Rosemount 3300 Specifications

Product Data Sheet

00813-0100-4811, Rev HA

Rosemount 3300 Series

Guided Wave Radar Level and Interface Transmitter

October 2014

Accurate, direct level measurement virtually

unaffected by process conditions

Minimized maintenance with no moving

parts and no re-calibration required

Fewer process penetrations and reduced

installation costs with a MultiVariable

and interface transmitter

™

level

Easy installation and commissioning through

two-wire technology and user-friendly

configuration

Versatile and easy-to-use transmitter with

field proven reliability

High application flexibility with a wide range

of process connections, probe styles, and

accessories

Reference

pulse

Level

Interface

level

Rosemount 3300 Series

October 2014

Proven, reliable, and easy to use guided wave radar

Measurement principle

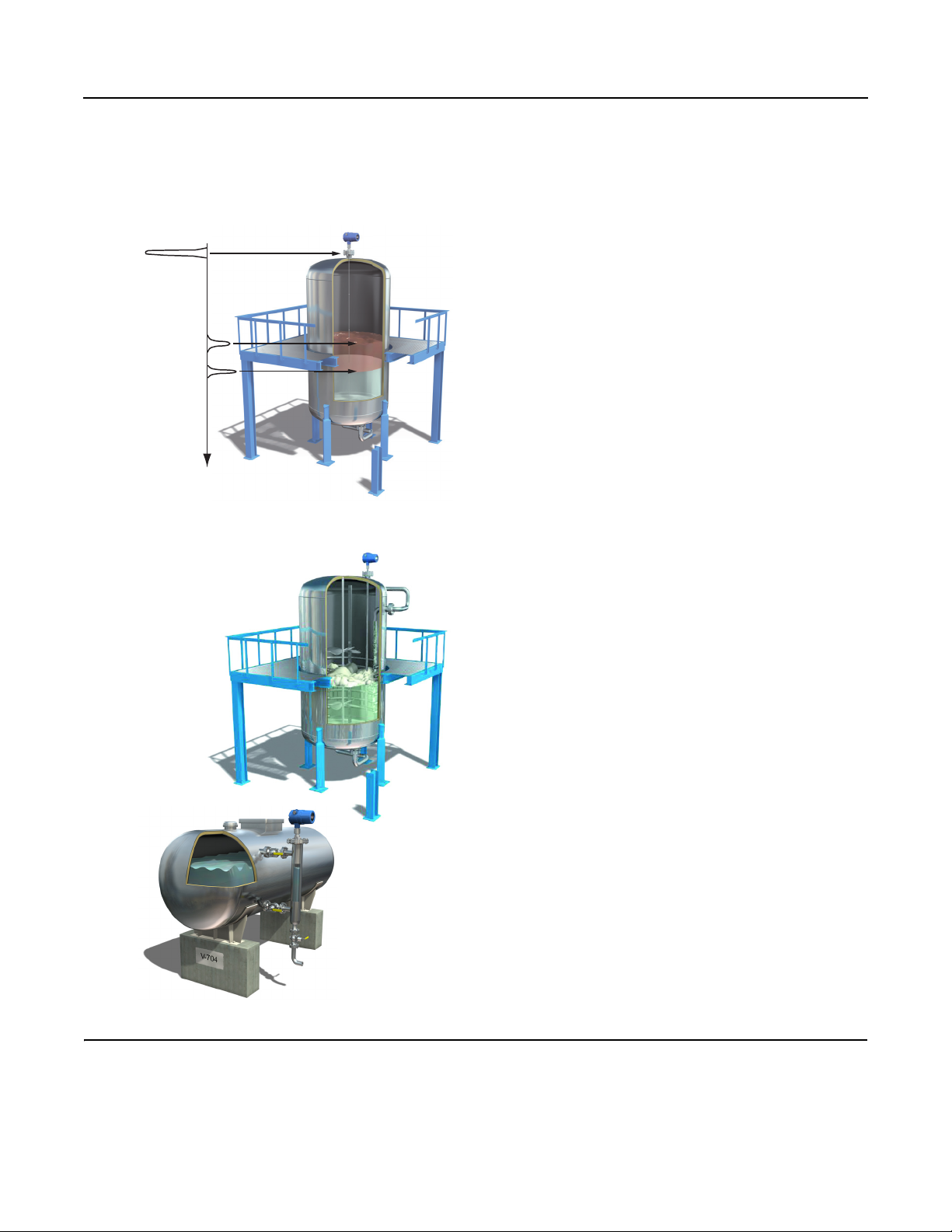

Low power, nano-second microwave pulses are guided down a

probe submerged in the process media. When a microwave

pulse reaches a media with a different dielectric constant, part

of the energy is reflected back to the transmitter.

The transmitter uses the residual wave of the first reflection for

measuring the interface level. Part of the wave, which was not

reflected at the upper product surface, continues until it is

reflected at the lower product surface. The speed of this wave

depends fully on the dielectric constant of the upper product.

The time difference between the transmitted and the reflected

pulse is converted into a distance, and the total level or interface

level is then calculated. The reflection intensity depends on the

dielectric constant of the product. The higher the dielectric

constant value, the stronger the reflection.

Guided wave radar technology

benefits

No moving parts and no re-calibration minimizes

maintenance

Direct level measurement means no compensation needed

for changing process conditions (i.e. density, conductivity,

temperature, and pressure)

Handles vapor and turbulence well

Suitable for small tanks, difficult tank geometry, and

interfering obstacles

Allows for easy upgrade

Top down installation minimizes risk for leakages

Contents

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

Product Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

www.rosemount.com

October 2014

High application flexibility

Electronics and cable

connections are located in

separate compartments,

providing safer handling and

improved moisture

protection

Modular design for reduced

spare parts and easy

replacement of the head

without opening the tank

Smart Wireless THUM Adapter enables access to online

configuration, multi-variable data, and diagnostics

Special 3300 features

Proven high reliability increases uptime

First 2-wire level and interface transmitter with field proven

reliability

More than 90,000 units installed

Advanced signal processing for reliable measurement

Accurate level unaffected by changing process conditions

High application flexibility

Suitable for most liquid storage and monitoring level and

interface applications

A wide selection of process connections and probe styles

Rosemount 3300 Series

Remote mounting, mounting bracket, Smart Wireless

THUM™ Adapter, HART

®

Tri-Loop™, and probe centering

discs accessories

External mounting using Rosemount 9901 high quality

chambers accessories

Robust design reduces costs and increases safety

Leakage prevention and reliable performance under

challenging conditions

Detachable transmitter head allows tank to remain sealed

Dual Compartment housing separates cable connections and

electronics

Easy installation and plant integration

Seamless system integration with HART, Modbus

62591 (WirelessHART

Allows for easy swap by matching existing tank connections

Cut-to-fit probes

®

) with the THUM adapter

®

, or IEC

Long lengths of rigid probes for robust measurements

becomes cost-effective and practical to ship, store and install

with the segmented probe option (code 4S)

Pre-configured or user-friendly configuration with wizard,

autoconnect, dielectric calculator, and on-line help

MultiVariable – measures simultaneously level and interface,

resulting in fewer process penetrations and reduces

installation and wiring cost

www.rosemount.com

3

Rosemount 3300 Series

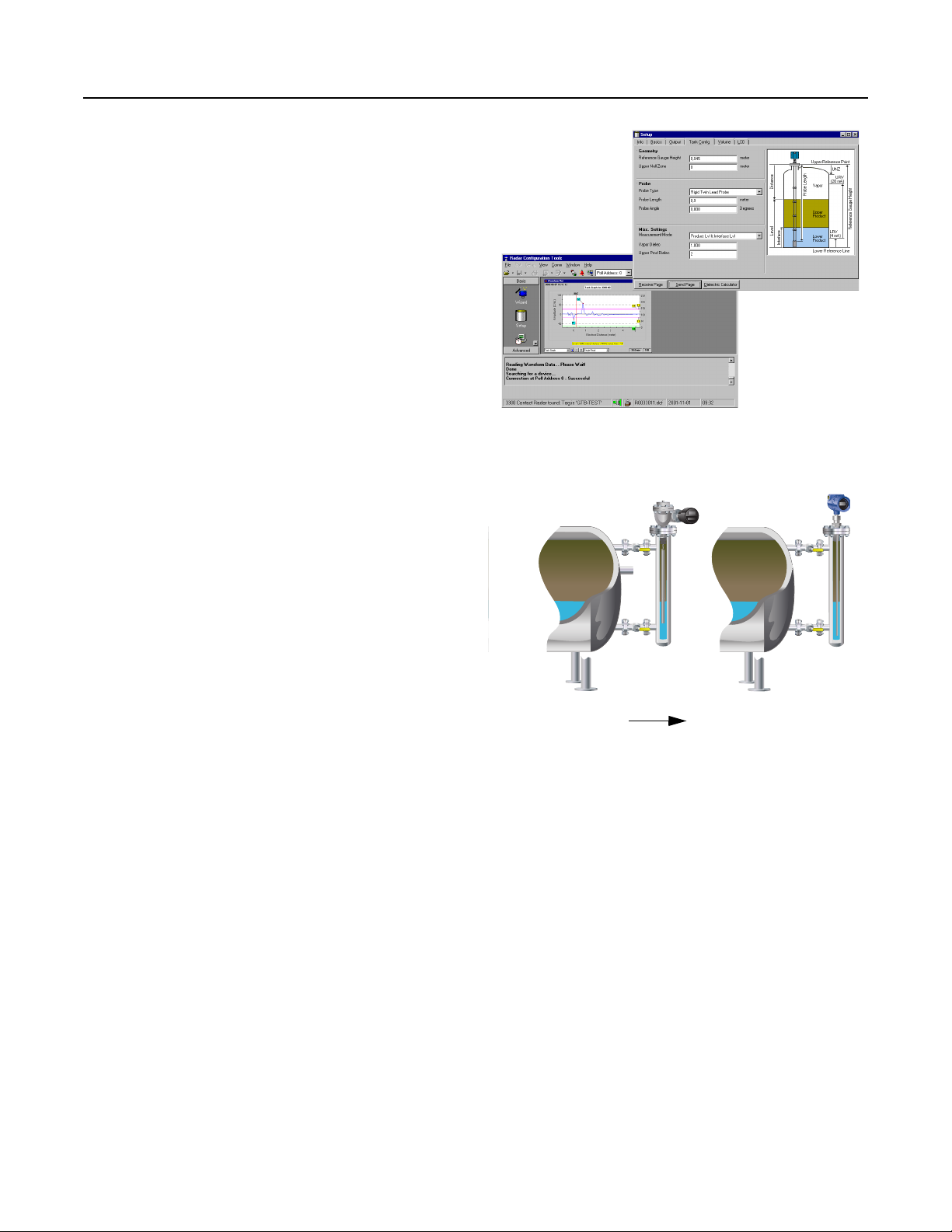

Radar Configuration Tool with installation wizard and waveform

plot possibilities provides easy configuration and service

From this... to this... in minutes

Minimized maintenance reduces cost

No mechanical moving parts that require maintenance

User-friendly software provides easy on-line troubleshooting

with echo curve tool and logging

Adjustments without opening tank

No re-calibration or compensation needed due to changing

process conditions

Easy replacement of old technology and best fit

for chambers

Less need for maintenance reduces costs and improves

measurement availability

Reliable measurement, independent of density, turbulence,

and vibrations

Unaffected by the mechanical configuration of the chamber

Wide range of options to find the best fit in existing chamber

or a complete assembly with Rosemount 9901 high quality

chambers

October 2014

4

www.rosemount.com

October 2014

Rosemount 3300 Series

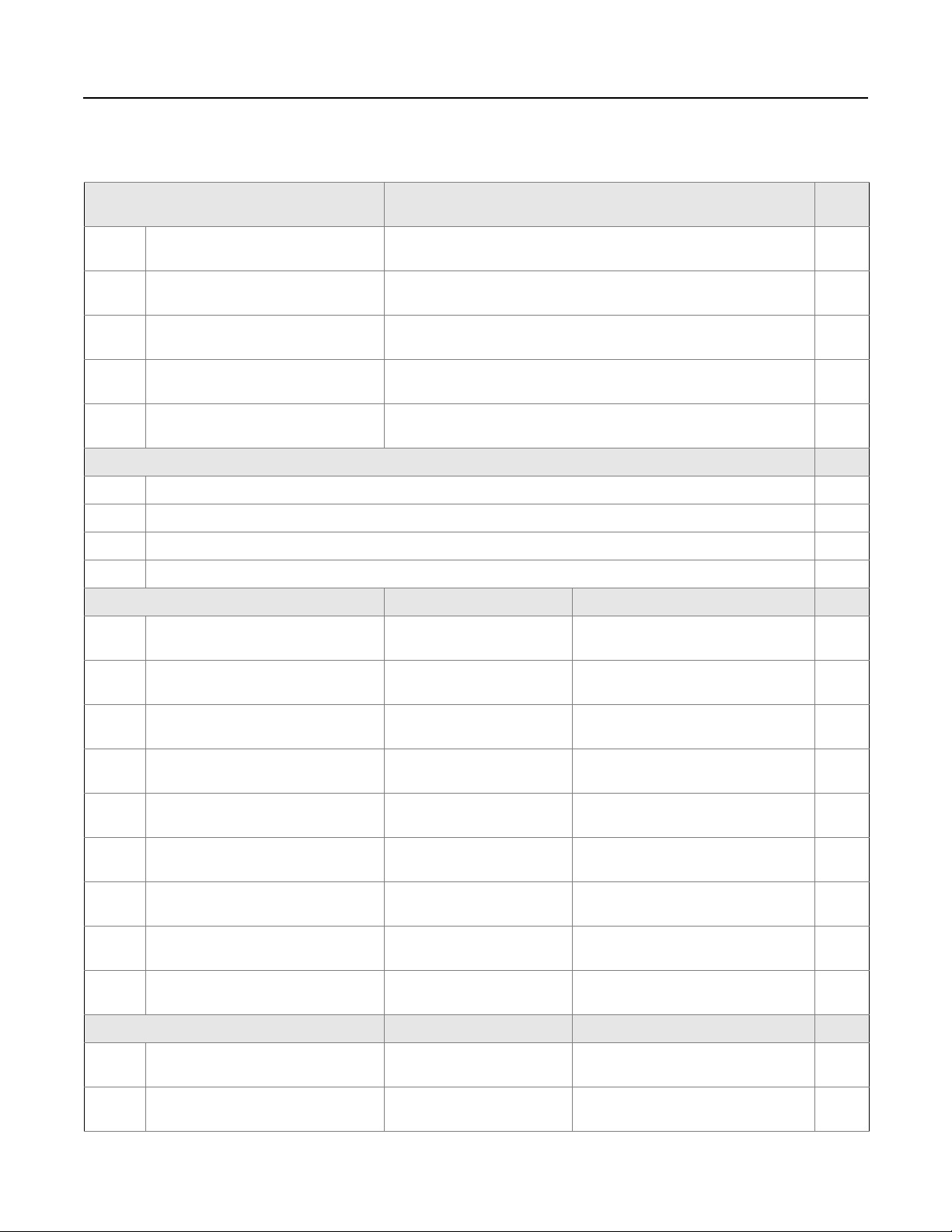

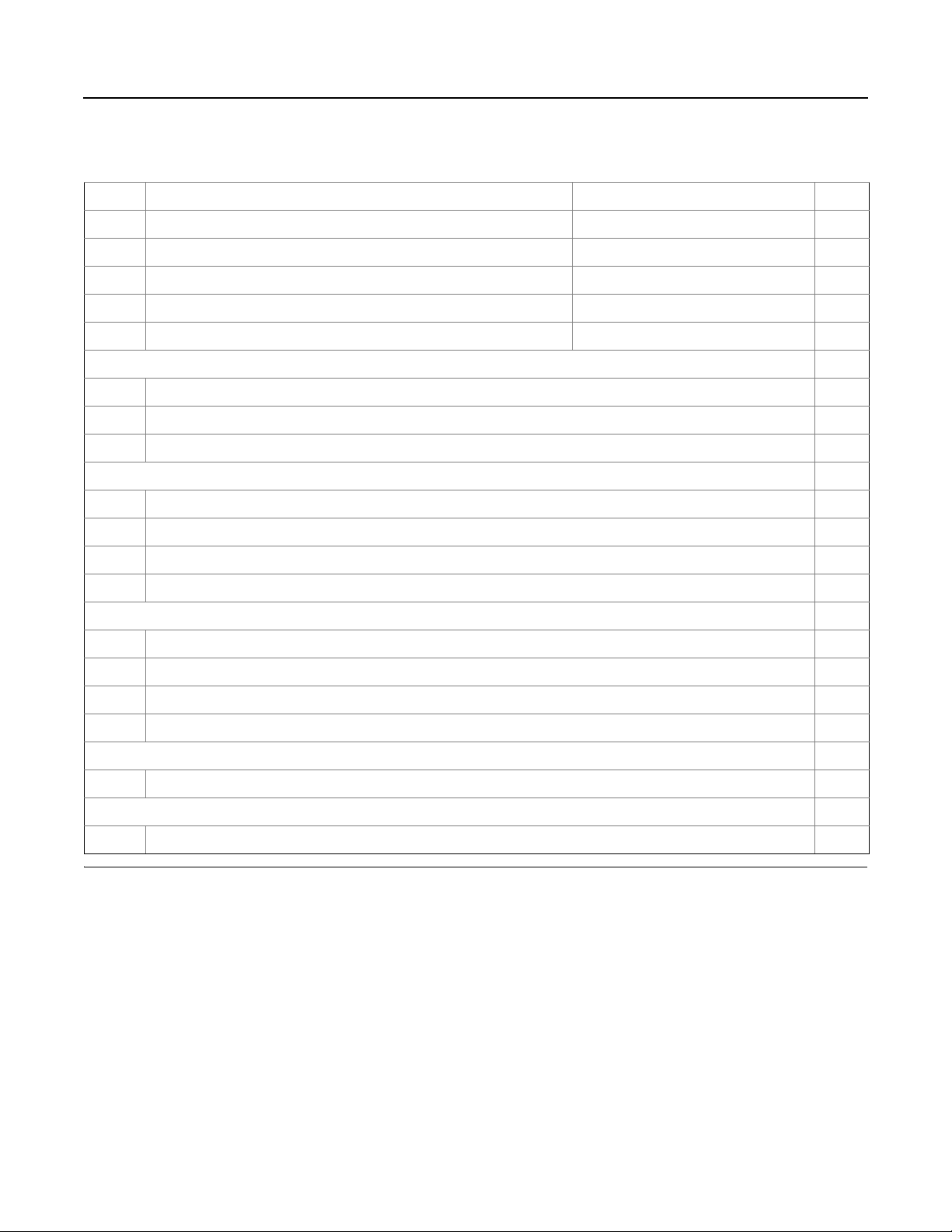

Rosemount 3301 and 3302 Level and/or Interface in Liquids Ordering Information

Rosemount 3301 and 3302 Guided Wave Radar Level transmitters are versatile and easy-to-use with

field proven measurement capabilities. Characteristics include:

High application flexibility with a wide range of probe styles, process connections, and materials

HART 4-20 mA, Modbus, or IEC 62591 (WirelessHART) with the THUM adapter

Radar Configuration Tool software package included for easy commissioning and troubleshooting

Additional Information

Specifications: page 14

Certifications: page 31

Dimensional Drawings: page 34

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 24 for more information on Material Selection.

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

3301 Guided Wave Radar Level Transmitter (interface available for fully submerged probe)

3302 Guided Wave Radar Level and Interface Transmitter

Signal output

H 4-20 mA with HART communication

M RS-485 with Modbus communication

Housing material

A Polyurethane-covered Aluminum

S Stainless Steel, Grade CF8M (ASTM A743)

Conduit / cable threads

1 ½–14 NPT

2 M20 x 1.5 adapter

Operating temperature and pressure

S - 15 psig (-1bar) to 580 psig (40 bar) @ 302 °F (150 °C) 3301: All

(2)

(1)

Probe type

3302: 1A, 2A, 3B, 4A, 4B, and 4S

★

★

★

★

★

★

★

★

www.rosemount.com

5

Rosemount 3300 Series

October 2014

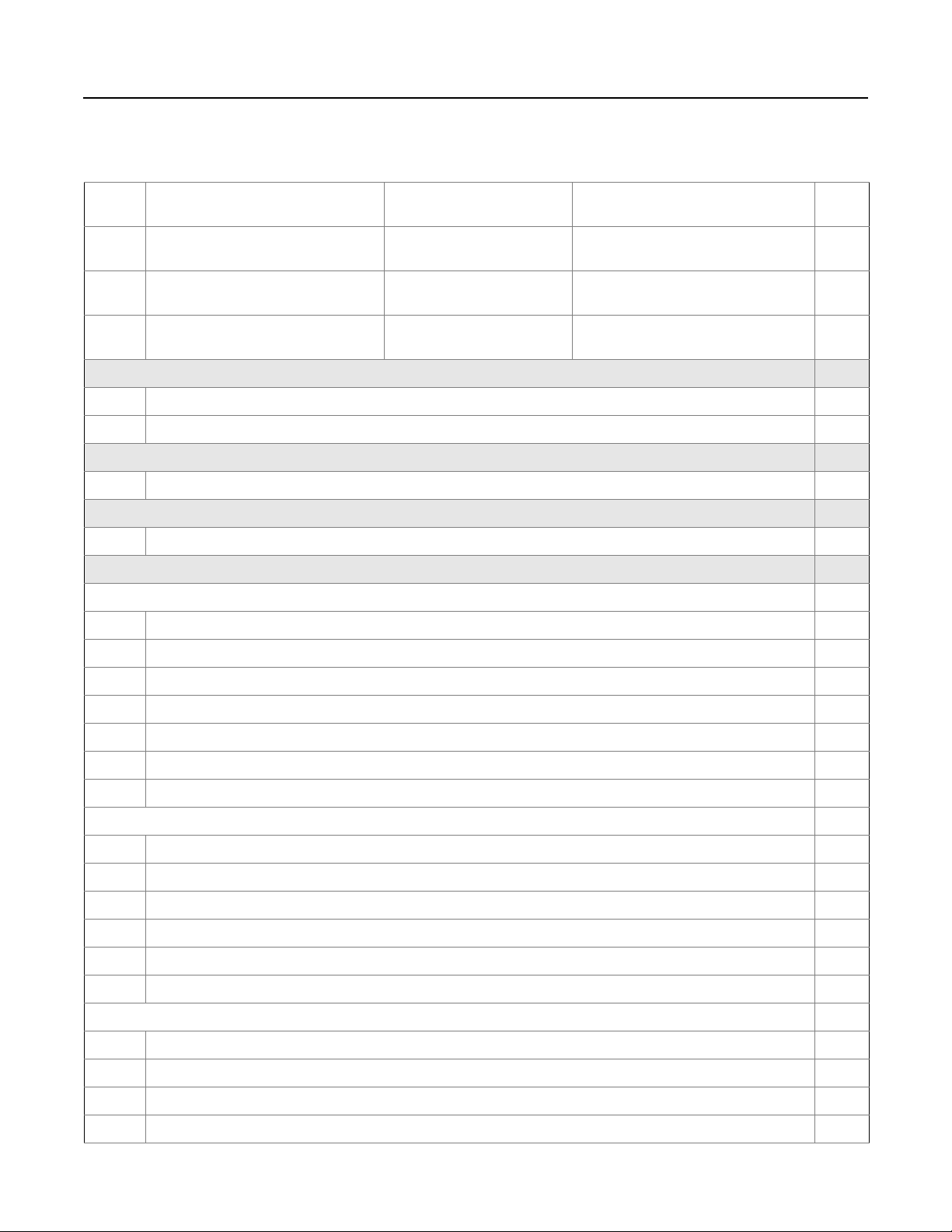

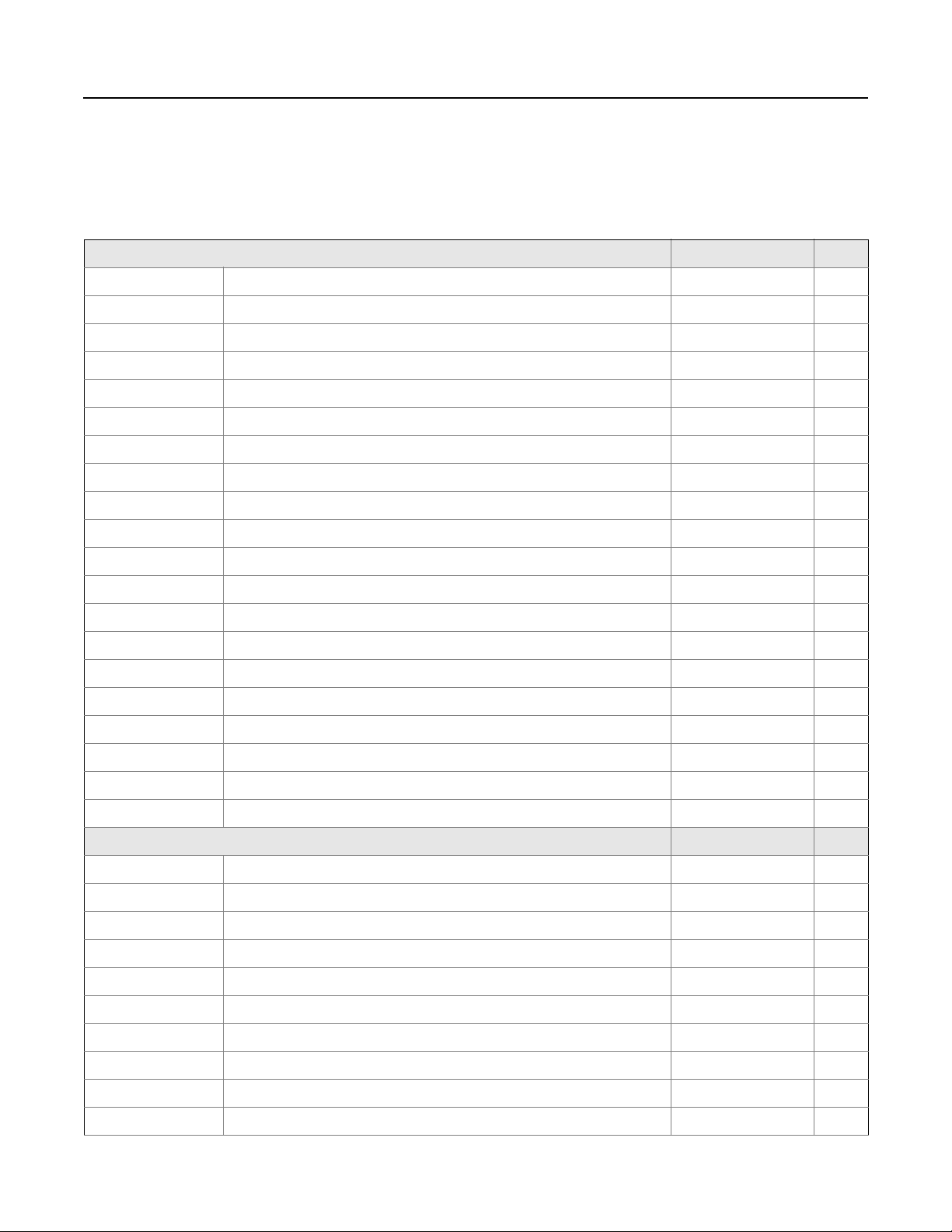

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Material of construction

Process connection / probe

1 316L SST (EN 1.4404) 3301: All

(3)

:

Probe type

★

3302: 1A, 2A, 3B, 4A, 4B, and 4S

2 Alloy C-276 (UNS N10276). With plate

design if flanged version.

3 Alloy 400 (UNS N04400). With plate

design if flanged version.

7 PTFE covered probe and flange. With

plate design.

3301: 3A, 3B, and 4A

3302: 3B and 4A

3301: 3A, 3B, 4A, 5A, and 5B

3302: 3B and 4A

3301: 4A and 5A, Flanged version

3302: 4A, Flanged version

8 PTFE covered probe 3301: 4A and 5A

3302: 4A

Sealing, o-ring material (consult factory for other o-ring materials)

V Viton® Fluoroelastomer

E Ethylene Propylene

K Kalrez® 6375 Perfluoroelastomer

B Nitrile Butadiene (NBR)

Probe type, model 3301 Process connection Probe lengths

3B Coaxial, perforated. For level and

interface measurement.

4B Rigid Single Lead 0.5 in. (13 mm)

5A Flexible Single Lead with weight Flange / 1-in., 1½-in.,

Flange / 1-in., 1½-in.,

2-in. Thread

(4)

Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp™

2-in. Thread / Tri-Clamp

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6.0 m)

Min.: 3 ft. 4 in. (1 m)

Max: 77 ft. (23.5 m)

★

★

★

★

★

★

★

1A Rigid Twin Lead Flange / 1½-in., 2-in. Thread Min.: 1 ft. 4 in. (0.4 m)

Max: 9 ft. 10 in. (3 m)

2A Flexible Twin Lead with weight Flange / 1½-in., 2-in. Thread Min.: 3 ft. 4 in. (1 m)

Max: 77 ft. (23.5 m)

3A Coaxial (for level measurement) Flange / 1-in., 1½-in.,

2-in. Thread

4A Rigid Single Lead 0.3 in. (8 mm) Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

4S Segmented Rigid Single Lead

0.5 in. (13 mm)

Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

5B Flexible Single Lead with chuck Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 9 ft. 10 in. (3 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6.0 m)

Min.: 3 ft. 4 in. (1 m)

Max: 77 ft. (23.5 m)

Probe Type, model 3302 Process connection Probe lengths

3B Coaxial, perforated. For level and

interface measurement.

4B Rigid Single Lead 0.5 in. (13 mm)

Flange / 1-in., 1½-in.,

2-in. Thread

(4)

Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6.0 m)

6

★

★

www.rosemount.com

October 2014

Rosemount 3300 Series

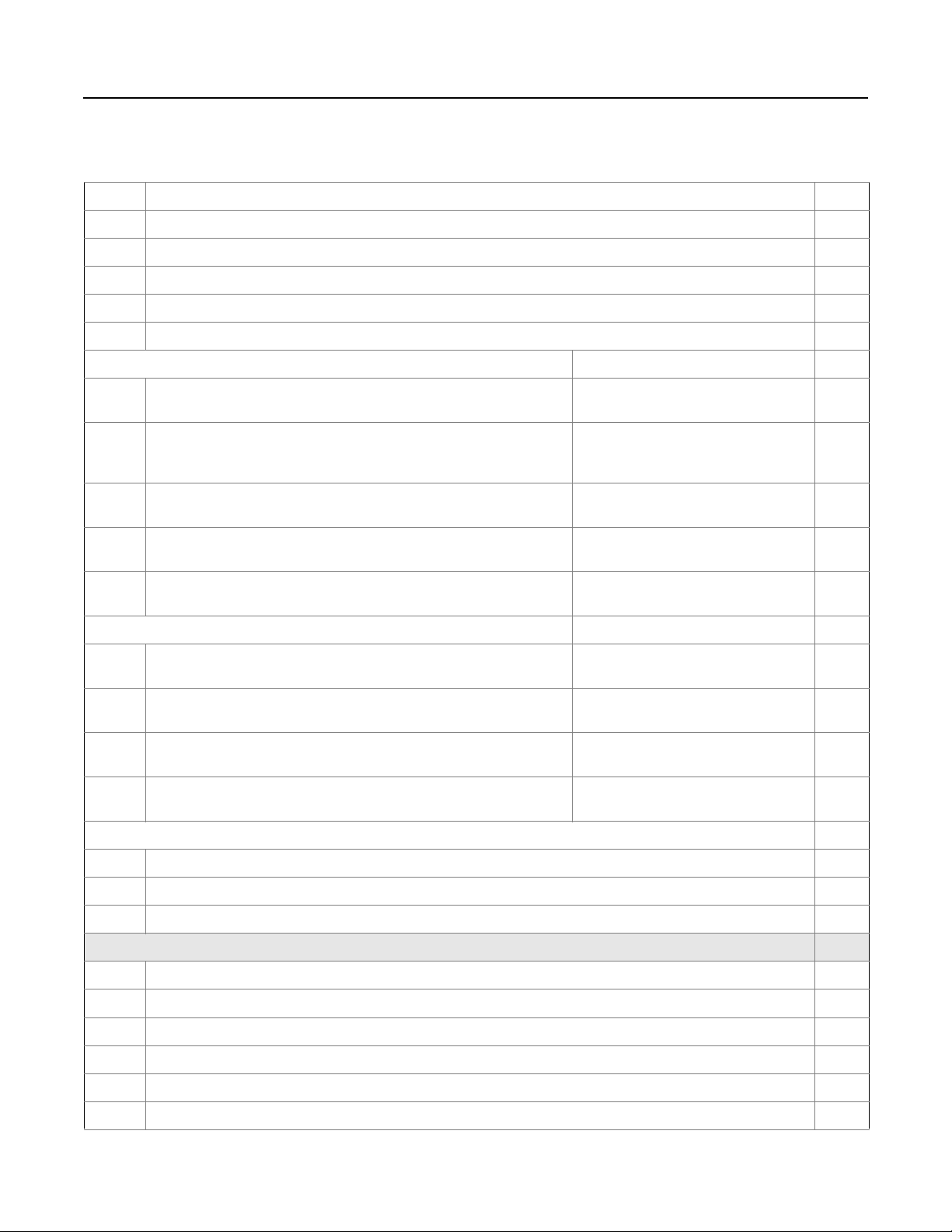

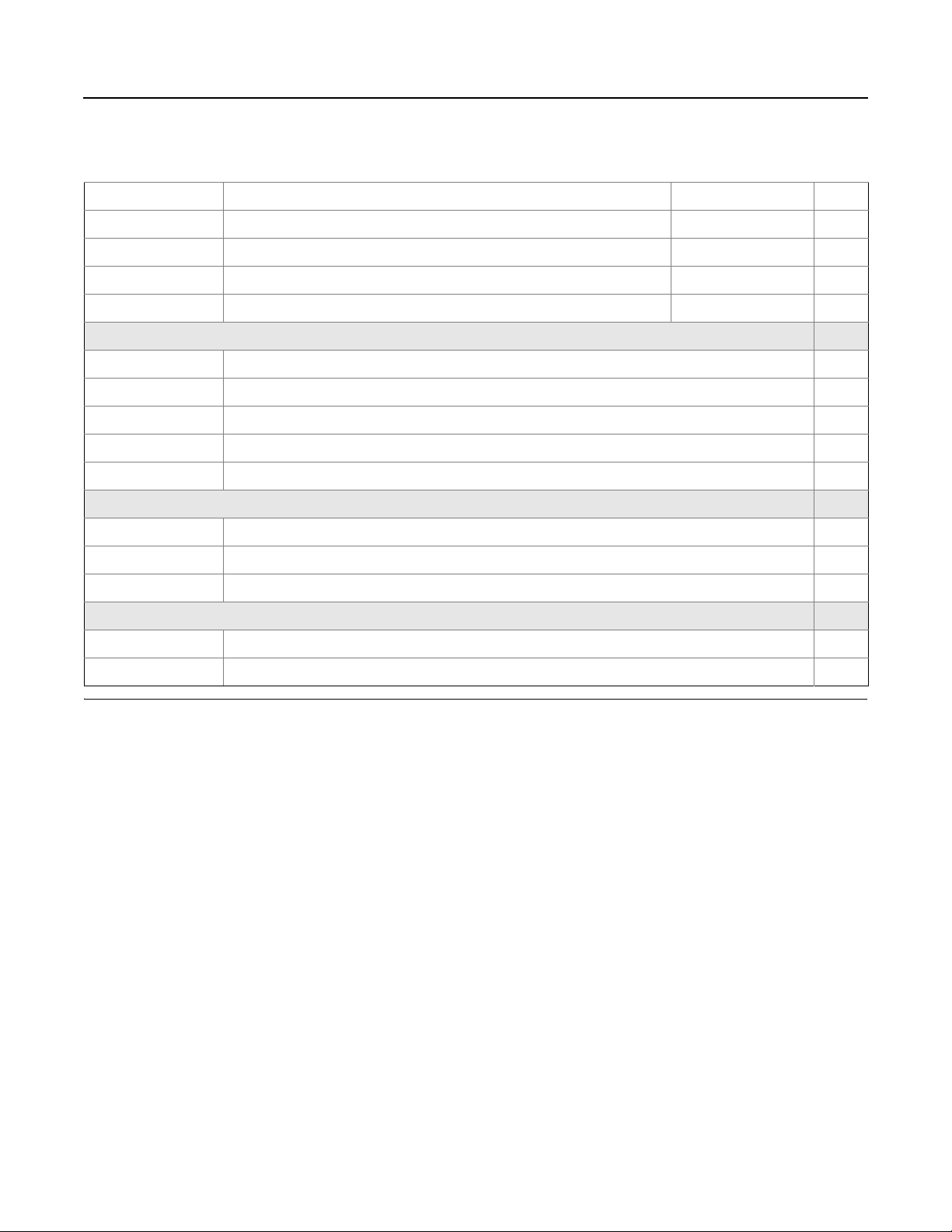

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

1A Rigid Twin Lead Flange / 1½-in., 2-in. Thread Min.: 1 ft. 4 in. (0.4 m)

Max: 9 ft. 10 in. (3 m)

2A Flexible Twin Lead with weight Flange / 1½-in., 2-in. Thread Min.: 3 ft. 4 in. (1 m)

Max: 77 ft. (23.5 m)

4A Rigid Single Lead 0.3 in. (8 mm) Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

4S Segmented Rigid Single Lead

0.5 in. (13 mm)

Flange / 1-in., 1½-in.,

2-in. Thread / Tri-Clamp

Probe length units

E English (feet, inch)

M Metric (meters, centimeters)

Tot al p rob e le ngt h

(5)

(feet/m)

xx 0 - 77 ft. or 0-23 m

Tot al p rob e le ngt h

(5)

(inch/cm)

xx 0 - 11 in. or 0-99 cm

Process connection - size / type (consult factory for other process connections)

ASME / ANSI flanges

(6)(7)

AA 2 in., 150 lb

AB 2 in., 300 lb

BA 3 in., 150 lb

BB 3 in., 300 lb

Min.: 1 ft. 4 in. (0.4 m)

Max: 9 ft. 10 in. (3 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 19 ft. 8 in. (6.0 m)

★

★

★

★

★

★

★

★

CA 4 in., 150 lb

CB 4 in., 300 lb

DA 6 in., 150 lb

EN (DIN) flanges

(6)(7)

HB DN50, PN40

IA DN80, PN16

IB DN80, PN40

JA DN100, PN16

JB DN100, PN40

KA DN150, PN16

JIS flanges

(6)(7)

UA 50A, 10K

VA 80A, 10K

XA 100A, 10K

UB 50A, 20K

www.rosemount.com

★

★

★

★

★

★

★

★

★

★

7

Rosemount 3300 Series

October 2014

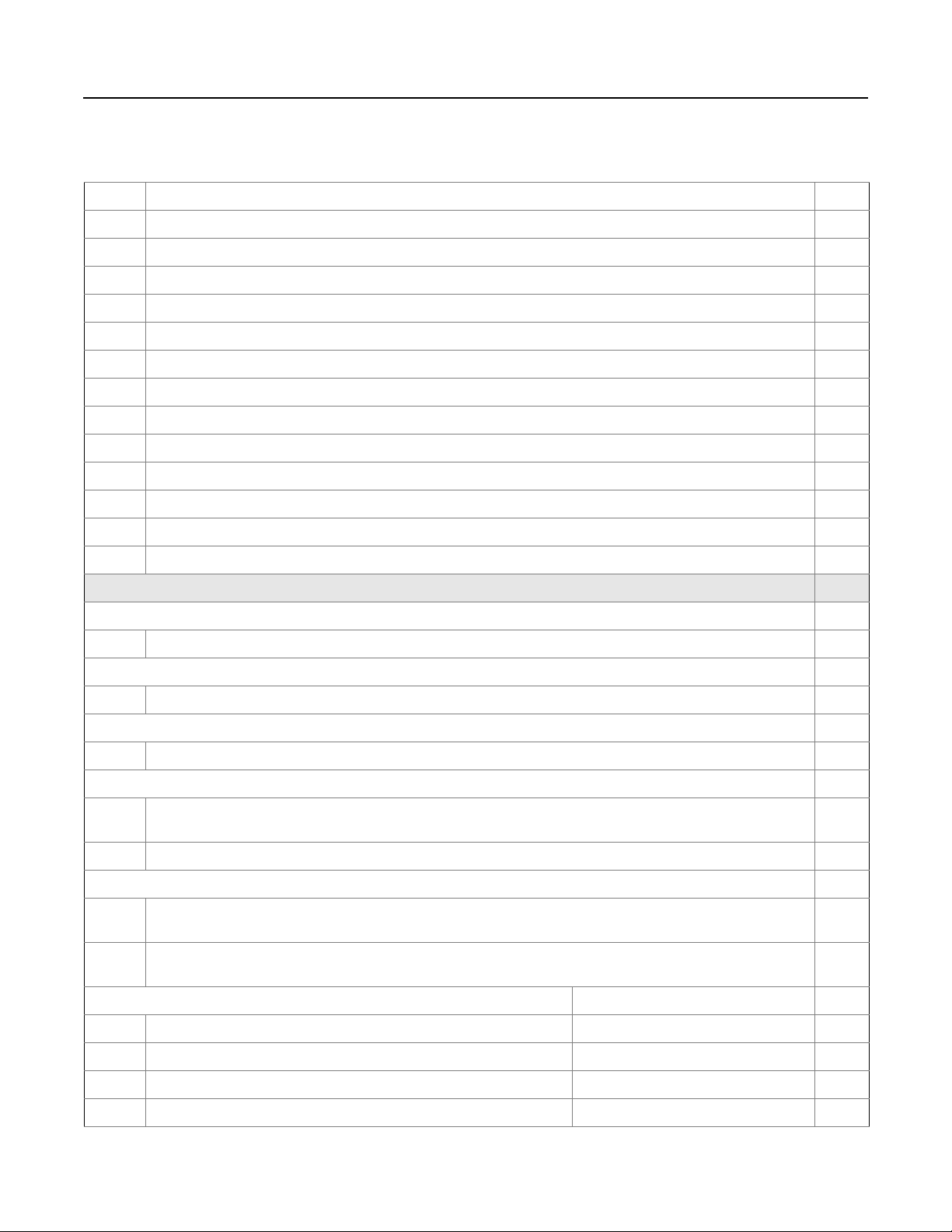

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

VB 80A, 20K

XB 100A, 20K

YA 150A, 10K

YB 150A, 20K

ZA 200A, 10K

ZB 200A, 20K

Threaded connections

(6)

Probe type

RA 1½-in. NPT thread 3301: All

3302: 1A, 2A, 3B, 4A, 4B, and 4S

RC 2-in. NPT thread 3301: 1A, 2A, 3A, 3B, 4A, 4B, 4S, 5A,

and 5B

3302: 1A, 2A, 3B, 4A, 4B, and 4S

RB 1-in. NPT thread 3301: 3A, 3B, 4A, 4B, 4S, 5A, and 5B

3302: 3B, 4A, 4B, and 4S

SA 1½-in. BSP (G 1½-in.) thread 3301: All

3302: 1A, 2A, 3B, 4A, 4B, and 4S

SB 1-in. BSP (G 1-in.) thread 3301: 3A, 3B, 4A, 4B, 4S, 5A, and 5B

3302: 3B, 4A, 4B, and 4S

Tri-Clamp fittings

(6)

Probe type

FT 1½-in. Tri-Clamp 3301: 4A, 4B, 4S, 5A, and 5B

3302: 4A, 4B, and 4S

AT 2-in. Tri-Clamp 3301: 4A, 4B, 4S, 5A, and 5B

3302: 4A, 4B, and 4S

BT 3-in. Tri-Clamp 3301: 4A, 4B, 4S, 5A, and 5B

3302: 4A, 4B, and 4S

CT 4-in. Tri-Clamp 3301: 4A, 4B, 4S, 5A, and 5B

3302: 4A, 4B, and 4S

Proprietary flanges

(8)

★

★

TF Fisher - proprietary 316L SST (for 249B, 259B cages) Torque Tube Flange

TT Fisher - proprietary 316L SST (for 249C cages) Torque Tube Flange

TM Masoneilan - proprietary 316L SST Torque Tube Flange

Hazardous locations certifications

NA No Hazardous Locations Certifications

(9)

(9)

(9)

(9)

(9)

E1 AT EX Fla mep roof

E3 NEPSI Flameproof

E4 TIIS Flameproof

E5 FM Explosion-proof

E6 CSA Explosion-proof

8

★

★

★

★

★

★

★

★

★

www.rosemount.com

October 2014

Rosemount 3300 Series

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

E7 IECEx Flameproof

(9)

★

I1 ATEX Intrinsic Safety

I3 NEPSI Intrinsic Safety

I5 FM Intrinsic Safety and Non-Incendive

I6 CSA Intrinsic Safety and Non-Incendive

I7 IECEx Intrinsic Safety

EM Technical Regulations Customs Union (EAC) Flameproof (consult factory for details)

IM Technical Regulations Customs Union (EAC) Intrinsic Safety (consult factory for details)

(9)

(9)

KA ATEX and CSA Flameproof/Explosion-proof

KB FM and CSA Explosion-proof

(9)

KC ATEX and FM Flameproof/Explosion-proof

KD ATEX and CSA Intrinsic Safety

KE FM and CSA Intrinsic Safety

KF ATEX and FM Intrinsic Safety

Options

Display

M1 Integral digital display

Hydrostatic testing

P1 Hydrostatic testing

(10)

★

★

★

★

★

★

★

Materials Certification

N2 NACE material recommendation per MR-0175

(11)

, MR-0103

Installation options

LS Long stud

(12)

9.8 in (250 mm) for flexible single lead probe to prevent contact with wall/nozzle.

Standard height is 3.9 in (100 mm)

BR Mounting Bracket for 1½-in. NPT Process Connection (RA)

Weight options for flexible single lead probe (5A)

W3 Heavy weight (recommended choice for most applications)

Weight=2.43 lb (1.10 kg), Length=5.5 in. (140 mm), Diameter=1.5 in. (37.5 mm)

W2 Short weight (when measuring close to the probe end)

(13)

Weight=0.88 lb (0.40 kg. Length=2 in. (50 mm), Diameter=1.5 in. (37.5 mm)

Sx and Px - centering discs Outer diameter

S2 2-in. Centering disc

S3 3-in. Centering disc

S4 4-in. Centering disc

P2 2-in. Centering disc PTFE

(14)

(14)

(14)

(15)

1.8 in. (45 mm)

2.7 in. (68 mm)

3.6 in. (92 mm)

1.8 in. (45 mm)

★

★

★

★

★

★

★

www.rosemount.com

9

Rosemount 3300 Series

October 2014

Table 1. 3301 and 3302 Level and/or Interface in Liquids Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

P3 3-in. Centering disc PTFE

P4 4-in. Centering disc PTFE

S6 6-in. Centering disc

S8 8-in. Centering disc

P6 6-in. Centering disc PTFE

P8 8-in. Centering disc PTFE

Remote housing

(16)

(15)

(15)

(14)

(14)

(15)

(15)

B1 1 m / 3.2 ft. Remote Housing Mounting Cable and Bracket

B2 2 m / 6.5 ft. Remote Housing Mounting Cable and Bracket

B3 3 m / 9.8 ft. Remote Housing Mounting Cable and Bracket

Cx - special configuration (software)

2.7 in. (68 mm)

3.6 in. (92 mm)

5.55 in. (141 mm)

7.40 in. (188 mm)

5.55 in. (141 mm)

7.40 in. (188 mm)

★

★

C1 Factory configuration (Configuration Data Sheet required with order, available at www.rosemount.com)

C4 Namur alarm and saturation levels, high alarm

C5 Namur alarm and saturation levels, low alarm

C8 Low alarm

(17)

(standard Rosemount alarm and saturation levels)

Qx - special certs

Q4 Calibration Data Certification

Q8 Material Traceability Certification per EN 10204 3.1

(18)

U1 WHG Overfill Approval. Only available with HART 4-20 mA output (output code H)

QG GOST Primary Verification Certificate

Consolidate to chamber

XC Consolidate to Chamber

(19)

Engineered solutions (see page 27)

Rxxx Engineered Solutions beyond standard model codes. (Consult factory for details)

(1) Requires external 8-30 Vdc power supply.

(2) Process seal rating. Final rating depends on flange and O-ring selection. See “Process temperature and pressure rating” on page 18”.

(3) For other materials, consult the factory.

★

★

★

★

★

★

★

(4) Available in SST. Consult the factory for other materials.

(5) Probe weight included if applicable. Give the total probe length in feet and inches or meters and centimeters, depending on selected probe length unit.

If tank heig ht is unknown, please ro und up to an even length when ordering. Probes can b e cut to exact length in field. Maximum allowable length is determined

by process conditions.

(6) Available in material 316L and EN 1.4404. For other materials consult the factory.

(7) A SME/ANSI: Raised face type for SST flanges. EN: Type A flat face for SST flanges. JIS: Raised face type for SST flanges.

(8) Available in material 316L. For pressure and temperature rating, see page 18.

10

www.rosemount.com

October 2014

(9) Probes are intrinsically safe.

(10) Available for flanged connection.

(11) 3301: valid for probe type 3A, 3B, 4A, 4B, and 4S. 3302: valid for probe type 3B, 4A, 4B, and 4S.

(12) Not available with PTFE covered probes.

(13) Only for Material of Construction code 1 and Probe Type 5A.

(14) Material in accordance with selected material of construction for probe types 2A, 4A, 4B, 4S, and 5A.

(15) Available for SST, Alloy C-276, and Alloy 400 probes, type 2A, 4A, 4B, 4S, and 5A.

(16) Requires software version 10 or higher

(17) The standard alarm setting is high.

(18) Option available for pressure retaining wetted par ts.

(19) Selecting the XC option code on the 3300 Guided Wave Radar and the 9901 Chamber will result in matching, consolidating, configuring, and shipping of the two

products in one crate. Note that the flange bolts are only hand-tightened. Long rigid single lead probes (>8 ft/2.5 m) are shipped separately in order to reduce

transportation risk damage.

Rosemount 3300 Series

www.rosemount.com

11

Rosemount 3300 Series

October 2014

Rosemount 3301 and 3302 Accessories

Table 2. Accessories

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Centering discs

(1)(2)

Outer diameter

03300-1655-0001 Kit, 2-in. Centering Disc, SST, Rigid Single 1.8 in. (45 mm)

03300-1655-0002 Kit, 3-in. Centering Disc, SST, Rigid Single 2.7 in. (68 mm)

03300-1655-0003 Kit, 4-in. Centering Disc, SST, Rigid Single 3.6 in. (92 mm)

03300-1655-0006 Kit, 2-in. Centering Disc, PTFE, Rigid Single 1.8 in. (45 mm)

03300-1655-0007 Kit, 3-in. Centering Disc, PTFE, Rigid Single 2.7 in. (68 mm)

03300-1655-0008 Kit, 4-in. Centering Disc, PTFE, Rigid Single 3.6 in. (92 mm)

03300-1655-1001 Kit, 2-in. Centering Disc, SST, Single / Twin Flex Lead 1.8 in. (45 mm)

03300-1655-1002 Kit, 3-in. Centering Disc, SST, Single / Twin Flex Lead 2.7 in. (68 mm)

03300-1655-1003 Kit, 4-in. Centering Disc, SST, Single / Twin Flex Lead 3.6 in. (92 mm)

03300-1655-1006 Kit, 2-in. Centering Disc, PTFE, Single / Twin Flex Lead 1.8 in. (45 mm)

03300-1655-1007 Kit, 3-in. Centering Disc, PTFE, Single / Twin Flex Lead 2.7 in. (68 mm)

03300-1655-1008 Kit, 4-in. Centering Disc, PTFE, Single / Twin Flex Lead 3.6 in. (92 mm)

03300-1655-0004 Kit, 6-in. Centering Disc, SST, Rigid Single 5.55 in. (141 mm)

03300-1655-0005 Kit, 8-in. Centering Disc, SST, Rigid Single 7.40 in. (188 mm)

03300-1655-0009 Kit, 6-in. Centering Disc, PTFE, Rigid Single 5.55 in. (141 mm)

03300-1655-0010 Kit, 8-in. Centering Disc, PTFE, Rigid Single 7.40 in. (188 mm)

03300-1655-1004 Kit, 6-in. Centering Disc, SST, Single / Twin Flex Lead 5.55 in. (141 mm)

★

★

★

★

★

★

★

★

★

★

★

★

03300-1655-1005 Kit, 8-in. Centering Disc, SST, Single / Twin Flex Lead 7.40 in. (188 mm)

03300-1655-1009 Kit, 6-in. Centering Disc, PTFE, Single / Twin Flex Lead 5.55 in. (141 mm)

03300-1655-1010 Kit, 8-in. Centering Disc, PTFE, Single / Twin Flex Lead 7.40 in. (188 mm)

Centering discs for mounting between segments (probe type 4S only) Outer diameter

03300-1656-1002 2-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-1003 3-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-1004 4-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-1006 6-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-1008 8-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

03300-1656-3002 2-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-3003 3-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-3004 4-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-3006 6-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-3008 8-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

12

www.rosemount.com

October 2014

Rosemount 3300 Series

Table 2. Accessories

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

03300-1656-5002 2-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-5003 3-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-5004 4-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-5006 6-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-5008 8-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

Segmented rigid single lead probe spare part kit

03300-0050-0001 15.2 in. / 385 mm Segment for Top connection (1 pc)

03300-0050-0002 31.5 in. / 800 mm Segment (1 pc)

03300-0050-0003 31.5 in. / 800 mm Segment (3 pcs)

03300-0050-0004 31.5 in. / 800 mm Segment (5 pcs)

03300-0050-0005 31.5 in. / 800 mm Segment (12 pcs)

Vented flanges

03300-1812-0091 Fisher 249B/259B

03300-1812-0092 Fisher 249C

03300-1812-0093 Masoneilan

(3)

(4)

(4)

(4)

HART modem and cables

03300-7004-0001 MACTek Viator HART Modem and cables (RS232 connection)

03300-7004-0002 MACTek Viator HART Modem and cables (USB connection)

(1) If a centering disc is required for a flanged probe the centering disc can be ordered with options Sx or Px on page 9 in the model code. If a centering disc is

required for a threaded connection or as a spare part it should be ordered using the item numbers listed below.

(2) To order a centering disc in a different material, consult the factory.

(3) 1½-in. NPT threaded connection (RA) is required.

(4) For pressure and temperature rating, see “Fisher & Masoneilan Flange Rating” on page 18.

★

★

www.rosemount.com

13

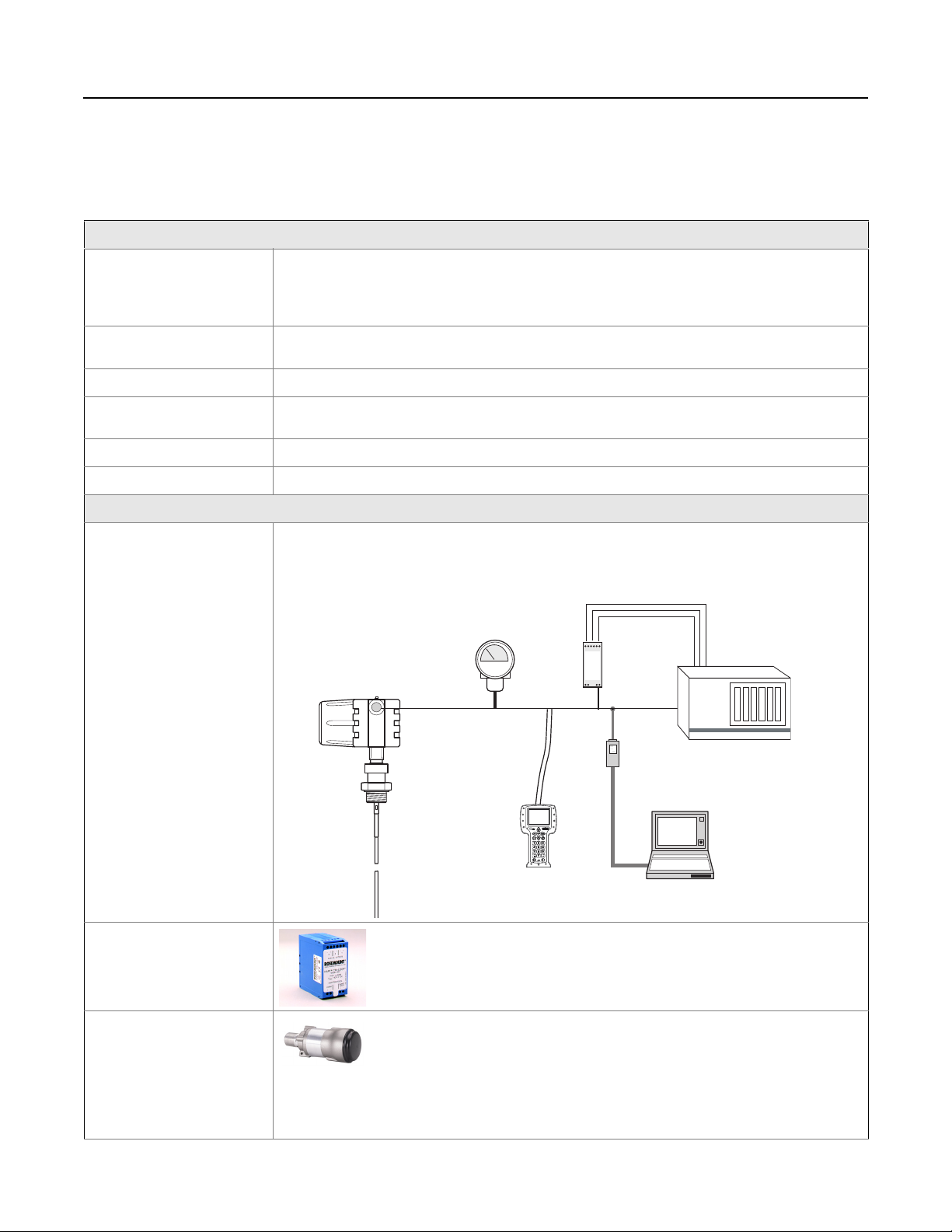

Rosemount 3300 Series

Rosemount 3300

Series Transmitter

Rosemount 751

Field Signal Indicator

4-20 mA / HART

475 Field

Communicator

Radar Configuration

Tools or AMS Device

Manager

Rosemo unt

333 HART

Tri - Lo op

3 x 4–20 mA

Control

System

HART

Modem

Specifications

Functional specifications

General

Liquids and semi-liquids level or liquid/liquid interfaces

Field of Application

Measurement Principle

Microwave Output Power Nominal 50 W, Max. 2 mW

Model 3301, for level or submerged probe interface measurement

Model 3302, for level and interface measurements

Time Domain Reflectometry (TDR).

(See “Measurement principle” on page 2 for a description of how it works)

October 2014

Telecommunication

(FCC and R&TTE)

FCC part 15 (1998) subpart B and R&TTE (EU directive 99/5/EC).

The 3300 Series is considered to be an unintentional radiator under the Part 15 rules

Humidity 0 to 100% relative humidity

Start-up time < 10 s

4–20 mA HART (output option code H) – (see signal output in Table 1 on page 5)

Two-wire, 4–20 mA. Digital process variable is superimposed on 4–20 mA signal, and available to

any host that conforms to the HART protocol (HART rev. 5). The HART signal can be used in a

multidrop mode.

Output

HART Tri-Loop

Smart Wireless THUM

Adapter

14

By sending the digital HART signal to the optional HART Tri-Loop, it is possible to

have up to three additional 4–20 mA analog signals. See the Rosemount 333 HART

Tri-Loop Product Data Sheet (document number 00813-0100-4754) for additional

information.

The optional THUM adapter can be mounted directly on the transmitter or by

using a remote mounting kit. IEC 62591 (WirelessHART) enables access to

multi-variable data and diagnostics, and adds wireless to almost any measurement

point. See the Rosemount Smart Wireless THUM adapter Product Data Sheet

(document number 00813-0100-4075) and Smart Wireless THUM Adapter for

Rosemount Process Level Transmitter Applications (document number

00840-0100-4026).

www.rosemount.com

Loading...

Loading...