Page 1

Installation Instructions

PowerFlex 700S Adjustable Frequency Drive - Phase II Control

Frames 1…6

0.75…132 kW (1…200 Hp)

Introduction

This document explains the 5 primary steps for mechanical installation and for

connecting incoming power, the motor, and basic I/O to the PowerFlex® 700S

adjustable frequency AC drive with Phase II control.

The information provided is intended for qualified installers only.

The Additional Resources section on page 5

Automation publications that provide detailed drive information from wiring

and grounding recommendations to troubleshooting and repair.

ATTENTION: This product contains a 3V Lithium battery if the DriveLogix

Controller option board is installed. Perchlorate Material - special handling may

apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

is a directory of Rockwell

Publication 20D-IN024C-EN-P - July 2013

Page 2

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

2 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 3

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Table of Contents

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 1: Read the General Precautions

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Class 1 LED Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 2: Prepare for Installation

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drive Rating to Frame Size Cross References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Common Bus and Precharge Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Conditions and Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Minimum Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Step 3: Lift and Mount the Drive

Drive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Attaching the Lifting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Step 4: Power Wiring

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shield Termination - SHLD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unbalanced, Ungrounded or Resistive Grounded Distribution Systems . . . . . . 26

RFI Filter Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

AC Input Phase Selection (Frames 5 and 6 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Selecting/Verifying Fan Voltage (Frames 5 and 6 Only) . . . . . . . . . . . . . . . . . . . . . 34

Important Common Bus (DC Input) Application Notes . . . . . . . . . . . . . . . . . . . 36

Auxiliary Control Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Accessing the Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Wire Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Terminal Block Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dynamic Brake Resistor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Using Input/Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Using PowerFlex 700S Drives with Regenerative Power Units . . . . . . . . . . . . . . . 43

Regenerative Unit to Drive Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fusing and Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 3

Page 4

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 5: Control and I/O Wiring

Control and I/O Wiring Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Main Control Board DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Hardware Enable Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

DriveLogix 5730 Controller Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DriveGuard® Safe Torque Off with Second Encoder Option . . . . . . . . . . . . . . . . 61

Second Encoder Feedback Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Stegmann Hi-Resolution Encoder Feedback Option . . . . . . . . . . . . . . . . . . . . . . . 64

Resolver Feedback Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Multi-Device Interface (MDI) Feedback Option. . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 5

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

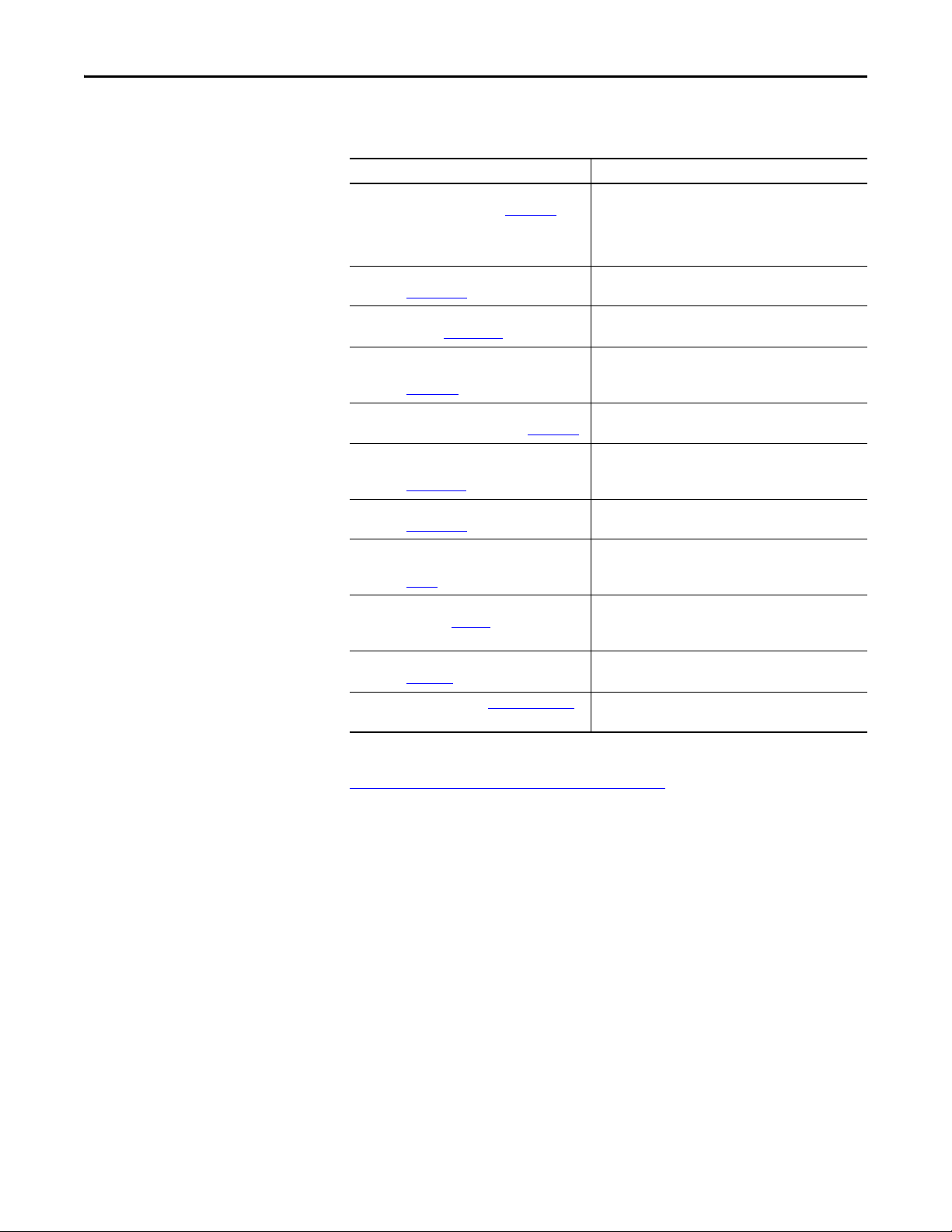

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerFlex 700S Drives with Phase II Control

Programming Manual, publication 20D-PM001

PowerFlex 7-Class HIM (DPI) Quick Reference,

publication 20HIM-QR001

PowerFlex 700S Drives with Phase II Control Reference

Manual, publication PFLEX-RM003

DriveLogix5730 Controller for PowerFlex 700S Drives

with Phase II Control User Manual,

publication 20D-UM003

DriveGuard® Safe-Off Option for PowerFlex 700S

Drives with Phase II Control, publication 20D-UM007

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives,

publication DRIVES-IN001

PowerFlex AC Drives in Common Bus Configurations,

publication DRIVES-AT002

Safety Guidelines for the Ap plication, Installation and

Maintenance of Solid State Control,

publication SGI-1.1

A Global Reference Guide for Reading Schematic

Diagrams, publication 100-2.10

Guarding Against Electrostatic Damage,

publication 8000-4.5.2

Product Certifications website, http://www.ab.com

Provides the following detailed information:

• Drive start-up instructions

• Parameters and programming

• Faults, alarms, and troubleshooting

• Human Interface Module (HIM) Operation Instructions

Provides a quick reference guide for using the PowerFlex 7Class HIM.

Provides detailed control functions and application

programming examples.

Provides instructions for developing DriveLogix controller

projects.

Provides information and instructions for properly planning

for and installing the DriveGuard Safe Torque Off option board.

Provides basic information needed to properly wire and

ground PWM AC drives.

Provides basic information needed to properly wire and

ground PWM AC drives using a common DC bus.

Provides general guidelines for the application, installation,

and maintenance of solid-state control.

Provides a simple cross-reference of common schematic/

wiring diagram symbols used throughout various parts of the

world.

Provides practices for guarding against Electrostatic damage

(ESD)

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 5

Page 6

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 1: Read the General

Precautions

ATTENTION: Only qualified personnel familiar with adjustable frequency AC drives and associated machinery should plan or

implement the installation, startup and subsequent maintenance of the system. Failure to comply may result in personal injury

and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged before per forming any

work on the drive. Measure the DC bus voltage at the +DC and –DC terminals of the Power Terminal Block (refer to page 40

location). The voltage must be zero.

ATTENTION: Hazard of personal injury or equipment damage exists when using bipolar input sources. Noise and drift in sensitive

input circuits can cause unpredictable changes in motor speed and direction. Use speed command parameters to help reduce input

source sensitivity.

ATTENTION: Risk of injury or equipment damage exists. DPI or SCANport host products must not be directly connected together

via 1202 cables. Unpredictable behavior can result if two or more devices are connected in this manner.

Qualified Personnel

Personal Safety

for

ATTENTION: The drive start/stop/enable control circuitry includes solid state components. If hazards due to accidental contact

with moving machinery or unintentional flow of liquid, gas or solids exists, an additional hardwired stop circuit may be required to

remove the AC line to the drive. An auxiliary braking method may be required.

ATTENTION: Hazard of personal injury or equipment damage due to unexpected machine operation exists if the drive is

configured to automatically issue a Start or Run command. Do not use these functions without considering applicable local,

national and international codes, standards, regulations or industry guidelines.

ATTENTION: Parameters 365 [Encdr0 Loss Cnfg] - 394 [VoltFdbkLossCnfg] let you determine the action of the drive in response to

operating anomalies. Precautions should be taken to be sure that the settings of these parameters do not create hazards of

personal injury or equipment damage.

ATTENTION: Parameters 383 [SL CommLoss Data] - 392 [NetLoss DPI Cnfg] let you determine the action of the drive if

communications are disrupted. You can set these parameters so the drive continues to run. Precautions should be taken to ensure

the settings of these parameters do not create hazards of personal injury or equipment damage.

ATTENTION: This product contains a 3V Lithium battery if the DriveLogix Controller option board is installed. Perchlorate Material special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

6 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 7

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Product Safety

ATTENTION: An incorrectly applied or installed drive can result in component damage or a reduction in product life. Wiring or

application errors such as under sizing the motor, incorrect or inadequate AC supply, or excessive surrounding air temperatures may

result in malfunction of the system.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are

required when installing, testing, servicing or repairing this assembly. Component damage may result if ESD control procedures are

not followed. If you are not familiar with static control procedures, reference Guarding Against Electrostatic Damage, publication

8000-4.5.2 or any other applicable ESD protection handbook.

ATTENTION: Configuring an analog input for 0-20 mA operation and driving it from a voltage source could cause component

damage. Verify proper configuration prior to applying input signals.

ATTENTION: A contactor or other device that routinely disconnects and reapplies the AC line to the drive to start and stop the

motor can cause drive hardware damage. The drive is designed to use control input signals that will start and stop the motor. If an

input device is used, operation must not exceed one cycle per minute or drive damage will occur.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical transmission equipment. This product emits intense

light and invisible radiation. Do not look into module ports or fiber optic cable connectors.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 7

Page 8

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 2: Prepare for

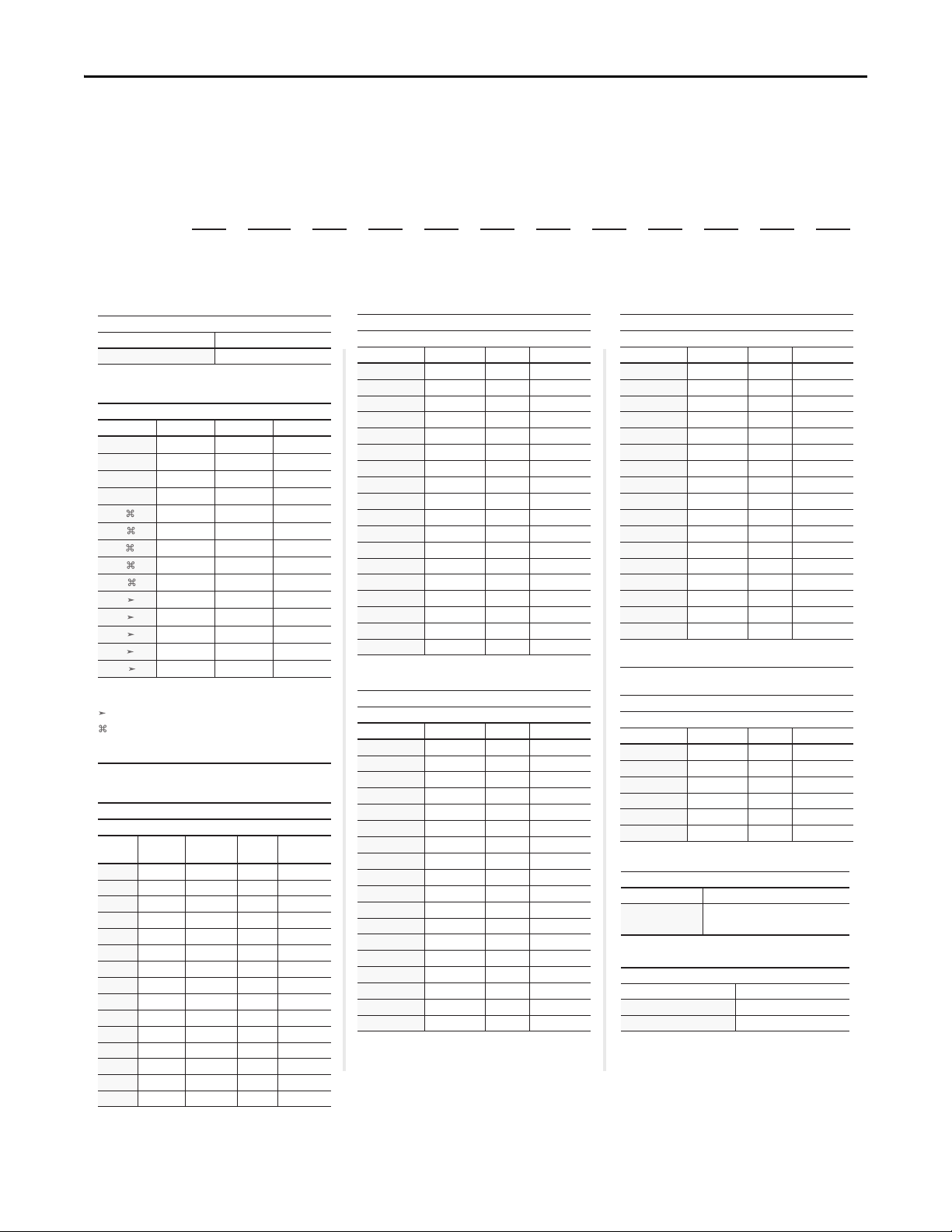

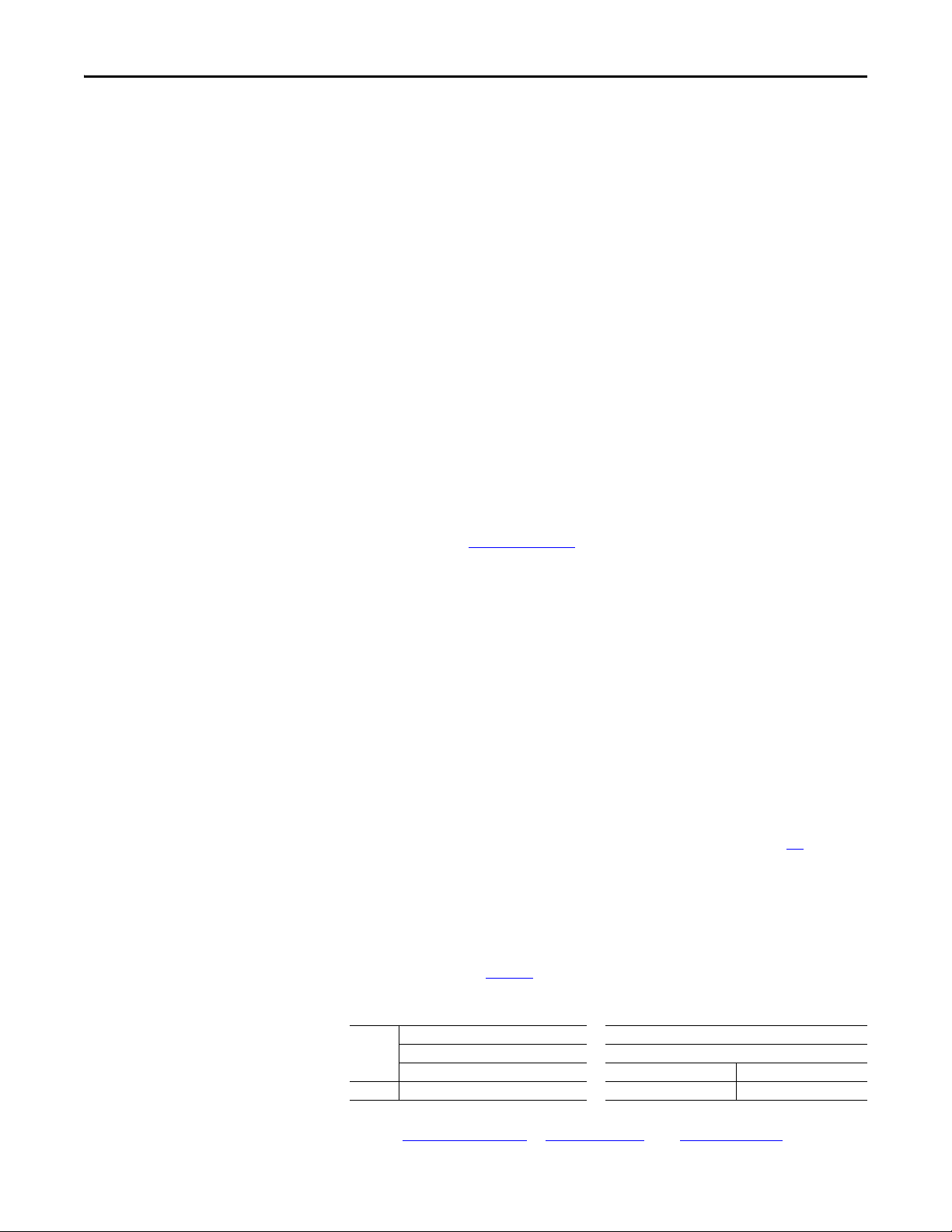

Catalog Number Explanation

Installation

Position

1-3 4 5-7 8 9 10 11 12 13 14 15 16 17

20D D 2P1 A 0 E Y N A N A N E

abcdefghijklm

a

Drive

Code Type

20D PowerFlex 700S

b

Voltage Rating

Code Voltage Ph. Prechg.

B §

240V AC

C §

400V AC

D §

480V AC

E ♣ §

F

H

J

K

M

N

P

R

T

W

♣ Note: CE Certication testing has not been

performed on 600V class drives, Frames 1…4.

Frames 5 & 6 only.

Frames 5 & 6 only.

§ For DC input on Frames 1…4, use the

corresponding AC input code B, C, D, or E.

600V AC

690V AC

540V DC

650V DC

810V DC

932V DC

325V DC

540V DC

650V DC

810V DC

932V DC

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

_

_

_

_

_

_

_

_

_

c1

ND Rating

208/240V, 60Hz Input

Code

4P2

6P8

9P6

015

022

028

042

052

070

080

104

130

154

192

260

208V

Amps

17.5

25.3

32.2

48.3

78.2

120

130

177

221

260

4.8

7.8

240V

Amps

4.2

6.8

11

56

92

9.6

15.3

22

28

42

52

70

80

104

130

154

192

260

Hp

1.0

2.0

3.0

5.0

7.5

10

15

20

25

30

40

50

60

75

100

_

_

_

_

_

N

N

N

N

Y

Y

Y

Y

Y

Frame

1

1

1

1

1

2

3

3

4

4

5

5

6

6

6

c2

ND Rating

400V, 50 Hz Input

Code Amps kW

2P1

3P5

5P0

8P7

011

015

022

030

037

043

056

072

085

105

125

170

205

260

2.1

3.5

5.0

8.7

11.5

15.4

22

30

37

43

56

72

85

105

125

170

205

260

0.75

1.5

2.2

4.0

5.5

7.5

18.5

110

132

c3

ND Rating

480V, 60 Hz Input

Code Amps Hp

2P1

3P4

5P0

8P0

011

014

022

027

034

040

052

065

077

096

125

156

180

248

2.1

3.4

5

8

11

14

22

27

34

40

52

65

77

96

125

156

180

248

1.0

2.0

3.0

5.0

7.5

100

125

150

200

Frame

1

1

1

1

1

1

11

15

22

30

37

45

55

55

90

10

15

20

25

30

40

50

60

75

1

2

2

3

3

3

4

5

5

6

6

6

Frame

1

1

1

1

1

1

1

2

2

3

3

3

4

5

5

6

6

6

Code Amps Hp

1P7

2P7

3P9

6P1

9P0

011

017

022

027

032

041

052

062

077

099

125

144

♣ Note: CE Certication testing has not been

performed on 600V class drives Frames 1…4.

Code Amps kW

052

060

082

098

119

142

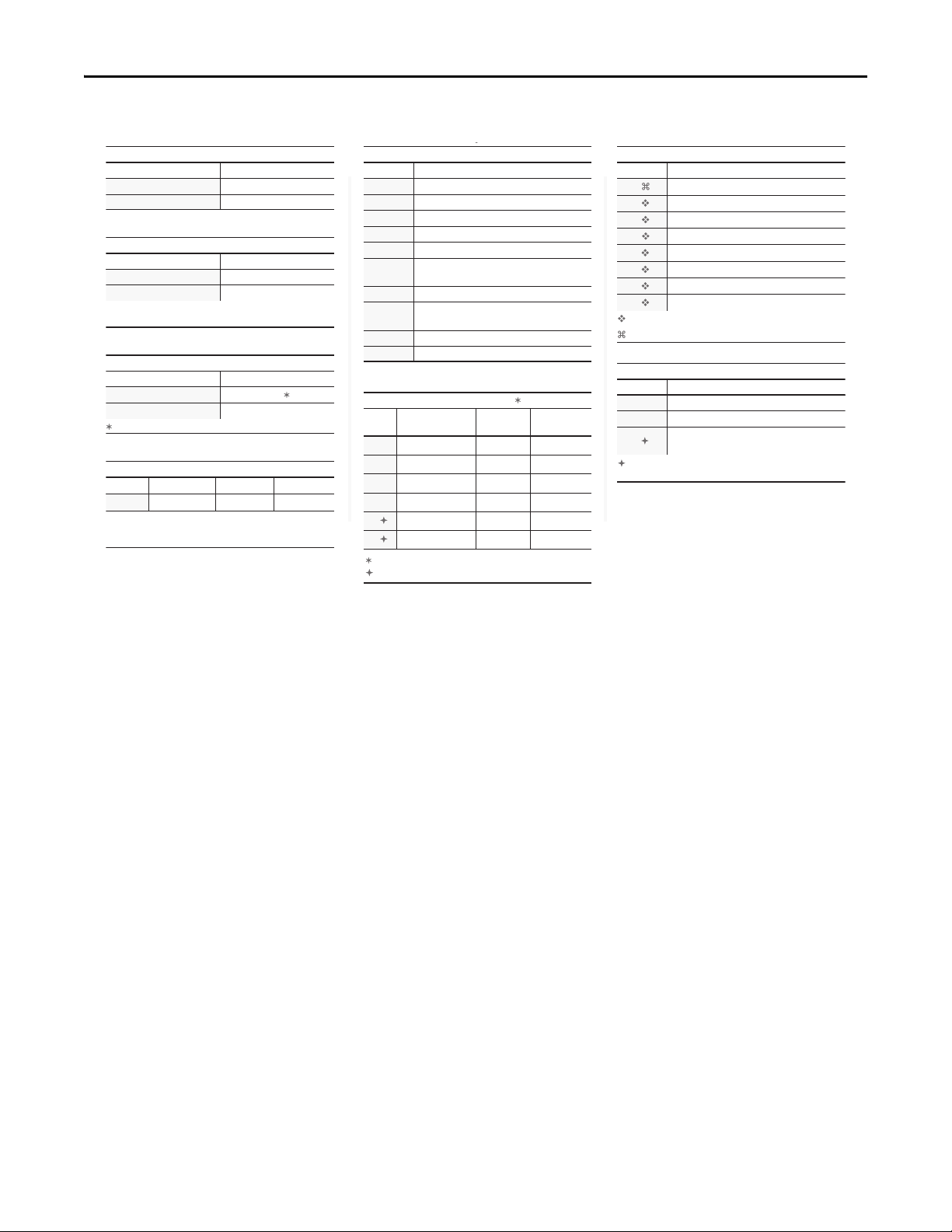

Code

A

Code Operator Interface

0 Blank Cover

3 Full Numeric LCD

c4

ND Rating

600V, 60 Hz Input

1.7

2.7

3.9

6.1

9

11

17

22

27

32

41

52

62

77

99

125

144

c5

ND Rating

690V, 50 Hz Input

52

60

82

98

119

142

d

Enclosure

Description

IP20, NEMA Type 1

with Conformal Coat

e

HIM

♣

0

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

45

55

75

90

110

132

Frame

1

1

1

1

1

1

1

2

2

3

3

3

4

5

5

6

6

Frame

5

5

5

5

6

6

8 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 9

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Feedback

Code Option

N

Standard (Incremental Encoder)

A

Resolver

B

Stegmann Hi-Resolution Encoder

C

Multi-Device Interface

E

2nd Encoder

S

Safe-O (w/2nd Encoder)

Expanded cassette required.

One encoder interface included with base drive.

m

Additional Cong.

Code Description

E Phase II Control

K Phase II DriveLogix5730

L

Phase II DriveLogix5730

w/EtherNet/IP

This is an embedded EtherNet/IP option that is

only available with DriveLogix5730.

T

Stegmann Hi-Res Enc. (w/2nd Encoder)

U

Stegmann Hi-Res Enc. (w/Safe-O)

Documentation

Code Documents

N No Documentation

g

Brake

Code w/Brake IGBT ‡

seYY

oNN

‡ Brake IGBT is standard on Frames 1…3 and

optional on Frames 4…9 ONLY.

h

Brake Resistor

Code w/Resistor

Y Ye s

oNN

Not available for Frame 3 drives or larger.

English ManualE

j

Comm Slot

Code Version

N None

C DPI ControlNet (Coax)

D DPI DeviceNet

E DPI EtherNet/IP

1 DriveLogix ControlNet (Coax)

2

DriveLogix ControlNet Redundant

(Coax)

3 DriveLogix ControlNet (Fiber)

4

DriveLogix ControlNet Redundant

(Fiber)

5 DriveLogix DeviceNet (Open Conn.)

6 DriveLogix EtherNet/IP

i

Emission

Code

CE Filter ♣

CM Choke

A

♣ Note: CE Certication testing has not been

performed on 600V class drives Frames 1…4.

Ye sYe s

du/dt Filter

No

k

Control Options

Code Cassette

A

Phase II Contol available only.

B

C

D

G

H

Logix Expansion Synchlink

No Expanded

Slim

No

No ExpandedYes

Yes ExpandedNo

Yes ExpandedYes

NoN/A

SlimYesN/A

Frames 1...9 only.

Catalog Number Explanation, Continued

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 9

Page 10

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

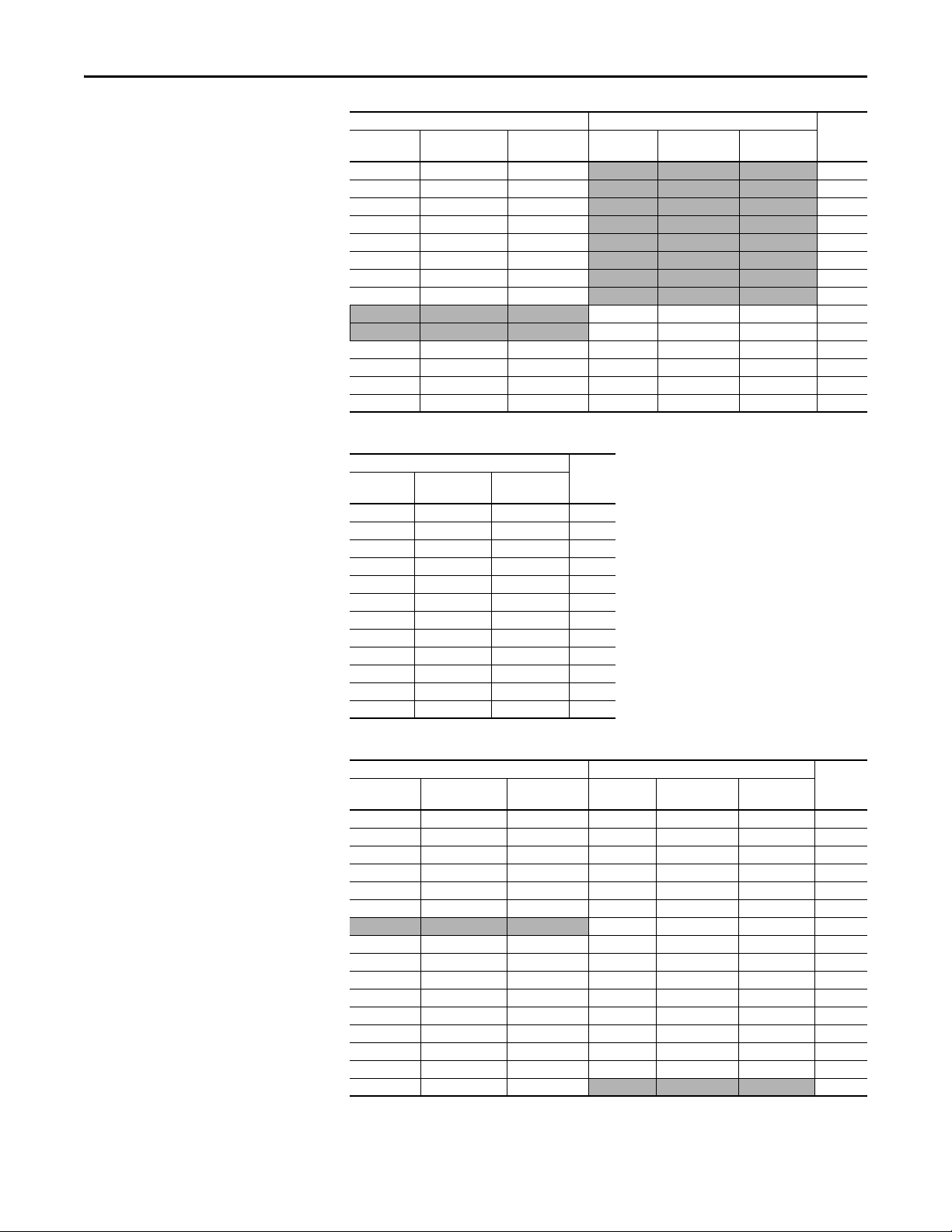

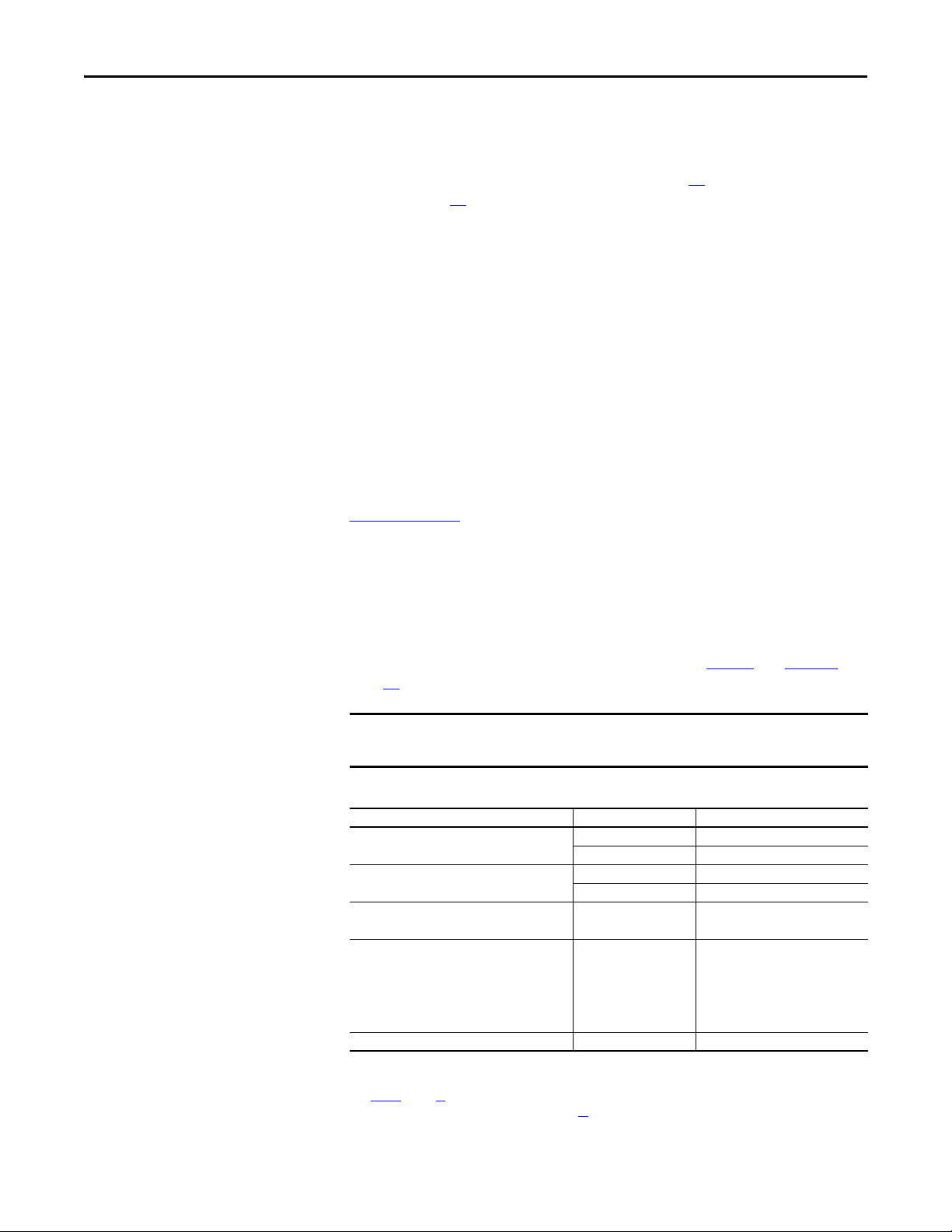

Drive Rating to Frame Size Cross References

Table 1 - 208/240 Volt AC Input, Six Pulse Drives

208V AC Input

Cat. No. Normal Duty

20DB4P2 0.75 0.55 20DB4P2 1 0.75 1

20DB6P8 1.5 1.1 20DB6P8 2 1.5 1

20DB9P6 2.2 1.5 20DB9P6 3 2 1

20DB015 4.0 3.0 20DB015 5 3 1

20DB022 5.5 4.0 20DB022 7.5 5 1

20DB028 7.5 5.5 20DB028 10 7.5 2

20DB042 11 7.5 20DB042 15 10 3

20DB052 15 11 20DB052 20 15 3

20DB070 18.5 15 20DB070 25 20 4

20DB080 22 18.5 20DB080 30 25 4

20DB104 30 22 20DB104 40 30 5

20DB130 37 30 20DB130 50 40 5

20DB154 45 37 20DB154 60 50 6

20DB192 55 45 20DB192 75 60 6

20DB260 66 55 20DB260 100 75 6

(1) The drive must be programmed to this voltage.

(1)

kW Rating

Heavy Duty kW

Rating

240V AC Input Frame

Cat. No. Normal Duty

Hp Rating

Heavy Duty Hp

Rating

Size

Table 2 - 400/480 Volt AC Input, Six Pulse Drives

400V AC Input 480V AC Input Frame

Cat. No. Normal Duty kW

Rating

20DC2P1 0.75 0.55 20DD2P1 1.0 0.75 1

20DC3P5 1.5 1.1 20DD3P4 2.0 1.5 1

20DC5P0 2.2 1.5 20DD5P0 3.0 2.0 1

20DC8P7 4.0 3.0 20DD8P0 5.0 3.0 1

20DC011 5.5 4.0 20DD011 7.5 5.0 1

20DC015 7.5 5.5 20DD014 10 7.5 1

20DC022 11 7.5 20DD022 15 10 1

20DC030 15 11 20DD027 20 15 2

20DC037 18.5 15 20DD034 25 20 2

20DC043 22 18.5 20DD040 30 25 3

20DC056 30 22 20DD052 40 30 3

20DC072 37 30 20DD065 50 40 3

20DC085 45 37 20DD077 60 50 4

20DC105 55 45 20DD096 75 60 5

20DC125 55 45 20DD125 100 75 5

20DC140 75 55

20DC170 90 75 20DD156 125 100 6

20DC205 110 90 20DD180 150 125 6

20DC260 132 110 20DD248 200 150 6

Heavy Duty kW

Rating

Cat. No. Normal Duty

Hp Rating

Heavy Duty Hp

Rating

Size

5

Table 3 - 600/690 Volt AC Input, Six Pulse Drives

600V AC Input 690V AC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE1P7 1.0 0.75

20DE2P7 2.0 1.5

20DE3P9 3.0 2.0

20DE6P1 5.0 3.0

20DE9P0 7.5 5.0

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

Heavy duty

kW Rating

Size

1

1

1

1

1

10 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 11

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

600V AC Input 690V AC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE011 10 7.5 1

20DE017 15 10

20DE022 20 15 2

20DE027 25 20

20DE032 30 25

20DE041 40 30

20DE052 50 40 3

20DE062 60 50 4

20DE077 75 60 20DF082 75 55 5

20DE099 100 75 20DF098 90 75 5

20DE125 125 100 20DF119 110 90 6

20DE144 150 125 20DF142 132 110 6

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

20DF052 45 37.5 5

20DF060 55 45 5

Heavy duty

kW Rating

Size

1

2

3

3

Table 4 - 325 Volt DC Input, Six Pulse Drives

325V DC input Frame

Cat. No. Normal Duty

Hp Rating

20DB015 5.0 3.0 1

20DB022 7.5 5.0 1

20DB028 10 7.5 2

20DB042 15 10 3

20DB052 20 15 3

20DB070 25 20 4

20DB080 30 25 4

20DN104 40 30 5

20DN130 50 40 5

20DN154 60 50 6

20DN192 75 60 6

20DN260 100 75 6

Heavy Duty Hp

Rating

Size

Table 5 - 540/650 Volt DC Input Drives

540V DC Input 650V DC Input Frame

Cat. No. Normal Duty kW

Rating

20DC3P5 1.5 1.1 20DD2P1 1.0 0.75 1

20DC5P0 2.2 1.5 20DD3P4 2.0 1.5 1

20DC8P7 4.0 3.0 20DD5P0 3.0 2.0 1

20DC011 5.5 4.0 20DD8P0 5.0 3.0 1

20DC015 7.5 5.5 20DD011 7.5 5.0 1

20DC022 11 7.5 20DD014 10 7.5 1

20DC030 15 11 20DD027 20 15 2

20DC037 18.5 15 20DD034 25 20 2

20DC043 22 18.5 20DD040 30 25 3

20DC056 30 22 20DD052 40 30 3

20DC072 37 30 20DD065 50 40 3

20DC085 45 37 20DD077 60 50 4

20DH105 55 45 20DJ096 75 60 5

20DH125 55 45 20DJ125 100 75 5

20DH140 75 55

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 11

Heavy Duty kW

Rating

Cat. No. Normal Duty

HP Rating

20DD022 15 10 1

Heavy Duty

HP Rating

Size

5

Page 12

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

540V DC Input 650V DC Input Frame

Cat. No. Normal Duty kW

Rating

20DH170 90 75 20DJ156 125 100 6

20DH205 110 90 20DJ180 150 125 6

20DH260 132 110 20DJ248 200 150 6

Heavy Duty kW

Rating

Cat. No. Normal Duty

HP Rating

Heavy Duty

HP Rating

Size

Table 6 - 810/932 Volt DC Input Drives

810V DC Input 932V DC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE1P7 1.0 0.75

20DE2P7 2.0 1.5 1

20DE3P9 3.0 2.0

20DE6P1 5.0 3.0 1

20DE9P0 7.5 5.0 1

20DE011 10 7.5

20DE017 15 10 1

20DE022 20 15 2

20DE027 25 20

20DE032 30 25 3

20DE041 40 30 3

20DE052 50 40

20DE062 60 50 4

20DT099 100 75 20DW098 90 75 5

20DT144 150 125 20DW142 132 110 6

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

Heavy Duty

kW Rating

Size

1

1

1

2

3

CE Conformity

Compliance with the Low Voltage (LV) Directive and Electromagnetic

Compatibility (EMC) Directive has been demonstrated using harmonized

European Norm (EN) standards published in the Official Journal of the

European Communities. PowerFlex drives comply with the EN standards listed

below when installed according to the PowerFlex 700S AC Drives Phase II

Control User and Reference Manuals.

CE Declarations of Conformity are available online at:

http://www.rockwellautomation.com/products/certification/

Low Voltage Directive (2006/95/EC)

• EN 61800-5-1 Adjustable speed electrical power drive systems –

Part 5-1: Safety requirements – Electrical, thermal and energy.

EMC Directive (2004/108/EC)

• EN 61800-3 Adjustable Speed Electrical Power Drive Systems Part 3: EMC Product Standard Including Specific Test Methods.

12 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 13

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

General Considerations

• If the adhesive label is removed from the top of the drive, the drive must be

installed in an enclosure with side openings less than 12.5 mm (0.5 in.) and

top openings less than 1.0 mm (0.04 in.) to maintain compliance with the

LV Directive.

• The motor cable should be kept as short as possible to avoid

electromagnetic emission as well as capacitive currents.

• Use of line filters in ungrounded systems is not recommended.

• PowerFlex drives may cause radio frequency interference if used in a

residential or domestic environment. The installer is required to take

measures to prevent interference, in addition to the essential requirements

for CE compliance provided in this section, if necessary.

• Conformity of the drive with CE EMC requirements does not guarantee

an entire machine or installation complies with CE EMC requirements.

Many factors can influence total machine/installation compliance.

• PowerFlex drives can generate conducted low frequency disturbances

(harmonic emissions) on the AC supply system.

• More information regarding harmonic emissions can be found in the

PowerFlex 700S AC Drives Phase II Control, Reference Manual,

publication PFLEX-RM003

• When operated on a public supply system, it is the responsibility of the

installer or user to be sure, by consultation with the distribution network

operator and Rockwell Automation, if necessary, that applicable

requirements have been met.

.

Essential Requirements for CE Compliance

Conditions 1…6 listed below must be satisfied for PowerFlex 700S Phase II

drives to meet the requirements of EN61800-3.

1. Standard PowerFlex 700S CE compatible drive.

2. Review important precautions/attentions statements throughout this

document before installing drive.

3. Grounding as described in Grounding Requirements on page 25

4. Output power, control (I/O) and signal wiring must be braided, shield

cable with a coverage of 75% or better, metal conduit or have shielding/

cover with equivalent attenuation.

5. All shielded cables should terminate with proper shielded connector.

6. Conditions in Ta b l e 7

Table 7 - PowerFlex 700S EN61800-3 EMC Compatibility

Frames Second Environment First Environment Restricted Distribution

Restrict Motor Cable to 30 m (98 ft) Restrict Motor Cable to 150 m (492 ft)

Any Drive and Option Any Drive and Option External Filter Required

1…6 √√√

(1) External filters for First Environment installations and increasing motor cable lengths in Second Environment installations are

available. Roxburgh models KMFA (RF3 for UL installations) and MIF or Schaffner FN3258 and FN258 models are recommended.

Refer to http://www.deltron-emcon.com

below.

(1)

and http://www.mtecorp.com (USA) or http://www.schaffner.com, respectively.

.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 13

Page 14

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

Common Bus and Precharge Considerations

The following notes must be read and understood. Also refer to Selecting/

Verifying Fan Voltage (Frames 5 and 6 Only) on page 34

Blocks on page 41

for additional common bus information.

1. If drives without internal precharge are used (frames 5 and 6 only), then:

a. precharge capability must be provided in the system to guard against

possible damage, and

b. disconnect switches Must Not be used between the input of the drive

and a common DC bus without the use of an external precharge device.

2. If drives with internal precharge (frames 1…6) are used with a disconnect

switch to the common bus, then an auxiliary contact on the disconnect

must be connected to a digital input of the drive. The corresponding input

(parameter 361…366) must be set to option 30, “Precharge Enable.” This

provides the proper precharge interlock, guarding against possible damage

to the drive when connected to a common DC bus.

Refer to PowerFlex AC Drives in Common Bus Configurations, publication

DRIVES-AT002

, for more information.

through Power Terminal

Operating Conditions and Temperatures

PowerFlex 700S frame 1…6 drives are designed to operate at 0…40 °C (32…104

°F) ambient. To operate most frame 1…4 drives in installations between 41 and

50 ° C (105.8 and 122 °F), you must remove the top adhesive label from the

drive. Frames 5 and 6 do not have an adhesive label. See Ta b l e 8

page 15

below for more information.

Removing the adhesive label from the top of frame 1…4 drives changes the

NEMA/UL enclosure rating from Type 1 to Type Open.

Table 8 - Enclosure Types and Acceptable Surrounding Air Temperature

Enclosure Type Temperature Rating Drive

IP20, NEMA/UL Type 1

(with Top Label)

IP20, NEMA/UL Type Open

(Top Label Removed)

IP00, NEMA/UL Type Open

(Top Label and Vent Plate Removed)

Flange Mount

Front (Inside Encl.) - IP00, NEMA/UL Type Open

Back/Heat Sink - IP54, NEMA/UL

Typ e 12

Stand-Alone/Wall Mount - IP54, NEMA/UL Type 12 0…40 °C (32…104 °F) Frames 5 and 6

(1) Frames 5 and 6 do not have a label.

(2) To remove the vent plate, lift the top edge of the plate away from the chassis and ro tate the plate out from the back plate. Refer to

Figure 3

(3) Refer to the Fusing and Circuit Breakers tables on page 44, for exceptions.

(1)

(1)

(2)

on page 17 for location of vent plate.

0…40 °C (32…104 °F) Frame 1…4, All Ratings

0…50 °C (32…122 °F) Frames 5 and 6, Most Ratings

0…50 °C (32…122 °F) Most Ratings

0…45 °C (32…113 °F) 20DC072 and 20DE062 Only

0…50 °C (32…122 °F) 20DC072 Only

Frames 5 a nd 6

0…55 °C (32…131 °F)

0…40 °C (32…104 °F)

and Figure 1 on

(3)

(2)

14 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 15

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

With Ad hesive

Label Removed

Adhesive LabelWith Adhesive Label

Left in Place

Air flow through the drive

must not be impeded.

PowerFlex 700S drives must be mounted in a clean, dry location. Contaminants

such as oils, corrosive vapors and abrasive debris must be kept out of the

enclosure. These enclosures are intended for indoor use primarily to provide a

degree of protection against contact with enclosed equipment. These

enclosures offer no protection against airborne contaminants.

Minimum Mounting Clearances

Specified vertical clearance requirements are intended to be from the drive to the

closest object that can restrict airflow through the drive heat sink and chassis. The

drive must be mounted in a vertical orientation as shown, and must make full

contact with the mounting surface. Do not use standoffs or spacers. In addition,

inlet air temperature must not exceed the product specification. See Ta b l e 8

page 14

Figure 1 - Minimum Mounting Clearance Requirements

for ambient air temperature limits.

on

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

50.8 mm

(2.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 15

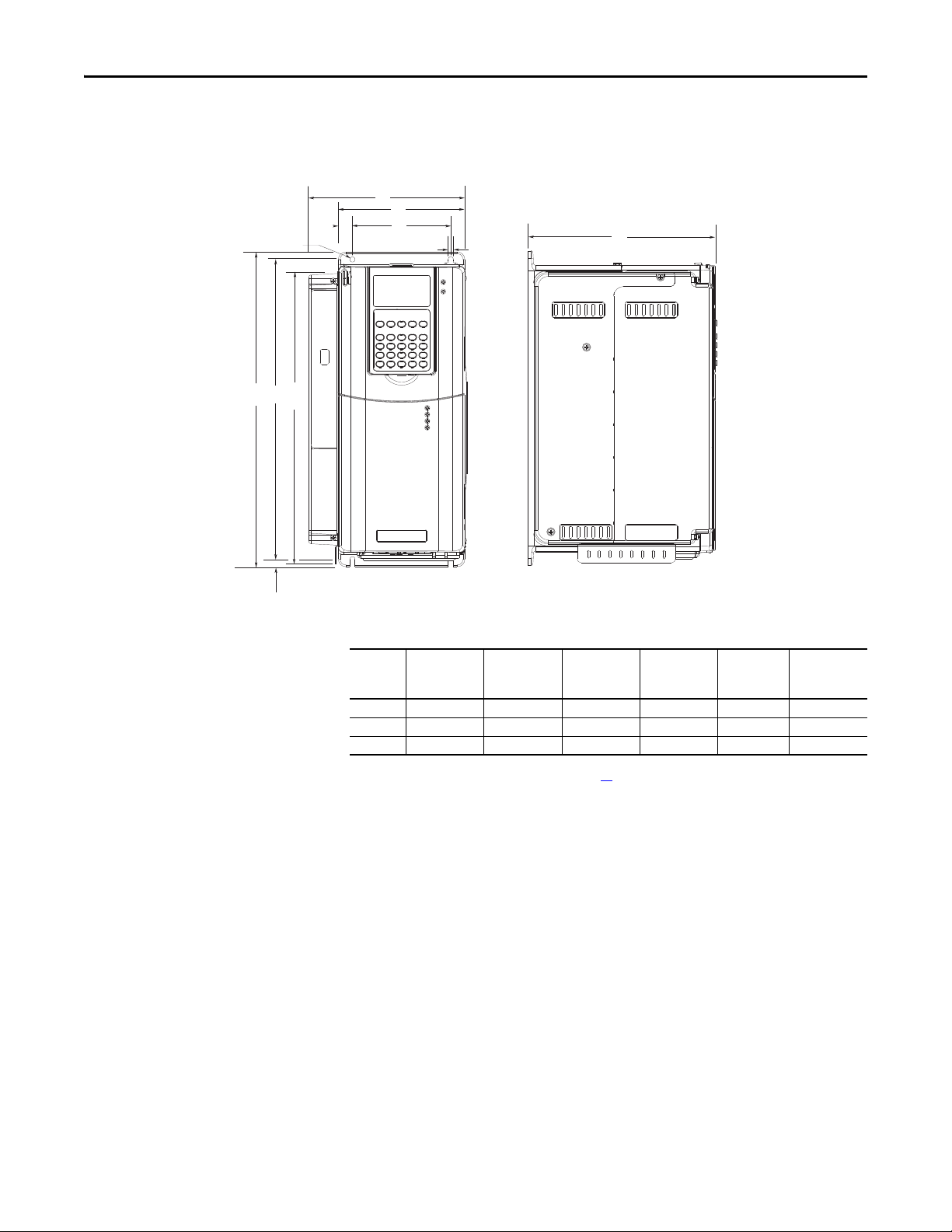

Page 16

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Dimensions are in millimeters and (inches)

Frame 1 Shown

15.0

(0.59)

5.8

(0.23) dia.

312

E

B

(12.28)

Approximate Dimensions

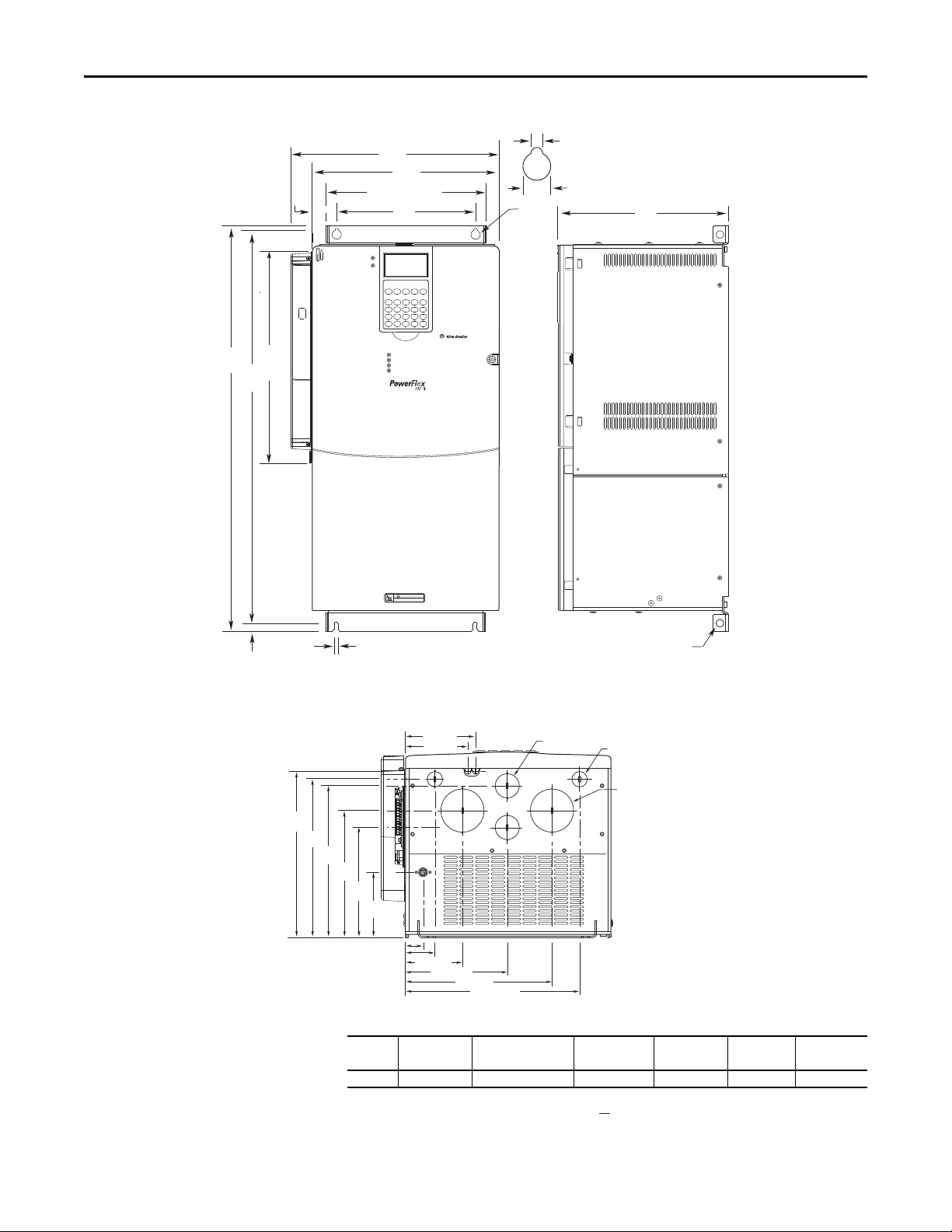

Figure 2 - Frames 1…3

AA

A

D

5.5 (0.22)

C

8.0

(0.31)

(1)

Frame

Slim CassetteAExpanded

BCDE

Cassette

AA

1 135.0 (5.31) 166.9 (6.57) 336.0 (13.23) 200.0 (7.87) 105.0 (4.13) 320.0 (12.60)

2 222.0 (8.74) 253.9 (9.99) 342.5 (13.48) 200.0 (7.87) 192.0 (7.56) 320.0 (12.60)

3 222.0 (8.74) 253.9 (9.99) 517.5 (20.37) 200.0 (7.87) 192.0 (7.56) 500.0 (19.69)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

16 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 17

Figure 3 - Bottom Views, Frames 1…3

133.3

(5.25)

187.6

(7.39)

25.5

(1.00)

70.0 (2.76)

43.0 (1.69)

96.0 (3.78)

75.9 (2.99)

108.5 (4.27)

67.5 (2.66)

47.5 (1.87)

87.5 (3.44)

22.2 (0.87) Dia.

3 Places

28.6 (1.13) Dia.

185.1

(7.29)

162.3

(6.39)

66.0 (2.60)

94.7 (3.73)

105.3 (4.15)

97.0 (3.82)

137.2 (5.40)

187.0 (7.36)

22.7 (0.89)

29.0 (1.14)

127.7

(5.03)

151.1

(5.95)

160.1

(6.30)

165.1

(6.50)

184.5

(7.26)

22.2 (0.87) Dia.

28.7 (1.13) Dia.

2 Places

37.3 (1.47) Dia.

2 Places

66.0 (2.60)

94.7 (3.73)

105.3 (4.15)

130.0 (5.12)

186.0 (7.32)

22.7 (0.89)

29.0 (1.14)

127.7

(5.03)

160.1

(6.30)

165.1

(6.50)

184.5

(7.26)

28.7 (1.13) Dia.

2 Places

46.7 (1.84) Dia.

2 Places

34.9 (1.37) Dia.

2 Places

Vent Plate

Frame 1 Frame 2

Frame 3 - All Drives, except 50 Hp, 480V (37 kW, 400V) Frame 3 - 50 Hp, 480V (37 kW, 400V) Normal Duty

Dimensions are in millimeters and (inches)

22.4 (0.88) Dia.

2 Places

157.5

(6.20)

150.9

(5.94)

112.1

(4.41)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

167.5 (6.59)

39.3 (1.55)

57.2 (2.25)

72.7 (2.86)

156.9 (6.18)

106.0 (4.17)

139.4 (5.49)

177.4 (6.98)

28.7 (1.13) Dia.

3 Places

184.8

(7.28)

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 17

Page 18

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

54.1 (2.13) Dia.

2 Places

47.0 (1.85) Dia.

2 Places

28.7 (1.13) Dia.

2 Places

26.8 (1.06)

36.8 (1.45)

50.7 (2.00)

141.9

(5.59)

105.1

(4.14)

157.9

(6.21)

177.9

(7.00)

189.7

(7.47)

22.2 (0.87) Dia.

63.8 (2.51)

112.0 (4.41)

180.0 (7.09)

65.3 (2.57)

76.0 (2.99)

Dimensions are in millimeters and (inches)

Bottom View

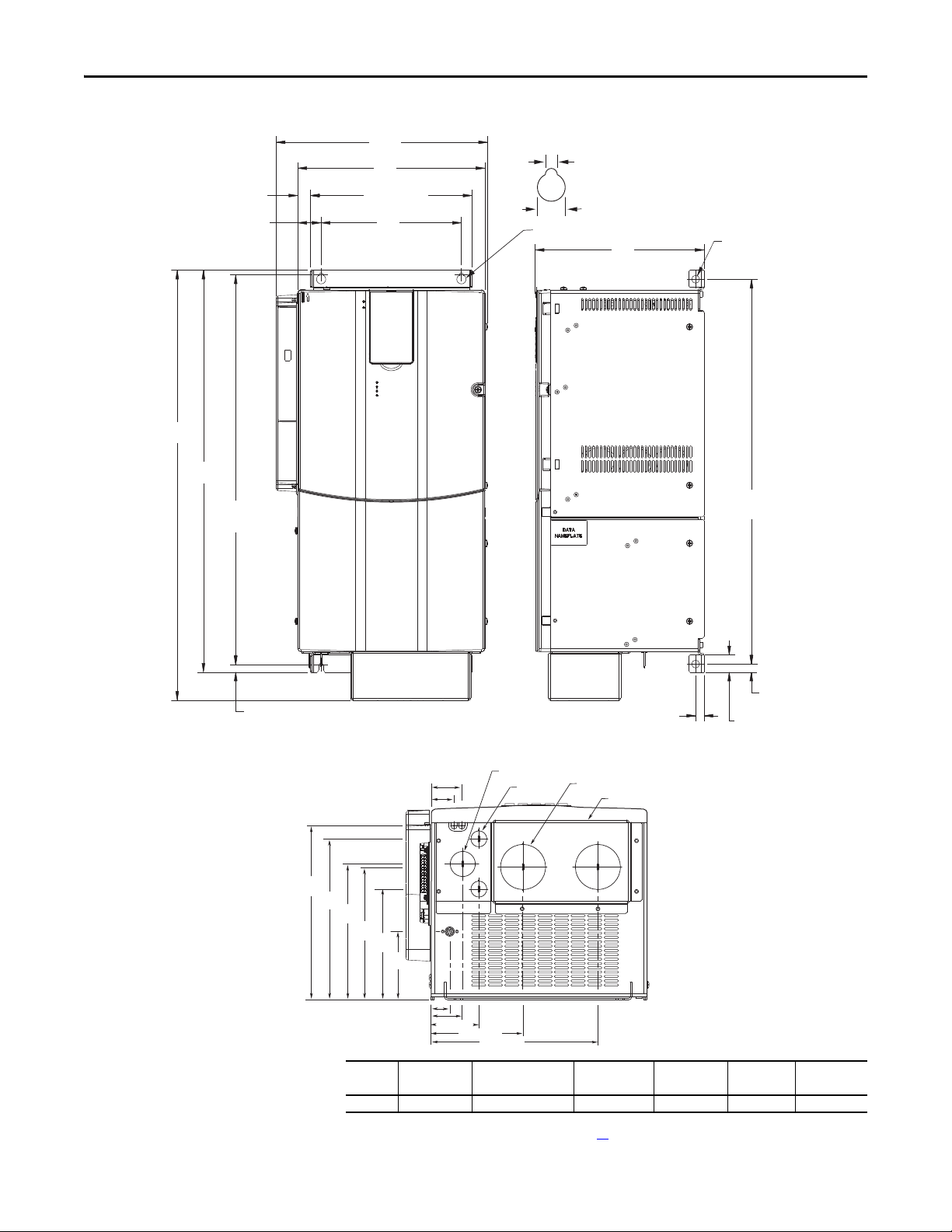

Figure 4 - Frame 4

AA

A

D

13.0 (0.55)

312

(12.28)

7.0 (0.28) 2 Places

S

E

15.1 (0.59)

B

C

Lifting Holes

4 Places

7.0 (0.28)

3 Places

8.0

(0.31)

(1)

Frame

Slim Cassette

Expanded CassetteAABC (Max) DE

A (Max)

4 220.0 (8.66) 251.9 (9.92) 758.8 (29.87) 201.7 (7.94) 192.0 (7.56) 738.2 (29.06)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

18 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 19

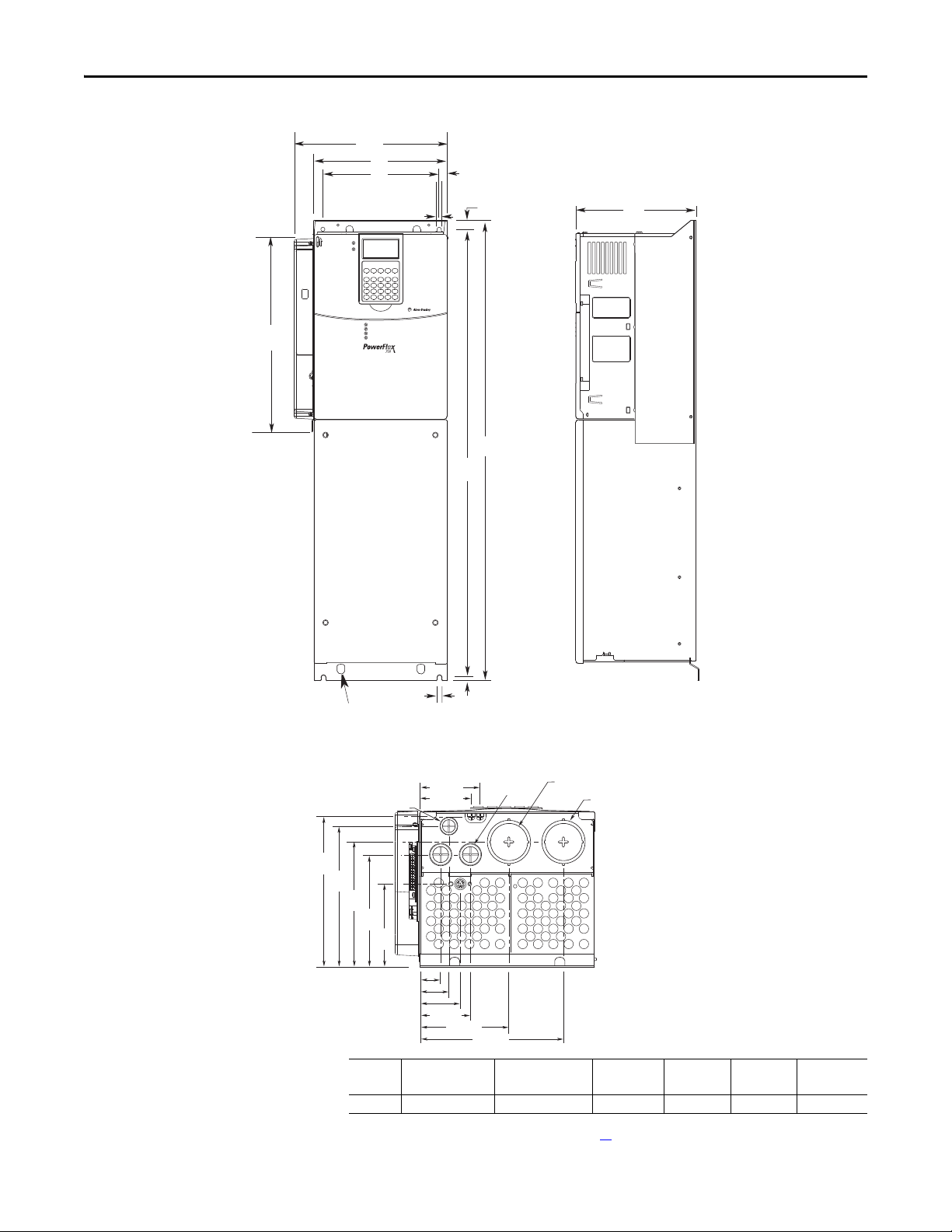

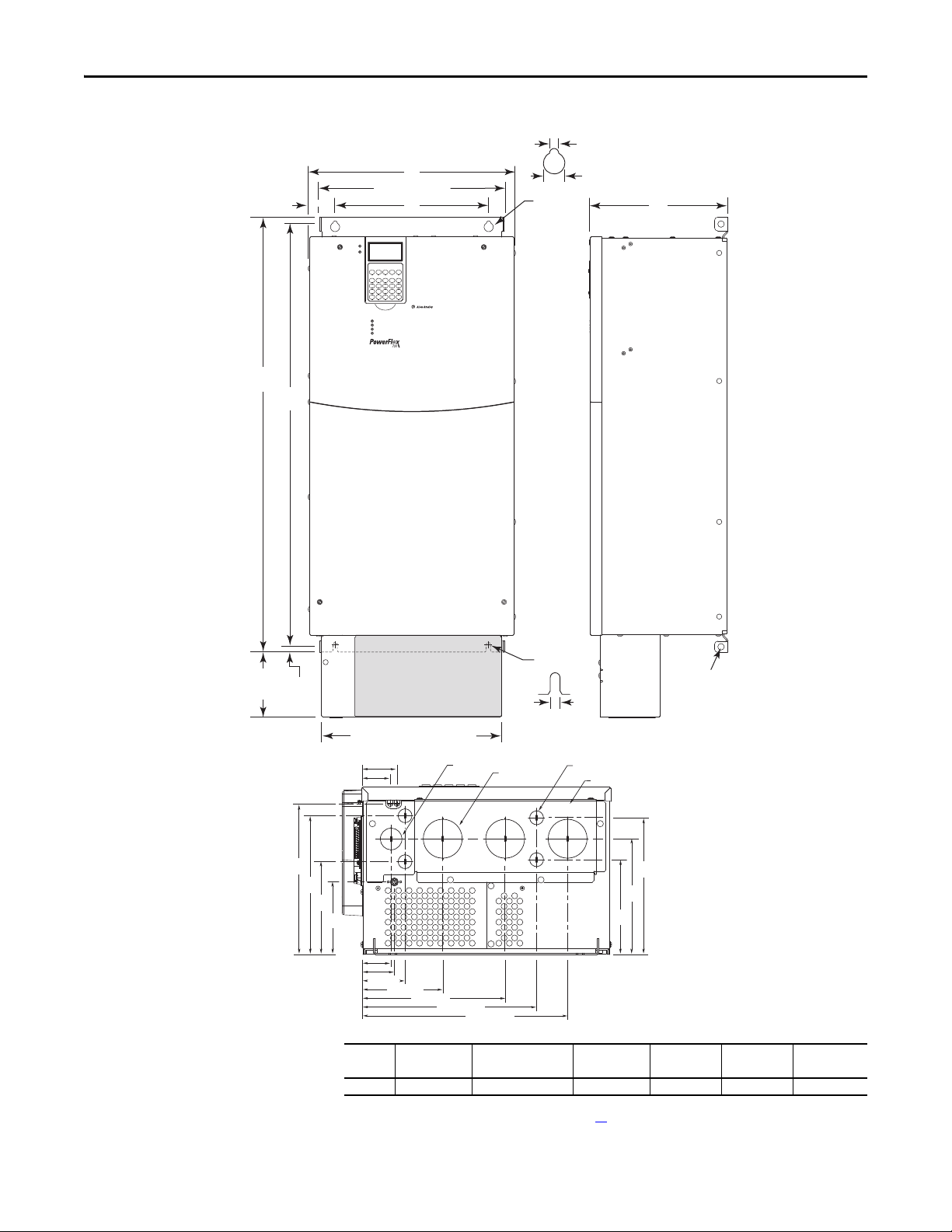

Figure 5 - Frame 5, 75 Hp, 480V (55kW, 400V)

Bottom View

HOT surfaces can cause severe burns

CAUTION

E

12.5

(0.49)

6.5 (0.26)

B

D

A

259.1 (10.20)

Detail

15.0 (0.59)

6.5 (0.26)

37.6

(1.48)

C

Lifting Holes - 4 Places

12.7 (0.50) Dia.

312

(12.28)

S

AA

96.0

(3.78)

159.5

(6.28)

184.0

(7.24)

220.0

(8.66)

229.5

(9.04)

241.9

(9.52)

45.0 (1.77)

85.0 (3.35)

93.2 (3.67)

104.0 (4.09)

150.0 (5.91)

215.0 (8.46)

255.0 (10.04)

28.0 (1.10)

22.2 (0.87) Dia.

2 Places

62.7 (2.47) Dia.

2 Places

34.9 (1.37) Dia.

2 Places

Dimensions are in millimeters and (inches)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Frame

(1)

Slim Cassette

Expanded CassetteAABC (Max) DE

A (Max)

5 308.0 (12.2) 339.9 (13.4) 644.5 (25.4) 275.4 (10.9) 225.0 (8.9) 625.0 (24.6)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 19

Page 20

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Bottom View

Dimensions are in millimeters and (inches)

20.5 (0.8)

37.6 (1.48)

B

E

625.0

(24.6)

Figure 6 - Frame 5, 100 Hp, 480V (55kW, 400V)

AA

A

259.1 (10.20)

D

6.5 (0.3)

Detail

15.0 (0.6)

4 x Ø 12.7

C

(0.5)

617.0

(24.3)

12.0

(0.5)

241.9

(9.52)

223.5

(8.80)

188.5

(7.42)

184.3

(7.26)

Frame

42.6 (1.68)

31.9 (1.26)

153.5

(6.04)

96.0

(3.78)

28.0 (1.10)

44.0 (1.73)

(1)

Slim Cassette

13.0

(0.5)

66.4 (2.61)

128.0 (5.04)

34.9 (1.37) Dia.

232.3 (9.15)

22.2 (0.87) Dia.

2 Places

62.7 (2.47) Dia.

2 Places

Removable

Junction Box

Expanded CassetteAABC (Max) DE

27.6

(1.1)

A (Max)

5 308.9 (12.2) 340.8 (13.4) 689.6 (27.1) 270.35 (10.6) 225.0 (8.9) 644.5 (25.4)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

13.0

(0.5)

20 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 21

Figure 7 - Frame 6

Dimensions are in millimeters and (inches)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

8.5 (0.33)

49.6

(1.95)

B

A

360.6 (14.20)

D

Detail

18.0 (0.71)

C

E

126.3

(4.97)

13.5

(0.53)

242.0

(9.53)

222.3

(8.75)

Detail

Old Style Junction Box

Lifting Holes

4 Places

12.7 (0.50) Dia.

219.0

(8.62)

C (Max) DE

New Style Junction Box

56.2 (2.21)

45.6 (1.80)

148.5

(5.85)

116.6

(4.59)

47.1 (1.85)

52.1 (2.05)

69.1 (2.72)

Frame

130.1 (5.12)

(1)

Slim Cassette

230.1 (9.06)

280.1 (11.03)

(0.33)

34.9 (1.37) Dia.

3 Places

62.7 (2.47) Dia.

3 Places

330.1 (13.00)

Expanded CassetteAAB

8.5

22.2 (0.87) Dia.

4 Places

Removable Junction Box

151.8

(5.98)

(2)

185.4

(7.30)

A (Max)

6 403.9 (15.90) 435.8 (17.16) 850.0 (33.46) 275.5 (10.85) 300.0 (11.81) 825.0 (32.48)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

(2) Junction Box can be removed if drive is mounted in a cabinet.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 21

Page 22

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 3: Lift and Mount the

Drive

Drive Weights

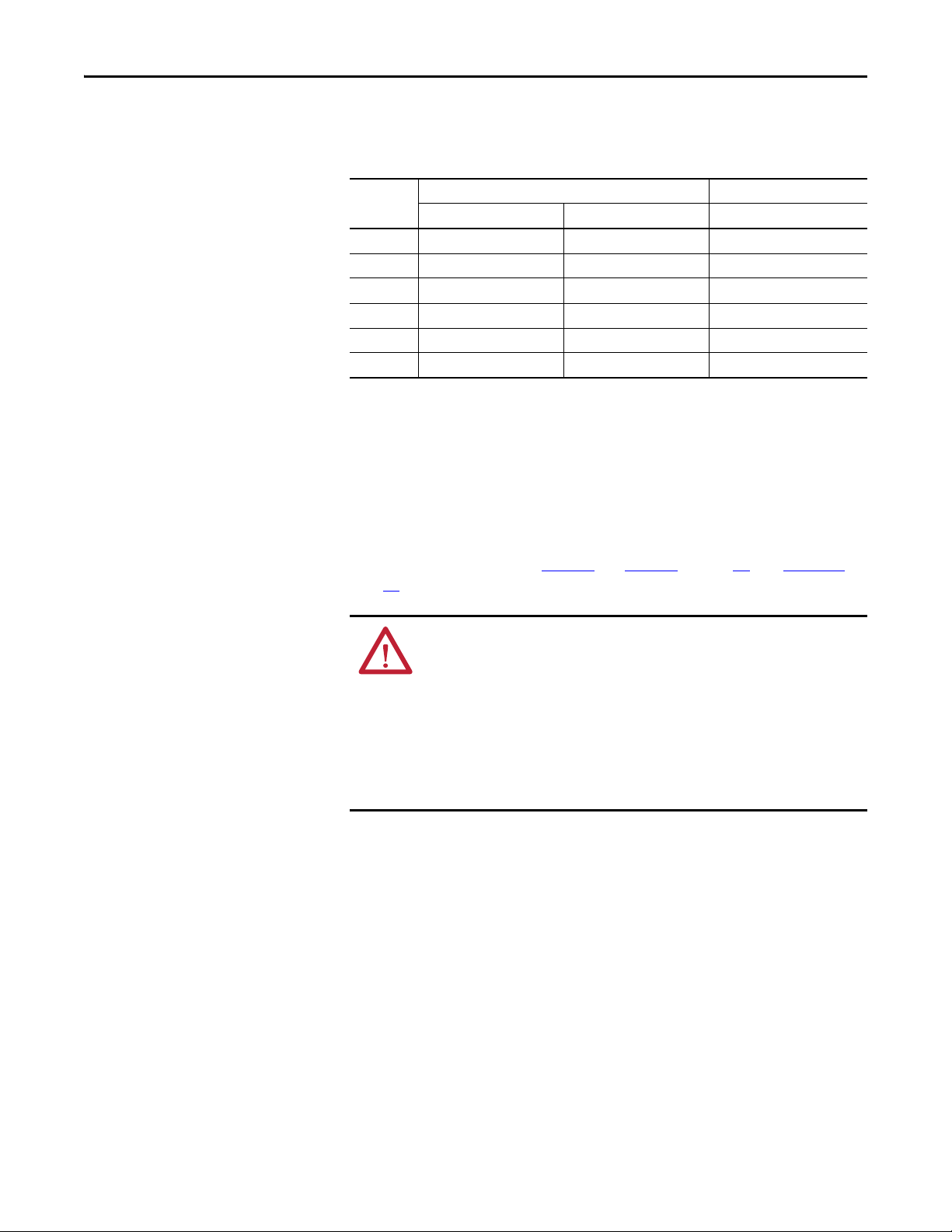

Table 9 - Approximate Drive Weights

Frame Size Drive Rating Drive Weight

kW Hp kg (lb)

1 0.75…11 1…10 7.0 (15.5)

2 7.5…18.5 10…25 12.5 (27.6)

3 11…37 15…50 18.6 (40.9)

4 25…60 18.5…55 24.5 (54.0)

5 40…100 30…90 37.2 (82.0)

6 60…200 45…132 71.5 (157.5)

(1) Weights include HIM, DriveLogix controller with ControlNet daughtercard, Hi-Resolution Encoder Option, and 20-COMM-C

Contro lNet adapt er.

(2) Add an additional 3.6 kg (8.0 lb) for 200 Hp drives.

(1)

(2)

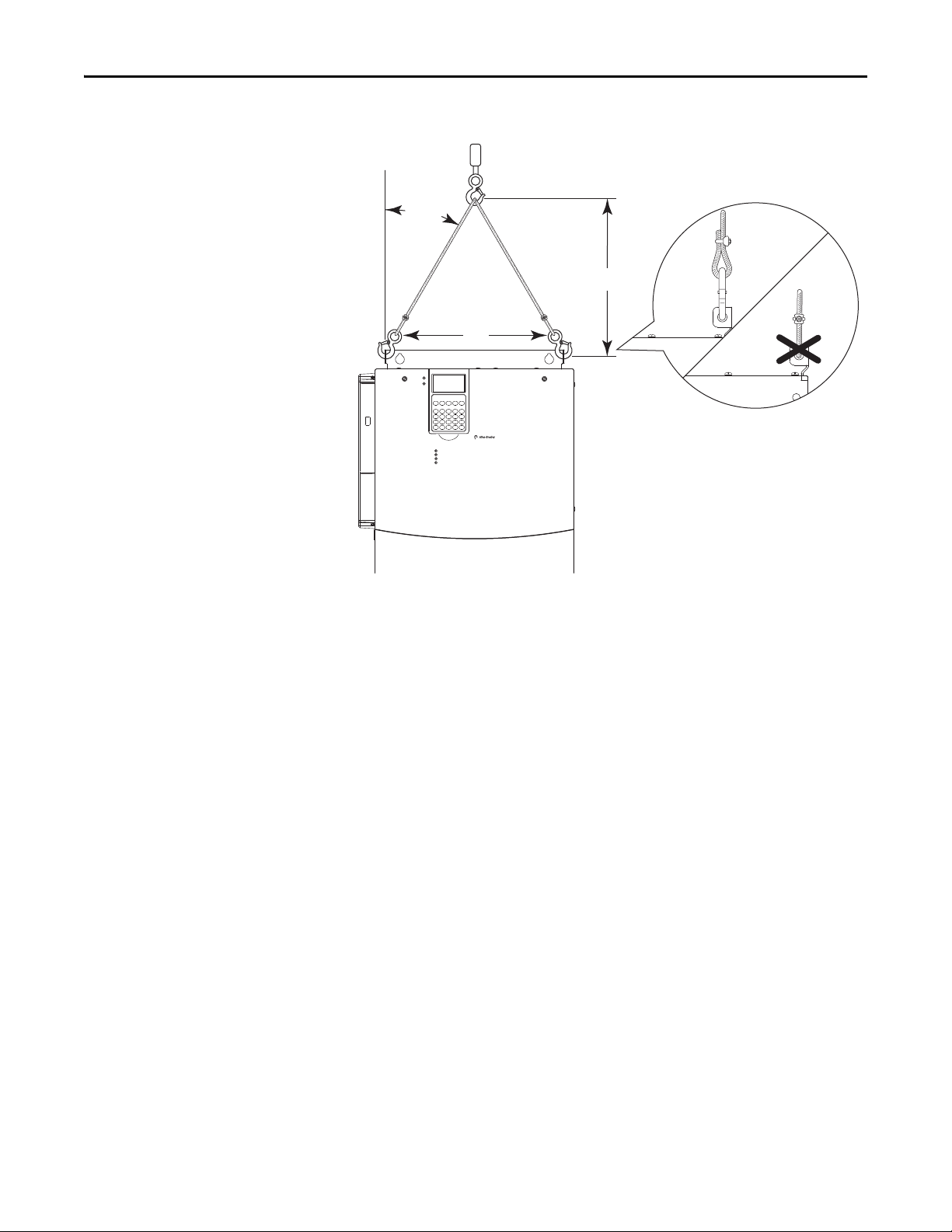

Attaching the Lifting Hardware

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

and so forth) must be properly sized and rated to safely lift and hold the weight of

the drive while mounting. See Figure 8

page 24

for lifting instructions.

and Figure 9 on page 23, and Figure 10 on

ATTENTION: To guard against possible personal injury and/or equipment

damage…

• Inspect all lifting hardware for proper attachment before lifting drive.

• Do not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• Do not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do not allow personnel or their limbs directly underneath the drive when it is

being lifted and mounted.

22 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 23

Figure 8 - Lifting Frame 4 Drives

S

>

1

/

2 A

A

< 45°

S

>

1

/

2 A

A

< 45°

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Figure 9 - Lifting Frame 5 Drives

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 23

Page 24

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

>

1

/

2 A

A

< 45°

Figure 10 - Lifting Frame 6 Drives

24 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 25

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

U (T1)

V (T2)

W (T3)

R (L1)

S (L2)

T (L3)

PE

SHLD

Step 4: Power Wiring

ATTENTION: National Codes and standards (NEC, VDE, BSI and so forth) and

local codes outline provisions for safely installing electrical equipment.

Installation must comply with specifications regarding wire types, conductor

sizes, branch circuit protection and disconnect devices. Failure to do so may

result in personal injury and/or equipment damage.

Grounding Requirements

The drive Safety Ground-PE must be connected to system ground. Ground

impedance must conform to the requirements of national and local industrial

safety regulations and/or electrical codes. The integrity of all ground connections

should be periodically checked.

Figure 11 - Typical Grounding

Shield Termination - SHLD

The Shield terminal (see page 39) provides a grounding point for the motor cable

shield. It must be connected to an earth ground by a separate continuous lead.

The motor cable shield should be connected to this terminal on the drive and the

motor frame. Use a shield terminating or EMI clamp to connect shield to this

terminal.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 25

Page 26

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Unbalanced, Ungrounded or Resistive Grounded Distribution

Systems

If phase to ground voltage will exceed 125% of normal or the supply system is

ungrounded, refer to Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives, publication DRIVES-IN001

information.

ATTENTION: PowerFlex 700S drives contain protective MOVs and common

mode capacitors that are referenced to ground. These devices must be

configured according to the recommendations in Ta bl e 10

, for more

on page 27.

RFI Filter Ground

Using an optional RFI filter may result in relatively high ground leakage currents.

Therefore, the filter must only be used in installations with grounded AC supply

systems and be permanently installed and solidly grounded (bonded) to the

building power distribution ground. Be sure that the incoming supply neutral is

solidly connected (bonded) to the same building power distribution ground.

Grounding must not rely on flexible cables and should not include any form of

plug or socket that would permit inadvertent disconnection. Some local codes

may require redundant ground connections. The integrity of all connections

should be periodically checked. Refer to the instructions supplied with the filter.

26 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 27

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

R/L1

S/L2

T/L3

DC+

DC–

MOV and AC EMI Capacitor Phase to Ground

Common Mode Capacitor Phase to Ground

Jumper Wire

Jumper Wire

Power Jumpers

PowerFlex 700S Phase II drives contain protective MOVs and Common Mode

Capacitors that are referenced to ground (see below). To guard against unstable

operation and/or damage, the drive must be properly configured

Ta b l e 1 0

on page 27.

as shown in

All PowerFlex 700S Phase II drives are shipped with the DC bus common mode

capacitors referenced to ground. The following installation instructions must

be completed before applying power to the drive.

Table 10 - Recommended Power Jumper Configurations

Power S ource Ty pe

Solid Ground

• AC fed, solidly grounded

• DC fed from passive rectifier, which has

an AC source and solid ground

Non-Solid Ground

• AC fed ungrounded

• Impedance grounded

• High resistive ground

• B phase ground

• Regenerative unit such as common DC

bus supply & brake

• DC fed from an active converter

(1) It is highly recommended to accurately determine the power source type and then configure appropriately.

(2) When MOVs are disconnected, the power system must have its own transient protection to verify known and controlled voltages.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 27

(1)

MOV/ Input Filter

(2)

Caps

Connected Connected

Disconnected D isconnected

DC Bus Common

Mode Caps

Benefits Of Correct Configuration on

Power S ource Ty pe

• UL compliance,

• Reduced electrical noise,

• Most stable operation,

• EMC compliance,

• Reduced voltage stress on

components and motor bearings

• Helps avoid severe equipment

damage when ground fault

occurs

Page 28

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

Volt age Co de

Frame

Current Rating

Series

To connect or disconnect these devices, refer to pages 29 through 32.

Common mode capacitors are required to conform with the EMC directive.

Removing these devices will withdraw the associated directive.

In addition, on an ungrounded distribution system where the line-to-ground

voltages on any phase could exceed 125% of the nominal line-to-line voltage, an

isolation transformer should be installed. See Wiring and Grounding Guidelines

for PWM AC Drives, publication DRIVES-IN001

for more information on

impedance grounded and ungrounded systems.

Jumper Installation, Removal and Storage

PowerFlex 700S drives utilize plug-in style jumpers and jumper wires. Most drives

will have a jumper storage area inside the front cover. Extra jumpers or jumpers

that have been removed should be stored in this location for use at a later time.

Insulating Jumper Wires

Some drives utilize nylon screws and spacers to insulate jumper

wires from ground and secure them to the chassis. The

components must be installed as shown.

Drive Identification

Refer to the drive nameplate and locate the “Voltage Code,” “Current Rating,”

“Frame,” and “Series”. Use this information to locate the proper procedure in the

following tables.

Cat No. 20D D xxx x x xxxxxxx

UL TYPE 1/IP20

Normal Duty Power

Heavy Duty Power

Input: 3 Phase, 47-63Hz

AC Voltage Range

Amps

Output: 3 Phase, 0-400 Hz

AC Voltage Range

Base Hz (default)

Continuous Amps

1 Min Overload Amps

3 Sec Overload Amps

Mfd. in 2007 on Aug 1

Made in the USA (TAC 1J)

Rockwell Automation, Mequon WI 53092-4400

400V 480V

xxx kW

xxx kW

342-440

0-400

50 Hz

xxx

xxx

xxx

xxx

432-528

xxx kW

xxx kW

xxx

0-460

60 Hz

xxx

xxx

xxx

Frame: 3

Serial Number: xxxxxxx

Series: B

Original Firmware V. x.xxx

U

c

L

®

US

Listed

Ind. Cont

Eq. 966X

N223

28 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 29

Frame

BR1

BR2

DC+

DC–

PE

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

Use 75C Wire Only

#10-#14 AWG

Torque to 7 in-lbs

!

DANGER

PE A

PE B

CM Cap

MOV

BR1 BR2 DC+ DC- U/T1 V/T2 W/T3

SHLD SHLD

PE R/L1 S/L2 T/L3

PE 2

MOV-PE JMPR

PE 1

AUX IN+ AUX OUT–

75C Cu Wire

6 AWG [10MM2] Max.

12 IN. LBS.

1.4 N-M

} TORQUE

WIRE

STRIP

CONTROL

POWER

PE 4

PE 3

MOV

PE_MOV

CM Cap

PE_CAP

1 B

Volt age

C

D

E

Factory Default Jumper Settings Power Source Type

MOV/Input Filter

Current

Rating

Caps

Code

All PE_B

Installed

Table 11 - Jumper Settings and Locations

DC Bus Common

Mode Caps

PE_A

Installed

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Solid Ground

• Remove the I/O Cassette (refer to the Installation

Instructions for details). Verify that jumpers are

installed at the “PE_A” and “PE_B” locations on

the Power Board.

Non-Solid Ground

• Remove the I/O Cassette (refer to the Installation

Instructions for details). Remove jumpers at the

“PE_A” and “PE_B” locations on the Power Board.

2 B

3 & 4 B

All PE_MOV

C

D

E

All PE_MOV

C

D

E

Installed

Installed

PE_CAP

Installed

PE-CAP

Installed

Solid Ground

• Verify that jumpers are installed at the “PE_CAP”

and “PE_MOV” locations.

Non-Solid Ground

• Remove jumpers at the “PE_CAP” and “PE_MOV”

locations.

Solid Ground

• Verify that jumpers are installed at the “PE_CAP”

and “PE_MOV” locations.

Non-Solid Ground

• Remove jumpers at the “PE_CAP” and “PE_MOV”

locations.

CM Cap

PE_CAP

SHLD

MOV

PE_MOV

PE CAP

BR1 BR2

75C Cu Wire

6 AWG [10MM2] Max.

12 IN. LBS.

} TORQUE

1.4 N-M

AUX IN

BR1 BR2 DC+ DC- U/T1 V/T2 W/T3 R/L1 S/L2 T/L3

+ –

3 AWG [25MM2] Max.

16 IN. LBS.

1.8 N-M

75C Cu Wire

PE MOV

WIRE

STRIP

POWER

CONTROL

} TORQUE

PE

SHLD

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 29

Page 30

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

POWER TERMINAL RATINGS

WIRE RANGE: 6-1/0 AWG (16-35 MM

2

)

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

GROUND TERMINAL RATINGS (PE)

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM

2

)

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

17

21

INPUT ACOUTPUT

Optional

Communications

Module

9

CM Cap

MOV

MOV / Input Filter Cap

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

POWER TERMINAL RATINGS

WIRE RANGE: 6-1/0 AWG (16-35 MM

2

)

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

GROUND TERMINAL RATINGS (PE)

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM

2

)

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

17

21

INPUT ACOUTPUT

Optional

Communications

Module

9

PE

CM Cap

MOV

MOV

Input Filter

Cap

Factory Default Jumper Settings Power Source Type

Frame

5 C

MOV /Input Filter

(1) (2)

Current

052

060

140

Rating

Caps

Two green/yellow

wires connected

the Power Terminal

Voltag e

Code

F

W

DC Bus Common

Mode Caps

Green/yellow wire to

to

CM Cap Board is

connected

to ground

Block rail

Solid Ground

1. CM Cap jumper wire should be connected to ground

with a metal screw. Verify. If necessary, remove the

nylon screw/spacer and insert a metal M5 x 8 screw.

Torque to 3.2 N•m (28 lb•in).

2. MOV/Input Filter Cap jumper wires should be

connected to ground with a metal screw. Verify. If

necessary, remove the nylon screw/spacer and insert

a metal M5 x 12 screw.

Non-Solid Ground

1. CM Cap jumper wire should be insulated from ground

with a nylon screw/spacer. Verify. If necessary,

remove the metal screw and insert a M5 x 15 nylon

screw/spacer.

2. MOV/Input Filter Cap jumper wires should be

insulated from ground with a nylon screw/spacer.

Verify. If necessary, remove the metal screw and

insert a

M5 x 20 nylon screw/spacer.

E

077

Two green/yellow

F

082

wires connected

T

098

W

chassis ground

099

Green/yellow wire to

CM Cap Board is

to

connected

to ground

Solid Ground

1. CM Cap jumper wire should be connected to ground

with a metal screw. Verify. If necessary, remove the

nylon screw/spacer and insert a metal M5 x 8 screw.

Torque to 3.2 N•m (28 lb•in).

2. MOV jumper wire should be connected to ground

with metal screws. Verify. If necessary, remove the

nylon screw/spacers and insert metal M5 x 12 screws.

3. Input Filter Cap jumper wire should be connected to

ground with a metal screw. Verify. If necessary,

remove the nylon screw/spacer and insert metal M5

x 8 screw.

Non-Solid Ground

1. CM Cap jumper wire should be insulated from ground

with a nylon screw/spacer. Verify. If necessary,

remove the metal screw and insert a M5 x 15 nylon

screw/spacer.

2. MOV jumper wire should be insulated from ground

with a nylon screw/spacer. Verify. If necessary,

remove the metal screws and insert a M5 x 20 nylon

screw/spacer.

3. Input Filter Cap jumper wire should be insulated from

ground with a nylon screw/spacer. Verify. If

necessary, remove the metal screws and insert a M5 x

15 nylon screw/spacer.

(1) AC input drives only. MOV’s and input filter caps do not exist on DC input drives.

(2) When removing MOV’s, the input filter capacitor must also be removed.

30 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 31

Frame

CM Cap Older Drives

MOV / Input Filter Cap

MOV

CM Cap - Newer Drives

5 B

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Factory Default Jumper Settings Power Source Type

MOV/Input Filter

(1) (2)

Current

All,

except

C140

(see

next

page)

Rating

Caps

Two green/yellow

wires connected

the Power Terminal

Block rail

Volt age

Code

C

D

H

J

N

P

R

DC Bus Common

Mode Caps

Green/yellow wire is

to

connected to ground

Solid Ground

1. CM Cap jumper wire should be connected to

ground with a metal screw. Verify.

• Newer Drives - If necessary, remove the nylon

screw/spacer and insert a metal M5 x 8 screw.

Torque to 3.2 N•m (28 lb•in).

• Older Drives - Remove the I/O Cassette (see

Installation Instructions for details). The green/

yellow CM Cap jumper wire is located on the

back of chassis and should be connected to

groun d with a metal screw. If necess ary, rem ove

the insulation from the wire terminal and

connect to chassis with a metal M5 x 12 screw.

Optional

Communications

Module

Torque screw to 3.2 N•m (28 lb•in).

2. MOV/Input Filter Cap jumper wires should be

Non-Solid Ground

1. CM Cap jumper wire should be insulated from

2. MOV/Input Filter Cap jumper wires should be

(1) AC input drives only. MOV’s and input filter caps do not exist on DC input drives.

(2) When removing MOV’s, the input filter capacitor must also be removed.

connected to ground with a metal screw. Verify. If

necessary, remove the nylon screw/spacer and

insert a metal M5 x 12 screw.

ground. Verify.

• Newer Drives - If necessary, remove the metal

screw and insert a M5 x 15 nylon screw/spacer.

• Older Drives - Remove the I/O Cassette (see

Installation Instructions for details). If

necessary, insulate/secure jumper wire to guard

against unintentional contact with chassis or

components.

insulated from ground with a nylon screw/spacer.

Verify. If necessary, remove the metal screw and

insert a M5 x 20 nylon screw/spacer.

POWER TERMINAL RATINGS

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

GROUND TERMINAL RATINGS (PE)

WIRE RANGE: 6-1/0 AWG (16-35 MM

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

17

2

)

21

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

2

)

9

INPUT ACOUTPUT

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 31

Page 32

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

DC–DC+BR1BR2

USE 75 C COPPER WIRE ONLY, TORQUE 52 IN-LB (6 N-M)

22-10

AWG

5.3 IN-LB

(0.6 N-M)

WIRE STRIP

PS+

PS–

USE 75 C

COPPER WIRE

ONLY

TORQUE

52 IN-LB

(6 N-M)

UT1VT2W

T3

RL1S

L2

INPUTOUTPUT

T

L3

PE PE

Optional

Communications

Module

PE PE

MOV

Input Filter Cap

CM Cap

DO NOT

REMOVE

MOV

DC–DC+BR1BR2

USE 75 C COPPER WIRE ONLY, TORQUE 52 IN-LB (6 N-M)

22-10

AWG

5.3 IN-LB

(0.6 N-M)

WIRE STRIP

PS+

PS–

USE 75 C

COPPER WIRE

ONLY

TORQUE

52 IN-LB

(6 N-M)

UT1VT2W

T3

RL1S

L2

INPUTOUTPUT

T

L3

PE PE

Optional

Communications

Module

Input Filter Cap

PE PE

MOV

CM Cap

DO NOT

REMOVE

MOV

Factory Default Jumper Settings Power Source Type

Frame

6 B

MOV/Input Filter

Code

Current

Rating

Caps

Volt age

All Two green/yellow

C

D

H

wires connected

Power Terminal

Block “PE”

(1) (2)

DC Bus Common

Mode Caps

Green/yellow wire to

to

CM Cap Board is

connected

Terminal Block “PE”

to Power

J

N

P

R

Solid Ground

1. The green/yellow CM Cap jumper wire should

be connected to “PE.”

2. The MOV/Input Filter Cap jumper wires should

be connected to “PE.”

Non-Solid Ground

1. The green/yellow CM Cap jumper wire should

be insulated from ground. If necessary, remove

the jumper wire from “PE” and insulate/secure

it to guard against unintentional contact with

chassis or components. Important: Do Not

Remove/Disconnect the larger green/

yellow wire.

2. MOV/Input Filter Cap jumper wires should be

insulated from ground. If necessary, remove

the jumper wires from “PE” and individually

insulate/ secure each jumper wire to guard

against unintentional contact with chassis or

components.

E

All Two green/yellow

F

T

W

wires connected

Power Terminal

Block “PE” and

chassis

Green/yellow wire to

to

CM Cap Board is

connected

Ter mi nal Bl ock “ PE”

to Power

Solid Ground

1. The green/yellow CM Cap and MOV jumper

wires should be connected to “PE.”

2. The Input Filter Cap jumper wire (top right)

should be connected to chassis ground with a

metal screw. Verify. If necessary, remove the

nylon screw/spacer and insert a metal M5 x 10

screw. Torque to 3.2 N•m (28 lb•in).

Non-Solid Ground

1. The green/yellow CM Cap and MOV jumper

wires should be insulated from ground. If

necessary, remove them from “PE” and

individually insulate/secure each jumper wire

to guard against unintentional contact with

chassis or components. Important: Do Not

Remove/Disconnect the larger green/

yellow wire.

2. The Input Filter Cap jumper wire (top right)

should be insulated from ground with a nylon

screw/spacer. Verify. If necessary, remove the

metal screw and insert a M5 x 15 nylon screw/

spacer.

(1) AC input drives only. MOV’s and input filter caps do not exist on DC input drives.

(2) When removing MOV’s, the input filter capacitor must also be removed.

32 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 33

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

AC Supply Source Considerations

PowerFlex drives are suitable for use on a circuit capable of delivering up to a

maximum of 200,000 rms symmetrical amperes, 600 volts with recommended s/

circuit breakers.

ATTENTION: To guard against personal injury and/or equipment damage

caused by improper fusing or circuit breaker selection, use only the

recommended line s/circuit breakers specified in Fusing and Circuit Breakers on

.

page 44

If a residual current detector (RCD) is used as a system ground fault monitor,

only Type B (adjustable) devices should be used to avoid nuisance tripping.

Input Power Conditioning

Certain events on the power system supplying a drive can cause component

damage or shortened product life. These conditions are divided into two basic

categories:

1. All Drives

• The power system has power factor correction capacitors switched in

and out of the system, either by the user or by the power company.

• The power source has intermittent voltage spikes in excess of 6000

volts. These spikes could be caused by other equipment on the line or by

events such as lightning strikes.

• The power source has frequent interruptions.

2. 5 Hp or Less Drives (in addition to “1” above)

• The nearest supply transformer is larger than 100 kVA or the available

short circuit (fault) current is greater than 100,000 A.

• The impedance in front of the drive is less than 0.5%.

If any or all of these conditions exist, it is recommended that the user install a

minimum amount of impedance between the drive and the source. This

impedance could come from the supply transformer itself, the cable between the

transformer and drive or an additional transformer or reactor. The impedance

can be calculated using the information supplied in Wiring and Grounding

Guidelines for Pulse Width Modulated (PWM) AC Drives, publication

DRIVES-IN001

.

Single-Phase Input Power

The PowerFlex 700S drive is typically used with a three-phase input supply.

Single-phase operation of the drive is not currently rated under the UL508C

listing. Rockwell Automation has verified that single-phase operation with

output current derated by 50% of the three-phase ratings identified in the Fusing

and Circuit Breakers tables on page 44

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 33

will meet all safety requirements.

Page 34

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

AC Input Phase Selection (Frames 5 and 6 Only)

ATTENTION: To avoid a shock hazard, be sure that all power to the drive has

been removed before performing the following.

Moving the “Line Type” jumper shown in Figure 12 on page 35 will select single

or three-phase operation. Remove plastic guard to access jumper.

When selecting single-phase operation, input power must be applied to the R

(L1) and S (L2) terminals only.

Selecting/Verifying Fan Voltage (Frames 5 and 6 Only)

ATTENTION: To avoid a shock hazard, be sure that all power to the drive has

been removed before performing the following.

Frames 5 and 6 utilize a transformer to match the input line voltage to the

internal fan voltage. If your line voltage is different than the voltage class specified

on the drive nameplate, it may be necessary to change transformer taps as shown

below. Common bus (DC input) drives require user supplied 120 or 240V AC to

power the cooling fans. The power source is connected between “0 VAC” and the

terminal corresponding to your source voltage (see Figure 12

on page 35).

34 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 35

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

POWER TERMINAL RATINGS

WIRE RANGE: 6-1/0 AWG (16-35 MM

2

)

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

GROUND TERMINAL RATINGS (PE)

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM

2

)

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

17

21

INPUT ACOUTPUT

Optional

Communications

Module

9

480 Volt Tap

600 Volt Tap

690 Volt Tap

400 Volt Tap

400 Volt or 600 Volt Tap

480V or 690 Volt Tap

LINE

TYPE

SPARE 1

SPARE 2

3-PH 1-PH

Line Type Jumper

Fan Voltage Selection

(Frame 5 shown)

Older drives Newer drives

Fan VA Rating (DC Input Drives Only)

Frame Fan Voltage (120V or 240V)

5 100 VA

6 138 VA

Figure 12 - Phase Selection Jumper and Fan Transformer Locations (Frame 5 shown)

Frame 5 and 6 Transformer Tap Access

The transformer is located behind the power terminal block in the area shown in

Figure 12

release terminal block and change tap:

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 35

. Access is gained by releasing the terminal block from the rail. To

1. Locate the small metal tab at the bottom of the end block.

2. Press the tab in and pull the top of the block out. Repeat for next block if

desired.

3. Select appropriate transformer tap.

4. Replace block(s) in reverse order.

Page 36

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Important Common Bus (DC Input) Application Notes

1. If drives without internal precharge are used (Frames 5 and 6 only), then:

• precharge capability must be provided in the system to guard against

possible damage, and

• disconnect switches Must

and a common DC bus without the use of an external precharge device.

2. If drives with internal precharge (Frames 1…6) are used with a disconnect

switch to the common bus, then an auxiliary contact on the disconnect

must be connected to a digital input of the drive. The corresponding input

(parameters 825…830) must be set to “Precharge Enable”. This provides

the proper precharge interlock, guarding against possible damage to the

drive when connected to a common DC bus.

Not be used between the input of the drive

Auxiliary Control Power Supply

An auxiliary power supply can be used to keep the 700S control assembly

energized when input power is de-energized. This allows the main control board,

DriveLogix controller and any feedback option cards to continue operation.

Refer to Power Terminal Block Specifications on page 39

information. You must set bit 17 “Aux Pwr Sply” of Par 153 [Control Options] to

enable this feature. Refer to the PowerFlex 700S Auxiliary Control Power Supply

(20-24V-AUX1), Installation Instructions, publication 20D-IN021

information.

for connection

, for more

36 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Page 37

Accessing the Terminals

=

Proper tightening torque for

reassembly is 0.7 N•m (6 lb•in)

Removing the Cassette

Task Description

Open the door of the power structure and disconnect the cables that

connect to the main board. Depress the locking tab on connector

before disconnecting cables.

Loosen the screws on the face of the cassette.

Remove the cassette.

A

B

C

Removing the Side Covers

Task Description

Loosen the screws on the face of the front cover and remove the cover.

Loosen the screws on the side of rear cover and remove the cover.

Frames 1…4

Locate the slot in the upper left corner. Slide the locking

tab up and swing the cover open. Special hinges allow

the cover to move away from the drive and lay on top of

an adjacent drive (if present).

Frame 5

Slide the locking tab up, loosen the right-hand cover

screw and remove th e cover.

Frame 6

Loosen the two screws at the bottom of the bottom

cover and carefully slide the cover down and out.

Loosen the two screws at top of the top cover and

remove the cover.

B

C

B

Figure 13 - Opening the Drive Cover

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

(x2)

W/T3

R/L1

L2

BR1

BR2

DC+

DC-

PE

U/T1

V/T2

A

B

A

(x2)

A

(x3)

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 37

Page 38

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

SHLD

SHLD

PE

(Frame 3 Shown)

Cable Entry Plate Removal

If additional wiring access is needed, the cable entry plate on frame 1…3 drives

can be removed. Loosen the screws securing the plate to the chassis and slide the

plate down and off the drive.

Removing the cable entry plate on frame 1…3 limits the maximum

surrounding air temperature to 40 °C (104 °F).

Power Wiring Access Panel Removal

ATTENTION: Removing the access panel/cover exposes dangerous voltages on

the terminals and negates the enclosure type rating. Replace the access panel/

cover when service is complete. Failure to comply may result in personal injury

or equipment damage.

Frame Removal Procedure (Replace when wiring is complete)

1, 2 & 6 The access panel is part of the front cover, see Figure 13

3 Open front cover and gently tap/slide the access panel down and out.

4 Loosen the 4 screws and remove the access panel.

38 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

5 Remove the front cover (see Figu re 13

on page 37) and gently tap/slide the access panel up and out.

on page 37.

Page 39

Power Wire Recommendations

Type Description Min Insulation

(1)(2)

Power

Standard • Four tinned copper conductors with XLPE insulation.

• Copper braid/aluminum foil combination shield and tinned

copper drain wire.

• PVC jacket.

(1) Control and signal wires should be separated from power wires by at least 0.3 meters (1 foot).

(2) The use of shielded wire for AC input power may not be necessary but is always recommended.

Power Terminal Block Specifications

Refer to illustrations on pages 40 and 41 for terminal block locations.

No. Name Frame Description Wire Size Range

Maximum Minimum Maximum Recommended

(10 AWG)

(6 AWG)

(3 AWG)

(6 AWG)

(1/0 AWG)

(1/0 AWG)

(1/0 AWG)

(2/0 AWG)

(1/0 AWG)

(1/0 AWG)

(4/0 AWG)

2

2

2

2

2

2

2

2

2

2

2

(5)

1 Power Terminal Block 1 Input power and motor connections 4.0 mm

2 Input power and motor connections 10.0 mm

3 Input power and motor connections 25.0 mm

BR1, BR2 10.0 mm

4 Input power and motor connections 35.0 mm

5

(75 HP)

R, S, T, BR1, BR2, DC+, DC-, U, V and W 50.0 mm

(3)

PE 50.0 mm

5