Page 1

Installation Instructions

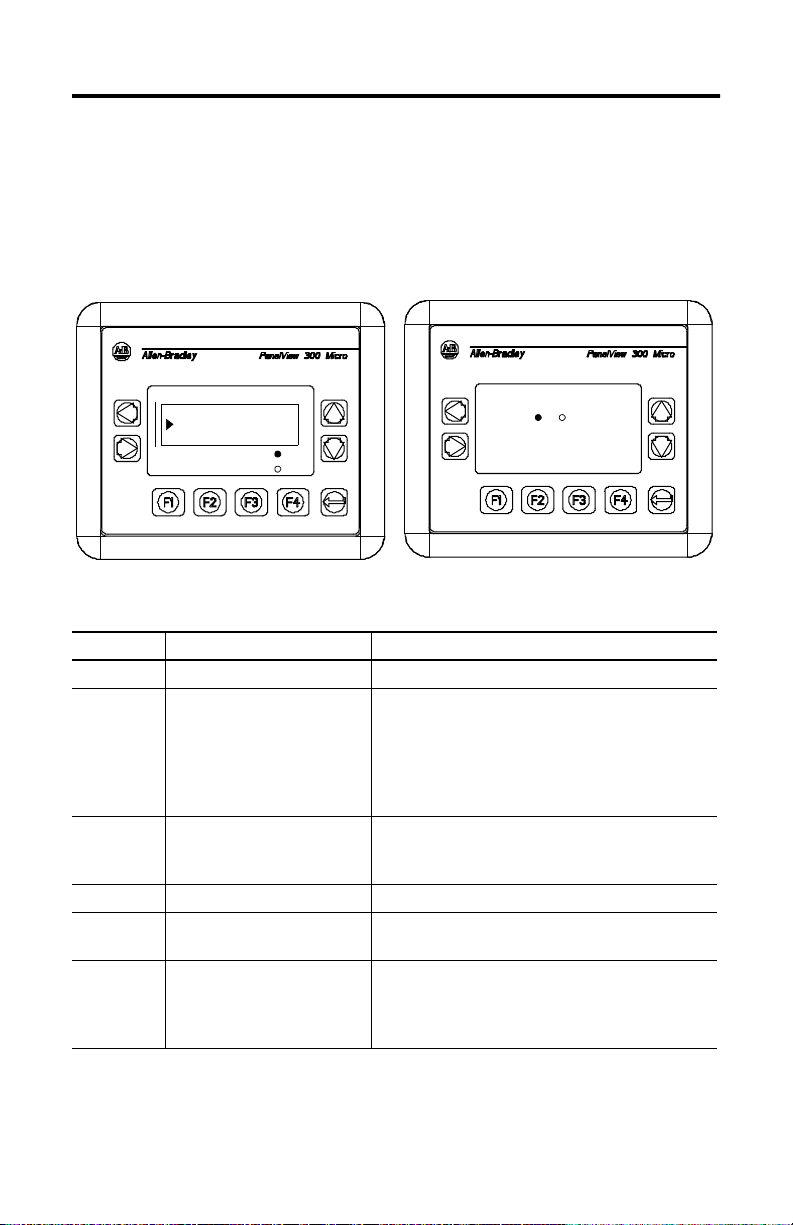

PanelView 300 Micro Terminals

(Catalog Numbers 2711-M3A18L1, 2711-M3A19L1)

Inside:

English..................................................................................................... 3

Français................................................................................................. 25

Deutsch................................................................................................. 47

Español.................................................................................................. 69

Italiano.................................................................................................. 91

41061-156-01(A)

Page 2

2 PanelView 300 Micro Terminals

41061-156-01(A)

Page 3

Installation Instructions

English

PanelView 300 Micro Terminal

(Catalog Numbers 2711-M3A18L1, 2711-M3A19L1)

Inside:

For More Information.............................................................................. 4

European Communities (EC) Directive Compliance ................................ 4

Hazardous Locations............................................................................... 5

Wiring and Safety Guidelines................................................................. 6

Mounting the Terminal............................................................................ 6

Connecting DC Power........................................................................... 10

Using the Communications Port ........................................................... 13

Accessing Configuration Mode............................................................ 18

Resetting the Terminal.......................................................................... 18

Comm and Fault Indicators................................................................... 19

Troubleshooting and Maintenance....................................................... 20

Accessories........................................................................................... 22

Specifications ....................................................................................... 23

41061-156-01(A)

Page 4

4 PanelView 300 Micro Terminal

For More Information

For Refer to Refer to

More detailed information on the 300 Micro and

the other Standard PanelView terminals.

If you would like a publication, you can:

• download a free electronic version from the PanelBuilder32 installation CD

• download a free electronic version from the internet:

www.ab.com/manuals/eoi or www.theautomationbookstore.com

To purchase a publication:

• visit the www.theautomationbookstore.com and place your order

• contact your local distributor or Rockwell Automation Representative

Standard PanelView

Terminals User Manual

2711-UM014A-EN-P

European Communities (EC) Directive Compliance

This product has the CE mark and is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet the

following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 61000-6-2 EMC - Generic Standard, Immunity for Industrial

Environments.

This product is intended for use in an industrial environment.

41061-156-01(A)

Page 5

PanelView 300 Micro Terminal 5

!

DANGER

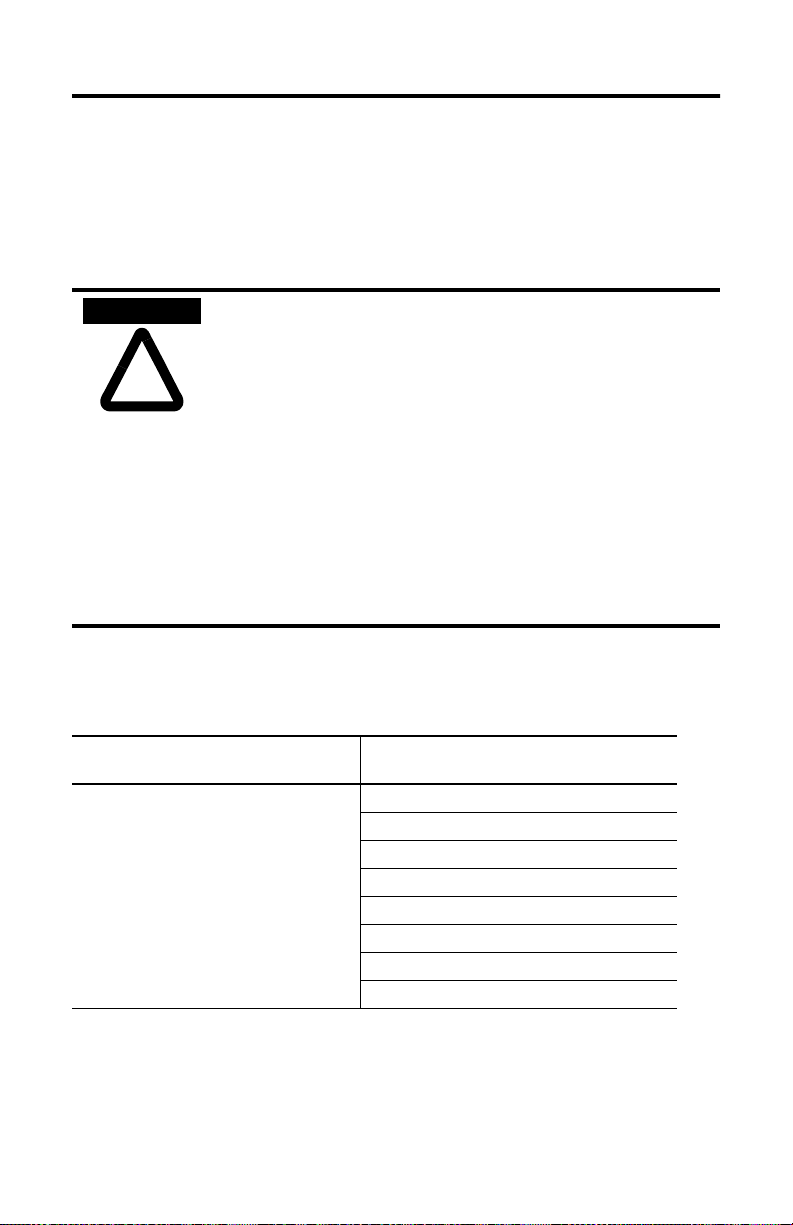

Hazardous Locations

This equipment is suitable for use in Class 1, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following DANGER statement applies to use

in hazardous locations.

Explosion Hazard

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not disconnect equipment unless power has been

switched off and area is known to be non-hazardous.

• Do not connect or disconnect componen ts unless po wer has

been switched off.

• All wiring must comply with N.E.C. article 501-4(b).

• Peripheral equipment must be suitable for the location it is

used in.

Use only the following communication cables in Class 1, Division 2, Hazardous

Locations.

Environmental Classification Communication Cable

1761-CBL-PM01, Series C

1761-CBL-HM02, Series C

1761-CBL-AM00, Series C

Class I, Division 2, Hazardous Locations

1761-CBL-AP00, Series C

2711-CBL-PM05, Series C

2711-CBL-HM05, Series C

2711-CBL-PM10, Series C

2711-CBL-HM10, Series C

41061-156-01(A)

Page 6

6 PanelView 300 Micro Terminal

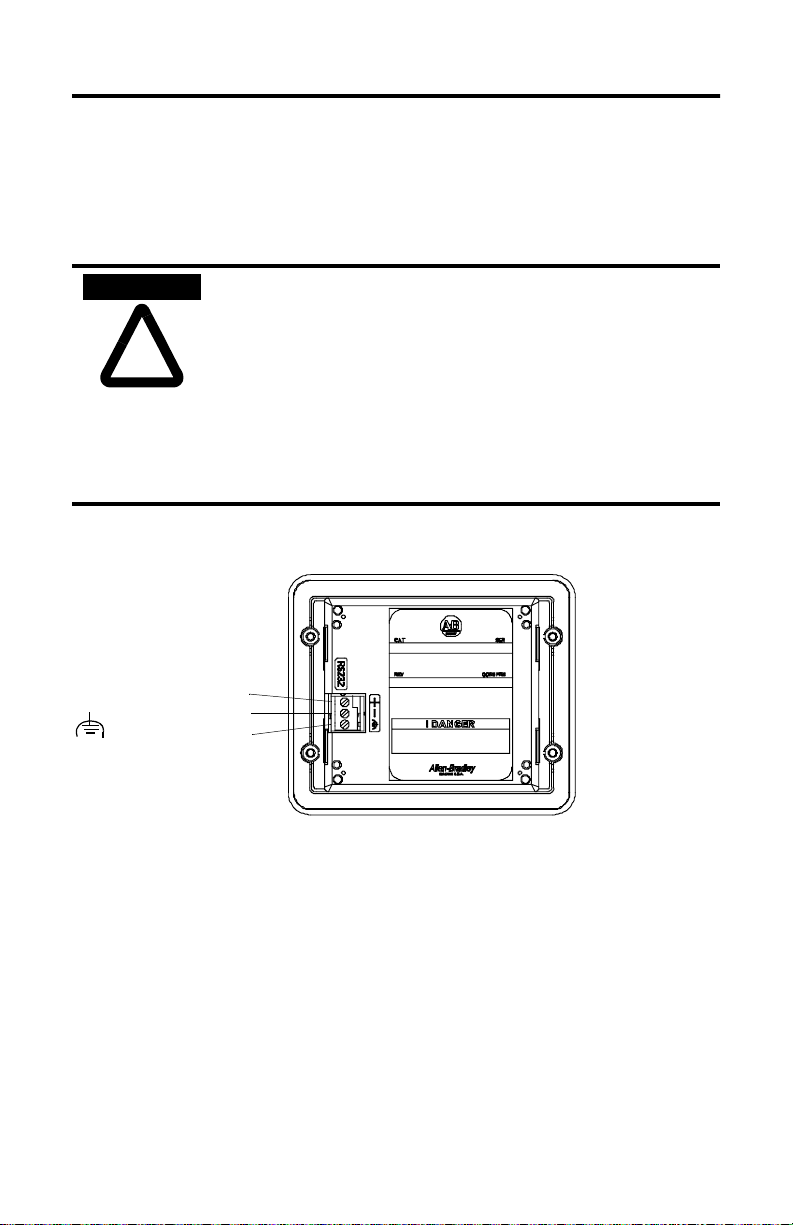

Wiring and Safety Guidelines

Install the PanelView 300 Micro terminal using publication 70E, Electrical

Safety Requirements for Employee Workplaces. In addition to the NFPA general

guidelines, follow these recommendations:

• Route incoming power to the PanelView 300 Micro by a separate path from

the communication cable.

• Where power and communication lines must cross, they should cross at right

angles. Communication lines can be installed in the same conduit as low level

DC I/O lines (less than 10 Volts).

• Grounding minimizes noise from Electromagnetic Interference (EMI) and is a

safety measure in electrical installations. To avoid EMI, shield and ground

cables appropriately.

A source for grounding recommendations is the National Electrical Code

published by the National Fire Protection Association of Boston.

Mounting the Terminal

Enclosures

Mount the PanelView 300 Micro terminal in a panel or enclosure to protect the

internal circuitry. The terminal meets NEMA 12/13 and 4X (indoor use) ratings

only when properly mounted in a panel or enclosure with the equivalent rating.

Allow enough space within the enclosure for adequate ventilation. Consider heat

produced by other devices in the enclosure. The ambient temperature around the

PanelView 300 Micro must be between 0

° and 55° C (32° and 131° F).

Make provisions for accessing the side panel of the terminal for wiring,

maintenance and troubleshooting.

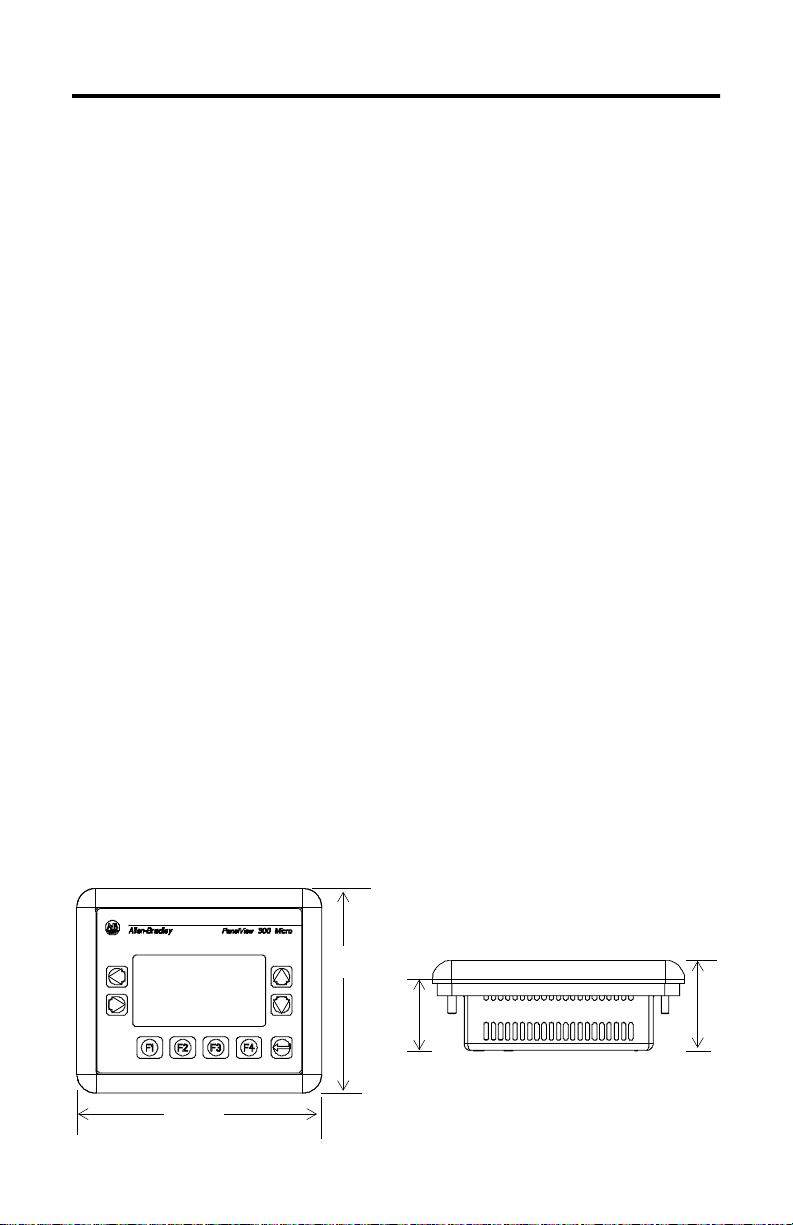

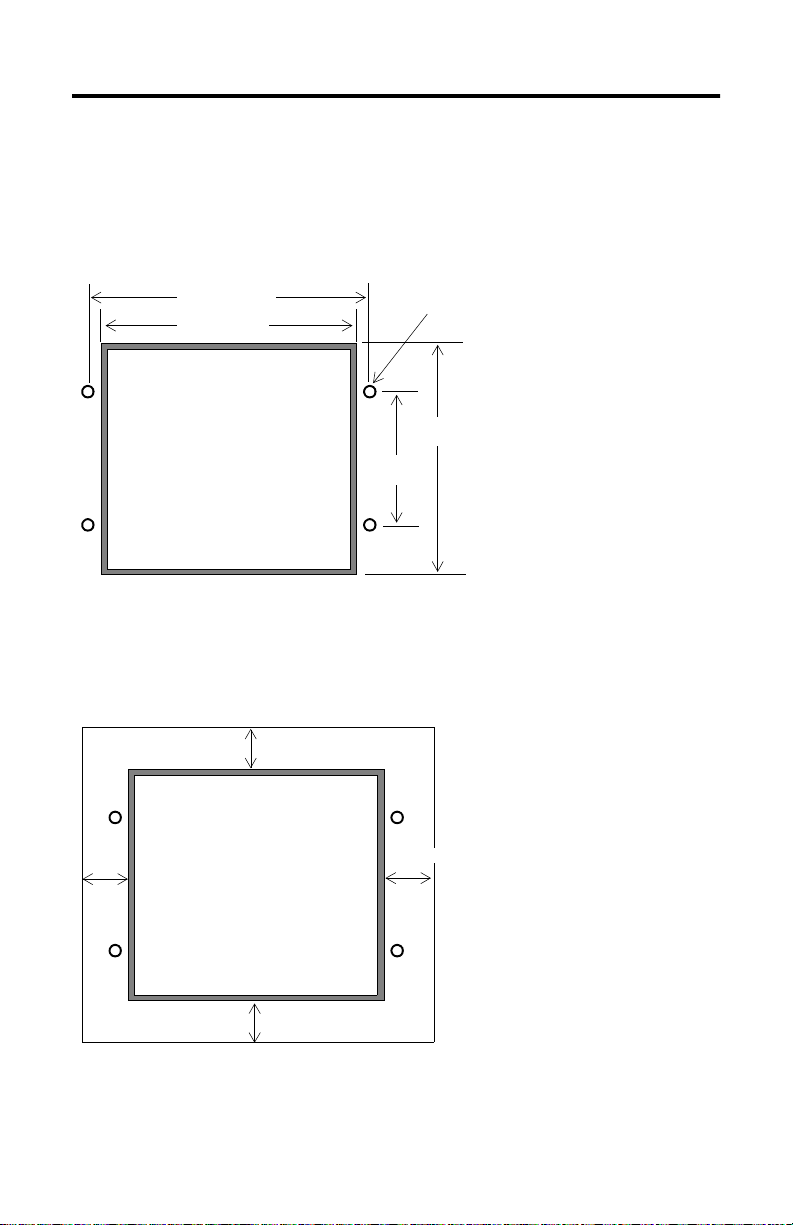

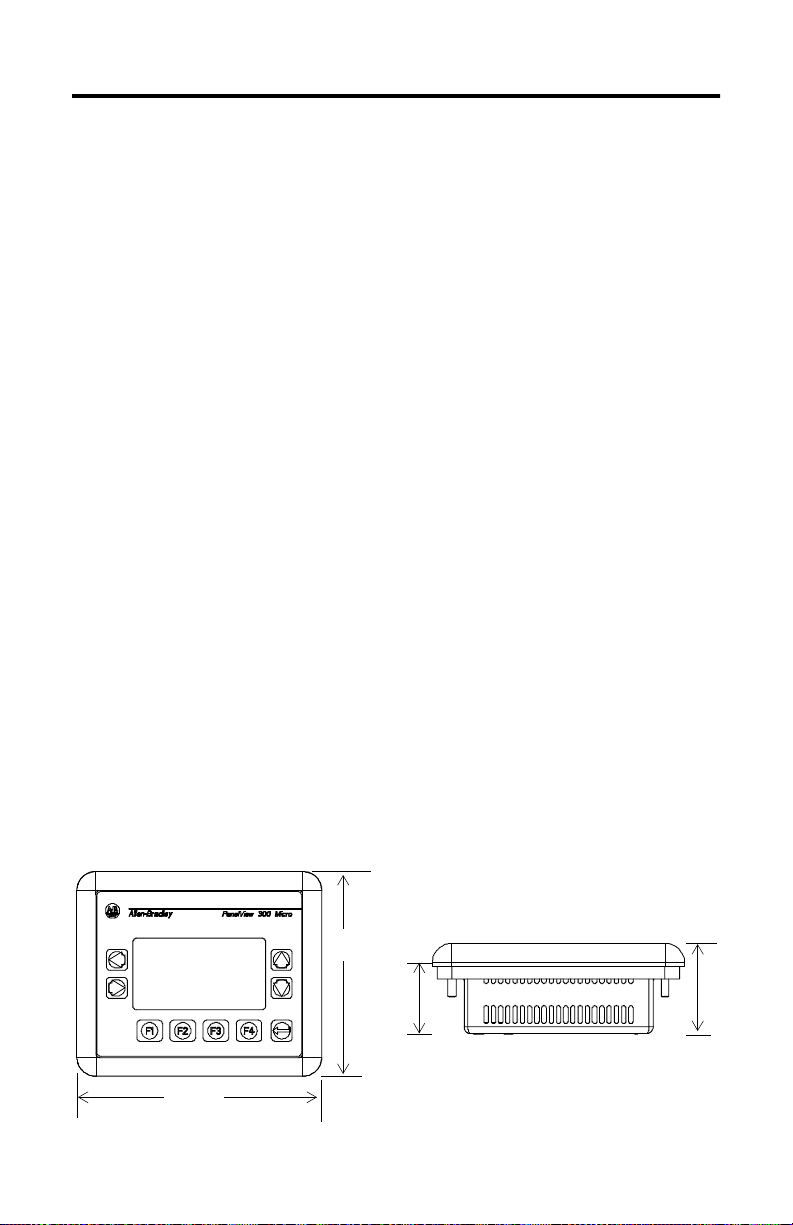

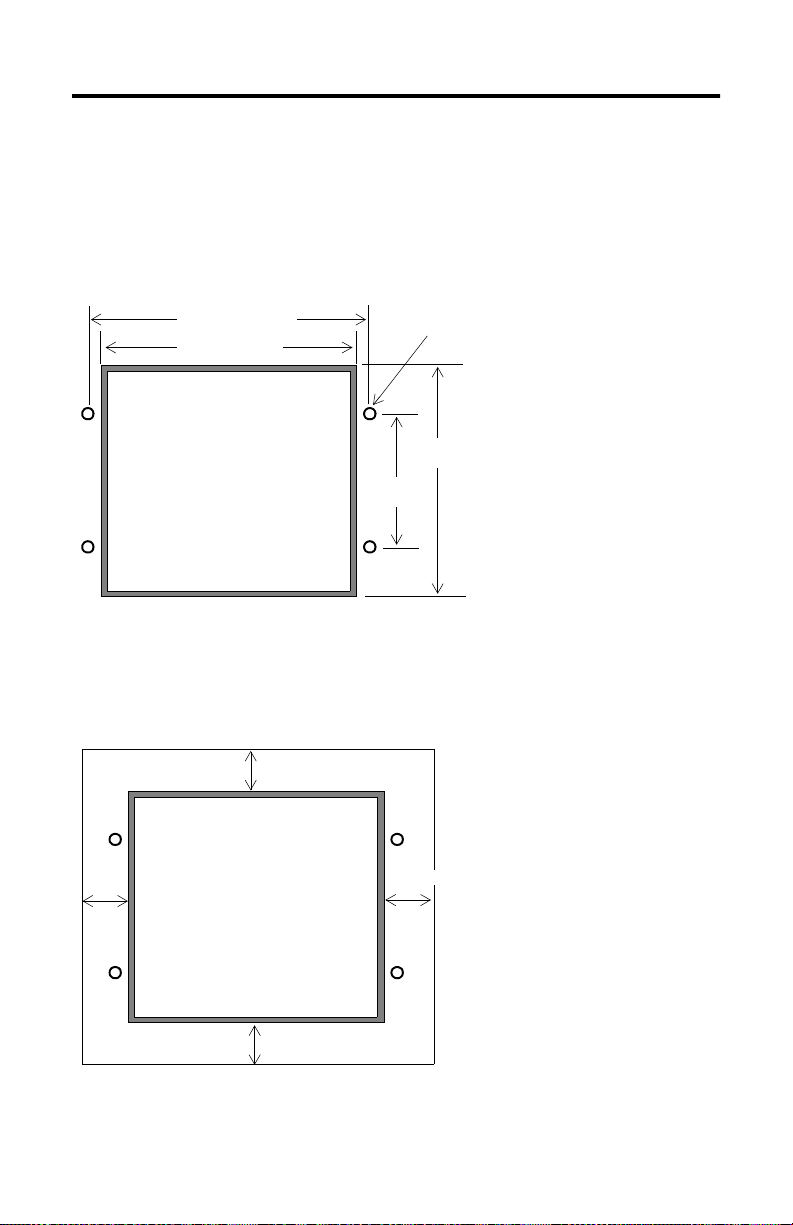

Mounting Dimensions

111 mm

(4.38 in.)

35 mm

(1.39 in.)

133 mm

(5.23 in.)

41061-156-01(A)

48 mm

(1.87 in.)

Page 7

PanelView 300 Micro Terminal 7

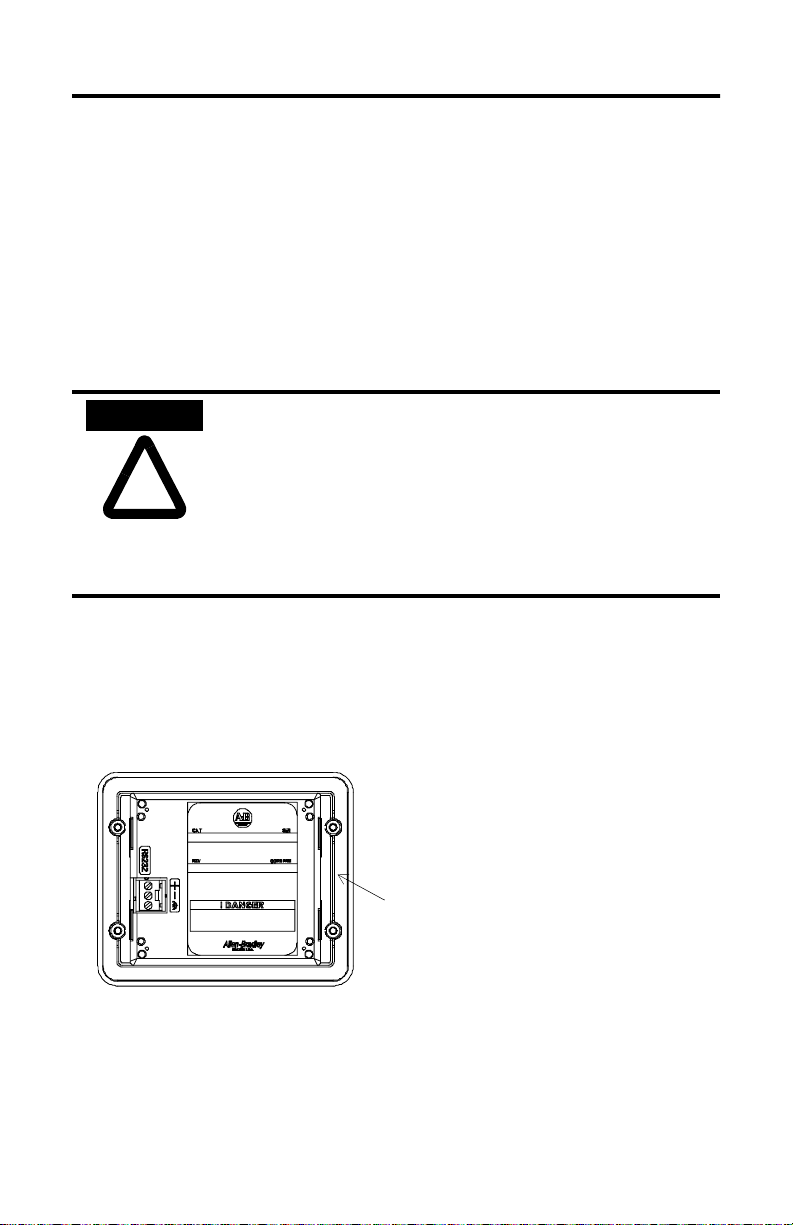

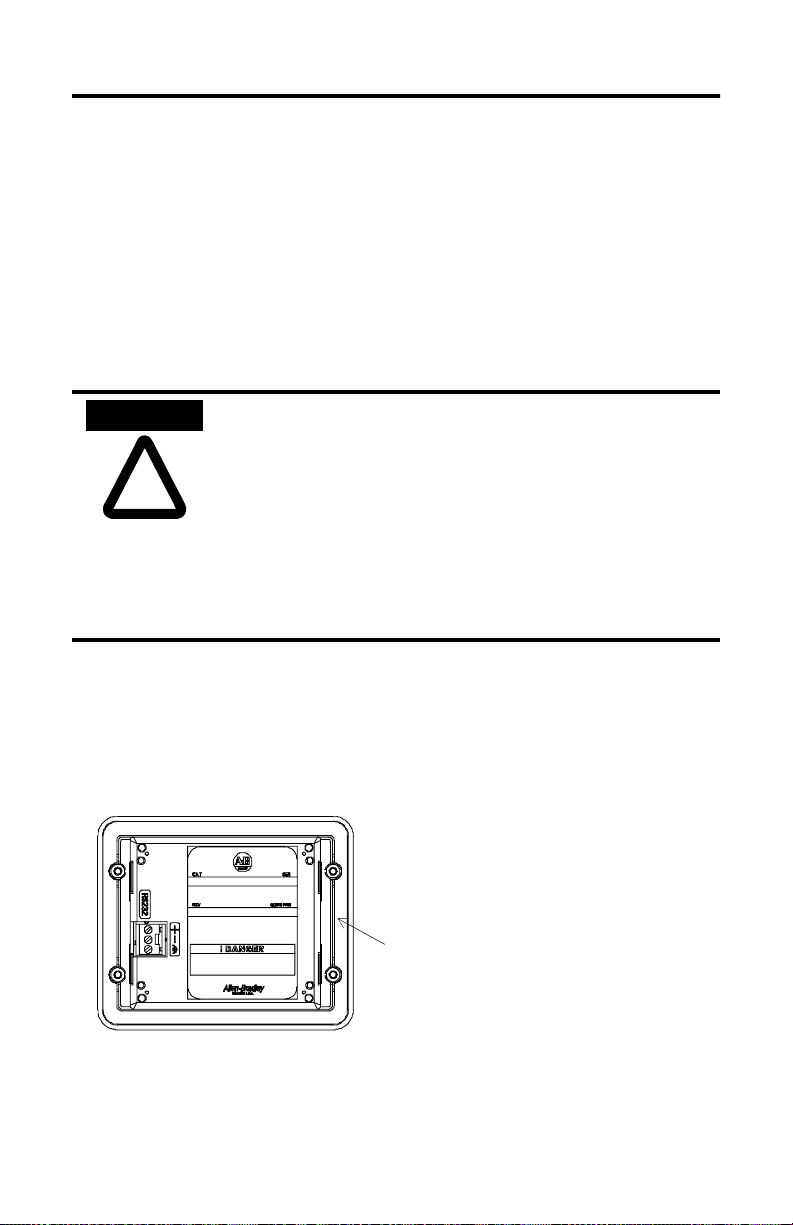

Cutout Dimensions

Use the full size template shipped with the PV300 Micro to mark the cutout

dimensions. The figure below sho ws a reduced scale cutout. A full scale template

is also available inside the back cover of this document.

4.42 in. (112 mm)

4.0 in. (102 mm)

0.178 in. (4.5 mm)

Diameter

3.62 in.

(92 mm)

2.12 in.

(54 mm)

Clearances

Allow 51 mm (2.0 inches) of space on all sides of the terminal for adequate

ventilation and maintenance.

2.0 in. (51 mm)

2.0 in. (51 mm)

41061-156-01(A)

Page 8

8 PanelView 300 Micro Terminal

!

ATTENTION

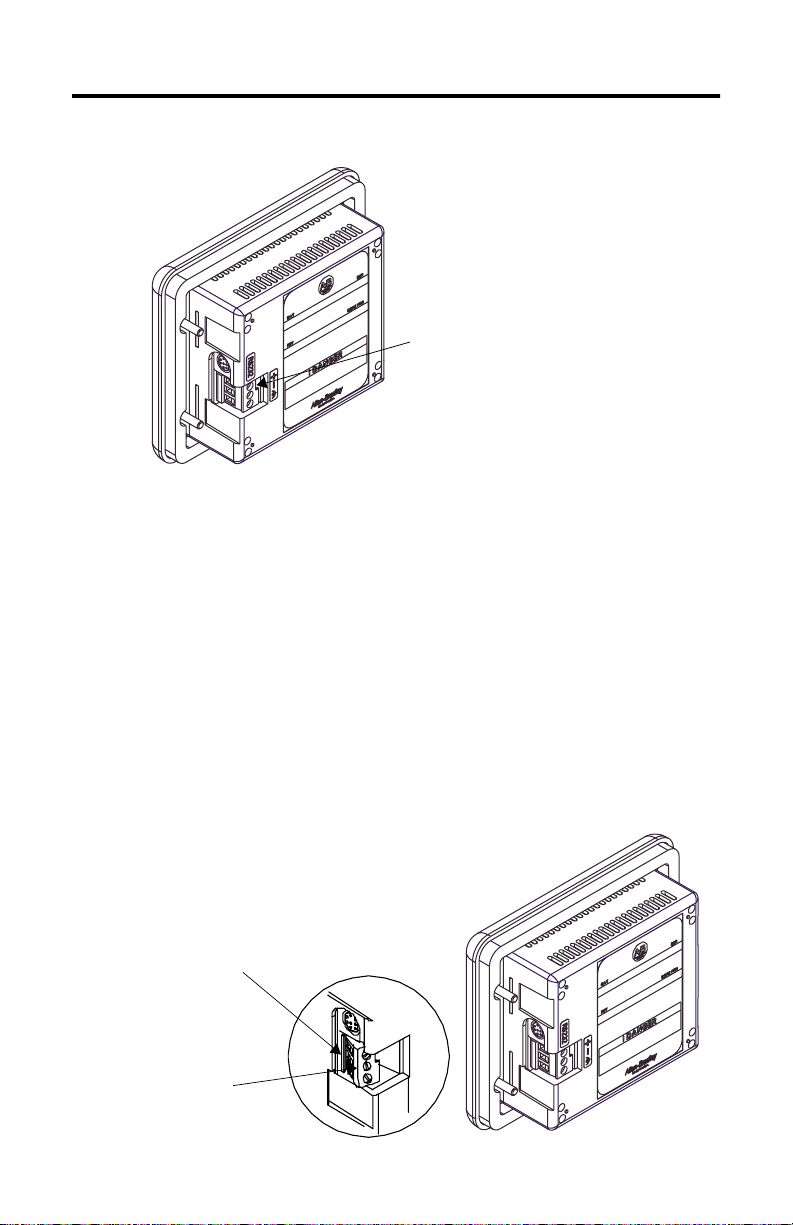

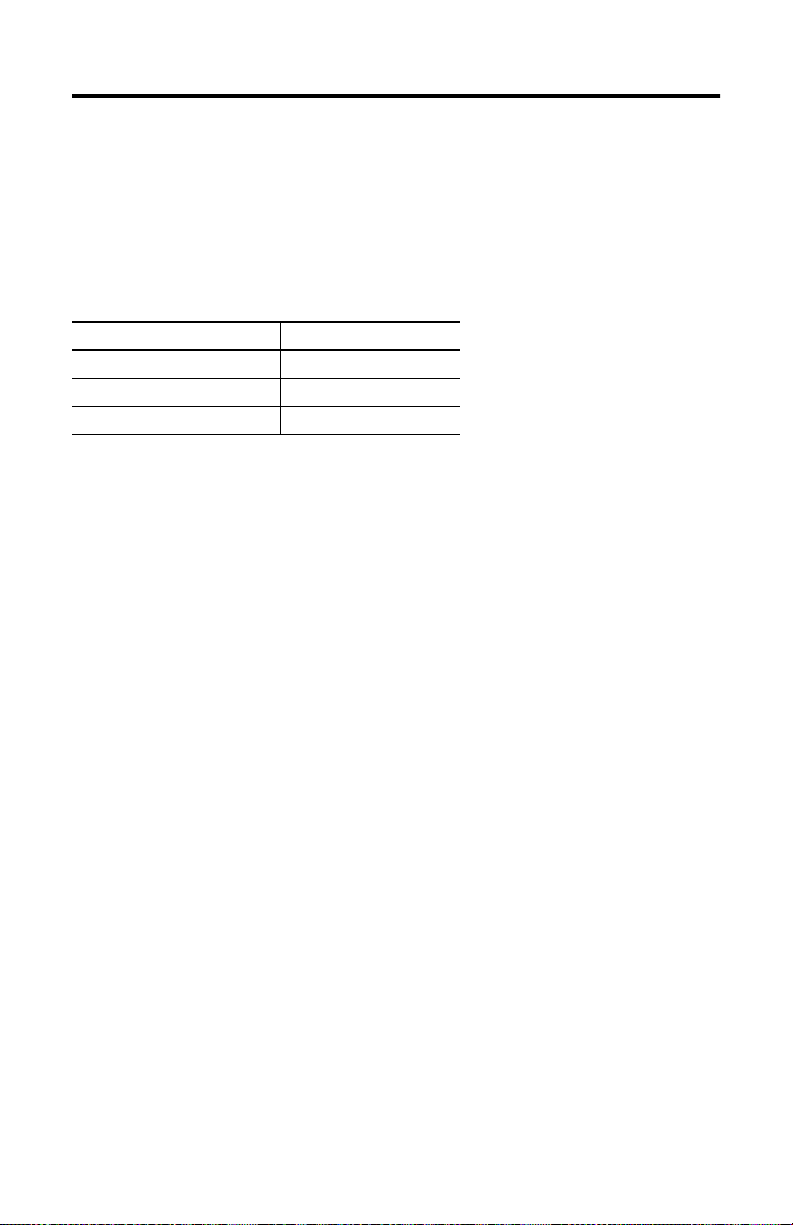

Installing Terminal in Panel

Other than the tools required to make the panel cutout, the tools required for

installation are:

• 7 mm (M4) deep well socket wrench or nut driver

• small slotted screwdriver

• torque wrench (in. / lbs.)

To install the PV300 Micro in a panel:

• Disconnect all electrical power from the panel before

making cutout.

• Make sure area around the panel cutout is clear.

• Take precautions so that metal cuttings do not enter any

components already installed in panel.

• Failure to follow this warning may result in personal injury

or damage to the panel components.

1. Cut an opening in the panel using the panel cutout provided with the terminal.

Remove sharp edges or burrs.

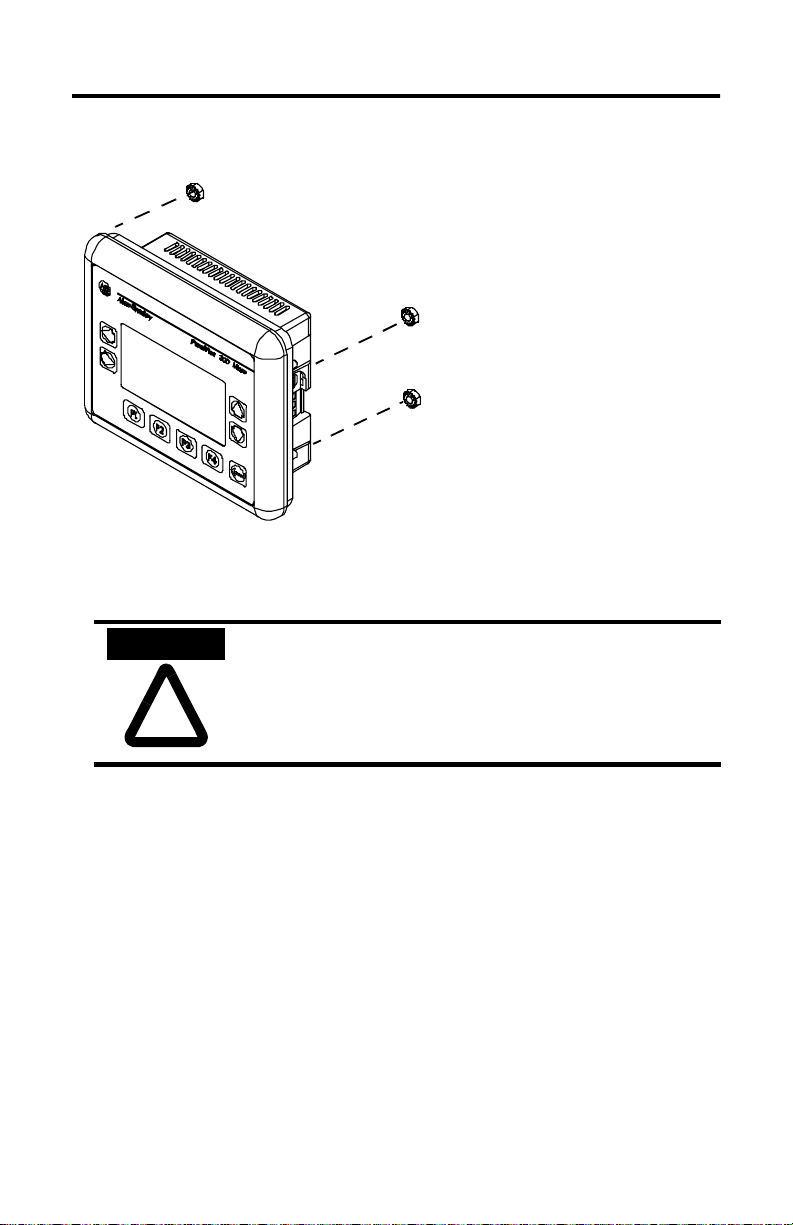

2. Make sure the sealing gasket is properly positioned on the terminal (as shown

below). This gasket forms a compression type seal. Do not use sealing

compounds.

Sealing Gasket

3. Place the terminal in the panel cutout.

41061-156-01(A)

Page 9

PanelView 300 Micro Terminal 9

!

ATTENTION

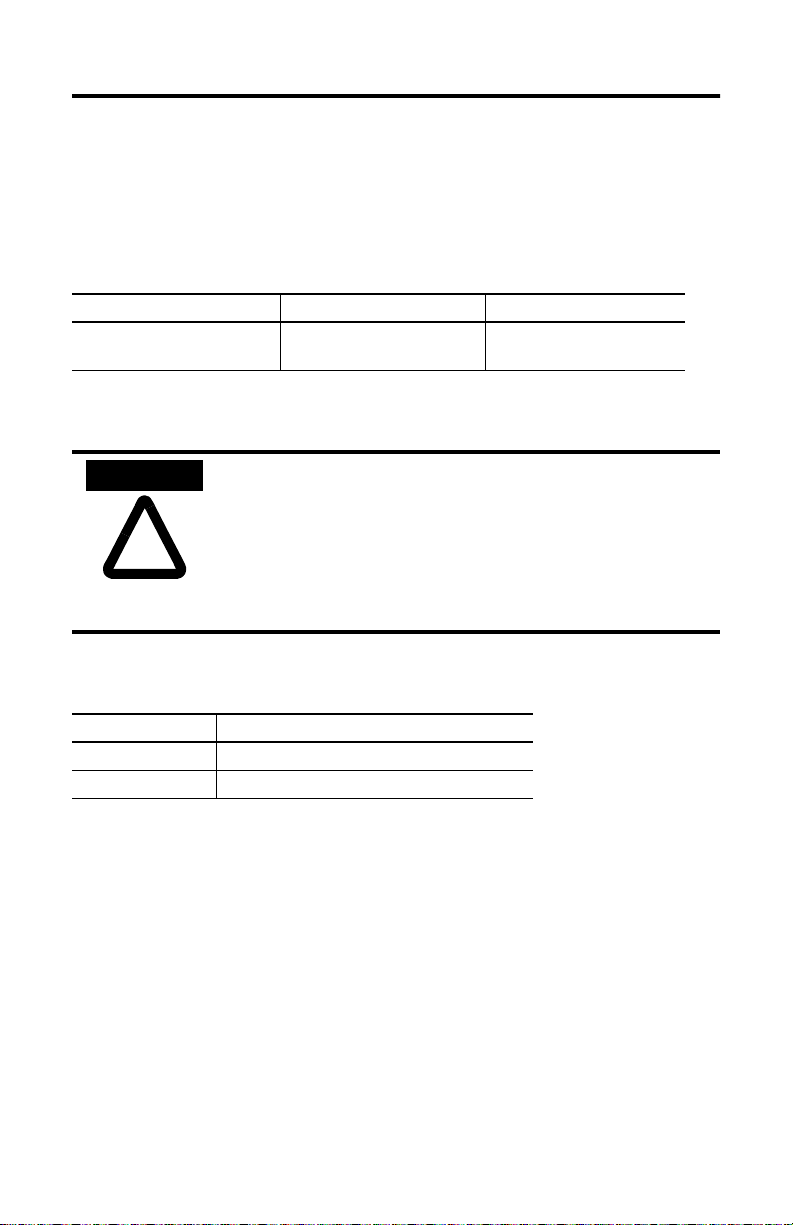

4. Install the 4 self-locking nuts, hand tight.

Self-Locking Nuts

(4 used, 6 provided)

5. Alternately tighten the self-locking nuts until the terminal is held firmly

against the panel. Tighten the nuts to a torque of 10 inch-pounds. Do not

overtighten.

Mounting nuts must be ti ghtened to a t orque of 10

inch-pounds to provide a proper seal and to prevent

potential damage to the terminal. Allen-Bradley assumes no

responsibility for water or chemical damage to the terminal

or other equipment within the enclosure because of

improper installation.

41061-156-01(A)

Page 10

10 PanelView 300 Micro Terminal

!

ATTENTION

Connecting DC Power

The PV300 Micro terminal connects to a 24V dc power source. The table below

shows the electrical ratings for the DC versions of the terminals. Electronic

circuitry and an internal fuse protect the terminals from reverse polarity and

over-voltage conditions.

Terminal Type Supply Voltage Power Consumption

PV300 Micro 11 to 30V dc

(24V dc nominal)

PV300 Micro terminal is designed for safe use when installed in a suitably rated

NEMA Type 12, 13, 4X (indoor use only), IP54 or IP65 enclosure.

• Do not connect the PanelView terminal to an AC power

source. Connecting to an AC power source will damage the

terminal.

• Use only a Safety Extra Low-Voltage (SELV) power supply

with an output rated between 11 - 30 V dc as a po wer source

for the PanelView 300 Micro. A SELV power supply does

not exceed 42.4V dc.

2.5 Watts maximum

(0.105 Amps @24V dc)

The input power terminal block on the PanelView 300 Micro is removable and

supports the following wiring types.

Wire Type Wire Size (2-wire maximum per terminal)

Solid #16 to #22 AWG

Stranded #18 to #22 AWG

41061-156-01(A)

Page 11

PanelView 300 Micro Terminal 11

!

DANGER

To connect DC power to the PanelView 300 Micro terminal:

1. Secure the DC power wires to the screw terminal block.

2. Secure the Functional Earth Ground wire to the screw terminal block.

Explosion Hazard

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not disconnect equipment unless power has been

switched off and area is known to be non-hazardous.

• Do not connect or disconnect componen ts unless po wer has

been switched off.

• All wiring must comply with N.E.C. article 501-4(b).

3. Apply power (24V dc nominal) to the terminal.

+ DC Positive

- DC Negative

Functional Earth Ground

Removing and Installing the Power Terminal Block

You can remove and re-install the power terminal block for ease of installation,

wiring and maintenance. The terminal block is pre-installed when shipped.

Additional terminal blocks (quantity of 10) are available by ordering Catalog

Number 2711-TBDC.

To remove the DC power terminal block:

1. Disconnect all electrical power from th e panel. See Explosion Hazar d Warning

above.

2. Insert tip of small flat-blade screw driver into DC power terminal access slot.

41061-156-01(A)

Page 12

12 PanelView 300 Micro Terminal

Insert tip of screw driver here.

3. Gently push the blade of the screw driver away from the terminal block to

release locking mechanism.

4. Remove DC power terminal block.

To re-install the DC power terminal block

Note: Install the terminal block with or without the power wires connected.

1. Disconnect all electrical power from the panel prior to installation. See

Explosion Hazard Warning on previous page.

2. Position the terminal block at a 45

° angle to the base surface and place lower

edge of the wire connection side into the base.

3. Gently push the top of the terminal block back to a vertical position to snap in

the locking tab.

Press terminal block

base in first with

block leaning outward

Push top back to

vertical position

to lock-in.

41061-156-01(A)

Page 13

PanelView 300 Micro Terminal 13

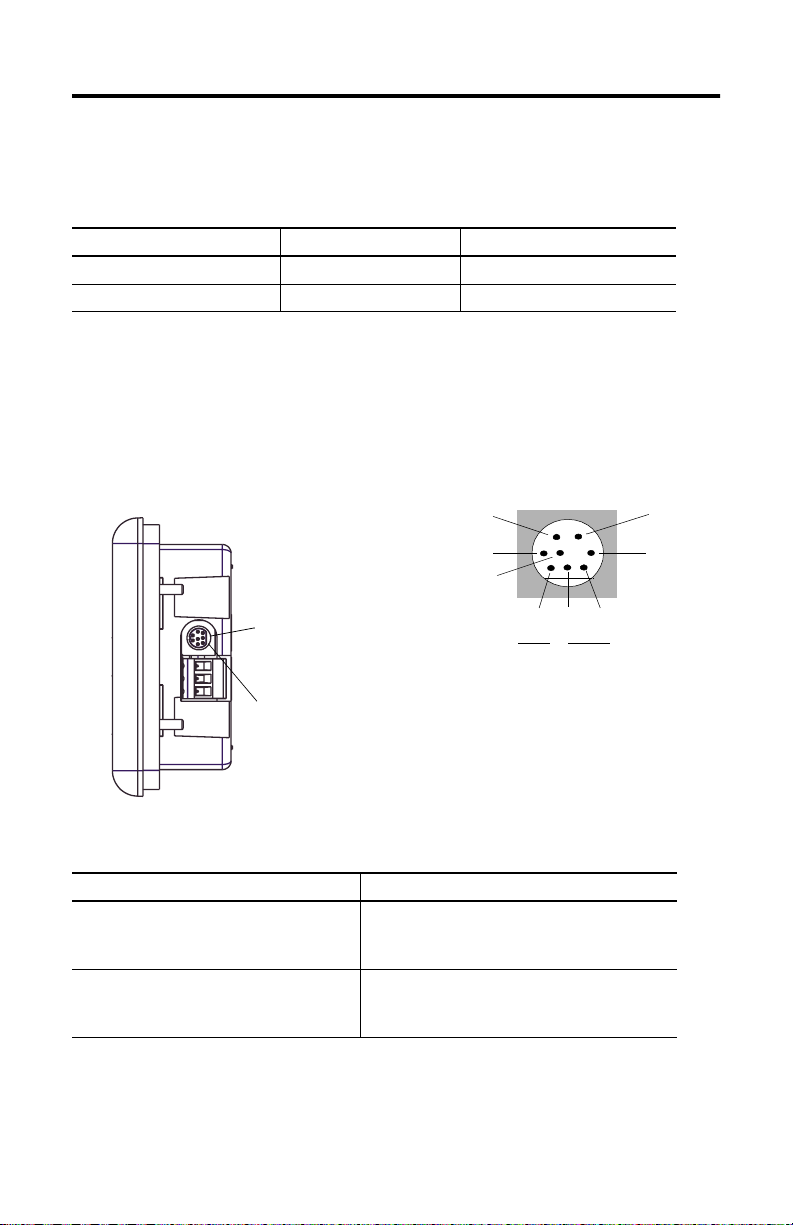

Using the Communications Port

The PanelView 300 Micro terminal is available in 2 versions.

Catalog Number Communication Port Communication Protocol

2711-M3A18L1 RS-232 DF1

2711-M3A19L1 RS-232 DH485

Both versions have an identical RS-232 communi cations port with a MicroLogix

8-pin mini-DIN style connector. The only difference is the protocol firmware

(DF1 or DH485) pre-loaded at the factory. Both versions of the protocol

firmware are supplied with the PanelBuilder32 software. You can change the

protocol by downloading the firmware to the terminal using the Windows

PanelView MotherBoard Firmware Download Utility (WinMBFWDL) utility.

This utility is included with the PanelBuilder32 software.

1

3

6

RS-232

8-pin mini-DIN

connector

Port is used for both

communications with a controller

and to transfer application files.

2

5

4

7

8

Pin # Signal

1 NC (No Connection)

2GND

3RTS

4 RXD

5 NC (No Connection)

6CTS

7TXD

8GND

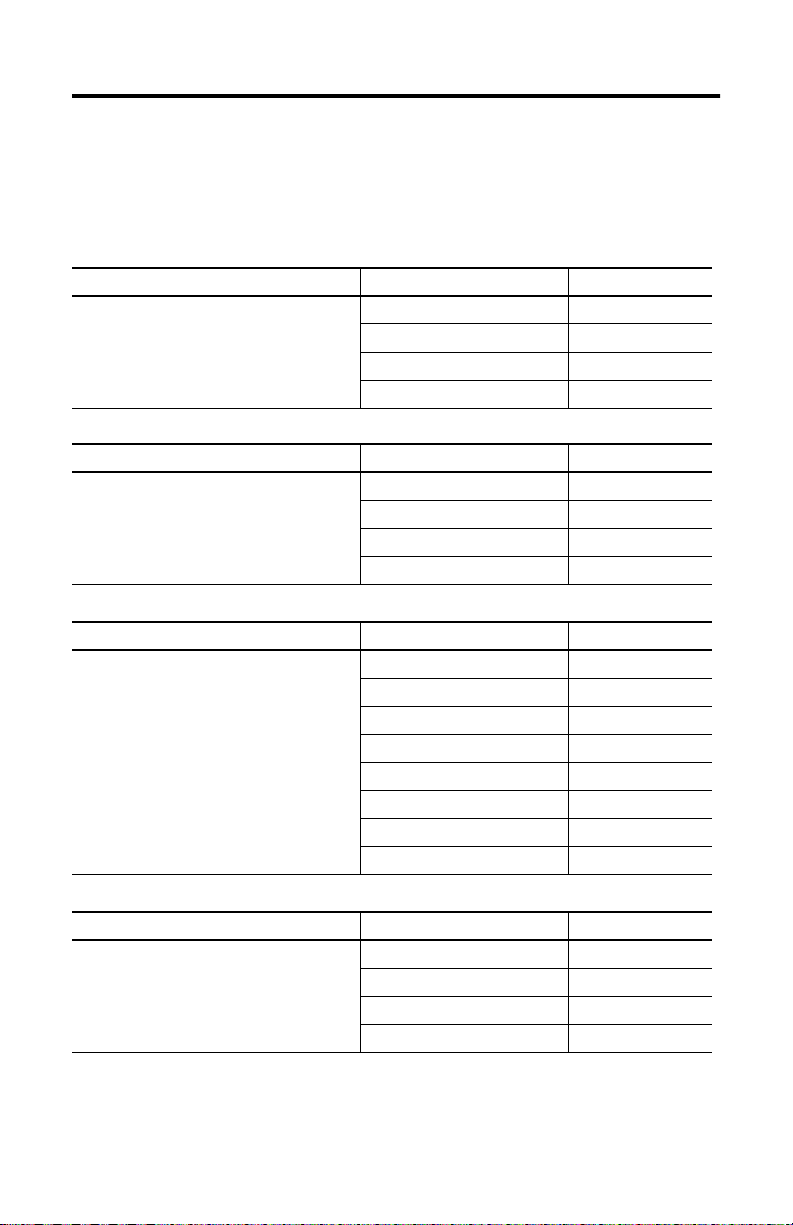

The following table lists the communication parameters supported b y each of th e

protocols on the RS-2 32 communica tions port.

Communication Link Communication Parameters

RS-232 or DH-485 Link Point-to-Point

Baud Rate:

Maximum Distance

DF1 - Full Duplex Communication

Baud Rate

Maximum Distance

1200, 2400, 9600, 19.2K Baud

6.1 meters (20 feet)

1200, 2400, 4800, 9600, 19.2K Baud

15.24 meters (50 feet)

41061-156-01(A)

Page 14

14 PanelView 300 Micro Terminal

Connecting to Controllers

This section lists the cables used by the PanelView 300 Micro to communicate

with Allen-Bradley controllers and to operate on a DH-485 or DeviceNet

network.

MicroLogix Controller Cable Cable Length

Point-to-Point Communications with a

MicroLogix 1000/1200/1500 controller

using either DF1 or DH485 protocol over an

RS-232 link.

SLC/PLC-5/ControlLogix Controller Cables Cable Length

Point-to-Point Communications with a SLC,

PLC-5 or ControlLogix processor or module

using either DF1 or DH485 protocol over an

RS-232 link.

Advanced Interface Converter (AIC+) Cables Cable Length

Point-to-point connection between the

PanelView 300 Micro and an AIC+ module

(Cat. No. 1761-NET-AIC). This connection

allows the DH-485 version of the 300

Micro to operate on a DH-485 network.

1761-CBL-AM00, Series C 0.5 meter (1.5 ft)

1761-CBL-HM02, Series C 2 meter (6.5 ft)

2711-CBL-HM05, Series C 5 meter (15 ft)

2711-CBL-HM10, Series C 10 meter (30 ft)

1761-CBL-AP00, Series C 0.5 meter (1.5 ft)

1761-CBL-PM02, Series C 2 meter (6.5 ft)

2711-CBL-PM05, Series C 5 meter (15 ft)

2711-CBL-PM10, Series C 10 meter (30 ft)

1761-CBL-AM00, Series C 0.5 meter (1.5 ft)

1761-CBL-APOO, Series C 0.5 meter (1.5 ft)

1761-CBL-PM02, Series C 2 meter (6.5 ft)

1761-CBL-HM02, Series C 2 meter (6.5 ft)

2711-CBL-PM05, Series C 5 meter (15 ft)

2711-CBL-HM05, Series C 5 meter (15 ft)

2711-CBL-PM10, Series C 10 meter (30 ft)

2711-CBL-HM10, Series C 10 meter (30 ft)

DeviceNet Interface (DNI) Cables Cable Length

Point-to-Point connection between a

PanelView 300 Micro and the DNI module

(Cat. No. 1761-NET-DNI). This connection

allows the DF1 version of the Micro 300 to

operate on a DeviceNet network.

41061-156-01(A)

1761-CBL-AM00, Series C 0.5 meter (1.5 ft)

1761-CBL-HM02, Series C 2 meter (6.5 ft)

2711-CBL-HM05, Series C 5 meter (15 ft)

2711-CBL-HM10, Series C 10 meter (30 ft)

Page 15

PanelView 300 Micro Terminal 15

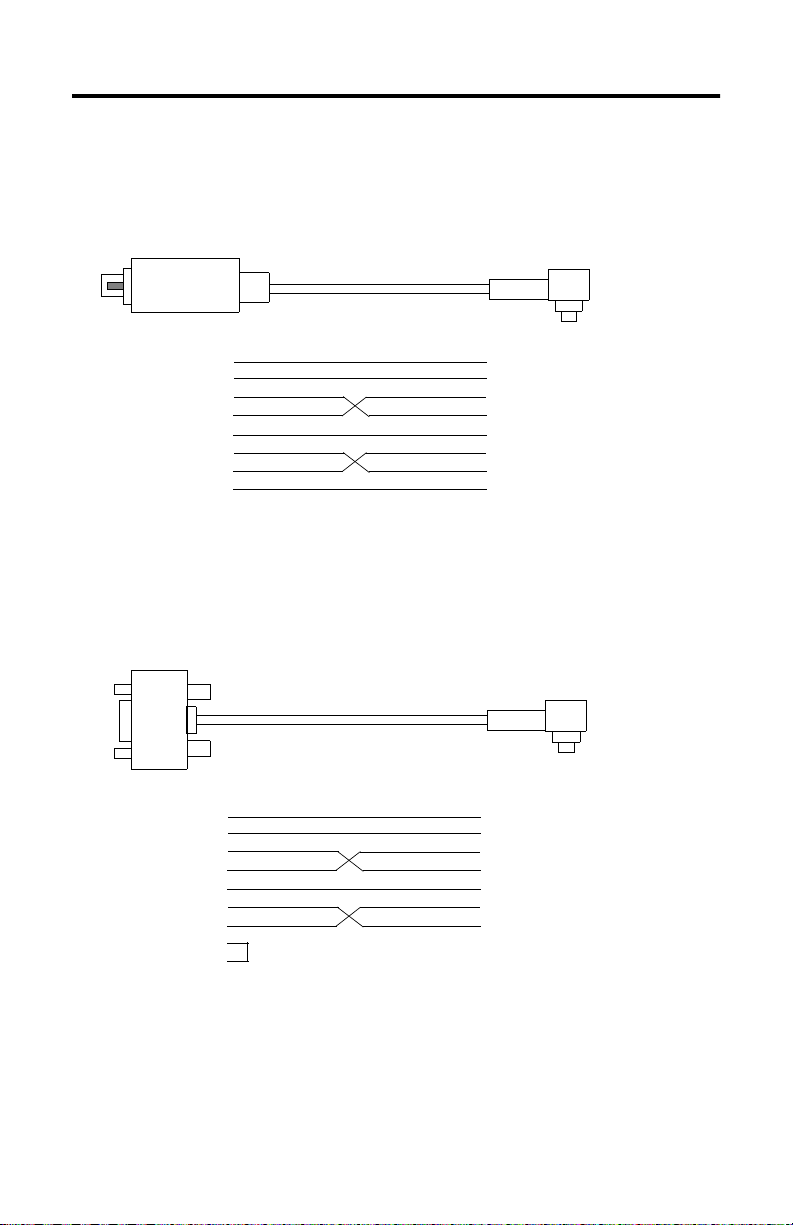

Bulletin 1761 or 2711-CBL-HMxx Cable Pinouts

These cables connect the PanelView 300 Micro terminal directly to a MicroLogix

controller, AIC+ or DNI module for runtime communications.

8-Pin mini-DIN

124V

2GND

3RTS

4CTS

5DCD

6 RXD

7TXD

8GND

8-Pin mini-DIN

24V 1

GND 2

RTS 3

CTS 6

DCD 5

RXD 4

TXD 7

GND 8

Bulletin 1761 or 2711-CBL-PMxx Cable Pinouts

These cables connect the PanelView 300 Micro terminal directly to a personal

computer for application file transfers or to an SLC, PLC-5 or ControlLogix

controller for runtime communications .

9-Pin D-Shell

9RI

5GND

7RTS

8CTS

1DCD

2 RXD

3TXD

4DTR

6DSR

8-pin mini-DIN

24V 1

GND 2

RTS 3

CTS 6

DCD 5

RXD 4

TXD 7

GND 8

41061-156-01(A)

Page 16

16 PanelView 300 Micro Terminal

Transferring Application Files

Applications for the PanelView 300 Micro terminal are developed using

PanelBuilder32 Software (Catalog Number 2711-ND3, V3.60 or later). You can

transfer application files between a computer and the terminal over an RS-232

communication link using one of the following cables.

Download Cable Cable Length

1761-CBL-PM02, Series C 2 meter (6.5 ft)

2711-CBL-PM05, Series C 5 meter (15 ft)

2711-CBL-PM10, Series C 10 meter (30 ft)

Three file transfer methods are available for the PanelView 300 Micro:

PanelBuilder32 Software

Supports the direct transfer of application files from PanelBuilder32 using an

RS-232 link.

Windows

Supports the direct transfer of PanelBuilder32 application files from WinPFT

over an RS-232 link. The WinPFT utility is included with the PanelBuilder32

Software. RSLinx software may be required to transfer applications to the

terminal for DH-485 and DF1 protocols.

This method is recommended for direct downloads to installed PanelView 300

Micro terminals using a portable or laptop computer.

Windows

Supports the direct transfer of PanelBuilder32 application files from the

PocketPFT software over an RS-232 link. The PocketPFT software and an

RS232 cable is available from Rockwell Software as part of the MaintenCE suite

of tools. You will also need one of the recommended download cables.

This method is recommended for direct downloads to installed PanelView 300

Micro terminals using an HPC JORNA DA portable CE computer, available only

from Rockwell Software.

PanelView File Transfer (WinPFT) Utility

CE Pocket PanelView File Transfer (PocketPFT) Utility

41061-156-01(A)

Page 17

PanelView 300 Micro Terminal 17

File Transfer Considerations

Because the communication port supports both runtime communications and

application transfers,you must make sure the port is set properly.

For successful communications, the PV300 Micro and the communicating d evice

must be set to the same communications settings and baud rate. The factory

default setting is 9600 baud.

Downloaded Baud Rate Changes - After a successful application download,

you may not be able to download another application. It is possible, the

downloaded application was conf igured with a different run-time communication

baud rate in the PanelBuilder32 software.

Run-Time Baud Rate Changes - After a successful application download, the

PanelView 300 Micro may not be communicating with the logic controller. It is

possible, the downloaded application was configured with a different

communication baud rate than the connected logic controller.

To adjust the baud rate, you can either:

• enter Configuration Mode on the terminal and select the Communication

Setup screen (looks similar to screen below). See page 18 to access

Configuration Mode.

Press F2 to change

baud rate setting.

DF1 - Full Duplex

F1 Comms

F2 Baud

F3 MORE

N/8/1

9600

F4 EXIT

Current baud

rate setting.

Press F4 to save

setting and exit.

• access the Communication Setup dialog from the Application Settings dialog

in PanelBuilder32 and then redownload the application to the PV300 Micro.

41061-156-01(A)

Page 18

18 PanelView 300 Micro Terminal

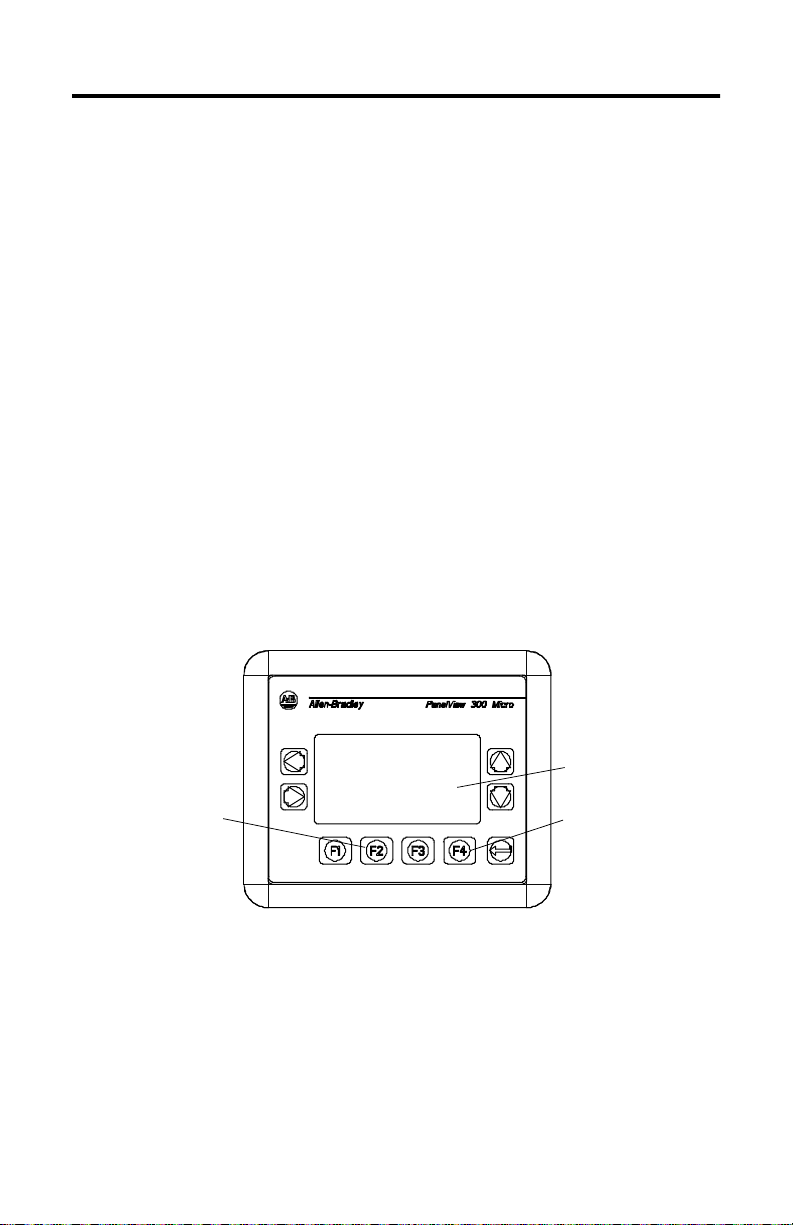

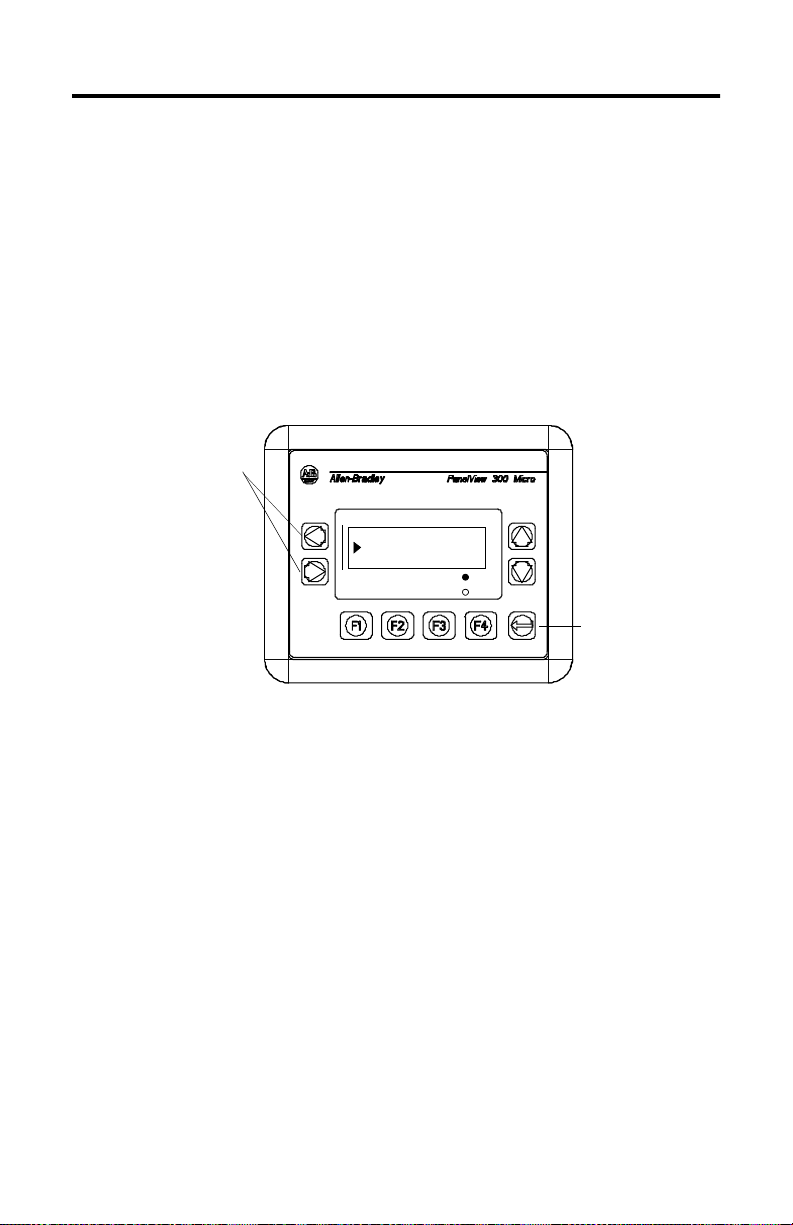

Accessing Configuration Mode

The PanelView 300 Micro terminal, like all standard PanelView terminals, has

configuration screens you can access to review or modify terminal settings.

1. Apply power to the PanelView 300 Micro as described in previous sections.

2. Simultaneously press both the Left and Right arrow keys on the front panel.

You will not be able to access Configuration mode if the arrow keys are

assigned to objects in the terminal application.

Press and release both the

Left and Right arrow keys

simultaneously to enter

Configuration Mode.

CONFIGURATION MODE

Language

Communication

Preset Operations

F1 RUN MODE

F2 RESET VIDEO

C

F

Enter Key

3. The Configuration Mode menu displays the various options. Using the up and

down arrow keys, navigate through the configuration screens to review

terminal information, communication settings, time/date settings, display

settings, and the current language setting.

Changes to settings take affect immediately (without powering off the terminal).

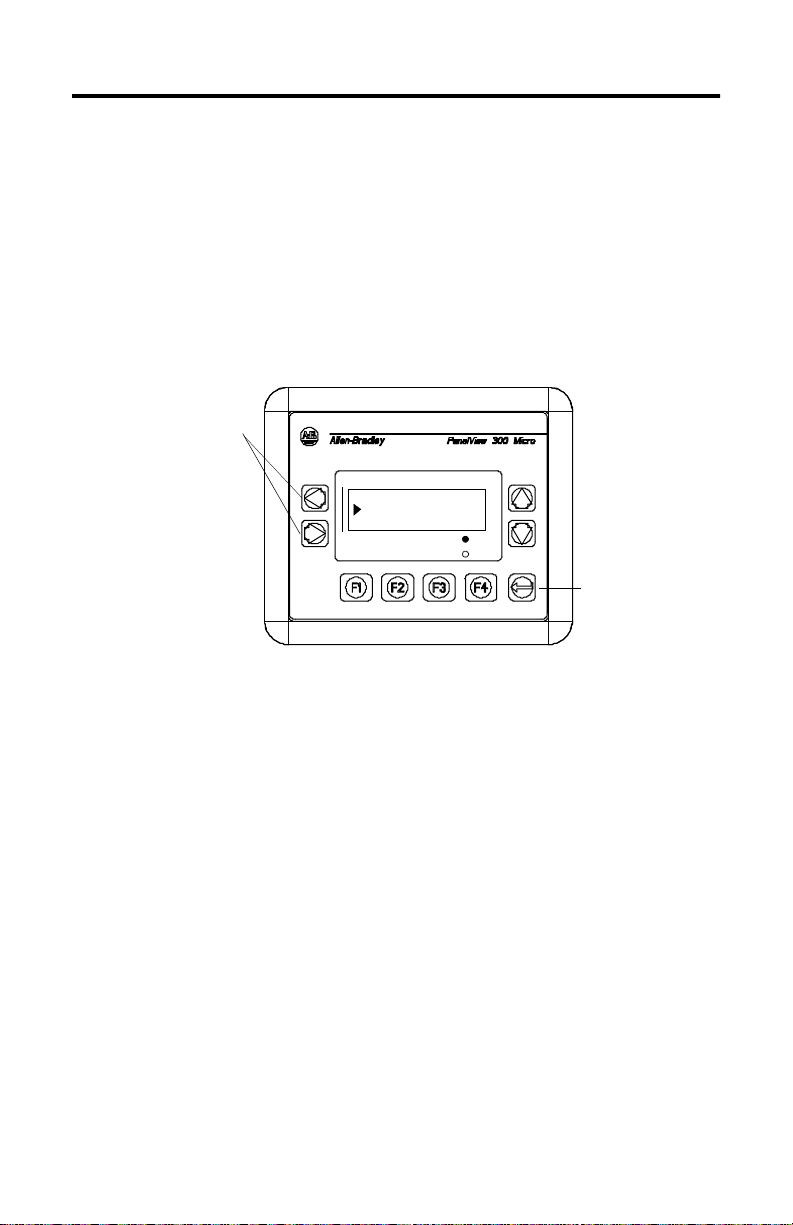

Resetting the Terminal

You can reset the PanelView 300 Micro from the fr ont panel without having to

remove and then re-apply power. A 3-key reset from the front panel is equivalent

to a power cycle.

To reset, the PanelView 300 Micro:

Press and release both the Left and Right arrow keys and the Enter key

simultaneously. The terminal resets.

41061-156-01(A)

Page 19

PanelView 300 Micro Terminal 19

Comm and Fault Indicators

The PanelView 300 Micro has a Comm (com mun ication) an d Fault (error) status

indicator. These indicators are visible from Configuration Mode when selecting

the Communication screen. Use the Comm and Fault indicators to isolate

operating problems.

CONFIGURATION MODE

Language

Communication

Preset Operations

F1 RUN MODE

F2 RESET VIDEO

C

F

DF1 - Full Duplex

Comm

PanelView Online

F3 MORE

Fault

F4 EXIT

Indicator State Indicates

Comm ON (steady state solid fill) Normal Operating (no communications fault)

OFF (no fill) Fault detected. Verify:

• controller is in run mode.

• communication settings for terminal and

controller.

• terminal and controller node addresses.

• terminal to controller connections.

Blinking (flashing) No communications established. For DF1 terminals,

the Comm indicator flashes until an application is

loaded.

Fault OFF (no fill pattern) Normal operating state

ON (steady state solid fill) Fault detected. Reset or cycle power to the terminal.

If the fault remains the terminal requires servicing.

Blinking (flashing) Hardware is functioning but no application is loaded

in the terminal or the current application is

corrupted. Reload the application file into the

terminal.

41061-156-01(A)

Page 20

20 PanelView 300 Micro Terminal

Troubleshooting and Maintenance

The troubleshooting chart below lists common operating problems, causes and

corrective steps.

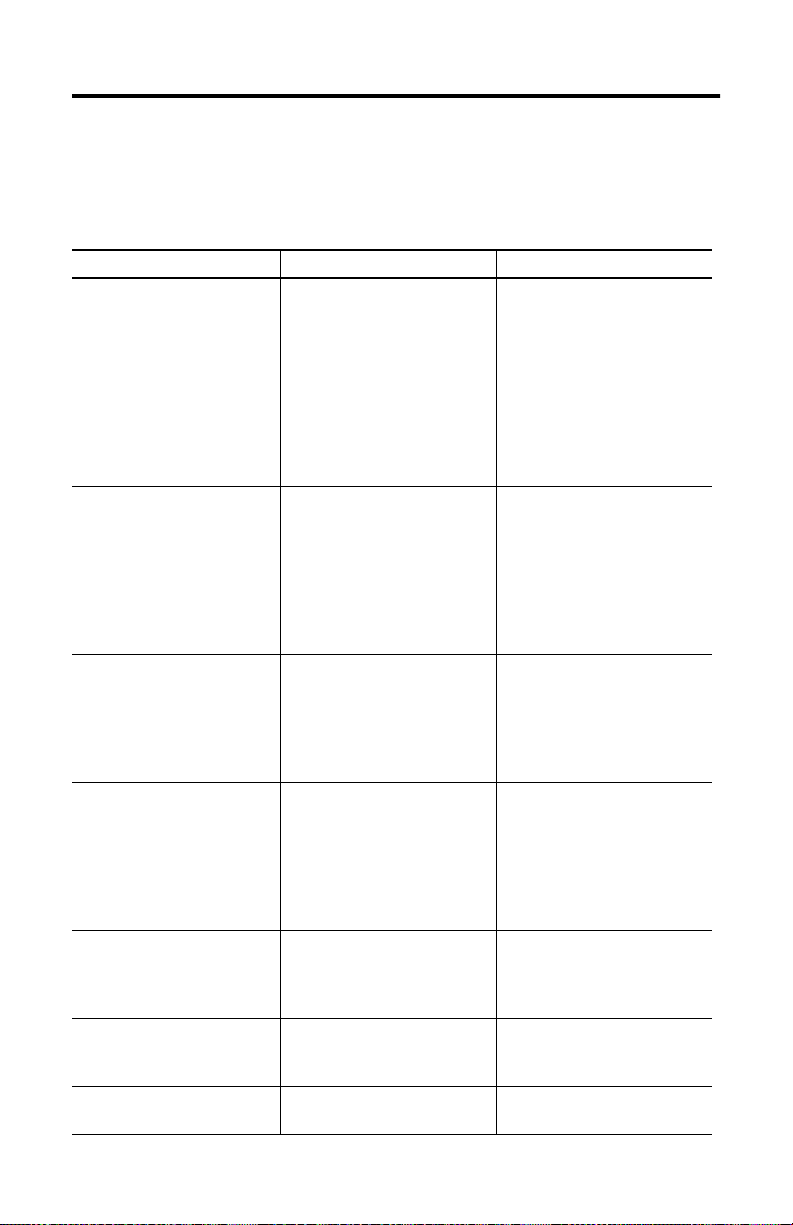

Problem Causes Corrective Action

Terminal does not powerup 1. Improper connection to

Application File will not

download (first download)

Application File will not

download (subsequent

downloads)

No communication with

MicroLogix, ControlLogix, SLC

or PLC controller.

No communication with

controller but Comm indicator

is active.

Clock Module Battery Low

message displayed.

Screen objects do not

function.

power source.

2. Incorrect input voltage level.

3. Power terminal block

removed.

4. DC power wires reversed.

1. Communication cable

disconnected.

2. Incorrect baud rate or

communication settings.

3. Incorrect computer COM

port selection.

1. Incorrect communication or

baud rate settings.

1. Communications Comm

fault.

2. Incorrect baud rates.

3. Controller not in run mode.

4. Incorrect terminal node and

max node addresses.

1. Incorrect node address of

controller.

2. Inhibit bit set as default on

PLC channel status screen.

1. Internal parameters corrupt.

2. Clock module battery failure.

1. Communication problem. 1. Check status of Comm

1. Verify correct voltage at

power terminals.

2. Verify power source output

is between 11 - 30V dc.

3. Snap power terminal block

onto base on back of

terminal.

4. Connect DC power positive

and negative wires to

correct terminals.

1. Check communication cable

type and connections.

2. Verify computer and

terminal are set to same

communication settings.

3. Verify correct COM port

number in WinPFT or

PanelBuilder32 software.

1. Verify computer and

terminal have same

communication settings.

Change settings in

Communication setup

screen of terminal.

1. Check Comm indicator. See

page 19.

2. Verify controller and

terminal set to same baud.

3. Place controller in run mode.

4. Verify node addresses.

1. Verify node address of

controller.

2. Change inhibit bit setting.

1. Reload application and cycle

power to terminal.

2. Replace terminal.

indicator.

41061-156-01(A)

Page 21

PanelView 300 Micro Terminal 21

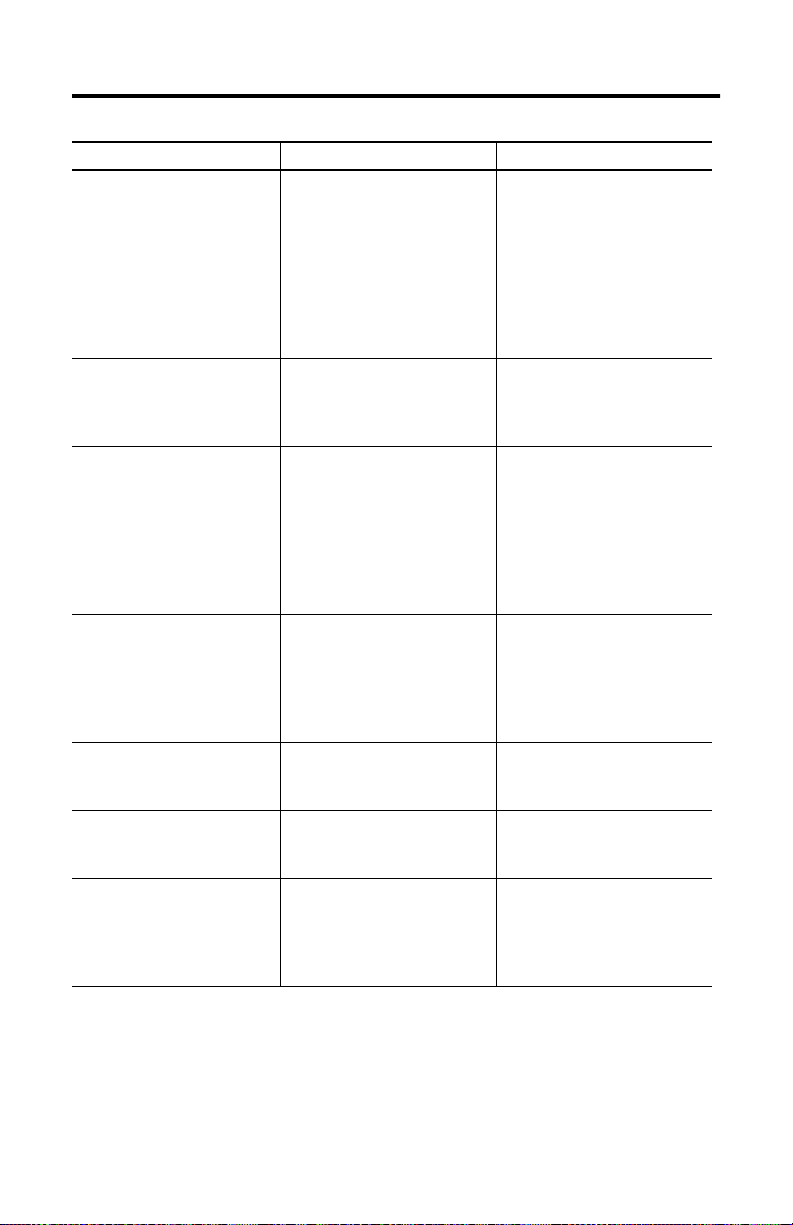

Problem Causes Corrective Action

No communications with

computer.

Application filename appears

as ****** on Terminal Info

screen.

Screen objects not visible. 1. Correct power not applied.

Values do not update on

display but appear as asterisks

****

LCD display is difficult to view. 1. Display contrast level set

Can’t Configuration Mode

when pressing Left and Right

arrow keys simultaneously.

No network found. 1. Node setting of controller

1. Communications Comm

fault.

2. Incorrect baud rate or

communication settings.

3. Incorrect terminal node or

max node address.

4. Computer fault.

5. Communications driver not

properly loaded.

1. Application file invalid.

2. Application unusable

because of error.

2. Contrast not set correctly.

3. Terminal in screen saver

mode.

1. Terminal not communicating

with logic controller.

2. Value is invalid or exceeds

the field width for object.

incorrectly.

1. Left and right arrow keys are

assigned to screen objects

in the terminal application.

does not match application.

2. Controller data file does not

have enough elements.

1. Check Comm indicator. See

page 19.

2. Verify computer and

terminal are at same baud.

3. Verify node addresses.

4. Refer to computer manual.

5. Refer to RSLinx online help

or manual.

1. Download application to

terminal.

2. Download new application.

1. Verify power connections.

2. Access Screen Setup from

Configuration Mode and

adjust display contrast.

3. Access Screen Setup from

Configuration Mode to

check if terminal is in Screen

Saver Mode.

1. Check status of Comm

indicator. See problem “No

communication with

controller” for details.

2. Change the field width set

for the object.

1. Access Configuration mode

and adjust the display

contrast level.

1. Contact Technical Support

for assistance.

1. Change node address in

application to match

controller node address.

2. Verify data file elements for

all tag addresses.

41061-156-01(A)

Page 22

22 PanelView 300 Micro Terminal

Maintenance

The PanelView 300 Micro has no internal components that are user accessible.

The rear cover is not removable, therefore, you should not remove it for

troubleshooting or maintenance. The real-time clock battery an d the LCD display

backlight are not replaceable.

To clean the display window of the PanelView 300 Micro:

1. Disconnect power from the terminal at the power source.

2. Use a clean sponge or soft cloth to clean with a mild soap or detergen t to clean

the display. Do not scrub, use brushes, abrasive cleaners or solvents.

3. Dry the display with a chamois or moist cellulose sponge to avoid water spots.

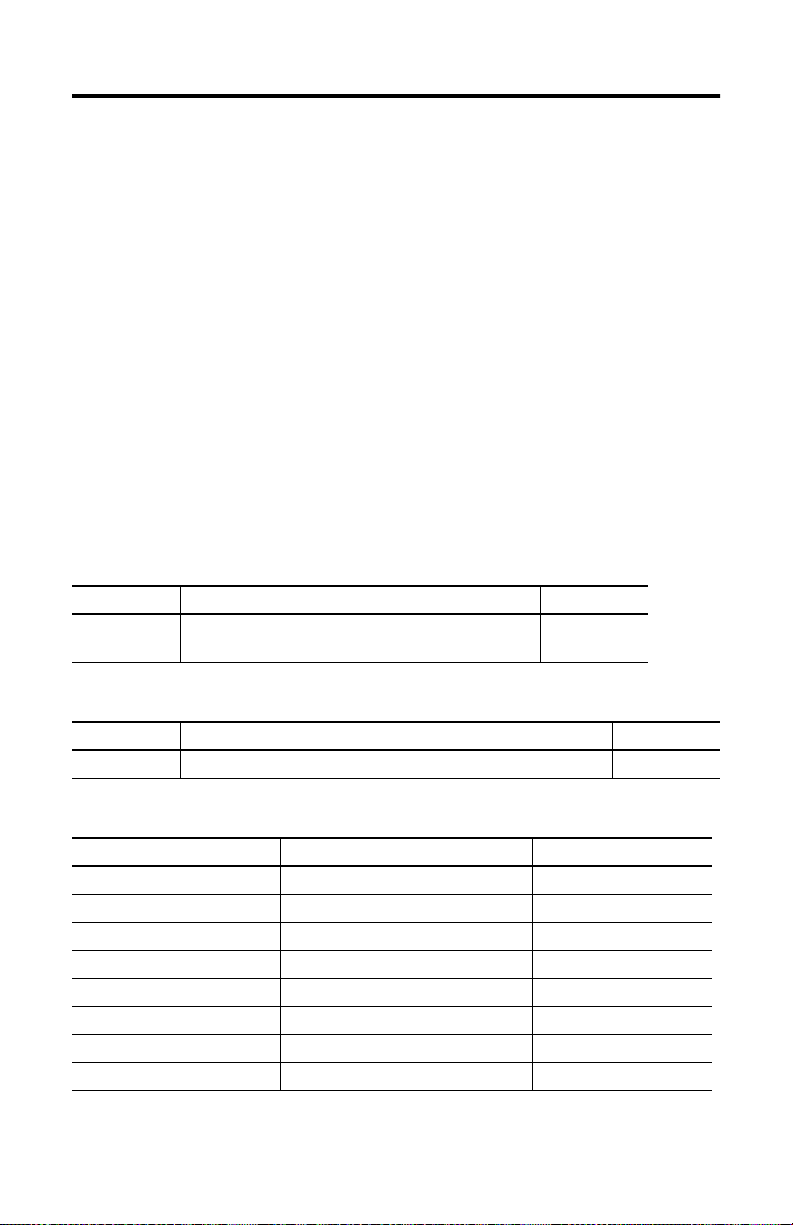

Accessories

The following accessories are available for the PanelView 300 Micro.

PanelBuilder32 Software

Catalog No. Description Version

2711-ND3 PanelBuilder32 Software for developing applications

for the line of Standard PanelView terminals.

3.60 or later

DC Power Input Terminal Block

Catalog No. Description Quantity

2711-TBDC Removable (3-position screw) DC Power Input Terminal Block 10

Communication Cables

Cable Connector Type Cable Length

1761-CBL-AM00, Series C 8-pin mini-DIN to 8-pin mini-DIN 0.5 meter (1.5 ft)

1761-CBL-AP00, Series C 8-pin mini-DIN to 9-pin D-Shell 0.5 meter (1.5 ft)

1761-CBL-PM02, Series C 8-pin mini-DIN to 9-pin D-Shell 2 meter (6.5 ft)

1761-CBL-HM02, Series C 8-pin mini-DIN to 8-pin mini-DIN 2 meter (6.5 ft)

2711-CBL-PM05, Series C 8-pin mini-DIN to 9-pin D-Shell 5 meter (15 ft)

2711-CBL-HM05, Series C 8-pin mini-DIN to 8-pin mini-DIN 5 meter (15 ft)

2711-CBL-PM10, Series C 8-pin mini-DIN to 9-pin D-Shell 10 meter (30 ft)

2711-CBL-HM10, Series C 8-pin mini-DIN to 8-pin mini-DIN 10 meter (30 ft)

41061-156-01(A)

Page 23

PanelView 300 Micro Terminal 23

Specifications

Electrical

Supply Voltage Limits 11 to 30V dc (24V dc nominal)

Power Consumption 2.5W maximum (0.105A @24V dc)

Mechanical

Enclosure NEMA Type 12/13, 4X (indoor use only), IP54, IP65

Weight 284 grams (10 oz.)

Dimensions 133 (H) x 111 (W) x 48 (D) mm

Installed Depth 35 mm (1.39 inches)

Display

Type Liquid Crystal Display (LCD) with LED backlighting

Size 73 mm (w) x 42 mm (h)

Pixels 128 x 64

Environment

Operating Temperature

Storage Temperature

Humidity (non-condensing)

Heat Dissipation 2.5W (8.5 BTU/Hour)

Impulse Shock 30G operating, 50G non-operating

Vibration 2G up to 2,000 Hz operating

Agency Certifications

When product is marked: UL

(1) CSA certification - Class I, Division 2, Group A,B,C,D or nonhazardous locations

5.23 (H) x 4.38 (W) x 1.87 (D) inches

2.87 in. (w) x 1.67 in. (h)

° to 55° C (32° to 131° F)

0

-20° to 85° C (-4° to 188° F)

5 to 95% at 0

CE marked for all applicable directives

c-UL Class I Div 2 Hazardous

° to 55° C (32° to 131° F)

(1)

41061-156-01(A)

Page 24

24 PanelView 300 Micro Terminal

41061-156-01(A)

Page 25

Notice d’installation

Français

Terminal PanelView 300 Micro

(Références 2711-M3A18L1, 2711-M3A19L1)

Sommaire :

Pour plus d’informations....................................................................... 26

Conformité aux directives de l’Union européenne............................... 26

Emplacements dangereux..................................................................... 27

Câblage et consignes de sécurité......................................................... 28

Dimensions de montage....................................................................... 28

Branchement de l’alimentation c.c....................................................... 32

Utilisation du port de communication .................................................. 35

Accès au mode de configuration.......................................................... 40

Réinitialisation du terminal .................................................................. 40

Indicateurs de communication et de défauts....................................... 41

Dépannage et maintenance.................................................................. 42

Maintenance......................................................................................... 45

Caractéristiques.................................................................................... 46

41061-156-01(A)

Page 26

26 Terminal PanelView 300 Micro

Pour plus d’informations

Pour Se reporter au

Une description plus détaillée sur le 300 Micro

et autres terminaux PanelView standard.

Pour obtenir l’une de ces publications, vous pouvez :

• charger une version électronique gratuite à partir du CD d’installation

PanelBuilder32

• charger une version électronique gratuite à partir d’internet à l’adresse suivante :

www.ab.com/manuals/eoi or www.theautomationbookstore.com

Pour acheter une publication :

• visitez le site www.theautomationbookstore.com et passez votre commande

• contactez votre distributeur local ou votre représentant de Rockwell

Automation

document

Manuel d’utilisation des

terminaux PanelView

N° de publication

2711-UM014A-FR-P

Conformité aux directives de l’Union européenne

Si ce produit porte le marquage CE, son installation dans les pays de l’Union

européenne et de l’Espace Economique Européen a été approuvée. Il a été conçu

et testé en conformité avec les directives suivantes.

Directive CEM

Cet appareil a été testé en termes de compatibilité électromagnétique (CEM)

selon la directive 89/336/EEC à l'aide d'un cahier des charges et d'après les

normes suivantes, en totalité ou partie :

• EN 50081-2 Compatibilité électromagnétique – Norme générique émission –

Partie 2 : Environnement industriel

• EN 50082-2 Compatibilité électromagnétique – Norme générique immunité –

Partie 2 : Environnement industriel.

Ce produit décrit dans le présent document est conçu pour une utilisation en

environnement industriel.

41061-156-01(A)

Page 27

Terminal PanelView 300 Micro 27

!

DANGER

Emplacements dangereux

Cet équipement ne convient qu’à une utilisation dans un environnement de

Classe 1, Di vision 2, Groupes A, B, C, D ou non dangere ux. L’avertissement

ATTENTION suivant concerne l’utilisation en environnements dangereux.

Risque d’explosion

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe I,

Division 2.

• Ne pas débrancher l’équipement tant que l’alimentation

électrique n’a pas été coupée et que la zone n’est pas sans

danger.

• Ne pas brancher ou débrancher de composants tant que

l’alimentation électrique n’a pas été coupée.

• Les câblages doiven t tous être conformes à la norme N.E.C.

article 501-4(b).

• Les équipements périphériques doivent être appropriés à

l’endroit dans lequel ils seront utilisés.

Utiliser exclusivement les câbles de communication suivants dans les

environnements dangereux de Classe 1, Division 2.

Classification relative aux

environnements

Emplacements dangereux de Classe 1,

Division 2

Câbles de communication

1761-CBL-PM01, série C

1761-CBL-HM02, série C

1761-CBL-AM00, série C

1761-CBL-AP00, série C

2711-CBL-PM05, série C

2711-CBL-HM05, série C

2711-CBL-PM10, série C

2711-CBL-HM10, série C

41061-156-01(A)

Page 28

28 Terminal PanelView 300 Micro

Câblage et consignes de sécurité

Installer le terminal PanelView 300 Micro en suivant les instructions figurant

dans la publication américaine 70E, Electrical Safety Requirements for

Employee Workplaces. Outre les consignes de sécurité générales NFPA

(Association nationale de protection contre l’incendie), il convient de suivre les

recommandations suivantes :

• Acheminer l’alimentation d’arrivée du PanelView 3 00 Micro par le biais d’un

chemin séparé du câble de communication.

• Lorsque les lignes de courant et de communication doivent se croiser, elles

doivent se croiser à angle droit. Les lignes de communication peuvent être

installées dans le même conduit que les lignes d’E/S c.c. de bas niveau (de

moins de 10 volts).

• La mise à la terre perme t de réduire les interférences électromagnétiques

(EMI) et constitue une mesure de sécurité sur les installations électriques. Pour

éviter les interférences électromagnétiques, il convient de blinder les câbles et

de les relier à la terre de manière appropriée.

Pour plus d’informatio ns relat ives aux recom m a ndatio ns en matière de mise à la

terre, se reporter au National Electrical Code publié par la National Fire

Protection Association of Boston.

Montage du terminal

Armoires

Monter le terminal PanelView 300 Micro dans un panneau ou une armoire pour

protéger les circuits internes. Le terminal est conforme aux normes NEMA 12/13

et 4X (s’appliquant à une utilisation sous-abri), à condition qu’il soit monté

correctement dans un panneau ou une armoire conformément aux normes

appropriées. Veiller à laisser un espace suffisant à l’intérieur de l’armoire pour

permettre une ventilation adéquate. Prendre en compte la chaleur produite par les

autres dispositifs installés dans l’armoire. La température ambiante autour du

PanelView 300 Micro doit être comprise entre 0

Prévoir les accès au panneau latéral du terminal pour le câblage, la maintenance

et le dépannage.

° et 55 °C (32 ° et 131 °F).

Dimensions de montage

133 mm

(5,23 in.)

41061-156-01(A)

111 mm

(4,38 in.)

35 mm

(1,39 in.)

48 mm

(1,87 in.)

Page 29

Terminal PanelView 300 Micro 29

Dimensions de la découpe

Utiliser le gabarit grandeur nature fourni avec le PV300 Micro pour déterminer

les dimensions de la découpe. La figure ci-dessous montre la découpe à échelle

réduite. Un gabarit grandeur nature est également disponible dans

l’avant-derrière de couverture de ce document.

112 mm (4,42 in.)

102 mm (4,0 in.)

4,5 mm (0,178 in.)

Diamètre

92 mm

(3,62 in.)

54 mm

(2,12 in.)

Espacements

Laisser 51 mm (2,0 in.) d’espace sur tous les côtés du terminal afin d’assurer une

ventilation adéquate et un accès pour la maintenance.

51 mm (2,0 in.)

51 mm (2,0 in.)

41061-156-01(A)

Page 30

30 Terminal PanelView 300 Micro

!

ATTENTION

Installation du terminal dans un panneau

Outre les outils requis pour découper le panneau, les outils suivants sont

nécessaires pour l’installation :

• une clé à tube de grande profondeur de 7 mm (M4) ou une clé à pipe

• un petit tournevis pour écrous à fente

• une clé dynamométrique

Pour installer le terminal PV300 Micro dans un panneau :

• Déconnecter toute alimentation électrique du panneau av ant

de réaliser la découpe.

• Vérifier que l’espace environnant la découpe du panneau

est dégagé.

• Prendre des précautions afin d’éviter que des copeaux

métalliques ne pénètrent dans les composants, quels qu’ils

soient, déjà installés dans le panneau.

• Si ces recommandations ne sont p as respectées , il y a risque

de blessures ou dommages.

1. Couper une ouverture dans le panneau à l’aide du gabarit fourni avec le

terminal. Eliminer les arêtes vives.

2. Veiller à ce que le joint d’étanchéité soit correctement positionné sur le

terminal (comme indiqué ci-dessous). Ce joint forme une étanchéité de type

compression. Ne pas utiliser de produit d’étanchéité.

Joint d'étanchéité

3. Placer le terminal dans la découpe du panneau.

41061-156-01(A)

Page 31

Terminal PanelView 300 Micro 31

!

ATTENTION

4. Installer les 4 écrous autobloquants en les serrant à la main.

Ecrous

autobloquants

(4 utilisés, 6 fournis)

5. Serrer les écrous autobloquants en alternance jusqu’à ce que le terminal soit

fermement maintenu contre le panneau. Serrer les écrous à un couple de

10 lb-in (1,2 Nm). Ne pas trop serrer.

Les écrous de montage doivent être serrés à un couple de

10 lb-in (1,2 Nm) afin d’assurer un joint approprié et

d’éviter des dommages potentiels au terminal.

Allen-Bradley ne saurait être tenu pour responsable des

dommages qui auraient été engendrés par de l’eau ou des

produits chimiques sur le terminal ou autre équipement,

inclus dans l’armoire, du fait d’une mauvaise installation.

41061-156-01(A)

Page 32

32 Terminal PanelView 300 Micro

!

ATTENTION

Branchement de l’alimentation c.c.

Le terminal PV300 Micro est raccordé à une source d’alimentation de 24 V c.c.

Le tableau ci-dessous indique les valeurs électriques nominales pour les

terminaux version c.c. Les circuit s électroniques et les fusibles internes prot ègent

le terminal contre l’inversion de polarité et les surtensions .

Type de terminal Tension d’alimentation Consommation d’énergie

PV300 Micro de 11 à 30 V c.c.

(24 V c.c. nominal)

Le terminal PV300 Micro a été conçu pour une utilisation en toute sécurité

lorsqu’il est installé dans un panneau conforme aux normes NEMA Type 12, 13,

4X (uniquement utilisation sous abri), IP54 ou IP65.

• Ne pas raccorder le terminal PanelView à une source de

courant c.a. Le fait de le raccorder à une source de courant

c.a. risque d’endommager le terminal.

• Pour l’alimentation du PanelView 300 Micro, utiliser

uniquement une source de courant à tension extrêmement

faible de type haute sécurité (SELV) avec une sortie

comprise entre 11 et 30 V c.c. Une alimentation de type

haute sécurité (SELV) ne dépasse pas 42,4 V c.c.

2,5 Watts maximum

(0,105 A @ 24 V c.c.)

Le bornier d’alimentation d’entrée est amovible sur le PanelView 300 Micro et

permet l’utilisat ion des types de câblage suivants.

Type de câble Section des câbles

Plein calibre de 16 à 22

Tor sa dé calibre de 18 à 22

41061-156-01(A)

(2 câbles maximum par borne)

Page 33

Terminal PanelView 300 Micro 33

!

DANGER

Pour raccorder le terminal PanelView 300 Micro à une source de courant

c.c. :

1. Fixer les câbles d’alimentation c.c. au bornier à vis.

2. Fixer le câble de mise à la terre au bornier à vis.

Risque d’explosion

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Ne pas débrancher l’équipement tant que l’alimentation

électrique n’a pas été coupée et que la zone n’est pas sans

danger.

• Ne pas brancher ou débrancher de composants tant que

l’alimentation électrique n’a pas été coupée.

• Les câblages doiven t tous être conformes à la norme N.E.C.

article 501-4(b).

3. Appliquer la source d’alimentation (24 V c.c. nominal) au terminal.

+ c.c. positif

- c.c. négatif

Mise à la terre

Retrait et installation du bornier d’alimentation

Le bornier d’alimentation peut être retiré et réinstallé afin de faciliter

l’installation, le câblage et la maintenance. Le bornier externe est préinstallé à la

livraison. Les terminaux supplémentaires (au nombre de 10) sont disponibles sur

commande, référence 2711-TBDC.

Pour retirer le bornier d’alimentation c.c. :

1. Déconnecter toute alimentation électrique du panneau. Se reporter à

l’avertissement relatif au Risque d’explosion.

2. Insérer le bout d’un tournevis fin à lame plate dans l a fent e d’accès d u bornier

d’alimentation c.c.

41061-156-01(A)

Page 34

34 Terminal PanelView 300 Micro

Insérer le bout du tournevis à

cet endroit.

3. Ecarter doucement la lame du tournevis du bornier en poussant afin de libérer

le mécanisme de verrouillage.

4. Retirer le bornier d’alimentation c.c.

Pour réinstaller le bornier d'alimentation c.c.

Remarque : Le bornier peut être installé, que les câbles d’alimentation soient

connectés ou non.

1. Déconnecter toute alimentation électrique du panneau avant de procéder à

l’installation. Se reporter à l’avertissement relatif au Risque d’explosion, page

précédente.

2. Incliner le bornier à 45

° et placer le côté connecteurs dans la base.

3. Pousser doucement le haut du bornier à nouveau en position verticale pour

qu’il s’enclenche dans l’ergot de blocage.

Enfoncer d’abord la

base du bornier,

câbles orientés

vers l'extérieur

Pousser le haut du

bornier en arrière en

position verticale afin de

le verrouiller.

41061-156-01(A)

Page 35

Terminal PanelView 300 Micro 35

Utilisation du port de communication

Deux versions de terminal PanelView 300 Micro sont disponibles.

Référence Port de communication Protocole de

communication

2711-M3A18L1 RS-232 DF1

2711-M3A19L1 RS-232 DH485

Les deux versions sont pourvues d’un port identique de communication RS-232

avec un connecteur à 8 broches de type mini-DIN. La seule différence réside

dans le firmware du protocole (DF1 ou DH485) qui est préchargé en usine. Les

deux versions de firmware sont fournies avec le logiciel PanelBuilder32. Le

protocole peut être changé en chargeant le firmware sur le terminal à l’aide de

l’utilitaire Windows WinMBFWDL (Windows PanelView MotherBoard

Firmware Download Utility). Cet utilitaire est inclus dans le logiciel

PanelBuilder32.

1

3

6

RS-232

avec connecteur 8 broches

de type mini-DIN

Ce port est utilisé pour les deux

types de communication avec un

automate et pour transférer des

fichiers d'application.

2

5

4

7

8

Broche n° Signal

1 NC (Pas de connexion)

2GND

3RTS

4 RXD

5 NC (Pas de connexion)

6CTS

7TXD

8GND

Le tableau suivant énumère les paramètres de communication reconnus par

chacun des protocoles sur le port de communication RS-232.

Interface de communication Paramètres de communication

Interface point à point RS-232 ou DH-485

Vitesse en bauds

Distance maximale

DF1 – Communication full duplex

Vitesse en bauds

Distance maximale

1200, 2400, 9600, 19,2 Kbauds

6,1 mètres (20 pieds)

1200, 2400, 4800, 9600, 19,2 Kbauds

15,24 mètres (50 pieds)

41061-156-01(A)

Page 36

36 Terminal PanelView 300 Micro

Connexion à des automates

Cette section énumère les câbles utilisés pour la communication entre le terminal

PanelView 300 Micro et les automates Allen-Bradley, ainsi que pour le

fonctionnement sur un réseau DH-485 ou DeviceNet.

Automate MicroLogix Câble Longueur de câble

Communications point à point avec un

automate MicroLogix 1000/1200/1500 à

l’aide du protocole DF1 ou DH485 par le

biais d’une interface RS-232.

Automate SLC/PLC-5/ControlLogix Câbles Longueur de câble

Communications point à point avec un

module ou un automate SLC, PLC-5 ou

ControlLogix à l’aide du protocole DF1 ou

DH485 par le biais d’une interface RS-232.

1761-CBL-AM00, série C 0,5 mètre (1,5 pied)

1761-CBL-HM02, série C 2 mètres (6,5 pieds)

2711-CBL-HM05, série C 5 mètres (15 pieds)

2711-CBL-HM10, série C 10 mètres (30 pieds)

1761-CBL-AP00, série C 0,5 mètre (1,5 pied)

1761-CBL-PM02, série C 2 mètres (6,5 pieds)

2711-CBL-PM05, série C 5 mètres (15 pieds)

2711-CBL-PM10, série C 10 mètres (30 pieds)

Convertisseur d’interface avancé

(AIC+)

Connexion point à point entre le PanelView

300 Micro et un module AIC+

(réf. 1761-NET-AIC). Cette version permet à

la version DH-485 du terminal 300 Micro

de fonctionner dans un réseau DH-485.

Interface DeviceNet (DNI) Câbles Longueur de câble

Connexion point à point entre un

PanelView 300 Micro et le module DNI

(réf. 1761-NET-DNI). Cette connexion

permet à la version DF1 du terminal

Micro 300 de fonctionner dans un réseau

DeviceNet.

41061-156-01(A)

Câbles Longueur de câble

1761-CBL-AM00, série C 0,5 mètre (1,5 pied)

1761-CBL-APOO, série C 0,5 mètre (1,5 pied)

1761-CBL-PM02, série C 2 mètres (6,5 pieds)

1761-CBL-HM02, série C 2 mètres (6,5 pieds)

2711-CBL-PM05, série C 5 mètres (15 pieds)

2711-CBL-HM05, série C 5 mètres (15 pieds)

2711-CBL-PM10, série C 10 mètres (30 pieds)

2711-CBL-HM10, série C 10 mètres (30 pieds)

1761-CBL-AM00, série C 0,5 mètre (1,5 pied)

1761-CBL-HM02, série C 2 mètres (6,5 pieds)

2711-CBL-HM05, série C 5 mètres (15 pieds)

2711-CBL-HM10, série C 10 mètres (30 pieds)

Page 37

Terminal PanelView 300 Micro 37

Brochages des câbles 1761 ou 2711-CBL-HMxx

Ces câbles permettent de raccorder directement le terminal PanelView 300 Micro

à un automate MicroLogix, à un module AIC+ ou DNI pour des communications

en temps réel.

8 broches mini-DIN

124V

2GND

3RTS

4CTS

5DCD

6 RXD

7TXD

8GND

8 broches mini-DIN

24V 1

GND 2

RTS 3

CTS 6

DCD 5

RXD 4

TXD 7

GND 8

Brochages des câbles 1761 ou 2711-CBL-PMxx

Ces câbles permettent de raccorder directement le terminal PanelView 300 Micro

à un ordinateur individuel pour transférer des fichiers, ou à un automate SLC,

PLC-5 ou ControlLogix pour des communications en temps réel.

9 broches D-Shell

9RI

5GND

7RTS

8CTS

1DCD

2 RXD

3TXD

4DTR

6DSR

8 broches mini-DIN

24V 1

GND 2

RTS 3

CTS 6

DCD 5

RXD 4

TXD 7

GND 8

41061-156-01(A)

Page 38

38 Terminal PanelView 300 Micro

Transfert de fichiers d’application

Les applications destinées au terminal PanelView 300 Micro ont été développées

à l’aide du logiciel PanelBuilder32 (référence 2711-ND3, V3.60 ou ultérieure).

Les fichiers d’application peuvent être transférés entre un ordinateur et le

terminal par le biais d’une interface de communication RS-232 au moyen d’un

des câbles suivants.

Câble de chargement Longueur de câble

1761-CBL-PM02, série C 2 mètres (6,5 pieds)

2711-CBL-PM05, série C 5 mètres (15 pieds)

2711-CBL-PM10, série C 10 mètres (30 pieds)

Trois méthodes de transfert de fichiers sont disponibles pour le PanelView

300 Micro :

Logiciel PanelBuilder32

Pour le transfert direct de fichiers d’application à partir de PanelBuilder32 à

l’aide d’une interface RS-232.

Utilitaire de transfert de fichiers PanelView Windows

Pour le transfert direct de fichiers d’application PanelBuilder32 à partir de

WinPFT par le biais d’une interface RS-232. L’utilitaire WinPFT est inclus dans

le logiciel PanelBuilder32. Le logiciel RSLinx peut être requis pour les

applications de transfert vers le terminal pour les protocoles DH-485 et DF1.

Cette méthode est recommandée pour les chargements directs lors de

l’installation des terminaux PanelView 300 Micro à l’aide d’un ordinateur

portable.

Utilitaire de transfert de fichiers Pocket PanelView Windows

(PocketPFT)

Pour le transfert direct de fichiers d’application PanelBuilder32 à partir du

logiciel PocketPFT par le biais d’une interface RS-232. Le logiciel PocketPFT et

un câble RS232 sont fournis par Rockwell Software dans le kit d’outils de

maintenance. Un des câbles de chargement recommandés sera également requis.

Cette méthode est recommandée pour le chargement direct dans des terminaux

PanelView 300 Micro installés à l’aide d’un ordinateur CE portable HP C

JORNADA, uniquement fourni par Rockwell Software.

41061-156-01(A)

(WinPFT)

CE

Page 39

Terminal PanelView 300 Micro 39

Informations relatives au transfert de fichiers

Etant donné que le port de communication reconn aît à la fois les communications

en temps réel et les transferts d’application, il faut veiller à ce que le port soit

correctement configuré.

Pour qu’une communication aboutisse, les paramètres de configuration de

communication et de vitesse de transmission doivent être identiques pour le

terminal PV300 Micro et le dispositif de communication. La valeur par défaut est

9600 bauds.

Modification de la vitesse de transmission chargée – Une fois qu’un

chargement d’application a abouti, il se peut qu’il ne soit pas possible de charger

une autre application. Ceci peut provenir du fait que l’application chargée était

configurée à une vitesse de t ransmission différente pour la communication en

temps réel dans le logiciel PanelBuilder32.

Modification de la vitesse de transmission en temps réel – Une fois qu’un

chargement d’application a abouti, il se peut que le terminal PanelView 300

Micro ne communique pas avec l’automate. Ceci peut provenir du fait que

l’application chargée était configurée à une vitesse de transmission différente de

celle de l’automate.

Pour régler la vitesse de transmission, vous pouvez :

• Soit activer le mode Configuration sur le terminal et sélectionner l’écran

Configuration de communication (analog ue à l’écran ci-dessous).

Voir page 40 pour accéder au mode Configuration.

Appuyer sur F2

pour changer le

réglage de vitesse

en bauds.

DF1 – Full Duplex

F1 Comms

F2 Baud

F3 MORE

N/8/1

9600

F4 EXIT

Réglage en cours

de la vitesse de

transmission.

Appuyer sur F4

pour enregistrer

le réglage et

quitter.

• Soit accéder à la boîte de dialogue Configuration de communication à partir de

la boîte de dialogue Configuration de l’application dans PanelBuilder32, puis

charger à nouveau l’application sur le terminal PV300 Micro.

41061-156-01(A)

Page 40

40 Terminal PanelView 300 Micro

Accès au mode de configuration

Le PanelView 300 Micro, comme tous les terminaux PanelView standard,

présente des écrans de configuration auxquels il est possible d’accéder pour

revoir ou modifier la configuration du terminal.

1. Raccorder la source d’alimentation au terminal PanelView 300 Micro comme

décrit dans les sections précédentes.

2. Appuyer simultanément s ur les touches fléchées Gauche et Droite situées sur

le panneau avant.

Il n’est pas possible d’accéder au mode Configuration si les touches fléchées

sont affectées aux objets dans l’application du terminal.

Appuyer et libérer

simultanément les deux

touches fléchées Gauche

et Droite pour activer le

mode Configuration.

CONFIGURATION MODE

Language

Communication

Preset Operations

F1 RUN MODE

F2 RESET VIDEO

C

F

Touche Entrée

3. Le menu Mode configurati on propose différentes options. A l’aide des touches

fléchées Haut et Bas, parcourir les écrans de configuration pour revoir les

informations relatives au terminal telles que paramètres de communication,

date/heure, configuration de l’affichage ainsi que sélection de la langue.

Les modifications apportées à la configuration sont immédiatement prises en

considération (sans qu’il soit nécessaire de mettre le terminal hors tension).

Réinitialisation du terminal

Le terminal PanelView 300 Micro peu t être réinitialisé à partir du panneau avant

sans avoir à le mettre hors puis sous tension. Une réinitialisation commandée à

l’aide de 3 touches équivaut à une remise sous tension.

Pour réinitialiser le PanelView 300 Micro :

Appuyer et l i bérer simultanément les deux touches fléchées Gauche et Droite,

puis appuyer simultanément sur la touche En t r ée. Le terminal est réinitialisé.

41061-156-01(A)

Page 41

Terminal PanelView 300 Micro 41

Indicateurs de communication et de défauts

Le terminal PanelView 300 Micro présente des indicateurs d’état Comm

(communication) et Fault (défaut). Ces indicateurs apparaissent en mode

Configuration lorsque l’écran Communication est activé. Les indicateurs Comm

et Fault permettent d’identifier les dysfonctionnements.

CONFIGURATION MODE

Language

Communication

Preset Operations

F1 RUN MODE

F2 RESET VIDEO

C

F

DF1 – Full Duplex

Comm

PanelView Online

F3 MORE

Indicateur Etat Signification

Comm Allumé (fixe) Fonctionnement normal

(pas de défaut de communication)

Eteint (aucune couleur) Dysfonctionnement détecté. Vérifier :

• si l’automate est en mode d’exécution.

• les paramètres de communication du terminal et

de l’automate.

• les adresses de station du terminal et de

l’automate.

• les connexions reliant le terminal à l’automate.

Clignotant Aucune communication n’a été établie. Dans le cas

des terminaux DF1, l’indicateur Comm clignote

jusqu’à ce qu’une application soit chargée.

Fault Eteint (pas de motif de

Etat de fonctionnement normal

remplissage)

Allumé (fixe) Dysfonctionnement détecté. Réinitialiser ou mettre

hors tension puis sous tension le terminal. Si le

dysfonctionnement persiste, le terminal requiert

une maintenance.

Clignotant Le matériel fonctionne mais aucune application

n’est chargée sur le terminal ou l’application

courante est altérée. Le fichier d’application doit

être chargé à nouveau sur le terminal.

Fault

F4 EXIT

41061-156-01(A)

Page 42

42 Terminal PanelView 300 Micro

Dépannage et maintenance

Le tableau de dépannage ci-dessous énumère les principaux problèmes de

fonctionnement, leurs causes et leurs remèdes.

Problème Causes Remèdes

Le terminal n’est pas alimenté

en courant

Impossible de charger le

fichier d’application (premier

chargement)

Impossible de charger le

fichier d’application

(chargements suivants)

Absence de communication

entre MicroLogix,

ControlLogix, SLC ou automate

PLC

1. Connexion impropre à la

source d’alimentation.

2. Niveau de tension d’entrée

incorrect.

3. Bornier d’alimentation

retiré.

4. Les câbles d’alimentation

c.c. ont été inversés.

1. Le câble de communication

est déconnecté.

2. Configuration non

appropriée de la vitesse de

transmission ou de

communication.

3. Sélection incorrecte de port

COM de l’ordinateur.

1. Configuration de la vitesse

de transmission ou de

communication non

appropriée.

1. Défaut de communications

2. Vitesse en bauds

inappropriée.

3. L’automate n’est pas en

mode d’exécution.

4. Adresses de station de

terminal et de station maxi

incorrectes.

1. Vérifier que la tension

correcte est appliquée aux

bornes d’alimentation.

2. Vérifier que la tension de

sortie est comprise entre 11

et 30 V c.c.

3. Enclencher le bornier

d’alimentation sur la base à

l’arrière du terminal.

4. Raccorder les câbles

d’alimentation c.c. positifs

et négatifs aux bornes

appropriées.

1. Vérifier le type de câble de

communication et les

connexions.

2. Vérifier que les paramètres

de communication de

l’ordinateur et du terminal

sont identiques.

3. Vérifier que le numéro de

port COM est correct dans le

logiciel WinPFT ou

PanelBuilder32.

1. Vérifier que les paramètres

de communication de

l’ordinateur et du terminal

sont identiques. Modifier les

paramètres sur l’écran

Configuration de

communication du terminal.

1. Contrôler l’indicateur Comm.

Voir page 41.

2. Vérifier que la vitesse de

transmission est identique

sur l’automate et le

terminal.

3. Sélectionner le mode

d’exécution sur l’automate.

4. Vérifier les adresses de

station.

41061-156-01(A)

Page 43

Terminal PanelView 300 Micro 43

Problème Causes Remèdes

Absence de communication

avec l’automate mais

l’indicateur Comm est actif

Un message indique que la

batterie du module Horloge

est faible

Les objets affichés à l’écran ne

sont pas opérationnels

Absence de communication

avec l’ordinateur

Le nom du fichier application

apparaît en tant que ******

sur l’écran d’information du

terminal

Les objets d’écran ne sont pas

visibles

1. Adresse de station de

l’automate incorrecte.

2. Le bit d’inhibition est réglé

par défaut sur l’écran d’état

du canal du PLC.

1. Paramètres internes altérés.

2. Défaillance de la batterie du

module Horloge.

1. Problèmes de

communication.

1. Défaut de communication

Comm.

2. Configuration de la vitesse

de transmission ou de

communication non

appropriée.

3. Adresse de station de

terminal ou de station maxi

incorrecte.

4. Défaillance de l’ordinateur.

5. Le module de gestion de

communication n’est pas

correctement chargé.

1. Le fichier d’application n’est

pas valide.

2. L’application est inutilisable

à cause d’une erreur.

1. La tension d’alimentation

appliquée ne convient pas.

2. Le contraste de l’affichage

n’est pas correctement

réglé.

3. Le terminal se trouve en

mode économiseur d’écran.

1. Vérifier l’adresse de station

de l’automate.

2. Changer le réglage du bit

d’inhibition.

1. Recharger l’application et

mettre le terminal hors

tension puis sous tension.

2. Remplacer le terminal.

1. Vérifier l’état de l’indicateur

Comm.

1. Contrôler l’indicateur Comm.

Voir page 41.

2. Vérifier que les paramètres

de communication de

l’ordinateur et du terminal

sont identiques.

3. Vérifier les adresses de

station.

4. Se reporter au manuel relatif

à l’ordinateur.

5. Se reporter à l’aide en ligne

ou au manuel relatif à

RSLinx.

1. Charger l’application sur le

terminal.

2. Charger une nouvelle

application.

1. Contrôler les connexions

d’alimentation.

2. Accéder aux paramètres de

configuration de l’écran à

partir du mode Configuration

et régler les contrastes de

l’affichage.

3. Accéder aux paramètres de

configuration de l’écran à

partir du mode Configuration

afin de vérifier si le mode

économiseur d’écran est

activé sur le terminal.

41061-156-01(A)

Page 44

44 Terminal PanelView 300 Micro

Problème Causes Remèdes

Les valeurs ne sont pas mises

à jour à l’écran et sont

remplacées par des

astérisques ****

L’affichage à cristaux liquides

est difficilement lisible

Impossible d’accéder au mode

Configuration lorsque les deux

touches fléchées Gauche et

Droite sont enfoncées

simultanément

Aucun réseau n’a été trouvé 1. Le réglage de station sur

1. Absence de communication

entre le terminal et

l’automate.

2. La valeur n’est pas valide ou

excède la zone

correspondant à l’objet.

1. Le niveau de contraste

d’affichage n’est pas

correct.

1. Les touches fléchées

Gauche et Droite sont

affectées à des objets

d’écran dans l’application du

terminal.

l’automate ne correspond

pas à l’application.

2. Le fichier relatif aux

données de l’automate n’a

pas suffisamment

d’éléments.

1. Vérifier l’état de l’indicateur

Comm. Se reporter à

«Absence de communication

avec l’automate» pour plus

de détails.

2. Modifier la longueur de la

zone de l’objet.

1. Accéder au mode

Configuration et régler le

niveau de contraste de

l’affichage.

1. Contacter le service

technique pour obtenir de

l’assistance.

1. Modifier l’adresse de

station dans l’application

pour qu’elle corresponde à

l’adresse de station de

l’automate.

2. Contrôler les éléments de

fichier de données pour

toutes les adresses de

points.

41061-156-01(A)

Page 45

Terminal PanelView 300 Micro 45

Maintenance

Aucun composant interne du terminal PanelView 300 Micro n’es t accessible pour

l’utilisateur. Le capot arrière n’étant pas amovible, il ne doit donc pas être retiré

pour le dépannage ou la maintenance. La batterie de l’horloge en temps réel et le

rétro-éclairage de l’affichage à cristaux liquides n e peuvent pas être remplacés.

Pour nettoyer la fenêtre d'affichage du terminal PanelView 300 Micro :

1. Déconnecter le terminal de la source d’alimentation.

2. Pour nettoyer l’écran d’affichage, utiliser une éponge propre ou un chiffon

doux avec une solution d’eau savonneuse ou un détergent do ux. Ne pas

gratter, utiliser de brosse, d’agent de nettoyage abrasif ou de dissolvant.

3. Sécher l’écran à l’aide d’une peau de chamois ou d’une éponge en cellulose

humide pour éviter les traces d’eau.

Accessoires

Les accessoires suivants sont disponibles pour le terminal PanelView 300 Micro.

Logiciel PanelBuilder32

Référence Description Version

2711-ND3 Logiciel PanelBuilder32 pour les applications de

développement destinées à la gamme de terminaux

PanelView standard.

3.60 ou

ultérieure

Bornier d'entrée c.c.

Référence Description Quantité

2711-TBDC Bornier d’entrée c.c. amovible (3 positions de vis) 10

Câbles de communication

Câble Type de connecteur Longueur de câble

1761-CBL-AM00, série C de 8 broches mini-DIN à 8 broches

1761-CBL-AP00, série C de 8 broches mini-DIN à 9 broches

1761-CBL-PM02, série C de 8 broches mini-DIN à 9 broches

1761-CBL-HM02, série C de 8 broches mini-DIN à 8 broches

2711-CBL-PM05, série C de 8 broches mini-DIN à 9 broches

2711-CBL-HM05, série C de 8 broches mini-DIN à 8 broches

2711-CBL-PM10, série C de 8 broches mini-DIN à 9 broches

2711-CBL-HM10, série C de 8 broches mini-DIN à 8 broches

mini-DIN

D-Shell

D-Shell

mini-DIN

D-Shell

mini-DIN

D-Shell

mini-DIN

0,5 mètre (1,5 pied)

0,5 mètre (1,5 pied)

2 mètres (6,5 pieds)

2 mètres (6,5 pieds)

5 mètres (15 pieds)

5 mètres (15 pieds)

10 mètres (30 pieds)

10 mètres (30 pieds)

41061-156-01(A)

Page 46

46 Terminal PanelView 300 Micro

Caractéristiques

Electriques

Plage de tension d’alimentation de 11 à 30 V c.c. (24 V c.c. nominal)

Consommation de courant 2,5 W maxi (0,105 A à 24 V c.c.)

Mécaniques

Armoire NEMA Type 12/13, 4X (sous abri exclusivement), IP54, IP65

Poids 284 grammes (10 oz.)

Dimensions 133 (H) x 111 (L) x 48 (P) mm

Profondeur installée 35 mm (1,39 in.)

Affichage

Type Affichage à cristaux liquides (LCD) avec rétro-éclairage

Dimensions 73 mm (L) x 42 mm (H)

Résolution 128 x 64

Conditions ambiantes

Tem pérature de fonctionnement

Tem pérature de stockage

Humidité (sans condensation)

Dissipation thermique 2,5 W

Tenue aux chocs Fonctionnement : 30 G, Hors fonctionnement : 50 G

Résistance aux vibrations de 2 G à 2 000 Hz en service

Homologations

Si le produit porte marquage : UL

(1) Homologation CSA – Classe 1, Division 2, Groupe A,B,C,D ou emplacements non dangereux

5,23 (H) x 4,38 (L) x 1,87 (P) in.

2,87 in. (L) x 1,67 in. (H)

° à 55 °C (de 32 ° à 131 °F)

de 0

de -20 ° à 85 °C (de -4 ° à 188 °F)

de 5 à 95 % à une température de 0

(de 32 ° à 131 °F)

CE pour toutes les directives en vigueur

c-UL Classe 1 Div 2 emplacements dangereux

° à 55 °C

(1)

41061-156-01(A)

Page 47

Installationsanleitung

Deutsch

PanelView 300-Microterminal

(Produkt-Bestellnummern: 2711-M3A18L1, 2711-M3A19L1)

Inhalt:

Weitere Informationen ......................................................................... 48

Erläuterung der EU-Richtlinie .............................................................. 48

Gefährliche Bereiche ........................................................................... 49

Verdrahtungs- und Sicherheitsrichtlinien ............................................ 50

Montage des Terminals ....................................................................... 50

Anschluss von Gleichstrom .................................................................. 54

Verwenden des Kommunikationsanschlusses ..................................... 57

Zugriff auf den Konfigurationsmodus .................................................. 62

Zurücksetzen des Terminals ................................................................. 62

Kommunikations- und Fehleranzeigen ................................................. 63

Fehlersuche und Wartung .................................................................... 64

Zubehör ................................................................................................ 66

Technische Daten ................................................................................. 67

Publikation 41061-156-01(A)

Page 48

48 PanelView 300-Microterminal

Weitere Informationen

Thema Siehe Siehe

Ausführliche Informationen zum

300-Microterminal und den anderen PanelViewStandardterminals.

Zum Herunterladen einer Publikation können Sie:

• eine kostenlose elektronische Version von der PanelBuilder32

Installations-CD herunterladen

• unter folgender Internet-Adresse eine kostenlose elektronische Version

herunterladen:

www.ab.com/manuals/eoi oder www.theautomationbookstore.com

Zum Erwerben einer Publikation können Sie:

• unter der Internet-Adresse www.theautomationbookstore.com Ihre Bestellung

aufgeben

• sich an Ihren lokalen Distributor bzw. den Vertreter von Rockwell Automation

wenden

Benutzerhandbuch für

PanelView

Standardterminals

2711-UM014A-DE-P

Erläuterung der EU-Richtlinie

Trägt dieses Produkt das CE-Zeichen, ist es für die Installation in EU-Ländern

und EWR-Regionen zugelassen. Es wurde entsprechend den folgenden

Richtlinien entwickelt und geprüft:

EMV-Richtlinie

Dieses Produkt wurde gemäß den Anforderungen der Richtlinie 89/336/EWR für

Elektromagnetische Verträglichkeit (EMV) des Rates der Europäischen

Gemeinscha ft geprüft un d erfüllt die fo lgenden technischen Spezifikationen:

• EN 50081-2 EMV Fachgrundnorm Störaussendung, Teil 2 - Industriebereich

• EN 61000-6-2 EMV Fachgrundnor m Störfestigkeit - Industriebereich.

Dieses Produkt ist für den Einsatz in einer industriellen Umgebung bestimmt.

41061-156-01(A)

Page 49

PanelView 300-Microterminal 49

!

ACHTUNG

Gefährliche Bereiche

Dieses Gerät ist nur für den Einsatz in Bereichen der Klasse I, Division 2,

Gruppen A, B, C, D bzw. für nicht gefährliche Bereiche ausgelegt. Der folgende

WARNHINWEIS ist b e im Betrieb in gefährlichen Bereichen zu beachten.

EXPLOSIONSGEFAHR

• Ein Austausch von Komponenten kann die Eignung für

Klasse I, Division 2 einschränken.

• Klemmen Sie die Geräte erst ab, wenn die Stromversorg ung

unterbrochen wurde, und Sie sich in einem nicht

gefährlichen Bereich befinden.

• Der Anschluss bzw. das Abklemmen von Komponenten

darf erst nach Unterbrechen der Stromversorgung erfolgen.

• Die Verdrahtung muss stets gemäß N.E.C.-Artikel 501-4(b)

vorgenommen werden.

• Peripheriegeräte müssen für die Umgebung, in de r sie

installiert werden, geeignet sein.

In gefährlichen Bereichen der Klass e I, Division 2, sind ausschließlich folgende

Kabel zu verwenden.

Umgebungsklassifizierung Kommunikationskabel

1761-CBL-PM01, Serie C

1761-CBL-HM02, Serie C

1761-CBL-AM00, Serie C

Gefährliche Bereiche

der Klasse I, Division 2

1761-CBL-AP00, Serie C

2711-CBL-PM05, Serie C

2711-CBL-HM05, Serie C

2711-CBL-PM10, Serie C

2711-CBL-HM10, Serie C

41061-156-01(A)

Page 50

50 PanelView 300-Microterminal

Verdrahtungs- und Sicherheitsrichtlinien

Installieren Sie das PanelVie w 300-Microterminal mit Hilfe der Publikation 70E,

„Electrical Safety Requirements for Employee Workplaces“. Neben den

allgemeinen NFPA-Richtlinien sollten Sie folgende Empfehlungen befolgen:

• Verlegen Sie ankommende Spannungsversorgungskabel zum PanelView 300Microterminal getrennt vom Kommunikationskabel.

• Spannungsversorgungs- und Kommunikationskabel müssen sich im rechten

Winkel kreuzen. Kommunikationskabel können im gleichen Kabelkanal mit

DC E/A-Niederspannungskabel (unter 10 Volt) installiert werden.

• Eine korrekte Erdung minimiert Störungen durch elektromagnetische

Interferenz (EMI) und stellt eine Sicherheitsmaßnahme bei

Elektroinstallationen dar. Zur Vermeidung elektromagnetischer Störungen

sind die Kabel korrekt abzuschirmen und zu erden.

Eine Beschreibung der maßgebl ichen Erdungs anforderungen en thält der National

Electrical Code, der von der National Fire Protection Association in Boston,

USA, veröffentlicht wurde.

Montage des Terminals

Gehäuse

Zum Schutz des inneren Scha ltkreis es mus s das P anel View 300 Microterminal in

einen Schaltschrank oder ein Gehäuse eingebaut werden. Das Terminal

entspricht den NEMA-Typen 12/13 und 4X (Innenräume) nur, wenn es in einem

Schaltschrank oder einem gleichwertigen Gehäuse eingebaut ist. Sehen Sie

ausreichend Abstand für eine angemessene Ventilation innerhalb des Gehäuses

vor. Berücksichtigen Sie außerde m die Wärmeentwicklung durch andere

Vorrichtungen innerhalb des Schaltschranks. Die Umgebungstemperatur um das

PanelView 300 Microterminal muss zwischen 0 und 55

Treffen Sie Vorkehrungen, um den Zugriff auf die Seitenwand des Terminals

(für Verdrahtung, Wartung und Fehlersuche) zu ermöglichen.

°C liegen.

Montageabmessungen

133 mm

41061-156-01(A)

111 mm

35 mm

48 mm

Page 51

PanelView 300-Microterminal 51

Ausschnittsabmessungen

Verwenden Sie die Originalschablone, die mit dem PV300 Microterminal

geliefert wird, um die Ausschnittsabmess ungen aufzuzeichnen. Die nachfo lgende

Abbildung zeigt eine verkleinerte Schablone. Eine Schablone im

Originalmaßstab finden Sie innen auf der Rückseite dieses Dokuments.

112 mm

102 mm

54 mm

4,5 mm

Durchmesser

92 mm

Abstände

Berücksichtigen Sie 51 mm Abstand auf allen Seiten des Terminals, um eine

ausreichende Belüftung zu gewährleisten und die Wartung zu vereinfachen.

51 mm

51 mm

41061-156-01(A)

Page 52

52 PanelView 300-Microterminal

!

ACHTUNG

Einbauen eines Terminals in einen Schaltschrank

Die folgenden Werkzeuge werden für den Einbau in einen Paneelausschnitt

benötigt:

• 7 mm (M4) Schrauben- oder Steckschlüssel

• Kleiner Schlitzschraubendreher

• Drehmomentschlüssel (Nm)

Zum Einbauen des PV300 Microterminals in einen Schaltschrank gehen Sie

wie folgt vor: