Page 1

Quick Start Guide

00825-0100-4570, Rev CB

Rosemount™ 5708 3D Solids Scanner

July 2017

Page 2

Quick Start Guide

Authorized personnel

All operation described in this document must be carried out by authorized, trained personnel only.

For safety and warranty reasons, any internal work on the devices must be carried out by

manufacturer-authorized personnel only.

Warnings about misuse

Inappropriate or incorrect use of the device may result in hazards and application-specific malfunctioning,

such as vessels overfill or damage to system components through incorrect mounting or adjustments.

If the device is used in a manner not specified in this document, the protection provided by the device will

be impaired.

General safety instructions

Consider local and national electrical codes and all common safety regulations and accident prevention

rules during installation.

Substitution of components may impair intrinsic safety.

For preventing ignition of flammable or combustible atmospheres, read, understand and adhere to the

manufacturer’s live maintenance procedures.

July 2017

Learn more

Visit Emerson.com/Level to download the Rosemount 5708

3D Solids Scanner Reference Manual.

Package components

Rosemount 5708 head

Rosemount 5708 antenna

Rosemount 5708 Quick Start Guide

USB to RS-485 converter (pre-wired in factory)

USB Flash drive containing:

a. Installation package of the Rosemount 3DVision software

b. Reference manual

c. Quick Start Guide

d. Configuration movie

e. Installation movie

f. Link to Emerson.com/Level

Contents

Site preparations . . . . . . . . . . . . . . . . . . . . . . . . . 3

Site and installation information . . . . . . . . . . . . 3

Physical mounting . . . . . . . . . . . . . . . . . . . . . . . . 8

Configuration using the LCD display . . . . . . . 15

Configuration using Rosemount 3DVision . . 23

2

Post installation procedures . . . . . . . . . . . . . . 26

Rosemount 5708S in a system . . . . . . . . . . . . 27

Product certifications . . . . . . . . . . . . . . . . . . . . 29

Rosemount 5708 Declaration of Conformity 35

Installation drawing . . . . . . . . . . . . . . . . . . . . . . 37

Page 3

July 2017

1.0 Site preparations

Prior to installation, complete and verify the site preparations described in this

section. For optimal installation, ensure the Rosemount 5708 can be

positioned and fitted according to the guidelines in section 2.0.

Recommended tools for installation:

A set of small precision screwdrivers (for the terminal blocks)

13 mm open wrench

4 mm Hex key (preferably with a handle)

Large adjustable wrench

Utility knife, cutter, pointed pliers, insulating tape

Laser measurement device or equivalent

RS-485 to USB converter, including drivers

120 Ω (RS-485) resistor

250 Ω (HART

PC or laptop

DC Voltmeter

Complete the following steps before installing the Rosemount 5708.

1.1 Power

Make sure grounding is done properly. Connect one end of the cable shield

to the power ground. It is highly recommended to have the same potential

grounding to all devices.

Prepare a 24 Vdc power supply near the device mounting location.

Make sure that you use proper cables for wiring. The Rosemount 5708 is a

4-wire device. The voltage supply and data output

(4-20 mA) are carried along two separate two-wire connection cables.

®

) resistor

Quick Start Guide

1.2 Communications

For RS-485 communication, use shielded, twisted-pair cables with 120 Ω

impedance. Make sure the cables are approved for RS-485

communications.

Route communication cables in proper conduits. Use a proper cable type.

For 4-20 mA communication, use shielded, twisted-pair, low resistance

cables. Make sure the cables are rated for analog signals.

For daisy chaining, a single 4-wire cable can be used, both for RS-485 and

the 24 Vdc power supply.

2.0 Site and installation information

The information listed on these pages is necessary for configuration of the

device.

2.1 Material characteristics

Material name:

Material density :

Max. temperature: °F °C Maximum pressure: Bar PSI

lbs/ft

3

tons/m3Angle of repose:

3

Page 4

Quick Start Guide

B

A

Y

X

A

A

Y

X

A

A

B

Y

X

A

Y

X

A

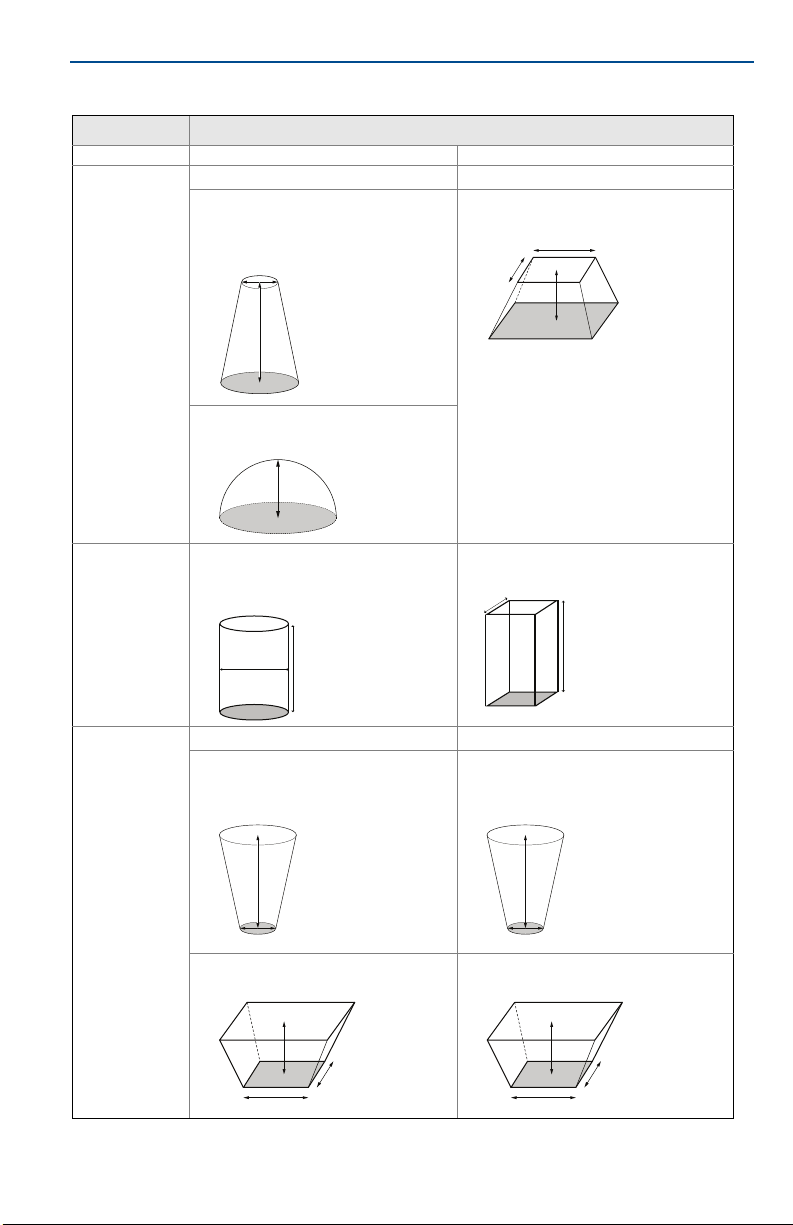

2.2 Vessel type and dimensions

Vessel d etail s

Vessel type Cylindrical Rectangular

Top sha pe

(1)

ft m

Flat

Cone

Top diameter (A): ______

Height (B): ______

Dome

Height (A): ______

Flat

Pyramid

Height (A): ______ X: ______ Y: ______

July 2017

Cylinder

Diameter (A): ______

Height (B): ______

Center shape

A

B

Flat

Cone

Height (A): ______

Bottom diameter (B): ______

Bottom shape

Pyramid

Height (A): ______ X: ______ Y: ______ Height (A): ______ X: ______ Y: ______

1. Required Field - Accurate Vessel dimensions are required to allow optimal location determination.

4

Cube

Height (A): ______ X: ______ Y: ______

Flat

Cone

Height (A): ______

Bottom diameter (B): ______

A

B

Pyramid

Page 5

July 2017

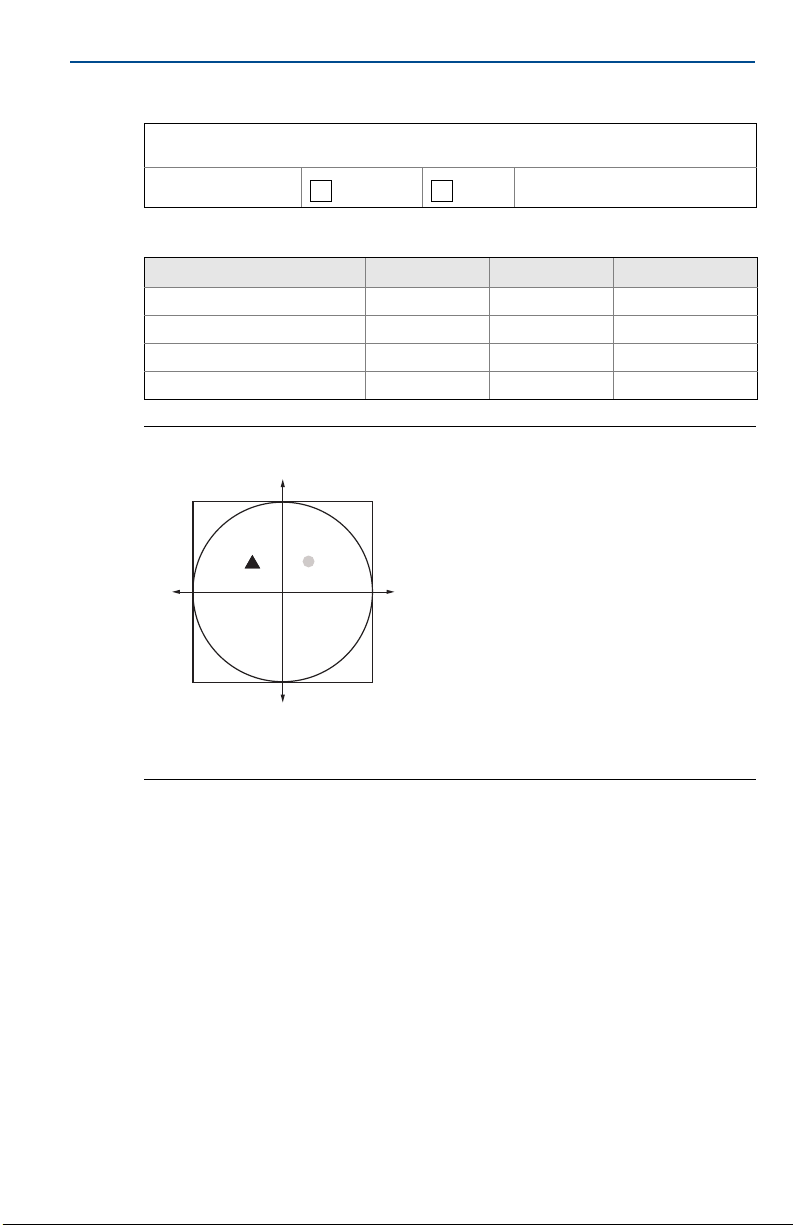

+Y

-Y

+X

-X

BA

2.3 Vessel details

Internal structure like: Ladder, pipe, window, screw, door, rail, support beam or any other obstacle

which is visible to the 5708 scanner. Drawings should be available.

Internal movement: YES NO If yes, please describe:

2.4 Rosemount 5708 and filling location

X Y Offset from roof

1st Rosemount 5708 location:

2nd Rosemount 5708 location:

3rd Rosemount 5708 location:

Filling location:

Figure 1. Rosemount 5708 and Filling Port Locations

Quick Start Guide

A. Rosemount 5708 (X1, Y1)

B. Fill (X2, Y2)

When mounting more than a single Rosemount 5708 (e.g. in a system of

multiple devices), the location of all devices must be specified.

When the application has more than a single filling point, all other filling

points must be specified as well.

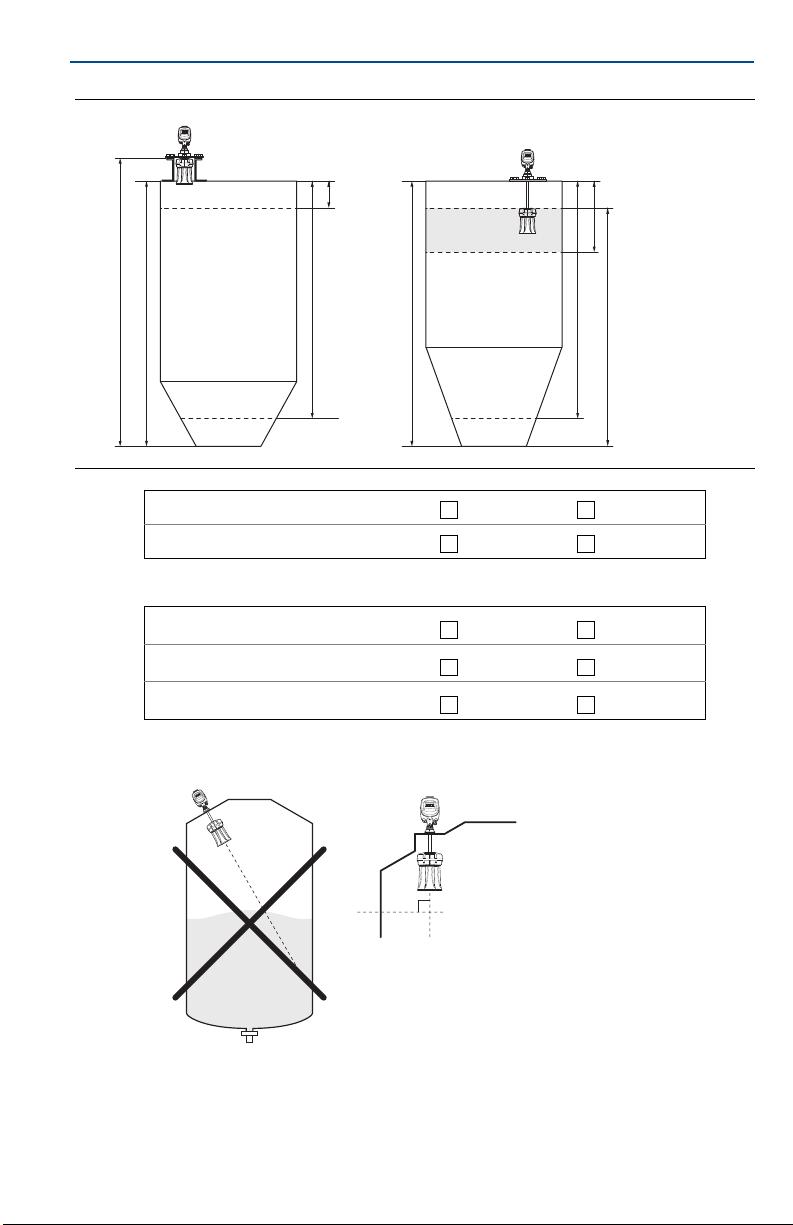

Full and empty calibration

Full and empty calibration levels are measured from the top of the vessel.

The full and empty calibration levels represent the 20 mA (100%) and 4 mA

(0%) of the volume respectably.

The Rosemount 5708 has a 20 in. (0.5 m) dead zone starting from the top

part of the antenna assembly.

5

Page 6

Quick Start Guide

Full

Calibration

Empty Calibration

Total Vessel Height

Empty Calibration

Full

Calibration

Total Vessel Height

Scanner Height

Scanner Height

D

90°

Figure 2. Full and Empty Calibration in Rectangular and Cylindrical Vessels

Full calibration: ft m

Empty calibration: ft m

2.5 Application process

July 2017

Maximum filling rate: lbs/hour tons/hour

Maximum emptying rate: lbs/hour tons/hour

Total capacity when vessel is full: lbs tons

2.6 Mounting location

Mount Rosemount 5708 perpendicular to the ground.

6

Page 7

July 2017

Minimum

24 in. (600 mm)

Minimum

24 in. (600 mm)

Minimum 0.4 in. (10 mm) for standpipe mounting

Quick Start Guide

Keep necessary distance from side wall.

Keep necessary distance from filling points.

Make sure there is no obstacle below the device.

In the case of standpipe mounting, assemble and position the Rosemount

5708 at a height that leaves at least 0.4 in. (10 mm) below the standpipe for

the antenna end to protrude.

7

Page 8

Quick Start Guide

Note

Make sure the hole diameter (D) in the center is

2.05 in. (52 mm).

D

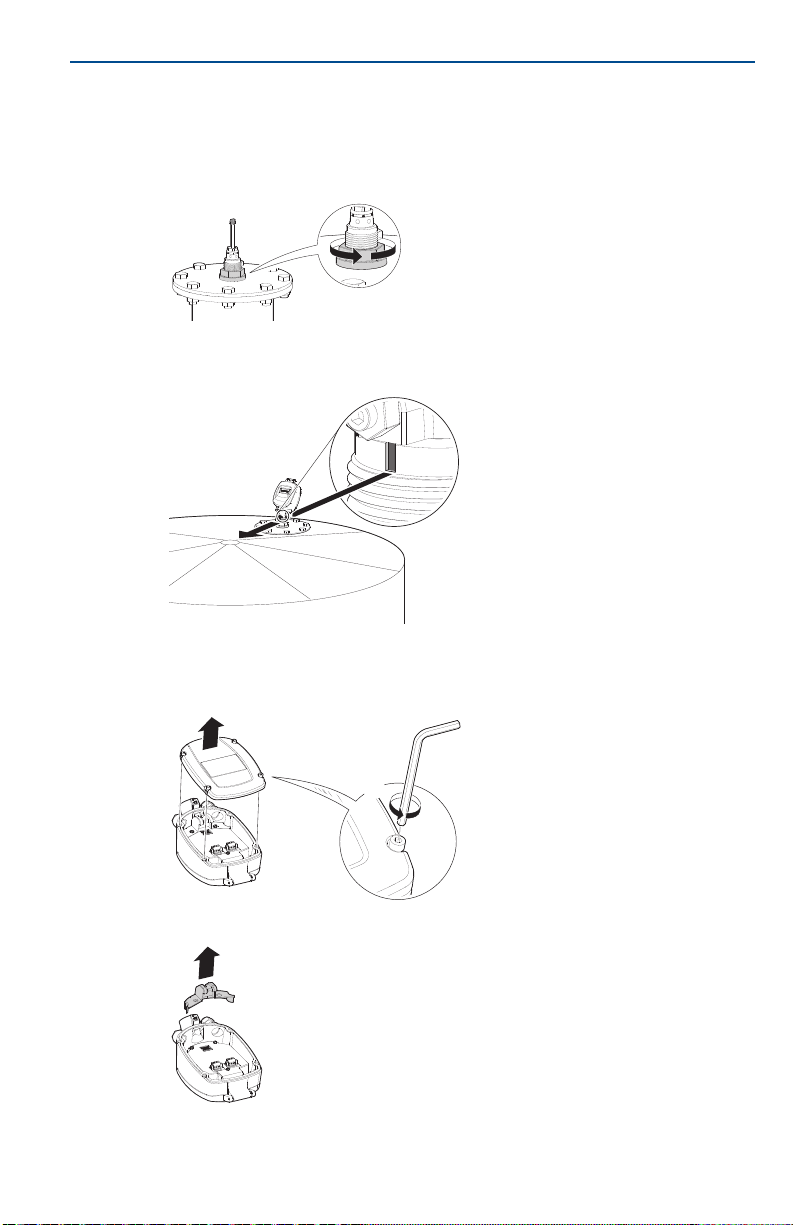

3.0 Physical mounting

Step 1: Check power and cables

1. Check the 24 Vdc with a voltmeter.

2. Check the resistance of the data communication lines.

3. Verify 60 Ω of resistance when connecting the 120 Ω resistors at both ends.

Step 2: Install the mounting plate

1. Verify the O-rings on the neck tube are in place.

2. Remove the nut from the neck tube.

July 2017

3. Place the mounting plate over the neck tube.

4. Replace the nut and tighten it over the neck tube to the mounting plate.

8

Page 9

July 2017

4x

Hex key (4 mm)

Quick Start Guide

5. Lower the antenna and mounting plate into the fitting location on the silo.

6. Bolt the mounting plate onto the flange of the silo.

Step 3: Rotate antenna toward silo center

1. Slightly loosen the nut that connects the antenna with the mounting plate.

2. Rotate the antenna. The notch on the top of the thread must be directed

toward the center of the silo.

3. Tighten nut.

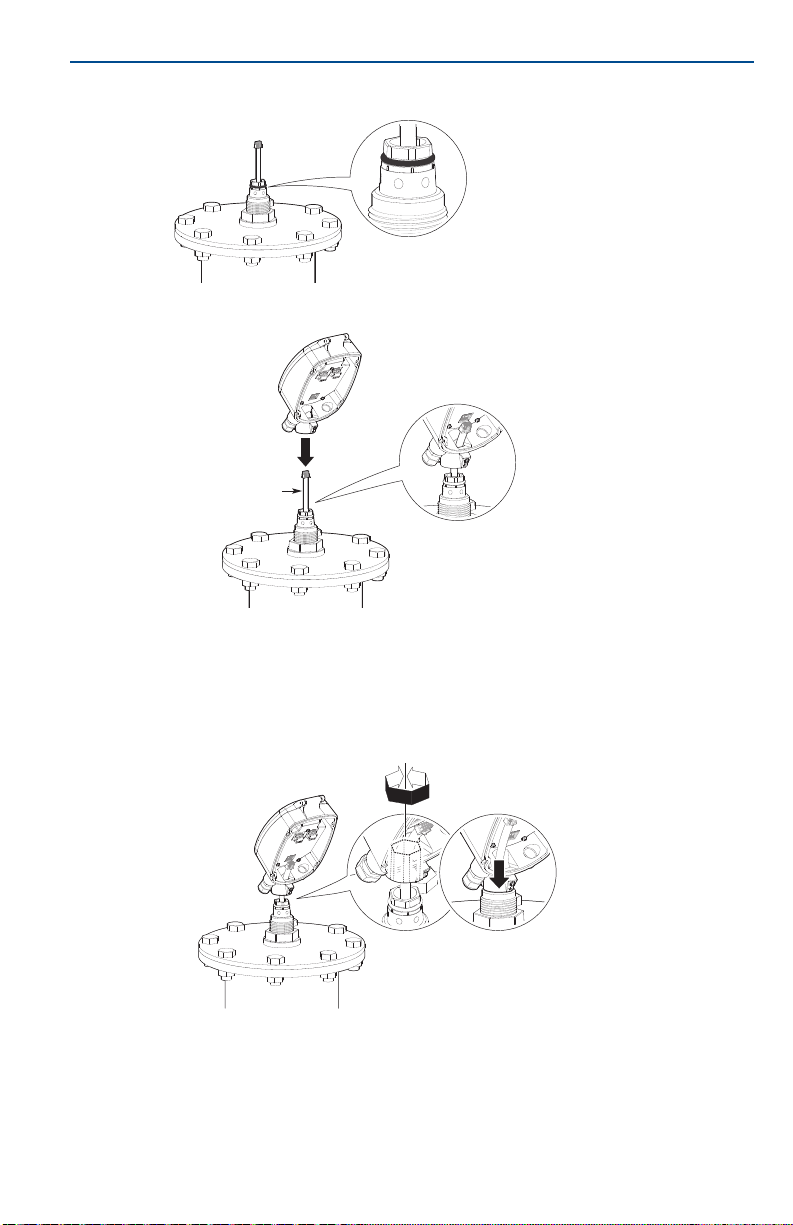

Step 4: Install head

1. Remove the rear panel.

2. Remove the cable clamp.

9

Page 10

Quick Start Guide

Antenna cable

3. Verify the presence of the O-ring on the tube neck.

4. Gently insert the antenna cable through the head.

July 2017

10

5. Insert the head onto the neck tube.

a. Rotate the head to the desired direction. The head may be installed in six

different positions. It is highly recommended to direct the head towards

the center of the silo.

b. Make sure to push the head all the way down until it fully contacts the top

of the neck tube.

Page 11

July 2017

Hex key

(4 mm)

Open wrench

(13 mm)

Quick Start Guide

6. Tighten the front screw.

7. Remount the cable clamp.

8. Gently connect the antenna cable connector. Make sure the latch is clicked

and locking the connector.

11

Page 12

Quick Start Guide

4 in. (100 mm)

0.4 in.

(10

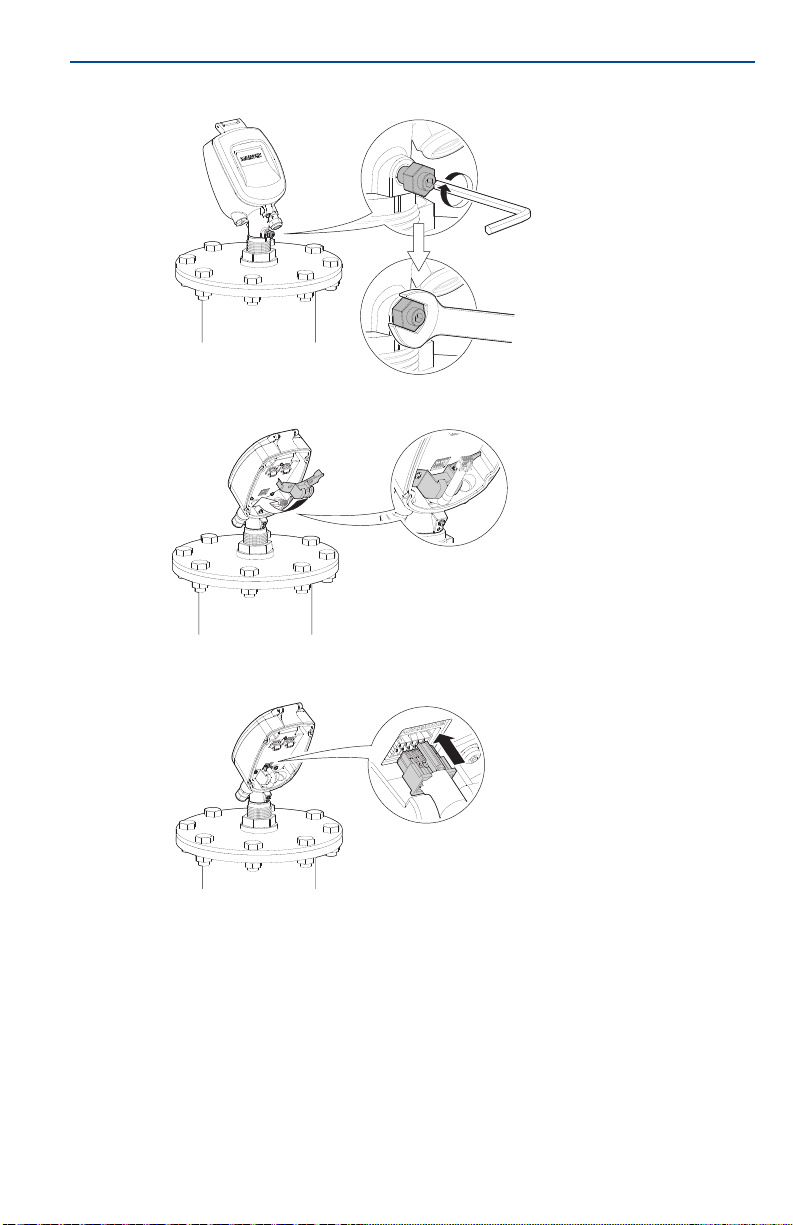

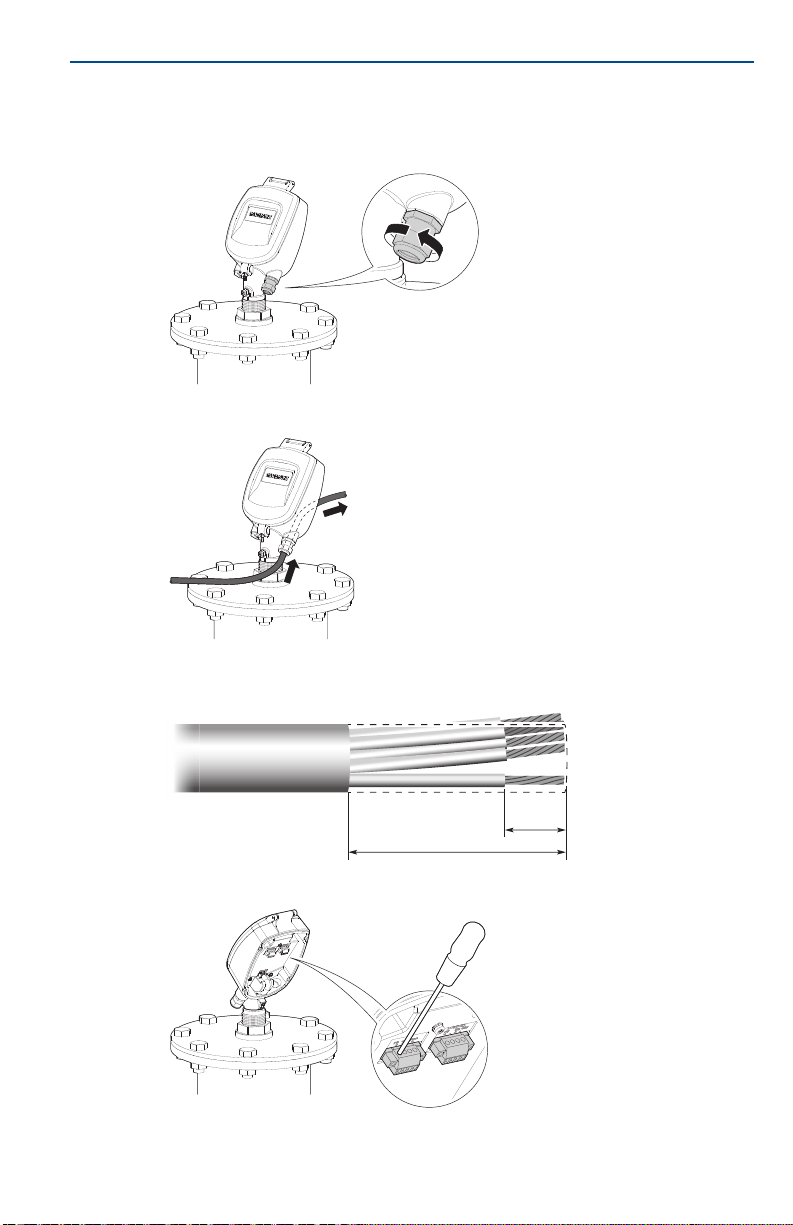

Step 5: Wire the Rosemount 5708

1. Verify the power supply is disconnected.

2. Loosen the compression nut of the cable gland entry.

3. Insert the cable into the head.

July 2017

12

4. Remove approximately 4 in. (100 mm) of the cable mantle and strip

approximately 0.4 in. (10 mm) off the edge of each conductor.

5. Loosen the terminal block screws located inside the head.

Page 13

July 2017

-

+

RS-485/Modbus RTU

communication terminals

4-20 mA

communication terminals

-

+

Feed in power supply

20-32 Vdc+-

Note

When connecting the last Rosemount 5708 in the chain, a 120 Ω resistor must be

connected as well. Check polarity of the power entity before connecting the device.

External ground screw

Note

An internal cable grounding connection is also possible using the inner connection as

shown below.

Internal ground screw

Quick Start Guide

6. Connect the cable wires according to the wiring diagram. See page 14 for

different connection methods.

7. Connect the external ground terminal.

The Rosemount 5708 must be grounded electrostatically.

For internal grounding, use the power cable ground.

For external grounding, use the earth potential equalization of the plant.

13

Page 14

Quick Start Guide

250 Ω

24DC

A

C

B

D

E

F

G

8. Tighten the compression nut over the cable gland entry opening.

9. Attach the rear panel back to position and tighten the screws.

4x

Step 6: Different connection methods

Use RS-485 or 4-20 mA connection for communication.

Figure 3. Wiring the 4-20mA to Smart Wireless THUM™ Adapter

July 2017

A. Rosemount 5708 housing ground shield E. White

B. THUM Adapter F. Bl a ck

C. Green G. Red

D. Yellow

14

Page 15

July 2017

Rosemo unt

5708 1

RS-485 (+)

120 Ω

RS-485 (-)

RS-485 (+)

120 Ω

RS-485 (-)

Rosemo unt

5708 2

Rosemo unt

5708 3

Rosemo unt

5708 n

Active

Passive

4-20 mA

PLC / Controller

Navigates back within a function menu.

Continuous 3 second press exits to the default screen.

Navigates upwards in the navigation list.

Navigates right within a function.

Navigates downwards in the navigation list.

Navigates left within a function.

Navigates to the right when within a function group.

Stores a value once configured.

Figure 4. Rosemount 5708 Connection

Figure 5. 4-20 mA Connection

Quick Start Guide

This type of connection is ac tive and not passive, hence the device is the active module and the PLC should

be the passive module.

4.0 Configuration using the LCD display

4.1 On-board configuration

The Rosemount 5708L can be completely configured via the LCD display.

For the Rosemount 5708V and 5708S, the Rosemount 3DVision software is

required.

Figure 6. User Interface

ESC

E

15

Page 16

Quick Start Guide

Rosemount

5708LNN

Initialization

Initialization

Please Wait...

m

ft

<tag name>

3.45m Avg Dist.

█████████████▒▒▒▒▒

M

July 2017

1. Connect power and open the front

cover.

A self-test will start and run for about

30 seconds the display remains blank

during this time.

2. After initialization, the version screen

appears.

According to the factory default

settings, after power initiation or

scanner restart, a screen prompts for

configuration.

In the main menu, select Basic

Settings.

3. Use the / keys to switch

between the options.

Press to select and continue with

E

the settings or to exit to the

ESC

main screen.

4. When the startup process is complete,

the following screen appears showing

the current average distance

measurement.

The top line displays the tag name. By

default, this line is empty.

Press to enter the main menu.

E

16

Page 17

July 2017

<tag name>

3.45m Avg Dist.

█████████████▒▒▒▒▒

M

E

Basic Settings

Advanced Settings

False Echo Mapping

Polling Address

Polling Address

0

0

ESC

<tag name>

3.45m Avg Dist.

█████████████▒▒▒▒▒

M

Basic Settings

Advanced Settings

False Echo Mapping

Polling Address

4.2 Setting the polling address

Setting the device address is mandatory when multiple devices are connected

over an RS-485 Multidrop (daisy chain). Set the addresses prior to use of the

Rosemount 3DVision software.

Quick Start Guide

For the Rosemount 5708V and 5708S, only polling address configuration is

done using the LCD display.

The rest of the configuration is completed with the Rosemount 3DVision

software.

1. From the main screen, press the key

to enter the main menu.

2. In the main menu, use the / keys

to scroll down to Polling Address.

Press to switch to the Polling

E

Address configuration screen.

3. Use the key to switch between the

two digits. Use the key to modify

the value.

The default polling address is 00. The

polling address ranges from 00 to 63.

E

Press to store the modified address

and to exit to the main screen.

4.3 Configuring the Rosemount 5708L

Basic Settings configuration

1. From the main screen, press the

key to enter the main menu.

2. In the main menu, use the /

keys to scroll down to Basic Settings.

Press to switch to the Basic

E

Settings screen.

E

17

Page 18

Quick Start Guide

m

ft

Set Vessel Height

2

0.000 m

Cylindrical Vessel

Rectangular Vessel

Set Vessel Diameter

1

0.000 m

Set Scanner Height

2

0.000 m

Scanner Distance

From Center

0

0.000 m

E

July 2017

3. Set the distance units, either meters

(m) or feet (ft).

4. Set Vessel Height from the vessel

bottom edge to the vessel top edge.

Use the key to switch between the

two digits. Use the key to modify

the value.

5. Select the vessel shape, either

Cylindrical or Rectangular.

Use the / keys to switch

between the options. Press to

E

continue.

a. If Cylindrical is selected, set

vessel diameter.

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

18

b. Set Scanner Height from the

bottom edge of the vessel to the

scanner’s mounting plate (point

above the antenna).

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

c. Set Scanner Distance from

Center.

Use the key to switch between

the two digits. Use the key to

modify the value. Press to exit

to the main screen.

Page 19

July 2017

Set Vessel Width

0

10.000 m

Set Vessel Length

0

10.000 m

Set Scanner Height

2

0.000 m

Scanner X To Center

±000.00 m

Scanner Y To Center

±000.00 m

Quick Start Guide

6. If Rectangular is selected, set vessel

width first (dimension on the x-axis).

a. Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

b. Set Vessel Length (dimension on

the y-axis).

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

c. Set Scanner Height from the

bottom edge of the vessel to the

scanner’s mounting plate (point

above the antenna).

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

d. Set the scanner’s distance from

the x-axis, see Figure 1 on page 5.

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

e. Set the scanner’s distance from

the y-axis, see Figure 1 on page 5.

Use the key to switch between

the two digits. Use the key to

modify the value. Press to exit

E

to the main screen.

19

Page 20

Quick Start Guide

<tag name>

3.45m Avg Dist.

█████████████▒▒▒▒▒

Menu

E

Basic Settings

Advanced Settings

False Echo Mapping

Polling Address

Set Distance

To Full Calibration

0

0.500 m

Set Distance

To Empty Calibration

2

0.000 m

Set Adaptor Angle

0

0

Advanced Settings configuration

After configuring the Basic Settings, perform Advanced Settings configuration.

July 2017

1. From the main screen, press the

key to enter the main menu.

2. In the main menu, scroll down to

Advanced Settings, using the key.

Press to switch to the Advanced

E

Settings configuration screen.

3. Set the distance from the mounting

plate (top of the scanner’s antenna) to

the Full calibration point/100% level

point.

Use the key to switch between the

two digits. Use the key to modify

the value. Press to continue.

E

4. Set the distance from the mounting

plate (top of the scanner’s antenna) to

the Empty calibration point/0% level

point.

Use the key to switch between the

two digits. Use the key to modify

the value. Press to continue.

E

20

5. Press to keep the default setting.

E

Note: if using an angle adaptor, set the

angle value.

Use the key to switch between the

two digits. Use the key to modify

the value. Press to continue.

E

Page 21

July 2017

Slow Process

Regular Process

Fast Process

Celsius

Fahrenheit

E

Distance

Level

Volume

Analog Output

SNR

<tag name>

3.45m Avg Dist.

█████████████▒▒▒▒▒

Menu

Basic Settings

Advanced Settings

False Echo Mapping

Polling Address

Quick Start Guide

6. Set the process rate using the key.

Press to continue.

E

Make sure to always use Regular

Process.

For the Slow and Fast Process options,

contact your local customer service.

7. Set the temperature units using the

key. Press to continue.

8. Set the displayed parameter desired

for the main screen using the key.

Press to exit to the main screen.

E

False Echo Mapping

When the configuration is finished, set False Echo Mapping.

1. From the main screen, press the

E

key to enter the main menu.

2. In the main menu, scroll down to False

Echo Mapping, using the key.

Press to switch to the False Echo

E

Mapping configuration screen.

21

Page 22

Quick Start Guide

Map False Echoes

Reset Mapping

Distance To Map

False Echo

0

0.000 m

Fal se Ec ho Area

Decline Mapping

Approve Mapping

E

Decline Mapping

Approve Mapping

E

July 2017

3. Select Map False Echoes for

automatically mapping all the false

echoes up to a certain distance.

Or select Reset Mapping for deleting

the stored mapped false echoes from

the memory of the scanner.

Use the key to go down the list.

Press to continue.

E

a. If Map False Echoes is selected,

set the distance from the top of

the antenna assembly to the end

of the scanning point. Always

make sure to map false echoes

above material level. The

recommended level is 3 ft. (1 m)

above actual material level.

Use the key to switch between

the two digits. Use the key to

modify the value. Press to

E

continue.

b. Approve or decline the false echo

mapping operation.

Use the key to go down the

list. Press to continue.

22

c. If Reset Mapping is selected,

approve or decline the operation.

Use the key to go down the

list. Press to continue.

Page 23

July 2017

Quick Start Guide

5.0 Configuration using Rosemount 3DVision

5.1 Installing the Rosemount 3DVision software

The software is comprised of two components: a server and a client. For initial

configuration, it is recommended to install both the server and the client on the

same computer. However, it is possible to install the Rosemount 3DVision

Server and Client on separate computers and connect to them accordingly.

1. Insert the flash drive into the USB port.

2. Select Install Rosemount 3DVision and follow the on-screen instructions.

If the installation program does not start automatically, run Installer.exe

from the flash.

5.2 Starting Rosemount 3DVision

1. Double-click the Rosemount 3DVision desktop icon .

After a few seconds, the Rosemount 3DVision Server Connection window

appears.

2. Select Device Configuration (default) to start configuration.

23

Page 24

Quick Start Guide

3. Set the correct connection type, polling address, and serial port. Select

Connect.

After selecting the Connect button, the software automatically connects

and downloads the parameters from the Rosemount 5708.

4. After the connection has been made, Configuration Wizard appears:

a. Step 1/4: Set up general information and vessel dimensions.

b. Step 2/4: Set up device position.

c. Step 3/4: Set up filling points.

d. Step 4/4: Set up full and empty calibration. Select Finish to complete

July 2017

vessel configuration.

5.3 Performing Echo Curve Analysis

This step should only be performed if the distance given by the Rosemount is

incorrect.

When first configuring the Rosemount 5708, it is recommended to perform

Echo Curve Analysis. Using the Echo Curve Analysis it is possible to determine if

any of the advanced parameters need additional changes.

24

Page 25

July 2017

On the Device menu, select Echo Curve Analysis. Then make sure the

check-box is checked, then select the Start button.

Once the Echo Curve Analysis is complete, the echo curve window will pop up.

This function is also available via Device > Echo Curve Analyze Viewer.

5.4 Performing False Echo Mapping

With this option it is possible to perform a false echo mapping on any of the

beams to ignore false echoes inside the vessel caused by internal objects or

other interferences.

1. On the Device menu, select Device False Echo Mapping.

2. Set the From and To distances to perform false echo mapping.

3. Select the Start Scanning button.

Quick Start Guide

25

Page 26

Quick Start Guide

6.0 Post installation procedures

1. Perform hand measurement to the material.

2. Compare data with the result of distance measurement performed by the

Rosemount 5708:

a. Reference point for measurements and comparisons is the top part of the

antenna assembly.

b. Test the device while silo is idle.

c. Measure as close to the Rosemount 5708 as possible.

d. In some models, the device has minimum and maximum values for

distance. Check if the hand dip is between these measurement.

3. Coordinate filling and emptying processes.

a. Follow the Rosemount 5708 measurements during the process.

b. Check and compare distance.

c. Follow the log trends in Rosemount 3DVision.

4. Perform echo curve analysis and false echo mapping. For detailed

information, see the Rosemount 5708 Reference Manual

5. Adjust advanced parameters. For more information, see the Rosemount

5708 Reference Manual.

July 2017

.

26

Page 27

July 2017

+ -

PS OUT

Display

+ -

PS OUT

Display

++--

PS IN 4...20mA

+ -

RS-485 PS IN 4...20mA RS-485

++-- + -

++--

PS IN 4...20mA

+ -

RS-485

++--

PS IN 4...20mA

+ -

RS-485

Convert

120 Ω

resistor

PLC / DCS / Display

4-20 mA is a 2 wire,

non-loop powered,

active device connection

24 Vdc

power

supply

Rosemount 3DVision Server

120

Ω resistor

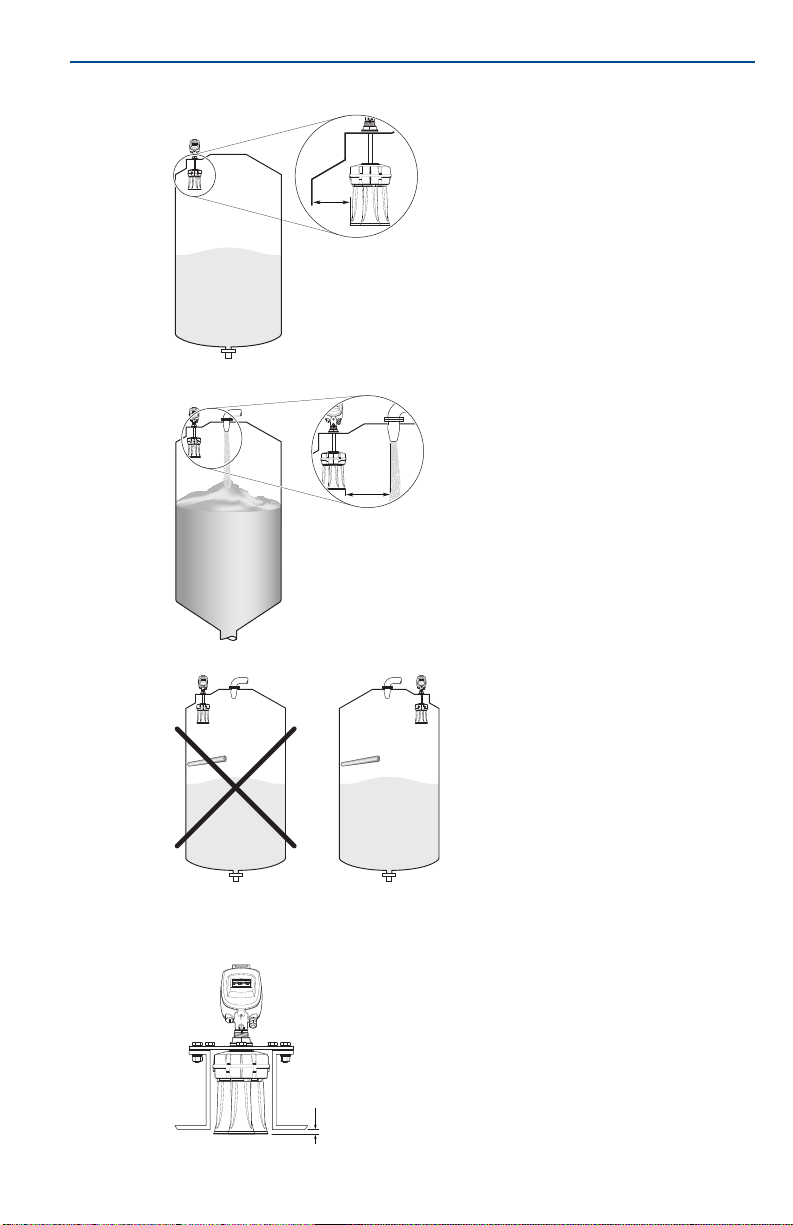

7.0 Rosemount 5708S in a system

7.1 System components

Multiple units of Rosemount 5708S

Quick Start Guide

7.2 Physical mounting

7.3 Wiring

Rosemount System Controller

1. Install the devices as written in “Physical mounting” on page 8.

2. Repeat installation steps until all are installed.

Power

A single 24 Vdc power supply is for all devices within the system.

27

Page 28

Quick Start Guide

RS-485 communication

Every Rosemount 5708 should be connected in daisy chain. For more

information, see “Rosemount 5708 Connection” on page 15.

4-20 mA connection

Since every Rosemount 5708 in the daisy chain outputs the same data, it does

not matter which device the 4-20 mA output is derived from. The 4-20 mA

output represents the volume calculated by devices in the vessel.

Grounding

For grounding information, see page 13.

7.4 On-board configuration (Rosemount 5708S)

1. Configure polling addresses only.

2. Make sure each device has a different polling address and at least one has

polling address 00.

For detailed information on polling address configuration, see “Setting the

polling address” on page 17.

7.5 Configuring using Rosemount 3DVision

For detailed information on configuring the Rosemount 5708 and Rosemount

System Controller, refer to the Rosemount 5708 Reference Manual.

7.6 Maintenance

July 2017

28

Preventive maintenance procedure

The following periodic maintenance procedure is recommended for keeping the

Rosemount 5708 in proper operating conditions and preventing unnecessary

malfunctioning which may be caused by environmental factors during time:

Clean the interior part of the antennas (see details below).

Visually check and ensure the communication and power cables are in good

condition and are not damaged.

Check and ensure proper sealing of cable entry openings.

Open the rear side of the Rosemount 5708 head and ensure absence of

wetness.

Antenna cleaning guidelines:

Disconnect power to the Rosemount 5708.

Disassemble the mounting plate and carefully pull out the entire Rosemount

5708.

Use a brush or wet cloth for the purpose of cleaning.

As necessary, water can be used for cleaning.

Avoid usage of sharp tools such as screwdrivers for cleaning. Such tools may

damage the membranes.

Preventive maintenance frequency

The frequency of the maintenance procedure is subject to the conditions and

the type of material stored in the vessel. In the case of materials such as salt,

sugar, calcium carbonate etc., treatments should be more frequent.

Page 29

July 2017

8.0 Product certifications

Rev 1.2

8.1 European Directive Information

A copy of the EC Declaration of Conformity can be found on page 35. The most recent

revision of the EC Declaration of Conformity can be found at Emerson.com/Rosemount

8.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and

Health Administration (OSHA).

8.3 North America

I5 US and Canada Intrinsic Safety (IS)

Certificate: 3052166

Standards: FM Class 3600 - 2011, FM Class 3610 - 2010, FM Class 3810 - 2005,

ANSI/IEC 60529 - 2004, CSA Std. C22.2. No. 25- 09,

CSA Std. C22.2. No.157-92, CSA Std. C22.2 No. 1010 - 04, CAN/CSA

E61241-1-1 - 2010

Markings: IS CL I, II DIV 1, GP C, D, E, F, G when connected per Rosemount

drawing 05708-1900; T4(-40 °C <

modules with serial number 836xxxxxxx:

Supplies - Terminals J5.1 (+), J5.2 (GND) U

= 3 W, Ci = 8 nF, Li = 0

P

i

Interfaces - Terminals J5.4 (4 - 20 mA signal),

J5.3 (GND common with J5.2): U

= 1.1 W, Ci = 8 nF, Li = 0 μH

P

i

RS-485 - Terminals J6.3 (P), J6.4 (N): U

I

= 651 mA, Pi = 1.06 W, Ci = 0 nF, Li = 0 μH

i

Approval valid for HART and Modbus

= 10.5 V, Ii = 106 mA,

i

Quick Start Guide

Ta < +85 °C); IP 6XFor electronic

= 24 V, Ii = 125 mA,

i

= 6.51 V,

i

®

options.

.

Special Conditions for Safe Use (X):

1. The 3D Solids Scanner is only for use with electronics unit marked with serial number

836xxxxxx, as these units are for use with the 3D Solids ambient temperature range.

2. Part of the enclosure is constructed of plastic. To prevent the risk of electrostatic

sparking, the plastic surface should be cleaned with a damp cloth.

29

Page 30

Quick Start Guide

8.4 Europe

I1 AT EX In trins ic S afet y

Certificate: BVS14ATEXE060X

Standards: EN60079-0:2012, EN60079-11:2012

Markings: II 2 G Ex ib [ia] IIB T4 Gb (-40 °C <

Tabl e 1. Inte rface P ara meter s

Parameter 4-20 mA RS-485

Volt age U

Current I

Power P

Capacitance C

Inductance L

Capacitance C

Inductance L

L

/ R

o

o

Characteristics Trapezoid Linear

Terminals J5.3 (4-20 mA), J5.4 (GND) J6.3 (+), J6.4 (RTN)

Table 2. Supply Circuit Parameters

Parameter 4-20 mA Output

Volt age U

Current I

Power P

Capacitance C

Inductance Li/L

Lo / Ro ratio

Characteristics

Ter mi na l s

II 1/2 D Ex ib [ia] IIIC T110 °C Da/Db (-40 °C <

/ U

i

/ I

i

o

/ P

i

o

/ U

i

i

/ P

i

o

10.5 V 6.51 V

o

106 mA 2 x 651 mA

1.1 W 2 x 1.06 W

8 nF 0 nF

i

~0 mH 0 mH

i

16 μF 2 x 285 μF

o

80 μH 83.9 μH

o

17.77 μH/Ω 67.12 μH/Ω

24 V N/A

o

Same values as the

interconnected IS power supply

3 W N/A

/ C

8 nF

i

o

~0 mH

o

N/A

N/A

J5.1 (+), J5.2 (GND) N/A

Ta < +85 °C)

Ta < +85 °C)

N/A

Same values of the

interconnected IS power supply

reduced by C

Same values of the

interconnected IS power supply

reduced by L

Same values of the

interconnected IS power supply

reduced by L

Same values as the

interconnected IS power supply

i

i

i

July 2017

30

Special Condition for Safe Use (X):

1. Dust application:

The installation of the 3D Solids Scanner or of the Antenna Unit of models providing

head separation in the wall to areas requiring EPL Da (apparatus category 1D)

equipment shall provide a degree of protection IP6X according to EN60529 and shall

be carried out in such a way, that all metallic parts are integrated in the local

equipotential bonding.

Manufacturer’s technical information related to use of the 3D Solids Scanner in

contact with aggressive/corrosive media and to avoid any risk of mechanical impact

shall be observed.

Page 31

July 2017

8.5 International

I7 IECEx Intrinsic Safety

Certificate: IECEx BVS 15.0042X

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ib [ia] IIB T4 Gb (-40 °C <

Ex ib [ia] IIIC T110°C Da/Db (-40 °C <

Table 3. Interface Parameters

Parameter 4-20 mA RS-485

Volta ge U

Current I

Power P

Capacitance C

Inductance L

Capacitance C

Inductance L

L

Characteristics

Ter mi na l s

Table 4. Supply Circuit Parameters

Parameter Input Output

Volta ge U

Current I

Power P

Capacitance C

Inductance Li/L

Lo / Ro ratio

Characteristics

Ter mi na l s

/ U

i

/ I

i

o

/ P

i

o

/ R

o

o

10.5 V 6.51 V

o

106 mA 2 x 651 mA

1.1 W 2 x 1.06 W

8 nF 0 nF

i

~0 mH 0 mH

i

16 μF 2 x 285 μF

o

80 μH83.9 μH

o

17.77 μH/Ω 67.12 μH/Ω

Tra pe zo id Li n ea r

J5.3 (4-20 mA), J5.4 (GND) J6.3 (+), J6.4 (RTN)

/ U

i

i

/ P

i

o

26.6 V N/A

o

Same values as the

interconnected IS power supply

3 W N/A

/ C

8 nF

i

o

~0 mH

o

N/A

N/A

J5.1 (+), J5.2 (GND) N/A

Ta < +85 °C)

Ta < +85 °C)

Quick Start Guide

N/A

Same values of the interconnected

IS power supply reduced by C

Same values of the interconnected

IS power supply reduced by L

Same values of the interconnected

IS power supply reduced by L

Same values as the interconnected

IS power supp ly

i

i

i

Special Condition for Safe Use (X):

1. Dust application:

The installation of the 3D-Solids Scanner or of the Antenna Unit of models providing

head separation in the wall to areas requiring EPL Da equipment shall provide a degree

of protection IP6X according to IEC 60529 and shall be carried out in such a way, that

all metallic parts are integrated in the local equipotential bonding. Manufacturer's

technical information related to use of the 3D Solids Scanner in contact with

aggressive/corrosive media and to avoid any risk of mechanical impact shall be

observed.

31

Page 32

Quick Start Guide

8.6 China

I3 China Intrinsic Safety

Certificate: GB3836.1-2010, GB3836.4-2010, IEC61241-0 - 2004,

Markings: Ex ib/ia IIB Gb T4

Special Condition for Safe Use (X):

1. The installation of the product shall provide a degree of protection IP6X according to

GB4208-2008, and in such a way that all metallic parts are integrated in the local

equipotential bonding.

8.7 Brazil

I2 INMETRO Intrinsic Safety

Certificate: UL-BR 15.0072X

Standards: ABNT NBR IEC 60079-0:2008 + Errata 1:2011,

Markings: Ex ib [ia] IIB T4 Gb (- 40 °C <

Special Condition for Safe Use (X):

1. Dust application:

The installation of the 3D Solids Scanner or of the Antenna Unit of models providing

head separation in the wall to areas requiring EPL Da (Zone 20) equipment shall

provide a degree of protection IP6X according to ABNT NBR IEC 60529 and shall be

carried out in such a way, that all metallic parts are integrated in the local equipotential

bonding.

Manufacturer's technical information related to use of the 3D Solids Scanner in contact

with aggressive/corrosive media and to avoid any risk of mechanical impact shall be

observed.

GB12476.4-2010

Ex ibD/iaD 21/20 T110 °C

ABNT NBR IEC 60079-11:2009

Ta < + 85 °C)

Ex ib [ia] IIIC T110 °C Da/Db (- 40 °C <

July 2017

Ta < + 85 °C)

32

Page 33

July 2017

8.8 EAC

IM Intrinsic Safety by TR CU 012/2011

Markings: 1Ex ib [ia] IIB T4 Gb X (-40 <

Ex ib [ia] IIIC T110 °C Da/Db X (-40 <

Table 5. Input parameters

Quick Start Guide

Tamb < 85 °C)

Tamb < 85 °C)

Parameters

Level of

protection

Vol tag e Ui = 24 V Uo = 24 V Ui = Uo = 10,5 V Ui = Uo = 6,51 V

Current I

Power Pi = 3 W Po = 3 W

Capacitance Ci 8 nF 8 nF мала

Capacitance CoN/A

Inductance Li Negligible Negligible Negligible

Inductance Lo N/A

Lo/Ro N/A

Characteristics N/A

Ter mi na l s J5.1 (+), J5.2 (GND) J6.1 (+), J6.2 (GND) J5.3 (4–20 mA), J5.4 (GND) J6.3 (+), J6.4 (RTN)

1. J5.1, J5.2 directly connected to J6.1, J6.2.

2. Same values as of the interconnected IS power supply.

3. Same values as of the interconnected IS power supply reduced by Ci, Li.

Input Output

Ex ib IIB /

Ex ib IIIC

(2)

i

Supply circuit Interface

Ex ib IIB /

Ex ib IIIC

(2)

I

o

(1)

(2)

(3)

(3)

(3)

(2)

4-20 mA RS 485

Ex ia IIB /

Ex ia IIIC

Ii = Io = 106 mA Ii = Io = 2 × 651 mA

Pi = Po = 1,1 W Pi = Po = 2 ×1,06 W

16 μF 2 × 285 μF

80 μH 83.9 μH

17.77 μH /Ohm 67.12 μH /Ohm

Tra pe zo id Linear

Ex ia IIB /

Ex ia IIIC

Special Conditions for Safe Use (X):

1. Level meter should be installed and operated in such a way that no danger of ignition

due to electrostatic discharge.

2. The instructions specified in the manual, eliminates the risk of corrosion and / or

mechanical action.

3. When the level meter, which provides separation of the head in areas requiring

protection level equipment Da, the degree necessary to provide protection for at least

IP6X in accordance with GOST 14254-96 and assembly should be performed so that all

metal parts have the same potential.

8.9 India

IW PESO Intrinsic Safety

Certificate: P351811/1

Standards: EN 60079-0: 2012, EN 60079-11: 2012

Markings: Ex ib {ia} IIB t4 Gb

33

Page 34

Quick Start Guide

8.10 Korea

IP KTL Intrinsic Safety

Certificate: 15-KA4BO-0298X - ex

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ib [ia] IIB T4 Gb, Ex ib [ia] IIIC T110C Da/Db

July 2017

For detailed information on configuring the Rosemount 5708 and Rosemount System

Controller, refer to the Rosemount 5708 Reference

Manual.

34

Page 35

July 2017

Figure 7. Rosemount 5708 Declaration of Conformity

Quick Start Guide

35

Page 36

Quick Start Guide

July 2017

36

Page 37

July 2017

9.0 Installation drawing

Figure 8. Wiring Drawing for Intrinsically Safe 3D Solids Scanner

Quick Start Guide

37

Page 38

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4570*

Quick Start Guide

00825-0100-4570, Rev CB

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasu rement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Term s

and Conditions of Sale page.

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

Modbus is a registered trademark of Gould Inc.

HART is a registered trademark of the FieldComm Group.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

July 2017

Loading...

Loading...