Page 1

Installation Instructions

Second Encoder Option Card for PowerFlex®

700S Drives with Phase II Control

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the DC bus voltage at the +DC &

–DC terminals of the Power Terminal Block. The voltage must

be zero.

ATTENTION: HOT surfaces can cause severe burns. Do not

touch the heatsink surface during operation of the drive. After

!

disconnecting power allow time for cooling.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

What This Kit Contains

Tools That You Need

Verify that your kit contains the items listed in the following table. If your

kit does not contain the correct items, contact your Allen-Bradley sales

representative.

Quantity: Description

1 Second Encoder Option circuit board

1 16-Pin “Stacker” Connector

3Screws

• Phillips® screwdriver for M3 screws

• Standard (flat blade) screwdriver

Phillips® is a registered trademark of Phillips Screw Company

Page 2

2 Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control

What You Need to Do

To remove the Second Encoder Option Card from a PowerFlex 700S drive:

❐ Step 1: Remove power from the drive

❐ Step 2: Open the main drive door

❐ Step 3: Remove the control cassette from the drive

❐ Step 4: Remove the inside cover from the control cassette

❐ Step 5: Remove the outside covers from the control cassette

❐ Step 6: Remove the old Second Encoder Option Card and Stacker

Connector

❐ Step 7: Remove the Embedded EtherNet/IP Option Card

❐ Step 8: Install the two-pin jumper

To replace the Second Encoder Option Card from a PowerFlex 700S drive:

❐ Step 8: Remove remove the two-pin jumper

❐ Step 9: Install the Stacker Connector and new Second Encoder

Option Card

❐ Step 10: Wire and configure the Second Encoder Option Card

❐ Step 11: Replace the covers and control cassette

❐ Step 12: Document revision changes

To return replaced Second Encoder Option Card, use packing material from

the new Second Encoder Option Card.

Page 3

Step 1: Removing Power from the Drive

Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control 3

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the DC bus voltage at the +DC &

–DC terminals of the Power Terminal Block. The voltage must

be zero.

Remove power before making or breaking cable connections.

When you remove or insert a cable connector with power

applied, an electrical arc may occur. An electrical arc can cause

personal injury or property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

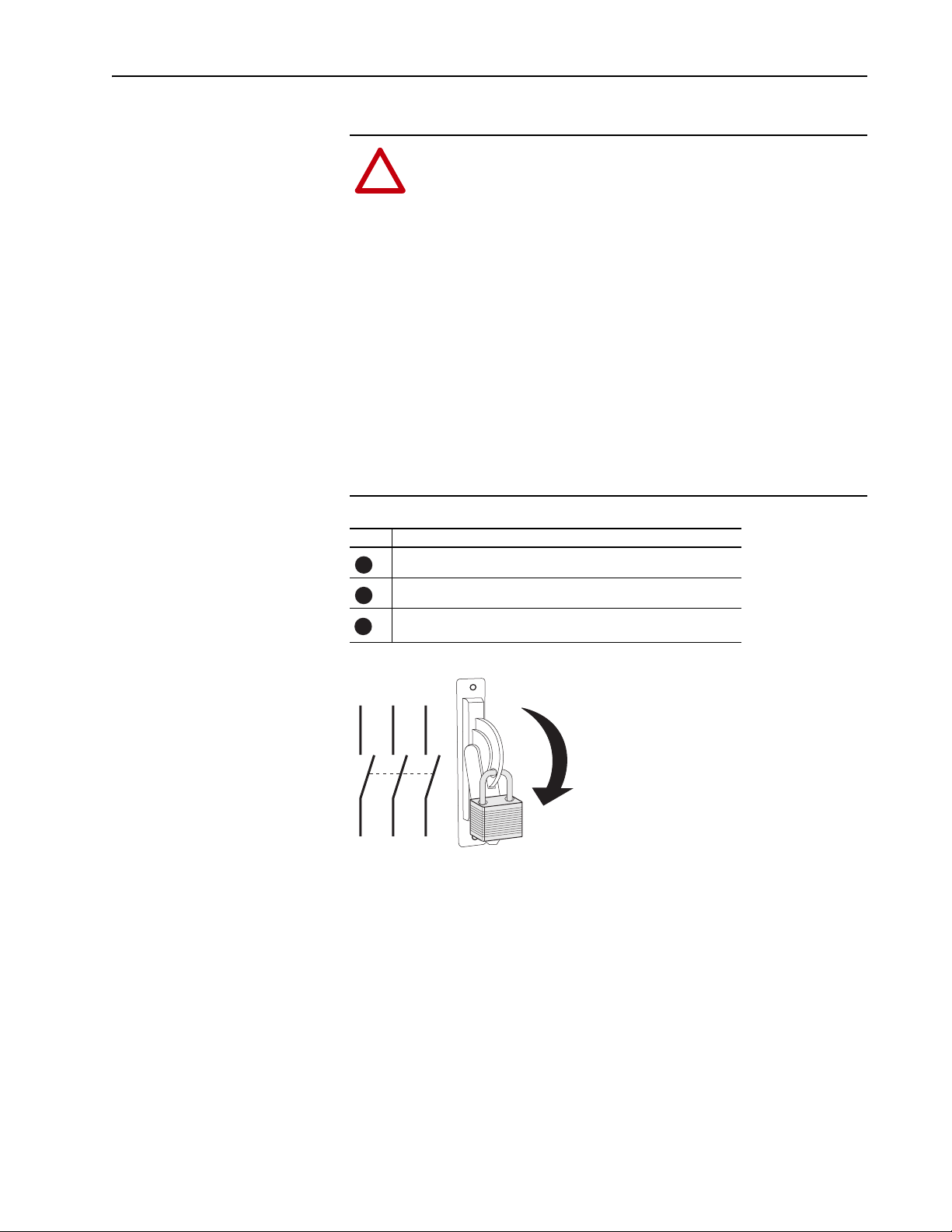

Task Description

Turn off and lock out input power. Wait five minutes.

A

Verify that there is no voltage at the drive’s input power terminals.

B

Measure the DC bus voltage at the +DC & -DC terminals on the

C

C

Power Terminal Block. The voltage must be zero.

L1 L2 L3

I

O

Page 4

4 Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control

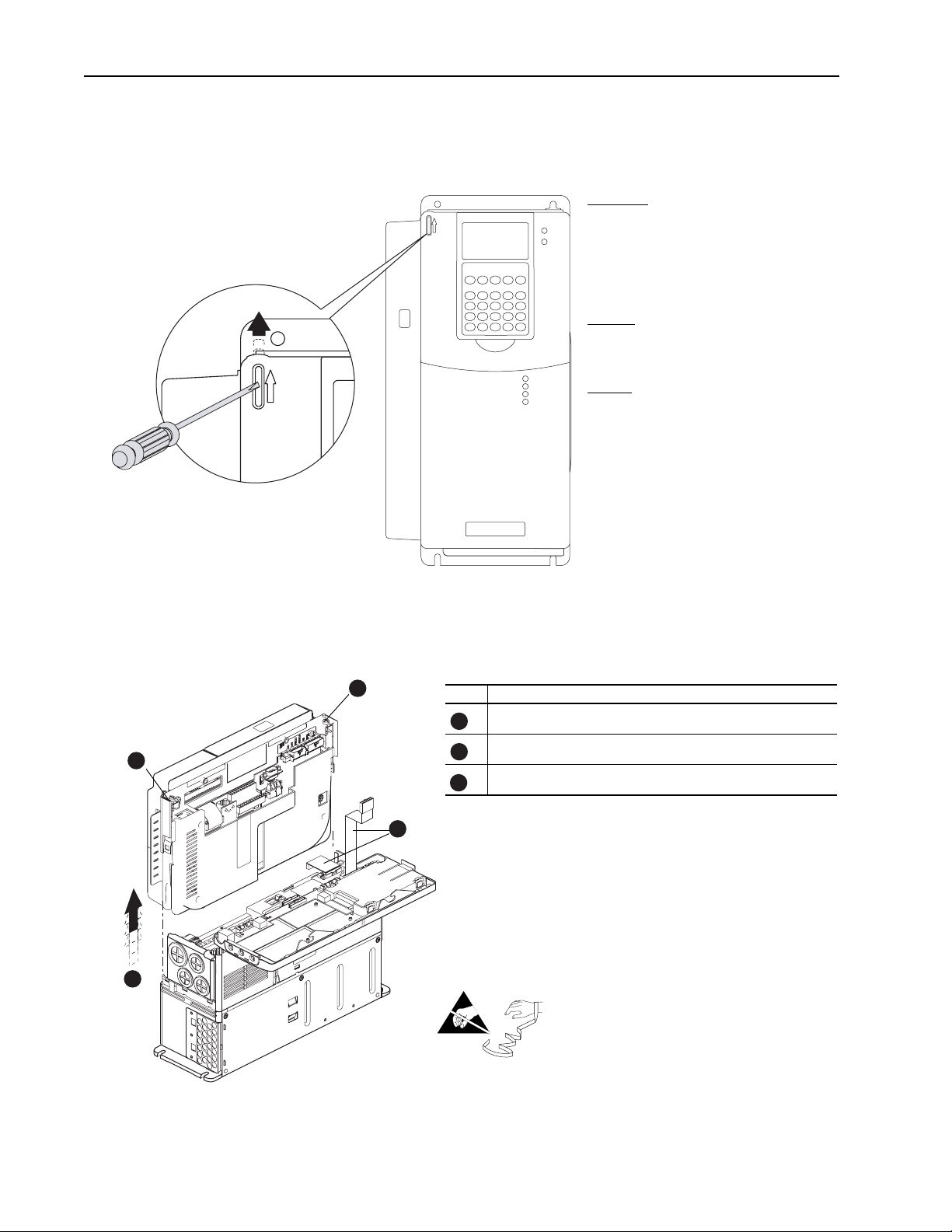

Step 2: Opening Door Over Power Structure and Main Control Board

Frames 1-4

Locate the slot in the upper left corner. Slide

the locking tab up and swing the cover open.

Special hinges allow cover to move away from

drive and lay on top of adjacent drive (if

present).

Frame 5

Slide the locking tab up, loosen the right-hand

cover screw and remove.

Frame 6

Loosen 2 screws at bottom of drive cover.

Carefully slide bottom cover down & out.

Loosen the 2 screws at top of cover and

remove.

Step 3: Removing the Control Cassette from Drive

B

BR1

B

R

2

D

C

+

D

C

-

PE

U/T1

V/T2

W/T3

R/L1

L2

C

B

A

Task Description

Disconnect the cables that connect to the main board

A

Loosen screws on face of cassette

B

Remove the cassette

C

C

=

Page 5

Step 4: Removing the Inside Cover from the Control Cassette

Task Description

Loosen screws on face of front cover and remove

A

the cover

Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control 5

Proper tightening torque for

reassembly is 7 to 10 lb.-in.

Step 5: Removing the Outside Covers from the Control Cassette

Task Description

Loosen screws on face of front cover and remove

A

the cover

Loosen screws on side of rear cover and remove

B

the cover

A

=

A

A

Proper tightening torque for

reassembly is 7-10 lb.-in.

A

=

B

Page 6

6 Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control

Step 6: Removing the Old Second Encoder Option Card and Stacker Connector

B

Skip this step if you are installing a new Second Encoder Option Card on a

drive that does not already have one.

Task Description

Disconnect the terminal block P1 from the Second Encoder Option Card

A

Remove three M3 screws (7-10 lb.- in.)

B

Carefully remove Second Encoder Option Card and Stacker connector

C

from the main control board

C

=

C

Important: Do not use a screwdriver to pry the P1 terminal plug from the

circuit board. This may damage the plug.

Step 7: Removing the Embedded EtherNet/IP Option Card

Skip this step if you are replacing a Second Encoder Option Card on a drive

that already has one.

If you are permanently removing the Second Encoder Option Card or are

performing the first installation of the Option Card you must remove the

EtherNet/IP Option Board (if present) to access the Two-Pin Jumper.

Task Description

Remove two screws which secure the Embedded

A

EtherNet/IP Option Board to the Main Board

Remove the Embedded EtherNet/IP Option Board

B

=

B

A

Proper tightening torque for

reassembly is 7-10 lb.- in.

Page 7

Step 8: Installing or Removing the Two-Pin Jumper

Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control 7

ATTENTION: If you fail to remove the Two-Pin Jumper before

installing the Stacker Connector, you may damage the main

!

control board. Make sure you remove the jumper before

installing the Stacker Connector.

Important: If you are permanently removing the Second Encoder Option

Card (running the drive without the option), you must install

the two-pin jumper. If you fail to install the jumper, the drive

will not run.

TIP: Save the jumper if you are installing the Option Card and removing

the jumper. You will need it if you remove the Option Card in the future.

Page 8

8 Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control

Step 9: Installing the Stacker Connector and Second Encoder Option Card

Task Description

A

B

C

D

ATTENTION: If you fail to remove the Two-Pin Jumper before

installing the Second Encoder Option Card, you may damage the

!

main control board. Make sure you remove the jumper before

installing the Stacker Connector.

Remove the terminal block P1 from the Second Encoder Option Card

It is much easier to remove before the card is installed

Plug the long pins of the Stacker connector into the Second Encoder

Option Card.

The end with the long pins must plug into the Option Card

Plug the Second Encoder Option Card and Stacker connector onto the

mating connector of the main control board.

The end with the short pins must plug into the main control board.

Install and tighten three M3 screws (7-10 lb.- in.)

B

The end with the long pins

must plug into the Option

=

D

Important: Do not use a screwdriver to pry the P1 terminal plug from the

circuit board. This may damage the plug.

Card.

C

Page 9

Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control 9

Step 10: Wiring and Configuring the Second Encoder Option Card

Terminal block P1 contains connection points for a differential encoder.

This terminal block resides on the Second Encoder Option Card.

Terminal Signal Description

1 N/C Not connected

2N/C

3N/C

4N/C

5 A Quadrature A input

6Not A

7 B Quadrature B input

8Not B

9Z Marker Pulse

10 Not Z

11 Power DC Power for encoder interface

12 Common

13 Shield Connection point for encoder

cable shield

Table A Recommended Cable

Cable Length Cable Description

less than or equal to 30m (98 ft.) Belden 9728 or equivalent 0.196 mm

shielded, twisted pairs

greater than or equal to 30m (98 ft.) Belden 9774 or equivalent 0.750 mm2 (18 AWG), individually

shielded, twisted pairs

2

(24 AWG), individually

Connection Examples

Differential Encoder with Internal Supply

A

Not A

B

Not B

Z

Not Z

Powe r

Common

Differential Encoder with External Supply

A

Not A

B

Not B

Z

Not Z

Powe r

Common

P1Encoder

1

2

3

4

5

6

7

8

9

10

11

12

13

P1Encoder

1

2

3

4

5

6

7

8

9

10

11

12

13

Powe r

Common

N/C

N/C

N/C

N/C

A

Not A

B

Not B

Z

Not Z

Powe r

Common

Shield

N/C

N/C

N/C

N/C

A

Not A

B

Not B

Z

Not Z

Powe r

Common

Shield

Page 10

10 Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control

Dip Switch Settings

Dip switch S1 configures the power supply output voltage and the encoder

interface input voltage. Almost all applications require you to set all four

switches on the assembly to either 5V dc or 12V dc.

Step 11: Replacing the Covers and Control Cassette

Voltage

Selection

5V dc Closed Closed Closed Closed

12V dc Open Open Open Open

The procedure for replacing the covers and control cassette is the reverse of

removing these components. Refer to Step 7: Removing the Embedded

EtherNet/IP Option Card on page 6, Step 5: Removing the Outside Covers

from the Control Cassette on page 5, Step 4: Removing the Inside Cover

from the Control Cassette on page 5 and Step 3: Removing the Control

Cassette from Drive on page 4.

SIDE VIEW

S1-1

(Supply)

S1

UP = OPEN = OFF

DOWN = CLOSED= ON

S1-2

(A Channel)

FRONT - TOP VIEW

OPEN

1

234

S1-3

(B Channel)

S1-4

(Z Channel)

Page 11

Second Encoder Option Card for PowerFlex® 700S Drives with Phase II Control 11

Step 12: Documenting Revision Changes

Document drive revisions on the “Field Installed Options” tag. Use the

blank line if you are installing the Second Encoder Option Card in a drive

that was manufactured without it.

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

20-HIM

HIM

28-IO-

I/O

20-COMM20B_-DB1-

COM Module

Internal Dynamic Brake

Specifications

TIP: Use packing material from new Second Encoder Option Card to

return the replaced Second Encoder Option Card

Consideration Description

Input Dual Channel Plus Marker, Isolated with differential transmitter Output

(Line Drive) Incremental, Dual Channel Quadrature type

Encoder Voltage Supply 5V dc or 12V dc 320 mA per channel

Maximum Input Frequency 400 kHz

Page 12

Publication 20D-IN009A-EN-P - August 2004 P/N 342528-P01

Copyright © 2004 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...