Page 1

Installation and Operating Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

This publication does not include all specifications, dimensions, or any special installation considerations.

Refer to the product catalog pages for additional information.

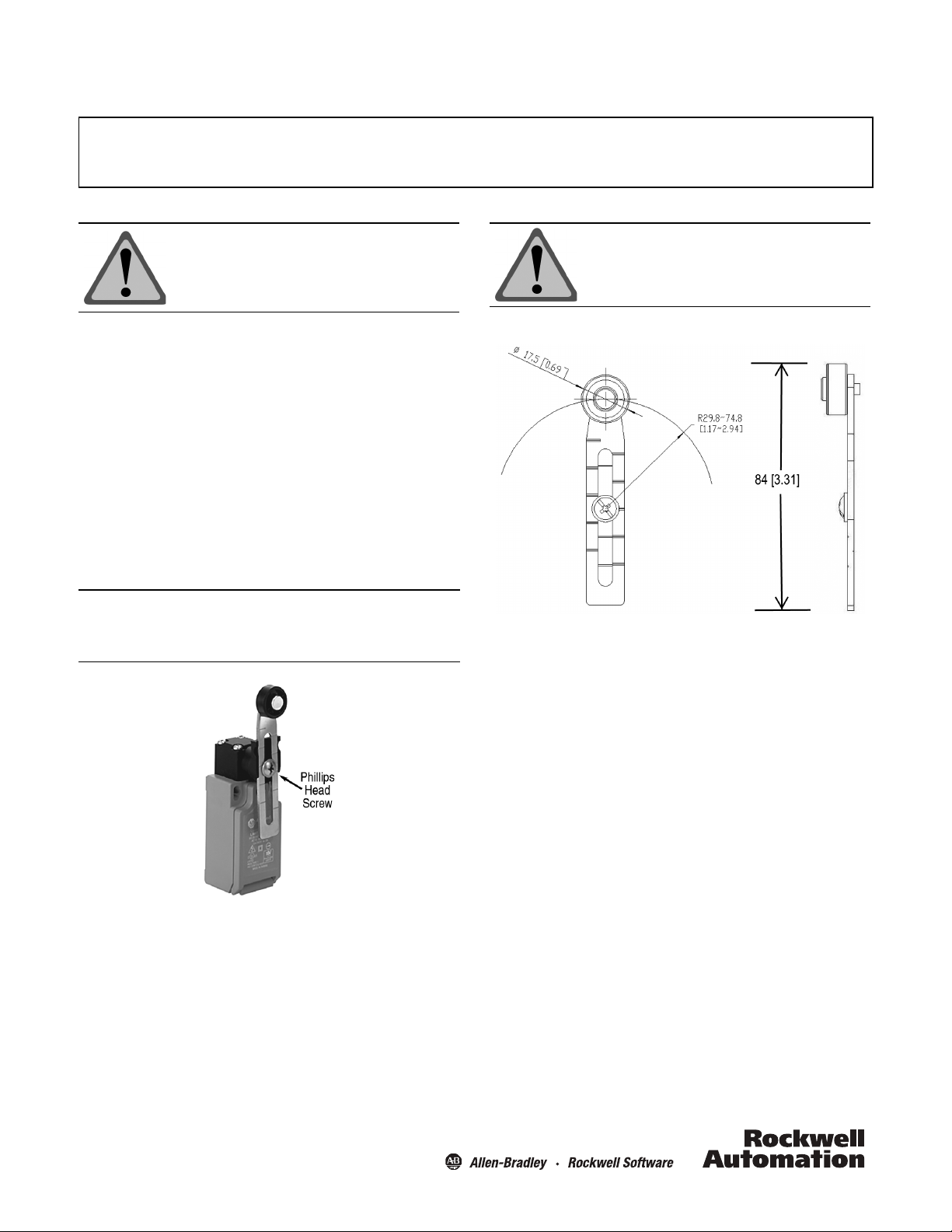

Adjustable lever shown installed

Bulletin 440P-WC2 & 440P-WC2B Adjustable Lever

ATTENTION: To avoid electrical shock and unintended

operation of equipment, disconnect all

power to the limit switch and the controlled

equipment before proceeding with any

repair or adjustment of the limit switch.

General Data

• Designed for 440P-C adjustable lever limit switches

• Nylon or metal roller

• Roller diameter 17.5 mm (0.68 in.) x width 7 mm (0.28 in.)

• Lever radius adjustable 45…90 mm (1.77…4.54 in.)

• Lever length 84 mm (3.31 in.)

• Includes Philips head screw

Principles, Standards, and Implementation

Operating specifications must be followed. Actuators should

be displaced beyond the point where direct opening action

occurs. If adjustable actuators become loose they may defeat

the direct opening action feature of the limit switch. These

devices are not to be used to directly control a motor.

IMPORTANT: Installation of Allen-Bradley limit switches should be in

accordance with local and/or national codes. Servicing

energized industrial control equipment can be hazarous if

not in accordance to recommended safety procedures.

ATTENTION: Operator heads with adjustable actuators

should NOT be used for safety

applications.

Approximate Dimensions [mm (in.)]

Instructions

1. Insert Philips head screw through the adjustable lever arm

slot.

2. Align the Philips head screw with the operating head shaft

hole.

3. Position the adjustable lever arm to the desired length.

4. Tighten the Philips head screw to 1.4…1.5 N•m

(12.39…13.28 lb•in).

Page 2

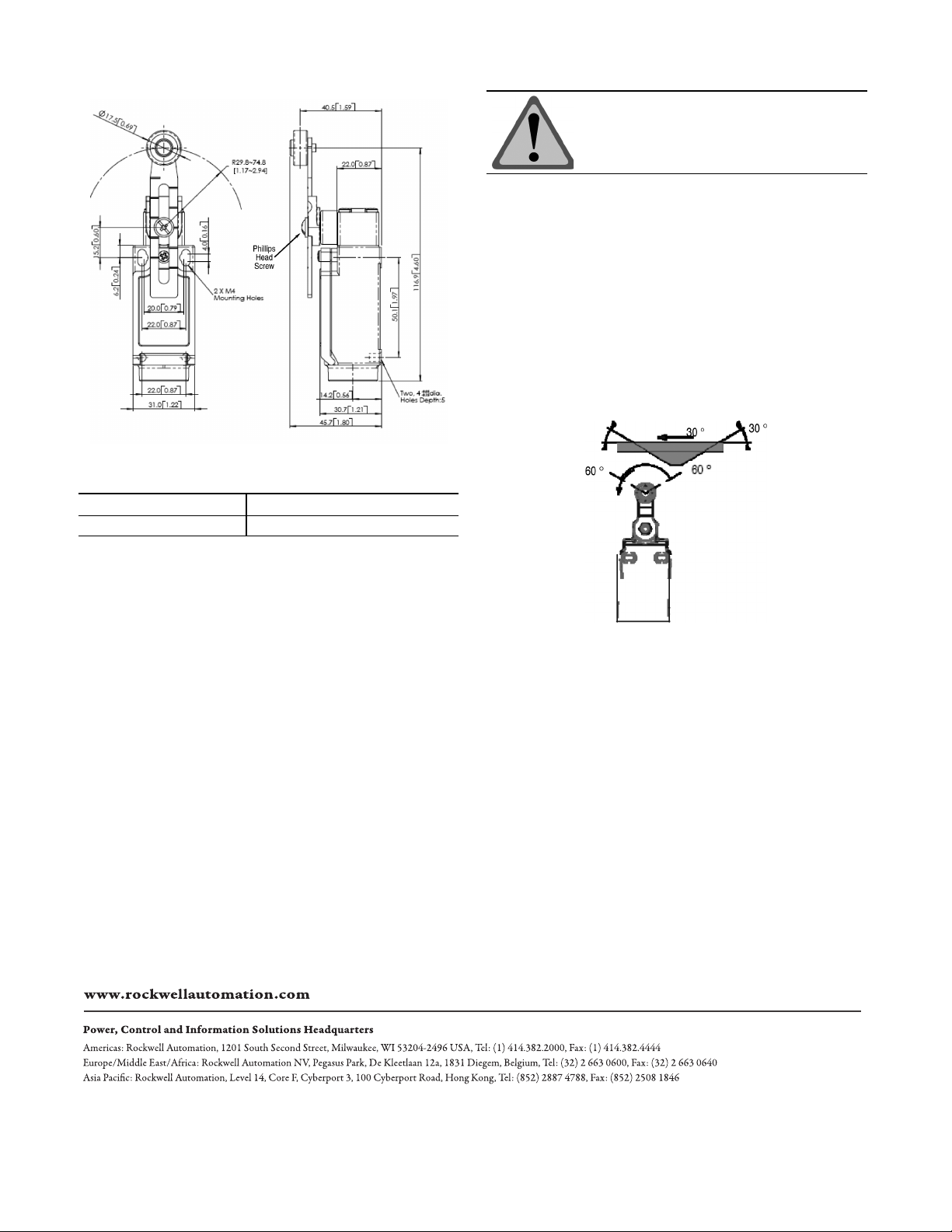

Mounting Dimensions [mm (in.)]

Torque Specifications

Location Torque

Philips head screw 1.4…1.5 N•m (12.39…13.28 lb•in)

ATTENTION: Under no circumstances must the switch

be actuated beyond the mechanical travel

specified. Serious damage to the device

and property could result.

Maintenance

These devices require little maintenance, but routine visual

inspection is recommended to keep foreign debris from

collecting on the exterior actuators and rollers.

Removing the operator head is not recommended as loose

internal components may be lost or improperly re-installed.

Actuation Guidelines

The method of actuation and over travel has significant

influence on the service life of the limit switch. To maximize

the service life, it is recommended to provide an actuator with

a 30° pressure angle and a surface hardness of RC-45 max.

Drwg. No. 10000101184 Ver 00

February 2011

Printed in USA

Loading...

Loading...