Page 1

Programming Manual

Logix5000 Controllers Import/Export Project Components

Catalog Numbers 1768-L43, 1768-L45

Page 2

Important user information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of

this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with

installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be

carried out by suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Important:

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be

present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc

Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Au tomation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are prope rty of their respective companies.

Page 3

Summary of changes

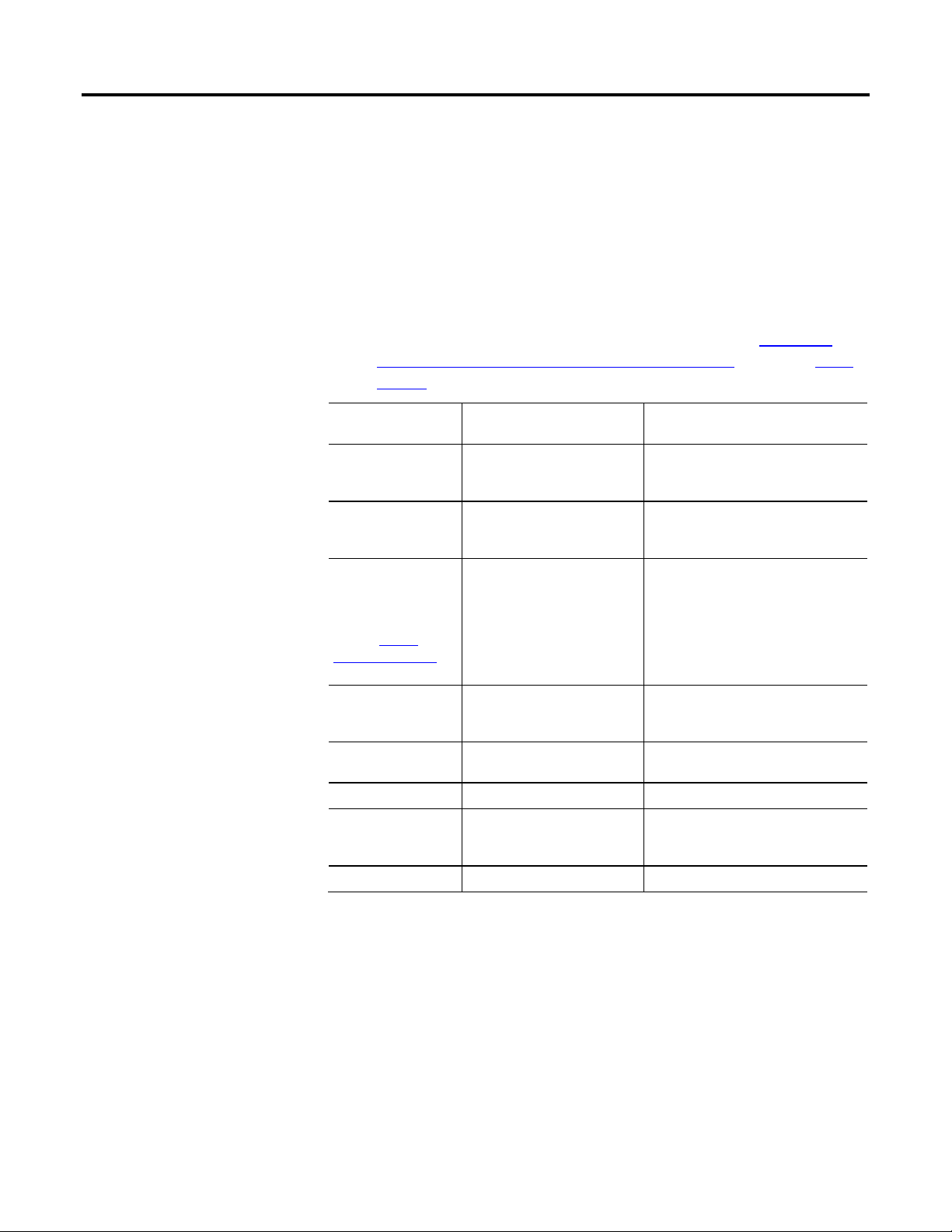

This manual contains new and updated information. This table contains the

changes made to this revision.

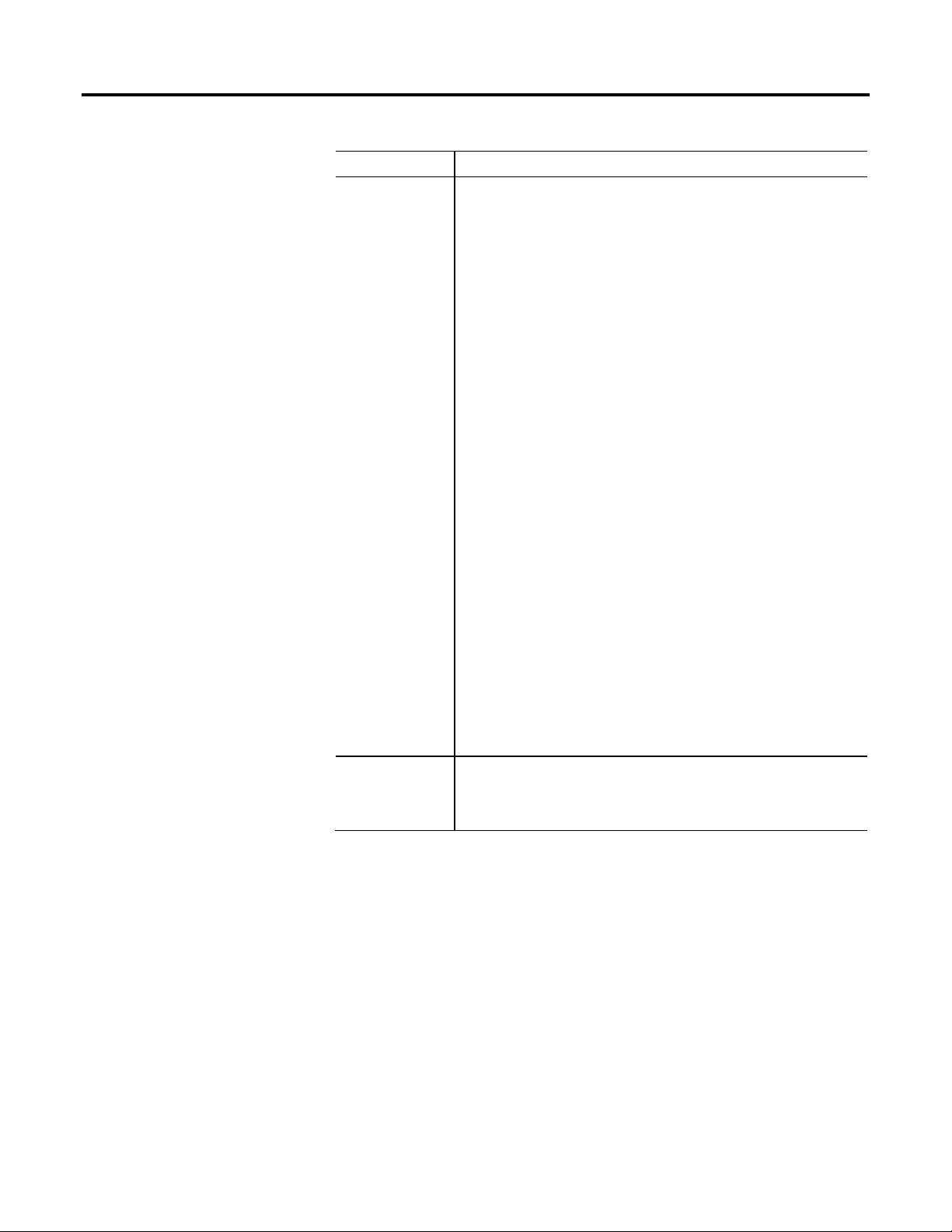

Topic Page

Introduction: Added a description of Library Management. See Introduction on page 9.

Export Components: Updated procedure to explain the

difference between exporting programs from the Logical

Organizer versus the Controller Organizer.

Export Considerations: Added a bullet to explain the difference

between exporting programs from the Logical Organizer versus

the Controller Organizer.

Configure Component Import: Updated dialog box graphic. See Properties for imported components on page

Configure Multiple Components: Added new section to describe

importing multiple components.

Online Import Considerations: Added explanation for new

'Preserve existing tag values in offline project checkbox.

Multiple Components Considerations: Added considerations for

importing multiple components.

Search and Replace: Updated procedure to explain the new

Replace All option.

Equipment Phases: Added new import considerations. See Import considerations on page 43.

Tags: Added new import considerations. See Import considerations on page 43.

See Export logic components on page 11.

See Export logic components on page 11.

16.

See Configure multiple component properties on

page 21.

See Online import on page 12.

See Multiple components on page 15.

See Find and replace on page 35.

Rockwell Automation Publication 1756-PM019E-EN-E - October 2014 3

Page 4

Page 5

Preface

Import and export logic

Additional considerations for

Additional considerations for

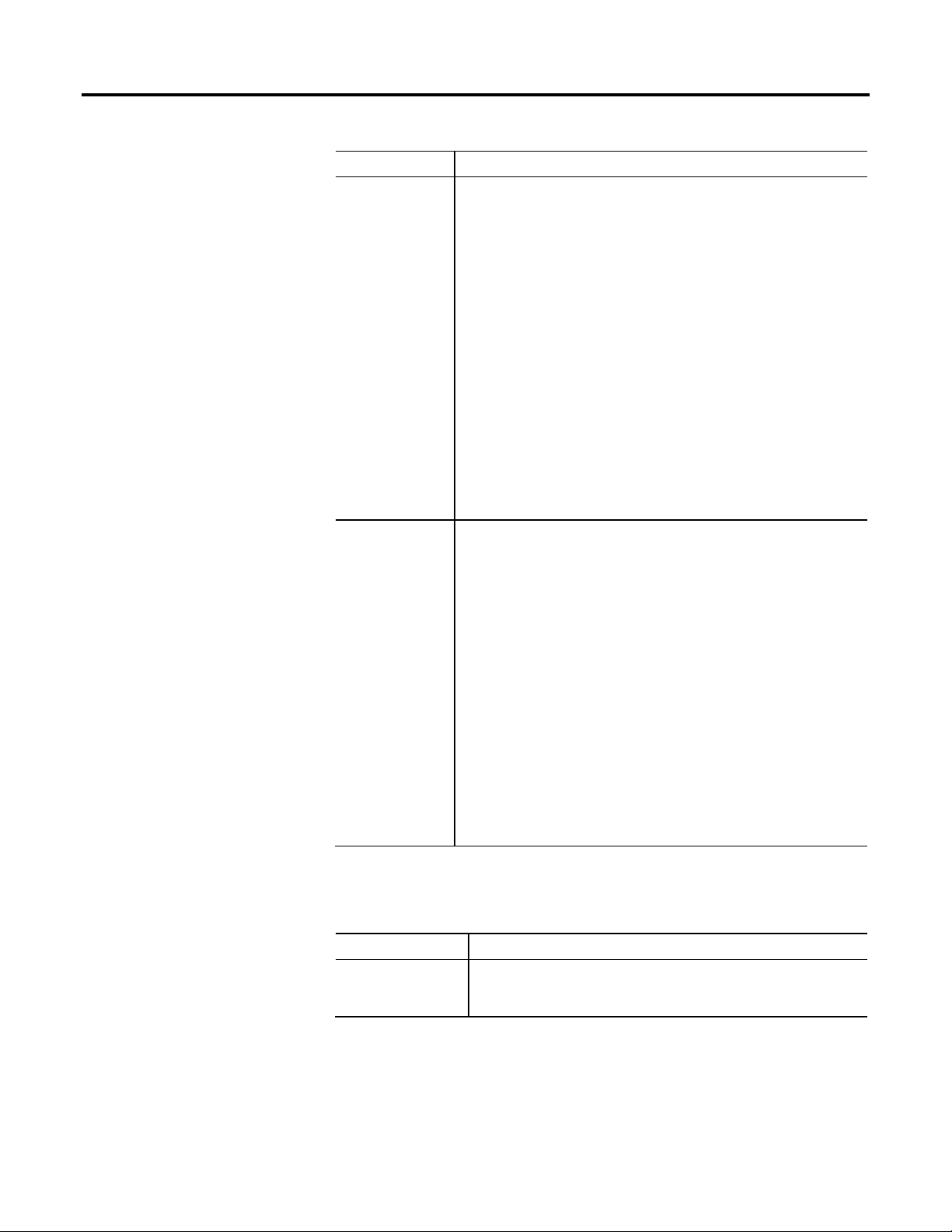

Table of contents

components

Studio 5000 environment ..................................................................................... 7

Chapter 1

Introduction ............................................................................................................ 9

Export considerations .......................................................................................... 10

Export logic components..................................................................................... 11

Import considerations .......................................................................................... 12

Online import ................................................................................................ 12

Motion ............................................................................................................. 14

Safety ................................................................................................................ 15

Security ............................................................................................................ 15

Multiple components ................................................................................... 15

Import logic components .................................................................................... 15

Configuration properties for import ................................................................. 16

Properties for imported components ......................................................... 16

Configure multiple component properties ............................................... 21

Configure program connections ................................................................. 24

Configure component references ............................................................... 29

References configuration example .............................................................. 31

Undefined references .................................................................................... 32

Attention flags ................................................................................................ 33

Errors and warnings on import ................................................................... 33

Project documentation ........................................................................................ 33

Find and replace .................................................................................................... 35

compatibility .................................................................................................. 36

rungs

routines

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 5

Chapter 2

Introduction .......................................................................................................... 39

Export considerations .......................................................................................... 39

Import considerations .......................................................................................... 39

Chapter 3

Introduction .......................................................................................................... 41

Export considerations .......................................................................................... 41

Import considerations .......................................................................................... 41

Page 6

Table of Contents

Additional considerations for

Additional considerations for

Import and export Add-On

Additional considerations for

Index

programs and equipment

phases

user-defined types

Instructions

Chapter 4

Introduction .......................................................................................................... 43

Export considerations .......................................................................................... 43

Import considerations .......................................................................................... 43

Chapter 5

Introduction .......................................................................................................... 45

Export considerations .......................................................................................... 45

Import considerations .......................................................................................... 45

Chapter 6

Introduction .......................................................................................................... 47

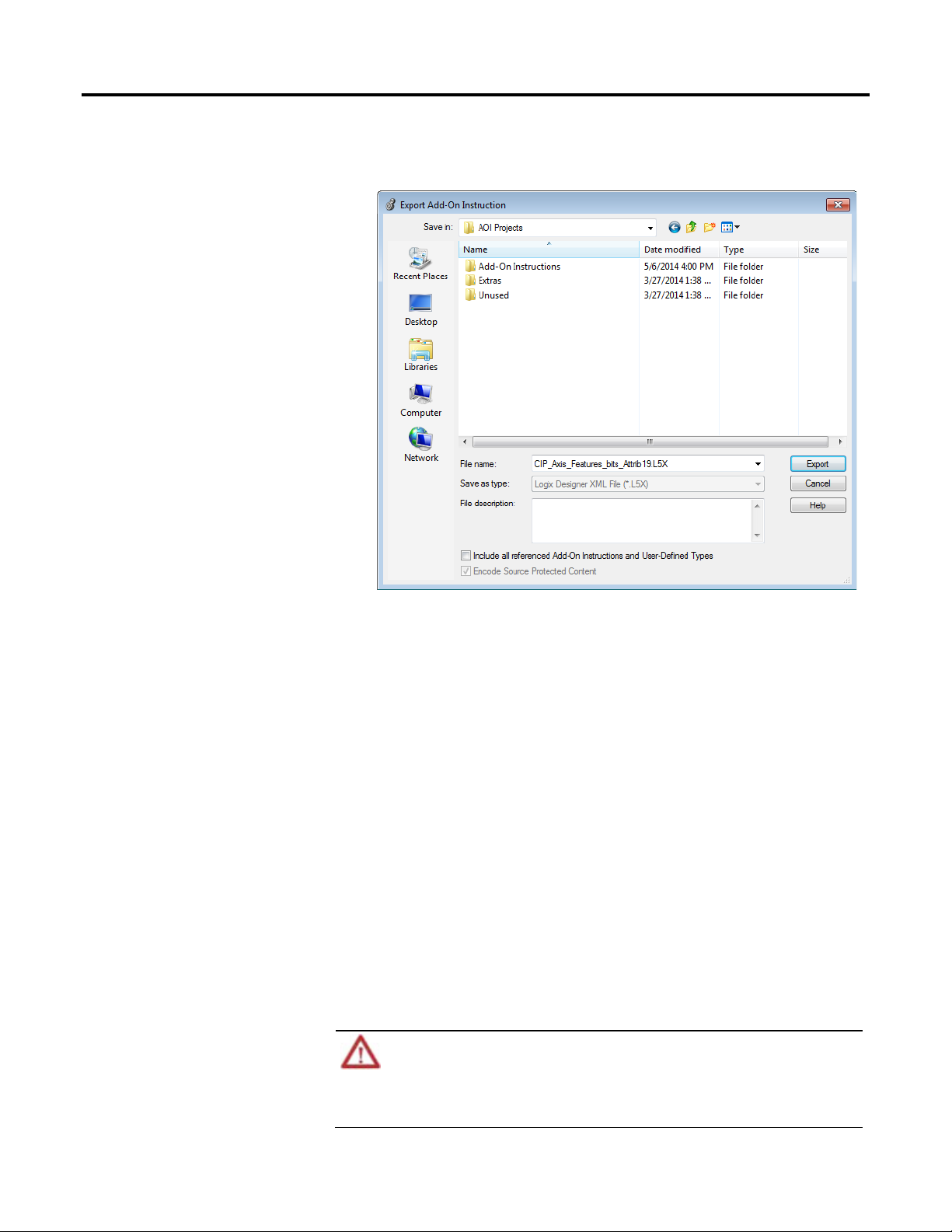

Create export files ................................................................................................. 47

Export to separate files .................................................................................. 48

Export to one file ........................................................................................... 49

Import an Add-On Instruction ......................................................................... 50

Import considerations .................................................................................. 50

Import configuration .................................................................................... 52

Update an Add-On Instruction to a later revision using import ................. 53

tags

6 Rockwell Automation Publication 1756-PM019E-EN-E - October 2014

Chapter 7

Introduction .......................................................................................................... 57

Export considerations .......................................................................................... 57

Import considerations .......................................................................................... 57

Page 7

Studio 5000 environment

Preface

Use this manual to become familiar with importing and exporting project

components for Logix5000 controllers. The project components covered in this

manual include the importing and exporting of rungs, routines, programs and

equipment phases, user-defined types, tags, and Add-On Instructions.

This manual is one of a set of related manuals that show common procedures for

programming and operating Logix5000 controllers.

For a complete list of common procedures manuals, see the

Common Procedures Programming Manual, publication 1756-PM001.

The term Logix5000 controller refers to any controller that is based on the

Logix5000 operating system.

The Studio 5000 Automation Engineering & Design Environment™ combines

engineering and design elements into a common environment. The first element is

the Studio 5000 Logix Designer™ application. The Logix Designer application is

the rebranding of RSLogix™ 5000 software and will continue to be the product to

program Logix5000™ controllers for discrete, process, batch, motion, safety, and

drive-based solutions.

Logix5000 Controllers

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 7

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all elements of their

control system.

Page 8

Page 9

Introduction

Chapter 1

Import and export logic components

This chapter explains import and export of logic components.

You use the Logix Designer application to perform online edits for the Logix

family of controllers.

The import/export functionality provides a greater degree of flexibility during

development and deployment of projects. It supports the ability to export a

component of a Logix Designer project and then import that component into

either the same, or a different project, offline or online (even in Remote Run

mode). It lets you import components to create something new in a project, or to

update something that exists.

You can export and import these logic components offline and online:

• Rungs

• Routines

• Programs and equipment phases

• User-defined data types (UDT)/user-defined string types

• Add-On Instructions

• Trends

Changes or additions to a project that may be impractical to do with online

editing can be completed offline and then imported in one operation into a

running controller by using the extended import/export feature. Engineering

collaboration is also facilitated because many engineers can work on one or more

of the project components independently offline and then use import to merge the

changes into one project.

With online editing, you modify or create a component and then modify other

components referenced by that component in the project sequentially. Importing

online differs from online edits in that it provides the ability to create and delete

components, as well as update referenced components, in one step.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 9

ATTENTION: All Rockwell Automation XML files are encoded in UTF-8 file format. Users editing XML files

must use a text editor like Notepad that supports UTF-8 encoding. If you save the edited file by using a nonUTF-8 compatible editor after making changes, the encoding breaks, resulting in a non-valid XML file.

Page 10

Chapter 1 Import and export logic components

Export considerations

Keep the following considerations in mind when exporting components.

• You may get more than you expected in an .l5x file. Some components

referenced by the exported component are also exported.

• Starting with version 24 of Logix Designer, you can use program parameters

to share data directly between programs in addition to Controller-scoped

tags. For more information on program parameters, see the

Logix5000

Controllers Program Parameters Programming Manual publication 1756PM021.

When exporting a

Set of rungs Rungs Controller-scoped tags, program-scoped tags,

Routine Routine Controller-scoped tags, program-scoped tags,

Program

(For considerations when

exporting multiple

programs using multi-

Multiple

select, see

components on page 15.

Equipment Phase Equipment phase, routines, phase-

User-defined data type User-defined data type User-defined data types, user-defined string

User-defined string type User-defined string type

Add-On Instruction Add-On Instruction, Logic routine and

Trend Trend

The exported component includes

the

Program, routines, and program-scoped

tags

scoped tags, and controller-scoped

PHASE tag

any scan mode routines, and parameter

and local tags

The exported file also includes referenced

user-defined data types, user-defined string

types, Add-On Instructions

user-defined data types, user-defined string

types, Add-On Instructions

Controller-scoped tags, user-defined data types,

user-defined string types, Add-On Instructions

When you export a program from the Logical

Organizer, the program logical hierarchy is

exported in addition to the program specified.

See the online help for information about the

Logical Organizer.

Controller-scoped tags, user-defined data types,

user-defined string types, Add-On Instructions

types, Add-On Instructions

User-defined data types, user-defined string

types, Add-On Instructions

10 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

For example, if you export a rung with an instruction that uses (references) a

bit in a tag that is a user-defined type tag, the export content includes the

referenced tag and the referenced user-defined type, along with the rungs.

When you import the rung, you can choose whether to also import the

referenced tag and user-defined type.

Page 11

Import and export logic components Chapter 1

Export logic components

• Only the offline data values of tags are exported to the .l5x file, even when

the project is online with the controller. When exporting components that

include tags while online, the software prompts you to upload tag values

before exporting the component.

Important:

Whether exporting while offline or online with the controller, only offline data values of tags

are exported to the .l5x file.

• You can export a component that has Test Edits, but the resulting file

cannot be imported. If an .l5x file with Test Edits is selected for import,

then the import aborts.

Follow these steps to export logic components.

1. In the Logix Designer Controller Organizer, select the logic component to

export.

Tip:

Tip:

You can select multiple programs, Add-On Instructions, and user-defined data types for export. See

Import and export Add-On Instructions on page 49 for detailed information.

You can also export logical components from the Logical Organizer, where you can select multiple

programs and include child folders and programs in their hierarchical levels. See the Logix Designer

application online he lp for instructions.

2. Right-click and select Export <logic component> as explained in the

following table.

To export a Choose

Set of rungs (For rung export, select the rungs in the

ladder routine editor.)

Routine

Program

Equipment Phase

User-defined data type

User-defined string type

Add-On Instruction

Trend

Export Rungs

Export Routine

Export Program

Export Equipment Phase

Export Data Type

Export Data Type

Export Add-On Instruction

Export Trend

3. In the File Name box, type a file name for the export file.

Tip:

You can export multiple Add-On Instructions to a single file or to multiple files. See

component properties on page 21 for detailed information.

Configure multiple

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 11

Page 12

Chapter 1 Import and export logic components

The timeout is caused by the (scan time) x (number of changed rungs). You could have a large program with

Import considerations

4. (Optional) In the File description, edit the default description or type a

description, if desired.

A default description is supplied for some component exports.

Tip:

The file description can be viewed in a tooltip during import when selecting which file to import.

5. Click Export.

This section covers general considerations for all component-type imports. See the

chapters for specific components (program, routine, rungs, Add-On Instructions,

user-defined data types, and tags) for additional export and import considerations

for that component, whether it is imported directly or as a reference during

another component import.

Important:

Tip:

When editing online, if the program scan time is large, or the number of modified rungs is large, you might

see HMI and Logix Designer communication timeouts when edits are finalized.

a very fast scan, or a lot of rungs (but you modified only a few), and you do not see a timeout.

Starting with version 24 of Logix Designer application, you can use program parameters to share data between

programs in much the same way that you use controller-scoped tags. Program parameters are imported and

exported in the same way as tags in most instances. For more information on program parameters, see the

Logix5000 Controllers Program Parameters Programming Manual, publication 1756-PM021

.

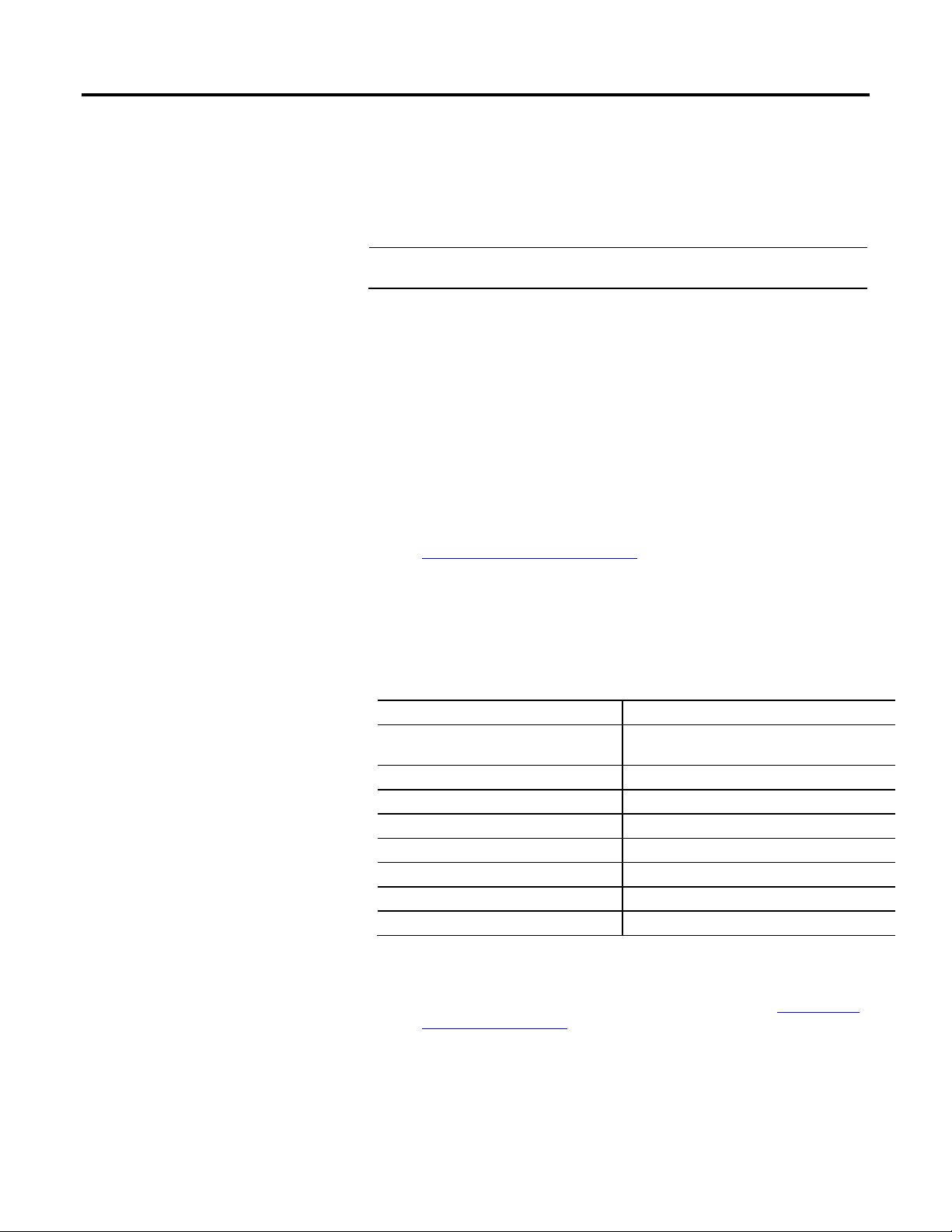

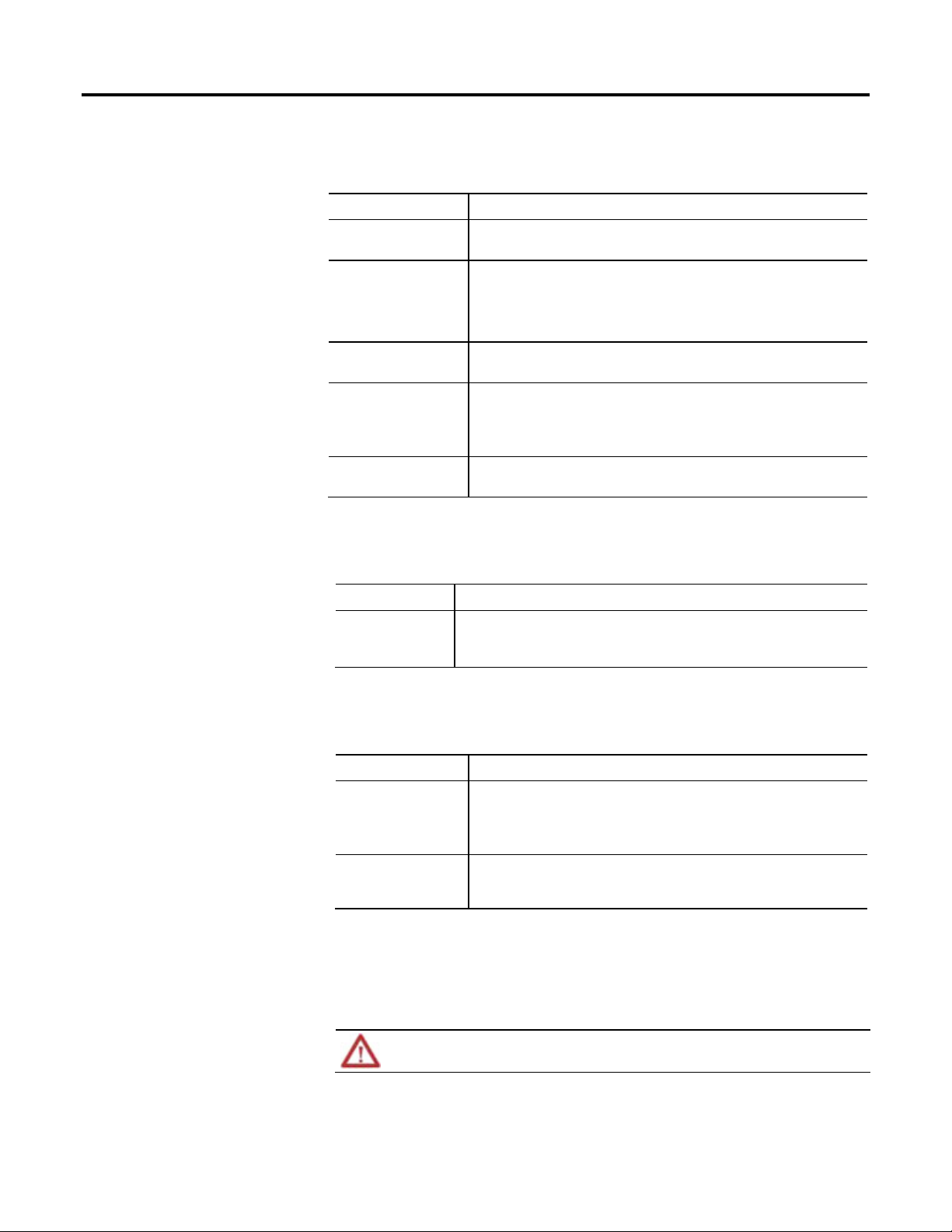

Online Import

Topic Consideration

Tag data values When overwriting tags while online, data values are not written to the online project. Data

values for overwritten tags while online are written only to the offline project.

Data values for tags created while online are written to the offline and online project.

Select the Preserve existing tag values in offline project check box to prevent tag values

from being overwritten in the offline project.

Locking controller edits When performing an online import, the controller is locked, preventing other workstations

connected to the controller from making edits until the import completes. If another

workstation has the controller locked, an online import cannot be initiated.

Tag attributes

12 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Tag attributes (for example, External Access, Constant, and Style) are written to the online

project and the offline project.

If existing tags are to be overwritten with new attributes that are incompatible with existing

user logic, the import is not allowed.

Page 13

Import and export logic components Chapter 1

program, or routine properties that are modified are downloaded immediately. These changes

Topic Consideration

Online options When importing programs, equipment phases, routines, or rungs online, the logic can be

imported as:

• Pending Edits that exist only in the offline project and are not downloaded to the

controller.

• Accepted Edits that are downloaded to the controller where they can be tested, accepted,

or canceled.

• Finalized Edits that are downloaded to the controller, assembled, and cannot be canceled.

As with normal online editing, with any online option chosen, any tags, data types, or Add-On

Instructions that are created or modified are downloaded immediately. In addition, any task,

remain in the controller, even if logic edits are later canceled. Pending Edits and Accepted

Edits options do not apply to Add-On Instructions and user-defined types, so Online Options

are not presented during an Add-On Instruction or user-defined type import.

Under the following conditions, only the Finalize All Edits in Program option is available.

• When you are online with t he controller and you import a program that contains

connections to InOut parameters and:

− You change the final connection of an InOut parameter online.

• When the connections are different than what is currently downloaded to the controller.

Finalize All Edits In Program is your only option because you chose to overwrite the

program on Import. You must configure the InOut connections such that the InOut

parameter connection is taken not from the destination controller but from the Import file,

or from a new final name for the connection entered by the user.

• When you import a program or programs with connections online and in Remote Run

mode, and:

− A connection is changed from connect to disconnect.

− A connection is changed from disconnect to connect.

− The final name of a connection is changed.

− A connection is added and its operation is set to connect.

• When you import program hierarchies or multiple programs online and in Remote Run

mode.

External access If the External Access is changed, it may change the behavior of your running HMI.

Changed External Access attributes for overwritten tags can cause changes to HMI behavior,

regardless of whether logic changes are tested, accepted, or finalized.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 13

Page 14

Chapter 1 Import and export logic components

ne (choosing Finalize Edits) does not cause the communication timeout,

Topic Consideration

Asynchronous import Import operations are not synchronized with the Program Scan (just as online editing

operations are not synchronized). For most objects, this does not matter because:

• Existing online tag data values are never overwritten.

• New tags and their initial data values are written to the controller before the new logic

runs.

• The switch-over to the new logic is synchronized with the program scan (just like online

editing).

In general, although online tag data values are not overwritten, some object attributes can

change asynchronously to the Program Scan. Some examples:

• Changed attributes of existing programs or equipment phases (such as changing the Initial

Step Index of an equipment phase) are written to the controller before switch-over, so old

logic can run with the new configuration.

• An existing program without a main routine could become configured with a main routine

as part of import, and that main routine runs immediately even though the new logic for

that routine has not yet been accepted.

• Changing Logix-based alarm tag configuration (such as alarm messages or associated tag

definitions) can go into effect while the old alarm trigger logic is still active, resulting in

alarm messages that do not match the condition.

Communication timeouts Communication timeouts may occur when rungs are deleted online in Run mode if the

program scan time is long or the number of rungs being deleted is large.

If you use Partial Import Online and choose Pending or Accept edits, when you later Finalize

those edits, a timeout can occur. This timeout can occur as HMI or Logix Designer

communication timeouts. Keep the following timing considerations in mind.

• Finalizing online edits while in Run mode causes brief interruptions to communication,

which are usually unnoticeable.

• The length of the communication interruption is related to the product of the (task scan

time) x (the number of changed rungs).

• When very long program scans or large quantities of changed rungs occur, the

communication interruption can be long enough to cause timeouts.

• The timeout of a Rockwell Automation HMI is typically 8 seconds, while a Logix Designer

online session typically has a 30-second timeout.

• It does not matter whether the edits came from individual online edits or from a Partial

Import Online (choosing Pending or Accepted edits).

• Partial Import Onli

due to the use of asynchronous transaction commit processing.

Motion

Topic Consideration

Motion components

limitations while online

14 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Motion tags (Axis, Coordinate System, and Motion Group) cannot be created, modified or

deleted during an online import, however, existing motion tags can be referenced. When

doing an offline import, motion tags can be created and modified.

Page 15

Import and export logic components Chapter 1

Import logic components

Safety

Topic Consideration

Safety components

limitations while online

Safety components

limitations while offline

Scheduled location In a Safety project, Safety programs cannot be imported into a Standard task and vice

Safety programs imported

into a standard project

Controller Fault Handler and

Power-Up Handler

Safety components cannot be created, modified or deleted during an online import.

Safety components cannot be created, modified or deleted during an offline import. If a

Safety Signature exists, the project is Safety locked. A non-recoverable safety fault is

present if the Safety Partnership status between the primary controller and the safety

partner is any value other than ‘OK’, or if Safety modify permissions are denied.

versa.

Safety programs imported into a Standard project are converted to Standard programs

during the import processing and a warning appears in the Errors/Results Pane during

initial parsing of the .l5x file. In this case, imported logic does not verify after import if it

contains instructions that are only valid in a Safety routine.

A Safety program cannot be scheduled in the Controller Fault Handler or Power-Up

Handler folders.

Security

Topic Consideration

Project is secured If the project is secured, the import process may not be able to create, delete, or modify some

components, depending on the security actions that have been granted or denied for those

components.

Multiple components

Topic Consideration

Importing multiple Userdefined types (UDTs) and

Add-On Instructions.

Controller Fault Handler and

Power-Up Handler disabled

Follow these steps to import logic components. You can import components from

the Controller Organizer and from the Logical Organizer.

When User-defined types (UDTs) and Add-On Instructions are imported using the Multiple

Components option, all UDTs and Add-On Instructions are treated as references. Unlike

child components, referenced components can be configured independently from the

import target.

When you import multiple target programs, the Controller Fault Handler and Power-Up

Handler are unavailable in the Schedule In list.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 15

Importing components into a controller while online can affect controller operation. Use caution when

modifying logic while online in Remote Run or Run mo de.

1. Right-click the item and choose the import component menu item as

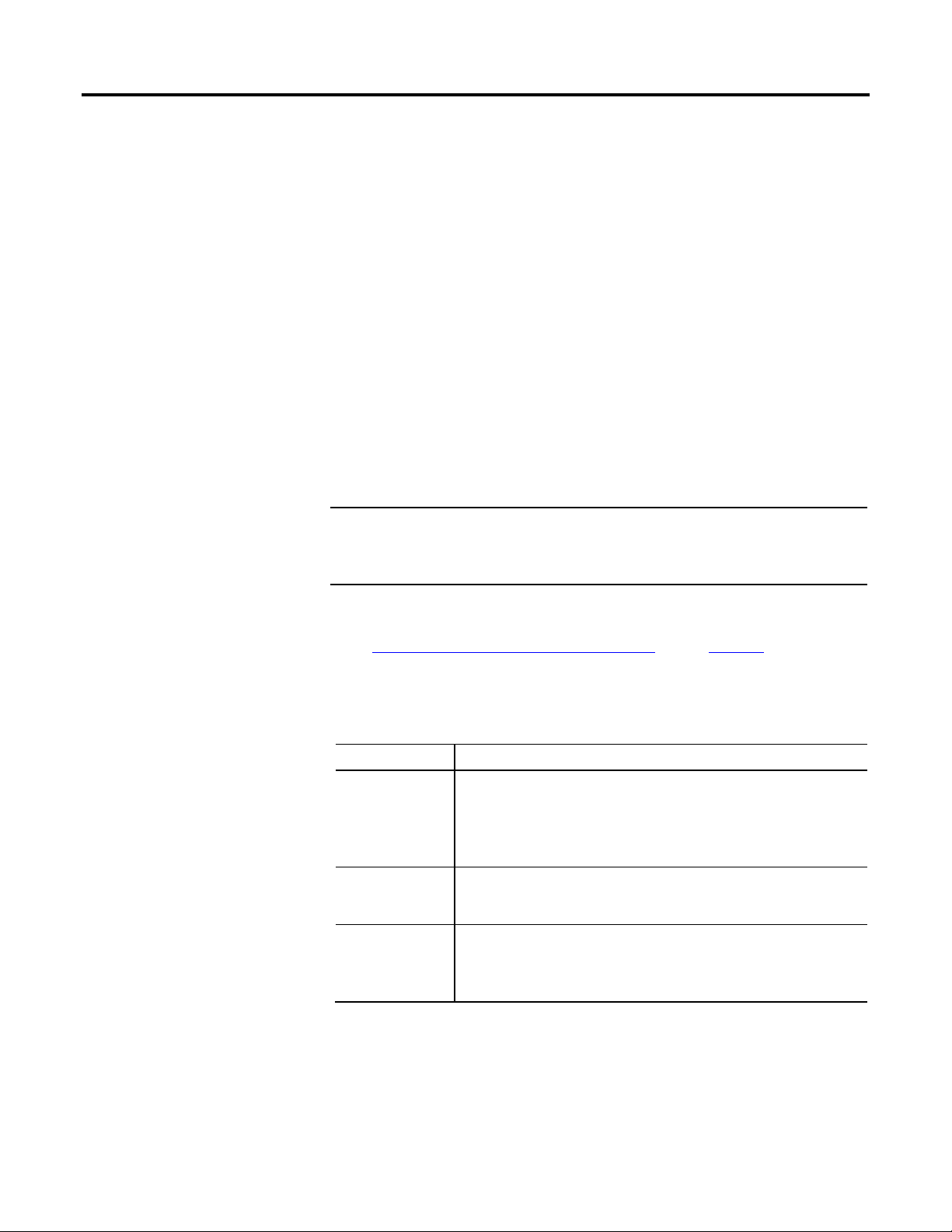

described in the following table.

Page 16

Chapter 1 Import and export logic components

Configuration properties

To import a Right-click And choose

Set of rungs A rung or set of rungs within a Ladder routine

editor

Routine A program or equipment phase

Program A task, the Controller Fault Handler folder, the

Power-Up Handler folder, or the Unscheduled

Programs/Phases folder

Equipment Phase A task or the Unscheduled Programs/Phases folder

Import Rungs

Import Routine

Import Program

Import Equipment Phase

for import

User-defined data type User-Defined folder

User-defined string type Strings folder

Add-On Instruction Add-On Instructions folder

Trend Trends folder

Import Data Type

Import String Type

Import Add-On Instruction

Import Trend

2. Select the file to import.

You can select multiple components for import. See

Configure multiple

component properties on page 21 for information.

3. Click Import.

4. Continue by selecting the configuration options described in Configuration

properties for import.

This section describes configuration options for importing components.

Tip:

Trends do not require any import configuration, so the Import Configuration dialog box does not appear and

the trend is imported immediately.

16 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Properties for imported components

When you import components, the previously exported information is brought

into the project based on the import configuration you select. You determine how

the imported component (a program, for example) connects to the existing project

either by overwriting an existing component of the same type, or by creating a new

one.

Page 17

Import and export logic components Chapter 1

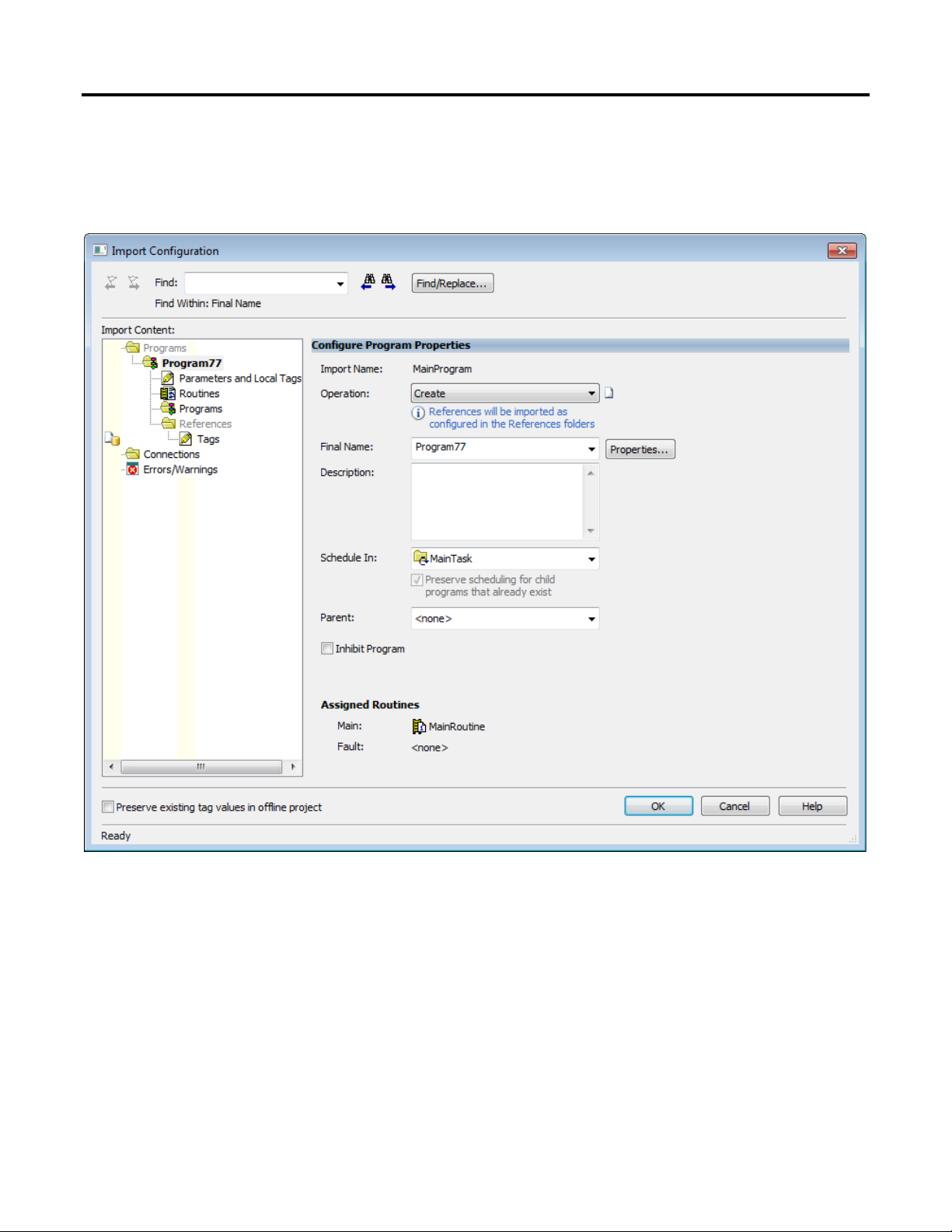

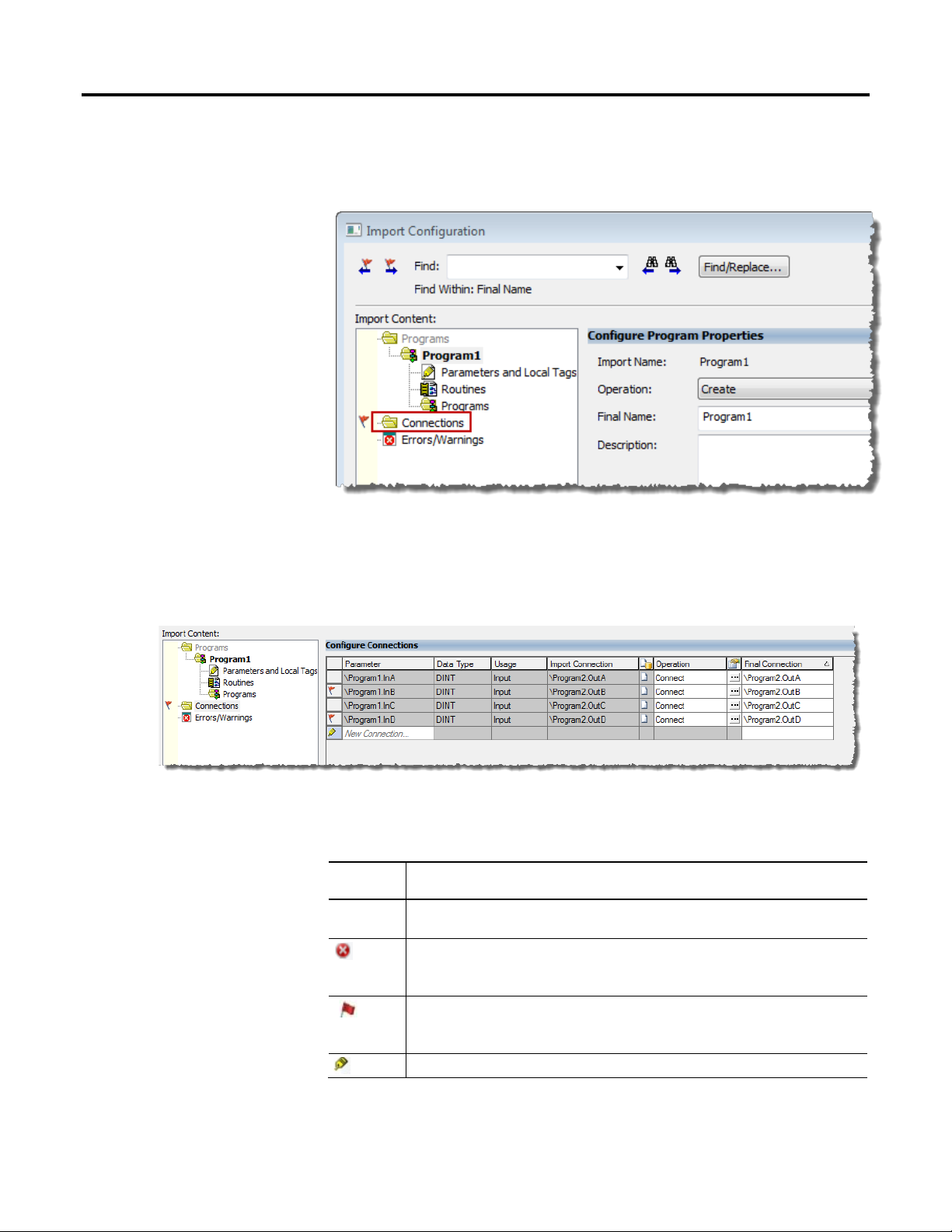

The following screen capture shows a typical Import Configuration dialog box.

Your dialog box might contain options different than those shown here,

depending on the component you import.

An import component collides with an existing component if a component of the

same type, scope, and with the same name exists in the project. By configuring the

Final Name of the imported component, you determine whether the imported

component collides with an existing component, or it does not (if a component of

the same type, scope and with the same name does not exist in the project). For a

collision, you can use the existing project component or you can overwrite it. For a

non-collision, you can create a project component or you can discard, and not

import, the component from the import file. In any case, any imported logic

references are updated to be the same as the Final Name.

By configuring the Operation for the component, you determine whether it is

imported from the file or an existing component is used. Incompatibility of a

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 17

Page 18

Chapter 1 Import and export logic components

collision or other situations, for example, project security privileges, may affect

what Operations are permitted for a component.

The following table describes the configuration options.

Configuration Description

Import Name

Operation

Final Name

Description

The Import Name is read-only and shows the name of the component as read from the

import file.

The Operation determines whether the component from the import file is imported. Not

all operations are applicable to a given component in all situations. Sometimes there is

only one possible operation permitted in a particular situation.

Choose from these options:

• Use Existing (collisions) to use the existing component in the project. The component

definition in the import file is not imported. If the component collides and there is no

definition for the component in the import file, then this is the only Operation

available.

• Overwrite (collisions) to import the component definition from the import file and

overwrite the existing component definition in the project.

Important: If you select Overwrite for a reference tag, the tag data that is different is

written to the offline project only, even if you are online with the controller.

• Create (non-collisions) to import the component from the import file creating a new

component in the project.

• Discard (non-collisions) to discard the component and abort import. If the main

component from the import file (the program during a program import, for example) is

discarded, the references can still be imported. If a referenced component is discarded,

any imported logic references are not defined in the project and might not verify after

impor t.

• Undefined (non-collision) is the only Operation available if the component does not

collide and there is no definition for the component in the import file. The imported

logic is not verified after import.

• Delete (non-collision) indicates that this component will be deleted from the project

on import.

The Final Name determines the name of the component that shows in the project after

the import (except in the case of a Delete Operation).

You can create or avoid collisions by changing the Final Name. If you change the Final

Name to differ from the Import Name, all logic references in the import content are

updated.

If you change the Final Name of a component during configuration so that it collides with a

different existing component after it was colliding with another, any changes you made to

the Operation are preserved.

The Description shown depends on the Operation. If the Operation is:

• Overwrite or Create, the description is initially the description from the import file.

You can edit it during import configuration.

• Discard, the description is initially the description from the import file. It is read-only

and may not be edited.

• Use Existing or Delete, the description is the existing component description. It is

read-only and may not be edited.

• Undefined, no description is shown.

The description for members of an expanded tag follow the same rule the tag follows. Only

members of the tag that have descriptions are shown when the tag is expanded.

18 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 19

Import and export logic components Chapter 1

Configuration Description

Schedule In

Preserve scheduling for child

programs that already exist

The Schedule In setting determines the task in which the imported component is

scheduled.

The default setting for Schedule In depends on the Operation setting and whether you

import the component into the Controller Organizer or the Logical Organizer.

If you import the component into the Controller Organizer:

• When you select a task or handler, and Operation is set to Overwrite, Schedule In is

set to the selected task or handler.

• When you select a task or handler and Operation is set to Use Existing, Schedule In

is set to the task or handler where the program is scheduled in the destination project.

• When the selection in Controller Organizer is not a task or handler, Schedule In is set

to Unscheduled Programs/Phases.

If you import the component into the Logical Organizer:

• When you set Operation to Create or Disca rd, Schedule In is set to Unscheduled

Programs/Phases.

• When you set Operation to Use Existing or Overwrite, Schedule In is set to the Task

or Handler for which the program is scheduled in the destination project.

You can adjust the S chedule In setting when:

• Operation is set to Create (the target component is being created).

• Operation is set to Overwrite and you are not online in Remote Run mode.

You cannot change the Schedule In setting when:

• You import a program folder.

• Operation is set to any setting other than Create or Overwrite.

When you select this setting, any child programs that exist in the destination project

remain scheduled as configured in the project. When you clear this setting, all imported

programs are scheduled in the task specified by the Schedule In setting.

This setting is available when Operation is set to Create or Overwrite; otherwise it is

read-only. When enabled, this setting is selected by default. The setting is not preserved

between import sessions.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 19

Page 20

Chapter 1 Import and export logic components

Configuration Description

Parent Determines where the imported component is organized.

The default setting for Parent depends on whether you exported the component from the

Controller Organizer or the Logical Organizer, whether you are importing it to the

Controller Organizer or the Logical Organizer, and on the Operation setting.

• If you exported the program from the Controller Organizer and you are importing it to

either the Controller Organizer or the Logical Organizer:

− Parent is set to the selected program in the Logical Organizer if the operation is

Create or Discard.

− Parent is set to the parent configured in the destination project if Operation is set

to Use Existing or Overwrite.

• If you exported the program from the Logical Organizer and you are importing it to the

Logical Organizer:

− Parent is set to the selected program in the Logical Organizer if Operation is set to

Create or Discard.

− Parent is set to the parent configured in the destination project if Operation is set to

Use Existing.

− Parent is set to the selected item in the Logical Organizer if Operation is set to

Overwrite.

• If you exported the program from the Logical Organizer and you are importing it to the

Controller Organizer:

− Parent is set to <none> if Operation is set to Create, Discard, or Overwrite.

− Parent is set to the parent configured in the destination project if Operation is set

to Use Existing.

When there is a collision, the components colliding may be identical, or they may

be different. If they are the same, the Operation defaults to Use Existing. If they

are different, imported components default to Overwrite while referenced

components default to Use Existing. Choose Overwrite to use the component

definition from the import file, or Use Existing to use the component in the

project. Icons on the Import Configuration dialog box (next to the Operation

control) show whether colliding components are identical or different.

Situation Icon

Component shows only in the import file (non-collision)

Component shows only in the project (non-collision)

Component collides with a component in the project and differences exist

Component collides with a component in the project and they are identical No icon

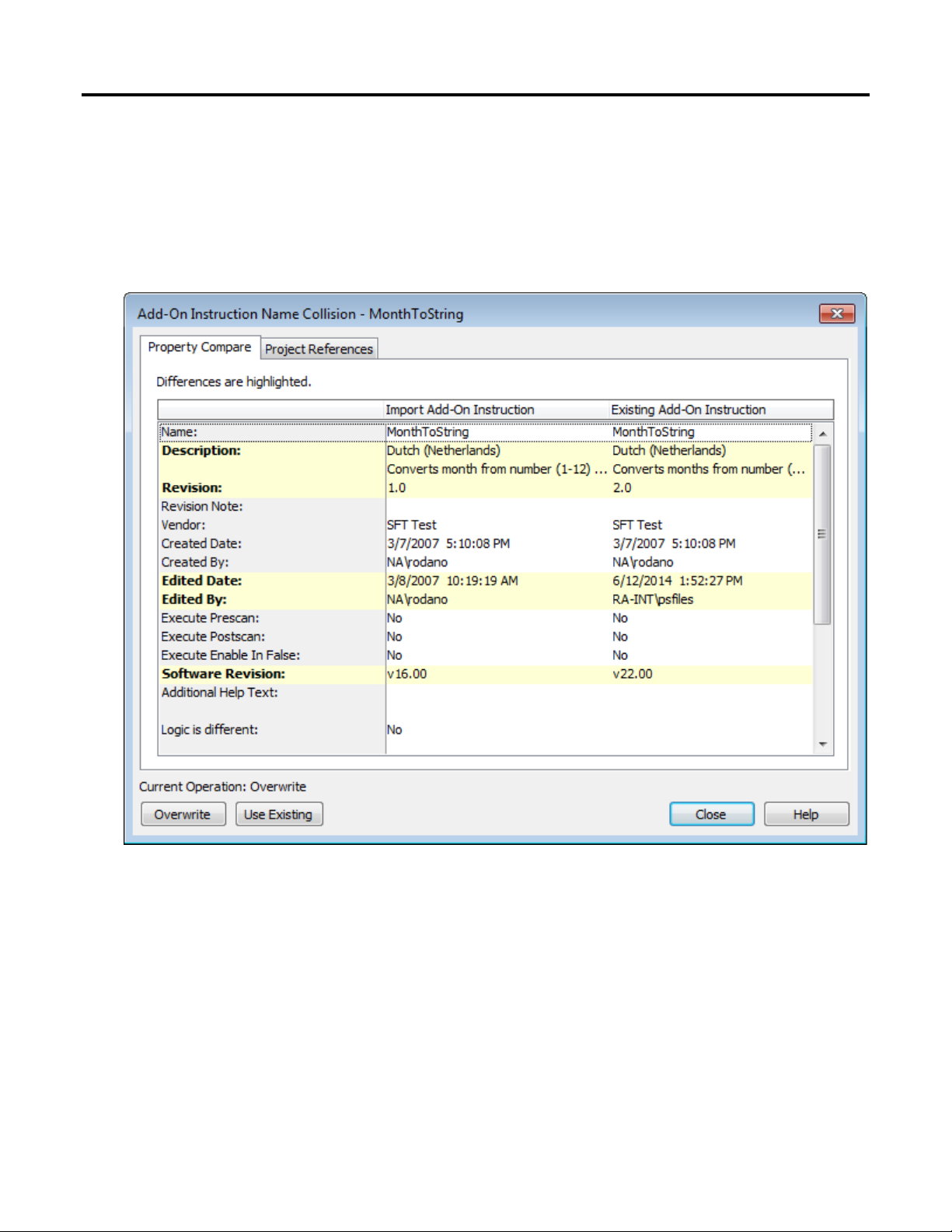

To see the differences between the import component and the colliding project

component, click Collision Details and a dialog box opens. Use the information

in the dialog box to determine whether to overwrite or to use the existing

component.

20 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 21

Import and export logic components Chapter 1

For components that do not collide, click Properties for more information on the

component.

Important:

A component you select for import that collides with an existing component defaults to overwriting the

project component unless the components are identical, in which case, the project component is used. If the

project component is used, references may still be imported.

Configure multiple component properties

This section describes the settings you use to import and configure multiple

components.

You carry out multiple steps when you import components.

• First, you select components for export from a project.

• You export those components.

• You select those components and import them into another project.

Use one of the following methods to import multiple components.

• Select Import Component from the File menu and choose the component

type that you want to import.

• Copy the programs, Add-On Instructions, or UDTs, right-click a task in

the organizer, and click Paste With Configuration on the menu.

Note:

The Paste With Configuration menu option works when copying from the Controller Organizer to the Logical Organizer,

and vice versa.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 21

Page 22

Chapter 1 Import and export logic components

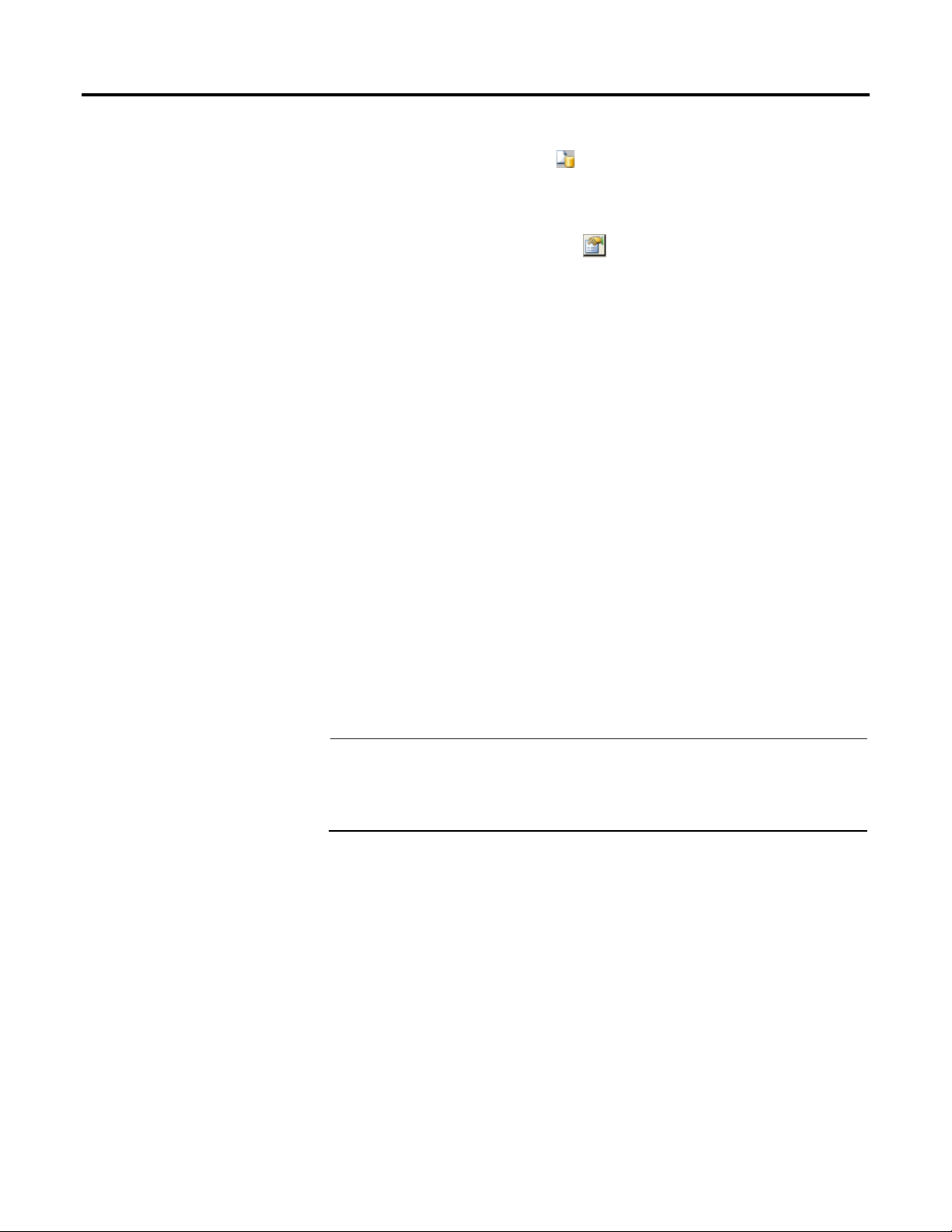

The following screen capture shows a typical Import Configuration dialog box

for multiple components. Your dialog box might contain options different than

those shown here, depending on the components you import.

Imported items are listed in the Import Content pane based on the items that are

part of the import content.

22 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 23

Import and export logic components Chapter 1

• Programs -- If you are importing multiple programs, the grid shows the

programs that are being imported into the project. If you are importing

multiple hierarchies, the grid shows the programs and the children of the

programs that are being imported into the project.

• Tags, Add-On Instructions, Data Types and Other Components --

References include any tags directly referenced by any imported logic or tags

(using Alias For).

• Connections -- Lists the connections, from programs that are external to

the programs in the import content, that are also connected to programs in

the existing project.

The following table describes the multiple-import configuration parameters.

Configuration Description

Multiple Programs

Imported Programs Shows the number of parent and child programs (if applicable) that are being imported

Operation Identifies what is done with the programs upon import.

Schedule In Shows the task in which the imported programs are scheduled.

Do not change scheduling of

existing programs

The Import Content pane shows the number of programs that are being imported into

the project.

The value shown in the parenthesis excludes children of the programs.

If differences occur among the programs, the difference icon appears in the Differences

column of the Programs grid.

into the project.

• If Import is selected, all programs are imported into the project.

• If Discard is selected, the programs are not imported into the project.

The box is set to Import by default. However, you can choose Discard from the menu.

Note: To see the Operation value for a specific program, check the Programs grid of the

program's child program.

The default value for the Schedule In value is the selected task or Unscheduled

Programs/Phases based on which method you use to import the content, and from which

organizer you initiate the import.

• If you use Paste Special>With Configuration in the Controller Organizer, the

default value is the selected task.

• If you use the Paste Special>With Configuration option or the File>Import

Component option in the Logical Organizer, the default value is Unscheduled

Programs/Phases.

The Operation box must be set to Import to modify the Scheduled In value.

When selected, programs that exist in the project remain scheduled as they are configured

in the project. The check box is selected by default.

When cleared, upon import, programs are scheduled in the task specified in the Schedule

In box.

To modify this option:

• The Operation box must be set to Import.

• The controller cannot be in Remote Run mode.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 23

Page 24

Chapter 1 Import and export logic components

Logical Organizer, or when you are importing programs into the Controller Organizer. If

Configuration Description

Parent Specifies how the programs are organized upon import.

• When you import a program into the Logical Organizer, the default is the Parent in the

selected program in the Logical Organizer.

• The default is <none> when a Parent is not specified in the selected program in the

a Parent is not specified, the programs remain organized as they are configured in the

project.

The Operation box must be set to Import to modify the Parent option.

Do not change parent of

existing programs

Select this check box and programs that exist in the project remain organized as they are

configured in the project. The check box is selected by default.

Clear this check box and upon import, programs are organized in the program that is

specified in the Parent box.

All child programs are imported as organized in the import content regardless if the check

box is selected or cleared.

The Operation box must be set to Import to modify this option.

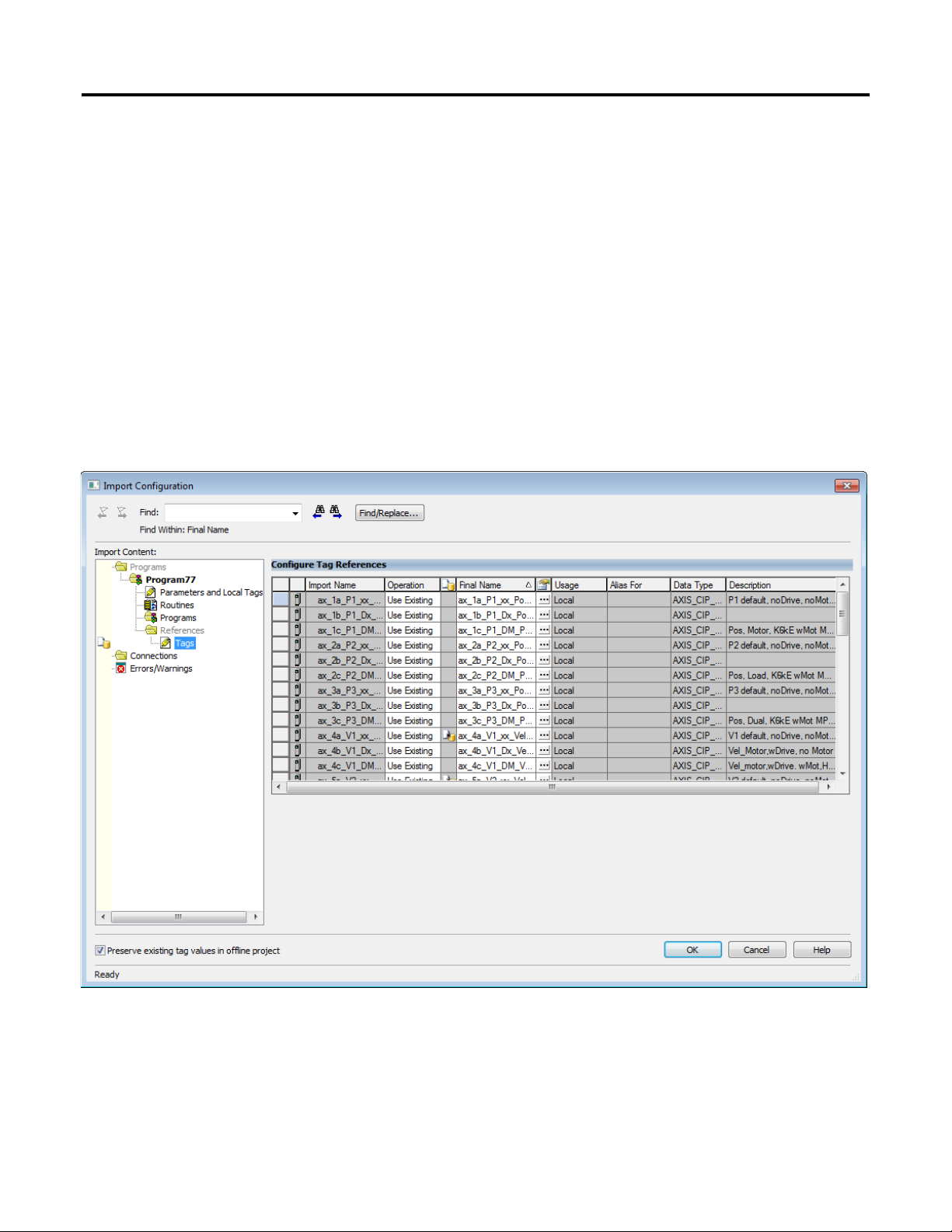

Configure program connections

When you import a program, you might need to configure connections to

program parameters or controller scope tags that exist in the project. You can

configure connections when you select the target program on the Import

Configuration dialog box and Operation is set to Overwrite or Create. If

Operation is set to Use Existing or Discard, the Connections grid does not

appear.

When you import multiple programs, any connections between the programs you

are importing cannot be configured, and do not appear in the Connections grid.

However, any connections with endpoints outside these programs do appear and

may be configured.

Logix Designer application imports the connection endpoints, and they remain

what they were in the original project. If the endpoints exist in the destination

project, they bind automatically. If the endpoints do not exist, they are flagged as

errors and you must change the Final Connection name to bind them to the

correct connections, or remove the connections.

The following diagrams describe how imported connections are established.

24 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 25

Import and export logic components Chapter 1

In My Original Project, the parameters in Program1 are connected to parameters

in Program2.

When you import the original Program1 into My New Project, the parameters in

Program1 connect automatically to matching parameters in Program2. Parameters

that do not match are flagged as errors. You need to change the Final Connector

for those parameters.

If the endpoint names are different in My New Project (for example, Program3)

you can either open the Connections grid and change the Final Connection

name on the endpoints from Program2 to Program3, or you can go to the

References grid and change the final name on Program2 to Program3 in one place,

and all the connections change automatically.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 25

Page 26

Chapter 1 Import and export logic components

To open the Connections grid, click Connections on the Import Configuration

dialog box.

The following screen capture shows the Connections grid as it would appear

when you import Program1 into My New Project, as described earlier in this

section. To fix the connection errors, you can select Disconnect in the Operation

box, or you can select a different connection in the Final Connection box.

The indicator column at the far left of the Connections grid shows the condition

of the connection. The following table describes the connection conditions.

Indicator Connection Condition

*

Indicates a row in which content has changed and the change has not been saved.

Indicates a row in which the connection endpoints are invalid due to a syntax error. If you click OK to

begin the import, you receive an error message and must fix or remove the connection before you can

proceed.

Indicates that the connection being imported will contain an error at the completion of the import. You

can proceed with the import, and the connection is created, but you must fix the error before you can

download the project to the controller.

Indicates a row in which you can create a connection.

The following table describes the Connections grid columns and settings.

26 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 27

Import and export logic components Chapter 1

Column Description

Parameter The parameter identified in this box is the parameter in the import content that is to be connected to

another parameter on a program that exists in the project.

A New Connection option is available on the last row of the grid if the import content contains only

one program. You can create connections that are not part of the import content by connecting a

program parameter in the import content to an endpoint connection on a program that is in the

project. You then have a new connection that did not exist in the import content nor in the program

that exist in the project. See Create a new connection on page 28 for more information.

Data Type Shows the data type of the parameter. A parameter can only be connected to a member or bit of a tag

or parameter with the same data type or an error occurs when you verify the program.

Usage Shows the usage type of the parameter as Input, Output, InOut, or Public.

Import Connection Shows the name of the connection endpoint for the parameter as read from the import file. This

Import Connection box is blank if the connection is only defined in the program that exists in the

project.

Differences

Indicates if there are differences between the connections in the import content and the connections

in the target project.

Also identifies if a connection exists in the import content, or if it exists in the program that is in the

project. Click the Browse button in the Details column to see more extensive component properties.

Two icons show how the imported content matches the content of the program that exists in the

project:

Indicates a connection that is present in the import content and not in the project.

Indicates a connection that is present in the project and not in the import content.

Operation Identifies whether the connection is made upon import of the program into the project. You can select

Connect or Disconnect to change the connection status for the connection.

• Connect - Upon import of the program, this connection that is defined in the import content will be

created in the project. This is the default value when a connection between the parameter and the

final connection is valid.

• Disconnect - Upon import of the project, the connection that is defined in the import content will

not be created in the project. This is the default value when the connection between the parameter

and the final connection is not valid.

See the example later in this section for more information on the Operation box.

Details

Click the Browse button to open the Connection Properties dialog box. On the Connecti on

Properties dialog box, click Connect or Disconnect to change the connection status for the

connection.

Final Connection The parameter or tag in the existing project that the import parameter will be connected to.

You have the option to change the value in the Final Connection box based on the value in the

Operation box. You can type the final connection name or click the down arrow to make a selection

from the tag browser. If the parameter is a MODULE InOut parameter, the module browser appears

instead of the tag browser. For more information about the tag browser and module browser, see the

online help topics Using the Tag Browser and Using the Module Browser.

If you enter an invalid final connection, the error indicator displays in the leftmost column. Hover the

cursor over the error indicator to see a description for the cause of the error.

See the example later in this section for more information on the Final Connection box.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 27

Page 28

Chapter 1 Import and export logic components

Example: using the operation and final connection boxes to establish connections

Parameter in

Imported File

\Prog1.InA \Prog2.OutA Connect \Prog2.OutA This connection exists in both the import content and in the program in the

\Prog1.InB \Prog2.OutB Connect \Prog2.OutB The endpoint parameter does not exist in the target project file.

\Prog1.InB \Prog2.OutB Disconnect \Prog2.OutB Example Row 3: Parameter \Prog2.OutB does not exist in the target project, so

\Prog1.InA \Prog2.OutA Connect \Prog3.OutB Example Row 4: Parameter \Prog2.OutA does not exist in the target project, so

\Prog1.InC none Connect \Prog3.OutD

Connection in

Imported File

Operation Value Final Connection box What happened in this case

project, so the connection is the same.

If you are importing the program offline, the error flag appears. You can

continue the import, but you must resolve the error before you can download

the project to the controller.

If you are importing the program online, the red-x error appears, and you

must resolve the error before continuing the import.

To resolve the error, you can either:

• Set the Operation Value to Disconnect (see Example Row 3 in this table).

• Select an existing parameter in the Final Connection box to reassign the

connection (see Example Row 4 in this table).

you set the Operation Value to Disconnect.

in the Final Connection box select an existing parameter to reassign the

connection.

This connection did not exist, so in the Final Connection box select an existing

parameter to create the connection. See Create a new connection on page 28

for more information on creating connections.

Create a new connection

When you import one program you can create a new connection on the last row of

the Connections grid. The new connection connects a program parameter in the

import content to an endpoint connection in a program that is in the project.

Your new connection did not previously exist in the import content nor in the

project. The New Connection row is not available when you import multiple

programs with existing connections between the programs you are importing.

You can type the parameter name for the new connection or click the down arrow

to make a selection from the tag browser. Because only parameters that are in the

import content are valid for the Parameters box, only the parameters that reside

in the import content are listed in the tag browser. For more information about

the tag browser, see Using the Tag Browser in the online help.

When both the parameter and final connection have been specified, the

connection is made (added) to the connection grid after you move off the New

Connection row or after you press Enter. If you enter an invalid parameter or

final connection, the connection is not created and the error indicator displays in

the leftmost column. Hover the cursor over the error indicator to see a description

for the cause of the error.

28 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 29

Import and export logic components Chapter 1

Configure component references

In addition to determining how the component is imported, you must configure

how references are imported. The references are all other components used by the

exported component at the time it was exported. For example, a program .l5x file

contains the definition of all controller-scoped tags, user-defined data types, userdefined string types, and Add-On Instructions referenced by the program at the

time the program was exported. During import configuration, you determine what

the references from the imported component connect to after import. You can

connect a reference to an existing component in the project and not import the

referenced component from the import file. Or, you can use the referenced

component in the import file either by creating a new component in the project

from the definition in the import file or by overwriting an existing component of

the same type in the project.

As with imported components, if the Final Name of a referenced component

(such as a tag) matches a component of the same type and scope in the project,

these components collide. If there is no collision, the component is identified as

needing to be created (Operation is Create).

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 29

Page 30

Chapter 1 Import and export logic components

Icons in the Differences column ( ) on the Import Configuration dialog box

show whether components collide with differences, or the component only exists

in the import file or the project.

Click the icon in the Details column ( ) and a Collision dialog box opens

showing the differences between the import component and the colliding project

component. Use the information in the Collision dialog box to determine

whether to overwrite or use the existing component.

For components that do not collide, click the same icon for more information on

the component.

A referenced component that collides with an existing component defaults to using the project component

Tip:

(Operation is Use Existing), even if the definitions of the components are different. To import the referenced

component definition from the import file, Overwrite must be selected.

Connecting a referenced component to a component of the same type, but with

another name in the project, causes any reference to the component in the

imported logic to be updated to the new name. For example, if you connect a

Boolean reference tag A to B[3].ACCUM.4 (where B is an existing tag in the

project that is an array of structures), then all references in the imported logic that

used to say A now say B[3].ACCUM.4. Another way to connect reference tags to

existing tags in the project is to modify their Alias For box. This is permitted

when the reference tag is being created or the reference tag is overwriting an

existing tag (offline only), regardless of whether it was originally an alias tag. The

Import Configuration dialog box lets you configure the references that you must

connect during the import process.

Important:

It is important to note that even if a component has an Operation of Discard, Use Existing, or

Undefined, if the Final Name differs from the Import Name, then the imported logic references to that

component are updated to reflect the Final Name. For example, if you enter an invalid name as the Final

Name for a tag reference, the Operation is set to Discard but the imported logic references to that tag are

still updated to the invalid Final Name.

30 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 31

Import and export logic components Chapter 1

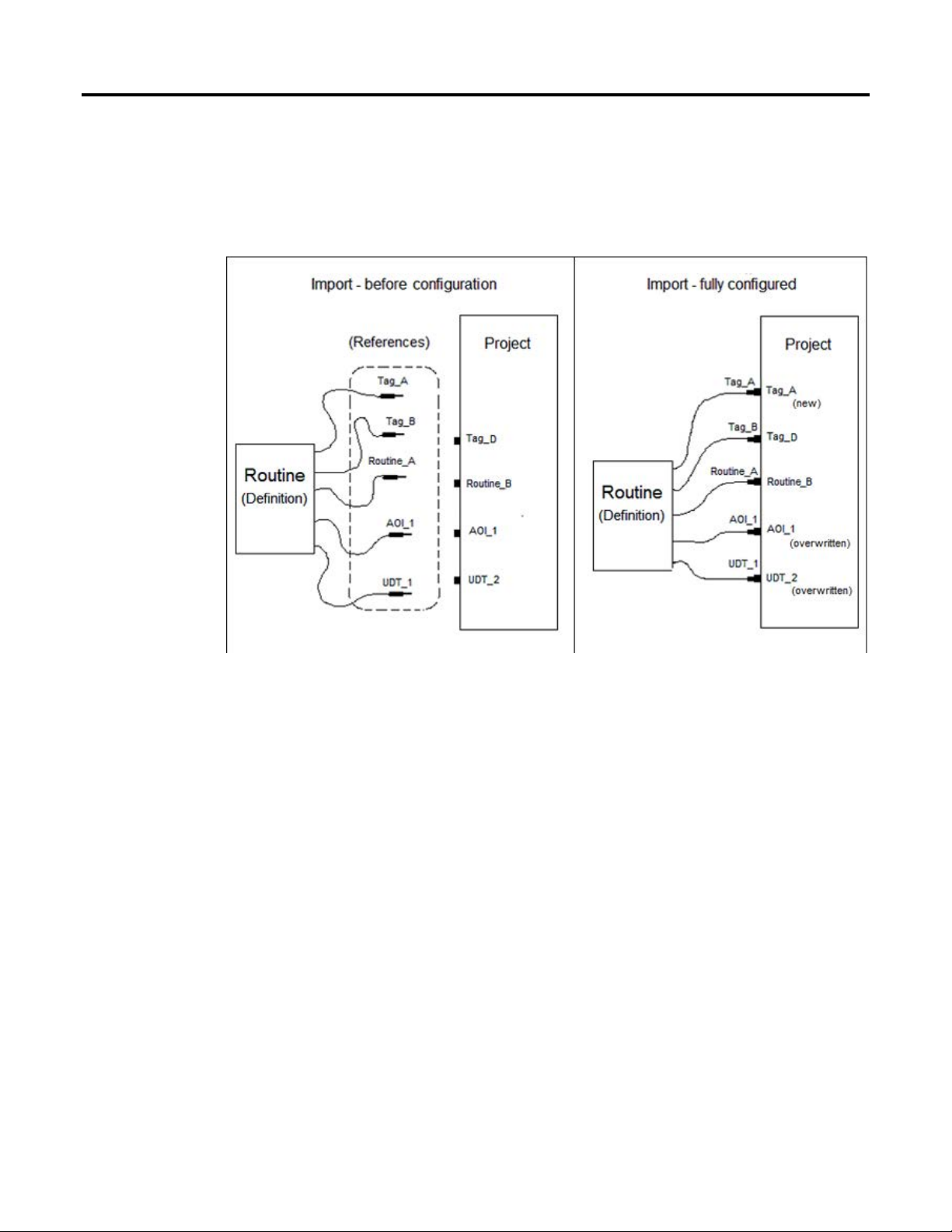

References configuration example

The following example shows how an imported routine plugs into the

components in a project after you configure it.

For example, if you import a routine, the routine itself is the main import

component. References that should be connected during the import could include

program-scope tags, controller-scope tags, user-defined data types, any routines

called by JSR instructions, and any Add-On Instructions in the routine logic.

In this example, a routine export file contains the definitions of Tag_A, Tag_B,

AOI_1, and UDT_1. The routine also contains a reference to Routine_A, but

excludes the logic in Routine_A.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 31

Page 32

Chapter 1 Import and export logic components

During import configuration, connect each:

• Reference tag in the import routine to a program or controller-scoped tag in

the project.

• Reference routine in the import routine to a routine in the project.

• User-defined data type defining a reference tag in the import routine to a

user-defined data type in the project.

• Add-On Instruction in the import routine to an Add-On Instruction in the

project.

These tags, user-defined data types, and Add-On Instructions might exist in the

project, or they can be created when you import the routine.

• Tag_A is set to Create, so the imported logic referencing Tag_A references

the newly created Tag_A in the project.

Tag_B has its Final Name changed to Tag_D and is set to Use Existing, so it is

not created, and imported logic referencing Tag_B instead references existing

Tag_D.

• Routine_A has its Final Name changed to Routine_B, so imported JSRs to

Routine_A uses the existing Routine_B.

• AOI_1 is set to Overwrite an existing Add-On Instruction called AOI_1,

so not only do imported logic and tags use AOI_1, but also any existing

references to AOI_1 in the project now uses the new definition of AOI_1

from the imported routine.

• UDT_1 is set to Overwrite an existing user-defined data type called

UDT_2, so imported logic and tags use UDT_2 and the existing UDT_2 is

overwritten (except for the name) with the definition from UDT_1. Logic

and tags from the project now use the new definition of UDT_2.

Undefined references

In the Logix Designer editor, it is possible to create logic that references tag, userdefined data type, or Add-On Instruction components that do not yet exist. These

are considered undefined references. If you export that logic, there is no

component definition to export for that undefined reference. On import, these

tags, user-defined data types, or Add-On Instructions appear with an Operation

of Undefined during Import Configuration unless the component exists in the

project (in which case the Operation is Use Existing). Similarly, when logic

references any type of component other than a tag, user-defined data type, userdefined string type, or Add-On Instruction (for example, a routine that is

referenced by a JSR instruction), the definition for these referenced components

32 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 33

Import and export logic components Chapter 1

Project documentation

are excluded from the import file and they also appear with an Operation of

Undefined if the component does not exist in the project.

During import configuration, these undefined references can be configured as

well. Since there is no definition for these components in the .l5x file, you cannot

overwrite a project component or create a component during the import process,

but you can use an existing component for that reference. You configure which

component in the project you want to connect the reference to, or leave the

reference undefined. An undefined reference that collides with an existing

component defaults to using the project component.

Attention flags

Attention (red) flags alert you to import situations that may be unintended or may

lead to a project that does not verify successfully after import. What they describe

may or may not prevent the import from proceeding. If online, and the project

does not verify successfully when accepting or finalizing edits, the import fails. Not

all attention flags cause a project to fail verification. The red flag indicates the

potential problem and you must decide what you want to do. You can ignore the

attention message or try to change the Final Name or Operation of the

component to resolve the issue.

Hover the cursor over the attention flag to open a tooltip that explains the issue.

Tip:

Errors and warnings on import

When an import fails or is canceled, all changes caused by the import are

discarded, leaving the project in the same state it was in before the import, even if

the project is online with the controller. If the import fails, the Import

Configuration dialog box opens with Errors/Warnings selected. To attempt to

import again, inspect the errors and warnings, reconfigure the import, and click

OK.

The Logix Designer application provides the option to set the display language for

project documentation, such as tag descriptions and rung comments, using any of

the supported localized languages. You can store project documentation for

multiple languages in one project file rather than in language-specific project files.

You define the localized languages that the project supports and set the current,

default, and optional custom localized language. The software uses the default

language if the current language's content is blank for a particular component of

the project. You can use a custom language to tailor documentation to a specific

type of project file user. When you configure project documentation in the Logix

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 33

Page 34

Chapter 1 Import and export logic components

Designer application for a project, you can dynamically switch between languages

in that project as you use the software.

The following project documentation items support multiple languages.

• Component descriptions in tags, routines, programs, equipment phases,

user-defined data types, and Add-On Instructions

• Engineering units and state identifiers added to tags, user-defined data

types, or Add-On Instructions

• Trends

• Controllers

• Alarm Messages (in configuration of ALARM_ANALOG and

ALARM_DIGITAL tags)

• Tasks

• Property descriptions for modules in the Controller Organizer

• Rung comments, Sequential Function Chart boxes, and Function Block

Diagram boxes

The export and import features of the Logix Designer application support project

documentation. You can transfer project components between projects that have

different project documentation settings.

If a component was exported to an .l5x file from a project with project

documentation turned off and is then imported into a project with project

documentation turned on, all project documentation brought in by the import is

associated with the project’s current language. If a component was exported to an

.l5x file from a project with project documentation turned on, all language

switched comments are exported with the component. When you import an .l5x

file that includes language switched comments, the Import Configuration dialog

box includes a Current Import Documentation Language selection.

34 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 35

Import and export logic components Chapter 1

Find and replace

If the project has project documentation turned on, all language-switched

comments from the .l5x file are imported into the project. This may result in

additional languages being available in the project after import. Selecting a

language in Current Import Documentation Language allows you to edit that

language’s comments from the import file during the import configuration

process.

If the project does not have project documentation turned on, you can import

only one set of localized comments from the import file. In this case, selecting a

language in Documentation to Import determines which language’s comments are

imported with components from the import file. You can edit the language’s

comments during the import configuration process, but only the final language

selected when import proceeds is imported with components.

Important:

Important:

Important:

Only comments associated with imported components are brought in from the import file. If an existing

component is used, import file comments for that component are not imported.

Multiple localized alarm messages can be stored (in configuration of ALARM_ANALOG or ALARM_DIGITAL

tags) even if the project does not have project documentation turned on. Therefore, all alarm messages are

imported, regardless of the Documentation Language to Import selection on the Import Configuration

dialog box.

The Documentation Language to Import selection does not affect the setting of the language defined in the

project after import.

Use the Find controls in the Import Configuration dialog box control bar to

search for text within the Import Configuration dialog box. Use the Find /

Replace dialog box to configure whether the Find searches through the Import

Name, Final Name, Description, Alias For, and the Data Type check boxes. As

the search progresses, the Import Configuration dialog box automatically

switches to different panes within the dialog as needed.

You can replace text boxes during the search to facilitate development of a

component template that you can import repeatedly, replacing template text

during each import. When designing a program template, during a program

import, the program tag names and descriptions cannot be edited or replaced.

However, during import you may edit the names and descriptions of controllerscoped tags referenced from the program. Similarly, when importing an equipment

phase, you cannot edit the names and descriptions of tags in the equipment phase,

and when importing an Add-On Instruction, you cannot edit the names and

descriptions of the parameters and local tags.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 35

Use these steps to find and replace text during the import configuration process.

1. Click Find/Replace in the Import Configuration dialog box.

2. In the Find What box, enter the desired text for the search. You can enter a

search string or select text from a previous search.

Page 36

Chapter 1 Import and export logic components

3. To replace text that is found, enter the replacement text in the Replace

With box.

To use wildcards in your search string and in the replacement text, select the

Use Wildcards check box. Use asterisks (*) as wildcard characters. This

table provides examples of Find-Replace operations using wildcards.

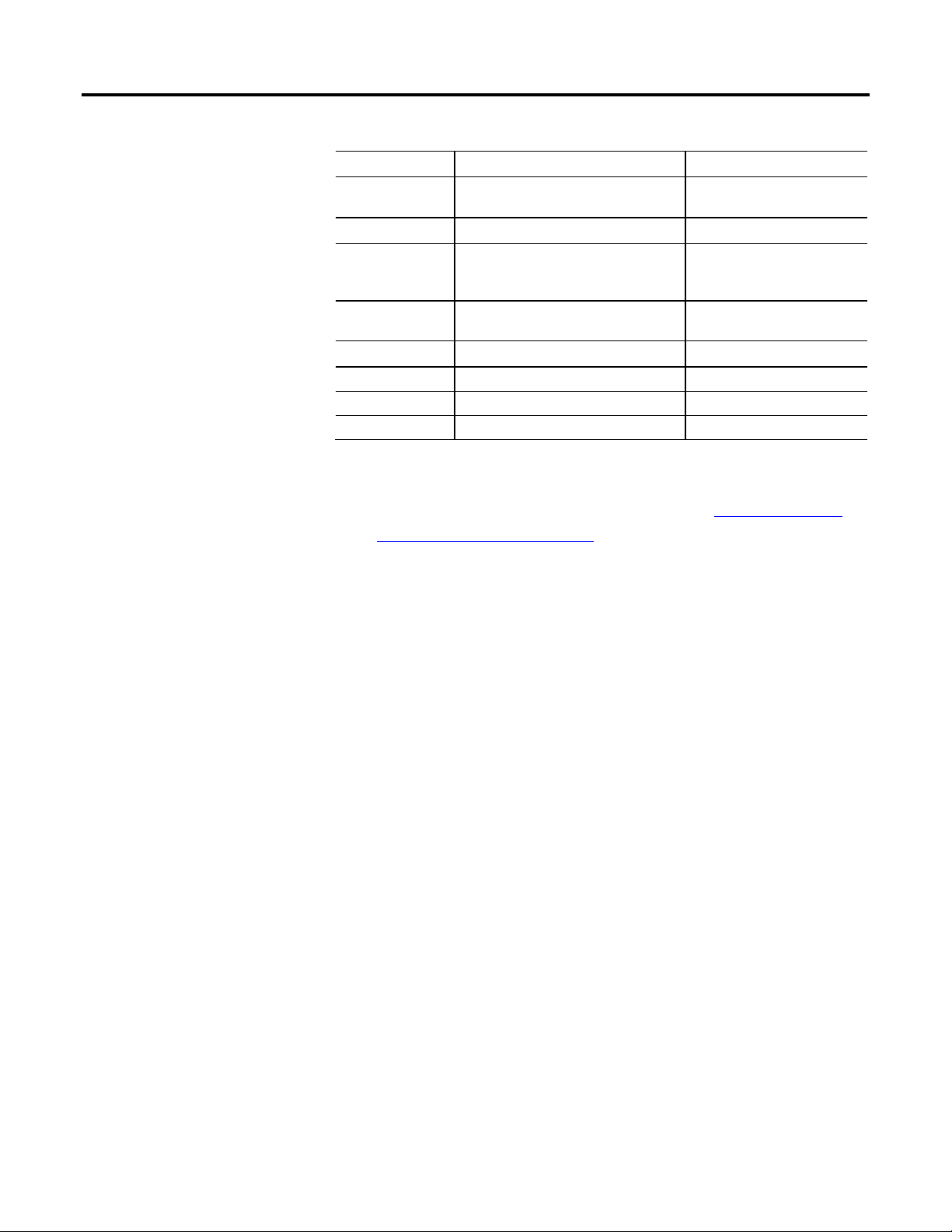

Find What Replace With Text Found Replacement Result

tk1_*_001 PRE_*_010 tk1_me_001 PRE_me_010

tk3_* tk4_* tk3_unit tk4_unit

*001 *002 mi_2001 mi_2002

*tank* *TNK* M1_tank_003 M1_TNK_003

* PRE_* some_name PRE_some_name

4. To limit search and replace to the currently selected pane, select the Search

current view only check box. You can change the selected pane without

closing the Find / Replace dialog box.

5. Select the applicable Find Within check boxes to configure the search.

6. Click Find Next to search for the next matching item.

7. Click Replace to replace the text in a text box. Click Replace All to replace

all instances of the search text specified in the Find What box with the text

in the Replace With box.

Compatibility

The import/export feature supports backward compatibility for import operations

and forward compatibility for export operations.

Backward compatibility means that the Logix Designer application can import

.l5k or .l5x files generated by a previous version of the application. In some cases,

an older .l5k file might not correctly import into a later version of the application.

36 Rockwell Automation Publication 1756-PM019E -EN-E - October 2014

Page 37

Import and export logic components Chapter 1

The import/export feature supports forward compatibility for export operations,

and does not support backward compatibility for export operations. Earlier

versions of the Logix Designer application cannot read .l5k or .l5x files that were

created with later versions of the application. In some cases, an .l5k or .l5x file

created with a later version of the Logix Designer application may import with

warnings into an earlier version of the application. In these cases, attributes on

components may be set to default values during import.

Each version of the Logix Designer application exports .l5k files with a specific

import/export Logix Designer application version number. The Logix Designer

application imports any .l5k file with the same major revision number and the

same or lower minor revision number. The major Logix Designer application

version number increments when file properties prevent the application from

supporting backward compatibility for import operations. The minor version

number increments whenever there is a change in the file (a new module, an

attribute is added, the set of options for an attribute is changed) that does not

affect backward compatibility for Logix Designer application import operations.

Important:

Use caution when copying and pasting components between different versions of Logix Designer

application. Logix Designer application supports pasting to only the same or later version. Pasting to an

earlier version of Logix Designer application is not supported. When pasting to an earlier version, the paste

action might succeed but the results might not be as intended.

Rockwell Automation Publication 1756-PM019E -EN-E - October 2014 37

Page 38

Page 39

Introduction

Export considerations

Import considerations

Chapter 2

Additional considerations for rungs

This chapter explains import and export of rungs.

One rung or a contiguous set of selected rungs may be exported to an .l5x file.

The export file may also include any program-scoped tags, controller-scoped tags,

Add-On Instructions, user-defined data types, and user-defined string types that