Page 1

Ultra5000 Intelligent

Positioning Drives

(Catalog Numbers

2098-IPD-005, -005-DN

2098-IPD-010, -010-DN

2098-IPD-020, -020-DN

2098-IPD-030, -030-DN, -HV030, -HV030-DN

2098-IPD-HV050, -HV050-DN

2098-IPD-075, -075-DN,

2098-IPD-HV100, -HV100-DN

2098-IPD-150, -150-DN, -HV150, -HV150-DN

2098-IPD-HV220, -HV220-DN

Installation Manual

Page 2

Important User Information

ATTENTION

!

IMPORTANT

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary

steps have been taken to assure that each application and use

meets all performance and safety requirements, including any

applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with

®

any particular installation, Allen-Bradley

responsibility or liability (to include intellectual property liability)

for actual use based upon the examples shown in this

publication.

does not assume

Allen-Bradley publication SGI-1.1

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into

consideration when applying products such as those described

in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of

safety considerations:

Identifies information about practices or

circumstances that can lead to personal injury

or death, property damage or economic loss.

, Safety Guidelines for the

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for

successful application and understanding of the

product.

Allen-Bradley is a registered trademark of Rockwell Automation.

ControlLogix, RSLogix 5000, Ultra5000, and Ultraware are trademarks of Rockwell Automation.

CSA is a registered trademark of Canadian Standards Association.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

UL and C-UL are registered trademarks of Underwriters Laboratories, Inc.

Page 3

Table of Contents

Preface Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . P-4

Product Receiving and Storage Responsibility . . . . . . . . . . . P-4

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-5

Comments Regarding this Manual . . . . . . . . . . . . . . . . . P-5

Chapter 1

Installing Your Ultra5000

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Complying with European Union Directives . . . . . . . . . 1-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Before Mounting Your System . . . . . . . . . . . . . . . . . . . . . . 1-3

How to Store Your Ultra5000 Before Installation . . . . . . 1-3

How to Unpack the System. . . . . . . . . . . . . . . . . . . . . . 1-4

Minimum Mounting Requirements. . . . . . . . . . . . . . . . . 1-5

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . 1-6

Sizing an Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Transformer Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Calculating Transformer Size Based on Speed/Torque

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Fuse Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Bonding Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Bonding Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Bonding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . 1-11

Mounting Your Ultra5000 Drive . . . . . . . . . . . . . . . . . . . . 1-12

Chapter 2

Ultra5000 Connector

Information

i Publication 2098-IN001E-EN-P — April 2002

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Understanding Ultra5000 Controller Functions. . . . . . . . . . . 2-2

Ultra5000 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . 2-2

Understanding Ultra5000 Connectors . . . . . . . . . . . . . . . . . 2-3

230V Ultra5000 Front Panel Connections . . . . . . . . . . . . 2-4

500W, 1 kW, and 2 kW Ultra5000

(2098-IPD-005, -010, and -020). . . . . . . . . . . . . . . . . 2-4

I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Motor Encoder Connector . . . . . . . . . . . . . . . . . . . . 2-6

Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . . 2-7

Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3 kW Ultra5000

(2098-IPD-030) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page 4

ii Table of Contents

7.5 kW, and 15 kW Ultra5000

(2098-IPD-075, and -150) . . . . . . . . . . . . . . . . . . . . 2-10

I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-11

Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-11

Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

230V Ultra5000 with DeviceNet Front Panel Connections . . .

2-13

500W, 1 kW, and 2 kW Ultra5000 with DeviceNet

(2098-IPD-005-DN, -010-DN, and -020-DN). . . . . . . 2-13

I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-14

Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-14

DeviceNet Connector. . . . . . . . . . . . . . . . . . . . . . . 2-14

3 kW, 7.5 kW, and 15 kW Ultra5000

(2098-IPD-005-DN, -010-DN, and -020-DN). . . . . . . 2-15

460V Ultra5000 Front Panel Connections . . . . . . . . . . . 2-16

I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-17

Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-17

Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Understanding Ultra5000 I/O Specifications. . . . . . . . . . . . 2-19

Digital I/O Power Supply . . . . . . . . . . . . . . . . . . . . . . 2-19

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Understanding Motor Encoder Feedback Specifications . . . 2-25

AM, BM, and IM Inputs . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Hall Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Thermostat Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

+ Limit and - Limit Inputs . . . . . . . . . . . . . . . . . . . . . . 2-28

Encoder Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Motor Encoder Connection Diagram . . . . . . . . . . . . . . 2-31

Unbuffered Motor Encoder Outputs . . . . . . . . . . . . . . 2-31

Buffered Motor Encoder Outputs . . . . . . . . . . . . . . . . 2-31

Understanding Auxiliary Encoder Feedback Specifications . 2-32

Auxiliary Encoder Interface . . . . . . . . . . . . . . . . . . . . . 2-32

Understanding the Serial Interface. . . . . . . . . . . . . . . . . . . 2-34

Default Serial Interface Settings . . . . . . . . . . . . . . . . . . 2-34

Publication 2098-IN001E-EN-P — April 2002

Page 5

Connecting Your Ultra5000

Table of Contents iii

Chapter 3

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering the Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Accessing the Internal Digital I/O Power Supply . . . . . . 3-2

Understanding Basic Wiring Requirements . . . . . . . . . . . . . 3-4

Building Your Own Cables . . . . . . . . . . . . . . . . . . . . . . 3-4

Routing High and Low Voltage Cables. . . . . . . . . . . . . . 3-5

Grounding Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Grounding Your System to the Subpanel . . . . . . . . . . . . 3-6

Grounding Multiple Subpanels . . . . . . . . . . . . . . . . . . . 3-7

Motor Power Cable Shield Termination . . . . . . . . . . . . . 3-7

Wiring Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting Interface Cables . . . . . . . . . . . . . . . . . . . . . 3-9

Wiring I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting to a DeviceNet Network . . . . . . . . . . . . . . 3-10

Connecting Your DeviceNet Cable . . . . . . . . . . . . . . . 3-11

Assigning Your Ultra5000 DeviceNet Address . . . . . . . 3-12

Wiring Power Connections . . . . . . . . . . . . . . . . . . . . 3-14

Commissioning Your Ultra5000

Maintaining Your Ultra5000

Chapter 4

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Startup Precautions . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Understanding Communication Switch Settings . . . . . . . . . . 4-2

Applying Power To Your System . . . . . . . . . . . . . . . . . . . . 4-3

Configuring Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintaining the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Cleaning the Drive . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Inspecting the Cables . . . . . . . . . . . . . . . . . . . . . . . 5-2

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Troubleshooting for DeviceNet Drives . . . . . . . . . . . . . . . . 5-6

DeviceNet Module Status LED. . . . . . . . . . . . . . . . . . . . 5-6

DeviceNet Network Status LED . . . . . . . . . . . . . . . . . . . 5-7

Node Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Device Failure - LED Status Check. . . . . . . . . . . . . . . . . 5-8

Scanner Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Cable Installation and Design Problems. . . . . . . . . . . . 5-10

Adjusting the Physical Network Configuration . . . . . . . 5-10

Publication 2098-IN001E-EN-P — April 2002

Page 6

iv Table of Contents

Specifications and

Dimensions

Appendix A

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Ultra5000 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

General Power Specifications . . . . . . . . . . . . . . . . . . . . A-1

2098-IPD-005-xx, -010-xx, and -020-xx . . . . . . . . . . . A-1

2098-IPD-030-xx, -075-xx, and -150-xx . . . . . . . . . . . A-2

2098-IPD-HV030-xx, -HV050-xx, -HV100-xx, -HV150-xx,

and -HV220-xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Physical and Environmental. . . . . . . . . . . . . . . . . . . . . . A-4

Power Dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

User Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Motor Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Auxiliary Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Interconnect Diagrams

Appendix B

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Ultra5000 and Motor Cable Diagrams . . . . . . . . . . . . . . . . . B-1

Ultra5000 Drive and Motor Cable Combinations . . . . . . . B-1

Ultra5000 to Motor Interconnect Diagrams . . . . . . . . . . . B-3

Ultra5000 Power Wiring Diagrams . . . . . . . . . . . . . . . . . . B-15

Using an Emergency Stop Contactor . . . . . . . . . . . . . . . . . B-20

Grounding for Ultra5000 CE Requirements . . . . . . . . . . . . B-22

Ultra5000 Shunt Module Information. . . . . . . . . . . . . . . . . B-23

300 Watt Active Shunt Module. . . . . . . . . . . . . . . . . . . B-23

200 Watt Passive Shunt Module . . . . . . . . . . . . . . . . . . B-23

900 Watt Passive Shunt Module . . . . . . . . . . . . . . . . . . B-24

2090 Passive Shunt Module . . . . . . . . . . . . . . . . . . . . . B-24

Publication 2098-IN001E-EN-P — April 2002

Page 7

Catalog Numbers and

Accessories

Wiring Three Phase Power to a

Single Phase Ultra5000

Table of Contents v

Appendix C

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Ultra5000 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Ultraware Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

External Shunt Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

300 Watt Active Shunt Ferrites. . . . . . . . . . . . . . . . . . . . C-5

2090 Series Passive Shunts . . . . . . . . . . . . . . . . . . . . . . C-5

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Motor Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Motor Feedback Cables . . . . . . . . . . . . . . . . . . . . . . . . C-7

MP-Series Motor Brake Cable . . . . . . . . . . . . . . . . . . . . C-8

Ultra5000 Interface Cables. . . . . . . . . . . . . . . . . . . . . . . C-8

Break Out Boards, Cables, and Kits . . . . . . . . . . . . . . . . . . C-8

Mating Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Appendix D

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Applicable Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Mandatory Neutral Connection of Isolation Transformer . . . D-2

Adding a Safety Ground to the Isolation Transformer. . . D-3

Three Phase Line Filtering Requirements for EMC . . . . . . . . D-3

Voiding of CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Publication 2098-IN001E-EN-P — April 2002

Page 8

vi Table of Contents

Publication 2098-IN001E-EN-P — April 2002

Page 9

Preface

Introduction

Who Should Use this Manual

Read this preface to familiarize yourself with the rest of the manual.

This preface contains the following topics:

Who Should Use this Manual

•

• Purpose of this Manual

• Contents of this Manual

• Related Documentation

• Conventions Used in this Manual

• Product Receiving and Storage Responsibility

• Allen-Bradley Support

Use this manual for designing, installing, programming, and

troubleshooting the Ultra5000™ Intelligent Positioning Drive (IPD). If

you do not have a basic understanding of the Ultra5000, contact your

local Allen-Bradley representative for information on available training

courses before using this product.

Purpose of this Manual

1 Publication 2098-IN001E-EN-P — April 2002

This manual describes the function and installation of the Ultra5000

products and standard Rockwell Automation/Allen-Bradley motors

recommended for use with the Ultra5000. The manual is intended for

engineers or technicians directly involved in the installation,

operation, and field maintenance of the Ultra5000.

Page 10

P-2 Preface

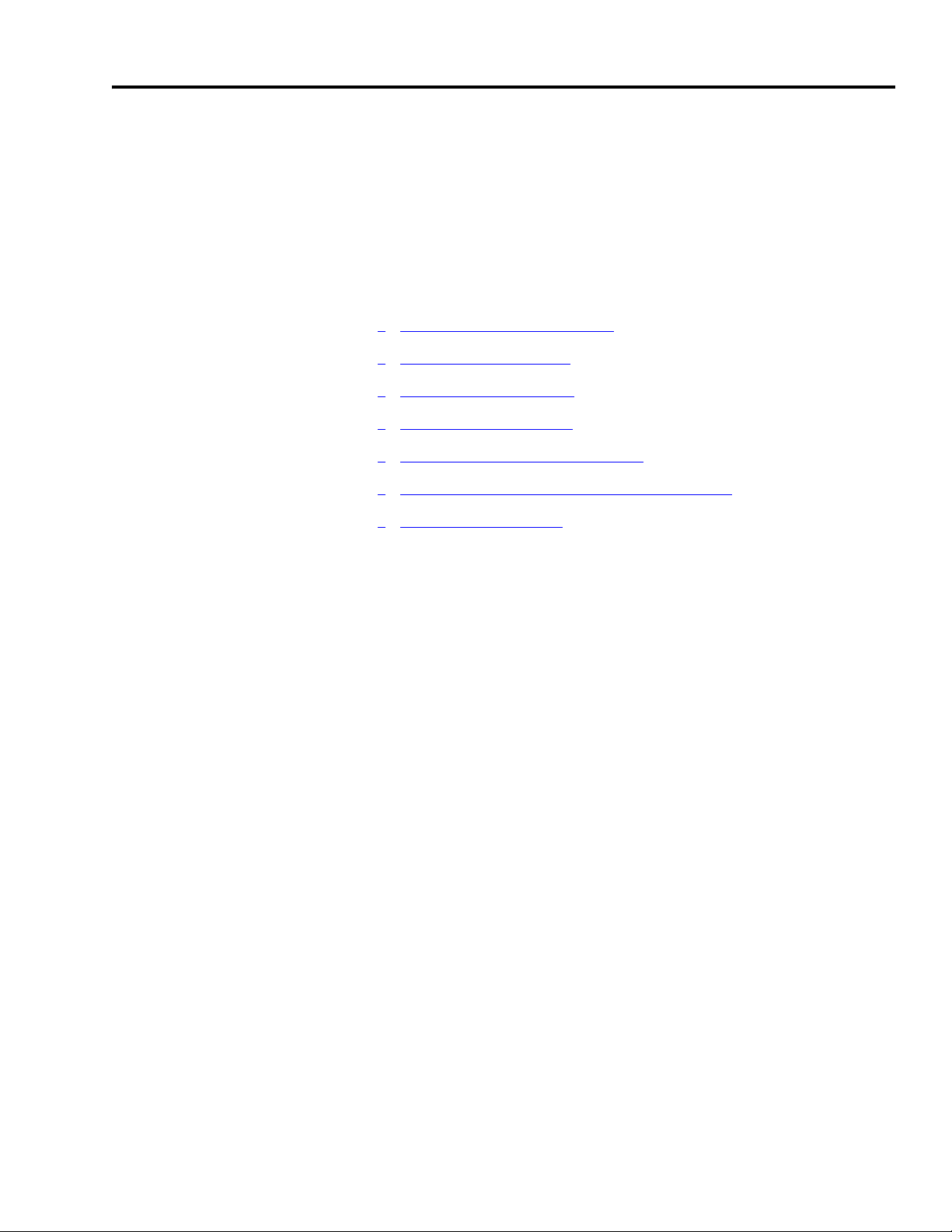

Contents of this Manual

Refer to the following listing for the descriptive contents of this

installation manual.

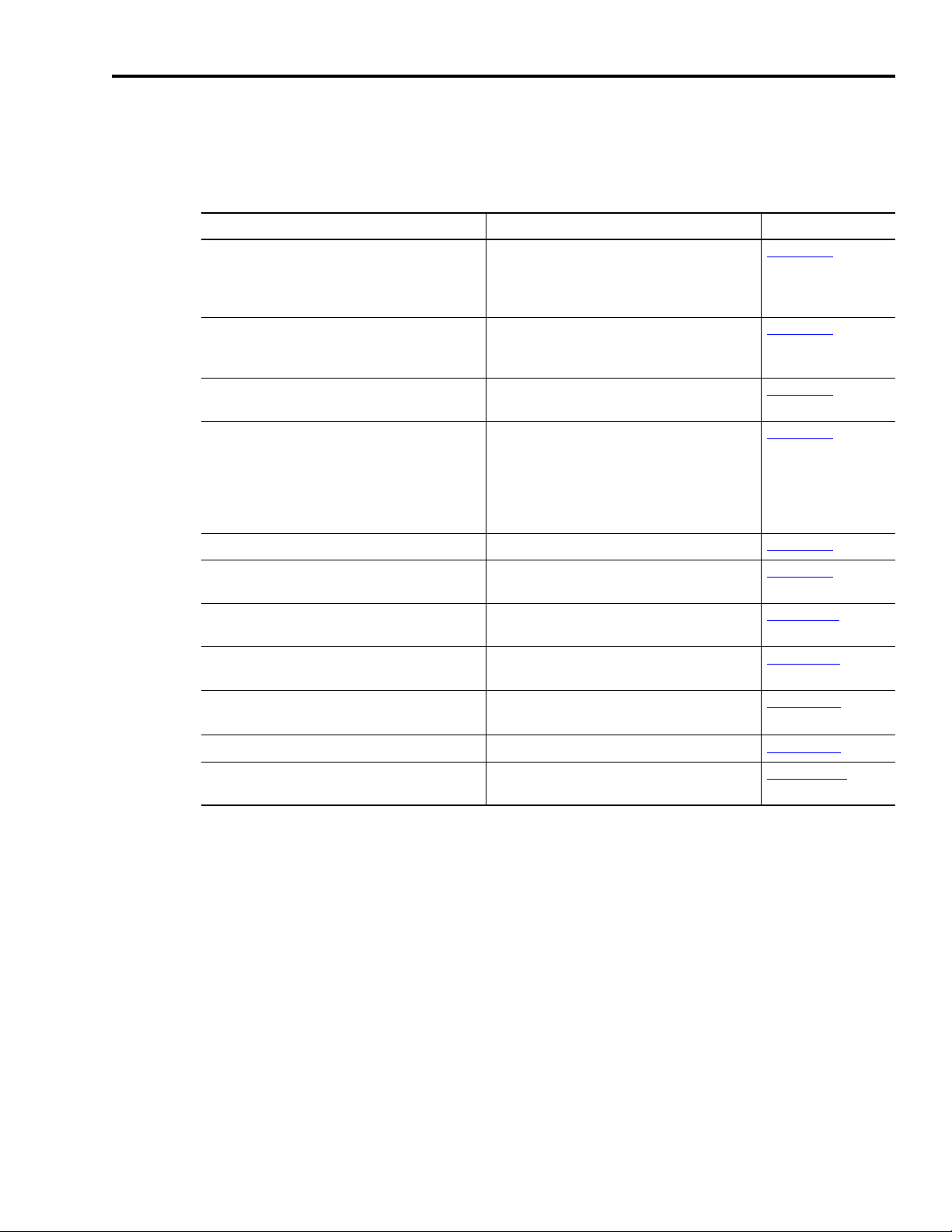

Chapter Title Contents

Preface Describes the purpose, background, and

scope of this manual. Also specifies the

audience for whom this manual is intended.

1 Installing Your Ultra5000 Provides mounting information for the

Ultra5000.

2 Ultra5000 Connector

Information

3 Connecting Your Ultra5000 Provides steps to follow when applying

4 Commissioning Your

Ultra5000

5 Maintaining Your Ultra5000

Appendix A Specifications and

Dimensions

Appendix B Interconnect Diagrams Provides interconnect diagrams for the

Provides connection and wiring information

for the Ultra5000.

power to the Ultra5000 for the first time.

Powering-up and configuring the Ultra5000

drive.

Provides diagnostic aids that help isolate

problems with a drive.

Provides physical, electrical, environmental,

and functional specifications for the

Ultra5000.

Ultra5000.

Appendix C Catalog Numbers and

Accessories

Appendix D Wiring Three Phase Power

to a Single Phase Ultra5000

Provides catalog numbers and descriptions

of the Ultra5000 and related products.

Discusses star (Y) connection of single

phase Ultra5000 drives to a three phase

power source.

Publication 2098-IN001E-EN-P — April 2002

Page 11

Preface P-3

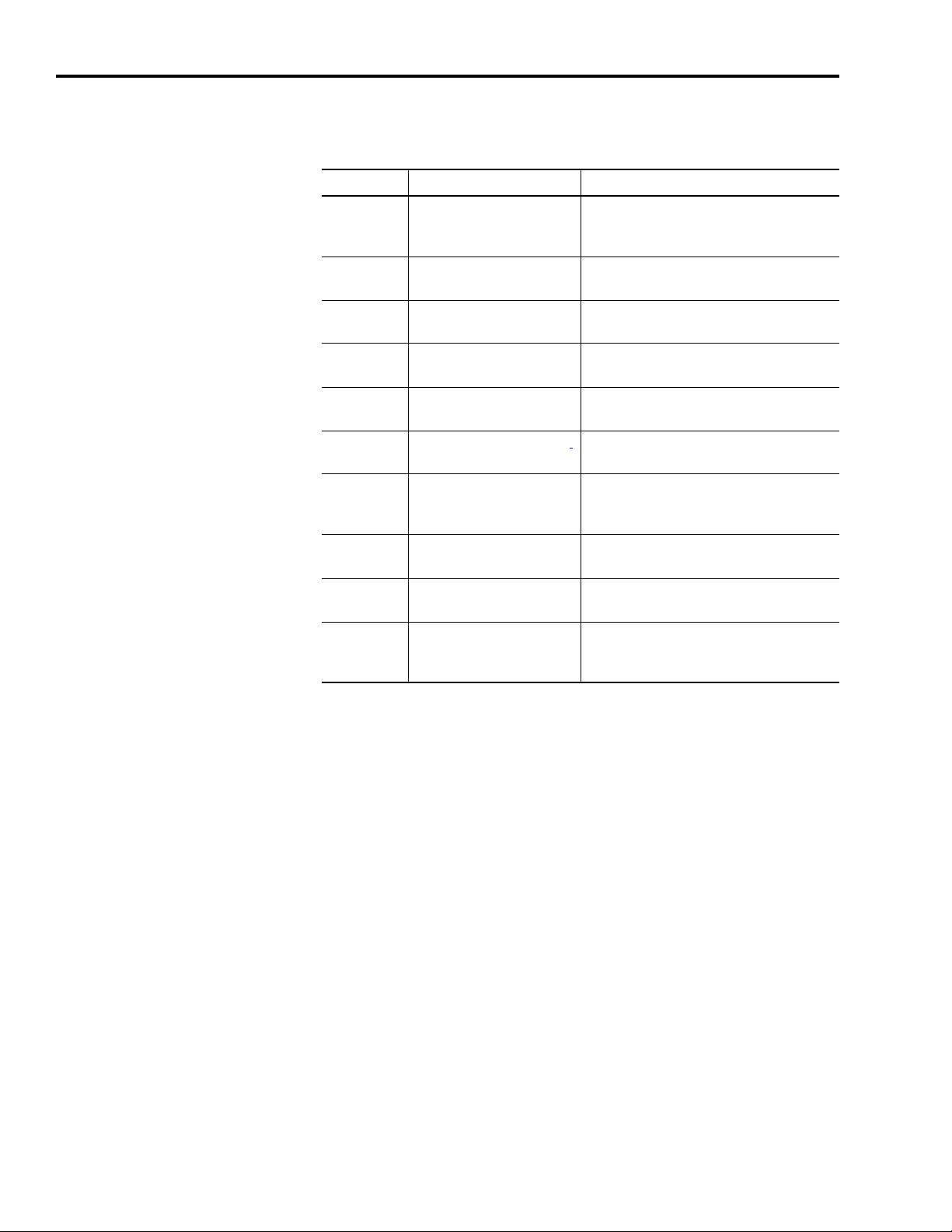

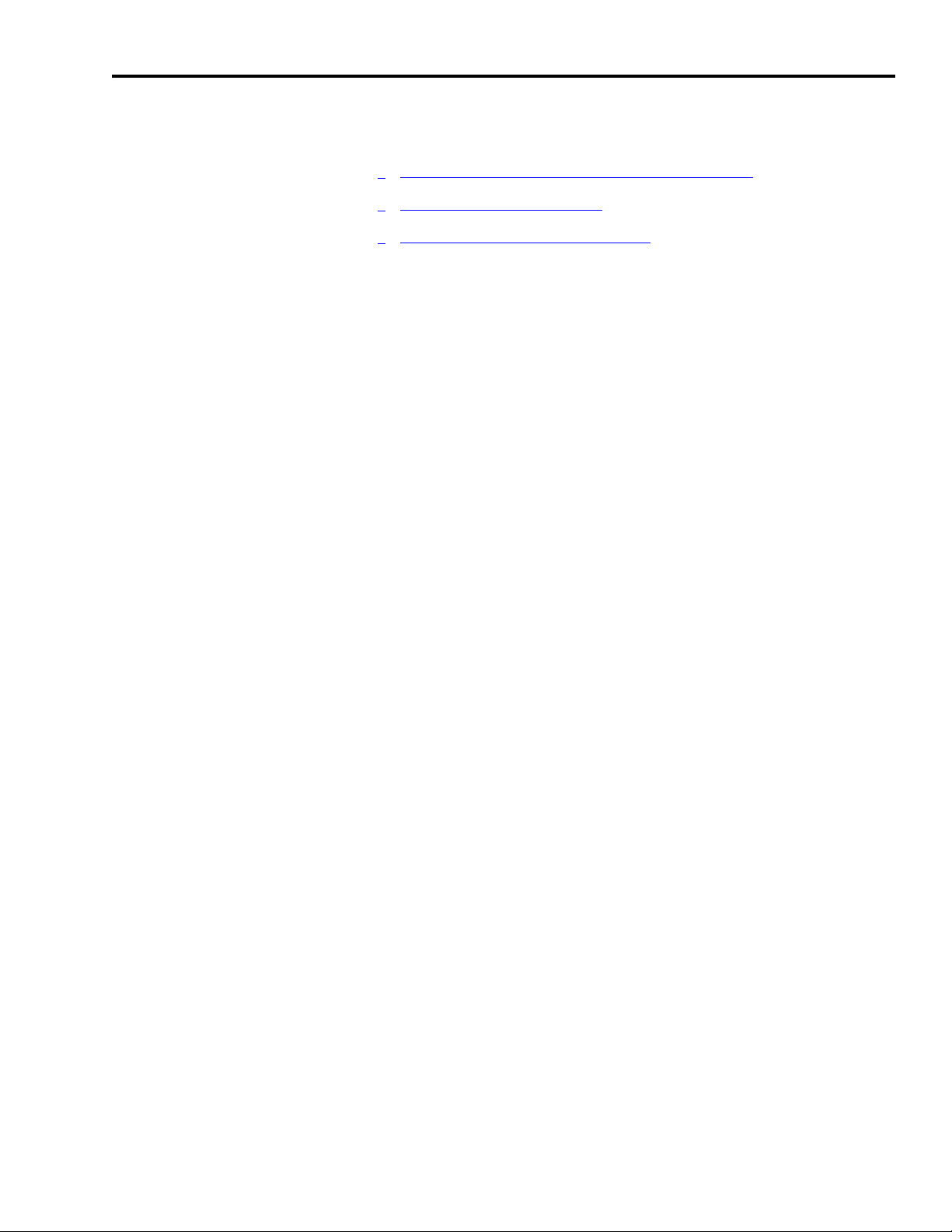

Related Documentation

For: Read This Document: Catalog Number:

Active shunt installation instructions for:

• 2098-IPD-005, -005-DN

• 2098-IPD-010, -010-DN

• 2098-IPD-020, -020-DN

Passive shunt installation instructions for:

• 2098-IPD-075, -075-DN

• 2098-IPD-150, -150-DN

Passive shunt installation instructions for:

• 2098-IPD-030, -030-DN

Passive shunt installation instructions for:

• 2098-IPD-HV030, -HV030-DN

• 2098-IPD-HV050, -HV050-DN

• 2098-IPD-HV100, -HV100-DN

• 2098-IPD-HV150, -HV150-DN

• 2098-IPD-HV220, -HV220-DN

Ultraware™ installation instructions Ultraware CD Installation Instructions 2098-IN002

The following documents contain additional information concerning

related Allen-Bradley products. To obtain a copy, contact your local

Rockwell Automation office or distributor, or access the documents

on-line at

www.theautomationbookstore.com

www.ab.com/manuals/gmc

300 Watt Active Shunt Regulator Installation

Instructions

900 Watt Passive Shunt Module Installation

Instructions

200 Watt Passive Shunt Module Installation

Instructions

2090 Series Passive Shunts Installation

Instructions

.

or

2090-IN001

2090-IN002

2090-IN003

2090-IN004

Information on how to add a DeviceNet™

Expansion Kit to a Ultra5000 drive

Information on programming the Ultra5000 using

the Motion Library

Information on communicating with the

Ultra5000 using DeviceNet

Information on configuring your Ultra5000 using

Ultraware

How to minimize and control system-level noise System Design for Control of Electrical Noise GMC-RM001

Information on attaching Ultra5000 drives to a

DeviceNet network

Ultra5000 DeviceNet Expansion Kit Installation

Instructions

Ultra5000 Motion Library C Programming

Manual

Ultra5000 DeviceNet Reference Manual 2098-RM002

Ultraware User Manual

DeviceNet Cable System Planning and

Installation Manual

2098-IN004

2098-PM001

2098-UM001

DNET-UM072

A copy of the DeviceNet Specification, Volumes I and II, Release 2.0

may be ordered from the web site http://www.odva.org of the Open

Device Vendor Association.

Publication 2098-IN001E-EN-P — April 2002

Page 12

P-4 Preface

Conventions Used in this Manual

Product Receiving and Storage Responsibility

The following conventions are used throughout this manual.

• Bulleted lists such as this one provide information, not procedural

steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Words that you type or select appear in bold.

• When we refer you to another location, the section or chapter

name appears in italics.

You, the customer, are responsible for thoroughly inspecting the

equipment before accepting the shipment from the freight company.

Check the item(s) you receive against your purchase order. If any

items are obviously damaged, it is your responsibility to refuse

delivery until the freight agent has noted the damage on the freight

bill. Should you discover any concealed damage during unpacking,

you are responsible for notifying the freight agent. Leave the shipping

container intact and request that the freight agent make a visual

inspection of the equipment.

Store the product in its shipping container prior to installation. If you

are not going to use the equipment for a period of time, store using

the following guidelines.

• Use a clean, dry location

• Maintain an ambient temperature range of -40 to 70° C

(-40 to 158° F)

• Maintain a relative humidity range of 5% to 95%, non-condensing

• Store it where it cannot be exposed to a corrosive atmosphere

• Store it in a non-construction area

Publication 2098-IN001E-EN-P — April 2002

Page 13

Preface P-5

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• Sales and order support

• Product technical training

• Warranty support

• Support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the chapter

call your local Allen-Bradley representative. For the quickest possible

response, please have the catalog numbers of your products available

when you call.

Maintaining Your Ultra5000 first, then

Comments Regarding this Manual

To offer comments regarding the contents of this manual, go to

www.ab.com/manuals/gmc and download the Motion Control

Problem Report form. Mail or fax your comments to the address/fax

number given on the form.

Publication 2098-IN001E-EN-P — April 2002

Page 14

P-6 Preface

Publication 2098-IN001E-EN-P — April 2002

Page 15

Installing Your Ultra5000

ATTENTION

!

Chapter

1

Chapter Objectives

This chapter provides system installation guidelines and procedures

for mounting your Ultra5000. This chapter covers the following topics:

• Complying with European Union Directives

• Before Mounting Your System

Bonding Your System

•

• Mounting Your Ultra5000 Drive

The following information is a guideline for proper

installation. The National Electrical Code and any

other governing regional or local codes overrule this

information. The Allen-Bradley Company cannot

assume responsibility for the compliance or the

noncompliance with any code, national, local or

otherwise, for the proper installation of this system

or associated equipment. If you ignore codes during

installation, the hazard of personal injury and/or

equipment damage exists.

Complying with European Union Directives

If this product is installed within the European Union or EEC regions

and has the CE mark, the following regulations apply.

Note: Declarations of Conformity (DOCs) to EU Directives are

available on-line at www.ab.com/certification for Motion

Control products. The web site is the authoritative source for

verifying compliance and suitability for use of this and other

Rockwell Automation/Allen-Bradley products.

The web site also provides links to other certification agencies

(UL, CSA, etc.).

1 Publication 2098-IN001E-EN-P — April 2002

Page 16

1-2 Installing Your Ultra5000

EMC Directive

This unit is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) using a technical construction

file and the following standards, in whole or in part:

• EN 50081-2 EMC - Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2 EMC - Immunity Standard, Part 2 - Industrial

Environment

• EN 61800-3 - Adjustable Speed Electrical Power Drive Systems,

Part 3 - EMC Product Standard including specific test methods

The product described in this manual is intended for use in an

industrial environment.

To meet CE requirements, the following additions are required:

• Install a power line filter between the AC power source and the

drive input, as close to the drive as possible. (Refer to

Filters on page C-3.)

AC Line

• Terminate the motor power cable shield to the chassis clamp

provided.

• To meet CE requirements, the following additions may also be

required:

– Run single-phase input wiring in conduit that is grounded to

the enclosure.

– Terminate the shields of the motor power cables and the

motor feedback cables to the enclosure at the point of entry.

Low Voltage Directive

These units are tested to meet Council Directive 73/23/EEC Low

Voltage Directive. The EN 60204-1 Safety of Machinery-Electrical

Equipment of Machines, Part 1-Specification for General Requirements

standard applies in whole or in part. Additionally, the standard

EN 50178 Electronic Equipment for use in Power Installations applies

in whole or in part.

Refer to Appendix

B for interconnect information.

Publication 2098-IN001E-EN-P — April 2002

Page 17

Installing Your Ultra5000 1-3

Before Mounting Your System

Before you mount your Ultra5000 system make sure you understand

the following:

How to Store Your Ultra5000 Before Installation

•

• How to Unpack the System

• Minimum Mounting Requirements

How to Store Your Ultra5000 Before Installation

The Ultra5000 should remain in the shipping container prior to

installation. If the equipment is not to be used for a period of time,

store it as follows:

• Use a clean, dry location

• Maintain an ambient temperature range of -40 to 70° C

(-40 to 158° F)

• Maintain a relative humidity range of 5% to 95%, non-condensing

• Store it where it cannot be exposed to a corrosive atmosphere

• Store it in a non-construction area

Publication 2098-IN001E-EN-P — April 2002

Page 18

1-4 Installing Your Ultra5000

IMPORTANT

How to Unpack the System

Each Ultra5000 ships with the following:

• One Ultra5000 drive

• One installation manual, publication 2098-IN001

• Two I/O connector plugs (28 pin CN1A and 14 pin CN1B)

• One screwdriver

• One clear plastic terminal strip cover

Do not discard the clear plastic terminal strip cover.

Installing the plastic strip on the power terminal strip

provides a physical barrier and protection.

Ultra5000 drives with DeviceNet (2098-IPD-xxx-DN and -HVxxx-DN

only) ship with the following additional items:

• One reference manual, publication 2098-RM002

, for Ultra5000

drives with DeviceNet

• One DeviceNet connector plug for Ultra5000 drives with DeviceNet

Remove all packing material, wedges, and braces from within and

around the components. After unpacking, check the item(s) name

plate catalog number against the purchase order.

Publication 2098-IN001E-EN-P — April 2002

Page 19

Installing Your Ultra5000 1-5

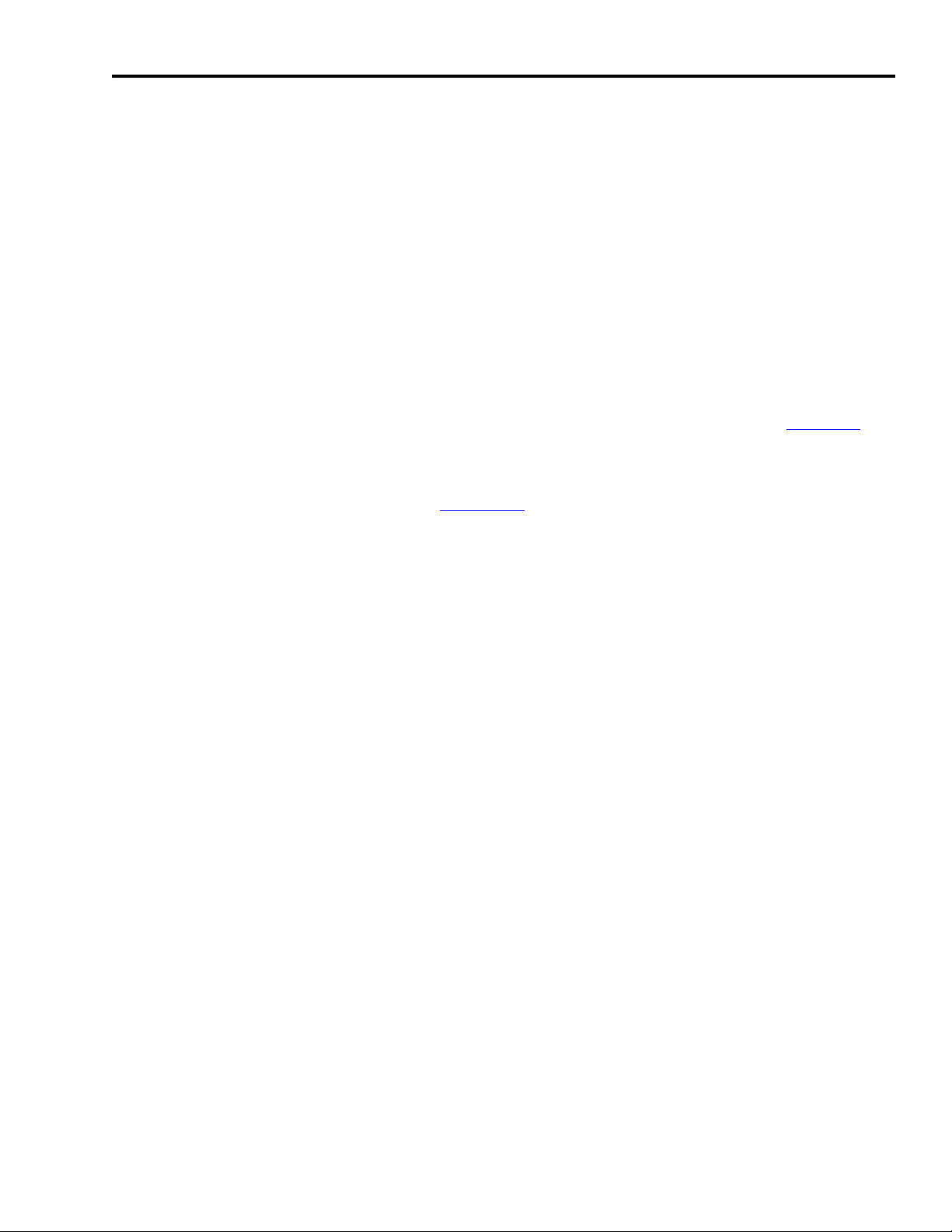

Minimum Mounting Requirements

There are several things that you need to take into account when

preparing to mount the Ultra5000:

• The Ultra5000 is classified as IEC controlgear, and must be housed

in an enclosure that meets IEC60529 requirements for electrical

enclosure of controlgear.

• The ambient temperature of the location in which you will install

the Ultra5000 must not exceed 55° C (131° F).

• You must install the enclosure on a flat, rigid, vertical surface that

will not be subjected to shock, vibration, moisture, oil mist, dust, or

corrosive vapors.

• You need to maintain minimum clearances (refer to Figure 1.1

within the enclosure for proper airflow, easy module access, and

proper cable bend radius.

Refer to Appendix

A for mounting dimensions, power dissipation, and

environmental specifications for the Ultra5000.

)

Publication 2098-IN001E-EN-P — April 2002

Page 20

1-6 Installing Your Ultra5000

50.8 mm (2.0 in.) clearance

for airflow and installation

50.8 mm (2.0 in.) clearance

for airflow and installation

Allow 12.7 mm (0.5 in.)

side clearance

Allow 12.7 mm (0.5 in.)

side clearance

Motor cable entry area for ground

clamp

Minimum cabinet depth = 243.8 mm (9.6 in.)

Minimum front clearance = 76.2 mm (3.0 in.)

IMPORTANT

Ventilation Requirements

This section provides information to assist you in sizing your cabinet

and locating your Ultra5000 drive(s) inside the cabinet.

Figure 1.1

Minimum Clearance Requirements

If the cabinet is ventilated, use filtered or

conditioned air to prevent the accumulation of dust

and dirt on electronic components. The air should be

free of oil, corrosives, or electrically conductive

contaminates.

Refer to Power Dissipation on page A-5 for Ultra5000 power

dissipation specifications.

Publication 2098-IN001E-EN-P — April 2002

Page 21

Installing Your Ultra5000 1-7

IMPORTANT

A

0.38Q

1.8T 1.1–

------------------------=

A

4.08Q

T 1.1–

----------------=

Sizing an Enclosure

As an additional aid in sizing an enclosure, with no active method of

heat dissipation, either of the following approximate equations can be

used:

Metric Standard English

Where T is temperature difference between

inside air and outside ambient (°C), Q is

heat generated in enclosure (Watts), and A

is enclosure surface area (m

surface of all six sides of an enclosure is

calculated as

A = 2dw + 2dh + 2wh A = (2dw + 2dh + 2wh) / 144

Where d (depth), w (width), and h (height)

are in meters.

2

). The exterior

Where T is temperature difference between

inside air and outside ambient (°F), Q is

heat generated in enclosure (Watts), and A

is enclosure surface area (ft²). The exterior

surface of all six sides of an enclosure is

calculated as

Where d (depth), w (width), and h (height)

are in inches.

Transformer Sizing

The Ultra5000 does not require isolation transformers. However, a

transformer may be required to match the voltage requirements of the

controller to the available service. To size a transformer for the main

AC power inputs, the power output (KVA) of each axis must be

known. This can be derived by calculating the horsepower for each

axis and converting that horsepower into units of watts. If you are

supplying power to more than one motor and an Ultra5000, simply

add the kW ratings together from each calculation to get a system kW

total.

If using an autotransformer, ensure that the phase to

neutral/ground voltages do not exceed the input

voltage rating of the drive referenced in General

Power Specifications on Page A-1.

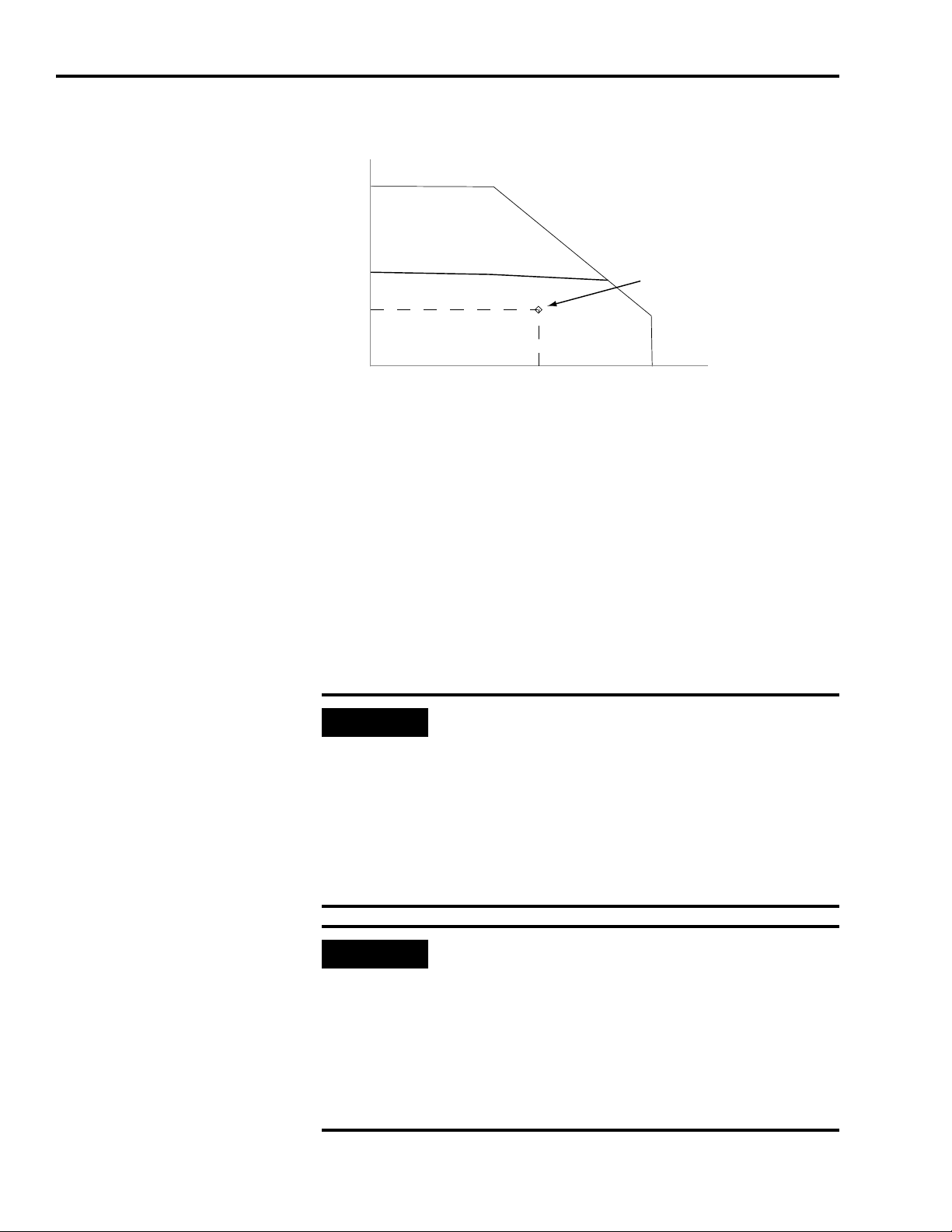

Calculating Transformer Size Based on Speed/Torque Data

Base the transformer size on the operating point within the speed/

torque curve for the drive and motor application as shown in Figure

1.2. The operating point for this hypothetical 230V drive/motor

combination is 23 lb-in and 3200 rpm.

Publication 2098-IN001E-EN-P — April 2002

Page 22

1-8 Installing Your Ultra5000

IMPORTANT

IMPORTANT

TORQUE (lb-in)

3200 rpm SPEED (RPM)

23.0 lb-in

Application

Operating Point

KVA

Speed RPM()Torque lb in–()×

63 025,

--------------------------------------------------------------------------------

746Watts

HP

----------------------- -

×

KVA

1000Watts

-------------------------- -

× 2.0×=

KVA

3200rpm 23.0lb in–×

42 250,

-------------------------------------------------------=

TransformerSize 1.75KVA=

Figure 1.2

Transformer Sizing Based on Speed/Torque Data for Single Phase System

The formula and calculation are:

Definitions:

kW = power or real power

KVA = apparent power

Transformer KVA rating = (Sum of average output power of each axis) x 2.0

.

Calculations are multiplied by a factor to compensate

for the power and loss elements within a power

system.

•A factor of 2.0 is used with a single phase system.

•A factor of 1.5 is used with a three phase system.

This factor minimizes the effects of the secondary

line voltage sagging in the transformer during peak

current periods.

If you are using the Rockwell Automation/

Allen-Bradley system sizing program, the average

speed and average torque data has already been

calculated and can be used in the equation. If you

are not sure of the exact speed and torque in your

application, another approach is to look at the

speed/torque curve for your Ultra5000/motor

combination and use the values for the worst case

continuous speed and torque.

Publication 2098-IN001E-EN-P — April 2002

Page 23

Installing Your Ultra5000 1-9

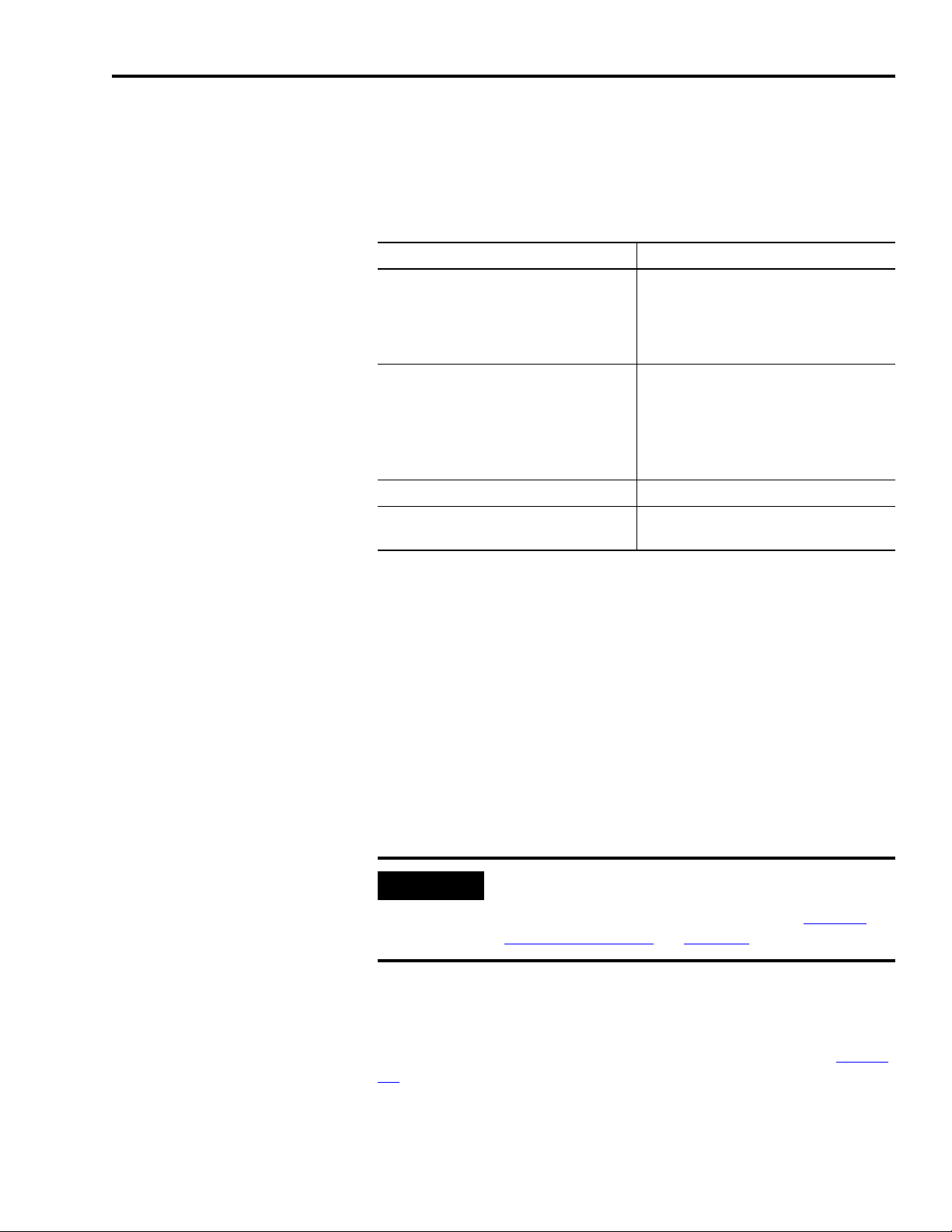

Fuse Sizing

The Ultra5000 is listed by Underwriters Laboratories, Inc. with fuses

sized as four times the continuous output current of the drives (FLA),

according to UL 508C.

In most cases, fuses selected to match the drive input current rating

will meet the NEC requirements and provide the full drive capabilities.

Dual element, time delay (slow acting) fuses should be used to avoid

nuisance trips during the inrush current of power initialization. Refer

to the section General Power Specifications

current and inrush current specifications.

The Ultra5000 utilizes solid state motor short circuit protection rated as

shown in the table below.

in Appendix A for input

Drive Models:

2098-IPD-xxx-xx Suitable for use on a circuit capable of

2098-IPD-HVxxx-xx Suitable for use on a circuit capable of

Short Circuit Current Rating with No

Fuse Restrictions:

delivering not more than 5000 rms

symmetrical amperes, 240V maximum.

delivering not more than 5000 rms

symmetrical amperes, 480V maximum.

Short Circuit Current Rating with Fuse

Restrictions:

Suitable for use on a circuit capable of

delivering not more than 200,000 rms

symmetrical amperes, 240V maximum,

when protected by high interrupting

capacity, current limiting fuses meeting UL

198C (Class CC, G, J, L, R, T).

Suitable for use on a circuit capable of

delivering not more than 200,000 rms

symmetrical amperes, 480V maximum,

when protected by high interrupting

capacity, current limiting fuses meeting UL

198C (Class CC, G, J, L, R, T).

Mains Input Fuses

Mains input fuses shall be dual element

time delay types class RK5, J or CC only.

Fuse current ratings shall be the following,

or the closest standard value to these

minimums:

2098-IPD-HV030-xx (3kW)

2098-IPD-HV050-xx (5kW)

2098-IPD-HV750-xx (10kW)

2098-IPD-HV100-xx (15kW)

2098-IPD-HV220-xx (22kW)

Auxiliary Input Fuses

Auxiliary input fuses shall be dual element

time delay types class RK5, J or CC only.

Fuse current rating shall be the following, or

the closest standard value to these

minimums.

All drive sizes 0.4 A

5 A

8 A

17 A

25 A

35 A

Publication 2098-IN001E-EN-P — April 2002

Page 24

1-10 Installing Your Ultra5000

Stud-mounting the subpanel

to the enclosure back wall

Stud-mounting a ground bus

or chassis to the subpanel

Subpanel Welded stud

Scrape

Flat washer

If the mounting bracket is coated

with a non-conductive material

(anodized, painted, etc.), scrape

the material around the mounting

hole.

Star washer

Nut

Nut

Flat washer

Mounting bracket or

ground bus

Use a wire brush to remove paint

from threads to maximize ground

connection.

Back wall of

enclosure

Welded

stud

Subpanel

Star washer

Use plated panels or scrape

paint on front of panel.

Subpanel

Nut

Nut

Star washer

Flat washer

Star washer

Star washer

Scrape paint on both sides

of panel and use star

Tapped

Bolt

Flat washer

Ground bus or

mounting bracket

If the mounting bracket is coated

with a non-conductive material

(anodixed, painted, etc.), scrape

the material around the mounting

Bolt-mounting a ground bus or chassis to the back-panel

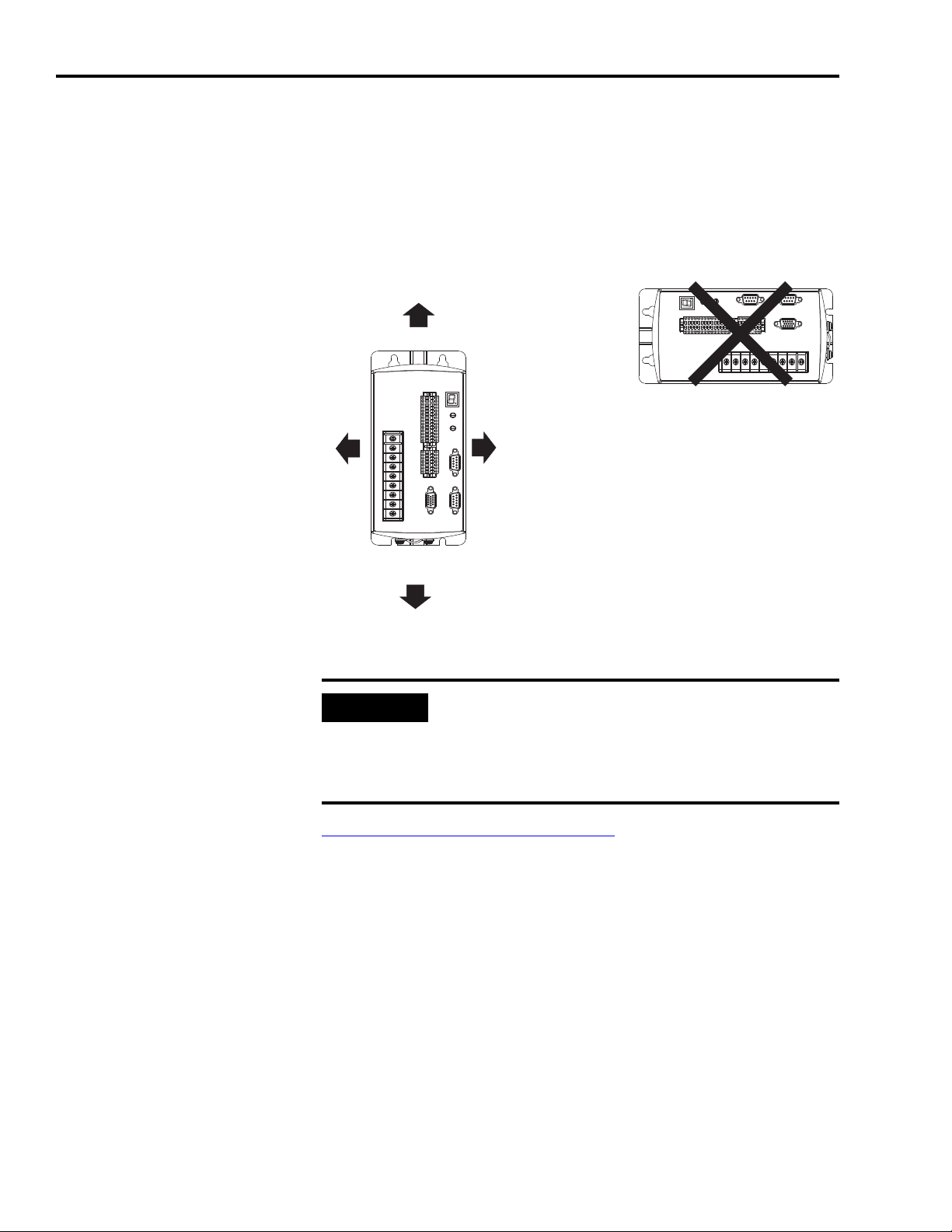

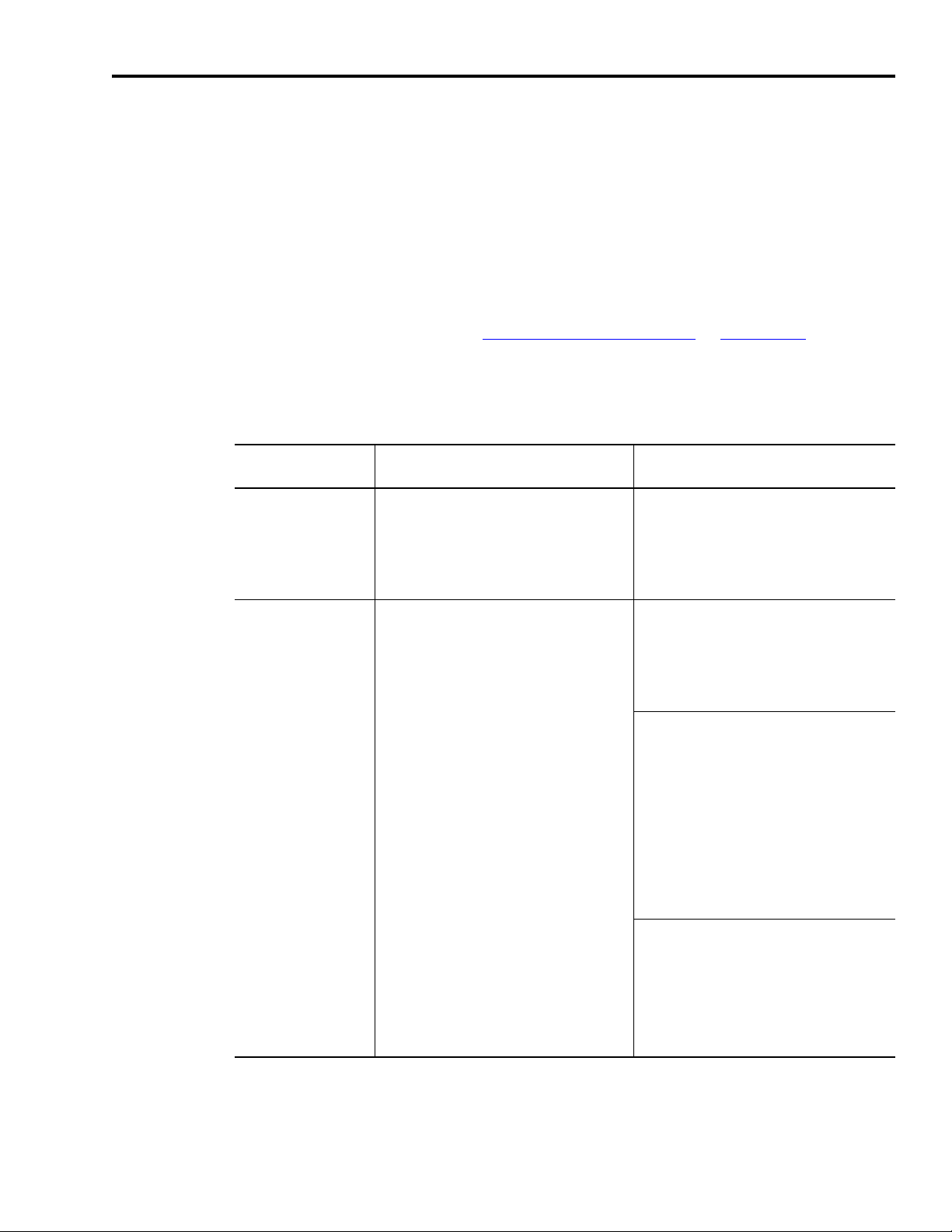

Bonding Your System

Bonding is the practice of connecting metal chassis, assemblies,

frames, shields and enclosures to reduce the effects of electromagnetic

interference (EMI).

Bonding Modules

Unless specified, most paints are not conductive and they act as

insulators. To achieve a good bond between modules and the

subpanel, surfaces need to be paint-free or plated. Bonding metal

surfaces creates a low-impedance exit path for high-frequency energy.

Improper bonding blocks that direct exit path and allows

high-frequency energy to travel elsewhere in the cabinet. Excessive

high-frequency energy can effect the operation of other

microprocessor controlled equipment. The illustrations that follow

(refer to Figure 1.3

for painted panels, enclosures, and mounting brackets.

Figure 1.3

Recommended Bonding Practices

) show details of recommended bonding practices

Publication 2098-IN001E-EN-P — April 2002

Page 25

Installing Your Ultra5000 1-11

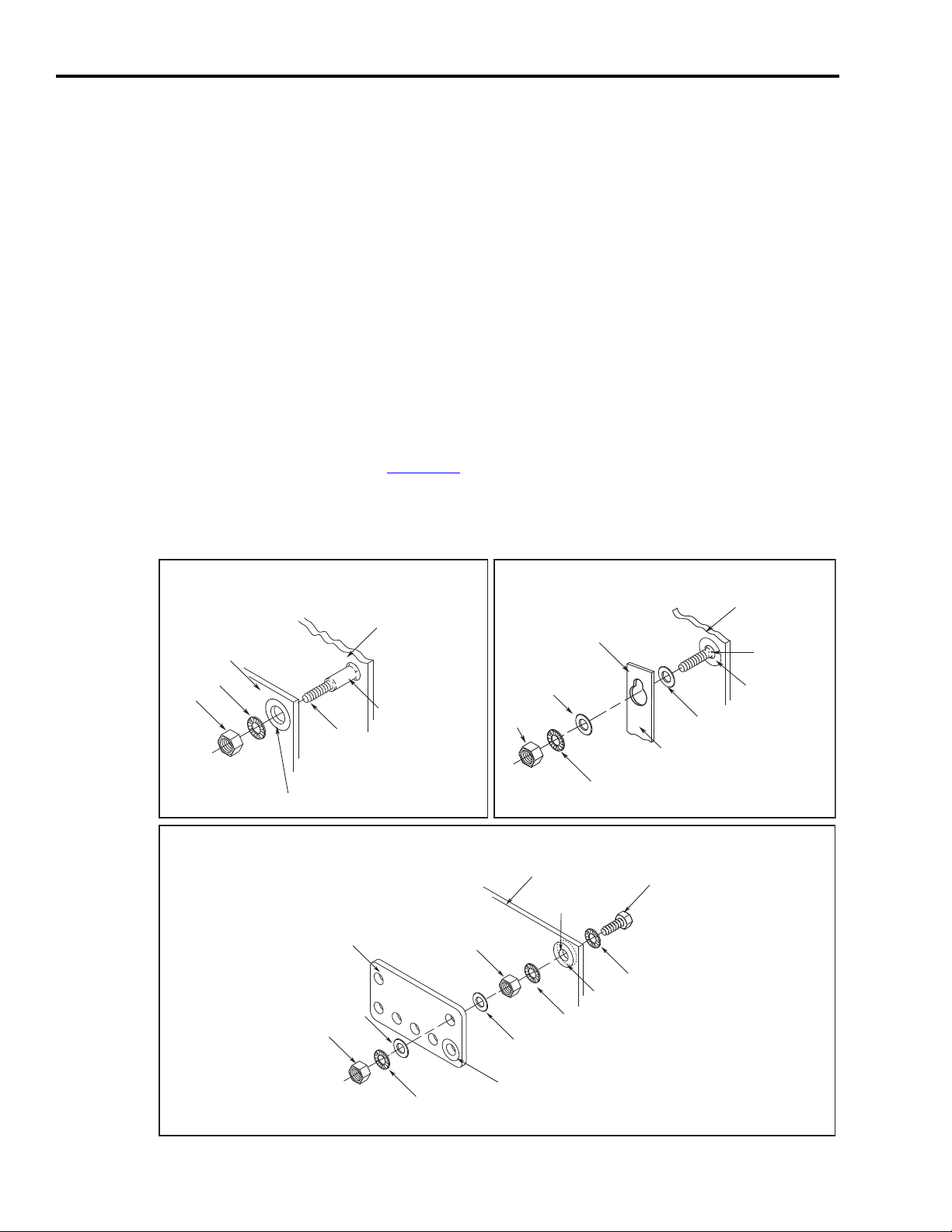

Recommended:

Bond the top and bottom of each subpanel to the cabinet

using 25.4 mm (1.0 in.) by 6.35 mm (0.25 in.) wire braid.

Scrape the paint around each fastener

to maximize metal to metal contact.

Bonded cabinet

ground bus to

subpanel

Recommended:

Bond the top and bottom of each subpanel to the cabinet

using 25.4 mm (1.0 in.) by 6.35 mm (0.25 in.) wire braid.

Scrape the paint around each fastener

to maximize metal to metal contact.

Bonded cabinet

ground bus to

subpanel

Bonding Multiple Subpanels

Bonding multiple subpanels creates a common low impedance exit

path for the high frequency energy inside the cabinet. Subpanels that

are not bonded together may not share a common low impedance

path. This difference in impedance may affect networks and other

devices that span multiple panels. Refer to the figure below for

recommended bonding practices.

Figure 1.4

Multiple Subpanels and Cabinet

Publication 2098-IN001E-EN-P — April 2002

Page 26

1-12 Installing Your Ultra5000

ATTENTION

!

Mounting Your Ultra5000 Drive

The procedures in this section assume you have prepared your panel

and understand how to bond your system. For installation instructions

regarding other equipment and accessories, refer to the instructions

that came with each of the accessories for their specific requirements.

This product contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Follow static control

precautions when you install, test, service, or repair

this assembly.

Refer to Allen-Bradley publication 8000-4.5.2

Guarding Against Electrostatic Damage or any other

applicable ESD Protection Handbook.

Failure to observe this precaution may result in

damage to the equipment.

To mount your Ultra5000 drive:

1. Layout the positions for the Ultra5000 and accessories in the

enclosure. Mounting hole dimensions for the Ultra5000 are shown

in Appendix A.

,

2. Attach the Ultra5000 to the cabinet, first using the upper mounting

slots of the drive and then the lower. The recommended mounting

hardware is M5 metric (1/4-20) or #10 MS bolts. Observe bonding

techniques as described in Bonding Your System

2. Tighten all mounting fasteners.

.

Publication 2098-IN001E-EN-P — April 2002

Page 27

Ultra5000 Connector Information

Chapter

2

Chapter Objectives

This chapter provides connector information and procedures for

wiring your Ultra5000 and making cable connections. This chapter

includes:

• Understanding Ultra5000 Controller Functions

• Understanding Ultra5000 Connectors

• Understanding Ultra5000 I/O Specifications

• Understanding Motor Encoder Feedback Specifications

• Understanding Auxiliary Encoder Feedback Specifications

• Understanding the Serial Interface

1 Publication 2098-IN001E-EN-P — April 2002

Page 28

2-2 Ultra5000 Connector Information

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

InterfaceInterface

Digital InputsDigital Inputs

Digital OutputsDigital Outputs

Auxiliary Encoder InputsAuxiliary Encoder Inputs

Motor Encoder OutputsMotor Encoder Outputs

Motor EncoderMotor Encoder

Analog InputsAnalog Inputs

Analog OutputsAnalog Outputs

Gate ArrayGate Array

QuadQuad

ADCADC

DualDual

DACDAC

QuadQuad

ADCADC

POWER MODULEPOWER MODULE

Bus VoltageBus Voltage

InputInput

CurrentCurrent

InputsInputs

PWMPWM

OutputsOutputs

I/O CARDI/O CARD

512Kx8512Kx8

Low SpeedLow Speed

FlashFlash

MemoryMemory

256Kx32256Kx32

System FlashSystem Flash

MemoryMemory

128Kx32128Kx32

High SpeedHigh Speed

SRAMSRAM

64Kx864Kx8

Non-VolatileNon-Volatile

SRAMSRAM

SerialSerial

InterfaceInterface

7-Segment7-Segment

LEDLED

DisplayDisplay

Rotary DIPRotary DIP

SwitchesSwitches

TMS320C32TMS320C32

DSPDSP

Serial Port 1Serial Port 1

Serial Port 2Serial Port 2

Option Card Port 1Option Card Port 1

Option Card Port 2Option Card Port 2

PROCESSOR CARDPROCESSOR CARD

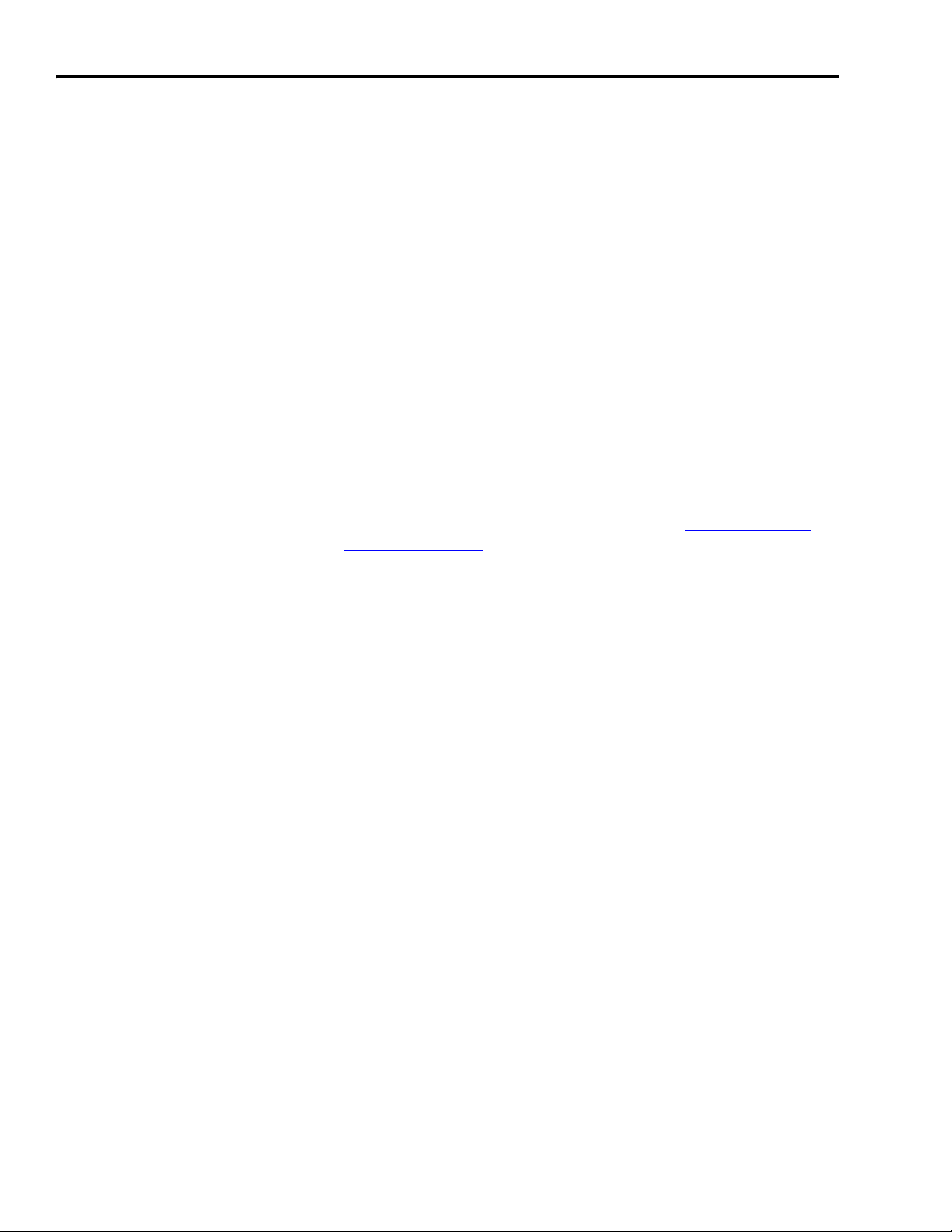

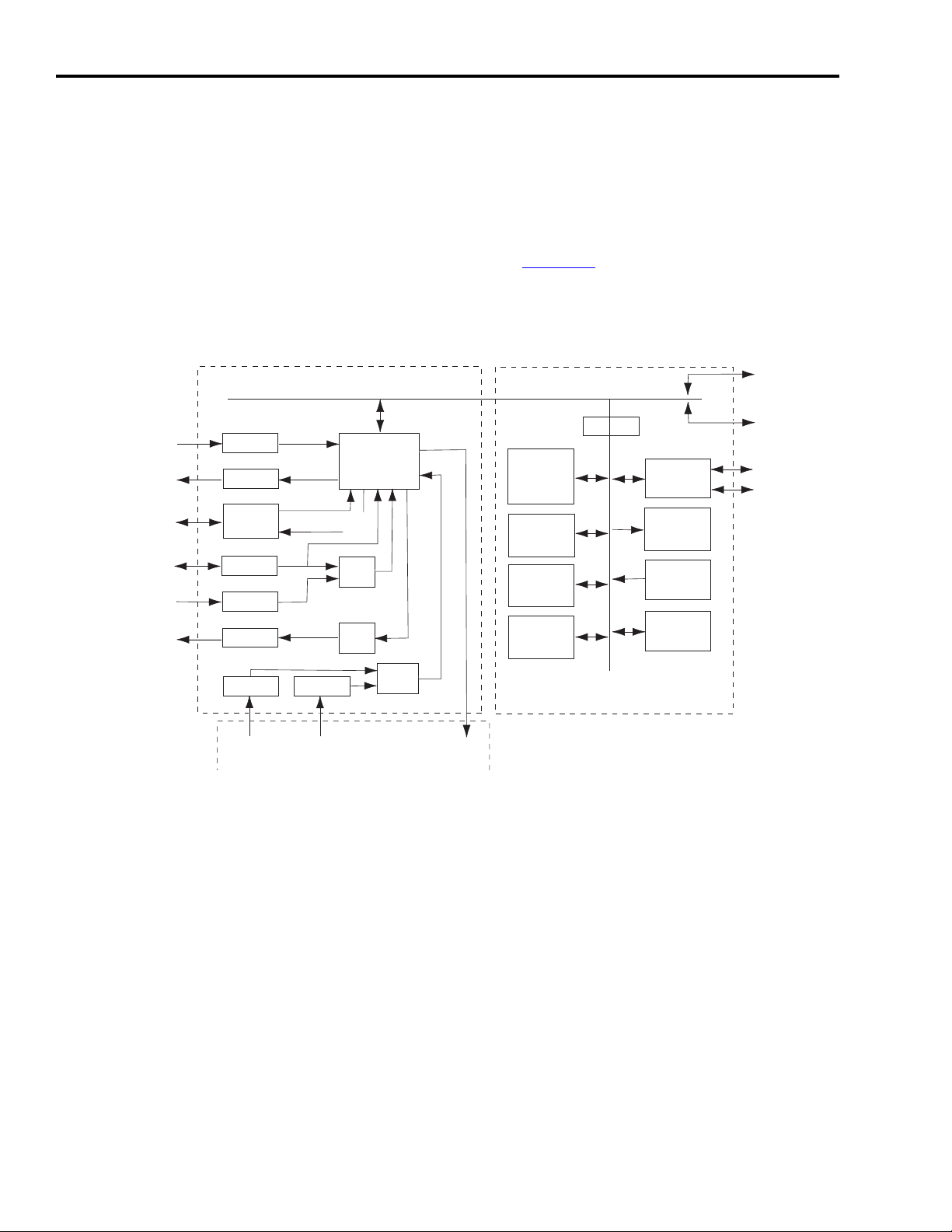

Understanding Ultra5000 Controller Functions

This section provides a short overview of the Ultra5000.

Ultra5000 Block Diagram

The Ultra5000 uses a two-stage circuit card solution with the capability

of adding two additional option cards. The first stage is the processor

circuit board and the second stage handles I/O connections including

a power module interface. Figure 2.1

interfaces.

Figure 2.1

Block Diagram of Ultra5000 Controller Functions

depicts the stages and the

Publication 2098-IN001E-EN-P — April 2002

Page 29

Ultra5000 Connector Information 2-3

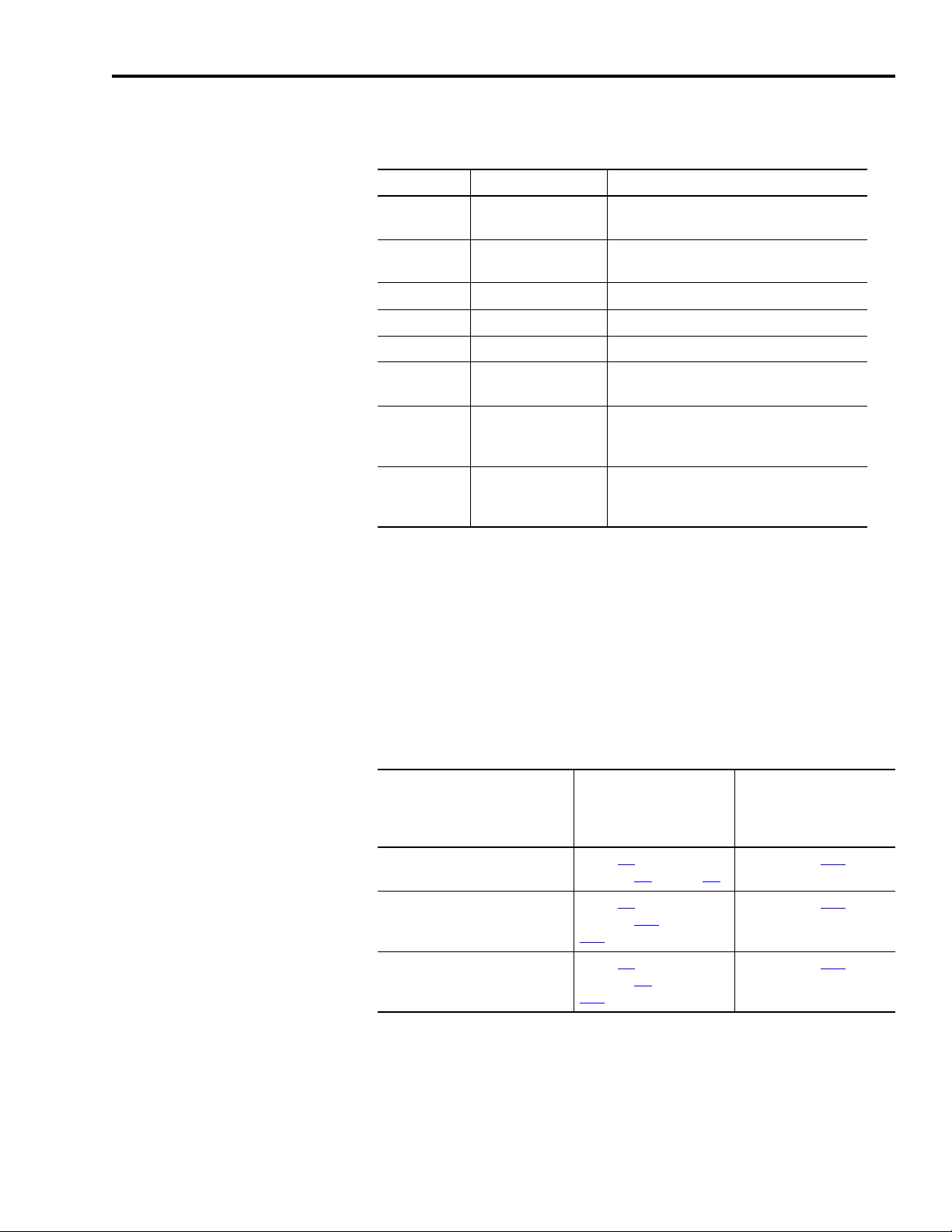

Understanding Ultra5000 Connectors

The following table provides a brief description of the Ultra5000 front

panel connectors and describes the connector type.

Designator Description Connector

CN1A User Input/Output 28-pin, 3.5mm, double-row, plugable spring

clamp

CN1B User Input/Output 14-pin, 3.5mm, double-row, plugable spring

clamp

CN2 Motor Feedback 15-pin high-density D-shell

CN3A Main Serial Port 9-pin standard D-shell

CN3B Auxiliary Serial Port 9-pin standard D-shell

TB DC bus, Motor and

AC power

TB1 DC bus, Motor, AC

power, and Auxiliary

AC power

TB2 Shunt 3-position screw style barrier terminal strip

9-position screw style barrier terminal strip

(2098-IPD-005xx, -010-xx, and -020-xx)

11- or 12-position screw style barrier

terminal strip (2098-IPD-030-xx, -075-xx,

-150-xx, and HVxxx-xx)

(2098-IPD-030-xx, -075-xx, -150-xx, and

HVxxx-xx)

CN1A and CN1B signal connections on the Ultra5000 use plugable,

spring-clamp connectors with 3.5mm spacing. Mating connectors for

discrete user wiring are included with your Ultra5000.

CN2, CN3A and CN3B signal connections on the Ultra5000. Mating

connectors for these D-shell type connectors are commonly available.

DeviceNet signal connections on the Ultra5000 with DeviceNet

(2098-IPD-xxx-DN and -HVxxx-DN only) use a 5-pin DeviceNet

connector. The mating connector is included with your Ultra5000.

For connector pin-outs and

the location of connectors,

switches, and status LEDs

on:

2098-IPD-xxx Ultra5000 drives Figure 2.2

2098-IPD-xxx-DN Ultra5000

drives with DeviceNet interface

2098-IPD-HVxxx high voltage

(460VAC) Ultra5000 drives

For I/O, Motor

Feedback and Serial

Communications Port

Connections refer to:

on pages 2-5

Figure 2.5

on pages 2-13

2-15

.

Figure 2.7

on pages 2-5

2-17

.

and the tables

through 2-7.

and the tables

through

and the tables

through

For Terminal Block

(Power) Connections

refer to:

table on page 3-17

table on page 3-17

table on page 3-17

.

.

.

Publication 2098-IN001E-EN-P — April 2002

Page 30

2-4 Ultra5000 Connector Information

PWR

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

Node Address

Selector Switche

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

CN3B 9-pin

Auxiliary Serial P

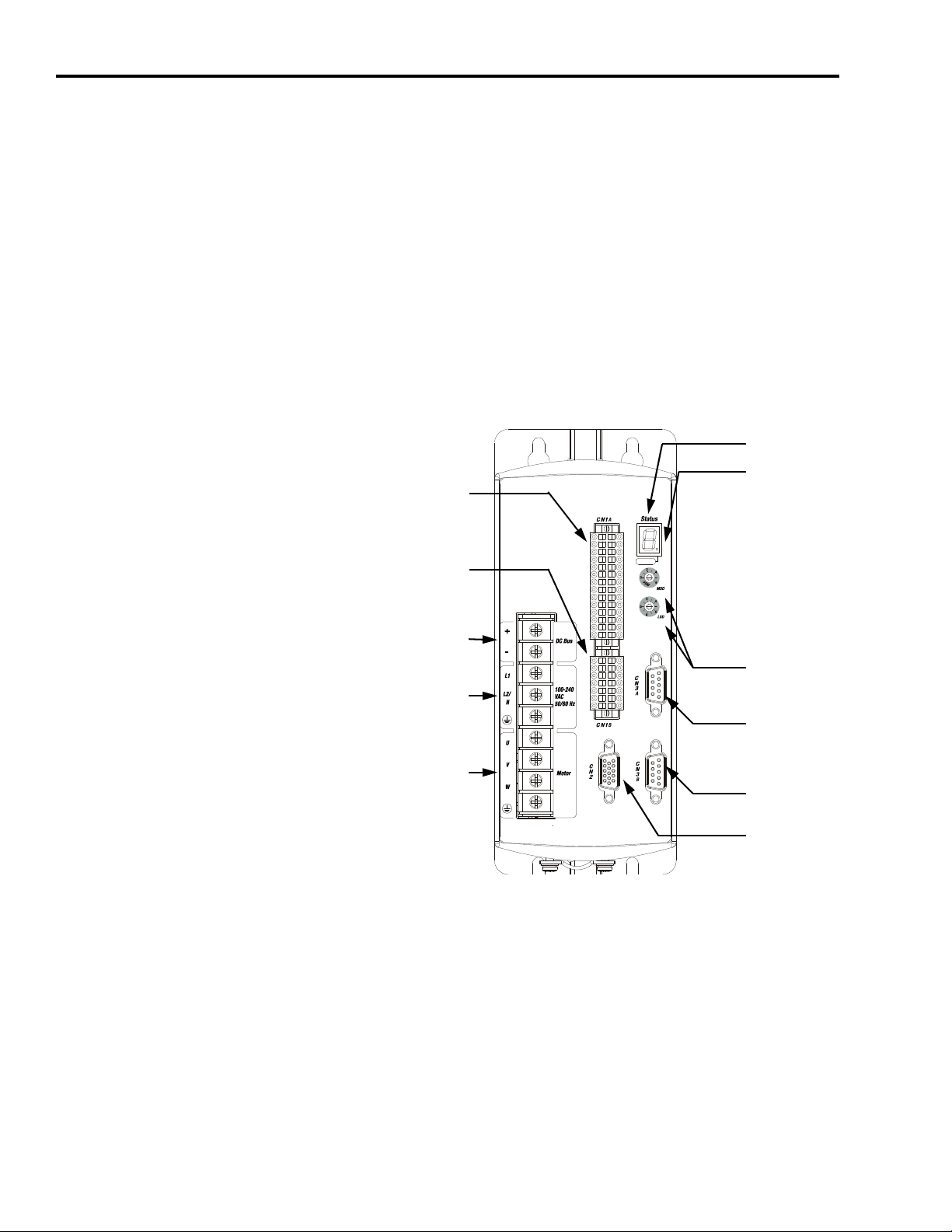

230V Ultra5000 Front Panel Connections

This section describes and provides a visual reference to the drive’s

connectors.

500W, 1 kW, and 2 kW Ultra5000 (2098-IPD-005, -010, and -020)

Use the figure below to locate the front panel connections on the

Ultra5000 230V drives (500W, 1 kW, and 2 kW). Detailed descriptions

of the connections are provided.

Figure 2.2

Ultra5000 Front Panel Connections

for 2098-IPD-005, -010, and -020

Publication 2098-IN001E-EN-P — April 2002

Page 31

Ultra5000 Connector Information 2-5

I/O Connectors

CN1A (28-pin) and CN1B (14-pin) are plugable, double-row, spring

clamp connectors with 3.5mm spacing. Maximum wire gauge for

these connectors is 0.75 mm

The following tables provide the signal description and pin-outs for

the CN1A and CN1B I/O connectors.

Note: These tables are arranged to match the drive’s I/O pin

arrangement..

2

(18 AWG).

CN1A

Pin

15 Digital Input 9 INPUT9 1 Digital Input 1

16 Digital Input 10 INPUT10 2 Digital Input 2

Description Signal CN1A

Pin

Description Signal

2

INPUT1

2

INPUT2

17 Digital Input 11 INPUT11 3 Digital Input 3 INPUT3

18 Digital Input 12 INPUT12 4 Digital Input 4 INPUT4

19 Digital Input 13 INPUT13 5 Digital Input 5 INPUT5

20 Digital Input 14 INPUT14 6 Digital Input 6 INPUT6

21 Digital Input 15 INPUT15 7 Digital Input 7 INPUT7

22 Digital Input 16 INPUT16 8 Digital Input 8 INPUT8

23 Digital Output 5 OUTPUT5 9 Digital Output 1 OUTPUT1

24 Digital Output 6 OUTPUT6 10 Digital Output 2 OUTPUT2

25 Digital Output 7 OUTPUT7 11 Digital Output 3 OUTPUT3

26 Relay Output 1+ OUTPUT8+ 12 Digital Output 4 OUTPUT4

27 Relay Output 1- OUTPUT8- 13 Shield Termination SHIELD

1

28 I/O Ground IOCOM

1

The Ultra5000 0.5, 1.0, and 2.0 kW drives (2098-IPD-005-xx, 2098-IPD-010-xx, 2098-IPD-020-xx, and 2098-IPD-HVxxx-xx

models) require a user supplied I/O power source. Refer to

2

High speed inputs. Refer to Digital Inputs on page 2-20 for additional information.

14 I/O Power Supply IOPWR 1

Digital I/O Power Supply on page 2-19 for more information.

CN1B

Pin

Description Signal CN1B

Pin

Description Signal

8 5V Ground +5VCOM 1 5V Power Supply +5V

9 Analog Input 1 AIN1 2 Auxiliary Encoder I/O A+ AX+

10 Analog Input 2 AIN2 3 Auxiliary Encoder I/O A- AX11 5V Ground +5VCOM 4 Auxiliary Encoder I/O B+ BX+

12 Analog Output 1 AOUT1 5 Auxiliary Encoder I/O B- BX13 Analog Output 2 AOUT2 6 Auxiliary Encoder I/O I+ IX+

14 Shield Termination SHIELD 7 Auxiliary Encoder I/O I- IX-

Publication 2098-IN001E-EN-P — April 2002

Page 32

2-6 Ultra5000 Connector Information

Connector Pinout

Pin 10

Pin 15

Pin 11

Pin 5

Pin 1

Pin 6

Motor Encoder Connector

The following table provides the signal descriptions and pin-outs for

the CN2 motor encoder (15-pin) connector.

CN2 Pin Description Signal

1 Channel A+ AM+

2 Channel A- AM3 Channel B+ BM+

4 Channel B- BM5 Channel I+ IM+

6Common ECOM

7 Reserved

on 2098-005-xx, -010-xx, -020-xx

Encoder Power (+9V)

on 2098-030-xx, -050-xx, -075-xx,

-150-xx, -HV030-xx, -HV050-xx,

-HV100-xx, -HV150-xx, and

-HV220-xx

–

EPWR +9V

8 Commutation Channel S3 S3

9 Positive Overtravel Limit +LIMIT

10 Channel I- IM11 Thermostat TS

12 Commutation Channel S1 S1

13 Commutation Channel S2 S2

14 Encoder Power (+5V) EPWR +5V

15 Negative Overtravel Limit -LIMIT

Publication 2098-IN001E-EN-P — April 2002

Page 33

Ultra5000 Connector Information 2-7

Connector Pinout

Pin 9

Pin 6

Pin 5

Pin 1

Serial Port Connectors

The following table provides the signal descriptions and pin-outs for

the CN3A (Main) and CN3B (Auxiliary) serial port (9-pin) connectors.

Refer to

information.

CN3 Pin Description Signal

1 RS-422/RS-485 Input+ RCV+

2 RS-232 Input RCV

3 RS-232 Output XMT

4 RS-422/RS-485 Output+ XMT+

5Common COM

6Reserved –

7 RS-422/RS-485 Input- RCV8 RS-422/RS-485 Output- XMT-

Default Serial Interface Settings on page 2-34 for additional

9Reserved –

Terminal Block

The following table lists the connections on the Ultra5000 230V drive

(500W, 1 kW, and 2 kW) power terminal block (TB). Refer to

Power Connections on page 3-14 for additional information.

Terminal Block (TB) Locations

(2098-IPD-005xx, -010-xx, -020-xx)

1

DC Bus+

DC BusL1 (Main AC)

L2/N (Main AC)

Safety (Earth) Ground

U (Motor)

V (Motor)

W (Motor)

Motor Case Ground

1

2

2

2

Wiring

1

Do not connect an external I/O power supply to the DC bus. The DC+ and DC- terminals

connect directly to the power bus of the drive.

2

Ensure motor power is wired with proper phasing relative to the motor terminals. On some

motors, the motor leads may be labeled R, S, and T which correspond to U, V, and W.

Publication 2098-IN001E-EN-P — April 2002

Page 34

2-8 Ultra5000 Connector Information

U

V

W

+

-

L1

L2

L1

AUX

L2/N

AUX

Motor

DC Bus

1

2

3

Intern al

Extern al

Shunt

DC Bus

C

N

3

A

C

N

3

B

C

N

2

CN1A

Status

PWR

Node Address

(00-63, PGM)

100-240 VAC

50/60 Hz

AC Input Power Terminals

Motor Power Terminals

DC Bus Terminals for

Shunt Resistor

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

Node Address

Selector Switches

CN3B 9-pin

Auxiliary Serial Port

DC Bus Terminals

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

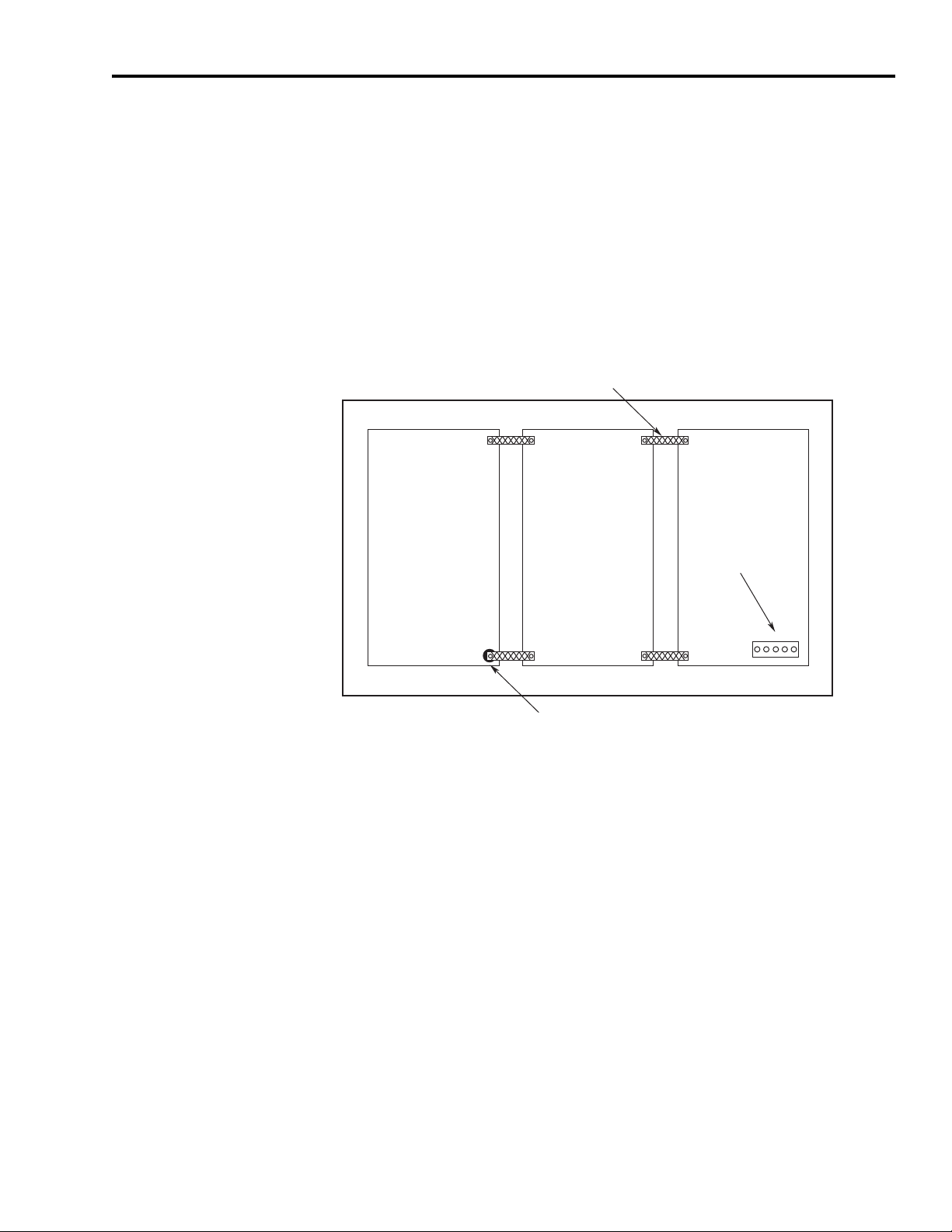

3 kW Ultra5000 (2098-IPD-030)

Use the figure below to locate the front panel connections on the

Ultra5000 230V drive (3 kW). Detailed descriptions of the digital

connections are provided on pages 2-5

connections are described below.

Figure 2.3

Ultra5000 Front Panel Connections

for 2098-IPD-030

Status

through 2-7. Power

External

Shunt

Internal

PWR

Node Address

(00-63, PGM)

DC Bus

Motor

DC Bus

100-240 VAC

50/60 Hz

AUX

L2/N

AUX

CN1A

L1

L2

L1

The following tables list the power and shunt connections on the

terminal block (TB). Refer to

Wiring Power Connections on page 3-14

for additional information.

Publication 2098-IN001E-EN-P — April 2002

Page 35

Ultra5000 Connector Information 2-9

Terminal Blocks

The following tables list the connections on the Ultra5000 230V drive

(3 kW) power (TB1) and the shunt (TB2) terminal blocks. Refer

to Wiring Power Connections on page 3-14 for additional information.

Terminal Block 1 (TB1) Locations

(2098-IPD-030-xx)

U (Motor)

V (Motor)

W (Motor)

Motor Case Ground

DC Bus+

DC BusL1 (Main AC)

L2/N (Main AC)

2

2

2

1

1

Safety (Earth) Ground

3

L1 (Aux AC)

L2/N (Aux AC)

1

Do not connect an external I/O power supply to the DC bus. The DC+ and DC- terminals

connect directly to the power bus of the drive.

2

Ensure motor power is wired with proper phasing relative to the motor terminals. On some

motors, the motor leads may be labeled R, S, and T which correspond to U, V, and W.

3 The auxiliary AC power inputs require dual element time delay (slow acting) fuses to

accommodate inrush current. Refer to the section General Power Specifications

A for the inrush current on the auxiliary AC power input.

3

in Appendix

Shunt Terminal Block 2 (TB2) Locations

(2098-IPD-030-xx)

1 - Common Terminal for External or Internal Shunt

1

2 - Internal Shunt Terminal

3 - External Shunt Terminal

1

A jumper, selecting the internal shunt, is factory installed between terminals 1 and 2. Remove the jumper for

applications requiring an external shunt.

Refer to External Shunt Kits on page C-4

1

for information about available external shunt kits.

1

Publication 2098-IN001E-EN-P — April 2002

Page 36

2-10 Ultra5000 Connector Information

U

V

W

+

-

L1L1

L2L2

L1L1

AUXAUX

L2/NL2/N

AUXAUX

MotorMotor

DC BusDC Bus

100-240 VAC100-240 VAC

50/60 Hz50/60 Hz

1

2

3

InternalInternal

ExternalExtern al

ShuntShunt

L3L3

DC BusDC Bus

C

N

3

A

C

N

3

B

C

N

2

CN1ACN1A

CN1BCN1B

TB1TB1

StatusStatus

PWRPWR

Node AddressNode Address

(00-63, PGM)(00-63, PGM)

AC Input Power Terminals

Motor Power Terminals

DC Bus Terminals for

Shunt Resistor

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

Node Address

Selector Switches

CN3B 9-pin

Auxiliary Serial Port

DC Bus Terminals

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

7.5 kW, and 15 kW Ultra5000 (2098-IPD-075, and -150)

Use the figure below to locate the front panel connections on the

Ultra5000 230V drives (7.5 kW, and 15 kW). Detailed descriptions of

the digital connections are provided on pages 2-5

connections are provided on page 2-11

Figure 2.4

Ultra5000 Front Panel Connections

for 2098-IPD-075, and -150

.

through 2-7. Power

Publication 2098-IN001E-EN-P — April 2002

Page 37

Ultra5000 Connector Information 2-11

I/O Connectors

CN1A (28-pin) and CN1B (14-pin) are plugable, double-row, spring

clamp connectors with 3.5mm spacing. Refer to the tables on page 2-5

for pin-outs.

Motor Encoder Connector

CN2 (15-pin) motor encoder connector is a standard D-shell

connector. Refer to the table on page 2-6

for pin-outs.

Serial Port Connectors

The CN3A (Main) and CN3B (Auxiliary) are standard D-shell

connectors for serial port (9-pin) communications. Refer to the table

on page 2-7

for pin-outs.

Terminal Blocks

The following tables list the connections on the Ultra5000 230V drives

(7.5 kW, and 15 kW) power (TB1) and the shunt (TB2) terminal

blocks. Refer to

additional information.

Wiring Power Connections on page 3-14 for

Publication 2098-IN001E-EN-P — April 2002

Page 38

2-12 Ultra5000 Connector Information

Terminal Block 1 (TB1) Locations

(2098-IPD-075-xx and -150-xx)

U (Motor)

V (Motor)

W (Motor)

2

2

2

Motor Case Ground

1

DC Bus+

DC Bus-

1

L1 (Main AC)

L2 (Main AC)

L3 (Main AC)

Safety (Earth) Ground

3

L1 (Aux AC)

L2/N (Aux AC)

1

Do not connect an external I/O power supply to the DC bus. The DC+ and DC- terminals

connect directly to the power bus of the drive.

2

Ensure motor power is wired with proper phasing relative to the motor terminals. On some

motors, the motor leads may be labeled R, S, and T which correspond to U, V, and W.

3 The auxiliary AC power inputs require dual element time delay (slow acting) fuses to

accommodate inrush current. Refer to the section General Power Specifications

A for the inrush current on the auxiliary AC power input.

3

in Appendix

Shunt Terminal Block 2 (TB2) Locations

(2098-IPD-075-xx and -150-xx)

1 - Common Terminal for External or Internal Shunt

1

2 - Internal Shunt Terminal

3 - External Shunt Terminal

1

A jumper, selecting the internal shunt, is factory installed between terminals 1 and 2. Remove the jumper for

applications requiring an external shunt.

External Shunt Kits on page C-4 for information about available external shunt kits.

Refer to

1

1

Publication 2098-IN001E-EN-P — April 2002

Page 39

Ultra5000 Connector Information 2-13

AUTOBAUD

DeviceNet

PWR

AC Input Power Terminals

Motor Power Terminals

DC Bus Terminals for

Active Shunt Resistor Kit

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

DeviceNet Interface

Node Address

Selector Switches

Data Rate

Switch

Module Status LED

Network Status LED

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

CN3B 9-pin

Auxiliary Serial Port

230V Ultra5000 with DeviceNet Front Panel Connections

This section describes and provides a visual reference to drive’s

having the DeviceNet interface.

500W, 1 kW, and 2 kW Ultra5000 with DeviceNet (2098-IPD-005-DN, -010-DN, and -020-DN)

Use the figure below to locate the front panel connections on the

230V Ultra5000 with DeviceNet drives (500W, 1 kW, and 2 kW).

Detailed descriptions of the digital connections are provided on pages

through 2-7. Power connections are provided on page 2-11.

2-5

DeviceNet connections are provided on page 2-14

Figure 2.5

Ultra5000 with DeviceNet Front Panel Connections

for 2098-IPD-005-DN, -010-DN, and -020-DN

.

Publication 2098-IN001E-EN-P — April 2002

Page 40

2-14 Ultra5000 Connector Information

I/O Connectors

CN1A (28-pin) and CN1B (14-pin) are plugable, double-row, spring

clamp connectors with 3.5mm spacing. Refer to the tables on page 2-5

for pin-outs.

Motor Encoder Connector

CN2 (15-pin) motor encoder connector is a standard D-shell

connector. Refer to the table on page 2-6

for pin-outs.

Serial Port Connectors

The CN3A (Main) and CN3B (Auxiliary) are standard D-shell

connectors for serial port (9-pin) communications. Refer to the table

on page 2-7

for pin-outs.

DeviceNet Connector

The following table provides the signal descriptions and pin-outs for

the DeviceNet port (5-pin) connector.

Terminal Signal Description

1 V- Network Power Common 24V DC

2 Can_L Network Communication Signal Line

3 Shield Shield

4 Can_H Network Communication Signal Line

5 V+ Network Power 24V DC

Publication 2098-IN001E-EN-P — April 2002

Page 41

Ultra5000 Connector Information 2-15

U

V

W

+

-

L1L1

L2L2

L1L1

AUXAUX

L2/NL2/N

AUXAUX

MotorMotor

DC BusDC Bus

100-240 VAC100-240 VAC

50/60 Hz50/60 Hz

1

2

3

InternalInte rnal

ExternalExte rnal

ShuntSh unt

L3L3

DC BusDC Bus

C

N

3

A

C

N

3

B

C

N

2

CN1ACN1A

CN1BCN1B

TB1TB1

StatusStatus

PWRPWR

Node AddressNode Address

(00-63, PGM)(00-63, PGM)

AUTOBAUDAUTOBAUD

DeviceNetDeviceNet

DeviceNet Interface

Data Rate

Switch

Module Status LED

Network Status LED

AC Input Power Terminals

Motor Power Terminals

DC Bus Terminals for

Shunt Resistor

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

Node Address

Selector Switches

CN3B 9-pin

Auxiliary Serial Port

DC Bus Terminals

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

ote: 2098-IPD-030-DN

3 kW, 7.5 kW, and 15 kW Ultra5000

(2098-IPD-005-DN, -010-DN, and -020-DN)

Use the figure below to locate the front panel connections on the

230V Ultra5000 with DeviceNet drives (3 kW, 7.5 kW, and 15 kW).

Detailed descriptions of the connections are provided. Detailed

descriptions of the digital connections are provided on pages 2-5

through 2-7

DeviceNet connections are provided on page 2-14

Figure 2.6

Ultra5000 with DeviceNet Front Panel Connections

for 2098-IPD-030-DN, -075-DN, and -150-DN

. Power connections are provided on page 2-11.

.

Publication 2098-IN001E-EN-P — April 2002

Page 42

2-16 Ultra5000 Connector Information

Device

Net

DANGER

DeviceNet Interface

Data Rate

Switch

Module Status LED

Network Status LED

AC Input Power Terminals

Motor Power Terminals

DC Bus Terminals for

Shunt Resistor

Seven Segment

Status LED

Logic Power LED

CN3A 9-pin

Main Serial Port

Node Address

Selector Switches

CN3B 9-pin

Auxiliary Serial Port

DC Bus Terminals

CN2 15-pin

Motor Encoder

CN1A 28-pin

Digital I/O

CN1B 14-pin

Auxiliary Encoder and

Analog I/O

460V Ultra5000 Front Panel Connections

Use the figure below to locate the front panel connections on the

460V Ultra5000 drives (3 kW, 5 kW, 10 kW, 15 kW and 22 kW).

Detailed descriptions of the digital connections are provided on pages

2-5

through 2-7. Power connections are provided on page 2-11.

DeviceNet connections are provided on page 2-14

Figure 2.7

Ultra5000 Front Panel Connections

for 2098-IPD-HV030-xx, -HV050-xx, -HV100-xx, -HV150-xx, and -HV220-xx

.

Device

Net

Publication 2098-IN001E-EN-P — April 2002

Page 43

Ultra5000 Connector Information 2-17

IMPORTANT

I/O Connectors

CN1A (28-pin) and CN1B (14-pin) are plugable, double-row, spring

clamp connectors with 3.5mm spacing. Refer to the tables on page 2-5

for pin-outs.

Motor Encoder Connector

CN2 (15-pin) motor encoder connector is a standard D-shell

connector. Refer to the table on page 2-6

for pin-outs.

Serial Port Connectors

The CN3A (Main) and CN3B (Auxiliary) are standard D-shell

connectors for serial port (9-pin) communications. Refer to the table

on page 2-7

for pin-outs.

Terminal Blocks

The following tables list the connections on the 460V Ultra5000 drives

(3 kW, 5 kW, 10 kW, 15 kW and 22 kW) power (TB1) and the shunt

(TB2) terminal blocks. Refer to

page 3-14 for additional information.

The 2098-IPD-HVxxx-xx drives can be powered with

230-240 Vrms in order to be used in conjunction with

motors designed for 230V operation. In such cases,

the voltage levels used for shunting and DC bus

overvoltage limits are adjusted to be compatible with

the voltage limit of the motor.

Wiring Power Connections on

Publication 2098-IN001E-EN-P — April 2002

Page 44

2-18 Ultra5000 Connector Information

.

Terminal Block 1 (TB1) Locations

(2098-IPD-HVxxx-xx)

DC Bus+

DC BusW (Motor)

V (Motor)

U (Motor)

Ground (

L3 (Main AC)

L2 (Main AC)

L1 (Main AC)

L1 (Aux AC)

L2 (Aux AC)

1

2

3 The auxiliary AC power inputs require dual element time delay (slow acting) fuses to

1

1

2

2

2

Motor and Earth

3

3

Do not connect an external I/O power supply to the DC bus. The DC+ and DC- terminals

connect directly to the power bus of the drive.

Ensure motor power is wired with proper phasing relative to the motor terminals. On some

motors, the motor leads may be labeled R, S, and T which correspond to U, V, and W.

accommodate inrush current. Refer to the section General Power Specifications

A for the inrush current on the auxiliary AC power input.

)

in Appendix

Shunt Terminal Block 2 (TB2) Locations

(2098-IPD-HVxxx-xx)

1 - Common Terminal for External or Internal Shunt

1

2 - Internal Shunt Terminal

3 - External Shunt Terminal

1

A jumper, selecting the internal shunt, is factory installed between terminals 1 and 2. Remove the jumper for

applications requiring an external shunt.

External Shunt Kits on page C-4 for information about available external shunt kits.

Refer to

1

1

Publication 2098-IN001E-EN-P — April 2002

Page 45

Ultra5000 Connector Information 2-19

Understanding Ultra5000 I/O Specifications

A description of the Ultra5000 input/output is provided on the

following pages.

Digital I/O Power Supply

Power for the digital I/O on 0.5 kW, 1.0 kW, and 2.0 kW Ultra5000

230V drives (2098-IPD-005 through -020) and all 460V drives

(2098-IPD-HVxxx-xx) must be provided by an external 12-24V dc

power supply.

Power for the digital I/O on 3.0 kW through 15 kW Ultra5000 drives

(2098-IPD-030 through -150) is provided by an external 12-24V dc

power supply or by a 24V dc power source internal to the drive.

Two jumpers on the regulator board must be repositioned if the

internal power source is to be used. Refer to Figure 3.2

for the location of the jumpers. The internal supply is fused by F1, a

fast acting 1A fuse. The common for the internal supply is lightly

referenced to ground, through a 1M ohm resistor. When using the

internal 24V supply, the common must be grounded during

installation to meet the European Low Voltage Directive.

on Page 3-3

The following table provides a description of the requirements for an

external digital I/O power supply for all Ultra5000 drives

(2098-IPD-005-xx through 2098-IPD-150-xx, and 2098-IPD-HV030-xx

through 2098-IPD-HV220-xx).

Parameter Description Minimum Maximum

I/O Power Supply

Voltage

I/O Power Supply

Current

Voltage range of the external power supply

for proper operation of the digital I/O.

Current draw from the external power

supply for the digital I/O, not including the

relay output usage.

10.8V 26.4V

— 300 mA

The following table provides specifications on the internal digital I/O

power supply for the 230V Ultra5000 3.0 kW through 15 kW drives

(2098-IPD-030 through -150 only).

Parameter Description Minimum Maximum

Output Voltage Voltage difference between I/O PWR and

I/O COM

Output Current Current flow — 300 mA

21.6V 28.0V

Publication 2098-IN001E-EN-P — April 2002

Page 46

2-20 Ultra5000 Connector Information

IMPORTANT

Digital Inputs

There are sixteen general purpose digital inputs. They are not

connected in hardware to perform a particular function. All digital

inputs have the same hardware configuration, shown in Figure 2.8

Configure your digital inputs, in a group, as active

high (current sinking) or active low (current

sourcing).

Inputs 1 and 2 use high-speed circuitry, with minimal propagation

delays, suitable for use in registration applications. Any input can be

assigned through firmware to latch the motor or auxiliary position in

hardware.

Figure 2.8

Digital Input Circuit

.

Publication 2098-IN001E-EN-P — April 2002

The following table provides a description of the digital input

specifications.

Parameter Description Minimum Maximum

ON State Voltage,

Active High

Configuration

ON State Voltage,

Active Low

Configuration

ON State Current Current flow to guarantee an ON State 3.0 mA 12.0 mA

OFF State Voltage,

Active High

Configuration

Voltage applied to the input, with

respect to IOCOM, to guarantee an ON

state.

Voltage applied to the input, with

respect to IOPWR, to guarantee an ON

state.

Voltage applied to the input, with

respect to IOCOM, to guarantee an OFF

state.

10.8V 26.4V

-26.4V -10.8V

-1.0V 3.0V

Page 47

Ultra5000 Connector Information 2-21

Parameter Description (Continued) Minimum Maximum

OFF State Voltage,

Active Low

Configuration

Propagation

Delay,

High Speed Inputs

Propagation

Delay,

Low Speed Inputs

Voltage applied to the input, with

respect to IOPWR, to guarantee an OFF

state.

Signal propagation delay from the high

speed digital input to the firmware

accessible registers, active high or

active low, turning ON or turning OFF.

Signal propagation delay from the low

speed digital input to the

firmware-accessible registers, active

high or active low, turning ON or turning

OFF.

-3.0V 1.0V

— 0.5 mS

— 100 mS

Publication 2098-IN001E-EN-P — April 2002

Page 48

2-22 Ultra5000 Connector Information

IMPORTANT

Digital Outputs

There are eight general purpose digital outputs. They are not

connected in hardware to perform a particular function. Seven digital

outputs are transistor outputs, and the drive has a single relay output

(Output 8) with normally open contacts.

The configuration of the transistor outputs is shown in Figure 2.9

the configuration of the relay output is shown in Figure 2.10

.

There is no overload protection on the transistor

outputs. To some degree, the bipolar transistors limit

their own current output, but they have not been

designed to specifically protect against shorts to

power or ground.

Figure 2.9

Transistor Output Hardware Configuration

, and

Publication 2098-IN001E-EN-P — April 2002

The following table provides a description of the transistor digital

output specifications.

Parameter Description Minimum Maximum

ON State

Current

OFF State

Current

ON State

Voltage

OFF State

Voltage

Current flow when the output transistor is ON — 50 mA

Current flow when the output transistor is OFF — 0.1 mA

Voltage across the output transistor when ON — 1.5V

Voltage across the output transistor when OFF — 50V

Page 49

Ultra5000 Connector Information 2-23

CN1A-26

Relay +

CN1A-27

Relay -

Normally

Open

Relay

AIN

1kW

1000pF

10kW

Figure 2.10

Relay Output Hardware Configuration

The following table provides a description of the relay output

specifications.

Parameter Description Minimum Maximum

ON State

Current

Current flow when the relay is closed — 1A

ON State

Contact resistance when the relay is closed — 1W

Resistance

OFF State

Voltage

OFF State

Voltage across the contacts when the relay is

— 30V

open

Current flow when the relay is open — 0.01 mA

Current

Analog Inputs

There are two single-ended general purpose analog inputs to use as

needed. A 12 bit A/D converter digitizes the signal. The configuration

of the input is shown in Figure 2.11

Figure 2.11

Analog Input Configuration

.

The following table provides a description of the analog COMMAND

input specifications.

Parameter Description Minimum Maximum

Resolution Number of states that the input signal is divided

into which is 2(to the number of bits).

Input

Impedance

Input Signal

Range

Open circuit impedance measured between the

+ and - inputs.

Voltage applied to the input - Usable -10V +10V

Voltage applied to the input - Limit -14V +14V

Publication 2098-IN001E-EN-P — April 2002

12 bits —

10 kW —

Page 50

2-24 Ultra5000 Connector Information

IMPORTANT

1kΩ