Page 1

MOV Replacement Kit - Frame 5

Installation Instructions

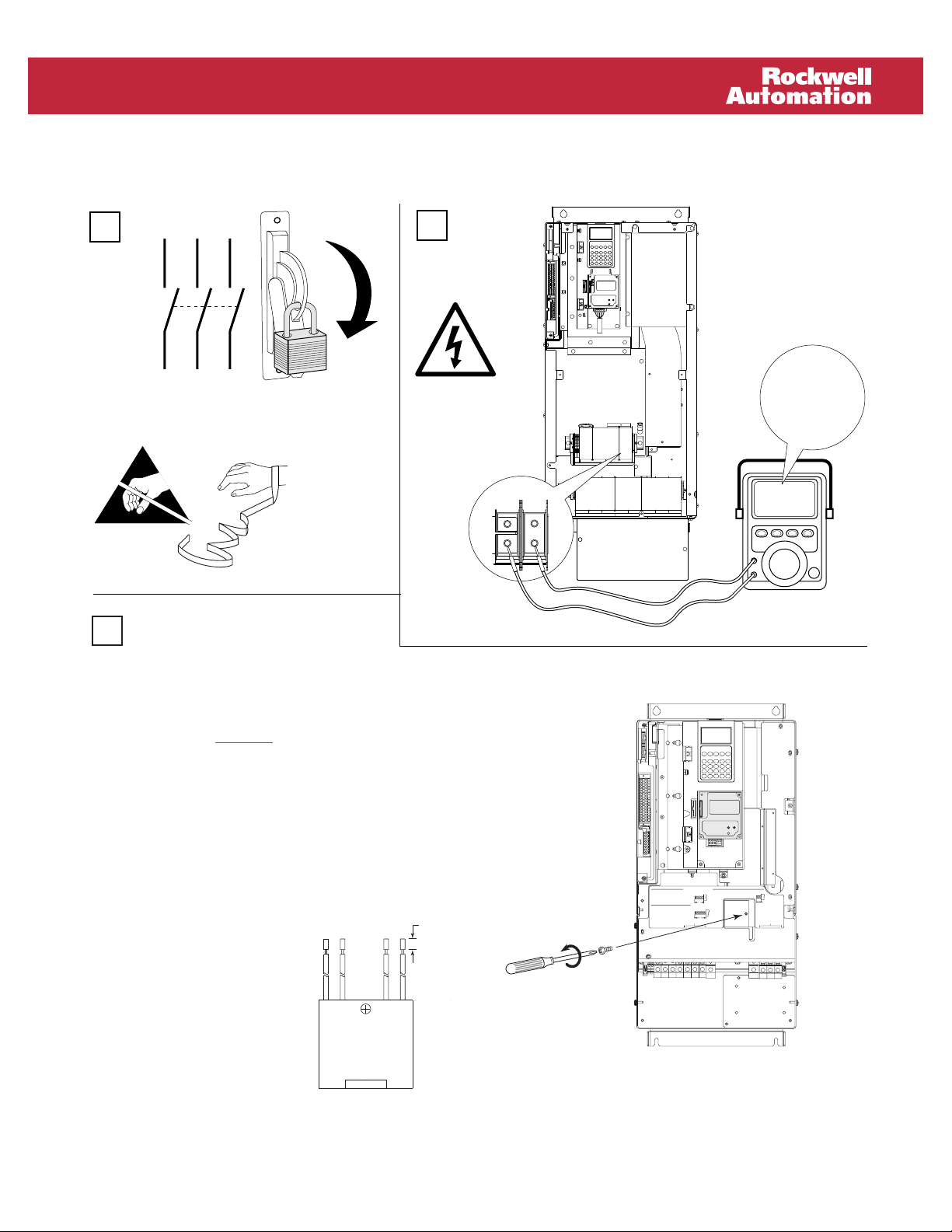

1

L1 L2 L3

I

2

O

=

3

A. Locate the MOV assembly. Note wire placement

and remove the 4 wires/lugs from the terminal

block. Remove the screw that secures the MOV to

the chassis. See Figure 1

.

Optional

Communications

Module

PS–

PS+

22-10

AWG

5.3 IN-LB

WIRE STRIP

BR2

BR1 DC+ DC–

(0.6 N-M)

USE 75 C COPPER WIRE ONLY, TORQUE 52 IN-LB (6 N-M)

DC–DC+

USE 75 C

COPPER WIRE

ONLY

TORQUE

52 IN-LB

(6 N-M)

L2L1T3T2T1 L3

INPUTOUTPUT

Figure 1 MOV Assembly (Frame 5 shown)

0V

0V

B. Compare lug styles between the MOV just removed

and the new one.

– If the lugs are identical, install the new MOV in

reverse order. Verify correct wire placement and

tighten the MOV screw to 3.2 N-m (28 lb.-in.).

– If the lugs are different,

cut the lugs off of the new

8 (0.31 in.)

MOV (as close to the lug

as possible). Strip the

insulation from each lead

approximately 8 mm

(0.31 in.). Crimp the

supplied lugs to the wires.

Install the new MOV in

reverse order. Verify

correct wire placement

and tighten the MOV screw to 3.2 N-m (28 lb.in.).

POWER TERMINAL RATINGS

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

GROUND TERMINAL RATINGS (PE)

WIRE RANGE: 6-1/0 AWG (16-35 MM

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

17

2

)

21

Optional

Communications

Module

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

2

)

9

INPUT ACOUTPUT

Page 2

*364600P01*

Publication RA-IN015A-EN-P – February, 2005 P/N 364600-P01

Copyright © 2005 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...