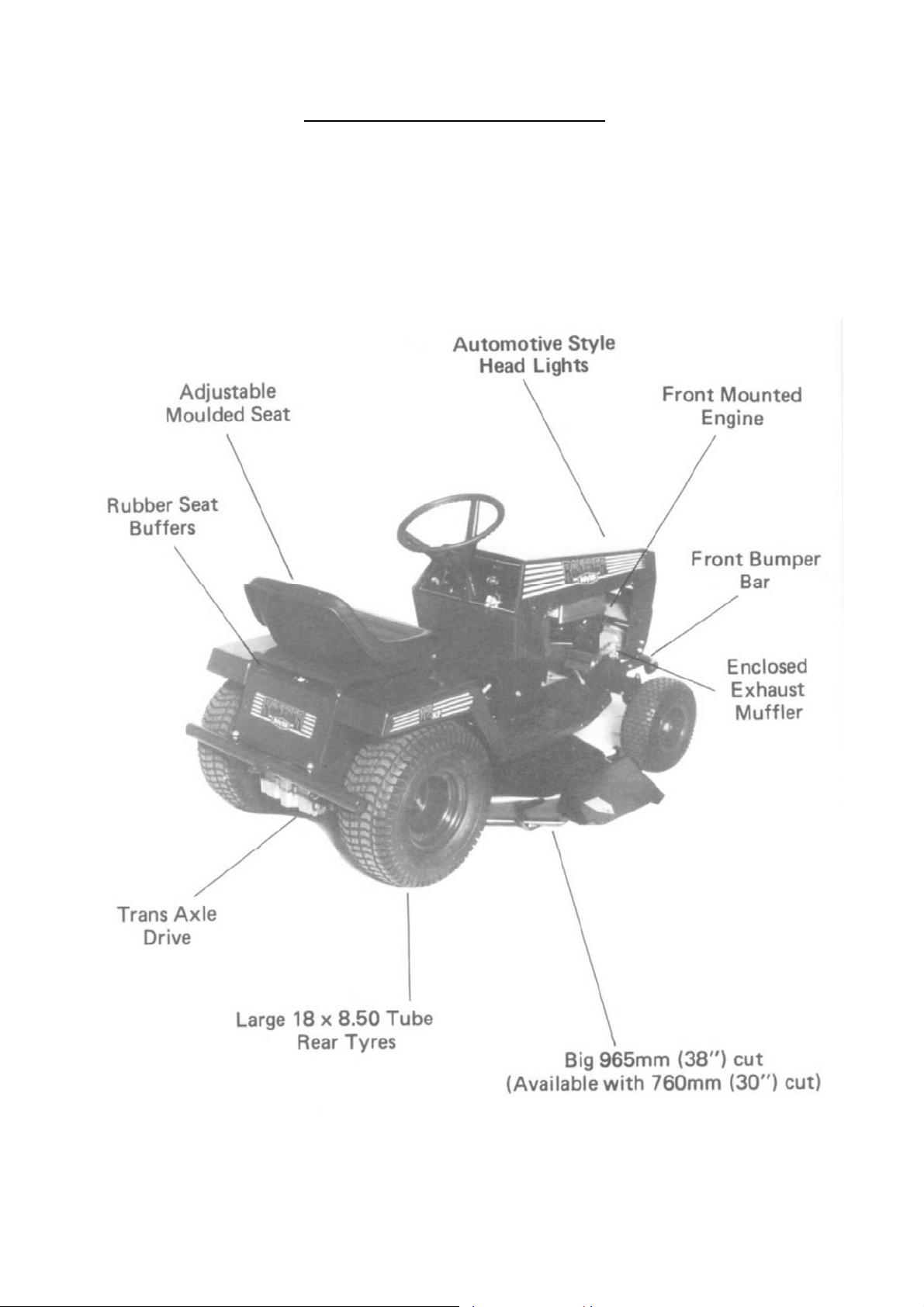

Rancher Ride-On

Owners Manual

Model No. 1766

WARNING

• A mower is a high speed cutting tool. Safety precautions must be observed to reduce the risk of accident.

• Careless or improper use may cause serious injury.

• Be sure that you read and fully understand the contents of this Owner’s Manual. Should any point me unclear,

contact Rover-Scott Bonnar Limited, in your state or an authorized Rover-Scott Bonnar Service Agent for

assistance.

• Keep the owners manual in a safe place for future reference. Read the Owners Manual periodically to, ensure

the continued safe and proper use of the mower.

Page 2

SAFETY INSTRUCTIONS

• A mower user must be in good physical condition and

mental health and not under the influence of any drug or

alcohol which might impair vision or judgment.

• Do not use a mower when tired or fatigued. Lack of

alertness may cause serious injury.

• Know your controls.

Read and understand Owner’s manual before operating

mower. Learn how to stop the mower in an emergency.

Refer Operator’s Instructions.

• Do not lend or sell the mower without the Owner’s Manual.

• Be sure that anyone using the mower reads and fully

understands the information contained in this Manual and

knows how to safely operate the mower.

• Do not allow children or people unfamiliar with these

instructions to use the mower.

• Never mow whilst bystanders or pets are present in the

mowing area.

• Never carry passengers.

• Never mow while barefoot or wearing open sandals or

thongs. Wear long trousers and heavy non-slip shoes.

• It is advisable to wear suitable eye protection when

operating a mower.

• Before using, always visually inspect to see that the

blades, blade bolts, and cutter assembly are not worn or

damaged. Replace worn or damaged blades and bolts in

sets to preserve balance.

• Damaged blades and worn bolts are major hazards.

• Replace worn or faulty silencers.

• Always mount and dismount mower from left-hand side

(opposite side to discharge chute).

• Make sure the area to be mowed is clear of sticks, stones,

bones, wire and debris. They could be thrown by the blades.

• Store fuel in a cool place in a container specifically

designed for that purpose. In general, plastic containers are

unsuitable. Handle fuel carefully. It is highly flammable.

• Refuel outdoors only. Do not smoke when refueling

engine. Add fuel before starting engine. Never remove the

cap from the fuel tank or add petrol while the engine is

running. Allow engine to cool for several minutes before

refueling if engine is hot. If petrol is spilled, do not attempt

to start the engine, but move the mower away from the area

of the spill and avoid creating any source of ignition until the

petrol vapors have dissipated.

• Remove the fuel cap slowly to relieve fuel tank pressure.

• Check for fuel leaks while refueling or using the mower. If

a fuel leak is found, do not start or run the engine until the

leak is fixed and spilled fuel is wiped away.

• Take care not to get fuel on your clothing. If this occurs,

change your clothing immediately.

• Do not operate mower in confined space where exhaust

fumes (carbon monoxide) can collect.

• Mow only in good daylight.

• Start the engine carefully with feet well away from the

blades.

•

When starting do not wrap the started rope around your

hand. Do not allow the started cord to snap back. Return the

started grip slowly to allow the cord to rewind properly.

• Strictly follow the operator instructions before attempting

to start the machine.

• Never mow where the machine could tip or slip.

• If machine stalls going uphill, stop blades and back slowly

down.

• Mow up and down slopes. Never mow across a slope.

Exercise extreme caution when changing direction on slopes.

Do not mow excessively steep slopes.

• Do not accelerate or stop the mower suddenly when on a

slope.

• Be extremely careful when using a mower on slopes. Stay

alert for holes in the terrain and other hidden hazards.

• Disengage cutter drive before mowing across gravel

drives, walks or roads.

• Do not mow in reverse. When reversing keep a careful and

continuous observation of the entire area behind the mower.

• Never use the mower unless all guards provided by Rover-

Scott Bonnar Limited are in position.

• Never disconnect the safety switches and never operate

the mower if any safety switch is inoperative.

• Never over-speed the engine or alter the governor settings.

Excessive speed is dangerous and shortens mower life.

• Take all precautions when leaving the mower unattended.

Disengage the cutter drive, set the park brake, shift into

neutral, stop the engine, and remove the key.

• Stop the engine and remove the key whenever you leave

the mower, even for a moment.

• Stop the engine and disconnect the spark plug lead and

inspect mower if:

a) The mower begins to vibrate abnormally: or

b) After striking a foreign object.

Repair the damage before continuing further operation of

the mower.

• Stop the engine and disconnect the spark plug lead before

clearing blockages, checking or working on the mower.

• Never pick up or carry a mower while it is operating.

• Where fitted, turn fuel tap off at the conclusion of mowing.

• When transporting in a vehicle, secure the mower to

prevent movement, roll-over, fuel spillage, and mower

damage.

• Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

• Never modify the mower in any way. Use only replacement

parts made and guaranteed by Rover-Scott Bonnar Limited.

• Keep all safety devices (guards and switches) in place and

working.

•

Keep the engine free of grass, leaves or excessive grease –

these can be a fire hazard.

• Store the mower in a well ventilated room away from

naked flames such ad may be found in hot water heaters.

Page 3

SAFETY FEATURES

⎯ Traction drive, blade drive and seat safety

interlock:

⎯ Enclosed engine and muffler: ⎯ Low centre of gravity stable wide track.

⎯ Enclosed drives: ⎯ Parking brake.

⎯ Full foot rest:

⎯ Convenient – easy to operate controls

1

Page 4

SPECIFICATIONS

ROVER RANCHER

Machine Model No.

Engine Model No.

Single Cylinder

4 Stroke

Fuel Capacity

Oil Capacity

Lubrication

Spark plug type

Spark Pl ug Gap

Ignition Type

Engine Oil

10w-30 or SAE 30

TRANSMISSION CONTROLS

Fully enclosed and permanen tly lubricated

transaxle. Diff and gearbo x combined featuring an

inline selector pattern with 5 Fo rwa rd speeds,

Neutral and Reverse.

Reduction are –

Speed1

Speed 2

Speed 3

46.8:1

30.1:1

20.1:1

Speed 4

Speed5

Reverse

Primary traction drive is by an A Section, V Belt

Clutch from engine to trans-axle input shaft.

Total Drive Reduction

Speed1

Speed 2

Speed 3

104:1

66.6:1

44.5:1

Speed 4

Speed5

Reverse

Ground Speed: At 3600 RPM

Speed1

Speed 2

Speed 3

2.5 km/hr

3.9 km/hr

5.8 km/hr

Speed 4

Speed5

Reverse

Note: Speeds must only be selected when

machine is stationary.

CUTTING HEAD

Model 178: Full floating die cast aluminum

housing with right side discharge.

Width of cut 965mm (38”)

Model 170: Full floating pressed steel housing

with right side discharge. Width of

cut 760mm (30”).

Tyres

Front Tyres –

13 x5.00 Tube

Pressure 140 KPA maximum

Rear Tyres – Tubeless

Pressure 70 KPA maximum

1766

280702

Briggs & Stratton

12 HP. 465cc

4.0 Litres

1.42 Litres

Gear Impellor

Champion CJ8

0.7 to 0.8

Magnetron

15.7:1

13.3:1

40.1:1

34.8:1

29.5:1

88.8:

7.5 km/hr

8.8 km/hr

2.9 km/hr

To emphasize special information the words

WARNING and CAUTION are used.

WARNING: The safety of the user and others

involved.

Personal injury may result should this information

be disregarded.

CAUTION: Follow these instructions carefully to

avoid mower damage and lo ss of warranty.

∗ Throttle control with Fast, Slow and Choke

positions;

∗ Key switch with Off, On and Start positions;

∗ Light switch Off/On;

∗ Amp Meter.

STEERING WHEEL

325mm Dia. Steering Wheel. 1-1/4 turns lock to lock.

CLUTCH BRAKE / PEDAL

Foot operated pedal. Right side of mac h ine.

PARK BRAKE KNOB:

Hand operated catch. Right hand side. Used in

conjunction with clutch/brake pedal.

SPEED SELECTOR:

Lever left hand side. 5 Forward speeds, Neutral and

reverse.

CUTTING HEIGHT:

Lever right hand side. 8 heig hts of cut positions from

15mm to 65mm.

Cutter drive:

Lever in rear cowl.

GENERAL:

Wheel Base, 111cm

Track 63cm R: 71cm F.

Turning Circle 4.0m

Turning Radius 85.0cm

Length

Width

Height

Weight

2

156cm

83cm

95cm

180kg

Page 5

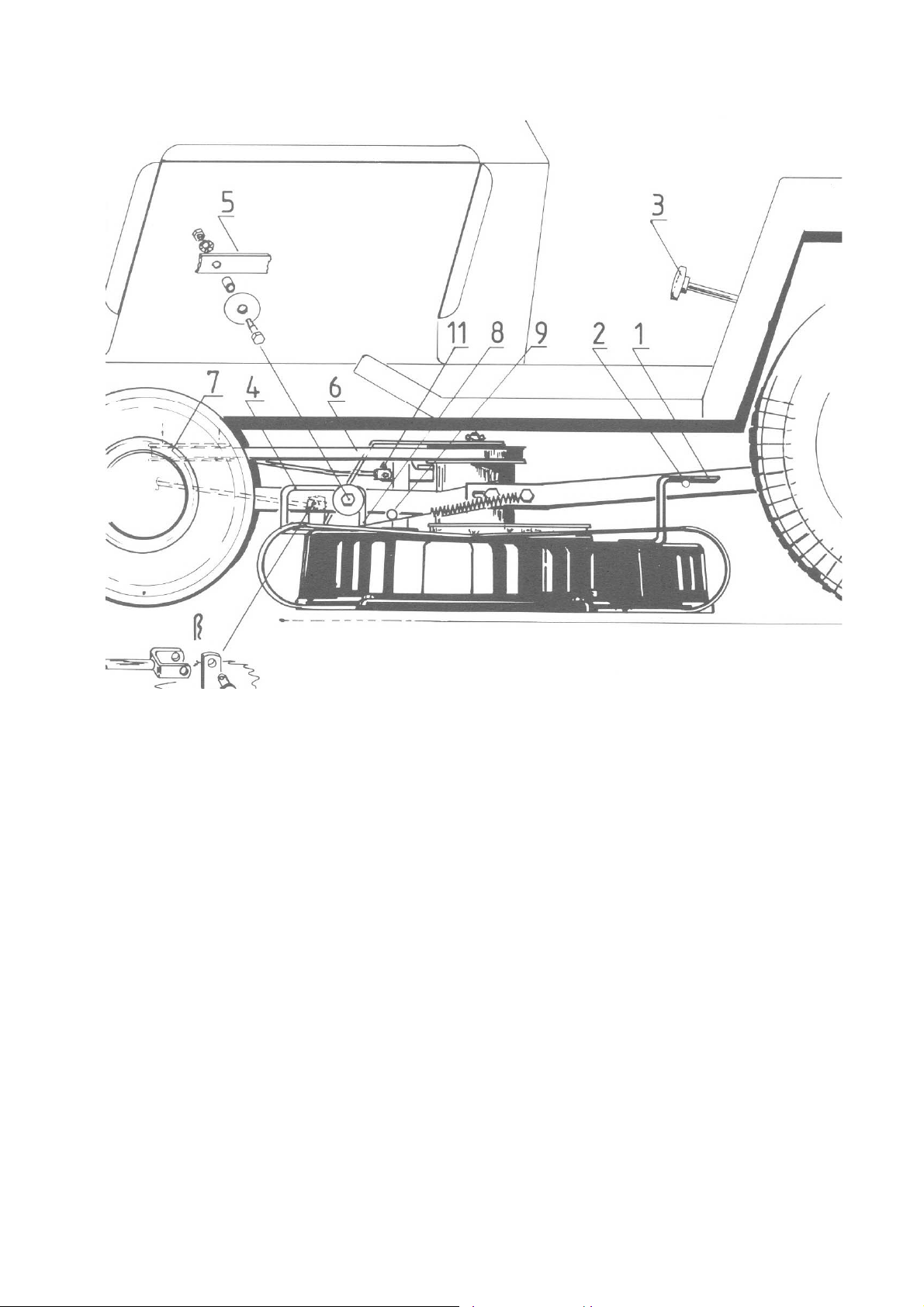

FITTING OF MODEL 170-178 CUTTING DECKS TO RANCHER

1. Remove spark plug lead.

2. Move height of cut lever to high cut (3)

3. Slide cutter deck under the Rancher from the right hand side with the ejection

chute facing out.

4. Move height of cut lever to low cut.

5. Lift the rear of the cutting deck and fit the support brackets (1) over the control

pins (2).

6. Fit the retaining bolts, spacers and was he rs through the U support bracket (4) in

the correct order, see illustration (5).

7. Fit the drive belt (^0 to the engine pulle y (7).

8. Attach the tension springs to the cutter head through the holes (8).

A piece of wire through the loops (9) in the spring will assist this operation.

9. Attach cutter head pushrods (10) as shown in illustration. (Pins on outside)

Refer page 10, fig 18 for cutter drive adjustment.

10. Attach and adjust cutter head brake rod. (11)

Refer page 10, Fig 19 for adjustment.

REFER TO PAGE 11 FOR CUTTERHEAD TILT ADJUSTMENT

3

Page 6

LOOSE PARTS KIT

DESCRIPTION

Steering wheel

Roll Pin

Stone Guard Assembly

Spring – Stone Guard

‘E’ Clip

Ignition keys

Plug Spanner

QTY

1

1

1

1

1

2

1

USE

On steering shaft

Secure steering wheel to shaft

Fitted to cutter head

On stone gu a rd pivot ro d

In groove in pivot rod

To start machine

To remove spark plug

SETTING UP INSTRUCTIONS

Fig.2 Fig.4

INSTALL STEERING WHEEL

1.

Slip steering wheel over steering shaft and

align the wheel hole with the shaft hole;

2.

Insert drift punch – partially through the

holes to maintain alignment and insert roll

pin in the opposite side; See Fig.2.

3.

Drive roll pin in until flush with the outside

of the wheel.

Fig.3

FIT STONE GUARD

1.

Slip spring onto stone guard pivot rod so

that the short leg rests on top on the stone

guard;

2.

Now twist the spring as shown and fed the

end of the pivot rod into the forward pivot

bracket; See fig.3

3.

Insert the short end of the pivot rod fully

into the rearward pivot bracket;

4.

Release the spring. It should spring down

onto the top of the cutter head and be

tensioning the stone guard down;

5.

Secure by clipping an ‘E’ Clip into the groove

on the pivot rod. See Fig.4.

INSTALLING THE BATTERY

BATTERY

1.

Remove battery as follows;

(a) Remove terminal cable from battery

(b) Undo wing nuts and remove clamp

bar.

2.

The battery is not fitted with Electrolyte.

This should be done by adding 33% strength

battery acid to each cell until plates are

covered. Electrolyte must be purchased

from a local battery supply outlet.

IMPORTANT: DO NOT OVERFILL BATTERY. ACID

WILL OVERFLOW INTO OTHER PARTS OF THE

MACHINE AND SEVERE CORROSSION AND

DETERIORATION WILL RESULT.

3.

Leave filler caps off and connect battery

charger to battery terminal. Charge at the

rate indicated in the instructions supplied

with the battery.

4.

After charging, check that Electrolyte is still

covering plates, if not, add to correct level.

Install filler caps.

5.

Replace battery and secure.

6.

Install the positive (red) cable to the positive

(+) terminal and the negative9black) cable

to the negative (-) terminal.

4

Page 7

BEFORE OPERATING

FILL CRANKCASE WITH OIL.

The rider mower may be delivered with out oil in the

crankcase. Oil must be added before attempting to start the

engine.

1.

Place machine on level surface. Open the bonnet. Ensure

that the oil plug is securely tightened. Clean around

dipstick.

2.

Unscrew and remove dipstick from oil filler tube.

3.

Insert funnel into filler tube and slowly add oil in

accordance with the engine manufacturer’s direction.

Note: Avoid premature engine failure by ensuring the

funnel is clean so contaminants are not introduced

into the crankcase. Wipe any oil spills so it will not

cause dirt to collect on the engine

4.

Ensure oil level is at the full mark on the dipstick, when

screwed completely in. When finished replace dipstick

and retighten.

Note: See Maintenance Instructions

FILL FUEL TANK – See Safety Instructions.

Use only regular grade or unleaded petrol.

Do not mix oil with petrol. – Engine damage may result.

1. Open bonnet and clean around fuel tank cap so foreign

matter cannot enter fuel tank when cap is removed.

2. Using a funnel, fill tank with regular grade or unleaded

petrol. Replace the cap.

3. Wipe up any petrol that may have spilled.

4. Close and secure bonnet.

CHECK TYRE PRESSURE.

Check and maintain tyre pressure at 140 KPA (20 PSI) front

and 70 KPA (10 PSI) rear maximum

ADJUSTING THE SEAT

Tip the seat forward, loosen

the seat securing screws.

Relocate the seat for

operator comfort. Tighten

the seat securing screws and

lower the seat

Fig 5

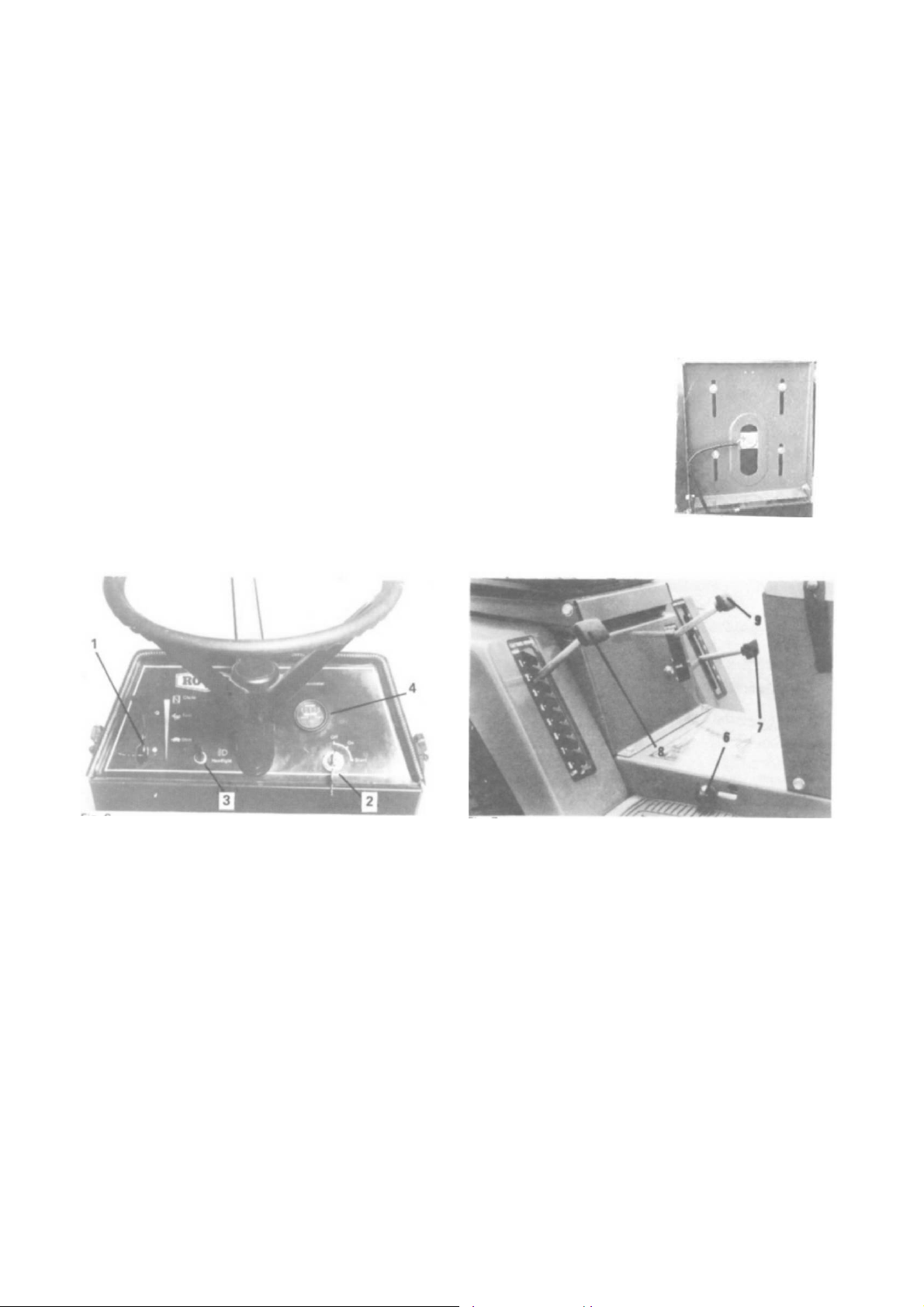

CONTROLS

Fig 6

1. Throttle control – Mounted on the dash panel and

connected to the engine carburetor controls. Has the

symbols for Slow, Fast and Choke.

2. Ignition Switch – This switch is part of the battery

ignition system and has three positions marked for Off,

On and Start. The switch is key operated and

automatically returns to the On position from Start

position when released.

3. Light Switch – On/Off toggle switch on dash panel for

actuating the headlights. Lights will not function when

engine is not running.

4. Amp Meter – Mounted in the dash panel it indicates the

battery charging current and discharge.

5. Brake/Clutch – Foot operated pedal on right side of

machine. Depressing the pedal disengages the drive belt

and engages Brake Disc .

6. Parking Brake – Hand operated knob right hand side.

Depressing the brake clutch foot pedal enables this knob

to be engaged and disengaged. Brake is locked on with

knob in up position.

7. Speed Selector – Located on left of seat. In line selector

with speeds 1, 2, 3, 4 and 5 Down from Neutral and

Reverse through spring gate and up from Neutral.

8. Cutting Height Adjuster – Located on right of seat with

low cut at bottom and high cut at top of setting.

9. Cutter Drive – Lever located on left hand side of seat

mounting box. Down position disengages blade drive and

applies blade brake, Up position engages blades.

5

Page 8

OPERATING INSTRUCTIONS

TO START THE ENGINE:

Note the engine will not start unless the cutter drive is

disengaged, and clutch/brake pedal is depressed.

-

Depress clutch/brake pedal – Apply the park brake;

-

Move the speed selector to neutral;

-

Disengage the cutter drive;

-

Move the throttle lever to the choke position;

-

Turn the ignition key to the start position and release;

-

when the engine starts;

-

Move the throttle lever to about ¼ position.

TO MOW OR DRIVE:

-

Depress clutch/brake pedal;

-

Disengage the parking brake;

-

Select height of cut;

-

Move throttle to about ¾ position;

-

Engage cutter drive;

-

Select desired speed;

-

Slowly release clutch/brake pedal to move off.

TO STOP ENGINE:

-

Depress clutch/brake pedal;

-

Move the speed selector to neutral;

-

Disengage the cutter;

-

Apply the parking brake;

MAINTENANCE INSTRUCTIONS

Periodically check the machine and cutting mechanism. If

parts are worn or need replacing do so by using only Genuine

Rover Replacement Parts.

There is a comprehensive Rancher Spare Parts List contained

in this book to help you select the right part quickly.

Before working o the mower, disconnect the spark plug lead

from the spark plug and place it where it cannot contact the

spark plug.

CHECK YOUR Rover rancher frequently for loose nuts,

bolts, belts, etc., and keep these items correctly tightened and

adjusted.

Note: A check after the first two hours operation is

recommended. Engine failure or rapid engine wear mainly

result from the following causes –

1. Dirt or abrasives entering the engine via the air

cleaner due to –

-

Move the throttle lever to the slow position;

-

Turn the ignition key to Off. Remove the keys;

IMPORTANT:

- The parking brake should always be applied before

leaving the machine;

- The parking brake must be released before attempting to

drive;

- Depress the clutch/brake pedal when selecting or

changing speed;

- Do not select speed while the machine is moving.

ENGAGING CLUTCHES:

- When engaging the cutter drive lever or releasing the

clutch/brake pedal, always operate slowly. Do not use a

jerking motion. Moving these controls too fast could

possibly overload and stall the engine.

CAUTION:

- To avoid loss of control always come to a complete

stop before selecting speeds and slow down when

turning.

REMEMBER:

- Always look behind the machine before reversing;

- Do not refuel when the engine is running or while it is

hot;

- Keep bystanders away – Keep hands and feet clear of

moving parts;

- Keep the machine clear of grass and debris;

- Keep all guards in place;

a).

The air cleaner element not being serviced

regularly;

b).

The air cleaner damaged or dislodged.

2. Dirt or abrasives entering the engine via the oil filler

tube due to –

a).

Using a funnel not cleaned of dirt and grit,

b).

Topping up with contaminated oil. Oil stored in

an unclean container.

3. Lack of oil. It is important to –

a).

Check the oil level regularly ( every 5 hours of

operation),

b).

Maintain a full sump.

6

Page 9

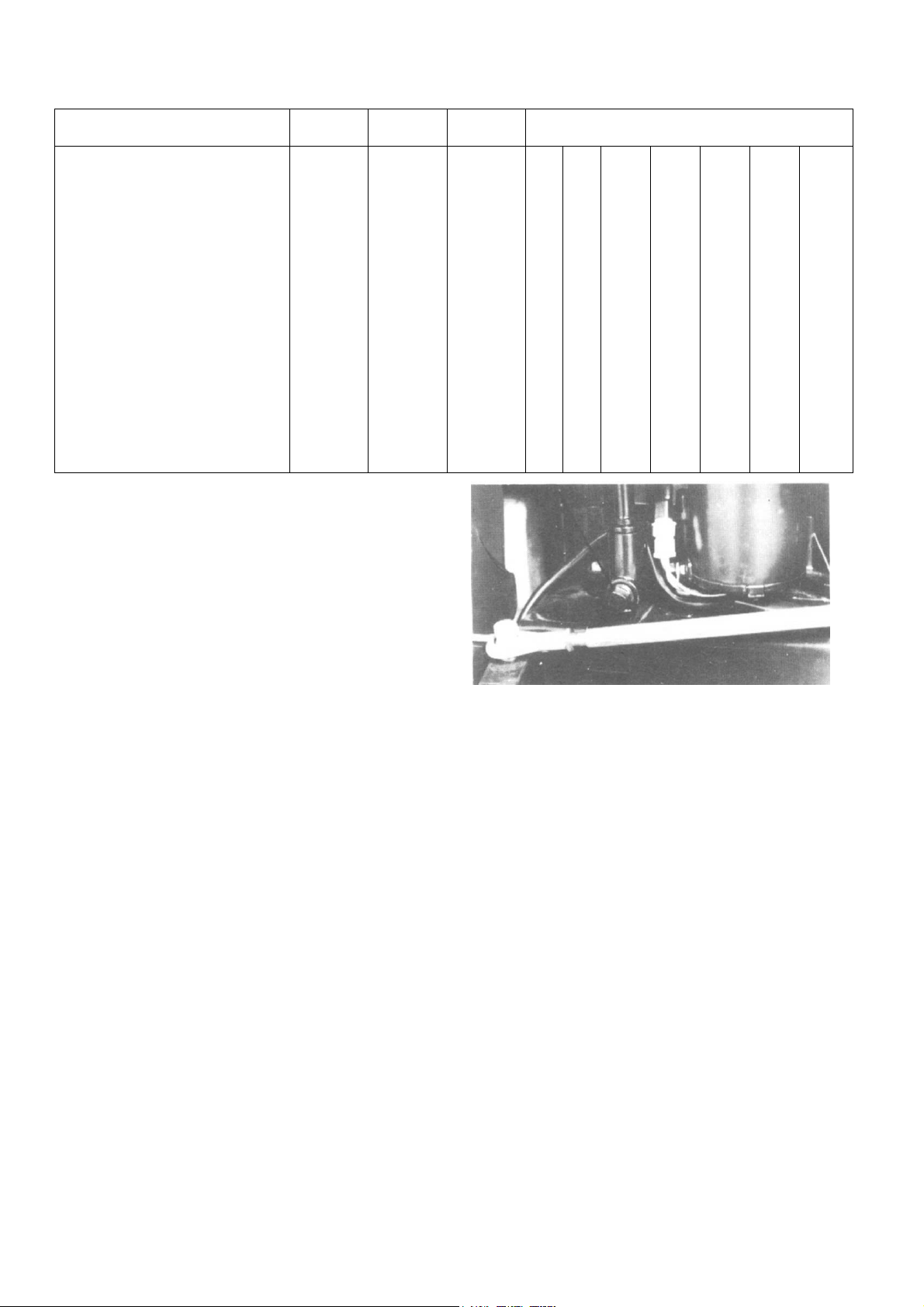

MAINTENANCE INTERVAL CHART

See 5 25 PERIODIC SERVICE EVERY 25 HOURS

page Hours Hours 50 75 100 125 150 175 200

Change oil (Initial) 7 x

Change oil (Periodic) 7 x

Check Interlock 11 x x

Check Cutting Blades - x x

Check Cutting Unit Brake 10 x

Check Rear Wheels Brake 10 x

Lubricate Pivot Points 8 x

Lubricate Throttle Cable 8 x

Grease Front Axle Spindles 8 x

Service Air Cleaner 7 x

Check Spark Plug 7 x

Check Drive Belts - x

Check Tyre Pressure 5 x

Clean Outside Of Engine - x

Clean Cutter Housing - x

Paint Chipped Surfaces - x

AIR CLEANER: Dual Element Type –

1.

Remove two cover knobs and remove air cleaner cover.

2.

Remove foam pre-cleaner, if so equipped.

(a).

Wash pre-cleaner in liquid detergent and warm water

to remove dirt.

(b).

Wrap pre-cleaner in cloth and squeeze dry.

(c).

Saturate foam in engine oil. Squeeze to remove

excess oil.

3.

Remove two nuts from top of cartridge.

4.

Remove cartridge and clean air cleaner body carefully to

prevent dirt from entering carburetor. Brush dirt from

lower air cleaner body into duct.

5.

Clean cartridge by gently tapping on flat surface.

(a).

If very dirty, replace cartridge or wash in low or non

sudsing detergent and warm water solution.

(b).

Rinse out thoroughly from INSIDE OUT until water

is clear.

(c).

Cartridge must be allowed to stand and air dry

6.

Note: Nuts holding air cleaner cartridge must be installed

with fiber washers down on cartridge plate to prevent dirt

from entering carburetor. Tighten nuts by hand. Over

tightening could collapse cartridge.

Note: Petroleum solvents, such as kerosene, are not to be

used to clean cartridge. They may cause deterioration of

the cartridge. DO NOT OIL CARTRIDGE. DO NOT USE

PRESSURIZED AIR TO CLEAN OR DRY THE

CARTRIDGE.

OIL CHANGE

See engine manufacturer’s instructions.

1. Place engine on a level surface. Start and run engine for a

thoroughly before using.

Reassemble air cleaner.

period to warm the oil;

Fig 8

2.

Place an oil pan under oil drain channel in side

on chassis.

3.

Remove oil drain plug and allow to dr ain

completely.

4.

Refit oil drain plug and tighten. Re fill sump

with new oil. For correct viscosity and service

classification see the engine manufac tures

Instruction

SPARK PLUG:

The spark plug gap gradually increases during engine running

and should be checked periodically and whenever the engine

malfunctions.

1. Clean around spark plug area so that dirt will not enter

engine when plug is removed;

2. Disconnect spark plug lead and remove spark plug;

3. Check condition of electrodes and ensure there is no

damage to insulator;

4. Carefully clean the spark plug. Do not grit blast.

5. Set gap to .8mm (.030”)

6. Install in engine and tighten to 20Nm. If a torque wrench

is not available hand tighten plug. Then with tube spanner

tighten plug about 1/12 of 1 turn.

7. Refit high tension lead. Push onto plug firmly.

7

Page 10

MAINTENANCE

COOLING SYSTEM:

The Rancher has an air cooled 4 stroke engine. It must be

cleaned frequently. Remove any build up of grass, dirt or

other debris from the –

1. Cylinder;

2. Cylinder head cooling fins;

3. Cooling air intake screen and

4. Carburettor governor levers and linkages.

This will ensure adequate cooling and correct engine speed.

COOLING SYSTEM:

Proper choke and stop switch operation is dependant on

adjustment of remote controls –

1. Loosen outer cable under clamp screw (D) on engine;

See Fig. 9.

2. Set throttle control to choke position;

3. Adjust outer cable under clamp plate so that choke is

operated;

4. Tighten clamp plate screw and check –

(a).

Choke does not operate in fast position, and

Stop switch operates correctly.

Fig. 10

5.

Move throttle to the slow position and adjust the slow

running stop screw (B) to give an engine speed of 1700

to 1800 RPM.

6.

Adjust the idle needle valve (C) slowly in (lean) and out

(rich) until engine idles smoothly.

7.

Reset engine idle speed.

8.

Check operation. Engine should increase speed without

hesitation when throttle control is moved quickly from

slow to fast. If the engine tends to die out, adjust the

high speed needle valve 1/8 turn anti-clockwise until

engine accelerates smoothly.

⎯

Never tamper with engine governor setting.

⎯

Changing of engine governor speed will void

engine warranty.

Fig. 9

CARBURETTOR ADJUSTMENT:

The carburettor has been factory set and should only require

occasional fine tuning. See Figs 9 and 10.

1.

Close high speed needle valve (A) in bottom of

carburettor bowl. Close finger tight in clockwise

direction;

2.

Open (anti-clockwise) the needle valve two turns

(that is an approx. setting);

3.

Start engine and let it warm up. Approx two minutes.

Cutter drive must be disengaged. Speed selector must

be in neutral position, air cleaner must be fitted and

secured and fuel tank must be half full.

4.

With the engine running at high speed, adjust the

needle valve1/8 turn at a time. Clockwise or anticlockwise until engine runs smoothly.

Note: Allow several seconds between each

adjustment for engine to adapt to new settings.

Fig. 11

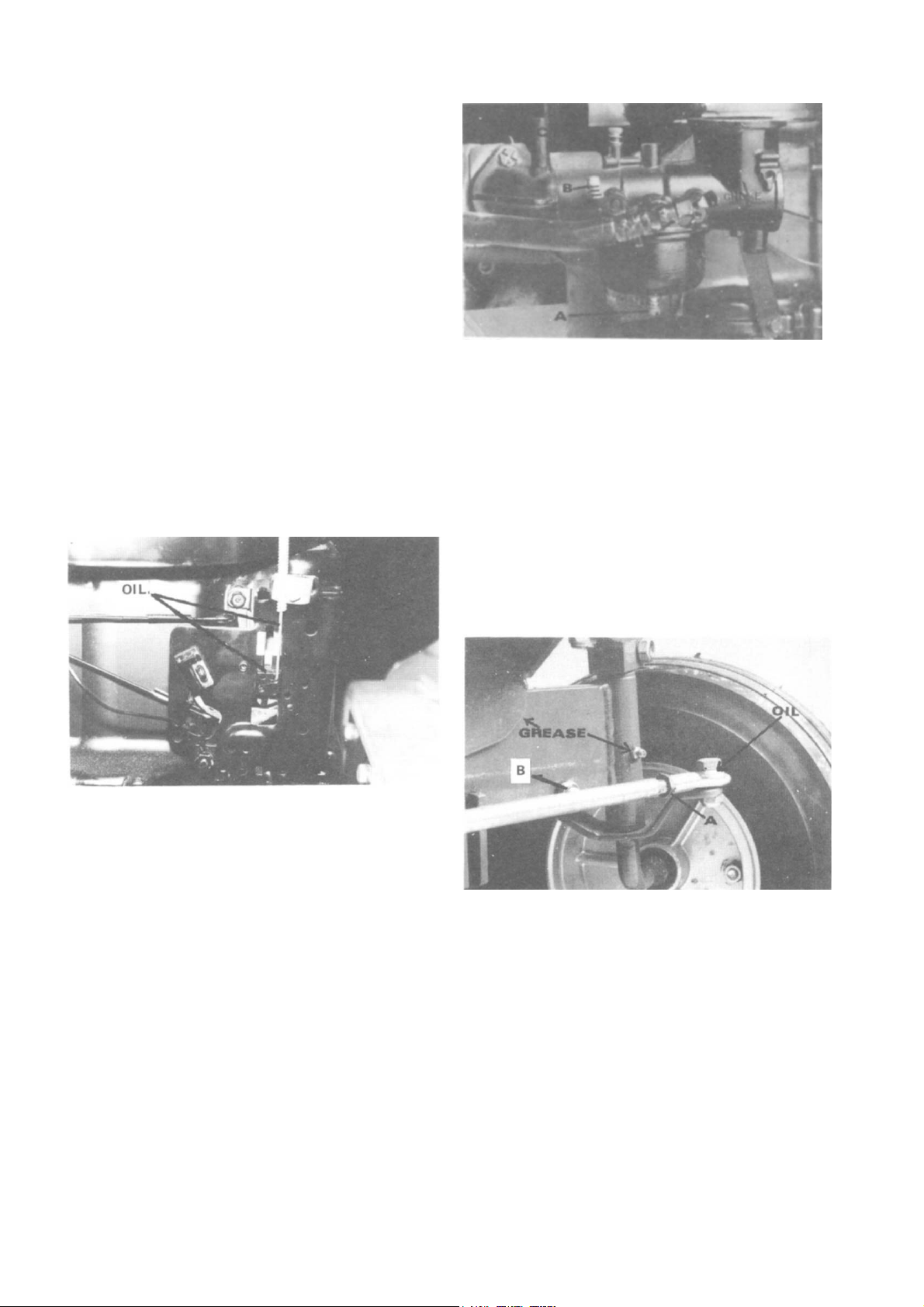

LUBRICATION GENERAL:

Using General Purpose Grease –

⎯ Grease nipples on front wheel pivots. See Fig.11

⎯ Front axle beam guides.

⎯ Grease nipples on steering pivot blocks Fig.21

⎯ Steering gears Fig. 21

Using Clean Engine Oil –

⎯ Jockey pivot arms

⎯ Throttle control cable fig.9

8

Page 11

MAINTENANCE

⎯ Cutter Drive Lever Pivot;

⎯ Clutch/brake pedal pivot; See Fig.15

⎯ Tie rod ball ends; See Fig. 11

⎯ All connecting rod pivot points.

Note: All ball bearings are sealed and require no maintenance.

TRANSAXLE:

This transmission is fully enclosed and permanently lubricated.

No maintenance necessary.

CUTTING UNIT:

Remove spark plug lead and disengage cutter drive before

working on cutter unit, to prevent accidental starting of the

machine.

Before using machine always inspect cutting unit to see that

then cutting disc, blades and blade fixings are not worn or

damaged.

Always check after striking a solid object. Do not operate

machine when unusual vibration occurs.

Replace worn or damaged blades in sets to preserve balance.

Remove any build-up of grass or clogging within the cutting

unit or discharge chute or safety flap.

CUTTING UNIT REMOVAL:

WHEEL REMOVAL:

Fig. 13 Fig. 14

CAUTION: Always deflate tyre before removing rim

nuts on front wheel only.

Front –

1. Chock wheels and remove axle nut; See Fig. 13

2. Raise front of engine;

3. Slide wheel from shaft;

4. Replace in reverse order;

5. Retighten axle nut firmly.

Rear-

1. Chock front and rear wheels of machine,

2. Remove four wheel nuts.

3. Slide wheel from hub.

4. Replace wheel nuts and tighten.

ADJUSTMENTS

CLUTCH ROD ADJUSTMENT

Fig. 12

1. Remove drive belt. Run it off of front pulley.

2. Remove tension springs. A loop has been provided on the

spring to assist in this operation; See Fig.12.

3. Disconnect cutter deck push rods and blade brake rod.

4. Undo and remove large retaining bolts (A).

5. Slide the cutter head forward this will allow the rear to be

lowered to the ground.

6. The cutter head can now be slid out from under the

machine.

7. Replace in reverse order.

Fig. 15

Required to take up transmission belt stretch.

1. Remove (R) clip from pedal pivot. See Fig. 15.

2. Slip rod to rear of machine.

3. Adjust nut on rod so that it is 3mm clear of pivot block when

pedal is in a fully up position;

4. Check for operation.

9

Page 12

MAINTENANCE

BRAKE ROD ADJUSTMENT

Should not normally require resetting.

Fig. 17

1. Loosen lock nuts;

(A) See Fig. 17

3. Retighten nuts.

BRAKE ADJUSTMENT

Required to take up brake pad wear.

1. Loosen lock nut; (B) See Fig. 17.

2. Adjust nut a small amount to take up wear;

3. Retighten lock nut;

4. Check operation.

Do not over-adjust. Set so that park brake knob engages.

PARKING BRAKE

Should always be checked for operation after clutch / brake

rods have been adjusted.

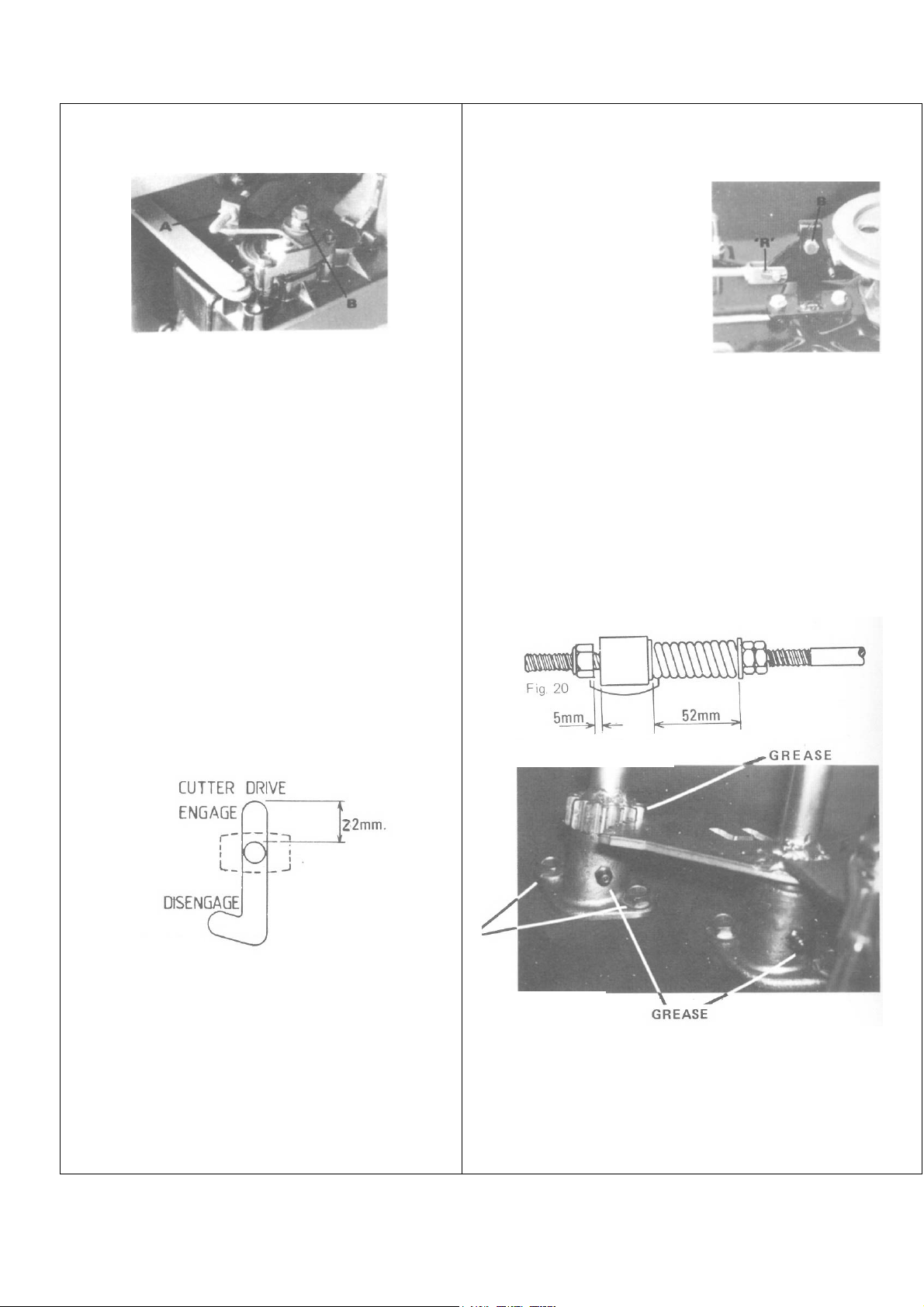

CUTTER DRIVE ADJUSTMENT

1. Mover cutter head lever to engaged position and lower

deck to low cut.

2. Adjust length of push rods so that cutter head engagement

shaft lugs are vertical.

3. Adjust nyloc nuts on engagement lever rod to give approx.

32mm gap between top of lever and end of slot. Fig. 18.

Note:- After adjusting cutter drive check blade brake

adjustment.

2. Adjust pivot block

position;

CUTTER HEAD BRAKE

Should regularly be checked for operation.

PAD REPLACEMENT

1. Remove ‘R’ clip and push

rod pin (See Fig. 19).

2. Remove brake rod pivot

bolt (B) and two spacers

(see Fig. 19).

3. Remove brake plate

assembly.

4. Drill out pad retaining rivets.

5. Rivet replacement pad in position.

6. Refit in reverse order.

CUTTER HEAD BRAKE ADJUSTMENT

1. With cutter head disengaged and in low cut position.

2. Adjust nyloc nut on rod till clearance of 5mm is obtained.

3. Adjust tension on spring using lock nuts to give length of

52mm. Fig. 20.

To adjust out excessive play caused by wear in the gears.

1. Loosen bolts securing steering shaft pivot block (A).

2. Lightly tap pivot block towards layshaft pivot block and retighten

3. Check steering gear engagement. Check that there are no tight spots

SPRING GEARS

Fig. 21

bolts (A).

when turning steering wheel from lock to lock.

10

Page 13

MAINTENANCE

STEERING RODS

Should not normally require resetting.

1. Loosen rod lock nut; (a) See Fig. 11.

2. Release the fixing bolt;

3. Turn tie rod end to adjust for length clockwise to shorten,

anti-clockwise to lengthen;

4. Replace the fixing bolt and tighten;

5. Tighten rod lock nut;

6. Make sure rod is free to pivot.

CUTTER HEAD TILT

This should not normally require resetting.

1. Loosen U-Bracket nuts; (B) See Fig. 12.

2. Adjust nuts up or down to set tilt;

3. Model 178 (965 mm cut) does not require tilt.

Model 170 (760 mm cut) does require back of blade

circle tilted 15mm above front of blade circle in low cut

position’

4. Retighten all nuts.

STEERING STOPS

This should not normally require resetting.

1. Check if steering segment gear rotates in both directions

and contacts peg on chassis. If segment gear contacts then

stops are correct. If not adjust as follows.

2. Loosen lock nut on front beam axle and adjust bolt till

contact is made between segment and peg. Check in both

directions.

3. Retighten lock nut.

HEIGHT OF CUT ADJUSTMENT

To adjust the height of

cut rotate the nyloc nut

(A) situated under the

centre of machine on the

rear cutter support

assembly.

Adjust nyloc nut to

obtain low cut at front of

blade circle of 15mm.

SAFETY INTERLOCK SYSTEM

The safety interlock system has been designed for your

protection and should not be tampered with. It gives the

Rancher the following characteristics.

The engine will not start unless the speed selector is in the

neutral position, the cutter drive is disengaged and the

clutch/brake pedal is depressed.

NOTE: The engine should stop if the operator leaves the seat

with the speed selector and/or the cutter drive

engaged.

WARNING: If the interlock system fails, see an

authorized dealer. Do not operate until the

fault is corrected

CAUTION: Safety switch circuit may become defective if

wet. Do not spray switches and connections.

STORAGE

Never store engine with fuel in tank indoors or in poor

ventilated enclosures where fuel may accumulate.

If machine is to be stores over 30 days proceed with the

following:-

1. Remove all fuel from carburettor and fuel tank to prevent

varnish-like gum deposits.

2. Remove spark plug and pour 30 ml of engine oil into

cylinder. Crank engine several times to distribute oil.

Replace spark plug.

3. Clean engine and cooling fins, etc., of any clippings, dirt

and chaff.

4. Clean underside of mower and cutting unit. Paint any

chips or scratches.

5. Lubricate chassis components.

6. Remove and charge battery and store in a cool dry spot.

Recharge every 30 days.

7. Store machine in a clean dry spot.

REMOVAL FROM STORAGE

1. Change oil.

2. Fill fuel tank with fuel.

3. Check spark plug.

4. Check drive belts.

5. Check drive chain.

6. Lubricate drive chain.

7. Lubricate pivot points.

8. Grease front axle spindles.

9. Check tyre pressure.

10. Check safety interlock.

11. Check cutting blades.

11

Page 14

NOTES

12

Page 15

SAFETY AND INSTRUCTION DECALS

The following safety and instruction decals are mounted on the RANCHER Front Engine Rider.

Replace any that become damaged or illegible.

Page 16

CIRCUIT DIAGRAMS

14

Page 17

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Engine loses power. 1. Oil level in crank case is low.

2. Cooling fins and air passages under

engine blower housing are blocked.

3. Engine load is excessive.

4. Air cleaner is dirty.

5. Dirt or water is in fuel.

6. Carburettor is adjusted incorrectly.

7. Spark plug is pitted, fouled or defective

in some other way.

Engine over heats. 1. Cooling fins and air passages under

engine blower housing are blocked.

2. Carburettor is adjusted incorrectly.

3. Oil level in crank case is low.

4. Engine load is excessive.

Mower vibrates abnormally. 1. Engine mounting bolts are loose.

2. Loose cutter pulley, idler pulley or drive

pulley.

3. Cutter assembly is unbalanced.

4. Cutter assembly is loose.

Cutter does not rotate. 1. Cutter belt is worn, loose or broken.

2. Cutter drive belt is off pu lley.

Mower does not drive. 1. Drive belt is worn, loose or broken.

2. Drive belt is off pulley.

3. Unable to select speed on transaxle.

Engine does not start, hard to

start, loses power, or fails to keep

running.

Engine does not idle or idles

poorly.

1. Fuel tank is empty.

2. Speed selector.

3. Cutter drive is engaged.

4. Spark plug is loose.

5. Spark plug lead is loose or disconnected

from spark plug.

6. Spark plug gap is incorrect.

7. Spark plug is pitted fouled or defective

in some other way.

8. Wrong spa rk plug is used.

9. Electrical connections are loose.

10. Carburettor is adjusted incorrectly.

11. Air cleaner is dirty.

12. Vent hole in fuel tank is plugged.

13. Dirt or water in furl system.

14. Dead battery.

15. Defective points, condenser, ignition

coil, or ignition switch.

16. Module or switch is defective.

1. Air cleaner is dirty.

2. Oil level in crank case is low.

3. Cooling fins and air passages under

engine blower housing are plugged.

4. Idle speed is too low or high speed

mixture is incorrect.

5. Dirt or water in fuel system.

6. Vent hole in fuel tank is plugged.

7. Spark plug is pitted fouled or defective

in some other way.

}

1. Add oil to crankcase.

2. Remove obstruction from passage.

3. Select a lower speed to reduce load.

4. Clean air cleaner element.

5. Have machine serviced by an Authorized

Service Dealer.

6. Adjust the carburettor.

7. Install new correctly gapped spark plug.

1. Remove obstruction from cooling fins and air

passage.

2. Adjust the carburettor.

3. Add oil to crankcase.

4. Select a lower speed to reduce load.

1. Tighten mount bolts.

2. Tighten the appropriate pulley.

3. Replace broken blades in set.

4. Tighten securing nut.

1. Install new cutter drive belt.

2. Install cutter drive belt.

1. Install new drive belt.

2. Install drive belt.

3. Have machine serviced by an Authorized

Service Dealer.

1. Fill fuel tank with petrol.

2. Select neutral.

3. Disengage cutter drive.

4. Tighten spark plug.

5. Install spark plug lead on spark plug.

6. Set gap between electrodes at 0.8mm

7. Install new correctly gapped spark plug.

8. Install correct spark plug.

9. Check electrical system to ensure good

contact.

10. Adjust the carburettor.

11. Clean the air cleaner element.

12. Inspect and open vent.

13. Have machine serviced by an Authorized

Service Dealer.

1. Clean air cleaner element.

2. Add oil to crankcase.

3. Remove obstruction from cooling fins and air

passages.

4. Adjust the carburettor.

5. Have machine serviced by an Authorized

Service Dealer.

6. Clean fuel tank vent.

7. Install new correctly gapped spark plug.

15

Page 18

Page 19

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

A12115

A10229

A10201

A07919

A07652

A12114

A07617

A07616

A10203

A07657

A10199

A07615

A00969

A00968

A01080

A01275

A07688

A10150

A10202

A07913

A07895

A07755

A07889

A04006

A10052

A02224

A010211

A07903

A07897

A10178

A07750

A07751

A07745

A07736

A07655

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

A12113

A07760

A06406

A12073

A01427

• COMMON HARDWARE ITEM

Lift Spring

Height Selector Shaft Assy.

Gear Selector Shaft Assy.

Floor Panel Label

Lever Knob

Selector Lever

Knob

Park Brake Rod

R.H. Rear mount Assy.

End Cap

Chassis Assy.

Pedal Rubber

Pedal Assy.

Pedal Control Bush Assy.

Spring Clip

Nylon Bush

Pivot Bush

Blade Clutch Lever Assy.

L.H. Rear Mount assy.

Rear Support – Transaxle

Cutter head Lifting Rod

Swivel Block

Blade Clutch Rod

Pin

Push-Rod Assy.

Circlip

Pivot Shaft Assy. – C/Head Engagement

Warning Sticker

Sleeve

Rear Support Arm Assy.

Retaining Washer

Spacer – Retainer Washer

Spring

Front Arm – Cutter head

Shaft Support Bracket

1/8” x 7/8” Roll Pin

¼” x 1 1/8” Roll Pin

5/16” x 1 ¼” UNC Hex Bolt

5/16” x ¾” UNC Hex Setscrew

5/16” x 1 ¼” UNC Hex Bolt

3/8” x 2 ¼” UNF Hex Bolt

5/16” x 5/8” UNC Hex Head W/F. S/S.

3/8” x 2” UNC Hex Setscrew

3/8” x 1 ½” UNC Hex Bolt

3/8” x 1” UNC Hex Setscrew

3/8” x 1 ¼” UNC Hex Setscrew

3/8” UNC Thin Nyloc Nut

5/16” UNC Hex Nut

5/16” UNC Nyloc Nut

3/8” UNF Thin Nyloc Nut

3/8” UNC Hex Nut

3/8” UNF Hex Nut

3/8” x ¾” x 16G Flat Washer

5/8” x 1” x 16G Flat Washer

5/16” x 7/8” x 18G Flat Washer

5/16” Internal Shakeproof Washer

5/16” x 5/8” x 18G Flat Washer

3/8” Internal Shakeproof Washer

Return Spring

Swivel Block

Safety Switch

Switch Mount Plate

Shim

17

Page 20

18

Page 21

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

30A

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

A07715

A10283

A01025

A07916

A07997

A02474

A08585

A12024

A12025

A07805

A12022

A07760

A07714

A07659

A01080

A01493

A07954

A10223

A10224

A07286

A07610

A07912

A05086

A02224

A07804

S2501116

A07915

A10204

A07724

A07918

A10247

A10246

A07645

A07723

A07150

*

*

*

*

*

*

*

*

*

*

*

*

*

*

A02289

A07763

*

*

*

*

*

A04021

• COMMON HARDWARE ITEM

Jockey Arm Pivot Bush

Transaxle Jockey Arm Assy.

Tension Washer

Transaxle Pulley

Transaxle Belt

Bearing Bush

Jockey Pulley – Transaxle

Wheel Hub

Spacer

Belt Guide

Engine Pulley Spacer

Swivel Block

Spring – Transaxle Jockey Arm

Clutch Rod

Spring Pin

Key – Engine Pulley

Engine Pulley

Belt Keeper Assy. – 30” Deck

Belt Keeper Assy. – 38” Deck

Washer – Engine Pulley

Spring

Brake Rod

Woodruff Key

Circlip

Washer – Special

Ratchet Plate

Gearbox Selector Arm

Gear Selector Rod Assy.

Transaxle

Tyre

Rear Wheel Assy. (Includes Items 30,31,33)

Rear Wheel Rim Assy.

Key

Valve stem

Tie-Rod End

5/16” x 1 ¼” UNC Hex Bolt

3/8” x 2 ½” UNC Hex Setscrew

5/16” x ¾” UNC sq Hd. Setscrew

5/16” x 1 ½” UNF H.T. Hex Setscrew

7/16” x 1” UNF H.T. Hex Setscrew

¼” x ½” UNF H.T. Hex Setscrew

5/16” x 2 ½” UNF H.T. Hex Setscrew

3/8” x 1 ½” UNC Hex Bolt

5/16” UNC Nyloc Nut

3/8” UNC Thin Nyloc Nut

5/16” UNC Hex Nut

3/8” UNC Hex Pressed Nut

5/16” UNF Hex Nut

3/8” UNF Hex Pressed Nut

Circlip

Washer – Special

5/16” Internal Shakeproof Washer

3/8” Shakeproof Washer

3/8” x ¾” x 16G Flat Blade

5/16” x 5/8” x 18G Flat Washer

¼” Internal Shakeproof Washer

Wheel Nuts – 3/8” UNC. Washer face Hex.

19

Page 22

20

Page 23

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

20A

20B

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

A07691

A10212

A07953

A07948

A02289

A10213

A07949

A07150

A07695

A02103

A07092

A07198

A04006

A07755

A00967

A10225

A00966

A02051

A00965

A00791

A07572

A01687

A07160

A07567

A01891

A01807

A07634

A12288

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

• COMMON HARDWARE ITEM

Steering Wheel

Steering Shaft Assy.

Steering Shaft Mount Block

Retainer Washer – Steering

Circlip

Layshaft Assy. – Steering

Layshaft Spacer

Tie-Rod End

Primary Tie – Rod

Ratchet Plate

Self – Lube Bush

Grease Nipple

Pin

Swivel Block

Steering Block Assy.

Front Beam Assy.

R.H.Stub Axle Assy.

Woodruff Key

L.H.Stub Axle Assy.

Front Wheel Assy. (Incl. Items 20A,20B,21,22,23,24,29,32,37)

Tyre

Tube

Male Hub

Female Hub

Wheel Bearing

Bearing Spacer

Tie – Rod

Tray – Grease

¼” x 2 ¼” Roll Pin

3/8” x 1 ½” UNC Hex Bolt

5/16” x ¾” UNC Hex Setscrew

3/32” x ½” Split Pin

3/8” UNF Hex Pressed Nut

5/16” UNC Hex Nut

3/8” UNC Thin Nyloc Nut

5/8” UNF Thin Nyloc Nut

5/8” x 1 ½” UNF H.T. Hex Bolt

¾” x 1 ½” x 14G Flat Washer

5/16” Internal Shakeproof Washer

3/8” x ¾” x 16G Flat Washer

5/15” x 5/8” x 18G Flat Washer

5/16” UNC Nyloc Nut

1/8” x 1 1/4'” Split Pin

21

22

Page 24

Page 25

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

12a

13

14

15

16

17*

18*

19*

20*

21

22

23*

24*

25*

26*

27*

28*

A10205

A07716

A07893

A10236

A07672

A07675

A10216

A12004

A07971

A10210

A12016

A07938

A0939

A02024

A07955

A07956

A07985

*

*

*

*

*

*

*

*

*

*

*

*

COMMON HARDWARE ITEM

Bonnet Trim

Trim Strip

Dash panel

Headlight Assembly

Bonnet Strap

Nylon Bush

Firewall Assembly

Clamp Rod Tube

Front Bumper Plug

Front Bumper Bar Assembly

Nose Piece Decal

Bonnet Label – L.H.

Bonnet Label – R.H.

Wing nut – 5/16 UNC

Battery Clamp Bar

Battery Clamp Rod

Throttle Cable

Setscrew – 5/16 x ¾ UNC. HEX

Setscrew – 1/4 x ¾ UNC. HEX

Setscrew – 5/16 x 5/8 UNC. Washer Face

Rivet – 73AS 5-5

Nut – 5/16 UNC. HEX.

Nyloc Nut – 5/15 UNC.

Nut – ¼ UNC. HEX.

Washer – 5/16 x 5/8 x 18G Flat

Washer – 5/16 Shakeproof

Washer – ¼ Shakeproof

23

Page 26

24

Page 27

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27A

28

29

30

31

32

33

34

A07539

A07705

A05424

A12027

A07704

A10191

A07701

A07699

A12099

A07769

A12098

A01427

*

*

*

A12104

*

*

S2501054

A07984

*

*

*

A07785

A07710

A12006

A12007

A12008

A07709

A06406

*

A05419

*

*

COMMON HARDWARE ITEM

Seat

Rubber Bumper

Seat Switch Spring

Vibration Damper

Seat Lid

Rear Cowl Assembly

Rubber Footrest

Footrest

Seat Switch Button

Bolt – Special

Seat Switch Base Plate

Safety Switch Shim

Setscrew – 5/16 x ¾” UNC. Hex.

Nut -3/8” UNC. Pressed

Nyloc Nut – 3/8” UNC

Spade Clip

Nyloc Nut – 5/16” UNC.

Nut 5/16” UNC Hex

Avdel fastener

Decal – Cutter Drive

Washer – 5/16” Shakeproof

Washer – 5/16” x 5/8” x 18g Flat

Setscrew – 5/16 “x 1”UNC. Hex

Decal – Maintenance

Decal - Height Adjustment

Decal – Mudguard LH

Decal – Mudguard RH

Decal – Rear Panel

Decals – Gears

Safety Switch

Setscrew – 5/16” x 5/8”UNC Washer Face

Switch Mount Plate

Pop Rivet – 73SS 5-5

Washer – 3/8” Shakeproof

25

26

Page 28

Page 29

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A07937

A12005

A07999

A12001

A12002

A12009

A12010

A12011

*

*

*

A03422

A03421

*

A12019

COMMON HARDWARE ITEM

Fuel Tank

Fuel Tank Cap

Fuel Tank Bracket

Fuel Tank Strap - Front

Fuel Tank Strap – Rear

Fuel Line – ¼ ID

Hose Clamp

Fuel Line Retainer ½” Copper Half Clip

¼” x 5/8” UNC Hex Bolt

¼”UNC Std. Nyloc Nut

73 AS 5-5 Blind Rivet

Filter – Vent Cap

Vent Cap

5/16” Shakeproof Washer

Fuel Tank Cauti on Label

27

Page 30

28

Page 31

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A07528

A07968

H270917

A07532

A07952

A07871

A10215

*

*

*

*

*

*

*

*

A12251

COMMON HARDWARE ITEM

Muffle Mounting Flange

Exhaust Pipe

Gasket

Exhaust Clamp

Muffle Mount Plate

Muffler

Heatshield Assembly

5/16” x 1” UNC Socket Cap Head Screw

¼” UNC Hex Nut

5/16” x ¾” UNC Hex Setscrew

¼” Internal Shakeproof Washer

5/16”Spring Washer

5/16” Internal Shakeproof Washer

5/16” UNC Hex Nut

¼” x ½” UNC Hex Setscrew

Decal - Warning

29

Page 32

30

Page 33

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

A07988

A07830

A07972

A08618

A02474

A07987

A02476

A07625

A02571

A10218

A07195

A07847

A08585

A02520

A07973

A07837

A10094

A10074

A07857

A02282

A10072

A00987

A07752

A07844

A10220

A10219

A07840

A05099

A02227

A06124

A10217

A10055

A04006

A07974

A01080

A10226

A07744

A07597

A07854

A07848

A12110

A07860

A10000

A00673

A07873

A07976

A07975

*

*

*

*

A07745

*

*

A07878

*

*

*

*

*

*

*

*

*

*

*

A07747

A07755

A07989

A04013

A12106

A12285

COMMON HARDWARE ITEM

Pulley Spacer

Bearing – Duel Pulley

Duel Pulley

Circlip

Bearing Bush

Pulley Spacer – Bottom

Bearing – Jockey Pulley

Jockey Pulley

Warning Label

Jockey arm Assy.

Spindle Washer

Single Pulley

Idler Pulley

Spacer

Spindle – Duel Pulley

Cast Cutter Deck

R.H. Rear Hanger Assy.

L.H. Rear Hanger Assy.

‘No Step’ Label

Circlip

R.H. Skid Rail Assy.

Chute Assy.

Spring

‘U’ Bolt

R.H. ‘U’ Bolt Plate Assy.

L.H. ‘U’ Bolt Plate Assy.

L.H. Skid Rail

Spindle Washer

Brake Pad Rivets

Brake Pad

Pulley Brace Assy.

Brake Plate Assy.

Pin

Jockey Pulley Spring

Spring Pin

Brake Rod Assy.

Bearing – Spindle Housing

Key

Blade Spindle

Spindle Housing

Bearing Washer

Bearing Cup

Disc Assy.

B.N.W. Kit

Blade

Cover Plate

Pulley Mount Plate

3/8” x 1” UNC Hex Setscrew

3/8” x 1” UNC Cuphead Bolt

3/8 x 1 ½” UNC Cuphead Bolt – Full Thread

5/8” x 1 ½” UNF H.T. Bolt

Tension Spring

3/8” UNC Hex Nut

¾” UNF Hex Locknut

‘V’ Belt – Cutter Drive

5/16” x 2” UNC Hex Setscrew

5/8” UNF Hex Locknut

3/8” x 1 ¼” UNC Hex Bolt

3/8” UNC Thin Nyloc Nut

5/16” UNC Nyloc Nut

5/16” UNC Hex Nut

3/8” Internal Shakeproof Washer

5/8” x 1 ¼” x 14G Flat Washer

3/8” x ¾” x 16 g Flat Washer.

5/16” x 5/8” x 18G Flat Washer

5/16” Internal Shakeproof Washer

‘V’ Belt

Swivel Block

Spring – Cutter head Brake Rod

¾” x 1 ½” x 14G Washer

Warning Decal

Cap

31

32

Page 34

Page 35

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

A10222

*

A07993

A07747

A07730

A10221

A07744

A06359

A01374

A02304

A00987

A07752

A07732

A07733

A07746

A07991

A12106

A10055

A06124

A02474

A01080

A02227

A00999

A10294

A07873

*

*

A00673

*

A02282

*

*

*

A07989

A07597

A02571

*

*

A04006

A01656

A07755

COMMON HARDWARE ITEM

Cutterhead Assembly

Flat washer ¾” x 1 ½” x 14G

Cutterhead Pulley

V Belt

Spindle Housing

Brake Rod Assy.

Bearing

Cutterhead Spindle

Felt Washer

Spacer Boss

Cutterhead Chute Assembly

Spring – Cutterhead Chute

‘U’ Bolt – Cutterhead

Washer Plate

Back Plate

Cutterhead Pulley Belt Guides

Warning Decal

Brake Plate Assembly

Brake Pad

Bushes

Spring Pin

Brake Pad Rivets

Disc Boss Assembly

Disc Assembly

Blade

3/8” x 1” UNC Hex Setscrew

3/8” x 1” UNF HT Hex Setscrew

Available in kit form A00673, Item 30

B.N.W. Set

¾” UNF Hex Locknut

‘E’ Retainer

3/8” UNC Hex Nut

Available in kit form A00673, Item 30

3/8” x ¾” x 16G Flat Washer

3/8” Internal Shakeproof Washer

Available in kit form A00673, Item 30

Spring – Cutterhead Brake Rod

Key

Warming Label

3/8” x 1 ¼” UNC Hex Bolt

3/8” UNC Hex Thin Nyloc Nut

Pin

Blade

Swivel Block

33

Page 36

34

Page 37

RANCHER SPARE PARTS LIST

ITEM PART No. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A07678

A07679

A06406

A07893

A10238

A07105

A07108

A07513

A7107

A10255

A12017

A07996

A07995

A12020

A10257

A10235

A11530

A11531

A11532

A11533

A10235

A11537

*

*

COMMON HARDWARE ITEM

Key Switch

Key

Safety Switch

Dash Panel

Wiring Loom – Safety Circuit

Amp Meter

Light Switch

Fuse

Solenoid

Wiring Loom – Main Circuit

Battery

Battery Power Lead - Red

Battery Earth Lead – Black

Engine Earth Lead – Black

Seat Switch Assembly

Headlight Assembly

Reflector

Lens

Bulb

Bulb Holder

Power lead Assembly

Earth Lead

Screw – No. 6 Pan Head

Screw – No. 8 Pan Washer face

35

Page 38

NOTES

36

Page 39

NOTES

37

Page 40

Warranty Condition:

Australia Only

Rover-Scott Bonnar Limited warrant that this

machine is free from defects in material and

workmanship. This warranty is limited to making

good or replacing any part which appears upon

inspection by the manufacturer or his agent to be

defective in material or workmanship.

The engine used to power this machine is

warranted by the manufacturer whose warranty

statement has been included with the machine. As the

warranty for the engine may differ from the

warranty for the other components, you are advised

to read the engine manufacturer’s warranty

carefully.

For other items this warranty shall apply for a

period of 12 months from date of purchase except for

products used commercially where the warranty is

limited to 90 days.

This warranty does not obligate the

manufacturer, his agents or dealers to bear the

transport costs incurred in the repair or replacement

of any defective part.

This warranty ex clu d es fair wear and tear, or any

damage caused by misuse or abuse. Parts such as

blades, blade bolts, v-belts and spark plugs, which

can be subjected to use beyond their normal intended

working capacity, are also excluded.

This warranty is void if parts other than genuine

have been used or if repairs or alterations have been

made without the manufacturer’s written authority.

The above warranty does not exclude any

conditions or warranty implied by the Trade

Practices Act 1974 or any other relevant legislation

which implies any condition which can not be

excluded.

Remember:

PROOF OF PURCHASE IS THE

RESPONIBILITY OF THE OWNER AND IS

NECESSARY PRIOR TTO WARRANTY WORK

BEING UNDERTAKEN. REPAIRS MUST BE

CARRIED OUT BY AN AUTHORISED DEALER

AND GENUINE SPARE PARTS MUST BE USED

OR YOUR WARRANTY WILL BE VOID.

Dealer…………………………………………

Date of Purchase……………………………..

Model………………………………………….

Serial No………………………………………

Rover-Scott Bonnar Limited reserves the right to make changes of and add

improvements upon its products at any time without notice or obligation. The

Company also reserves the right to discontinue manufacture of any product at

its discretion at any time.

Head Office and Factory:

Rover-Scott Bonar Limited

155 Fison Ave., Eagle Farm

Brisbane, Qld. 4007

Ph: (07) 868 0222

Telex: AA41930

Fax: (07) 8681010

New Zealand Auckland

04012021

Queensland/N.T.

155 Fison Ave.,

Eagle Farm

Brisbane, 4007

Ph: (07) 868 0222

Telex: AA41930

Fax: (07) 8681010

Rover Mowers Limited

122 Stoddard Road

Mt Roskill, Auckland 4

Ph: (09) 694 701

(09) 699 625

Fax: (09) 362 239

Telex: NZ60509

For you record:

New South Wales

11 Cooper Street,

Smithfield,

Sydney, 2164.

Ph: (02) 725 1877

Fax: (02) 6095710

Victoria/ Tasmania

28 Treforest Drive,

Clayton,

Melbourne, 3168

Ph: (03) 565 6500

Fax: (03) 543 8675

Christchurch

Rover Mowers Limited

570Wairakie Road,

Christchurch

Ph: (03) 58 2647

Fax: (03) 587482

South Australia

377 Cross Road,

Edwardstown,

Adelaide, 5039.

Ph: (08) 371 0100

Fax: (08) 2978404

© Copyright

Western Australia

104 Belgravia Street,

Belmont,

Perth. 6104.

Ph: (09) 277 1288

Fax: (09) 478 1769

1-90

Loading...

Loading...