Page 1

Installation Instructions

Multi-Device Interface Option Board for

PowerFlex® 700S Drives

ATTENTION: To avoid an electric shock hazard, ensure that

all power to the drive has been removed before performing the

!

following.

ATTENTION: To avoid an electric shock hazard, verify that

the voltage on the bus capacitors has discharged before

!

performing any work on the drive. Measure the DC bus voltage

at the DC+ & DC- terminals. The voltage must be zero.

ATTENTION: HOT surfaces can cause severe burns. Do not

touch the heatsink surface during operation of the drive. After

!

disconnecting power allow time for cooling.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

What This Kit Contains

ATTENTION: Hazard of permanent eye damage exists when

using optical transmission equipment. This product emits intense

!

light and invisible radiation. Do not look into SynchLink

fiber-optic ports or SynchLink fiber-optic cable connectors.

ATTENTION: The sheet metal cover and mounting screws on

the ASIC Board located on the power structure are energized at

!

(-) DC bus potential high voltage. Risk of electrical shock,

injury, or death exists if someone comes in contact with the

assembly.

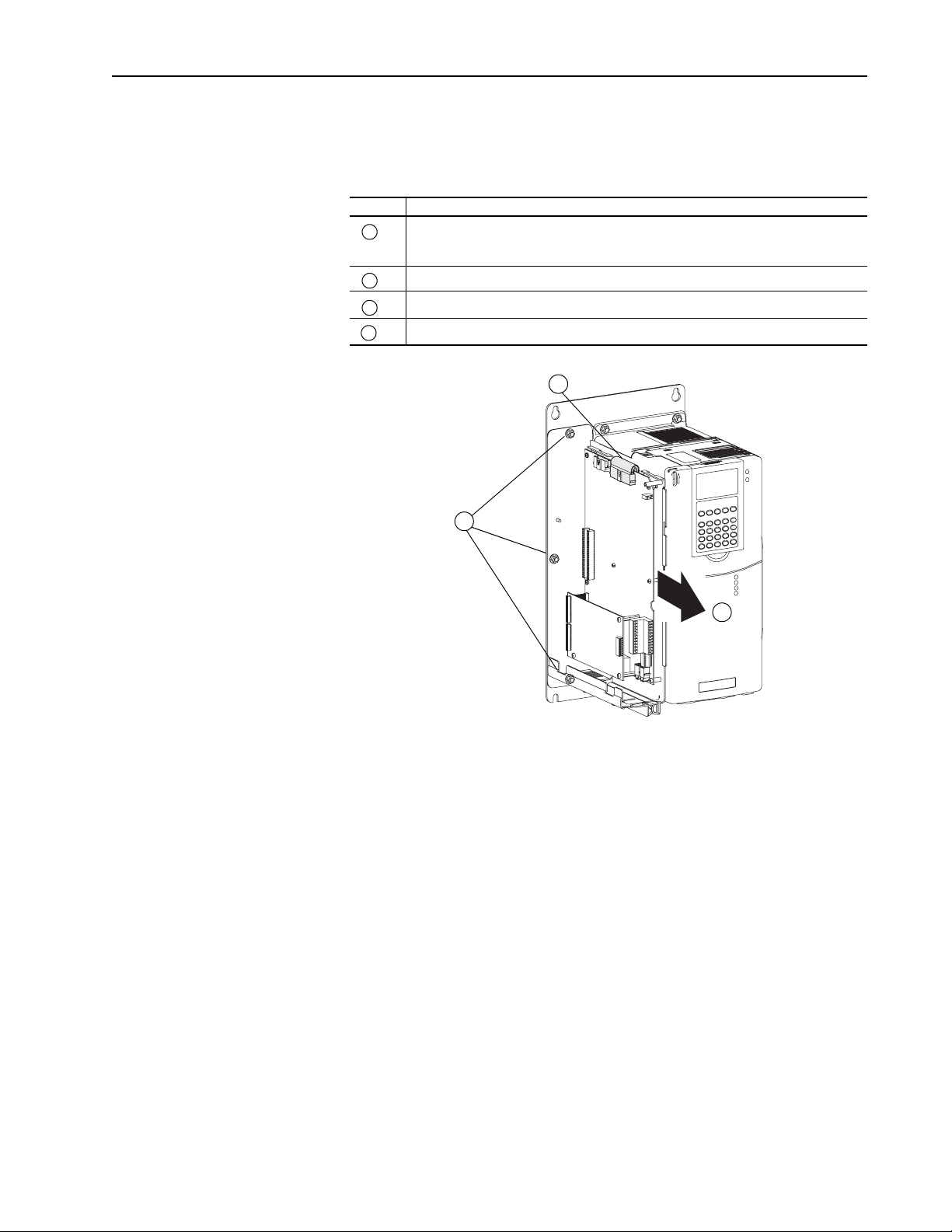

Verify that your kit contains the items listed in the following table. If your

kit does not contain the correct items, contact your Rockwell Automation

sales representative.

Quantity: Description

1 MDI Option circuit board

2 “Stacker” connectors

1Screw

3 Stand-offs

Page 2

2 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Tools That You Need

What You Need to Do

• Phillips® screwdriver for M3 screws

• POZIDRIV

• Nut driver or wrench for M3 hex nut

• Nut driver or wrench for M5 hex nut

Phillips® is a registered trademark of Phillips Screw Company

POZIDRIV

To remove the MDI option board from the PowerFlex 700S drive:

To install the new MDI option board on the PowerFlex 700S drive:

®

is a registered trademark of Phillips Screw Company

❐ Step 1: Remove power from drive

❐ Step 2: Remove drive cover(s)

❐ Step 3: Remove Control Assembly from Phase I drive (if necessary)

❐ Step 4: Remove Phase II Control Cassette covers

❐ Step 5: Remove existing MDI option board

❐ Step 6: Install new MDI option board

❐ Step 7: Install Control Assembly on Phase I drive (if removed in step

3)

❐ Step 8: Wire MDI option board

❐ Step 9: Install Phase II control cassette covers

❐ Step 10: Document revision changes

❐ Step 11: Install drive cover(s)

®

screwdriver for M4 screws (for high power drives only)

Step 1: Remove Power from the Drive

To return replaced MDI option board, use packing material from the new

MDI option board.

ATTENTION: To avoid an electric shock hazard, verify that

the voltage on the bus capacitors has discharged before

!

performing any work on the drive. Measure the DC bus voltage

at the +DC & –DC terminals of the Power Terminal Block (DC+

& DC- in high power drives). The voltage must be zero.

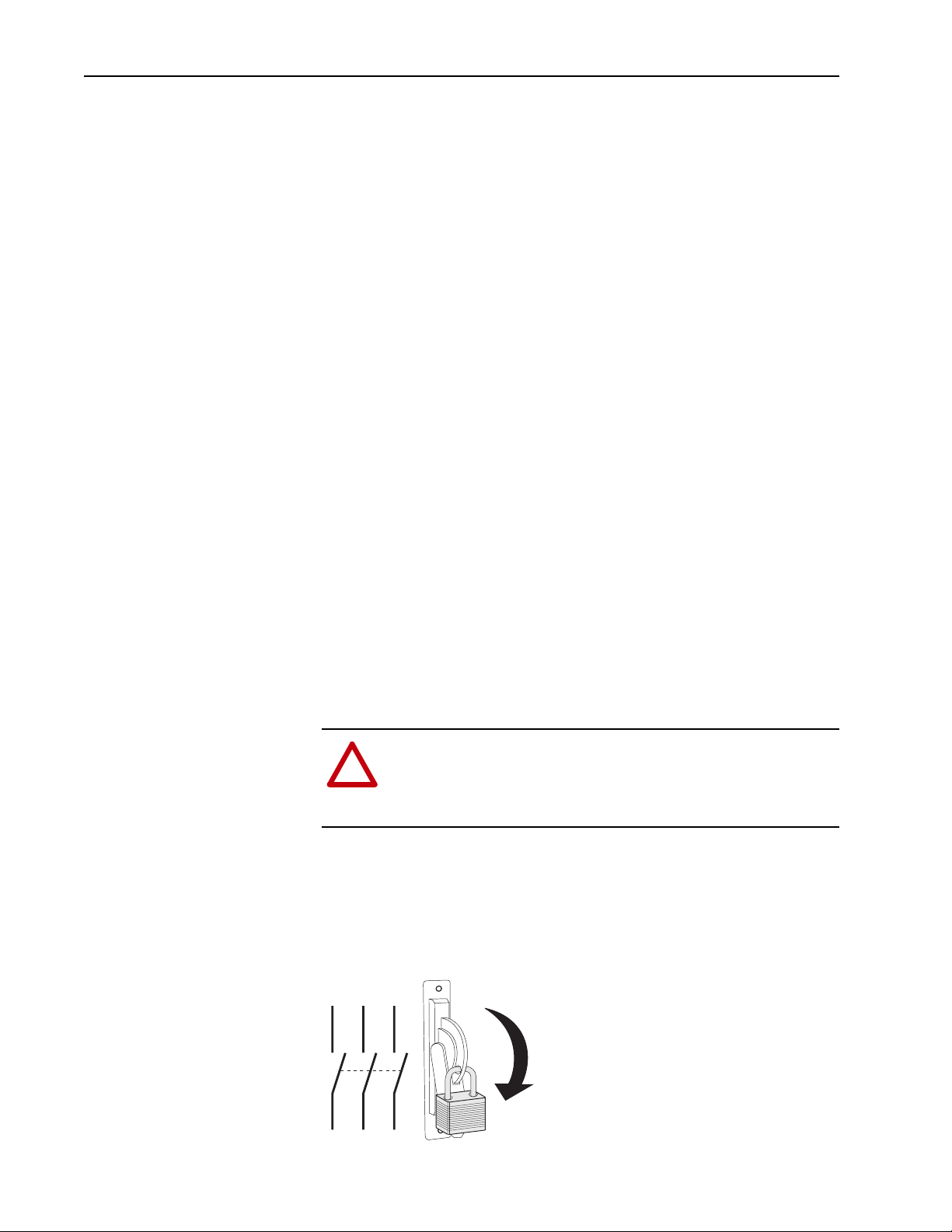

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power terminals.

3. Measure the DC bus voltage at the DC+ & DC- terminals on the Power

Terminal Block. The voltage must be zero.

L1 L2 L3

I

O

Page 3

Multi-Device Interface Option Board for PowerFlex® 700S Drives 3

Ph

Step 2: Remove the Drive Cover(s)

=

B

C

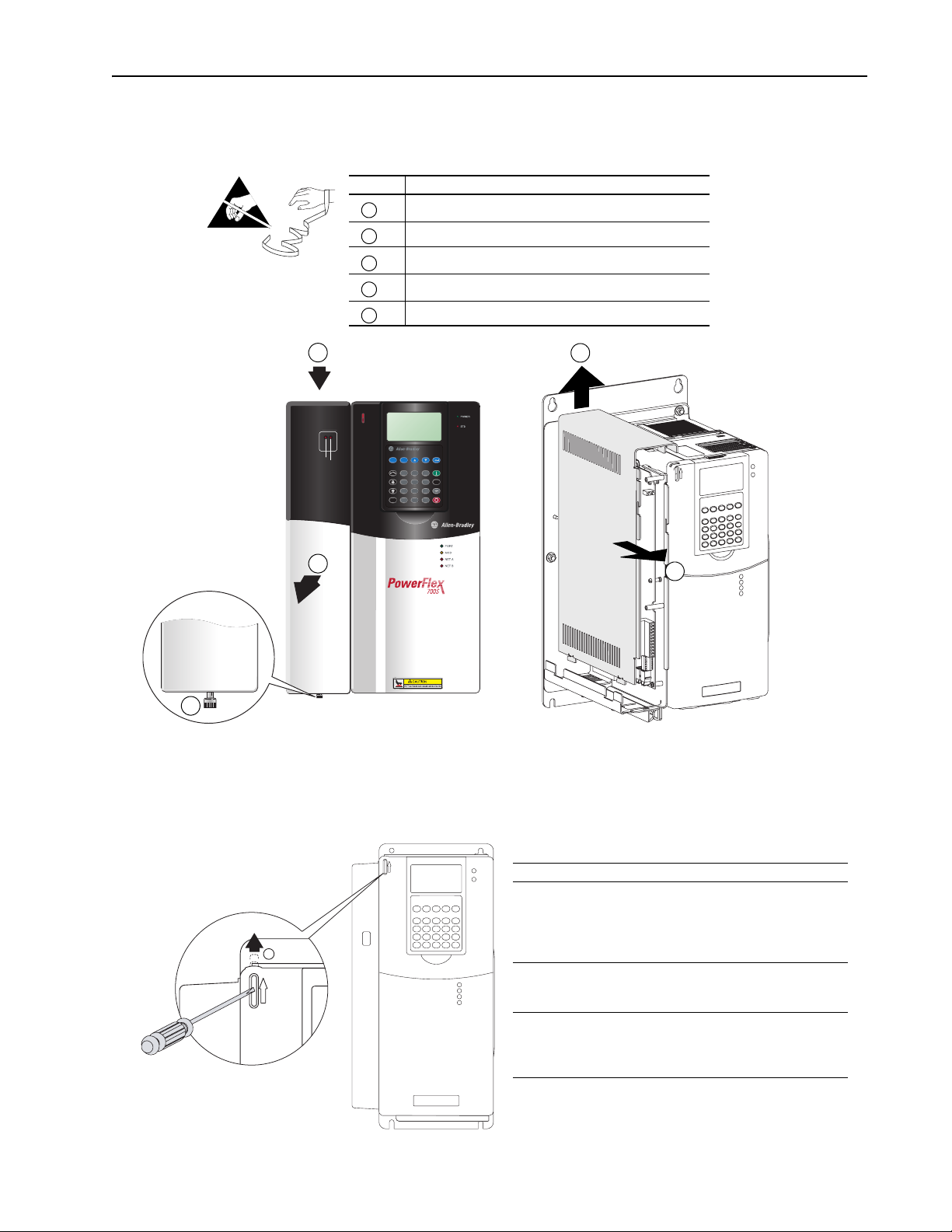

Frame 1 - 6 Size Drives

ase I Control

Tas k Ac ti on

Loosen the captive screw.

A

Push down on the front cover.

B

Pull the front cover away from the assembly.

C

Pull the side cover forward.

D

Lift the side cover off of the control assembly.

E

DRIVE

DRIVE

R

e

o

m

e

v

L

n

a

g

E

x

it

.

.T

S

.R

.M

.A

n

a

/ M

A

u

ENABLE

SYNCHLINK

Esc

Alt

Sel

7 8 9

4 5 6

1 2 3

.

0 +/-

Exp

to

Jog

Param #

E

D

A

Phase II Control

Action

Frames 1-4

Locate the slot in the upper left corner of the drive cover. Slide

the locking tab up and swing the cover open. Special hinges

allow cover to move away from drive and lay on top of an

adjacent drive (if present).

Frame 5

Slide the locking tab up, loosen the right-hand cover screw and

remove the cover.

Frame 6

Loosen the two screws at the bottom of the drive cover. Carefully

slide the bottom cover down and out. Loosen the two screws at

the top of the cover and remove the cover.

Page 4

4 Multi-Device Interface Option Board for PowerFlex® 700S Drives

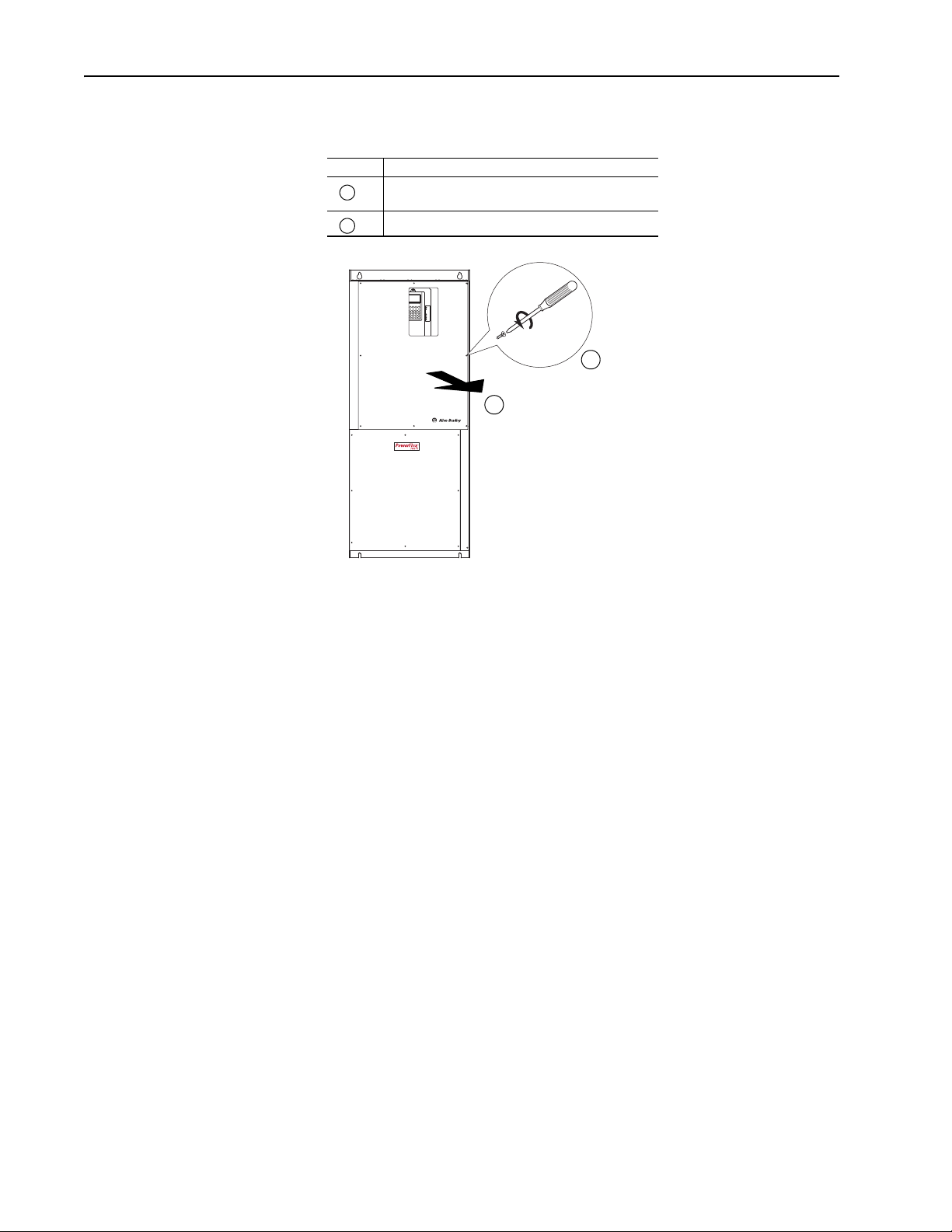

Frame 9 Size Drives

Tas k Ac ti on

Remove the eight screws that secure the top cover to

A

the drive frame using a POZIDRIV screwdriver.

Remove the top (power) cover.

B

The proper tightening

torque for reassembly

is 20 lb.•in.

8 Screws

B

Frame 10 - 13 Size Drives

Open the door of the drive enclosure containing the control frame.

A

Page 5

Multi-Device Interface Option Board for PowerFlex® 700S Drives 5

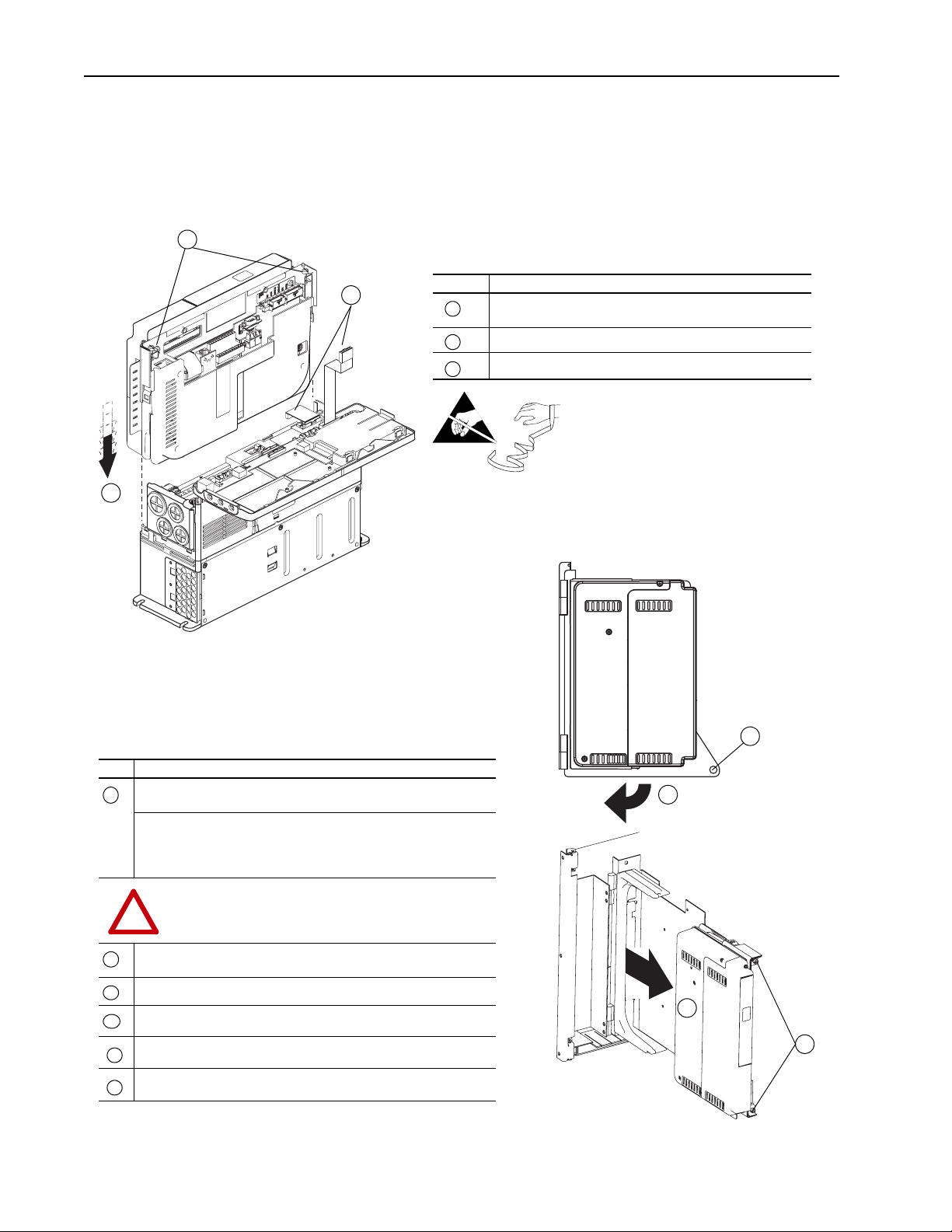

Step 3: Remove the Control Assembly from Phase I Drive (if necessary)

This step is necessary only when another drive or panel component blocks

access to the control assembly on Phase I drives. Avoid removing it if

possible.

Task Description

Unplug any I/O and SynchLink cables from the main control board, unplug the feedback

A

wiring from MDI Option board, and unplug any communication cables from the DriveLogix

controller.

Unplug the ribbon cable.

B

Remove the three M5 nuts that secure the control assembly to the drive frame.

C

Remove the control assembly from the drive.

D

B

C

Proper tightening

torque for reassembly

is 18 lb.•in.

D

Page 6

6 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Step 4: Remove the Phase II Control Cassette Covers

B

BR1

B

R

2

D

C+

D

C

-

PE

U/T1

V/T2

W/T3

R/L1

C

L2

It is necessary to remove the cassette from the drive before removing the

cassette covers for Phase II control.

Remove the Phase II Control Cassette from the Drive

Frame 1 - 6 Size Drives

A

Task Action

Disconnect the cables at the ends that connect to the Main

A

Control board.

Loosen the screws on the face of the cassette.

B

Remove the cassette from the drive.

C

=

Frame 9 - 13 Size Drives

Important:Before removing connections and wires, mark

the connections and wires to avoid incorrect

wiring during assembly.

Task Description

Unplug any fiber optic ControlNet and SynchLink cables from the

A

Control Assembly.

Important: Minimum inside bend radius for SynchLink and ControlNet

fiber-optic cable is 25.4 mm (1 in.). Any bends with a shorter inside

radius can permanently damage the fiber-optic cable. Signal

attenuation increases with decreased inside bend radii.

Attention: Hazard of permanent eye damage exists when

using optical transmission equipment. This product emits

intense light and invisible radiation. Do not look into fiber-optic

!

ports or fiber-optic cable connectors.

Unplug any remaining I/O and communications cables from the

B

Control Assembly and set them aside.

Loosen the captive screw .

C

Swing the Control Assembly away from the control frame.

D

Loosen the screws on the face of the cassette.

E

Remove the cassette from the drive.

F

C

D

F

E

Page 7

Multi-Device Interface Option Board for PowerFlex® 700S Drives 7

Remove the Phase II Cassette Covers (All Drive Sizes)

Removing the Side Covers

Task Description

Loosen the screws on the front cover and

A

remove the cover.

Loosen the screws on the side of the rear cover

B

and remove the cover.

A

Proper tightening torque

for reassembly is 6 lb.•in.

=

B

Step 5: Remove the Existing MDI Option Board

Task Description

Remove the screw that secures the board to the control frame.

A

Loosen the captive screws.

B

Remove the MDI Option board, through-board pin connectors and insulating washer from

C

main Control board.

Remove the stand-offs from main Control board (on Phase I drives only).

D

B

A

C

D

Note: Phase I shown.

Page 8

8 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Step 6: Install the New MDI Option Board

Phase I Drives

Task Description

Remove terminal block P1 from the Resolver Feedback option board. It is much easier to

A

remove before the board is installed.

Install and tighten the stand-offs (min/max 7 in•lb / 10 in•lb).

B

Insert the short pins of the through-board pin connectors into the mating connectors on the

C

main Control board. The end with the short pins must plug into the main Control board.

Plug the mating connectors of the MDI Feedback option board onto the long pins of

D

through-board pin connectors. The end with the longer pins must plug into the MDI

Feedback option board.

Secure the board to the stand-offs, using the screw (supplied with this kit) and the captive

E

screws on the circuit board. Tighten the screws using a phillips screwdriver (min/max 6

in.•lb. / 8 in.•lb.).

The end with longer pins must

plug into the MDI option board

D

D

C

C

B

E

Note: Phase I shown.

Important:Do not use a screwdriver to pry the P1 terminal block from the

circuit board. This may damage the terminal block.

The end with short pins must

plug into the main control board

Page 9

Phase II Drives

Task Description

Remove the P1 terminal block from the MDI Feedback option board. It is much easier to

A

remove before the board is installed.

Insert the short pins of the through-board pin connectors into the mating connectors on the

B

main Control board. The end with the short pins must plug into the main Control board.

Plug the mating connectors of the MDI Feedback option board onto the long pins of the

C

through-board pin connectors. The end with longer pins must plug into the MDI Feedback

option board.

Secure the board to the stand-offs, using the screw supplied with this kit and the captive

D

screws on the circuit board. Tighten the screws using a phillips screwdriver (min/max 6

in.•lb. / 8 in.•lb.).

Multi-Device Interface Option Board for PowerFlex® 700S Drives 9

The end with longer pins must

plug into the MDI Feedback

option board

Step 7: Install the Control Assembly on a Phase I Drive (if removed in Step 3)

D

B

C

The end with short pins

must plug into the main

control board

Important:Do not use a screwdriver to pry the P1 terminal block from the

circuit board. This may damage the terminal block.

The procedure for installing the Control Assembly is the reverse of removal.

Refer to Remove the Control Assembly from Phase I Drive (if

necessary) on page 5.

D

D

Page 10

10 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Step 8: Wire the MDI Option Board

Terminal block P1 contains connection points for a linear sensor, rotary

encoder and registration strobe. This terminal block resides on the MDI

Option board

.

TIP: On Phase I drives, remember to route wires through the

sliding access panel at the bottom of the Control Assembly.

Terminal Signal Description

17 Rotary Encoder POWER COMMON Power supply for Rotary Encoder interface

16 Rotary Encoder POWER

15 Rotary Encoder REFSIN Positive Sine signal for Rotary Encoder interface

14 Rotary Encoder +SIN Negative Sine signal for Rotary Encoder interface

13 Rotary Encoder REFCOS Negative Cosine signal for Rotary Encoder interface

12 Rotary Encoder +COS Positive Cosine signal for Rotary Encoder interface

11 Rotary Encoder DATA+ (RS485) Positive DH485 terminal for Rotary Encoder interface

10 Rotary Encoder DATA- (RS485) Negative DH485 terminal for Rotary Encoder interface

9 Linear Sensor CLOCK+ Positive Clock terminal for Linear Sensor interface

8 Linear Sensor CLOCK- Negative Clock terminal for Linear Sensor interface

7 Linear Sensor DATA+ Positive SSI terminal for Linear Sensor interface

6 Linear Sensor DATA- Negative SSI terminal for Linear Sensor interface

1 5432 876 913121110 161514 17

5 Rotary Encoder REGISTRATION+ Positive terminal for Rotary Encoder registration strobe

4 Rotary Encoder REGISTRATION- Negative terminal for Rotary Encoder registration strobe

3 Linear Sensor REGISTRATION+ Positive terminal for Linear Sensor registration strobe

2 Linear Sensor REGISTRATION- Negative terminal for Linear Sensor registration strobe

1 CHASSIS GND Connection point for cable shields

Page 11

Multi-Device Interface Option Board for PowerFlex® 700S Drives 11

Recommended Cables

If you are using this motor and feedback device: Use this cable: See this wiring diagram:

Temposonics R-Series Linear sensors with MTS part

numbers ending in 1S2G1102

Allen-Bradley 1326AB-BXXXX-M2L, -M2KXL, -S2L,

and -S2KXL motors with embedded Stegmann rotary

encoder

Allen-Bradley MPL-A5xx and MPL-Bxxx motors

motors with embedded Stegmann rotary encoder

Allen-Bradley 1326AB-BXXXX-M2L, -M2KXL, -S2L,

and -S2KXL motors with embedded Stegmann rotary

encoder

Allen-Bradley MPL-A5xx and MPL-Bxxx motors

motors with embedded Stegmann rotary encoder

Allen-Bradley MPL-A3xx - MPL-A45xx and all MPG

series motors with embedded Stegmann rotary

encoder

Allen-Bradley MPL-A3xx - MPL-A45xx and all MPG

series motors with embedded Stegmann rotary

encoder

HPK-Series motors with embedded Stegmann rotary

encoder

Any other motor with external Stegmann SHS-170

rotary encoder

Any other motor with external Stegmann SCS-60,

SCS-70, SCM-60 or SCM-70, SRS-50, SRS-60,

SRM-60, SRM-60, SRS-25 or SRM-25 rotary encoder

Any other motor with external Stegmann SCS-Kit 101

or SCK-Kit 101 rotary encoder

Any other motor with external Stegmann SRS660

rotary encoder

Mating MTS molded extension cable for RG connector or integral

Figure 1 on page -11

P cable

Allen-Bradley 2090-CDNFDMP-SXX Figure 2 on page -12

Allen-Bradley 2090-CDNFDMP-SXX Figure 2 on page -12

Allen-Bradley 2090-XXNFMP-SXX Figure 3 on page -12

Allen-Bradley 2090-XXNFMP-SXX Figure 3 on page -12

Allen-Bradley 2090-XXNFMP-SXX Figure 4 on page -12

Allen-Bradley 2090-UXNFDMP-SXX Figure 5 on page -13

Allen-Bradley 2090-XXNFMF-SXX Figure 6 on page -13

Stegmann shielded twisted-pair cable with 12-pin DIN style

Figure 7 on page -13

connector

Stegmann shielded twisted-pair cable with 10-pin MS style

Figure 8 on page -14

connector

Stegmann shielded twisted-pair cable with 8-pin Berg style

Figure 9 on page -14

connector

Is available only with pre-attached Stegmann shielded

Figure 10 on page -14

twisted-pair cable of various lengths

Connection Examples

Figure 1 Linear Sensor connections with MDI RG connector or P integral cable

EXTERNAL

SUPPLY

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

24 Vdc

POWER

COMMON

CHASSIS GND

POWER

RD or BN

WH

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

YE

GN

GY

PK

WH

RD or BN

GN

YE

GY

PK

LINEAR SENSOR

No Connection

7

DC Ground

6

+24 Vdc

5

(-) CLOCK

4

(+) CLOCK

3

(+) DATA

2

(-) DATA

1

Page 12

12 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Connection Examples

Figure 2 Rotary Encoder connections for MPL-A5xx and MPL-Bxxx motors or 1326AB-BXXXX-M2L, -M2KXL, -S2L, and

-S2KXL motors with 2090-CDNFDMP-SXX cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

WH/OR

OR

BK/WH

BK

WH/RD

RD

GN

WH/GN

BU

WH/BU

BK

BK/WH

RD

WH/RD

GN

WH/GN

OR

WH/OR

BU

WH/BU

ROTARY ENCODER

+SIN

A

REFSIN

B

+COS

C

REFCOS

D

DATA+ (RS-485)

E

DATA- (RS 485)

F

POWER

N

COMMON

P

TS+

R

TS-

S

Figure 3 Rotary Encoder connections for MPL-A5xx and MPL-Bxxx motors or 1326AB-BXXXX-M2L, -M2KXL, -S2L, and

-S2KXL motors with 2090-XXNFMP-SXX cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

WH/GY

OR

BK/WH

BK

WH/RD

RD

GN

WH/GN

BK

BK/WH

RD

WH/RD

GN

WH/GN

OR

WH/GY

ROTARY ENCODER

+SIN

A

REFSIN

B

+COS

C

REFCOS

D

DATA+ (RS-485)

E

DATA- (RS 485)

F

POWER

N

COMMON

P

TS+

R

TS-

S

Note: Thermal Switch cannot be accessed using 2090-XXNFMP-SXX cable.

Figure 4 Rotary Encoder connections for MPL-A3xx - MPL-A45xx and all MPG series motors with 2090-XXNFMP-SXX cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

Rotary Encoder +COS

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

WH/GY

GY

BK/WH

BK

WH/RD

RD

GN

WH/GN

BK

BK/WH

RD

WH/RD

GN

WH/GN

GY

WH/GY

ROTARY ENCODER

+SIN

A

REFSIN

B

+COS

C

REFCOS

D

DATA+ (RS-485)

E

DATA- (RS 485)

F

POWER

N

COMMON

P

TS+

R

TS-

S

Note: Thermal Switch cannot be accessed using 2090-XXNFMP-SXX cable.

Page 13

Multi-Device Interface Option Board for PowerFlex® 700S Drives 13

Connection Examples

Figure 5 Rotary Encoder connections for MPL-A3xx - MPL-A45xx and all MPG series motors with 2090-UXNFDMP-SXX cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

WH/GY

GY

BK/WH

BK

WH/RD

RD

BU

WH/BU

GN

WH/GN

BK

BK/WH

RD

WH/RD

GN

WH/GN

GY

WH/GY

BU

WH/BU

ENCODER

A

+SIN

B

REFSIN

C

+COS

D

REFCOS

E

DATA+ (RS-485)

F

DATA- (RS 485)

K

POWER

L

COMMON

R

TS+

S

TS-

Figure 6 HPK-Series motors with 2090-XXNFMF-SXX cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

WH/GY

OR

BK/WH

BK

WH/RD

RD

GN

WH/GN

Note: Thermal Switch cannot be accessed using 2090-XXNFMP-SXX cable.

Figure 7 Stegmann shielded twisted-pair cable with 12-pin DIN style connector

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BU

RD

BN

WH

BK

PK

GY

GN

BK

BK/WH

RD

WH/RD

GN

WH/GN

OR

WH/GY

RD

BU

PK

GN

BN

WH

GY

BK

ENCODER

+SIN

A

REFSIN

B

C

+COS

REFCOS

D

DATA+ (RS-485)

E

DATA- (RS 485)

F

POWER

N

COMMON

P

TS+

R

TS-

S

ROTARY ENCODER

POWER

12

N/C

11

POWER COMMON

10

SHIELD

9

+COS

8

DATA- (RS 485)

7

REFSIN

6

+SIN

5

N/C

4

N/C

3

DATA+ (RS 485)

2

REFCOS

1

Page 14

14 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Connection Examples

Figure 8 Rotary Encoder connections with Stegmann shielded twisted-pair cable and 10-pin MS style connector

ROTARY ENCODER

POWER

A

POWER COMMON

B

REFSIN

C

REFCOS

D

DATA+ (RS 485)

E

DATA- (RS 485)

F

+SIN

G

+COS

H

N/C

I

SHIELD

J

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BU

RD

BN

WH

BK

PK

GY

GN

RD

BU

BN

BK

GY

GN

WH

PK

Figure 9 Rotary Encoder connections with Stegmann shielded twisted-pair cable and 8-pin Berg style connector

ROTARY ENCODER

1

POWER

2

POWER COMMON

3

REFSIN

4

REFCOS

5

DATA+ (RS 485)

6

DATA- (RS 485)

7

+SIN

8

+COS

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BU

RD

BN

WH

BK

PK

GY

GN

RD

BU

BN

BK

GY

GN

WH

PK

Figure 10 Rotary Encoder connections with Stegmann pre-attached shielded twisted-pair cable

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

CHASSIS GND

MDI Feedback Option Board

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BU

RD

BN

WH

BK

PK

GY

GN

BU

RD

BN

WH

BK

PK

GY

GN

POWER COMMON

POWER

REFSIN

+SIN

REFCOS

+COS

DATA+ (RS 485)

DATA- (RS 485)

ROTARY ENCODER

Page 15

Connection Examples

Figure 11 Registration Sensor connection

Multi-Device Interface Option Board for PowerFlex® 700S Drives 15

EXTERNAL

12 or 24 Vdc

POWER

SUPPLY

Rotary Encoder POWER COMMON

Rotary Encoder POWER

Rotary Encoder REFSIN

Rotary Encoder +SIN

Rotary Encoder REFCOS

Rotary Encoder +COS

Rotary Encoder DATA+ (RS485)

Rotary Encoder DATA- (RS485)

Linear Sensor CLOCK+

Linear Sensor CLOCK-

Linear Sensor DATA+

Linear Sensor DATA-

Rotary Encoder REGISTRATION+

Rotary Encoder REGISTRATION-

Linear Sensor REGISTRATION+

Linear Sensor REGISTRATION-

POWER

COMMON

CHASSIS GND

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Step 9: Install the Phase II Control Cassette Covers

MDI Feedback Option Board

Rotary

Registration Sensor

Powe r+

Common

Linear

Registration Sensor

Powe r+

Common

In order to install the Phase II Control Cassette in the drive, you must first

install the covers.

Installing the Phase II Cassette Covers

Installing the Side Covers

Task Description

Secure the rear cover to the cassette with three

A

screws.

Secure the front cover to the cassette with two

B

screws.

B

Proper tightening torque

for reassembly is 6

lb.•in.

=

A

Page 16

16 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Install the Phase II Control Cassette

A

B

Frame 1 - 6 Size Drives

Task Action

C

Slide the control cassette onto the mounting bracket.

A

Tighten the screws on the face of the cassette.

B

Connect the cables at the ends that connect to the main

C

Control board.

=

BR1

B

R

2

D

C+

D

C

-

PE

U/T1

V/T2

W/T3

R/L1

L2

Frame 9 - 13 Size Drives

Task Description

Slide the cassette onto the mounting bracket.

A

Tighten the screws on the face of the cassette.

A

B

B

Swing the Control Assembly in toward the control frame.

C

Tighten the captive screw.

D

Plug any I/O and communications cables in to the Control Assembly.

E

Attention: Hazard of permanent eye damage exists when

using optical transmission equipment. This product emits

intense light and invisible radiation. Do not look into fiber-optic

!

ports or fiber-optic cable connectors.

Important: Minimum inside bend radius for SynchLink and ControlNet

F

fiber-optic cable is 25.4 mm (1 in.). Any bends with a shorter inside

radius can permanently damage the fiber-optic cable. Signal

attenuation increases with decreased inside bend radii.

Unplug any fiber optic ControlNet and SynchLink cables from the

Control Assembly.

C

D

Page 17

Multi-Device Interface Option Board for PowerFlex® 700S Drives 17

Step 10: Document the Change

Document the installation of the MDI option board on the Field Installed

Options label. Use the blank line if you are installing the MDI option board

in a drive that was manufactured without it.

Frame 1 - 6 Size Drives

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

20-HIM

HIM

28-IO20-COMM20B_-DB1-

I/O

COM Module

Internal Dynamic Brake

Firmware #: Date

Firmware

20-HIM

28-IO20-COMM20B_-DB1-

TIP: Use packing material from new MDI option board to return the

replaced MDI option board

Frame 9 - 13 Size Drives

FIELD INSTALLED OPTIONS

#: Date

HIM

I/O

COM Module

Internal Dynamic Brake

Frame 9

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

HIM

20-HIM

I/O

28-IO-

COM Module

20-COMM-

Internal Dynamic Brake

20B_-DB1-

Frames 10 & 11

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

20-HIM

HIM

28-IO-

I/O

COM Module

20-COMM-

Internal Dynamic Brake

20B_-DB1-

FIELD INSTALLED OPTIONS

Firmware #: Date

#: Date

Firmware

20-HIM

28-IO20-COMM20B_-DB1-

HIM

I/O

COM Module

Internal Dynamic Brake

Page 18

18 Multi-Device Interface Option Board for PowerFlex® 700S Drives

Step 11: Install the Drive Cover(s)

Phase I Drives Frames 1 - 6

The procedure for installing the covers on Phase I drives, frames 1 - 6, is the

reverse of removal. Refer to Remove the Drive Cover(s)

on page 3.

Phase II Drives Frames 1 - 6

The procedure for installing the covers on Phase II drives, frames 1 - 6, is

the reverse of removal. Refer to Remove the Drive Cover(s)

on page 3.

Frame 9 Size Drives

The procedure for installing covers on frame 9 size drives is the reverse of

removal. Refer to Frame 9 Size Drives

on page 4.

Frame 10 - 13 Size Drives

The procedure for installing covers on frame 10 - 13 size drives is the

reverse of removal. Refer to Frame 10 - 13 Size Drives

on page 4.

Specifications

MDI Option Board Specifications

Consideration Description

Rotary Encoder Voltage Supply 11.5V dc @ 130 mA

Rotary Encoder Hi-Resolution

Feedback

Rotary Encoder Maximum Cable

Length

Rotary Encoder RS-485 Interface The MDI Option board obtains the following information via the

Registration Inputs high speed 12-24V dc sinking digital inputs

Customer-I/O plug (P1) Allen-Bradley PN: S94274917

Sine/Cosine 1V P-P Offset 2.5

90m (295 ft.)

Hiperface RS-485 interface shortly after power-up:

• Address

• Command Number

• Mode

• Number of turns

• Number of Sine/Cos cycles

• Checksum

Weidmuller PN: 67601782

Page 19

Multi-Device Interface Option Board for PowerFlex® 700S Drives 19

Supported Linear Sensors

Important:Only one Linear Sensor can be installed at a time.

Temposonics Linear Sensors

Temposonics® R-Series Linear sensors with MTS® part numbers ending in

1S2G1102 work with the MDI Option.

Part Number

Character Characteristic

1 Input Voltage = +24V dc

S SSI output

2 Data Length = 24 Bits

G Output Format = Gray Code

1 Resolution = 0.005 mm

1 Performance = Standard

02 Scale Orientation = Forward-acting Synchronized

Temposonics® is a registered trademark of MTS Systems Corporation.

Stahltronic Linear Sensor

Stahltronic WCS Position Encoding System works with the MDI Option.

Characteristic

Input Voltage = +24V dc

SSI output

Data Length = 19 Bits

Output Format = Binary or Gray Code

Resolution = 0.80 mm

Supported Rotary Encoders

Please note that encoders must be ordered as "Single Ended". This will

ensure that the RS-485 channel has the proper termination network installed

at the factory.

Model Resolution Comment

SINCOS® SCS-60, SCS-70,

SCM-60, and SCM-70

SINCOS® SCS-KIT-101 and

SCM-KIT-101

SINCOS® SRS-50, SRS-60,

SRM-50, and SRM-60

SINCOS® SRS/M 25 1024 sine cycles per revolution SRS25 and SRM25 have built-in

SINCOS® SRS660 1024 sine cycles per revolution Hollow-shaft up to 14 mm diameter

SINCOS® SHS-170 512 sine cycles per revolution. While the software supports this

512 sine cycles per revolution. SCM-60 and SCM-70 have built-in

mechanical turns counter.

1024 sine cycles per revolution. SCM-60 and SCM-70 have built-in

mechanical turns counter.

1024 sine cycles per revolution. SRM-50 and SRM-60 have built-in

mechanical turns counter.

mechanical turns counter. IP65

Protection Class. Size 25 square

flange mounting.

encoder, the SHS-170 draws

excessive current and should only be

used with an external power supply.

SINCOS®, SINCODER® and LINCODER® are registered trademarks of Stegmann Inc.

Page 20

A

A

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 20D-IN004B-EN-P - May 2008 P/N 314350-P01

Supersedes 20D-IN004A-EN-P – August 2005 Copyright © 2008 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...