Page 1

GV3000/SE AC Drive

ControlNet Network Communication

Option Board

M/N 2CN3000

Instruction Manual

D2-3390-2

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, and/or service this equipment.

!

Read and understand this instruction manual in its entirety before proceeding. Failure to observe

this precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming AC power. Disconnect,

lockout, and tag all incoming power to the drive before performing installing any option kits. Failure

to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power, wait five minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to ensure that the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when installing, testing, servicing, or repairing the drive.

Erratic machine operation and damage to, or destruction of, equipment can result if this procedure

is not followed. Failure to observe this precaution can result in bodily injury.

ControlNet is a trademark of ControlNet International, Ltd.

PLC, GV3000/SE, ReSource, and Reliance are are trademarks of Rockwell Automation.

©2005 Rockwell International Corporation

Page 3

Chapter 1

Chapter 2

CONTENTS

Introduction

1.1 About the ControlNet Network Communication Option Board......................... 1-1

1.2 Where to Find Additional Information .............................................................. 1-3

1.3 Getting Assistance from Reliance Electric....................................................... 1-3

Installation

2.1 Installing the ControlNet Option Board in 1 to 5 HP @ 460 VAC Drives ............ 2-4

2.2 Installing the ControlNet Option Board in 7.5 to 10 HP @ 460 VAC Drives ....... 2-8

2.3 Installing the ControlNet Option Board in 1 to 20 HP @ 230 VAC Drives ........ 2-12

2.4 Installing the ControlNet Option Board in 30 to 100 HP @ 230 VAC and

75 to 200 HP@460 VAC Drives ..................................................................... 2-16

2.5 Installing the ControlNet Option Board in 15 to 25 HP and 25 to 60 HP @

460 VAC Drives ....................... ............................................. .......................... 2-21

2.6 Installing the ControlNet Option Board in 50 to 100 HP and 100 to 150 HP @

460 VAC Drives ....................... ............................................. .......................... 2-26

2.7 Installing the ControlNet Option Board in 200 to 400 HP @ 460 VAC Drives .. 2-31

2.8 Installing the ControlNet Option Board in 2 to 43 Amp GV3000/SE

Bookshelf Drives............................................................................................ 2-34

2.9 Connecting the GV3000/SE Drive to a ControlNet Network.......................... 2-41

2.10 Connecting a Programming Device to the Option Board’s Network

Access Port ................................................................................................... 2-42

Chapter 3

Chapter 4

Setting Up the GV3000/SE Drive

3.1 Setting the Control Type (P.048) ..................................................................... 3-1

3.2 Setting the Node Number (P.060) ................................................................... 3-2

3.3 Setting the Control Source (P.000).................................................................. 3-2

3.4 Setting the Run/Program Response (P.061) ................................................... 3-3

3.5 Setting the Communication Loss Response (P.062)....................................... 3-4

3.6 Setting the Network Output Register Sources P.066 to P.069) ....................... 3-6

3.7 Option Port: Type and Version (P.065) ........................................................... 3-7

3.8 Network Reference Source (P.063) and Network Trim Reference

Source (P.064) ................................................................................................ 3-7

Programming the Drive

4.1 About ControlNet Network Communication ..................................................... 4-1

4.2 Configuring Drive Reference and Feedback Data as Scheduled Transfers .... 4-1

4.2.1 Configuring Scheduled Data Transfers ................................................. 4-2

4.2.2 Programming Scheduled Drive Reference Data ................................... 4-3

4.2.3 Using Scheduled Drive Feedback Data ................................................ 4-4

4.3 Using Unscheduled Transfers ......................................................................... 4-7

4.3.1 Programming the MSG Instruction in a PLC-5 ...................................... 4-7

4.3.2 About MSG Instruction Timing .............................................................. 4-8

4.3.3 About the Files You Can Access........................................................... 4-8

Contents

I

Page 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

4.3.4 Using the Drive Parameters Data (N10:X).............................................4-9

4.3.5 Using the Drive Display Data (N11:X) ...................................................4-9

4.3.6 Using the Drive Reference and Feedback Data (N12:X).....................4-10

4.3.7 Using the Write Status File (N20:X) to Troubleshoot a Drive

Parameter Write Command .................................................................4-10

Configuring ControlLogix Applications

Configuring SLC500 Applications

6.1 Required Software and Equipment ..................................................................6-1

6.2 Network Configuration......................................................................................6-1

6.3 1747-KFC15 Set Up.........................................................................................6-2

6.4 Scheduled Messaging (I/O)..............................................................................6-5

6.5 Unscheduled Messaging..................................................................................6-6

6.6 SLC500 Support...............................................................................................6-7

Register Map

Troubleshooting

8.1 Diagnostic LEDs...............................................................................................8-1

8.2 Communication Error Codes............................................................................8-2

II

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 5

List of Figures

Figure 1.1 – ControlNet Network Communication Option Board ............................. 1-2

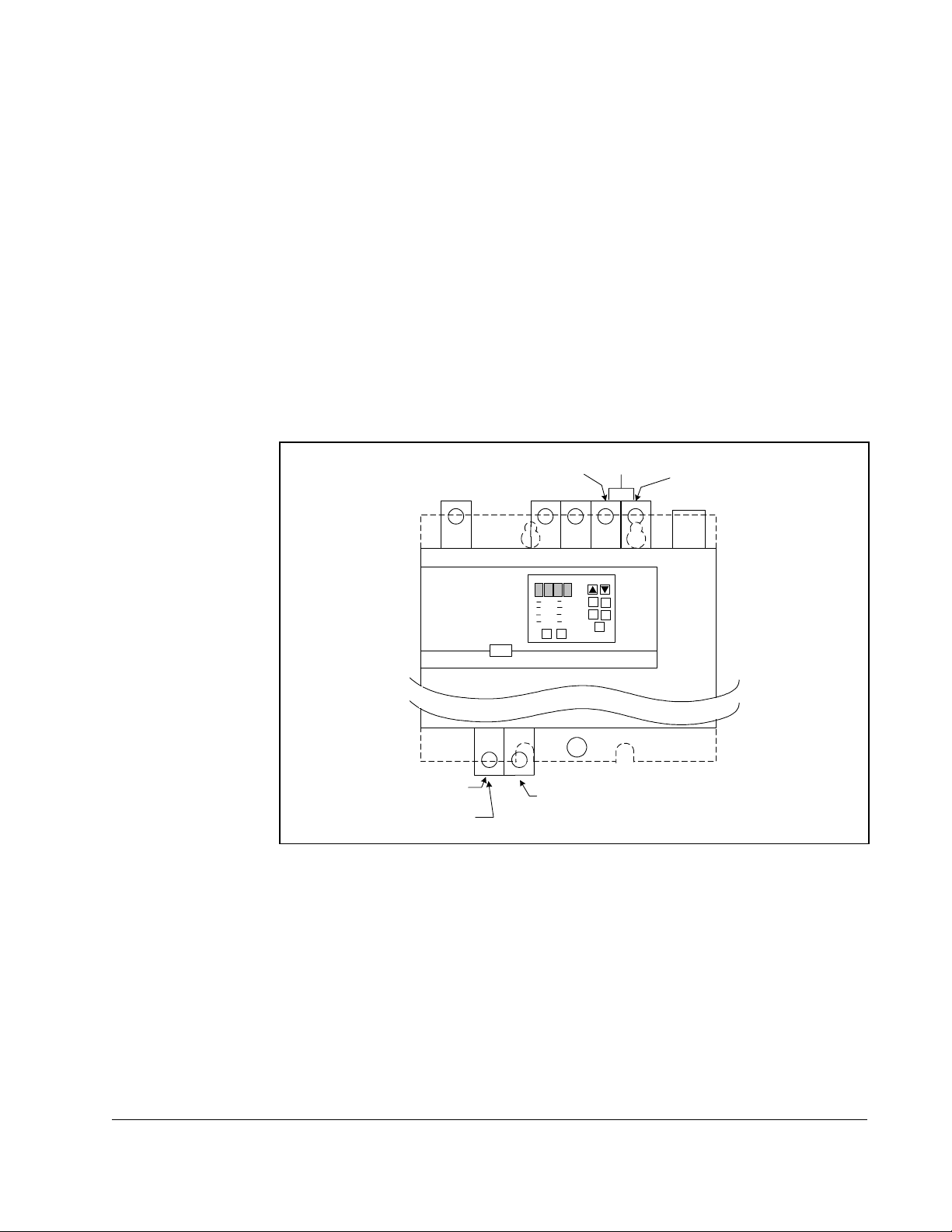

Figure 2.1 – DC Bus Voltage Terminals (1 to 5 HP @ 460 VAC) ............................. 2-5

Figure 2.2 – 1 to 5 HP @ 460 VAC GV3000/SE Drive .............................................. 2-6

Figure 2.3 – DC Bus Voltage Terminals (7.5 to 10 HP) ............................................ 2-9

Figure 2.4 – 7.5 to 10 HP @ 460 VAC GV3000/SE Drive ....................................... 2-10

Figure 2.5 – DC Bus Voltage Terminals (1 to 20 HP @ 230 VAC) .......................... 2-13

Figure 2.6 – 1 to 20 HP @ 230 VAC GV3000/SE Drive........................................... 2-14

Figure 2.7 – DC Bus Voltage Terminals (30 to 100 HP @ 230 VAC and 75 to 200

HP @ 460 VAC Drives) ......................................................................... 2-17

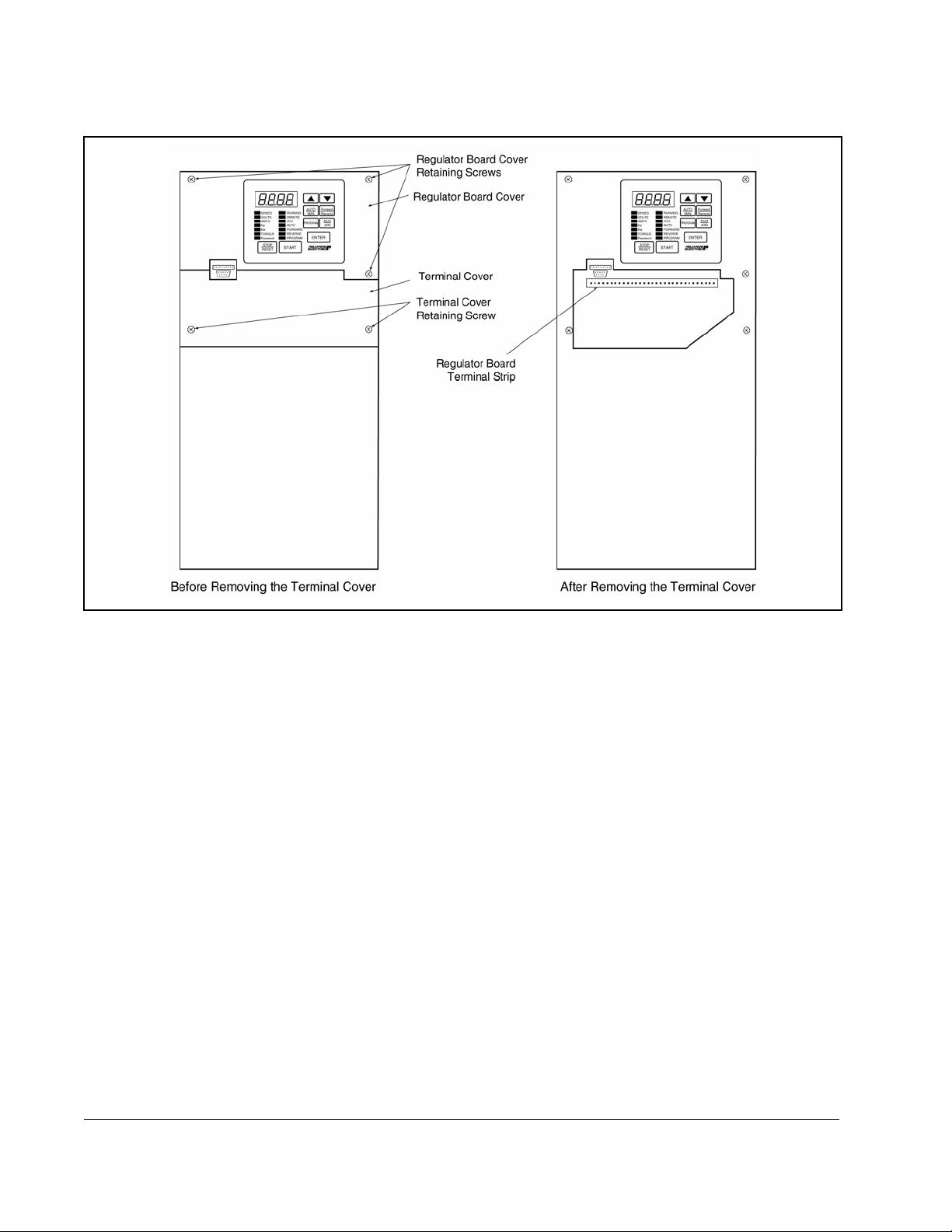

Figure 2.8 – Location of Terminal Cover and Regulator Board Cover in 75

to 200 HP (460 VAC) and 30 to 100 HP (230 VAC) Drives ................. 2-18

Figure 2.9 – Regulator Board’s Connections to Option Board, Keypad,

and Base Board .................................................................................... 2-19

Figure 2.10 – DC Bus Voltage Terminals (15 to 25 HP @ 460 VAC) ..................... 2-22

Figure 2.11 – DC Bus Voltage Terminals (25 to 60 HP @ 460 VAC) ..................... 2-23

Figure 2.12 – GV3000/SE Drive (15 to 25 and 25 to 60 HP @ 460 VAC) .............. 2-24

Figure 2.13 – 50 to 100 HP Drive Components and Locations .............................. 2-27

Figure 2.14 – 100 to 150 HP Drive Components and Locations ............................ 2-29

Figure 2.15 – GV3000/SE Drive (200 to 400 HP) ................................................... 2-32

Figure 2.16 – 2 to 15 Amp GV3000/SE Bookshelf Drives ...................................... 2-36

Figure 2.17 – 24 to 30 Amp GV3000/SE Bookshelf Drives .................................... 2-37

Figure 2.18 – 43 Amp GV3000/SE Bookshelf Drives ............................................. 2-38

Figure 2.19 – 24 to 30 Amp GV3000/SE Bookshelf Drive (Cover

and Front Panel Removed)................................................................. 2-39

Figure 2.20 – Installing the ControlNet Option Board ............................................. 2-40

Figure 2.21 – Connecting a GV3000/SE Drive to the ControlNet Network............. 2-42

Figure 3.1 – Signal Selection for Network Output Registers .................................... 3-7

Figure 4.1 – An Example of a MSG Instruction in a PLC-5 ...................................... 4-7

Figure 4.2 – Drive Information Map .......................................................................... 4-9

Figure 5.1 – RSLogix 5000: I/O Configuration Selection .......................................... 5-1

Figure 5.2 – RSLogix 5000: New Module Selection ................................................. 5-2

Figure 5.3 – Select Module Type: 1756-CNB/B Selection........................................ 5-2

Figure 5.4 – Module Properties: Name Selection ..................................................... 5-3

Figure 5.5 – Module Properties: Controller-to-Module Behavior Screen .................. 5-3

Figure 5.6 – Module Properties: Identification/Status Screen................................... 5-4

Figure 5.7 – Module Properties: Informational Screen ............................................. 5-4

Figure 5.8 – RSLogix 5000: I/O Configuration Folder............................................... 5-5

Figure 5.9 – RSLogix 5000: New Module Selection Screen..................................... 5-5

Figure 5.10 – Select Drive Type: GV3000 ................................................................ 5-6

Figure 5.11 – Module Properties: Name Selection ................................................... 5-6

Figure 5.12 – Module Properties: RPI Selections ..................................................... 5-7

Figure 5.13 – Module Properties: Cnet_Bridge ........................................................ 5-7

Figure 5.14 – RSLogix: Configure Additional Nodes Screen.................................... 5-8

Figure 5.15 – RSLogix 5000: Module-Defined Screen ............................................. 5-8

Figure 5.16 – Download to the Controller Dialog Box............................................... 5-9

Contents

III

Page 6

Figure 5.17 – RSLogix: Attention Symbol .................................................................5-9

Figure 5.18 – RSNetWorx for ControlNet Screen ...................................................5-10

Figure 6.1 – Network Configuration: Connection Properties .....................................6-2

Figure 6.2 – Channel Configuration: Chan 0-System ...............................................6-3

Figure 6.3 – Controller Properties: Controller Communications................................6-4

Figure 6.4 – 1747-KFC15 Set Up..............................................................................6-4

Figure 6.5 – Scheduled Messaging Example 1a.......................................................6-5

Figure 6.6 – Scheduled Messaging Example 1b.......................................................6-6

Figure 6.7 – Unscheduled Messaging Setup Screen................................................6-6

Figure 6.8 – Unscheduled Messaging Example........................................................6-7

IV

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 7

List of Tables

Table 2.1 – Locating the Appropriate Installation Procedure .................................... 2-1

Table 2.2 – Model Numbers for 1 to 5 HP @ 460 VAC Drives .................................... 2-4

Table 2.3 – Model Numbers for 1 to 20 HP @230 VAC Drives ................................ 2-12

Table 2.4 – Model Numbers for 30 to 100 HP @ 230 VAC and

75 to 200 HP@460 VAC Drives ............................................................. 2-16

Table 2.5 – Model Numbers for 15 to 60 HP @460 VAC Drives ............................. 2-21

Table 2.6 – Model Numbers for 2 to 15 Amp and 24 to 43 Amp Drives ................. 2-34

Table 4.1 – Network Update Time Components....................................................... 4-1

Table 4.2 – ControlNet Scheduled Traffic Configuration Information ....................... 4-2

Table 4.3 – Scheduled Drive Reference Data .......................................................... 4-3

Table 4.4 – Scheduled Drive Feedback Data ........................................................... 4-5

Table 4.5 – Signals That Can Be Displayed in Words 2 - 5...................................... 4-6

Table 4.6 – MSG Configuration Information ............................................................. 4-8

Table 6.1 – Required Software and Equipment........................................................ 6-1

Table 7.1 – File N10:X (Drive Read/Write Parameters)............................................ 7-1

Table 7.2 – File N11:X (Drive Display Data (Read Only)) ........................................ 7-6

Table 7.3 – File N12:X (Drive Reference and Feedback Data) ................................ 7-7

Table 8.1 – Health LED ............................................................................................ 8-1

Table 8.2 – Communications LEDs .......................................................................... 8-2

Table 8.3 – Communication Error Codes ................................................................. 8-2

Contents

V

Page 8

VI

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 9

CHAPTER 1

Introduction

This manual describes the GV3000/SE™ ControlNet™ Network Communication

Option Board (M/N

drive over the ControlNet network.

For normal operation, the GV3000/SE drive can be completely controlled using the

Network Option board. The only connections you need are a network interface

connection, hardwired emergency stop, and three-phase input and output power

wiring. Start, stop, reset, fault codes, and complete control can be done over the

ControlNet network.

1.1 About the ControlNet Network Communication

Option Board

The ControlNet Network Communication Option Board makes the GV3000/SE drive a

node on the ControlNet network. It is a printed circuit board assembly that mounts

inside a GV3000/SE drive and connects to the drive’s Regulator board using a ribbon

cable. The Network Option board is powered from the standard drive power supply.

2CN3000). This board lets you operate and monitor a GV3000/SE

The Network Option board is equipped with flash memory that lets you easily update

the board with the latest firmware revisions without having to remove the board from

the drive. An RS-232C serial port lets you connect a serial programming device to the

Network Option board for updating the board’s flash memory.

The Network Option board connects to the ControlNet network using two BNC

connectors that provide for redundant communication. You can connect a

programming device for accessing nodes using the Network Access Port, which is an

RJ-45 connector.

Three LEDs provide information to you about the board. Refer to chapter 8 for

descriptions of how the LEDs function.

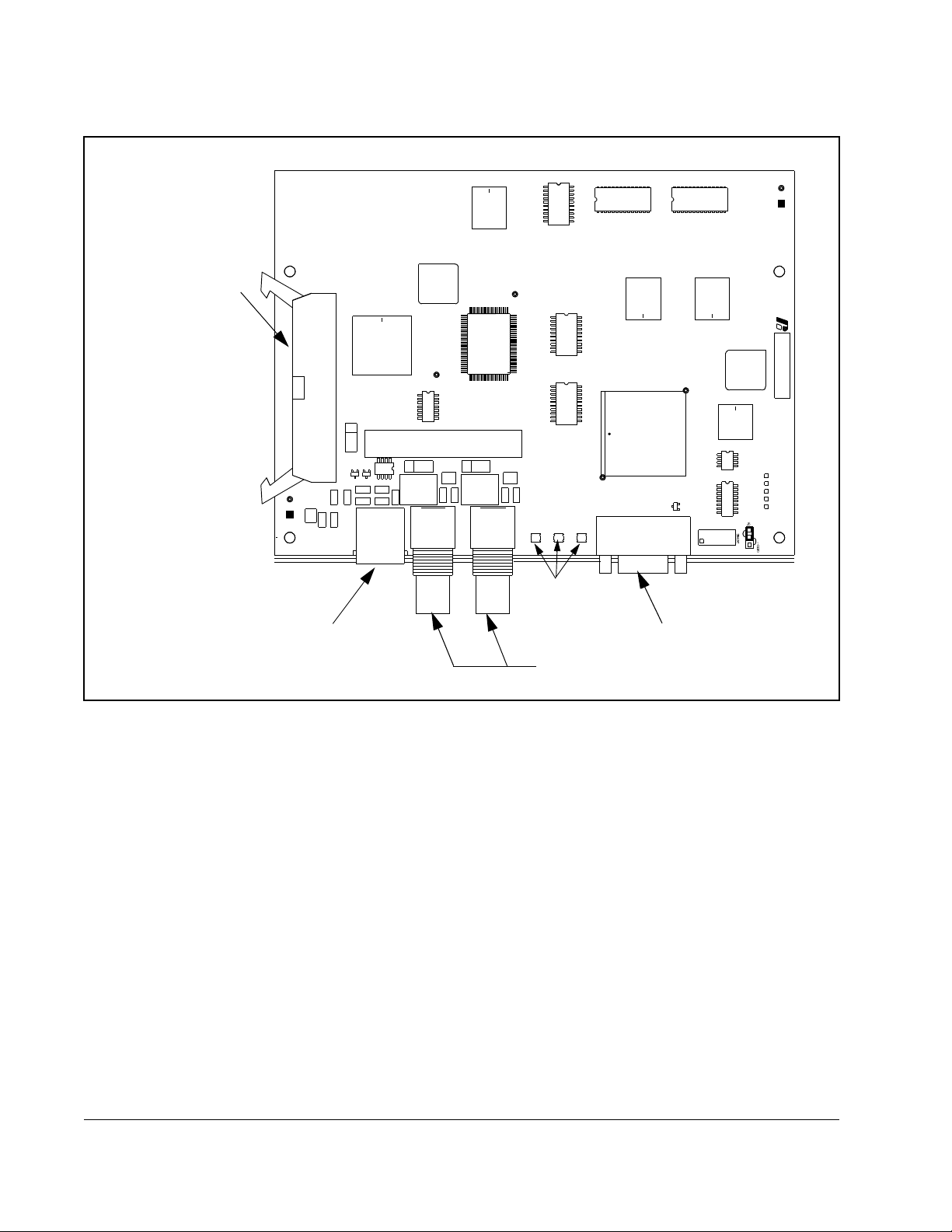

See figure 1.1 for the locations of the connectors and LEDs.

Introduction

1-1

Page 10

Ribbon Connector

to Regulator Board

ControlNet Network

Access Port

Figure 1.1 – ControlNet Network Communication Option Board

B

A

LEDs

RS-232 Connector

ControlNet Network Connectors

1-2

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 11

1.2 Where to Find Additional Information

You must be familiar with all the instruction manuals that describe your system

configuration. These manuals can include:

• GV3000/SE AC General Purpose (Volts/Hertz) and Vector Duty Drive Software

Start-Up and Reference Manual (D2-3359)

• GV3000/SE AC Drive Hardware Reference, Installation, and Troubleshooting

(D2-3360)

• GV3000/SE AC General Purpose (Volts/Hertz) and Vector Duty Bookshelf Drive

Software Start-Up and Reference Manual (D2-3426)

• GV3000/SE AC Bookshelf Drive Hardware Reference, Installation, and

Troubleshooting (D2-3427)

• ControlNet Network System Overview (1786-2.9)

• ControlNet Cable System Component List (AG-2.2)

• ControlNet Cable Planning and Installation Manual (1786-6.2.1)

• ControlNet Coax Tap Installation Manual (1786-5.7)

• ControlNet Network Access Cable Installation Instructions (1786-2.6)

• ControlNet Repeater Installation Instructions (1786-5.8)

You can obtain the ControlNet manuals listed above from The Automation Bookstore

at http://www.theautomationbookstore.com.

1.3 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office.

For technical assistance, call 1-864-284-5444. Before calling, please review the

troubleshooting section of this manual and check the standard drives website for

additional information. When you call this number, you will be asked for the drive

model number and this instruction manual number. Also, please have your product

version number ready.

Introduction

1-3

Page 12

1-4

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 13

CHAPTER 2

Installation

Contact Reliance if the drive installation must be in compliance with the European

Community Electromagnetic Compatibility Standards.

The ControlNet option board installation procedure differs depending on the drive

type. Use

table 2.1 to locate the appropriate procedure for your drive.

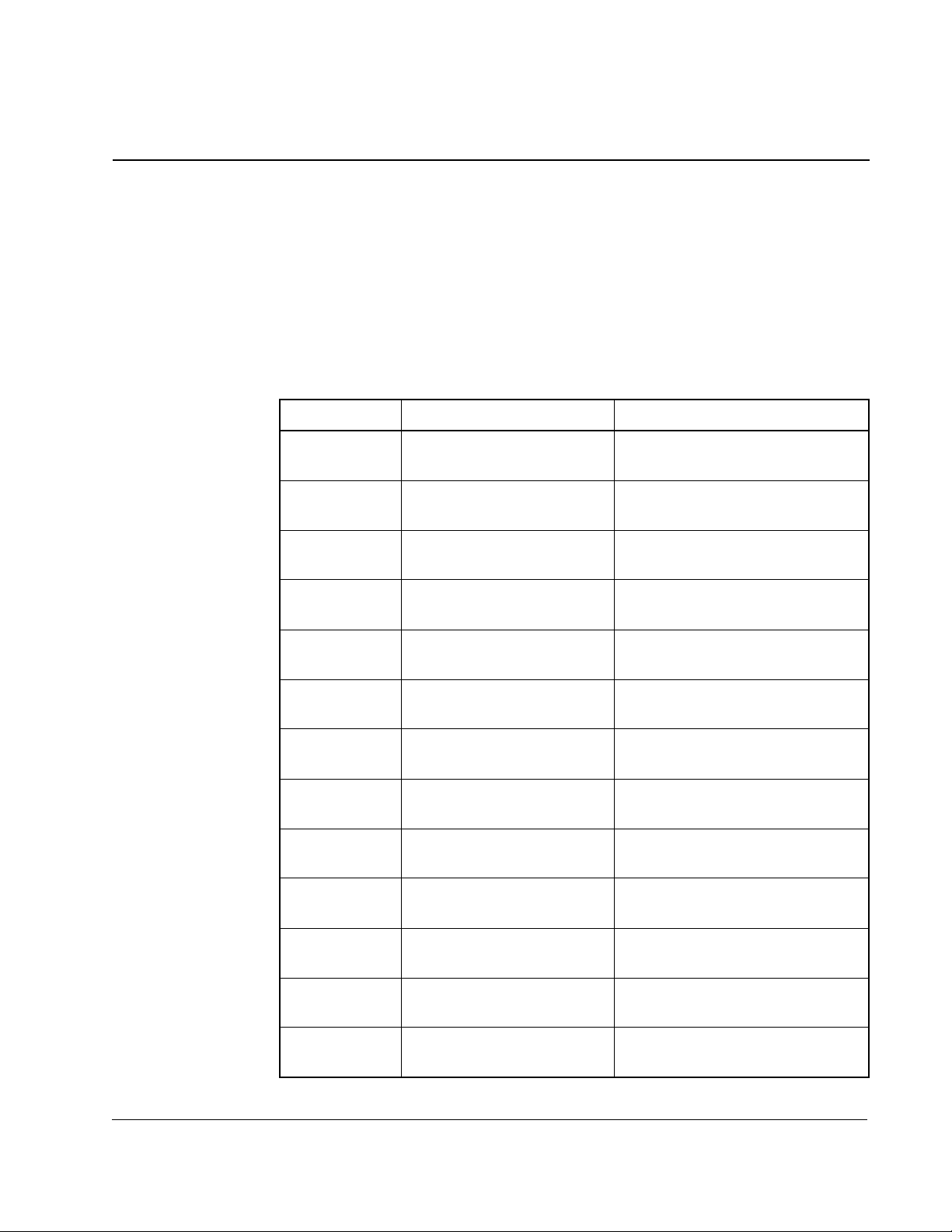

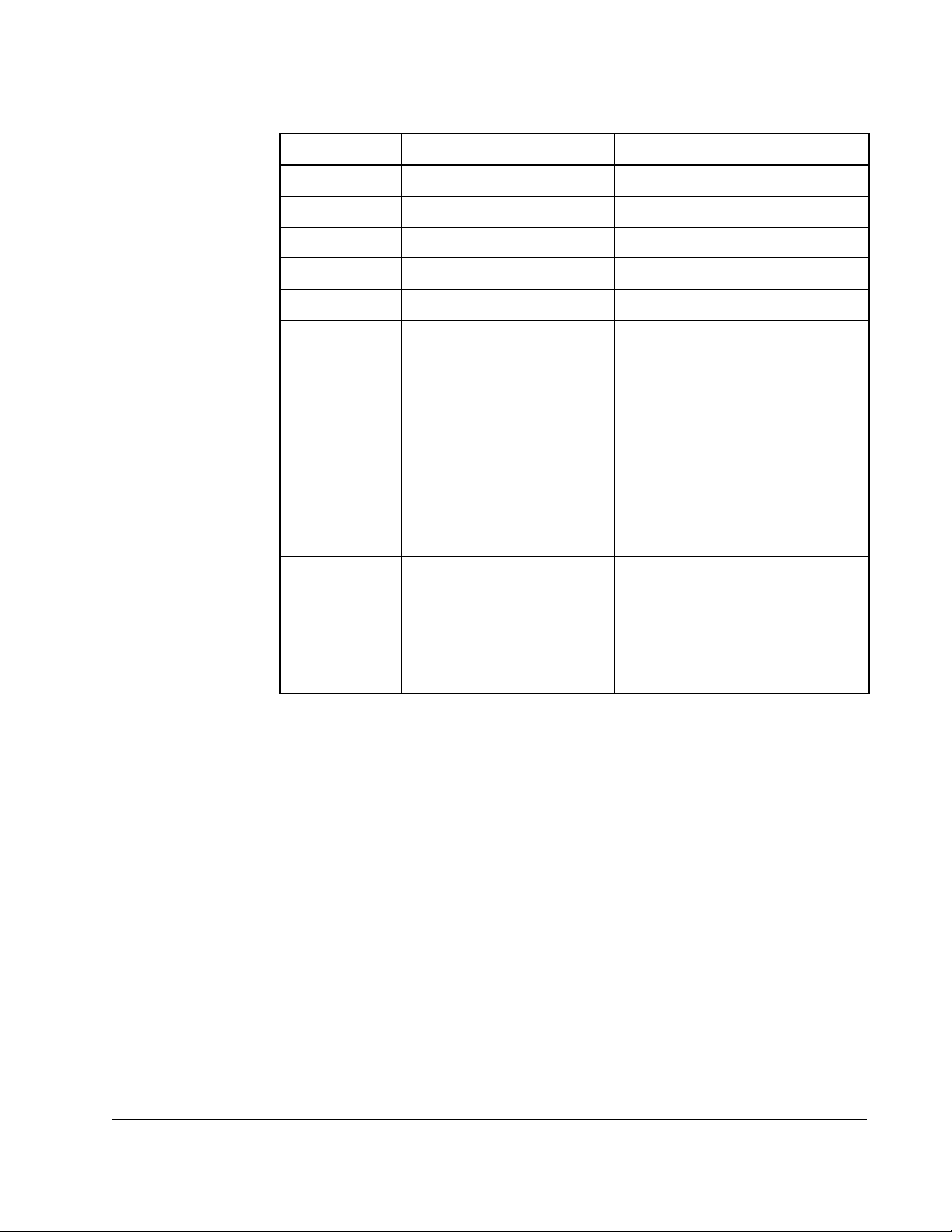

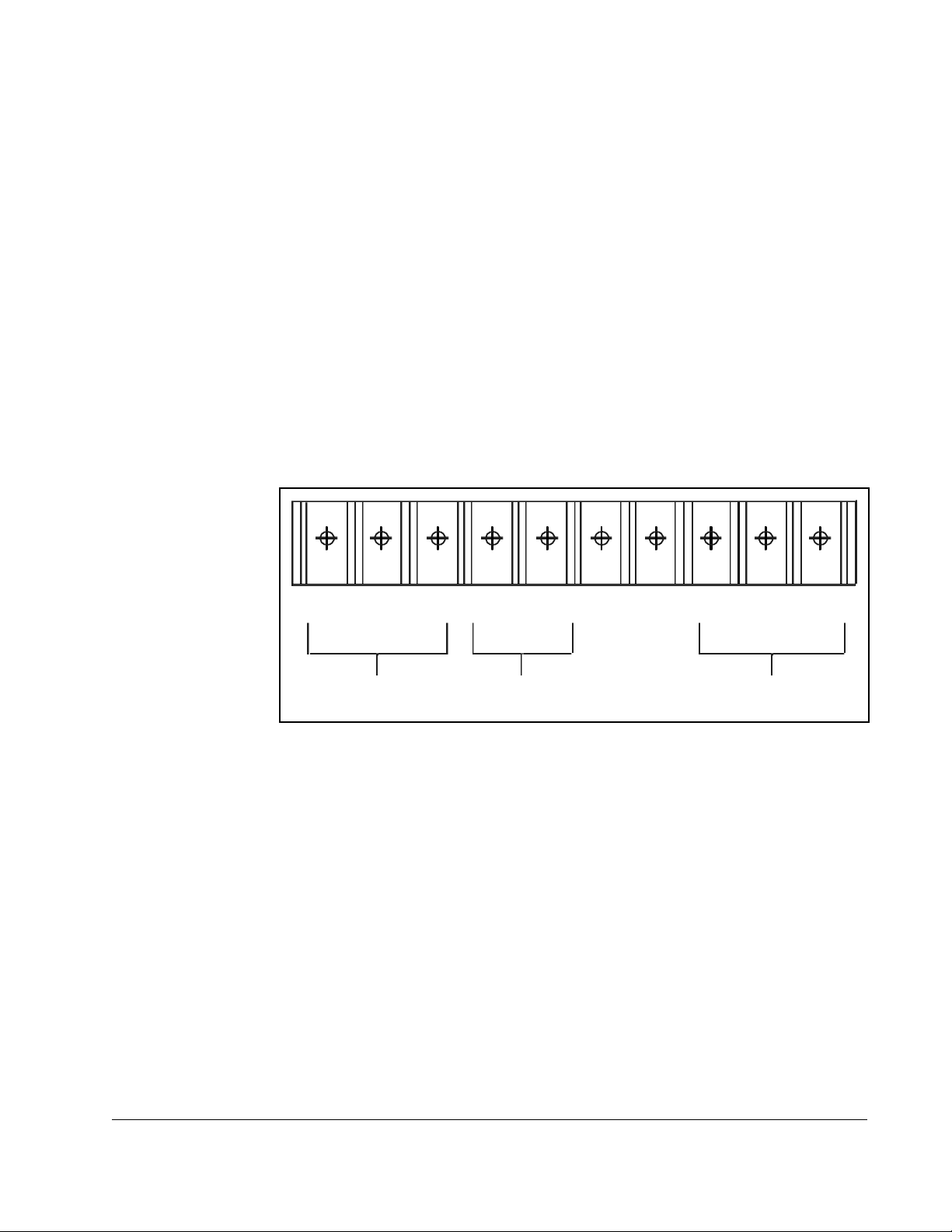

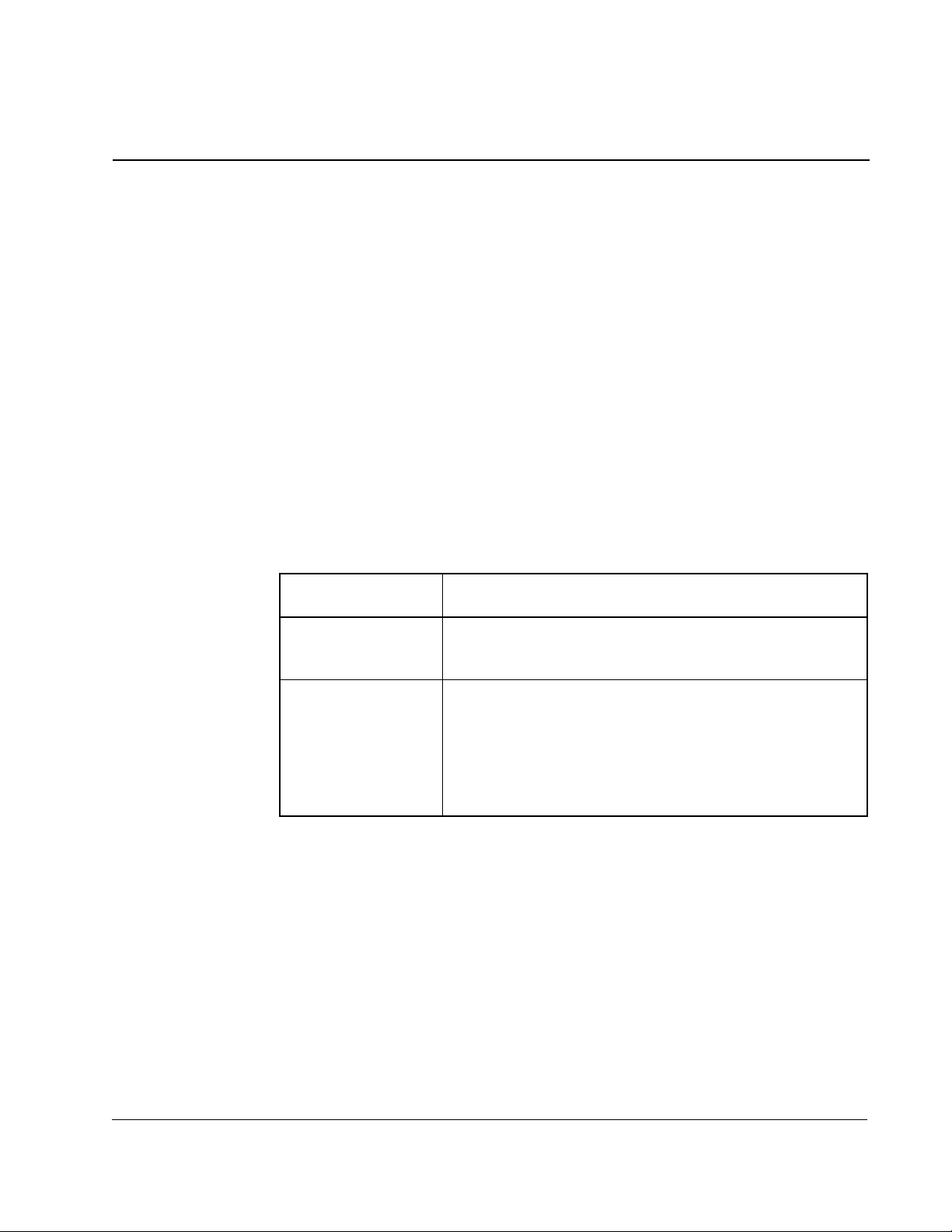

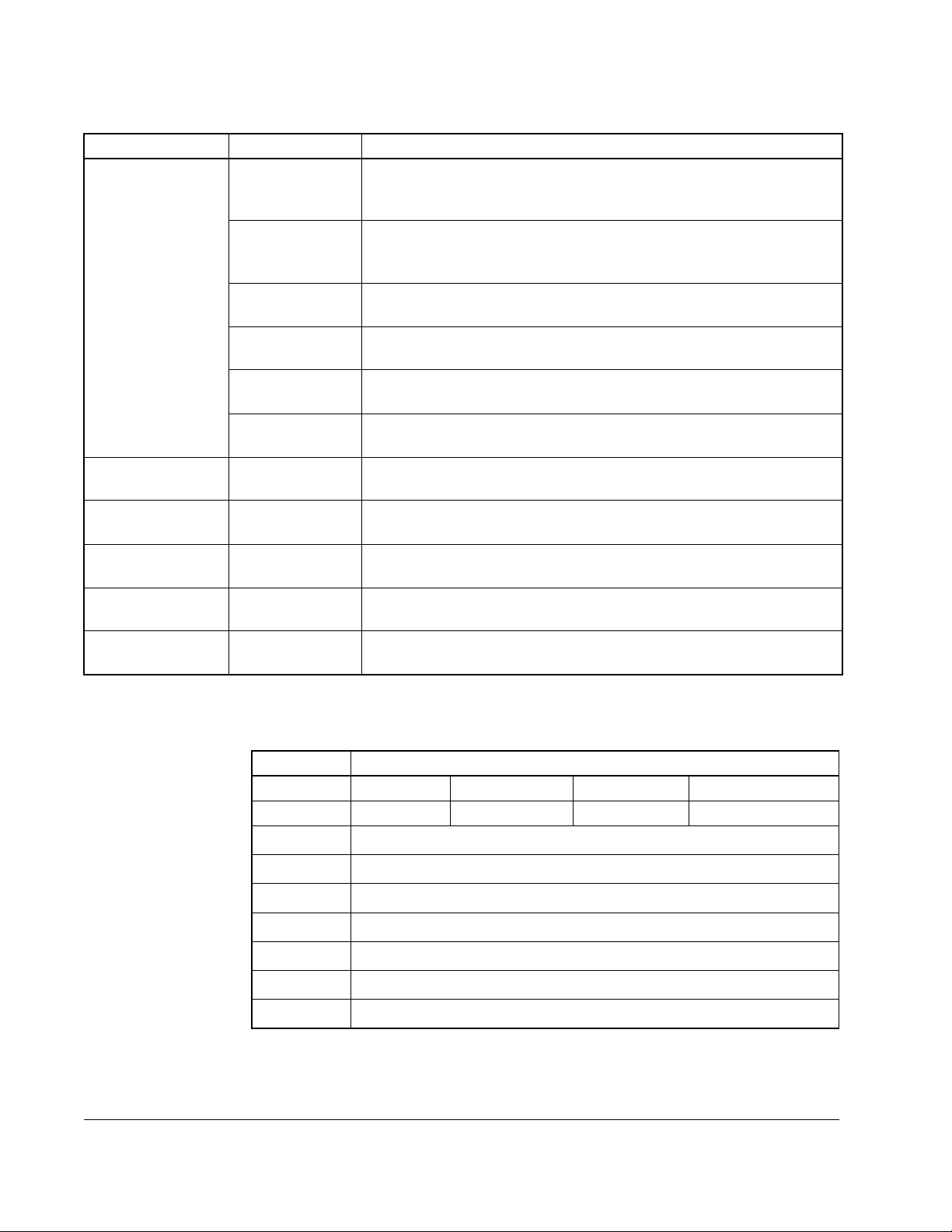

Table 2.1 – Locating the Appropriate Installation Procedure

Rating GV3000/SE Model Number Use the Procedure in Section …

1 HP 1V21xx

1V24xx

1 HP 1V41xx

1V44xx

2 HP 2V21xx

2V24xx

2 HP 2V41xx

2V44xx

3 HP 3V21xx

3V24xx

3 HP 3V41xx

3V44xx

5 HP 5V21xx

5V24xx

5 HP 5V41xx

5V44xx

7.5 HP 7V21xx

7V22xx

7.5 HP 7V41xx

7V42xx

2.3

2.1

2.3

2.1

2.3

2.1

2.3

2.1

2.3

2.2

Installation

10 HP 10V21xx

10V22xx

10 HP 10V41xx

10V42xx

15 HP 15V21xx

15V22xx

2.3

2.2

2.3

2-1

Page 14

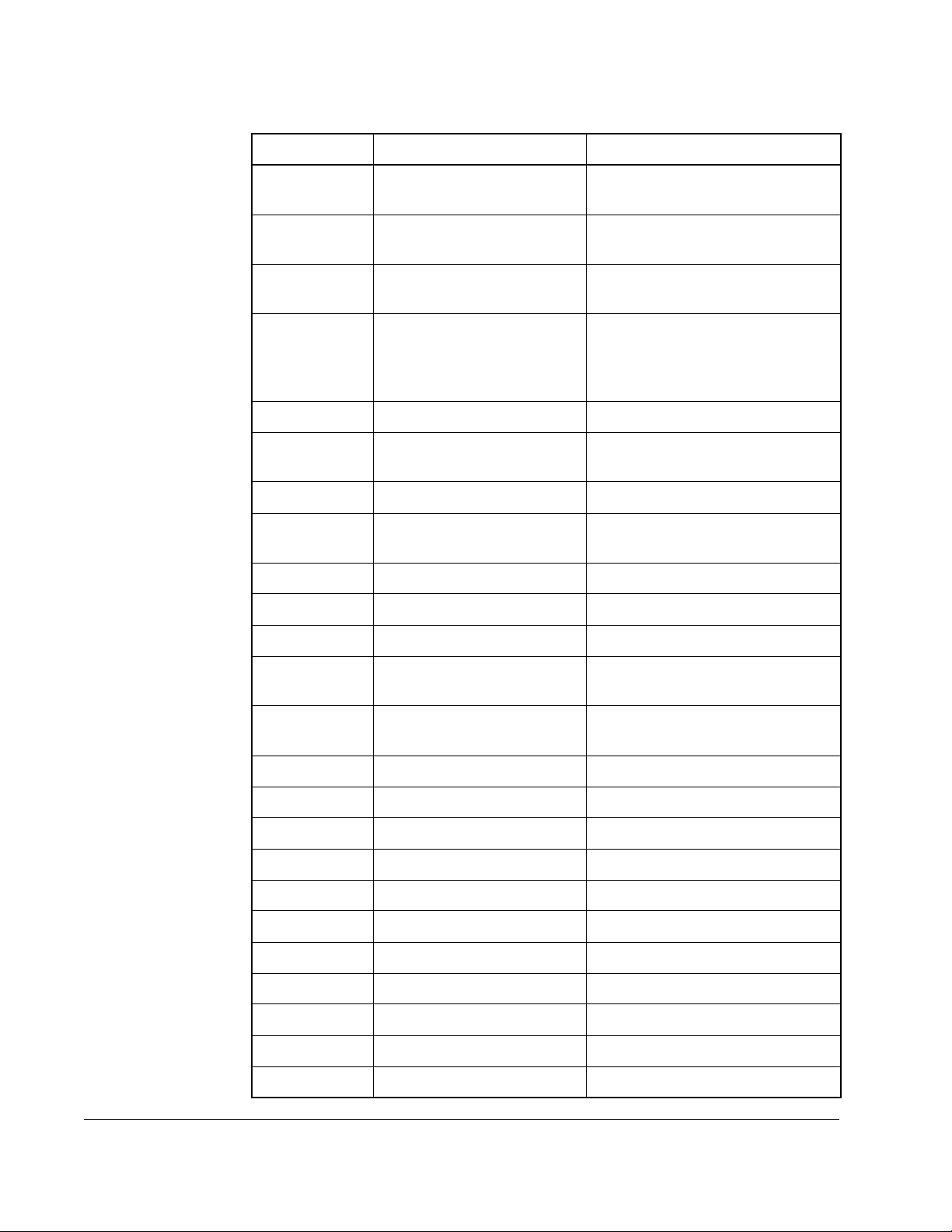

Table 2.1 – Locating the Appropriate Installation Procedure

Rating GV3000/SE Model Number Use the Procedure in Section …

15 HP 15V41xx

2.5

15V42xx

20 HP 20V21xx

2.3

20V22xx

20 HP 20V41xx

2.5

20V42xx

25 HP 25G41xx

2.5

25G42xx

25V41xx

25V42xx

30 HP 30V20xx 2.4

30 HP 30V41xx

2.5

30V42xx

40 HP 40V20xx 2.4

40 HP 40V41xx

2.5

40V42xx

50 HP 50R41xx 2.6

50 HP 50T41xx 2.6

50 HP 50V20xx 2.4

50 HP 50V41xx

2.5

50V42xx

60 HP 60G41xx

2.5

60G42xx

60 HP 60V20xx 2.4

75 HP 75R41xx 2.6

75 HP 75T41xx 2.6

75 HP 75V20xx 2.4

75 HP 75V40xx 2.4

100 HP 100V20xx 2.4

100 HP 100V40xx 2.4

125 HP 125R41xx 2.6

125 HP 125V40xx 2.4

150 HP 150V40xx 2.4

200 HP 200V40xx 2.4

2-2

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 15

Table 2.1 – Locating the Appropriate Installation Procedure

Rating GV3000/SE Model Number Use the Procedure in Section …

200 HP 200V41xx 2.7

250 HP 250V41xx 2.7

300 HP 300V41xx 2.7

350 HP 350V41xx 2.7

400 HP 400V41xx 2.7

2 to 15 Amp 31ER40xx

31ET40xx

38ER40xx

38ET40xx

55ER40xx

55ET40xx

85ER40xx

85ET40xx

126ER40xx

126ET40xx

150ER40xx

150ET40xx

24 to 30 Amp 240ER40xx

240ET40xx

300ER40xx

300ET40xx

43 Amp 430ER40xx

430ET40xx

2.8

2.8

2.8

Installation

2-3

Page 16

2.1 Installing the ControlNet Option Board in

1 to 5 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in the drives listed in

table 2.2.

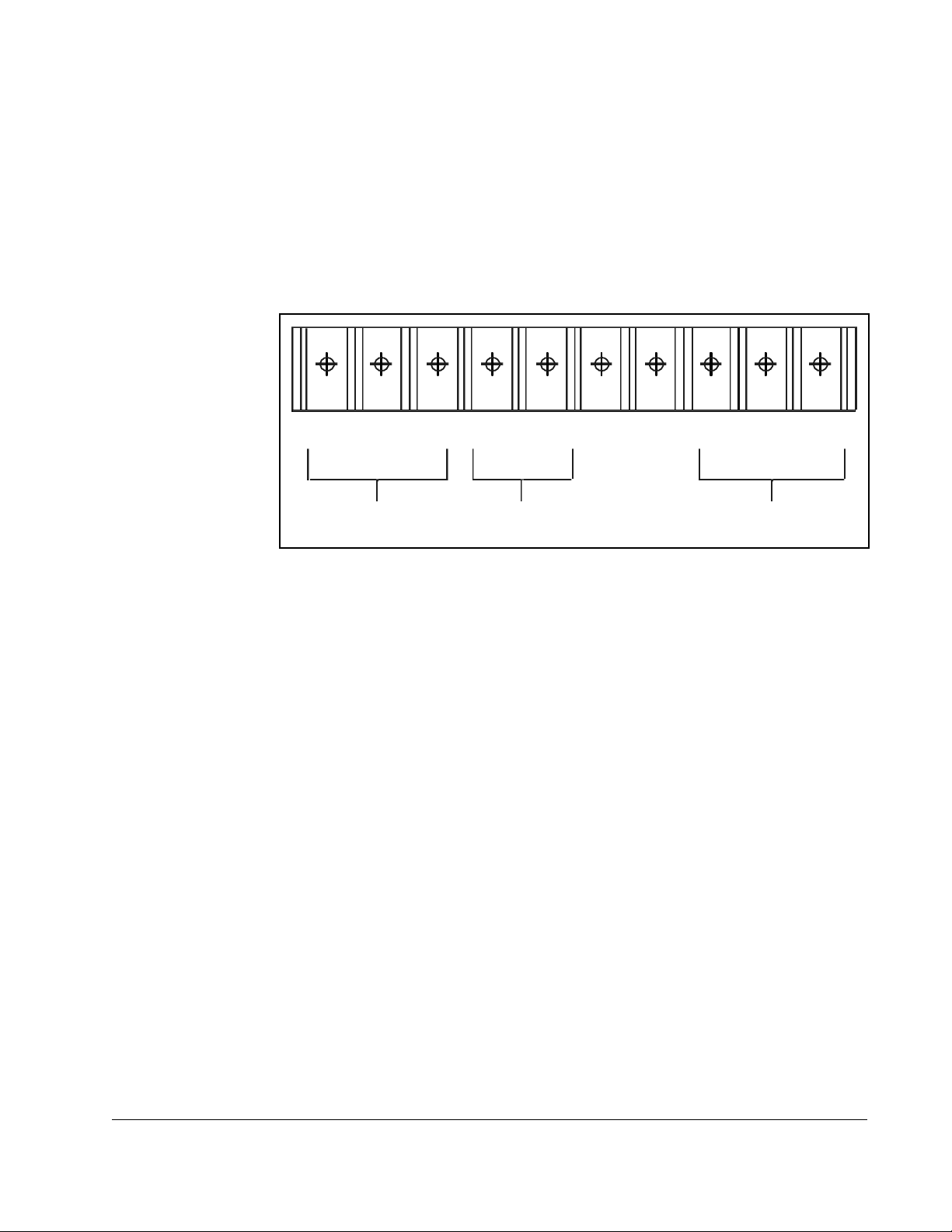

Table 2.2 – Model Numbers for 1 to 5 HP @ 460 VAC Drives

1V41xx

1V44xx

2V41xx

2V44xx

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

3V41xx

3V44xx

5V41xx

5V44xx

2-4

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 17

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

bus potential:

DC

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals as shown in

figure 2.1.

R/L1 T/L3

S/L2 1 0V 10 CO M

AC Power

Input Leads

Figure 2.1 – DC Bus Voltage Terminals (1 to 5 HP @ 460 VAC)

+

–+

DC Bus

Volts

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Use a magnetic screwdriver to remove the three M4 x 10 screws that fasten

the bottom of the keypad support bracket to the drive heat sink.

Important: The keypad support bracket is connected to the drive by wiring. Do not lift

the bracket completely out of the drive to prevent damage to wiring.

Step 3.3 Spread the retaining clips on the 26-conductor Regulator board ribbon

cable connector to disconnect it from the Current Feedback board. The

Current Feedback board is located on the right below the keypad.

Step 3.4 Move the keypad support bracket aside.

–

W/T3V/T2U/T1

Motor Leads

Installation

Step 3.5 Pinch the retaining clip that is through the center of the Current Feedback

board and carefully pull out the Current Feedback board.

Step 3.6 Unplug the internal fan assembly power connector (CONN7) from the drive.

2-5

Page 18

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figure 2.2 for component locations.

Regulator Board

To p Vi ew

ControlNet Option

Board

Current Feedback

Board

2-6

Front View

Figure 2.2 – 1 to 5 HP @ 460 VAC GV3000/SE Drive

Side View

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Step 4.3 Route the 26-conductor ribbon cable for the Current Feedback board out of

the side of the keypad bracket.

Step 4.4 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.5 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 19

Step 4.6 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Reconnect the internal fan assembly power connector (CONN7) to the

drive. Align the key on the connector with the slot in the receptacle. Press

the connector into position.

ATTENTION:Proper alignment of the Current Feedback board is critical.

Verify that the connector pins on the Current Feedback board are

!

Step 5.2 Reinstall the Current Feedback board. Carefully align the two sets of

Step 5.3 Inspect the Current Feedback board connector thoroughly for bent or

Step 5.4 Align the keypad support bracket with the mounting holes in the drive heat

correctly aligned with their corresponding con nectors on the drive. Failure

to observe this precaution can result in bodily injury.

connector pins on the Current Feedback board with their matching

connectors on the drive. Gently press the board into place. The board

should go in easily. If you feel resistance, a pin might be bent or misaligned.

Recheck alignment and retry installation.

misaligned pins.

sink. Fasten the bracket with the three M4 x 10 screws removed earlier.

Step 5.5 Align the Regulator board’s 26-conductor ribbon cable connector with the

Current Feedback board connector. Press it in until it locks into position.

Step 5.6 Route the Network Drop Cable through the left-most opening at the bottom

of the drive.

Step 5.7 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.8 Reconnect any wiring that was removed from the Regulator board.

Step 5.9 NEMA 4X/12 drives only: Before installing the cover, check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.10 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

Nm (20 in-lb) of torque on these screws.

2.2

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed

instruction on connecting to the ControlNet network.

section 2.9, which provides

Installation

2-7

Page 20

2.2 Installing the ControlNet Option Board in

7.5 to 10 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in drives with model numbers

7V41xx, 7V42xx, 10V41xx, or 10V42xx.

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

2-8

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 21

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in

figure 2.3.

R/L1 T/L3

S/L2 10V 10 CO M

AC Power

Input Leads

Figure 2.3 – DC Bus Voltage Terminals (7.5 to 10 HP)

+

–+

DC Bus

Volts

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Loosen the thumb screw on the left side of the keypad bracket. Hold the

bracket on the left and lift the bracket up and to the left to separate it from

the keypad support bracket.

Important: The bracket is connected to the drive by wiring. Do not attempt to lift the

bracket out completely as this can damage or pull out wiring. Tie up or

support the bracket to prevent damage to the wiring.

Step 3.3 Spread the retaining clips on the 26-conductor Regulator board ribbon

cable connector to disconnect it from the Current Feedback board. The

Current Feedback board is located on the right below the keypad.

–

W/T3V/T2U/T1

Motor Leads

Installation

2-9

Page 22

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figure 2.4 for component locations.

Top Vi ew

Current Feedback Board

Regulator Board

Front View

Figure 2.4 – 7.5 to 10 HP @ 460 VAC GV3000/SE Drive

Network Option Board

Side View

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

2-10

Step 4.3 Route the 26-conductor ribbon cable for the Current Feedback board out of

the side of the keypad bracket.

Step 4.4 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.5 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 23

Step 4.6 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

Step 4.7 Reconnect the keypad bracket to the keypad support bracket by inserting

the mounting tabs into the slots in the support bracket and tightening the

thumb screw.

Step 4.8 Align the Regulator board’s 26-conductor ribbon cable connector with the

Current Feedback board connector. Press it in until it locks into position.

Step 5. Reinstall the Keypad Support Bracket in the Drive

Step 5.1 Route the Network Drop Cable through the left-most opening at the bottom

of the drive.

Step 5.2 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.3 Reconnect any wiring that was removed from the Regulator board.

Step 5.4 NEMA 4X/12 drives only: Before installing the cover, check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.5 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

Installation

2-11

Page 24

2.3 Installing the ControlNet Option Board in

1 to 20 HP @ 230 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in the drives listed in

table 2.3.

Table 2.3 – Model Numbers for 1 to 20 HP @230 VAC Drives

1V21xx

1V24xx

2V21xx

2V24xx

3V21xx

3V24xx

5V21xx

5V24xx

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

7V21xx

7V22xx

10V21xx

10V22xx

15V21xx

15V22xx

20V21xx

20V22xx

2-12

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 25

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in

figure 2.5.

R/L1 T/L3

S/L2 1 0V 10 CO M

AC Power

Input Leads

Figure 2.5 – DC Bus Voltage Terminals (1 to 20 HP @ 230 VAC)

+

–+

DC Bus

Volts

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Use a magnetic screwdriver to remove the M4 x 10 screws that fasten the

bottom of the keypad support bracket to the drive heat sink.

Step 3.3 Spread the retaining clips on the Regulator board ribbon cable (on the right

side) to disconnect it from the Base Board.

Step 3.4 Remove the keypad bracket. Place it with the keypad down on a flat

surface. If you cannot lay it flat, tie it up to prevent damage to wiring.

–

W/T3V/T2U/T1

Motor Leads

Installation

2-13

Page 26

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figure 2.6 for component locations.

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Step 4.3 Route the other ribbon cable out of the side of the keypad bracket.

Step 4.4 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.5 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

Step 4.6 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

Keypad Bracket

Regulator Board

Te rm in al St ri p

Power Terminal

Strip

Figure 2.6 – 1 to 20 HP @ 230 VAC GV3000/SE Drive

2-14

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 27

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Place the keypad support bracket back into position. Use a magnetic

screwdriver to fasten it to the heatsink with the screws removed earlier.

Step 5.2 Realign the 26-conductor ribbon cable connector with the connector inside

the slot in the keypad support bracket. Carefully press the ribbon cable

connector in until the retaining clips lock into place.

Step 5.3 Route the Network Drop Cable through the left-most opening at the bottom

of the drive.

Step 5.4 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.5 Reconnect any wiring that was removed from the Regulator board.

Step 5.6 NEMA 4X/12 drives only: Before installing the cover, check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.7 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

Installation

2-15

Page 28

2.4 Installing the ControlNet Option Board in

30 to 100 HP @ 230 VAC and 75 to 200 HP@460 VAC

Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in the drives listed in

table 2.4.

Table 2.4 – Model Numbers for 30 to 100 HP @ 230 VAC and 75 to 200 HP@460 VAC Drives

30V20xx 100V20xx

40V20xx 100V40xx

50V20xx 125V40xx

60V20xx 150V40xx

75V20xx 200V40xx

75V40xx

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

2-16

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 29

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals shown in

R

figure 2.7.

S

P (+)

DC Bus

Volts

T

N (-)

Installation

U (T1)

W (T3)

Figure 2.7 – DC Bus Voltage Terminals (30 to 100 HP @ 230 VAC and 75 to 200 HP @ 460 VAC Drives)

GND

V (T2)

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 If the drive has:

• A Regulator board cover and terminal cover: Remove the three M4

screws from the Regulator board cover. Remove the cover. See

figure 2.8.

• A terminal cover only: If you have this type of drive, this procedure is

easier to perform if you lay the drive on its side. Remove the side cover

from the drive. Use a long magnetized screwdriver to unfasten the four

screws that hold the keypad bracket in.

2-17

Page 30

Figure 2.8 – Location of Terminal Cover and Regulator Board Cover in 75 to 200 HP (460 VAC) and 30 to 100 HP (230 VAC) Drives

Step 3.2 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.3 Remove the terminal cover, which is below the keypad and fastened with

two M4 screws. See

figure 2.8.

Step 3.4 Pull the keypad assembly partly out of the drive. Spread the retaining clips

on the Regulator board ribbon cable (on the right side) to disconnect it from

the Base Board. See

figure 2.9.

Step 3.5 Remove the keypad bracket. Place it with the keypad down on a flat

surface. If you cannot lay it flat, tie it up to prevent damage to wiring.

2-18

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 31

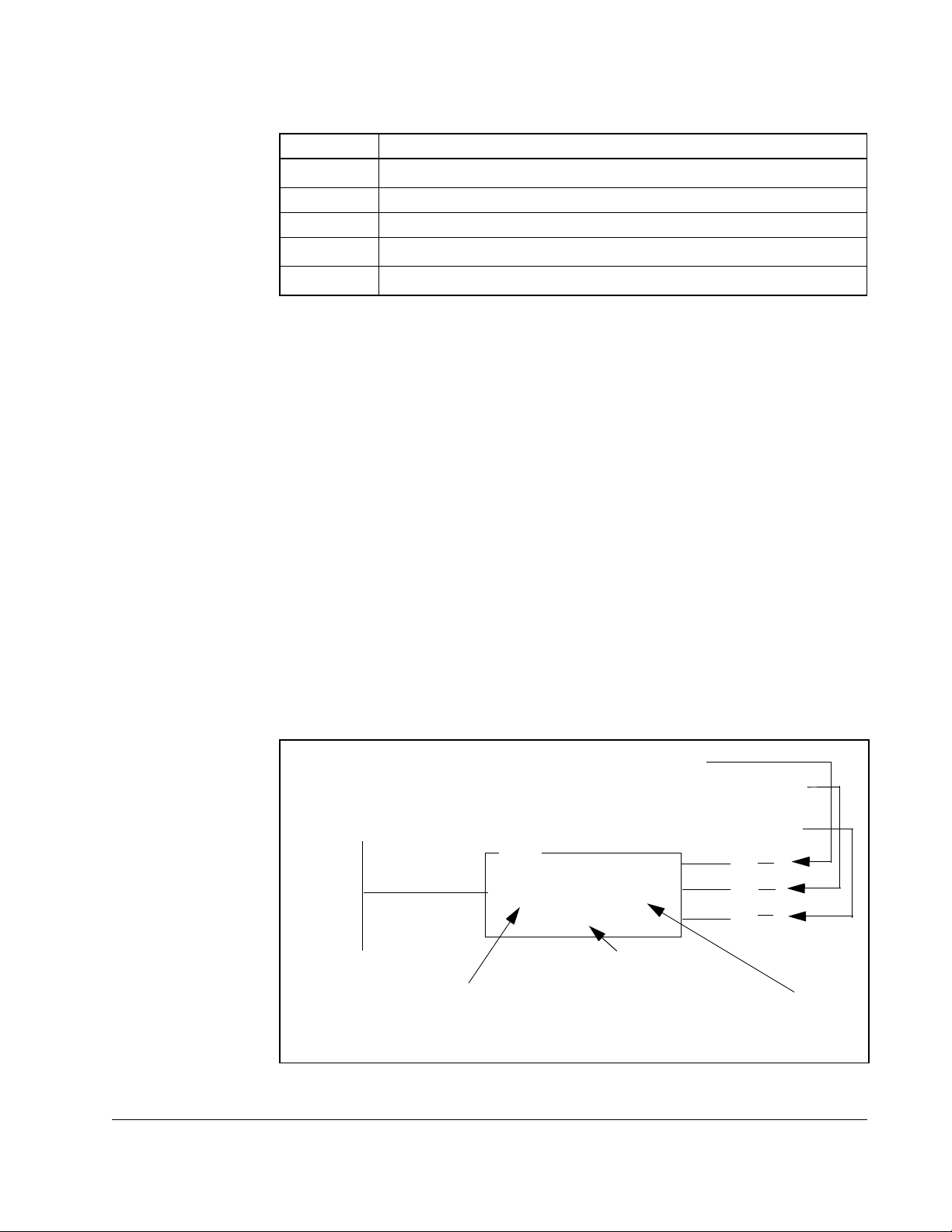

Front

Regulator Board

Ribbon Cable

Connecting

Regulator Board and

Base Board

Metal Screw

Ribbon Cable

Connector to

Connect Base

Board

Ribbon Cable

Connector to

Connect Keypad

Plastic Rivet

To p V iew

Back Side of

Regulator Board

Network

Option Board

Rear View of Regulator Board

Ribbon Cable

Connecting

Regulator Board and

Option Board

To Base Board

Insulator

Ribbon Cable

Connector to

Connect Option

Board

Terminal Strip

Installation

Figure 2.9 – Regulator Board’s Connections to Option Board, Keypad, and Base Board

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figures 2.8 and 2.9.

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Step 4.3 Route the other ribbon cable out of the side of the keypad bracket.

Step 4.4 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.5 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

2-19

Page 32

Step 4.6 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Align the Regulator board ribbon cable connector with the connector to the

Base board. Carefully press the ribbon cable connector in until the retaining

clips lock into place.

Step 5.2 Place the keypad bracket back into position.

Step 5.3 If the drive has:

• A Regulator board cover and terminal cover: Replace the Regulator board

cover. Fasten it using the three M4 screws removed earlier.

• Only a terminal cover: Use a long magnetized screwdriver to fasten the

four screws that hold the keypad bracket. Replace the side cover on the

drive.

Step 5.4 Route the Network Drop Cable through the left-most opening at the bottom

of the drive.

Step 5.5 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.6 Reconnect any wiring that was removed from the Regulator board.

Step 5.7 Replace the terminal cover (below the keypad). Fasten it using the two M4

screws removed earlier.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

2-20

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 33

2.5 Installing the ControlNet Option Board in 15 to 25 HP

and 25 to 60 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in drives with the model

numbers listed in

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

If the drive is panel-mounted, this procedure will be easier to perform if the drive is

removed from the panel.

Important: Read and understand the warning labels on the outside of the drive

table 2.5.

Table 2.5 – Model Numbers for 15 to 60 HP @460 VAC Drives

15V41xx

15V42xx

20V41xx

20V42xx

25G41xx

25G42xx

25V41xx

25V42xx

before proceeding.

30V41xx

30V42xx

40V41xx

40V42xx

50V41xx

50V42xx

60G41xx

60G42xx

Installation

2-21

Page 34

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover by loosening the four cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (R/L1, S/L2, T/L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. Use a voltmeter to measure the DC bus potential at the DC bus power

terminals as shown in figures

2.10 (15 to 25 HP) and 2.11 (25 to 60 HP).

U/T1 T/L3

V/T2

Motor Leads

Figure 2.10 – DC Bus Voltage Terminals (15 to 25 HP @ 460 VAC)

+

DC Bus

Volts

–

R/L1W/T3

S/L2

AC Power

Input Leads

2-22

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 35

DC Bus Volts

Input Wiring

+

–

Figure 2.11 – DC Bus Voltage Terminals (25 to 60 HP @ 460 VAC)

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Loosen the thumb screw on the left side of the keypad bracket. Hold the

bracket on the left and lift the bracket up and to the left to separate it from

the keypad support bracket.

Important: The bracket is connected to the drive by wiring. Do not attempt to lift the

bracket out completely as this can damage or pull out wiring. Tie up or

support the bracket to prevent damage to the wiring.

Step 3.3 Disconnect the 26-conductor Regulator board ribbon cable from the Power

Supply board (located on the right side below the keypad). You can see the

connector through the slot on the keypad support bracket. Use a small

screwdriver inserted through the slot to spread the retaining clips on the

connector to release it.

R/L1

S/L2

T/L3

Installation

2-23

Page 36

Top Vi ew

Top View

Network Option Board

Regulator Board

Regulator Board

Front View

15 to 25 HP @ 460 VAC

25 to 60 HP @ 460 VAC

Figure 2.12 – GV3000/SE Drive (15 to 25 and 25 to 60 HP @ 460 VAC)

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figure 2.12 for component locations.

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Network Option Board

Front View

2-24

Step 4.3 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.4 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

Step 4.5 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

Step 4.6 Realign the 26-conductor ribbon cable connector with the Power Supply

board connector inside the slot in the keypad support bracket. Carefully

press the ribbon cable connector in until the retaining clips lock it into place.

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 37

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.7 Reconnect the keypad bracket to the keypad support bracket by inserting

the mounting tabs into the slots in the support bracket and tightening the

thumb screw.

Step 5.8 Route the Network Drop Cable through the left-most opening at the bottom

of the drive.

Step 5.9 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.10 Reconnect any wiring that was removed from the Regulator board.

Step 5.11 NEMA 4X/12 drives only: Before installing the cover, check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.12 Reinstall the cover. Align all cover screws into the heat sink before

tightening any of them.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

Installation

2-25

Page 38

2.6 Installing the ControlNet Option Board in

50 to 100 HP and 100 to 150 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in drives with the model

numbers 50R41xx, 50T41xx, 75R41xx, 75T41xx, or 125R41xx.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Step 1.3 Remove the cover from the drive by removing the six cover screws.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

2-26

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 39

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals (1L1, 1L2, 1L3).

Step 2.2 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves.

b. 50 to 100 HP @ 460 V only: Use a voltmeter to measure the DC bus

potential at the diode bridge. Refer to

figure 2.13.

c. 100 to 150 HP @ 460 V only: Take care not to touch any conductive

traces. Use a voltmeter to measure the DC bus potential at the bottom of

the fuse holders on the Power Module Interface board on the back of the

Regulator panel. Refer to

figure 2.14.

–

DC Bus

Measuring Points

+

Keypad

Regulator

Board

Power Module

Interface Board

Figure 2.13 – 50 to 100 HP Drive Components and Locations

Step 3. Remove the Keypad Bracket from the Drive

Step 3.1 Loosen the two screws from the top of the hinged panel (where the keypad

bracket is mounted). Tilt the mounting panel forward out of the drive

chassis.

Step 3.2 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.3 Spread the retaining clips on the Regulator board’s 60-conductor ribbon

cable connector to disconnect it from the Power Module Interface board.

This ribbon cable runs from the top of the Regulator board through a slot in

the mounting panel to the Power board on the other side. Slip the ribbon

cable out of the slot to free it from the mounting panel.

Installation

2-27

Page 40

Step 3.4 Use a magnetic screwdriver to remove the four screws and lock washers

that fasten the keypad bracket to the hinged mounting panel. Hold the

keypad bracket as you remove the screws.

Step 4. Install the ControlNet Option Board in the Keypad Bracket

Refer to figure 2.13 (50 to 100 HP drives) or 2.13 (100 to 150 HP drives) for

component locations.

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

Step 4.2 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Step 4.3 Align the ControlNet option board on the four mounting tabs on the keypad

bracket. Make sure that the ribbon cable is not pinched between the keypad

bracket and the ControlNet option board.

Step 4.4 Fasten the right side of the ControlNet option board to the keypad bracket.

Use the two metal M3 screws and lock washers for grounding.

Important: You must use the lock washers to properly ground the option board.

Improper grounding of the option board can result in erratic operation of

the drive.

Step 4.5 Fasten the left side of the ControlNet option board to the keypad bracket

using the two plastic rivets.

2-28

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 41

Power Module

Interface Board

Power Module Interface Board

(-)

(+)

DC Bus Measuring Points

Regulator Panel

DC bus measuring

points are behind the

Regulator Panel on the

Power Module Interface

board.

Fuses

Keypad

Figure 2.14 – 100 to 150 HP Drive Components and Locations

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Reconnect the keypad bracket to the hinged mounting panel using the four

screws and lock washers removed earlier.

Step 5.2 100 to 150 HP drives only: Remove the tie that was fastened to the Power

Module Interface board earlier.

Regulator Board

Power Module

Interface Board

Installation

2-29

Page 42

Step 5.3 100 to 150 HP drives only: Align the Power Module Interface board on the

eight plastic standoffs on the back of the mounting panel. Carefully press it

into place. Make sure that good contact has been made with the two

grounding standoffs.

Step 5.4 Route the Regulator board’s 60-conductor ribbon cable through the slot in

the hinged mounting panel to the connector on the Power Module Interface

board. Align the two connectors. Place your thumb beneath the Power

Module Interface board for support and carefully press the ribbon cable

connector in until it locks into position.

Step 5.5 Swing the hinged mounting panel back into position. Make sure no wires or

cables are pinched by the panel.

Step 5.6 Refasten the two screws at the top of the panel.

Step 5.7 Route the Network Drop Cable through the right-most opening at the

bottom of the drive, away from the AC lines.

Step 5.8 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 5.9 Reconnect any wiring that was removed from the Regulator board.

Step 5.10 Replace mounting panel and fasten with two screws at the top of the hinged

panel (where the keypad bracket is mounted).

Step 5.11 NEMA 4X/12 drives only: Before installing the cover, check that the gaskets

on the cover are flat and within the gasket channels.

Step 5.12 Reinstall the cover with the six screws removed in step 1.3. Make sure no

wires or cables are pinched by the cover.

To maintain the integrity of NEMA 4X/12 drives, sequentially tighten the six

cover screws to ensure even compression of the gaskets. Do not exceed

2.2 Nm (20 in-lb) of torque on these screws.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

2-30

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 43

2.7 Installing the ControlNet Option Board in

200 to 400 HP @ 460 VAC Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use this procedure to install the ControlNet option board in drives with part number

200V41xx, 250V41xx, 300V41xx, 350V41xx, or 400V41xx.

Unless otherwise indicated, keep all hardware that is removed. You will need it for

reassembly. This includes screws, lock washers, and rivets.

Important: Read and understand the warning labels on the outside of the drive

before proceeding.

Step 1. Shut Down the Drive

Step 1.1 Disconnect, lock out, and tag all incoming power to the drive.

Step 1.2 Wait five minutes for the DC bus capacitors to discharge.

Important: Read and understand the warning labels on the inside of the drive before

proceeding.

Step 2. Verify that the DC Bus Capacitors are Discharged

Step 2.1 Open the drive’s outer cabinet door.

Step 2.2 Lower the plastic terminal strip shield at the top of the drive.

Step 2.3 Use a voltmeter to verify that there is no voltage at the drive’s AC input

power terminals, R, S, and T.

Installation

Step 2.4 Replace the plastic terminal strip shield.

2-31

Page 44

Step 2.5 Ensure that the DC bus capacitors are discharged. To check

DC bus potential:

a. Stand on a non-conductive surface and wear insulated gloves. (600 V)

b. Use a voltmeter to check the DC bus potential at the Voltmeter Test

Points on the Power Module Interface board. See

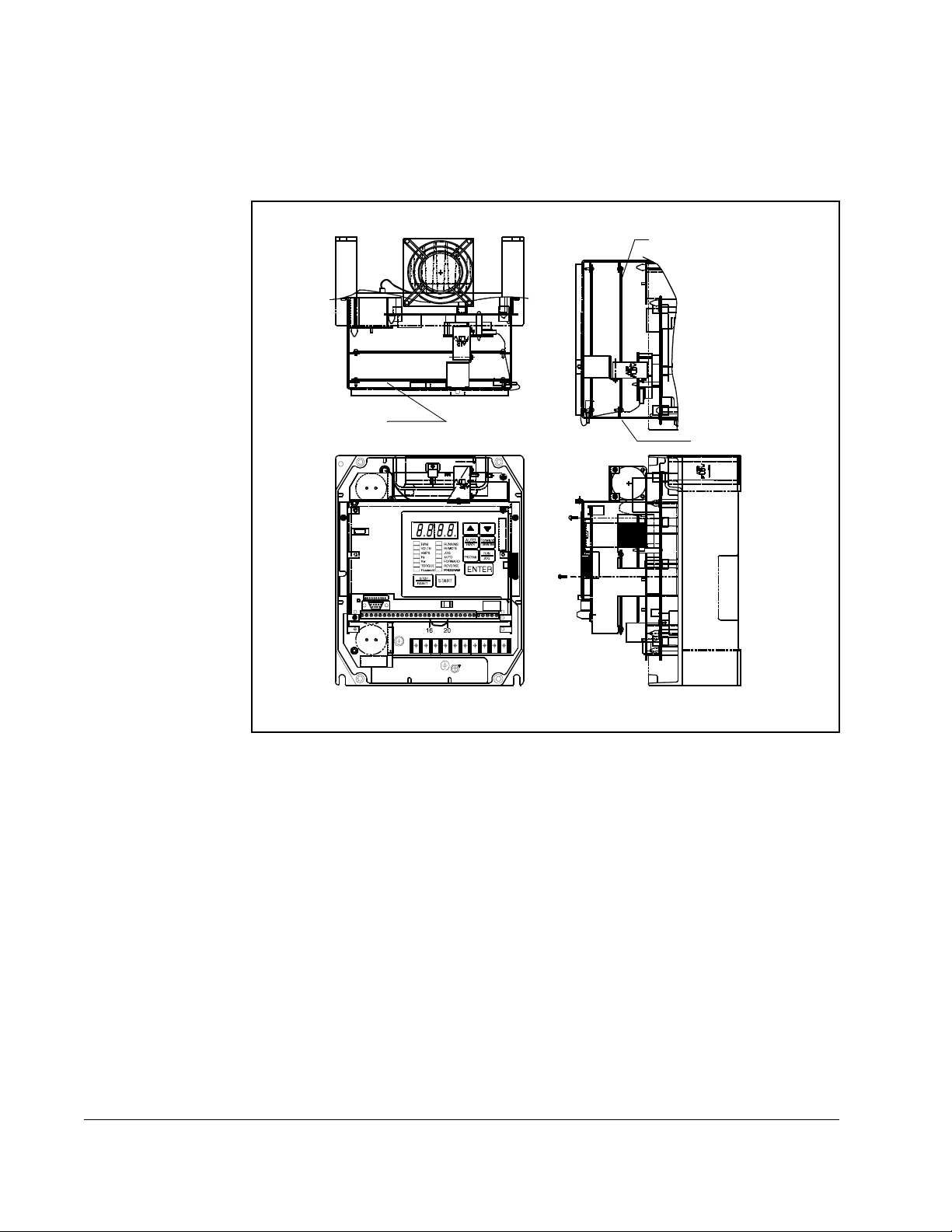

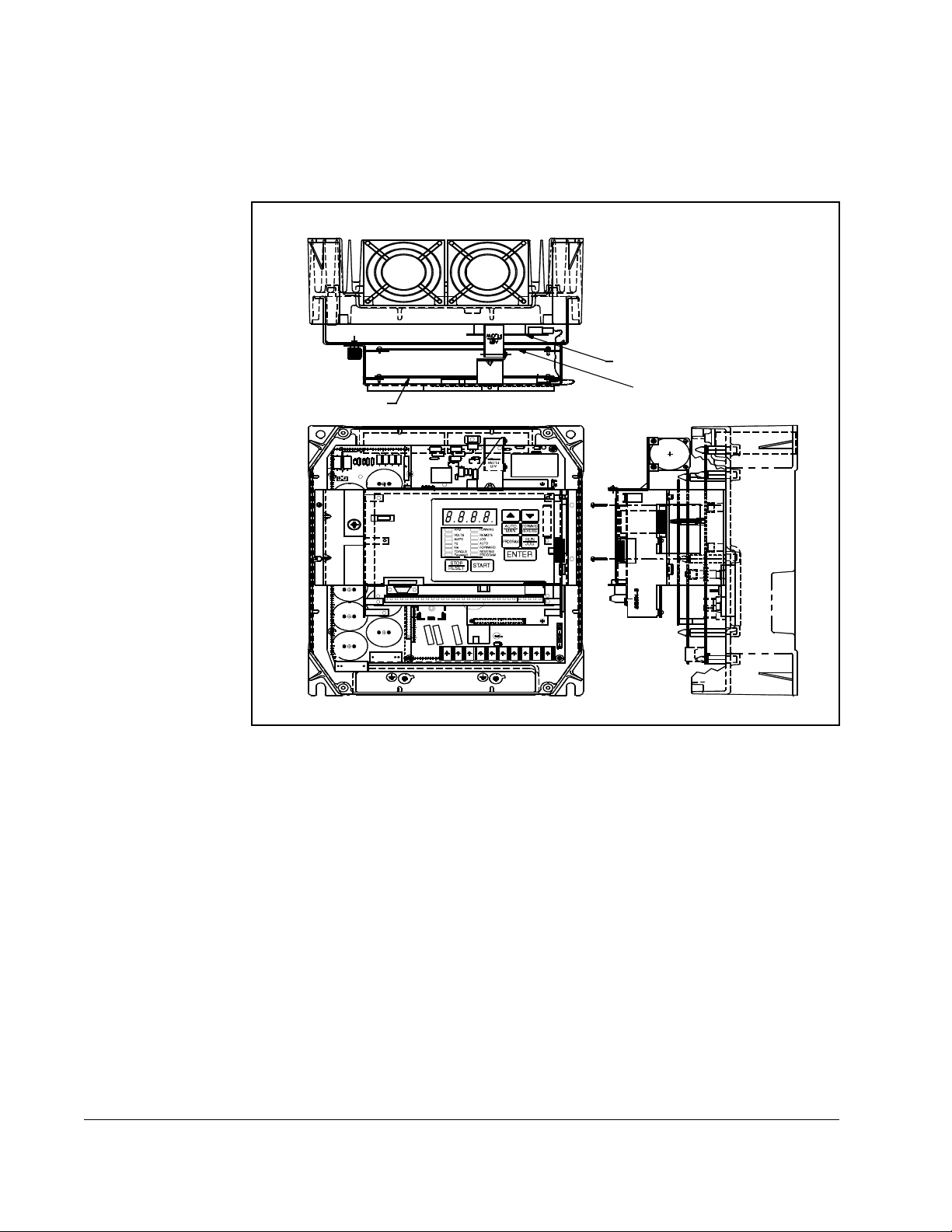

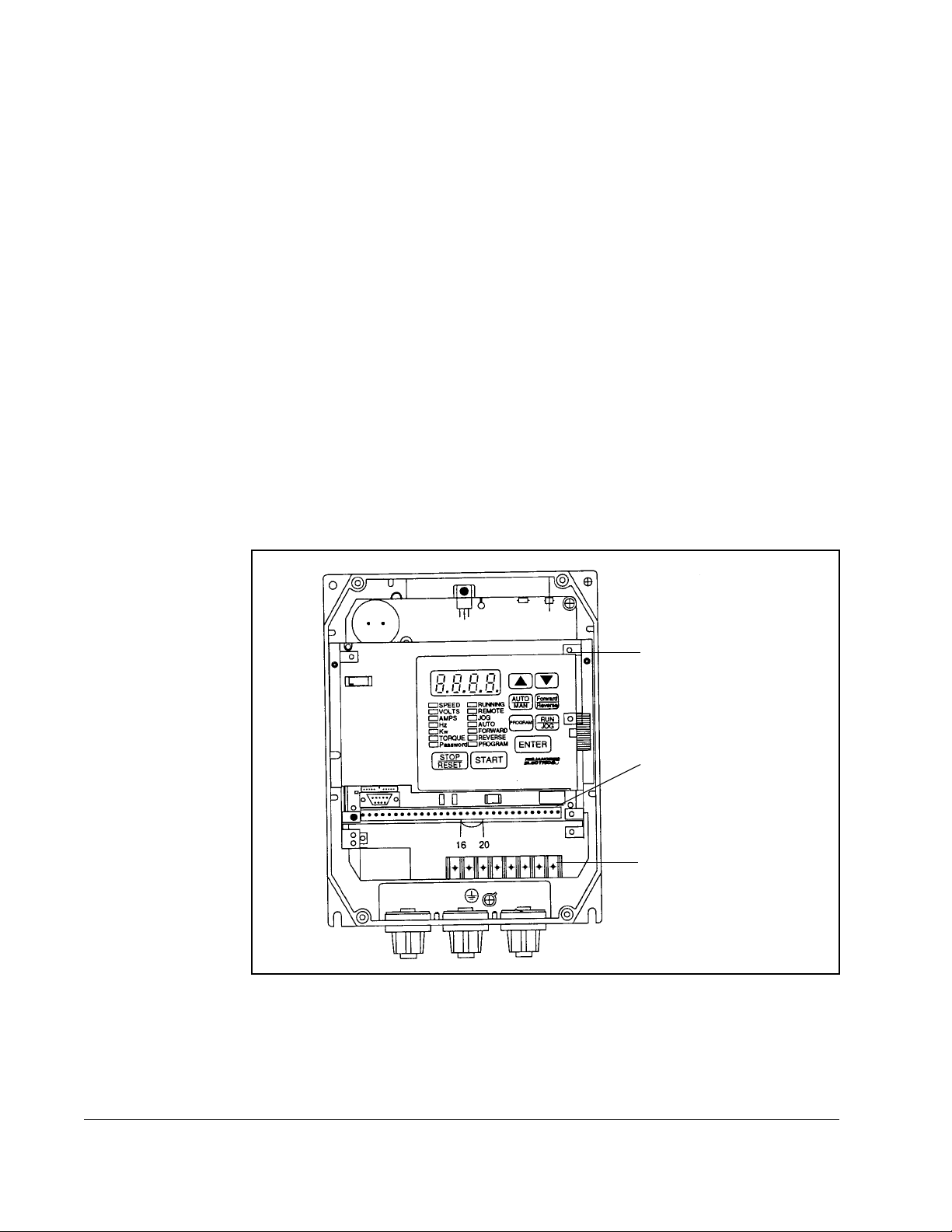

Step 3. Remove the Keypad Bracket from the Drive

Refer to figure 2.15 for component locations.

POWER CONNECTIONS

FULL SHIELD TABS IN AND ROTATE SHIELD OUT

CONNECT USING 360MCM TWO HOLE TERMINAL LUGS

TORQUE TO 3 25IN-LB

DC–

GND

GND

WT1 WT2VRL1WWT3

DC+

U

DC+

DC–

DANGER

SL2 T

RST

Wiring Tray

Power Module

Interface Board

figure 2.15.

RUNNI NG

RPM

REMOTE

VOLTS

JOG

AMPS

AUTO

Hz

FORWAR D

Kw

REVERSE

TORQUE

PROGRAM

Passwo rd

ENTER

STOP

START

RESET

Front View

Figure 2.15 – GV3000/SE Drive (200 to 400 HP)

Step 3.1 Record connections to the Regulator board terminal strip if they must be

disconnected to remove the keypad bracket.

Step 3.2 Use a magnetic screwdriver to remove the four screws and lock washers

that fasten the keypad bracket to the hinged mounting panel. Hold the

keypad bracket as you remove the screws.

Step 3.3 Disconnect the Regulator board ribbon cable from the Power Module

Interface board.

Step 4. Install the ControlNet Option Board

Keypad

Regulator

Board

Network

Option

Board

Side View

(Enlarged)

2-32

Step 4.1 Remove the ControlNet option board from its anti-static wrapper.

The ControlNet option board mounts on four standoffs behind the

Regulator board.

Step 4.2 Align the ControlNet option board’s four mounting holes with the four

standoffs on the hinged mounting panel of the drive.

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 45

Step 4.3 Fasten the board to the drive with four ″ nuts. Metal nuts must be used

for proper grounding of the ControlNet option board.

Step 4.4 Connect the brown wire to terminal 1 of the 2-connector terminal strip.

Connect the white wire to terminal 2.

Step 4.5 Align the key on the connector of the ControlNet option board ribbon cable

with the key on the Regulator board connector. Press the ribbon cable

connector in until it locks into position.

Step 4.6 Route the Network Drop Cable through the signal wiring tray on the right

side of the drive.

Step 5. Reinstall the Keypad Bracket in the Drive

Step 5.1 Align the key on the connector from the Regulator board with the key of the

connector on the Power Module Interface board. Press the ribbon cable

connector in until it locks into position.

Step 5.2 Reconnect the keypad bracket to the hinged mounting panel using the four

screws removed earlier.

Step 5.3 Reconnect any wiring that was removed from the Regulator board.

Step 5.4 Close and secure the outer cabinet door of the drive.

This completes the hardware installation of the ControlNet option board. Do not

remove the lockout and tag until you have completed section 2.9, which provides

instruction on connecting to the ControlNet network.

7

⁄

32

Installation

2-33

Page 46

2.8 Installing the ControlNet Option Board in 2 to 43 Amp

GV3000/SE Bookshelf Drives

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:The drive is at line voltage when connected to incoming

AC power. Disconnect, lock out, and tag all incoming power to the drive

before performing the following procedure. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive contains ESD- (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing the drive. Erratic machine

operation and damage to, or destruction of, equipment can result if this

procedure is not followed. Failure to observe this precaution can result

in bodily injury.

Use the procedure in this section to install the ControlNet option board in the drives

listed in

This procedure requires access to the right side of the drive. Remove the drive from

the panel if necessary.

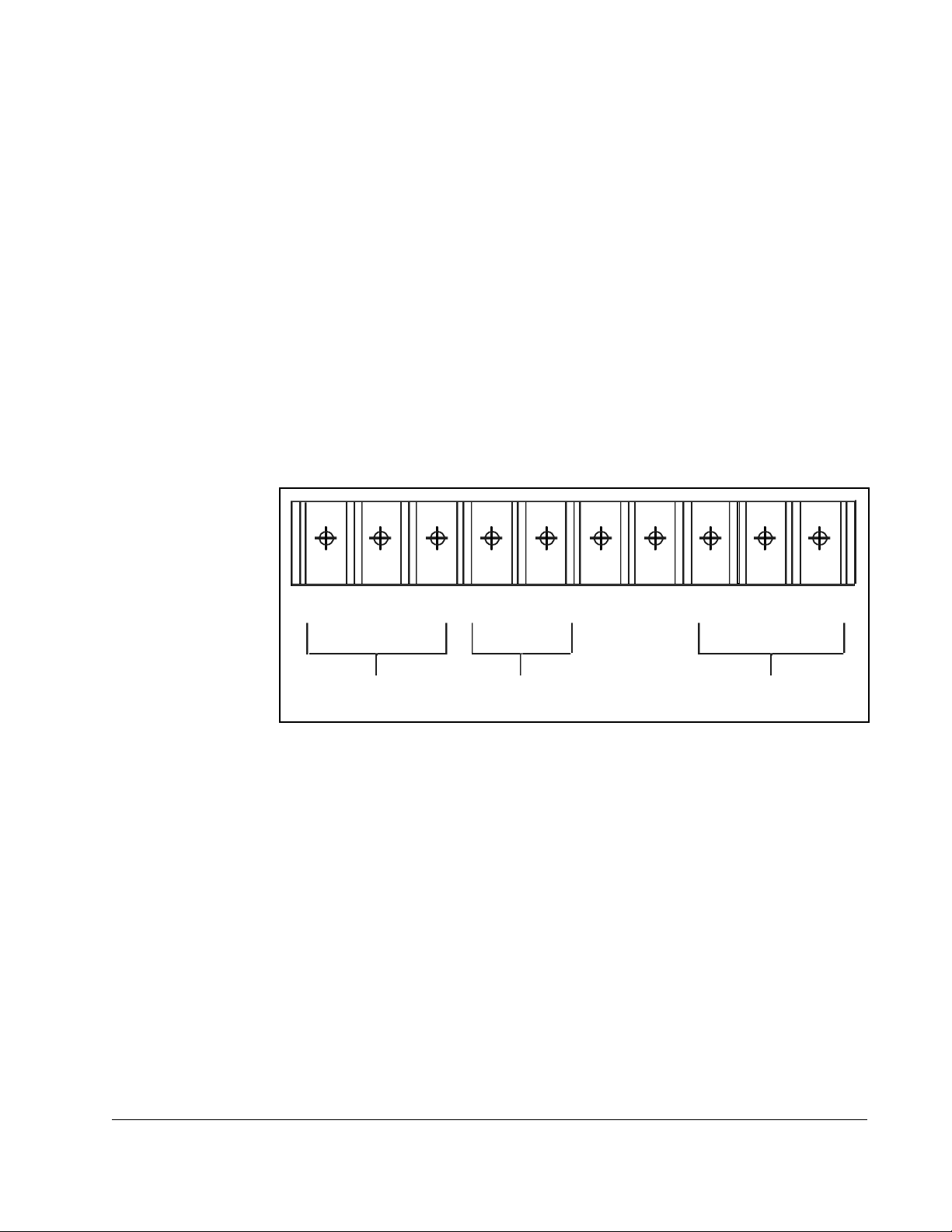

table 2.6.

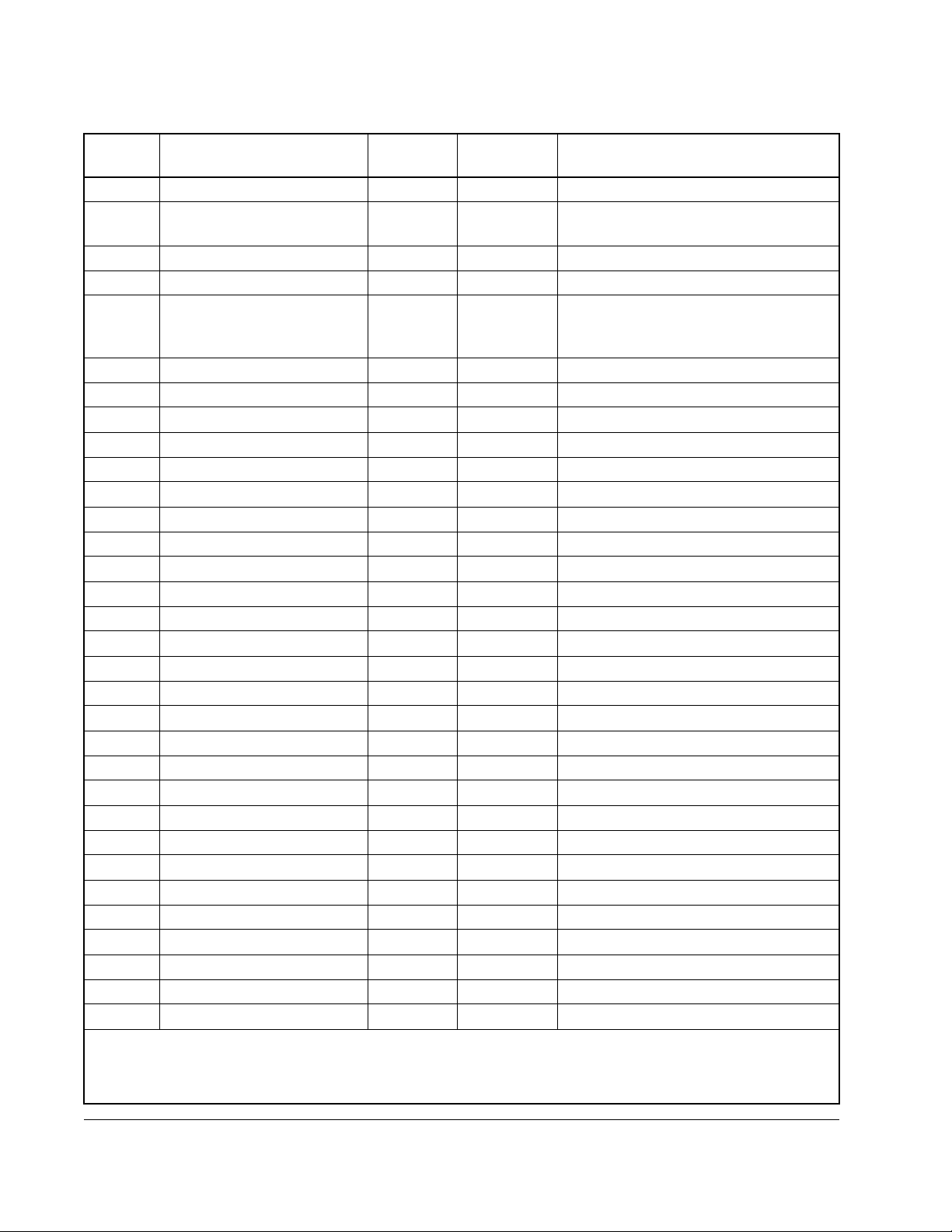

Table 2.6 – Model Numbers for 2 to 15 Amp and 24 to 43 Amp Drives

2 to 15 Amp 24 to 30 Amp 43 Amp

31ER40xx

31ET40xx

38ER40xx

38ET40xx

55ER40xx

55ET40xx

85ER40xx

85ET40xx

126ER40xx

126ET40xx

150ER40xx

150ET40xx

240ER40xx

240ET40xx

300ER40xx

300ET40xx

430ER40xx

430ET40xx

2-34

GV3000/SE AC Drive ControlNet Network Communication Option Board

Page 47