Page 1

User Manual

EtherNet/IP and ControlNet to FOUNDATION Fieldbus Linking Devices

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Automation, ControlLogix, FactoryTalk, Studio 5000, Logix Desig ner, and RSNetWorx are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Linking Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Network Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1788-EN2FFR EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1788-CN2FFR ControlNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environment and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

European Hazardous Location Approval . . . . . . . . . . . . . . . . . . . . . . . 10

NNorth American Hazardous Location Approval. . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

H1 Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ControlNet and EtherNet/IP Connections. . . . . . . . . . . . . . . . . . . . . 16

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Set the Linking Device Network Address. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardware Switches Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Set the ControlNet Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Set the EtherNet/IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ethernet Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Set Up in the Studio 5000

Logix Designer Application

Chapter 2

Add the 1788-EN2FFR Linking Device to the I/O Tree . . . . . . . . . . . . 21

Add the 1788-CN2FFR Linking Device to the I/O Tree . . . . . . . . . . . . 22

RSNetWorx for ControlNet Configuration . . . . . . . . . . . . . . . . . . . . 23

Linking Device Configuration Using the AOP . . . . . . . . . . . . . . . . . . . . . 26

Master Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Add and Manage Device Description Files. . . . . . . . . . . . . . . . . . . . . . 31

Field Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Field Device Block Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Field Device Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Scheduling and the LAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Redundant Master Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Redundant Master Mismatch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Redundant Master Disabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

MultiMaster Connecting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 1

Page 4

Table of Contents

Logix Assemblies

Diagnostics

Connect Safe Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Start the Back-up LAS Master (Already Configured) . . . . . . . . . . . . 46

Reconnect Two Separate Running LAS Devices. . . . . . . . . . . . . . . . . 47

Swap Out Linking Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 3

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Master Device Tag Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Field Device Tag Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Field Device Output Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 4

Status Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PV Data Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Oscilloscope Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

The Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Device Type Manager (DTM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Linking Device Display Status

HSProcessUtility

Field Device Block Configuration

Examples

H1 Topology

Appendix A

Main Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

H1 Master Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Field Device Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix B

Use the HSProcessUtility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix C

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

AO Function Block Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

DO Function Block Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Appendix D

Master Mode 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Master Mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Master Mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Master Mode 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Master Mode 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Master Mode 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Master Mode 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Master Mode 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Master Mode 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Master Mode 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Master Mode 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 5

Glossary

Index

Table of Contents

Master Mode 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Master Mode 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Master Mode 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Master Mode 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Master Mode 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Master Mode 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 3

Page 6

Table of Contents

4 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 7

Preface

Introduction

This user manual describes the installation and operation of the 1788-EN2FFR

and 1788-CN2FFR linking devices.

About the Linking Devices

The 1788-EN2FFR linking device provides a gateway between an EtherNet/IP

network and a single segment FOUNDATION Fieldbus H1 layer.

The 1788-CN2FFR linking device provides a gateway between a ControlNet

network and a FOUNDATION Fieldbus network.

In this manual, both modules are referred to as the linking device.

The linking device can support up to16 field devices. It is configurable through

the Studio 5000® Logix Designer™ application by use of a dedicated Add-on

Profile (AOP). Multiple levels of media redundancy are supported, including

ring, split, and redundant trunk, plus options for H1 media, redundant linking

devices, redundant controllers, and redundant ControlNet media.

The linking device has full FOUNDATION fieldbus host capability, including

link active scheduler (LAS) capability.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 5

Page 8

Preface

Network Diagrams

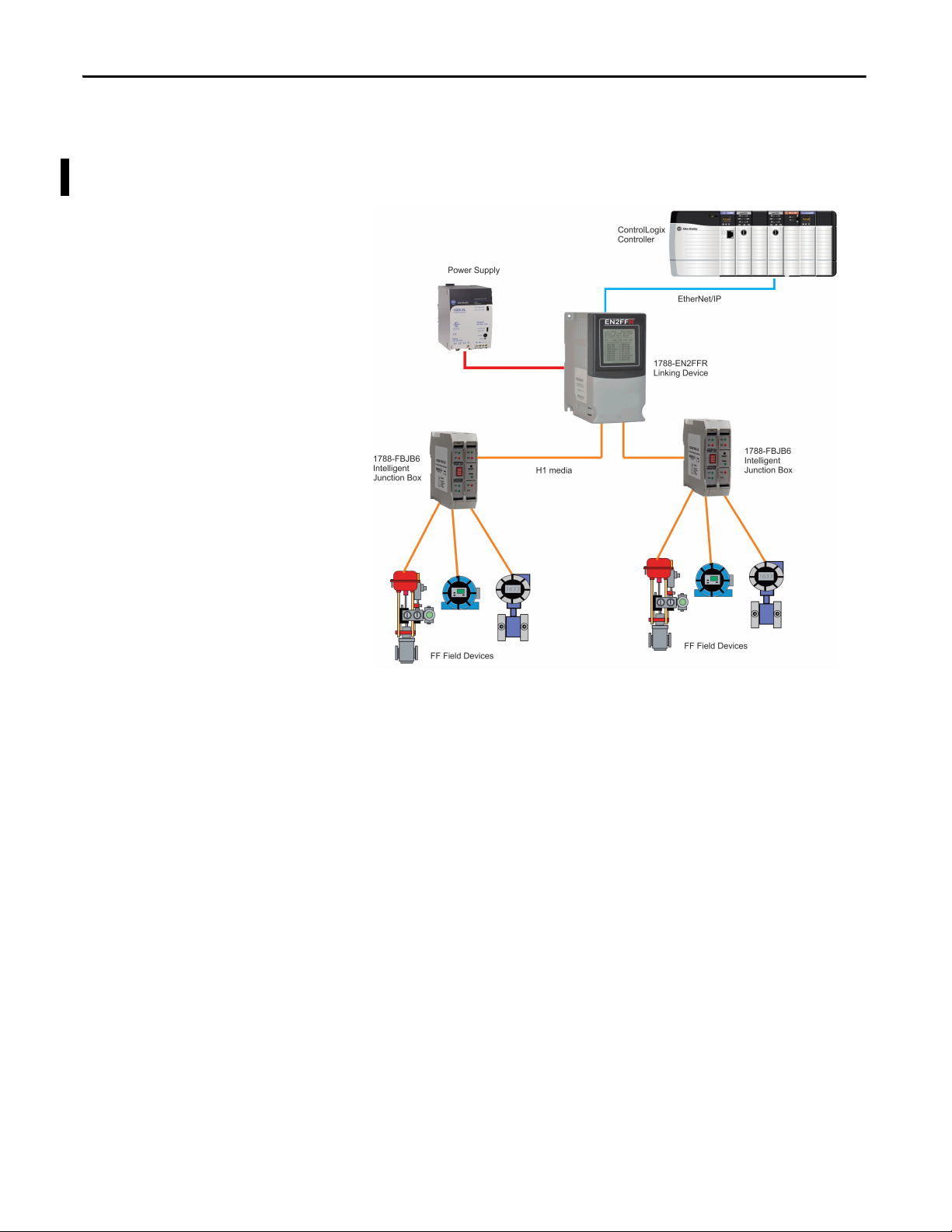

1788-EN2FFR EtherNet/IP Network

The diagram below is an example of how a 1788-EN2FFR linking device could

be used with an EtherNet/IP network..

6 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 9

Preface

1788-CN2PAR

Linking Device

1788-FBJB4R

Junction Boxes

1788-CN2PAR

Linking Device

ControlLog ix

Controller

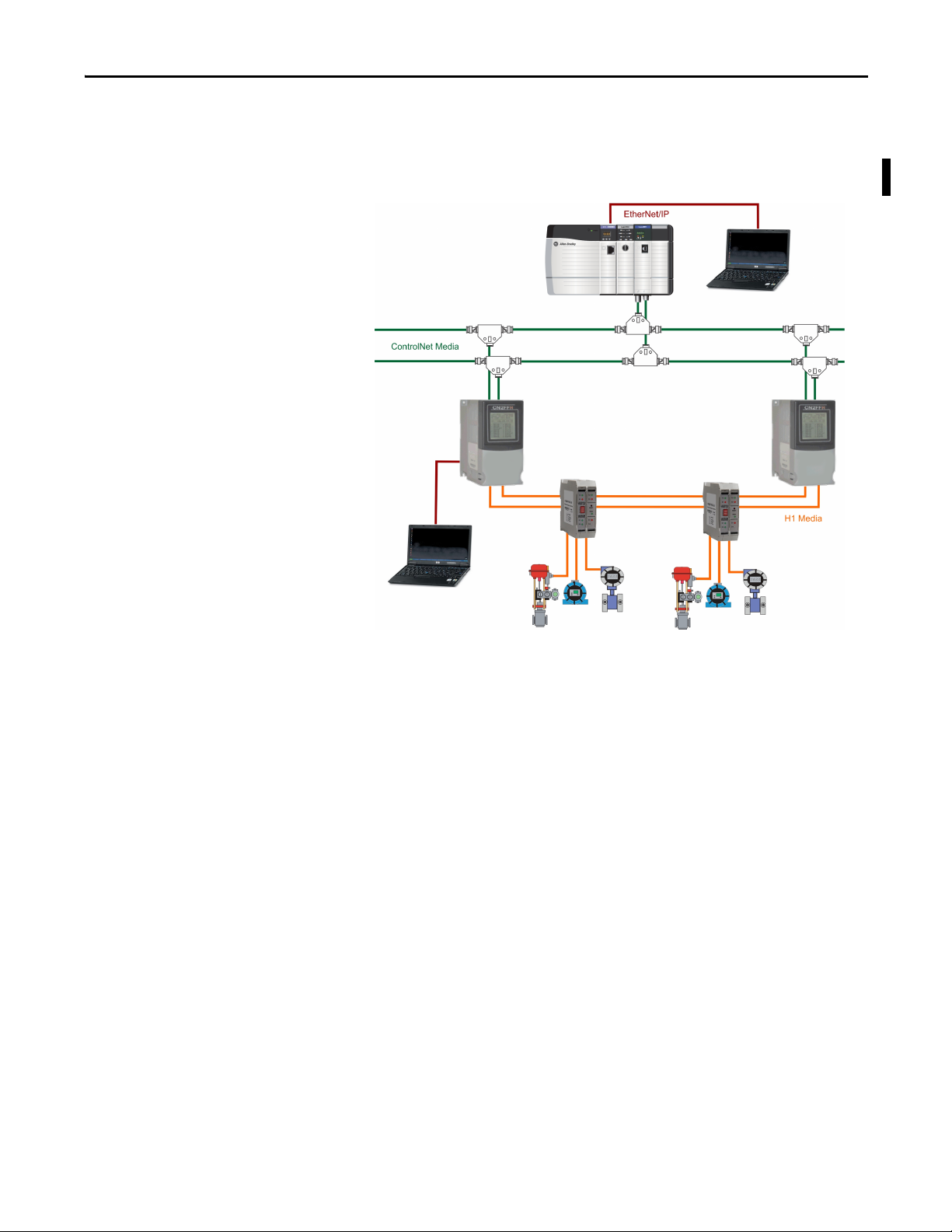

1788-CN2FFR ControlNet Network

This diagram shows an example of how a 1788-EN2FFR linking device could be

used with a ControlNet network.

Features

The AOP provides an intuitive graphical interface to configure devices. A

predefined data structure for each field device provides eight input process

variables (PVs), eight output PVs, and eight PVs for inter-device communication

for full distributed control.

The linking device uses four controller connections. The data for the 16 field

devices is distributed over the four CIP connections. Connection A has the data

for the linking device and four field devices. Connection B, C, and D have the

data of four field devices each. The minimum requested packet interval (RPI) is

100 ms, and the maximum is 3,000 ms.

The HSProcessUtility is used to manage and register the field device description

(DD) files. The utility is launched from the AOP in the Studio 5000 Logix

Designer application, or directly in the Microsoft Windows operating system.

Field Device Tool/Device Type Manager (FDT/DTM) technology is supported.

This allows access to field device configuration and diagnostics via FDT Frames

such as FactoryTalk® AssetCentre. In addition, the Rockwell Automation FDT

ThinFrame (read only) can be launched from a FactoryTalk View or via the AOP

providing access to each field devices status and extended diagnostics.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 7

Page 10

Preface

Built-in power conditioners and protection are provided, which helps to

minimize installation space requirements. The H1 segment is divided between

two physical ports (A and B) with individual protection and a supply of 500 mA

per port. See H1 Network Connections on page 14

The basic diagnostics of the linking device and the field devices, is found in the

input assemblies. Advanced configuration is found only through the AOP.

To assist with troubleshooting, a 128 x 128 pixel display provides access to the

status of the linking device. Information available includes network voltages and

currents, internal temperature, and communication quality to each field device.

A built-in web server provides remote access to network and field device data.

.

Safety Precautions

Read and understand all precautions before using the linking device.

Prevent Electrostatic Discharge

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal

damage and affect normal operation. Follow these guidelines when you handle

this equipment

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

8 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 11

Environment and Enclosure

ATTENTION: Environment and Enclosure

• This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC 60664-

1), at altitudes up to 2000 m (6562 ft) without derating.

• This equipment is not intended for use in residential environments and may

not provide adequate protection to radio communication services in such

environments.

• This equipment is supplied as open-type equipment. It must be mounted

within an enclosure that is suitably designed for those specific environmental

conditions that will be present and appropriately designed to prevent personal

injury resulting from accessibility to live parts. The enclosure must have

suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application

if nonmetallic. The interior of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to

comply with certain product safety certifications.

• In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1,

for additional installation requirements.

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the

degrees of protection provided by enclosures.

Preface

European Hazardous Location Approval

ATT EN TI ON : Do not place the module in direct sunlight. Prolonged exposure to

direct sunlight could degrade the LCD.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 9

Page 12

Preface

European Hazardous Location Approval

The following applies when the product bears the marking.

This equipment is intended for use in potentially explosive atmospheres as

defined by European Union Directive 94/9/EC and has been found to comply

with the Essential Health and Safety Requirements relating to the design and

construction of Category 3 equipment intended for use in Zone 2 potentially

explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured

by compliance with EN 60079-15 and EN 60079-0.

ATT EN TI ON : This equipment is not resistant to sunlight or other sources of UV

radiation.

WARNING: This equipment shall be mounted in an ATEX-certified enclosure

with a minimum ingress protection rating of at least IP54 ( as defined in

IEC60529) and used in an environment of not more than Pollution Degree 2 (as

defined in IEC 60664-1) when applied in Zone 2 environments. The enclosure

must have a tool-removable cover or door.

WARNING: This equipment shall be used within its specified ratings defined by

Rockwell Automation.

WARNING: Should the unit be installed in an environment where induced

transients could exceed 44V, then external transient/surge arrestors should be

installed.

WARNING: Secure any external connections that mate to this equipment by

using screws, sliding latches, threaded connectors, or other means provided

with this product.

WARNING: Do not disconnect equipment unless power has been removed or

the area is known to be nonhazardous.

WARNING: Devices shall be used in an environment of not more than Pollution

Degree 2.

10 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 13

Preface

NNorth American Hazardous Location Approval

The following information applies when operating this equipment in hazardous

locations.

The following information applies when operating this equipment

in hazardous locations:

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division

2 Groups A, B, C, D, Hazardous Locations and nonhazardous locations only. Each

product is supplied with markings on the rating nameplate indicating the

hazardous location temperature code. When combining products within a

system, the most adverse temperature code (lowest "T" number) may be used to

help determine the overall temperature code of the system. Combinations of

equipment in your system are subject to investigation by the local Authority

Having Jurisdiction at the time of installation

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous

Informations sur l'utilisation de cet équipement

en environnements dangereux:

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D dangereux

et non dangereux. Chaque produit est livré avec des marquages sur sa plaque

d'identification qui indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un système, le code

de température le plus défavorable (code de température le plus faible) peut

être utilisé pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation.

AVERTISSEMENT: RISQUE D'EXPLOSION

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

WARNING: If you connect or disconnect the communications cable with power

applied to this module or any device on the network, an electrical arc can occur.

This could cause an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before proceeding.

WARNING: Temperature rating of conductors must be

higher than 82 °C (179.6 °F).

WARNING: If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 11

Page 14

Preface

Additional Resources

These documents contain more information about related products from

Rockwell Automation®.

Resource Description

FOUNDATION Fieldbus Linking Devices Technical Data, publication 1788-TD001 Provides technical data and specifications for the FOUNDATION Fieldbus linking devices.

FOUNDATION Fieldbus Junction Boxes Installation Instructions, publication 1788-IN006

ControlLogix® Enhanced Redundancy System User Manual, publication 1756-UM535

ControlLogix EtherNet/IP Module Installation Instructions, publication 1756-IN603

EtherNet/IP Network Configuration User Manual, publication ENET-UM001 Describes how you can use EtherNet/IP communication modules with your Logix5000

RSNetWorx™ for ControlNet Getting Results Guide, publication CNET-GR001 Provides information on how to install and navigate the RSNetWorx for ControlNet software.

RSNetWorx for EtherNet/IP Getting Results Guide, publication ENET-GR001

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

Provides installation instructions and technical information about the FOUNDATION Fieldbus

junction boxes (1788-FBJB4R, 1788-FBJB6)

Provides information specific to enhanced redundancy systems including design and

planning considerations, installation procedures, configuration procedures, and

maintenance and troubleshooting methods.

Provides hardware installation instructions for the ControlLogix EtherNet/IP module.

controller and communicate with various devices on the Ethernet network.

It explains how to use RSNetWorx for ControlNet software and how to access and navigate

the online help.

Provides information on how to install and navigate the RSNetWorx for EtherNet/IP

software. It explains how to use the RSNetWorx for EtherNet/IP software and how to access

and navigate the online help.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

12 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 15

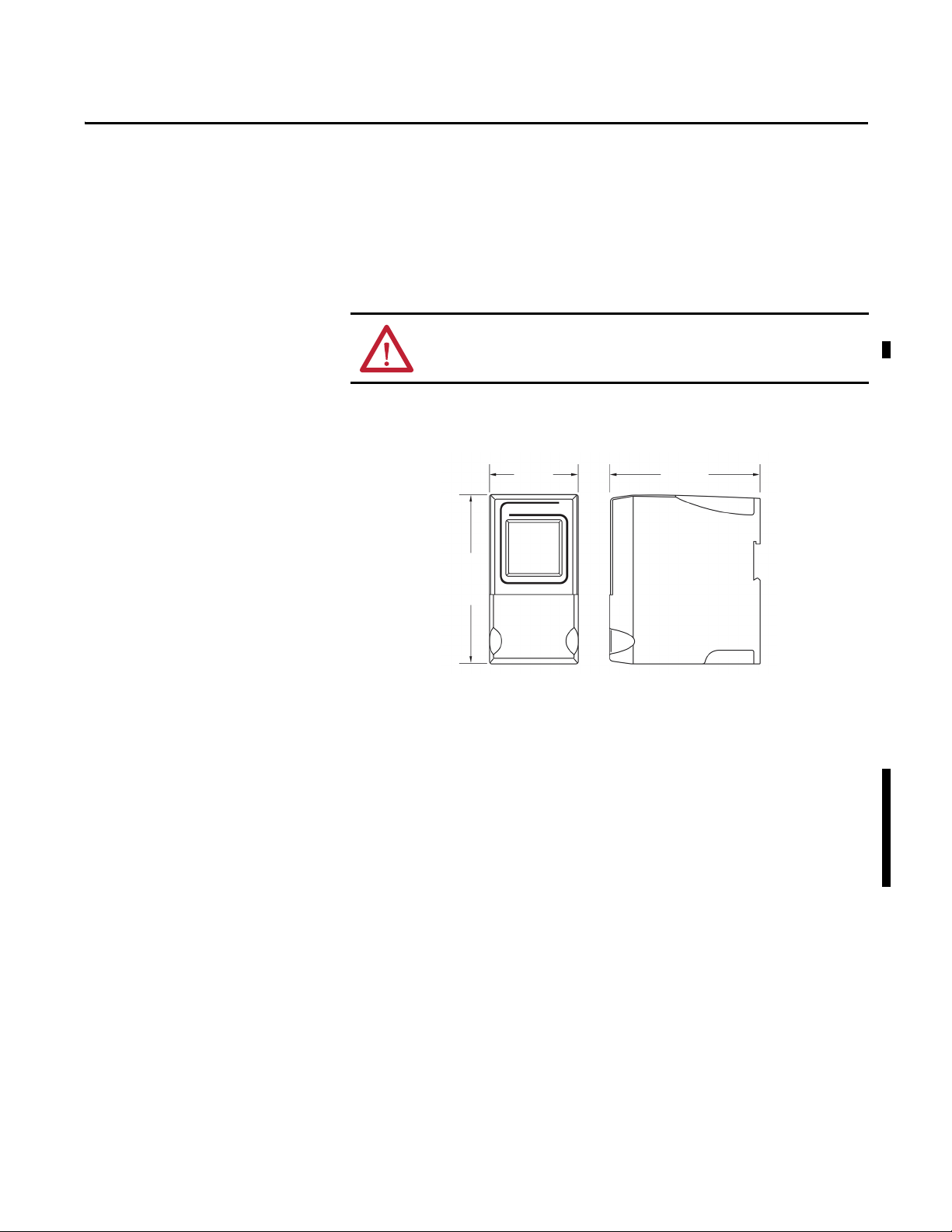

Hardware

80 mm

(3.15 in)

136 mm

(5.35 in)

152 mm

(5.98 in)

Chapter 1

Installation

ATTENTION: Do not wire more than one conductor on any single terminal.

Dimensions

Power Connection

To comply with the CE Low Voltage Directive (LVD), this equipment must be

powered from a source compliant with Safety Extra Low Voltage (SELV) or

Protected Extra Low Voltage (PELV).

To comply with UL restrictions, this equipment must be powered from a source

compliant with Class 2 or Limited Voltage/Current.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 13

Page 16

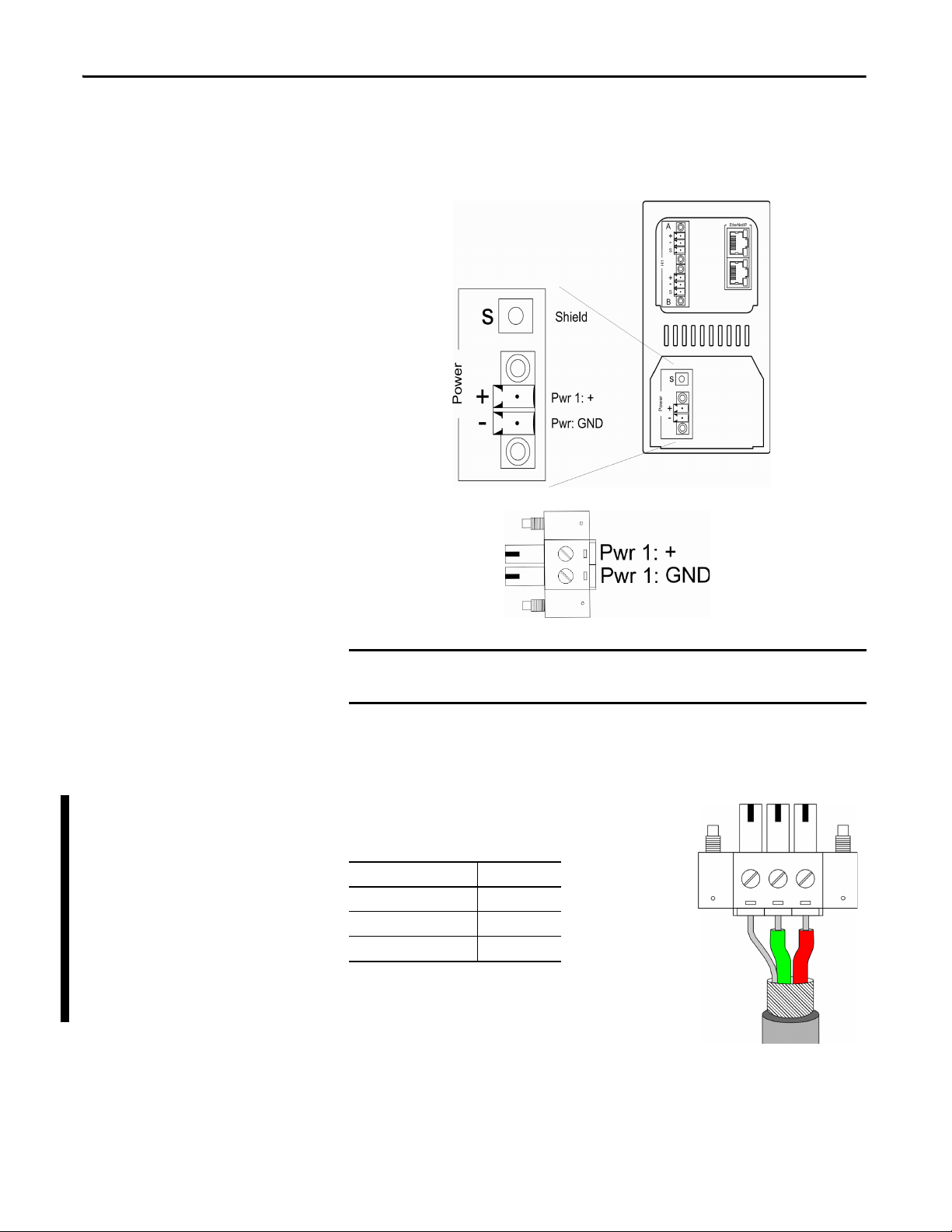

Chapter 1 Installation

IMPORTANT

We re co mm en d a 24 …32V DC power supply for the linking device to operate

correctly. No additional power supplies or power conditioners are required. The

power supply connection is described here. Tighten DC Power connections to a

torque of 0.22…0.25Nm (2…2.2 lb-in).

Do not use additional power supplies or power conditioners with the

1788-EN2FFR and 1788-CN2FFR linking devices.

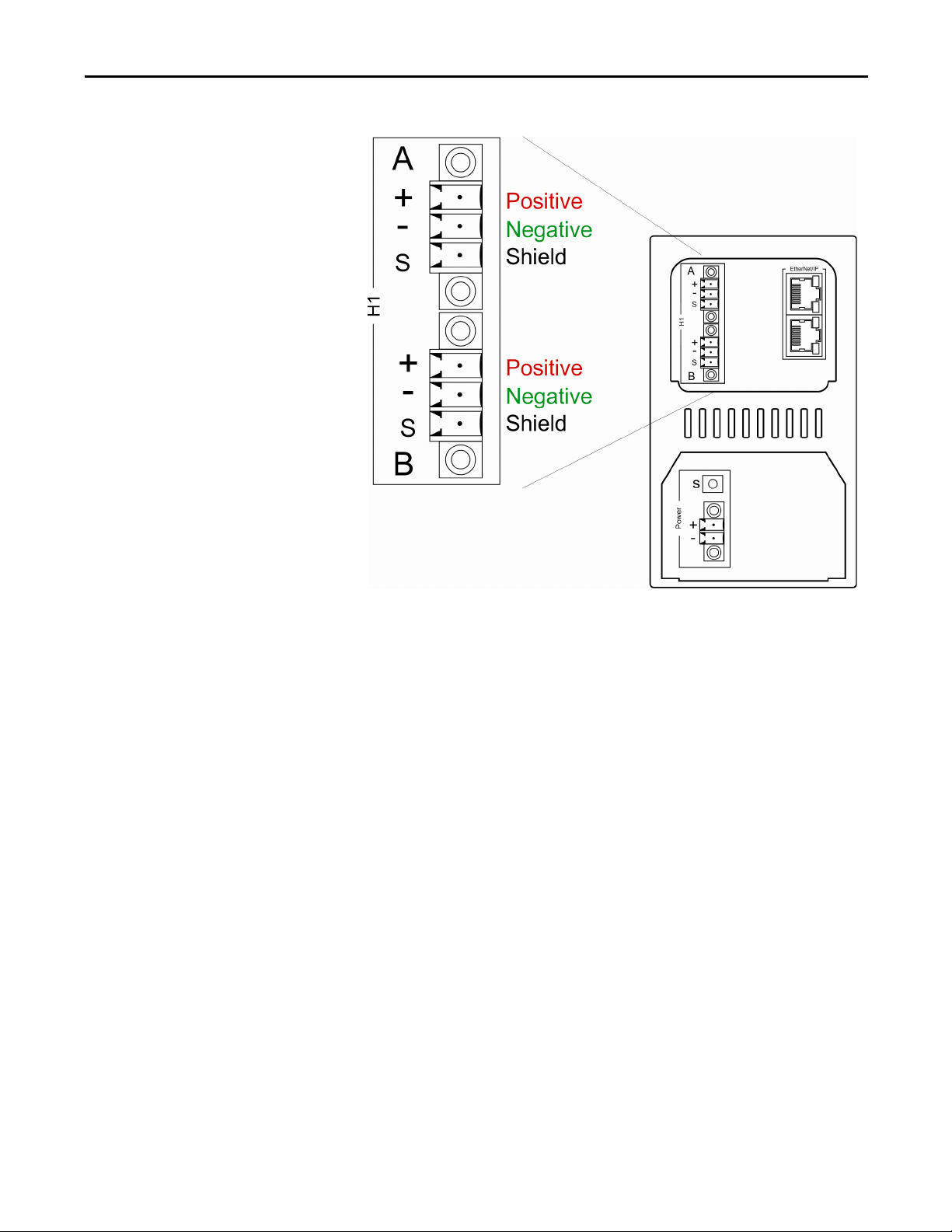

H1 Network Connections

The H1 network must be connected via the H1

terminal on the linking device. The H1 network

connection and pinout is described here.

Pin Description

Right/Top (red) FF +

Middle (green) FF -

Left/Bottom Shield

Make Fieldbus connections to a torque of

0.5…0.6 Nm (4.4…5.3 lb-in)

The H1 Segment is split between two physical

ports, A and B.

14 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 17

Installation Chapter 1

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 15

Page 18

Chapter 1 Installation

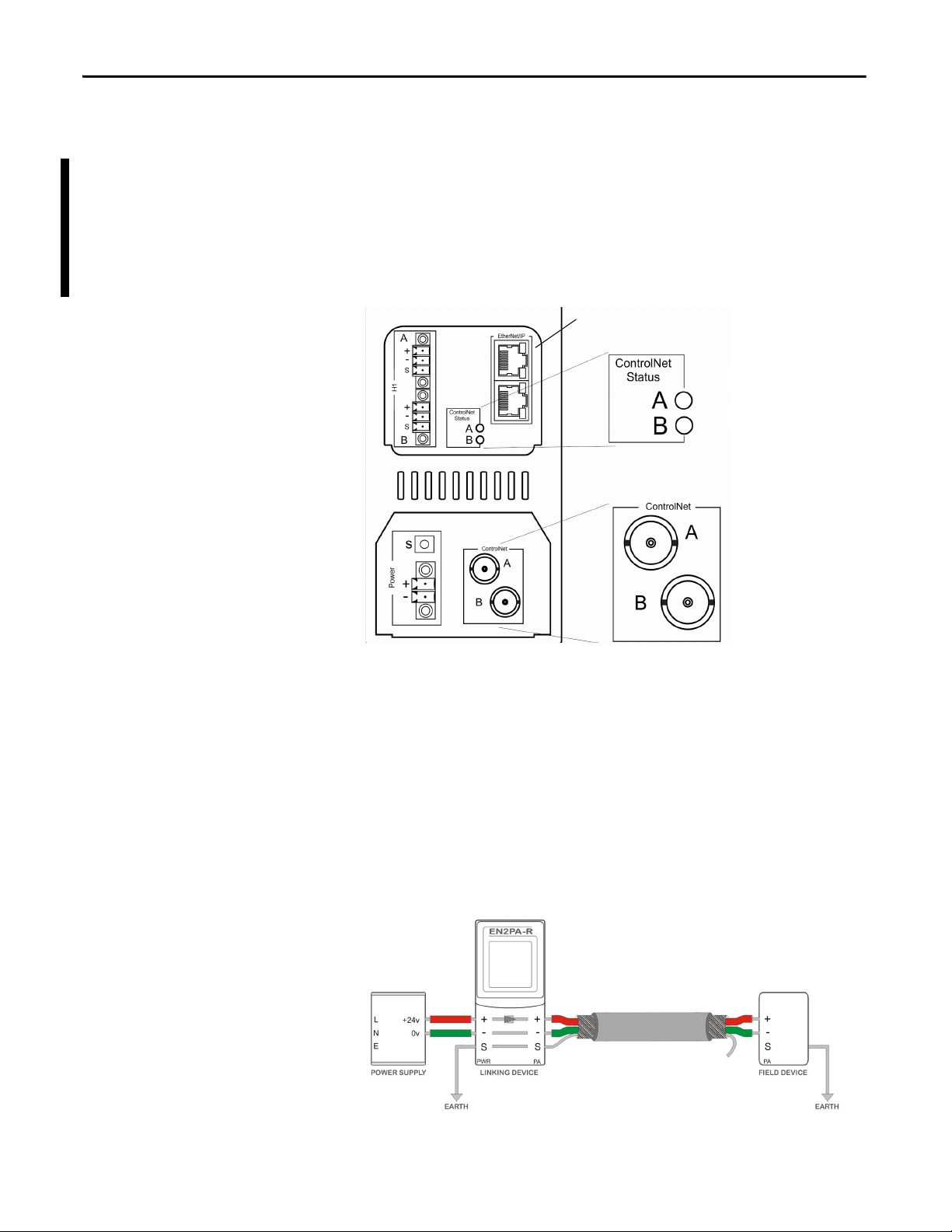

EtherNet/IP Port

ControlNet Status

(1788-CN2FFR)

Control Net Connec tions

(1788-CN2FFR)

ControlNet and EtherNet/IP Connections

Two BNC connectors on the base of the 1788-CN2FFR linking device provide

connections for single or dual ControlNet media. The 1788-EN2FFR linking

device uses an RJ45 connector to connect to an EtherNet/IP network. The dual

port EtherNet/IP switch on the 1788-EN2FFR linking device provides

connections for multiple Ethernet topologies, including device level ring (DLR).

The EtherNet/IP port can also be used as a connection point in the field to access

the web server or asset management tools.

Shielding

Ground the linking device shield connection to a clean earth connection.

Connect the shield to the H1 media so that connectivity runs through all

junction boxes, but is not connected to the field device shield or grounded at the

device.

Do not attach the H1 media shield to the field device. Tape the media shield back

to avoid accidental contact with other conductors or ground.

16 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 19

Installation Chapter 1

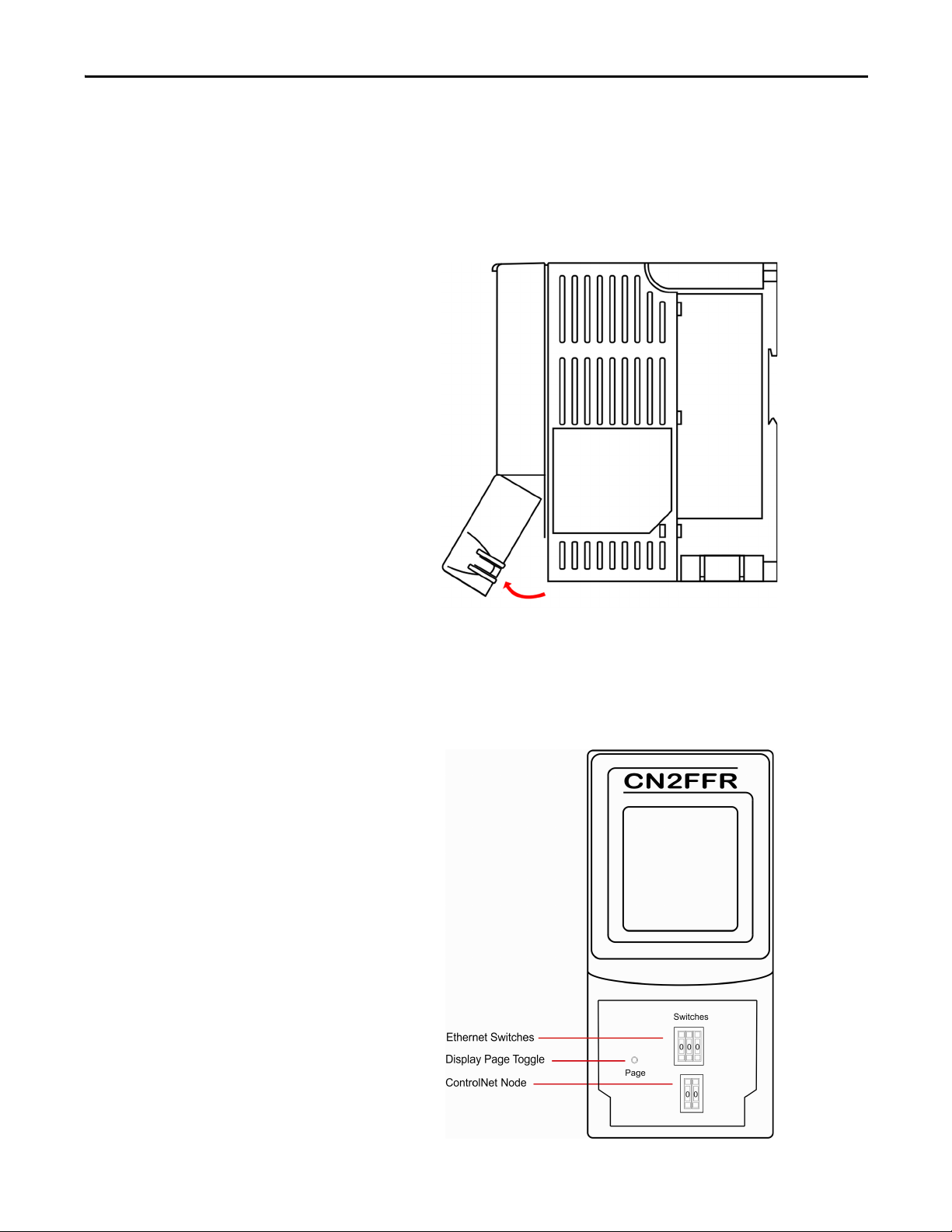

Set the Linking Device Network Address

This section describes the network address switches.

Hardware Switches Location

The hardware switches are located under the front cover of the linking device.

Use the Page button to toggle between different diagnostics on the display.

Set the ControlNet Node Address

To set the ControlNet node address of the 1788-CN2FFR linking device, use the

hardware switches behind the front cover.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 17

Page 20

Chapter 1 Installation

IMPORTANT

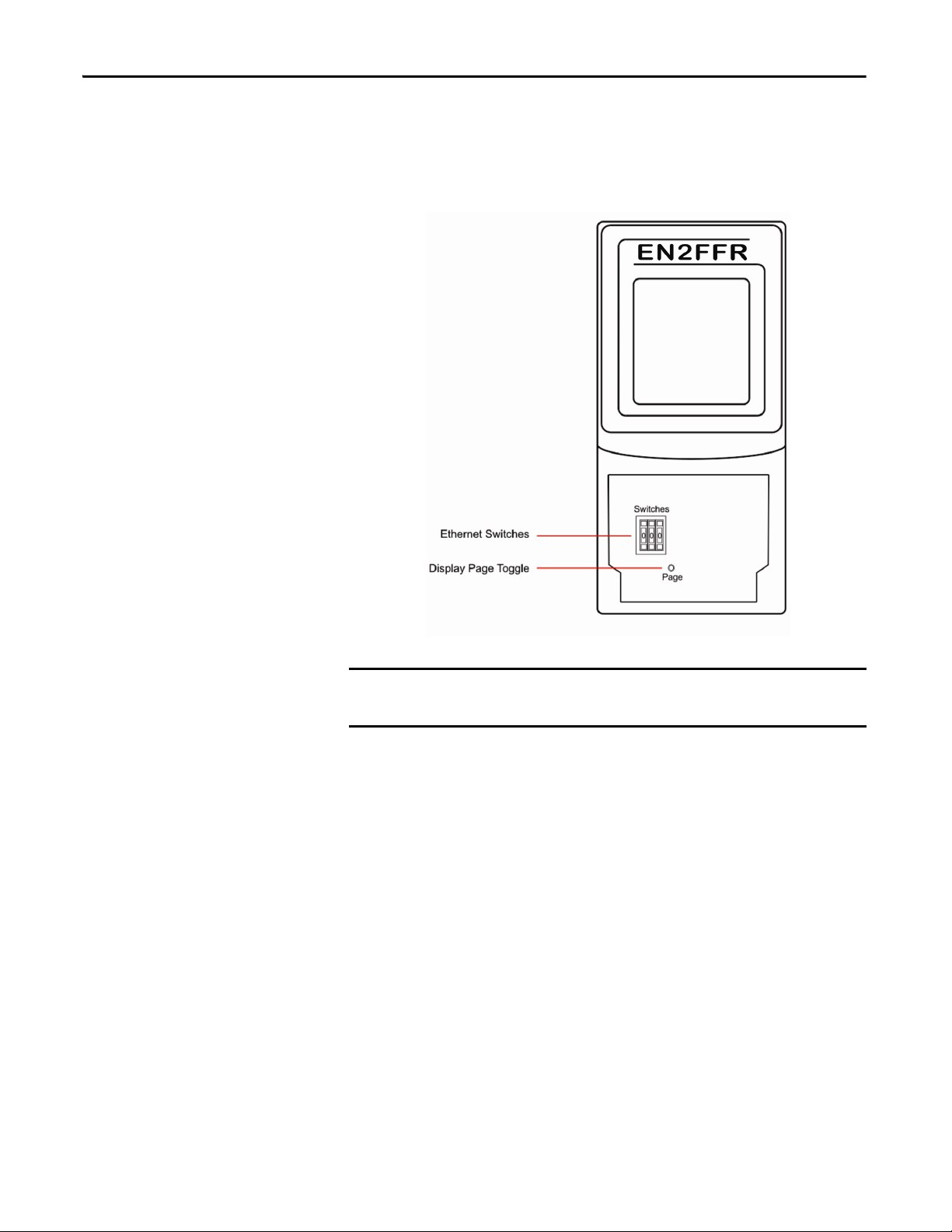

Set the EtherNet/IP Address

The linking device ships with BOOTP enabled. To set the IP address of the

1788-EN2FFR linking device, use a BOOTP server or use the hardware switches.

Power down the linking device before changing the Ethernet switch settings.

The IP address is set during powerup.

18 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 21

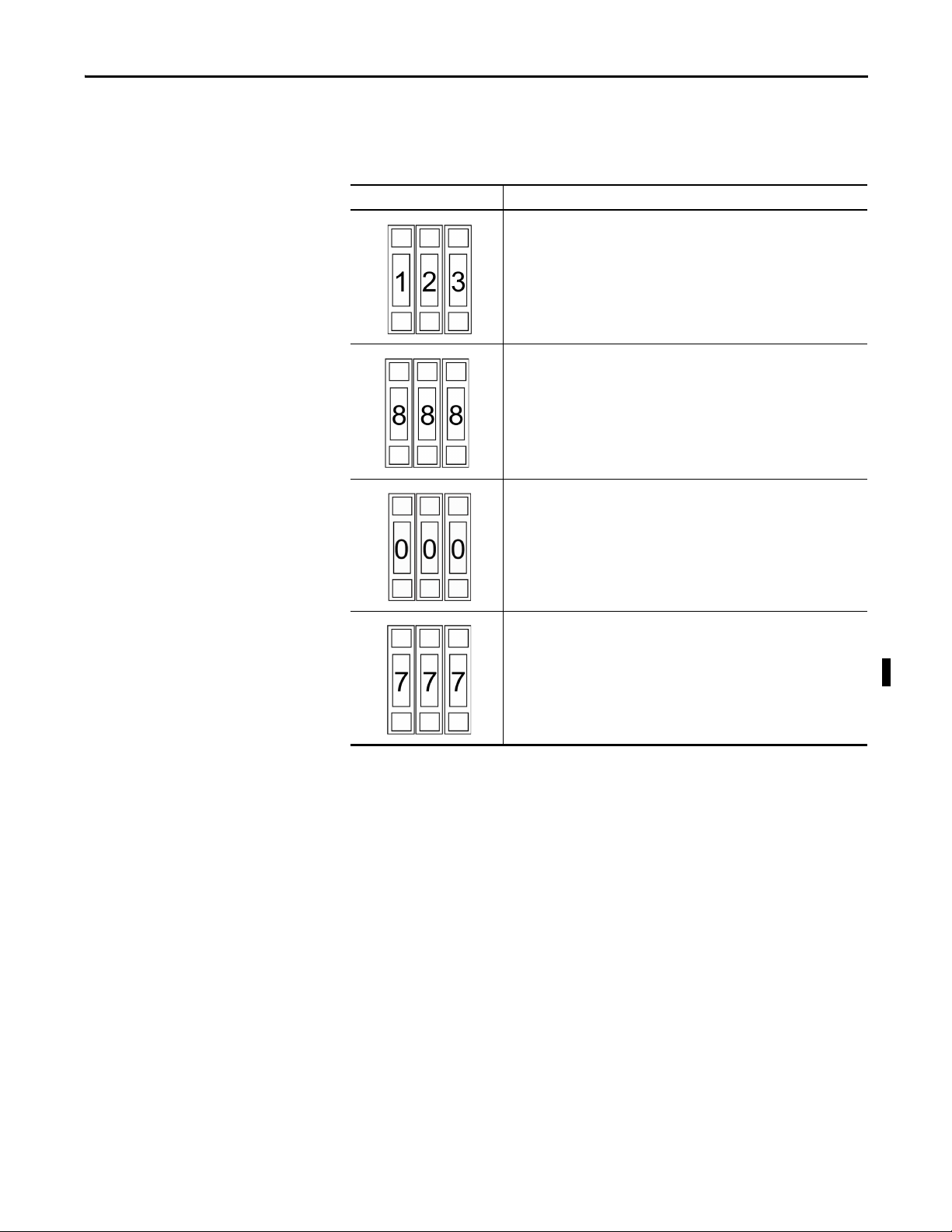

Ethernet Switch Settings

This table describes the Ethernet switch settings.

Ethernet Switch Setting Description

To set the IP address of the linking device to the 192.168.1.xxx sub net, set the

switches to the required last three digits.

In this example, the linking device will start up with IP address: 192.168.1.123.

To set the IP address of the linking device via a BOOTP server, set the switches to

888 (factory default setting).

Power up the linking device and set the IP address by using any BOOTP server.

Once the new IP address has been set, power down the linking device, return the

switches to 000, and power up the linking device.

Installation Chapter 1

Normal setting after setting IP address with BOOTP.

The 000 setting disables BOOTP and holds the IP address.

The linking device can run the firmware with which it was originally shipped.

If power was cycled while upgrading the firmware, the firmware can be corrupted

and prevent the linking device from starting up.

Set the switches to 777 to set the linking device into Safe mode and upgrade the

firmware again.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 19

Page 22

Chapter 1 Installation

TIP

Software Installation

You need the AOP for the Studio 5000 Logix Designer application to configure

and manage the linking device. The installation of the AOP includes the

HSProcessUtility that is used to manage DTMs and DD service libraries. See

Appendix B

For the latest compatible software information and to download the AOP, see the

Product Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/

pcdc.page#/tab2.

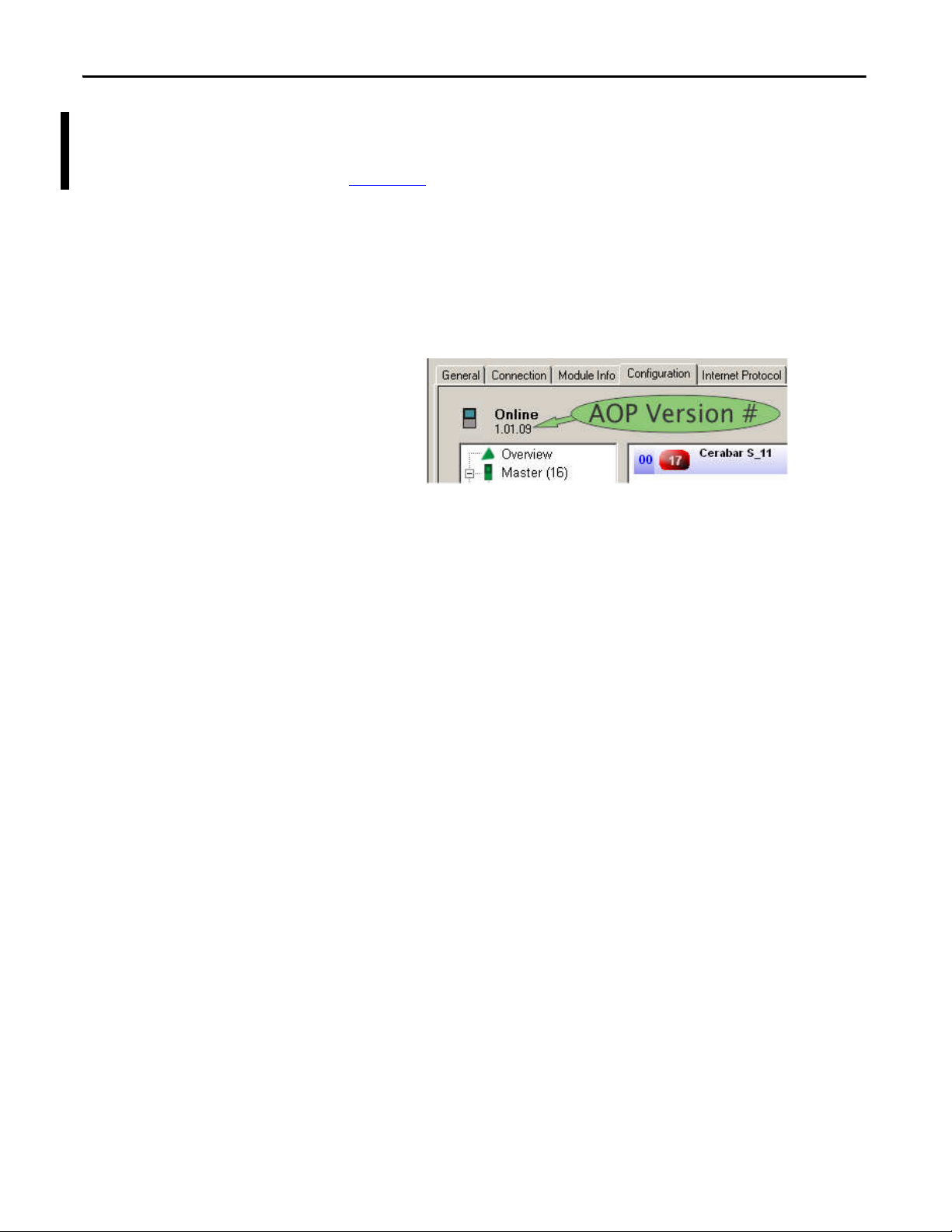

The AOP version of the linking device is located on the display during the start

up process, or via the web server.

.

You can also click the upper-left corner of the profile window and click About

Module Profile to view the AOP version.

Firmware Version

The firmware version is printed on the linking device and displayed on the screen

during power-up.

20 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 23

Set Up in the Studio 5000

Logix Designer Application

Chapter 2

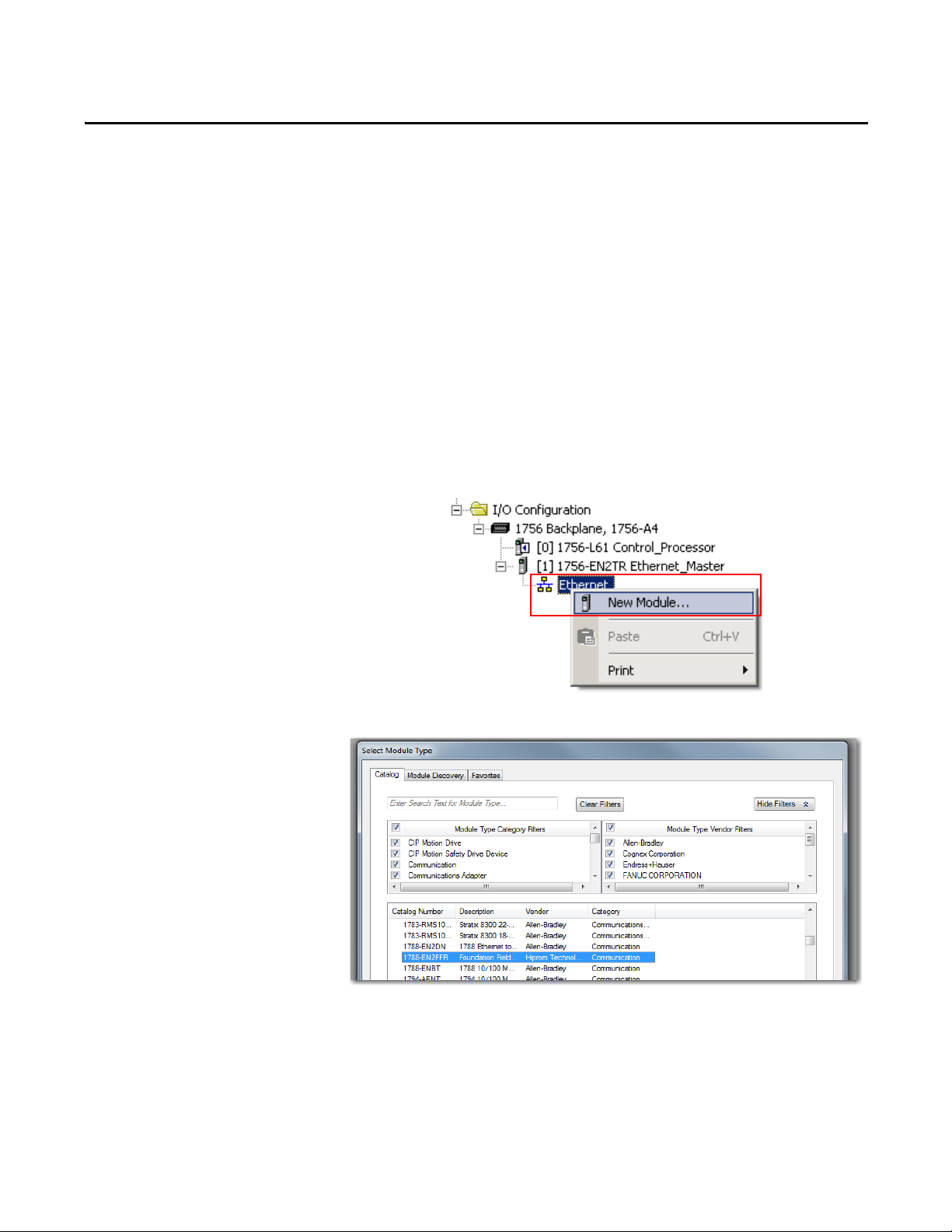

Add the 1788-EN2FFR Linking Device to the I/O Tree

The 1788-EN2FFR linking device must be added to the I/O tree of the Logix

controller. The linking device must be added to an Ethernet bridge, such as an

Allen-Bradley® 1756-EN2T or 1756-EN2TR module.

Follow these steps to add the linking device to the I/O tree of the Logix

controller. This example uses the 1756-EN2TR module.

1. Right-click the Ethernet bridge and choose New Module.

2. Select the linking device that you want to add to the Ethernet bridge.

3. Click the General tab and set the name, description, and IP address.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 21

Page 24

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

IMPORTANT

4. Set the RPI for the linking device.

The recommended RPI is 1/2 the macrocycle time. Calculate the macrocycle by

calculating the total response time of all field devices on the segment and then

add 100

…200 ms for class 2 (DTM message) data. If the RPI is too low, class 1

data (PVs and status) does not update each cycle, and class 2 data responses

can be slow.

5. Click OK to add the linking device to the I/O tree.

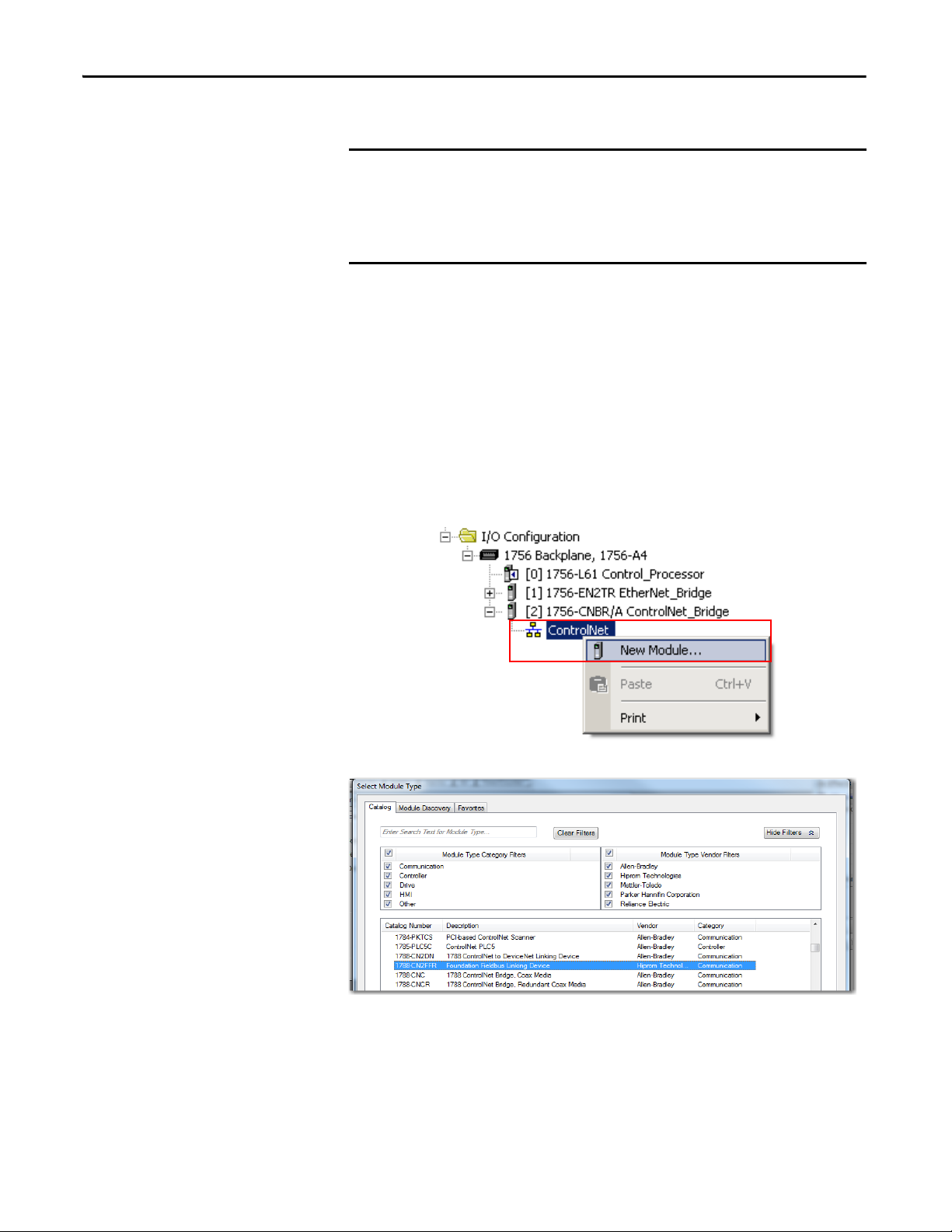

Add the 1788-CN2FFR Linking Device to the I/O Tree

The 1788-CN2FFR linking device must be added to the I/O tree of the Logix

controller. The linking device must be added to a ControlNet bridge, such as an

Allen-Bradley 1756-CNB or 1756-CNBR module.

Follow these steps to add the linking device to the I/O tree of the Logix

controller. This example uses the 1756-CNBR/A module.

1. Right-click the ControlNet bridge and choose New Module.

2. Select the linking device to add to the ControlNet bridge.

3. Click the General tab and set the name, description, and ControlNet node

address.

22 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 25

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

4. Set the RPI for the linking device.

The recommended RPI is 1/2 the macrocycle time. Calculate the macrocycle by

calculating the total response time of all field devices on the segment and then

add 100

…200 ms for class 2 (DTM message) data. If the RPI is too low, class 1

data (PVs and status) does not update each cycle, and class 2 data responses

can be slow.

5. Click OK to add the linking device to the I/O tree.

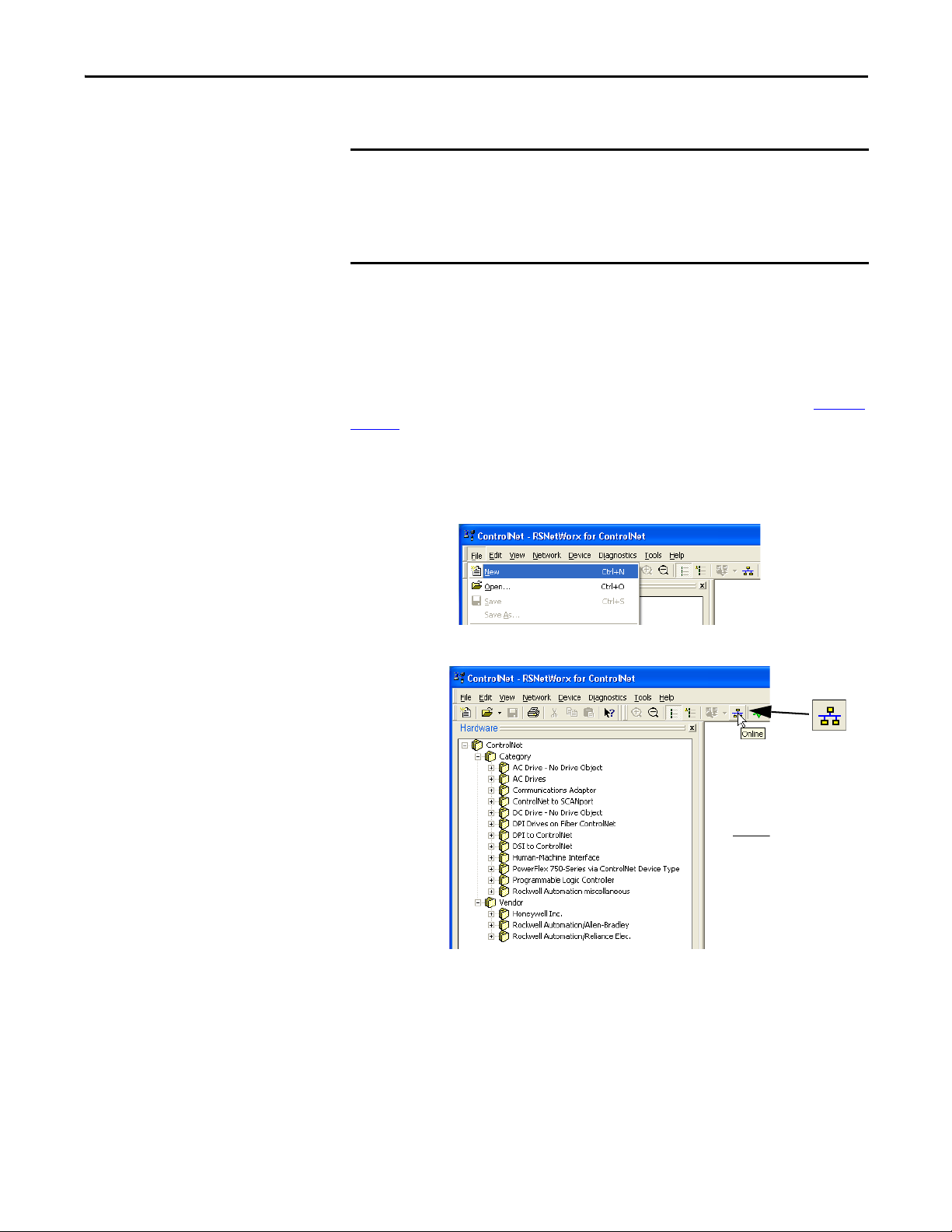

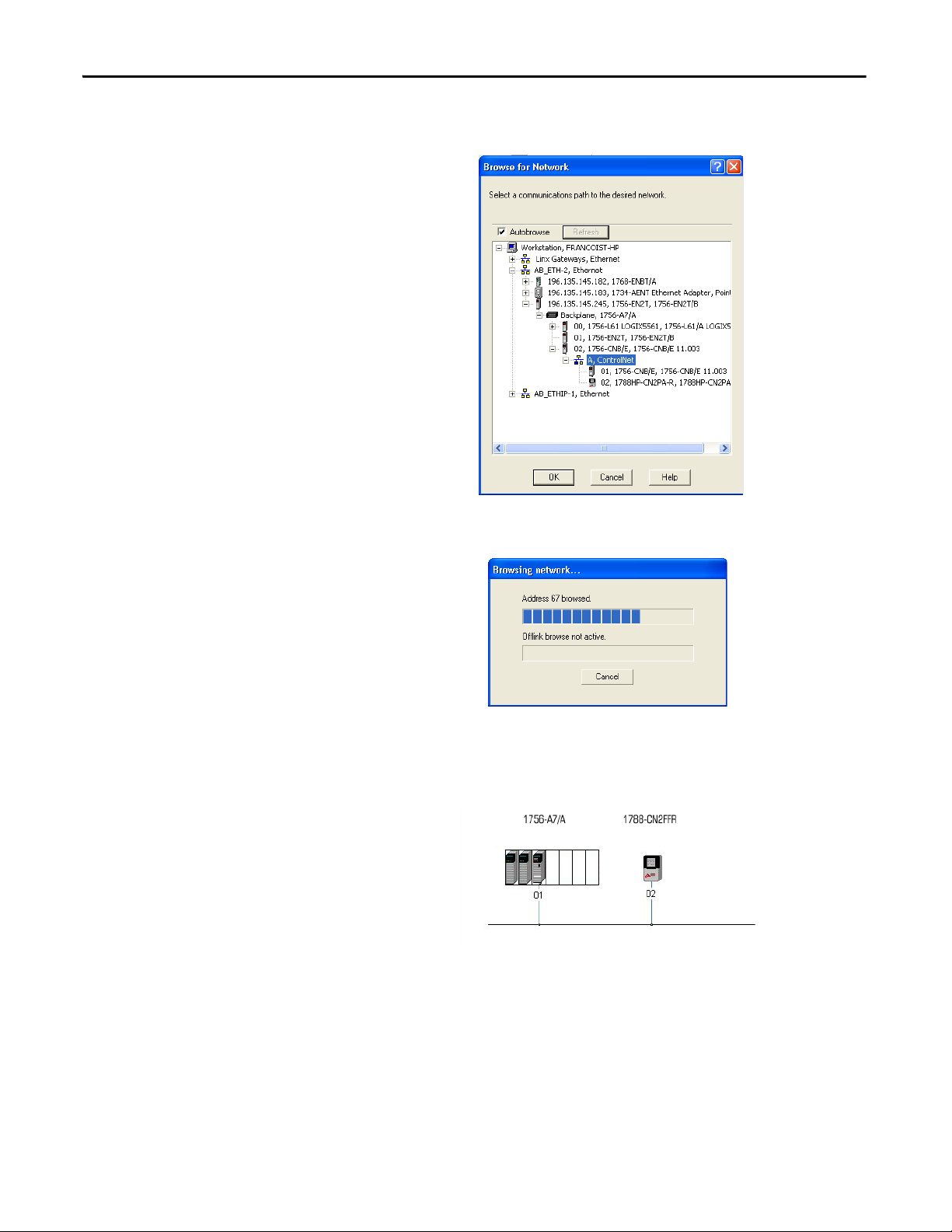

RSNetWorx for ControlNet Configuration

See the RSNetWorx for ControlNet Getting Results Guide, publication CNET-

GR001, for more details.

Follow these steps to configure the ControlNet network.

1. Launch RSNetWorx™ for ControlNet and create a file.

2. Click the Online button.

The Browse for Network window appears with the drivers you have

installed on your system.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 23

Page 26

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

3. Select the communication path to the ControlNet network, select the

ControlNet port, and click OK.

The following pop-up window appears while RSNetWorx browses the

network.

Once complete, all devices on the network are displayed in the graphic

window on the right side of the window.

4. Right-click any white space around the graphics and select Enable Edits.

5. Right-click any white space around the graphics and select Properties.

24 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 27

Set Up in the Studio 5000 Logix Designer Application Chapter 2

6. On the Networks Parameters Tab, update the Max Unscheduled Address

if you are sure that the allocated range is less than 99.

7. Click OK.

8. Right-click any white space around the graphics and choose Download to

Network.

9. Select the correct save option for your configuration and click OK.

10. Enter a suitable file name.

11. Click Yes to download the configuration.

The ControlNet network is now scheduled and the graphics display green plus

signs.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 25

Page 28

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

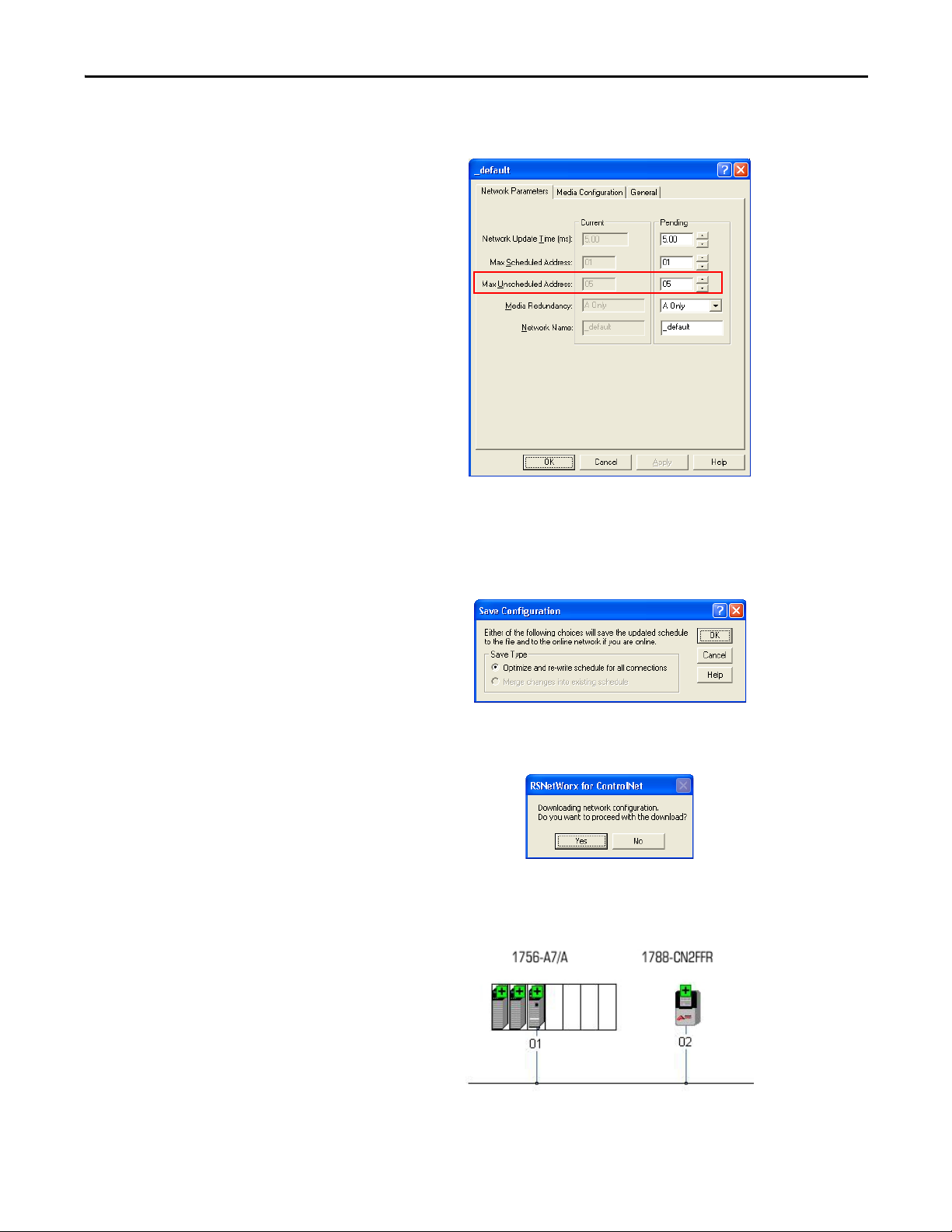

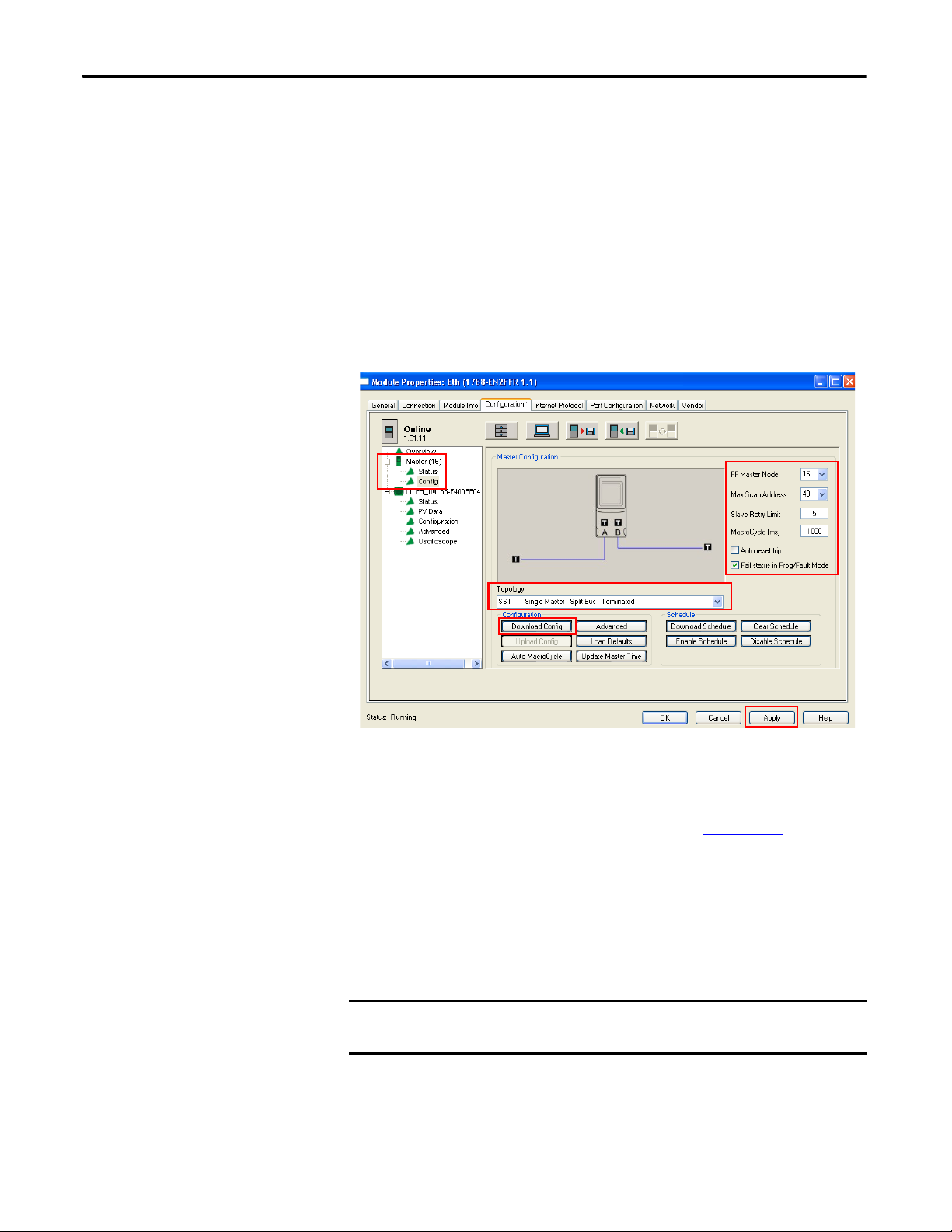

Linking Device Configuration Using the AOP

Once the linking device has been added to the config tree, you can access the

property settings. Right-click the linking device and select Properties. Then click

the Configuration tab as shown in Figure 1

Once the linking device is connected to the controller, you can see the linking

device in the Configuration tab.

• Master green in the config tree = linking device is online

• Master gray in the config tree = linking device is offline

The layout of the Configuration tab is shown in Figure 1

Figure 1 - Module Properties Configuration Tab

.

.

Live List

Once a field device is found and has an address between 16 (0x10) and

247 (0xF7), the device appears in the live list. You can configure this device.

Visitor List

Once a field device is found and has an address above 247 (0xF7), the device

appears in the visitor list. You cannot configure this device until an address

between 16 (0x10) and 247 (0xF7) is given to the field device. See Live List.

26 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 29

Set Up in the Studio 5000 Logix Designer Application Chapter 2

TIP

LAS

The LAS icon indicates if the master is the LAS that requests and receives live

data from each field device, or if the master is the back-up LAS. (The back-up

LAS has a red X over the icon.) See Redundant Master Setup

on page 43 for

more information.

Config Tree

Once you have configured the slot for a device (even if not downloaded yet), the

device appears in the config tree. Use the config tree to navigate between

configuration and status pages for each master and field device.

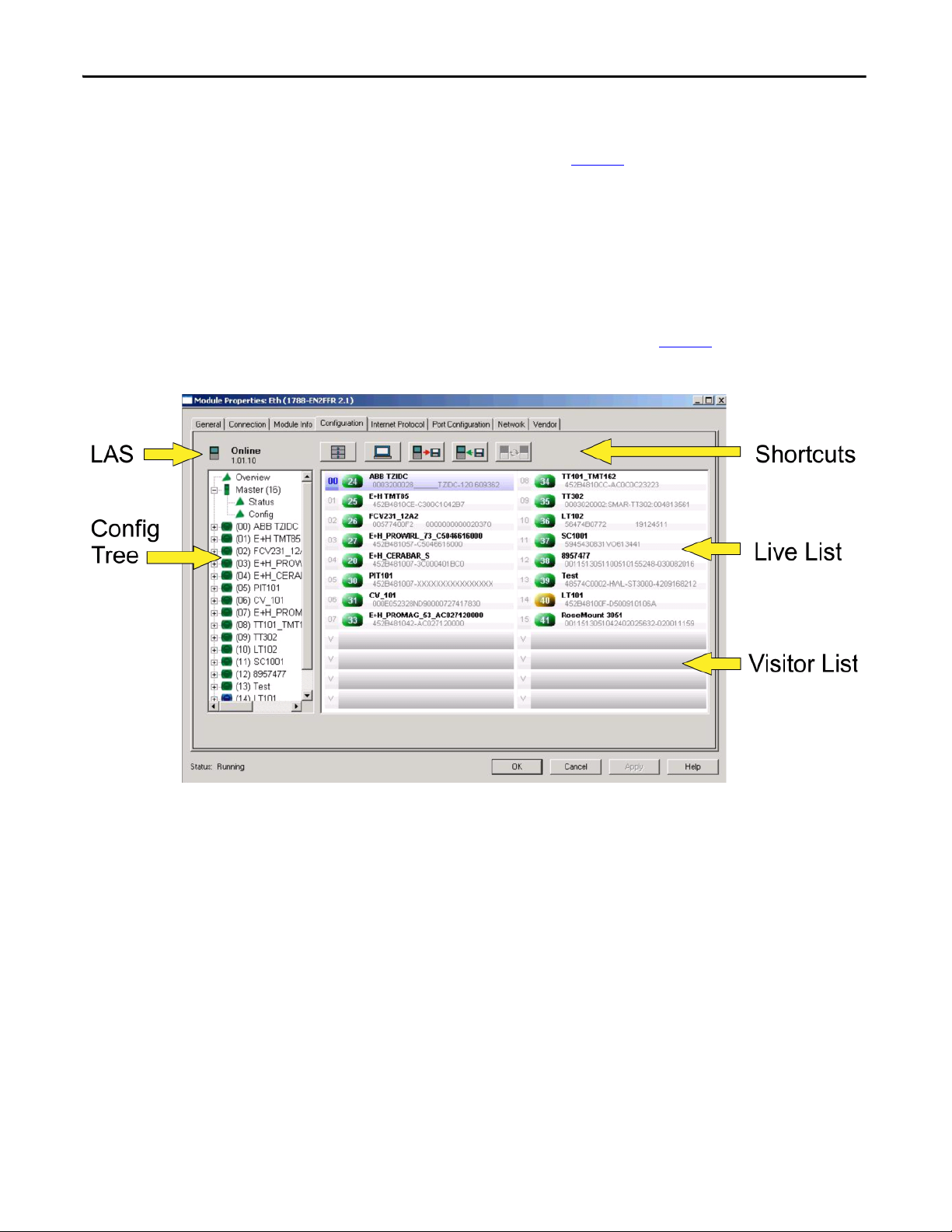

Shortcuts

These shortcuts are located above the live list on the configuration tab.

Table 1 - Configuration Tab Shortcuts

Shortcut Button Description

Used to open the HSProcessUtility, or to refresh the device catalog.

The Overview page displays a list of configured and attached field devices.

Export configuration for entire linking device,

(including all field devices that are configured under linking device).

Import configuration for entire linking device,

(including all field devices that are configured under linking device).

Used to synchronize the back-up link active scheduler (LAS) to the current LAS. You must first

export the project from the LAS AOP. Note that this button is only available to the back-up LAS

and is disabled on the LAS.

You can export or import the configuration for either a field device or linking

device (with all field devices connected).

If you want to replicate the configuration to many devices, the synchronize

shortcut can speed up the process.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 27

Page 30

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

IMPORTANT

Master Configuration

1. Open the master configuration page from the config tree to access the

linking device master configuration settings.

2. Choose the Topology for the master linking device.

3. Enter the configuration values.

4. Click the Download Config button to download the settings to the

linking device.

The settings are stored in nonvolatile memory in the linking device.

5. Click the Apply button to store the configuration in the project file.

To p o l o g y

Choose the correct Topology mode for the application. The graphical

representation must be used to match the topology. See Appendix D

options. Use this setting to configure redundant linking devices, redundant H1

media, and the internal H1 segment terminators.

FF Master Node

The H1 Master (linking device) needs a node number to operate on the H1

network. The default is node number 16 (0x10).

Do not modify the default node number; doing so can result in loss of

communication.

28 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

for available

Page 31

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

TIP

Max Scan Address

When the linking device is operating, a background scan constantly probes each

unused node number to see if any new field devices were connected. The

background scan runs to the max scan address, then restarts at one.

Slave Retry Limit

The slave retry limit sets the number of times the H1 Master re-requests data

before dropping the connection. The default setting is 5.

Do not modify the default setting. A limit above 5 can slow down

communication.

MacroCycle (ms)

The amount of time between data compels (process variables). Too low a number

can cause poor performance when downloading and going online with a field

device.

Auto Reset Trip

Selects the option to reset H1 bus trips due to over-current.

• If the checkbox is selected, the trip automatically resets. The linking device

resets the trip each 5 seconds. If the trip is still persistent, the bus will trip

again.

• If the checkbox is not selected, reset the bus via the reset button on the

master status page.

Fail Status in Prog/Fault Mode

The fail status is used when field devices use output blocks (AO or DO) that are

receiving data from the Logix controller via the linking device. When the linking

device loses connection to the Logix controller, or the Logix controller goes into

Program mode or Fault mode, you can choose one of two operations:

• If the checkbox is selected, the linking device detects that there is a comms

fault on the Ethernet network and forces all output PV status to

Bad:NoComms. If the field device is configured correctly, the field device

goes to fail-safe value.

• If the checkbox is not selected, the linking device continues to send the last

received data.

When Logix is in Prog/Fault mode, you can still go into the tags and

change values as the linking device is still connected.

Upload Config

Uploads the configuration store on the attached linking device.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 29

Page 32

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

TIP

IMPORTANT

IMPORTANT

Auto MacroCycle

Calculates the Macro Cycle based on the configured field devices and the number

of PVs configured. A window is also added for class II data communication.

Advanced

Opens the Advanced Settings window.

Load Defaults

Resets the configuration settings to their default values.

Update Master Time

Update the master time to local computer time.

Download Schedule

Download schedule to linking device.

This task is performed automatically when field devices are added or edited.

Enable Schedule

The default is enabled. Used only when the Disable Schedule Function disables

the schedule.

Clear Schedule

Clear the schedule from the linking device and the AOP.

This action causes the module to stop compelling data.

Disable Schedule

Disable the schedule from executing in the linking device.

Advanced

The Advanced button on the master configuration page launches the Master

Advanced configuration dialog box (see Master Configuration

on page 28).

We recommend that you do not alter these settings; doing so can cause loss of

communication.

30 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 33

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

Figure 2 - Master Advanced Configuration Screen

Auto MacroCycle

Click the Auto MacroCycle button on the master configuration page to calculate

the recommended MacroCycle for the current linking device (see Master

Configuration on page 28).

Auto MacroCycle Calculation

Macrocycle = [(time for request + receive) x (configured field devices) x

(configured PVs for each field device)] + [(configured field devices) x (time for

one token exchange)] + [fixed amount of unscheduled time].

The Auto MacroCycle only takes effect after you download it to the master and

field devices.

Add and Manage Device Description Files

Before field devices can be added to the 1788-CN2FFR/1788-EN2FFR linking

device, add a copy of the DD file to the field device catalog by using the

HSProcessUtility as described in Appendix B

The DD file defines the capabilities and configuration parameters of the field

device.

.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 31

Page 34

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

Field Device Configuration

The overview page on the configuration tab displays the field device live list with

colored icons that depict the status of each field device (see page 26

5000 Logix Designer application is online with the 1788-CN2FFR/1788EN2FFR link master correctly configured, the attached field devices appear in

the live list.

The field device index (00→15) provides a unique index for each of the 16 field

devices that can be connected to the linking device. This index corresponds with

the index in the linking device data structure that is located in the controller tags.

The H1 node address and physical tag are also displayed together with the device

ID and serial number of the field device.

A right-click menu in the overview page displays functions for addition,

configuration, and diagnostics of field devices.

Figure 3 - Overview Page on the Configuration Tab

). If the Studio

Field Device Status

The icon color indicates the status of the field device.

Table 2 - Field Device Status Icons

Icon Description

Green – Field device is online, allocated to a field device index and configured, producing process

variables.

Yellow – Field device is online, not allocated to a field device index and not configured.

Blue – Field device is online, allocated but not configured or producing process variables.

Red – Field device is not online.

Light blue – Field device identification mismatch (occurs when the field device identity [ident] that is

downloaded to the linking device is different than the actual field device).

32 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 35

Set Up in the Studio 5000 Logix Designer Application Chapter 2

The color of the text indicates if the online device has the same node address and

tag as the offline configured device.

• If the text is black, the online and offline node address and tag name

match.

• If the text is red, the online and offline node address and tag name

do not match.

Add New

Use this function to add field devices when the linking device is not connected to

the field device. The Select Device dialog box displays a list of devices from the

field device catalog. Set the H1 Node Address and Tagname.

Figure 4 - Select Device Dialog Box

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 33

Page 36

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

IMPORTANT

Configure

Launches the field device block configuration screen that is used to configure

each field device.

Auto Configure Online

You can right-click on a device (of which the DD files are registered) and choose

the Auto Configure Online option. A configuration is applied for basic operation

of the field device.

Figure 5 - Field Device Configuration Screen

Requires the field device to be online.

• The AOP adds a resource block and sets the target mode to auto.

• A transducer block is added and the mode block is set to auto.

• An analog input block (if available) is added with the target mode set to

auto.

• The channel is set to 1 (in most cases the primary value).

Advanced Configuration

Used to assign DTM to the field device and to launch the Thin-Frame DTM

viewer.

Oscilloscope

Displays an oscilloscope trace of the response message from the field device.

34 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 37

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

Copy and Paste

After the device configuration is done, you can copy and paste the configuration

to speed up the configuration process.

Move

You can move a device in the live list to another field device index even if the

devices have been configured and are providing process variables.

Remove

A device configuration can also be removed (deleted).

If a configuration is stored in the linking device at the specific field device

index, it is also removed (deleted).

Set H1 Node Address

Used to change the H1 node address on the field device. We recommend that you

set the node address from 17 through 247. The linking device uses 16, and node

addresses above 247 are placed in the visitor List.

Set H1 Physical Tag

Use to change the tag name that is stored in the field device.

Merge Online and Offline

The device merge option is used when you want to merge an online device with

the offline configuration of a certain device index. Use this option when

performing a device exchange for a faulty device.

Mapping Report

Produces a report that describes in detail the configuration of the field device.

Export Device and Import Device

A device configuration can be exported to a file which can later be imported

again. This option helps when you have multiple devices with the same

configuration.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 35

Page 38

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

Field Device Block Configuration

You can configure the field device blocks

from the block configuration view.

Choose the Configuration option of the

device in the config tree, or from the

right-click menu in the live list.

Configuration is device-centric and

performed in a graphical view using

blocks, wires, and connectors (see

Figure 5 on page 34

interface also provides access to

parameters for each block for detailed

configuration of each device.

). The graphical

See Appendix C

, Field Device Block

Configuration Examples on page 69 for

detailed information about how to

configure AO and DO function blocks.

Table 3 - Field Device Configuration Tools

Icon Description

Select and move objects.

Draw wire.

Go online with device.

Download configuration to device.

Print.

36 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 39

Set Up in the Studio 5000 Logix Designer Application Chapter 2

Add a Block

Blocks are defined by the field

device manufacturer and

described in the DD files.

There are three classes of blocks:

R – Resource Block

T – Transducer Block

F – Function Block

Only function blocks have ports that are used to transfer data to and from the

block:

• Ports on the left of the function blocks are inputs.

• Ports on the right of the function blocks are outputs.

For detailed descriptions and uses of each block, refer to the user manual of the

field device.

Follow these steps to add a block.

1. To add (instantiate) a block, right-click in the window and choose New

Block.

A list of all available blocks for the specific device appears.

2. Choose the block that you want to use.

The block appears on the screen.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 37

Page 40

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

Adjust Block Parameters

To change the parameters of a block, right-click

the title portion of the block and choose

Parameters.

To enable a parameter for editing, click the box in

the En column. A green check mark indicates the

parameter is enabled for editing. Different

parameters will have different classes as shown in Tab l e 4

Table 4 - Parameter Class Descriptions

Icon Parameter Class Description

.

Configurable parameter but non output

Input port

Read-only

Tun e

Output port

Alarm

Parameter help (provides information about the parameter)

1. Click a parameter that is enabled for editing to display a list of options to

choose from.

2. Select a new value in the pop-up dialog box and click OK.

38 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 41

Set Up in the Studio 5000 Logix Designer Application Chapter 2

TIP

Add a Connector

A connector enables transfer of data between the

block of the field device and the data structure in the

controller, or between field device blocks on the same

segment. Data transfers between segments are

performed via the controller.

Follow these steps to add a connector.

1. To add a connector, right-click in the window and choose New Connector.

2. Set the desired options in the Add Connector dialog box to configure the

connector, and click OK.

The configuration of input and output connectors requires the definition of the

data being transferred. See the user manual of the field device for data type,

length, offset, and number of status bytes. The default is the most common.

Ta b l e 5

Table 5 - Connector Types

describes the four types of connectors.

Connector Type Data Transfer Use Icon

Input : I.PV From a field device to the controller.

Output : O.PV From the controller to the field device.

Network Publication

Network Subscription

From a field device to another field device on

the same segment.

From another field device on the same

segment to the field device.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 39

Page 42

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

IMPORTANT

The field device index, PV slot, and data type define where the connector points

to in the data structure of the controller tags.

Figure 6 - Example of a Field Device Index

• For Input : I.PV connectors, the data types of float and integer both

connect to PVReal in the input image, while binary data types connect to

PVBinary.

• For Output : O.PV connectors, the output image of the linking device

provides separate data types for float, integer, and binary.

•Network Publication and Network Subscription are used for control in

the field where data is sent from one field device to another without any

intervention from the LAS (master).

Each Network Publication connector must be given a unique name that is

used as the reference for the Network Subscription connectors.

Network Publication connectors must be defined first.

40 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 43

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

Add Wires

Wires are used to connect input and output ports on

the blocks to other ports or connectors.

Follow these steps to add a wire.

1. To add a wire, right-click in the window and

choose New Wire.

2. Drag the ends of the wires to the docking points on the block and the

connectors.

Download the Configuration

When the configuration is complete, click the Download button to

download the configuration to the field device. The download status is

displayed in the progress bar.

The first configuration download for a device requires more time than

subsequent downloads due to extra data required for configuring the

communication links (virtual communication relationship [VCR]).

After the communication links are created, configuration downloads are

quicker.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 41

Page 44

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

IMPORTANT

Once the download is done and the device is providing process variables, the

device will be green in the configuration tree and the live list.

If the device is not producing data (for example, incorrect configuration) the

device will be blue in the configuration tree and the live list.

Go Online

Click the Go Online button to see process variables and change

parameters in real time.

Click a parameter to change it in real time. If the block is in Auto mode, you are

prompted to change the mode to Out of Service (OOS). Some parameters

cannot be changed while the block is in Auto mode.

See Appendix C

, Field Device Block Configuration Examples on page 69 for

detailed information about how to configure AO and DO function blocks.

Field Device Class

A field device can have one of two classes. It can be a

basic device (normal operation) or it can be a link

master (LAS capability). Choose Basic or Link

Master on the block configuration screen. Power

cycle the field device for the changes to take effect.

We recommend that you set up all field devices as basic (default).

42 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 45

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

IMPORTANT

IMPORTANT

Scheduling and the LAS

The 1788-CN2FFR/1788-EN2FFR linking device generates the LAS schedule,

which determines when each function block executes and transmits data. Newly

added field devices are automatically added to the schedule, and removed from

the schedule when removed from the live list.

Figure 7 - Master Configuration Dialog Box

Redundant Master Setup

The Download Schedule function is only needed when the 1788-CN2FFR/

1788-EN2FFR linking device has been replaced.

You can configure a second 1788-CN2FFR/1788-EN2FFR linking device to act

as a backup. You can choose from various architectures (see Appendix D

figure shows an example of MultiMaster architecture, A bus only, with a shared

termination.

When connecting to running linking devices, you must follow the procedures

in MultiMaster Connecting Procedures

connection to certain devices.

You must not have any other back-up LAS devices. Be sure that the field devices

have been configured with the class set to basic. See Field Device Class

page 42.

on page 46 to avoid losing the

). The

on

Test and verify that the specific field devices that are connected to the

MultiMaster operate correctly when one of the linking devices fails.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 43

Page 46

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

We recommend you use the given AOI when using redundant masters. The AOI

swaps between masters when one fails and automatically updates the destination

PV with the back-up master data.

Only one of the masters is the LAS that requests and receives live data from each

field device.

Follow these steps to configure one master to take priority as the primary

master.

• If the device is the LAS, the device icon is displayed without a

cross (see page 26

).

• If the device is the back-up LAS, the device icon is displayed with

a cross.

1. Set the back-up master Primary Link Master to No in the Master

Advanced options (see Figure 2 on page 31

).

2. Create the network on the LAS.

3. Click the Export button to export the bridge configuration.

4. On the back-up LAS, click the Sync Masters button and

choose the file that was exported.

All scheduled configurations are downloaded to the back-up LAS. Once

this download is done, the status indicates Active - Backup LAS as shown.

44 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 47

Set Up in the Studio 5000 Logix Designer Application Chapter 2

Redundant Master Mismatch

If the two masters are not synchronized (for example, there is a configuration

mismatch) one of the following errors on the back-up LAS is displayed.

• Master + Device Config Mismatch indicates that there is a difference

between the LAS and back-up LAS master configuration.

•Device Config Mismatch indicates that there is a difference in at least one

of the field devices between the LAS and back-up LAS configuration.

Redundant Master Disabled

If a redundant master is not in use, the Multi-Master status is disabled.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 45

Page 48

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

MultiMaster Connecting Procedures

To avoid communication loss, or a field device going to the visitor address range,

follow the MultiMaster connection procedures in this section.

Connect Safe Mode

The Connect Safe mode is used in the Reconnect Two Separate Running LAS

Devices on page 47 and Swap Out Linking Devices on page 47 procedures.

To en te r t he Connect Safe mode, hold the Page button for at least 5 seconds.

The LCD displays the time until communication is re-established to the linking

device (10 seconds).

Figure 8 - Location of the Page Button for Connect Safe Mode

Start the Back-up LAS Master (Already Configured)

Follow these steps to start the Back-up LAS master.

1. Plug in all communication connectors (H1, EtherNet/IP or ControlNet

cables), but not the power.

2. Once all communication connectors are plugged in, connect the power to

the linking device.

The linking device starts in Back-up LAS mode and does not disturb

communication.

46 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 49

Set Up in the Studio 5000 Logix Designer Application Chapter 2

IMPORTANT

IMPORTANT

Reconnect Two Separate Running LAS Devices

If two masters are configured on a network (one on each end) and the cable

between them is broken, some devices will be connected to one master, and the

remaining devices will be connected to the other master.

See master modes 9, 12, and 15 in Appendix D

Follow these steps to connect the two H1 segments.

1. Hold the Page button for 5 seconds to put one of the masters into

Connect Safe mode (see Connect Safe Mode

You have 10 seconds to reconnect the segments.

Failure to enter Connect Safe mode can result in a loss of

communication, or devices going to the visitor range.

2. Reconnect the cable between the masters.

.

on page 46).

Swap Out Linking Devices

Follow these steps to swap out a linking device.

1. Plug in all communication and power connectors, but not the H1

segment.

2. Once the linking device is connected to Logix, change the node address to

anything other than the node address of the running master.

3. Hold the Page button for 5 seconds to put the linking device into Connect

Safe mode (see Connect Safe Mode

You have 10 seconds to reconnect the segments.

Failure to enter Connect Safe mode can result in a loss of

communication, or devices going to the visitor range.

4. Click the Master Sync button in the overview window to synchronize the

new master with the current running master (see Redundant Master Setup

on page 43)

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 47

on page 46).

Page 50

Chapter 2 Set Up in the Studio 5000 Logix Designer Application

48 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 51

Logix Assemblies

Chapter 3

Input

The linking device uses four CIP connections for the 16 field devices.

Connection A has the master instance and four field devices. The other

connections (B, C, and D) have only the four field devices. All device assemblies

are identical.

Figure 9 - Example of Linking Device Connections Tag Data Structure

Master Device Tag Structure

This section describes the values on the elements in the master device status tag

structure.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 49

Page 52

Chapter 3 Logix Assemblies

Bus A/BTripped

If too much current (> 500 mA) is drawn on Bus A or Bus B, a trip occurs and the

bus is no longer functional. The trip is indicated in the input image.

NewFieldDevice

If a new field device is found which is not in the configuration of the H1 master, a

new field device bit is set.

LinkActiveScheduler

This bit indicates if the current device is the LAS or the back-up LAS (set

indicating that the linking device is the LAS).

MasterMode

N/A

LinkingDeviceStatus

This is currently reserved.

ConnectionStatus

If a field device is online and running (exchanging cyclic data), its field device

index bit (in the connection status) is set. If the device goes offline, the bit is

cleared.

FFBusVoltageA/B

The voltage on the H1 bus as measured at port A and port B on the linking

device.

FFBusCurrentA/B

The current being drawn by the H1 bus through port A and port B.

ExternalVoltage

The voltage of the external power supply.

Te m p e r a t u r e

The internal temperature of the linking device.

BusA/BEnabled

The master mode setting enables and disables the H1 ports A and B. For example,

if the master mode setting is Master Mode 0 - Single Master, A Bus Only, then A

is enabled and B is disabled (see page 85

50 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

).

Page 53

Logix Assemblies Chapter 3

BusA/BTerminated

The master mode setting sets the termination for H1 ports A and B. For example,

if the mode setting is Master Mode 0 - Single Master, A Bus Only, then A is

enabled and terminated (see page 85

).

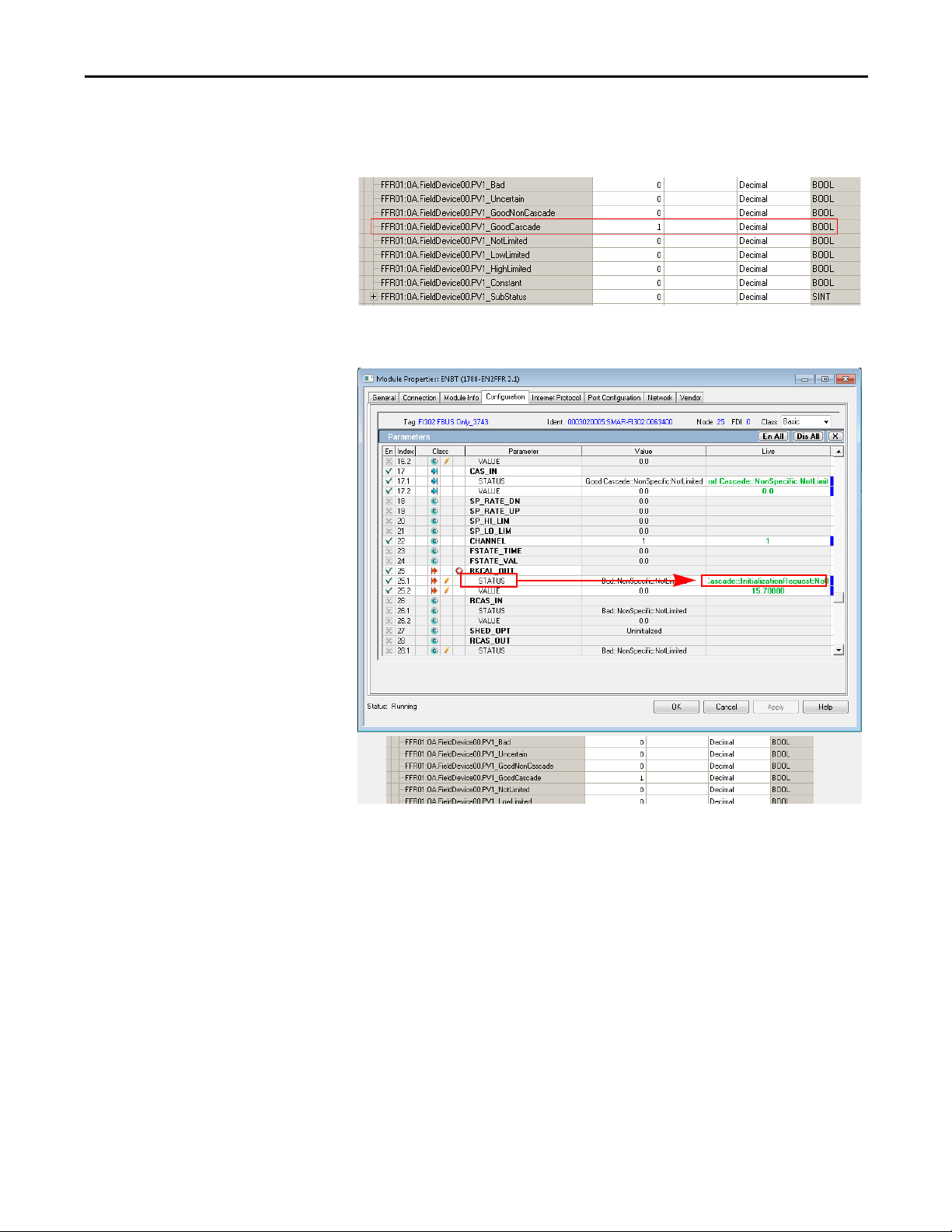

Field Device Tag Structure

This section describes the elements of the field device tag structure.

FFNode

The node value specifies the number of the field device.

Allocate

Indicates that this field device index has been allocated for a specific field device

and another device cannot use it.

Compel

If this bit is set, the linking device is requesting process variable data from the field

device.

Live

A connection has been established to the field device and the linking device is

receiving live data.

Ta g

This element specifies the tag name of the field device.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 51

Page 54

Chapter 3 Logix Assemblies

PVReal1…PVReal8

This element contains the process variable (PV) float or integer value from the

field device. Each field device can have a maximum of eight real PVs.

PVBinary1…PVBinary8

This element contains the process variable (PV) Boolean value from the field

device. Each field device can have a maximum of eight binary PVs.

PVStatus

The PV status indicates these quality values:

• Bad

• Unc er tain

• GoodNonCascade

• GoodCascade

The PV status indicates these limit values:

• NotLimited

• LowLimited

• HighLimited

• Constant

52 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 55

Logix Assemblies Chapter 3

PVDiagnostics

This tag contains the diagnostics information that is associated with each PV.

Output

This section describes the values on the field device output status screen.

Field Device Output Values

PVReal1…PVReal8

For a field device that requires an output, the data must be updated in the output

image of that field device. If the data type for the connector is set to Float, then

the data for that connector is read from the real value in the output image.

PVInt1…PVInt8

For a field device that requires an output, the data must be updated in the output

image of that field device. If the data type for the connector is set to Integer, then

the data for that connector is read from the integer value in the output image.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 53

Page 56

Chapter 3 Logix Assemblies

PVBinary1…PVBinary8

For a field device that requires an output, the data must be updated in the output

image of that field device. If the data type for the connector is set to Boolean,

then the data for that connector is read from the binary value in the output

image.

PVStatus1…PVStatus8

If the connector for the PV output is set to have a status, you must put a status in

the output image that will be sent with the process variable.

PV Status Status

PVStatus ≥ 0x80 Green = good

0x40 ≤ PVStatus < 0x80 Orange = uncertain

PVStatus < 0x40 Red = bad

Figure 10 - Example of Field Device Output Screen

54 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 57

Diagnostics

Chapter 4

Status Screen

The diagnostic status provides basic device data and statistics. Click Status in the

config tree to view basic data and statistics for the device.

Status

The connectivity status of the linking device.

Value Description

80…100 Good

41…79 Uncertain

0…40 Bad

Ta g

The tag name that is stored in the field device.

Ident

The identity of field device.

Device

The field device type.

Ve n d o r

The field device vendor.

Good Packets

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 55

Page 58

Chapter 4 Diagnostics

The count of good quality reply packets that are received from the field device.

(Cyclic Redundant Code [CRC] check passed.)

Bad CRC Packets

The count of reply packets that are received from the field device that were

rejected because the CRC check failed.

No Replies

The count of communication request to which the field device did not respond.

Success Rate

The rate of good replies to the number of requests for the last 100 requests.

Signal Quality

Displays the quality of the waveform for the field device by evaluating slew rate,

amplitude, distortion, noise, and balance.

Value Description

0…33 Bad

34…66 Poor

67…100 Good

Allocated

True if the field device has been allocated a field device index of 00 through 15.

If a field device is in the visitor list, it has not been allocated.

Compel

True if the field device has been allocated and configured to compel data.

The field device is also included in the schedule.

Live Data

True if the field device is allocated and configured, and is currently producing

live data.

56 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 59

Diagnostics Chapter 4

PV Data Screen

If a field device has been configured and scheduled, its scheduled PV values are

displayed here. The name of the function block parameter that produces or

consumes the data is also displayed.

Table 6 - PV Status Colors

PV Status Status Color

PVStatus ≥ 0x80 Green = good

0x40 ≤ PVStatus < 0x80 Orange = uncertain

PVStatus < 0x40 Red = bad

Click PV Data in the config tree to view the PV data for the device.

Oscilloscope Screen

The last packet received (good or bad) is displayed in the oscilloscope trace. Click

Oscilloscope in the config tree to view the last packet that is received for the

device.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 57

Page 60

Chapter 4 Diagnostics

IMPORTANT

The Web Server

To view detailed status and diagnostic information for the device in the web

server, enter the IP address of the device into the address field of a web browser

and press Enter.

If data is not being updated, turn off page caching or try a different web

browser.

58 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 61

Diagnostics Chapter 4

IMPORTANT

Device Type Manager (DTM)

Use the HSThinFrame to open the device DTM in the Studio 5000 Logix

Designer application. The DTM is read-only when opened in the Studio 5000

Logix Designer application.

The correct DTM must be installed and the HSProcessUtility DTM Catalog must

be updated for the correct DTM to display in the pull-down list.

Follow these steps to open the DTM.

1. Click Advanced in the config tree.

2. Choose the DD revision from the pull-down list.

3. Click Open DTM.

4. Choose the device information that you want to view.

Rockwell Automation Publication 1788-UM057B-EN-P - September 2014 59

Page 62

Chapter 4 Diagnostics

5. View the selected device information.

60 Rockwell Automation Publication 1788-UM057B-EN-P - September 2014

Page 63

Appendix A

Linking Device Display Status

The display of the linking device provides status and diagnostic data in one of

three page formats: main page, H1 master page, or field device page. Use the

display Page button behind the front cover to scroll through the pages (see

Figure 8 on page 46

for location of the Page button).

Main Page

The main page is the default display, and

the linking device returns to this page after

10 seconds.

H1Bus A/B: Displays the bus voltages on

each port.

IP: Displays the current IP address or

BOOTP if enabled.

STS: Displays the status (see Ta b l e 7

Table 7 - STS Status Descriptions

Status Description

Ok No events

New device found New device on the bus

Redundancy ok Masters are synchronized

Redundancy err Masters out of sync

Bus A Tripped Bus A over current trip

Bus B Tripped Bus B over current trip

SAFE MODE linking device set to Safe mode

).

The lower portion of the main page shows the communication quality to each

field device as the percentage of data packets sent compared to data packets

received for each field device index (see Ta b l e 8

Table 8 - Field Device Communication Quality

Display Communication Quality Display Communication Quality

>>> 95+ ??? Unknown

>> 80+ OOS Allocated, On-line, not Compelling Data

> 60+ Off Allocated, Off-line