Page 1

MINOTAUR MSR17T SAFETY RELAYS

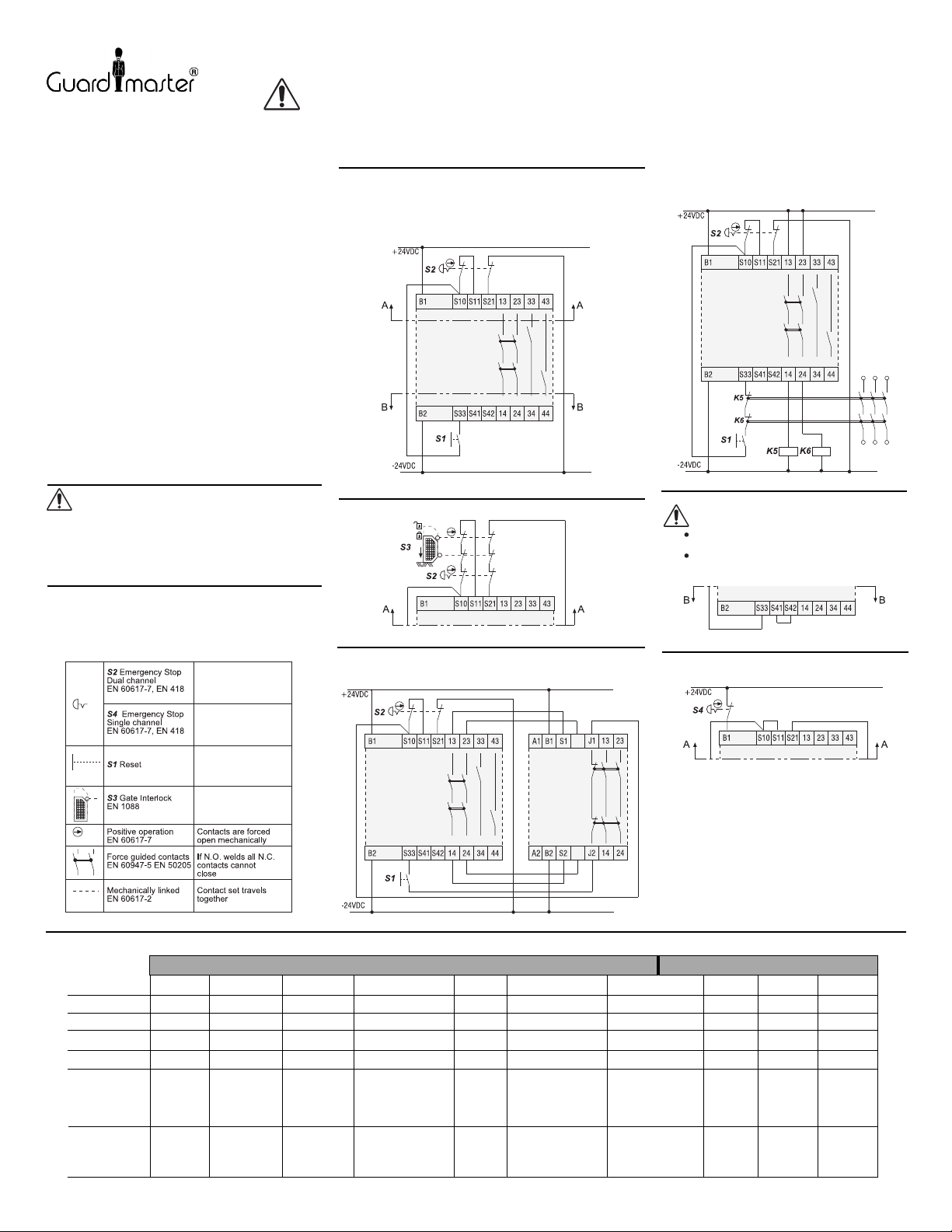

ATTENTION: To prevent electrical shocks, disconnect power

source before servicing.

IMPORTANT: Save these instructions for future use.

General

The safety relay by itself can not provide safety. The

safety relay requires proper component application

and

maintenance. The application must anticipate

failures by using system safety risk assessment. This

product must

accordance with the manufacturer’s instructions as

well as applicable standards.

Mounting

The units must be mounted on a 35 mm DIN rail.

Construction

The relay has (4) groups of terminals:

1. Power Terminals:

(+B1 -B2) for 24V DC

2. Input Terminals:

The E-Stop and Gate interlock operator: Ch 1 (S10 &

S11), Ch 2 (S21 & B2) (Fig. 1, 2)

Start button: S10, S33 (Fig. 1, 2)

*3. Safety Output Terminals:

13-14, 23-24

These are monitored outputs. These outputs are

voltage free.

**4. Auxiliary Terminals:

33-34 (K1 Aux.), 43-44 (K2 Aux.)

be installed and maintained in

Applications: E-Stop, Gate Interlock, Expanders

and Auxiliary Relays, Automatic Start

E-Stop (Fig. 1)

a) Use an E-Stop button conforming to EN 418. It must have (2)

Normally Closed (N.C.) contact blocks. The contact blocks

must conform to EN 60947-5-1 positive-opening operation.

b) Use a start/reset momentary pushbutton with (1) Normally

Open (N.O.) contact block.

k1

k2

MSR17T

INSTRUCTION SHEET

Attaching Auxiliary Relays (Fig. 4

The auxiliary relays must be of the "positively-guided /

Direct Drive

auxiliary relays may be monitored by connecting

N.C. contacts in series to the reset circuit.

TM

"

style conforming to EN 50205. The

k1

MSR17T

k2

)

ATTENTION:

Protection of Safety Circuits.

To avoid contact welding, a fuse (5A quick or 1.6A

*

slow) must be connected externally.

The auxiliary terminals are NOT monitored

**

and must not be used as safety outputs. These

may be used for data and signaling.

Wiring:

Use 0,2-2,5 mm2 (24-14 AWG) Cu only. Typical

screwdriver needed is a flat blade 3 mm (.125 in.) wide

Tighten screws to 0.5-0.8 Nm

LEDs: Run & Fault Conditions (Fig. 1-4)

POWER LED

CH 1 LED

CH 2 LED

K1 LED

K2 LED

CONDITION

ACTION

(5-7 lb.in.).

Refer to

Guardmaster catalogue

Refer to

Guardmaster catalogue

Refer to

Guardmaster catalogue

Refer to

Guardmaster catalogue

l

l

l

l

l

proper

running

conditions

none replace

l

l

l

l

l

channel 1

contacts

may be open

channel 1

contact

block

,

channel 2

contacts

may be open

replace

channel 2

contact

block

Gate Interlock (Fig. 2)

.

Attaching an Expander (Fig. 3)

The expander can be used with E-Stop and Gate Interlock Control.

l

l

l

l

l

Drg No: 23963 / Issue No: 1 (Ref. 40063-239-01 (A))

MSR17T

k1

MSR17T

k2

l

l

l

l

start/reset actuator

contacts may be

welded

replace reset

contacts

Fig. 1

Fig. 2

S3

MSR19E

S4

Fig. 3

Automatic Start

ATTENTION:

Unexpected/unintended start-up may occur

after power supply interruption.

Autostart is not allowed for E-Stops per

EN 292-2, 954-1, 60204-1 and 418.

MSR17T

Single Channel E-Stop (Fig. 6

MSR17T

Maintenance

The relay and its application must be inspected

periodically based on environmental and

operating conditions. Causes of contamination

must be eliminated. Worn and broken assemblies

must be replaced. Fasteners must be securely

re-tightened. Unit has no customer serviceable

parts. Fault c

restoring power.

control system under controlled conditions.

onditions must be corrected before

STOP ACTUATEDSTOP RESET

l

l l

l

l

l

l

l

l l

safety

contacts

may be

welded

replace

safety

relay

l

waiting for

l

start/reset signal

expander or aux.

l

contacts may be

welded

replace expander

or aux. relay

l

l

l

ll

l

input short

or no power

after clearing

short, power

must be off 20 sec.

to reset fuse

l l l

l

l

l

l

input

circuit is

open

reset

E-stop or

gate

Fig. 4

Fig. 5

)

Fig. 6

After maintenance, test the

l

l

l

l

l

ll

channel 1

contacts

may be

welded

replace

channel 1

contact

block

channel 2

contacts

may be

welded

replace

channel 2

contact

block

Loading...

Loading...