Rockwell Automation FlexPak-WebPak 3000 DC Drive AutoMax Network Communication Board User Manual

Page 1

AutoMax™ Network Communication Option Board

For Use With

FlexPak™ 3000 DC Drives and

WebPak™ 3000 DC Drives

M/N 915FK0101

Instruction Manual

D2-3318-5

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are property of their

respective companies.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown in the outside margin of this page will be used throughout this instruction manual to

identify new or revised text or figures.

ATTENTION: Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: Do not install modification kits with power applied to the drive. Disconnect and lock

out incoming power before attempting such installation or removal. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION: The user must provide an external, hardwired emergency stop circuit outside of the

drive circuitry. This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed. Failure to observe this precaution

could result in bodily injury.

ATTENTION: The drive contains ESD- (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when installing, testing, servicing, or repairing the drive.

Erratic machine operation and damage to, or destruction of, equipment can result if this procedure

is not followed. Failure to observe this precaution can result in bodily injury.

ATTENTION: The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

Microsoft and Windows are trademarks of Microsoft Corporation.

ReSource, FlexPak, WebPak, WebPakCS, AutoMax, and Reliance are trademarks of Rockwell Automation.

Copyright © 2005 Rockwell Automation. All rights reserved.

Page 3

Chapter 1 Introduction

1.1 Before You Start .............................................................................................. 1-1

1.2 Where to Find Additional Information .............................................................. 1-1

1.3 Getting Assistance from Reliance Electric....................................................... 1-1

1.4 Related Hardware and Software ..................................................................... 1-2

1.5 AutoMax Network Option Board Description ................................................... 1-2

Chapter 2 Installation

2.1 Installing the Network Option Board ................................................................ 2-1

2.2 Connecting the Drive to an AutoMax Network................................................. 2-3

Chapter 3 Drive Configuration

3.1 Setting Up the Drive for Network Communication ........................................... 3-1

3.2 Selecting a Network Reference Source........................................................... 3-2

3.3 How the Drive Responds to a Loss of Network Communication ..................... 3-2

3.3.1 Setting NETW COMM LOSS SELECT (P.901)

(FlexPak 3000 Drives Only) .................................................................. 3-3

Chapter 4 Programming

4.1 Selecting a Register Map (FlexPak 3000 Drives Only) ................................... 4-1

4.2 How the Control Source Selection Affects Data Transfers.............................. 4-1

4.3 About Network Transfer Rates ........................................................................ 4-1

4.3.1 I/O Update Enable Logic Summary....................................................... 4-3

4.4 Setting Up Data Types That Can Be Transferred............................................ 4-3

4.5 Tune/Config Update Synchronization Flag ...................................................... 4-4

4.6 Monitoring Unacceptable Parameter Values ................................................... 4-5

4.7 Timing Requirements ...................................................................................... 4-5

4.8 Drive Ready Status Bit .................................................................................... 4-6

4.9 Display of Parameter Values Over the AutoMax Network ............................... 4-6

4.10 Parameters That Are Not Accessible Over the AutoMax Network .................. 4-7

4.11 Parameters That Are Only Available in the FlexPak Alternate Register Map.. 4-8

4.12 Settings for Analog and Frequency Outputs.................................................... 4-8

CONTENTS

Contents

Chapter 5 FlexPak 3000 Drives: Original Register Map

5.1 Accessing the Original Register Map .............................................................. 5-1

5.2 Finding Data in the Original Register Map Tables........................................... 5-1

Chapter 6 FlexPak 3000 Drives: Alternate Register Map

6.1 Accessing the Alternate Register Map ............................................................ 6-2

6.2 Diagnosing Processing Errors ......................................................................... 6-2

6.3 Finding Data in the Alternate Register Map Tables ......................................... 6-4

I

Page 4

Chapter 7 WebPak 3000 Drives: Register Map

7.1 Using Indirect Parameters................................................................................7-1

7.1.1 Enabling the AutoMax Indirect Parameter Numbers .............................7-2

7.1.2 Changing the AutoMax Indirect Register Values ...................................7-2

7.1.3 Disabling the AutoMax Indirect Registers ..............................................7-2

7.2 Diagnosing Processing Errors..........................................................................7-3

7.3 Finding Data in the Register Map Tables.........................................................7-4

Appendix A Cross Reference of Parameter Name to Drop and Register

(FlexPak 3000 Original Map) ................................................................................... A-1

Appendix B Cross Reference of Parameter Name to Drop and Register

(FlexPak 3000 Alternate Map) ................................................................................. B-1

Appendix C Cross Reference of Parameter Name to Drop and Register

(WebPak 3000 Drives) ............................................................................................. C-1

Index ...........................................................................................................................Index-1

II

AutoMax Network Communication Option Board

Page 5

List of Figures

Figure 1.1 – AutoMax Network Communication Option Board ................................. 1-3

Figure 2.1 – Removing Drive Cover ......................................................................... 2-1

Figure 2.2 – Removing the Carrier Shield ................................................................ 2-2

Figure 2.3 – Removing Shield Ground Wire ............................................................. 2-2

Figure 2.4 – Installing the Network Communication Option Board ........................... 2-3

Figure 2.5 – Connecting a Drive to the AutoMax Network........................................ 2-4

Figure 4.1 – I/O Update Enable Logic Strings .......................................................... 4-3

List of Figures

III

Page 6

IV

AutoMax Network Communication Option Board

Page 7

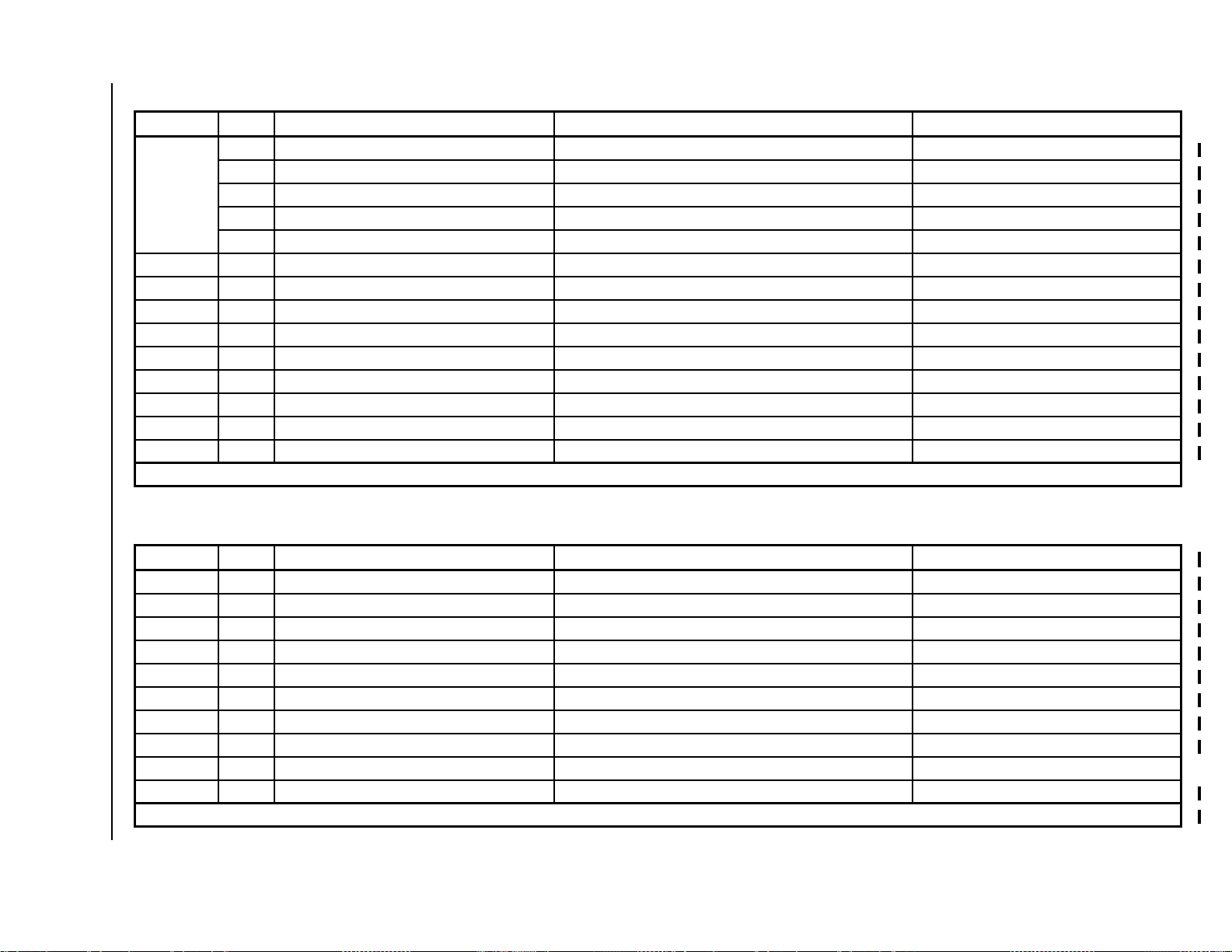

List of Tables

Table 1.1 – Hardware and Software Options Available for the Network Option

Board (Purchased Separately).............................................................. 1-2

Table 4.1 – Synchronization Flag Register Locations (Alternate and Original

Register Maps)...................................................................................... 4-4

Table 4.2 – Front Panel Display Compared to Network Displays............................. 4-6

Table 5.1 – Location of Information in the Original Register Map Tables................. 5-1

Table 5.2 – Original Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Runtime Signal Data

(Drive Output Data) ............................................................................... 5-2

Table 5.3 – Original Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Tunable, Configurable, and Status Data

(Drive Output Data) ............................................................................... 5-4

Table 5.4 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Control/Reference Data

(Drive Input Data).................................................................................. 5-6

Table 5.5 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Tunable Data (Drive Input Data) ........ 5-7

Table 5.7 – Original Register Map, Drop_2: Master Read Registers,

FULL Connection. Runtime Signal Data (Drive Output Data) ............... 5-8

Table 5.8 – Original Register Map, Drop_2: Master Read Registers,

FULL Connection. Tunable, Configurable, and Status Data

(Drive Output Data) ............................................................................... 5-8

Table 5.6 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Configurable Data (Drive Input Data) . 5-8

Table 5.9 – Original Register Map, Drop_2: Master Write Registers,

FULL Connection. Tunable Data (Drive Input Data) ............................. 5-9

Table 5.10 – Original Register Map, Drop_2: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ............................. 5-10

Table 5.11 – Original Register Map, Drop_3: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data)....................... 5-11

Table 5.12 – Original Register Map, Drop_3: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) ............................................................................. 5-12

Table 5.13 – Original Register Map, Drop_3: Master Write Registers, FULL

Connection. Tunable Data (Drive Input Data) ..................................... 5-12

Table 5.14 – Original Register Map, Drop_3: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ............................. 5-13

Table 5.15 – Original Register Map, Drop_4: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data)....................... 5-14

Table 5.16 – Original Register Map, Drop_4: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) ............................................................................. 5-14

Table 5.17 – Original Register Map, Drop_4: Master Write Registers, FULL

Connection. Tunable Data (Drive Input Data) ..................................... 5-15

Table 5.18 – Original Register Map, Drop_4: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ............................. 5-16

List of Tables

V

Page 8

Table 6.1 – Error Processing Parameters Reported by Group .................................6-3

Table 6.2 – Location of Information in the Alternate Register Map Tables ...............6-4

Table 6.3 – Alternate Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Runtime Signal Data

(Drive Output Data) ...............................................................................6-5

Table 6.4 – Alternate Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Tunable, Configurable, and Status Data

(Drive Output Data) ...............................................................................6-7

Table 6.5 – Alternate Register Map, Drop_1: Master Write Registers

BASIC and FULL Connections. Control/Reference Data

(Drive Input Data) ..................................................................................6-9

Table 6.7 – Alternate Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Configurable Data

(Drive Input Data) ................................................................................6-10

Table 6.6 – Alternate Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Tunable Data (Drive Input Data) .......6-10

Table 6.8 – Alternate Register Map, Drop_2: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data) .......................6-11

Table 6.9 – Alternate Register Map, Drop_2: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) .............................................................................6-11

Table 6.10 – Alternate Register Map, Drop_2: Master Write Registers, FULL

Connection. Tunable Data (Drive Input Data) .....................................6-12

Table 6.11 – Alternate Register Map, Drop_2: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ..............................6-13

Table 6.12 – Alternate Register Map, Drop_3: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data) .......................6-14

Table 6.13 – Alternate Register Map, Drop_3: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) .............................................................................6-14

Table 6.14 – Alternate Register Map, Drop_3: Master Write Registers, FULL

Connection. Tunable Data (Drive Input Data) .....................................6-15

Table 6.15 – Alternate Register Map, Drop_3: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ..............................6-16

Table 6.16 – Alternate Register Map, Drop_4: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) .............................................................................6-17

Table 6.17 – Alternate Register Map, Drop_4: Master Write Registers FULL

Connection. Tunable Data (Drive Input Data), ....................................6-17

Table 6.18 – Alternate Register Map, Drop_4: Master Write Registers, FULL

Connection. Configurable Data (Drive Input Data) ..............................6-18

VI

Table 7.1 – Error Processing Parameters Reported by Group .................................7-3

Table 7.2 – Location of Information in the Original Register Map Tables .................7-4

Table 7.3 – Original Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Runtime Signal Data

(Drive Output Data) ...............................................................................7-5

Table 7.4 – Original Register Map, Drop_1: Master Read Registers,

BASIC and FULL Connections. Tunable, Configurable, and Status Data

(Drive Output Data) ...............................................................................7-7

Table 7.5 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Control/Reference Data

(Drive Input Data) ..................................................................................7-8

AutoMax Network Communication Option Board

Page 9

Table 7.6 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Tunable Data (Drive Input Data) ........ 7-9

Table 7.7 – Original Register Map, Drop_1: Master Write Registers,

BASIC and FULL Connections. Configurable Data (Drive Input Data)7-11

Table 7.8 – Original Register Map, Drop_2: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data)....................... 7-11

Table 7.9 – Original Register Map, Drop_2: Master Read Registers, FULL

Connection. Tunable, Configurable, and Status Data

(Drive Output Data) ............................................................................. 7-12

Table 7.10 – Original Register Map, Drop_2: Master Write Registers, FULL

Connection. Tunable Data (Drive Input Data) ..................................... 7-13

Table 7.11 – Original Register Map, Drop_3: Master Read Registers, FULL

Connection. Runtime Signal Data (Drive Output Data)....................... 7-15

Table 7.12 – Original Register Map, Drop_3: Master Write Registers, FULL

Connection. Tunable/Configurable Data (Drive Input Data) ............... 7-16

List of Tables

VII

Page 10

VIII

AutoMax Network Communication Option Board

Page 11

CHAPTER 1

This manual describes the AutoMax™ Network Communication Option Board

(M/N 915FK0101). This board enables a FlexPak™ 3000 or a WebPak™ 3000 DC

drive to be operated and monitored over the AutoMax network.

For normal operation, the drive can be completely controlled using the AutoMax

Network Option board. This allows use of only a network interface connection,

hardwired emergency stop, and three-phase input and output power wiring. Drive

control (such as start, stop, and reset), reference changes, parameter modification,

and drive monitoring can all be performed over the AutoMax network.

1.1 Before You Start

In this manual, parameters are shown by the parameter name used on the OIM,

followed by the parameter number in parentheses. For example, the parameter to set

acceleration time, parameter P.001, is shown as

1.2 Where to Find Additional Information

ACCELERATION TIME (P.001).

Introduction

You must be familiar with the instruction manuals that describe your system. This can

include, but is not limited to:

• FlexPak 3000 DC Drive Hardware Reference manual, D2-3404.

• FlexPak 3000 DC Drive Software Reference manual, D2-3405.

• WebPak 3000 DC Drive Hardware Reference manal, D2-3443.

• WebPak 3000 DC Drive Software Reference manual, D2-3444.

• AutoMax Network Communications Module manual, J2-3001.

• ReSource AutoMax Programming Executive Instruction manual (various part

numbers).

• Control and Configuration Software manual, D2-3348.

• WebPakCS Software manual, D2-3447.

1.3 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office. For technical assistance, call

1-800-726-8112.

Introduction

1-1

Page 12

1.4 Related Hardware and Software

When the Network Option board is installed in a FlexPak 3000 or WebPak 3000 drive,

the drive can be used with the hardware and software listed in table 1.1.

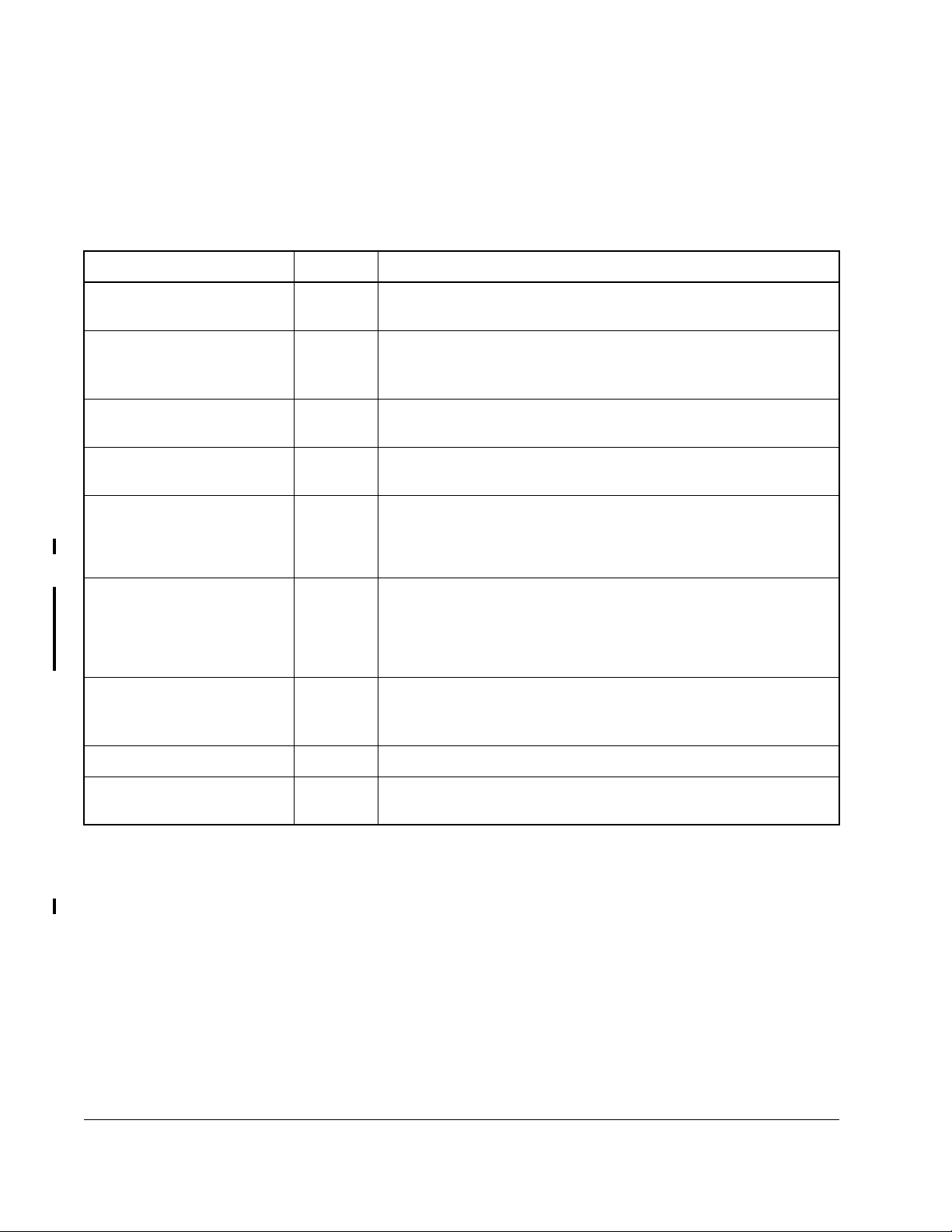

Table 1.1 – Hardware and Software Options Available for the Network Option Board (Purchased Separately)

Option Name Model # Description

75 Ohm Terminating Load 45C71 A terminating load is required at both ends of an AutoMax

network coaxial cable system.

AutoMax Processor 57C430A

55C431

57C435

AutoMax Programming

Executive

Communications

Passive Tap

Control and Configuration

Software

(FlexPak Drives Only)

WebPakCS Software

(WebPak 3000 Drives Only)

AutoMax Network

Communications Module

Network Drop Cable 57C381 Cable that connects all network drops and the passive taps.

ReSource™ Interface

Cable

Various Includes the tools required for programming in Enhanced BASIC,

Control Block, and Ladder Logic/PC languages.

57C380 Required at each network drop for connection to coaxial cabling.

2CS3000 Windows-based software that enables you to connect any

personal computer running Microsoft Windows version 3.1 or

later to a FlexPak 3000 drive. Enables you to create, store,

upload, and download drive configurations.

?

57C404

57C404A

57C404B

61C127 Cable that connects a personal computer to the AutoMax

Windows-based software that enables you to connect any

personal computer running Microsoft Windows version 9x or

later (including NT) and Internet Explorer version 5.0 or later to a

WebPak 3000 drive. Enables you to create, store, upload, and

download drive configurations.

The master drop (and all AutoMax rack slave drops) on the

AutoMax network must contain a Network Communications

module.

Processor module

1.5 AutoMax Network Option Board Description

1-2

The AutoMax Network Option board makes the FlexPak 3000 or WebPak 3000 drive a

slave drop on the AutoMax network. It is a printed circuit board assembly that mounts

inside the drive and connects to the drive’s Regulator board through a ribbon cable.

The Network Option board is powered from the standard drive power supply.

The Network Option board has a 9-pin D-shell connector that connects to a network

drop cable (M/N 57C381). The network drop cable is then connected to a passive tap

on the AutoMax network.

The board contains its own microprocessor. The microprocessor connects to one port

of the board’s dual-port memory. The other port interfaces with the drive’s Regulator

board.

AutoMax Network Communication Option Board

Page 13

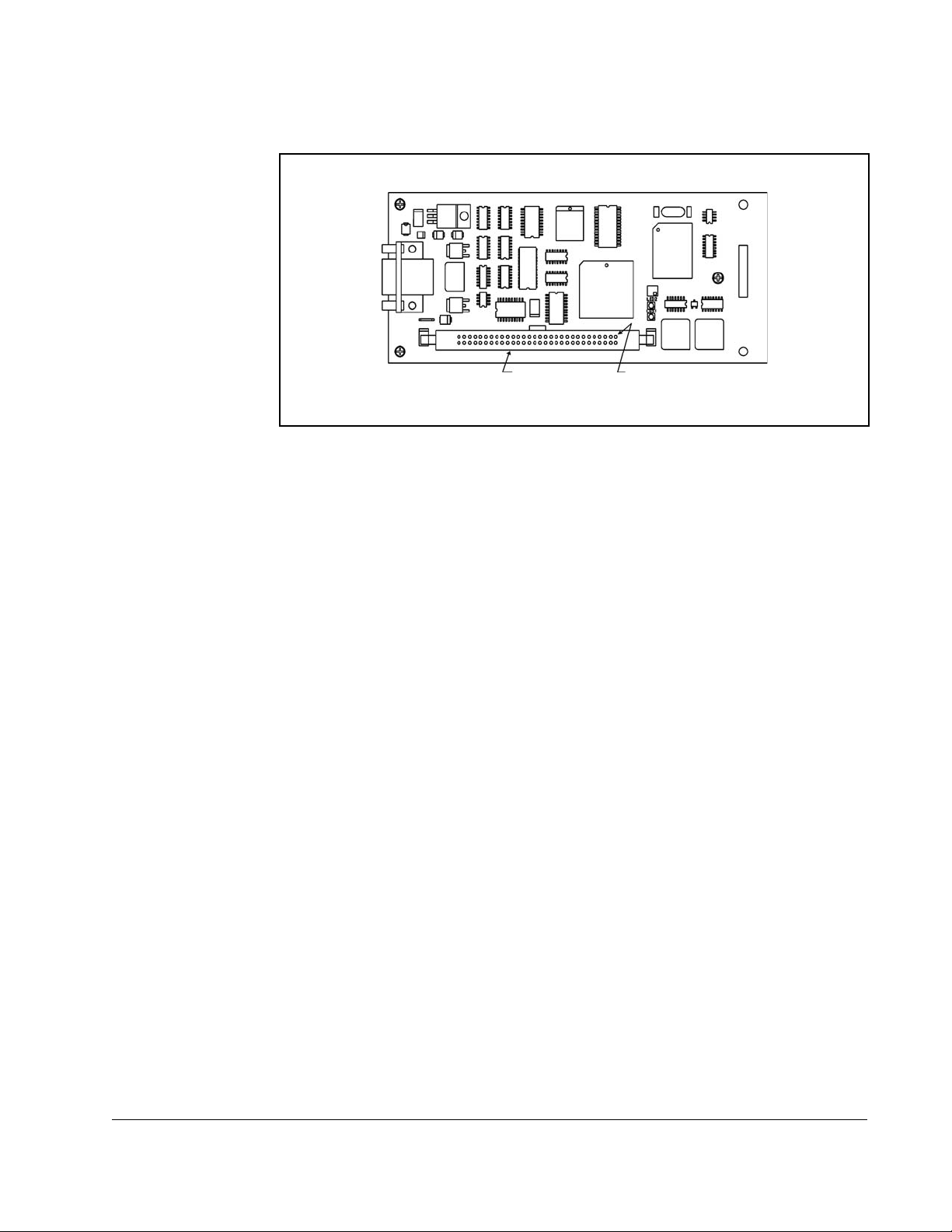

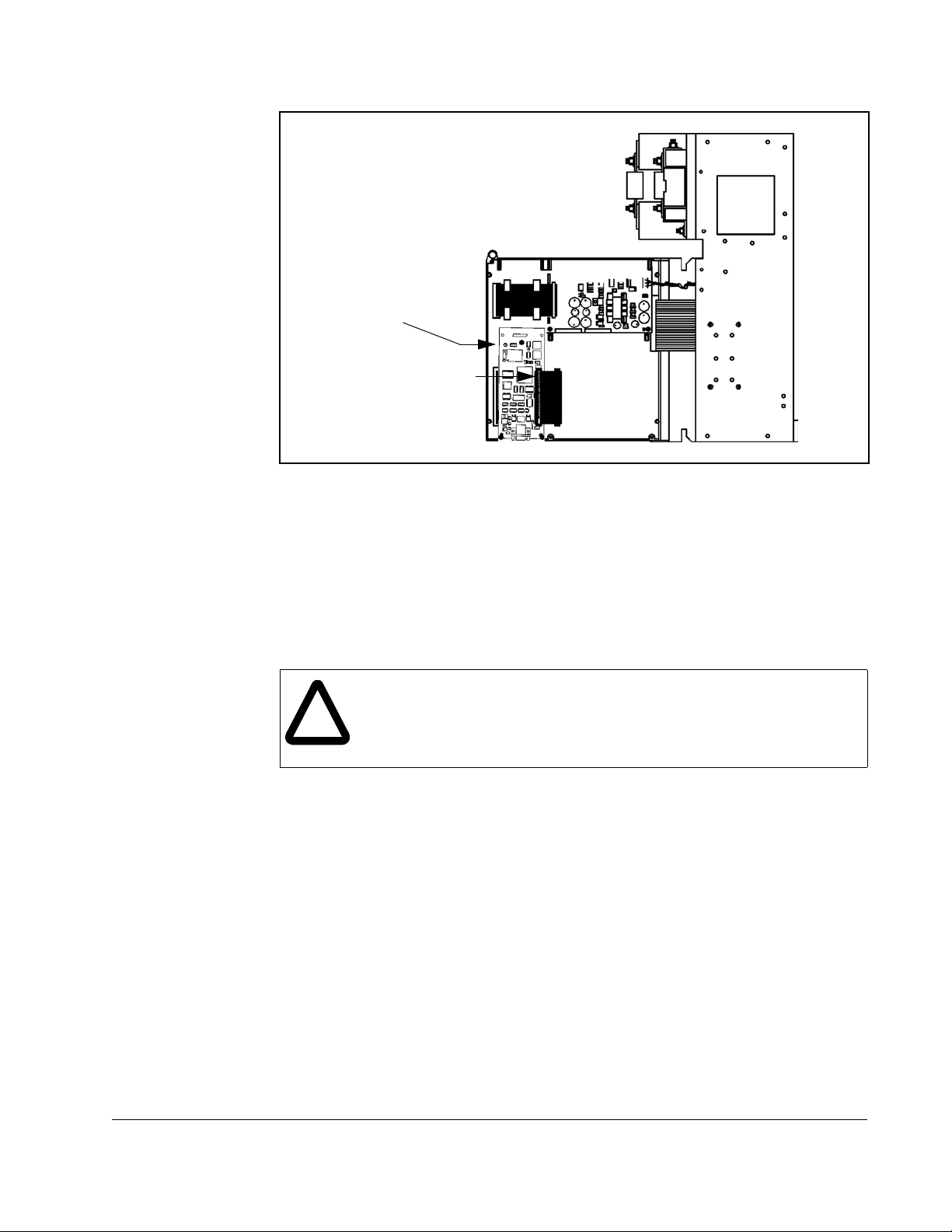

The AutoMax Network Communication Option board is shown in figure 1.1.

9-Pin

D-Shell

Connector

Ribbon Cable

Connector

Pin 1

Figure 1.1 – AutoMax Network Communication Option Board

Introduction

1-3

Page 14

1-4

AutoMax Network Communication Option Board

Page 15

CHAPTER 2

This section describes how to install the Network Option board in the FlexPak 3000 or

WebPak 3000 drive and connect the drive to an AutoMax network.

2.1 Installing the Network Option Board

ATTENTION: Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:

local, national, and international codes. Wiring practices, grounding,

disconnects, and overcurrent protection are particularly impor tant. Failure

to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: Do not install modification boards with power applied to

the drive. Disconnect and lock out incoming power before attempting

such installation. Failure to observe this precaution could result in severe

bodily injury or loss of life.

The user is responsible for conforming with all applicable

Installation

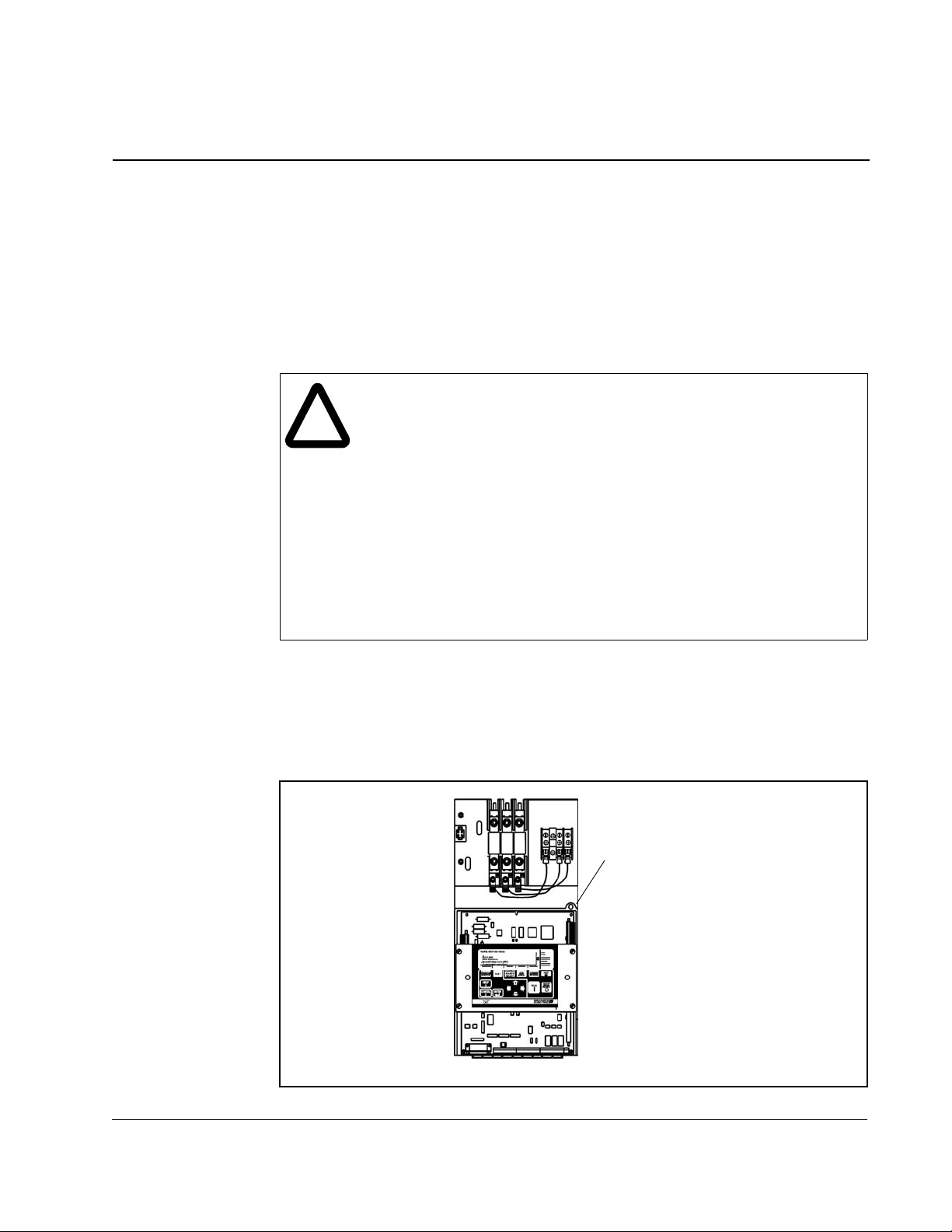

To install the Network Option board:

Step 1. Turn off, lock out, and tag all incoming power to the drive.

Step 2. Loosen the two (2) captive screws on the drive cover. Remove the cover.

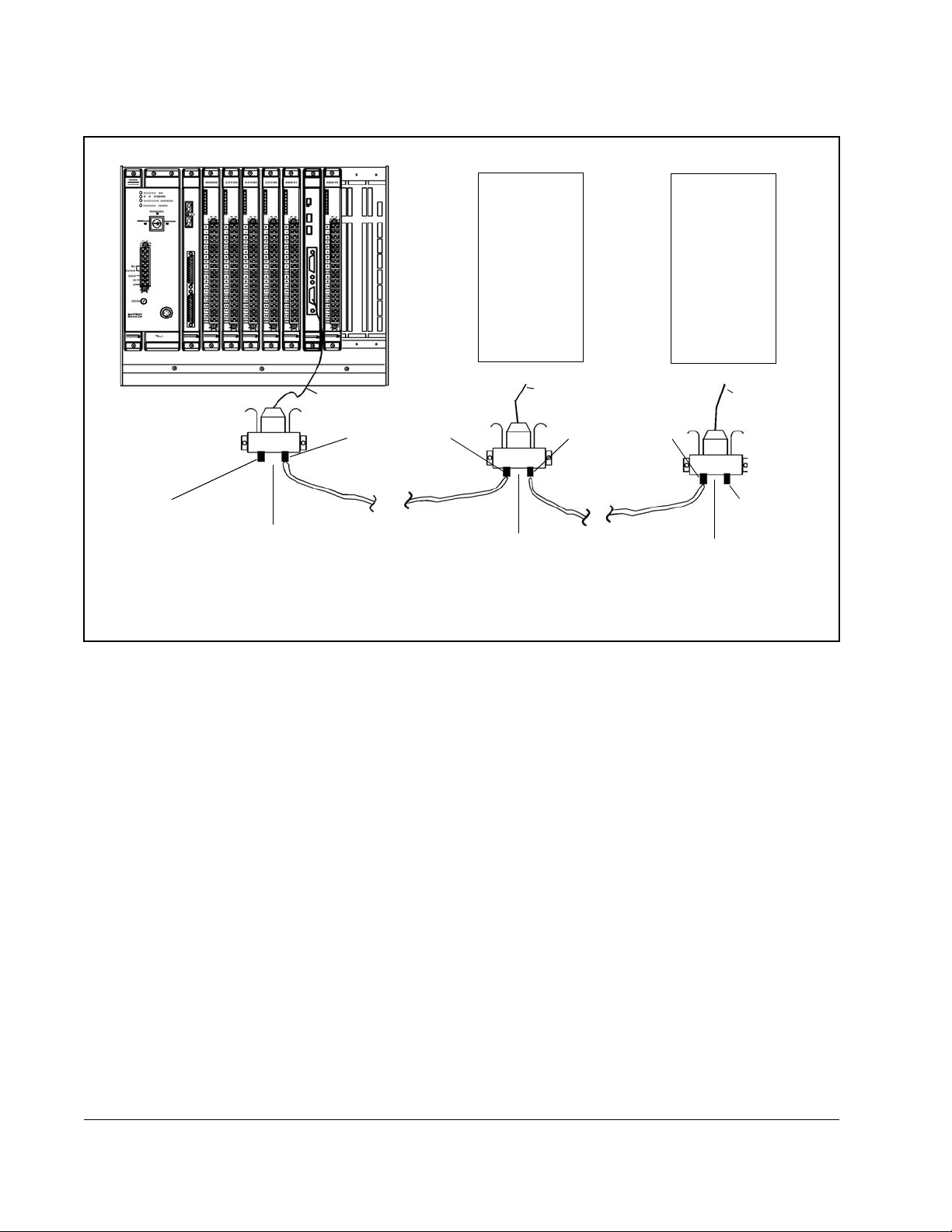

Step 3. Loosen the captive screw on the carrier. Swing open the carrier. See figure 2.1.

Loosen Captive Screw

and Swing Carrier Open

Figure 2.1 – Removing Drive Cover

Installation

2-1

Page 16

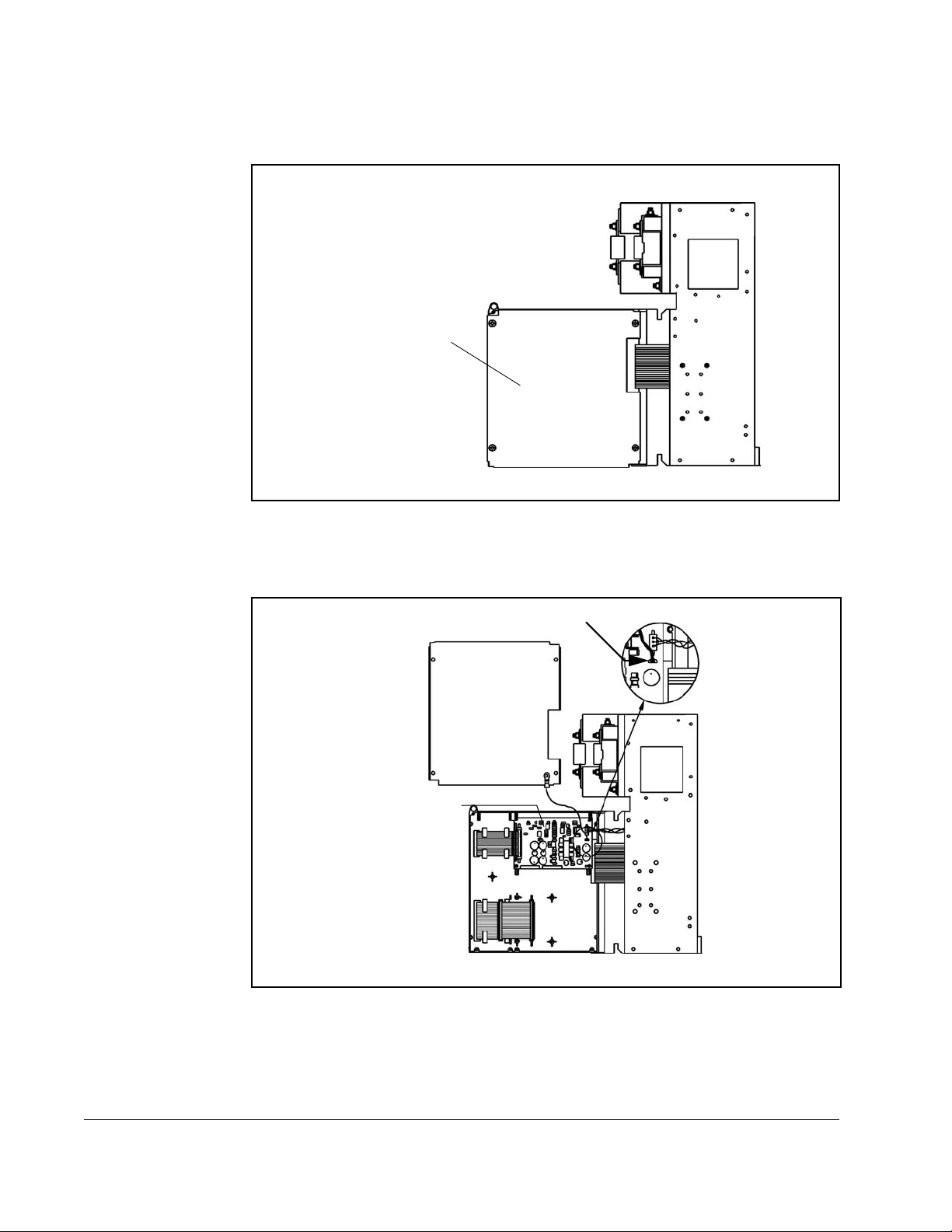

Step 4. Remove the screws that attach the carrier shield to the carrier. See

figure 2.2.

Carrier Shield

Figure 2.2 – Removing the Carrier Shield

Step 5. Remove the connector that attaches the shield ground wire to the drive

power supply. Set the shield aside. See figure 2.3.

Ground Wire

Power Supply

Figure 2.3 – Removing Shield Ground Wire

Step 6. Position the Network Option board over the standoffs. Refer to figure 2.4.

2-2

Step 7. Secure the Network Option board using three captive screws on the board.

Step 8. Plug the option board ribbon cable into the Network Option board.

AutoMax Network Communication Option Board

Page 17

Attach Network board to

carrier’s molded standoffs

using captive screws

(qty. 3)

Plug option board ribbon

cable into Network board

Figure 2.4 – Installing the Network Communication Option Board

Step 9. Re-attach the carrier shield ground wire to the drive power supply.

Step 10. Re-attach the carrier shield to the carrier.

Step 11. Close the carrier and fasten it with the captive screw.

Step 12. Re-install the drive cover.

2.2 Connecting the Drive to an AutoMax Network

ATTENTION: AutoMax networks with more than 5 drops might produce

communication errors if 10-foot drop cables are used. Wherever possible,

!

3-foot drop cables or, if necessary, 5-foot drop cables should be used.

Failure to observe this precaution could result in damage to, or

destruction of, equipment.

Installation

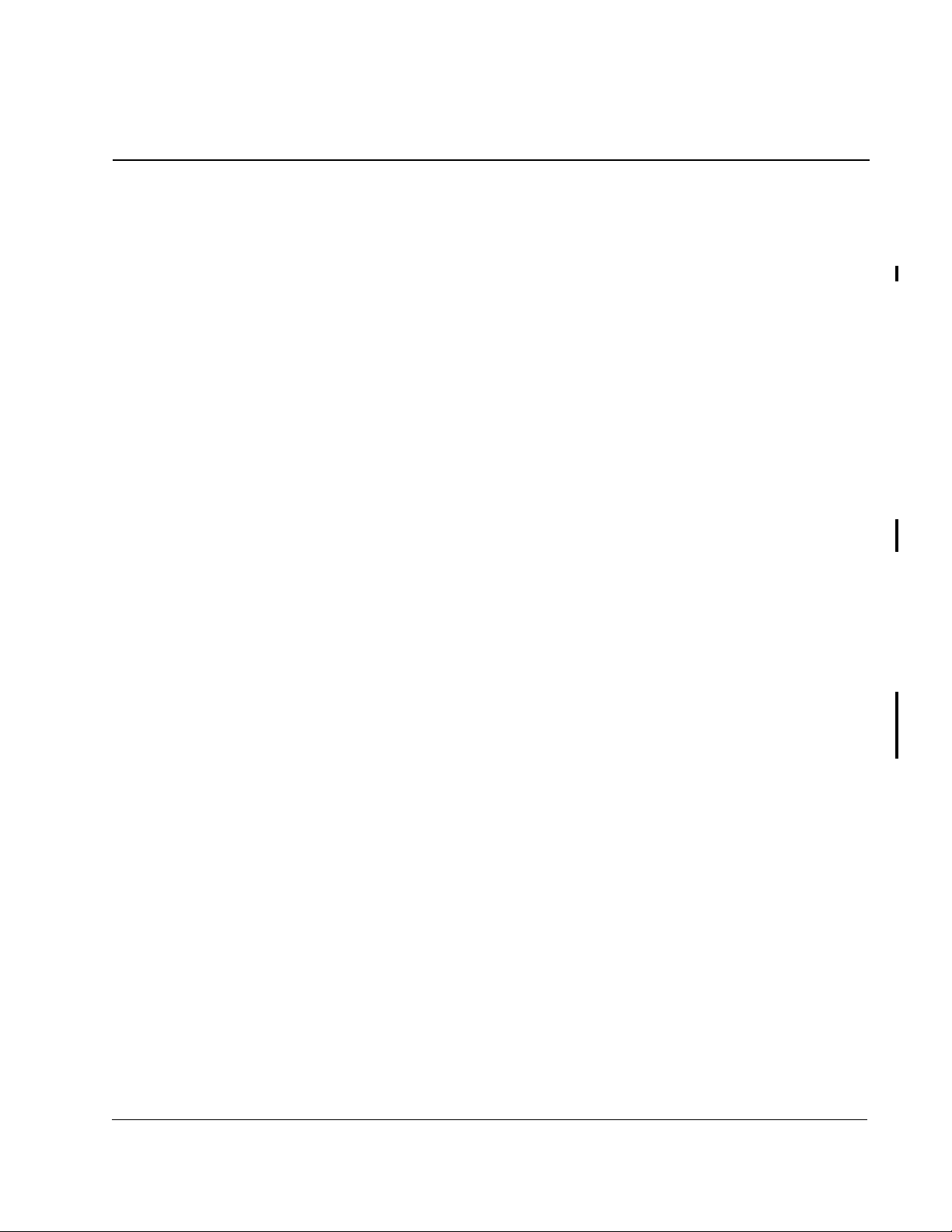

See figure 2.5 for cabling and termination connections.

Refer to the Network Communications Module instruction manual (J2-3001) for a

detailed description of how to add a drop to the network.

Step 1. Stop any application tasks that are running.

Step 2. Use the Network Drop Cable (M/N 57C381) to connect to the

Communications Passive Tap (M/N57C380).

Step 3. If the drop is at the end of the coaxial cable system, it must be terminated.

Terminate by connecting a 75-Ohm Terminating Load (M/N 45C71) to the

remaining BNC connector on the passive tap.

Step 4. Remove the lockout and tag. Apply power to the drive. If a problem is

detected during diagnostics, a fault or alarm will occur. See your drive

software manual for information on faults and alarms.

2-3

Page 18

Drop Cable

(M/N 57C381)

BNC Connector

FlexPak 3000

FlexPak 3000

or

WebPak 3000

Drive

WebPak 3000

Drive

To Drive To Drive

Drop Cable

(M/N 57C381)

BNC Connector

or

Drop Cable

(M/N 57C381)

75 Ohm

Terminating Load

Passive Tap

(M/N 57C380)

Figure 2.5 – Connecting a Drive to the AutoMax Network

Coaxial

Cable

Passive Tap

(M/N 57C380)

Coaxial

Cable

75 Ohm

Terminating Load

Passive Tap

(M/N 57C380)

2-4

AutoMax Network Communication Option Board

Page 19

CHAPTER 3

Drive Configuration

This section describes how to configure a FlexPak 3000 or WebPak 3000 drive for use

with an AutoMax network.

3.1 Setting Up the Drive for Network Communication

The drive becomes active on the AutoMax network after you complete the following

steps:

Step 1. Connect the Network Option board to the network using a passive tap. See

section 2.2.

Step 2. Apply power to the drive.

Step 3. Assign a valid AutoMax network drop number to the drive using parameter

NETW DROP NUMBER (P.900). You must set this parameter through the drive

keypad (

WebPakCS). This drop number is the base drop the drive will occupy. In this

manual, the base drop number is called Drop_1.

When

the network.

FlexPak 3000 drives

sequential network drops, including Drop_1. Subsequent drops are called

Drop_2, Drop_3, and Drop_4 in this manual. Your application might use

different drop numbers.

WebPak 3000 drives:

sequential network drops, including Drop_1. Subsequent drops are called

Drop_2 and Drop_3 in this manual. Your application might use different drop

numbers.

Step 4. Set the network connection type using NETW CONNECT TYPE (P.910). This

defines the scope of data that will be communicated. It also determines the

level of control that the master has with the connected drive. You can select

one of two connection types:

• BASIC: Only essential drive data (reference, sequencing, basic tuning, and

• FULL: The entire set of drive data that has been assigned network

OIM or DCM) or using drive configuration software (CS3000 or

NETW DROP NUMBER

feedback data) are transferred over the network. This allows a higher

density network with moderate functionality. Select this connection type if

you do not need to completely configure the drive over the network. When

BASIC is selected, the drive occupies a single network drop.

registers is transferred over the network. Select this connection type if

your application must be able to configure the drive over the network and

have access to most parameters, operating variables, and diagnostic

information.

The large amount of data transferred in the full connection type requires

that the drive occupy multiple network drops, thus decreasing the

potential number of devices on the network.

(P.900) is set, you can set other parameters over

: For

FULL

connections, the drive occupies four

For

FULL

connections, the drive occupies three

Drive Configuration

3-1

Page 20

FlexPak 3000 drives:

sequential network drops.

WebPak 3000 drives:

sequential network drops using indirect registers in Drop_2 and Drop_3 (see

section 7.1 for information about using indirect registers).

Step 5. Apply power to the AutoMax rack.

Serial communication is now established and information can be exchanged with the

network master. The drive transfers output data whenever this connection is made. To

transfer input data, you must complete the steps in the next section.

When

When

FULL

is selected, the drive will occupy four

FULL

is selected, the drive will occupy three

3.2 Selecting a Network Reference Source

AMX NETW REF SELECT (P.911) specifies the source of the speed/torque reference

when

CONTROL SOURCE SELECT (P.000) is set to NETWORK. You can select either:

• DIRECT: The reference is from register 33 in the drive’s Drop_1 register map. See

table 5.4 (FlexPak 3000 original map), table 6.4 (FlexPak 3000 alternate map), or

table 7.5 (WebPak 3000 map).

• BROADCAST n: The reference is from one of the eight network broadcast data

registers (network drop area 0, registers 32 to 39). The specific broadcast register

(1 to 8) is assigned using a register in the drive’s Drop_1 register map. See

register 30 in table 5.3 (FlexPak 3000 original map), register 63 in table 6.6 (FlexPak

3000 alternate map), or register 30 in table 7.4 (WebPak 3000 map). See the

Network Communications Module instruction manual (J2-3001) for information on

broadcast data registers.

3.3 How the Drive Responds to a Loss of Network

Communication

The Network Option board attempts to remain active on the network at all times,

regardless of the control source setting.

At power up, the drive delays for approximately 10 seconds before indicating a loss of

network communication.

If communication is interrupted:

• The Network Option board immediately notifies the drive Regulator.

• The Network Option board tries to re-establish communication with the network

master.

• For FlexPak 3000 drives, if CONTROL SOURCE SELECT (P.000) is set to NETWORK, the

drive reacts to a network communication loss as specified by

SELECT (P.901).

• For WebPak 3000 drives, a fault is generated when network communication is lost if

CONTROL SOURCE SELECT (P.000) is set to NETWORK.

• If the drive includes an OIM, the NETWORK indicator above the CONTROL SOURCE

SELECT key blinks to indicate that network communication is inactive.

NETW COMM LOSS

3-2

AutoMax Network Communication Option Board

Page 21

3.3.1 Setting NETW COMM LOSS SELECT (P.901)

(FlexPak 3000 Drives Only)

ATTENTION: NETW COMM LOSS SELECT (P.901) allows you to configure

the drive to continue to run of a loss of network communication occurs.

!

NETW COMM LOSS SELECT (P.901) is not used in WebPak 3000 drives. For

WebPak 3000 drives, a fault is generated when network communication is lost if

CONTROL SOURCE SELECT (P.000) is set to NETWORK. This causes the drive to coast/DB

stop. The drive cannot be restarted until the fault is cleared.

You must provide some form of hardwired stop in case of communication

loss, since stopping the drive over the network might not be possible.

Failure to observe this precaution could result in bodily injury or damage

to, or destruction of, equipment.

For FlexPak 3000 drives,

responds to network communication loss when

to network. Alarms do not cause the drive to stop. Therefore, some form of hardwired

stop must be available in case of communication loss since stopping the drive over the

network might not be possible.

You can set

TRMBLK REF (2), or USE TRMBLK CNTL (3).

P.901 = FAULT (0)

When

lost, the following occurs:

NETW COMM LOSS SELECT (P.901) to FAULT (0), USE LAST REF (1), USE

NETW COMM LOSS SELECT (P.901) is set to FAU LT and network communication is

NETW COMM LOSS SELECT (P.901) defines how the drive

CONTROL SOURCE SELECT (P.000) is set

• The drive latches a fault condition and performs a coast/DB stop.

• A NETWORK COMMUNICATION LOSS fault is generated.

When network communication is re-established, you must reset the fault before the

drive can be re-started. See the drive software manual for information on resetting

faults.

ATTENTION: The drive is not equipped with a coast-stop pushbutton.

You must install a hardwired operator-accesible pushbutton that provides

!

a positive interrupt and shuts down the drive. Failure to observe this

precaution could result in bodily injury.

ATTENTION:

MAP SEL

NETWORK

SPD LOOP PI RESET

these values are appropriate for your application before changing the

control source. Failure to observe this precaution could result in severe

bodily injury or loss of life.

If you are using the alternate register map (

(P.914) set to

, the parameters

ALTERNATE

are reset to their default values (0 for each). Ensure

) and you change the control source from

SPD LOOP PI INIT SEL, SPD LOOP PI INIT VAL

NETW REGISTER

, and

Drive Configuration

3-3

Page 22

P.901 = USE LAST REF (1)

NETW COMM LOSS SELECT (P.901) is set to USE LAST REF and network

When

communication is lost, the following occurs:

• The drive continues to run, using the last reference received from the network

master.

• A NETWORK COMMUNICATION TIMEOUT alarm (A00004) is generated.

• An entry is made into the drive’s alarm log for each active-to-inactive transition of

network communication status.

• If network communication is re-established and the drive is still running, the drive

will again follow the reference and sequencing control inputs supplied by the

network master.

You can stop the drive using the hardwired stop input or the

However, you cannot restart the drive until network communication is re-established or

CONTROL SOURCE SELECT (P.000) is changed.

P.901 = USE TRMBLK REF (2)

NETW COMM LOSS SELECT (P.901) is set to USE TERMBLK REF (2) and network

When

communication is lost, the following occurs:

OIM STOP/RESET key.

• The drive continues to run, using the auto reference value selected by AUTO

REFERENCE SELECT (P.103)

(or Regulator board terminals 19 and 20?)

• A NETWORK COMMUNICATION TIMEOUT alarm (A000014) is generated.

• If network communication is re-established and the drive is still running, the drive

will again follow the reference and sequencing control inputs supplied by the

network master.

You can stop the drive using the hardwired stop input, the

hardwired stop input (coast/DB stop, Regulator board terminal 8). However, you

cannot restart the drive until network communication is re-established or

SOURCE SELECT (P.000) is changed.

P.901 = USE TRMBLK CNTL (3)

NETW COMM LOSS SELECT (P.901) is set to USE TRMBLK CNTL (3), and network

When

communication is lost, the following occurs:

OIM STOP/RESET key, or the

CONTROL

3-4

• The drive continues to run using the Regulator board terminal strip as the source for

all control (run, jog, stop, fault reset, direction, and OCL enable) and speed (auto)

reference signals.

• A NETWORK COMMUNICATION TIMEOUT alarm (A000014) is generated.

• The Speed Loop PI Reset and Underwind/Overwind bits cannot be changed while

operating in this mode. They will remain at the last values received from the

network.

If network communication is re-established and the drive is still running, the drive will

again frollow the reference and sequencing control inputs supplied by the network

master.

AutoMax Network Communication Option Board

Page 23

CHAPTER 4

Programming

This section describes the organization of data in the AutoMax Network

Communication Option board and how the network accesses the data.

4.1 Selecting a Register Map (FlexPak 3000 Drives Only)

There are two register maps available for the FlexPak 3000 drive: original and

alternate.

The original register map allows you to use programs developed for versions earlier

than 4.0 of the FlexPak 3000 drive. Register assignments for the original register map

are listed in chapter 5.

The alternate register map is similar to the original register map, except that the most

commonly accessed data is in the base drop area (Drop_1). The alternate register

map also includes functions that were added in regulator software version

FlexPak 3000 DC Drive Software Reference Manual

the

details on the new version

map are listed in chapter 6.

4.2

features. Register assignments for the alternate register

, manual number D2-3405, for

4.2

. See

Important: When a version

existing AutoMax network that uses the ALTERNATE register map, you

may need to reprogram the master task so that it writes valid data in the

registers that are now being used (where previously they were marked as

reserved).

The register map is selected using the

4.2

Regulator board is used as a replacement in an

NETW REGISTER MAP SEL (P.914) parameter.

4.2 How the Control Source Selection Affects Data

Transfers

You can use the keypad to change parameter values when CONTROL SOURCE SELECT

(P.000) is set to

overwritten when the next network update occurs.

You cannot transfer data using the CS3000

SOURCE SELECT (P.000) is set to NETWORK.

NETWORK. However, changes made through the keypad might be

OR WebPakCS software while CONTROL

4.3 About Network Transfer Rates

To transfer data, the Network Option board must be communicating with the master.

To transfer input data, the Network Option board must be communicating with the

master and

CONTROL SOURCE SELECT (P.000) must be set to NETWORK.

Programming

Data transfer rates between the Network Option board and Regulator board depend

on the type of data being transferred.

4-1

Page 24

Data can be input or output data.

Input data is one of three types:

• Control/Reference: Data that require the fastest update rates, including data such

as the sequencing inputs (Stop, Run, Jog, Fwd/Rev) and speed/torque reference.

These inputs are transferred every speed loop scan period. An exception to this

occurs if the drive is configured to get its torque reference from the network. If the

torque reference is from the network, the drive reads the

CML reference from the

Network Option board every current minor loop scan.

•

Tunable:

TIME

Data that can be changed while the drive is running, such as

ACCELERATION

(P.001). Tunable inputs are transferred approximately every 600 msec while the

drive is running or stopped.

• Configurable: Data that cannot be changed while the drive is running, such as

CONTROL SOURCE SELECT (P.000). Configurable inputs are transferred from the

Network Option board to the Regulator board approximately every 600 msec when

the drive is stopped. Values sent from the network master while the drive is running

are stored in Network Option board memory but are not scanned into Regulator

board memory until the drive is stopped.

Output data is one of two types:

• Runtime Signal: Data such as the selected speed reference value, drive status

(such as ready or running), drive fault flags, the state of terminal strip digital inputs,

and motor status values (

speed loop scan period.

RPM, VOLTS, AMPS). This information is transferred every

• Tunable, Configurable, and Status: All other information provided by the drive.

This typically includes all stored drive parameter values. Tunable, configurable, and

status data are transferred approximately every 600 msec.

Output data is transferred from the Regulator board to the Network Option board

regardless of the status of AutoMax network communication (active or inactive) or the

selected drive control source (

For FlexPak 3000 drives, the speed loop scan period is 10 msec when

SELECT (P.200) is set to ARMATURE VOLT. It is 5 msec when FEEDBACK SELECT (P.200) is

set to any other value.

For WebPak 3000 drives, the speed loop scan period is 10 msec.

KEYPAD, TERMBLK, or NETWORK).

FEEDBACK

4-2

AutoMax Network Communication Option Board

Page 25

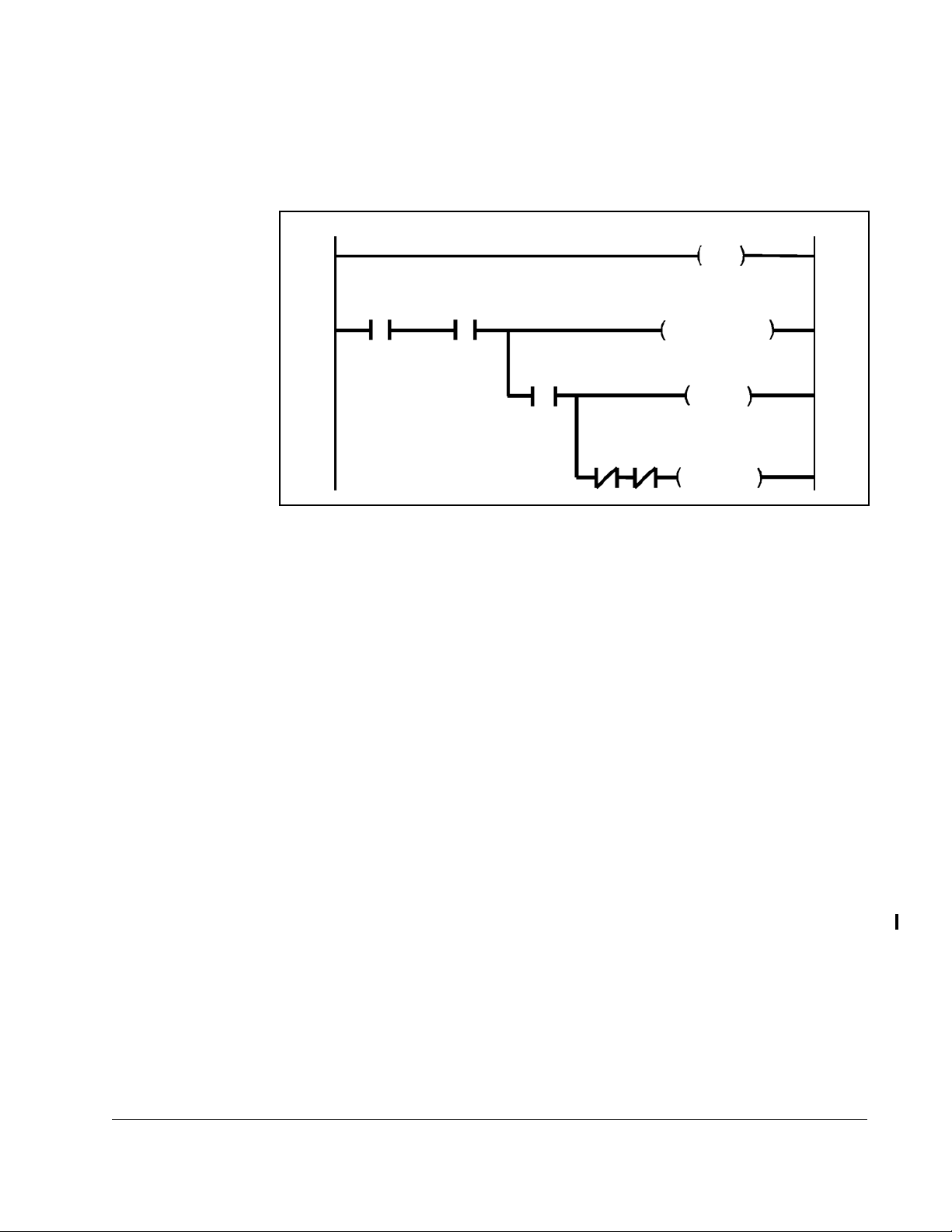

4.3.1 I/O Update Enable Logic Summary

The logic strings shown in figure 4.1 summarize the output and input enable logic

described in this chapter.

Outputs

Updated

CONTROL SOURCE

NETW COMM STATUS

(P.908) = ACTIVE

SELECT = NETWORK

Tune/Config

Input Enable

Running

Jogging

Figure 4.1 – I/O Update Enable Logic Strings

Control/Reference

Inputs Read

Tu na b le

Inputs Read

Configurable

Inputs Read

4.4 Setting Up Data Types That Can Be Transferred

You must enable the transfer of tunable and configurable inputs from the Network

Option board to the Regulator board. Until you enable transfer, only control/reference

data are read by the Regulator board.

To enable transfer of tunable and configurable data, set the network-master-controlled

Tune/Config Input Enable bit (Drop_1, register 32, bit 14) to 1.

For example, the master application program would typically:

1. Initialize the tunable and configurable input data in the dual-port memory of the

master’s Network module

2. Delay for an appropriate amount of time to ensure data have been transferred to

the drive

3. Set the Tune/Config Input Enable bit to 1.

If you only want to transfer control/reference data, leave the Tune/Config Input Enable

bit at 0 (off). This forces you to configure the drive through another source, such as the

OIM, CS3000 software, or WebPakCS software, but allows you to control the drive

(including

RUN, JOG, STOP, RESET, and the reference) from the network master.

Programming

4-3

Page 26

4.5 Tune/Config Update Synchronization Flag

This flag allows the network master application program to track when the drive has

updated tunable and configurable inputs. By toggling the tune/config update

synchronization flag in the master and monitoring the copied value from the drive, the

master’s program can determine when the drive has read in that data. This feature has

no effect on drive operation.

The drive regulator copies the tune/config update synchronization flag bit to its

corresponding loopback bit after it has read in and processed all tunable input

registers. Configurable inputs are only read in by the drive while it is not running. This

will not affect copying the synchronization flag to the loopback bit, since tunable inputs

will still be transferred.

When using WebPak 3000 indirect parameters, use the tune/config update

synchronization flag with the network synchronization flag as described in section 7.1.

To use the synchronization flag, the tune/config input enable bit must be set to 1.

To determine when changes to tunable and configurable data in the drive have been

completed, the master:

1. Modifies the tunable and configurable register data in the appropriate network

registers.

2. Sets the tune/config input enable flag.

3. Toggles the tune/config update synchronization flag.

4. Monitors the tune/config update synchronization flag loopback bit until it equals

the value written in item 3, above.

The tune/config update synchronization flag is defined in the first drop of the drive

network drop connection. Therefore, it can only be used to indicate when data for the

first drop has been read in and processed by the drive.

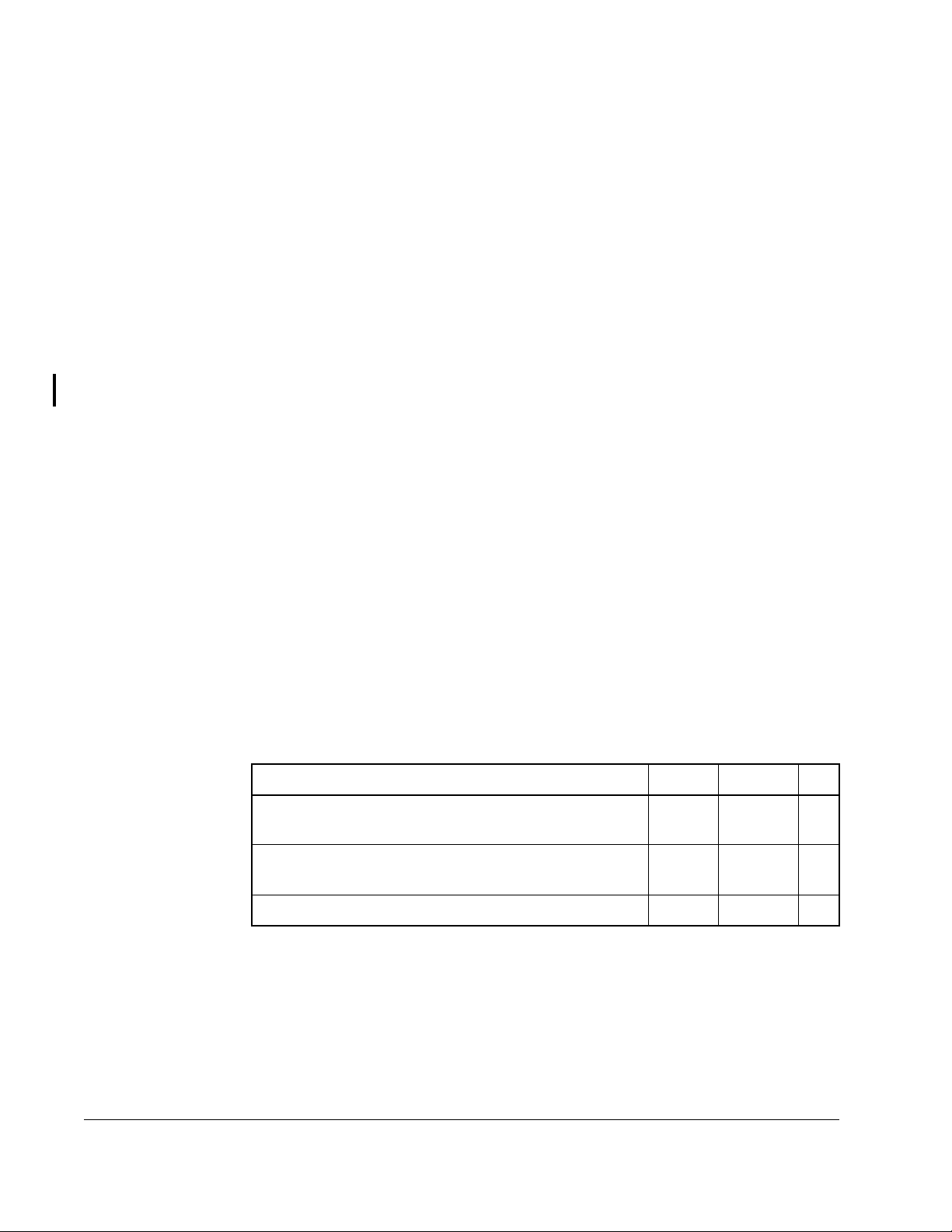

Table 4.1 – Synchronization Flag Register Locations (Alternate and Original Register Maps)

Flag Drop Register Bit

Tune/Config Update Synchronization Flag Loopback

(Master Read) Bit

Tune/Config Update Synchronization Flag (Master

Write)

Tune/Config Input Enable Bit Drop_1 32 14

Alternative Synchronization Methods

The tune/config update synchronization flag applies only to Drop_1. To determine if

the drive received data written to other drops, you must use other methods.

One method is to program a delay after writing to the network master’s memory.

Calculate the delay as needed for the number of drops on the network, adding

600 msec for processing time. See your AutoMax documentation for information on

calculating the delay.

Drop_1 0 7

Drop_1 32 15

4-4

AutoMax Network Communication Option Board

Page 27

Note that this method assumes that all requirements have been met for the drive to

obtain its inputs from the network (see figure 4.1).

4.6 Monitoring Unacceptable Parameter Values

The parameter processing error status flag (FlexPak drives: Drop_1, register 0, bit 12;

WebPak drives: Drop_1, register 0, bit 13) allows the network master to monitor

parameter values that are unacceptable to the drive.

When this flag is set to 1, one or more parameters sent to the drive were rejected.

When this flag is set to 0, all parameters sent to the drive were accepted.

Note that the Tune/Config Inputs Enable bit (Drop_1, register 32, bit 14) must be set

to 1 before the drive will read or process any tune/config parameters. The parameter

processing error flag is updated approximately every 600 msec.

More information on parameter processing errors is available when using the

FlexPak 3000 alternate register map (see section 6.2) or the WebPak 3000 register

map (see section 7.1).

4.7 Timing Requirements

The amount of time required by the network master to transmit data to the drive

depends on the number of active drops on the network. This time is referred to as the

“data update time.” Refer to I/M J2-3001 for details on calculating this time.

Tunable and configurable drive input register values must be maintained by the

network master’s application program for the data update time plus at least 600 msec

to assure that they are read by the drive.

Most of the control/reference data types do not have this 600 msec requirement

because they are read by the drive every 5 or 10 msec.

To start the drive, the Run and Jog inputs must be set to 0 for at least 20 msec, then

set to 1 for at least 20 msec (a 0-to-1 transition). The drive might delay the start for up

to 100 msec after receiving the 0-to-1 transition because of variable processing

delays.

For the following actions, the inputs must be set to 0 for at least 600 msec, then set to

1 for at least 600 msec (a 0-to-1 transition):

• Fault log clear

• Alarm log clear

• Alarm reset

• Memory save

Programming

To reset faults, the inputs must be set to 0 for at least 10 msec, then set to 1 for at

least 10 msec (a 0-to-1 transition).

4-5

Page 28

4.8 Drive Ready Status Bit

The Drive Ready status bit (Drop_1, register 0, bit 0) indicates that a 0-to-1 transition

on the Run or Jog input will start the drive.

FlexPak 3000 drives: The Drive Ready bit is

conditions are met, and

OFF (0) if any one of these conditions is not met:

ON (1) when all of the following

• No drive faults are active (Drop_1, register 0, bit 2 = 0)

• Network stop input is de-asserted (Drop_1, register 32, bit 1 = 1)

• Front-panel STOP/RESET button is not pressed

• Coast/DB Stop terminal strip input is closed (Drop_1, register 0, bit 10 = 1)

• Customer Interlock terminal strip input is closed (Drop_1, register 0, bit 11 = 1)

• A download from the serial port (using the CS3000 software) is not in progress

WebPak 3000 drives: The Drive Ready bit is on (1) when all of the following

conditions are met, and off (0) if any one of these conditions is not met:

•

•

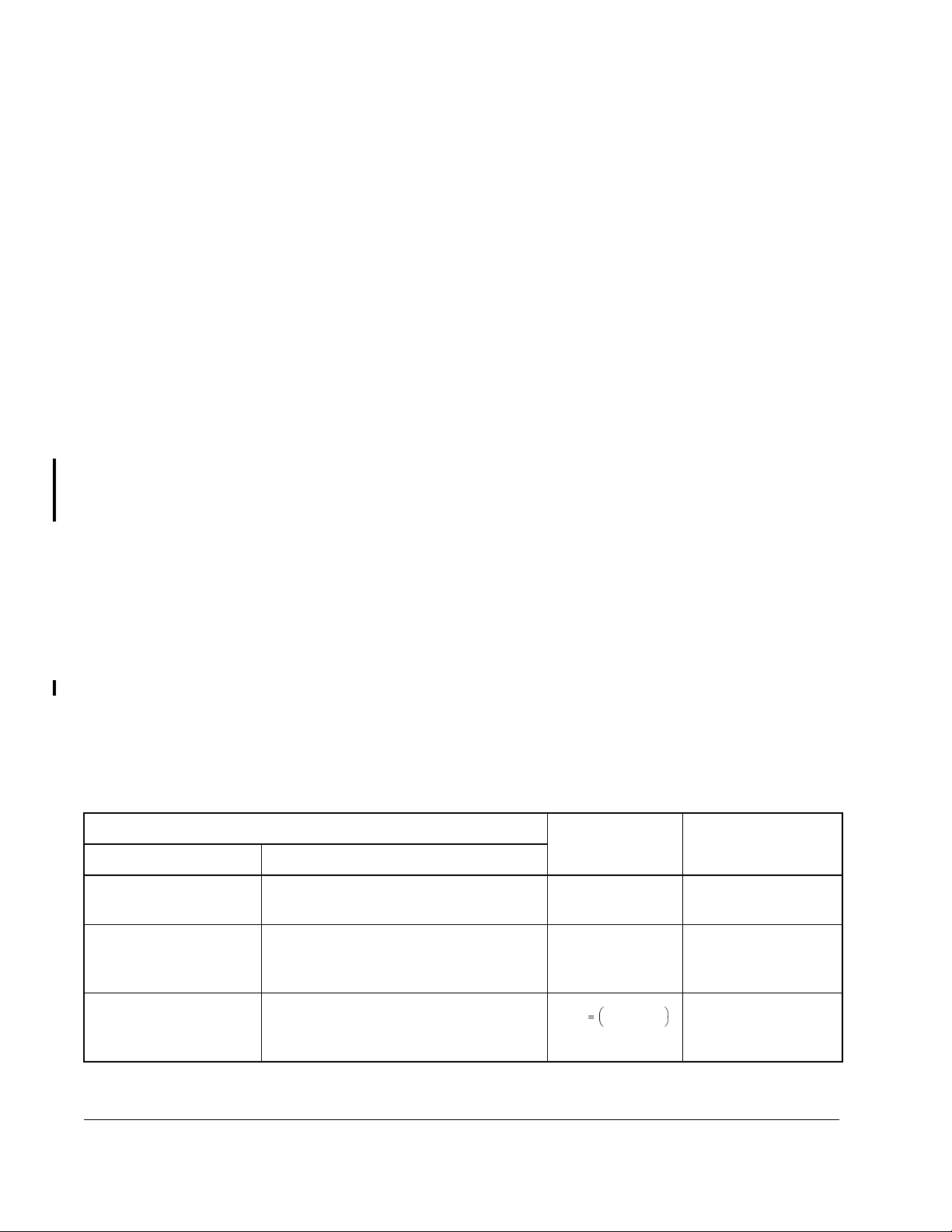

4.9 Display of Parameter Values Over the

AutoMax Network

The display of parameter values on the network will be different than the display when

on the

OIM, DCM, or when using CS3000 or WebPakCS software.

Examples of these differences are shown in table 4.2. Refer to the register maps in

chapters 5 and 6 for detail on the scaling parameter for transfer over the AutoMax

network.

Front Panel Display (OIM or DCM)

Values with a decimal

point

Parameters with text

choices

Speed/voltage loop

and current minor loop

parameters

*

For speed parameters, a value of 4095 corresponds to TOP SPEED (P.011). For load parameters, 4095 corresponds to MAXIMUM CURRENT

(P.007).

4-6

(Does this table need to be revised for WebPak?)

Table 4.2 – Front Panel Display Compared to Network Displays

Network Value

Set

MOTOR RATED ARM AMPS (P.008) to

27.3 amps.

TRIM MODE SELECT (P.110) choices are

NO TRIM, INCREMENTAL, or

PROPORTIONAL.

TOP SPEED (P.011) = 1750 RPM. On the

front panel, you read

FEEDBACK (P.296) = 1000 RPM.

SPD LOOP

2340

AutoMax Network Communication Option Board

Register Map Table

Listing ExampleDescription Example

273 amps * 10

0, 1, 2 0 =

NO TRIM

1 = INCREMENTAL

2 = PROPORTIONAL

4095 1000×

⎛⎞

-------------------- ------------ -

=

⎝⎠

1750

4095 at

(P.011)

TOP SPEED

*

Page 29

4.10 Parameters That Are Not Accessible Over the

AutoMax Network

These FlexPak 3000 parameters are not accessible over the AutoMax network at

any time.

ANALOG MAN REFERENCE (P.192)

ANLG OUT 1 SIG TYPE (P.419)

*

ARMATURE DELTA (P.399)

*

CML ERROR (P.398)

*

CML FEEDBACK (P.397)

*

CT TURNS RATIO (P.010)

*

CURRENT COMPOUND TP (P.293)

DEVNET POLL MSG TYPE (P.913)

DIG IN 0 (P.490)

*

DRAW PERCENTAGE OUT (P.196)

*

FIELD DELTA (P.588)

*

FIELD DELTA HIGH LIM (P.587)

*

FLD CURRENT REGULATOR (P.586)

*

I/O EXPANSION KIT (P.797)

*

INV FAULT AVOID SEL (P.312)

*

IR COMPENSATION TP (P.290)

*J11

ANLG TACH VLT SCL (P.792)

*J14

ANLG TACH VLT RNG (P.793)

*J15

REGULATOR TYPE (P.799)

*J18

ARM I FB RESISTOR (P.395)

J20

FIELD LOSS DETECT (P.597)

J21

FLD SUPPLY JUMPER (P.598)

*

JOG OFF DELAY TIME (P.121)

*

JOG RAMP OUTPUT (P.294)

JOG SPEED 2 (P.017)

*

LEVEL DETECT 1 OUTPUT (P.648)

*

LEVEL DETECT 2 OUTPUT (P.649)

MANUAL REF SELECT (P.106)

METER OUT 1 GAIN ADJ (P.400)

METER OUT 1 SELECT (P.404)

METER OUT 1 ZERO ADJ (P.402)

METER OUT 2 GAIN ADJ (P.401)

METER OUT 2 SELECT (P.405)

METER OUT 2 ZERO ADJ (P.403)

MOP ACCEL TIME (P.115)

MOP DECEL TIME (P.120)

MOP OUTPUT (P.191)

MOP RESET ENABLE (P.116)

*

NETW COMM STATUS (P.908)

*

NETW DROP NUMBER (P.900)

*

NETW IN REG 1 (P.905)

*

NETW IN REG 2 (P.906)

*

NETW IN REG 3 (P.907)

*

NETW TYPE & VERSION (P.909)

NETWORK BAUD RATE (P.912)

*

NETWORK KIT (P.796)

OCL ENABLE (P.849)

OCL FEED BACK (P.847)

OCL REFERENCE (P.845)

*

PHASE FIRE TEST DELTA (P.309)

*

PHASE FIRE TST BRIDGE (P.310)

*

POWER UNIT TYPE (P.795)

PRESET SPEED 1 (P.117)

PRESET SPEED 2 (P.118)

PRESET SPEED 3 (P.119)

PULSE TACHOMETER KIT (P.798)

*

SELF TUNE BRIDGE (P.220)

SELF TUNE FIELD RANGE (P.218)

*

SELF TUNE STABILITY (P.219)

*

SPD LOOP LAG OUTPUT (P.298)

*

SPEED RAMP INPUT TP (P.198)

*

SPEED RAMP OUTPUT (P.199)

*

TACH LEAD FLT DELAY (P.228)

*

TACH LEAD FLT THRESH (P.227)

*

TORQUE REFERENCE (P.189)

*

CNI PROG/RUN MODE (P.915)

Programming

* Indicates WebPak parameters. Are there other WebPak parameters? Should

we make separate sections for WebPak and FlexPak?

4-7

Page 30

4.11 Parameters That Are Only Available in the FlexPak

Alternate Register Map

RAMP STOP DECEL TIME (P.018)

STOP DECEL SELECT (P.122)

NEG CUR LIM INV EN (P.226)

CML REF LIMIT SELECT (P.311)

INV FAULT AVOID SEL (P.312)

DIG IN 0 SELECT (P.428)

TACH LOSS SCR ANGLE (P.608)

PHASE LOSS DETECT (P.609)

OCL PROP TRIM SELECT (P.813)

OCL TYPE3 POSN REG EN (P.814)

NETW REGISTER MAP SEL (P.914)

SPD LOOP PI INIT SEL

LOOP PI INIT VAL

SPD

LOOP PI RESET

SPD

UNDERWIND

ENABLE

Process Error Parameter Number

4.12 Settings for Analog and Frequency Outputs

These are the options you can set for the I/O Expansion kit analog and frequency

output parameters.

CML FEEDBA CK (P.397)

0=

1=

CML REFERENCE (P.396)

2=

CML ERROR (P.398)

3=

SPD LOOP FEEDBACK (P.296)

4=

SPD LOOP REFERENCE (P.295)

5=

SPD LOOP ERROR (P.297)

6=

SPD LOOP OUTPUT (P.299)

7=

SPEED RAMP OUTPUT (P.199)

8=

SPEED RAMP INPUT TP (P.198)

9=

SPD SOURCE SELECT OUT (P.193)

10=

TRIM OUTPUT (P.197)

11=

ARMATURE VOLTAGE (P.289)

12=

ANALOG TACH FEEDBACK (P.291)

PULSE TACH FEEDBACK (P.292)

13=

14=

ZERO

15=FULL SCALE

16=POWER OUTPUT

17=OCL REFERENCE (P.845)

18=

OCL RAMP OUTPUT (P.846)

19=

OCL FEEDBACK (P.847)

20=

OCL OUTPUT (P.848)

21=

FIELD REFERENCE (P.590)

22=

FIELD FEEDBACK (P.589)

23=

NETW IN REG 1 (P.905)

24=

NETW IN REG 2 (P.906)

25=

NETW IN REG 3 (P.907)

4-8

Same for WebPak?

AutoMax Network Communication Option Board

Page 31

CHAPTER 5

FlexPak 3000 Drives:

Original Register Map

This section lists the original register map, which allows you to use programs

developed for versions earlier than 4.0 of the FlexPak 3000 drive. It also offers a

different set of options in Drop_1 than the alternate register map.

Brief descriptions of parameters are in the register map tables. For detailed parameter

descriptions, refer to the

5.1 Accessing the Original Register Map

To access the original register map, set NETW REGISTER MAP SEL (P.914) to ORIGINAL.

FlexPak 3000 DC Drive Software Reference Manual

.

Some parameters are not available and others are mapped differently when

REGISTER MAP SEL

correct mappings if you switch from the alternate register map to the original register map.

(P.914) is set to

ALTERNATE

. Make sure your application uses the

NETW

5.2 Finding Data in the Original Register Map Tables

The original register map shown in tables 5.2 through 5.18 describes the registers and

bits used by the FlexPak 3000 drive on the AutoMax network when

MAP SEL (P.914) is set to ORIGINAL.

There are no write registers for control/reference data for Drop_2, Drop_3, and Drop_4.

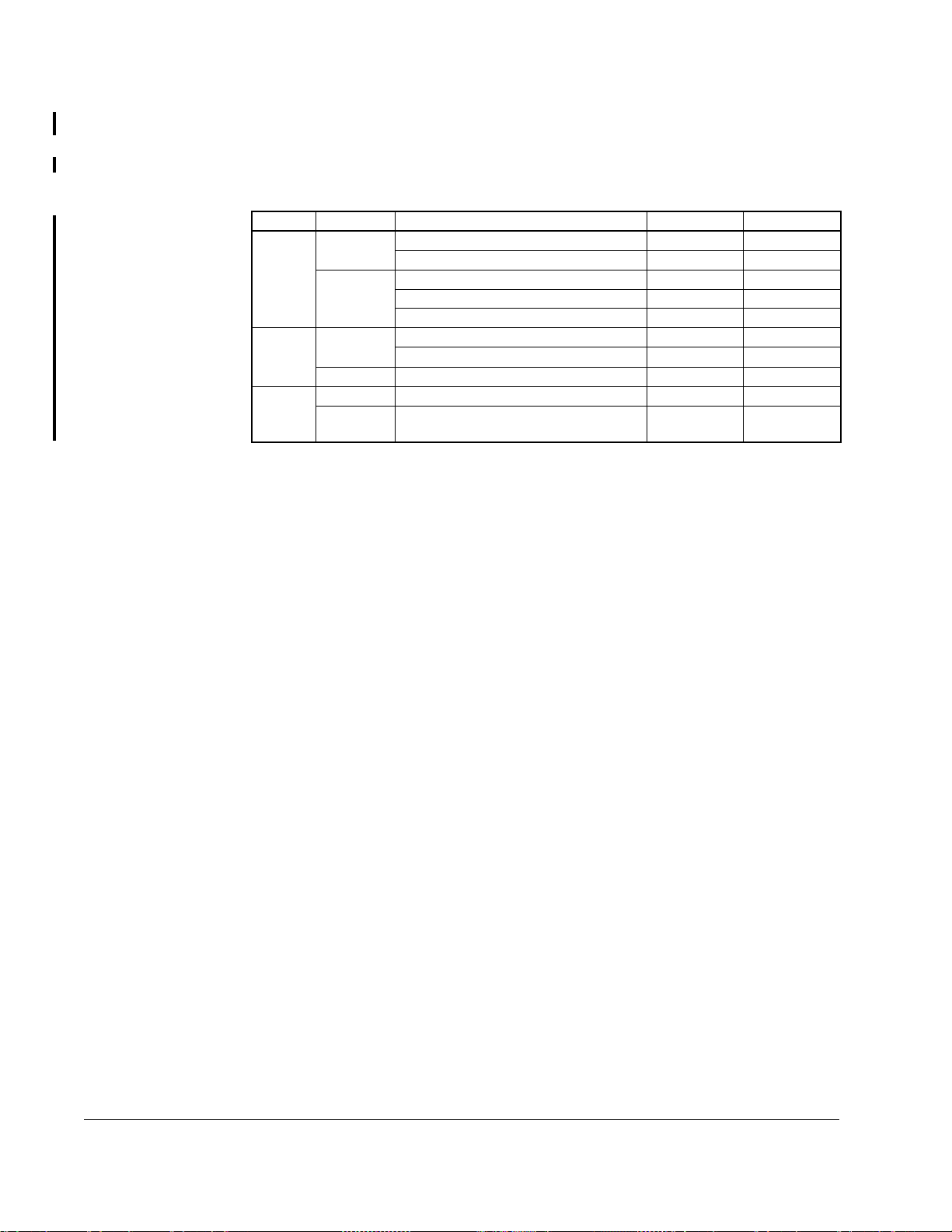

Table 5.1 – Location of Information in the Original Register Map Tables

Drop_# Master… Data Type Table Page

1 Read Runtime Signal 5.2 5-2

Tunable, Configurable, and Status 5.3 5-4

Write Control/Reference 5.4 5-6

Tunable 5.5 5-7

Configurable 5.6 5-8

2 Read Runtime Signal 5.7 5-8

Tunable, Configurable, and Status 5.8 5-8

Write Tunable 5.9 5-9

Configurable 5.10 5-10

3 Read Runtime Signal 5.11 5-11

Tunable, Configurable, and Status 5.12 5-12

Write Tunable 5.13 5-12

Configurable 5.14 5-13

4 Read Runtime Signal 5.15 5-14

Tunable, Configurable, and Status 5.16 5-15

Write Tunable 5.17 5-16

Configurable 5.18 5-17

NETW REGISTER

FlexPak 3000 Drives: Original Register Map

5-1

Page 32

5-2

AutoMax Network Communication Option Board

Table 5.2 – FlexPak 3000 Original Register Map, Drop_1: Master Read Registers, BASIC and FULL Connections. Runtime Signal Data (Drive Output Data)

Register Bit Parameter Name (Number) Description Settings

0 Drive status word 1 Bit-packed word containing information on the present status of the drive

0 Drive ready

1Drive running

2 Fault active

3 Drive jogging

4 Forward/reverse command 0=forward; 1=reverse

5 Drive stopping

6 Tune/config input enable loopback 0=disabled; 1=enabled

7 Tune/config update synch. flag loopback (master read)

8 Alarm active

9 In current limit

10 Coast/DB interlock 0=open; 1=closed

11 Customer interlock 0=open; 1=closed

12 Parameter processing error 0=no errors; 1=one or more errors

13 Terminal strip forward/reverse input state (terminal 5)

14 Terminal strip auto/manual input state (terminal 6)

15 Terminal strip fault/alarm reset input state (terminal 10)

1

2

3

4

5

6Average

7 Network Output Register 1 Value of the parameter selected by

8 Network Output Register 2 Value of the parameter selected by NETW OUT REG 2

9 Network Output Register 3 Value of the parameter selected by

10 to 15 Tunable, Configurable and Status Data See table 5.3 on page 5-4.

Runtime signal data are updated by the regulator every 5 msec, unless

SPD SOURCE SELECT OUT (P.193) Selected speed/voltage loop reference value 4095 at TOP SPEED (P.011)

SPD LOOP REFERENCE (P.295) Final speed/voltage loop reference value 4095 at TOP SPEED (P.011)

SPD LOOP FEEDBACK (P.296) Final speed/voltage loop feedback value after all scaling 4095 at TOP SPEED (P.011)

SPD LOOP OUTPUT (P.299) Speed loop PI block output value 4095 at MAXIMUM CURRENT (P.007

ARMATURE VOLTAGE (P.289) Armature voltage feedback value 4095 at MOTOR RATED ARM VOLTS (P.009)

CML feedback CML feedback average over eight CML scans 4095 at MAXIMUM CURRENT (P.007)

NETW OUT REG 1

SELECT (P.902)

If no valid parameter value selected,

0=motor speed in RPM

If no valid parameter value selected,

SELECT (P.903)

NETW OUT REG 3

SELECT (P.904)

FEEDBACK SELECT (P.200) is set to ARMATURE VOLT, in which case the update time is 10 msec.

0=armature voltage in volts

If no valid parameter value selected,

0=armature current in amps*10 or amps

Page 33

FlexPak 3000 Drives: Original Register Map

Table 5.2 – FlexPak 3000 Original Register Map, Drop_1: Master Read Registers, BASIC and FULL Connections. Runtime Signal Data (Drive Output Data) (Continued)

Register Bit Parameter Name (Number) Description Settings

16 ANALOG AUTO REFERENCE (P.188) The analog reference value in auto mode after all scaling 4095 at TOP SPEED (P.011)

17

18

19

20

21

22

23

Runtime signal data are updated by the regulator every 5 msec, unless FEEDBACK SELECT (P.200) is set to ARMATURE VOLT, in which case the update time is 10 msec.

ANALOG MAN TRIM REF (P.194) Analog manual trim reference input value 4095 at TOP SPEED (P.011)

ANLG IN 1 (P.492) I/O Exp. kit analog input 1 after gain and zero applied 4095 at full scale

ANLG IN 2 (P.493) I/O Exp. kit analog input 2 after gain and zero applied 4095 at full scale

FREQ IN (P.491) I/O Expansion kit frequency input value after all scaling 4095 at full scale

OCL OUTPUT (P.848) Outer control loop output value RPM

FIELD FEEDBACK (P.589) Motor field current feedback value after scaling and gain 4095 at MOTOR HOT FLD AMPS (P.510)

AC LINE VOLTAGE (P.392) Measured AC line RMS voltage volts RMS

5-3

Page 34

5-4

AutoMax Network Communication Option Board

Table 5.3 – FlexPak 3000 Original Register Map, Drop_1: Master Read Registers, BASIC and FULL Connections. Tunable, Configurable, and Status Data (Drive Output Data)

Register Bit Parameter Name (Number) Description Settings

10 Fault latch bits word 1 Bit-packed word indicating latched faults

0

1

2

3

4

5

6

7 Reserved

8

9

10

11 OPEN ARMATURE (F00007)

12

13

14

15

11 Reserved

12 First fault Fault code of the first fault since the last fault reset

13 Alarm latch bits word Bit-packed word containing latched alarm bits

0

1

2

3 to 15 Reserved

14 Last alarm Alarm code of the most recent alarm

15

CONTROL SOURCE SELECT (P.000) Selected source for drive control signals

16 ACCELERATION TIME (P.001) Min. time to accelerate from zero to TOP SPEED (P.011) seconds * 10

17

DECELERATION TIME (P.002) Min. time to decelerate from TOP SPEED (P.011) to zero seconds * 10

Tunable, configurable, and status data are updated by the regulator approximately every 600 msec.

AC LINE SYNCHRONIZATION FAULT (F00010)

FIELD CURRENT LOSS (F00004)

SUSTAINED OVERLOAD (F00005)

SELF TUNING FAULT (F00060 to F000099)

MOTOR THERMOSTAT TRIP (F00008)

CONTROLLER THERMOSTAT TRIP (F00009)

BLOWER MOTOR STARTER OPEN (F00006)

IET (OVERCURRENT) (F00001)

OVERSPEED (F00003) / ARMATURE OVERVOLTAGE

(F00012)

SCR N

or

MULTIPLE SCRS NOT OPERATING

TACHOMETER LOSS (F00002)

OIM COMMUNICATIONS TIMEOUT (F00011)

NETWORK COMMUNICATION TIMEOUT (F00013)

REVERS ED TACH LEADS (F00014)

MOTOR BRUSH WEAR LOW (A00001)

AC LINE VOLTAGE LOW (A00002)

AC LINE VOLTAGE HIGH (A00003)

(F00030–F00042)

0=

TERMBLK

; 1=

KEYPAD

; 2=

SERIAL

; 3=

NETWORK

Page 35

FlexPak 3000 Drives: Original Register Map

Table 5.3 – FlexPak 3000 Original Register Map, Drop_1: Master Read Registers, BASIC and FULL Connections. Tunable, Configurable, and Status Data (Drive Output Data) (Continued)

Register Bit Parameter Name (Number) Description Settings

18 MINIMUM SPEED (P.003) Lowest operating speed RPM

19

20

21

22

23

24

25

26

27

28 0

29 NETW COMM LOSS SELECT (P.901) How the drive responds to network communication loss 0=FAUL T; 1 = USE LAST REF; 2=USE TRMBLK

30 AMX NETW REF SELECT (P.911) AutoMax network reference selection 0=DIRECT; 1 to 8 = BROADCAST 1 to 8

31

MAXIMUM SPEED (P.004) Highest operating speed RPM

POSITIVE CURRENT LIM (P.005) Highest amount of current for the forward bridge % of MOTOR RATED ARM AMPS (P.008)

NEGATIVE CURRENT LIM (P.006) Highest amount of current for reverse bridge % of MOTOR RATED AR M AMPS (P.008)

TRIM RANGE (P.109) Amount the trim reference will affect the drive reference %

SPD LOOP PI PROP GAIN (P.211) Speed loop PI proportional gain gain * 100

SPD LOOP PI LEAD FREQ (P.212) Speed loop PI block lead break frequency radians/second * 100

CML PI PROP GAIN (P.301) CML PI proportional gain gain * 1000

CML PI LEAD FREQUENCY (P.302) CML PI lead break frequency radians/second

CML REF RATE LIMIT (P.303)

NETW CONNECT TYPE (P.910) AutoMax network connection type 0=BASIC; 1=FULL

Min. time for

CML

ref. to go from zero to

MAXIMUM CURRENT

milliseconds

8 NETW REGISTER MAP SEL (P.914) Network register map selected 0=ORIGINAL; 1=ALTERNATE

REF, 3=USE TRMBLK CNTL

REGULATOR SW VERSION (P.794) Regulator board software version

Tunable, configurable, and status data are updated by the regulator approximately every 600 msec.

5-5

Page 36

5-6

AutoMax Network Communication Option Board

Table 5.4 – FlexPak 3000 Original Register Map, Drop_1: Master Write Registers, BASIC and FULL Connections. Control/Reference Data (Drive Input Data)

Register Bit Parameter Name (Number) Description Settings

32 Sequencing control word Word containing drive sequencing and control bits

0 Run 0 to 1 transition to run

1 Stop 0=stop; 1= not stop

2 Fault reset 0 to 1 transition to reset

3 Jog 0 to 1 transition to jog; 0=stop jogging

4 Forward/reverse select 0=forward; 1=reverse

5 to 6 Reserved

7 Outer control loop enable 0 =hold

8 Fault log clear and reset 0 to 1 transition to clear

9 Alarm log clear and reset 0 to 1 transition to clear

10 Alarm reset 0 to 1 transition to reset

11 Memory save 0 to 1 transition to save

12 – 13 Reserved

14 Tune/config input enable: Determines what is read from

network. “Read all” includes control/reference, tunable,

and configurable inputs

15 Tune/config update synchronization flag (master write)

33 Network Reference Speed/voltage loop or

CONTROL SOURCE SELECT (P.000) is set to NETWORK and

AMX NETW REF SELECT (P.911)= 0

CML reference value when

34 Network Input Register 1 Written by network master. Read this value through the

OIM or DCM using NETW IN REG 1 (P.905)

35 Network Input Register 2 Written by network master. Read this value through the

OIM or DCM using NETW IN REG 2 (P.906)

36 Network Input Register 3 Written by network master. Read this value through the

OIM or DCM using NETW IN REG 3 (P.907)

37

FIELD REF REGISTER (P.513) Reference for the field current loop 4095 at MOTOR HOT FLD AMPS (P.510)

38 to 39 Reserved

Control/reference data are read by the regulator every 5 msec, unless

FEEDBACK SELECT (P.200) is set to ARMATURE VOLT, in which case the update time is 10 msec.

0=read only control/reference inputs

1=read all

4095 at

ARM VOLTS (P.009) or MAXIMUM CURRENT

(P.007)

OCL in reset; 1=OCL enabled

TOP SPEED (P.011)/MOTOR RATED

Page 37

FlexPak 3000 Drives: Original Register Map

Table 5.5 – FlexPak 3000 Original Register Map, Drop_1: Master Write Registers, BASIC and FULL Connections. Tunable Data (Drive Input Data)

Register Bit Parameter Name (Number) Description Settings

40 ACCELERATION TIME (P.001) Min. time to accelerate from zero to TOP SPEED (P.011) seconds * 10

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55 IR COMPENSATION (P.206) Armature voltage loss compensation %

56

57

58 NETW OUT REG 1 SELECT (P.902) Number of the parameter readable in Drop_1, register 7 If no valid parameter value selected, this is set to

59 NETW OUT REG 2 SELECT (P.903) Number of the parameter readable in Drop_1, register 8 If no valid parameter value selected, this is set to

60

DECELERATION TIME (P.002) Min. time to decelerate from TOP SPEED (P.011) to zero seconds * 10

MINIMUM SPEED (P.003) Lowest operating speed RPM

MAXIMUM SPEED (P.004) Highest operating speed RPM

POSITIVE CURRENT LIM (P.005) Highest amount of current for the forward bridge % of MOTOR RATED ARM AMPS (P.008)

NEGATIVE CURRENT LIM (P.006) Highest amount of current for reverse bridge % of MOTOR RATED ARM AMPS (P.008)

S-CURVE ROUNDING (P.014) Amount of smoothing of speed/voltage loop reference %

TRIM RANGE (P.109) Amount the trim reference will affect the drive reference %

SPD LOOP PI PROP GAIN (P.211) Speed loop PI proportional gain gain * 100

SPD LOOP PI LEAD FREQ (P.212) Speed loop PI block lead break frequency radians/second * 100

CML PI PROP GAIN (P.301) CML PI proportional gain gain * 1000

CML PI LEAD FREQUENCY (P.302) CML PI lead break frequency radians/second

CML REF RATE LIMIT (P.303)

JOG SPEED 1 (P.012) Operating speed while jogging RPM

STOP MODE SELECT (P.114) Selects how drive responds to a normal stop command 0=RAMP; 1= COAST/DB; 2 = CURRENT LIMIT

CURRENT COMPOUNDING (P.209) Sets the level of current compounding %

NETW COMM LOSS SELECT

(P.901)

Min. time for

CML

ref. to go from zero to

MAXIMUM CURRENT

milliseconds

How the drive responds to network communication loss 0=FAUL T; 1=USE LAST REF; 2=USE TRMBLK REF,

USE TRMBLK CNTL

3=

0=motor speed in

RPM

0=armature voltage in volts

NETW OUT REG 3 SELECT (P.904) Number of the parameter readable in Drop_1, register 9 If no valid parameter value selected, this is set to

0=armature current in amps*10 or amps

Tunable data are read by the regulator approximately every 600 msec while Tune/Config Input Enable bit=1

5-7

Page 38

5-8

AutoMax Network Communication Option Board

Table 5.6 – FlexPak 3000 Original Register Map, Drop_1: Master Write Registers, BASIC and FULL Connections. Configurable Data (Drive Input Data)

Register Parameter Name (Number) Description Settings

61 FEEDBACK SELECT (P.200) Type of feedback for speed/voltage loop feedback 0= ARMATURE VOLT; 1=DC TACH ; 2 = PULSE TACH; 3=AC TACH

62 NETW CONNECT TYPE (P.910) AutoMax network connection type 0= BASIC; 1 = FULL

63 AMX NETW REF SELECT (P.911) AutoMax network reference selection 0=DIRECT; n=BROADCAST n (n=1 to 8)

Configurable data are read by the regulator approximately every 600 msec when Tune/Config Input Enable bit= 1 and the drive is not running or jogging

Table 5.7 – FlexPak 3000 Original Register Map, Drop_2: Master Read Registers, FULL Connection. Runtime Signal Data (Drive Output Data)

Register Parameter Name (Number) Description Settings

0 ANALOG AUTO REFERENCE (P.188) The analog reference value in auto mode after all scaling 4095 at TOP SPEED (P.011)

1 Reserved

2

ANALOG MAN TRIM REF (P.194) Analog manual trim reference input value 4095 at TOP SPEED (P.011)

3 to 10 Reserved

Runtime signal data are updated by the regulator every 5 msec, unless

Table 5.8 – FlexPak 3000 Original Register Map, Drop_2: Master Read Registers, FULL Connection. Tunable, Configurable, and Status Data (Drive Output Data)

FEEDBACK SELECT (P.200) is set to ARMATURE VOLT, in which case the update time is 10 msec.

Register Bit Parameter Name (Number) Description Settings

11 OCL RAMP OUTPUT (P.846) OCL reference S-curve block output 4095

12

13

14

15

16

17

18

19 ANLG AUTO GAIN ADJ (P.101) Scales analog auto reference signal gain * 1000

20

21

22

OCL OUTPUT (P.848) Outer control loop output value RPM

TOP SPEED (P.011) Highest running speed of motor RPM

JOG SPEED 1 (P.012) Operating speed while jogging RPM

JOG ACCEL/DECEL TIME (P.013) Minimum time in which jog reference can change from

TOP SPEED (P.011) and from TOP SPEED to zero

zero to

S-CURVE ROUNDING (P.014) Amount of smoothing of speed/voltage loop reference %

REVERS E DISABLE (P.015) Prevents speed/voltage loop ref. from going negative 0=OFF (bipolar ref); 1= ON (positive ref)

ANLG AUTO SIGNAL TYPE (P.100) Type of signal applied to analog auto reference input

ANLG AUTO ZERO ADJ (P.102) Offset removed from analog auto reference signal

AUTO REFERENCE SELECT (P.103) Selects the type of auto reference 0= ANALOG; 1 = FREQUENCY IN

ANLG MAN REF GAIN ADJ (P.104) Scales the analog manual reference gain gain * 1000

seconds * 10

0=0-10V; 1=±10V; 2=4-20mA; 3=10-50mA

Tunable, configurable, and status data are updated by the regulator approximately every 600 msec.

Page 39

FlexPak 3000 Drives: Original Register Map

Table 5.8 – FlexPak 3000 Original Register Map, Drop_2: Master Read Registers, FULL Connection. Tunable, Configurable, and Status Data (Drive Output Data) (Continued)

Register Bit Parameter Name (Number) Description Settings

23 ANLG MAN REF ZERO ADJ (P.105) Offset removed from the analog manual reference signal

24

25

26

27

28

29

30

31 TRIM OUTPUT (P.197)

TRIM REF REGISTER (P.107) Trim reference value % TOP SPEED (P.011) * 10

TRIM REFERENCE SELECT (P.108) Trim reference selection 0= REGISTER; 1 = ANALOG MANUAL;

2=

ANALOG IN 1; 3=NETW IN REG 1;

NETW IN REG 2; 5= NETW IN REG 3;

4=

ANALOG IN 2

6=

TRIM MODE SELECT (P.110) Type of trim mode selected 0=NO TRIM; 1=INCREMENTAL;

2=

PROPORTIONAL

AUTO MODE MIN BYPASS (P.111) Disables minimum speed limit while in auto mode 0 = OFF; 1= ON (min speed bypassed)

AUTO MODE RAMP BYPASS (P.112) Bypasses speed loop S-curve block while drive is in auto 0 =OFF; 1 = ON (rate limit bypassed)

STOP SPEED THRESHOLD (P.113) Speed threshold at which the main contactor will open

RPM

during a controlled stop

STOP MODE SELECT (P.114) Selects how drive responds to a normal stop command 0=RAMP; 1=COAST/DB; 2=CURRENT LIMIT

Signal that trims the selected speed/voltage loop reference

4095 at TOP SPEED (P.011)

Tunable, configurable, and status data are updated by the regulator approximately every 600 msec.

Table 5.9 – FlexPak 3000 Original Register Map, Drop_2: Master Write Registers, FULL Connection. Tunable Data (Drive Input Data)

Register Bit Parameter Name (Number) Description Settings

32 Reserved

33

34

35

36

37

38

39

40 JOG ACCEL/DECEL TIME (P.013) Minimum time in which jog reference can change from

41

5-9

42

NORMALIZED INERTIA (P.222) Combined inertia of motor and load seconds*100

OCL REF REGISTER (P.801) Outer control loop reference 4095

OCL REF RAMP TIME (P.802) Ramp time for OCL reference seconds * 10

OCL REF ROUNDING (P.803) Amount of smoothing of the outer control loop reference %

OCL LEADLAG SELECT (P.805) Outer control loop lead/lag block select 0=LEAD/LAG; 1=BYPASS; 2 = LAG/LEAD

OCL LEADLAG LOW FREQ (P.806) OCL lead/lag block low break frequency radians/second * 100

OCL LEADLAG RATIO (P.807) Ratio between low and high frequencies of OCL

seconds * 10

zero to

TOP SPEED (P.011) and from TOP SPEED to zero

ANLG AUTO GAIN ADJ (P.101) Scales analog auto reference signal gain * 1000

ANLG AUTO ZERO ADJ (P.102) Offset removed from analog auto reference signal

Tunable data are updated by the regulator approximately every 600 msec when Tune/Config Input Enable bit = 1.

Page 40

5-10

Table 5.9 – FlexPak 3000 Original Register Map, Drop_2: Master Write Registers, FULL Connection. Tunable Data (Drive Input Data) (Continued)

Register Bit Parameter Name (Number) Description Settings

43 Reserved