Page 1

Installation Instructions

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

This document explains the 5 BASIC STEPS needed to install and perform a

Basic Start-Up of the PowerFlex 700 AC drive. A Human Interface Module

(HIM) is required to perform the Basic Start-Up routine covered in this manual.

The information provided is intended for qualified installers only.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerFlex 700 Standard Control User Manual, publication

20B-UM001

PowerFlex 700 Vector Control User Manual (v4.001 & up),

publication 20B-UM002

PowerFlex 700 AC Drive Technical Data, publication

20B-TD001

PowerFlex Comm Adapter Manuals, publication

20COMM-UM…

PowerFlex 70 and PowerFlex 700 Reference Manual,

publication PFLEX-RM001

PowerFlex 70 Enhanced Control and PowerFlex 700 Vector

Control Reference Manual, publication PFLEX-RM004

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives, publication DRIVES-IN001

Safety Guidelines for the Application, Installation and

Maintenance of Solid State Control, publication SGI-1.1

Guarding Against Electrostatic Damage, publication

8000-4.5.2

Product Certifications website, http://ab.com

Provides detailed information on:

• Parameters and programming

• Faults, alarms, and troubleshooting

This publication provides detailed drive specifications,

option specifications and input protection device ratings.

These publications provide information on configuring,

using, and troubleshooting PowerFlex communication

adapters.

These publications provide detailed application specific

information for programming and configuring the

PowerFlex 700 drive.

Provides basic information needed to properly wire and

ground PWM AC drives.

Provides general guidelines for the application,

installation, and maintenance of solid-state control.

Provides practices for guarding against Electrostatic

damage (ESD)

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Page 2

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Allen-Bradley Drives Technical Support

Use the contacts below for PowerFlex 700 technical support including spare parts

information.

Online at… By Email at… By Telephone at…

www.ab.com/support/abdrives support@drives.ra.rockwell.com 262-512-8176

Documentation in Other Languages

User Manuals are available in multiple languages at:

http://www.rockwellautomation.com/literature

Select publication language and type “20B-UM002” in the search field.

.

2 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 3

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Table of Contents

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 1: Read the Precautions and General Information . . . . . . . . . . . . . . . . . . . . . 5

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 2: Lifting and Mounting the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Minimum Mounting Clearances & Heat Dissipation. . . . . . . . . . . . . . . . . . . . . . .14

Removing the Frame 7 Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Step 3: Wire the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Cable Types Acceptable for 200…600 Volt Installations . . . . . . . . . . . . . . . . . . . .31

Single-Phase Input Power – Frame 7 Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Power Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fan Circuit Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Additional Frame 10 Wiring Requirement for IP00 AC Input Drives. . . . . . . .38

DC Link Chokes – Frames 8…10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Auxiliary Control Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

General Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Motor Overload Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Drive, Fuse & Circuit Breaker Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Using Input/Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Disconnecting MOVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Step 4: I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Hardware Enable Circuitry (Vector Control Only) . . . . . . . . . . . . . . . . . . . . . . . .54

Encoder Interface Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Reference Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Step 5: Start-Up Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Prepare For Drive Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Supplemental Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

DC Input (Common Bus) and Precharge Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Human Interface Module (HIM) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Start-Up Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Drive Status Indicators & DPI Port Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Common I/O Programming Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Common Symptoms and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Manually Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 3

Page 4

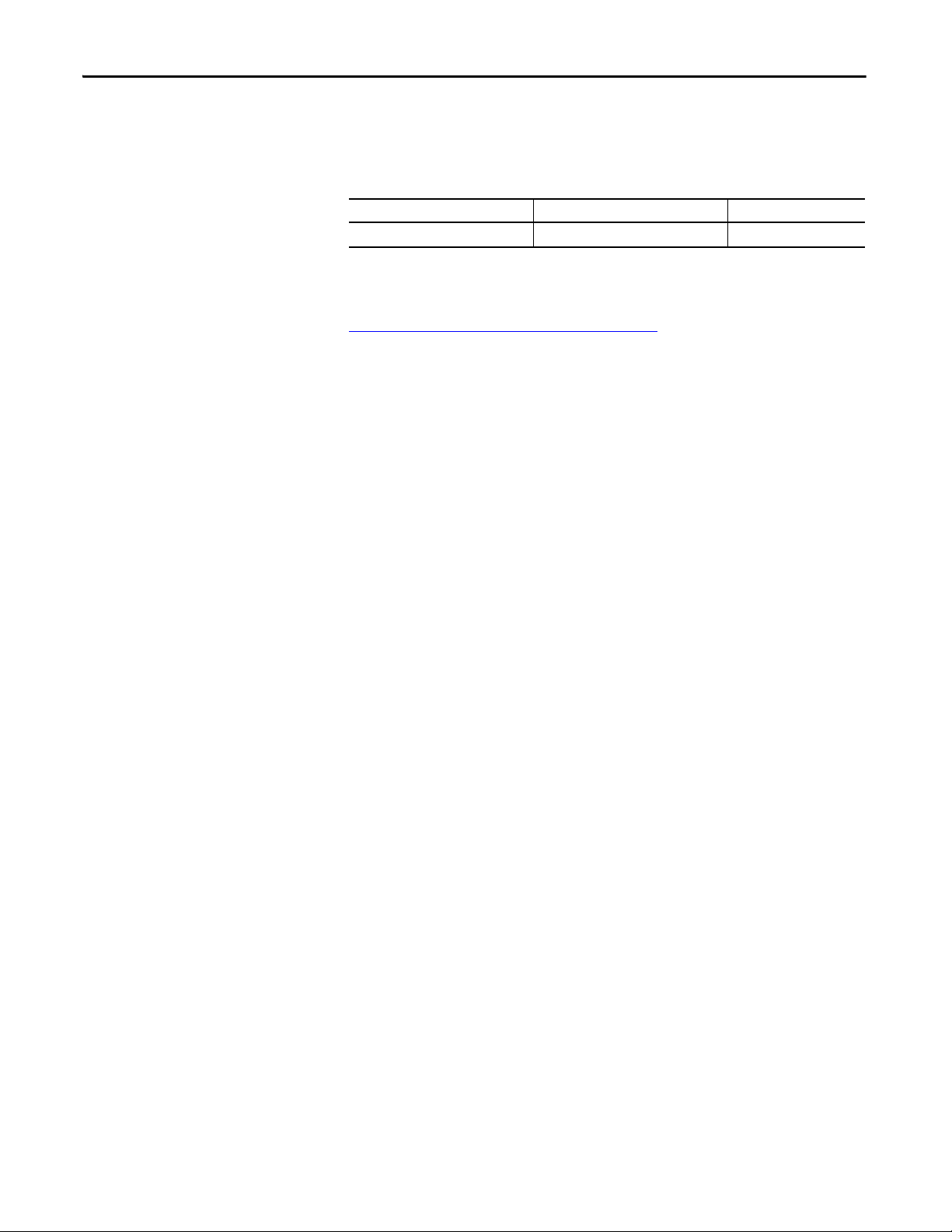

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

20B D 325 A 3 A N N N E C 0

abcdefghijklmn

a

Drive

Code Type

20B PowerFlex 700

b

Voltage Rating

Code Voltage Ph. Prechg. Frames

C 400V AC 3 - 7…10

D 480V AC 3 - 7…10

H 540V DC - N 10

J 650V DC - N 10

P 540V DC - Y 7…9

R 650V DC - Y 7…9

c

ND Rating §

400/480V, 60 Hz Input

Code Amps Hp Frame

292 292 250 7

325 325 250 7

365 365 300 8

415 415 350 8

481 481 400 8

535 535 450 8

600 600 500 8

730 730 600 9

875 875 700 10

§ Refer to the rating tables for further

information.

d

Enclosure

Code Enclosure

A IP20, NEMA/UL Type 1

N

Open/Flange Mount

Front: IP00, NEMA/UL Type Open

Back/Heatsink: IP54, NEMA 12

U

Roll-In

Front: IP00, NEMA/UL Type Open

Back/Heatsink: IP54, NEMA 12

Frames 8 & 9 Only

f

Documentation

Code Type

A Manual

N No Manual

Q

No Shipping Package

(Internal Use Only)

j

Comm Slot

Code Network Type

C ControlNet (Coax)

D DeviceNet

E EtherNet/IP

NNone

l

Feedback

Code Type

0None

1 Encoder, 12V/5V

m

Future Use

e

HIM

Code Operator Interface

0 Blank Cover

3 LCD Display, Full Numeric Keypad

g

Brake

Code w/Brake IGBT

‡

NNo

‡ Brake IGBT is not available on Frames 7…10.

h

Internal Braking Resistor

Code w/Resistor

NNo

Not available on Frames 7…10.

i

Emission

Code CE Filter

§ CM Choke

NNoNo

§ Frames 7…10, 400/480V AC drives (Voltage

Rating codes "C" and "D") meet CE

certification requirements when installed per

recommendations.

n

Future Use

k

Control & I/O

Code Control I/O Volts

C

Vector

Δ

24V DC

D

Vector

Δ

115V AC

Δ Vector Control Option utilizes DPI Only.

Catalog Number Explanation

4 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 5

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Step 1: Read the Precautions and General Information

Qualified Personnel

ATT EN TI ON : Allow only qualified personnel familiar with adjustable frequency

AC drives and associated machinery to plan or implement the installation, startup and subsequent maintenance of the system. Failure to comply can result in

personal injury and/or equipment damage.

Personal Safety

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged before performing any work on the drive.

Measure the DC bus voltage at the following points (refer to pages 8

for locations):

• +DC and -DC terminals of the Power Terminal Block

• +DC terminal of the Power Terminal Block and the chassis

• -DC terminal of the Power Terminal Block and the chassis

The voltage must be zero for all three measurements.

through 11

ATT EN TI ON : Risk of injury or equipment damage exists. DPI or SCANport host

products must not be directly connected together via 1202 cables.

Unpredictable behavior can result if two or more devices are connected in this

manner.

ATT EN TI ON : The drive start/stop/enable control circuitry includes solid state

components. If hazards due to accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exist, an additional hardwired stop

circuit can be required to remove the AC line to the drive. An auxiliary braking

method can be required.

ATT EN TI ON : Loss of control in suspended load applications can cause personal

injury and/or equipment damage. Loads must always be controlled by the drive

or a mechanical brake. Parameters 600…611 are designed for lifting/torque

proving applications. It is the responsibility of the engineer and/or end user to

configure drive parameters, test any lifting functionality and meet safety

requirements in accordance with all applicable codes and standards.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 5

Page 6

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Product Safety

ATT EN TI ON : An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive ambient

temperatures can result in malfunction of the system.

ATT EN TI ON : This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage can result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference Guarding Against Electrostatic Damage, publication

8000-4.5.2 or any other applicable ESD protection handbook.

ATT EN TI ON : The “adjust freq” portion of the bus regulator function is

extremely useful for preventing nuisance overvoltage faults resulting from

aggressive decelerations, overhauling loads, and eccentric loads. It forces the

output frequency to be greater than commanded frequency while the drives

bus voltage is increasing toward levels that will cause a fault. However, it can

also cause either of the following two conditions to occur.

• Fast positive changes in input voltage (more than a 10% increase within 6

minutes) can cause uncommanded positive speed changes. However an

“OverSpeed Limit” fault (F25) occurs if the speed reaches [Maximum Speed] +

[Overspeed Limit], (parameters 82 and 83). If this condition is unacceptable,

action must be taken to 1) limit supply voltages within the specification of the

drive and, 2) limit fast positive input voltage changes to less than 10%.

Without taking such actions, if this operation is unacceptable, the “adjust freq”

portion of the bus regulator function must be disabled (see parameters 161

and 162).

• Actual deceleration times can be longer than commanded deceleration times.

However, a “Decel Inhibit” fault (F24) is generated if the drive stops

decelerating altogether. If this condition is unacceptable, the “adjust freq”

portion of the bus regulator must be disabled (see parameters 161 and 162). In

addition, installing a properly sized dynamic brake resistor provides equal or

better performance in most cases.

Important: These faults are not instantaneous. Test results have shown that they

can take between 2…12 seconds to occur.

6 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 7

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

EMC Compliance

Frame 7…10 drives are CE Certified for use with 400V AC and 480V AC center

grounded neutral power supply systems only. The General Grounding

Requirements on page 40 must be followed for CE Compliance.

It is strongly recommended that the PowerFlex 700 User Manual, publication

20B-UM002

Modulated (PWM) AC Drives, publication DRIVES-IN001

assure CE EMC compliance.

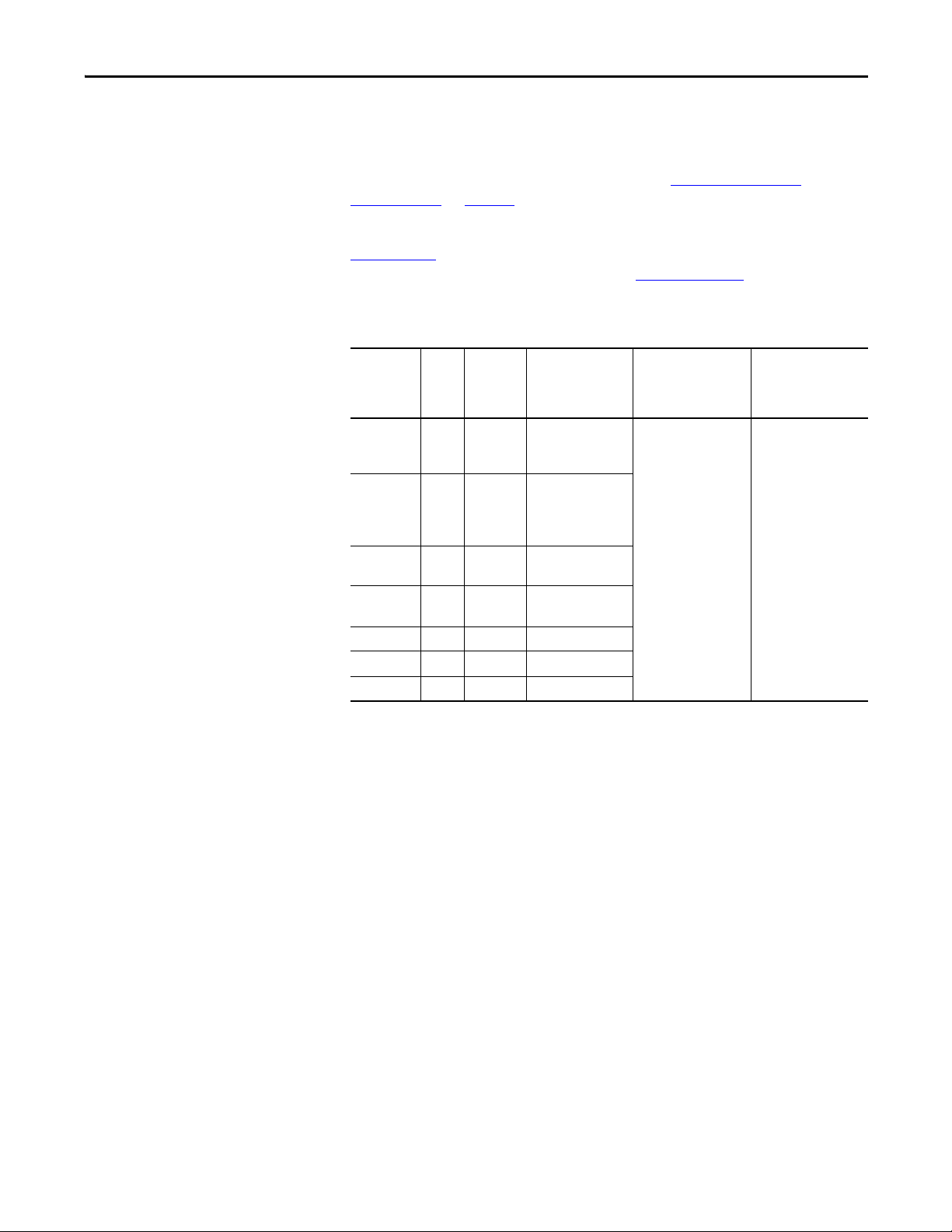

Table 1 - Recommended Filters

and the Wiring and Grounding Guidelines for Pulse Width

be referenced to

EN61800-3 Cat. C1,

Power

Base Drive

Catalog No.

20BC292

20BD248

20BD292

20BC325

20BC365

20BD325

20BD365

20BC415

20BD415

20BC535

20BD535

20BD600 355 800 FN3359-800-99

20BD730 400 800 FN3359-800-99

20BD875 500 1000 FN3359-1000-99

(1) Motor cable length limit with this filter. Supplementary EMC enclosure required to provide attenuation of radiated emissions.

Current

(kW)

A (at 50° C) Schaffner Part No.

160 320 FN3359-320-99 100

200 400 FN3359-400-99

250 600 FN3359-600-99

315 600 FN3359-600-99

EN6100-6-3, CISPR11,

Group 1, Class B

(Meters)

(1)

EN61800-3 Cat. C2

EN6100-6-4, CISPR11,

Group 1, Class A

(Meters)

(1)

150

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 7

Page 8

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

+DC

USE 75° COPPER WIRE ONLY

TORQUE LARGE TERMINALS TO 10 N-m (87LB-IN)

-DC PE PE R-L1 T-L3

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

U-M1 V-M2 W-M3S-L2

TB11

25 AMPERES RMS

MAXIMUM

CAUTION

HOT SURFACES

ALLEN-BRADLEY

MADE IN U.S.A.

PE

!

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

➊

➋

➌

➍

➒

➐

➑

➏

➎

➓

➋

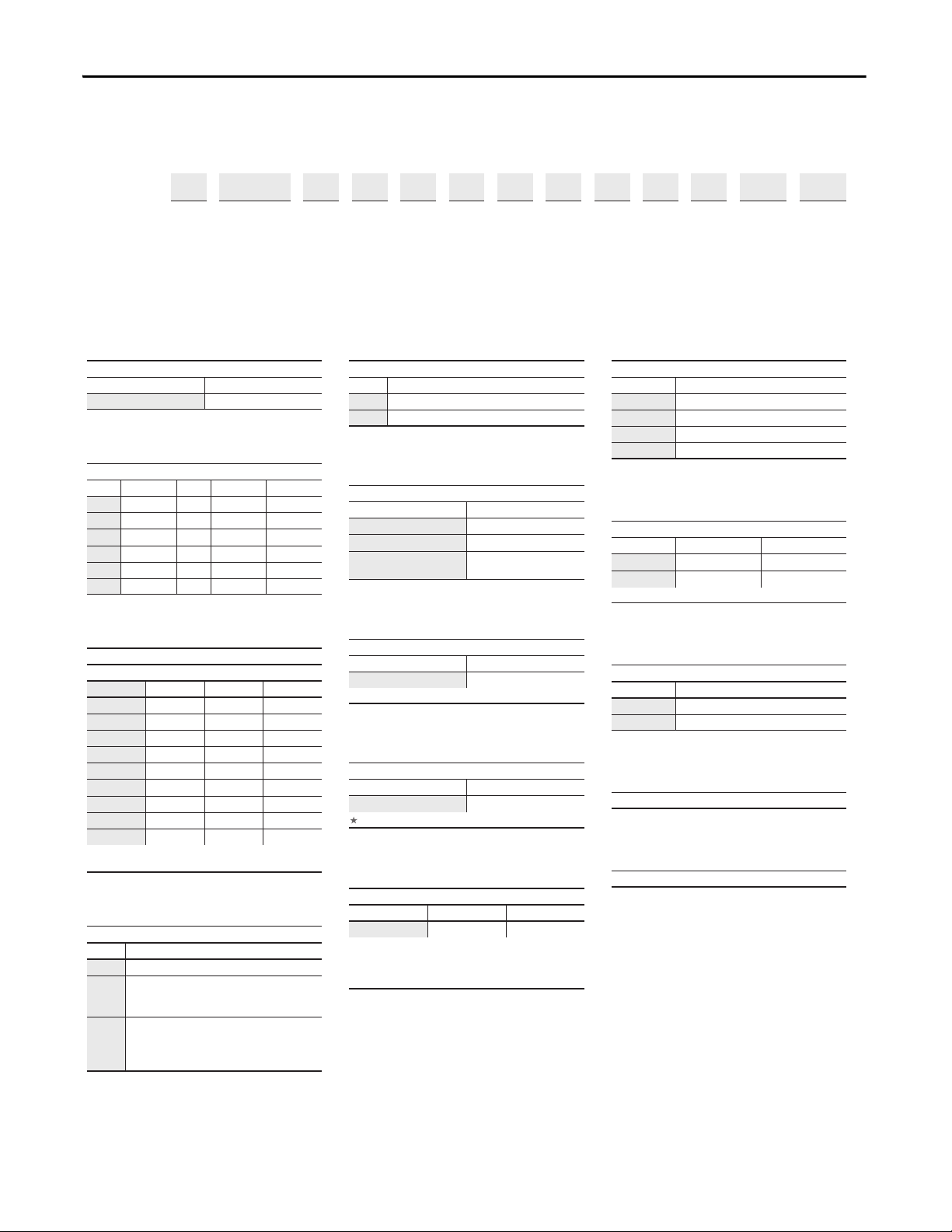

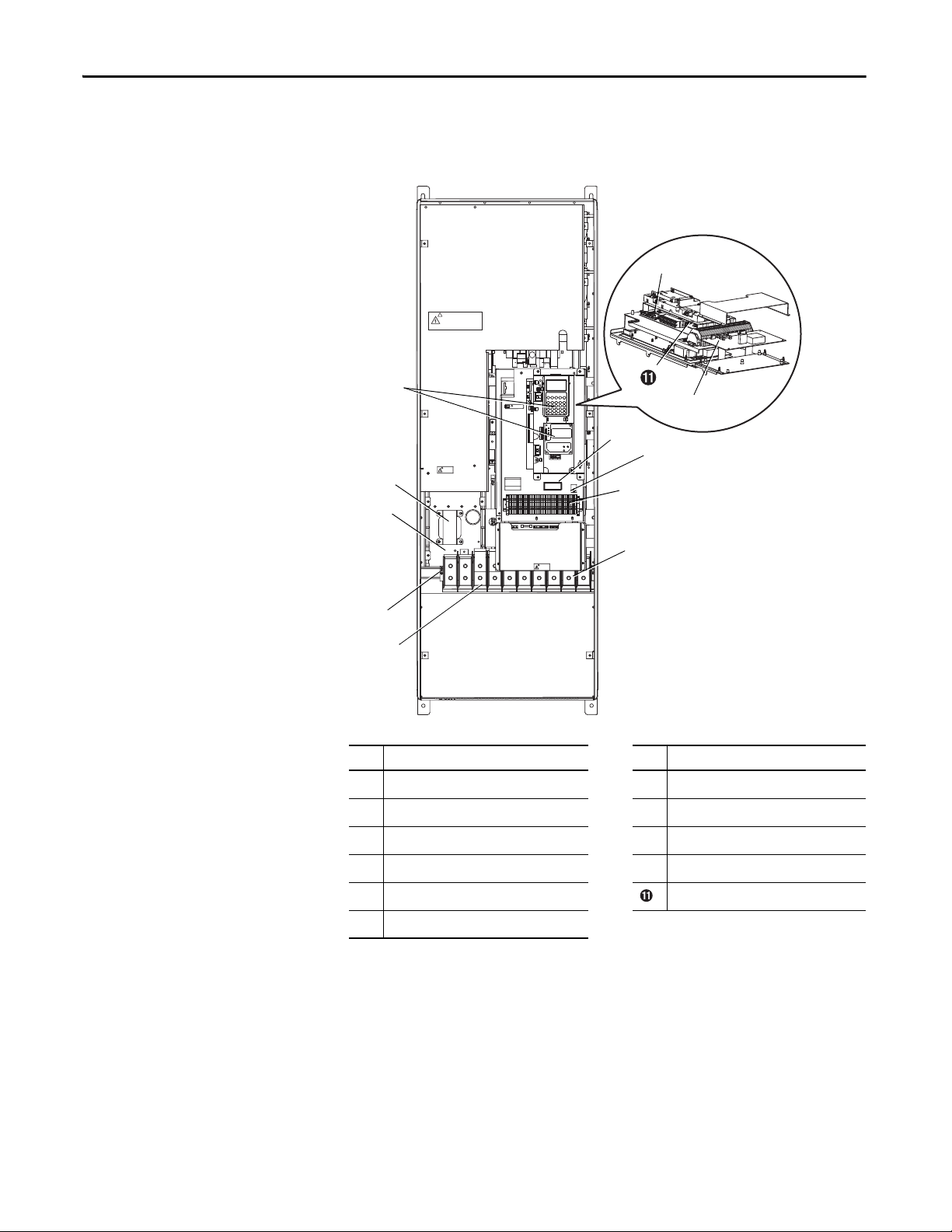

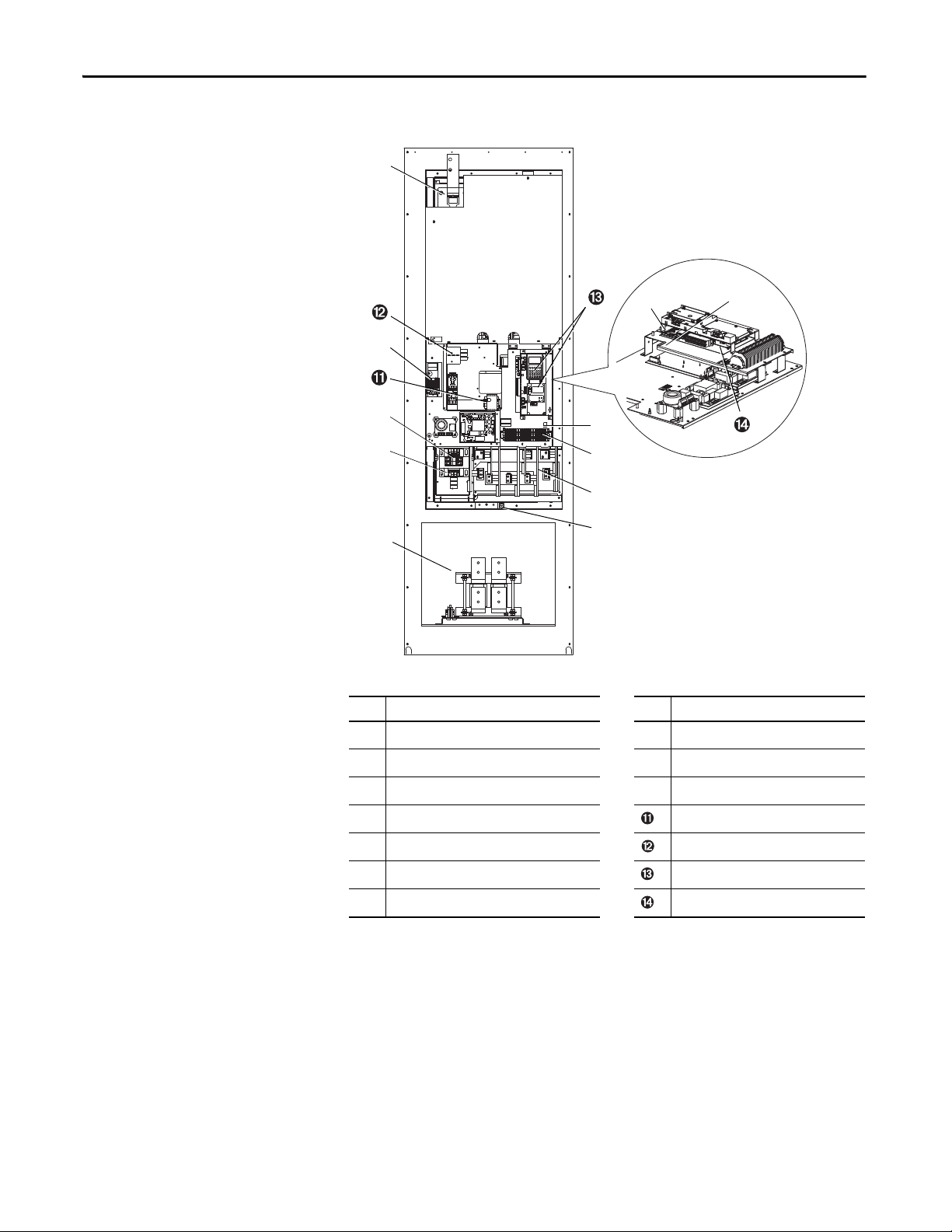

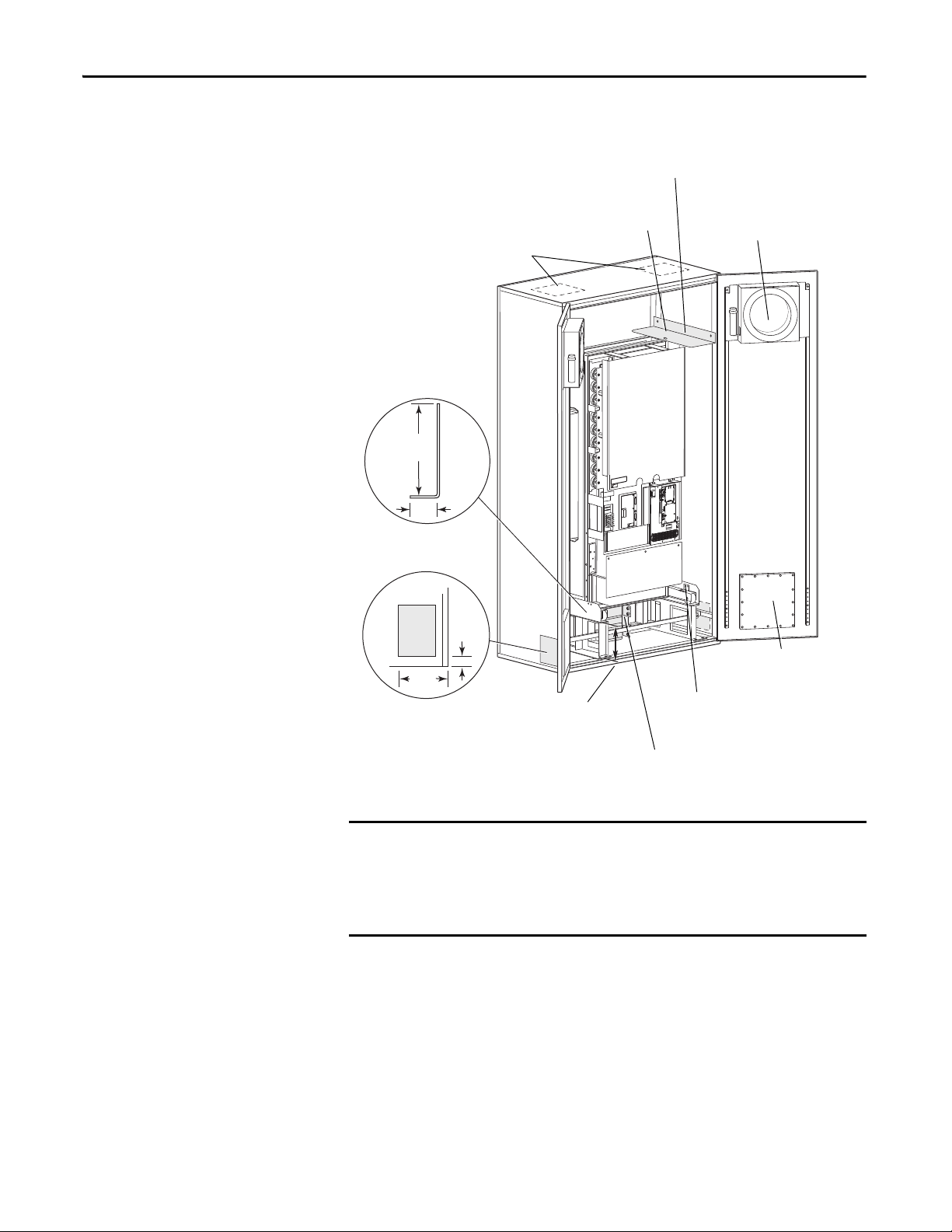

Component Locations

Frame 7

No. Component No. Component

Power Terminal Block

➊

PE Ground

➋

I/O & Auxiliary Control Voltage - TB11

➌

Fan Terminal Block (DC input only)

➍

Fan Transformer (AC input only) Encoder Feedback Board (Optional)

➎

Main Control Board

➏

8 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Nameplate

➐

Precharge Board

➑

MOV

➒

HIM/Comm Module (Optional)

➓

Page 9

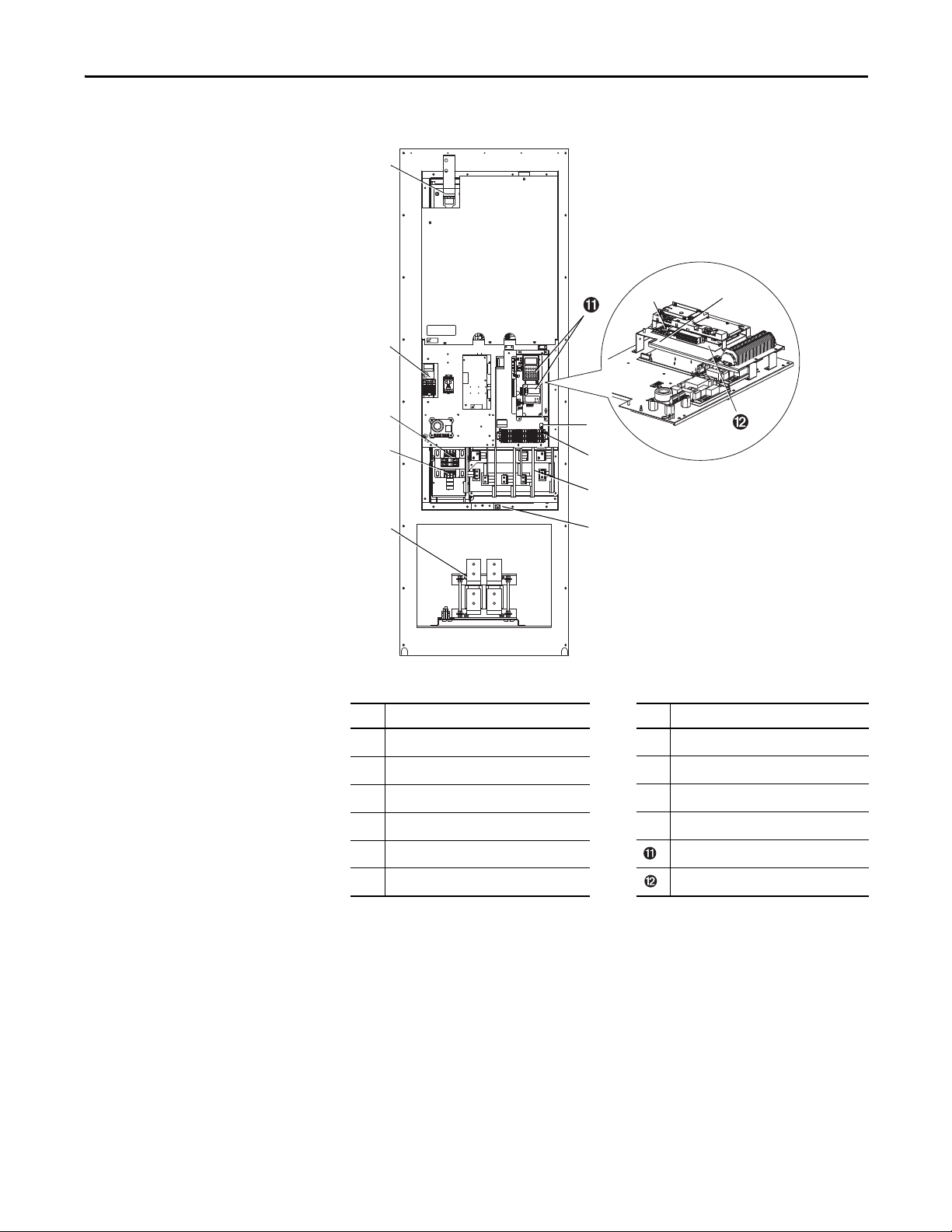

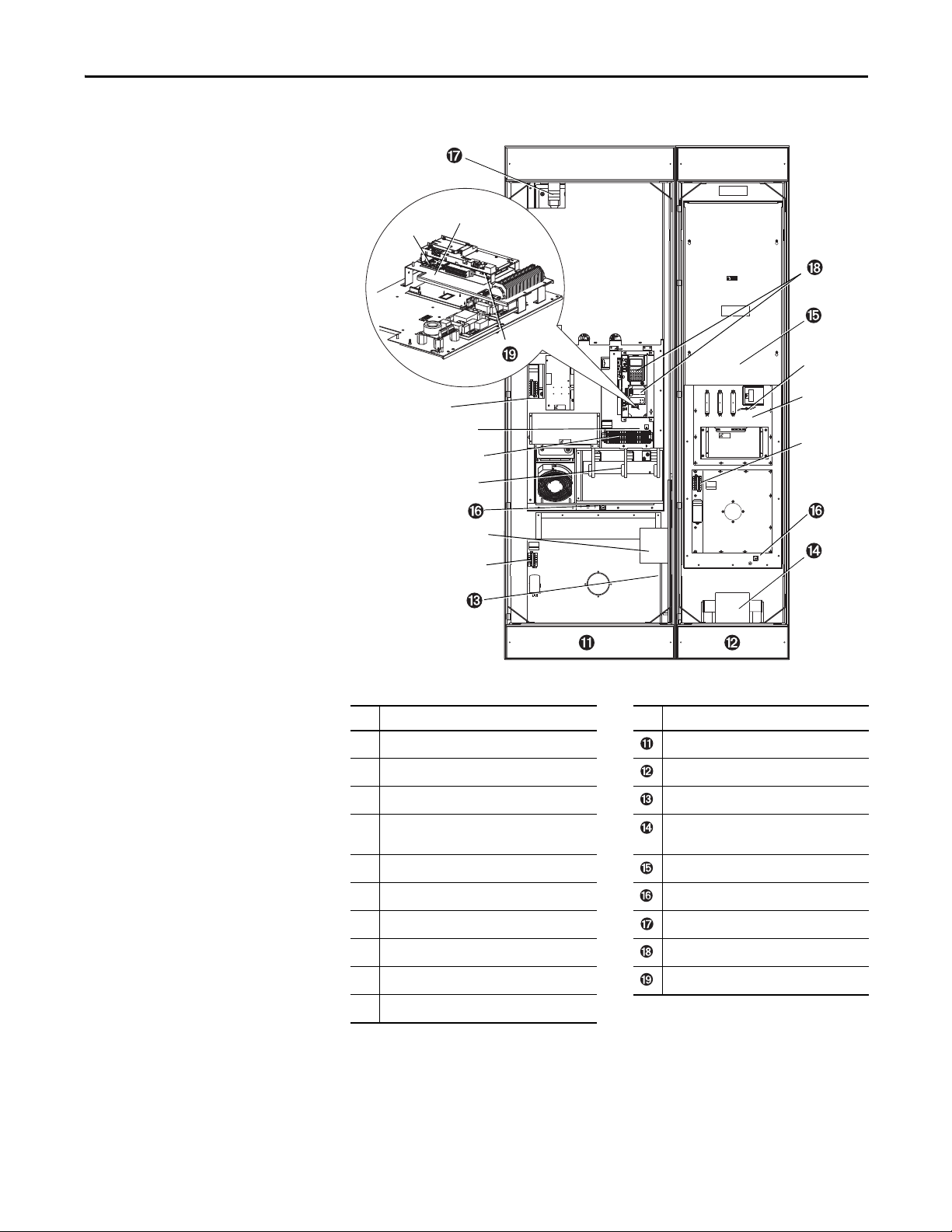

Frame 8

TB11

TE

25 AMPERES RMS

MAXIMUM

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB9

8 AMPERES RMS

MAXIMUM

DC+

V

W

U

R S T DC-DC+

GND

➊

➋

➌

➍

➓

➎

➐

➑

➏

➒

➋

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

No. Component No. Component

Power Terminals

➊

PE Ground (and MOV wire)

➋

I/O & Auxiliary Control Voltage - TB11

➌

Fan Terminal Block - TB9

➍

Fan Tra nsfor mer (AC input on ly) HIM/Comm Module (Optional)

➎

Main Control Board Encoder Feedback Board (Optional)

➏

Nameplate

➐

DC Bus/Brake Terminals

➑

MOV (under boards)

➒

DC Link Choke (AC input only)

➓

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 9

Page 10

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

TB11

TE

25 AMPERES RMS

MAXIMUM

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB9

8 AMPERES RMS

MAXIMUM

DC+

V

W

U

R S T DC-DC+

GND

4 T22 T1 6 T3

CAUTION

➊

➋

➌

➍

➓

➎

➑

➐

➏

➒

➋

Frames 9

No. Component No. Component

Power Terminals

➊

PE Ground (and MOV wire)

➋

I/O & Auxiliary Control Voltage - TB11

➌

Fan Terminal Block (cap. fan) - TB9 Phase Monitor Relay

➍

Fan Transformer (cap. fan) - AC input only Blower Terminal Block (three-phase)

➎

Main Control Board HIM/Comm Module (Optional)

➏

Nameplate Encoder Feedback Board (Optional)

➐

DC Bus/Brake Terminals

➑

MOV (under boards)

➒

DC Link Choke (AC input only)

➓

10 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 11

Frame 10

➋

➍

➎

➒

➐

➏

➑

➌

➓

➊

➐

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

DC+

DANGER

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

TB9

8 AMPERES RMS

MAXIMUM

120

IN1

120

IN2

3

4

5

6

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

TB11

25 AMPERES RMS

MAXIMUM

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

PE

VWU

GND

TB10

8 AMPERES RMS

MAXIMUM

120

IN1

120

IN2

3

4

5

6

DANGER

DANGER

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

120

IN1

120

IN2

3

TB10

4

8 AMPERES RMS

MAXIMUM

5

6

GND

AC Input drive is shown. For DC Input drives, reference the left Inverter section.

No. Component No. Component

Motor Terminal Block Inverter Section

➊

PE Ground Converter Section

➋

I/O & Auxiliary Control Voltage - TB11 PE Bus Bar (IP20 Only)

➌

Fan Terminal Block - TB9

➍

(Capacitor Assembly Fan)

Fan Transformer (IP20 Only) AC Input Terminals (Behind Shield)

➎

Fan Terminal Block - TB10 (Heatsink Fan) PE Connection Point (IP00)

➏

Nameplate DC Bus/Brake Terminals

➐

Main Control Board HIM/Comm Module (Optional)

➑

MOV Jumper Encoder Feedback Board (Optional)

➒

Fan Terminal Block - TB12 (Heatsink Fan)

➓

DC Link Choke

(AC input only, supplied loose for IP00)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 11

Page 12

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IMPORTANT

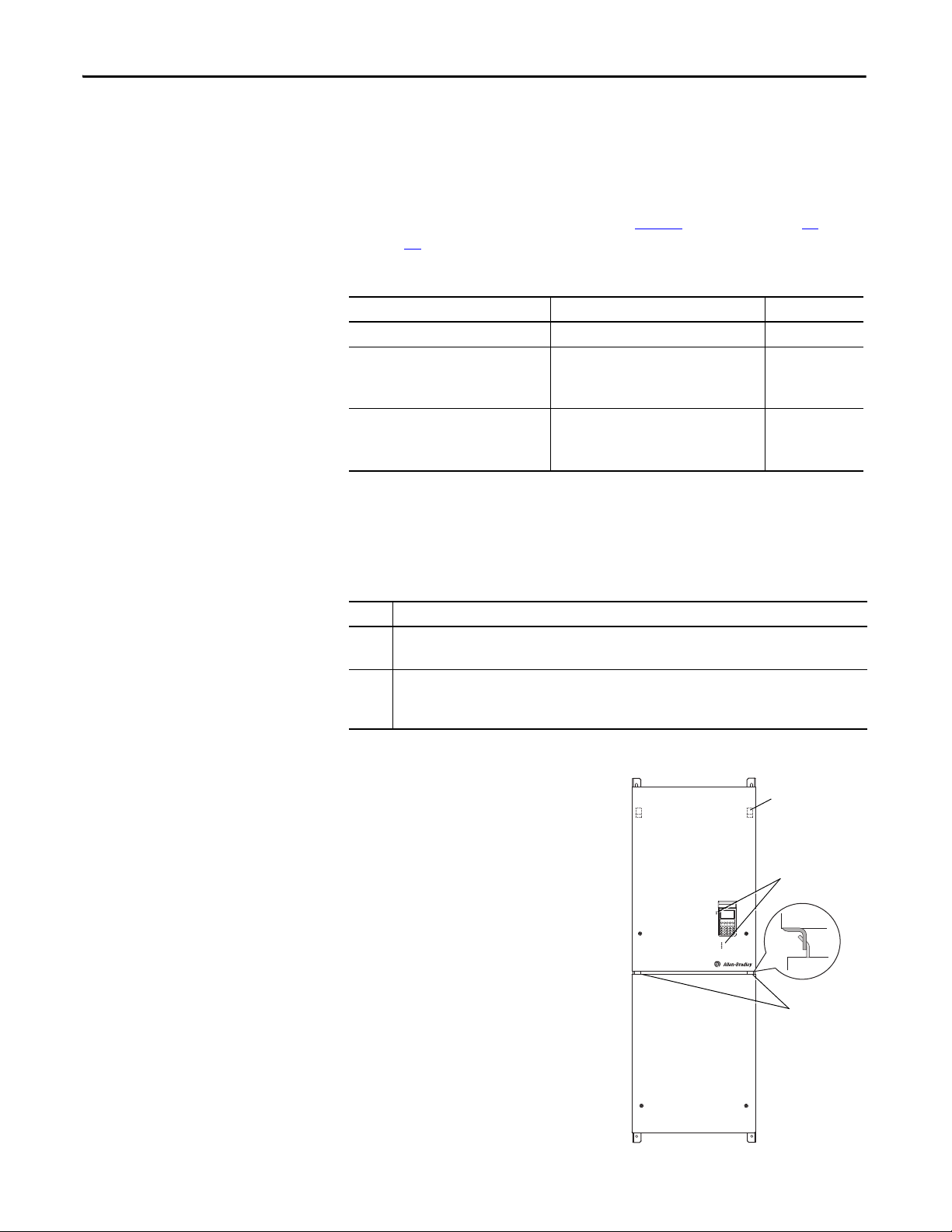

Lifting Holes

4 Places

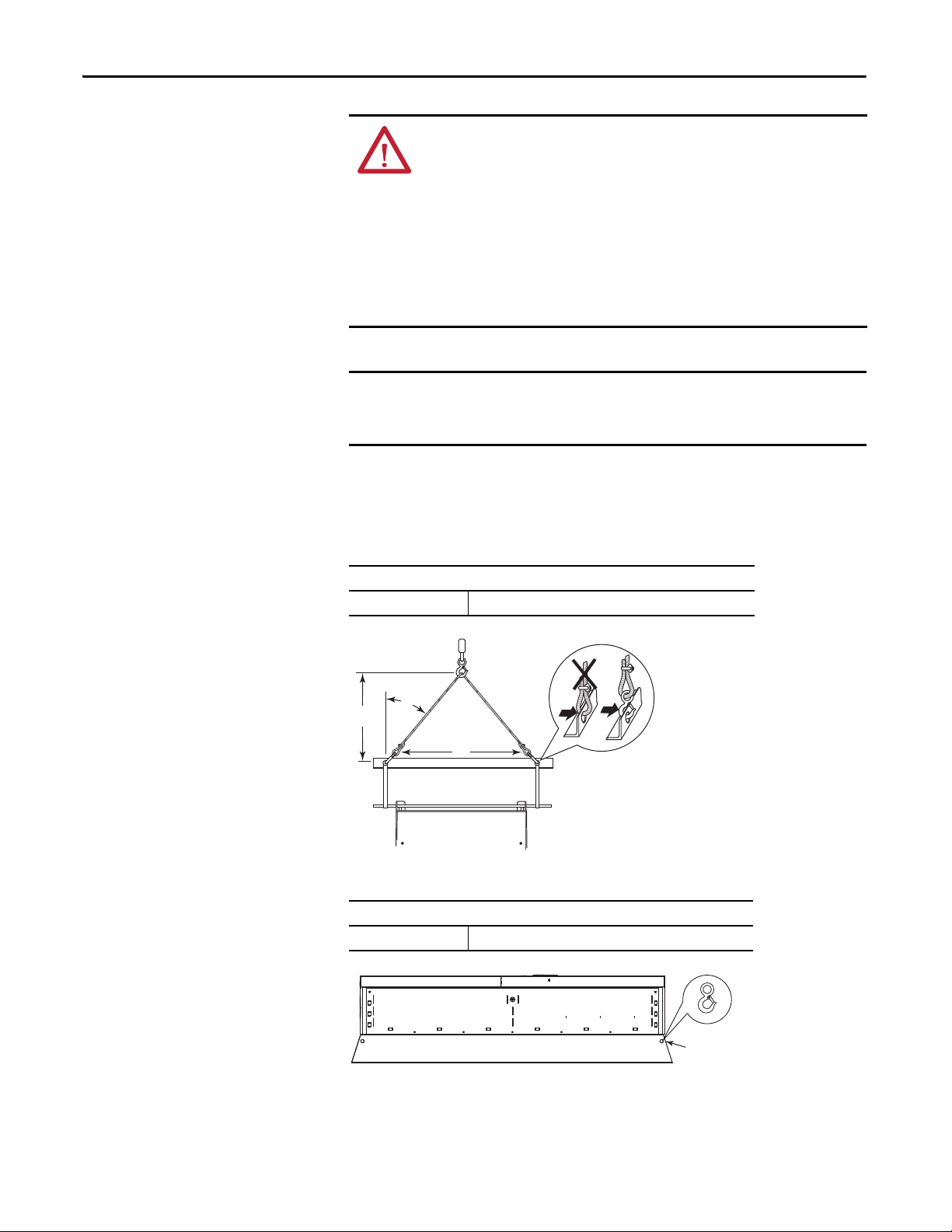

Step 2: Lifting and Mounting the Drive

ATT EN TI ON : To guard against possible personal injury and/or equipment

damage:

• Do Not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• At no time should a person or their limbs be directly underneath the items

being lifted.

• Do not subject the load to high rates of acceleration or deceleration.

• Inspect all lifting hardware for proper attachment before lifting drive unit.

Braces attached to the front of Frame 8, 9 or 10 IP20, NEMA/UL Type 1 drives

are required for structural integrity. If necessary, the braces can be removed for

wiring, but must be replaced upon completion.

Lifting

Frame 7

IP00, NEMA/UL Type Open

Approximate Weight 147 kg (324 lbs.) + 26 kg (58 lbs.) for shipping materials

45°

1

/

>

2 A

A

IP20, NEMA/UL Type 1

Approximate Weight 170 kg (375 lbs.) + 26 kg (58 lbs.) for shipping materials

12 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 13

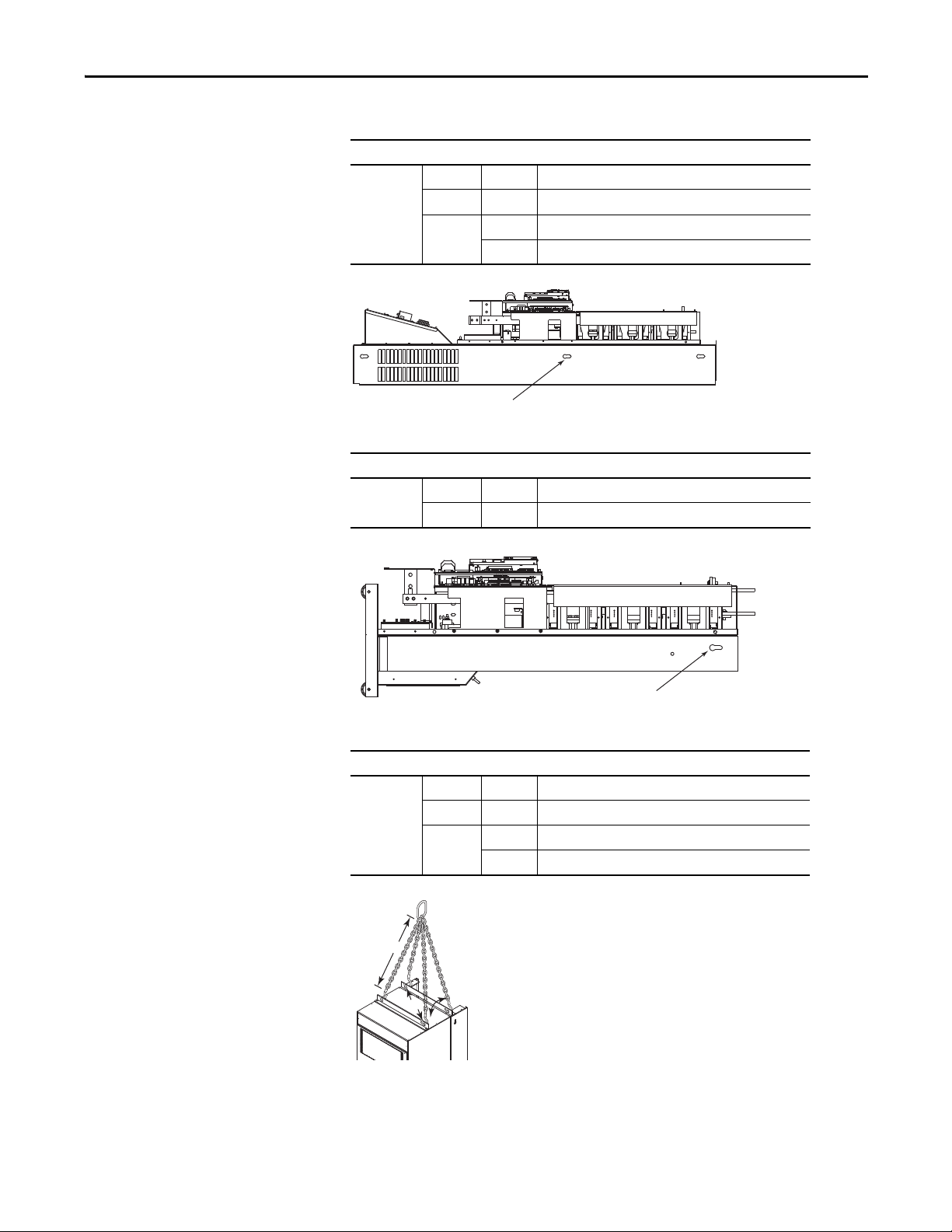

Frames 8, 9 and 10

Lifting Holes 2 Places

>A

A

>60°

Important: a lifting angle must be used. Do Not

use the lifting holes on the side of the cabinet

IP00, NEMA/UL Type Open

Approximate

Wei ght

IP00, NEMA/UL Type Open Roll-In

Approximate

Wei ght

Frame 8 – 384 kg (847 lbs.) + 47 kg (103 lbs.) for shipping materials

Frame 9 – 401 kg (884 lbs.) + 47 kg (103 lbs.) for shipping materials

Frame 10 DC Input 305 kg (672 lbs.) + 47 kg (103 lbs.) for shipping materials

AC input 532 kg (1172 lbs.) + 91 kg (200 lbs.) for shipping materials

Lifting Holes 6 Places

Frame 8 – 250 kg (552 lbs.) + 47 kg (103 lbs.) for shipping materials

Frame 9 – 267 kg (589 lbs.) + 47 kg (103 lbs.) for shipping materials

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IP20, NEMA/UL Type 1

Approximate

Wei ght

Frame 8 – 509 kg (1122 lbs.) + 47 kg (103 lbs.) for shipping materials

Frame 9 – 526 kg (1159 lbs.) + 47 kg (103 lbs.) for shipping materials

Frame 10 DC Input 468 kg (1032 lbs.) + 47 kg (103 lbs.) for shipping materials

AC input 867 kg (1912 lbs.) + 91 kg (200 lbs.) for shipping materials

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 13

Page 14

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Locating Tabs

(backside of panel)

Hinge Tabs

Light Pipes

Environment

Operating Temperatures

PowerFlex 700 drives are designed to operate at 0…40 °C ambient. To operate the

drive in installations between 41…50 °C, see Ta b l e 2

through 44

Table 2 - Acceptable Surrounding Air Temperature & Required Actions

Enclosure Rating Temperature Range Drive

IP20, NEMA/UL Type 1 0…40 °C (0…104 °F) Frames 7…10

IP00, NEMA/UL Type Open/Flange Mount

Front: IP00, NEMA/UL Type Open

Back/Heat Sink: IP54, NEMA12

Roll In

Front: IP00, NEMA/UL Type Open

Back/Heat Sink: IP54, NEMA12

for exceptions.

0…65 °C (0…149 °F) Control Board

0…40 °C (0…104 °F) Heat Sink Entry Air

0…65 °C (0…149 °F) Control Board

0…40 °C (0…104 °F) Heat Sink Entry Air

and refer to pages 42

Frames 7…10

Frames 8…9

Minimum Mounting Clearances & Heat Dissipation

The drive must be mounted with sufficient space at the top, sides, and front of the

cabinet to allow for proper heat dissipation.

Frame Recommendations

7 Minimum of 152 mm (6.0 in.) at the top and bottom of the enclosure and 102 mm (4.0 in.) on the sides.

Flange Mount - Minimum of 152 mm (6.0 in.) at the back of the enclosure (flange mount sur face to wall).

8…10 Minimum of 152 mm (6.0 in.) at the top of the enclosure. Additionally, allow a minimum of 102 mm (4.0 in.)

on each side OR 152 mm (6.0 in.) in the back.

Flange Mount - Minimum of 102 mm (4.0 in.) on each side.

Removing the Frame 7 Cover

1. Loosen lower panel screws and pull

the bottom edge out.

2. Tilt panel sufficiently to remove

Hinge Tabs from the upper panel.

Remove panel and set aside.

3. Loosen upper panel screws and pull

bottom edge out slightly.

POWER

STS

PORT

MOD

NET A

NET B

4. Slide panel down until Locating

Tabs clear chassis. Remove panel

and set aside.

5. Replace panels in reverse order.

Carefully align tabs and light pipes.

14 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 15

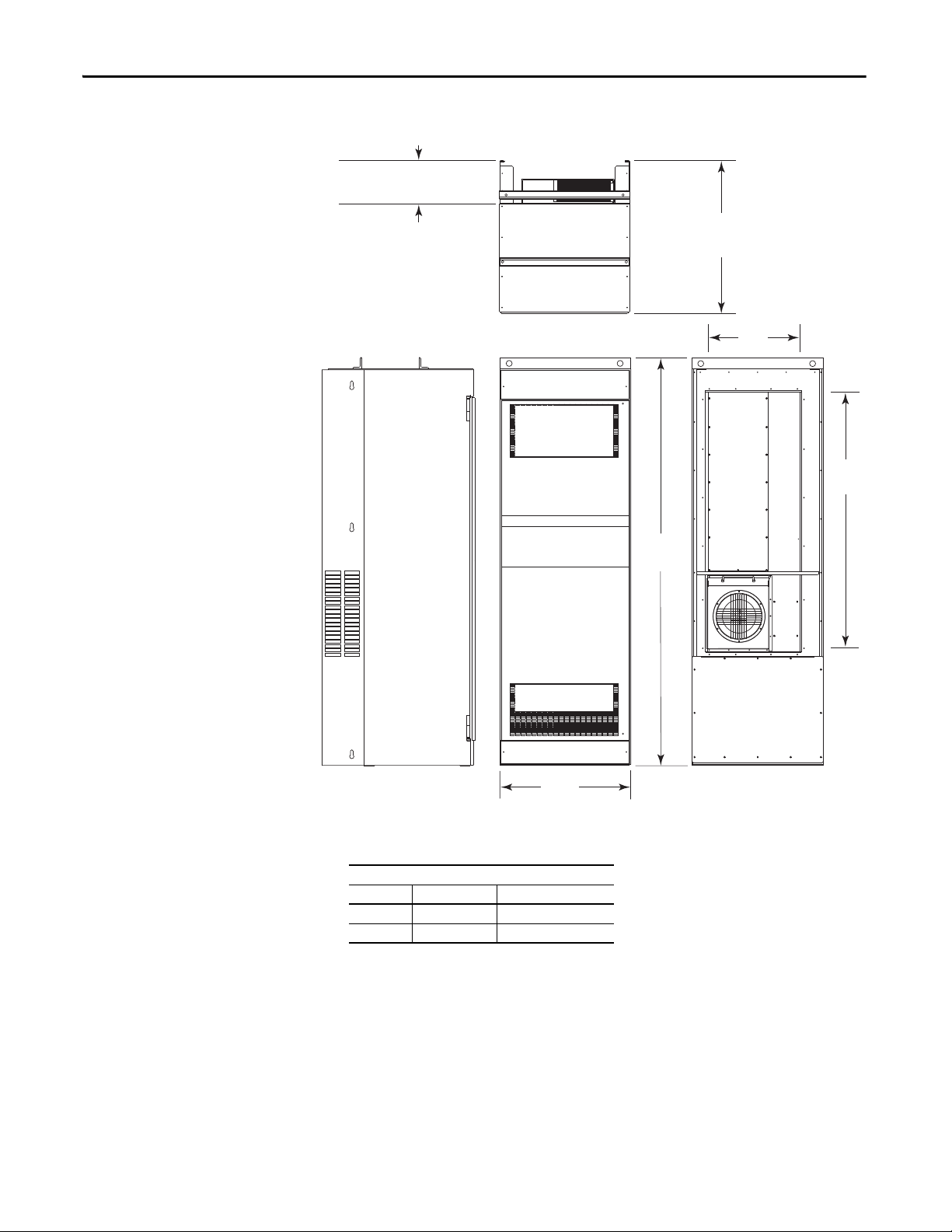

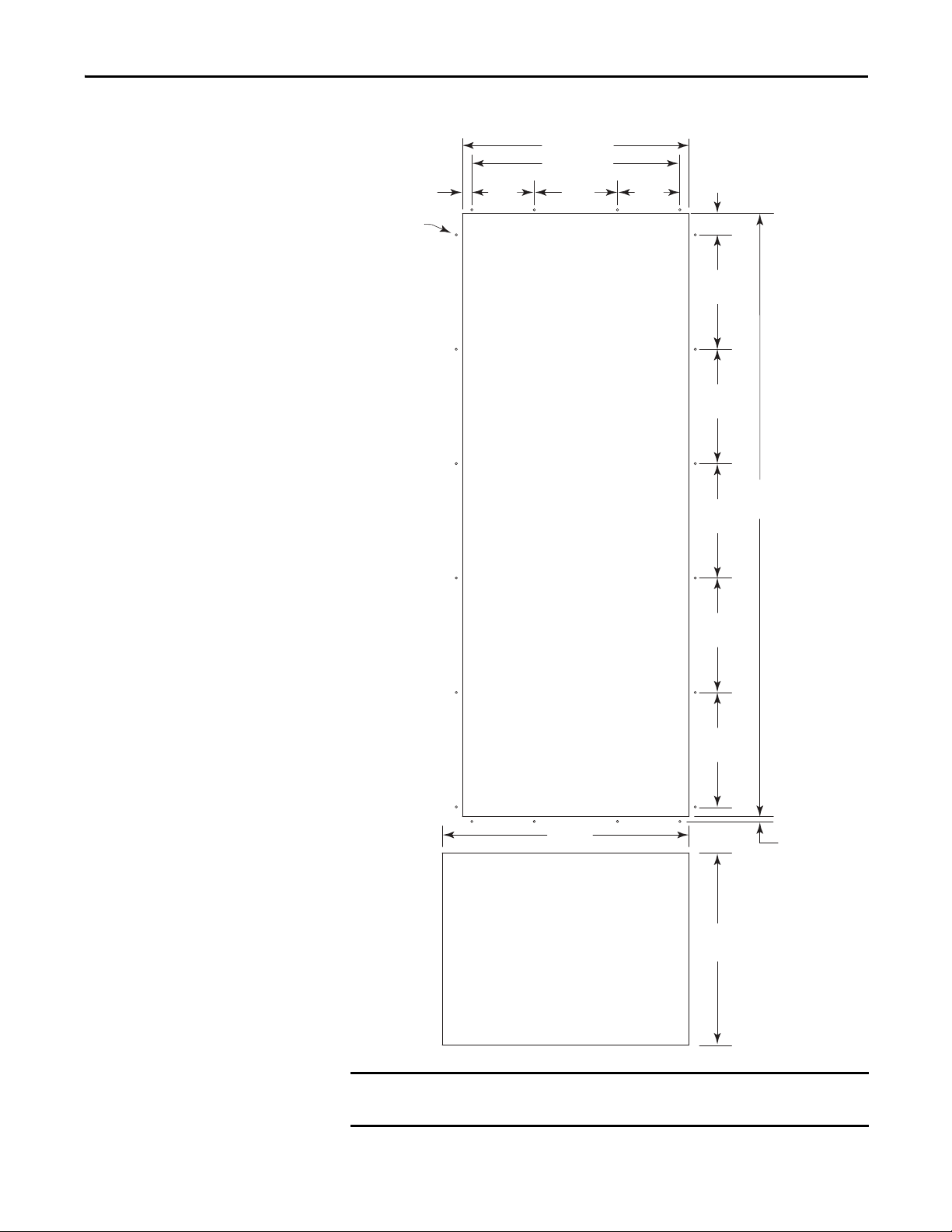

Dimensions

Dimensions are in millimeters and (inches)

Frame 7 – IP20, NEMA/UL Type 1

514.4 (20.25)

477.3 (18.79)

440.2 (17.33)

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

406.5 (16.00)

1424.7

(56.01)

1447.8

PORT

MOD

NET A

NET B

(57.00)

1498.6

(59.00)

406.7

(16.01)

354.3

(13.95)

312.4

261.6

(10.30)

(12.30)

38.7 (1.52)

Approx. Weight kg (lbs.)

Drive Drive & Packaging

170 (375) 1 96 (433)

210.8

(8.30)

89.5 (3.52)

178.4 (7.02)

Lifting Holes

4 Places

134.6

(5.30)

58.5

(2.30)

305.4 (12.02)

432.4 (17.02)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 15

Page 16

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Dimensions are in

millimeters and (inches)

Frame 7 – IP00, NEMA/UL Type Open

509.3 (20.05)

477.3 (18.79)

440.2 (17.33)

!

DANGER

409.3 (16.11)

1419.1

(55.87)

354.3

(13.95)

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

+DC

-DC PE PE R-L1 T-L3

USE 75° COPPER WIRE ONLY

CAUTION

!

HOT SURFACES

TB11

25 AMPERES RMS

MAXIMUM

ALLEN-BRADLEY

MADE IN U.S.A.

TORQUE LARGE TERMINALS TO 10 N-m (87LB-IN)

1447.8

(57.00)

1498.6

PE

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

U-M1 V-M2 W-M3S-L2

(59.00)

Lifting Holes

4 Places

133.4

(5.25)

58.9

(2.32)

Approx. Weight kg (lbs.)

Drive Drive & Packaging

147 (324) 173 (382)

16 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 17

Frame 7 – Flange Mount Cutout

Dimensions are in millimeters and (inches)

IMPORTANT

5.8

(0.23)

1422.4

(56.00)

1095.8

(43.14)

1084.1

(42.68)

508.0

(20.00)

Cutout

489.0

(19.25)

477.3

(18.79)

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

127.0

(5.00)

54.1

(2.13)

Shading indicates approximate size

of drive inside enclosure.

127.0

(5.00)

75.4

(2.97)

5.8

(0.23)

Drive

26 Required

4.3 (0.171) Dia. for 10-32 x 9.7 (0.38) Self-Tap

4.0 (0.159) for 10-32 x 9.7 (0.38) Threaded

* Minimum dimension allowed – More space

will improve fan eectiveness and heat

dissipation.

Back of Enclosure

132.3 (5.21) *

Use gasket kit catalog number SK-G1-GASKET1-F7 with user supplied IP54,

NEMA/UL Type 12 enclosure.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 17

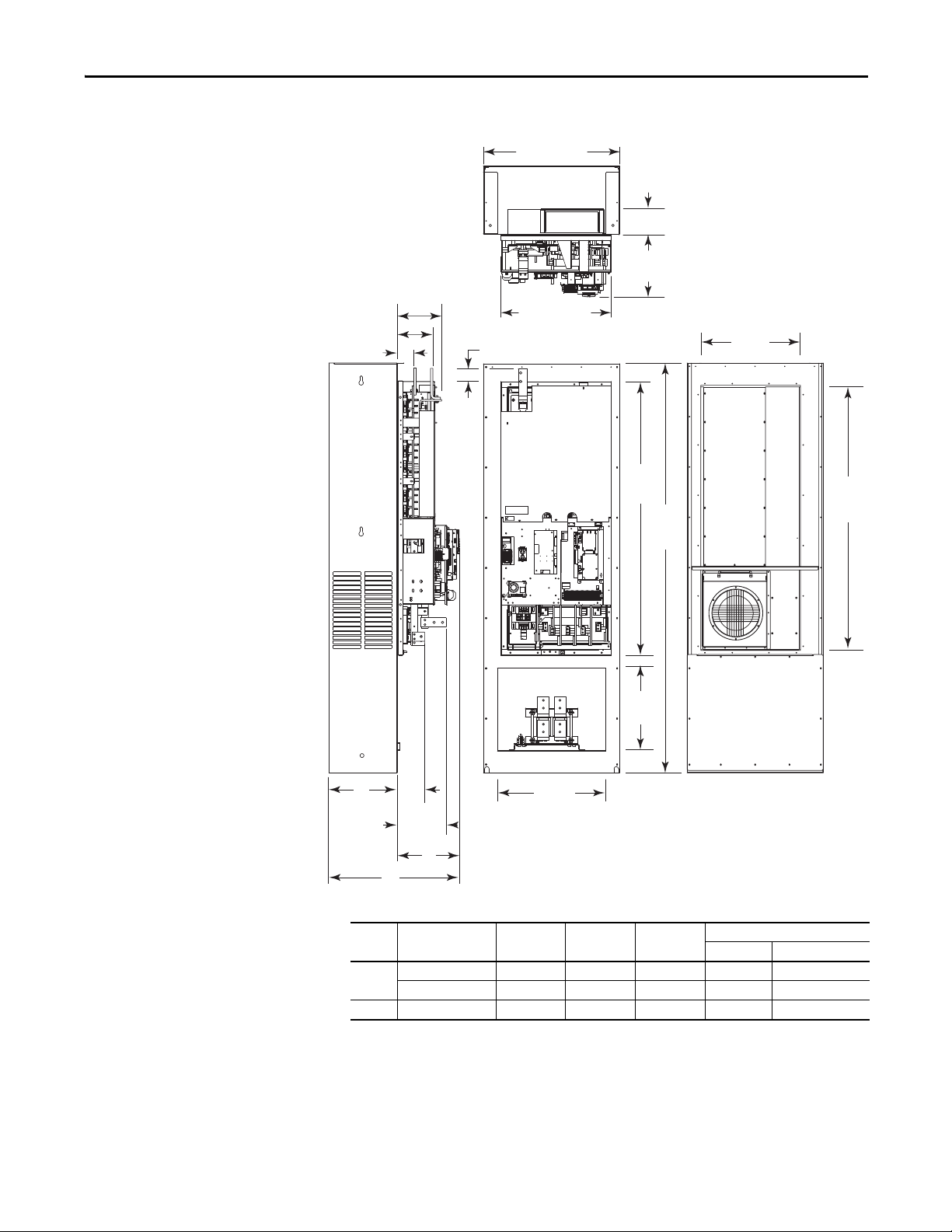

Page 18

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

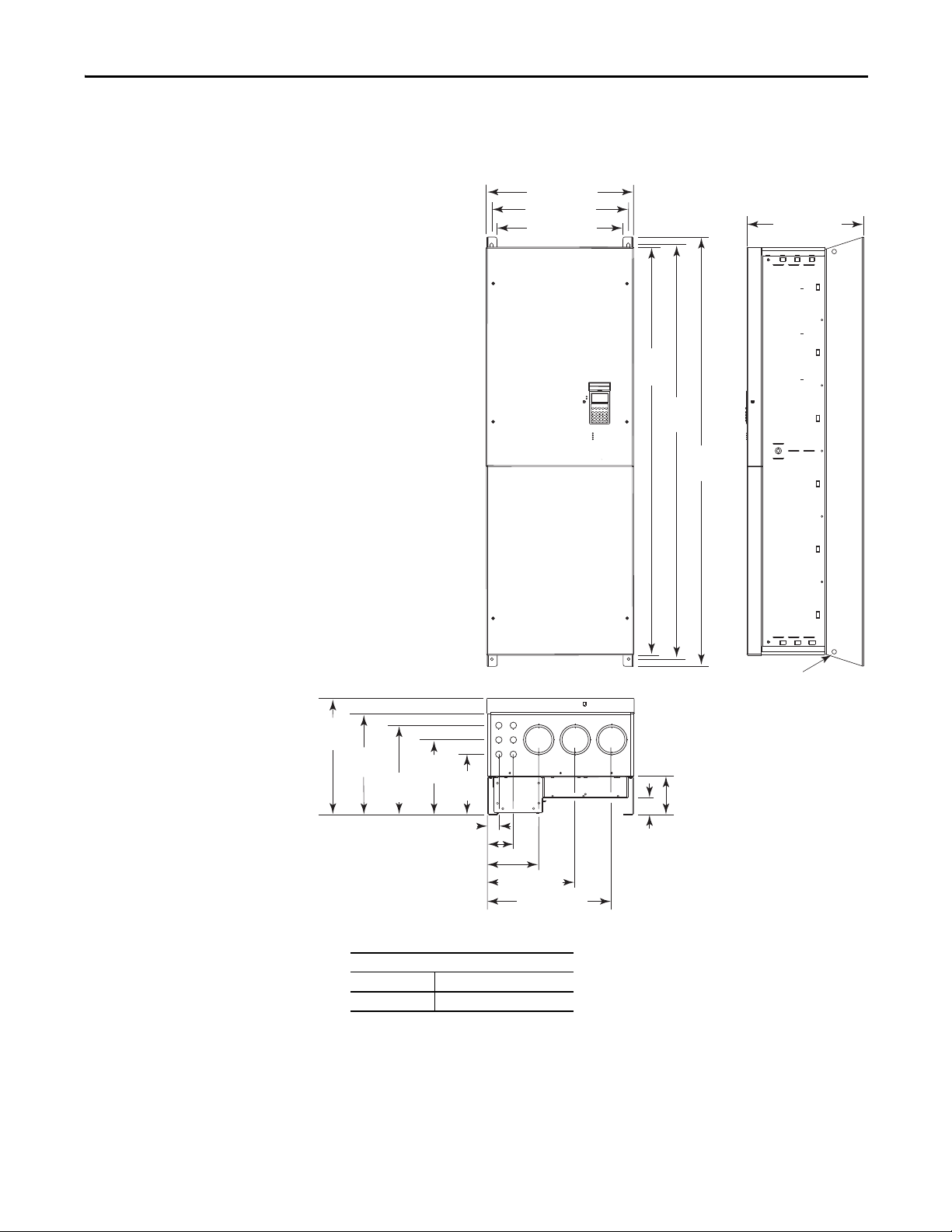

Dimensions are in millimeters and (inches)

Frames 8 and 9 – IP20, NEMA/UL Type 1

254.6 (10.02) - 20Bx365, 415, 481

381.7 (15.03) - 20Bx535, 600, 730

898.8 (35.39) - 20Bx365, 415, 481

1025.9 (40.39) - 20Bx535, 600, 730

549.7

(21.64)

1466.6

(57.74)

757.9

(29.84)

Approx. Weight kg (lbs.)

Frame Drive Drive & Packaging

8 509 (1122) 55 6 (1225)

9 526 (1159) 60 3 (1262)

2349.1

(92.49)

18 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 19

TB11

TE

25 AMPERES RMS

MAXIMUM

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB9

8 AMPERES RMS

MAXIMUM

DC+

VWU

R S T DC-DC+

GND

2283.7

(89.91)

463.8

(18.26)

603.0

(23.74)

1524.0

(60.00)

71.3 (2.81)

A

C

B

153.0

(6.02)

274.3

(10.80)

193.3 (7.61)

241.0 (9.49)

549.7

(21.64)

1466.6

(57.74)

85.5 (3.37)

757.8 (29.83)

145.3

(5.72)

See

Table

612.8 (24.13)

Dimensions are in millimeters and (inches)

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Frames 8 and 9 – IP00, NEMA/UL Type Open

Frame Cat. No. A B C

8 20Bx365, 415, 481 254.6 (10.02) 345.3 (13.59) 599.4 (2 3.60) 384 (847) 431 (950)

20Bx535, 600 381.7 (15.03) 345.5 (13. 60) 726.6 (28.61) 384 (847) 431 (950)

Approx. Weight kg (lbs.)

Drive Drive & Packaging

9 20Bx730 381.1 (15.00) 345.3 (13.60) 771.9 (30.39) 401 (884) 448 (987)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 19

Page 20

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

TB11

TE

25 AMPERES RMS

MAXIMUM

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB9

8 AMPERES RMS

MAXIMUM

DC+

VWU

R S T DC-DC+

GND

➊

➋

➌

Frames 8 and 9 – Converting an IP00 Drive for Flange Mounting

No. Component

Remove these IP00 enclosure components.

➊

Drive assembly to be flange mounted.

➋

DC link choke - mounts separately in enclosure (see page 28 for dimensions) and is wired direc tly to drive.

➌

20 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 21

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

TB11

TE

25 AMPERES RMS

MAXIMUM

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

DANGER

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB9

8 AMPERES RMS

MAXIMUM

DC+

V

W

U

RSTDC-DC+

648.2 (25.52)

1612.4

(63.48)

719.8 (28.34)

A

45.2

(1.78)

31.8

(1.24)

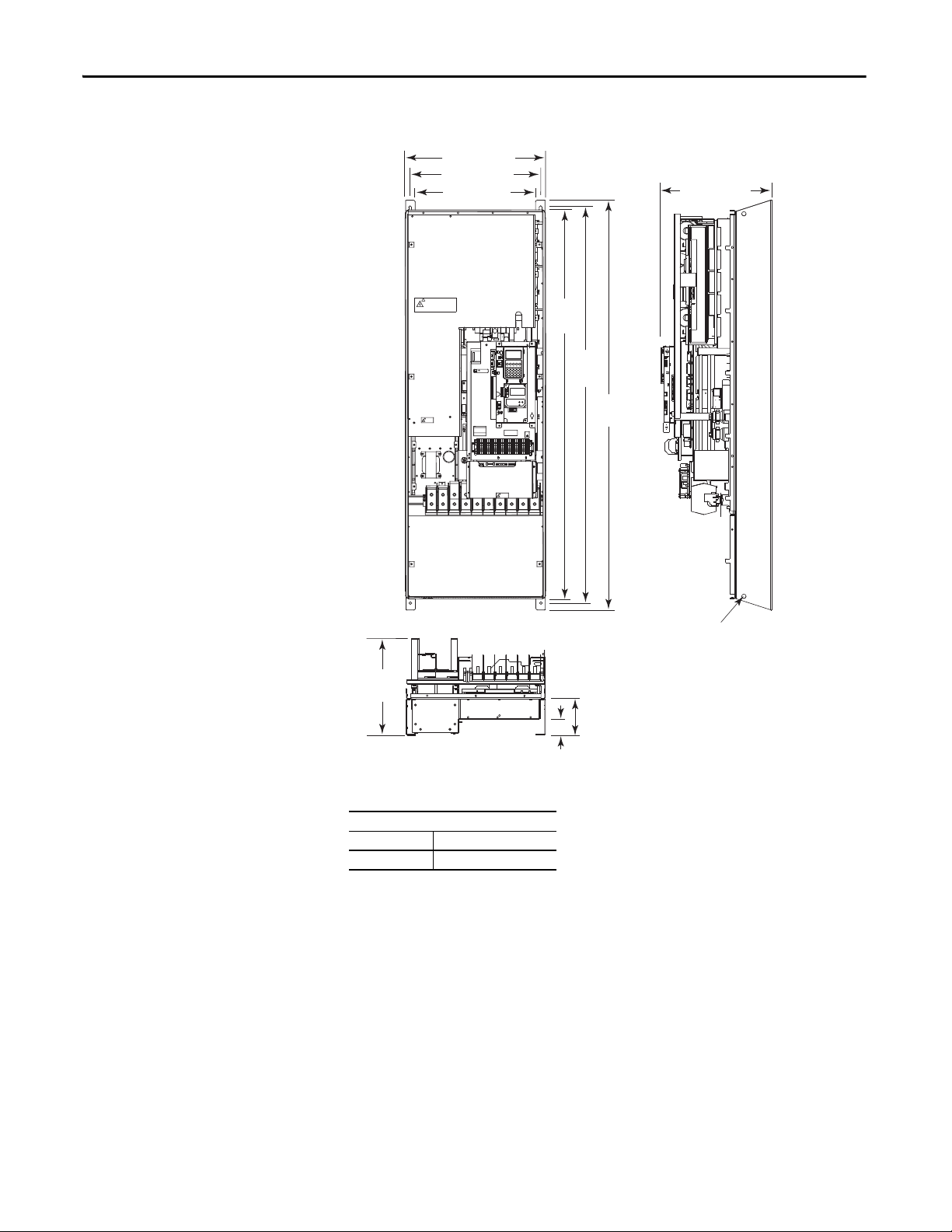

Dimensions are in millimeters and (inches)

Frames 8 and 9 Roll-In – IP00, NEMA/UL Type Open

Frame C at. No. A

Approx. Weight kg (lbs.)

Drive Drive & Packaging

8 20Bx365, 415, 481 574.8 (22.63) 25 0 (552) 297 (655)

8 20Bx535, 600 574.8 (22.63) 25 0 (552) 297 (655)

9 20Bx730 594.3 (23.40) 267 (589) 314 (692)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 21

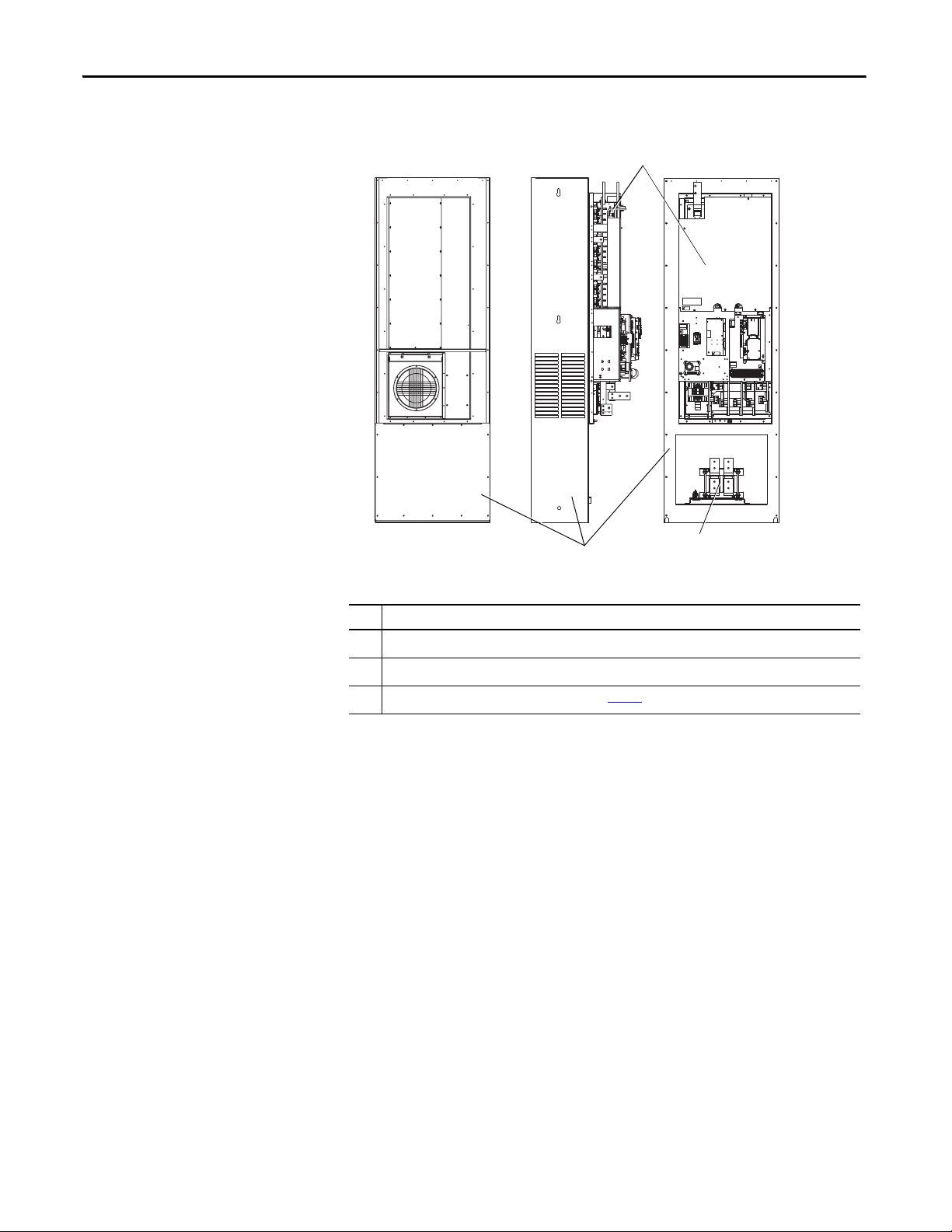

Page 22

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IMPORTANT

Typical Fan Location

(2 Places - 1 Each Door)

Typ ica l Bra cke t

(May require additional anchoring for shipping)

Suggested Anchoring Point

(M10 Ha rdware Required)

Alternate Fan Locations

Typical Rail Detail

Cable Access Plate

(2 Places)

DC Link Choke

Mounted Separately - Typical Placement Shown

203.2…355.6 mm

(8.00…14.00 in.) Typical

Suggested Anti-Roll

Anchoring Point

Typical Air Inlet

(2 Places - 1 Each Door)

Frames 8 and 9 Roll-In Mounting Considerations

107.4

D =

(4.23)

465.8 (18.34)

58.9

(2.32)

GER

N

DA

R

E

G

N

A

K

!

C

D

O

H

S

F

O

K

IS

R

R

E

T

F

A

E

AC

L

P

E

R

G

IN

IC

V

R

SE

9

B

T

S

M

R

S

E

R

E

P

M

A

8

M

U

M

I

X

A

M

R

E

G

N

A

K

!

D

OC

H

S

F

O

K

IS

R

R

TE

F

A

E

C

A

L

P

E

R

G

IN

C

I

V

R

E

S

E

T

1

1

B

T

S

M

R

S

E

R

E

P

M

A

5

2

M

U

M

I

X

A

M

108.0 x 158.8

(4.25 x 6.25)

196.9

(7.75)

19.1

(0.75)

This information illustrates how an open roll-in style drive could be mounted in

a user supplied enclosure. Illustrations are intended only to identify structural

mounting points and hardware shapes. You must design and fabricate steel

components based on the actual mounting configuration, calculated loads and

enclosure specifications. Minimum thickness of all parts = 4.6 mm (0.18 in.).

22 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

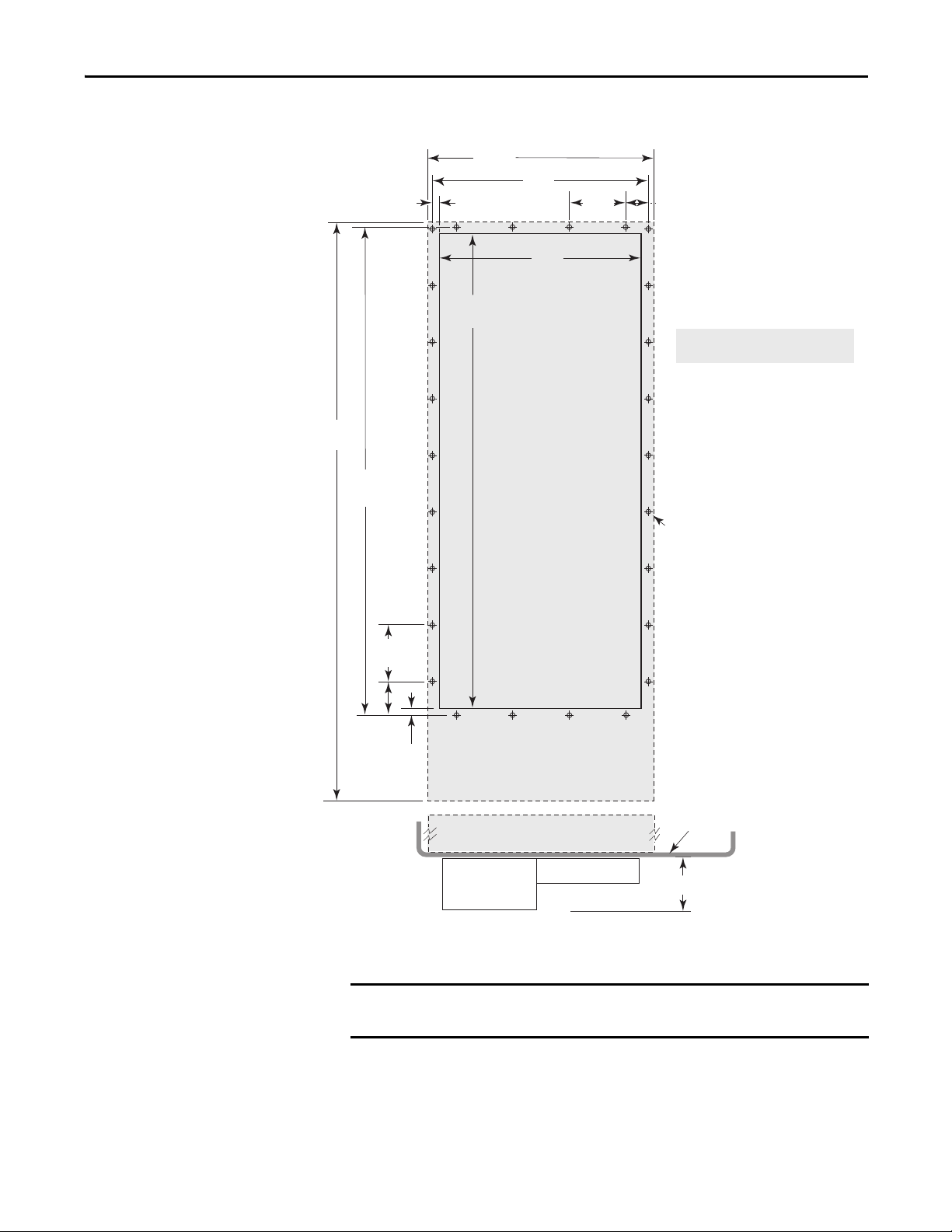

Page 23

IMPORTANT

1471.9

(57.95)

279.4

(11.00)

279.4

(11.00)

279.4

(11.00)

152.4

(6.00)

152.4

(6.00)

203.2

(8.00)

5.6 (0.22)

20 Places

52.1 (2.05)

22.9 (0.90)

553.3 (21.79)

279.4

(11.00)

279.4

(11.00)

603.0

(23.74)

12.7 (0.50)

508.0 (20.00)

463.8

(18.26)

This cutout is only needed

if recessing the choke

Dimensions are in millimeters and (inches)

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Frames 8 & 9 Flange Mount Cutout

Use gasket kit catalog number SK-G1-GASKET1-F89 with user supplied IP54,

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 23

NEMA/UL Type 12 enclosure.

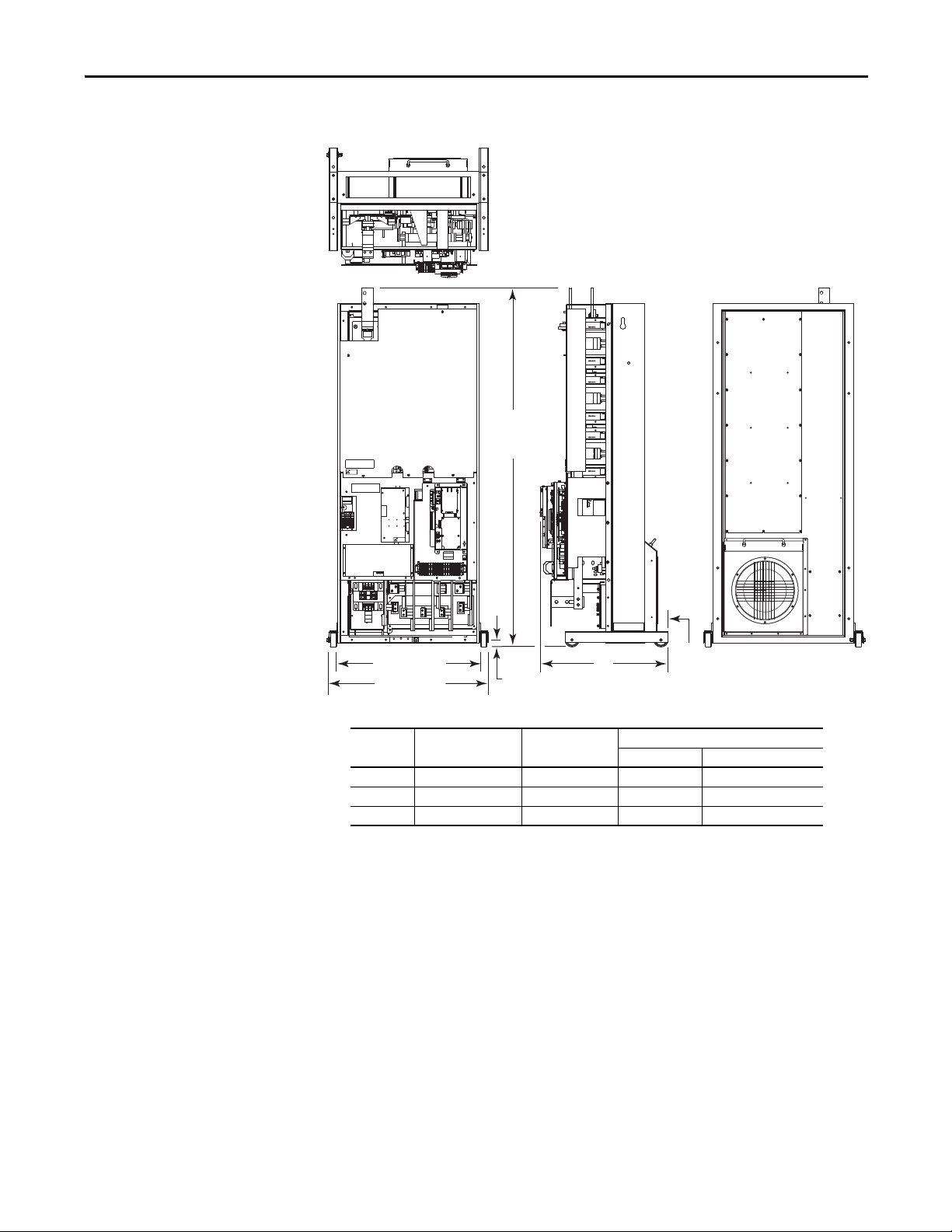

Page 24

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

890.8

(35.07)

2374.0

(93.46)

1268.7

(49.95)

761.3

(29.97)

507.4

(19.98)

Dimensions are in millimeters and (inches)

Frame 10 – IP20, NEMA/UL Type 1

AC Input Shown, for DC Input Dimensions use the Inverter (Left) Bay

Approx. Weight kg (lbs.)

Type Drive Drive & Packaging

DC Input 468 (1032) 515 (1135)

AC Input 867 (1912) 958 (2112)

24 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 25

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

120

IN1

120

IN2

3

4

5

6

DC+

DANGER

DANGER

DANGER

TB9

8 AMPERES RMS

MAXIMUM

120

IN1

120

IN2

3

4

5

6

VWU

TB11

PE

25 AMPERES RMS

MAXIMUM

GND

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

TB10

8 AMPERES RMS

MAXIMUM

120

IN1

120

IN2

3

4

5

6

TB10

8 AMPERES RMS

MAXIMUM

GND

RISK OF SHOCK

REPLACE AFTER

SERVICING

!

DANGER

543.6

(21.40)

591.8

(23.30)

2275.8

(89.60)

252.7

(9.95)

473.4

(18.64)

1267.8

(49.91)

757.8

(29.83)

503.7

(19.83)

353.8

(13.93)

445.8

(17.55)

Dimensions are in millimeters and (inches)

Frame 10 – IP00, NEMA/UL Type Open

AC Input Shown, for DC Input Dimensions use the Inverter (Left) Bay

Approx. Weight kg (lbs.)

Type Drive Drive & Packaging

DC Input 305 (672) 352 (775)

AC Input 532 (1172) 623 (1372)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 25

Page 26

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IMPORTANT

Dimensions are in millimeters and (inches)

Frame 10 – Flange Mount Cutout

22.9

(0.90)

52.1 (2.05)

279.4 (11.00)

hole spacing,

5 places,

both sides

66.5 (2.62)

508.0 (20.00)

355.6 (14.00)

152.4

(6.00)

553.3 (21.79)

1471.9

(57.95)

Inverter Converter

22.5

(0.89)

37.7

(1.49)

22.9 (0.90)

12.7 (0.50)

58.6 (2.31)

38.1

(1.50)

152.4

(6.00)

381.0 (15.00)

152.4

(6.00)

32.3 (1.27)

39.9 (1.57)

7.6 (0.30)

1588.5

(62.54)

254.0 (10.00)

hole spacing

5 places,

both sides

See Detail

Holes are for M6 self tapping screws.

Backplate and extension are a single piece. Drive chassis can be removed from

backplate to mount in user supplied IP54, NEMA/UL Type 12 enclosure.

26 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 27

Frame 10 – Flange Mount Cutout Detail

IMPORTANT

Dimensions are in millimeters and (inches)

95.9 (3.77)

178.8(7.04)

558.2 (21.98)

543.3 (21.39)

24.9 (0.98)

28.7 (1.13)

*

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

328.8 (12.94)

478.8 (18.85)

*

530.8 (20.90)

486.5 (19.15)

414.7 (16.33)

363.7 (14.32)

271.2 (10.68)

127.7 (5.03)

Ref. (0.00)

15.8 (0.62)

*

*

*

**

14.7 (0.58)

Ref. (0.00)

Fan studs are installed in alternating

directions. “ * ” indicates that the stud

points-in, all others point-out.

Fan Stud “Pointing-Out”

(Outside of Enclosure)

93.7 (3.69)

121.1 (4.77)

Enclosure Wall

Fan Stud “Pointing-In”

(Inside of Enclosure)

253.7 (9.99)

413.8 (16.29)

*

*

*

**

507.5 (19.98)

522.2 (20.56)

Backplate and extension are a single piece. Drive chassis can be removed from

backplate to mount in user supplied IP54, NEMA/UL Type 12 enclosure.

425.6 (16.75)

343.0 (13.50)

199.5 (7.85)

56.0 (2.20)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 27

Page 28

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

370.8 (14.60)

396.2 (15.60)

179.8

(7.08)

217.9

(8.58)

228.6

(9.00) Max.

19.1 (0.75)

16.0 x 9.7 (0.63 x 0.38)

4 Places

203.2 (8.00)

279.4 (11.00)

4.7 (0.19)

215.9

(8.50) Max.

4.8

(0.19)

54.1

(2.13)

54.1

(2.13)

10.2 (0.40) Min.

162.1

(6.38)

Dimensions are in millimeters

and (inches)

Dimensions are in millimeters

and (inches)

DC Link Choke – Frame 8

DC Link Choke – Frame 9

14.2 (0.56)

188.0

(7.40)

218.4

(8.60)

28 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

101.6

(4.00)

287.0

(11.30)

214.4

(8.44)

35.3

(1.39)

342.9 (13.50)

304.8 (12.00)

50.8

(2.00)

L1

L2 L3

50.8

(2.00)

25.4 (1.00)

L4

Page 29

See Detail

Dimensions are in millimeters and (inches)

DC Link Choke – Frame 10

266.7 (10.50) Max

220.9 (8.70)

Top

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Detail

219.7

(8.65)

31.8 (1.25)

9.5 (0.38) Dia.

280.7

(11.05)

251.0

(9.90)

244.6 (9.63)

57.2 (2.25)

121.8 (4.80)

25.4

(1.00) Dia.

2 Places

Front Side

12.7 (0.50)

34.9 (1.38)

222.0

(8.74)

247.7

(9.75)

12.7 (0.50)

13.5 (0.53)

31.8 (1.25)

11.8 (0.47)

7.9 (0.31)

4 PLACES

305.0

(12.00)

248.0

(9.76)

Step 3: Wire the Drive

280.7 (11.05)

Special Considerations

PowerFlex 700 drives are suitable for use on a circuit capable of delivering up to a

maximum of 200,000 rms symmetrical amperes.

ATT EN TI ON : To guard against personal injury and/or equipment damage

caused by improper fusing or circuit breaker selection, use only the

recommended line fuses/circuit breakers specified on page 41

.

If a system ground fault monitor (RCD) is used, only Type B (adjustable) devices

can be used to avoid nuisance tripping.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 29

Page 30

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Unbalanced, Ungrounded, Resistive or B Phase Grounded Distribution Systems

If phase to ground voltage exceeds 125% of normal line to line voltage or the

supply system is ungrounded, refer to the Wiring and Grounding Guidelines for

Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

ATT EN TI ON : To guard against drive damage, PowerFlex 700 drives contain

protective MOVs and common mode capacitors that are referenced to ground.

These devices must be disconnected if the drive is not

grounded system. See page 46

for details.

installed on a solidly

.

Input Power Conditioning

Certain events on the power system supplying a drive can cause component

damage or shortened product life. These conditions include:

• The power system has power factor correction capacitors switched in and

out of the system, either by the user or by the power company.

• The power source has intermittent voltage spikes in excess of 6000 volts.

These spikes could be caused by other equipment on the line or by events

such as lightning strikes.

• The power source has frequent interruptions.

If any or all of these conditions exist, it is recommended that the user install a

minimum amount of impedance between the drive and the source. This

impedance could come from the supply transformer itself, the cable between the

transformer and drive or an additional transformer or reactor.

EMC Compliance

Frames 7…10: Drives are CE Certified for use with 400V AC and 480V AC

center grounded neutral power supply systems only. Refer to page 7

for details.

Cable Trays and Conduit

If cable trays or large conduits are to be used, refer to the guidelines presented in

the Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC

Drives, publication DRIVES-IN001

ATT EN TI ON : To avoid a possible shock hazard caused by induced voltages,

unused wires in the conduit must be grounded at both ends. For the same

reason, if a drive sharing a conduit is being serviced or installed, all drives using

this conduit must be disabled. This helps to minimize the possible shock hazard

from “cross coupled” motor leads.

.

Motor Cable Lengths

Typically, motor lead lengths less than 91 meters (300 feet) are acceptable.

However, if your application dictates longer lengths, refer to the Wiring and

Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives,

publication DRIVES-IN001

20B-TD001

30 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

.

or the PowerFlex 700 Technical Data, publication

Page 31

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Cable Types Acceptable for 200…600 Volt Installations

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated from

sensitive circuits. As an approximate guide, allow a spacing of 0.3 meters (1 foot)

for every 10 meters (32.8 feet) of length. In all cases, long parallel runs must be

avoided. Do not use cable with an insulation thickness less than or equal to 15

mils (0.4mm/0.015 in.). Use Copper wire only. Wire gauge requirements and

recommendations are based on 75 °C. Do not reduce wire gauge by using higher

temperature wire.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry

environments provided adequate free air space and/or conduit fill rates limits are

provided. Do not use THHN or similarly coated wire in wet areas. Any wire

chosen must have a minimum insulation thickness of 15 Mils and not have large

variations in insulation concentricity.

Shielded/Armored Cable

Shielded cable contains all of the general benefits of multi-conductor cable with

the added benefit of a copper braided shield that can contain much of the noise

generated by a typical AC Drive. Strong consideration for shielded cable must be

given in installations with sensitive equipment such as weigh scales, capacitive

proximity switches and other devices that can be affected by electrical noise in the

distribution system. Applications with large numbers of drives in a similar

location, imposed EMC regulations or a high degree of communications/

networking are also good candidates for shielded cable.

Shielded cable can also help reduce shaft voltage and induced bearing currents for

some applications. In addition, the increased impedance of shielded cable can

help extend the distance between the motor and drive without the addition of

motor protective devices such as terminator networks. Refer to Reflected Wave

in the Wiring and Grounding Guidelines for Pulse Width Modulated (PWM)

AC Drives, publication DRIVES-IN001

Consideration must be given to all of the general specifications dictated by the

environment of the installation, including temperature, flexibility, moisture

characteristics and chemical resistance. In addition, a braided shield can be

included and be specified by the cable manufacturer as having coverage of at least

75%. An additional foil shield can greatly improve noise containment.

A good example of recommended cable is Belden® 295xx (xx determines gauge).

This cable has four (4) XLPE insulated conductors with a 100% coverage foil and

an 85% coverage copper braided shield (with drain wire) surrounded by a PVC

jacket.

.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 31

Page 32

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IMPORTANT

IMPORTANT

Other types of shielded cable are available, but the selection of these types can

limit the allowable cable length. Particularly, some of the newer cables bundle 4

conductors of THHN wire and wrap them tightly with a foil shield. This

construction can greatly increase the cable charging current required and reduce

the overall drive performance. Unless specified in the individual distance tables as

tested with the drive, these cables are not recommended and their performance

against the lead length limits supplied is not known. See Ta b l e 3

Table 3 - Recommended Shielded Wire

Location Rating/Type Description

Standard

(Option 1)

Standard

(Option 2)

Class I & II;

Division I & II

600V, 90 °C (194 °F)

XHHW2/RHW-2 Anixter

B209500-B209507, Belden

29501-29507, or equivalent

Tray rated 600V, 90 °C

(194 °F) RHH/RHW-2 Anixter

OLF-7xxxxx or equivalent

Tray rated 600V, 90 °C

(194 °F) RHH/RHW-2 Anixter 7V7xxxx-3G or equivalent

• Four tinned copper conductors with XLPE insulation.

• Copper braid/aluminum foil combination shield and tinned

copper drain wire.

• PVC jacket.

• Three tinned copper conductors with XLPE insulation.

• 5 mil single helical copper tape (25% overlap min.) with three

bare copper grounds in contact with shield.

• PVC jacket.

• Three bare copper conductors with XLPE insulation and

impervious corrugated continuously welded aluminum armor.

• Black sunlight resistant PVC jacket overall.

• Three copper grounds on #10 AWG and smaller.

.

Single-Phase Input Power – Frame 7 Only

The PowerFlex 700 drive is typically used with a three-phase input supply. Frame

7 drives have been listed by UL to operate on single-phase input power with the

requirement that the output current is derated by 50% (at maximum ambient

temperature of 25 °C) of the three-phase ratings. Refer to Ta b l e 4

AC Input Phase Selection

ATT EN TI ON : To avoid a shock hazard, ensure that all power to the drive has

been removed before performing the following.

Frames 8…10 are not designed for single-phase operation.

Moving the “Line Type” jumper on the Precharge Board (see below) allows single

or three-phase operation.

When selecting single-phase operation, input power must be applied to the R

(L1) and S (L2) terminals. This ensures that the fan is properly powered.

on page 33.

32 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 33

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Typical Location - Phase Select Jumper

333

1-PH 3-PH

LINE TYPE

JP1JP2 JP3

AC Input

Precharge

Board

3-PH 1-PH

LINE

TYPE

SPARE 1

SPARE 2

Table 4 - 380…480 Volt Single-Phase AC Input Ratings

480V Single-Phase AC Input 380…400V Single-Phase AC Input

Drive

Catalog

Number

20BD292 7 125 237.4 0-460 146 20BC292 7 80 247.7 0-400 146 25

20BD325 7 125 264.3 0-460 162.5 20BC325 7 90 275.7 0-400 162.5 25

Frame

Hp

Rating

Three-Phase

Output

Input

Amps

V AC Am ps V AC Amp s °C

Drive

Catalog

Number

kW

RatingInput

Frame

Amps

Three-Ph ase

Output

Power Terminal Blocks

Tem p.

ATT EN TI ON : National Codes and standards (NEC, VDE, BSI etc.) and local codes

outline provisions for safely installing electrical equipment. Installation must

comply with specifications regarding wire types, conductor sizes, branch circuit

protection and disconnect devices. Failure to do so can result in personal injury

and/or equipment damage.

Refer to pages 8 through 11 for typical locations.

Wire Size Range

(2)

see Note

Name Frame Description

Power

Ter mi na l Bl oc k

7Input power, DC+,

DC–, PE, motor

connections

8…10 Input power, DC+,

DC–, PE, motor

connections

AUX Terminal

(1)

Block

Fan Terminal

Block

7…10 Auxiliary Control

Volt age

(1)

PS+, PS–

7User Supplied Fan

Volt age

8…10 4.0 mm

(1) External control power - select drives only, see Auxiliary Control Power Supply on page 39 for details.

(2) Maximum/minimum sizes that the terminal block accepts - these are not recommendations.

(3) If can be necessary to connect multiple wires in parallel to these terminals by using multiple lugs.

Maximum Minimum Maximum Recommended

150.0 mm2

(300 MCM)

see Note

300.0 mm2

(600 MCM)

see Note

4.0 mm

(12 AWG)

4.0 mm

(12 AWG)

(12 AWG)

2

2

2

(3)

(3)

2.5 mm

(14 AWG)

2.5 mm

(14 AWG)

0.049 mm

(30 AWG)

0.5 mm

(22 AWG)

0.5 mm

(22 AWG)

2

2

2

2

2

Tor que

2.7 N•m

(24 lb•in)

10.0 N•m

(87 lb•in)

0.6 N•m

(5.3 lb•in)

0.9 N•m

(8.0 lb•in)

0.6 N•m

(5.3 lb•in)

2.7 N•m

(24 lb•in)

10.0 N•m

(87 lb•in)

0.6 N•m

(5.3 lb•in)

0.6 N•m

(5.3 lb•in)

0.6 N•m

(5.3 lb•in)

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 33

Page 34

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

DC+

DC

–

W

U

V

DC Bus/Brake

(top of drive)

PE

Terminal Block

Frame

AC Input DC Input

7

8…9

10

DC–DC+ PE PE R-L1 S-L2 T-L3 U-T1 V-T2 W-T3

Bus Input Output

DC+

–

DC

DC Bus/Brake

(top of drive)

DC+*

PE

DC

–

DC Bus/Brake

(top of drive)

PE

(IP20 Versions Only)

* for DC link choke wiring

T

DC+

T

L3

L3

S

S

L2

L2

U

120

USE 75° COPPER WIRE ONLY

PE

W

DC

–*

T

V

S

R

U

R

R

L1

L1

DC

–

DC Bus/Brake

(top of drive)

W

V

PE

(IP20 Versions Only)

TORQUE LARGE TERMINALS TO 10 N-m (87 LB-IN)

DC+ DC-

DC+

U-T1 V-T2 W-T3

BUS OUTPUT

U

W

V

Terminal Description Notes

DC+/DCTop of drive

DC+/DCPower TB

DC Bus (+)

DC Bus (–)

DC Bus (+)

DC Bus (–)

DC Input/Brake Chopper Connections

DC Link Choke - wire to:

Bottom of drives (Frames 8…9)

Converter section (Frame 10)

PE PE Ground

PS+

PS–

AUX (+)

AUX (–)

Auxiliary Control Voltage (see page 39

Motor Ground

U

V

W

R

S

T

34 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

U (T1)

V (T2)

W (T3)

R (L1)

S (L2)

T (L3)

To M oto r

AC Lin e Input Power

Three-Phase = R, S & T

Single-Phase = R & S Only

) for details.

Page 35

Fan Circuit Power Supply

IMPORTANT

Input Line Voltage

480/400V AC, 50/60 Hz

F2

H3

480 400

F3

to TB9

JMP

0

115 0

F1

H2H1

X1 XF X2

ATT EN TI ON : To avoid a shock hazard, ensure that all power to the drive has

been removed before connecting the fan supply.

Some drives utilize a fan transformer to power the internal fan(s). This

transformer is sized specifically for the internal fan(s) and must not be used to

power other circuitry.

Frame 7

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Drive

Type En closu re

DC

IP00, NEMA/UL Type Open 250 VA 1 Power Terminal Block

Input

IP20, NEMA/UL Type 1 250 VA 1

AC

IP00, NEMA/UL Type Open 250 VA 1 N/A (Connected internally)

Input

IP20, NEMA/UL Type 1 250 VA 1

Frame 8

Drive

Type En closu re

DC

IP00, NEMA/UL Type Open 500 VA 1 TB9

Input

IP20, NEMA/UL Type 1 500 VA 1

AC

IP00, NEMA/UL Type Open 500 VA 1 TB9

Input

IP20, NEMA/UL Type 1 500 VA 1

Rating

(120VAC)

Rating

(120VAC)

No. of

Fans Connect at …

Requires user supplied 120V AC. See page 34

location.

No. of

Fans Connect at …

Requires user supplied 120V AC. See page 9

location and page 37

for terminal designations.

A transformer

matches the input

line voltage to the

internal fan voltage. If

line voltage is

different than the

voltage class specified

on the drive

nameplate, the

transformer taps may

require changing.

for

for TB

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 35

Page 36

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Input Line Voltage

480/400V AC, 50/60 Hz

F2

H3

480 400

F3

to TB9

JMP

0

115 0

F1

H2H1

X1 XF X2

v

~

L1 L2 L3

Frame 9

Drive

Type E nclosu re

DC

IP00, NEMA/UL Type Open 500 VA 2 TB9

Input

IP20, NEMA/UL Type 1 500 VA 2

AC

IP00, NEMA/UL Type Open 500 VA 2 TB9

Input

IP20, NEMA/UL Type 1 500 VA 2

Rating

(120VAC)

No. of

Fans Connect at …

Requires user supplied 120V AC for cap. bank fan and

phase monitor.

Blower Terminal Block

Three-phase power must be supplied to the Blower TB.

See page 10

designations.

A transformer (see

page 10

matches the input line

voltage to the internal

voltage used for the

capacitor fan and phase

detector module. If the

line voltage is different

than the voltage class

specified on the drive

nameplate, the

transformer taps may

require changing.

for TB locations and page 37 for terminal

for location)

Frame 9 Blower Operation

Frame 9 drives use a single-phase capacitor bank fan and a three-phase blower for

cooling. Proper phasing must be supplied to terminals R, S, and T of the Power

Terminal Block (AC drives) or the Blower Terminal Block (DC drives) to assure

correct blower rotation. To verify this, a Phase Monitor relay (see page 10

for

location) is used.

When wiring is complete, apply drive power and check for proper fan operation.

Depending on when the drive was manufactured, one of two different phase

monitor relays is used:

• Drives Manufactured Before

January 20, 2011: If

phasing is correct, a solid triangle is displayed on

the phase monitor relay (shown at right).

• Drives Manufactured January 20, 2011 and

after

: If phasing is correct, the “R/T” LED on

the phase monitor relay illuminates.

• If phasing is not correct, the “F1” and “F2” LEDs alternately illuminate.

Regardless of which phase monitor relay is used in the drive, if the blower does

not operate:

1. Remove all input power and wait 5 minutes for the DC bus to discharge.

Verify that the DC bus has discharged by measuring across the + and - DC

bus terminals. The reading must be less than 50 volts.

2. Verify blower fuses and replace if necessary.

3. Switch any two input power leads at the top of the blower fuse block.

4. Apply power and verify proper operation.

36 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 37

Frame 10

Input Line Voltage

480/400V AC, 50/60 Hz

F2

H3

480 400

F3

to TB9

JMP

0

115 0

F1

H2H1

X1 XF X2

Frame 10, AC Input, IP20 Only

120V

120V

N

120V

AC Input

N

PE

PE

7

Line

Neutral

To Fan(s)

Ground

NC

TB9, TB10 TB12

Frame 9 Onl y

Blower TB

Frames 8…10

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Drive

Type E nclosu re

DC

IP00, NEMA/UL Type Open 1000 VA 2 TB9 & 10

Input

IP20, NEMA/UL Type 1 1000 VA 2

AC

IP00, NEMA/UL Type Open 1000 VA 3 TB9, 10 & 12

Rating

(120VAC)

Input

IP20, NEMA/UL Type 1 1000 VA 3 TB9, 10 & 12

Fan/Blower Terminal Blocks - Frames 8…10

120V

AC Input

Line

Neutral

Ground

120V

120V

N

N

PE

PE

7

NC

To Fan(s)

RTS

No. of

Fans Connect at …

Requires user supplied 120V AC. See page 11

locations and page 37

for terminal designations.

Requires user supplied 120V AC. See page 11

locations and page 37

for terminal designations.

A transformer (see

page 11

) matches the

input line voltage to

the internal fan

voltage. If line voltage

is different than the

voltage class specified

on the drive

nameplate, the

transformer taps may

require changing.

for TB

for TB

Fan Transformer Specifications/Fusing

Recommended Fuses

Frame Rating

Primary (Quantity 2) Secondary (Quantity 1)

8 & 9 500 VA 2.8A, 600V AC, KLDR/ATQR Type 6.25A, 250V AC, Time Delay

10 1000 VA 6A, 600V AC, KLDR/ATQR Type 9A, 250V AC, Time Delay

Three-Phase Blower Fusing

Frame Recommended Fuses (Quantity 3)

9 5A, 600V AC, Time Delay

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 37

Page 38

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Output to Inverter

Capacitor Bank

Input from

Converter

CNV+

CNV–

INV+

(1) (2)

(4) (3)

INV–

DC–

DC+

to Mounting Foot

Additional Frame 10 Wiring Requirement for IP00 AC Input Drives

The Inverter and Converter sections of Frame 10 AC Input IP00, NEMA/UL

Type Open drives are shipped separately. Once installed, the following

connections are required.

1. DC Link Choke Wiring

DC link chokes are supplied loose for customer mounting and wiring in

IP00 drives. Refer to DC Link Chokes – Frames 8…10

2. Thermistor Wiring

Thermistor wiring is coiled loose in the Converter section for shipping.

Locate the wire (labeled “To INV”) and route through the enclosure wall.

Connect it to the mating connector above the HIM cradle.

ATTENTION: To avoid possible drive damage, ensure that the

thermistor wiring described above has been properly performed.

3. Ground the drive chassis

Refer to page 11

for IP00 PE grounding locations.

below.

DC Link Chokes – Frames 8…10

DC Link Chokes are supplied with Frame 8…10 AC input drives.

Frame Type DC Link Choke is supplied …

8…9 IP00, NEMA/UL Type Open Mounted and wired

IP20, NEMA/UL Type 1 Mounted and wired

IP00, NEMA/UL Type Open Roll-In Loose without cables (see wiring info below)

10 IP00, NEMA/UL Type Open Loose without cables (see wiring info below)

IP20, NEMA/UL Type 1 Mounted and wired

DC Link Choke Wiring

Refer to the diagram and page 34 for

connection information. Drive rating

information can be found on pages 42

…42.

38 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 39

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Auxiliary Control Power Supply

If desired, an auxiliary control power supply can be used with certain drives to

keep the drive control logic up when the main AC power is removed.

An auxiliary control power supply can only be used with:

• 400/480

and 600/690 Volt drives with Vector Control (15th position of

the catalog number string equals “C,” or “D”).

Using an auxiliary control power supply requires the use of some type of AC line

monitoring, as well as control of the Precharge Enable signal. Consult the factory

for additional guidance.

ATT EN TI ON : An Auxiliary Control Power Supply Must Not be used with any

PowerFlex 700 Standard Control drive or 200/240 Volt Vector Control drive.

Using the power supply with these drives causes equipment/component

damage.

Connection is performed at the I/O terminal block (see pages 8

Power supply must provide

UL Installation 300V DC, ±10%

Non UL Installation 270…600V DC, ±10%

Auxiliary Control Voltage Terminal Block Specification

Wire Size Range

Maximum Minimum Maximum Recommended

4.0 mm2 (12 AWG) 0.049 mm2 (30 AWG) 0.6 N•m (5.3 lb•in) 0.6 N•m (5.3 lb•in)

(1)

Tor que

…11).

PS+ PS –

(1) Maximum/minimum that the terminal block accepts - these are not recommendations.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 39

Page 40

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

IMPORTANT

General Grounding Requirements

The drive Safety Ground - PE must be connected to system ground. Ground

impedance must conform to the requirements of national and local industrial

safety regulations and/or electrical codes. The integrity of all ground connections

must be periodically checked.

For installations within a cabinet, use only a single safety ground point or ground

bus bar connected directly to building steel. All circuits including the AC input

ground conductor must be grounded independently and directly to this point/

bar.

Do Not discard or replace grounding hardware.

Typical Grounding

SHLD

U (T1)

V (T2)

W (T3)

R (L1)

S (L2)

T (L3)

PE

Safety Ground - PE

This is the safety ground for the drive that is required by code. This point must be

connected to adjacent building steel (girder, joist), a floor ground rod or bus bar

(see above). Grounding points must comply with national and local industrial

safety regulations and/or electrical codes.

Shield Termination

The Shield terminal (PE) provides a grounding point for the motor cable shield.

Connect the motor cable shield to this terminal on the drive (drive end) and the

motor frame (motor end). A shield terminating cable gland can also be used.

When shielded cable is used for control and signal wiring, ground the shield at

the source end only, not at the drive end.

RFI Filter Grounding

Using an optional RFI filter can result in relatively high ground leakage currents.

Therefore, the filter must be used only in installations with grounded AC

supply systems and be permanently installed and solidly grounded (bonded)

to the building power distribution ground. Ensure that the incoming supply

neutral is solidly connected (bonded) to the same building power distribution

ground. Grounding must not rely on flexible cables and must not include any

form of plug or socket that permits inadvertent disconnection. Some local codes

can require redundant ground connections. Periodically check the integrity of all

connections. Refer to the instructions supplied with the filter.

40 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 41

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Motor Overload Protection

Class 10 motor overload protection according to NEC article 430 and motor

over-temperature protection according to NEC article 430.126 (A)(2). UL 508C

File E59272.

Drive, Fuse & Circuit Breaker Ratings

The PowerFlex 700 can be installed with input fuses or an input circuit breaker.

National and local industrial safety regulations and/or electrical codes can

determine additional requirements for these installations.

ATT EN TI ON : The PowerFlex 700 does not provide branch short circuit

protection. Specifications for the recommended fuse or circuit breaker to

provide protection against short circuits are provided on pages 42

The tables on the following pages provide recommended AC line input fuse and

circuit breaker information. See Fusing and Circuit Breakers below for UL and

IEC requirements. Sizes listed are the recommended sizes based on 40 °C (104

°F) and the U.S. NEC. Other country, state, or local codes can require different

ratings. Tables with DC link fuse recommendations for DC input drives are also

provided.

through 44.

Fusi ng

The recommended fuse types are listed below. If available current ratings do not

match those listed in the tables provided, choose the next higher fuse rating.

• IEC – BS88 (British Standard) Parts 1 & 2, EN60269-1, Parts 1 & 2

(1)

,

type gG or equivalent must be used.

• UL Class T, RK1, J, or L must be used.

Circuit Breakers

The “non-fuse” listings in the following tables include inverse time circuit

breakers and instantaneous trip circuit breakers (motor circuit protectors). If one

of these is chosen as the desired protection method, the following requirements

apply:

• IEC – Both types of circuit breakers are acceptable for IEC installations.

• UL - Only inverse time circuit breakers are acceptable for UL installations.

(1) Typical designations include, but may not be limited to the following; Parts 1 & 2: AC, AD, BC, BD, CD, DD, ED, EFS, EF, FF, FG, GF, GG,

GH.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 41

Page 42

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

(7)

Dual Element Time

Delay Fuse

(1)

Max.

Non-Time Delay

Fuse

(2)

Min.

Circuit

(3)

(1)

Max.

Breaker

(2)

Max.

(5)

Drive Catalog

(6)

Number

400 Volt AC Input Protection Devices

kW Rating PWM Freq. Temp.

ND HD kHz °C Amps kVA Cont. 1 Min. 3 Sec. Min.

Frame

(8)

Input Ratings Output Amps

20BC292 7 160 4 40 293 203 292 322 438 375 650 375 850 850 400

150 4 40 264 183 263 395 526 3 50 550 350 550 750 400

20BC325 7 180 4 40 326 226 325 358 488 425 700 425 950 950 600

180 4 40 326 226 325 488 650 4 25 700 425 950 950 600

20BC365 8 200 2 40 366 253 365 402 548 475 800 475 1000 1000 600

180 2 40 326 226 325 488 650 4 25 700 425 950 950 600

20BC415 8 240 2 40 416 288 415 457 623 525 900 525 1200 1200 600

200 2 40 366 253 365 548 730 4 75 800 475 1000 1000 600

20BC481 8 280 2 40 483 334 481 530 722 600 1000 600 1400 1400 700

240 2 40 416 288 415 623 830 5 25 900 525 1200 1200 600

20BC535 8 300 2 40 537 372 535 589 803 700 1200 700 1600 1600 700

280 2 40 483 334 481 722 962 6 00 1000 600 1400 1400 700

20BC600 8 350 2 40 602 417 600 660 900 750 1300 750 1800 1800 800

300 2 40 537 371 535 803 1070 700 1200 700 1600 1600 700

20BC730 9 400 2 40 702 486 730 803 1095 900 1500 900 2100 210 0 900

350 2 40 602 417 600 900 1200 750 1300 750 1800 1800 800

20BC875 10 500 2 40 877 608 875 963 1313 1100 1900 1100 2600 2600 1200

400 2 40 877 486 700 1050 1400 900 1500 900 2100 2100 900

See page 43

for Notes.

Motor Circuit

(4)

Protector

(5)

Max.

Drive

Catalog

Number

20BD292

20BD325

20BD365

20BD415

20BD481

20BD535

20BD600

20BD730

20BD875

See page 43

Hp Rating PWM Freq. Temp. Input Ratings Output Amps

ND HD kHz °C Amps kVA Cont. 1 Min. 3 Sec. Min.

Frame

(6)

7 250 4 40

200 4 40

(6)

7 250 4 40

250 4 40

(6)

8 300 2 40

250 2 40

(6)

8 350 2 40

300 2 40

(6)

8 400 2 40

350 2 40

(6)

8 450 2 40

400 2 40

(6)

8 500 2 40

450 2 40

(6)

9 600 2 40

500 2 40

(6)

10 700 2 40

600 2 40

for Notes.

480 Volt AC Input Protection Devices

(8)

281 233 292 322 438 375 650 37 5 850 850 400

(8)

253 210 263 395 526 350 550 35 0 550 750 400

(8)

313 260 325 358 488 425 700 42 5 950 950 600

(8)

313 260 325 488 650 425 700 42 5 950 950 600

(8)

351 292 365 402 548 475 800 47 5 1000 1000 600

(8)

313 260 325 488 650 425 700 42 5 950 950 600

(8)

399 331 415 457 623 525 900 52 5 1200 1200 600

(8)

351 291 365 548 730 475 800 47 5 1000 1000 600

(8)

462 384 481 530 722 600 1000 600 1400 1400 700

(8)

399 331 415 623 830 525 900 52 5 1200 1200 600

(8)

514 427 535 589 803 700 1200 700 1600 1600 700

(8)

462 384 481 722 962 600 1000 600 1400 1400 700

(8)

577 479 600 660 900 750 1300 750 1800 1800 800

(8)

514 427 535 803 1070 700 1 200 70 0 1600 1600 700

(8)

673 559 730 803 1095 900 1 500 90 0 2100 2100 900

(8)

577 479 600 900 1200 750 1 300 75 0 1800 1800 800

(8)

841 699 875 963 1313 1100 1900 1100 2600 2600 1200

(8)

673 559 700 1050 1400 900 1500 900 2100 2100 900

(7)

Dual Element Time

Delay Fuse

(1)

Max.

Non-Time Delay

Fuse

(2)

Min.

(1)

Max.

(2)

Circuit

Breaker

Max.

(5)

(3)

Motor Circuit

(4)

Protector

(5)

Max.

42 Rockwell Automation Publication 20B-IN014H-EN-P - June 2013

Page 43

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

Notes:

(1)

Minimum protection device size is the lowest rated device that supplies maximum protection without nuisance tripping.

(2)

Maximum protection device size is the highest rated device that supplies drive protection. For US NEC, minimum size is 125% of

motor FLA. Ratings shown are maximum.

(3)

Circuit Breaker - inverse time breaker. For US NEC, minimum size is 125% of motor FLA. Ratings shown are maximum.

(4)

Motor Circuit Protector - instantaneous trip circuit breaker. For US NEC minimum size is 125% of motor FLA. Ratings shown are

maximum.

(5)

Maximum allowable rating by US NEC. Exact size must be chosen for each installation.

(6)

Drives have dual current ratings; one for normal duty applications, and one for heavy duty applications. The drive can be operated at

either rating.

(7)

Frame 7…10 drives are CE Certified for use with 400V AC and 480V AC center grounded neutral power supply systems only. It is the

responsibility of the user to determine compliance to the EMC directive.

(8)

Temperature rat ing is for IP 20, NEMA/UL Ty pe 1. For IP00 , NEMA Type Open the temperatu re rating is 65 °C for the co ntrol board and

40 °C for the heat sink entry air.

Rockwell Automation Publication 20B-IN014H-EN-P - June 2013 43

Page 44

PowerFlex 700 Adjustable Frequency AC Drive – Frames 7…10

540 Volt DC Input with Precharge

Drive

Catalog

Number

kW Rating

ND HD kHz °C Amps kW Cont. 1 Min. 3 Sec.

Frame

PWM

Freq. Temp.

20BP292 7 160 4 40 342 185 292 322 438 500 170M6608

150 4 40 309 166 263 395 526 630 170M6610

20BP325 7 180 4 40 381 206 325 358 488 630 170M6610

180 4 40 381 206 325 488 650 800 170M6612

20BP365 8 200 2 40 428 231 365 402 548 630 170M6610

180 2 40 381 206 325 488 650 800 170M6612

20BP415 8 240 2 40 487 262 415 457 623 800 170M6612

200 2 40 428 231 365 548 730 900 170M6613

20BP481 8 280 2 40 564 304 481 530 722 900 170M6613

240 2 40 487 262 415 623 830 1000 170M6614

20BP535 8 300 2 40 627 338 535 589 803 1000 170M6614

280 2 40 564 304 481 722 962 1100 170M6615

20BP600 8 350 2 40 703 379 600 660 900 1100

300 2 40 627 338 535 803 1070 1200