Page 1

Ultra5000 Series

Intelligent Positioning

Drives with DeviceNet

(Catalog Numbers

2098-IPD-005-DN,

2098-IPD-010-DN, and

2098-IPD-020-DN,

Reference Manual

Page 2

Important User Information

ATTENTION

!

IMPORTANT

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample progra

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

®

installation, Allen-Bradley

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI–1.1, Sa

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important di

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written perm

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

fferences between solid-state equipment and

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

does not assume responsibility or liability

ission of Rockwell Automation, is

ms and layout examples shown

fety Guidelines for the

Attention statements help you to:

• identif

• avoid a

• recognize the consequences

Allen-Bradley is a registered trademark of Rockwell Automation.

RSNetWorx, Ultra3000, Ultra5000 and Ultraware are trademarks of Rockwell Automation.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

y a hazard

hazard

Identifies information that is critical for successful

application and understanding of the product.

Publication 2098-RM002A-EN-P – October 2001

Page 3

Table of Contents

Preface Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . P-3

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-4

Chapter 1

The DeviceNet Interface

Installing, Connecting, & Commissioning Your Ultra5000 with

DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

DeviceNet Connector Pins and Signals (P2) . . . . . . . . . . 1-2

Planning Your DeviceNet Network . . . . . . . . . . . . . . . . 1-2

Connecting Your DeviceNet Cable . . . . . . . . . . . . . . . . 1-3

Configuring Your Ultra5000 with DeviceNet . . . . . . . . . . . . 1-5

DeviceNet Driver Installation

DeviceNet Overview

Chapter 2

Configuring Ultra5000 DeviceNet Using the DNetConfigData

Array. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Array Index 0 – PGM MAC ID. . . . . . . . . . . . . . . . . . . . 2-2

Array Index 1 – PGM Baudrate . . . . . . . . . . . . . . . . . . . 2-2

Array Index 2 – DeviceNet Module Fault Action. . . . . . . 2-2

Array Index 3 – DeviceNet Idle Fault Action . . . . . . . . . 2-3

Array Index 4 – DeviceNet Comm Fault Action . . . . . . . 2-3

Array Index 5 – I/O Transmit Select . . . . . . . . . . . . . . . 2-4

Array Index 6 – I/O Receive Select . . . . . . . . . . . . . . . . 2-5

Array Index 7 – DeviceNet Modules Status. . . . . . . . . . . 2-5

Array Index 8 – DeviceNet Loader Version . . . . . . . . . . 2-6

Array Index 9 – DeviceNet Server Version . . . . . . . . . . . 2-6

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Parameters and Electronic Data Sheet . . . . . . . . . . . . . . . . . 3-1

DeviceNet Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Predefined Master/Slave Connection Set . . . . . . . . . . . . 3-2

Explicit Response/Request Messages . . . . . . . . . . . . . . . 3-2

Polled I/O Command/Response Messages . . . . . . . . . . . 3-2

I/O Messaging and Explicit Messaging with DeviceNet . . . . 3-3

Selecting Input and Output Assemblies for I/O Messages . . 3-3

i Publication 2098-RM002A-EN-P – October 2001

Page 4

ii Table of Contents

Programming Reference

Chapter 4

Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

How Objects Affect Behavior . . . . . . . . . . . . . . . . . . . . 4-2

The Defined Object Interface . . . . . . . . . . . . . . . . . . . . 4-3

Object Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Data Type Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Identity Object (Class ID 01H) . . . . . . . . . . . . . . . . . . . . . . . 4-5

Reset Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Message Router Object (Class ID 02H) . . . . . . . . . . . . . . . . . 4-8

DeviceNet Object (Class ID 03H) . . . . . . . . . . . . . . . . . . . . . 4-9

Assembly Object (Class ID 04H) . . . . . . . . . . . . . . . . . . . . 4-11

DeviceNet Comm Fault Action. . . . . . . . . . . . . . . . . . . 4-14

DeviceNet Idle Fault Action. . . . . . . . . . . . . . . . . . . . . 4-14

Using Explicit Messaging to Control the Ultra5000 . . . . 4-15

Connection Object (Class ID 05H) . . . . . . . . . . . . . . . . . . . 4-16

Parameter Object (Class ID 0FH) . . . . . . . . . . . . . . . . . . . . 4-17

Get_Attribute_All Response . . . . . . . . . . . . . . . . . . . . . 4-52

Troubleshooting DeviceNet

Drives

Chapter 5

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Module Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Network Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Node Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Device Failure - LED Status Check . . . . . . . . . . . . . . . . . . . 5-3

Scanner Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cable Installation and Design Problems . . . . . . . . . . . . . . . 5-5

Adjusting the Physical Network Configuration . . . . . . . . . . . 5-5

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Publication 2098-RM002A-EN-P – October 2001

Page 5

Preface

Introduction

Who Should Use this Manual

Purpose of this Manual

Read this preface to become familiar with the organization of the

manual. In this preface, you will read about the following:

• Who Should Use this Manual

urpose of this Manual

• P

• Contents of this Manual

• Related Documentation

• Conventions Used in this Manual

• Allen-Bradley Support

This manual is intended for qualified service personnel responsible for

setting up and servicing the Ultra5000™ drive with DeviceNet™. You

must have previous experience with and a basic understanding of

electrical terminology, programming procedures, networking,

required equipment and software, and safety precautions.

This manual is a reference guide for using DeviceNet to configure,

monitor, or control Ultra5000 drives with DeviceNet.

Publication 2098-RM002A-EN-P – October 2001

Page 6

P-2 Preface

Contents of this Manual

This manual contains the following sections:

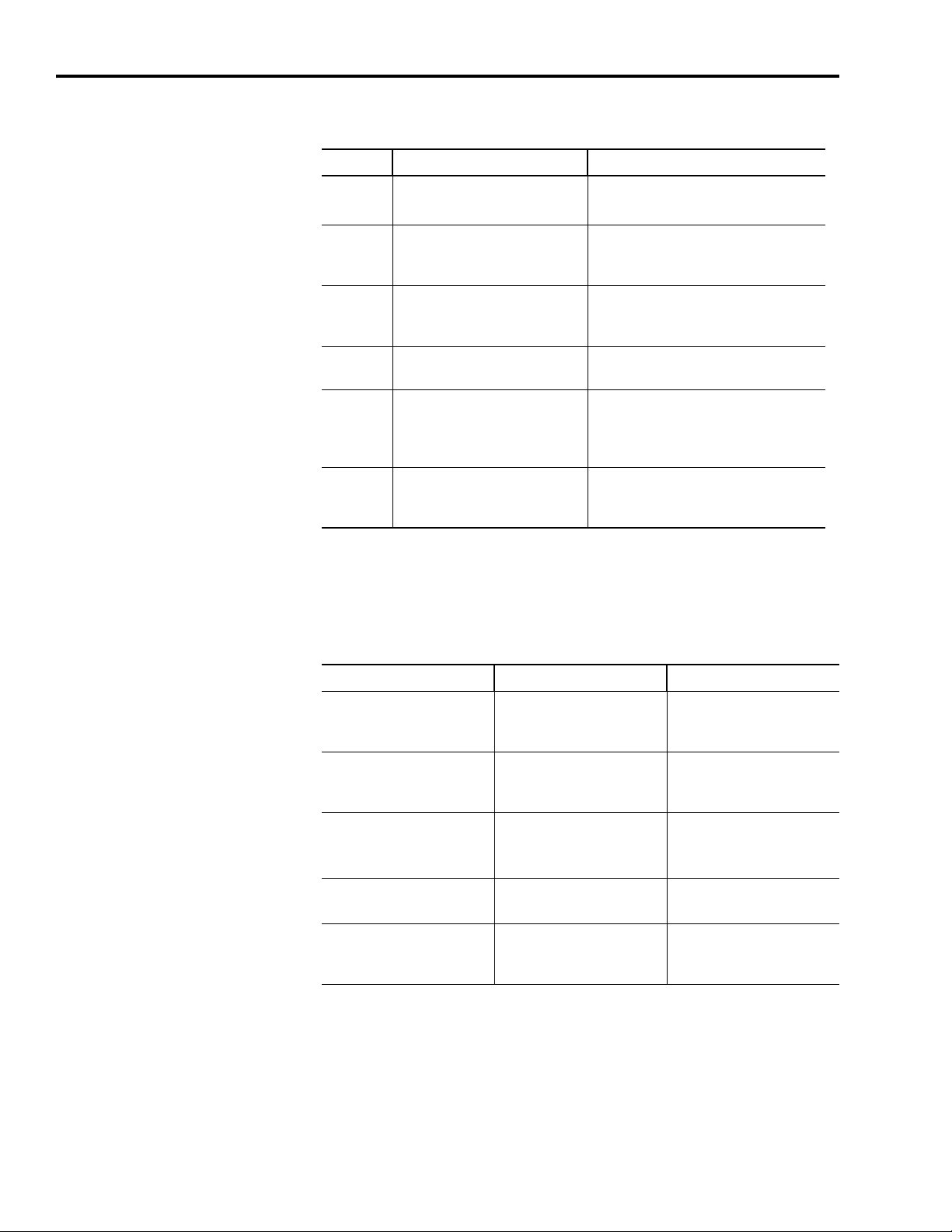

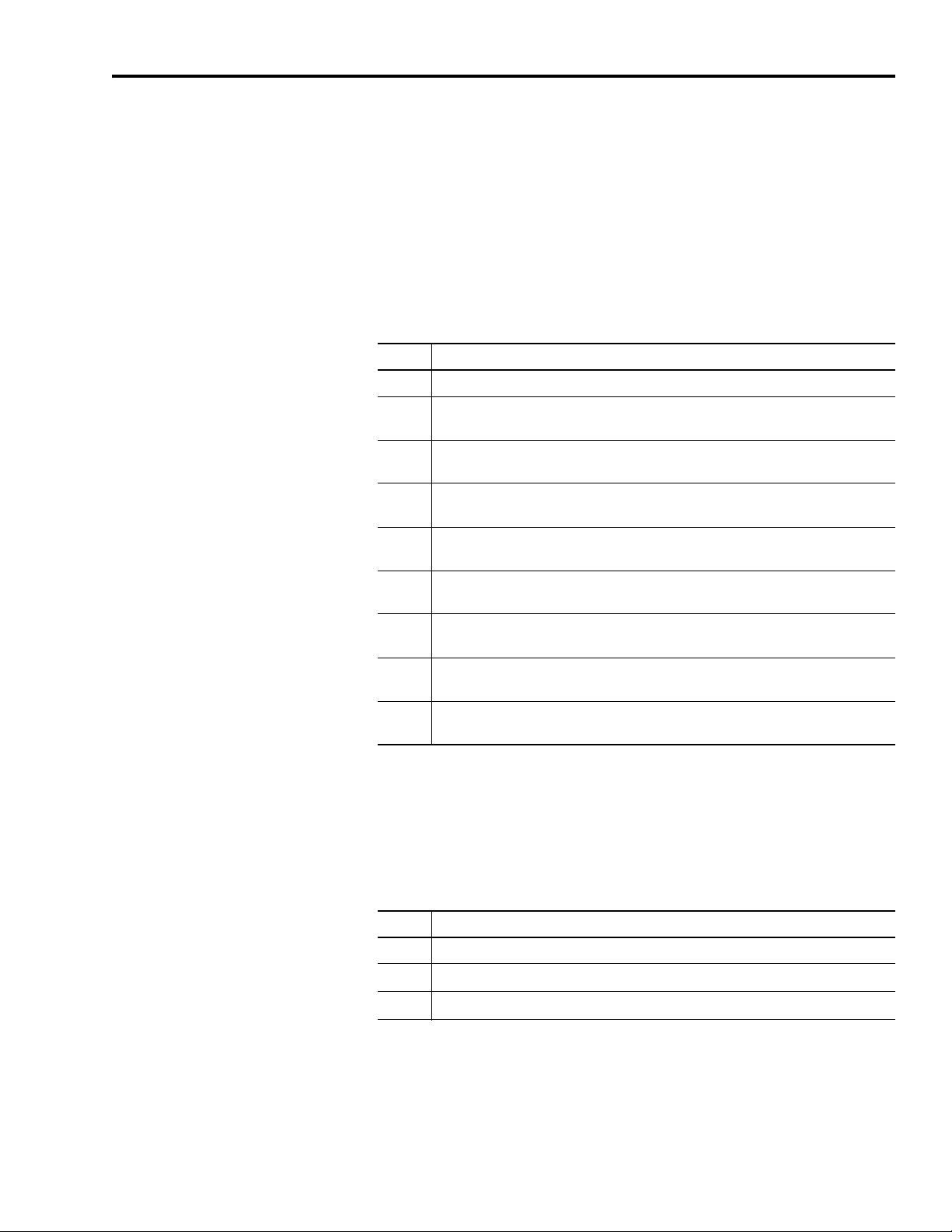

Chapter Title Contents

Preface An overview of this manual and

Allen-Bradley technical support.

1 The DeviceNet Interface Describes how to install, connect and

commission an Ultra5000 with

DeviceNet.

2 DeviceNet Driver Installation Describes loading of the drivers and

setup files for the Ultra5000 Drive with

DeviceNet.

3 DeviceNet Overview Introduces DeviceNet parameters and

messaging

4 Programming Reference Configuration data and behaviors

implemented in the Ultra5000 Drive

with DeviceNet are defined using object

modeling.

5 Troubleshooting DeviceNet

Drives

Describes troubleshooting actions for

DeviceNet interfaces to Ultra5000

drives.

Related Documentation

These publications provide additional information specific to the

Ultra5000 Drive with DeviceNet or DeviceNet in general. To obtain a

copy, contact your local Rockwell Automation office or distributor.

For information about: Read this document: Publication Number

A glossary of industrial

automation terms and

abbreviations

How to commission a

DeviceNet system.

An overview of

Allen-Bradley motion

controls and systems

How to use RSNetWorx™

A description of the

Ultra3000™ and Ultra5000

drives

Allen-Bradley Industrial

Automation Glossary

DeviceNet Cable System

Planning and Installation

Manual

Motion Control Selection

Guide

RSNetWorx for DeviceNet

Getting Results Manual

Ultra Family Brochure 2098-BR001x-EN-P

AG-7.1

DN-6.7.2

GMC-SG001x-EN-P

9399-DNETGR

Publication 2098-RM002A-EN-P – October 2001

Page 7

Preface P-3

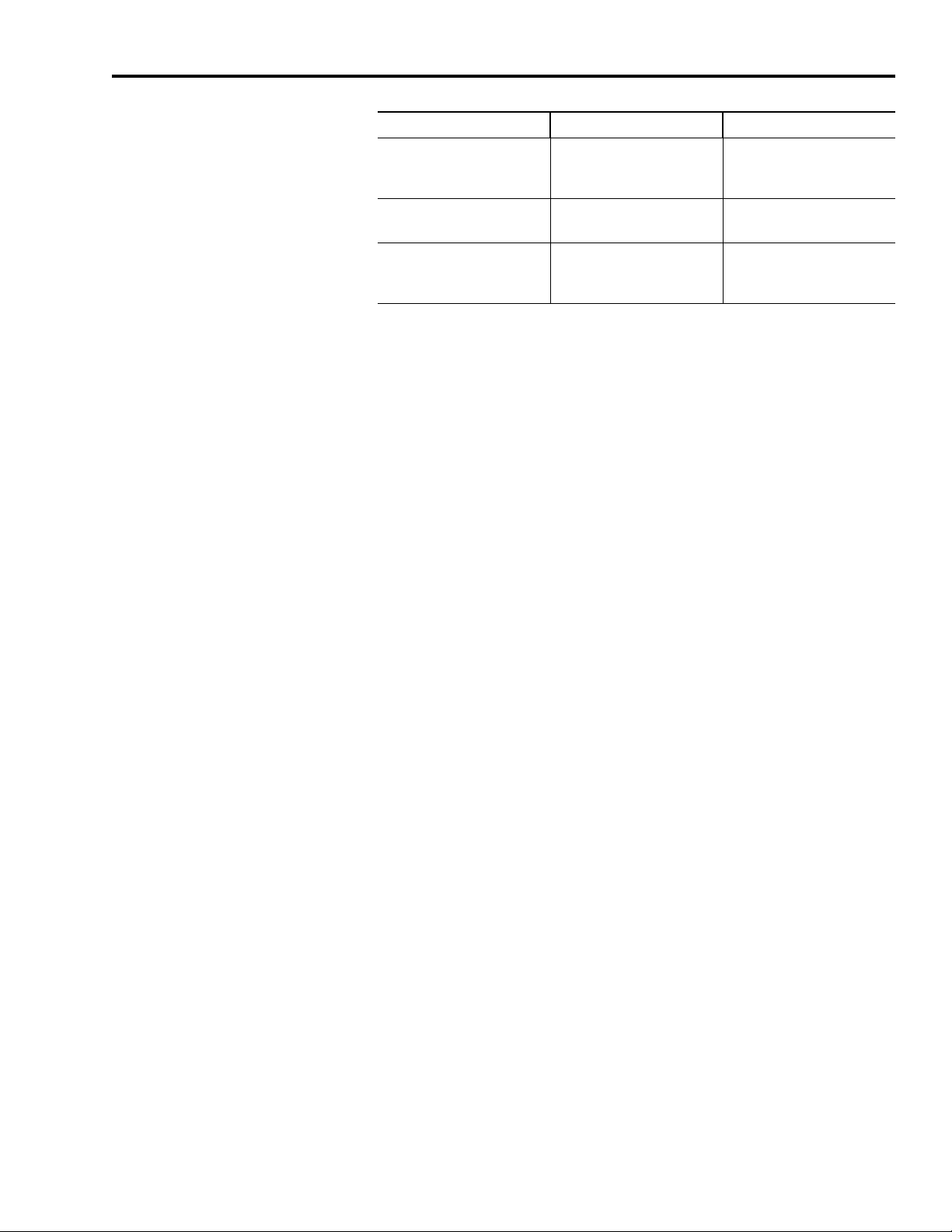

For information about: Read this document: Publication Number

How to install and

troubleshoot the Ultra5000

drive

How to install Ultraware™ Ultraware CD Installation

Ultra5000 Intelligent

Positioning Drive

Installation Manual

Instructions

2098-IN001x-EN-P

2098-IN002x-EN-P

Conventions Used in this Manual

Configuring the Ultra3000

DSD and Ultra5000 IPD

using Ultraware

Ultraware User Manual 2098-UM001x-EN-P

A copy of the DeviceNet Specification, Volumes I and II, Release 2.0

may be ordered from the web site http://www.odva.org of the Open

Device Vendor Association.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide infor

mation, not procedural

steps

• Numbered lists provide sequential steps or hierarchical information

• Words you type or select appear in bold.

• When we refer you to another location, the section or chapter

name appears in italics

• Software commands and parameters are listed with initial capitals

and hardware signals are listed in all capitals (e.g., Jog Program

Velocity parameter, and ENABLE signal).

Publication 2098-RM002A-EN-P – October 2001

Page 8

P-4 Preface

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors and 260 authorized

systems integrators locate

Allen-Bradley representatives in every major country in the world.

d throughout the United States alone, plus

Local Product Support

Contact your local Allen-Bradley representative for:

• Sales and order support

oduct technical training

• Pr

• Warranty support

• Support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in this manual or that listed in Related

Documentation on page Prepresentative. For the quickest possible response, we recommend

that

you have the catalog numbers of your products available when

you call.

2 first. Then call your local Allen-Bradley

Publication 2098-RM002A-EN-P – October 2001

Page 9

The DeviceNet Interface

Module Status

Network Status

LSD Node Address Selector Switch

Data Rate Selector Switch

MSD Node Address Selector Switch

DeviceNet Connector

Chapter

1

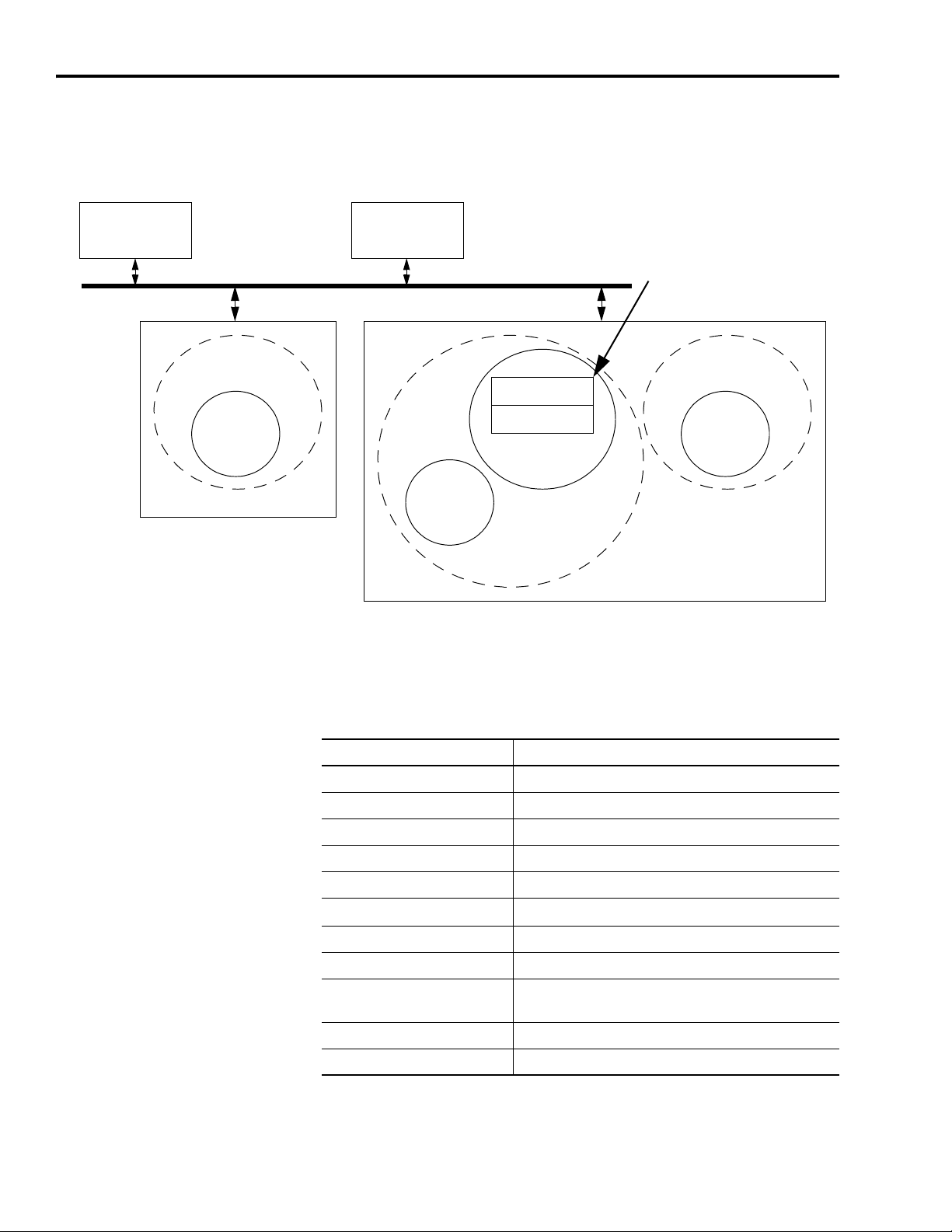

Installing, Connecting, & Commissioning Your Ultra5000 with DeviceNet

This manual serves as a reference for configuring, monitoring, and

controlling an Ultra5000 drive through a DeviceNet interface. The

following information is contained in this chapter.

iring the DeviceNet connector.

• W

• Setting

• Configuring the data (baud) rate.

• Understanding the DeviceNet LED indicators.

Refer to the Ultra5000 Intelligent Position

Manual (2098-IN001x-EN-P) for

installation and troubleshooting of the main drive unit.

Figure 1.1

Ultra5000 DeviceNet External Connections

drive addresses through the rotary switches.

g Drive Installation

in

additional information regarding

Publication 2098-RM002A-EN-P – October 2001

Page 10

1-2 The DeviceNet Interface

DeviceNet Connector Pins and Signals (P2)

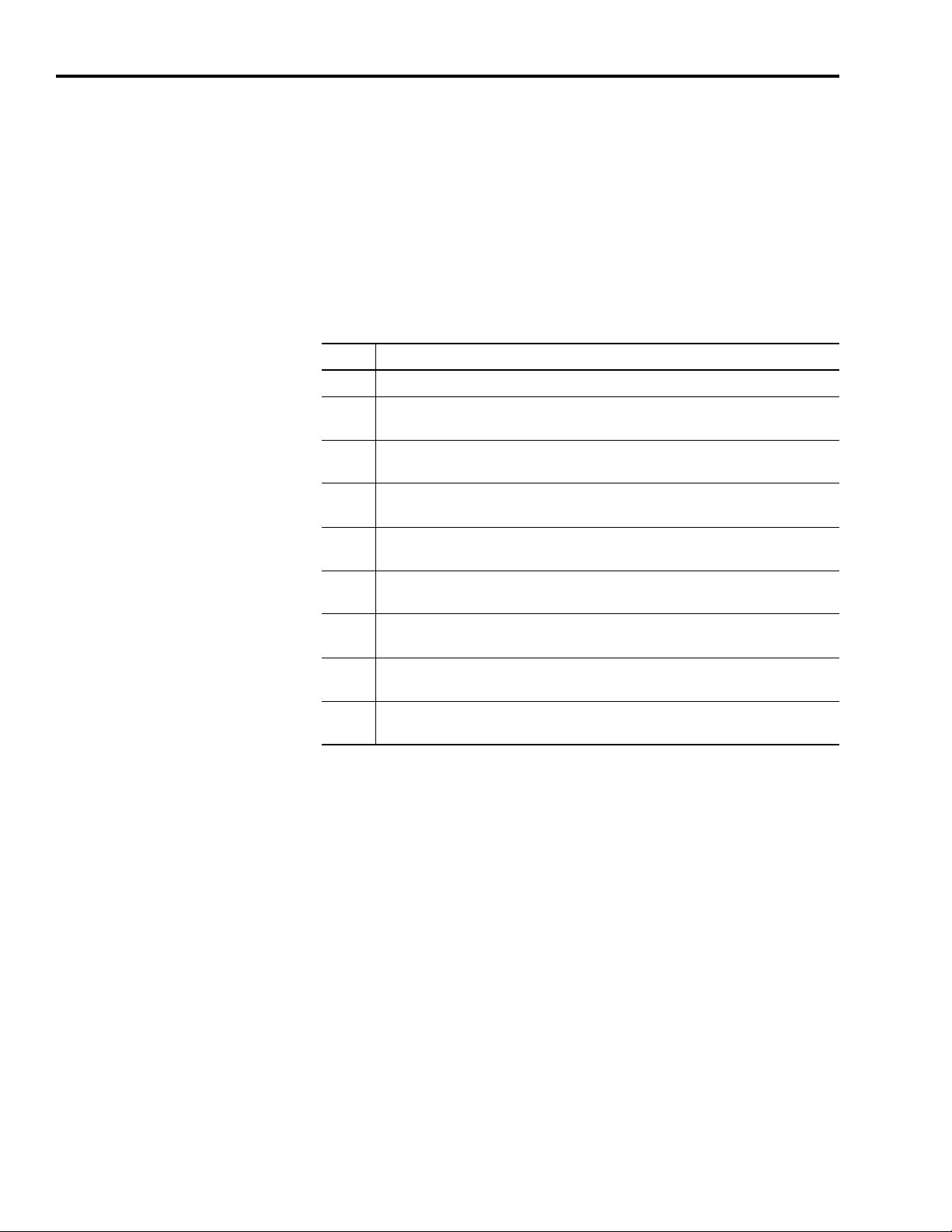

Pin Description Signal

1 Network Power Common 24V DC V-

2 Network Communication Signal Line Can_L

3 Shield Shield

4 Network Communication Signal Line Can_H

5 Network Power 24V DC V+

Planning Your DeviceNet Network

A DeviceNet network is a planned arrangement of electrical power

and device distribution that is adjusted for optimal communications.

Before you add devices, record the following:

• Net

• Ne

work data rate

twork cable system map (topology) to which you are connecting

• Distances between cable system components

• Device current draw and voltage drop for each device on the

network

• Limitation of the trunk and drop cables

Refer to the table below for recommended trunk and drop lengths.

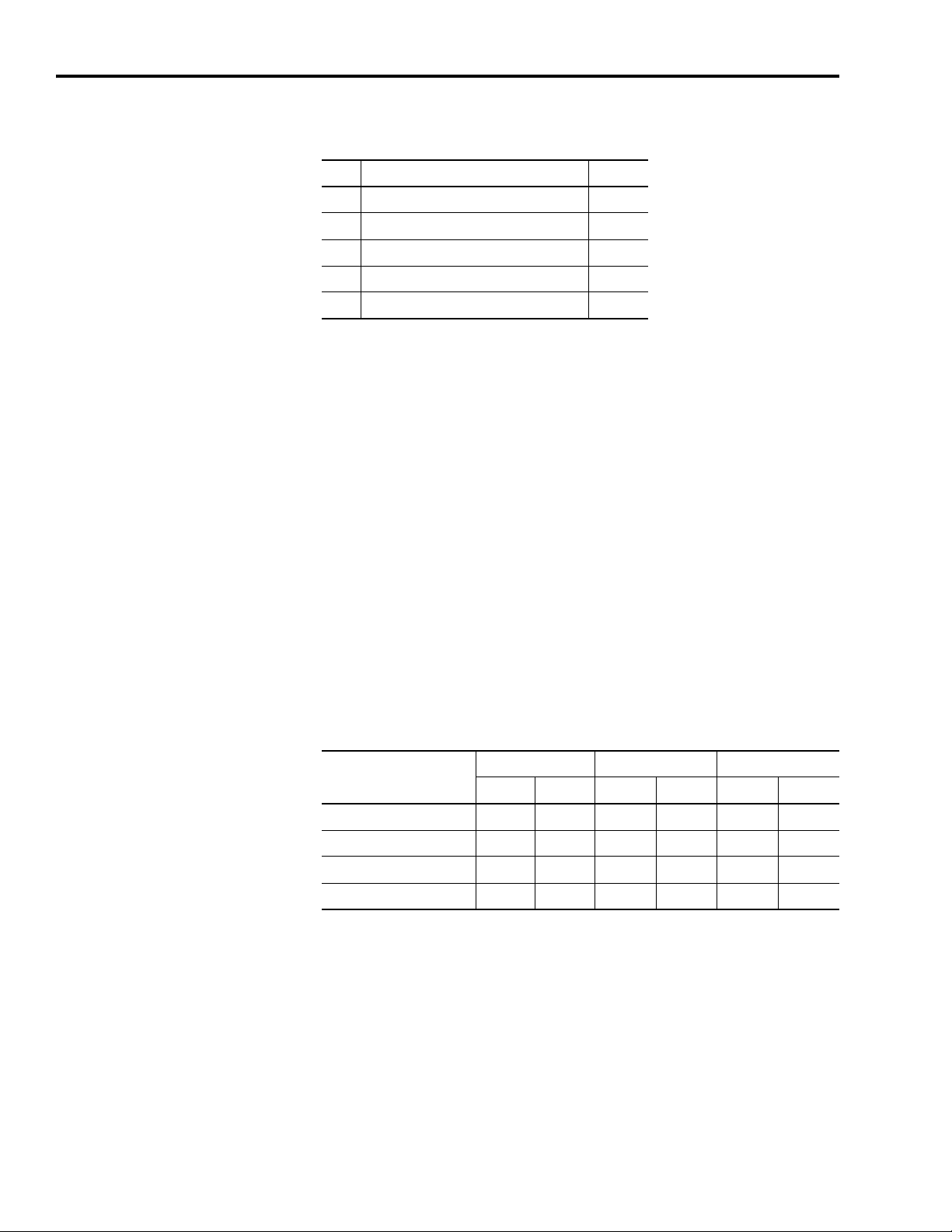

Data Rates 125 Kbps 250 Kbps 500 Kbps

meters feet meters feet meters feet

Thick Trunk Lines 500 1640 250 820 100 328

Thin Trunk Lines 100 328 100 328 100 328

Maximum Drop Length 6 20 6 20 6 20

Cumulative Drop Budget 156 5120 78 256 39 128

Refer to the DeviceNet Cable System Planni

ng and

Installation

Manual (publication DN-6.7.2) for specific guidance in calculating

and attaching the Ultra500

0 to a network.

Publication 2098-RM002A-EN-P – October 2001

Page 11

The DeviceNet Interface 1-3

Outer Jacket

Braided Shield

6.4 mm

(0.25 in)

Outer Jacket

Shrink Wrap

38 mm

(1.5 in)

Outer Jacket

Shrink Wrap

8.1 mm

(0.32 in)

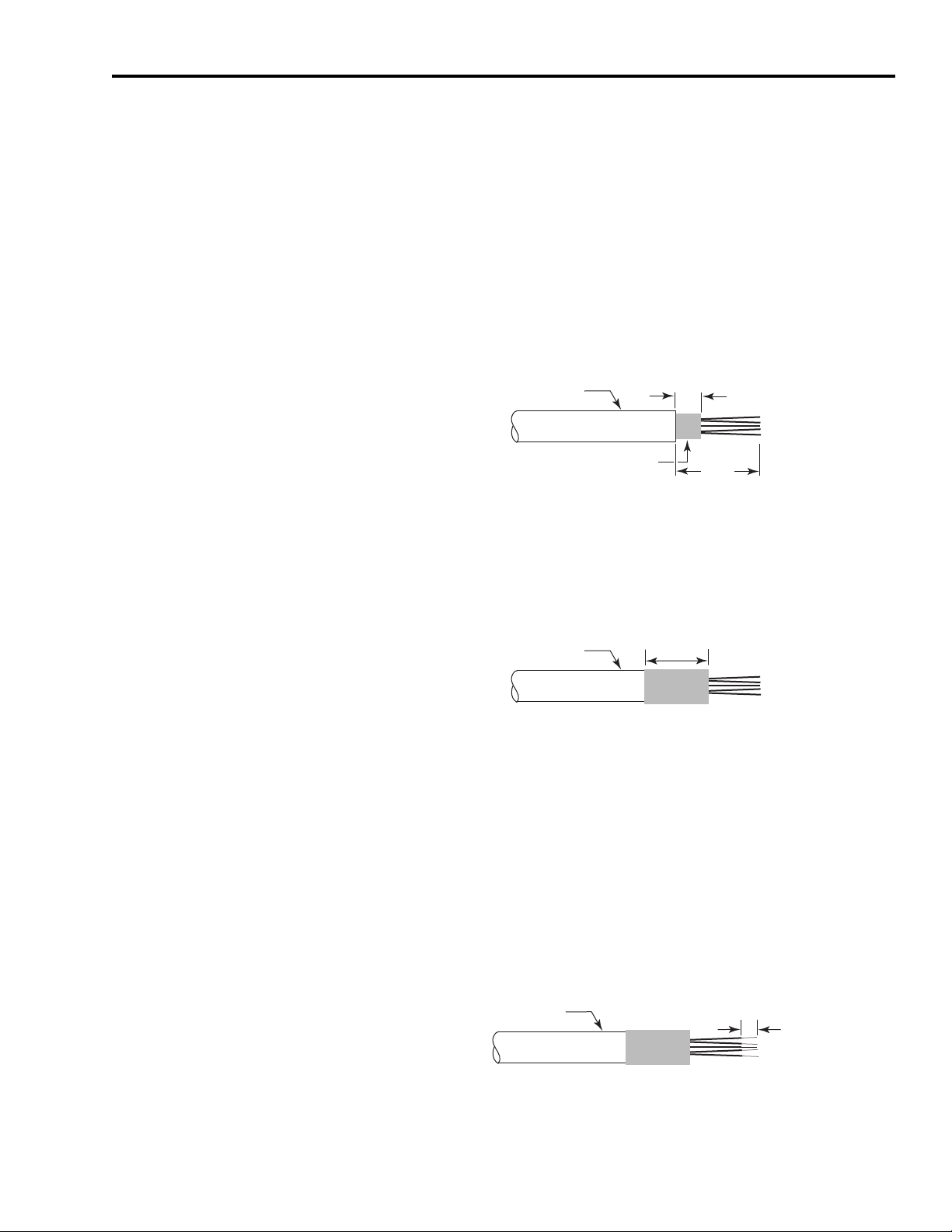

Connecting Your DeviceNet Cable

To attach a plugable, open style, screw-connector to the DeviceNet

cable:

1. Strip 65 mm (2.6 in.) to 75 mm (2.96 in.) of the outer jacket from

the end of the cable, leaving no more than 6.4mm (0.25 in.) of the

braided shield exposed.

Figure 1.2

Exposing the braided shield

2. Wrap the end of the cable with 38 mm (1.5 in.) of shrink wrap,

covering part of the exposed wires and part of the outer jacket.

Figure 1.3

Adding shrink wrap

3. Strip 8.1 mm (0.32 in.) of the insulation from the end of each of

the insulated wire.

Note: Be careful not to nick, cut, or otherwise damage the

individual strands of wire.

Trim the last 6.5 mm (0.26 in.) of the bare wires so that the outside

dimension does not exceed 0.17 mm (0.045 in.).

Figure 1.4

Exposing wire stands

Publication 2098-RM002A-EN-P – October 2001

Page 12

1-4 The DeviceNet Interface

5

4

3

2

1

23 145

Red (V+)

White (Can_H)

Bare (Shield)

Blue (Can_L)

Black (V-)

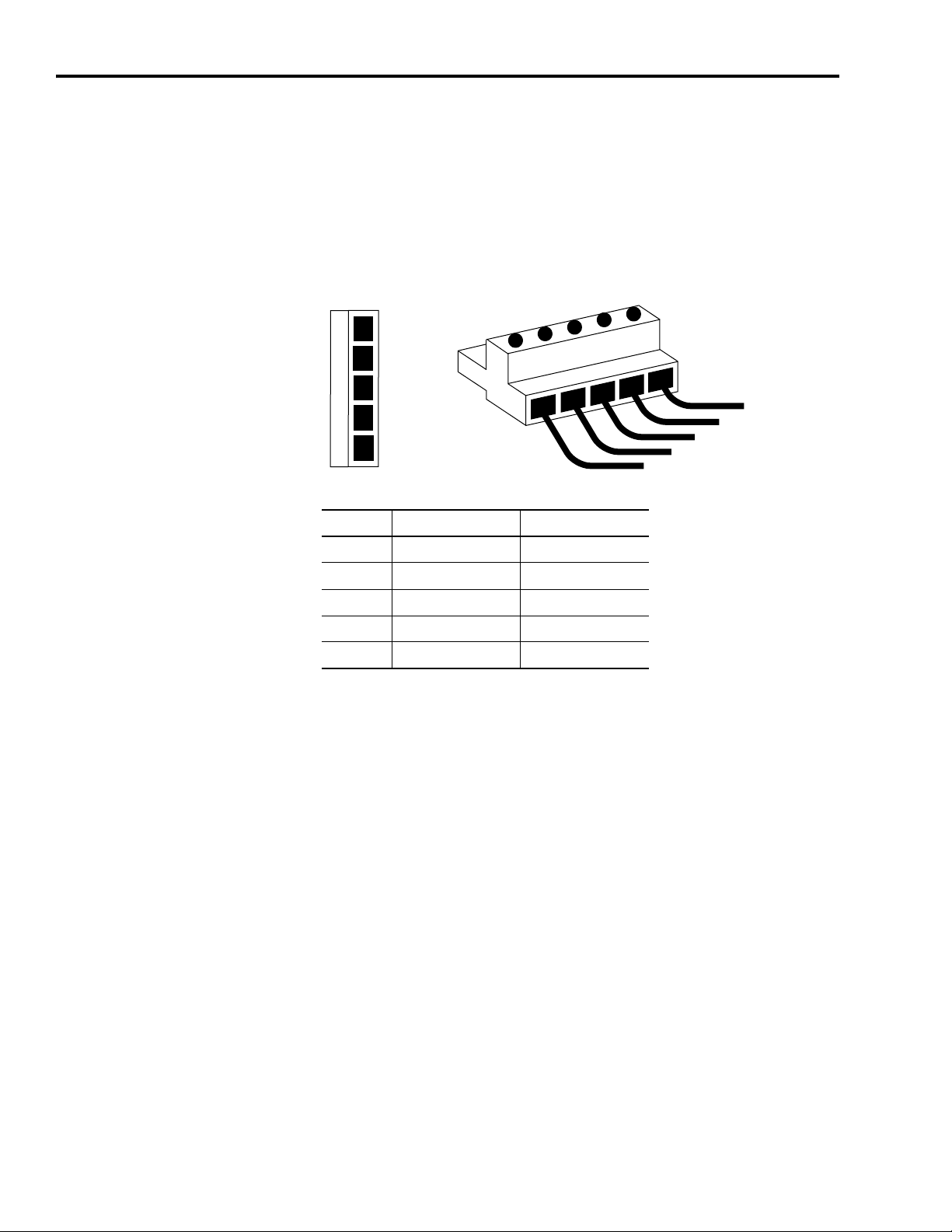

Plug Connector

4. Insert each wire into the appropriate clamping cavity of the

plugable screw connector, according to the color of the cable

insulation.

5. Use an 1/8 inch flat blade screwdriver to attach wires in the

connector. Firmly tighten the clamping screws to secure each wire.

Figure 1.5

Wiring the DeviceNet connector

Terminal Cable Color Designation

1 Black V -

2 Blue Can_L

3 Bare Shield

4 White Can_H

5 Red V +

6. Insert the connector on the Ultra5000 drive to attach the

DeviceNet network.

Publication 2098-RM002A-EN-P – October 2001

Page 13

The DeviceNet Interface 1-5

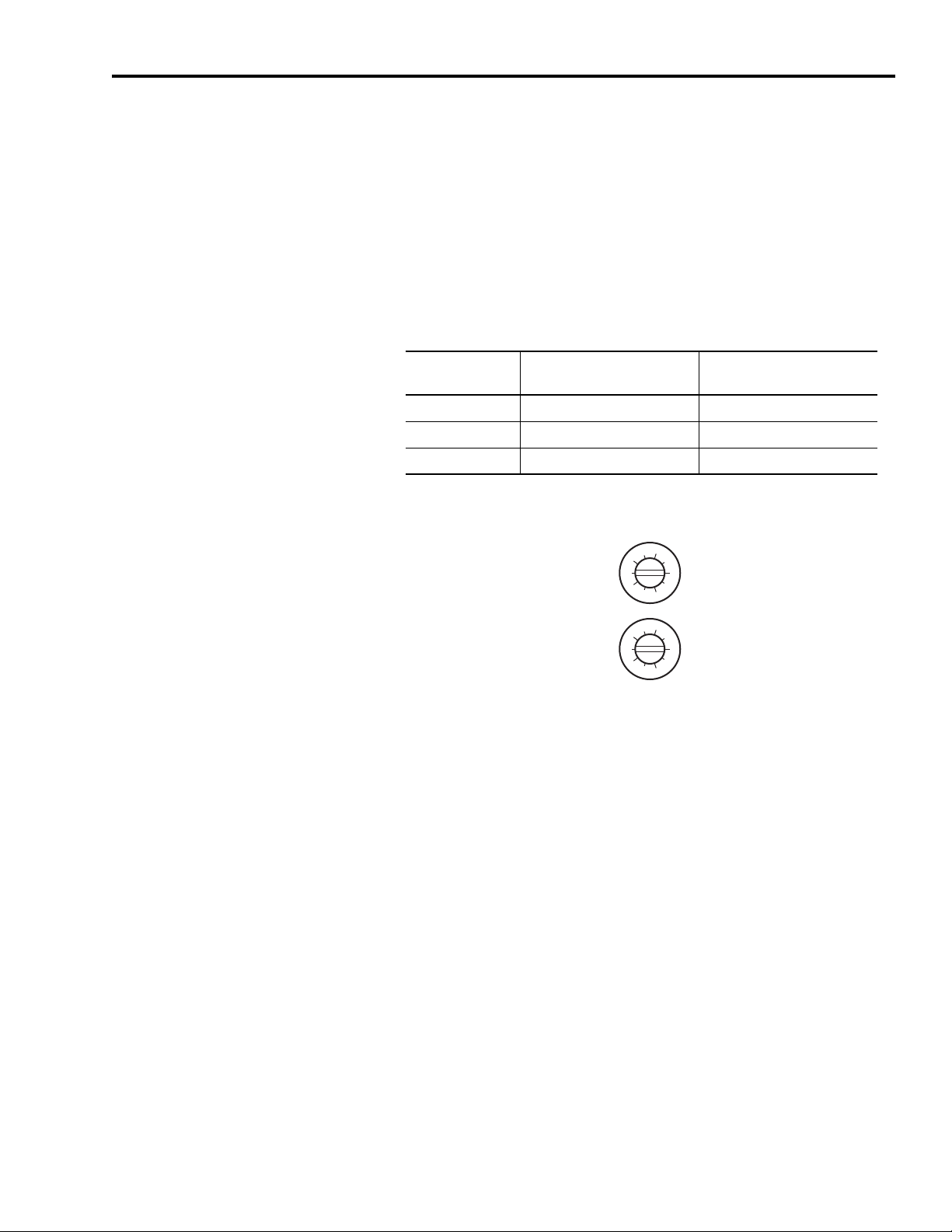

Use the MSD and LSD rotary switches on the

DeviceNet panel of the drive to set node

addresses.

MSD

LSD

0

8

6

4

2

0

8

6

4

2

Configuring Your Ultra5000 with DeviceNet

To configure your Ultra5000 drive with DeviceNet:

1. Verify that there is no power applied to the drive, and the

Dev

iceNet cable is connected (refer to figures 1.1 through 1.5 in

this chapter.

2. Set the node address for each drive in your system. Valid node

addresses are 00-63 and PGM. The MSD rotary switch, Figure 1.6,

sets the most significant digit and the LSD rotary switch sets the

least significant digit. For switch locations, refer to Figure 1.1 on

page 1-1 of this chapter. The following table provides examples.

For this Node

Address:

10 1 0

11 1 1

12 1 2

Figure 1.6

MSD and LSD Rotary Switches

Set the MSD switch to: Set the LSD switch to:

Note: Selecting an invalid node address (> 63) sets the node

address according to a non-volatile parameter stored in the

drive.

Refer to the Ultra5000 Intelligent Positioning Drive Installation

Manual (2

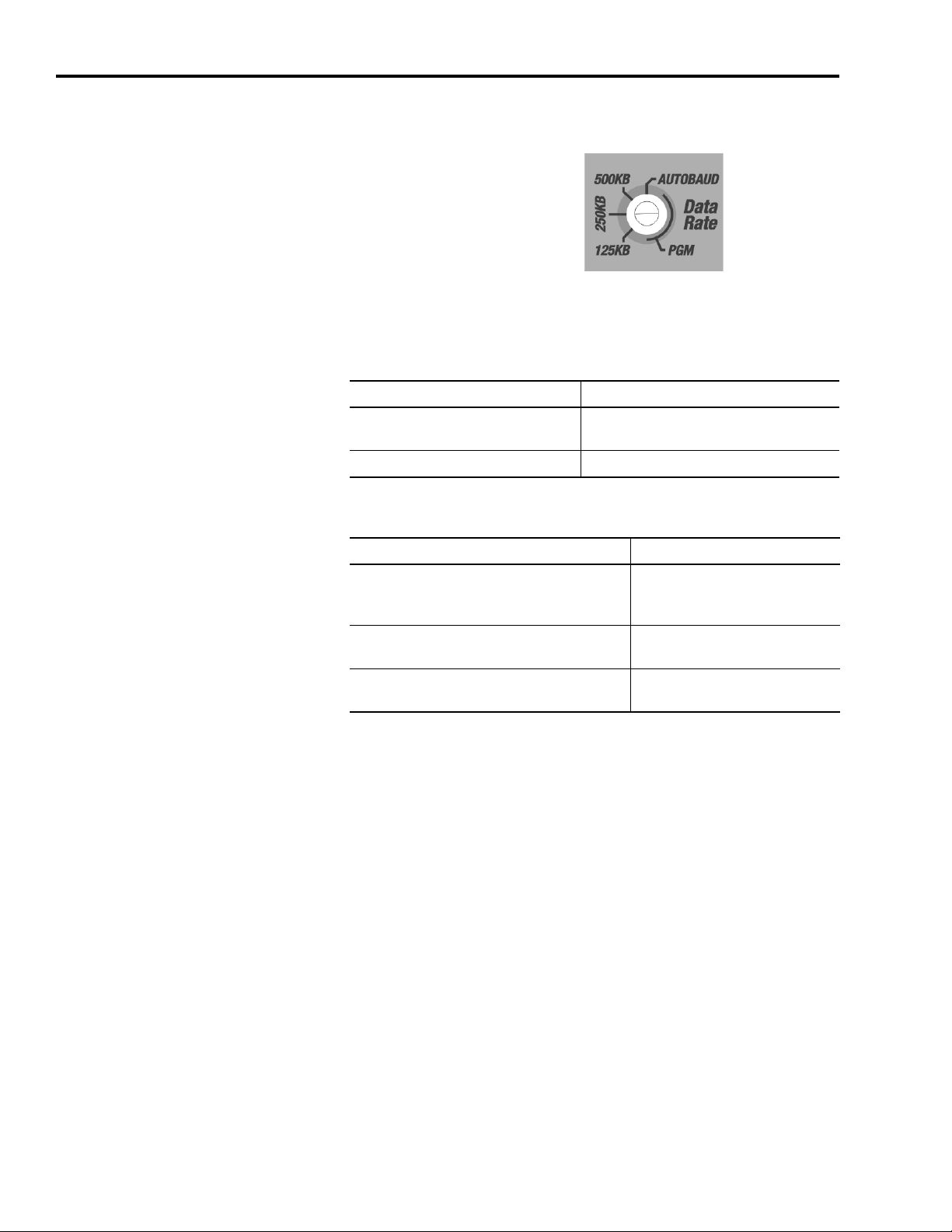

3. Set the data rate switch, Figure 1.

098-IN001x-EN-P) for a listing of reserved node addresses.

7, to the established DeviceNet

network data rate. Valid data rates are 125 kbps, 250 kbps, 500

kbps, AUTO, and PGM. Refer to Figure 1.1 on page 1-1 for the

switch location on the drive.

Note: Selecting AUTO automatically matches the device data rate

to the rate of the network. Selecting PGM sets the data rate

according to a non-volatile parameter stored in the drive.

Publication 2098-RM002A-EN-P – October 2001

Page 14

1-6 The DeviceNet Interface

Use the Data Rate rotary switch on the DeviceNet

panel of the drive to set the data rate.

Figure 1.7

Data Rate Rotary Switch

4. Apply power to the drive.

5. Observe the module status LED.

If the module status LED: Then:

Is not steady green Refer to Troubleshooting DeviceNet Drives

on page 5-1.

Is steady green The drive is ready. Go to step 6.

6. Observe the network status LED.

If the network status LED: Then:

Is off Establishing communication with

network (wait for flashing or

steady green).

Is not flashing or steady green Refer to Troubleshooting

DeviceNet Drives on page 5-1.

Is flashing or steady green Communication is ready. Go to

Chapter 2.

Publication 2098-RM002A-EN-P – October 2001

Page 15

Chapter

IMPORTANT

2

DeviceNet Driver Installation

Follow the procedure listed in the Ultraware User Manual (publication

2098-UM001x-EN-P) to load and create the requisite DeviceNet drivers

for the Ultra5000 drive.

1. Install the following files as Drivers to the Ultra5000 drive:

• DNetLoad.exe

• DNe

. Load the following files to the Files branch of the Ultra5000 drive:

2

• DNetBoot.hex

• DNetMain.hex

3.

Cycle power on the Ultra5000 and verify that within

approximate

DeviceNet interface is lit (on). This indicates successful installation

of the drivers. The Module Status LED will flash red-green while

the DeviceNet interface card is being initialized.

4. Select Rescan from the Tools menu. Verify the DNetServ.exe

automatically creates

Workspace of the Ultra5000 drive.

Name Type Number of Elements

DNetConfigData Long Int 8

DNetIntArray Long Int 32

DNetFltArray Float 32

tServ.exe

l

y 15 seconds the green Module Status LED on the

the following Global Variables in the

If the Ultra5000 Drive Properties are Reset to Factory

Settings with Ultraware, the DeviceNet drivers are

erased and must be reinstalled.

Publication 2098-RM002A-EN-P – October 2001

Page 16

2-2 DeviceNet Driver Installation

ATTENTION

!

Configuring Ultra5000 DeviceNet Using the DNetConfigData Array

The DNetConfigData array is the interface for configuring

DeviceNet on the Ultra5000. The array is a standard Ultra5000 long

integer array and is automatically created by the DeviceNet driver

program. For more information on arrays, see the Ultra5000

Programming Manual.

Array Index 0 – PGM MAC ID

The programmed non-volatile DeviceNet Node Address (MAC ID).

Value Description

0 to 63 MAC ID range (default is 63)

Array Index 1 – PGM Baudrate

The programmed non-volatile DeviceNet Data Rate.

Value Description

0 125 kps (default)

1 250 kps

2 500 kps

3 Autobaud

Array Index 2 – DeviceNet Module Fault Action

Risk of severe bodily injury or equivalent damage

exists.

The Module Fault Action value allows you to change

the default configuration, and to potentially allow the

drive to continue to operate when communication

with the DeviceNet module is lost.

Determines the action the drive should take when it cannot

communicate with the DeviceNet module.

Value Description

0

DeviceNet fault E14 (default)

Publication 2098-RM002A-EN-P – October 2001

1 Ignore

Page 17

DeviceNet Driver Installation 2-3

ATTENTION

!

ATTENTION

!

Array Index 3 – DeviceNet Idle Fault Action

Risk of severe bodily injury or equivalent damage

exists.

The Idle Fault Action value allows you to change the

default configuration, and to potentially allow the

drive to continue to operate when communication

with the DeviceNet module is lost.

Determines the action the drive should take if the master sends a zero

length I/O message to the drive, which may occur if a PLC (master) is

set to program mode. No action will be taken if I/O Receive Select is

set to 0 (No data consumed).

Value Description

0

1 Ignore

DeviceNet fault E14 (default)

Array Index 4 – DeviceNet Comm Fault Action

Risk of severe bodily injury or equivalent damage

exists.

The Comm Fault Action value allows you to change

the default configuration, and to potentially allow the

drive to continue to operate when communication

with the DeviceNet module is lost.

Determines the action the drive should take if the drive detects a

network failure while an I/O messaging connection is active.

Value Description

0

1 Ignore

DeviceNet fault E14 (default)

Publication 2098-RM002A-EN-P – October 2001

Page 18

2-4 DeviceNet Driver Installation

Array Index 5 – I/O Transmit Select

Selects the input (produced) assembly that is transmitted by the drive

over a Polled I/O Messaging Connection. If the value is modified, you

have to either close any existing I/O Messaging connection(s), power

cycle the drive, reset the drive, or remove and reapply DeviceNet

power for the drive to use the modified value.

Refer to Assembly Object, Instance ID = 1 - 16 on page 4-12 for

information on the data format.

Value Description

0 No data produced.

1 One Integer:

DNetIntArray[0]

2 Two Integers:

DNetIntArray[0], DNetIntArray[1]

3 One Float:

DNetFltArray[0]

4 Two Floats:

DNetFltArray[0], DNetFltArray[1]

5 One Integer, One Float:

DNetIntArray[0], DNetFltArray[0]

6 Two Integers, One Float:

DNetIntArray[0], DNetIntArray[1], DNetFltArray[0]

7 One Integer, Two Floats:

DNetIntArray[0], DNetFltArray[0], DNetFltArray[1]

8 Two Integers, Two Floats:

DNetIntArray[0], DNetIntArray[1], DNetFltArray[0], DNetFltArray[1]

Publication 2098-RM002A-EN-P – October 2001

Page 19

DeviceNet Driver Installation 2-5

Array Index 6 – I/O Receive Select

Selects the output (consumed) assembly that is updated when a

Polled I/O Message is received by the drive. If the value is modified,

you have to either close any existing I/O Messaging connection(s),

power cycle the drive, reset the drive, or remove and reapply

DeviceNet power for the drive to use the modified value.

Refer to Assembly Object, Instance ID = 1 - 16 on page 4-12 for

information on the data format.

Value Description

0 No data consumed

1 One Integer:

DNetIntArray[2]

2 Two Integers:

DNetIntArray[2], DNetIntArray[3]

3 One Float:

DNetFltArray[2]

4 Two Floats:

DNetFltArray[2], DNetFltArray[3]

5 One Integer, One Float:

DNetIntArray[2], DNetFltArray[2]

6 Two Integers, One Float:

DNetIntArray[2], DNetIntArray[3], DNetFltArray[2]

7 One Integer, Two Floats:

DNetIntArray[2], DNetFltArray[2], DNetFltArray[3]

8 Two Integers, Two Floats:

DNetIntArray[2], DNetIntArray[3], DNetFltArray[2], DNetFltArray[3]

Array Index 7 – DeviceNet Modules Status

This is a read-only value that indicates the last modules fault status.

This value defaults to zero on power up and reset.

Value Description

0 No Fault (default)

1

DeviceNet Idle Fault

2

DeviceNet Comm Fault

Publication 2098-RM002A-EN-P – October 2001

Page 20

2-6 DeviceNet Driver Installation

Array Index 8 – DeviceNet Loader Version

This is a read-only value that indicates the current version of

DNetLoad.exe. The version number is displayed without periods (e.g.

version 1.2.0 will display as 120).

Array Index 9 – DeviceNet Server Version

This is a read-only value that indicates the current version of

DNetServ.exe. The version number is displayed without periods (e.g.

version 1.2.0 will display as 120).

Publication 2098-RM002A-EN-P – October 2001

Page 21

DeviceNet Overview

Chapter

3

Introduction

Features

DeviceNet is an open, global industry-standard communication

network. It is designed to provide an interface from a programmable

controller through a single cable directly to smart devices such as

sensors, push buttons, motor starters, simple operator interfaces and

drives.

The Ultra5000 Drive with DeviceNet Interface provides the following

features:

tra5000 Drive with DeviceNet implements the Unconnected

• Ul

Me

ssage Manager (UCMM) which is used to establish a Group 3

Explicit Message connection. Up to five Group 3 Explicit Messaging

connections can be established.

• Faulted-node Recovery, allows the node address of a device to be

changed even when it is faulted on the network. This feature

requires the support of proper PC software tools and the Node

Address (0-63, PGM) switches be set to the PGM (program)

position.

• Software configuration lets you configure the Ultra5000 Drive with

DeviceNet using RSNetWorx for DeviceNet (3.00.01 or later, version

3.00 with Service Pack 1).

Parameters and Electronic Data Sheet

• Autobaud allows the drive to determine the network data rate.

Note: User programs and files cannot be loaded to the Ultra5000 drive

over DeviceNet.

The Ultra5000 with DeviceNet contains a set of parameters that are

used to configure and monitor the drive. You can perform

configuration by changing the values associated with individual

parameters. Parameter values may be written and read via DeviceNet.

Writing a value to a parameter may configure drive operations such as

the acceleration or deceleration rates. Writing a value to a parameter

may also configure DeviceNet operations such as which input and

output assemblies are to be used for I/O communications with a

master (scanner). The parameter set is documented in Programming

Reference beginning on page 4-1.

Publication 2098-RM002A-EN-P – October 2001

Page 22

3-2 DeviceNet Overview

Electronic Data Sheet (EDS) files are specially formatted ASCII files

that provide all of the information necessary for a configuration tool

such as RSNetworx for DeviceNet to access and alter the parameters

of a device. Information about each parameter is contained in the file

such as parameter min, max, and default values, parameter data

format and scaling, and the parameter name and units. You can create

or access an EDS file stored in the Ultra5000 Drive with DeviceNet via

RSNetworx for DeviceNet (3.00.01 or later, version 3.00 with Service

Pack 1) or download an EDS file for the Ultra5000 Drive with

DeviceNet f

www.ab

rom Rockwell Automation/Allen-Bradley web-site

.com/networks/eds.

DeviceNet Messaging

The Ultra5000 with DeviceNet operates as a slave device on a

DeviceNet network. The drive supports Explicit Messages and Polled

I/O Messages of the predefined master/slave connection set. The

drive also supports the Unconnected Message Manager (UCMM) so

that up to five Group 3 Explicit Message connections may be

established with the drive.

Predefined Master/Slave Connection Set

A set of messaging connections that facilitate communications and is

typically seen in a master/slave relationship is known as the

Predefined Master/Slave Connection set. The master is the device that

gathers and distributes I/O data for the process controller. A

DeviceNet master scans its slave devices based on a scan list it

contains. Each slave device returns I/O data to its master device.

The I/O data exchanged over this connection is pre-defined.

Explicit Response/Request Messages

Publication 2098-RM002A-EN-P – October 2001

Explicit Request messages are used to perform operations such as

reading and writing parameter values. Explicit Response messages

indicate the results of the attempt to service an Explicit Request

message.

Polled I/O Command/Response Messages

The Poll Command is an I/O message transmitted by the master

device. A Poll Command is directed toward a specific slave device. A

separate Poll Command must be sent to each slave device that is to be

Page 23

DeviceNet Overview 3-3

polled. The Poll Response is the I/O message that the slave device

transmits back to the master device.

I/O Messaging and Explicit Messaging with DeviceNet

Selecting Input and Output Assemblies for I/O Messages

You can configure and monitor the drive with either I/O Messaging or

Explicit Messaging. I/O messages are for time-critical, control-oriented

data. I/O messages typically are used for moving predefined data

repeatedly with minimum protocol overhead. Explicit Messages

provide multi-purpose, point-to-point communication paths between

two devices. Explicit Messaging typically would not be used to

exchange data periodically since I/O Messages have a higher priority

and lower protocol overhead than Explicit Messages. However,

Explicit Messages have more flexibility by specifying a service to be

performed and a specific address.

The Ultra5000 with DeviceNet provides sixteen generic Input and

Output Assemblies. The choice of which Input and/or Output

Assembly to use should be based on the type of information that is

appropriate in the particular system. The I/O Assemblies are mapped

to the first four 32-bit values of the Long Integer (DNetIntArray) and

Floating-point (DNetFltArray) arrays

The Ultra5000 has no pre-defined information stored in these

location

control, and it is the responsibility of the user program(s) to update

and utilize the values as necessary.

s. The contents of the locations are under user program

The choice of which Input and Output Assembly to use should be

ba

sed on what sort of information is appropriate in a particular

system. You should keep in mind that larger assemblies utilize more

network bandwidth. Information on the data format of all the

Assemblies is given in Assembly Object (Class ID 04H) on page 4-11.

Publication 2098-RM002A-EN-P – October 2001

Page 24

3-4 DeviceNet Overview

Publication 2098-RM002A-EN-P – October 2001

Page 25

Chapter

4

Programming Reference

The Ultra5000 Drive with DeviceNet implements a vendor specific

device profile - Rockwell Automation Miscellaneous (Device Type:

73hex).

The configuration data and behaviors implemented in the Ultra5000

Drive with De

Ultra5000 Drive with DeviceNet is modeled as a collection of objects.

An Object is a collection of related attributes and services. An attribute

is an externally visible characteristic or feature of an object, while a

service is a procedure an object can perform.

The following general definitions also may be useful in understanding

DeviceNe

viceNet are defined using object modeling. The

t object modeling:

Object Model

ject - A representation of a particular type of data component

• Ob

withi

n the DeviceNet node.

• Instance - A specific occurrence of an Object.

• Attribute - A description of a characteristic or feature of an Object.

Attributes provide status information or govern the operation of an

Object.

• Service - A function performed by an Object.

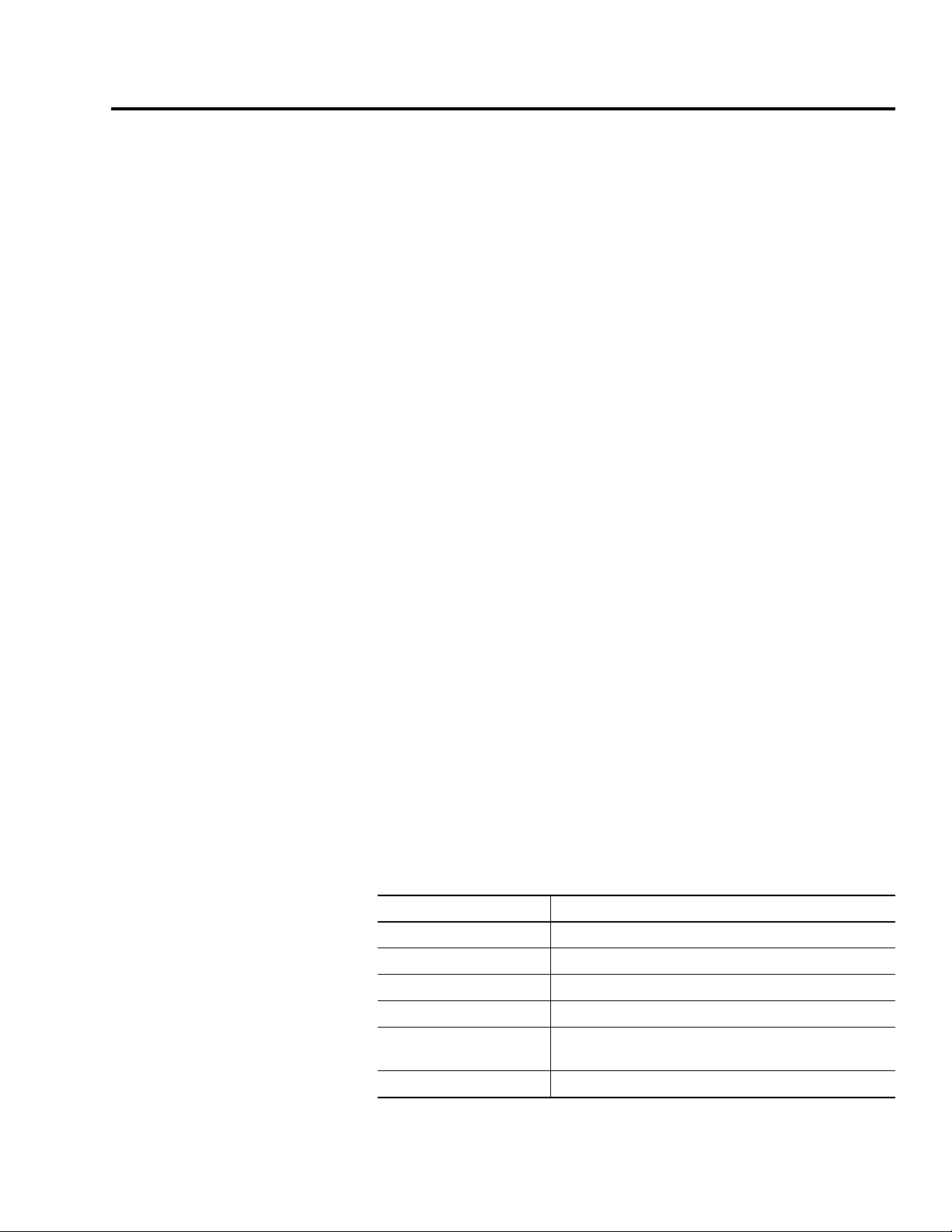

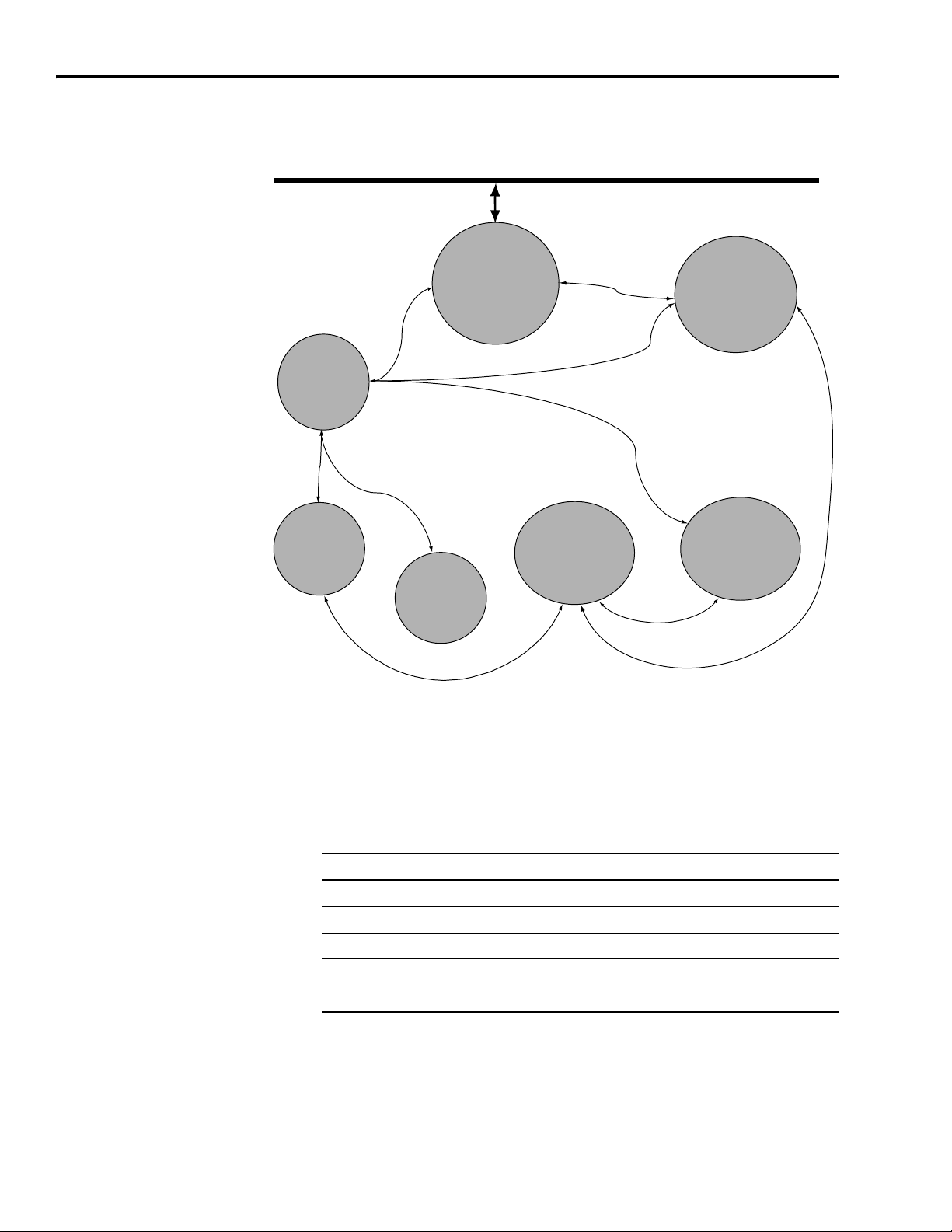

The Object Model diagram on Page 4-2 depicts the objects supported

in the Ultra5000 Drive with DeviceNet. The following table indicates

object classes present in this device, and the number of instances

the

present in each class.

Object Class Number of Instances

Identity 4

Message Router 1

DeviceNet 1

Assembly 16

Connection 1 - I/O

6 - Explicit

Parameter 340

Publication 2098-RM002A-EN-P – October 2001

Page 26

4-2 Programming Reference

Class ID #2

0X02

02

H

Class ID #1

0X01

01

H

Class ID #3

0X03

03

H

Class ID #15

0X0F

0F

H

Class ID #4

0X04

04

H

05

H

Class ID #5

0X05

05

H

DeviceNet Network

DeviceNet

Node

Message

Router

Connection

Object

Ultra5000

(no public

DeviceNet

Object

Application

Object

Identity

Object

Parameter

Object

Assembly

Object

Interface)

Figure 4.1

Object Model

How Objects Affect Behavior

The objects in the Ultra5000 Drive with DeviceNet affect its behavior

as shown in the table below.

Object Effect on Behavior

Message Router No effect

DeviceNet Configures port attributes (node address, data rate, and BOI)

Assembly Defines I/O data format

Connection Contains the number of logical ports into or out of the device

Parameter Provides a public interface to the device configuration data

Publication 2098-RM002A-EN-P – October 2001

Page 27

Programming Reference 4-3

The Defined Object Interface

The objects in the Ultra5000 Drive with DeviceNet have the interface

listed in the following table.

Object Interface

Message Router Explicit Messaging Connection Instance

DeviceNet Message Router

Assembly I/O Connection or Message Router

Connection Message Router

Parameter Message Router

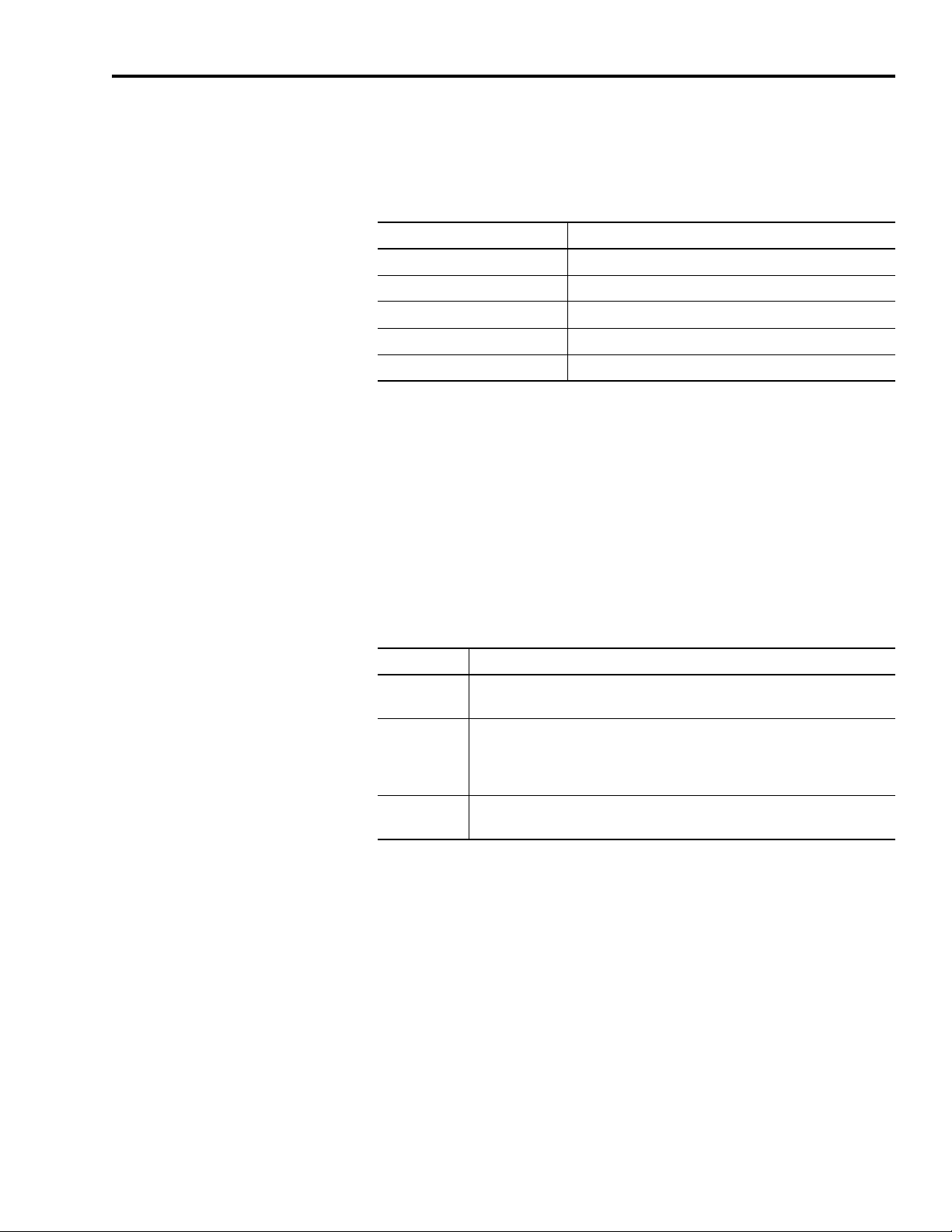

Object Addressing

The Media Access Control Identifier (MAC ID) is the common basis for

logically addressing separate physical components across DeviceNet.

The M

distin

network. The MAC ID often is referred to as the node address. Each

component (object) is further identified with the following address

components:

AC ID is a unique integer assigned to each DeviceNet node that

guishes it specifically from among other nodes on the same

Component Description

Class ID The Class ID is a unique integer value assigned to each Object Class

accessible from the network. The Ultra5000 supports an 8-bit Class ID.

Instance ID The Instance ID is a unique identification assigned to an Object Instance

that identifies it among all Instances of the same Class.

It is also possible to address the Class itself by utilizing the Instance ID

value zero (0). The Ultra5000 supports an 16-bit Instance ID.

Attribute ID The Attribute ID is a unique identification assigned to a Class Attribute

and/or Instance Attribute.

Publication 2098-RM002A-EN-P – October 2001

Page 28

4-4 Programming Reference

MAC ID #1 MAC ID #2

Instance

Object

MAC ID #4

MAC ID #3

DeviceNet Network

Class #5

#1

Instance

Object

Class #3

#1

Instance

#2

Object

Class #5

Instance

#1

Attribute #1

Attribute #2

MAC ID #4:

Object Class #5

Instance #2

Attribute #1

DeviceNet Node 1 DeviceNet Node 2

DeviceNet Node 3 DeviceNet Node 4

Figure 4.2

Node Objects

Data Type Definitions

The following mnemonics define the Ultra5000 with DeviceNet data

types.

Mnemonic Description

ARRAY Sequence of Data

BOOL Boolean (1 byte)

BYTE Bit String (1 byte)

DINT Signed Double Integer (4 bytes)

DWORD Bit String (4 bytes)

EPATH

INT Signed Integer (2 bytes)

REAL Floating Point (4 bytes)

SHORT_STRING Character String

SINT Signed Short Integer (1 byte)

UDINT Unsigned Double Integer (4 bytes)

Publication 2098-RM002A-EN-P – October 2001

DeviceNet Path Segments

(1 byte length indicator, 1 byte per character)

Page 29

Programming Reference 4-5

Mnemonic Description

UINT Unsigned Integer (2 bytes)

USINT Unsigned Short Integer (1 byte)

WORD Bit String (2 bytes)

Identity Object

(Class ID 01

)

H

This object provides identification and general information about the

device. The interface card implements four Identity Objects.

Identity Object,

Attribute for Instance ID = 0 (Class Attributes)

AttrIDAccess

Rule

2 Get Max Instance UINT Maximum instance

Identity Object,

Instance ID = 1 - 4

Instance ID Description

1 Adapter Main Firmware

2 Ultra5000 Main Firmware

3 Adapter Boot Firmware

4 Ultra5000 Boot Firmware

Attribute

Name

Type Description Semantics

of Values

The largest instance

number of an object

currently created in

this class level of the

device.

number of a created

object at this class

hierarchy level.

Publication 2098-RM002A-EN-P – October 2001

Page 30

4-6 Programming Reference

Identity Object,

Attributes of Instance ID 1

Attr.IDAccess

Rule

Attribute

Name

Data

Ty pe

Description Semantics

1 Get Vendor ID UINT Identification of

each vendor by

number

2 Device Type Indication of

general type of

product.

3 Product code Identification of a

particular product

of an individual

vendor

of Values

01 = Rockwell

Automation/

Allen-Bradley

Instance 1:

115 = Rockwell

Automation

Miscellaneous

Instances 2-4:

105 = Subcomponent

Instance 1:

64 = 2098-IPD-005-DN

65 = 2098-IPD-010-DN

66 = 2098-IPD-020-DN

102 = 2098-IPD-030-DN

103 = 2098-IPD-075-DN

104 = 2098-IPD-150-DN

105 = 2098-IPD-HV030-DN

106 = 2098-IPD-HV050-DN

107 = 2098-IPD-HV100-DN

108 = 2098-IPD-HV150-DN

109 = 2098-IPD-HV220-DN

Instances 2-4:

01 = Firmware

4 Revision

STRUCT

of:

Major

Minor

USINT

USINT

5 Status WORD This attribute

Revision of the

item the Identity

Object

represents.

represents the

current status of

the entire device.

Major Revision

Minor Revision

See table: Identity

Object, Status

Description of Attribute

ID 5

Its value changes

as the state of

the device

changes.

6 Serial Number UDINT Serial number of

device

7 Product Name SHORT_

STRING

Readable

identification

Unique identifier for each

device.

Unique identifier for each

product.

Identity Object,

Status Description of Attribute ID 5

Bit (s) Description Semantics of Values

0 Owned TRUE = device has an owner

1 Reserved, set to 0

2 Configured Always = 0

Publication 2098-RM002A-EN-P – October 2001

Page 31

Programming Reference 4-7

Identity Object,

Status Description of Attribute ID 5 (Continued)

Bit (s) Description Semantics of Values

3 Reserved, set to 0

4, 5, 6, 7 Vendor specific

8 Minor recoverable

Always = 0

fault

9 Minor unrecoverable

Always = 0

fault

10 Major recoverable

TRUE if self diagnosis detects a major fault

fault

11 Major unrecoverable

Always = 0

fault

12, 13 Reserved, set to 0

14, 15

Identity Object,

Common Services

Service

Code

0E

H

05

H

11

H

Implemented for Service

Class Instance

Name

Yes Yes Get_Attribute_Single Returns the contents of the

No Reset Invokes the Reset service for

Yes n/a Find_Next_Object_

Instance

Service

Description

specified attribute.

the device.

Causes the specified class to

search and return a list of

instance IDs of existing

instances of the Identity

Object.

Reset Service

When the Identity Object receives a Reset request, it:

• determines if it can perform the reset

• responds to the request

• attempts to perform the reset

Publication 2098-RM002A-EN-P – October 2001

Page 32

4-8 Programming Reference

The Reset common service has the following object-specific

parameter:

Identity Object,

Reset Service

Name Data

Ty pe

Type USINT Type of Reset 0 = Emulate as closely as possible cycling power of

Description Semantics

of Values

the drive. (default)

1 = Emulate cycling power as closely as possible.

The drive can not be returned to out-of-box

configuration without deletion of DeviceNet drivers

and files.

Message Router Object

(Class ID 02

)

H

The Message Router Object provides a messaging connection point

through which a Client may address a service to any object class or

instance residing in the physical device.

Message Router Object,

Attributes of Instance ID = 1

Attr.IDAccess

Rule

2 Get Number Available UINT Maximum number

3 Number active Number of

4 Active connections ARRAY

Attribute

Name

Data

Ty pe

of

UINT

Description Semantics

of Values

Count of the max

of connections

supported

connections

currently used by

system

components

A list of the

connection IDs of

the currently active

connections

number of

connections

supported

Current count of

the number of

connections

allocated to

system

communication

Array of system

connection IDs

Publication 2098-RM002A-EN-P – October 2001

Message Router Object,

Common Services

Service

Code

0E

H

Service

Name

Get_Attribute_Single Returns the contents of the specified attribute

Service

Description

Page 33

Programming Reference 4-9

DeviceNet Object

(Class ID 03

)

H

The DeviceNet Object provides configuration and status attributes of a

DeviceNet port.

DeviceNet Object,

Attribute of Instance ID = 0 (Class Attribute)

Attr. ID Access

Rule

1 Get Revision UINT Revision of the DeviceNet Object

DeviceNet Object,

Attributes of Instance ID = 1

Attr.IDAccess

Rule

1 Set MAC ID USINT Node Address Range 0-63

Set is only supported if the MAC ID is programmable.

Refer to Ultra5000 Intelligent Positioning Drive Installation Manual listed on page P-3

for Rotary DIP switch data setting.

2 Set Baud Rate Data Rate 0 = 125K,

Set is only supported if the data rate is programmable.

Refer to Ultra5000 Intelligent Positioning Drive Installation Manual for Rotary DIP

switch data setting.

3 Set Bus OFF

4Bus OFF

Attribute

Name

Attribute

Name

Interrupt

(BOI)

Counter

Data

Description Semantics

Ty pe

Class definition upon which the

implementation is based.

Data Type Description Semantics

BOOL Bus-OFF Interrupt Default = 0

USINT Number of times

Controller Area

Network (CAN)

went to the

bus-OFF state

of Values

= 2

of Values

1 = 250K,

2 = 500K

Range 0-255

Publication 2098-RM002A-EN-P – October 2001

Page 34

4-10 Programming Reference

DeviceNet Object,

Attributes of Instance ID = 1 (Continued)

Attr.IDAccess

Rule

5 Get Allocation

Attribute

Name

information

Data Type Description Semantics

STRUCT of:

BYTE

USINT

6 MAC ID

BOOL The Node

Switch

Changed

7 Baud Rate

Switch

Changed

Allocation choice

(1 byte)

+ Master MAC

ID (1 byte)

Address

switch(es) have

changed since

last power-up/

reset.

The Baud Rate

switch(es) have

changed since

last power-up/

reset.

of Values

Refer to the

DeviceNet Object

definition in the

DeviceNet

Specification.

Range 0-63, 255

Modified via

Allocate only.

0 = No change

1 = Change since

last reset or

power-up

0 = No change

1 = Change since

last reset or

power-up

8 MAC ID

Switch

Value

9 Baud Rate

Switch

Value

DeviceNet Object,

Common Services

Service

Code

0E

H

10

H

Service

Name

Get_Attribute_Single Returns the contents of the

Set_Attribute_Single Modifies the specified attribute.

USINT Actual value of

Node Address

switch(es).

Actual value of

Baud Rate

switch(es), or

operating value

after an autobaud

was completed.

Service

Description

specified attribute.

Range 0-63

Range 0-2

Publication 2098-RM002A-EN-P – October 2001

Page 35

DeviceNet Object,

IMPORTANT

Class Specific Services

Service

Code

4B

H

Service

Name

Allocate_Master/Slave_

Connection_Set

Programming Reference 4-11

Service

Description

Requests the use of the Predefined

Master/Slave Connection Set.

Assembly Object

(Class ID 04

)

H

4C

H

Release_Group_2_

Identifier_Set

Indicates that the specified

Connections within the Predefined

Master/Slave Connection Set are

no longer desired. These

connections are to be released

(deleted).

The Ultra5000 with DeviceNet uses Assembly Objects to send generic

data to and from a Master (scanner) device over an I/O connection.

The terms Input and Output are defined from the scanner's point of

view:

• Output Assemblies are defined as the information that is output by

e scanner and consumed by the Ultra5000.

th

• Input Assemblies are consumed by the scanner or are the scanner's

input.

The Ultra5000 with DeviceNet allows you to choose between various

Input and Output As

semblies, thereby choosing the data format of the

messages that are passed back and forth between the Ultra5000 with

DeviceNet and the scanner over the I/O connection. The following

parameters select the Assembly Object instances that are exchanged

over an I/O messaging connection.

Parameter

Instance

8 I/O Receive Select Selects the Assembly Object instance that is

9 I/O Transmit (Xmit)

1

Refer to the section on the Parameter Object for more information about parameter instances.

Parameter Name Description

1

updated when a Polled I/O message is received

by the drive. See page 4-19 for more information.

Selects the Assembly Object instance that is

Select

transmitted by the drive over a Polled I/O

connection. See page 4-19 for more information.

If the above parameters are modified, you must

perform one of the following before the modified

value(s) are active:

•Close any existing I/O messaging connection.

•Power cycle the drive.

•Remove and reapply DeviceNet power to the drive.

•Reset the drive.

Publication 2098-RM002A-EN-P – October 2001

Page 36

4-12 Programming Reference

The following Assembly Objects are implemented in the drive and

buffer I/O in the following fashion:

• RO = Read Only

• R/W = Read/Write Protected.

Assembly Object,

Instance ID = 1 - 16

ID Data Type Access Size

Description

(Bytes)

1 Static Output R/W 4 One Integer:

DNetIntArray[2]

2 Static Output R/W 8 Two Integers:

DNetIntArray[2], DNetIntArray[3]

3 Static Output R/W 4 One Float:

DNetFltArray[2]

4 Static Output R/W 8 Two Floats:

DNetFltArray[2], DNetFltArray[3]

5 Static Output R/W 8 One Integer, One Float:

DNetIntArray[2], DNetFltArray[2]

6 Static Output R/W 12 Two Integers, One Float:

DNetIntArray[2], DNetIntArray[3],

DNetFltArray[2]

7 Static Output R/W 12 One Integer, Two Floats:

DNetIntArray[2], DNetFltArray[2],

DNetFltArray[3]

8 Static Output R/W 16 Two Integers, Two Floats:

DNetIntArray[2], DNetIntArray[3],

DNetFltArray[2], DNetFltArray[3]

9 Static Input RO 4 One Integer:

DNetIntArray[0]

10 Static Input RO 8 Two Integers:

DNetIntArray[0], DNetIntArray[1]

11 Static Input RO 4 One Float:

DNetFltArray[0]

12 Static Input RO 8 Two Floats:

DNetFltArray[0], DNetFltArray[1]

13 Static Input RO 8 One Integer, One Float:

DNetIntArray[0], DNetFltArray[0]

14 Static Input RO 12 Two Integers, One Float:

DNetIntArray[0], DNetIntArray[1],

DNetFltArray[0]

15 Static Input RO 12 One Integer, Two Floats:

DNetIntArray[0], DNetFltArray[0],

DNetFltArray[1]

16 Static Input RO 16 Two Integers, Two Floats:

DNetIntArray[0], DNetIntArray[1],

DNetFltArray[0], DNetFltArray[1]

1

The arrays are automatically saved in non-volatile storage.

1

Publication 2098-RM002A-EN-P – October 2001

Page 37

Programming Reference 4-13

Assembly Object,

Attribute of Instances ID 1 - 16

Attr ID Access

Rule

Attribute

Name

Data Type

3 Set Data ARRAY

Assembly Object,

Common Services

Service

Code

0E

H

10E

H

Implemented for Service

Class Instance

Name

Service

Description

Yes Yes Get_Attribute_Single Returns the contents of the

specified attribute.

No Set_Attribute_Single Modifies an attribute value.

Publication 2098-RM002A-EN-P – October 2001

Page 38

4-14 Programming Reference

ATTENTION

!

ATTENTION

!

DeviceNet Comm Fault Action

The Ultra5000 with DeviceNet will fault depending on the Comm

Fault Action setting if the Output (command) Assembly is not

periodically updated after the Output Assembly has been written to.

You can configure the Ultra5000 with DeviceNet to perform a Comm

Fault

Action if the Output Assembly is not periodically updated after

the I/O (or explicit) messaging connection has been established.

Possible reasons the Output Assembly may not be updated in this way

include the following:

e messaging connection is closed

• Th

• Th

e DeviceNet cable is unplugged

Risk of severe bodily injury or equivalent damage

exists.

The Comm Fault Action value allows you to change

the default configuration, and to potentially allow the

drive to continue to operate when communication

with the DeviceNet Module is lost.

By default, the Ultra5000 drive with DeviceNet will fault and disable

rive when a DeviceNet Comm Fault is triggered. However, you

the d

can configure the drive to ignore the DeviceNet Comm Fault by

setting the Ultra5000 DNetConfigData Array Index 4 – DeviceNet

Comm Fault Action to 1 (Ignore).

DeviceNet Idle Fault Action

The Ultra5000 with DeviceNet will fault depending on the Idle Fault

Action setting if the Master (scanner) sends I/O idle messages

(zero-length messages) and the drive expects non-zero length I/O

messages.

Risk of severe bodily injury or equivalent damage

exists.

The Idle Fault Action value allows you to change the

default configuration, and to potentially allow the

drive to continue to operate when communication

with the DeviceNet Module is lost.

Publication 2098-RM002A-EN-P – October 2001

By default, the Ultra5000 drive with DeviceNet will fault and disable

the

drive when an Idle Fault is triggered. However , no action will be

taken if the Ultra5000 DNetConfigData Array Index 6 – I/O Receive

Page 39

Programming Reference 4-15

Select, Parameter 8 is set to 0 (No data consumed), or if you configure

the drive to ignore Array Index 3 – DeviceNet Idle Fault Action by

setting the DNetConfigData array to 1 (Ignore).

Using Explicit Messaging to Control the Ultra5000

Explicit messages provide multi-purpose, point-to-point

communication paths between two devices. It is possible to control

the drive through explicit messaging on DeviceNet by following

particular guidelines and by writing to various Assembly Objects that

are buffering the I/O data. Although it is possible to control the drive

by writing to various parameter objects, you should consider using a

user program interfacing with the Assembly Objects for controlling the

drive. The guidelines are as follows:

rite to the various Assembly Objects that are buffering the I/O

• W

dat

a.

• Write access to any Assembly Object is not allowed if the message

is passed through a connection whose expected packet rate (EPR)

is zero or if I/O data is being sent over an I/O messaging

connection.

• The drive marks any explicit connection after allowing a write to

an Assembly Object through the connection.

• If a marked explicit connection times out based on the EPR, then

the fault action will be that for Communication Loss over the I/O

connection, using Array Index 4 – DeviceNet Comm Fault Action of

the DNetConfigData array.

• If a marked explicit connection is deleted, then the fault action will

be that configured for Idle over the I/O connection, using Array

Index 3 – DeviceNet Idle Fault Action of the DNetConfigData array.

• Multiple explicit connections can write/overwrite the control I/O if

they meet the guidelines specified. Each connection will be

marked individually within the drive.

• If the drive gets allocated/re-allocated by a controller such that

valid I/O data is being sent to the drive, or if an Idle condition

from the allocating controller is transitioned back to valid data,

then all marked explicit connections will be reset to unmarked and

future writes blocked.

• If a marked connection has its EPR value reset to zero (0) after

being marked, then the connection will become unmarked.

Publication 2098-RM002A-EN-P – October 2001

Page 40

4-16 Programming Reference

Connection Object

The Connection Object manages the internal resources associated

with both I/O and Explicit Messaging Connections. The specific

(Class ID 05

)

H

instance generated by the Connection Class is referred to as a

Connection Instance or a Connection Object. A Connection Object

within a particular module actually represents one of the end-points of

a connection.

DeviceNet Connection Object,

Instance ID = 1 - 10

Instance IDInstances

1 Group 2 Explicit Message Connection

2 Poll I/O Connection

6-10 Group 3 Explicit Message Connections

DeviceNet Connection Object,

Attributes of Instances ID = 1 - 10 /

Attr ID Access

Rule

1 Get State USINT State of the Connection

2 Instance Type I/O or Message Connection

3 Transport_class_trigger BYTE Defines the behavior of the Connection

4 Produced_connection_id UINT CAN identifier to transmit on

Attribute

Name

Data Type Description

5 Consumed_connection_id CAN identifier to receive on

6 Initial_comm_characteristics BYTE Defines the Message Group(s) associated with

this Connection

7 Produced_connection_size UINT Maximum number of bytes transmitted across

this Connection

8 Consumed_connection_size Maximum number of bytes received across this

Connection

9 Set Expected_packet_rate Defines timing associated with this Connection

12 Watchdog_timeout_action USINT Defines how to handle Inactivity/Watchdog

timeouts

13 Get Produced_connection_path_

length

14 Produced_connection_path EPATH Specifies the Application Object whose data is

15 Consumed_connection_path_length UINT Number of bytes in the

16 Consumed_connection_path EPATH Specifies the Application Object(s) that are to

17 Set Production_inhibit_time UINT Defines minimum time between new data

UINT Number of bytes in the

produced_connection_path attribute

to be produced by this Connection object

Consumed_connection_path attribute

receive the data consumed by this Connection

production for COS connections.

Publication 2098-RM002A-EN-P – October 2001

Page 41

IMPORTANT

DeviceNet Connection Object,

Common Services

Service Code Service Name Service Description

0E

10

05

H

H

H

Get_Attribute_Single Returns the contents of the specified attribute.

Set_Attribute_Single Modifies the specified attribute.

Reset Used to reset the Inactivity/Watchdog Timer associated with a Connection Object

Programming Reference 4-17

Parameter Object

The DeviceNet Parameter Object provides the interface to the

Ultra5000 Drive with DeviceNet configuration data. It supplies a full

(Class ID 0F

)

H

description of the parameter, including its minimum and maximum

values and a readable text string describing the parameter. The

instances start at one and increment with no gaps.

Parameter Object,

Attributes for Instance ID = 0 (Class Attributes)

Attr ID Access

Rule

1 Get Revision UINT Revision of this object Current value = 01

2 Max Instances Maximum instance number of an

8 Parameter Class

9 Configuration

Name Data

Ty pe

WORD Bit field that describe parameters Bit 0 = supports parameter instances

Descriptor

UINT Instance number of the configuration

Assembly

Instance

Description Semantics of Values

The largest instance number of a created

object currently created in this class

level of the device

assembly

object at this class hierarchy level

Bit 1 = full attributes

Bit 2 = nonvolatile storage save command

Bit 3 = params are stored in nonvolatile

storage

0 = configuration assembly not supported

The table Parameter Instance on

page 4-18 lists the parameter

instances implemented in the Ultra5000 Drive with DeviceNet. The

table Parameter Object Instance Attributes on

page 4-49 lists the

instance attributes of the parameter object. A parameter value is

accesse

d via Attribute 1 of a parameter instance. Additional

information about the parameter object is located beginning on

Page 4-51.

Some parameters can not be modified while the

Ultra5000 Drive with DeviceNet is enabled. The drive

returns the error code, 10

- Device State Conflict, if

h

you attempt to modify one of these parameters while

the drive is enabled.

Publication 2098-RM002A-EN-P – October 2001

Page 42

4-18 Programming Reference

Parameter Object,

Instances ID 1- 340

Note: The Set_Attribute_Single service saves parameter values to RAM,

but not to non-volatile storage. To transfer parameter values

from RAM to non-volatile storage, perform one of the following:

• Perform the Save service on the Parameter Object.

• Write the value Execute Command (1) to Parameter 13 - Save

Parameter Values.

Parameter

Instance

1 Get DNet Main

2 Get DNet Boot

3 Get Drive Model SHORT_S

4GetDN-SW Node

5 Get DN-SW Data

6 Set DN-NV Node

Access

Rule

Parameter

Name

Firmware Version

Firmware Version

Address

Rate

Address

Data

Type

SHORT_S

TRING

SHORT_S

TRING

TRING

USINT 1 DeviceNet Node Address (Mac_ID) switch

USINT 1 DeviceNet Data Rate switch setting.

USINT 1 The programmed nonvolatile DeviceNet Node

Data

Size

(Bytes)

1 byte

length

indicator,

1 byte per

character

1 byte

length

indicator,

1 byte per

character

1 byte

length

indicator,

1 byte per

character

Units /

Scale

Description

The version of the main firmware in the

DeviceNet adapter. The format is XX.YY.ZZ,

where:

XX = major revision

YY = minor revision

ZZ = maintenance revision

The version of the boot firmware in the adapter.

The format is XX.YY.ZZ, where:

XX = major revision

YY = minor revision

ZZ = maintenance revision

The model number of the drive.

setting.

0 = 125 kps

1 = 250 kps

2 = 500 kps

3 = Autobaud

4 = Program

5 = Programmable

6 = Programmable

7 = Programmable

Address (Mac_ID).

Range: 0 to 63

Default: 63

Automatically saved in non-volatile storage.

7 Set DN-NV Data Rate USINT 1 The programmed nonvolatile DeviceNet Data

Rate.

0 = 125 kps (default)

1 = 250 kps

2 = 500 kps

3 = Autobaud

Automatically saved in non-volatile storage.

Publication 2098-RM002A-EN-P – October 2001

Page 43

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Programming Reference 4-19

Description

8 Set I/O Receive

Select

USINT 1 Selects the output (consumed) assembly that is

updated when a polled I/O message is received

by the drive. If the value is modified, the user has

to either, close any existing I/O messaging

connection(s), power cycle the drive, reset the

drive, or remove and reapply DeviceNet power for

the drive to use the modified value. Refer to the

Assembly Object for information on the data

format.

0 = No Data Consumed

1 = Assembly Instance 1 (default)

2 = Assembly Instance 2

3 = Assembly Instance 3

4 = Assembly Instance 4

5 = Assembly Instance 5

6 = Assembly Instance 6

7 = Assembly Instance 7

8 = Assembly Instance 8

Automatically saved in non-volatile storage.

9 Set I/O Transmit

(Xmit) Select

USINT 1 Selects the input (produced) assembly that is

transmitted by the drive over a polled I/O

messaging connection. If the value is modified,

the user has to either, close any existing I/O

messaging connection(s), power cycle the drive,

reset the drive, or remove and reapply DeviceNet

power for the drive to use the modified value.

Refer to the Assembly Object for information on

the data format.

0 = No Data Produced

1 = Assembly Instance 9 (default)

2 = Assembly Instance 10

3 = Assembly Instance 11

4 = Assembly Instance 12

5 = Assembly Instance 13

6 = Assembly Instance 14

7 = Assembly Instance 15

8 = Assembly Instance 16

Automatically saved in non-volatile storage.

10 Set Axis Enable

Command

USINT 1 Enable the drive.

0 = No Action (default)

1 = Execute Command

11 Set Disable Axis

Command

USINT 1 Disable the drive.

0 = No Action (default)

1 = Execute Command

12 Set Reset Drive USINT 1 Reset the drive.

0 = No Action (default)

1 = Execute Command

13 Set Save Parameter

Values

USINT 1 Save parameters in non-volatile storage.

0 = No Action (default)

1 = Execute Command

Publication 2098-RM002A-EN-P – October 2001

Page 44

4-20 Programming Reference

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Description

14 Set Control Digital

USINT 1 Select a digital I/O type:

Typ e

0 = Sourcing: Digital Inputs should be connected

to a 24 volt power supply, so current flows into

the drive when the input is ON. Digital Outputs

should be connected to ground, so current flows

from the drive when the output is ON. (default)

1 = Sinking: Digital Inputs should be connected to

ground, so current flows from the drive when the

input is ON. Digital Outputs should be connected

to a 24 volt power supply, so current flows into

the drive when the output is ON.

15 Get Axis State USINT 1 Indicates if the axis is enabled or disabled.

0 = Disabled

1 = Enabled

16 Get Controller Fault USINT 1 Provides the fault status of the drive.

0 = No Fault

4 = Motor Overtemperature

5 = IPM Fault

9 = Bus Undervoltage

10 = Bus Overvoltage

11 = Bad (Illegal) Hall State

14 = Network Communication

17 = User Current

18 = Overspeed

19 = Position (Following) Error

20 = Motor Encoder Error

21 = Auxiliary Encoder Error

22 = Motor Filter

23 = IPM Filter

24 = Velocity Error

26 = User Velocity

58 = Excess CPU Load

17 Get Controller State USINT 1 Provides the state of the controller.

0 = Idle

1 = Running

2 = Erasing

3 = Programming

4 = FlashFault

18 Get Average Current REAL 4 Amps Average current.

19 Get Torque Command REAL 4 Amps Torque command.

20 Get Torque Feedback REAL 4 Amps Torque feedback.

21 Get Torque Error REAL 4 Amps Torque error.

Publication 2098-RM002A-EN-P – October 2001

Page 45

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Programming Reference 4-21

Description

22 Set Enable Position

Limit

23 Set Disable Position

Limit

24 Set Reset Position

Limit

25 Set Position Limit

Decel

USINT 1 Enables the position limits. This causes the drive

to start monitoring the position limits. The

Position Limit State - Parameter 34 will transition

to “Running”.

0 = No Action (default)

1 = Execute Command

USINT 1 Disables the position limits. This causes the drive

to stop monitoring the position limits. The

Position Limit State - Parameter 34 will transition

to “Disabled”.

0 = No Action (default)

1 = Execute Command

USINT 1 After a position limit violation, the position limits

will go to the “Stopped” state. The drive will not

allow commanded motion in this state. Pressing

this button will allow the drive to respond to

commanded motion to back off of the limit

condition.

0 = No Action (default)

1 = Execute Command

REAL 4

cnts/ sec

2

When a limit is detected, the drive will use this

deceleration rate to bring the axis to a stop,

unless doing so would violate the Position Limit

Distance - Parameter 26. If necessary to stay

within the Position Limit Distance, the drive will

calculate a greater deceleration rate.

Range: 0 to 3.4e10

Default: 0

26 Set Position Limit

Distance

27 Set Position Soft

Limits

DINT 4 cnts When a limit is detected, the drive will bring the

axis to a stop within this distance.

Range: 0 to 2147483647

Default: 0

USINT 1 Enables or disables detection of soft limit

violations. The Position Limits (see Enable

Position Limit - Parameter 22) must also be

enabled for soft limit violations to be detected.

Not saved in non-volatile memory.

0 = Disable (default)

1 = Enable

Publication 2098-RM002A-EN-P – October 2001

Page 46

4-22 Programming Reference

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Description

28 Set Position Hard

Limits

29 Set Position Motor

Limits

30 Set Position Positive

Soft Limit

USINT 1 Enables or disables detection of hard limit

violations. The Position Limits (see Enable

Position Limit - Parameter 22) must also be

enabled for hard limit violations to be detected.

The inputs to use for positive and negative hard

limits must be set (see Parameters 32 and 33

below) for the hard limits to be detected. Not

saved in non-volatile memory.

0 = Disable (default)

1 = Enable

Note: Hard limits are enabled on power-up if

either hard limit is assigned.

USINT 1 Enables or disables detection of motor integral

limit violations. The Position Limits (see Enable

Position Limit - Parameter 22) must also be

enabled for motor limit violations to be detected.

The motor limits will only work when using a

motor that supports integral limits (see Parameter

249). Not saved in non-volatile memory.

0 = Disable (default)

1 = Enable

Note: Motor limits are enabled on power-up if

Integral Limits - Parameter 249 are enabled on

the motor.

DINT 4 cnts The position, in counts, when a positive soft limit

violation will be detected by the drive. This is the

point where the drive will begin decelerating the

axis.

Range: -2147483648 to 2147483647

Default: 0

31 Set Position Negative

Soft Limit

Publication 2098-RM002A-EN-P – October 2001

DINT 4 cnts The position, in counts, when a negative soft limit

violation will be detected by the drive. This is the

point where the drive will begin decelerating the

axis.

Range: -2147483648 to 2147483647

Default: 0

Page 47

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Programming Reference 4-23

Description

32 Set Position Positive

Hard Limit

33 Set Position Negative

Hard Limit

USINT 1 The selected digital input to use to indicate a

positive hard limit violation. The drive will begin

decelerating the axis when the input becomes

active.

0 = Unassigned (default)

1 = Input 1

2 = Input 2

3 = Input 3

4 = Input 4

5 = Input 5

6 = Input 6

7 = Input 7

8 = Input 8

9 = Input 9

10 = Input 10

11 = Input 11

12 = Input 12

13 = Input 13

14 = Input 14

15 = Input 15

16 = Input 16

USINT 1 The selected digital input to use to indicate a

negative hard limit violation. The drive will begin

decelerating the axis when the input becomes

active.

0 = Unassigned (default)

1 = Input 1

2 = Input 2

3 = Input 3

4 = Input 4

5 = Input 5

6 = Input 6

7 = Input 7

8 = Input 8

9 = Input 9

10 = Input 10

11 = Input 11

12 = Input 12

13 = Input 13

14 = Input 14

15 = Input 15

16 = Input 16

Publication 2098-RM002A-EN-P – October 2001

Page 48

4-24 Programming Reference

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Description

34 Get Position Limit

State

35 Get Position Limit

Flags

36 Set Jog Forward

Command

37 Set Jog Reverse

Command

38 Set Jog Stop

Command

39 Set Jog Abort

Command

40 Set Jog Program

Velocity

USINT 1 State of the position limit function.

0 = Disabled – Position Limits are not being

monitored.

1 = Enabling – The drive is transitioning from the

Disabled state to Running.

2 = Running – The drive is monitoring position

limits.

3 = Stopping – The drive has detected a limit

violation and is decelerating the motor.

4 = Stopped – The motor has been stopped in

response to a limit violation. The drive will not

allow any commanded motion until the Position

Limits are reset.

5 = Resetting – The drive is transitioning from the

Stopped state to Running.

DWORD 4 Indicates which position limit violation(s) have

been detected.

Bit 0 = Positive Soft Limit

Bit 4 = Positive Hard Limit

Bit 8 = Positive Motor Limit

Bit 16 = Negative Soft Limit

Bit 20 = Negative Hard Limit

Bit 24 = Position Motor Limit

USINT 1 Spins the motor at the Jog Program Velocity -

Parameter 40 in the forward direction.

0 = No Action (default)

1 = Execute Command

USINT 1 Spins the motor at the Jog Program Velocity -

Parameter 40 in the reverse direction.

0 = No Action (default)

1 = Execute Command

USINT 1 Brings the motor to a stop, using the Jog Program

Decel - Parameter 42 rate.

0 = No Action (default)

1 = Execute Command

USINT 1 Brings the motor to an immediate stop.

0 = No Action (default)

1 = Execute Command