Page 1

Installation Instructions

PowerFlex® 700S and 700H Fan Inverter

Upgrade Kit (Frame 10-11)

Introduction

Use this document to upgrade the fan inverters on PowerFlex 700S or 700H

frame 10 or frame 11 drives.

ATTENTION: To avoid an electric shock hazard, ensure that all

power to the drive has been removed before performing the

!

following.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the DC bus voltage at the DC+ &

DC- terminals. The voltage must be zero.

ATTENTION: HOT surfaces can cause severe burns. Do not

touch the heatsink surface during operation of the drive. After

!

disconnecting power allow time for cooling.

ATTENTION: Hazard of permanent eye damage exists when

using optical transmission equipment. This product emits intense

!

light and invisible radiation. Do not look into fiber-optic ports or

fiber-optic cable connectors.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

What this Kit Contains

Verify that your kit contains the items listed in the following table. If your

kit does not contain the correct items, contact your Allen-Bradley sales

representative.

Quantity:

Frame 10

Part No.

FR10844 1 0 Left-hand Inverter Chassis

FR10845 1 3 Right-hand Inverter Chassis

133256 1 1 Disposable Static Discharge Wrist-strap

Kit

Frame 11

Kit

Description

Page 2

2 PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11)

What You Need to Do

Step 1: Removing Power from the Drive

❐ Step 1: Remove power from the drive.

❐ Step 2: Remove the covers from the power structure.

❐ Step 3: Prepare the power structure for inverter assembly removal.

❐ Step 4: Remove the old inverter assemblies from the drive.

❐ Step 5: Remove the inverters from the old assemblies.

❐ Step 6: Install the inverters on the new assemblies.

❐ Step 7: Install the new inverter assemblies and prepare the drive for

use.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the DC bus voltage at the DC+ &

DC- terminals of the Power Terminal Block. The voltage must be

zero.

Remove power before making or breaking cable connections.

When you remove or insert a cable connector with power

applied, an electrical arc may occur. An electrical arc can cause

personal injury or property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

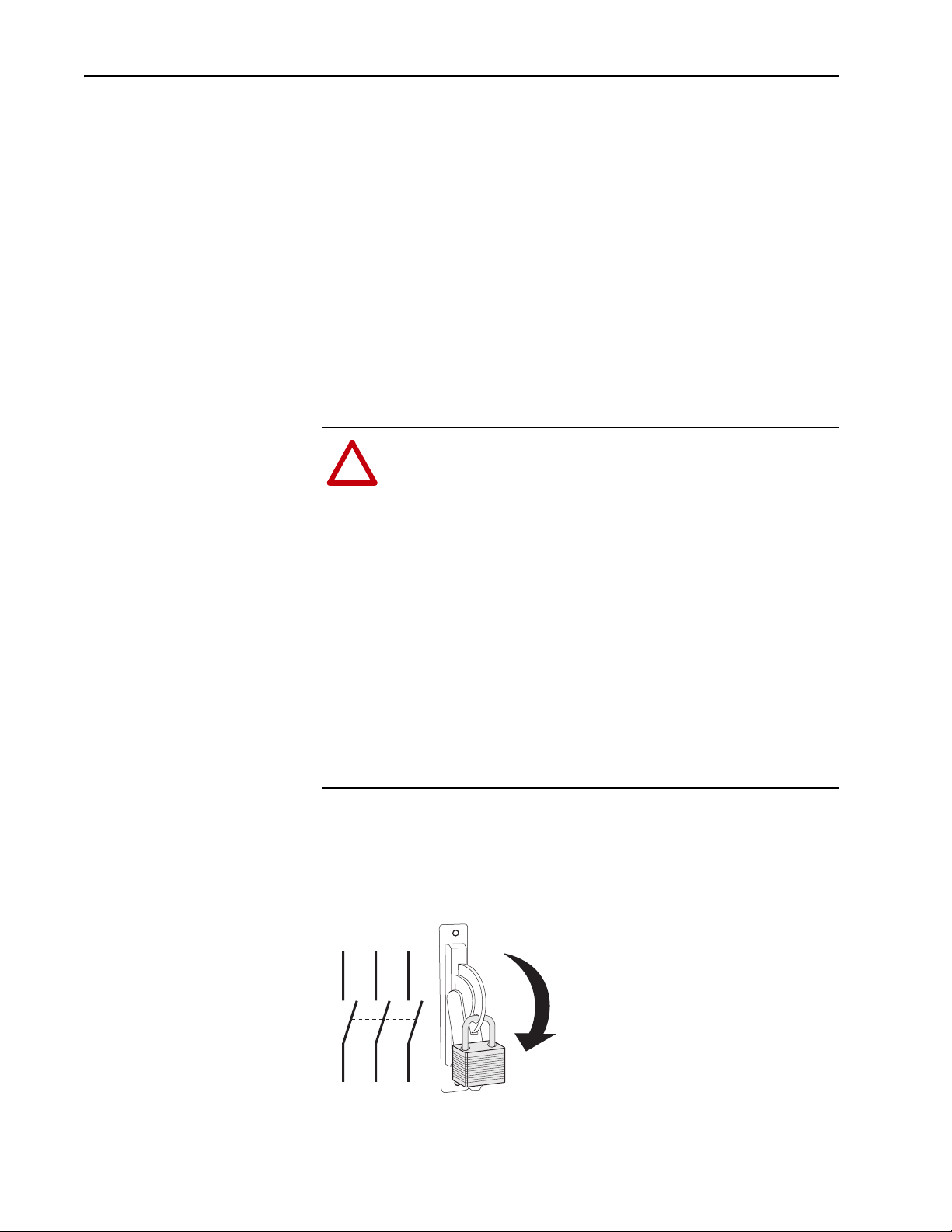

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power terminals.

3. Measure the DC bus voltage at the DC+ & DC- terminals on the Power

Terminal Block. The voltage must be zero.

L1 L2 L3

I

O

Page 3

PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11) 3

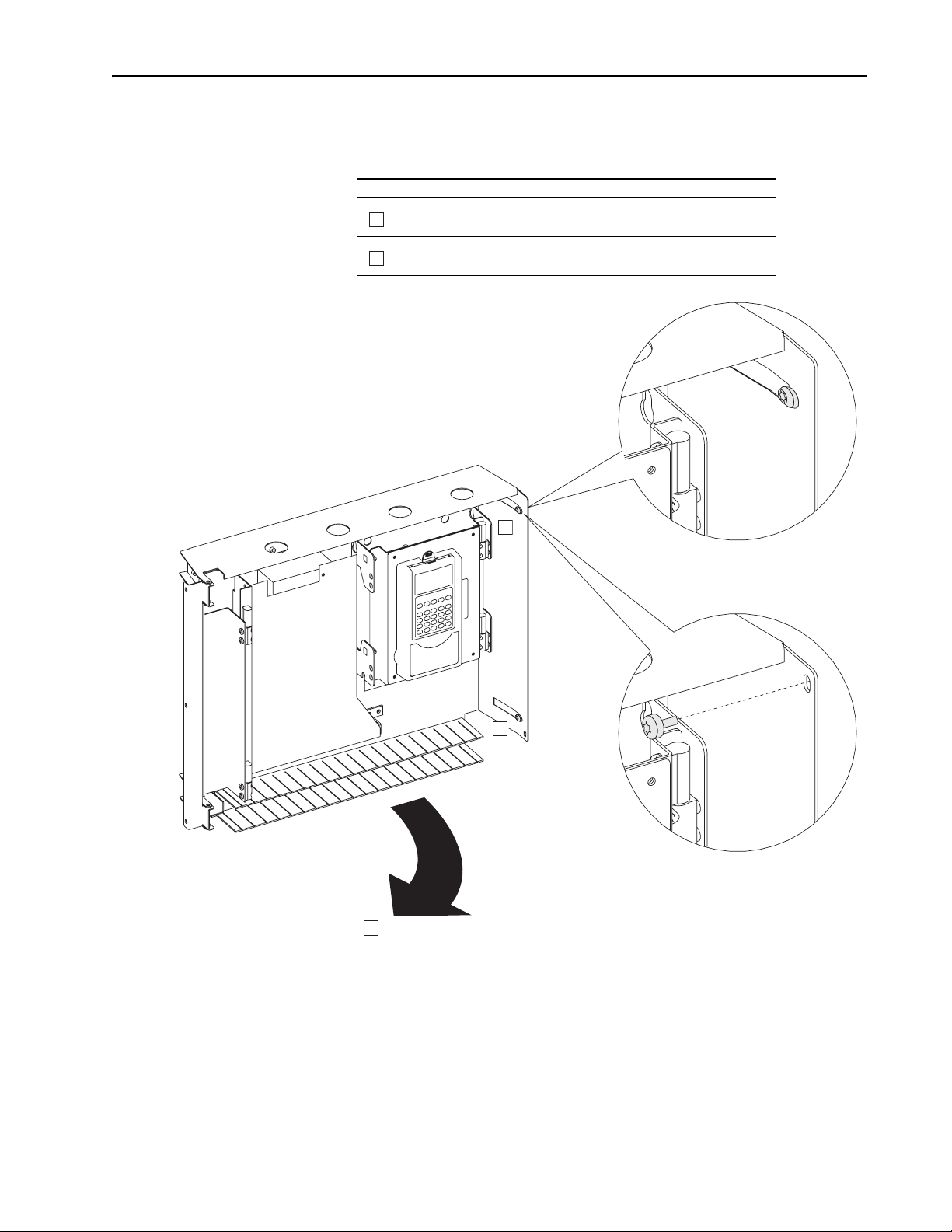

Step 2: Removing Covers from the Power Structure

Moving Control Frame

Task Description

Loosen the T8 Torx-head screws, which secure the Control Frame to

A

the drive enclosure (Remove screws on early frame 10 drives).

Swing the Control Frame out and away from the power structure.

B

A

Frame 10 Drive Shown

or

A

Frame 10 drives, from early production runs, have

holes instead of slots for these screws. You must

completely remove the screws from these drives in

B

order to swing-open the control frame.

Page 4

4 PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11)

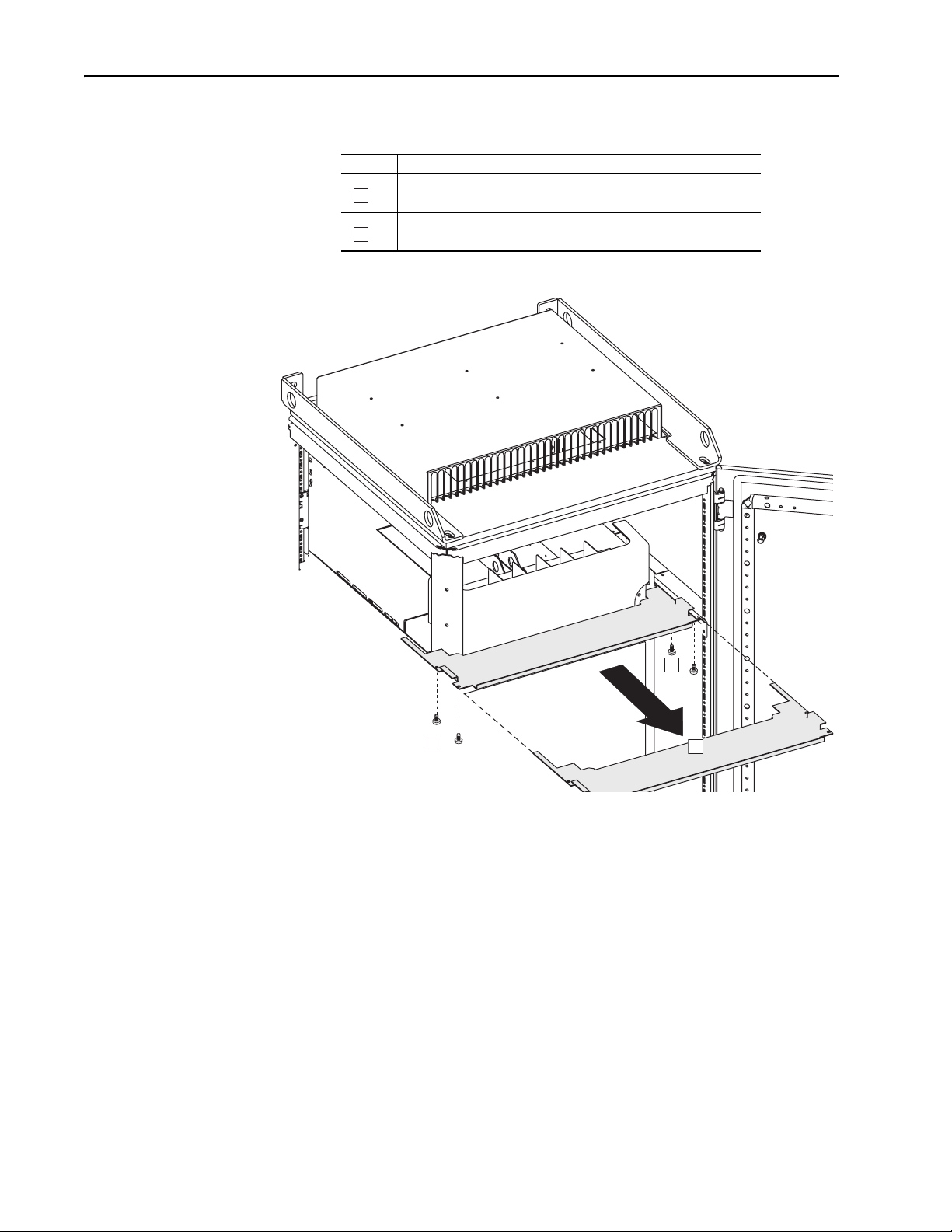

Removing the Airflow Plate

Task Description

Remove the T8 Torx-head screws, which secure the airflow plate to the

A

drive.

Slide the airflow plate off the drive.

B

Frame 10 Drive Shown

A

A

B

Page 5

PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11) 5

Removing the Protective Covers

Task Description

Remove the four M5 Pozi-drive screws, which secure the top and

A

bottom protective covers to the main front protective cover, then

remove the top and bottom protective covers.

Note: you only need to remove the top and bottom covers to gain

access to the power terminals. You can remove the other covers

without removing the top and bottom ones.

Remove the four M5 Pozi-drive screws, which secure the main front

B

protective cover to the drive, then remove the protective cover.

Remove side protective covers

C

(Not necessary for Frame 11 Drives).

A

A

Frame 10 Drive Shown

C

B

C

B

B

B

Proper tightening torque for

A

A

reassembly is 4 N-m (35 lb.-in.).

Page 6

6 PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11)

Step 3: Preparing Power Structure for Inverter Assembly Removal

Left-hand

Inverter

Preparing a Frame 10 Power Structure

Task Description

Remove the cable-ties that secure the cables with orange insulation

A

(on both left-hand and right-hand sides). This will allow you to move the

cables while removing the inverter assemblies.

Right-hand

Inverter

Left-hand

Side

View

Fron t Vi ew

on Left-hand Side

A

A

A

Page 7

PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11) 7

Preparing a Frame 11 Power Structure

Task Description

Using a 17 mm wrench, loosen the three connections to the output

A

terminal next to the inverter assembly.

Proper tightening torque for reassembly is 29 ft - lb.

Cut cable-tie, which secures the cable to the capacitor and disconnect

B

that cable.

Disconnect the four wires from the fuse block on the center inverter

C

assembly.

Left-hand

Inverter

Center

Inverter

of Center of Power Structure

Right-hand

Inverter

Fron t Vi ew

of Left-hand Side

Fron t Vi ew

A A

A

B

C

C

C

C

Page 8

8 PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11)

Step 4: Removing Inverter Assemblies

Left-hand and Right-hand Inverter Assemblies

Task Description

Remove the two M5 Pozi-drive screws, which secure the front of the

A

fan inverter to the drive.

Proper tightening torque for reassembly is 4 N-m (35 lb.-in.).

Disconnect the fan motor cable under the inverter.

B

Remove the four M5 Pozi-drive screws, which secure the bottom of the

C

fan inverter to the drive.

Proper tightening torque for reassembly is 4 N-m (35 lb.-in.).

Disconnect the cables at X2, X8 and X3 (on left-hand and center

D

inverters); and X2 and X8 (on right-hand inverter).

Carefully remove the inverters by sliding them out towards the front of

E

the drive.

A

A

C

C

B

Bottom View

C

Important: Do not damage the output transformer when removing or

installing the inverter.

C

of Power Structure

Page 9

Step 5: Removing the Inverter from the Old Inverter Assembly

PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11) 9

Tas k De scr ip ti on

Disconnect the cables at connectors X4 (Blue) and X5 (Black).

A

=

A

Right-hand Inverter Shown

A

Task Description

Remove two M5 Pozi-drive screws, which secure the inverter board

B

and its heatsink to the assembly carriage.

Proper tightening torque for reassembly is 4 N-m (35 lb.-in.).

Carefully remove the inverter board and its heatsink from the assembly

C

carriage.

B

B

=

Task Description

On center inverter assemblies, using a 13 mm wrench, remove the nut,

D

which secures the capacitor and fuse block bracket to the assembly.

Then remove the capacitor and fuse block. You will re-use the fuse

block on the new assembly.

Hand tighten this nut during reassembly.

Page 10

10 PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11)

Step 6: Installing the Inverter on the New Inverter Assembly

Step 7: Installing the New Inverter Assemblies and Preparing the Drive for Use

Contacting Rockwell Automation Support

Installation is reverse of removal. Refer to:Step 5: Removing the Inverter

from the Old Inverter Assembly on page -9.

Installation is reverse of removal. Refer to: Step 4: Removing Inverter

Assemblies on page -8, Step 3: Preparing Power Structure for Inverter

Assembly Removal on page -6 and Step 2: Removing Covers from the

Power Structure on page -3.

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained in the

supporting product publications first (e.g. publications PFLEX-TG002,

Hardware Service Manual - PowerFlex 700S and 700H Drives, and

PFLEX-IN006, Installation Instructions - PowerFlex 700S and 700H

Drives).

If the problem persists, call your local distributor or contact Rockwell

Automation in one of the following ways:

Phone United States/

Canada

Outside United

States/Canada

1.262.512.8176 (7 AM - 6 PM CST)

1.440.646.5800 (24 hour paid support available

through the TechConnect Support Program)

You can access the phone number for your country via

the Internet:

Go to http://www.ab.com

Click on Support

(http://support.rockwellautomation.com/)

Under Contact Customer Support, click on Phone

Support

Internet

E-mail

Be prepared to furnish the following information when you contact support:

• Product Catalog Number

• Product Serial Number

• Firmware Revision Level

⇒

⇒

Go to http://www.ab.com/support/abdrives/

support@drives.ra.rockwell.com

Page 11

Notes:

PowerFlex® 700S and 700H Fan Inverter Upgrade Kit (Frame 10-11) 11

Page 12

Publication PFLEX-IN016A-EN-P - March 2005 12 366153-P01

Copyright © 2005 Rockwell Automation. All rights reserved. Printed in the U.S.A.

Loading...

Loading...