Page 1

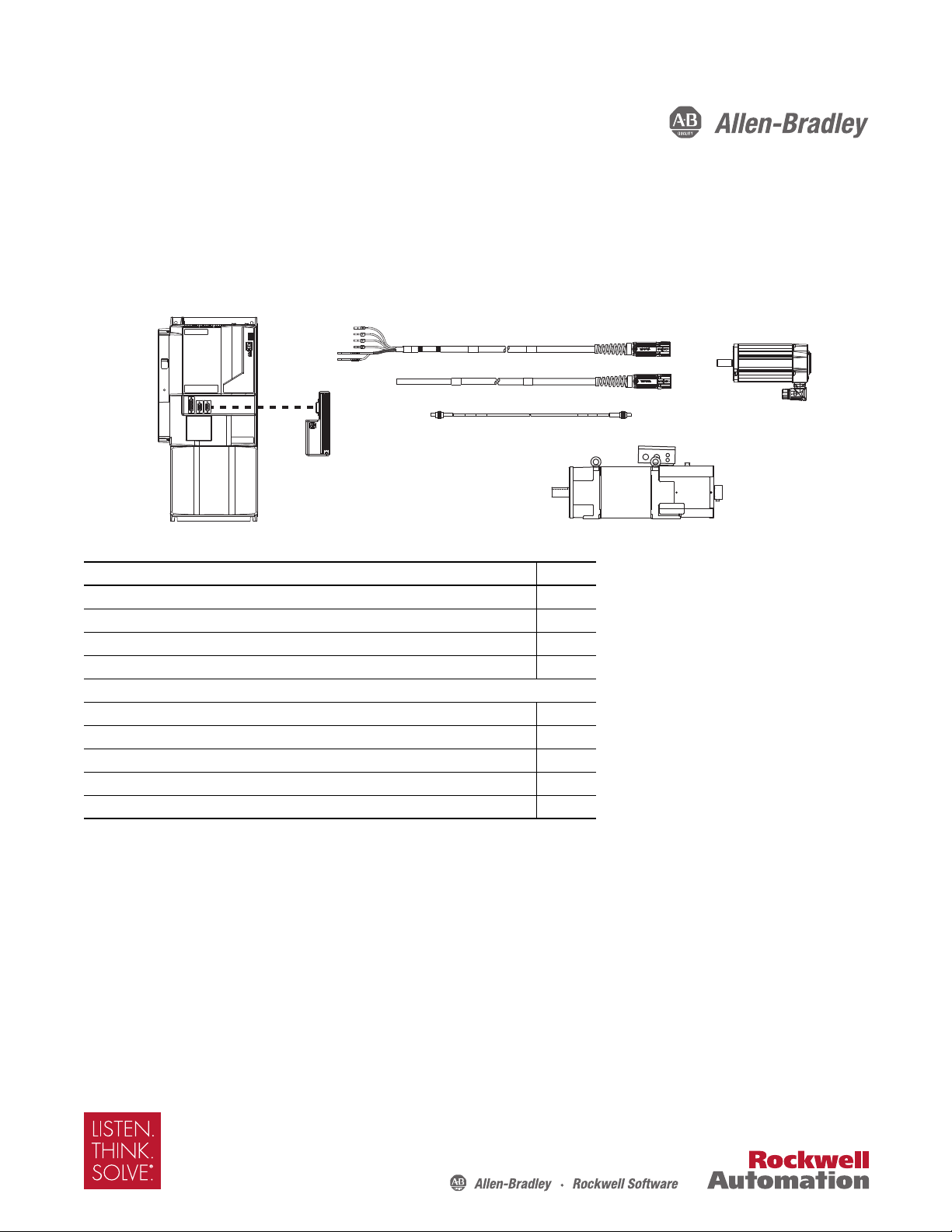

Design Guide

Motor Cables, Interface Cables,

Connector Kits, and Other Drive

Accesso ries

Kinetix 7000

Servo Drives

Rotary Motion

Servo Motors

Rotary Motion

Induction Motors

Kinetix 7000 Drive Systems

Catalog Numbers 2099-BM06-S, 2099-BM07-S, 2099-BM08-S, 2099-BM09-S, 2099-BM10-S, 2099-BM11-S, 2099-BM12-S

Top ic Pag e

Introduction 2

Determine What You Need 3

Kinetix 7000 System Examples 4

2090-Series Motor/Actuator Cables Overview 9

Rotary Motion System Combinations

HPK-Series Asynchronous Servo Motors 11

MP-Series Low Inertia Motors 17

MP-Series Medium Inertia Motors 22

RDD-Series Direct Drive Motors 27

Additional Resources 30

Page 2

Kinetix 7000 Drive Systems

IMPORTANT

Introduction

This publication assumes that the drive family for your application is Kinetix® 7000 and that you have already determined

your motor catalog number. To revisit those decisions, refer to the Kinetix Motion Control Selection Guide, publication

GMC-SG001

The purpose of this publication is to assist you in identifying the drive system components and accessory items you’ll need

for your Kinetix 7000 drive/motor combination. Diagrams in this publication illustrate how many of the common drive

accessory items are used in a typical system, but refer to the Kinetix Motion Accessories Technical Data, publication

GMC-TD004

Also provided are drive/motor or drive/actuator system combinations that include the following:

• Motor/cable combinations table

• Drive/motor performance specification table

• Torque/speed curves with each motor matched to the drive with optimum performance

Performance specification data and curves reflect nominal system performance of a typical system with motor/drive at

rated ambient temperature and line voltage. For additional information on ambients, line conditions, and valid

combinations not shown in this publication, refer to Motion Analyzer software.

, or Motion Analyzer software.

, for detailed accessory descriptions and specifications.

These system combinations do not include all possible motor/drive combinations. Please refer to Motion Analyzer software to

verify compatibility. Download is available at http://www.ab.com/motion/software/analyzer.html

.

2 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 3

Kinetix 7000 Drive Systems

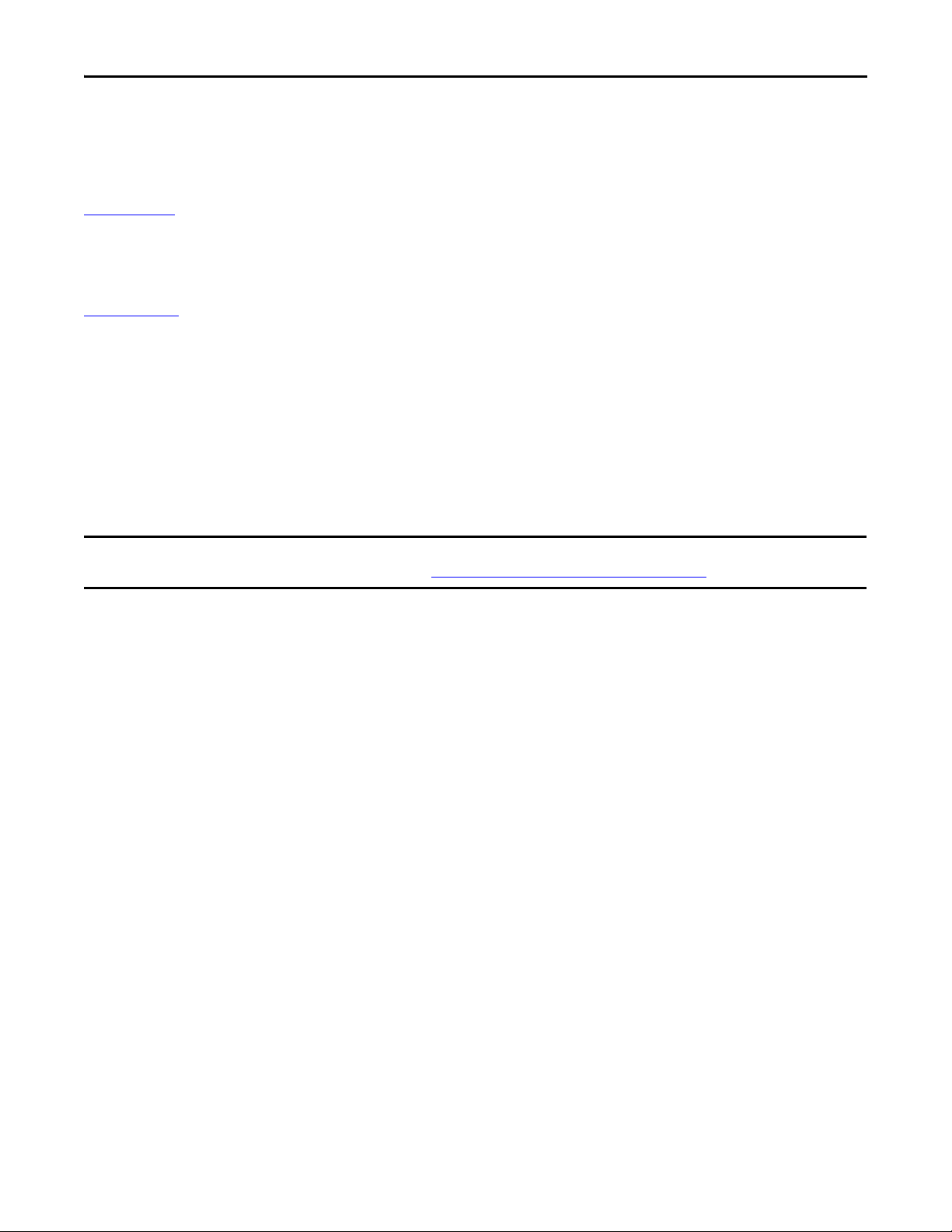

Determine What You Need

For each Kinetix 7000 drive system, you need to know the drive and motor catalog numbers to determine the motor power

and feedback cable catalog numbers. Interface cables and connector kits are also required. Optional equipment includes the

line interface module (LIM), AC line filter, Bulletin 8720MC regenerative power supply (RPS), and others. Example

diagrams of the required equipment listed on this page are shown on page 4

Kinetix 7000 Drive Modules

.

Drive Cat. No.

2099-BM06-S

2099-BM07-S 30 kW 40 Hp 52 A rms

2099-BM08-S 37 kW 50 Hp 65 A rms

2099-BM09-S 56 kW 75 Hp 96 A rms

2099-BM10-S 75 kW 100 Hp 125 A rms

2099-BM11-S 112 kW 150 Hp 180 A rms

2099-BM12-S 149 kW 200 Hp 248 A rms

(1) The -S designator indicates safe-off safety func tionality.

(1)

Input Voltage Output Power (continuous)

22 kW 30 Hp 40 A rms

400V series,

Three-phase

Output Current

(continuous)

Refer to the Kinetix Servo Drives Technical Data, publication GMC-TD003, for detailed descriptions and additional

specifications for the Kinetix 7000 drive family.

Required Drive Accessories

Drive Accessory Description Cat. No.

24V power supply

Low-profile connector kits

(required for flying-lead cables)

SERCOS fiber-optic cables

(required as needed)

Motor power and feedback cables

24V DC for control power and motor

brakes

Motor feedback connections

Auxiliary feedback connections 2094-K6CK-D15F

I/O connections 2094-K6CK-D26M

Plastic, in-cabinet duty 2090-SCEPx-x

Plastic, on-machine duty 2090-SCNPx-x

Plastic, outdoor and conduit duty 2090-SCVPx-x

Glass, outdoor and conduit duty 2090-SCVGx-x

Refer to the specific drive/motor combination for the motor cables required for

your system.

1606-XLxxx

2094-K6CK-D15M

2094-K7CK-KENDAT

(1)

(1) Applies to only Bulletin RDB direc t-drive motors with EnDat encoder.

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these servo drive accessories.

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 3

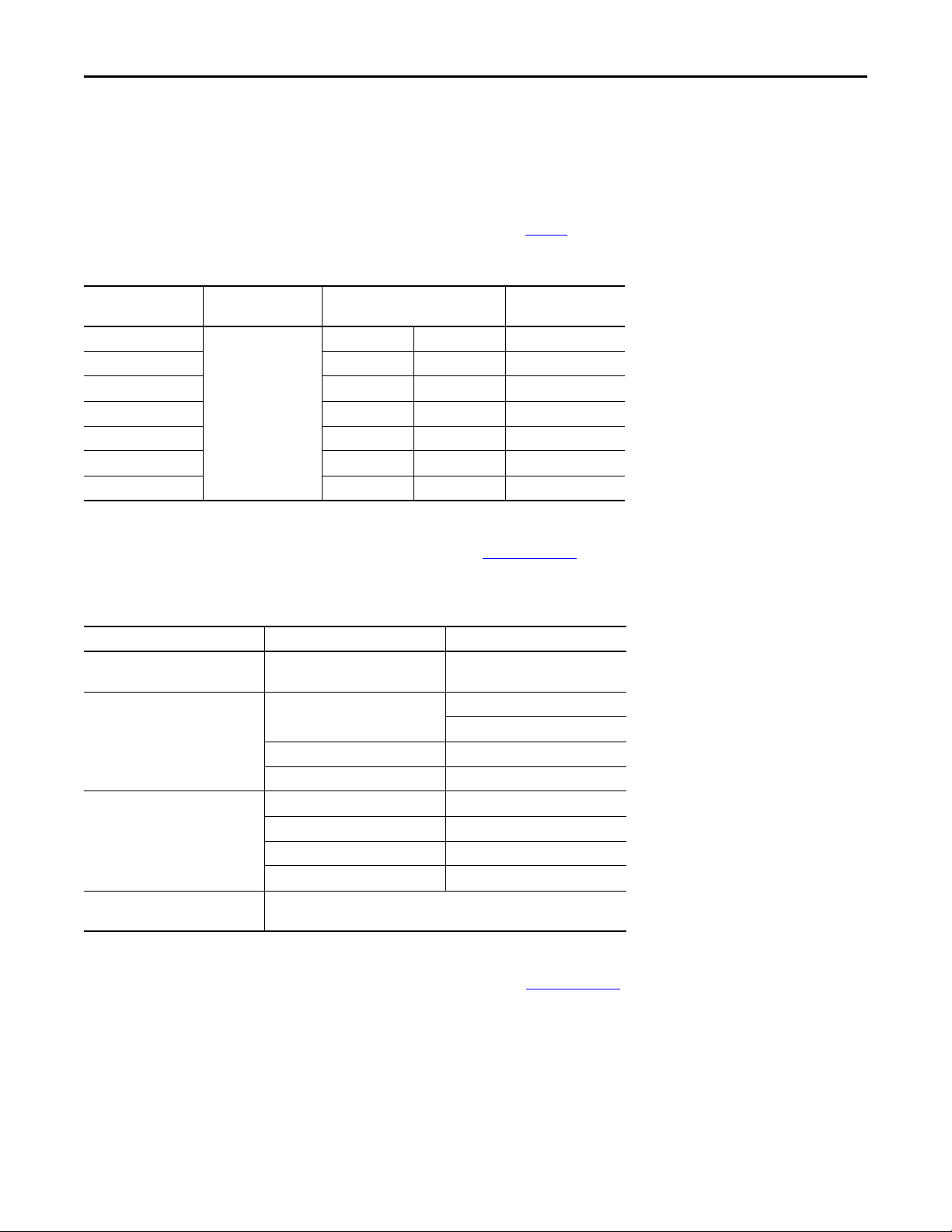

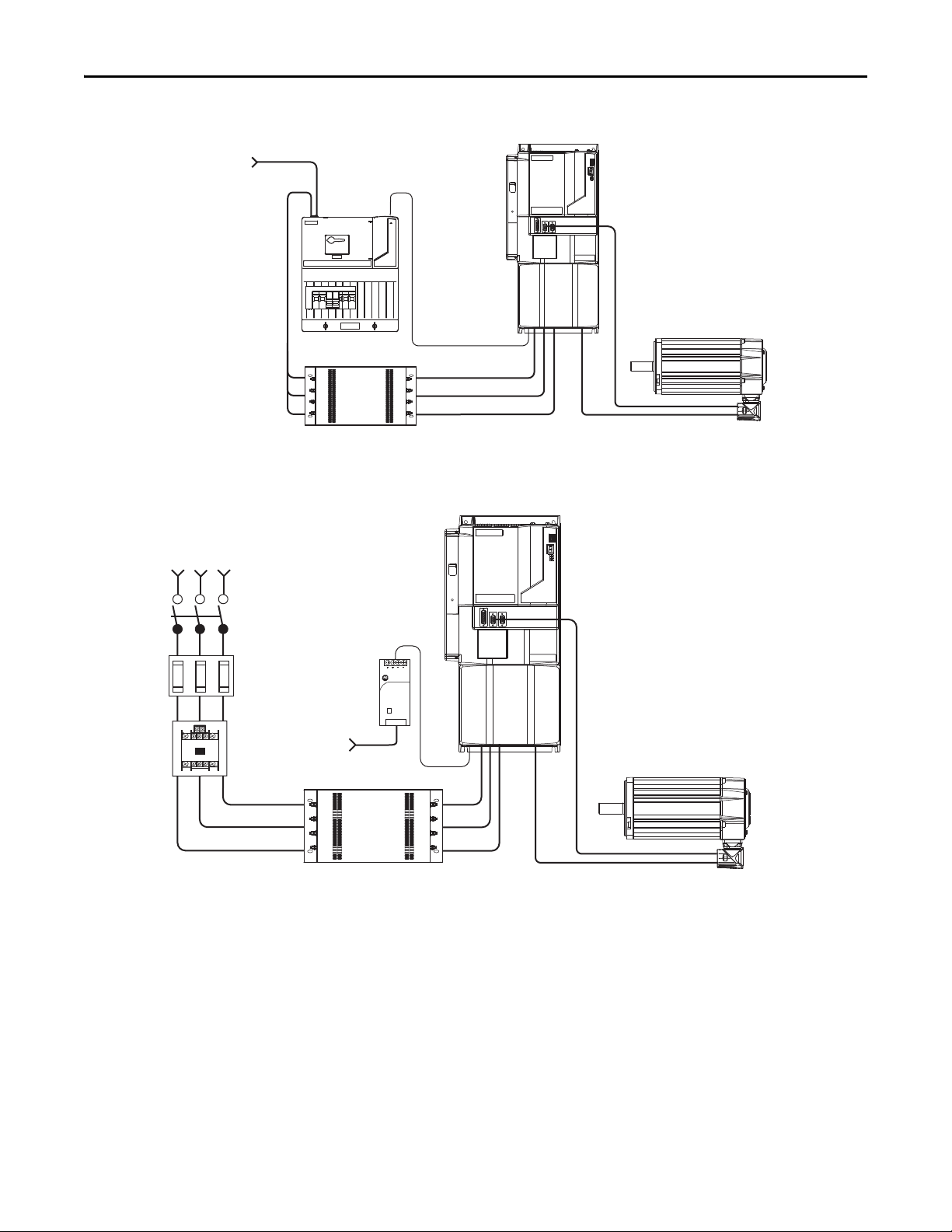

Page 4

Kinetix 7000 Drive Systems

2090-SCxxx-x

SERCOS Fiber-optic Cables

2099-BMxx-S

Kinetix 7000 Servo Drive

2094-K6CK-xxxx

(1)

Low-profile Connector Kits for

Motor Feedback, I/O, and Auxiliary Feedback

Bulletin 2090 Motor Feedback Cable

Bulletin 2090 Motor Power Cable

Logix SERCOS interface Module

24V DC

Control Power

1606-XLxxx

Control Power

Supply Input

Logix Controller Platform

(ControlLogix® controller is shown)

RSLogix™ 5000

Software

Logix Controller Programming Network

Kinetix 7000 System Examples

These system examples illustrate how the required drive modules and accessories are used in typical systems.

Kinetix 7000 System Example (SERCOS interface)

Allen-Bradley

1606-XL

Power Supply

Input

(1) RDD-Series direct-drive motors require 2090-K7CK-KENDAT low-profile feedback modules.

Optional Drive Accessories

Drive Accessory Description Cat. No.

2094 line interface module

2090 AC line filters AC line conditioning for EMC. 2090-XXLF-TCxxxx

Safety headers

Safety interface cables 1202-Cxx

External auxiliary encoders Allen-Bradley® sine/cosine and incremental external encoders. Bulletin 842A, 844D, 845H, and 845T

Connector set

Control board kit Control board assembly kit. Replacement control board. 2099-K7KCB-1

DC-DC converter kit DC-DC converter cassette kit. Replacement DC-DC converter. 2099-K7KCP-1

8720MC regenerative power supply (RPS)

8720MC line reactors 8720MC-LRxx-xxxx

Motor-end cable connector kits, for use when building your own cables, and panel-mounted breakout components are also

available. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

specifications of these servo drive accessories.

4 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Replaces many of the common input power devices for your drive system (including

24V DC supply).

Cascading safe-off connections from drive-to-drive.

Replacement connectors for safe-off (SO), general purpose I/O (GPIO), general

purpose relay (GPR), and control power (CP) connectors.

Power components required in regenerative applications.

2094-BLxxS, 2094-BL02, 2094-XL75S-Cx

2090-XNSM-x

2099-K7KCK-1

8720MC-RPSxxx

, for detailed descriptions and

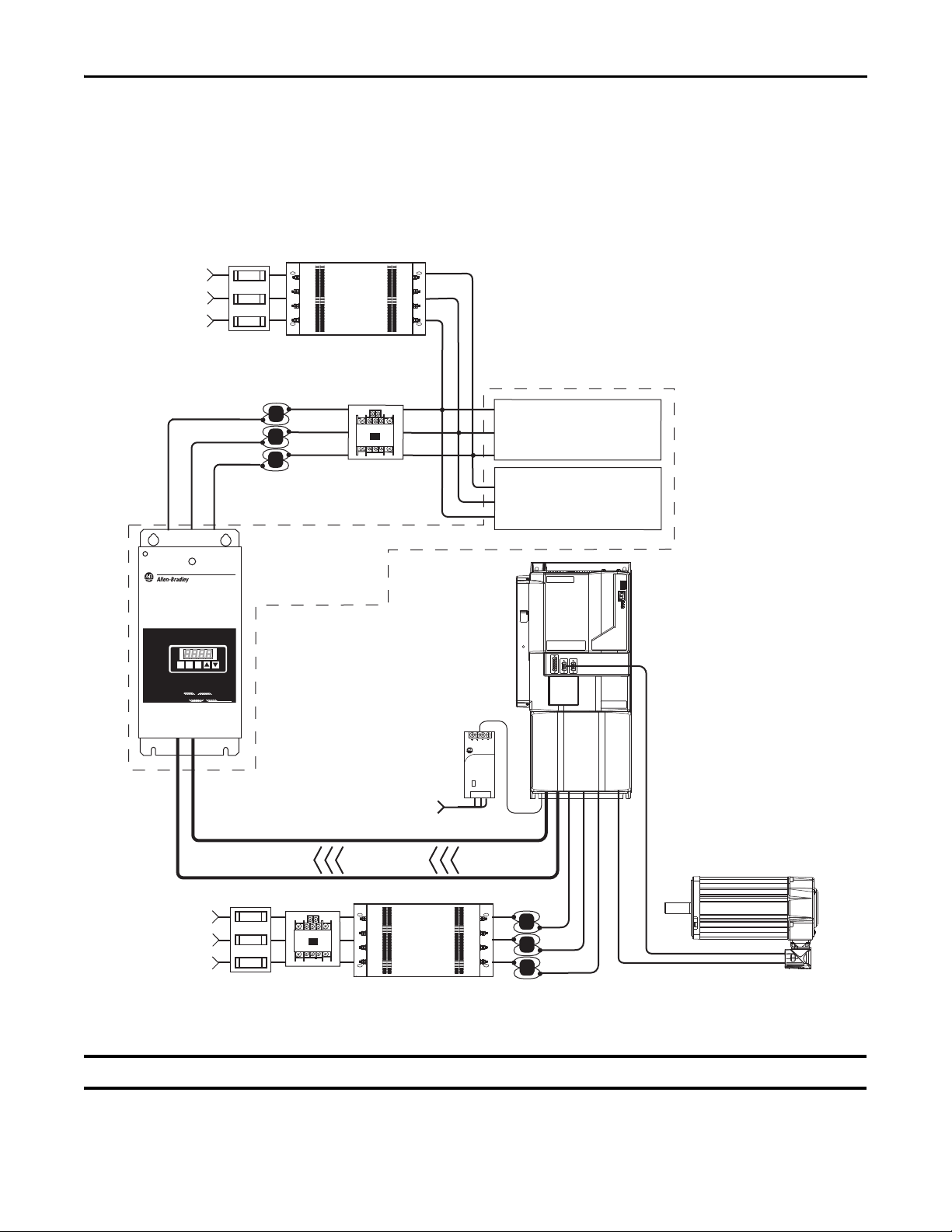

Page 5

Kinetix 7000 AC Input Power Example (with LIM module)

Three-phase

Input Power

24V DC

Control Power

2090-XXLF-TCxxxx

AC Lin e Filter

2094-xLxxS

Line Interface Module

(optional component)

2099-BM06-S, 2099-BM07-S,

2099-BM08-S Servo Drives

HPK-Series, RDD-Series, and

MP-Series (Bulletin MPL or MPM)

Servo Motors

External Shunt Module (optional component)

Refer to Rockwell Automation Encompass™ Partners

Kinetix 7000 Drive

2099-BMxx-S

24V DC

Control Power

1606-XLxxx

External Shunt Module (optional component)

Refer to Rockwell Automation Encompass Partners

Control Power

Supply Input

Line

Disconnect

Device

Magnetic

Contac tor

Input

Fusing

Three-phase

Input Power

AC Lin e Filter

2090-XXLF-TCxxxx

(required for CE)

HPK-Series, RDD-Series, and

MP-Series (Bulletin MPL or MPM)

Servo Motors

Kinetix 7000 AC Input Power Example (without LIM module)

Kinetix 7000 Drive Systems

Allen-Bradley

1606-XL

Power Supply

Input

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 5

Page 6

Kinetix 7000 Drive Systems

IMPORTANT

1606-XL

Power Supply

Input

Allen-Bradley

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

L

Y

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

L

Y

87208720

MCMC

RST

PRG

ENT

READYREADY

FAULTFAULT

PROGRAMPROGRAM kWkW

V

A

DC Bus

Regenerative Power Supply

8720MC-RPS065-BM-HV2

Common Bus Leader

Line Reactor

8720MC-LRxx

Three-phase

Input Power

Varistor (8720MC-VA-B)

Included with

8720MC-RPS065-BM-HV2.

Harmonic Filter (8720MC-HF-B2)

Included with

8720MC-RPS065-BM-HV2.

Magnetic

Contac tor

24V DC

Control Power

1606-XLxxx

AC Line Filter 8720MC-RFI80

(required for CE)

Input

Fusing

Three-phase

Input Power

Magnetic

Contactor

Input

Fusing

Line Reactor

8720MC-LRxx

Regenerative

Power Only

Kinetix 7000 Drive

2099-BMxx-S

Common Bus Follower

Control Power

Supply Input

AC Lin e Filter

2090-XXLF-TCxxxx

(required for CE)

HPK-Series, RDD-Series, and

MP-Series (Bulletin MPL or MPM)

Servo Motors

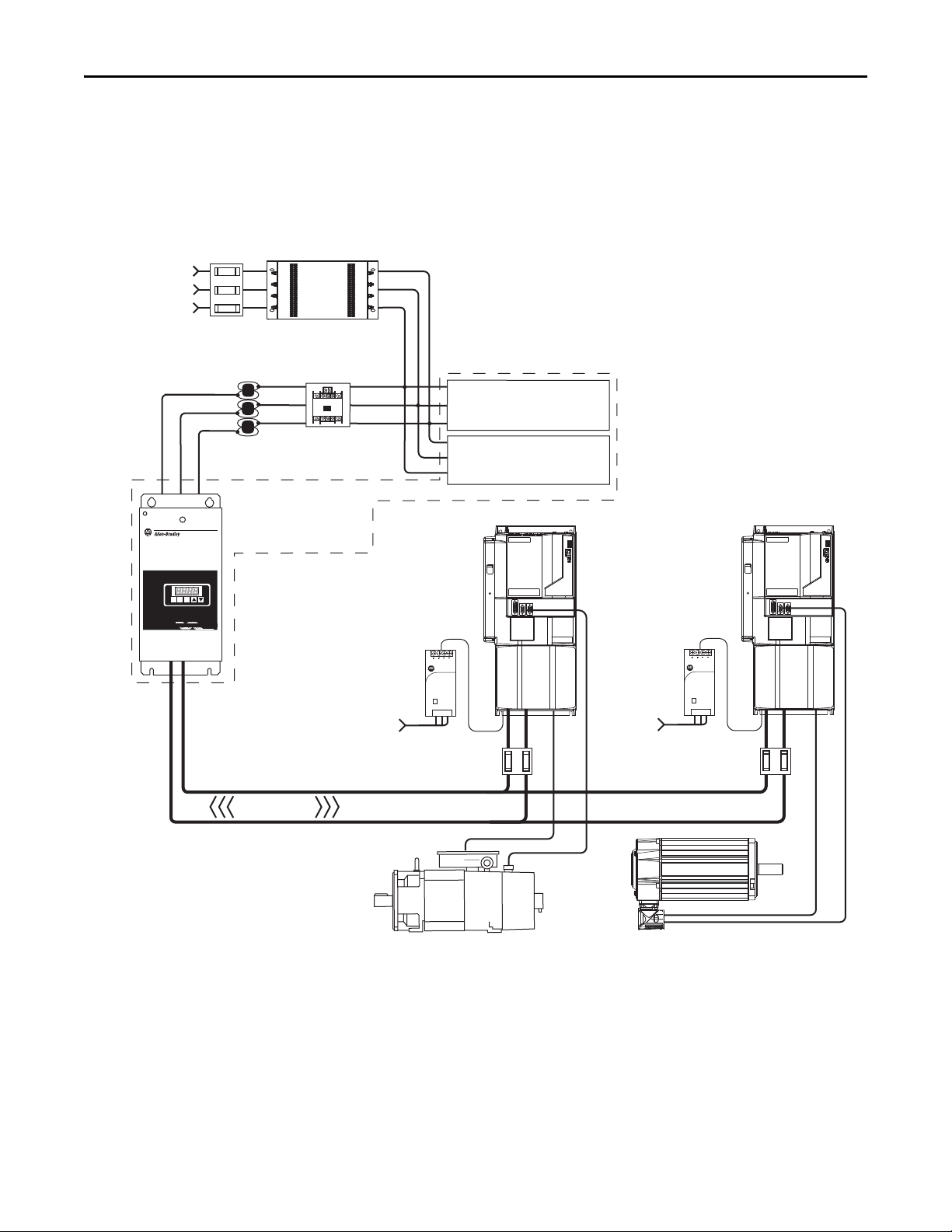

In this example, the Kinetix 7000 drive system is shown with the 8720MC Regenerative Power Supply (RPS) in a

regenerative braking configuration. Harmonic filter and varistor are available separately, but are included with the RPS unit

when ordering catalog number 8720MC-RPS065-BM-HV2.

In this configuration, the Kinetix 7000 drive provides motoring power and the RPS unit provides regenerative power.

Kinetix 7000 AC Input Power Example (with regenerative power)

Regenerative braking applications are limited to only one Kinetix 7000 common-bus follower drive.

6 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 7

Kinetix 7000 Drive Systems

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

LY

REG

E

N

ERAT

IVE POW

ER SUP

PLY

87208720

MCMC

RST

PRG

ENT

READYREADY

FAULTFAULT

PROGRAMPROGRAM kWkW

V

A

1606-XL

Power Supply

Input

Allen-Bradley

1606-XL

Power Supply

Input

Allen-Bradley

Kinetix 7000 Drive

2099-BMxx-S

Common Bus Follower

Regenerative Power Supply

8720MC-RPS065-BM-HV2

Common Bus Leader

Line Reactor

8720MC-LRxx

Three-phase

Input Power

Varistor (8720MC-VA-B)

is included with

8720MC-RPS065-BM-HV2.

Harmonic Filter (8720MC-HF-B2)

is included with

8720MC-RPS065-BM-HV2.

Magnetic

Contac tor

AC Line Filter 8720MC-RFI80

(required for CE)

Input

Fusing

Kinetix 7000 Drive

2099-BMxx-S

Common Bus Follower

DC Bus

Full Re generative

DC Bus

Fusing

DC Bus

Fusing

24V DC

Control Power

1606-XLxxx

Control Power

Supply Input

24V DC

Control Power

1606-XLxxx

Control Power

Supply Input

MP-Series (Bulletin MPL or MPM) and

RDD-Series Servo Motors

HPK-Series Asynchronous

Servo Motors

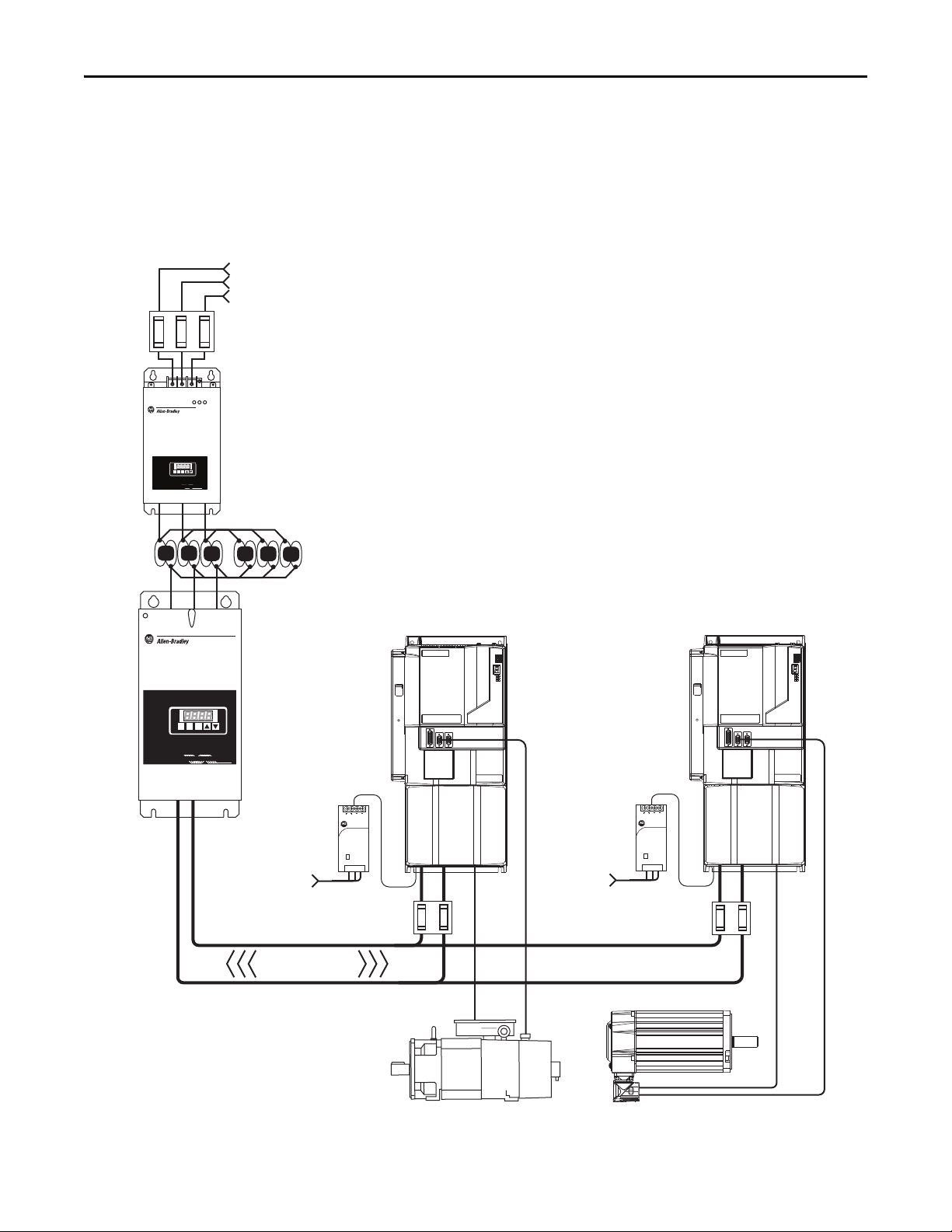

In this example, the Kinetix 7000 drive system is shown with the 8720MC Regenerative Power Supply (RPS) in

DC common-bus configuration with two follower Kinetix 7000 drives. Harmonic filter and varistor are available

separately, but are included with the RPS unit when ordering catalog number 8720MC-RPS065-BM-HV2.

In this full-line regenerative example, the 8720MC-RPS065 unit provides motoring power and regenerative braking.

Kinetix 7000 DC Input Power Example (full-line regeneration)

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 7

Page 8

Kinetix 7000 Drive Systems

1606-XL

Power Supply

Input

Allen-Bradley

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

LY

R

E

G

E

N

E

R

AT

IV

E

P

O

W

E

R

S

U

P

P

L

Y

87208720

MCMC

RST

PRG

ENT

READYREADY

FAULTFAULT

PROGRAMPROGRAM kWkW

V

A

1606-XL

Power Supply

Input

Allen-Bradley

R

E

G

E

N

E

R

A

T

IV

E

P

O

W

E

R

S

U

P

P

L

Y

87208

7

2

0

MCM

C

RST

PRG

ENT

READYREADY

FAULFAULT

PROGRAM

PROGRAM kWkW

V

A

DC Bus

Kinetix 7000 Drive

2099-BM11-S

Common Bus Follower

Regenerative Power Supply

8720MC-RPS190-BM

Common Bus Leader

Line Reactor

8720MC-LR10-100B

(two units in parallel)

Three- phase

Input Power

EMC Line Filter 8720MC-EF190-VB

This unit includes an AC line filter (required for CE),

magnetic contactor, harmonic filter, and varistor.

IMPORTANT The Bulletin 8720MC line filter unit and

line reactor are required when using the

8720MC-RPS190 regenerative power supply.

Input

Fusing

Full Regenerative

Kinetix 7000 Drive

2099-BM11-S

Common Bus Follower

24V DC

Control Power

1606-XLxxx

24V DC

Control Power

1606-XLxxx

HPK-Series Asynchronous

Servo Motors

DC Bus

Fusin g

DC Bus

Fusing

Control Power

Supply Input

Control Power

Supply Input

MP-Series (Bulletin MPL or MPM)

and RDD-Series Servo Motors

In this example, the Kinetix 7000 drive system is shown with the 8720MC Regenerative Power Supply (RPS) in

DC common-bus configuration with two follower 2099-BM11-S drives. Harmonic filter, varistor, and magnetic contactor

are included when ordering the 8720MC-EF190-VB EMC line filter.

In this full-line regenerative example, the 8720MC-RPS190 unit provides motoring power and regenerative braking.

Kinetix 7000 DC Input Power Example (with full-line regeneration)

8 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 9

2090-Series Motor/Actuator Cables Overview

IMPORTANT

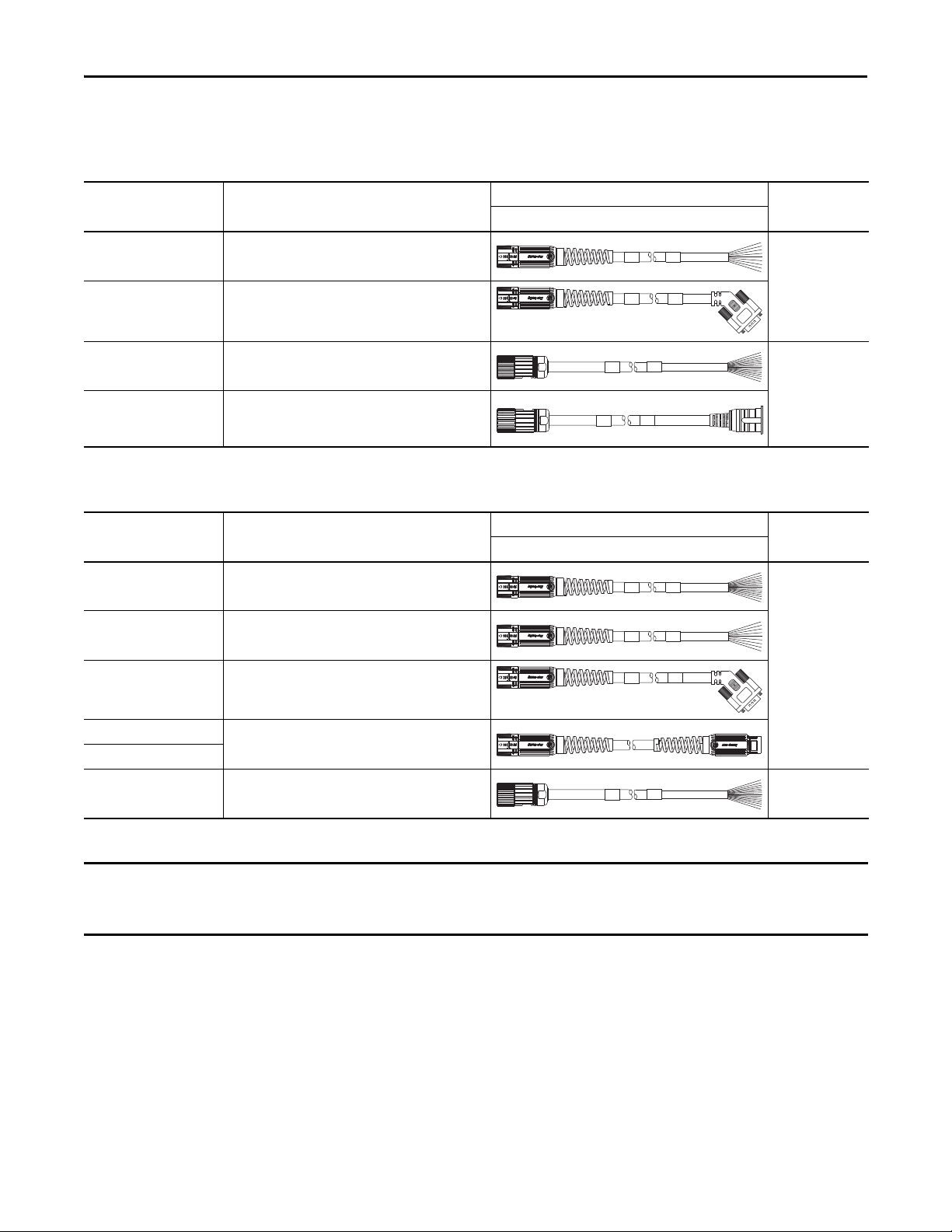

Feedback Cable Descriptions (standard, non-flex)

Kinetix 7000 Drive Systems

Standard Cable

Cat. No.

2090-CFBM7DF-CEAAxx

2090-CFBM7DD-CEAAxx

2090-XXNFMF-Sxx

2090-CFBM4E2-CATR

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Description

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end 15-pin connector (DD)

• High-resolution or resolver applications (CE)

• Drive-end flying-leads

• High-resolution or incremental applications

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• All feedback types (CA)

Feedback Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CFBM7DF-CDAFxx

2090-CFBM7DF-CEAFxx

2090-CFBM7DD-CEAFxx

Description

• Drive-end flying-leads (DF)

• High-resolution or incremental applications (CD)

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end 15-pin connector (DD)

• High-resolution or resolver applications (CE)

Cable Configuration

Motor/Actuator End Drive End

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

Motor/Actuator

Connector

SpeedTec DIN

(M7)

2090-CFBM7E7-CDAFxx

2090-CFBM7E7-CEAFxx

2090-CFBM4DF-CDAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

• Drive-end flying-leads

• High-resolution or incremental applications

(1)

Feedback cables with the CE designation, for example 2090-CFBM7DF-CEAAxx, are intended for high-resolution encoder or

resolver applications and have fewer conductors than feedback cables with the CD designation, for example

2090-CFBM7DF-CDAFxx, which are intended for high-resolution or incremental encoder applications.

Threaded DIN

(M4)

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 9

Page 10

Kinetix 7000 Drive Systems

BR+

BR-

BR+

BR-

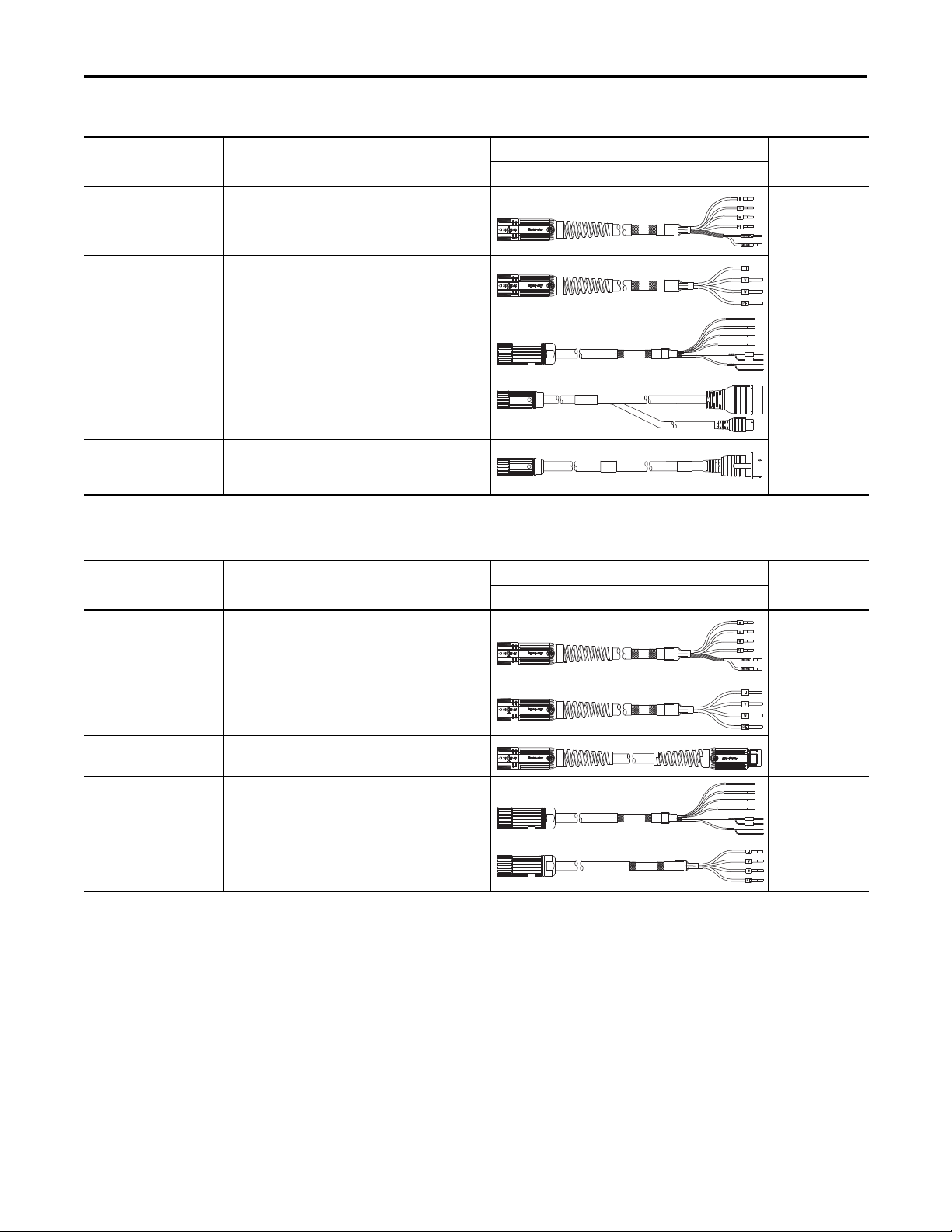

Power/Brake Cable Descriptions (standard, non-flex)

Standard Cable

Cat. No.

2090-CPBM7DF-xxAAxx

2090-CPWM7DF-xxAAxx

2090-XXNPMF-xxSxx

Description

• Drive-end flying-leads (DF)

• Power/brake w ires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (PW)

• Drive-end flying-leads

• Power/brake w ires

• Drive-end bayonet (E2), transition (TR) cable

2090-CPBM4E2-xxTR

• Motor-end threaded DIN (M4)

• Power/brake w ires (PB)

• Drive-end bayonet (E2), transition (TR) cable

2090-CPWM4E2-xxTR

• Motor-end threaded DIN (M4)

• Power wire s only (PW)

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Power/Brake Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

Description

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

(1)

Threaded DIN

(M4)

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

2090-CPBM7DF-xxAFxx

2090-CPWM7DF-xxAFxx

2090-CPBM7E7-xxAFxx

2090-CPBM4DF-xxAFxx

2090-CPWM4DF-xxAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

• Drive-end flying-leads (DF)

• Power/brake w ires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (PW)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

• Drive-end flying-leads (DF)

• Power/brake w ires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (PW)

(1)

SpeedTec DIN

(M7)

Threaded DIN

(M4)

10 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 11

Kinetix 7000 Drive Systems

Kinetix 7000 (400V class) Drives with HPK-Series Asynchronous Servo Motors

This section provides system combination information for the Kinetix 7000 (400V class) drives when matched with

HPK-Series™ motors. These motors are available with 460V and 400V windings. Included are motor power/brake and

feedback cable catalog numbers, system performance specifications, and the optimum torque/speed curves.

HPK-Series Motor Cable Combinations (460V motors)

Motor Cat. No. Motor Power Cable Motor Feedback Cable

HPK-B1307C and HPK-B1308C

HPK-B1307E and HPK-B1310C

HPK-B1308E, HPK-B1609E, and HPK-B1613C

HPK-B1611E and HPK-B1613E

HPK-B1815C

HPK-B2010C, HPK-B2010E

HPK-B2212C, HPK-B2510C

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) on the drive end. Refer to Required Drive Accessories on page 3.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 9.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to 2090-Series Motor/Actuator Cables Overview on page 9

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

Customer Supplied

, for standard cable lengths.

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM4DF-CDAFxx (continuous-flex)

Absolute High-resolution Feedback

(1)

HPK-Series (460V) Performance Specifications with Kinetix 7000 (400V class) Drives

Rotary Motor

HPK-B1307C

HPK-B1308C 59.6 141 (1248) 119.3 262 (2319) 21.6 (28.9) 2099-BM07-S

HPK-B1310C 64.9 155 (1372) 144.0 325 (2876) 23.8 (31.9) 2099-BM08-S

HPK-B1613C 109.8 271 (2398) 217.0 542 (4797) 41.7 (55.9) 2099-BM09-S

HPK-B1815C 153.7 360 (3186) 402.0 850 (7523) 55.9 (74.9) 2099-BM11-S

HPK-B2010C 196.4 482 (4266) 440.0 970 (8585) 75.0 (100.5) 2099-BM11-S

HPK-B2212C 278.0 714 (6319) 524.0 1356 (12,000) 112 (151) 2099-BM12-S

HPK-B2510C 351.0 865 (7656) 526.0 1216 (10,762) 136 (180) 2099-BM12-S

HPK-B1307E

HPK-B1308E 91.4 115 (1018) 190.3 230 (2035) 35.7 (47.8) 2099-BM09-S

HPK-B1609E 124.4 156 (1381) 217.0 270 (2390) 48.4 (64.8) 2099-BM09-S

HPK-B1611E 149.0 183 (1619) 338.4 400 (3540) 57.0 (76.4) 2099-BM11-S

HPK-B1613E 191.0 237 (2097) 440.0 459 (4062) 73.7 (98.8) 2099-BM11-S

HPK-B2010E 254.0 295 (2610) 440.0 500 (4425) 92.0 (125.0) 2099-BM11-S

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software, ve rsion 4.7 or later.

Speed, base

rpm

1500

3000

System Continuous

Stall Current

A 0-pk

102.0 112 (991) 113.0 257 (2274) 17.1 (22.9) 2099-BM07-S

81.0 96.0 (849) 146.6 165 (1460) 29.8 (39.9) 2099-BM08-S

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

Kinetix 7000

(400V class) Drives

.

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 11

Page 12

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2099-BM07 and HPK-B1307C

0

0

30

60

90

120

150

180

210

240

270

300

Speed (rpm)

250

1000750

0

1500

1250

500

531

1062

2655

1328

1593

1859

2124

2390

797

265

Torque

(N•m)

Torque

(lb•in)

2099-BM08 and HPK-B1310C

0

885

1770

4425

0

50

100

150

200

250

300

350

400

450

500

2213

2655

3098

3540

3982

1328

442

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(lb•in)

2099-BM11 and HPK-B2010C

0

1770

3540

8850

0

100

200

300

400

500

600

700

800

900

1000

4425

5310

6195

7080

7965

2655

885

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(N•m)

Torque

(lb•in)

2099-BM11 and HPK-B1815C

0

1770

3540

8850

0

100

200

300

400

500

600

700

800

900

1000

4425

5310

6195

7080

7965

2655

885

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(N•m)

= Intermittent operating region

= Continuous operating region

= Drive operation with 750V DC (rms) input voltage

Kinetix 7000 (400V class) Drives/HPK-Series (460V) Motor Curves

Torque

(N•m)

Torque

(N•m)

300

270

240

210

180

150

120

600

540

480

420

360

300

240

180

120

2099-BM07 and HPK-B1308C

90

60

30

0

1250

1250

1500

1500

250

0

60

0

0

500

Speed (rpm)

2099-BM09 and HPK-B1613C

250

500

Speed (rpm)

1000750

1000750

2655

2390

2124

1859

1593

1328

1062

797

531

265

0

5310

4749

4248

3717

3186

2655

2124

1593

1062

531

0

Torque

(lb•in)

Torque

(lb•in)

12 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 13

Kinetix 7000 (400V class) Drives/HPK-Series (460V) Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

2099-BM12 and HPK-B2212C

0

0

150

300

450

600

750

900

1050

1200

1350

1500

Speed (rpm)

250

1000750

0

1500

1250

500

2655

5310

13,276

6638

7966

9293

10,621

11,948

3983

1327

Torque

(N•m)

Torque

(lb•in)

2099-BM08 and HPK-B1307E

0

531

1062

2655

0

30

60

90

120

150

180

210

240

270

300

1328

1593

1859

2124

2390

797

265

Speed (rpm)

500

20001500

0

3000

2500

1000

Torque

(N•m)

Torque

(lb•in)

2099-BM09 and HPK-B1609E

0

0

30

60

90

120

150

180

210

240

270

300

Speed (rpm)

500

20001500

0

3000

2500

1000

531

1062

2655

1328

1593

1859

2124

2390

797

265

= Intermittent operating region

= Continuous operating region

= Drive operation with 750V DC (rms) input voltage

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(N•m)

1500

1350

1200

1050

900

750

600

450

300

150

300

270

240

210

180

150

120

2099-BM12 and HPK-B2510C

0

1250

2500

1500

3000

250

0

90

60

30

0

0

500

Speed (rpm)

2099-BM09 and HPK-B1308E

500

1000

Speed (rpm)

1000750

20001500

13,276

11,948

10,621

9293

7966

6638

5310

3983

2655

1327

0

2655

2390

2124

1859

1593

1328

1062

797

531

265

0

Torque

(lb•in)

Torque

(lb•in)

Torque

500

(N•m)

450

400

350

300

250

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 13

200

150

100

50

2099-BM11 and HPK-B1611E

0

500

0

1000

Speed (rpm)

Torque

4425

(lb•in)

3982

3540

3098

2655

2213

1770

1328

885

442

0

2500

20001500

3000

Page 14

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2099-BM11 and HPK-B1613E

0

885

1770

4425

0

50

100

150

200

250

300

350

400

450

500

2213

2655

3098

3540

3982

1328

442

Speed (rpm)

500

20001500

0

3000

2500

1000

= Intermittent operating region

= Continuous operating region

= Drive operation with 750V DC (rms) input voltage

Kinetix 7000 (400V class) Drives/HPK-Series (460V) Motor Curves (continued)

Torque

(N•m)

600

540

480

420

360

300

240

180

120

60

2099-BM11 and HPK-B2010E

0

500

0

1000

Speed (rpm)

20001500

HPK-Series Motor Cable Combinations (400V motors)

Motor Cat. No. Motor Power/Brake Cable Motor Feedback Cable

HPK-E1307C

HPK-E1307E, HPK-E1308E, and HPK-E1310C

HPK-E1609E, HPK-E1611E, HPK-E1613C, and HPK-E1613E

HPK-E1815C and HPK-E2010C

Customer Supplied

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM4DF-CDAFxx (continuous-flex)

Absolute High-resolution Feedback

2500

(1)

3000

5310

4749

4248

3717

3186

2655

2124

1593

1062

531

0

Torque

(lb•in)

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) or panel-mounted breakout components on drive end. Refer to Required Drive Accessories on page 3

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 9.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to 2090-Series Motor/Actuator Cables Overview on page 9

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

, for standard cable lengths.

HPK-Series (400V) Performance Specifications with Kinetix 7000 (400V class) Drives

Rotary Motor

HPK-E1307C

HPK-E1310C 80.0 155 (1372) 200.0 380 (3363) 23.8 (32.4) 2099-BM09-S

HPK-E1613C 133.0 271 (2398) 310.0 625 (5531) 41.7 (55.9) 2099-BM11-S

HPK-E1815C 187.0 360 (3186) 440.0 840 (7434) 55.9 (74.9) 2099-BM11-S

HPK-E2010C 243.0 482 (4266) 440.0 870 (7700) 75.0 (100.5) 2099-BM11-S

HPK-E1307E

HPK-E1308E 112.8 107 (947) 217.7 200 (1770) 33.2 (45.0) 2099-BM09-S

HPK-E1609E 153.7 156 (1381) 356.7 359 (3176) 48.4 (64.9) 2099-BM11-S

HPK-E1611E 185.0 183 (1619) 440.0 430 (3805) 57.0 (76.4) 2099-BM11-S

HPK-E1613E 242.5 237 (2097) 440.0 430 (3805) 73.7 (98.8) 2099-BM11-S

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software, ve rsion 4.7 or later.

14 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Speed, base

rpm

1500

3000

System Continuous

Stall Current

A 0-pk

58.5 112 (991) 146.6 263 (2327) 17.1 (22.9) 2099-BM08-S

102.0 96.0 (849) 217.0 202 (1788) 29.8 (39.9) 2099-BM09-S

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

.

Kinetix 7000

(400V class) Drives

Page 15

Kinetix 7000 (400V class) Drives/HPK-Series (400V) Motor Curves

Torque

(N•m)

Torque

(lb•in)

2099-BM08 and HPK-E1307C

0

0

30

60

90

120

150

180

210

240

270

300

Speed (rpm)

250

1000750

0

1500

1250

500

531

1062

2655

1328

1593

1859

2124

2390

797

265

Torque

(N•m)

Torque

(lb•in)

2099-BM09 and HPK-E1310C

0

885

1770

4425

0

50

100

150

200

250

300

350

400

450

500

2213

2655

3098

3540

3982

1328

442

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(lb•in)

2099-BM11 and HPK-E1613C

0

1770

3540

8850

0

100

200

300

400

500

600

700

800

900

1000

4425

5310

6195

7080

7965

2655

885

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(N•m)

Torque

(lb•in)

2099-BM11 and HPK-E2010C

0

1770

3540

8850

0

100

200

300

400

500

600

700

800

900

1000

4425

5310

6195

7080

7965

2655

885

Speed (rpm)

250

1000750

0

1500

1250

500

Torque

(N•m)

= Intermittent operating region

= Continuous operating region

= Drive operation with 750V DC (rms) input voltage

Kinetix 7000 Drive Systems

Torque

1000

(N•m)

900

800

700

600

500

400

300

200

100

Torque

250

(N•m)

225

200

175

150

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 15

125

100

75

50

25

2099-BM11 and HPK-E1815C

0

250

0

2099-BM09 and HPK-E1307E

0

500

0

500

Speed (rpm)

1000

Speed (rpm)

1250

2500

1500

3000

1000750

20001500

8850

7965

7080

6195

5310

4425

3540

2655

1770

885

0

2213

1991

1770

1549

1328

1106

885

664

442

221

0

Torque

(lb•in)

Torque

(lb•in)

Page 16

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2099-BM09 and HPK-E1308E

0

442

885

2213

0

25

50

75

100

125

150

175

200

225

250

1106

1328

1549

1770

1991

664

221

Speed (rpm)

500

20001500

0

3000

2500

1000

Torque

(N•m)

Torque

(lb•in)

2099-BM11 and HPK-E1611E

0

885

1770

4425

0

50

100

150

200

250

300

350

400

450

500

2213

2655

3098

3540

3982

1328

442

Speed (rpm)

500

20001500

0

3000

2500

1000

= Intermittent operating region

= Continuous operating region

= Drive operation with 750V DC (rms) input voltage

Kinetix 7000 (400V class) Drives/HPK-Series (400V) Motor Curves (continued)

Torque

(N•m)

Torque

(N•m)

500

450

400

350

300

250

200

150

100

500

450

400

350

300

250

200

150

100

2099-BM11 and HPK-E1609E

50

0

2500

2500

3000

3000

500

0

50

0

0

1000

Speed (rpm)

2099-BM11 and HPK-E1613E

500

1000

Speed (rpm)

20001500

20001500

4425

3982

3540

3098

2655

2213

1770

1328

885

442

0

4425

3982

3540

3098

2655

2213

1770

1328

885

442

0

Torque

(lb•in)

Torque

(lb•in)

16 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 17

Kinetix 7000 Drive Systems

IMPORTANT

Kinetix 7000 (400V class) Drives with MP-Series Low Inertia Motors

This section provides system combination information for the Kinetix 7000 (400V class) drives when matched with

MP-Series™ low-inertia motors. Included are motor power/brake and feedback cable catalog numbers, system performance

specifications, and the optimum torque/speed curves.

The MP-Series low-inertia motors on this page are equipped with DIN connectors (specified by 7 in the catalog number) and are

not compatible with cables designed for motors equipped with bayonet connectors (specified by 2 in the catalog number). The

motors with bayonet connectors (for example, MPL-A310P-xx2xAA) are being discontinued and require 2090-XXNxMP (bayonet)

cables. For help with migration or to select bayonet cables, contact your Rockwell Automation® sales representative.

Bulletin MPL Motor Cable Combinations

Motor Cat. No. (400V class) Motor Power/Brake Cable Motor Feedback Cable

MPL-B540K-xx7xAA, MPL-B560F-xx7xAA

MPL-B580F-xx7xAA, MPL-B580J-xx7xAA

MPL-B640F-xx7xAA

MPL-B660F-xx7xAA, MPL-B680D-xx7xAA,

MPL-B960B-xx7xAA, MPL-B980B-xx7xAA

MPL-B680F-xx7xAA, MPL-B860D-xx7xAA

MPL-B880C-xx7xAA

MPL-B880D-xx7xAA

MPL-B960C-xx7xAA, MPL-B960D-xx7xAA,

MPL-B980C-xx7xAA, MPL-B980D-xx7xAA

MPL-B980E-xx7xAA 2090-CPBM7DF-02AAxx (standard, non-flex)

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) or panel-mounted breakout components on drive end. Refer to Required Drive Accessories on page 3.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 9.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to 2090-Series Motor/Actuator Cables Overview on page 9

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPxM7DF-14AAxx (standard, non-flex)

2090-CPxM7DF-14AFxx (continuous-flex)

2090-CPxM7DF-10AAxx (standard, non-flex)

2090-CPxM7DF-10AFxx (continuous-flex)

2090-CPxM7DF-08AAxx (standard, non-flex)

2090-CPxM7DF-08AFxx (continuous-flex)

2090-CPBM7DF-06AAxx (standard, non-flex)

2090-CPBM7DF-04AAxx (standard, non-flex)

, for standard cable lengths.

2090-CFBM7DF-CEAAxx or

2090-CFBM7DD-CEAAxx (standard, non-flex)

2090-CFBM7DF-CEAFxx or

2090-CFBM7DD-CEAFxx (continuous-flex)

Absolute High-resolution Feedback

(1)

.

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 17

Page 18

Kinetix 7000 Drive Systems

Bulletin MPL Motor Performance Specifications with Kinetix 7000 (400V class) Drives

Rotary Motor

MPL-B540K 3000 20.4 19.5 (172) 60.0 48.6 (430) 5.4 2099-BM06-S

MPL-B560F 3000 20.6 27.0 (239) 68.0 67.7 (599) 5.5 2099-BM06-S

MPL-B580F 3000 26.0 34.0 (301) 94.0 87.0 (770) 7.1 2099-BM06-S

MPL-B580J 3800 32.0 34.0 (301) 94.0 81.0 (717) 7.9 2099-BM06-S

MPL-B640F 3000 27.8 36.7 (325) 65.0 72.3 (640) 6.1 2099-BM06-S

MPL-B660F 3000 33.0 48.0 (425) 96.0 101 (894) 6.1 2099-BM06-S

MPL-B680D 2000 29.4 62.8 (556) 94.0 154 (1363) 9.3 2099-BM06-S

MPL-B680F 3000 41.5 59.4 (526) 96.0 108 (956) 7.5 2099-BM06-S

MPL-B860D 2000 40.9 83.1 (735) 95.5 152 (1345) 12.5 2099-BM06-S

MPL-B880C 1500 41.1

MPL-B880D 2000

MPL-B960B 1200 36.8 130 (1150) 94.0 231 (2044) 12.7 2099-BM06-S

MPL-B960C 1500 47.6 124 (1097)

MPL-B960D 2000

MPL-B980B 1000 34.6 162 (1434) 94.0 278 (2460) 15.2 2099-BM06-S

MPL-B980C 1500

MPL-B980D 2000

MPL-B980E 2750 105 141 (1250) 218 237 (2100) 13.0 2099-BM09-S

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software, ve rsion 4.7 or later.

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

57.0 92.5 (818)

58.0 110 (973) 2099-BM07-S

57.0 100 (885) 96.0 171 (1513)

60.6 124 (1097)

57.0 131 (1159) 96.0 198 (1752)

59.0 158 (1398)

57.0 113 (1000) 96.0 183 (1619)

68.4

System Continuous

Stall Torque

N•m (lb•in)

108 (956) 96.0 200 (1796)

109 (965) 97.5 203 (1770) 2099-BM07-S

148 (1310) 113 213 (1885) 2099-BM07-S

158 (1398) 140 259 (2292) 2099-BM08-S

System Peak

Stall Current

A 0-pk

96.0 147 (1301) 12.6

96.0 184 (1628)

113 209 (1850) 2099-BM07-S

125 226 (2000) 2099-BM08-S

113 201 (1779) 2099-BM07-S

125 223 (1973) 2099-BM08-S

113 227 (2009) 2099-BM07-S

140 270 (2389) 2099-BM08-S

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

12.6

14.8

15.0

16.8

18.6

Kinetix 7000

(400V class) Drives

2099-BM06-S

2099-BM06-S

2099-BM06-S

2099-BM06-S

2099-BM06-S

2099-BM06-S

18 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 19

Kinetix 7000 (400V class) Drives/MP-Series Low Inertia Motor Curves

Torque

(N•m)

Torque

(lb•in)

0

0

10

20

30

50

40

88.5

177

265

354

2099-BM06 and MPL-B540K

442

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

2099-BM06 and MPL-B560F

70

60

50

40

30

20

10

0

619

531

442

354

265

177

88.5

0

Speed (rpm)

500

1000

1500 200002500 3000

Torque

(N•m)

Torque

(lb•in)

0

0

20

40

60

100

80

177

354

531

708

885

2099-BM06 and MPL-B580F

Speed (rpm)

500 1000 1500 20000 2500 3000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

1000

2000

0

0

0

3000

20

40

60

100

80

4000

177

354

531

708

885

2099-BM06 and MPL-B580J

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

0

20

40

60

80

177

354

531

708

500 1000 1500 20000 2500 3000

2099-BM06 and MPL-B640F

100

885

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Kinetix 7000 Drive Systems

2099-BM06 and MPL-B660F

120

Torque

(N•m)

100

80

60

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 19

40

20

0

2500

0

500 1500

1000

Speed (rpm)

2000

1062

885

708

531

354

177

0

3000

Torque

(lb•in)

Page 20

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0 20001000500 1500

160

00

20 177

40 354

60 531

80 708

1416

140 1239

120 1062

100 885

2099-BM06 and MPL-B680D

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0 20001000500 1500

160

00

20 177

40 354

60 531

80 708

1416

140 1239

120 1062

100 885

2099-BM06 and MPL-B860D

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0 20001000500 1500

160

00

20 177

40 354

60 531

80 708

1416

140 1239

120 1062

100 885

2099-BM07 and MPL-B880D

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Kinetix 7000 (400V class) Drives/MP-Series Low Inertia Motor Curves (continued)

2099-BM06 and MPL-B680F

120

Torque

(N•m)

100

1062

885

Torque

(lb•in)

Torque

(N•m)

250

200

150

100

80

60

40

20

0

2500

0

500 1500

1000

Speed (rpm)

2099-BM07 and MPL-B880C

50

2000

3000

708

531

354

177

0

2213

1770

1328

885

442

Torque

(lb•in)

20 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Torque

(N•m)

250

200

150

100

50

0 15001000500 1250750250

0

0

Speed (rpm)

2099-BM06 and MPL-B960B

300

600

Speed (rpm)

900

1200

0

0

2213

1770

1328

885

442

0

0

Torque

(lb•in)

Page 21

Kinetix 7000 (400V class) Drives/MP-Series Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

0

2099-BM08 and MPL-B960C

442

885

1328

1770

2213

0

50

100

150

200

250

Speed (rpm)

0 15001000500 1250750250

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

0

50

100

150

200

442

885

1328

1770

2213

250

200

400

600

0 1000

800

2099-BM08 and MPL-B980B

300

2655

Torque

(N•m)

Torque

(lb•in)

0

0

50

100

150

200

442

885

1328

1770

2213

250

2099-BM08 and MPL-B980C

300

2655

Speed (rpm)

250

500

750

0 1250

1000

1500

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

0

50

100

150

200

442

885

1328

1770

2213

250

400

800

1200

0 2000

1600

2099-BM08 and MPL-B980D

300

2655

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Torque

(N•m)

Torque

(lb•in)

0

0

50

100

150

200

442

885

1328

1770

2213

250

2099-BM09 and MPL-B980E

300

2655

Speed (rpm)

500

1000

1500

0 2500

2000

3000

2099-BM08 and MPL-B960D

250

Torque

(N•m)

200

Kinetix 7000 Drive Systems

2213

Torque

(lb•in)

1770

150

100

1328

885

50

0

500

100001500

Speed (rpm)

442

0

2000

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 21

Page 22

Kinetix 7000 Drive Systems

Kinetix 7000 Drives with MP-Series Medium Inertia Motors

This section provides system combination information for the Kinetix 7000 (400V class) drives when matched with

MP-Series medium-inertia motors. Included are motor power/brake and feedback cable catalog numbers, system

performance specifications, and the optimum torque/speed curves.

Bulletin MPM Motor Cable Combinations

Motor Cat. No. (400V class) Motor Power/Brake Cable Motor Feedback Cable

MPM-B1651F, MPM-B1653C

MPM-B1651M, MPM-B1652E, MPM-B1652F, MPM-B1653E

MPM-B2152C, MPM-B2153B

MPM-B1653F

MPM-B2152F, MPM-B2152M, MPM-B2153E, MPM-B2153F,

MPM-B2154B, MPM-B2154E, MPM-B2154F

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) with flying-lead cables on the drive end. Refer to Required Drive Accessories on page 3.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 9.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to 2090-Series Motor/Actuator Cables Overview on page 9

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPxM7DF-14AAxx (standard, non-flex)

2090-CPxM7DF-14AFxx (continuous-flex)

2090-CPxM7DF-10AAxx (standard, non-flex)

2090-CPxM7DF-10AFxx (continuous-flex)

2090-CPxM7DF-08AAxx (standard, non-flex)

2090-CPxM7DF-08AFxx (continuous-flex)

, for standard cable lengths.

2090-CFBM7DF-CEAAxx or

2090-CFBM7DD-CEAAxx (standard, non-flex)

2090-CFBM7DF-CEAFxx or

2090-CFBM7DD-CEAFxx (continuous-flex)

Absolute High-resolution Feedback

(1)

.

22 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 23

Bulletin MPM Motor Performance Specifications with Kinetix 7000 (400V class) Drives

Kinetix 7000 Drive Systems

Rotary Motor

MPM-B1651M 4500 5000 22.46 11.3 (100) 56.8 21.4 (189) 2.50 2099-BM06-S

MPM-B1652E 2250 3500 20.94 21.1 (187) 60.5 48.0 (425) 4.30 2099-BM06-S

MPM-B1652F 3000 4500 28.74 21.1 (187) 84.1 45.0 (398) 4.30 2099-BM06-S

MPM-B1653C 1500 2500 20.05 26.7 (236) 59.2 67.7 (599) 4.60 2099-BM06-S

MPM-B1653E 2250 3500 27.0 26.8 (237) 72.9 62.0 (549) 5.10 2099-BM06-S

MPM-B1653F 3000 4000 34.94 31.0 (274) 94.3 56.1 (496) 5.10 2099-BM06-S

MPM-B2152C 1500 2500 27.40 36.7 (325) 55.4 72.2 (639) 5.60 2099-BM06-S

MPM-B2152F 3000 4500 43.54 34.1 (302)

MPM-B2152M 4500 5000 44.58 34.1 (302) 76.3 52.9 (468) 5.90 2099-BM06-S

MPM-B2153B 1250 2000 24.06 48.0 (425) 60.0 101 (895) 6.80 2099-BM06-S

MPM-B2153E 2250 3000 39.63 47.9 (424)

MPM-B2153F 3000 3800 43.86 45.6 (403)

MPM-B2154B 1250 2000 35.46 62.7 (555)

MPM-B2154E 2250 3000 43.68 55.9 (495)

MPM-B2154F 3000 3300 44.40 56.2 (497) 83.6 87.9 (778) 7.50 2099-BM06-S

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software, ve rsion 4.7 or later.

Speed,

base

rpm

Speed,

max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

96.0 70.8 (626)

98.0 72.2 (639) 2099-BM07-S

96.0 98.8 (468)

98.6 101 (895) 2099-BM07-S

96.0 96.6 (855)

98.4 98.9 (875) 2099-BM07-S

96.0 151 (1336)

98.0 154 (1363) 2099-BM07-S

96.0 110 (973)

98.3 112 (991) 2099-BM07-S

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

5.90

7.20

7.20

6.90

7.50

Kinetix 7000

400V-class Drives

2099-BM06-S

2099-BM06-S

2099-BM06-S

2099-BM06-S

2099-BM06-S

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 23

Page 24

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2099-BM06-S and MPM-B1651M

35.4

70.8

106

142

177

212

0

4.0

8.0

12.0

16.0

20.0

24.0

28.0

248

0

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

0

0

10

20

30

50

40

88.5

177

265

354

442

2099-BM06-S and MPM-B1652F

Speed (rpm)

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2099-BM06-S and MPM-B1653E

88.5

177

265

354

442

531

0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

619

0

4000

3000

1000

2000

0

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Kinetix 7000 (400V class) Drives/MP-Series Medium Inertia Motor Curves

50

Torque

(N•m)

40

2099-BM06-S and MPM-B1652E

442

354

Torque

(lb•in)

Torque

(N•m)

30

20

10

70.0

60.0

50.0

40.0

30.0

20.0

10.0

265

177

88.5

0

1500

3000

2000500

1000

0

Speed (rpm)

2099-BM06-S and MPM-B1653C

0

0

1000

2000

Speed (rpm)

2500

4000

3000

0

619

Torque

(lb•in)

531

442

354

265

177

88.5

0

Torque

(N•m)

24 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

70.0

60.0

50.0

40.0

30.0

20.0

10.0

2099-BM06-S and MPM-B1653F

0

1000

0

2000

Speed (rpm)

3000

4000

619

531

442

354

265

177

88.5

0

Torque

(lb•in)

Page 25

Kinetix 7000 (400V class) Drives/MP-Series Medium Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

0

0

20

40

60

100

80

177

354

531

708

885

2099-BM06-S and MPM-B2152C

Speed (rpm)

500

1000 1500 20000 2500

3000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2099-BM06-S and MPM-B2152M

88.5

177

265

354

442

531

0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

619

0

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

133

265

398

531

664

796

0

15

30

45

60

75

90

105

929

0

500

1000 1500 20000 2500

3000

2099-BM07-S and MPM-B2153E

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

2099-BM07-S and MPM-B2152F

100

Torque

(N•m)

80

Kinetix 7000 Drive Systems

885

Torque

(lb•in)

708

Torque

(N•m)

60

40

20

105

531

354

177

0

0

2099-BM06-S and MPM-B2153B

90

75

60

45

30

15

0

500

0

2000

Speed (rpm)

1000

Speed (rpm)

3000

40001000

1500

5000

2000

0

929

Torque

(lb•in)

796

664

531

398

265

133

0

2099-BM07-S and MPM-B2153F

100

Torque

(N•m)

80

60

40

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 25

20

0

1000

0

2000

Speed (rpm)

3000

4000

885

708

531

354

177

0

Torque

(lb•in)

Page 26

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

221

442

664

885

1106

1327

0

25

50

75

100

125

150

175

1549

0

2000

1500

500

1000

0

2099-BM07-S and MPM-B2154B

Torque

(N•m)

Torque

(lb•in)

0

0

20

40

60

100

80

177

354

531

708

885

2099-BM06-S and MPM-B2154F

Speed (rpm)

4000

3000

1000

2000

0

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Kinetix 7000 (400V class) Drives/MP-Series Medium Inertia Motor Curves (continued)

2099-BM07-S and MPM-B2154E

125

Torque

(N•m)

100

1106

885

Torque

(lb•in)

75

50

25

0

500

1000 1500 20000 2500

Speed (rpm)

664

442

221

0

3000

26 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 27

Kinetix 7000 Drive Systems

Kinetix 7000 Drives with RDD-Series Direct Drive Motors

This section provides system combination information for the Kinetix 7000 (400V class) drives when matched with

RDD-Series™ direct-drive motors. Included are motor power/brake and feedback cable catalog numbers, system

performance specifications, and the optimum torque/speed curves.

Bulletin RDB Motor Cable Combinations

Motor Cat. No. (400V class) Motor Power/Brake Cable Motor Feedback Cable

RDB-B2152C 2090-CPWM7DF-12AAxx (standard, non-flex)

RDB-B2153C, RDB-B29036

RDB-B29029, RDB-B41016, RDB-B41024

RDB-B29039, RDB-B41018, RDB-B41026, RDB-B41035 2090-CPBM7DF-06AAxx (standard, non-flex)

(1) Use low-profile feedback module (catalog number 2090-K7CK-KENDAT). Refer to Required Drive Accessories on page3.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 9.

Motor-end connector kits (drive end) are available for motor power/brake and feedback cables. Refer to 2090-Series Motor/Actuator Cables Overview on page 9

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPWM7DF-10AAxx (standard, non-flex)

2090-CPWM7DF-10AFxx (continuous-flex)

2090-CPWM7DF-08AAxx (standard, non-flex)

2090-CPWM7DF-08AFxx (continuous-flex)

, for standard cable lengths.

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM7DF-CDAFxx (continuous-flex)

Absolute High-resolution Feedback

.

(1)

Bulletin RDB Motor Performance Specifications with Kinetix 7000 (400V class) Drives

Speed,

Rotary Motor

RDB-B2152C 1500 2125 23.5 43.4 (384) 63.2 111 (982) 6.41 2099-BM06-S

RDB-B2153C 1500 2250 29.4 51.5 (456) 82.6 137 (1212) 5.87 2099-BM06-S

RDB-B29029 750 1200 36.2 97.5 (863)

RDB-B29036 375 750 26.0 140 (1239) 84.9 318 (2814) 5.49 2099-BM06-S

RDB-B29039 750 1000 52.7 122 (1080) 147 268 (2372) 4.41 2099-BM08-S

RDB-B41016 375 700 33.2 183 (1619) 95.5 339 (3000) 4.83 2099-BM06-S

RDB-B41018 625 700 51.3 183 (1619)

RDB-B41024 200 365 31.5 330 (2929) 95.5 690 (6107) 7.29 2099-BM06-S

RDB-B41026 375 600 52.0 308 (2726)

RDB-B41035 250 490 52.6 425 (3761)

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software, ve rsion 4.7 or later.

base

rpm

Speed,

max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

96.0 193 (1708)

111 214 (1894) 2099-BM07-S

113 299 (2646)

140 339 (3000) 2099-BM08-S

147 626 (5540)

218 688 (6089) 2099-BM09-S

147 897 (7939)

218 1050 (9293) 2099-BM09-S

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

4.05

4.83

7.29

8.69

Kinetix 7000

(400V class) Drives

2099-BM06-S

2099-BM07-S

2099-BM08-S

2099-BM08-S

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 27

Page 28

Kinetix 7000 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

25

50

75

125

100

221

442

664

885

1106

2099-BM06-S and RDB-B2152C

Speed (rpm)

0

1000

2000

1500500

2500

Torque

(N•m)

Torque

(lb•in)

0

0

50

100

150

250

200

442

885

1327

1770

2212

2099-BM07-S and RDB-B29029

Speed (rpm)

250

500 750 10000 1250

1500

Torque

(N•m)

Torque

(lb•in)

0

0

60

120

180

300

240

531

1062

1593

2124

2655

2099-BM08-S and RDB-B29039

Speed (rpm)

0

400

800

600200

1000

Peak curve represents

480V and 400V inputs

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

Kinetix 7000 (400V class) Drives with RDD-Series Direct Drive Motor Curves

140

Torque

(N•m)

120

2099-BM06-S and RDB-2153C

1239

1062

Torque

(lb•in)

Torque

(N•m)

100

350

300

250

200

150

100

885

80

60

40

20

0

0

2099-BM06-S and RDB-B29036

50

1500500

1000

Speed (rpm)

2000

2500

70

531

354

177

0

3098

2655

2212

1770

1327

885

442

8

Torque

(lb•in)

1000

1000

0

3098

2655

2212

1770

1327

885

442

0

Torque

(lb•in)

0

0

2099-BM06-S and RDB-B41016

350

Torque

(N•m)

300

250

200

150

100

50

0

0

600200

400

Speed (rpm)

600200

400

Speed (rpm)

800

800

28 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 29

Kinetix 7000 (400V class) Drives with RDD-Series Direct Drive Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

442

885

1327

1770

2212

2655

0

50

100

150

200

250

300

350

3098

0

0

400

800

600200

1000

2099-BM08-S and RDB-B41018

Torque

(N•m)

Torque

(lb•in)

0

0

150

300

450

750

600

1327

2655

39

83

5310

6638

2099-BM09-S and RDB-B41026

Speed (rpm)

100

200 300 4000 500

600

Torque

(N•m)

Torque

(lb•in)

0

0

250

500

750

1250

1000

2212

4425

6638

8851

11,063

2099-BM09-S and RDB-B41035

Speed (rpm)

0

200

400

300100

500

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC (rms) input voltage

2099-BM06-S and RDB-B41024

750

Torque

(N•m)

600

Kinetix 7000 Drive Systems

6638

Torque

(lb•in)

5310

450

300

150

3983

2655

1327

0

0

300100

200

Speed (rpm)

400

0

500

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 29

Page 30

Kinetix 7000 Drive Systems

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

Kinetix Motion Control Selection Guide, publication GMC-SG001

Kinetix Rotary Motion Specifications, publication GMC-TD001

Kinetix Linear Motion Specifications, publication GMC-TD002

Kinetix Servo Drives Specifications, publication GMC-TD003

Kinetix Motion Accessories Specifications, publication GMC-TD004

Kinetix 6000 and Kinetix 6200/6500 Drive Systems Design Guide,

publication GMC-RM003

Kinetix 300/350 Drive Systems Design Guide, publication GMC-RM004

Kinetix 3 Drive Systems Design Guide, publication GMC-RM005

Kinetix 2000 Drive Systems Design Guide, publication GMC-RM006

Ultra™ 3000 Drive Systems Design Guide, publication GMC-RM008

Kinetix 6200 and Kinetix 6500 Safe Speed Monitoring Servo Drives Safety

Reference Manual, publication 2094-RM001

Kinetix 6200 and Kinetix 6500 Safe Torque-off Servo Drives Safety

Reference Manual, publication 2094-RM002

Kinetix Safe-off Feature Safety Reference Manual,

publication GMC-RM002

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

EMC Noise Management DVD, publication GMC-SP004

ControlLogix Selection Guide, publication 1756-SG001

CompactLogix Selection Guide, publication 1769-SG001

Integrated Architecture Recommended Literature Reference Manual,

publication IASIMP-RM001

Industrial Ethernet Media Brochure, publication 1585-BR001

Motion Analyzer software download from

http://www.ab.com/motion/software/analyzer.html

Rockwell Automation Configuration and Selection Tools,

website http://w ww.ab.com

Overview of Kinetix servo drives, motors, actuators, and motion accessories designed to help make

initial decisions for the motion control products best suited for your system requirements.

Product specifications for MP-Series (Bulletin MPL, MPM, MPF, MPS), TL-Series™, RDD-Series, and

HPK-Series rotary motors.

Product specifications for Bulletin MPAS and MPMA linear stages, Bulletin MPAR, MPAI, and TLAR

electric cylinders, and LDC-Series™ and LDL-Series™ linear motors.

Product specifications for Kinetix Integrated Motion over the EtherNet/IP network, Integrated Motion

over SERCOS interface, EtherNet/IP networking, and component servo drive families.

Product specifications for Bulletin 2090 motor and interface cables, low-profile connector kits, drive

power components, and other servo drive accessory items.

System design guide to determine and select the required (drive specific) drive module, power

accessory, connector kit, motor cable, and interface cable catalog numbers for your drive and motor/

actuator motion control system. Included are system performance specifications and torque/speed

curves (rotary motion) and force/velocity curves (linear motion) for your motion application.

Information on wiring, configuring, and troubleshooting the safe-speed features of your Kinetix 6200

and Kinetix 6500 drives.

Information on wiring, configuring, and troubleshooting the safe torque-off features of your

Kinetix 6200 and Kinetix 6500 drives.

Information on wiring and troubleshooting your Kinetix 6000 and Kinetix 7000 servo drives with the

safe-off feature.

Information, examples, and techniques designed to minimize system failures caused by electrical noise.

Information to determine which ControlLogix controller fits your application and the product

specifications to help design a ControlLogix system and select the appropriate components.

Information to determine which CompactLogix™ controller fits your application and the product

specifications to help design a CompactLogix system and select the appropriate components.

This document provides lists of technical publications for Integrated Architecture™ products. These lists

are not all-inclusive, but they do include the most-commonly accessed publications for the related

products.

Information to determine which Bulletin 1585 Ethernet cable fits your application and the product

specifications to help select the appropriate components.

Comprehensive motion application sizing tool used for analysis, optimization, selection, and validation

of your Kinetix Motion Control system.

Online product selection and system configuration tools, including AutoCad (DXF) drawings.

You can view or download publications at http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

30 Rockwell Automation Publication GMC-RM007A-EN-P - September 2011

Page 31

Notes:

Kinetix 7000 Drive Systems

Rockwell Automation Publication GMC-RM007A-EN-P - September 2011 31

Page 32

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Important Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this publication are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

available from

) describes some

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication

Allen-Bradley, CompactLogix, ControlLogix, Encompass, HPK-Series, Integrated Architecture, Kinetix, LDC-Series, LDL-Series, LISTEN. THINK. SOLVE., MP-Series, RDD-Series, RSLogix, TL-Series,

Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belong ing to Rockwell Automation are property of their respective companies.

RA-DU002, available at http://www.rockwellautomation.com/literature/.

Publication GMC-RM007A-EN-P - September 2011

Supersedes Publication GMC-SG001Q-EN-P - April 2011 Copyright © 2011 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...