Page 1

Installation Instructions

SynchLink™ Board for PowerFlex® 700S Drives with Phase II

Control

ATTENTION: To avoid an electric shock hazard, verify that the voltage on

the bus capacitors has discharged before performing any work on the

drive. Measure the DC bus voltage at the +DC & –DC terminals of the

Power Terminal Block (DC+ & DC- in high power drives). The voltage must

be zero.

ATTENTION: HOT surfaces can cause severe burns. Do not touch the

heatsink surface during operation of the drive. After disconnecting power

allow time for cooling.

ATTENTION: Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into module ports or fiber-optic cable connectors.

What This Kit Contains

Tools That You Need

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive

parts and assemblies. Static control precautions are required when

installing, testing, servicing or repairing this assembly. Component

damage may result if ESD control procedures are not followed. If you are

not familiar with static control procedures, reference A-B publication

8000-4.5.2, “Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

Verify that your kit contains the items listed in the following table. If your kit

does not contain the correct items, contact your Rockwell Automation sales

representative.

Quantity: Description

1 SynchLink Board

1 “Stacker” connector

2Screws

2 Stand-offs

• Phillips® screwdriver

• POZIDRIV® screwdriver

• Standard (flat blade) screwdriver

20D-IN010B-EN-P

Phillips

®

and POZIDRIV® are registered trademarks of Phillips Screw Company

Page 2

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

What You Need to Do

To install or replace a SynchLink board, complete the following steps:

❐ Step 1: Remove power from the drive.

❐ Step 2: Open/Remove the drive cover(s).

❐ Step 3: Remove the control cassette from the drive.

❐ Step 4: Remove the inside cover from the control cassette.

❐ Step 5: Remove the existing SynchLink board.

❐ Step 6: Install the new SynchLink board.

❐ Step 7: Install the control cassette inside cover.

❐ Step 8: Install the control cassette in the drive.

❐ Step 9: Connect the SynchLink cables.

❐ Step 10: Close/Install the drive cover(s).

❐ Step 11: Document the change.

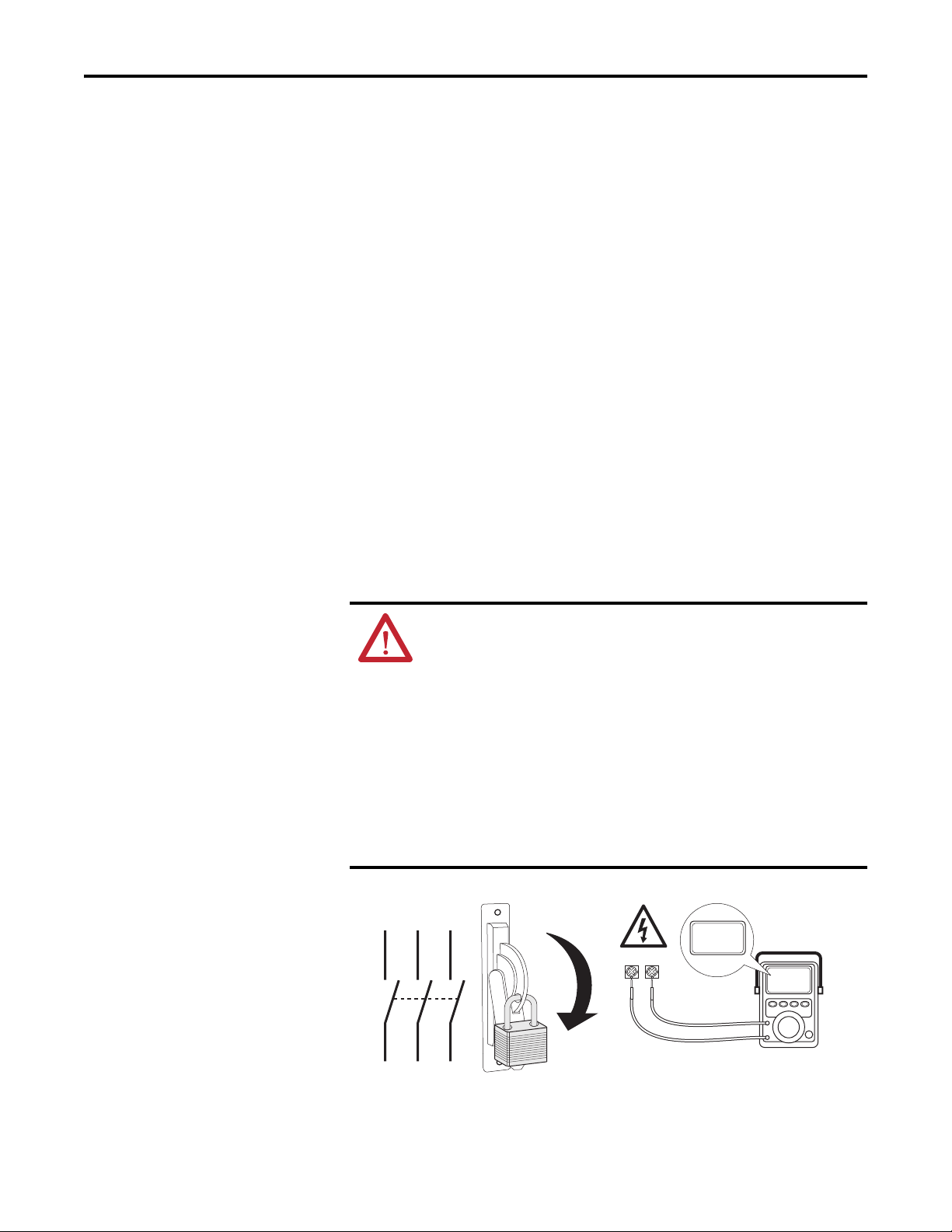

Step 1: Remove Power

from the Drive

ATTENTION: To avoid an electric shock hazard, verify that the voltage on

the bus capacitors has discharged before performing any work on the

drive. Measure the DC bus voltage at the +DC & –DC terminals of the

Power Terminal Block. The voltage must be zero.

Remove power before making or breaking cable connections. When you

remove or insert a cable connector with power applied, an electrical arc

may occur. An electrical arc can cause personal injury or property damage

by:

• sending an erroneous signal to your system’s field devices, causing

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical resistance.

L1 L2 L3

unintended machine motion

I

0V

DC+ DC–

0V

O

2 Rockwell Automation Publication 20D-IN010B-EN-P - November 2010

Page 3

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

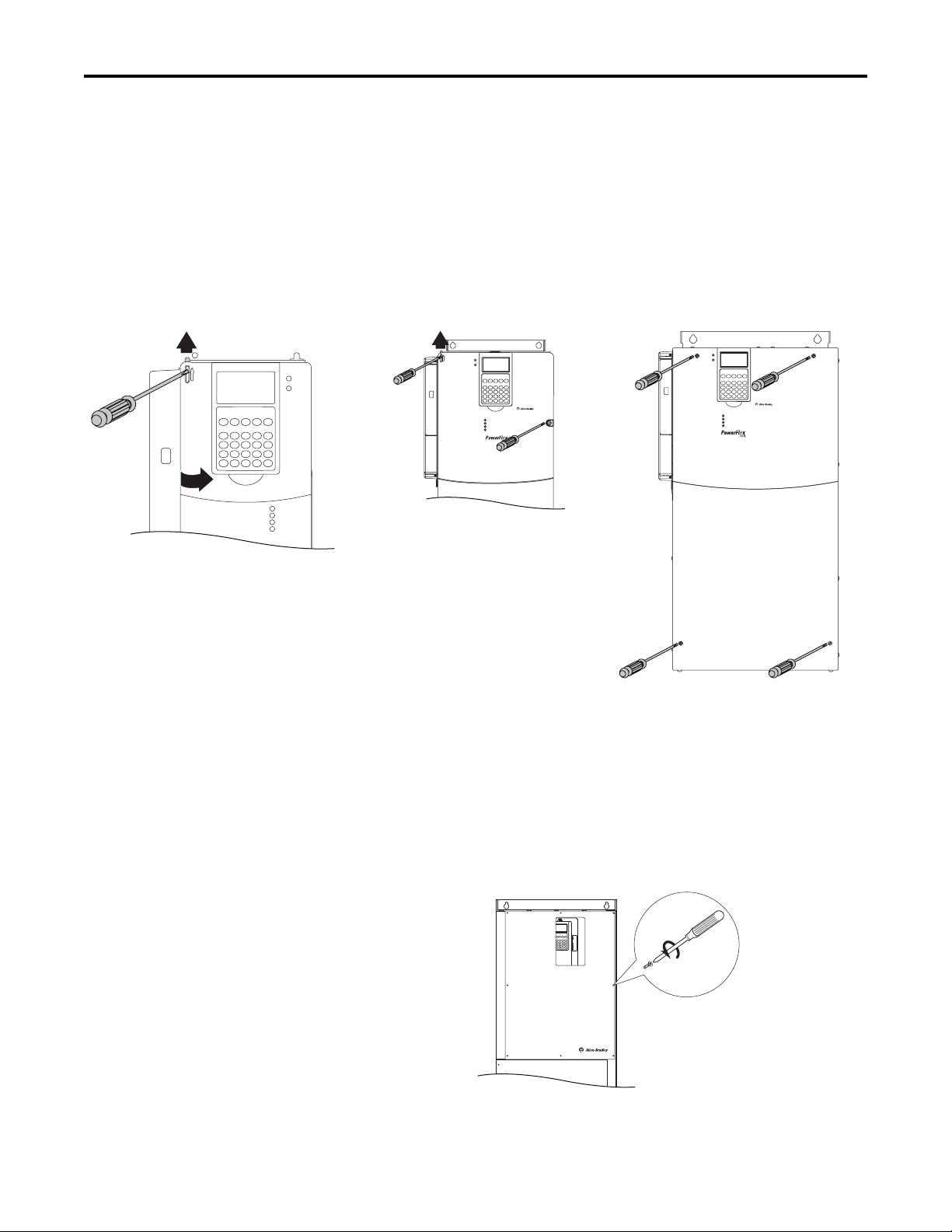

Step 2: Open/Remove the

Drive Cover(s)

Frames 1…4 Frame 5 Frame 6

Frames 1…6

• Frames 1…4: Locate the slot in the upper left corner. Slide the locking tab

up and swing the cover open.

• Frame 5: Slide the locking tab up, loosen the right-hand cover screw and

remove the cover.

• Frame 6: Loosen the two screws on the bottom drive cover and slide the

bottom cover down and out. Loosen the two screws on the top cover and

remove the cover.

S

Frames 9…14

• Frame 9: Remove the eight POZIDRIV screws that secure the top cover

to the drive and remove the cover.

• Frame 10…14: Open the enclosure door on the bay that holds the control

frame.

Frame 9

Proper tightening torque

for reassembly is

3 N•m (27 lb•in)

Rockwell Automation Publication 20D-IN010B-EN-P - November 2010 3

Page 4

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Step 3: Remove the

Control Cassette from the

Drive

Loosen two screws

Frames 1…6

See page 3 for Frames 9…14 control cassette removal instructions.

1. If necessary, disconnect any fiber-optic ControlNet and SynchLink cables

from the control assembly.

ATTENTION: Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into fiber-optic ports or fiber-optic cable connectors.

2. Disconnect any remaining I/O and communications cables from the

control assembly.

3. Disconnect the ribbon cables that connect to the main control board.

4. Loosen the two screws on the front of the cassette.

5. Remove the cassette from the drive chassis.

=

Remove

cassette

Disconnect

ribbon cables

BR1

BR2

DC+

DC-

PE

U/T1

V/T2

W/T3

R/L1

L2

4 Rockwell Automation Publication 20D-IN010B-EN-P - November 2010

Page 5

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Frames 9…14

1. If necessary, disconnect any fiber-optic ControlNet and SynchLink cables

from the control assembly.

ATTENTION: Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into fiber-optic ports or fiber-optic cable connectors.

2. Disconnect any remaining I/O and communications cables from the

control assembly.

3. Disconnect the ribbon cables from the main control board.

4. Loosen the captive screw on the control assembly mounting plate and

swing the control assembly mounting plate away from the control frame.

Frame 9 Frames 10…14

X50

=

Loosen captive screw and swing

mounting plate away from drive.

Rockwell Automation Publication 20D-IN010B-EN-P - November 2010 5

Page 6

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

5. Loosen the two mounting screws on the front of the control assembly and

slide the control cassette off the mounting bracket.

Frame 9 shown

=

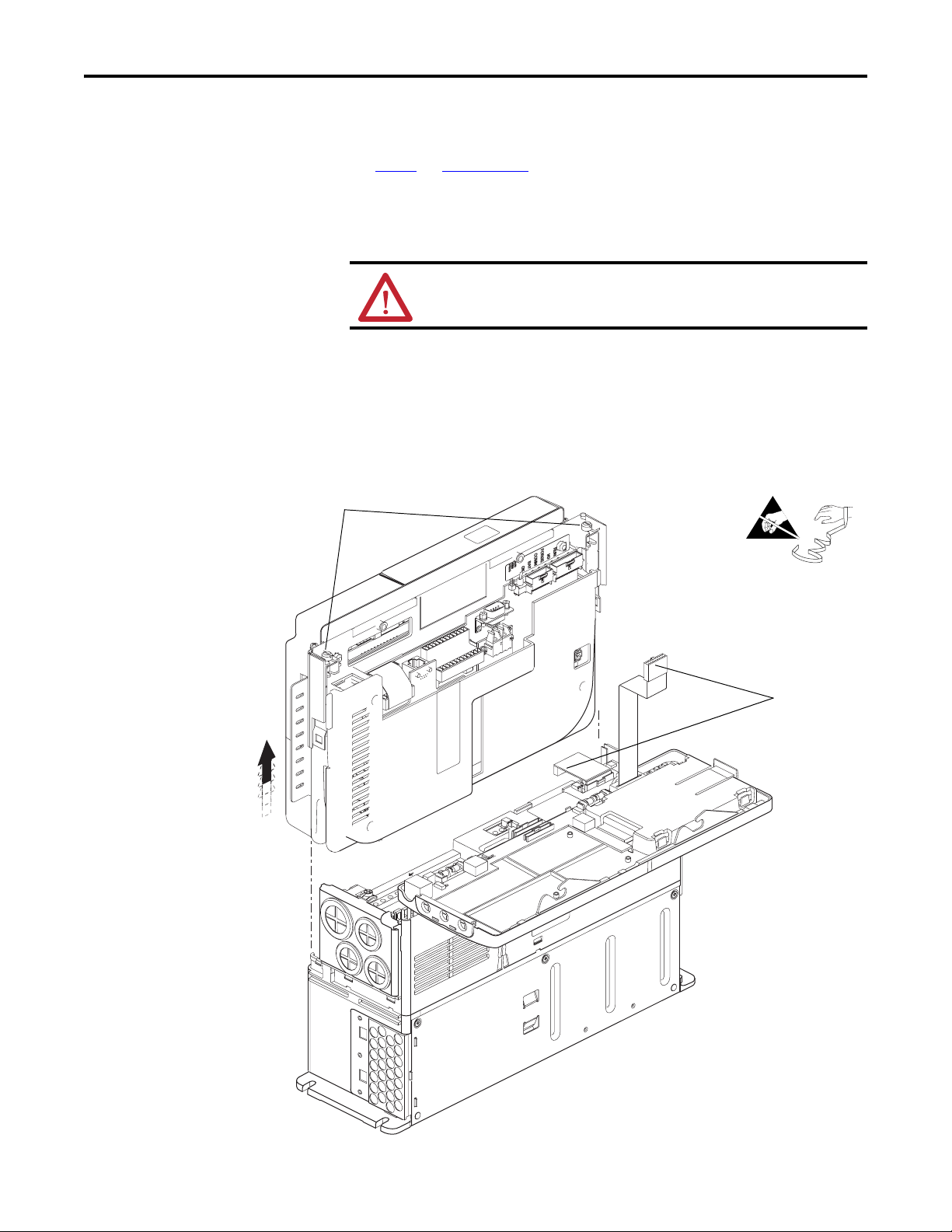

Step 4: Remove the Inside

Cover from the Control

Cassette

• Loosen the three screws on the face of the front cover and remove the

cover.

=

Loosen three screws and remove cover

6 Rockwell Automation Publication 20D-IN010B-EN-P - November 2010

Proper tightening torque for reassembly

is 0.8… 1.1 N•m (7…10 lb•in)

Page 7

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Step 5: Remove the

Existing SynchLink Board

If you are installing a new SynchLink board only, continue with Step 6: Install the

New SynchLink Board on page 8.

If you are replacing an existing SynchLink board continue with these steps.

1. Remove the two screws that secure the SynchLink board to the standoffs

on the main control board and remove the SynchLink board from the

stacker connector.

2. Remove the stacker connector from the mating connector on the main

control board.

3. Remove the two standoffs from the main control board.

=

Remove the stacker connector

Remove two standoffs

Remove two screws

and board

Rockwell Automation Publication 20D-IN010B-EN-P - November 2010 7

Page 8

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Step 6: Install the New

SynchLink Board

1. Secure the two standoffs to the main control board. Tighten to 0.8… 1.1

N•m (7…10 lb•in).

2. Insert the short pins

of the stacker connector into the mating connector on

the main control board. See the Important statement below.

3. Connect the mating connectors of the new SynchLink board to the long

pins of the stacker connector. See the Important statement below.

4. Secure the SynchLink board to the standoffs using the two screws

provided. Tighten to 0.8… 1.1 N•m (7…10 lb•in).

=

Install two standoffs

IMPORTANT

The end of the stacker connector with the short pins

must connect to the main control board. The end of

the stacker connector with the long pins must connect

to the SynchLink board.

Step 7: Install the Control

Cassette Inside Cover

Install the stacker connector

(see Bottom View below)

Main control board

mating connector

End with short

Stacker connector

Bottom View

Standoff

pins

End with long pins

Install two screws

to secure board to

standoffs

SynchLink board

mating connector

Install the control cassette inside cover in the reverse order of removal. Refer to

Step 4: Remove the Inside Cover from the Control Cassette

on page 6.

8 Rockwell Automation Publication 20D-IN010B-EN-P - November 2010

Page 9

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Step 8: Install the Control

Cassette in the Drive

Step 9: Connect the

SynchLink Cables

Install the control cassette in the reverse order of removal. Refer to Step 3:

Remove the Control Cassette from the Drive

on page 4.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into module ports or fiber-optic cable connectors.

• Connect the fiber-optic cables to the J1 (transmit) and J2 (receive)

connectors on the SynchLink board. Push the plug into the socket until it

produces an audible click.

IMPORTANT

Minimum inside bend radius for SynchLink fiber-optic cable is 25.4

mm (1 in.). Any bends with a shorter inside radius can permanently

damage the fiber-optic cable. Signal attenuation increases with

decreased inside bend radii.

IMPORTANT

Do not overtighten tie-wraps.

=

J2 (Receive)

J1 (Transmit)

Rockwell Automation Publication 20D-IN010B-EN-P - November 2010 9

Page 10

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Step 10: Close/Install the

Drive Cover(s)

Step 11: Document the

Change

Close/Install the drive cover(s) in the reverse of removal. Refer to Step 2: Open/

Remove the Drive Cover(s) on page 3.

Document the SynchLink board installation on the “Field Installed Options”

label. Use the blank line if you are installing the SynchLink board in a drive that

was manufactured without it.

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

20-HIM

HIM

28-IO-

20-COMM-

20B_-DB1-

I/O

COM Module

Internal Dynamic Brake

TIP

Use the packing material from the new SynchLink board to return the

replaced SynchLink board.

10 Rockwell Automation Publication 20D-IN010B-EN-P - November 2010

Page 11

SynchLink™ Board for PowerFlex® 700S Drives with Phase II Control

Additional Information

Refer to The SynchLink Design Guide, publication 1756-TD008, when planning

and connecting the SynchLink network.

Table 1 - SynchLink Cables and Accessories

Description Cat. No.

3 M Fiber-Optic Link (Qty 2) 1403-CF 003

5 M Fiber-Optic Link (Qty 2) 1403-CF 005

10 M Fiber-Optic Link (Qty 2) 1403-CF 010

500 M Fiber-Optic Bulk 1403-CF BLK

Termination Kit 1403-NTOL

Connector (Qty 10) 1403-N10

Splice Bushing (Qty 5) 1403-N11

Pulling Bullet 1403-N12

Fiber Stripper Tool 1403-N13

SynchLink Fiber-Hub, 1 input, Base 1751-SLBA

SynchLink Fiber-Hub, 4 output, “Star” Splitter 1751-SL4SP

SynchLink Bypass Switch 1751-SLBP/A

Table 2 - Fiber-Optic Cable Assembly Specifications

Parameter Value

Connecting Cables 200/230 micron HCS (Hard Clad Silica)

Versalink V-System

Lucent Technologies,

Specialty Fibers Technology Division

Maximum Cable Length 300 meters with no more than one splice or one adapter

Minimum Cable Length 1 meter

Minimum inside bend radius 25.4mm (1 in.). Any bends with a shorter inside radius can permanently

damage the fiber-optic cable. Signal attenuation increases with

decreased inside bend radii.

Operating Wavelength 650 nm (Red)

Data Rate 5 Mbps

Maximum Node Count 10 - Daisy Chain

256 - Star Configuration

Rockwell Automation Publication 20D-IN010B-EN-P - November 2010 11

Page 12

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street,

/

Middle East/Africa: Rockwell Automati

Europe

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

on,

Publication 20D-IN010B-EN-P – November 2010 PN-92652

Supersedes 20D-IN010A-EN-P – July 2004 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Milwaukee, WI 53204-2496 USA,

Pegasus Park, De Kleetlaan 12a,

Tel:

(1) 414.382.2000, Fax: (1) 414.382.4444

1831 Diegem, Belgium,

Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Loading...

Loading...