Page 1

User Manual

PowerFlex 700H AC Drive Safe Torque Off Option

Catalog Number 20C-DG01

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Page 3

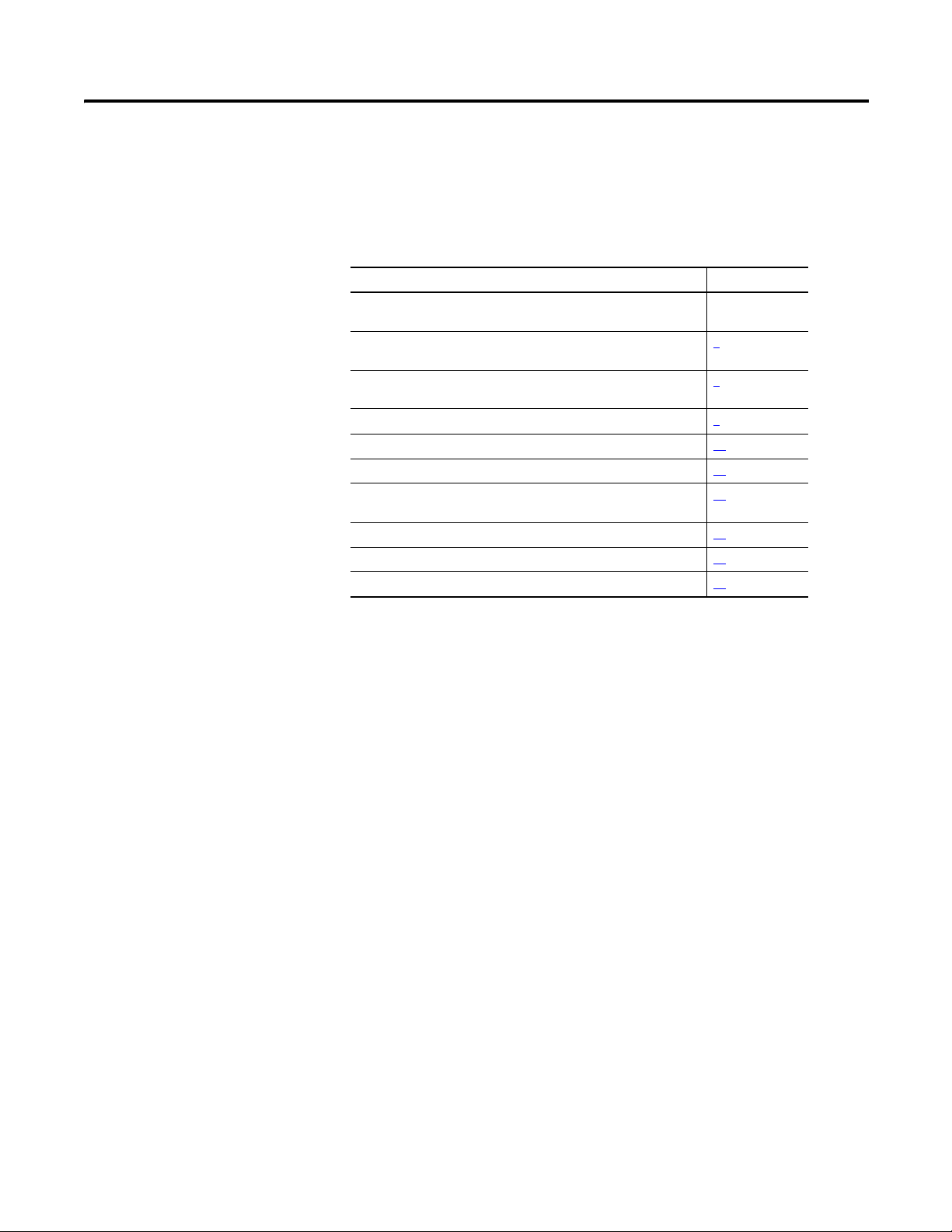

Summary of Changes

This manual contains new and updated information.

New and Updated Information

This table contains the changes made to this revision.

Topic Page

All instances of the term “Safe-Off” are changed to the term “Safe

Torque Off”

Added applicable machinery safety standards to Safety and

Machinery Standards.

Removed Safety Certificate Examples and provided new link to

online certificates.

Added new Important Safety Considerations section. 9

Added new PL d/Category 3 Performance Definition section. 10

Added new Stop Category Definitions section. 10

Added new System Performance Level and Safety Integrity Level

(SIL) section.

Added new PFD and PFH Definitions section. 11

Added new PFD and PFH Data section. 12

Added an Index. 25

Throughout

manual

8

8

11

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 3

Page 4

Summary of Changes

4 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 5

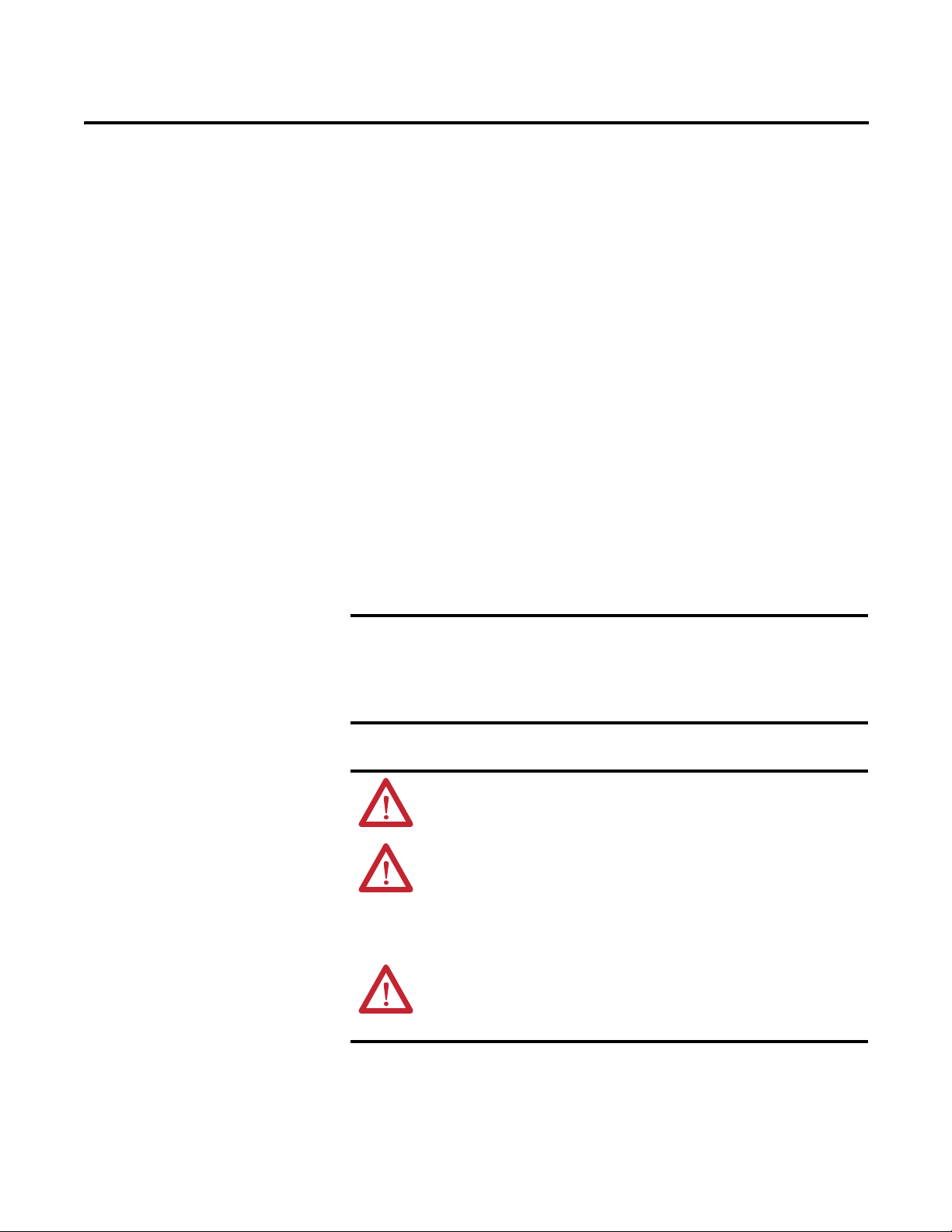

Table of Contents

Summary of Changes

Overview

Installation and Wiring

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1

What is the Safe Torque Off Option?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety of Machinery Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Certified Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Certifications Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PL d/Category 3 Performance Definition . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stop Category Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Performance Level and Safety Integrity Level (SIL) . . . . . . . . . . 11

PFD and PFH Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PFD and PFH Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Functional Proof Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contact Information if Safety Option Failure Occurs . . . . . . . . . . . 12

Chapter 2

Safe Torque Off Option Board Installation. . . . . . . . . . . . . . . . . . . . . . . . . 14

Wire the Safe Torque Off Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fault/Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Verify Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safe Torque Off Option Board (20C-DG01) Removal . . . . . . . . . . . . . . 23

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 5

Page 6

Table of Contents

6 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 7

Chapter

1

Overview

The PowerFlex 700H control board, 24V DC Digital Input with Analog I/O

(20C-DA1-A) board, and the Safe Torque Off option board (20C-DG01), when

used with other safety components, helps provide a hardware-based safe torque

off to prevent torque on the motor shaft.

The Safe Torque Off option is just one component in a safety control system.

Components in the system must be chosen and applied appropriately to achieve

the desired level of operator safeguarding.

What is the Safe Torque Off Option?

The Safe Torque Off option is designed to safely remove power from the gate

firing circuits of the drive’s output power devices (IGBT’s). This helps prevent

the drive’s output power devices from switching in the sequence necessary to

generate torque in the motor.

IMPORTANT

This option is suitable for performing mechanical work on the drive

system or affected area of a machine only. It does not provide electrical

safety.

This option should not be used as a control for starting and/or stopping

the drive.

ATTENTION: Electrical Shock Hazard. Verify that all sources of AC and DC

power are de-energized and locked out or tagged out in accordance with

the requirements of ANSI/NFPA 70E, Part II.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on

the bus capacitors has discharged completely before servicing. Check the

DC bus voltage at the Power Terminal Block by measuring between the +DC

and -DC terminals, between the +DC terminal and the chassis, and

between the -DC terminal and the chassis. The voltage must be zero for all

three measurements.

ATTENTION: In Safe Torque Off mode, hazardous voltages may still be

present at the motor. To avoid an electric shock hazard, disconnect power to

the motor and verify that the voltage is zero before performing any work on

the motor.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 7

Page 8

Chapter 1 Overview

Safety of Machinery Standards

Certified Equipment

The Safe Torque Off option is compliant with the following safety standards:

• EN 60204-1:2006 Safety of Machinery – Electrical equipment of

machines – Part 1: General Requirements

• EN ISO 13849-1:2008 Safety of Machinery – Safety-related parts of

control systems - Part 1: General Principles for Design

• EN ISO 13849-2:2003 Safety of Machinery – Safety-related parts of

control systems – Part 2: Validation

• EN 61800-5-2:2007 Adjustable Speed Electrical Power Drives Systems –

Part 5-2 Safety Requirements: Functional

• EN 62061:2005 Safety of Machinery, Functional safety of safety-related

electrical, electronic and programmable electronic control systems

• IEC 61508 Parts 1…7: 1998 and 2000 Functional Safety of electrical/

electronic/programmable electronic control systems

The Safe Torque Off option for the following PowerFlex 700H AC drives has

been evaluated to meet the safety parameters for SIL 2 according to IEC 61508

and PL d/category 3 according to EN ISO 13849-1.

• 400/480V Frames 9-14

• 600/690V Frames 9-14

Note: The TUV certification stamp is only included on the drive data nameplate

label when the Safe Torque Off option board is factory installed.

Certifications Online

See the Product Certifications link at http://ab.com for Declarations of

Conformity, Certificates, and other certifications details.

8 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 9

Overview Chapter 1

Important Safety Considerations

The system user is responsible for:

• the set-up, safety rating, and validation of any sensors or actuators

connected to the system.

• completing a system-level risk assessment and reassessing the system any

time a change is made.

• certification of the system to the desired safety performance level.

• project management and proof testing.

• programming the application software and the safety option

configurations in accordance with the information in this manual.

• access control to the system, including password handling.

• analyzing all configuration settings and choosing the proper setting to

achieve the required safety rating.

IMPORTANT

When applying Functional Safety, restrict access to qualified, authorized

personnel who are trained and experienced.

ATTENTION: When designing your system, consider how personnel will

exit the machine if the door locks while they are in the machine.

Additional safeguarding devices may be required for your specific

application.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 9

Page 10

Chapter 1 Overview

PL d/Category 3 Performance Definition

To achieve PL d/category 3 according to EN ISO 13849-1, the safety-related

parts have to be designed such that:

• the safety-related parts of machine control systems and/or their protective

equipment, as well as their components, shall be designed, constructed,

selected, assembled, and combined in accordance with relevant standards

so that they can withstand expected conditions.

• well tried safety principles shall be applied.

• a single fault in any of its parts does not lead to a loss of safety function.

• some but not all faults will be detected.

• the accumulation of undetected faults can lead to loss of safety function.

• short circuits in the external wiring of the safety inputs is not one of the

faults that can be detected by the system, therefore, according to

EN ISO 13849-2, these cables must be installed so as to be protected

against external damage by cable ducting or armor.

• whenever reasonably practical a single fault shall be detected at or before

the next demand of the safety function.

• the average diagnostic coverage of the safety-related parts of the control

system shall be low to medium.

• the mean time to dangerous failure of each of the redundant channels shall

be medium to high.

Stop Category Definitions

The selection of a stop category for each stop function must be determined by a

risk assessment.

• Stop Category 0 is achieved with immediate removal of power to the actuator,

resulting in an uncontrolled coast to stop. See “Description of Operation”

Example 1 on page 17

• Stop Category 1 is achieved with power available to the machine actuators to

achieve the stop. Power is removed from the actuators when the stop is

achieved. See “Description of Operation” Example 2 on page 18

IMPORTANT

When designing the machine application, timing and distance should be

considered for a coast to stop (Stop Category 0 or Safe Torque Off). For

more information regarding stop categories, refer to EN 60204-1.

.

.

10 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 11

Overview Chapter 1

System Performance Level and Safety Integrity Level (SIL)

PFD and PFH Definitions

For safety-related control systems, Performance Level (PL), according to

EN ISO 13849-1, and SIL levels, according to IEC 61508 and EN 62061,

include a rating of the system’s ability to perform its safety functions. All of the

safety-related components of the control system must be included in both a risk

assessment and the determination of the achieved levels.

Refer to the EN ISO 13849-1, IEC 61508, and EN 62061 standards for complete

information on requirements for PL and SIL determination.

Safety-related systems can be classified as operating in either a Low Demand

mode, or in a High Demand/Continuous mode.

• Low Demand mode: where the frequency of demands for operation made on

a safety-related system is no greater than one per year or no greater than twice

the proof-test frequency.

• High Demand/Continuous mode: where the frequency of demands for

operation made on a safety-related system is greater than once per year or

greater than twice the proof test interval.

The SIL value for a low demand safety-related system is directly related to orderof-magnitude ranges of its average probability of failure to satisfactorily perform

its safety function on demand or, simply, average probability of failure on demand

(PFD). The SIL value for a High Demand/Continuous mode safety-related

system is directly related to the probability of a dangerous failure occurring per

hour (PFH).

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 11

Page 12

Chapter 1 Overview

PFD and PFH Data

PFD and PFH calculations are based on the equations from Part 6 of IEC 61508

and show worst-case values. This table provides data for a 20-year proof test

interval and demonstrates the worst-case effect of various configuration changes

on the data.

Table 1 - PFD and PFH for 20-year Proof Test Interval

Attribute Test Result

PFD

av

PFH 1.7 x 10-8 1/h (calculated according to IEC 61508)

MTTF

D

DC

av

-3

1.52 x 10

High (2172 years)

low (66%)

Functional Proof Tests

The functional safety standards require that functional proof tests be performed

on the equipment used in the system. Proof tests are performed at user-defined

intervals and are dependent upon PFD and PFH values.

IMPORTANT

Your specific application determines the time frame for the proof test

interval for the overall safety system.

Contact Information if Safety Option Failure Occurs

If you experience a failure with any safety-certified device, contact your local

Rockwell Automation distributor. With this contact, you can:

• return the device to Rockwell Automation so the failure is appropriately

logged for the catalog number affected and a record is made of the failure.

• request a failure analysis (if necessary) to determine the probable cause of the

failure.

12 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 13

Chapter

2

Installation and Wiring

Installation must be in accordance with the following steps and must be carried

out by suitably competent personnel. The Safe Torque Off option board (device)

is intended to be part of the safety related control system of a machine. Before

installation, a risk assessment should be performed to determine whether the

specifications of this device are suitable for all foreseeable operational and

environmental characteristics of the machine to which it is to be fitted.

At regular intervals during the life of the machine check the safety function for

proper operation. How frequently the safety function is checked is dependent on

the safety analysis of the machine section controlled by the drive.

Rockwell Automation, Inc. cannot accept responsibility for a failure of this device

if the procedures given in this publication are not implemented or if it is used

outside the recommended specifications in this publication.

ATTENTION: The following information is merely a guide for proper

installation. Rockwell Automation, Inc. cannot assume responsibility for the

compliance or the noncompliance to any code, national, local or otherwise

for the proper installation of this equipment. A hazard of personal injury and/

or equipment damage exists if codes are ignored during installation.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 13

Page 14

Chapter 2 Installation and Wiring

Safe Torque Off Option Board Installation

ATT ENTI ON: To avoid an electric shock hazard, verify that the voltage on

the bus capacitors has discharged completely before servicing. Check the

DC bus voltage at the Power Terminal Block by measuring between the

+DC and -DC terminals, between the +DC terminal and the chassis, and

between the -DC terminal and the chassis. The voltage must be zero for all

three measurements.

Remove power before making or breaking cable connections. When you

remove or insert a cable connector with power applied, an electrical arc may

occur. An electrical arc can cause personal injury or property damage by:

• sending an erroneous signal to your system’s field devices, causing

unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and

its mating connector. Worn contacts may create electrical resistance.

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power terminals.

3. Measure the DC bus voltage at the DC+ & DC- terminals on the Power

Terminal Block. The voltage must be zero.

L1 L2 L3

I

O

IMPORTANT

4. Open the door of the enclosure that contains the control and I/O circuit

boards and unplug any I/O cables from the I/O board in Slot B.

Before removing connections and wires, mark the connections and wires

to avoid incorrect wiring during assembly.

14 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 15

5. Remove the I/O board in Slot B (if present).

Do not remove enclosure cover.

Enclosure is illustrated without

the cover for clarity.

Installation and Wiring Chapter 2

=

6. Install the new Safe Torque Off option board (20C-DG1) in Slot B.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 15

Page 16

Chapter 2 Installation and Wiring

Wire the Safe Torque Off Option

The Safe Torque Off option disables the drive’s output IGBT’s by disconnecting

the gate control power supply (see Figure 1 on page 17

). The system satisfies the

requirements of EN ISO 13849-1 PL d/Category 3 for Safe Torque Off and

protection against restart.

Under normal drive operation, the Safe Torque Off inputs (SD1 and SD2) are

energized and gate control power is available to the gate control circuit. If either

or both of these inputs is/are de-energized, the gate control circuit is disabled and

the drive will stop as programmed (coast or controlled). The drive can be

configured to display a “Gate Disable” fault or alarm (F59) on the HIM when the

gate control circuit is disabled.

Both Safe Torque Off inputs must be used to meet EN ISO 13849-1 PL d/

Category 3 operation and must be energized in order to run the drive. Refer to

the wiring examples on the following pages for details.

The Safe Torque Off activation delay time is less than 20 ms. When the drive is

enabled, there is a delay time of 1 second before a valid start command can be

issued.

PowerFlex 700H drives containing the Safe Torque Off option board will only

accept an edge sensitive start command when the drive is in a “ready” state.

IMPORTANT

By itself, the Safe Torque Off option initiates a coast-to-stop action. If

coasting to a stop is not desired, additional protective measures must be

taken. See Figure 3 on page 20

for a controlled stop wiring example.

Important points to remember about wiring:

• Always use copper wire.

• 0.5 mm

2

(20 AWG), 3 conductor, shielded cable is required.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at least

0.3 m (1 ft).

• According to EN 60204-1, part 13.5: The voltage drop from the supply

point to the load should not exceed 5%.

• Due to electromagnetic disturbances, the cable length should be limited to

200 m (656 ft) maximum. In a noisy environment, the length of the cable

should be less than 200 m (656 ft).

16 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 17

X10

28 29

X7

ON OFF

21 22 23

Table 2 - Safe Torque Off Option Board Terminal Descriptions

Term. Blk. No. Signal Description

X5 1 SD1+ Isolated Disable input 1 +24V +/-20% 10... 15 mA

2 SD1– Virtual GND 1

3 SD2+ Isolated Disable input 2 +24V +/-20% 10... 15 mA

4 SD2– Virtual GND 2

21 Digital Out 1 - N.C. Max. Resistive Load:

22 Digital Out 1 Common

23 Digital Out 1 - N.O.

25 Digital Out 2 Common

26 Digital Out 2 N.O.

240V AC / 30V DC - 1200 VA, 150 W

Max. Current: 5A, Min. Load: 10 mA

Max. Inductive Load:

240V AC / 30V DC - 8400 VA, 105 W

Max. Current: 3.5 A, Min. Load: 10 mA

28 TI1+ Thermistor input: R

29 TI1–

25 26

X3

X2

X3

X7

(1)

(1)

(1)

Installation and Wiring Chapter 2

≥ 4.0 kΩ (PTC)

trip

1 2 3 4

X5

X2

(1) This terminal block is not used as part of the Safe Torque Off function.

IMPORTANT

The drive will not run unless a wire is installed in the hardware

thermistor input (X7-28 and X7-29) and the thermistor short circuit

supervisor jumper X10 is installed in the OFF position.

Figure 1 - Safe Torque Off Drive Circuitry

PowerFlex 700H Control Unit

Safe-Off

Option Board

SD1+

SD1-

SD2+

SD2-

Micro-

controller

Hardware

Safe-Off 1

Hardware

Safe-Off 2

PWM

Control

PowerFlex 700H

Power Unit

=

3~

M

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 17

Page 18

Chapter 2 Installation and Wiring

Figure 2 - Example 1 - Drive Safe Torque Off Connections with Coast-to-Stop Action

and Emergency Stop Operation, Dual Channel, without External Relay

AC Line

Input Po wer

PowerFlex 700H

AC Drive

GuardM aste r

Trojan

E-Sto p

Latching

Button

Stop

Start

+24VDC

24V Com

Stop

Start

DigIn Com

Gate Enab le

Safe-Off Option Board

1 SD1+

2 SD1-

3 SD2+

4 SD2-

Gate

Contro l

Circuit

Circuit Status – Circuit shown with guard door and E-stop closed and system

ready for normal operation.

Operating Principle – Opening the guard door or pressing the E-stop button

will disable the drive gate firing circuit, the motor will coast to stop. The drive can

be configured to display a “Gate Disable” fault or alarm (F59) on the HIM when

the gate control circuit is disabled.

When the guard door or the E-stop button is closed, the drive remains in a

faulted state. Once the drive fault is cleared a valid start command will restart the

drive.

18 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

M

Page 19

Installation and Wiring Chapter 2

Application Considerations – When the hazard analysis for the overall machine

determines the need for external mechanical brakes or other stopping means, the

external means shall be activated after the removal of power for Stop Category 0.

When used, the E-stop button must utilize direct-opening contacts. The button

must latch to an open state when the contacts open. The button must be red with

a yellow background.

Fault Detection – A redundant (two) set of double break contacts on the Trojan

gate interlock are designed to ensure that at least one signal is sent to the Safe

Torque Off option board when the gate is opened. A single fault detected on the

safety input circuits will result in the lock-out of the system to a safe state (off) at

the next operation and will not cause loss of the safety function.

Each of the inputs on the Safe Torque Off option board independently monitors

the status of the safety circuit and the status of the other input on the board.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 19

Page 20

Chapter 2 Installation and Wiring

Figure 3 - Example 2 - Drive Safe Torque Off Connections with Controlled Stop

Action and Emergency Stop Operation, Dual Channel, with External Relay

AC Line

Input Power

GuardMaster

Trojan

E-Stop

Latching

Button

+24V DC

24V DC

Com

S12S11A1

Minota ur

MSR138DP

X2X1 X4X3 Y40Y39

S22S52S21 4737

48385758

2313

2414 Y2A2

S33 S34

PowerFlex 700H

AC Drive

+24VDC

24V Com

Stop

Start

Y1

Stop

Start

DigIn Com

Safe-Off Option Board

1 SD1+

2 SD1-

3 SD2+

4 SD2-

Gate Ena ble

Gate

Control

Circuit

M

Circuit Status – Circuit shown with guard door and E-stop closed and system

ready for normal operation.

Operating Principle – Opening the guard door or pressing the E-stop button

will switch the input circuits (S11-S12 & S21-S22) to the Minotaur monitoring

safety relay unit. The immediate output circuits (23-24) will issue a Stop

command and the drive will follow the programmed stop configuration. After

the programmed delay, the timed output circuits (47-48 & 57-58) will cause the

Safe Torque Off option to go to a safe state (off ). If the motor has not stopped

rotating, it will coast to stop. The drive can be configured to display a “Gate

Disable” fault or alarm (F59) on the HIM when the gate control circuit is

disabled. To restart the drive, the Minotaur safety relay inputs (S11-S12, S21S22) must first be ready for normal drive operation, the drive fault must be

cleared and a valid start command must be issued to the drive.

Application Considerations – When used, the E-stop button must utilize

direct-opening contacts. The button must latch to an open state when the

contacts open. The button must be red with a yellow background.

Fault Detection – A redundant (two) set of double break contacts on the Trojan

gate interlock are designed to ensure that at least one signal is sent to the Safe

20 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 21

Installation and Wiring Chapter 2

Torque Off option board when the gate is opened. A single fault detected on the

Minotaur safety input circuits will result in the lock-out of the system to a safe

state (off) at the next operation and will not cause loss of the safety function.

Each of the inputs on the Safe Torque Off option board independently monitors

the status of the safety circuit and the status of the other input on the board.

Fault/Alarm Configuration

The drive’s fault or alarm response to a gate circuit disable can be configured in

one of four ways when using the 20C-DG1 option board, each resulting in the

drive being put into a gate disabled state when digital inputs (SD1 and SD2) are

de-energized.

1. Gate Disable Fault (59):

Configured by setting bit 10 “Gate Disable” of parameter 238 [Fault

Config1].

If either or both digital inputs open, the drive output will be disabled and

the motor will stop as programmed. The drive HIM will display fault 59

“Gate Disable”.

When the condition is cleared, the fault can be reset and the drive can be

restarted. Refer to Ta b l e 3

and actions.

2. Gate Disable Alarm (59):

Configured by setting bit 15 “Gate Disable” of parameter 259 [Alarm

Config1].

on page 23 for a description of drive conditions

If either or both digital inputs open, the drive output will be disabled and

the motor will stop as programmed. The drive HIM will display alarm 59

“Gate Disable”.

When the condition is cleared, the alarm will automatically clear in 10

seconds and the drive can be restarted. Refer to Ta b l e 3

description of drive conditions and actions.

3. Neither of the “Gate Disable” bits, 10 in parameter 238 [Fault Config1] or

15 in parameter 259 [Alarm Config1], are set.

If either or both digital inputs open, the drive output will be disabled and

the motor will stop as programmed. No fault or alarm will be displayed on

the HIM, but the Gate Disable status can be seen in bit 0 “Gate Disable” of

parameter 359 [20C-DG1 Status].

When the condition is cleared, the drive can be restarted after 3 seconds.

Refer to Ta b l e 3

actions.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 21

on page 23 for a description of drive conditions and

on page 23 for a

Page 22

Chapter 2 Installation and Wiring

4. Both “Gate Disable” bits, 10 in [Fault Config1] and 15 in [Alarm

Config1], are set:

The Gate Disable fault takes precedence.

Installation Checklist

The following items must be completed when installing and configuring the Safe

Torque Off option for PowerFlex 700H drives.

Item Description ✓ Complete

A risk assessment has been performed to determine whether the specifications of this

device are suitable for all foreseeable operational and environmental characteristics

of the machine to which it is to be fitted.

The safety switch and/or safety relay used is EN ISO 13849-1 PL d/Category 3 and

EN60947-5-1:1997 annex K compliant.

The reset function is edge sensitive.

In an IGBT fault situation, the safety system has been designed to allow the shaft of

the permanent magnet motor to rotate up to 360 degrees / pole of the motor.

The cabling has been installed to be EMC compliant.

The safety system has been designed so that enabling the drive through the Safe

Torque Off inputs will not lead to an unexpected start of the drive.

Only an approved PowerFlex 700H drive(s) and safety components have been used in

this installation.

The PowerFlex 700H control board, VB00561, revision H, or newer is installed in the

drive (see label on control board).

Revision 2.001, or higher, of firmware is installed in the drive.

Regular intervals have been planned to check the safety function for proper operation.

All information and instructions in this manual have been read, understood and

completed.

22 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 23

Installation and Wiring Chapter 2

Verify Operation

At regular intervals during the life of the machine check the safety function for

proper operation. Both safety channels shall be verified. How frequently the

safety function is checked is dependent on the safety analysis of the machine

section controlled by the drive.

Table 3 - Gate Disable Status and Verification

Protective System Status Drive In

SD1 - terminals X5-1 & X5-2

Par 359 [20C-DG1 Status], bit

3 “No Enable CH1”

SD2 - terminals X5-3 & X5-4

Par 359 [20C-DG1 Status], bit

4 “No Enable CH2”

PowerFlex 700H Drive

Status

Par 359 [20C-DG1 Status],

Bit 0 “Gate Disable”

or Bits 2 “Unexp In Pro” and

15 “Unexp HW Pro”

Fault or Alarm F59 “Gate

Gate Disable

State

Channel Operation

Bit 3 = 1

No Power

Applied

Bit 4 = 1

No Power

Applied

Description For Verification

Output

Disabled

Bit 0 = 1

Disable” (Fault

or Alarm based

on drive set up)

Drive In

Gate Disable

State

Bit 3 = 0

Power Applied

Bit 4 = 1

No Power

Applied

Output

Disabled

Bit 2 = 1

Bit 15 = 1

F10 “System

Fault”

Drive In

Gate Disable

State

Bit 3 = 1

No Power

Applied

Bit 4 = 0

Power Applied

Output

Disabled

Bit 2 = 1

Bit 15 = 1

F10 “System

Fault”

Drive Able

To Run

Bit 3 = 0

Power Applied

Bit 4 = 0

Power Applied

Output

Enabled

Bit 0 = 0

None

Safe Torque Off Option Board (20C-DG01) Removal

During maintenance or service there may be a need to remove the Safe Torque

Off (20C-DG1) option board.

The drive is designed to generate a non-resettable fault F10 “System Fault” if the

option board is removed. The operator must manually change parameter 358

[20C-DG1 Remove] to 1- “Remove” and then back to 0 - “Ready” to clear and

acknowledge the fault.

Once maintenance or service is completed and the 20C-DG1 option card has

been reinstalled, the drive will recognize the option card on power-up.

it is recommended that the safety function be checked for proper operation after

any maintenance is performed. Refer to Veri fy O pe ra tio n

above.

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 23

Page 24

Chapter 2 Installation and Wiring

Notes:

24 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 25

Index

Numerics

24V DC digital input with analog I/O (20C-

DA1-A)

option board

7

A

alarm configuration 21

C

coast-to-stop action and emergency stop

operation

connection example

controlled stop action and emergency stop

operation

connection example

18

20

D

definition

high demand/continuous mode

low demand mode

performance level

PFD 11

PFH

11

stop category 0

stop category 1 10

drive circuitry diagram

Safe Torque Off

11

11

10

17

11

F

fault configuration 21

functional proof tests

12

H

high demand/continuous mode

definition

11

I

installation

Safe Torque Off option board

installation checklist

22

14

L

low demand mode

definition

11

O

option board

24V DC digital input with analog I/O (20C-

DA1-A)

7

P

performance definition

PL d/Category 3

performance level

definition

PFD

definition

PFD data

PFH

PFH data 12

PL d/Category 3

12

definition

performance definition

10

11

11

11

10

S

Safe Torque Off

description

drive circuity diagram 17

Safe Torque Off option board

installation

removal

terminals

wiring 16

safety

considerations

operation verification

standards

safety of machinery

stop category 0

definition

stop category 1

definition

7

14

23

17

9

23

8

10

10

T

terminals

Safe Torque Off option board

17

W

wiring

Safe Torque Off option board

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011 25

16

Page 26

Index

26 Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Page 27

Page 28

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

, available at http://www.rockwellautomation.com/literature/.

Publication 20C-UM001B-EN-P - June 2011 28

Supersedes Publication 20C-UM001A-EN-P - March 2009 Copyright © 2011 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...